Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Ensure on-site construction quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

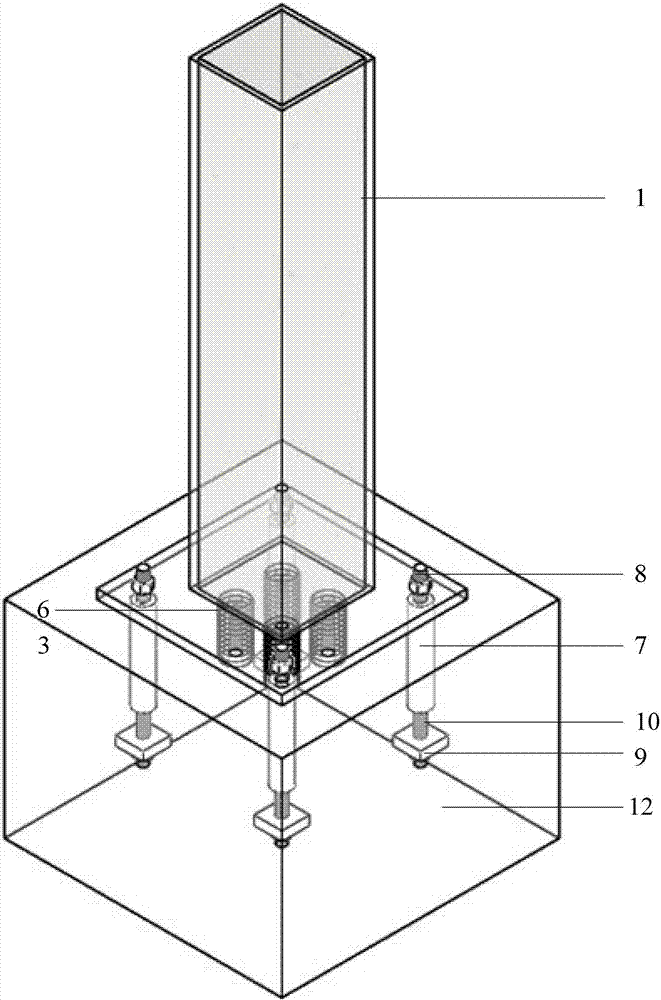

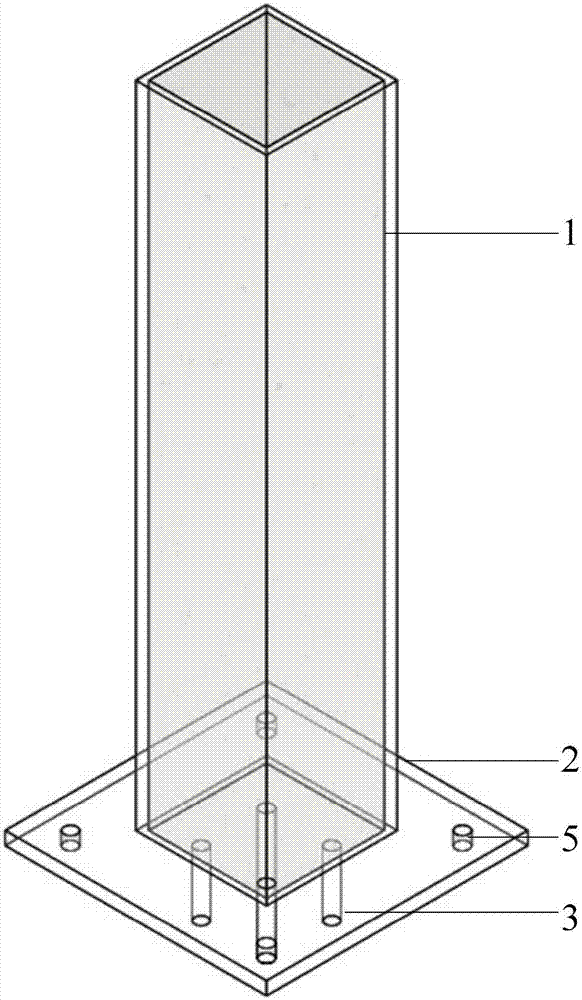

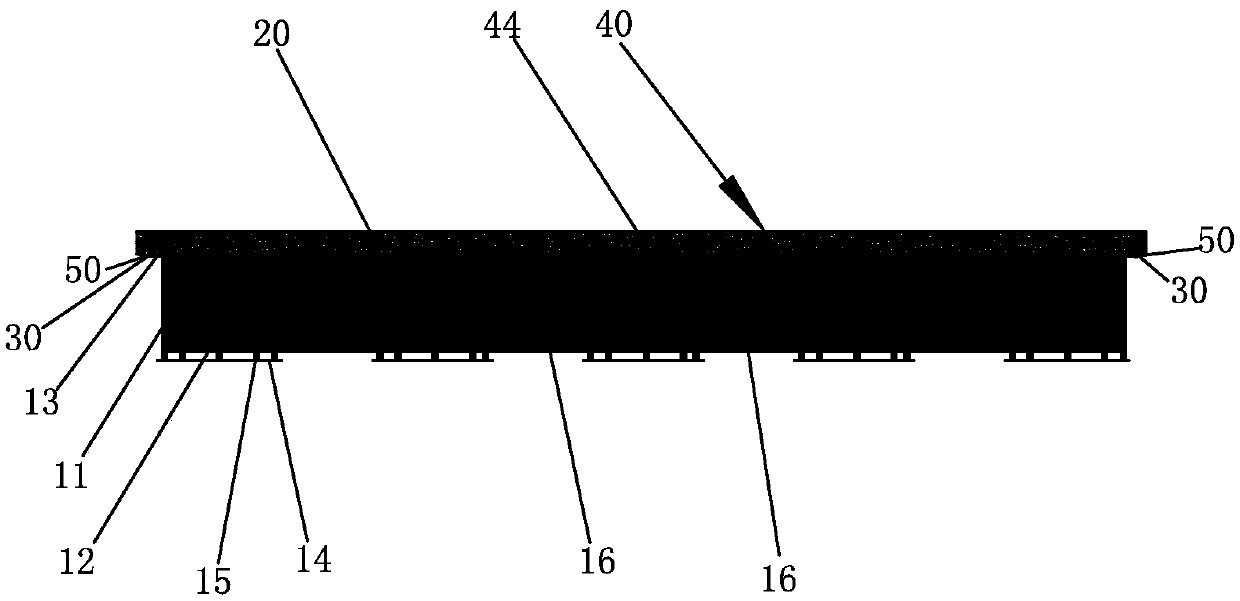

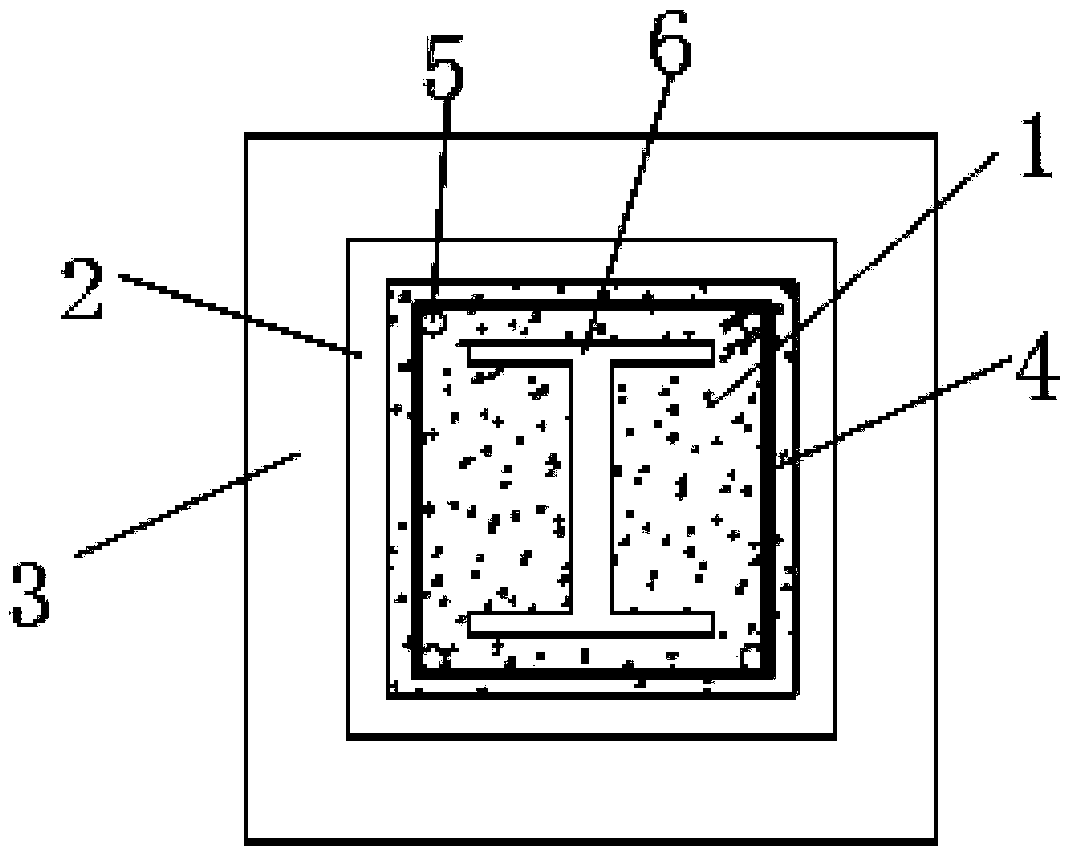

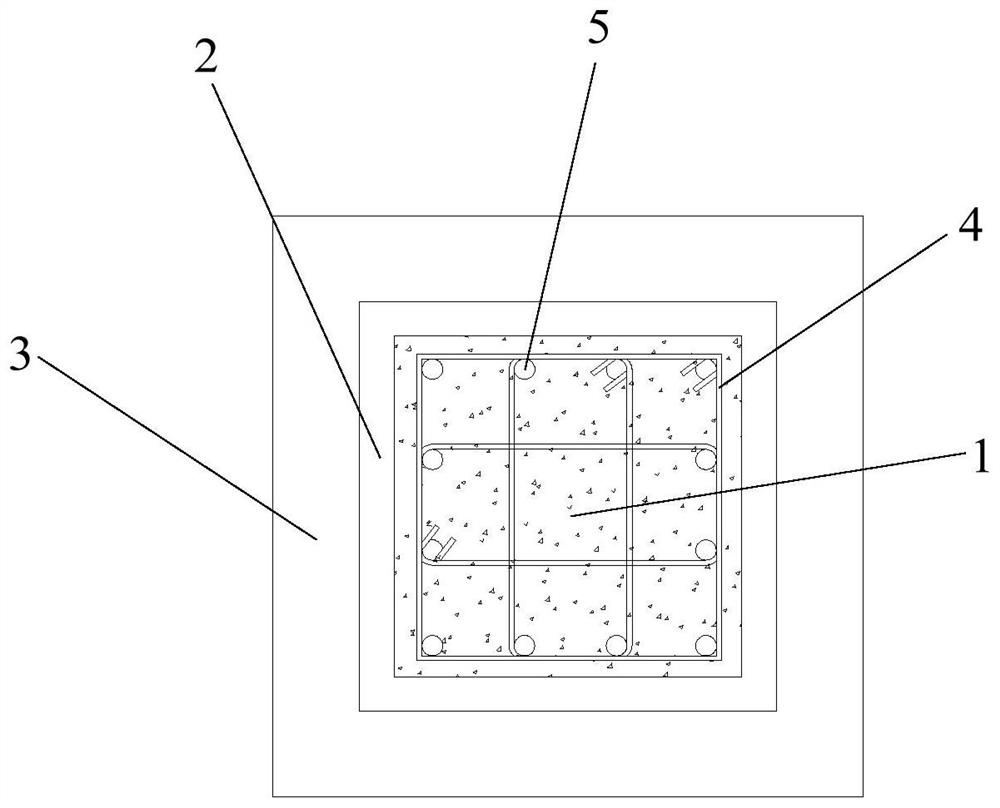

Detachable prefabricated assembly type square steel tube concrete column base joint

InactiveCN107254884AReduce welding work and form workGuarantee the construction qualityFoundation engineeringBuilding constructionsSteel tubeRebar

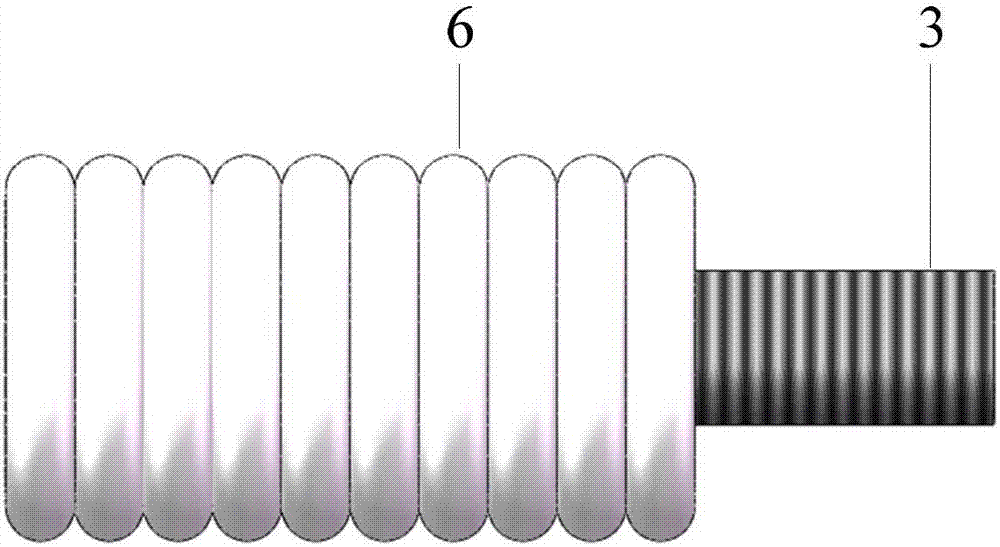

The invention discloses a detachable prefabricated assembly type square steel tube concrete column base joint. The detachable prefabricated assembly type square steel tube concrete column base joint comprises a square steel tube concrete column and a reinforced concrete foundation, wherein a bottom plate is welded to the end of the square steel tube concrete column, high-strength screw rods are welded to the inner side of the bottom plate, the high-strength screw rods as anti-shearing members are connected with pre-embedded corrugated sleeves of the foundation, and meanwhile, the welding screw rods are coated with plastic films. Preformed screw holes are formed in the outer side of the steel tube bottom plate and used for making splice anchor bolts and the bottom plate connected. When the square steel tube concrete column base joint is assembled, connecting screw rods are screwed into the upper ends of through tang inner screw-thread steel sleeves through the preformed screw holes in the bottom plate respectively, so that splicing between the square steel tube concrete column and the foundation is achieved. When the steel tube concrete column is disassembled and replaced, the screw rods are screwed out, the anti-shearing members are taken out, high-strength castables in the corrugated sleeves are removed, and then the steel tube concrete column can be disassembled and replaced. All the members used in the square steel tube concrete column base joint can be assembled and connected on the site, site welding work and formwork engineering are reduced, the building industrialization assembly efficiency is improved, and the new architectural concepts that building members save energy and are environmentally friendly and detachable are embodied.

