Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Easy to connect with each other" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

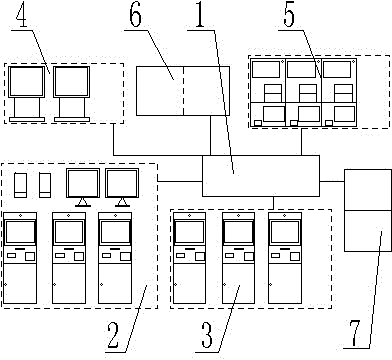

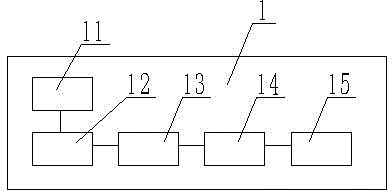

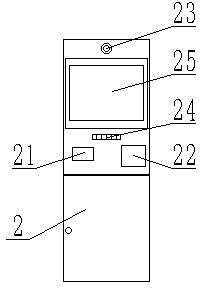

Public employment service management system and equipment

InactiveCN104680265AEasy to connect with each otherIncrease success rateResourcesRemote computerTerminal system

The invention relates to a public employment service management system and equipment, comprising a central control information processing system, a remote self-service terminal system, an on-site self-service terminal system, an on-site query service desk, an on-site interview system and the like. The remote self-service terminal system is connected with the central control information processing system through a network. The central control information processing system is connected with the on-site self-service terminal system, the on-site query service desk, the on-site interview system, an information publishing system, and an individual case one-on-one meeting device. The central control information processing system is a system device having the functions of registration and logging, job-hunting and business-establishing selection, comprehensive information publishing, employment interview and public service data processing. By combining on-site service and logging through remote computers and mobile phones, the organic combination of a visible labor market and an invisible market is realized, the employment service function is stronger, job-hunting is more convenient, and employment is linked with the social insurance of trainees, thereby greatly facilitating the government tracking service.

