A kind of low-temperature continuous phase change method for extracting the oil of the blue round trevally and the blue round trevally oil

A technology of low-temperature continuous phase change and blue scad, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems that the research on the oil composition of blue scorpion has not been reported, and achieve the reduction of the loss of low boiling point components, no solvent residue, large volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present embodiment provides the preparation of blue round trevally oil, and the preparation method comprises the following steps:

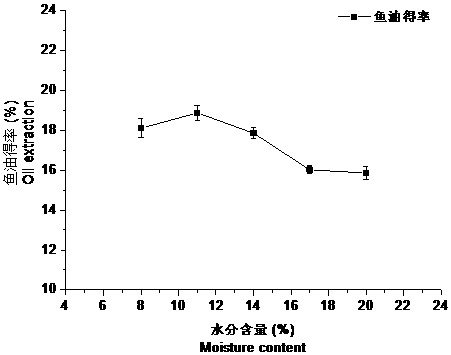

[0047] S1. Wash the fresh blue squid, dry other tissue parts except the viscera at 56°C, take out the viscera and use vacuum freeze-drying, crush to make the water content of 10-13%, and obtain the powdery raw material of blue squid;

[0048] The vacuum freeze-drying can refer to the prior art. Preferably, the vacuum freeze-drying conditions adopted in this embodiment are heating plate temperature 45°C, material thickness 5mm, drying chamber pressure 50pa, and pre-freezing temperature -20°C.

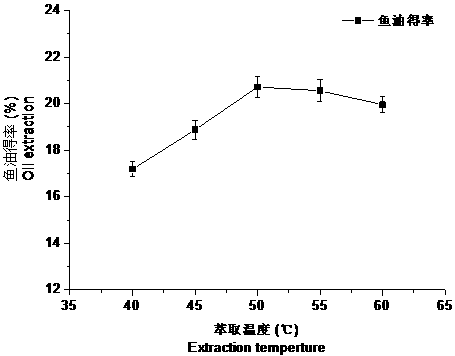

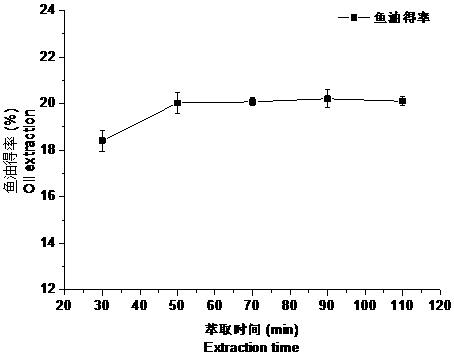

[0049] S2. Weigh 300g of the processed blue scad powder raw material, put it into the extraction kettle of the continuous phase change extraction device, and flow it at a flow rate of 120L / h under the conditions of extraction temperature 50°C and extraction pressure 0.6Mpa Continuously extract for 50 minutes through the extraction tank, after ext...

Embodiment 2

[0052] The present embodiment provides the preparation method of blue round trevally oil, comprises the following steps:

[0053] S1. Wash the fresh blue carp, dry other tissue parts except the internal organs at a temperature of 52° C., take out the viscera and use vacuum freeze-drying, crush to make the water content 10-13%, and obtain the powdery raw material of blue carp; Vacuum freeze-drying can refer to prior art. Preferably, the vacuum freeze-drying conditions adopted in this embodiment are heating plate temperature of about 48°C, material thickness of 6mm, drying chamber pressure of 55pa, and pre-freezing temperature of -18°C.

[0054] S2. Weigh 300g of the treated trevally powder raw material, put it into the extraction kettle of the continuous phase change extraction device, and flow through the extraction at a flow rate of 110L / h under the conditions of extraction temperature 45°C and extraction pressure 0.5Mpa Kettle, continuous extraction for 70min. After extract...

Embodiment 3

[0057] The present embodiment provides the preparation method of blue round trevally oil, comprises the following steps:

[0058] S1. Wash the fresh blue carp, dry other tissue parts except the viscera at 48°C, take out the viscera, use vacuum freeze-drying, crush to make the water content 10-13%, and obtain the blue carcass powder raw material; Vacuum freeze-drying can refer to prior art. Preferably, the vacuum freeze-drying conditions adopted in this embodiment are heating plate temperature 40°C, material thickness 4mm, drying chamber pressure 50pa, and pre-freezing temperature -20°C.

[0059] S2. Weigh 300g of the treated trevally powder raw material, put it into the extraction kettle of the continuous phase change extraction device, and flow through the extraction at a flow rate of 100L / h under the conditions of extraction temperature 60°C and extraction pressure 0.3Mpa Kettle, continuous extraction for 110min, after the fish oil is extracted, it flows into the analysis k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com