Owner:HUNAN UNIV

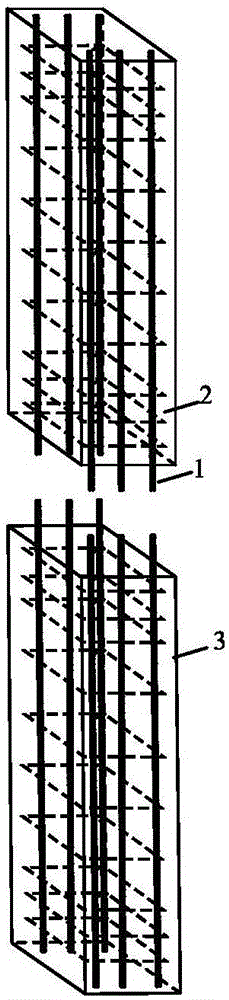

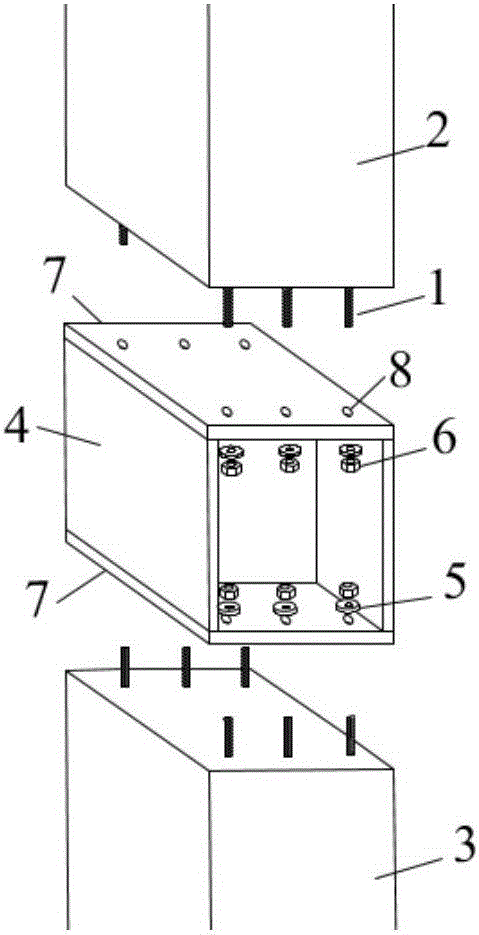

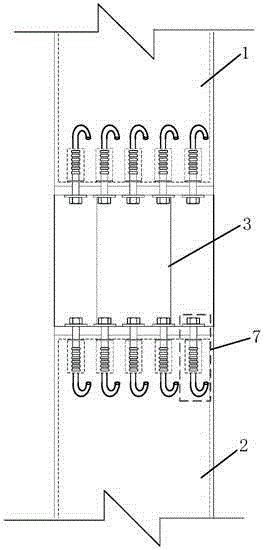

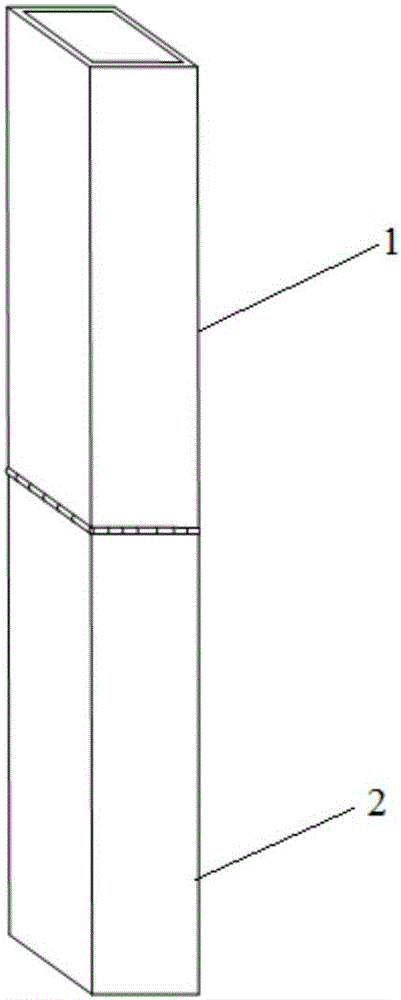

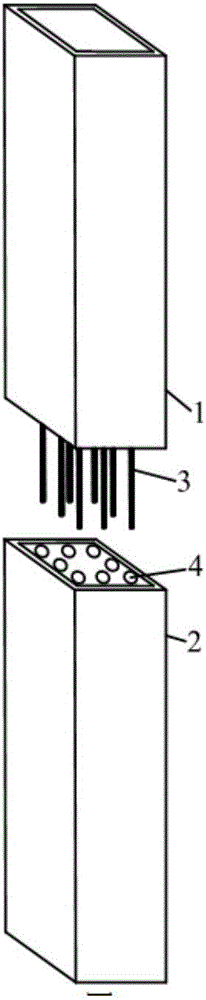

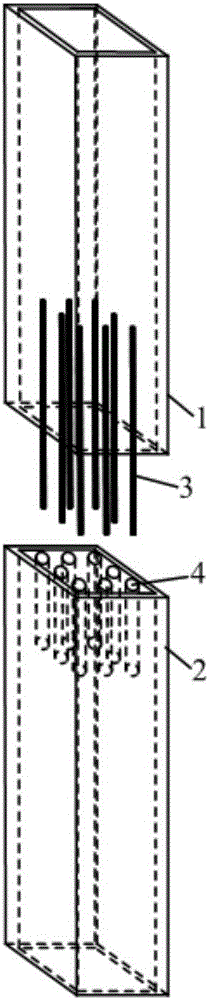

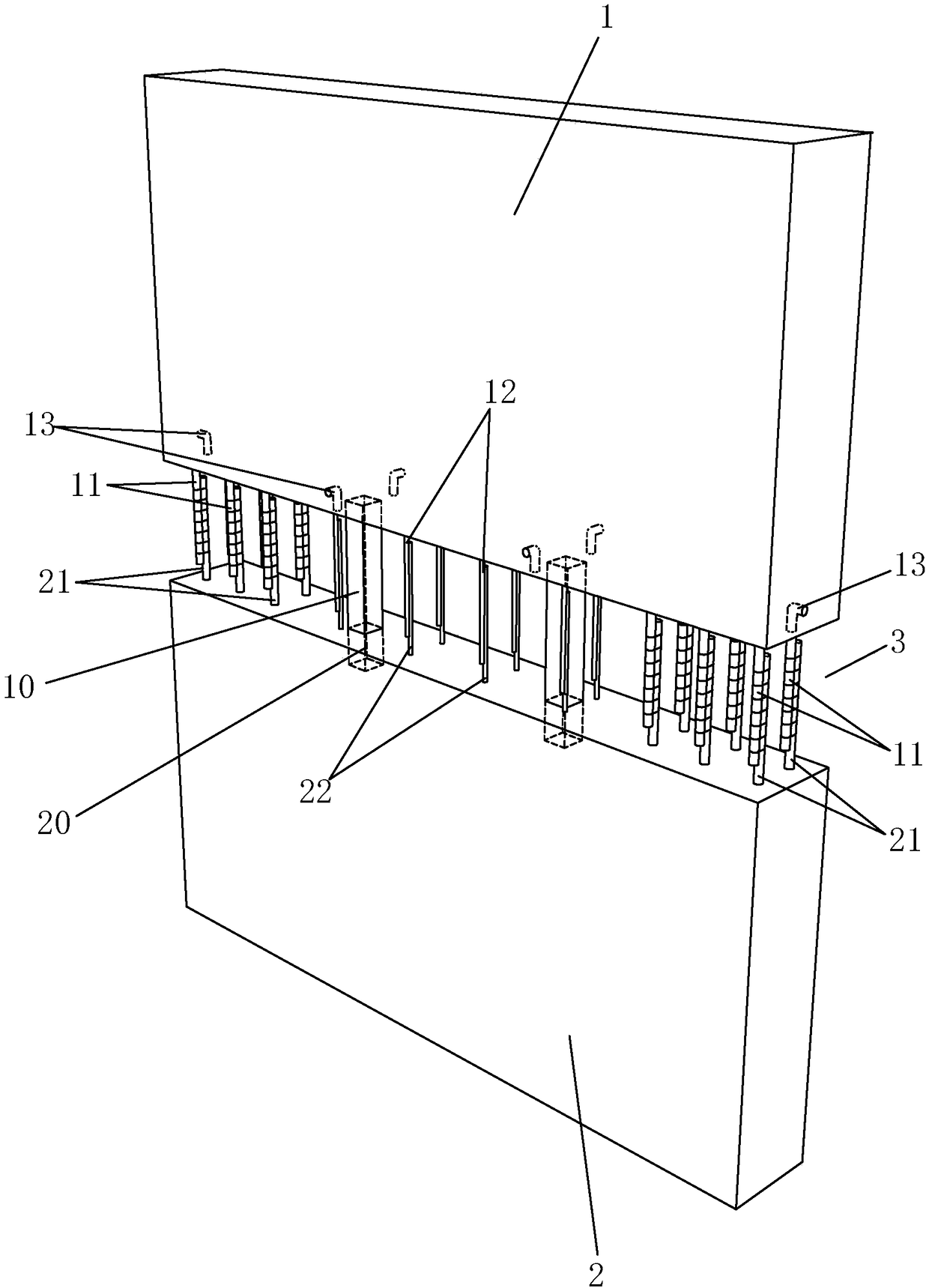

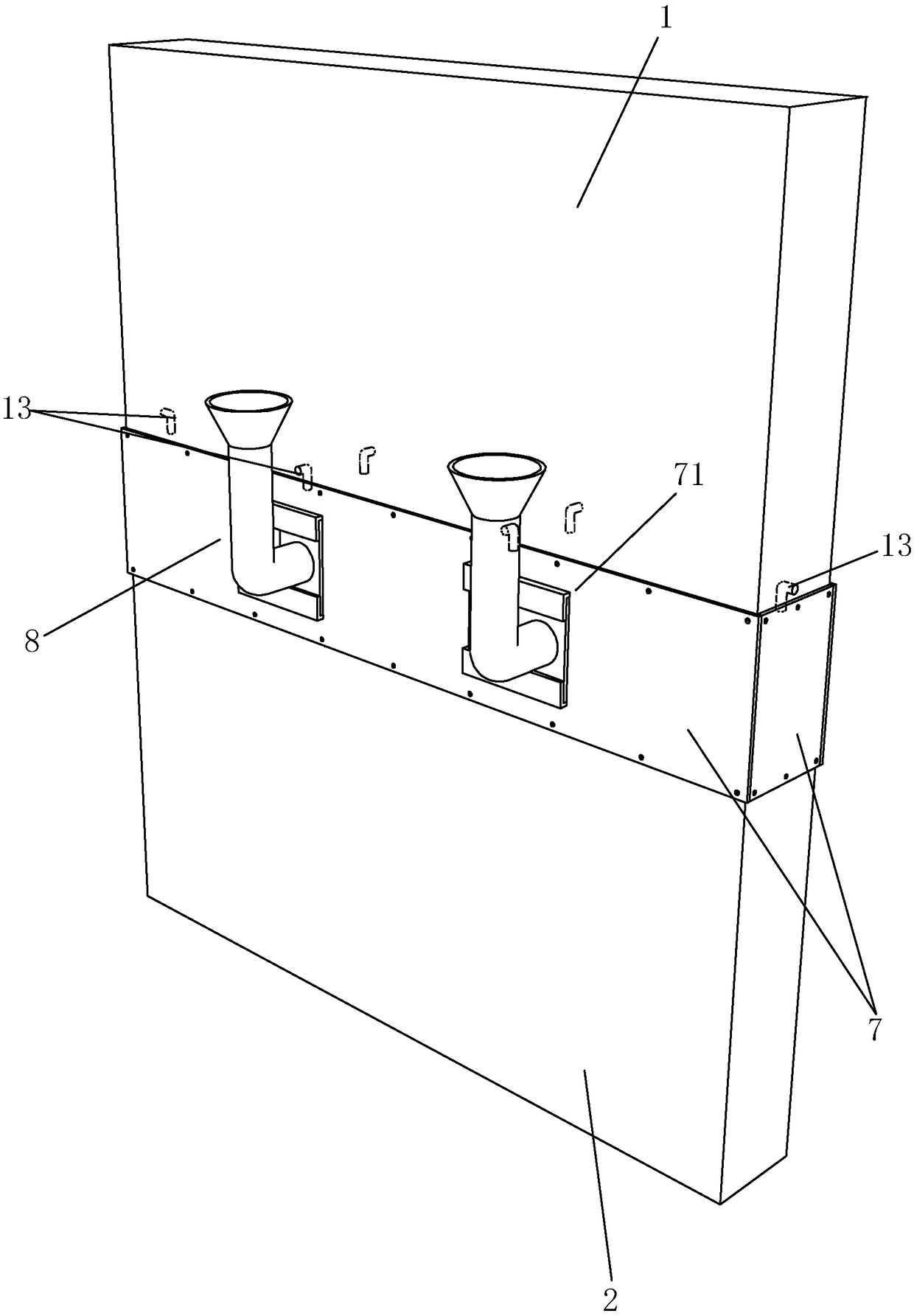

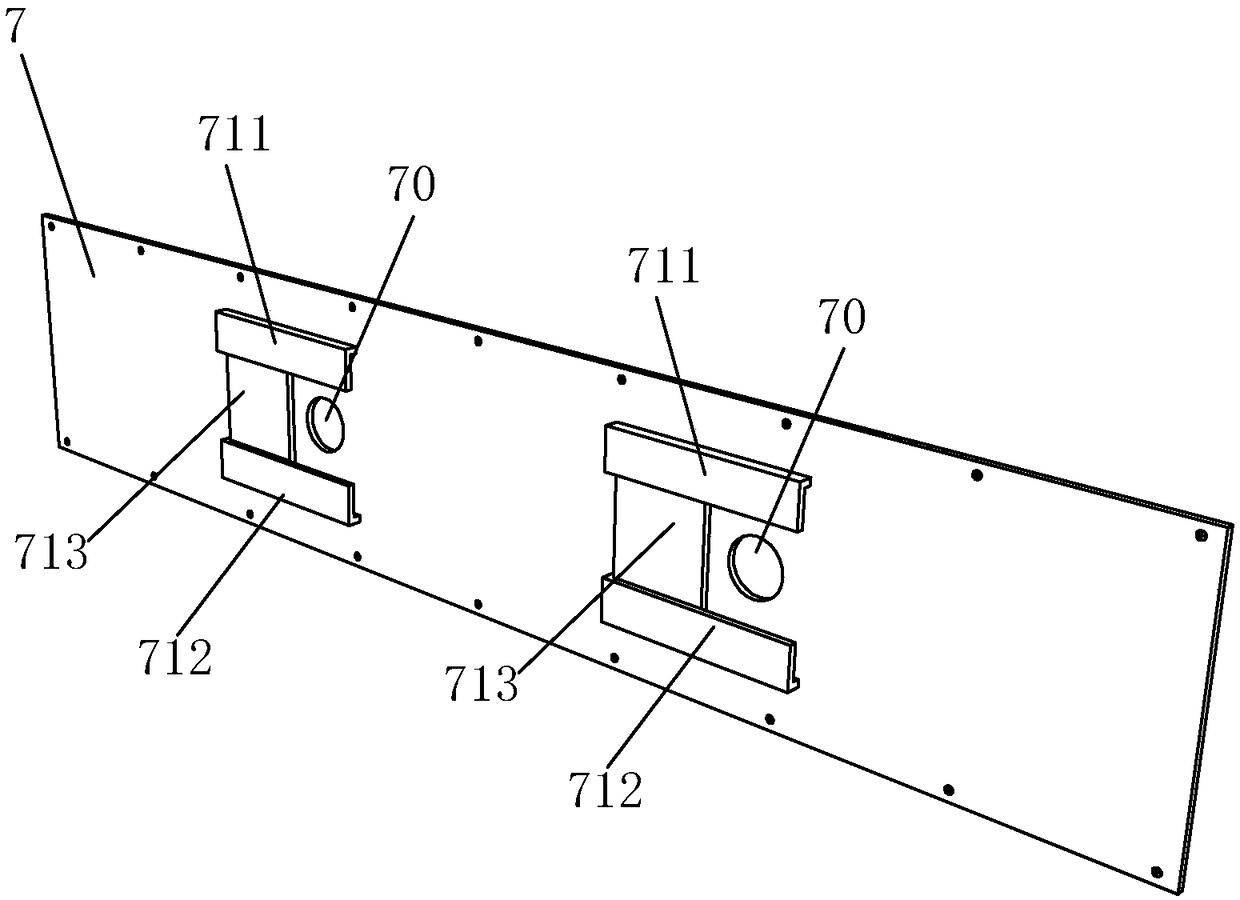

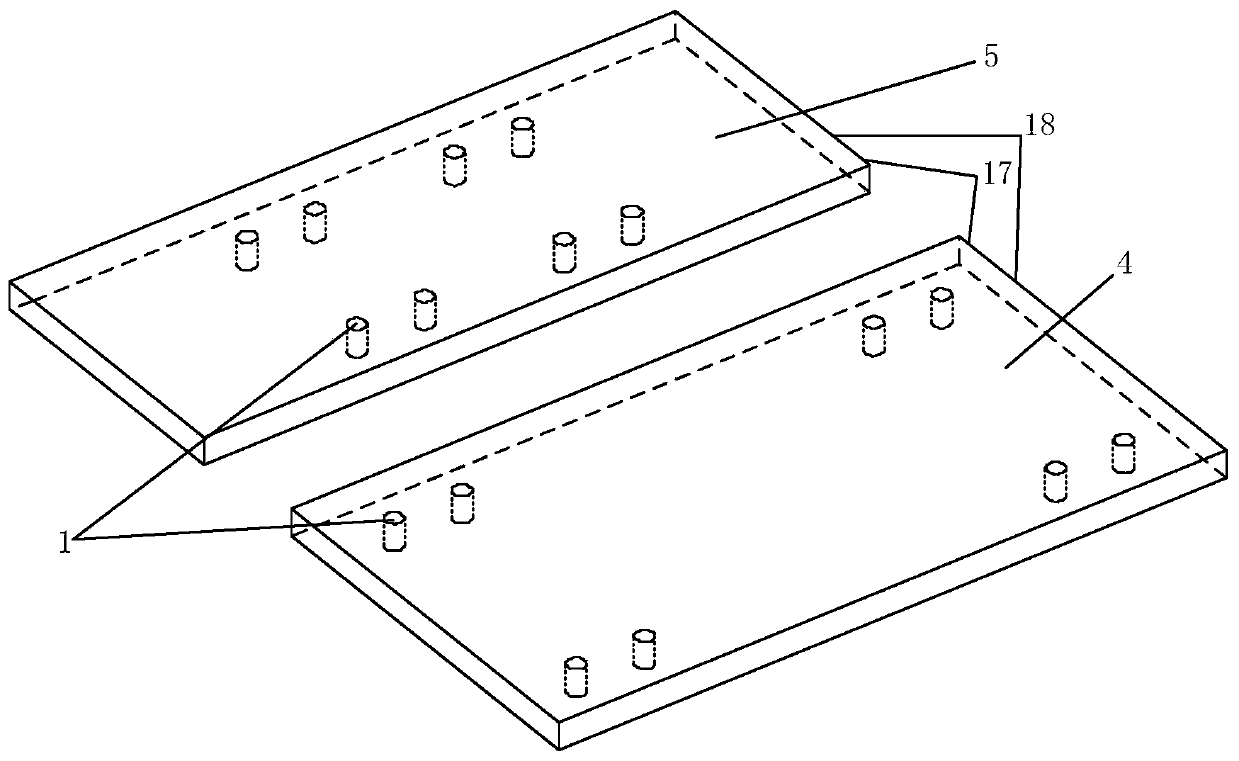

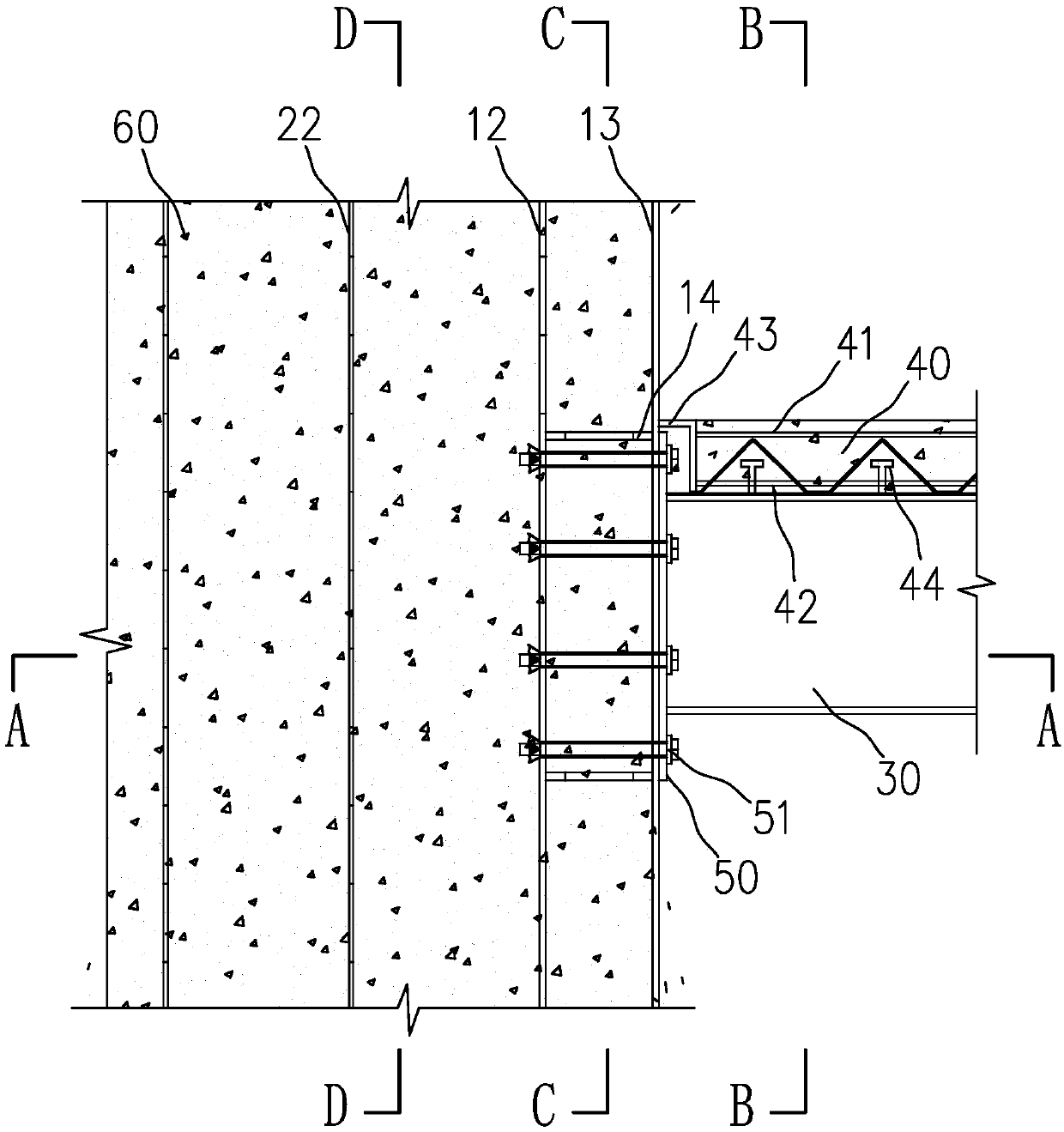

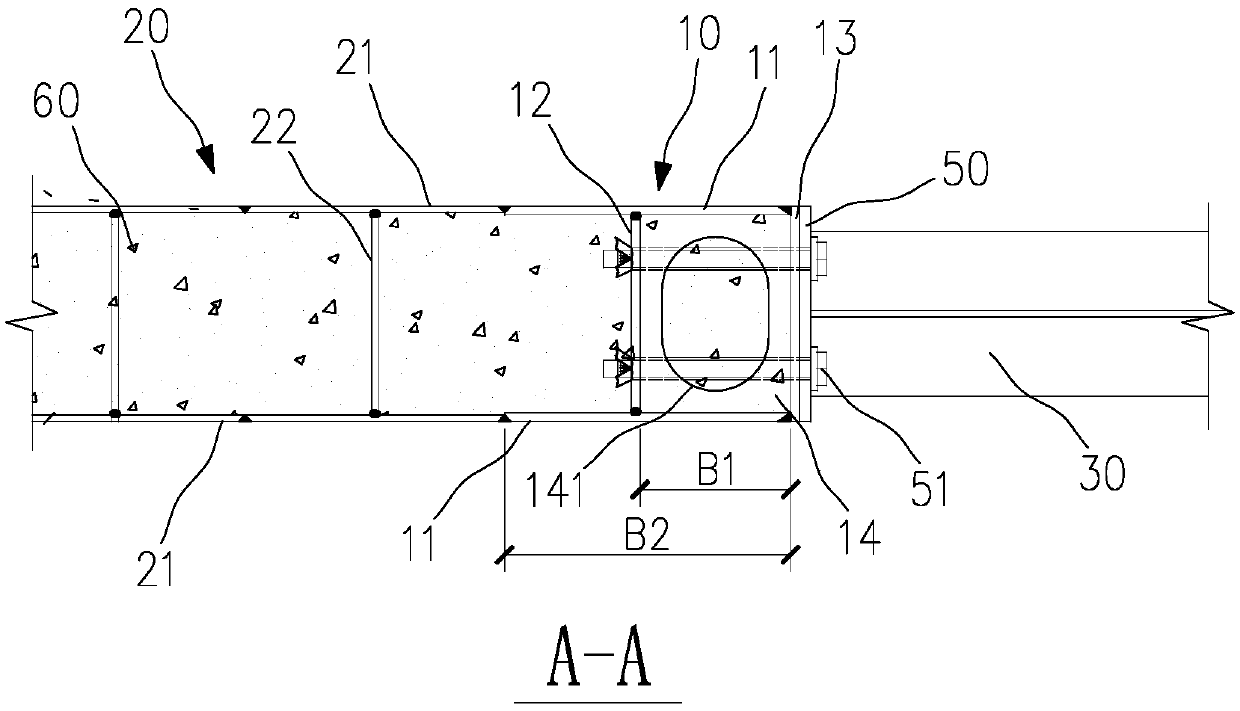

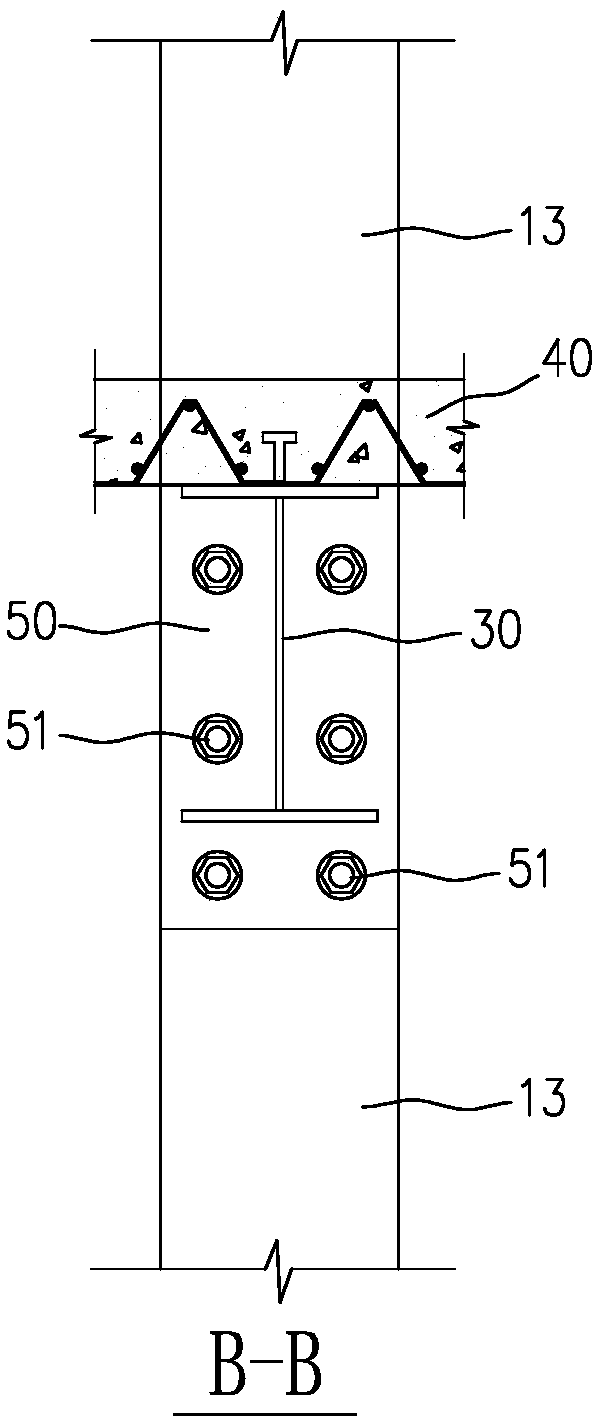

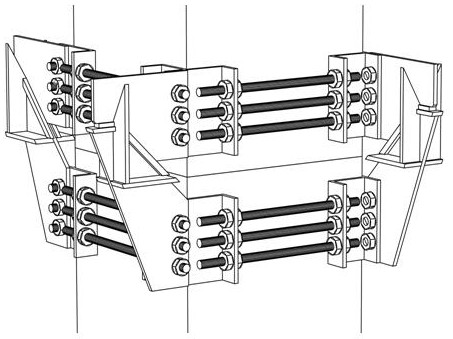

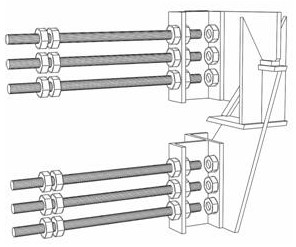

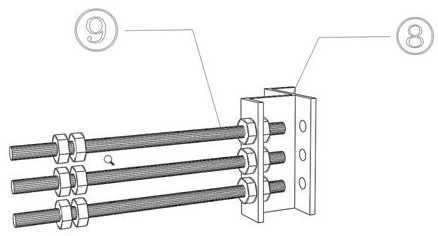

Detachable assembly type splicing node for reinforced concrete columns

InactiveCN106381926AImprove assembly efficiencyWork lessBuilding constructionsReinforced concrete columnRebar

The invention discloses a detachable assembly type splicing node for reinforced concrete columns by adopting steel connecting pieces. The splicing node mainly comprises a reinforced concrete upper column, a reinforced concrete lower column, steel connecting pieces, outward extending longitudinal ribs and two steel sealing plates with grouting holes, wherein by outwards extending the longitudinal ribs of the reinforced concrete columns, firstly the outward extending longitudinal ribs of the reinforced concrete columns are inserted into bolt holes of the steel connecting pieces and are screwed up by nuts and spacers, then the two sides of the steel connecting pieces are sealed by the steel sealing plates with holes, and grouting is implemented through the grouting holes, so that the reinforced concrete columns can be spliced. When the reinforced concrete columns are changed, the reinforced concrete columns are separated from the steel connecting pieces by cutting the steel sealing plates, cleaning mortar and disassembling the nuts, so that the disassembly and replacement of the upper column and the lower column are realized. According to the splicing node, the all used members are assembled and connected on site, the onsite welding work and template engineering can be reduced, the construction industrialization assembly efficiency can be improved, and a novel energy-saving, environment-friendly and detachable construction concept of the construction members is reflected.

Owner:HUNAN UNIV

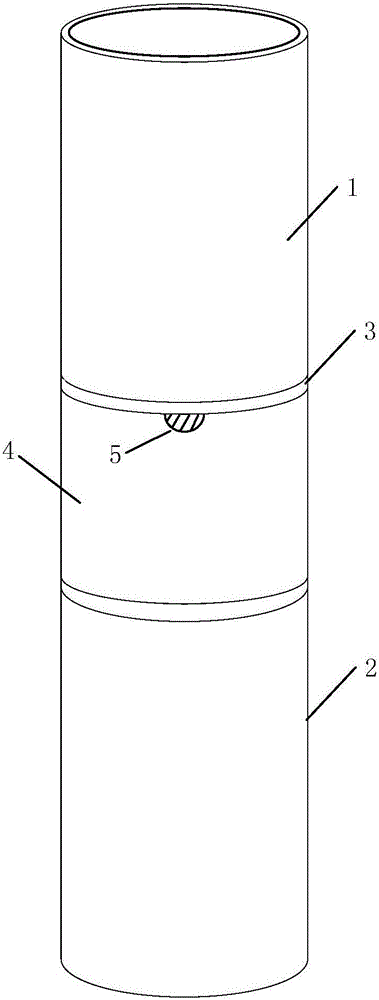

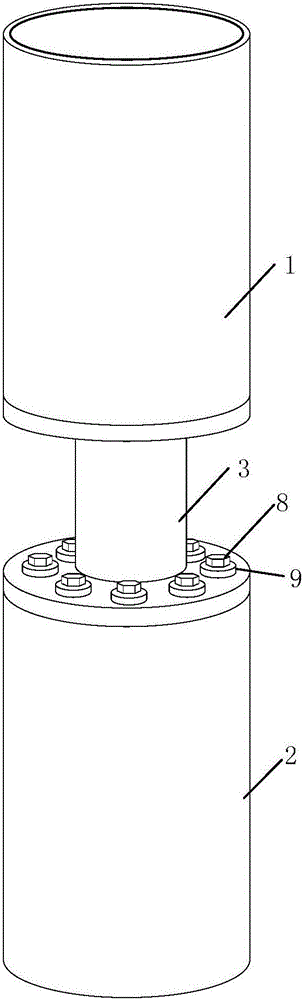

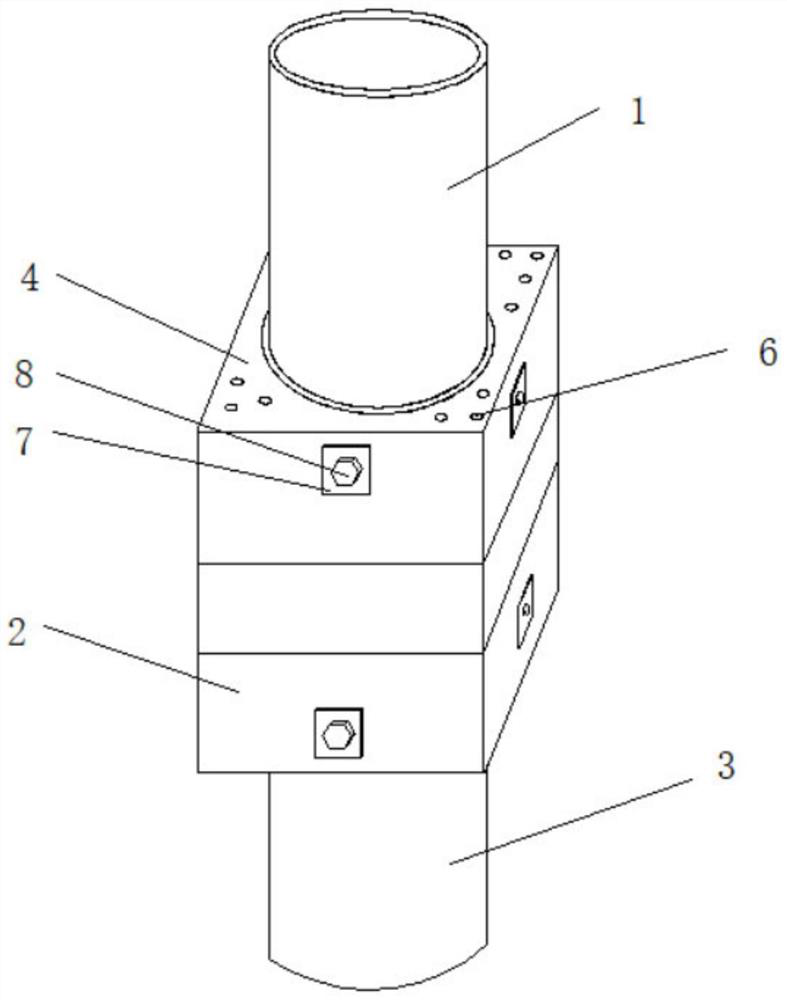

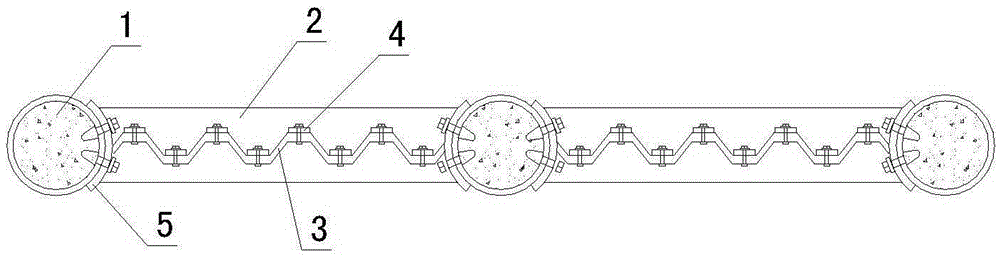

Dismountable assembly type circular steel tube concrete column

InactiveCN105863167AReduce welding work and formworkGuarantee the construction qualityStrutsPillarsSteel platesSteel tube

The invention provides a dismountable assembly type circular steel tube concrete column. The dismountable assembly type circular steel tube concrete column mainly comprises an upper circular steel tube concrete column, a lower circular steel tube concrete column, a column flange connecting piece, two semicircular steel plates with holes and a pulling-resistant connecting pair. Structural measures of the circular steel tube concrete columns and the column flange connecting piece are reasonably designed, the pulling-resistant connecting pair is adopted for splicing the circular steel tube concrete columns, then grouting is carried out from the reserved semicircular holes of the semicircular steel plates, and finally, the dismountable fabricated circular steel tube concrete column is formed. When the circular steel tube concrete columns are replaced, a bolt bar is dismounted, so that the circular steel tube concrete columns and the column flange connecting piece are taken down, and further removal and replacement of the circular steel tube concrete columns are realized. The dismountable assembly type circular steel tube concrete column has the advantages that all the components are connected in a field assembly manner, building industrialization assembling efficiency is improved, dismounting, separating and replacing functions of an assembly type combined structure column-column component are realized, and a novel energy-saving and environment-friendly architectural concept that a building component can be dismounted and altered is shown.

Owner:HUNAN UNIV

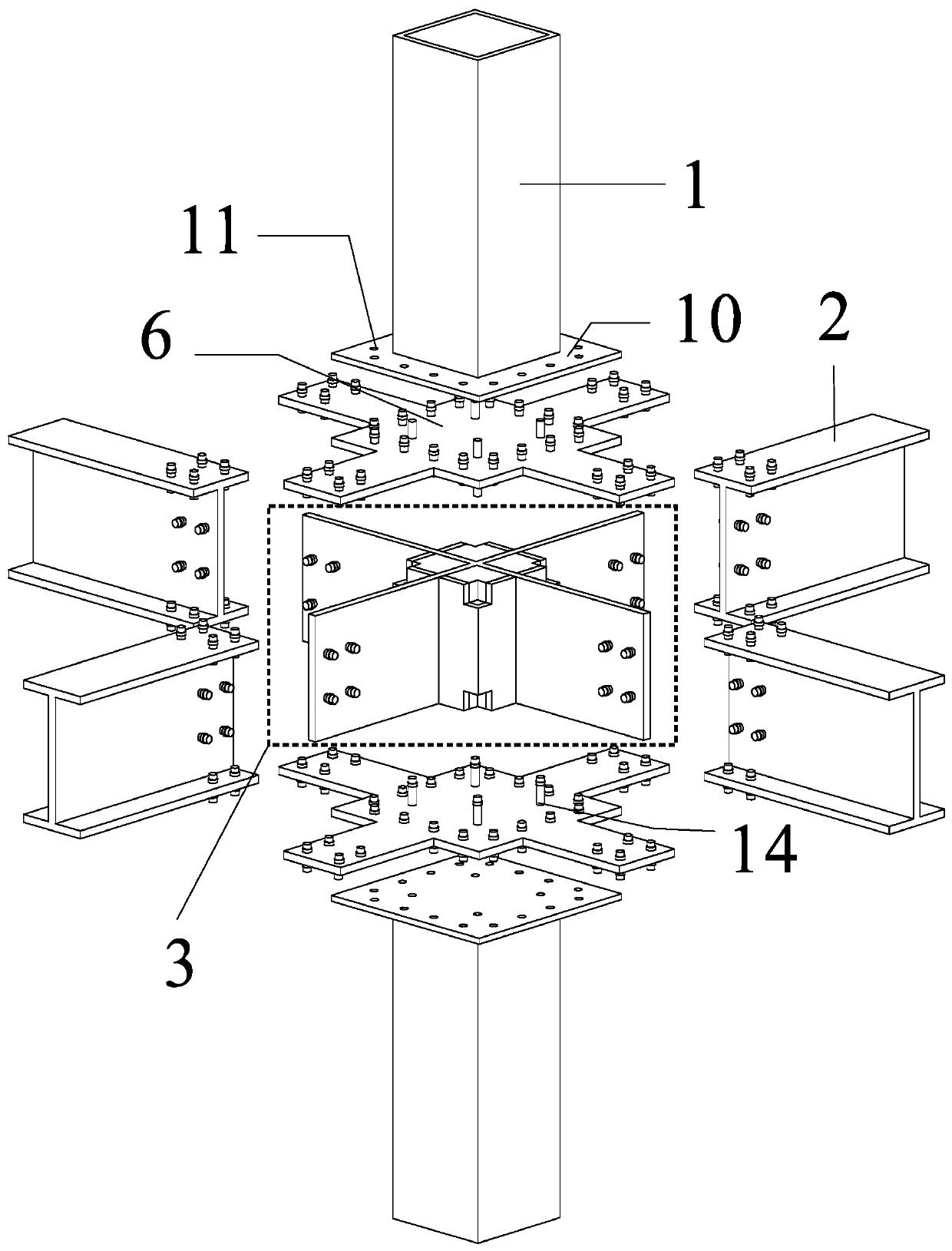

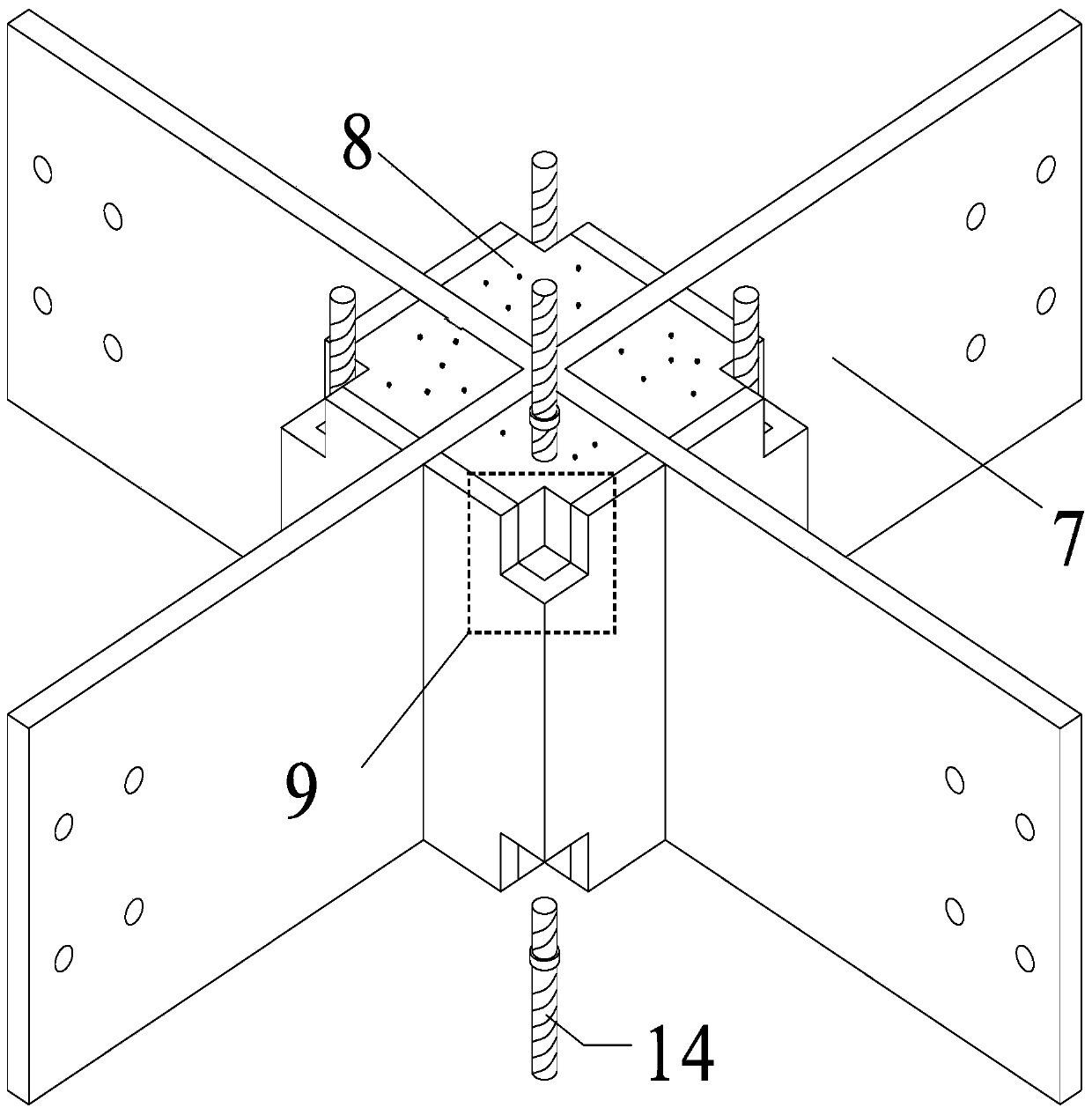

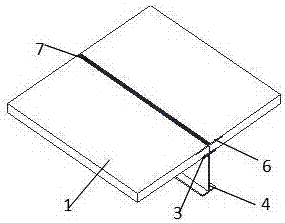

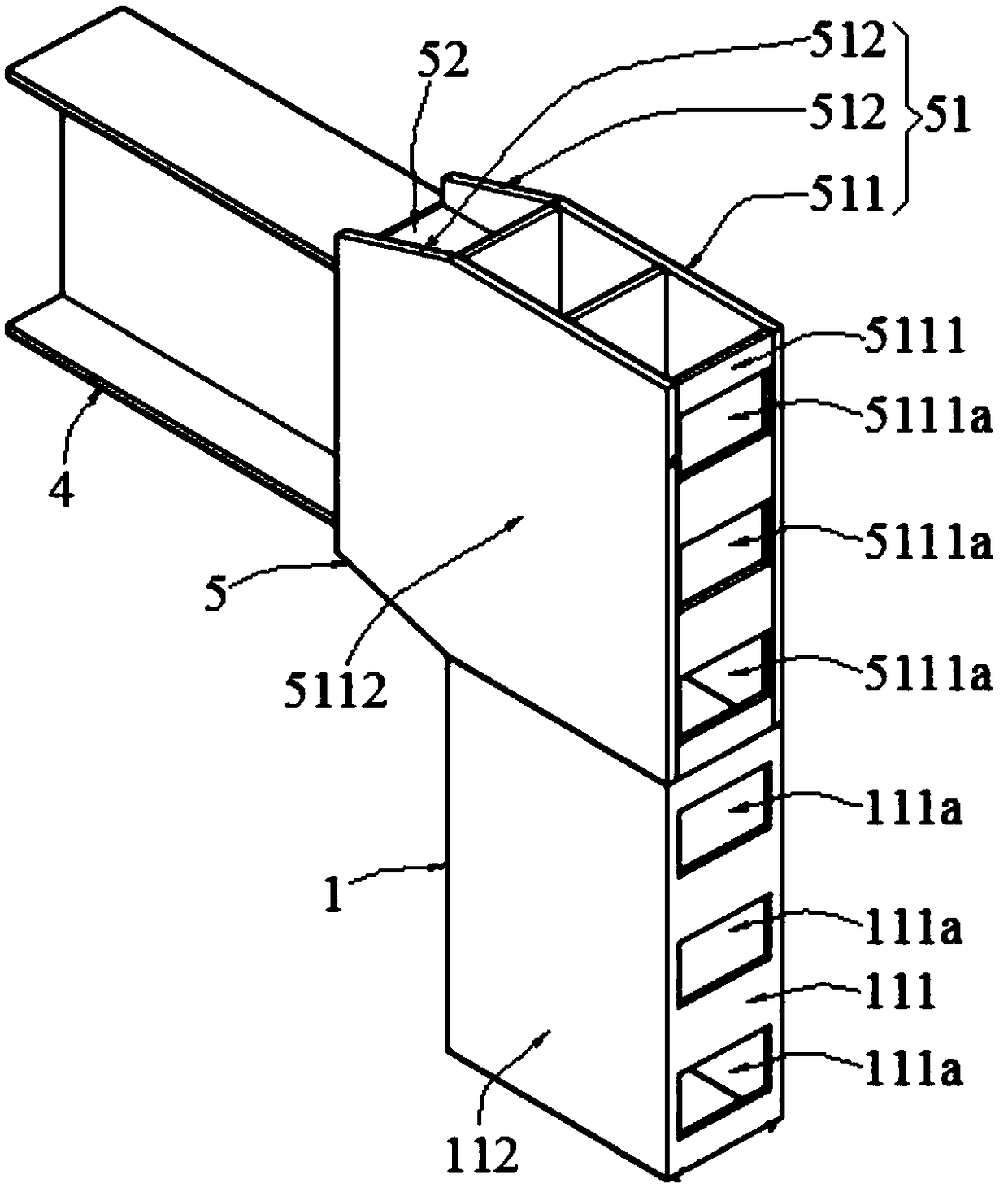

Detachable steel beam-concrete filled steel tube column penetrating connection joint

PendingCN109881789AEasy to pourImprove assembly efficiencyBuilding constructionsSteel tubeMaterials science

The invention relates to a detachable steel beam-concrete filled steel tube column penetrating connection joint, which includes a concrete-filled steel tube column, H-shaped steel beams and a joint domain, a flange ring plate is arranged at one end of concrete-filled steel tube column, the joint domain comprises a steel pipe and a vertical connection plate communicating with the steel pipe, reinforcing ring plates are arranged on the upper part and the lower part of the steel pipe, the steel pipe, the vertical connection plate and the reinforcing ring plates are all fixed by welding, the steelpipe is poured with ultra-high performance concrete, the flange ring plate is connected with the reinforcing ring plates, and the four H-shaped steel beams are fixed to the joint domain in the shapeof a cross. According to the detachable steel beam-concrete filled steel tube column penetrating connection joint, all components adopt prefabricated connection, the workload of field welding and formwork consumption are significantly reduced, and the construction efficiency is greatly improved; and meanwhile, due to the fact that only bolts and a small amount of anchor bolts are used for connection, after the mission of an original building is completed, the components can be quickly disassembled and reused in a new building, and a more thorough green building structure concept is reflected.

Owner:SOUTH CHINA UNIV OF TECH

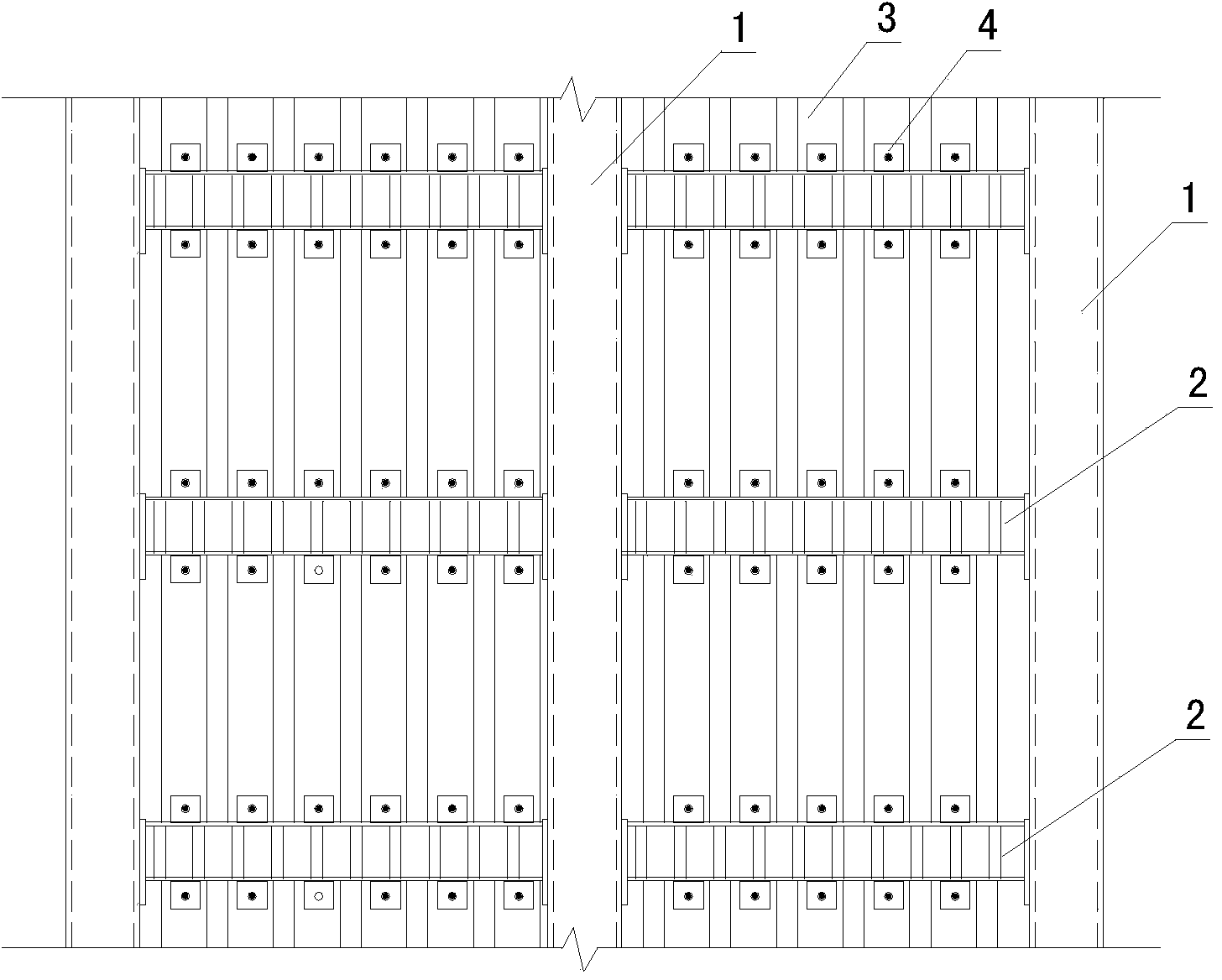

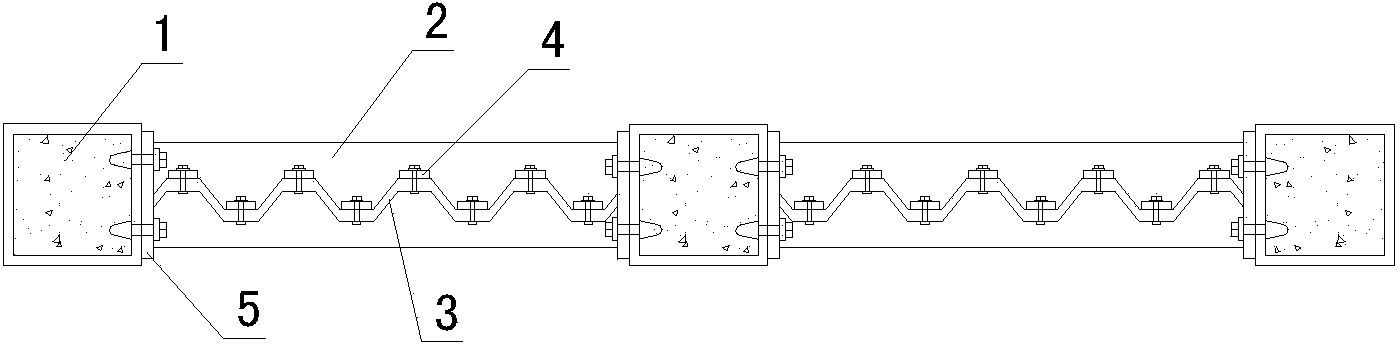

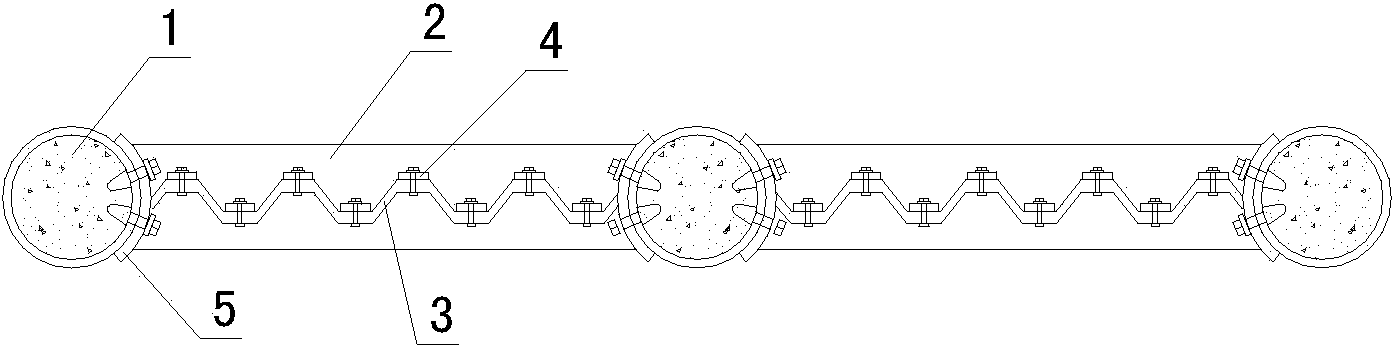

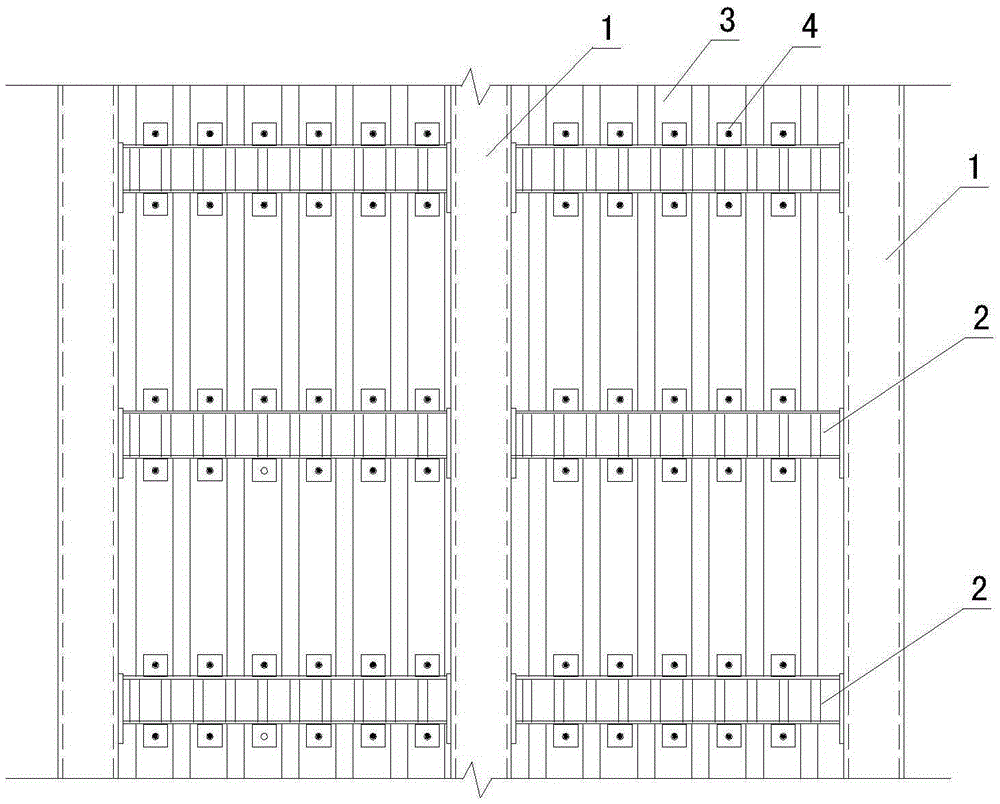

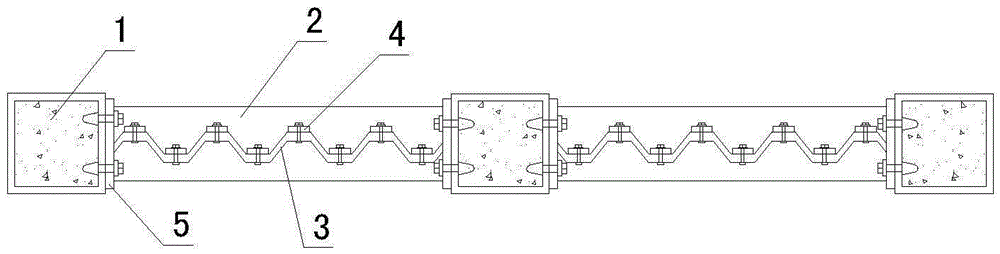

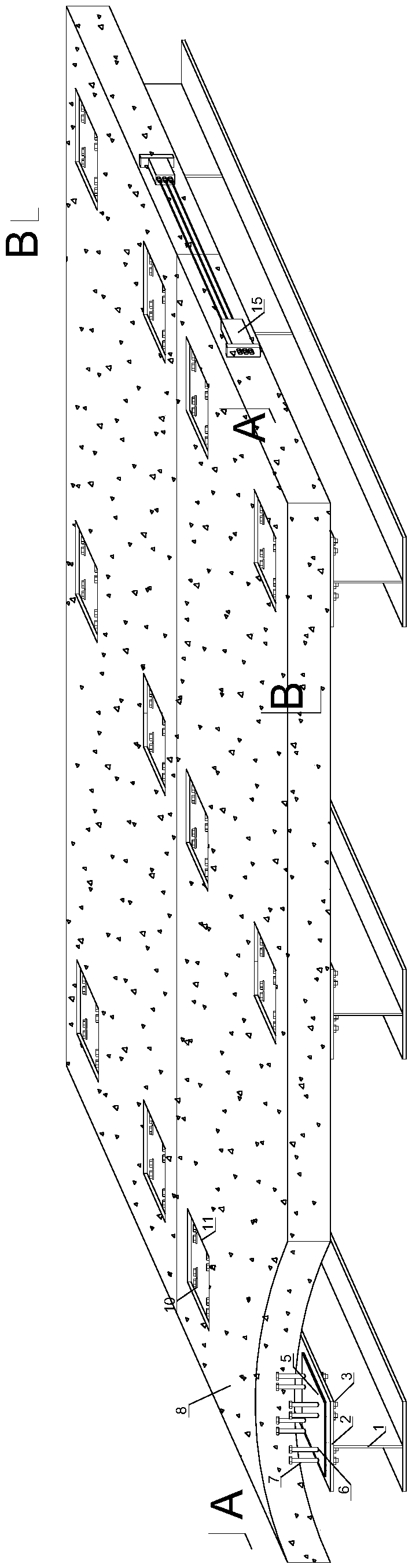

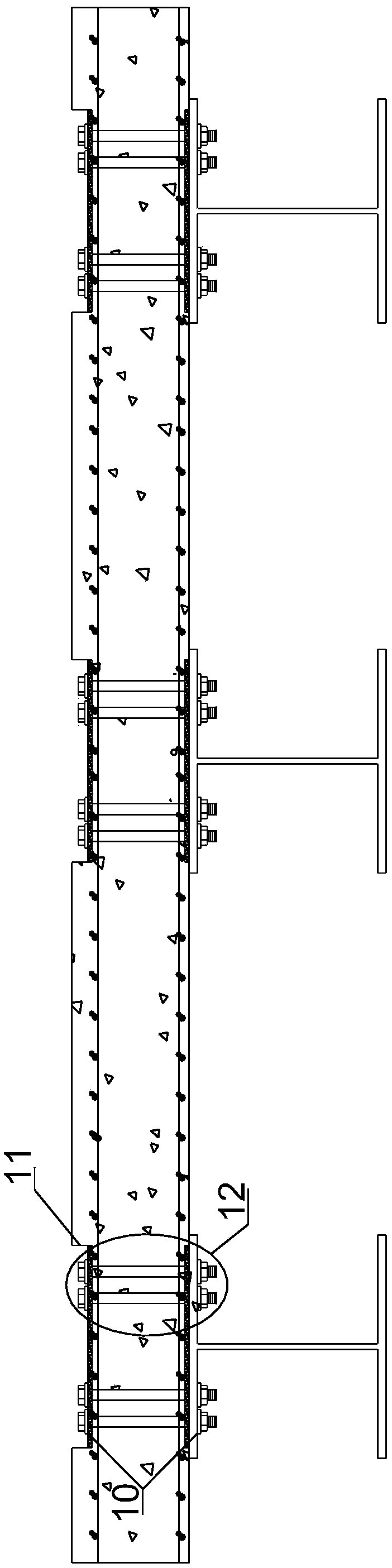

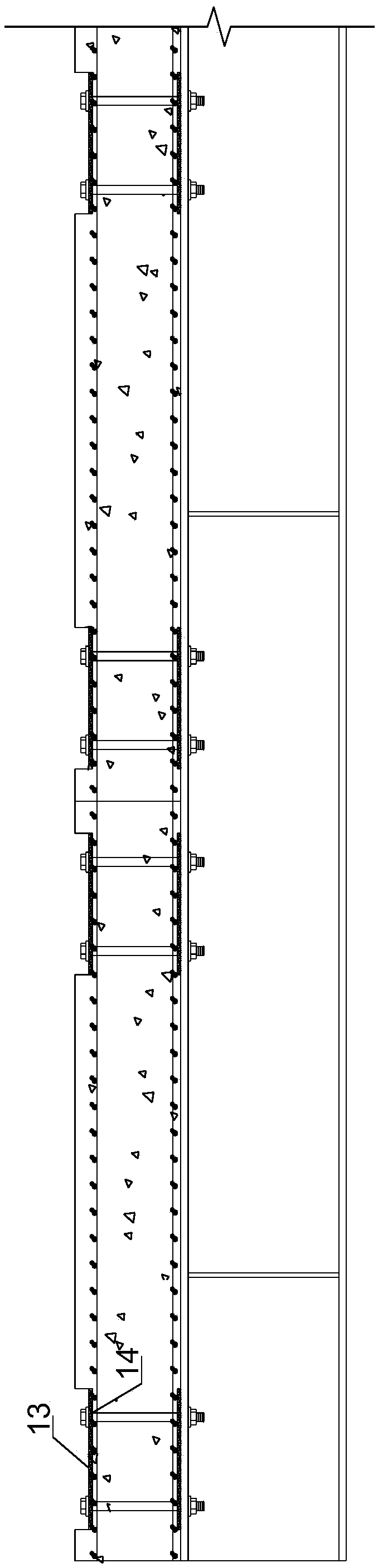

Assembling and energy consuming structural system with combined fluted frameworks and shear walls

The invention discloses an assembling and energy consuming structural system with combined fluted frameworks and shear walls. The system is characterized in that the system comprises concrete-filled steel tubular columns, fluted web plate beams and fluted steel plate shear walls; the concrete-filled steel tubular columns, the fluted web plate beams and the fluted steel plate shear walls are connected through bolts; the cross section of each fluted web plate beam is of an H shape; flange plates comprising the fluted web plate beams with the H-shaped cross sections are smooth steel plates; web plates are fluted steel plates; the fluted steel plate shear walls are made of fluted steel plates. The assembling and energy consuming structural system with the combined fluted frameworks and the shear walls is an assembly type high-rise steel-structure energy consuming building system which has the advantages that the construction progress is fast, the force transmission path is simple, and the energy consuming capacity is high.

Owner:HEFEI UNIV OF TECH

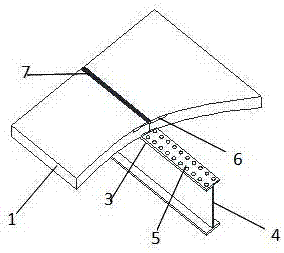

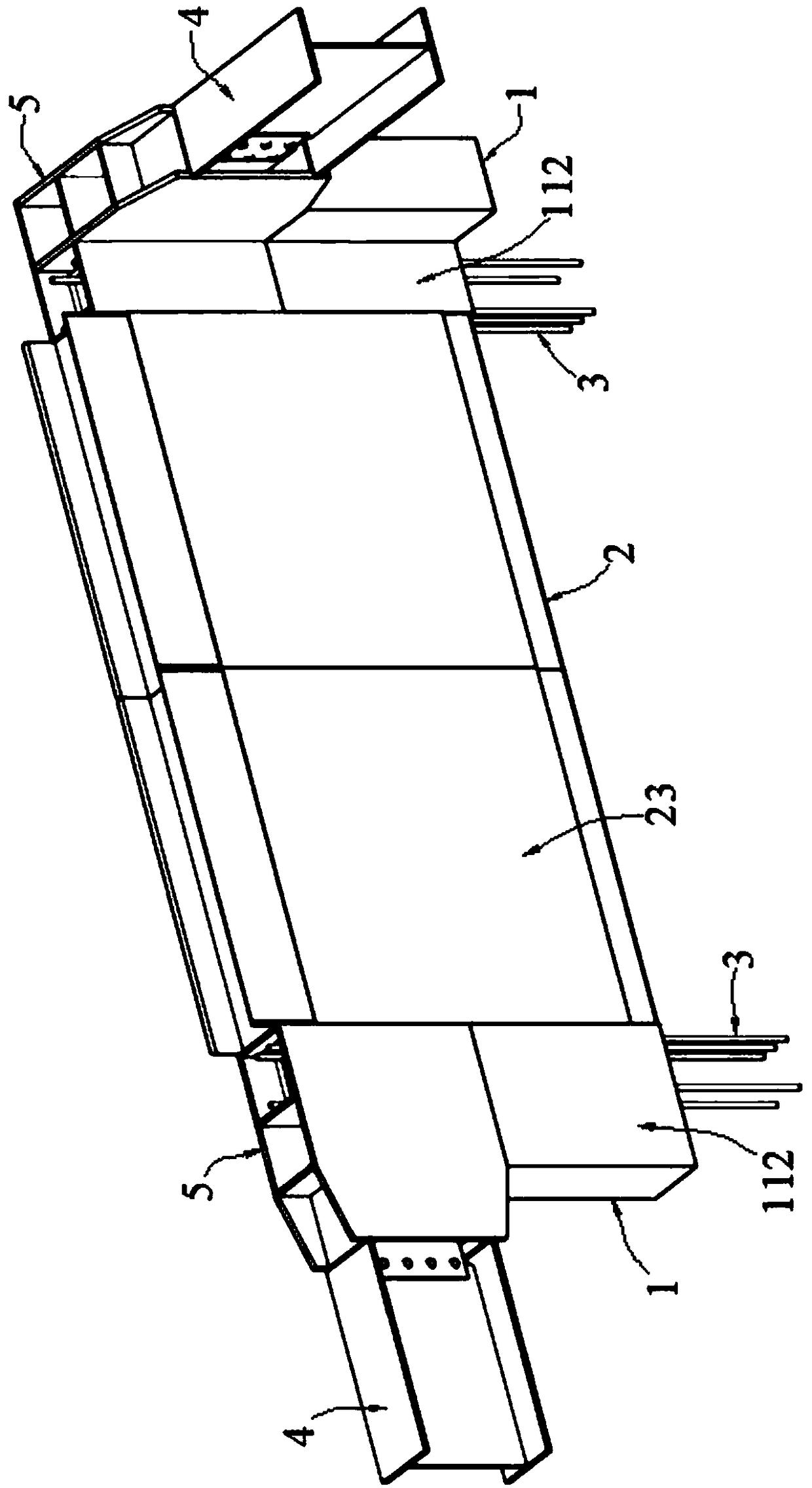

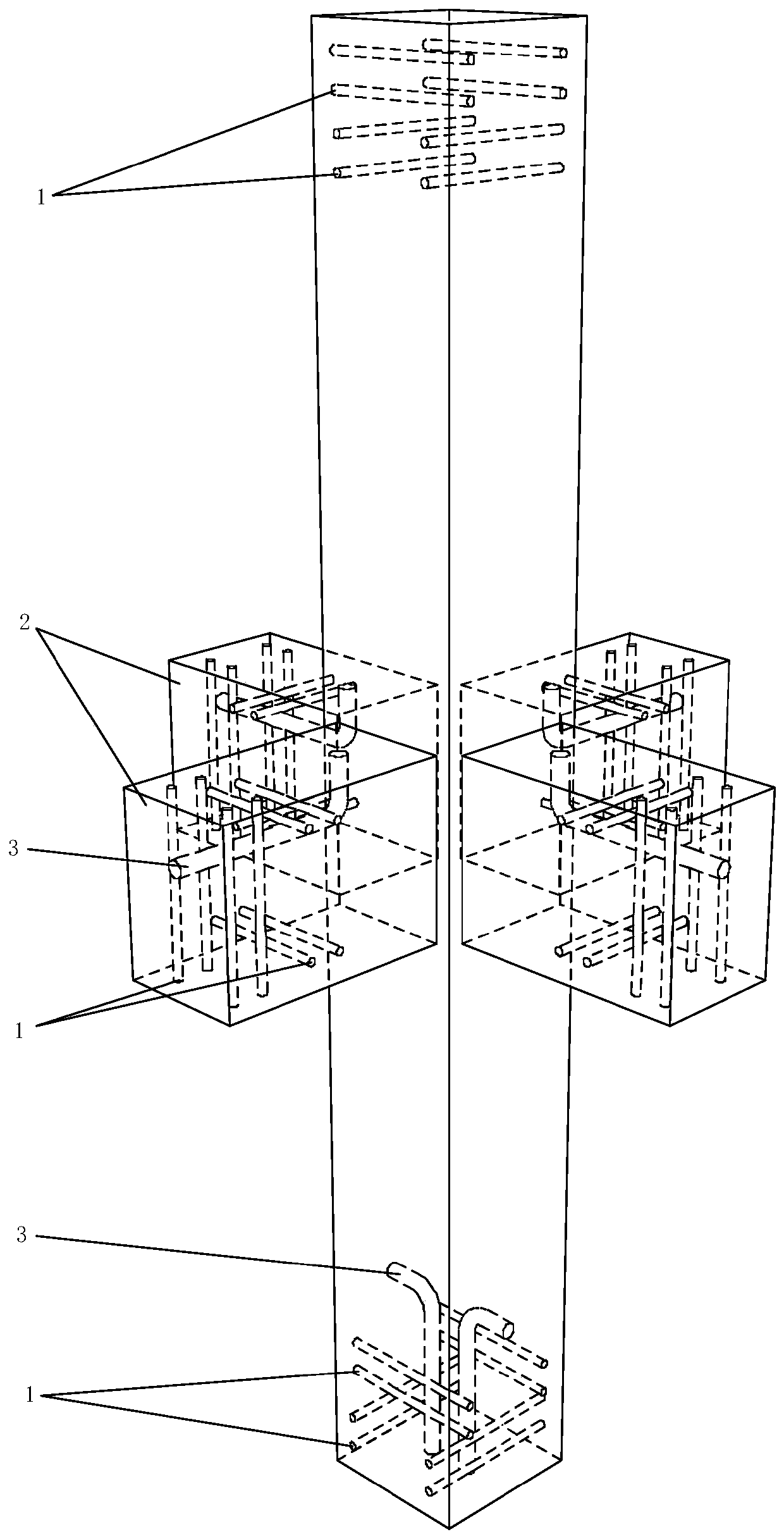

Assembled concrete filled steel tubular column splicing structure and method

InactiveCN106437032AReduce on-site welding work and form workGuarantee the construction qualityStrutsPillarsSteel tubeRebar

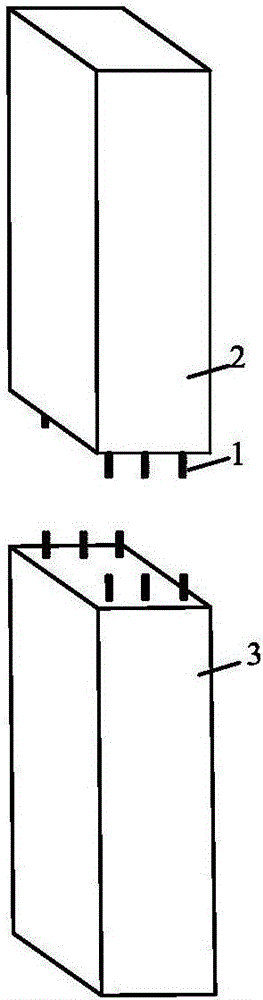

The invention discloses an assembled concrete filled steel tubular column splicing structure and method. The assembled concrete filled steel tubular column splicing structure comprises prefabricated upper and lower concrete filled steel tubular columns, steel bars are embedded in the upper concrete filled steel tubular columns, and corrugated casing pipes are embedded in the upper concrete filled steel tubular columns. After the reserved corrugated casing pipes are filled with concrete grout in a constructions site, the embedded steel bars in the upper concrete filled steel tubular columns are inserted into the corrugated casing pipes to make the upper concrete filled steel tubular columns arranged on the lower concrete filled steel tubular columns and in butt joint with the lower concrete filled steel tubular columns, and then steel pipe connecting parts are welded to achieve concrete filled steel tubular column splicing. All the members used in the structure are assembled and connected in the site, a site formwork project and welding work are decreased, the industrialized assembling efficiency of a building is improved, and the energy-saving and environmentally friendly building design concept for sustainable development of building members is embodied.

Owner:HUAQIAO UNIVERSITY

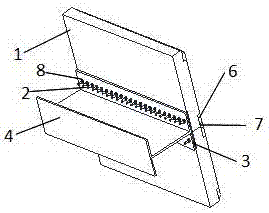

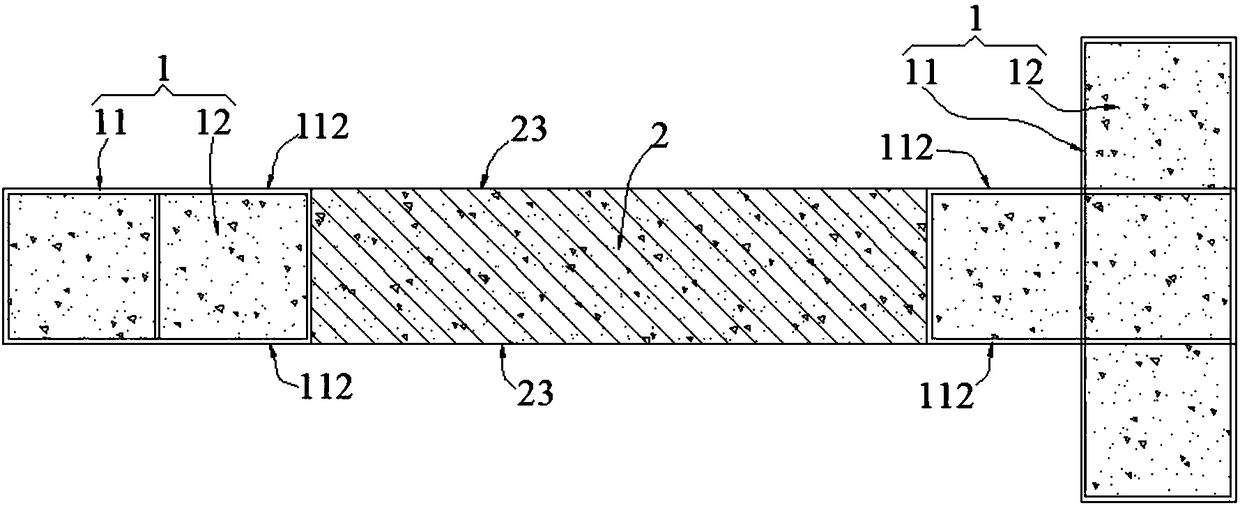

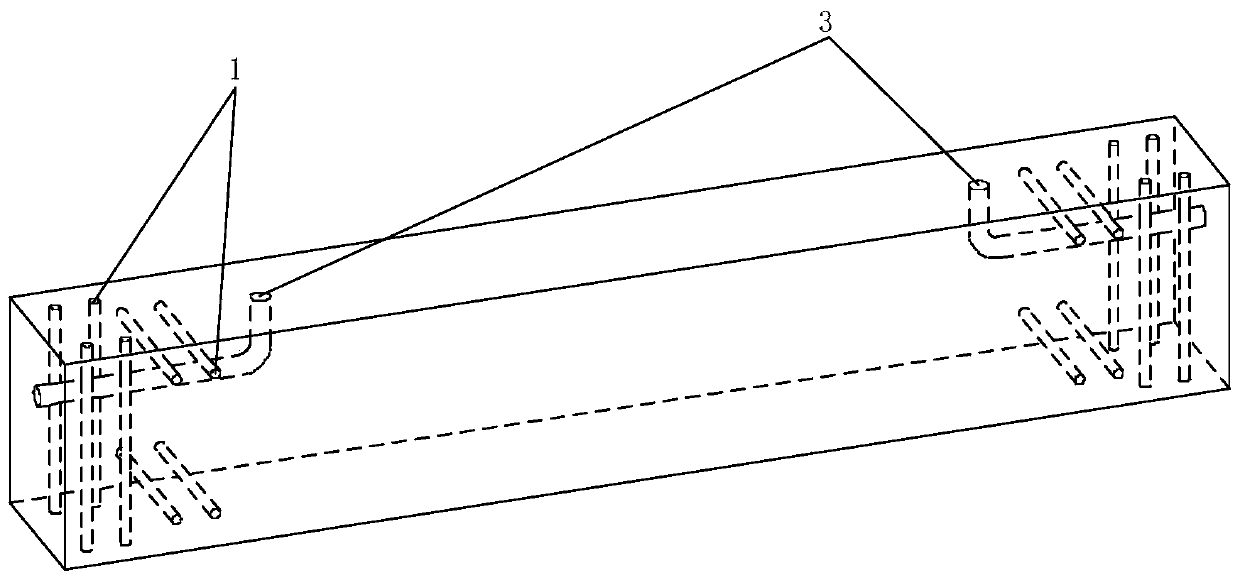

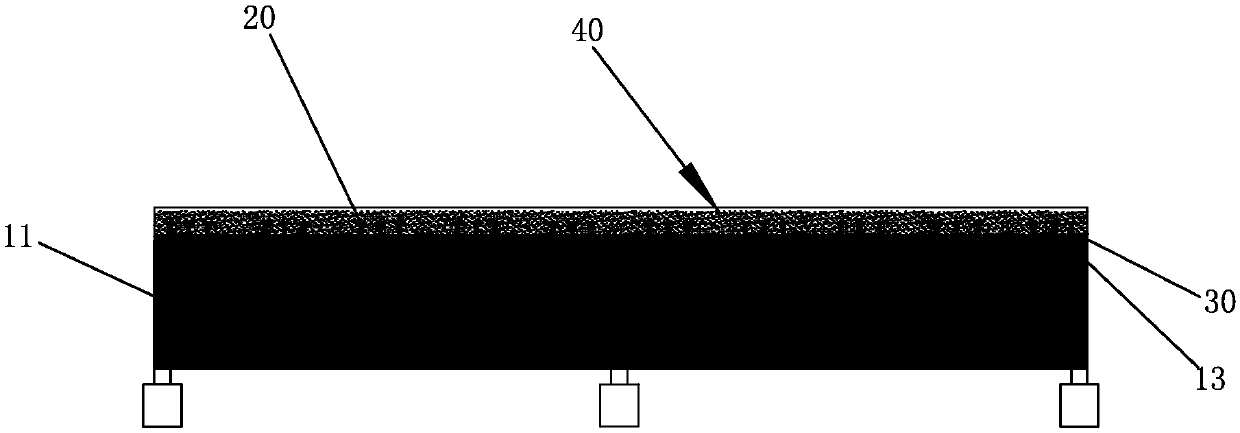

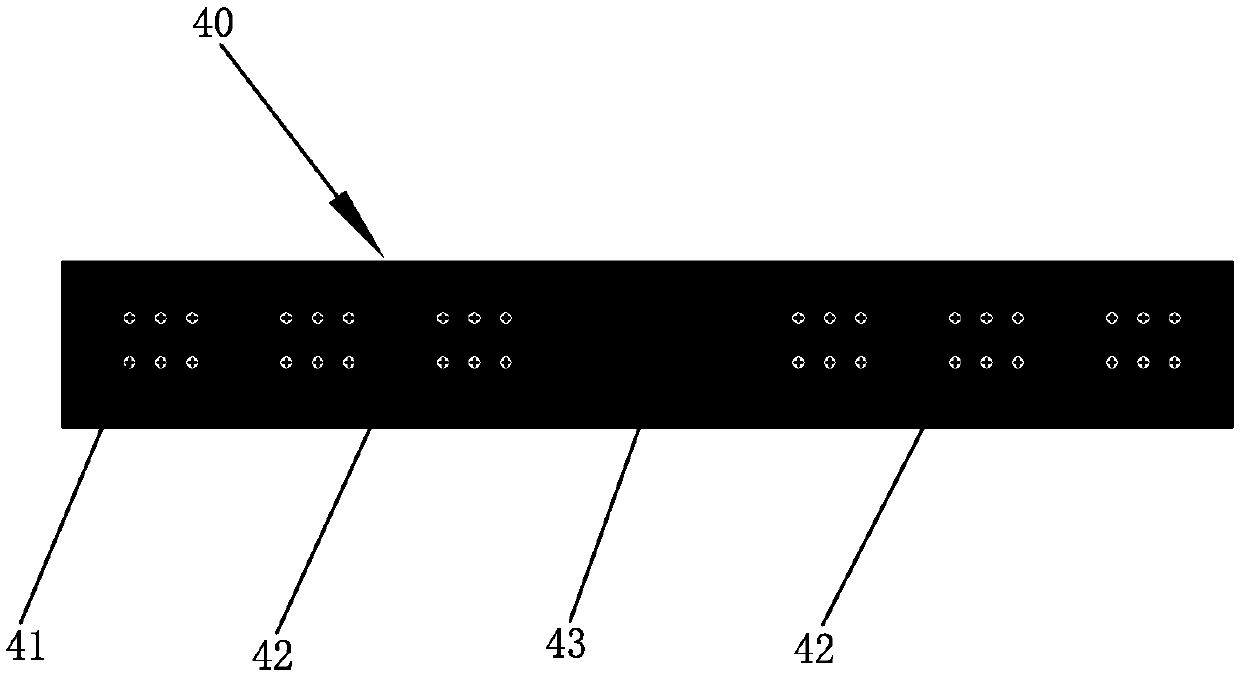

Prefabricated assembly type bolted connection reinforced concrete box-girder

InactiveCN106869404AImprove assembly efficiencyWork lessLoad-supporting elementsPrecast concreteMaterials science

A prefabricated assembly type bolted connection reinforced concrete box-girder comprises a prefabricated concrete slab, a steel beam, embedded bolts, an embedded thin-wall steel plate, embedded steel plates and a butt weld. Firstly, the steel beam and the prefabricated concrete slab are connected through the bolts embedded in the midspan of the prefabricated slab, the bearing capacity of a joint is improved, and the progressive collapse resistance of a structure is facilitated. Secondly, the embedded steel plates embedded at the two ends of the slab can be connected through the butt weld, the two adjacent plates are connected to resist hogging moment of a support part of the structure, and the integrity of the structure is improved. According to the assembly type steel beam, industrialized production is achieved, on-site fast assembly is achieved, the effect that concrete is poured on site is avoided, the construction efficiency is improved, and the environment pollution is reduced. Meanwhile, by the adoption of the assembly type structure system, the detachment and replacement functions of a member can be achieved, and the energy-saving and environment-friendly idea of the building is achieved.

Owner:XIJING UNIV

Prefabricated reinforced concrete shear wall vertical splicing joint structure and construction method thereof

PendingCN109339281ATake advantage of stress resistanceTake advantage of the tensile strengthWallsBuilding reinforcementsReinforced concreteRebar

The invention discloses a prefabricated reinforced concrete shear wall vertical splicing joint structure and a construction method thereof. The prefabricated reinforced concrete shear wall vertical splicing joint structure comprises an upper reinforced concrete shear wall and a lower reinforced concrete shear wall, and an area between the lower end of the upper reinforced concrete shear wall and the upper end of the lower reinforced concrete shear wall is a connecting area. Ultra-high performance concrete is poured in the connecting area to enable the upper reinforced concrete shear wall and the lower reinforced concrete shear wall to be connected as a whole. The prefabricated reinforced concrete shear wall vertical splicing joint structure applies the ultra-high performance concrete between the reinforced concrete shear walls, and fully utilizes the excellent compression resistance and tensile performance of the ultra-high performance concrete, thereby solving the problem of weak connection in joint regions.

Owner:HUAQIAO UNIVERSITY

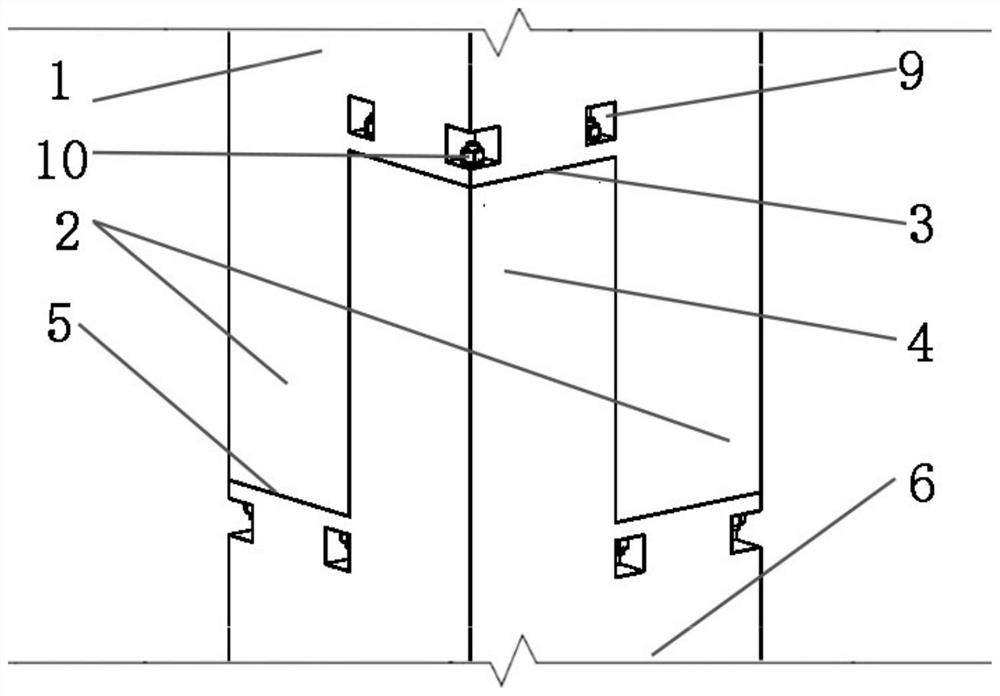

Fabricated composite shear wall and connection structure with steel beams and floors thereof

The invention discloses a fabricated composite shear wall and a connection structure with steel beams and floors thereof. The connection between edge members and walls is realized by cast-in-situ concrete poured in cavities of steel pipes of the edge members, the connection structure is simple and reliable, the quality of field construction of the shear wall can be guaranteed, and the advantages of concrete and a steel structure can be given full play, namely, the compressive performance of the concrete and convenient construction of the steel structure, and it is ensured that the fabricated composite shear wall has good lateral stiffness; and compared with existing double-layer steel plate composite shear walls, the fabricated composite shear wall and the connection structure with the steel beams and the floors thereof can save more than 50% of the amount of steel, and reduce the amount of concrete pouring in the construction site and the amount of framework construction in the construction site, so that the construction of the shear wall is speeded up and the use of workers is reduced. The connection structure of the shear wall and the steel beams realizes the connection betweenthe steel beams and the fabricated composite shear wall by using joint members, and the occupied space of the connection structures can be saved.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

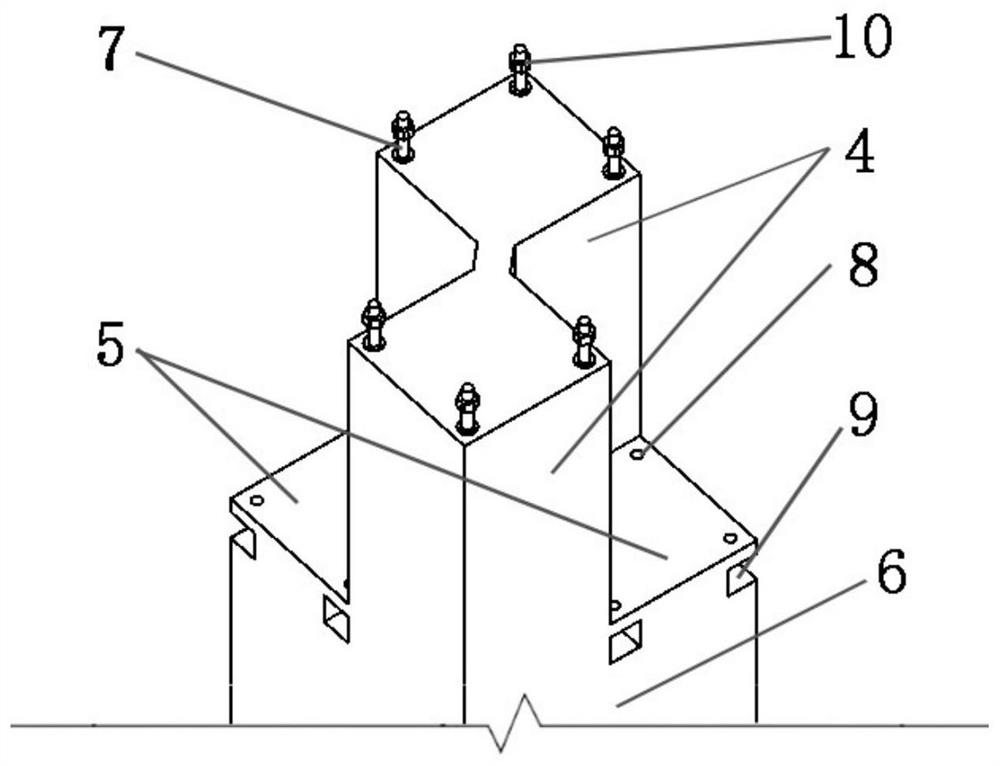

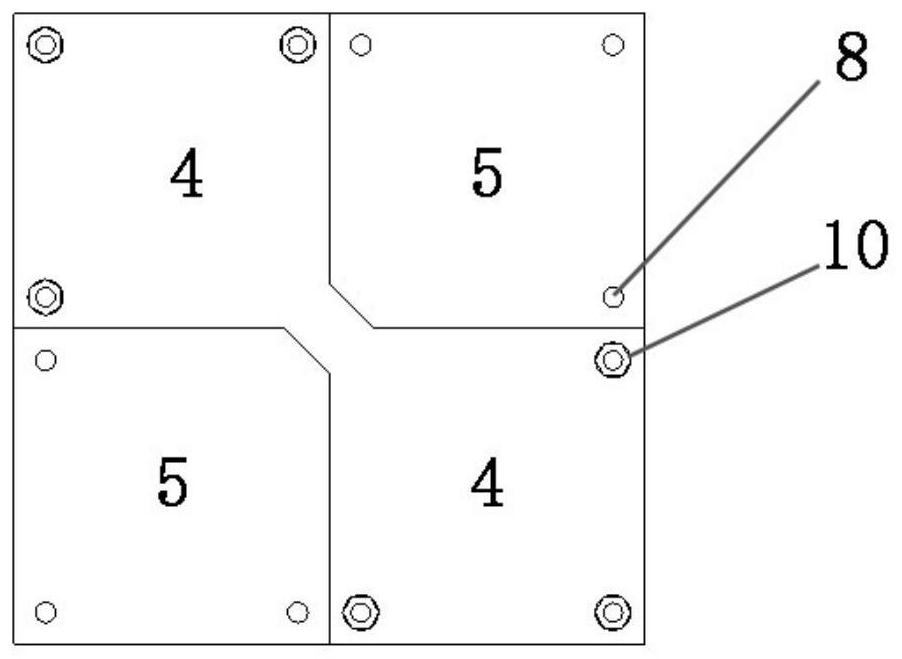

Assembly type PC column-column tenon type bolt connection joint

PendingCN113047455AImprove assembly efficiencyReduce on-site secondary processing workStrutsPillarsEngineeringAxial force

The invention provides an assembly type PC column-column tenon type bolt connection joint. The assembly type PC column-column tenon type bolt connection joint comprises an upper concrete column and a lower concrete column; an upper tenon and an upper mortise are arranged at the bottom of the upper concrete column in a crossed mode in the diagonal direction; a lower tenon and a lower mortise are arranged at the top of the lower concrete column in a crossed mode in the diagonal direction; the upper tenon and the lower mortise are connected in an adaptive and inserted mode, and the upper mortise and the lower tenon are connected in an adaptive and inserted mode; the upper tenon and the lower mortise are connected in an inserted mode, and the upper mortise and the lower tenon are connected in an inserted mode; a steel bar reserved on the upper tenon is aligned with a screw hole reserved in the lower mortise, a steel bar reserved on the lower tenon is aligned with a screw hole reserved in the upper mortise, and the steel bars are fixed in bolt mounting grooves through nuts correspondingly; and the vertical bearing capacity of the concrete columns is transmitted through connection of the upper tenon and the lower tenon, the area of the force transmission section is the same as that of the column section, bolt connection only bears the vertical load of the columns, part of axial force is borne in the normal state, tensile force is borne under the earthquake action, and stress is clear. The assembly type PC column-column tenon type bolt connection joint has the advantages of being simple in structure, convenient to construct, efficient in assembly and high in shear capacity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

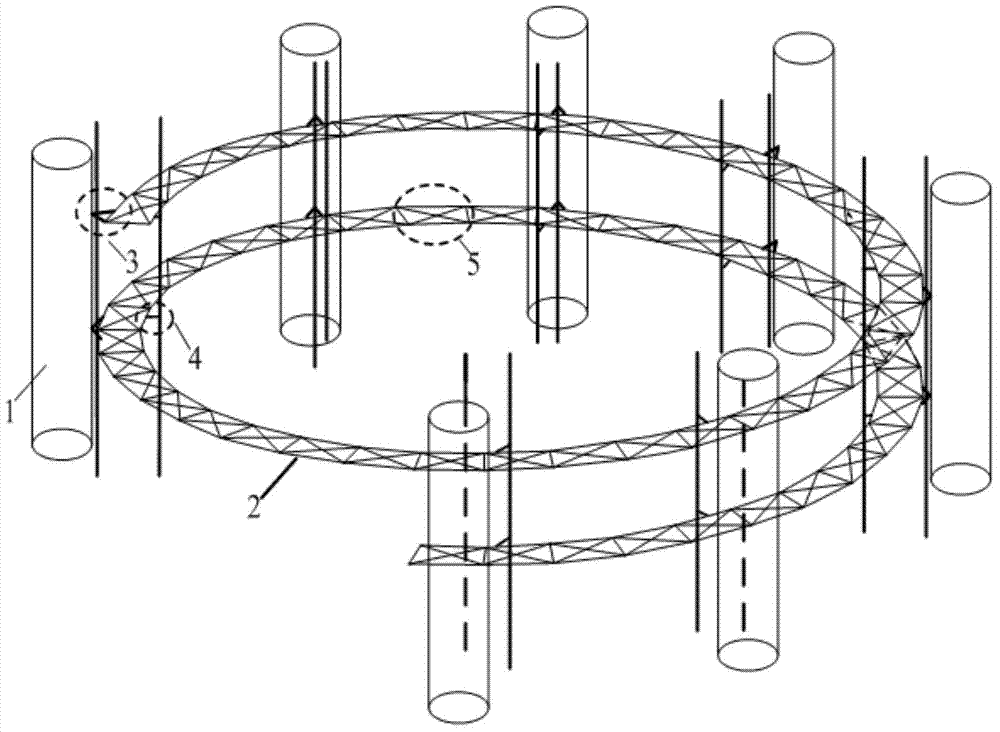

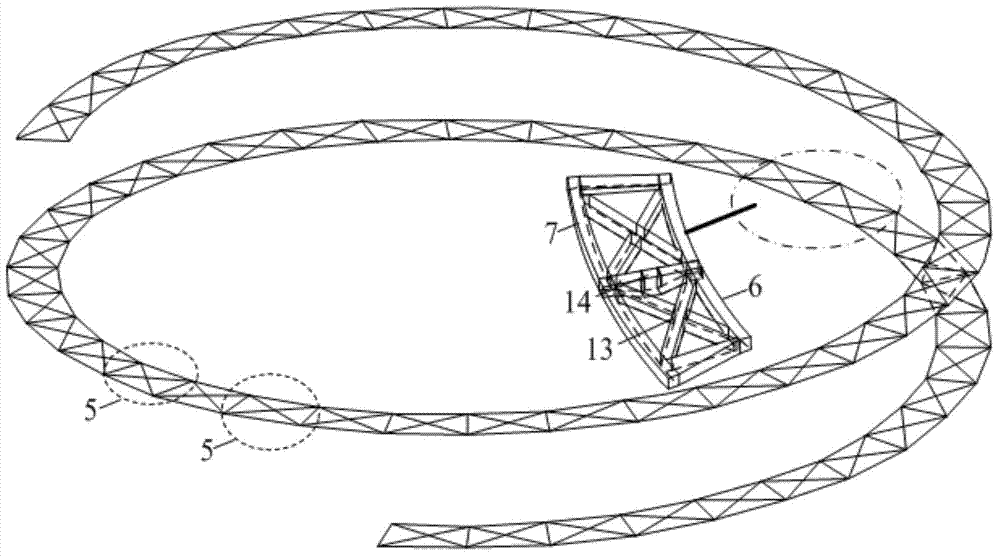

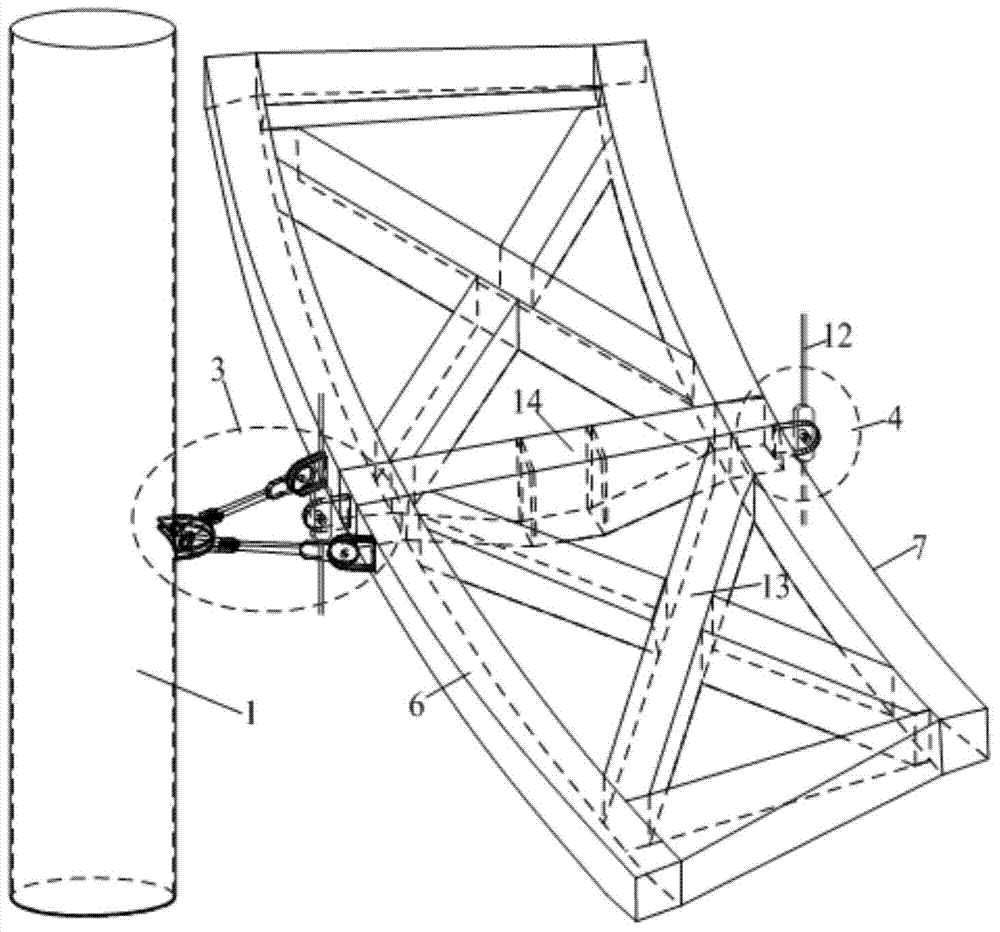

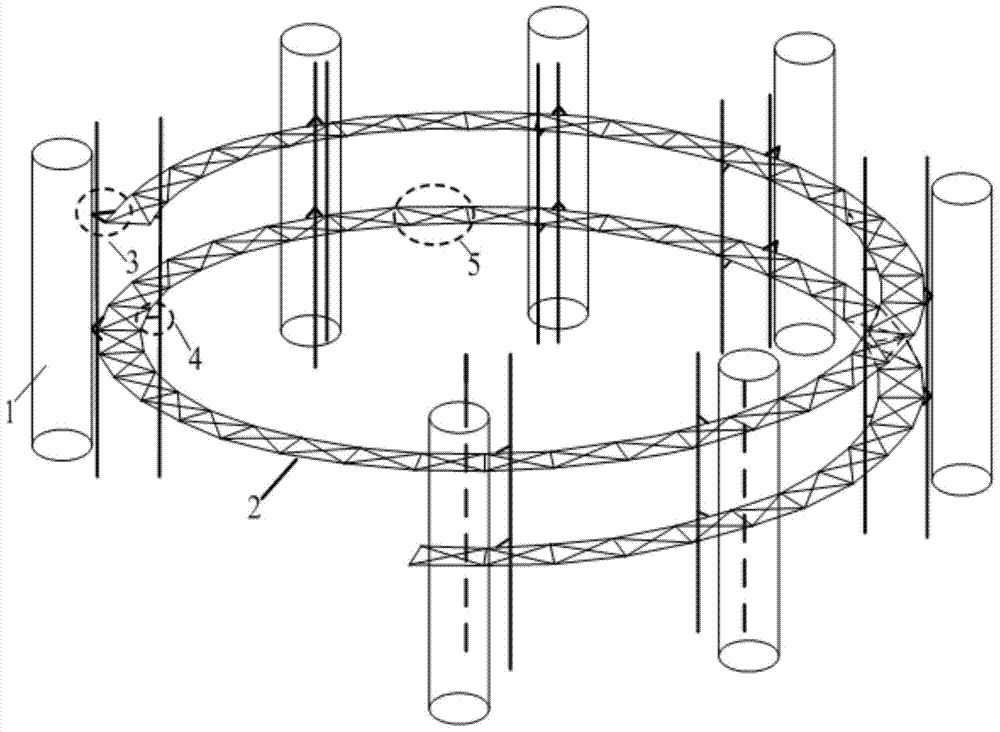

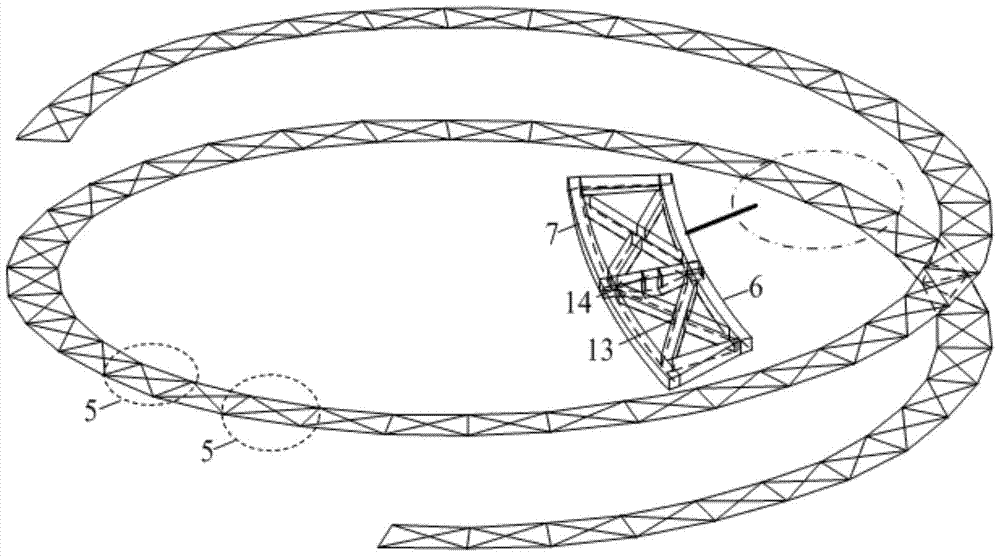

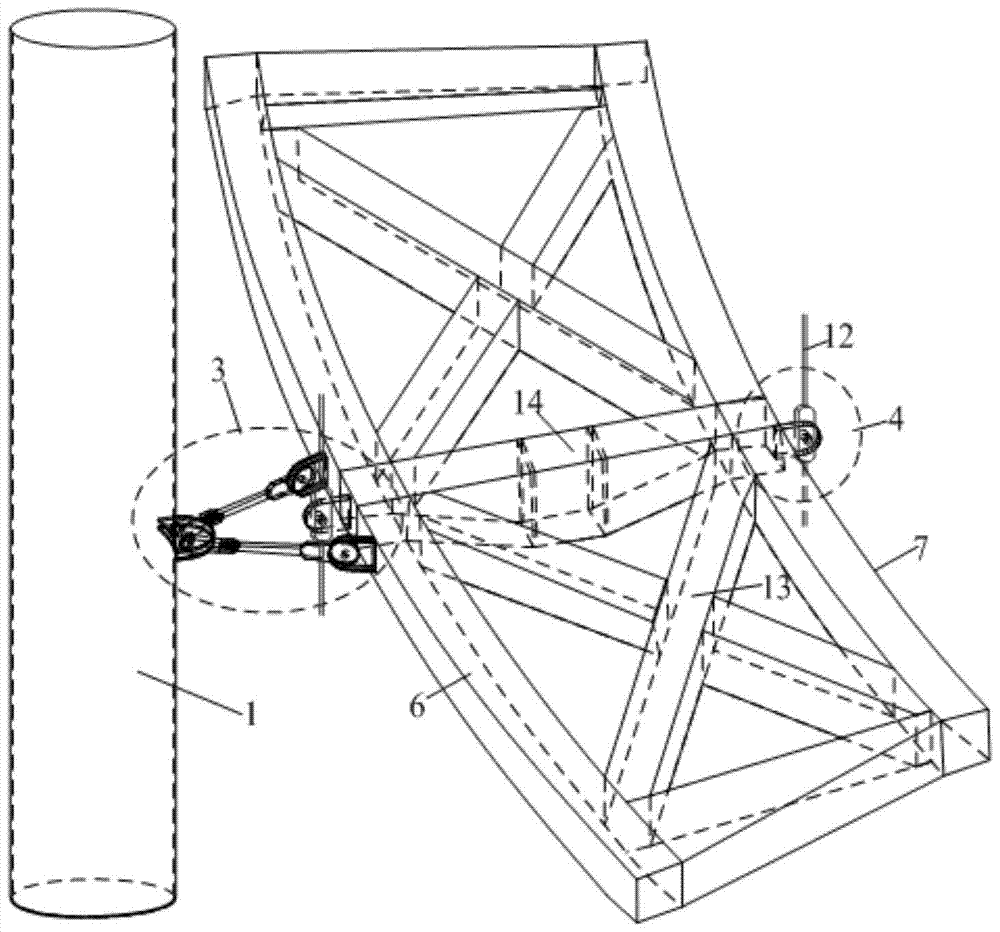

Column and curved beam horizontal and flexible connection space structure system

The invention provides a column and curved beam horizontal and flexible connection space structure system. Columns and curved beams are horizontally and flexibly connected through horizontal and flexible connecting devices, each horizontal and flexible connecting device comprises a column connector, a curved beam connector a and a steel pull rod for connecting the column connector with the curved beam connector. A vertical suspending connecting device is further connected onto each curved beam and comprises a curved beam connector b and a movable steel suspending rod. The column and curved beam horizontal and flexible connection space structure system is a grid structure and suspended-cable structure combined space structure system. In a space truss structure system, the strength and ductility of a grid curved beam structure are improved, bending resistance bearing capacity of the curved beams is remarkably improved, and deflection deformation of the curved beams is reduced. In a suspended-cable structure, suspended steel structure curved beams are connected through flexible suspending rods. The column and curved beam horizontal and flexible connection space structure system has the flexible connection characteristic, accordingly is simple in overall appearance, even in stress, good in anti-seismic energy dissipation performance and easy to repair and maintain and meets the comfort degree requirement of a suspended steel structure.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD +1

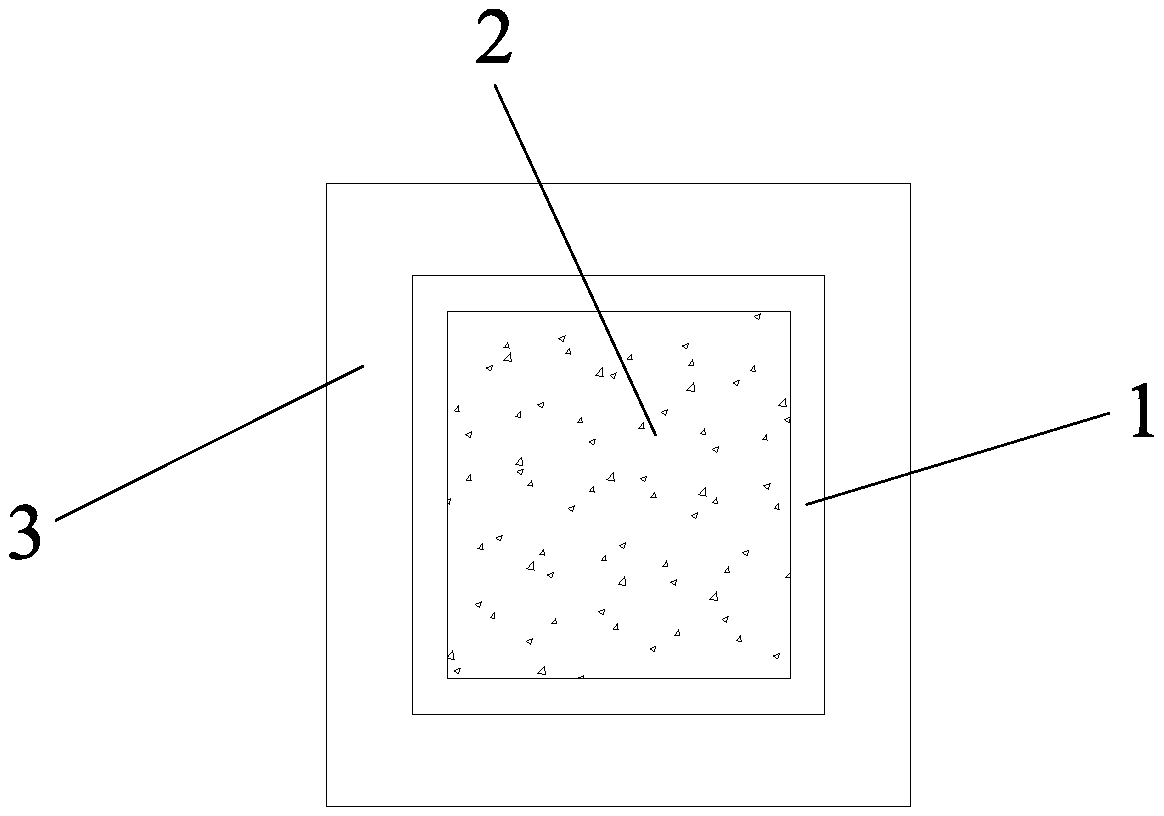

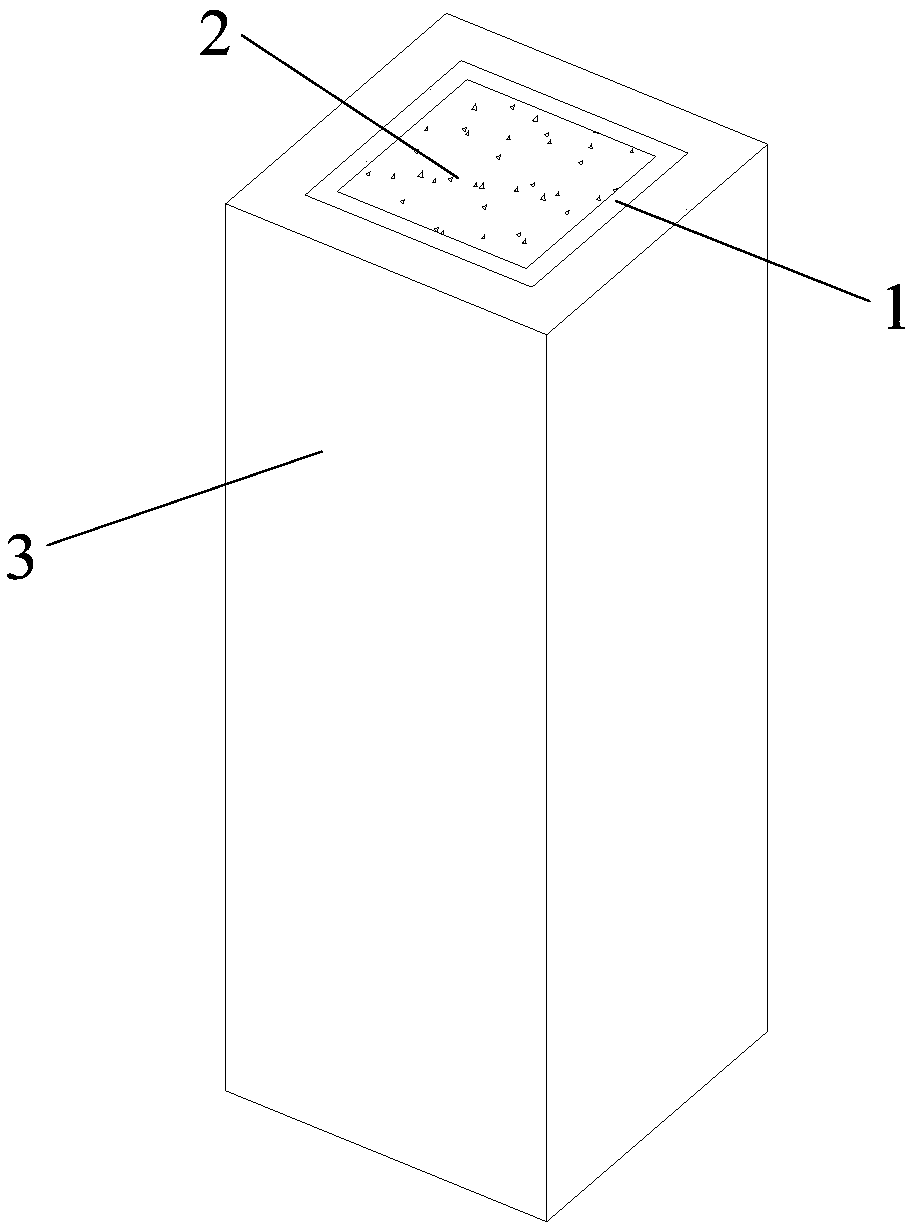

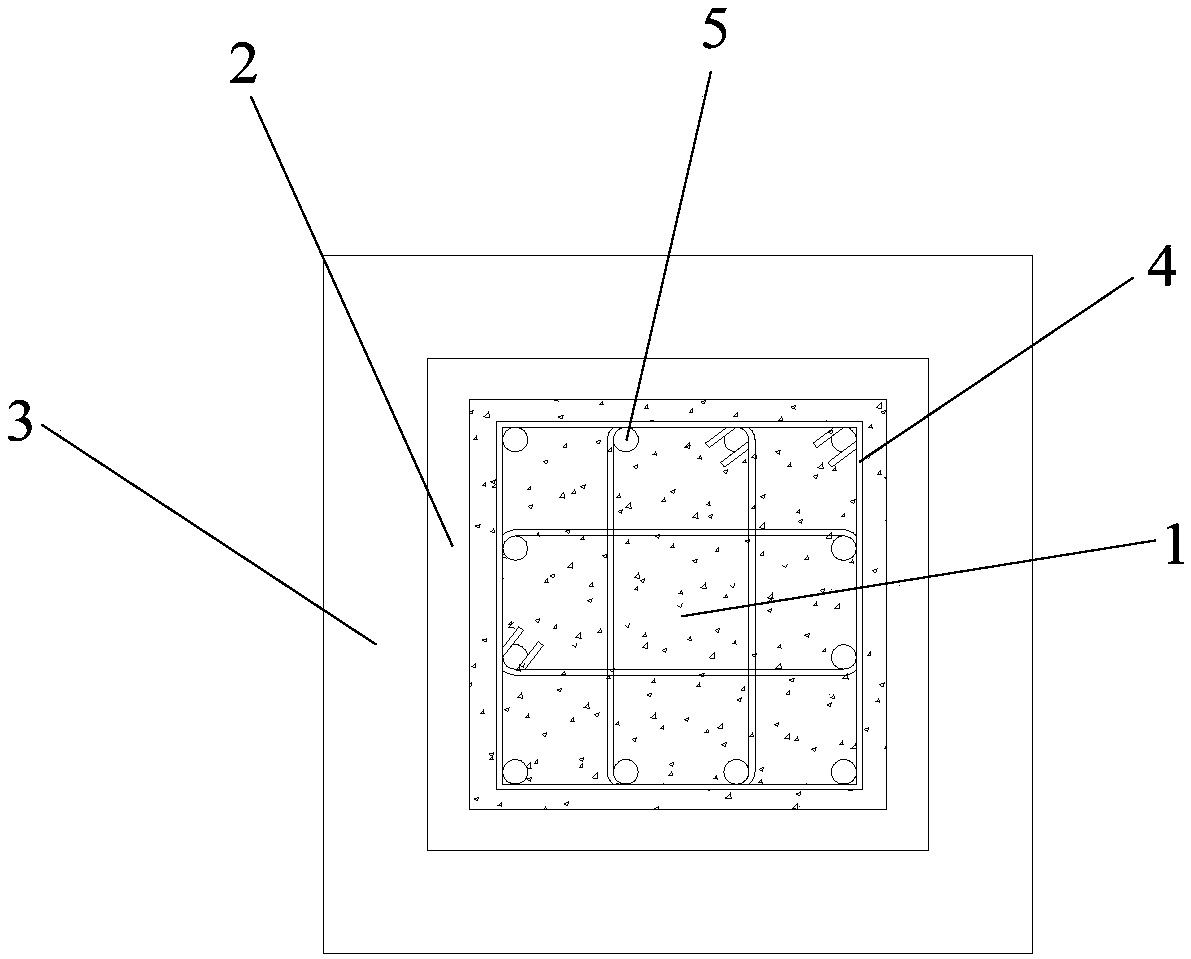

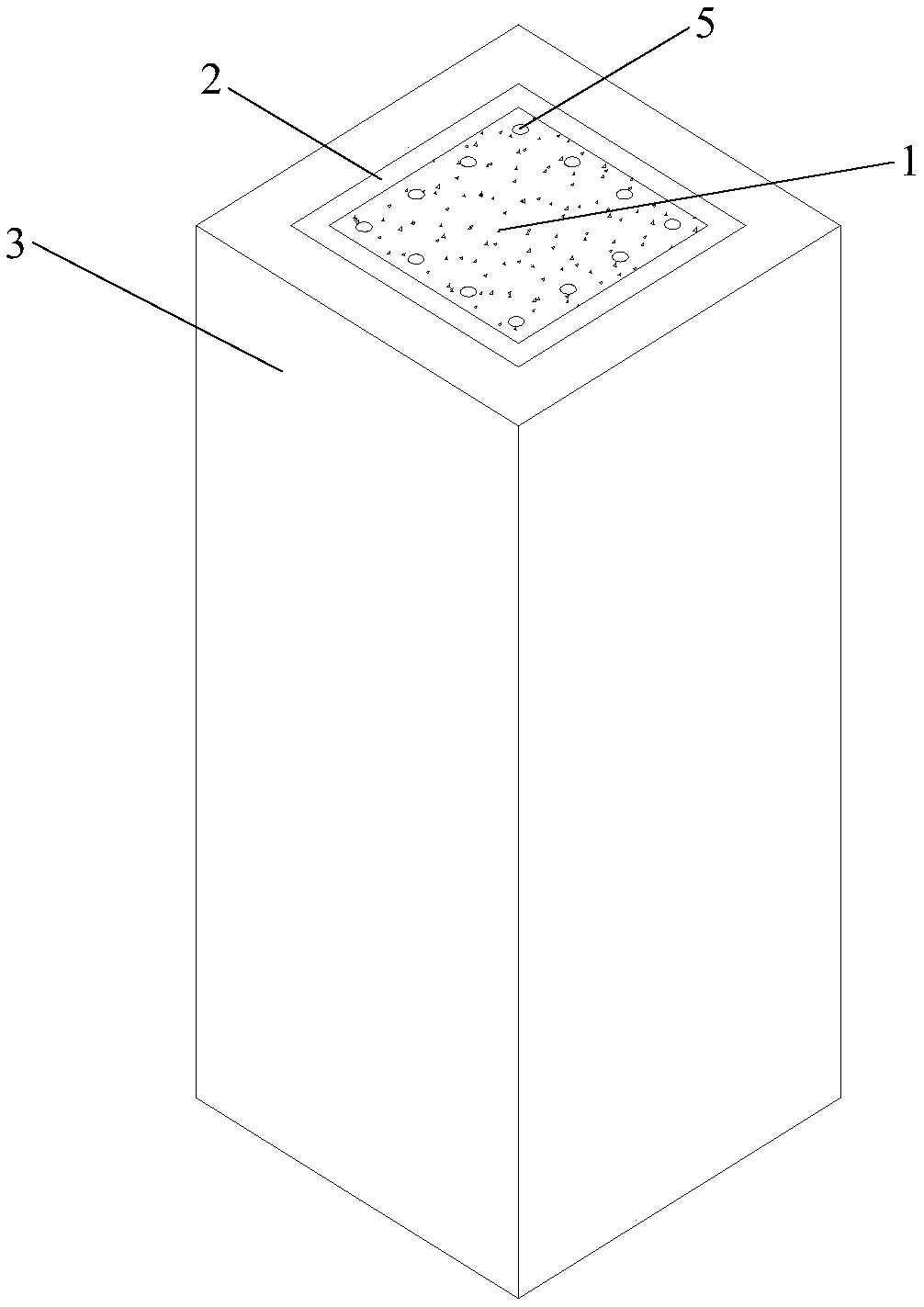

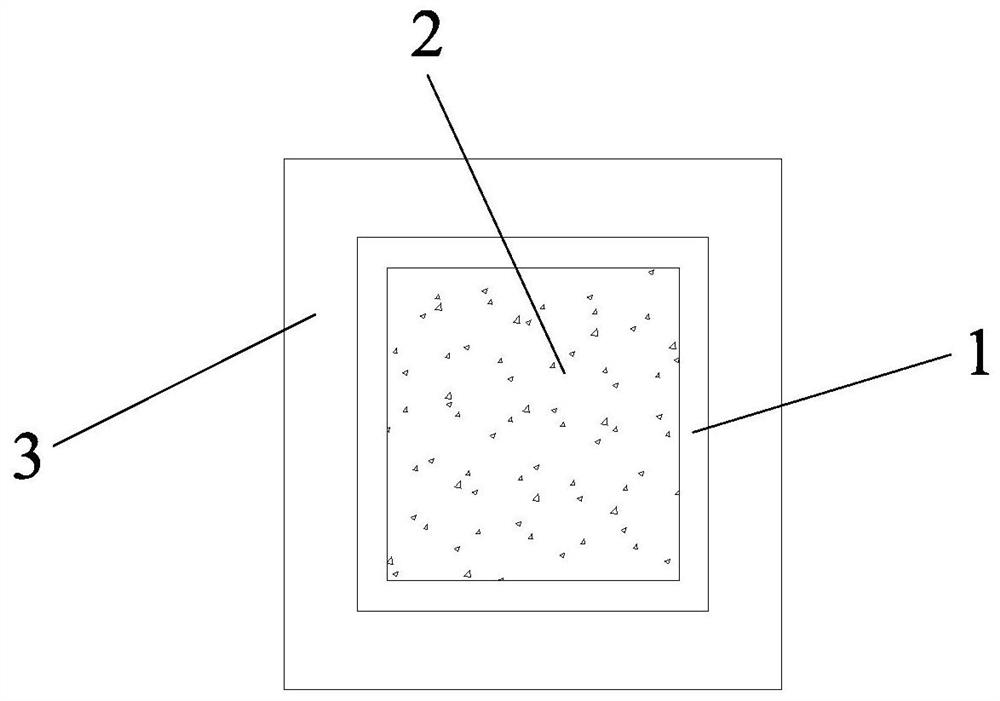

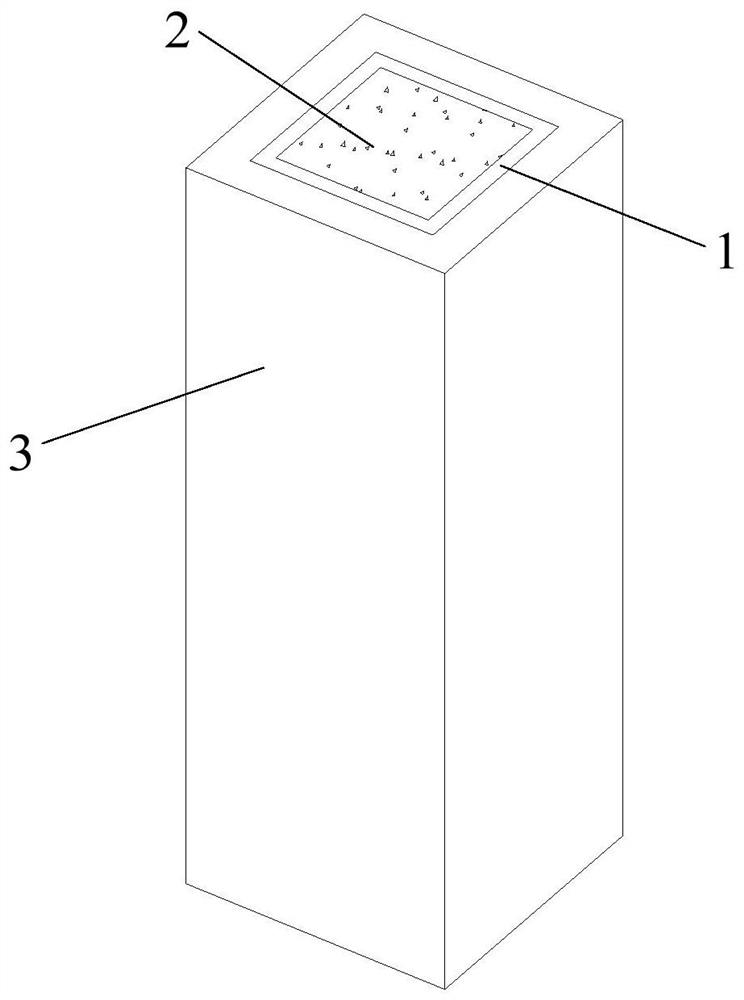

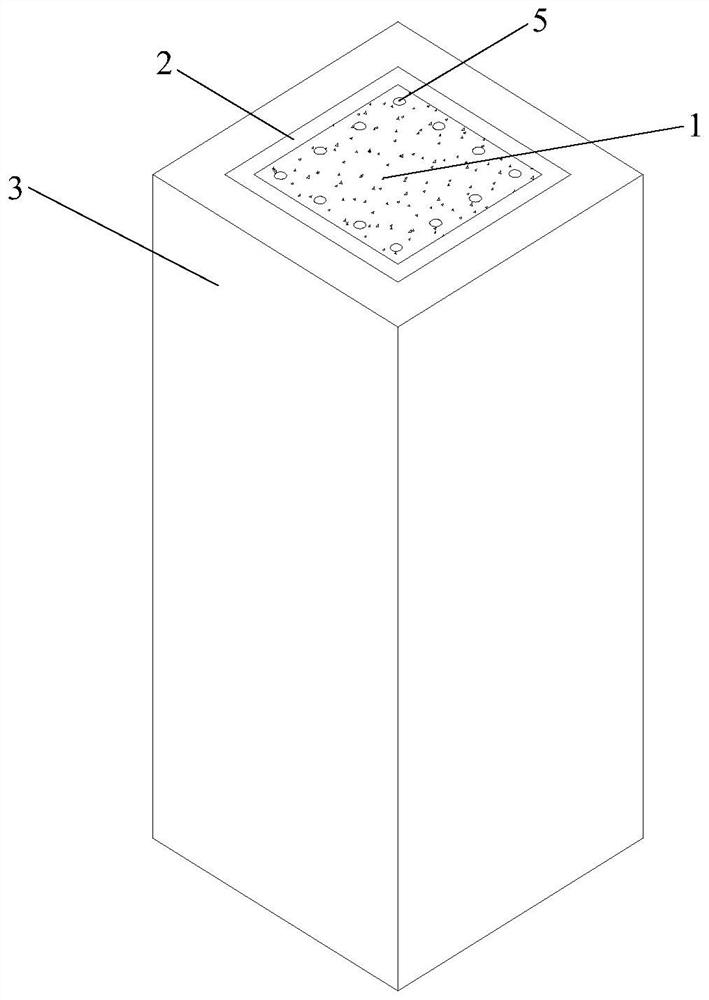

Construction device and construction method for curing ultra-high performance concrete filled steel tubular column at room temperature

ActiveCN109386092AAvoid getting lostUnique ratioStrutsBuilding material handlingMass ratioSuperplasticizer

The invention discloses a construction device and a construction method for curing an ultra-high performance concrete filled steel tubular column at room temperature. The construction device comprisesa concrete column, steel tubes and an insulating layer, wherein the concrete column is prepared by mixing water, cement, silica fume, quartz powder, a polycarboxylic type superplasticizer, quartz sand and sodium polyacrylate according to the mass ratio of 0.2 to 1 to 0.15 to 0.2 to 0.009 to 1.75 to 0.03; the concrete is cured for seven days to obtain the ultra-high performance concrete with the strength being more than 150MPa. The construction device and construction method disclosed by the invention have the advantages of good technical feasibility and convenient construction; by use of theconstruction device and the construction method, the concrete can be cured in a normal temperature environment, so that the ultra-high performance concrete is obtained and further the bearing capacityof a concrete filled steel tubular column is greatly improved; in addition, the site construction quality is ensured and the construction efficiency is improved. Besides, no autoclaved equipment is required, so that the construction cost is reduced and the promotion in practical engineering is facilitated.

Owner:HUAQIAO UNIVERSITY

Prefabricated non-reinforced concrete framework and construction method thereof

The invention provides a prefabricated non-reinforced concrete framework. The prefabricated non-reinforced concrete framework is composed of prefabricated concrete joint columns, prefabricated concrete beams, steel connecting parts and grouting pipes. The prefabricated concrete joint columns and the prefabricated concrete beams are formed by pouring polyethylene fiber concrete. The polyethylene fiber concrete is formed by mixing cement, sand, water, coal ash, water reducer and polyethylene fibers. The invention further provides a construction method of the prefabricated non-reinforced concreteframework. Use of rebars is avoided while the strength and the ductility of components are guaranteed, splicing joints and the construction method are adopted, resources can be effectively saved, andthe site construction efficiency and the quality safety level can be improved.

Owner:HUAQIAO UNIVERSITY

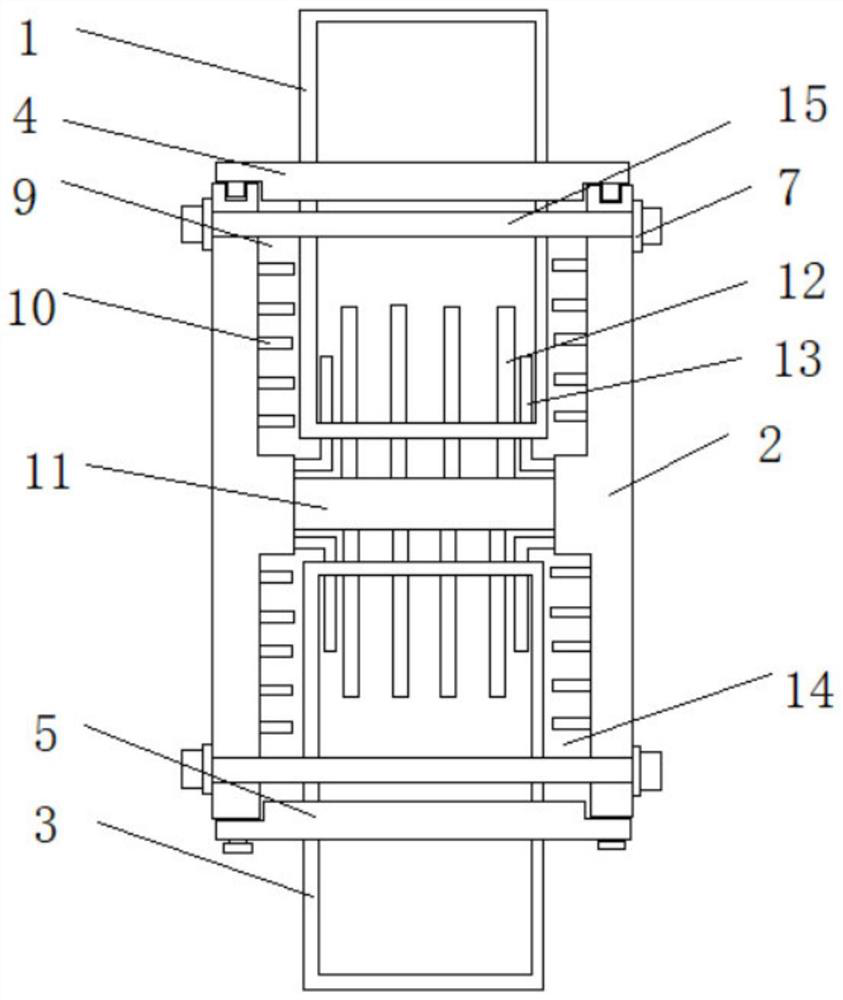

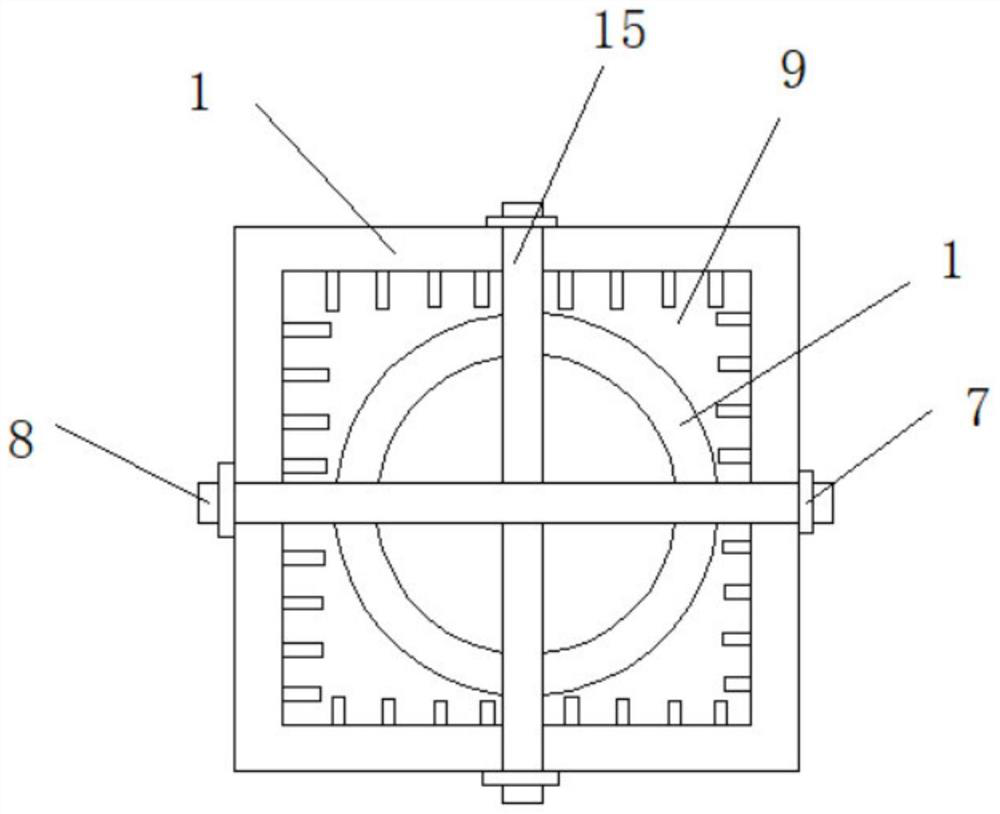

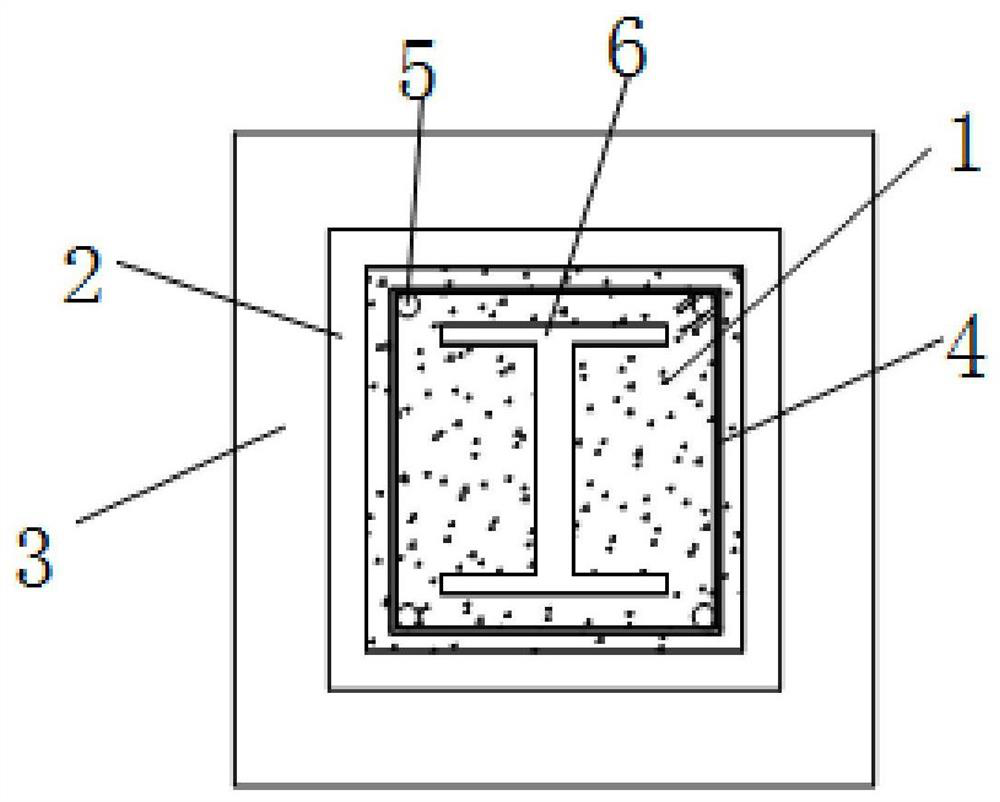

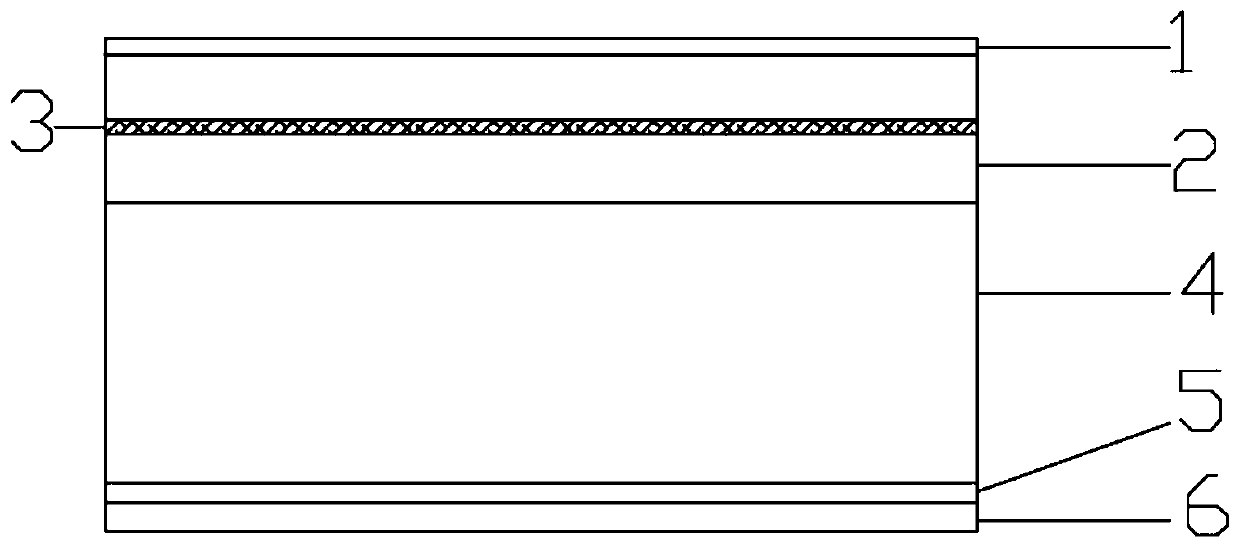

Splicing structure of fabricated concrete-filled steel pipe column

PendingCN113136952AImprove assembly efficiencyImprove bearing capacityBuilding constructionsArchitectural engineeringPipe

The invention relates to the related field of constructional engineering, in particular to a splicing structure of a fabricated concrete-filled steel pipe column. The splicing structure of the fabricated concrete-filled steel pipe column comprises an upper steel pipe column, a splicing shell and a lower steel pipe column. According to the splicing structure of the fabricated concrete-filled steel pipe column, the splicing shell, a connecting and fixing rod, an upper sealing plate and a lower sealing plate used in the splicing structure are all processed in a factory and can be assembled and connected on a construction site after being transported to the construction site, on-site welding work and formwork work are reduced, the on-site construction quality is guaranteed, and the building industrial assembly efficiency is improved; second reinforcing ribs are connected to the upper end and the lower end of a mounting frame, the top ends of the second reinforcing ribs are arranged in the upper steel pipe column and the lower steel pipe column, a plurality of arc-shaped grooves are evenly formed in the surfaces of the second reinforcing ribs, and first reinforcing ribs are horizontally welded to the inner cavity walls of an upper splicing groove and a lower splicing groove in parallel, so that the second reinforcing ribs and the first reinforcing ribs are better adhered to concrete when the concrete is poured, so that the bearing capacity and the deformability of the concrete-filled steel pipe column are improved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Combined bridge capable of prolonging fatigue life of shear connectors and manufacturing method thereof

PendingCN108677683AImprove stress concentrationReduce stress concentrationBridge erection/assemblyBridge materialsStress concentrationBond interface

The invention discloses a combined bridge capable of prolonging the fatigue life of shear connectors and a manufacturing method thereof. Each steel box beam comprises two steel beams extending in thelength direction of the bridge and a plurality of first transverse diaphragms arranged in the length direction of the bridge at intervals. Each first transverse diaphragm is fixedly connected with thetwo corresponding steel beams, a supporting plate extending in the length direction of the bridge is arranged at the top end of each steel beam, and the shear connectors are fixedly connected to thesupporting plates; reserved holes which are the same as the shear connectors in number and are in one-to-one correspondence with the shear connectors are formed in the bottom end of a concrete deck slab, and when the concrete deck slab is placed on the steel box beams, each shear connector extends into the corresponding reserved hole; and an epoxy mortar layer is poured into the space between thetwo ends of each supporting plate and the concrete deck slab. According to the combined bridge, the bonding force of a bonding interface between the steel box beams and the concrete deck slab is effectively increased, the shear capacity of the bonding interface is improved, stress concentration of the shear connectors and the concrete deck slab is improved, and thus the fatigue life of the shear connectors is effectively prolonged.

Owner:HUAQIAO UNIVERSITY

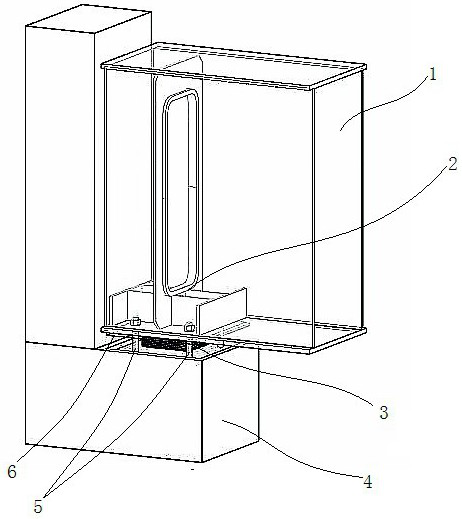

Steel box beam and concrete column hinged joint and construction method thereof

PendingCN111827467AImprove reliabilityHigh implementabilityBuilding constructionsArchitectural engineeringSteel box girder

The invention provides a steel box beam and concrete column hinged joint and a construction method thereof. The steel box beam and concrete column hinged joint comprises a concrete column and a steelbox beam. The end of the steel box beam is located on the column side bracket of the concrete column, and a rubber support is arranged between the steel box steam and the column side bracket. The steel box beam and the column side bracket are fixed through multiple foundation bolts. An inner supporting assembly is arranged in the steel box beam and located in the foundation bolt installation area.According to the steel box beam and concrete column hinged joint, the rubber support and the inner supporting assembly are adopted to jointly connect the steel box beam and the concrete column, so that shear force transmitted by the steel box beam can be transmitted, rotation deformation of the steel box beam in the bent direction is reasonably released, and reliability and implementation performance of joint connection are improved; and meanwhile, a bolted fixation manner is adopted, on-site fixation of the steel box beam and the concrete column is adjusted into the steel box beam, on-site welding operation is canceled, the space in the steel box beam is fully utilized, the space problem of on-site installation is solved, and on-site construction quality and component stress requirementsare effectively guaranteed.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

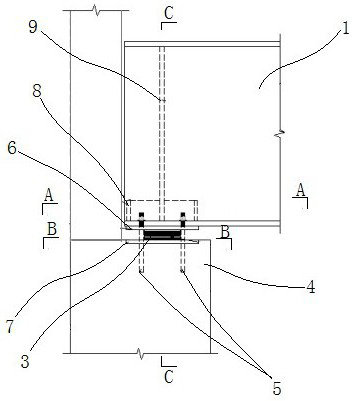

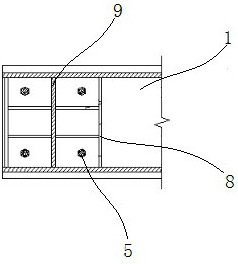

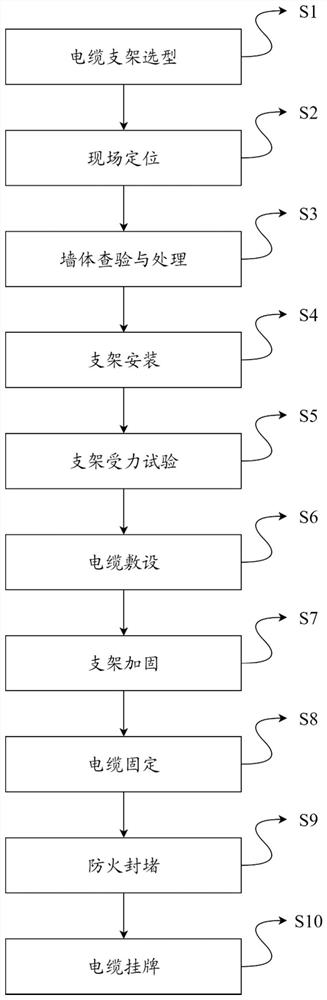

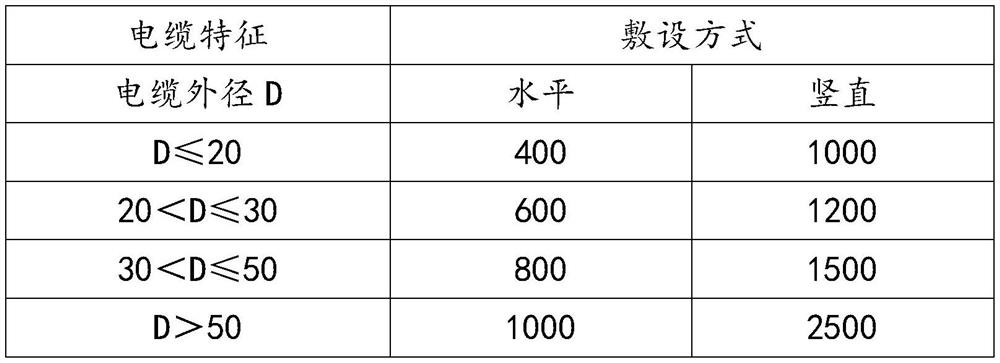

Flexible mineral insulated cable construction method

InactiveCN112290460ASimple constructionConstruction progress and project quality promotionApparatus for laying cablesStructural engineeringSocial benefits

The invention provides a flexible mineral insulated cable construction method, which belongs to the technical field of electric wire and cable engineering. The method comprises the steps of cable bracket model selection, field positioning and the like, and is characterized in that a cable path is planned in advance, including wall body treatment and bracket manufacturing and mounting; under the condition of ensuring firmness, cable laying is carried out, the cables are classified and sorted according to the types and specifications of the cables and then are fixed through ribbons; the on-siteconstruction quality is guaranteed, construction is easy, convenient and rapid, the construction progress and the engineering quality are greatly promoted, and good economic benefits and social benefits are obtained. The problems that according to a common laying method, many bridges are needed, the construction investment is large, the construction space is small, and the construction period is long are well solved, a launching type laying part adopts a bridge-free construction mode, and the construction cost is reduced; and a trunk type laying part adopts a prefabricated branch cable and adopts a cable bracket for laying, so that the fireproof requirement of a super high-rise building on the cable is successfully met.

Owner:中建八局发展建设有限公司

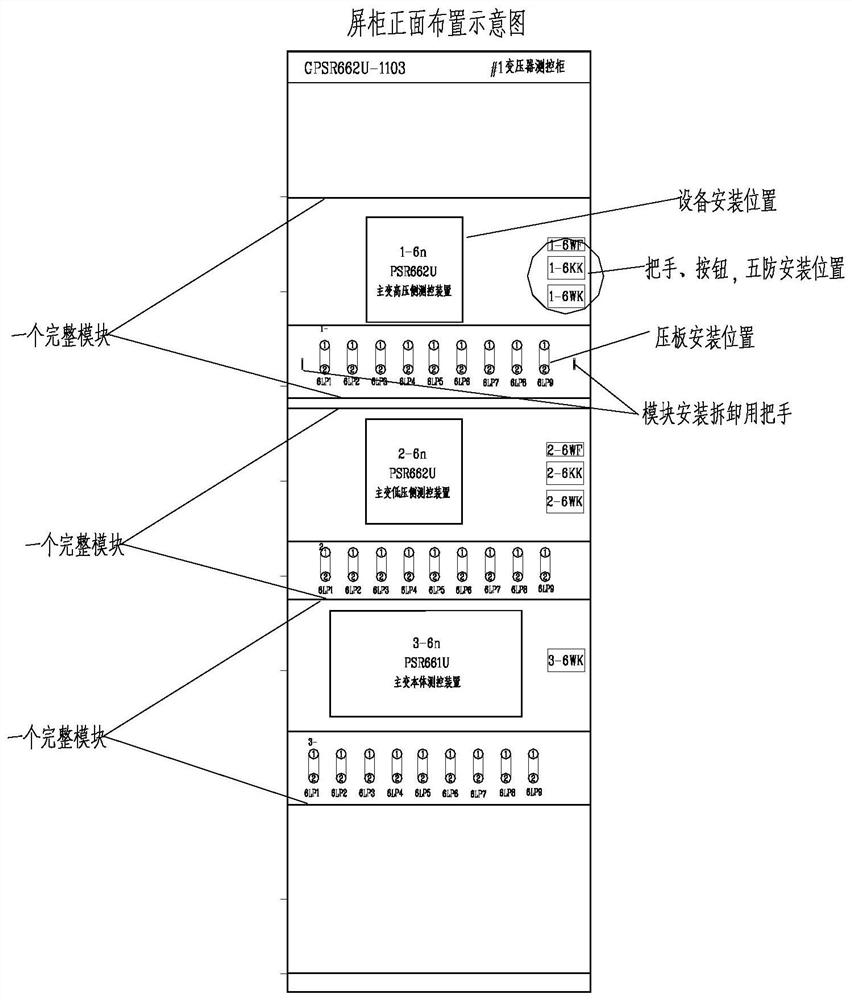

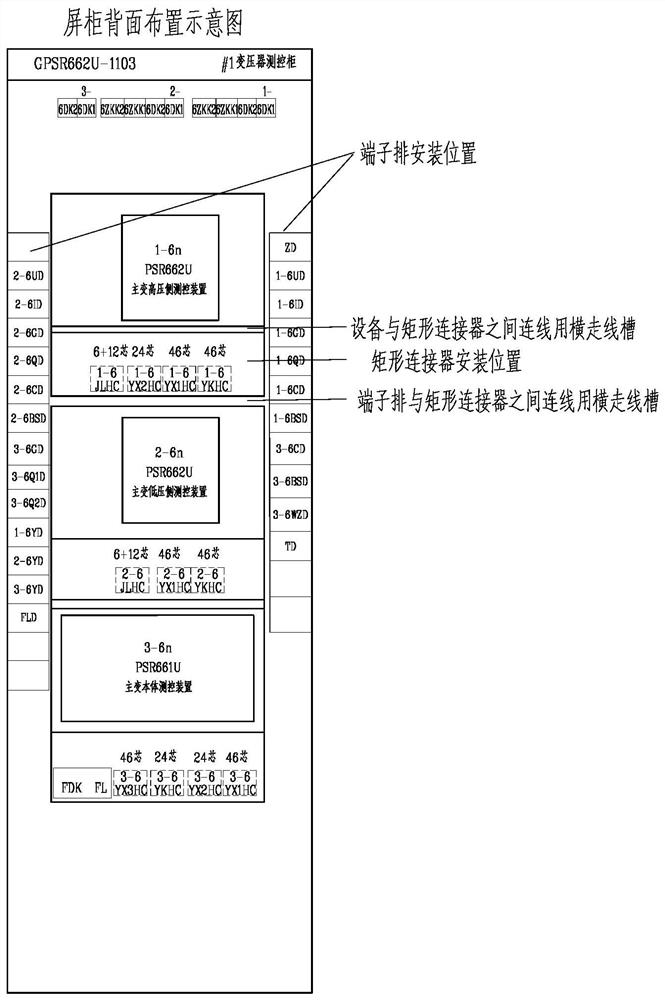

Object-oriented configuration prefabricated secondary equipment screen cabinet

InactiveCN113346373ARealize plug and playQuality improvementBus-bar/wiring layoutsSubstation/switching arrangement casingsControl signalPrefabrication

The invention discloses an object-oriented configuration prefabricated secondary equipment screen cabinet. A standard screen cabinet size is adopted, secondary equipment configuration modules are arranged in a screen cabinet in a partitioned manner; according to the object-oriented secondary equipment configuration module, secondary equipment is taken as a core, accessories such as a pressing plate, a handle and a button related to the equipment are regarded as a whole to be uniformly packaged, and an integrated standardized module is integrated. Connection modes of standardized connectors are adopted, and power input, analog input, control signal I / O and the like of the secondary equipment are respectively connected to different connectors. According to the object-oriented configuration prefabricated secondary equipment screen cabinet of the invention, the plug and play of the whole module is realized, the factory configuration module prefabrication can improve the manufacturing quality and efficiency of the secondary equipment and accessories, the on-site construction quality is ensured, the project construction period is shortened, and the on-site operation difficulty is reduced.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

Normal-temperature curing type concrete column with superhigh property and construction method thereof

ActiveCN109455987AUnique ratioAvoid getting lostBuilding material handlingReinforced concrete columnRebar

The invention discloses a normal-temperature curing type concrete column with superhigh property and a construction method thereof. The normal-temperature curing type concrete column has the advantages that the technique is feasible, and the construction is convenient and rapid; the concrete can be cured under the normal temperature environment, so as to obtain the concrete with superhigh property; the bearing capacity of the reinforced concrete column is greatly improved, the site construction quality is guaranteed, and the construction efficiency is improved; the autoclave equipment is not required, the construction cost is reduced, and the normal-temperature curing type concrete column is suitable for popularization in actual engineering.

Owner:HUAQIAO UNIVERSITY

Composite shear wall and steel truss composite beam connection energy dissipation node and its preparation method

ActiveCN106121049BResolve reliable connectionGood energy dissipation and shock absorptionWallsFloorsHigh energyRebar

Owner:HEFEI UNIV OF TECH

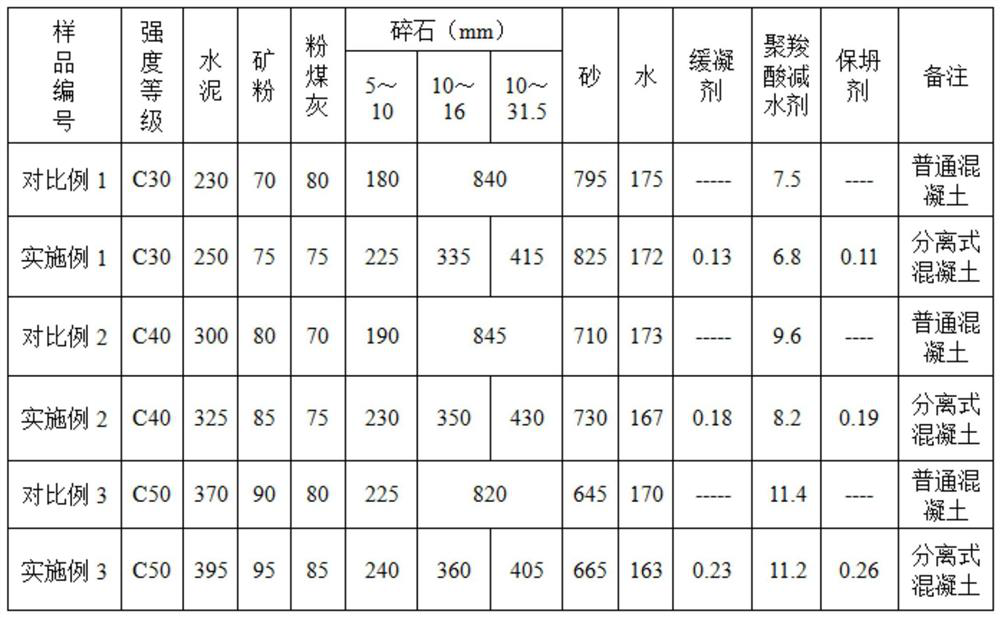

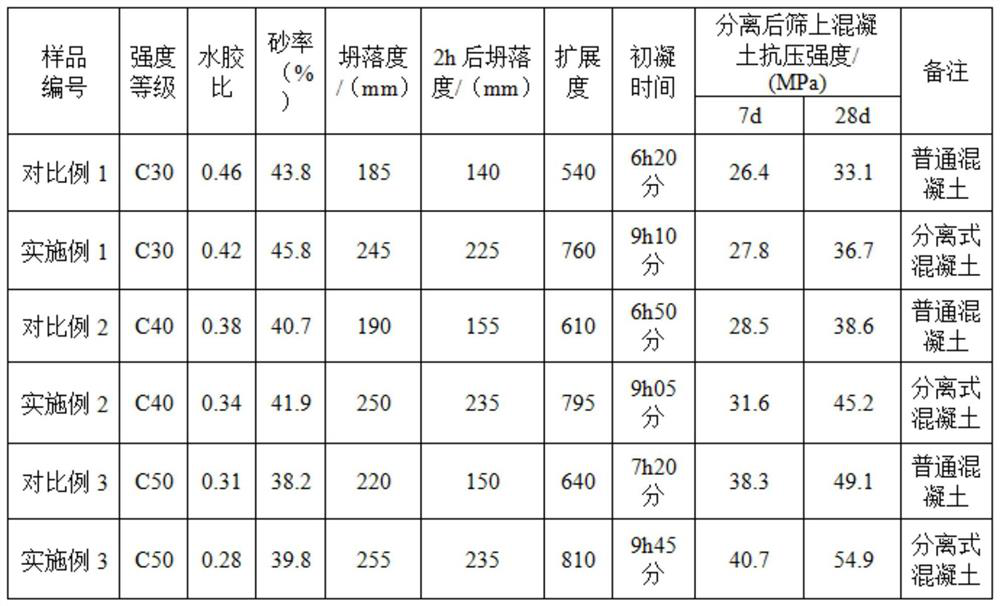

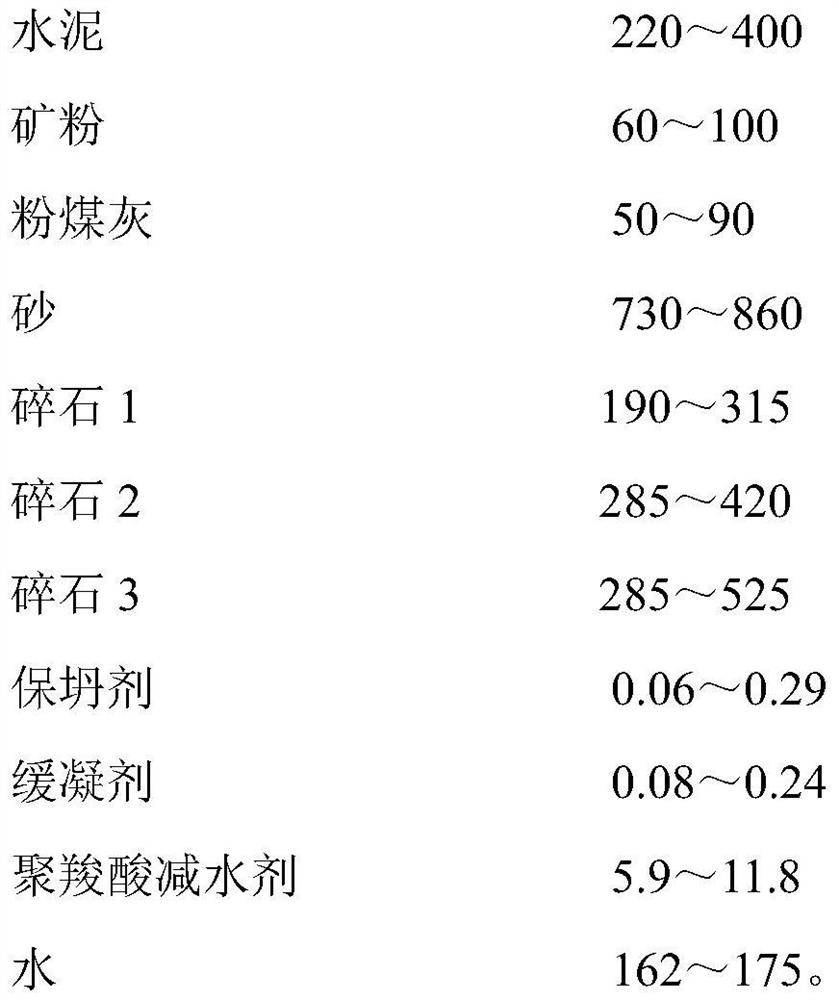

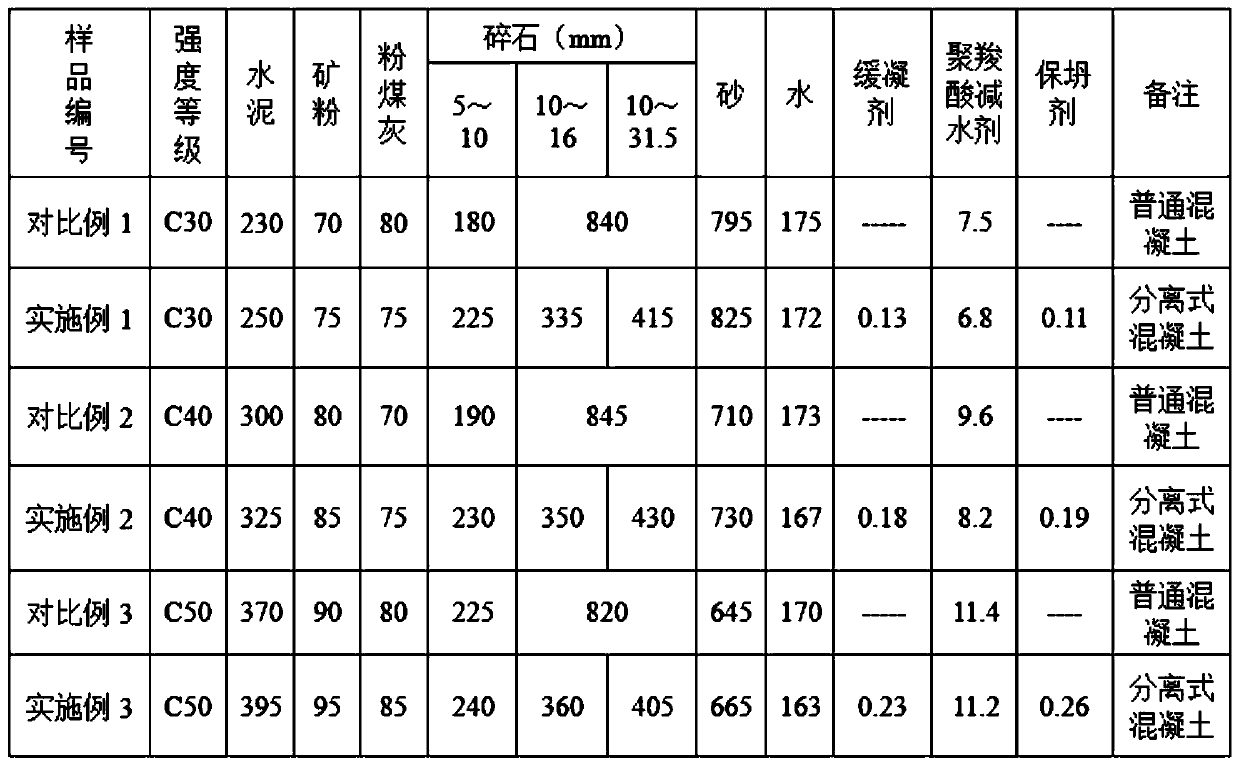

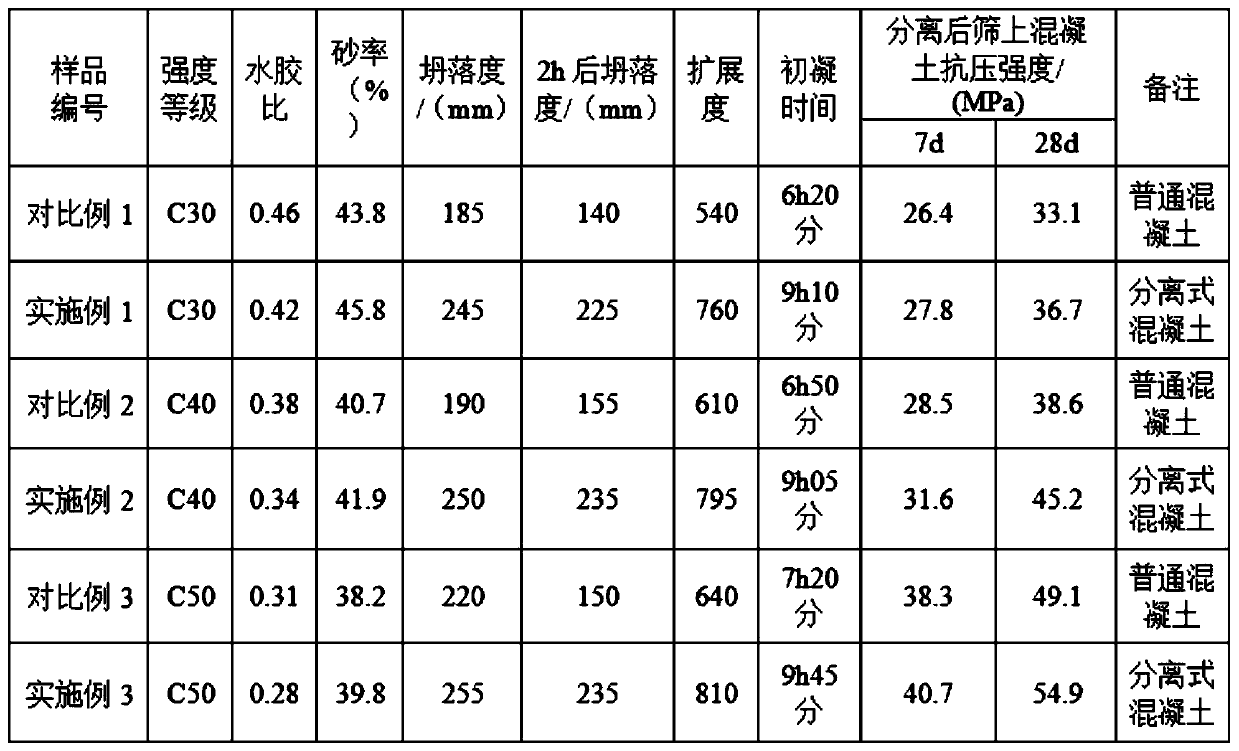

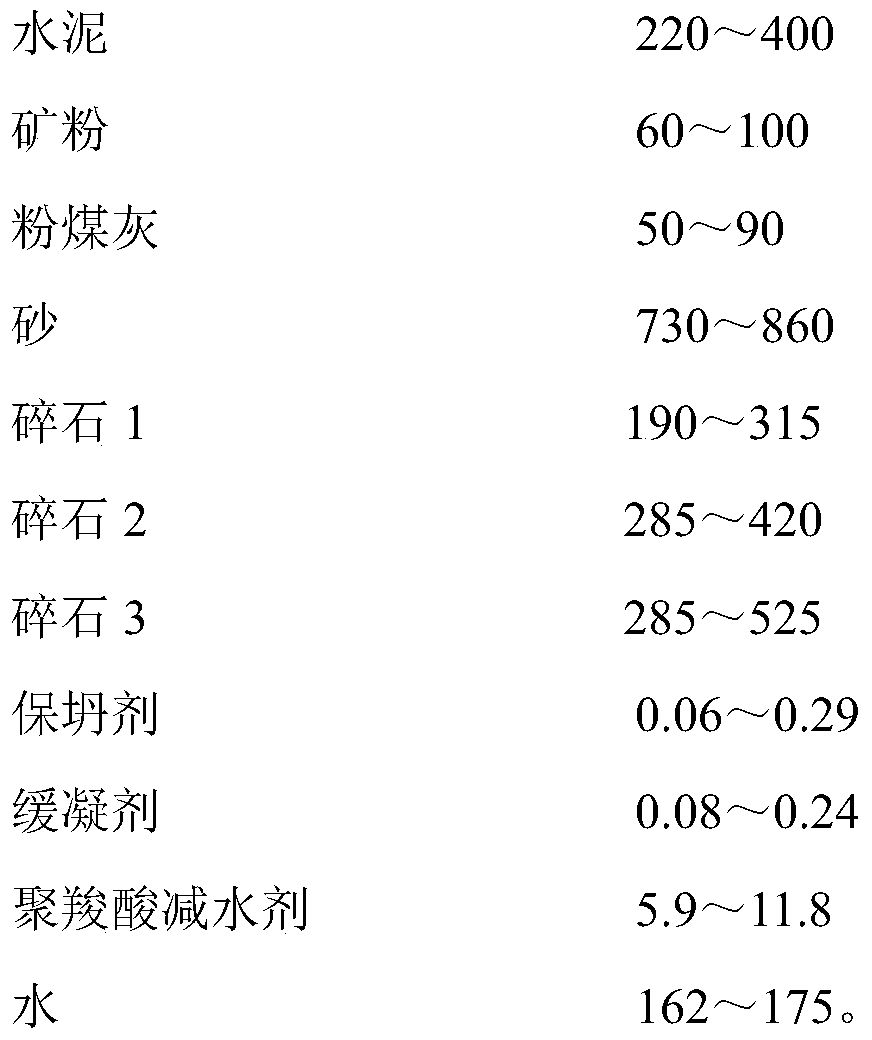

Preparation and construction method of separate concrete for CCW thermal insulation curtain wall

ActiveCN110563414BWorkability is goodWarranty Strength RequirementsWallsArchitectural engineeringCurtain wall

The invention discloses a preparation and construction method of separated concrete for a CCW thermal insulation curtain wall, and belongs to the technical field of building material concrete. The preparation method comprises the steps of first preparing the primary mixture, then standing it, remixing and sieving it, and then performing a performance test, and adjusting the concrete mix ratio according to the test result. The present invention optimizes the design of its overall preparation process, especially the initial composition and proportion of concrete, and then conducts tests by simulating the environment of on-site pouring, and detects the various technical indicators of the separated concrete again, and according to The test results adjust the mix ratio of the concrete, which can effectively improve the quality of the concrete and ensure that the obtained concrete can meet the performance requirements of the inner leaf load-bearing shear wall concrete and the outer leaf wall concrete during the on-site construction process, which is conducive to ensuring the construction quality .

Owner:CHINA MCC17 GRP

Condensation control type repair mortar for prefabricated parts and preparation method of solidification control type repair mortar

The invention discloses a set-control type repair mortar for a prefabricated part and a preparation method thereof. The set-control type repair mortar is characterized by comprising the following components in parts by mass: 10-15 parts of ordinary cement; 30 to 35 parts of special cement; 5-8 parts of gypsum; 30 to 45 parts of sand; 1-2 parts of a water reducing agent; 1-4 parts of a thickening time control agent; 0.5 to 2 parts of a defoaming agent; 0.5-2 parts of a penetrant; the special cement is one or a mixture of sulphoaluminate cement and aluminate cement, and the thickening time control agent is a mixture of lithium silicate, silica sol and bauxite. The thickening time control agent is prepared through high-speed stirring, and then the repairing mortar is prepared through mixing. The prepared repairing mortar is adjustable in setting time, high in early strength and high in bonding strength, and can meet the repairing requirements of the fabricated prefabricated parts.

Owner:FUKE TECH (SUZHOU) CO LTD

Preparation and construction method of CCW thermal insulation curtain wall separated concrete

ActiveCN110563414AWorkability is goodWarranty Strength RequirementsWallsThermal insulationMix proportion

The invention discloses a preparation and construction method of CCW thermal preservation curtain wall separated concrete, and belongs to the technical field of building material concrete. The preparation method comprises the following steps: firstly preparing a primary mixture, then standing, re-stirring and sieving the primary mixture, then carrying out performance test, and adjusting the concrete mix proportion according to a detection result. According to the invention, the overall preparation process is optimally designed; particularly, the initial composition and the proportion of the concrete are optimally designed; then a test is carried out by simulating a cast-in-place environment; various technical indexes of the separated concrete are detected again; and the mixing ratio of theconcrete is adjusted according to the detection result, so that the quality of the concrete can be effectively improved, the obtained concrete can simultaneously meet the performance requirements onthe concrete of the inner bearing shear walls and the concrete of the outer walls in the field construction process, and the construction quality is favorably guaranteed.

Owner:CHINA MCC17 GRP

A combined corrugated frame shear assembly energy dissipation structure system

Owner:HEFEI UNIV OF TECH

A replaceable prefabricated composite beam structure and its manufacturing process

ActiveCN106835951BEasy constructionImprove bearing capacityBridge structural detailsBridge erection/assemblyPre stressEngineering

Owner:宁波联合龙门重工钢构有限公司

Spatial structure system of horizontal flexible connection between columns and curved beams

The invention provides a spatial structural system for horizontally flexible connection of columns and curved beams. The columns and curved beams are connected by a horizontal flexible connection device. The horizontal flexible connection device includes a column connector, a curved beam connector a, a column connector and The steel tie rod of the curved beam connector; the curved beam is also connected with a vertical suspension connection device, and the vertical suspension connection device includes a curved beam connector b and a movable steel suspender. The invention adopts a space structure system combining a grid structure and a suspension cable structure. In the grid structure system, the strength and ductility of the grid curved beam structure are improved, the bending bearing capacity of the curved beam is significantly increased and the deflection deformation of the curved beam is reduced. In the suspension structure, flexible suspenders are used to connect the suspended steel structure curved beams. The flexible connection features make the overall appearance simple, uniform in force, good in seismic energy consumption, easy to repair and maintain, and meet the comfort of suspended steel structures. Require.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD +1

Rapid installation, in-place and leveling device and method for columnar part

PendingCN113818700AReduce wasteHigh turnover utilizationBuilding material handlingClassical mechanicsBolt connection

The invention relates to the technical field of construction of steel structures, in particular to a rapid installation, in-place and leveling device and method for a columnar part. The rapid installation, in-place and leveling device is characterized in that the rapid installation, in-place and leveling device comprises a positioning base, a connecting seat and a shelf, the positioning base comprises hoops and hoop connecting pieces, the hoops are arranged around the columnar part and connected with one another through the hoop connecting pieces to form an annular base, the positioning base is arranged on the hoops and comprises a supporting arm, a platform and a guide plate, and the platform and the guide plate are arranged at the top of the supporting arm. The positioning base is connected with the hoops through bolts; and the shelf is placed on the platform through guiding of the guide plate. The whole installation process of the device does not need to operate the part, and the damage to a base material is avoided.

Owner:中冶(上海)钢结构科技有限公司

A construction device and method for maintaining ultra-high performance concrete filled steel pipe columns at room temperature

ActiveCN109386092BAvoid getting lostUnique ratioStrutsBuilding material handlingInsulation layerRoom temperature

The invention discloses a construction device and method for maintaining an ultra-high-performance concrete-filled steel pipe column at room temperature, including a concrete column, a steel pipe, and an insulation layer; the concrete column is made of water, cement, silica fume, quartz powder, and polycarboxylic Water agent, quartz sand and sodium polyacrylate are mixed according to the mass ratio of 0.2:1:0.15:0.2:0.009:1.75:0.03. After 7 days of curing, ultra-high performance concrete with a strength exceeding 150MPa can be obtained. The invention has good technical feasibility and convenient construction, and the concrete can be cured under normal temperature to obtain ultra-high performance concrete, thereby greatly improving the bearing capacity of the steel pipe concrete column, which not only ensures the construction quality on site, but also improves the construction efficiency. In addition, no autoclave equipment is needed, which saves construction costs and is beneficial to popularization in actual projects.

Owner:HUAQIAO UNIVERSITY

A normal temperature curing ultra-high performance concrete column and its construction method

ActiveCN109455987BUnique ratioAvoid getting lostBuilding material handlingReinforced concrete columnArchitectural engineering

The invention discloses an ultra-high-performance concrete column maintained at normal temperature and a construction method thereof. It has good technical feasibility and is convenient for construction. The concrete can be cured under normal temperature to obtain ultra-high-performance concrete, thereby greatly improving The bearing capacity of reinforced concrete columns not only ensures the quality of on-site construction, but also improves the construction efficiency. Moreover, the present invention does not need to use autoclave equipment, which saves construction costs and is beneficial to popularization in actual projects.

Owner:HUAQIAO UNIVERSITY

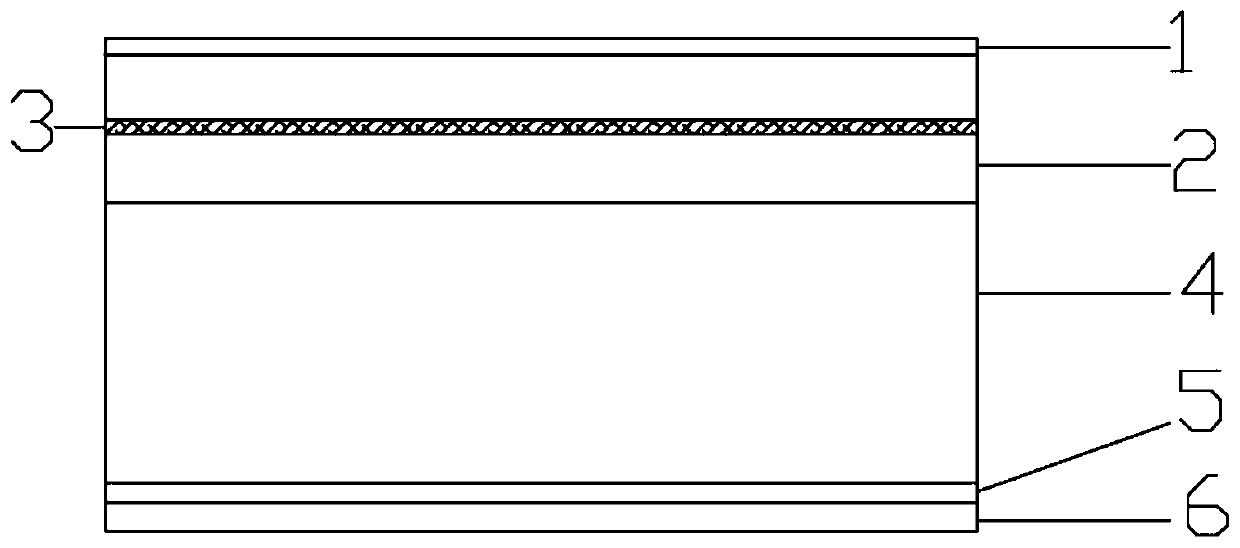

Decorative insulation board with self-cleaning function and preparation method thereof

PendingCN111173219AEasy constructionShorten the construction periodCovering/liningsLaminationInsulation layerThermal insulation

The invention provides a decorative insulation board with a self-cleaning function and a preparation method of the decorative insulation board. The insulation board comprises a self-cleaning layer, adecorative surface layer, an insulation layer, a bonding layer and a base layer which are sequentially stacked from top to bottom. The preparation method comprises the following steps that (I), a layer of mineral aggregate coated with a nano self-cleaning coating on the surface is laid on the bottom of a mold, and the self-cleaning layer is formed; (II), slurry is poured on the self-cleaning layer, a reinforcing material and a thermal insulation material are sequentially laid on the surface of the slurry, and the mold is vibrated so that the reinforcing material can be embedded into the slurry; and (II), curing is performed until the slurry is cured and molded, the decorative surface layer formed by the slurry and the insulation layer formed by the thermal insulation material are obtained,the decorative surface layer is subjected to hardening treatment, the insulation layer and the base layer are bonded through the bonding layer, and the decorative insulation board is obtained. The decorative insulation board with the self-cleaning function not only has high strength, good integrity and good insulation performance, but also is attractive in decoration effect and durable in use.

Owner:湖北卓宝建筑节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com