Owner:如皋市劳动就业管理处

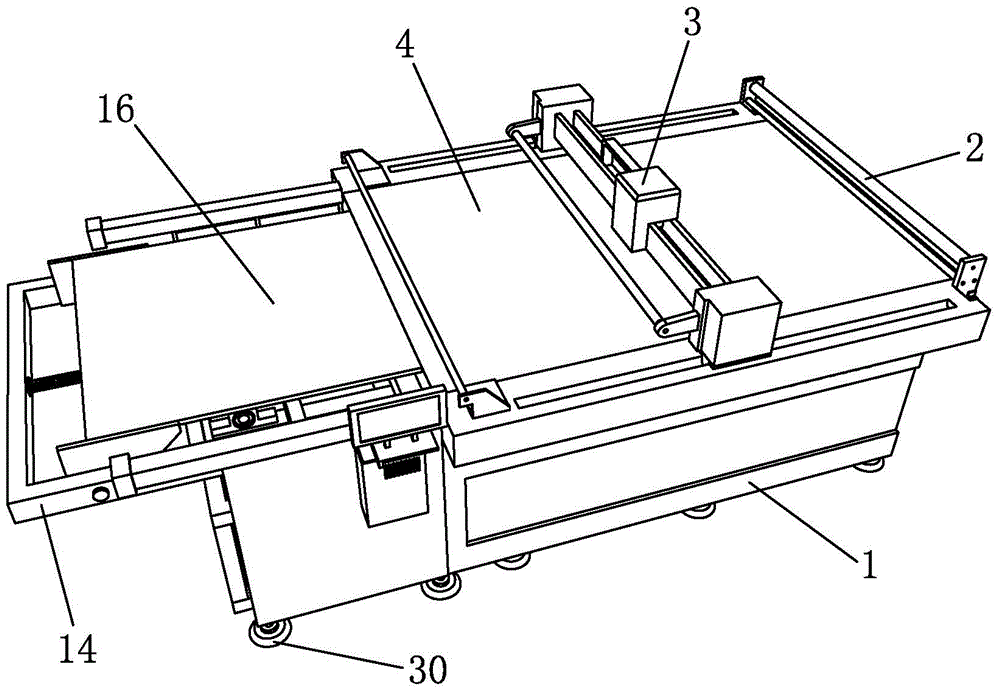

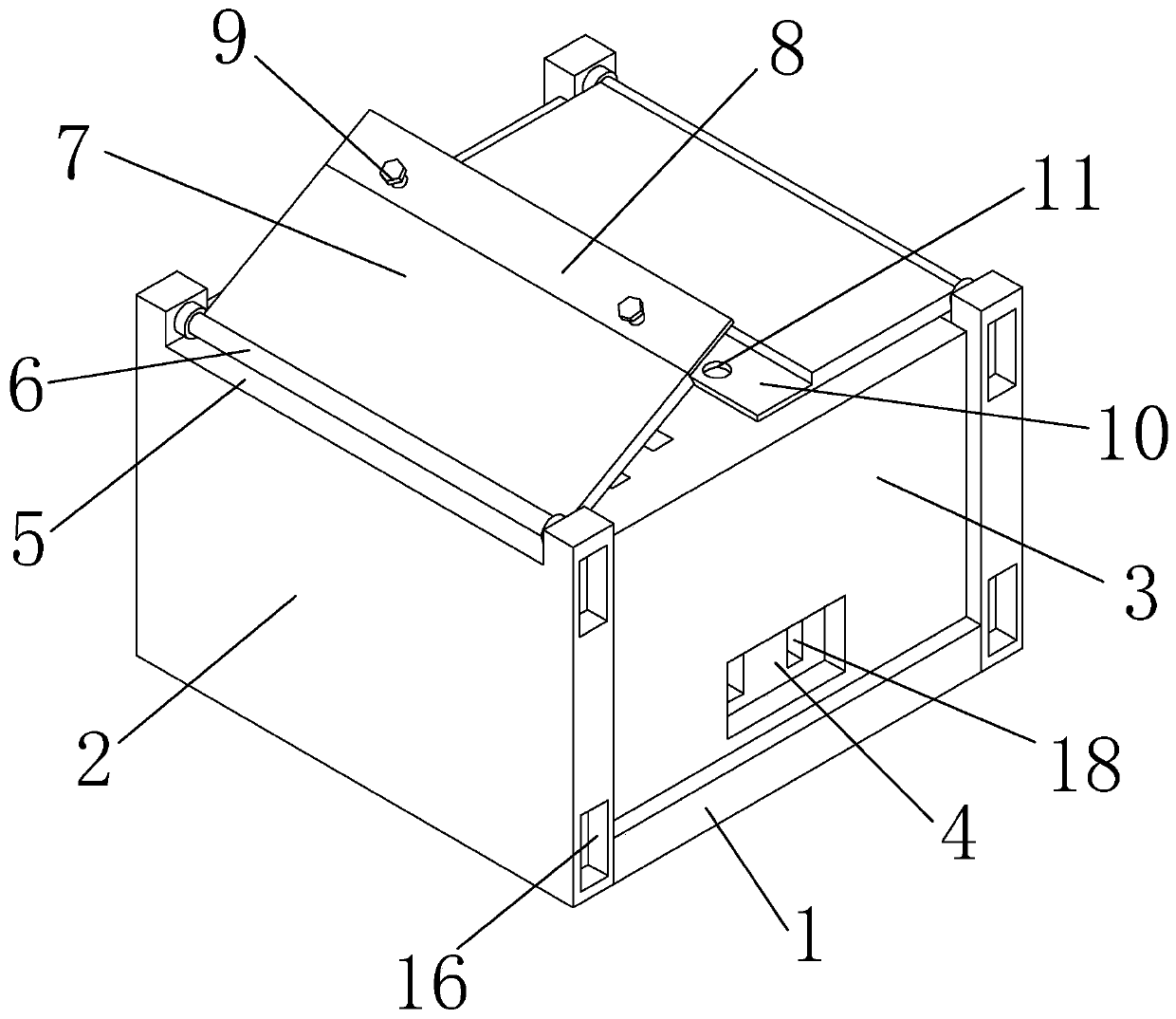

Tailoring machine for clothing production

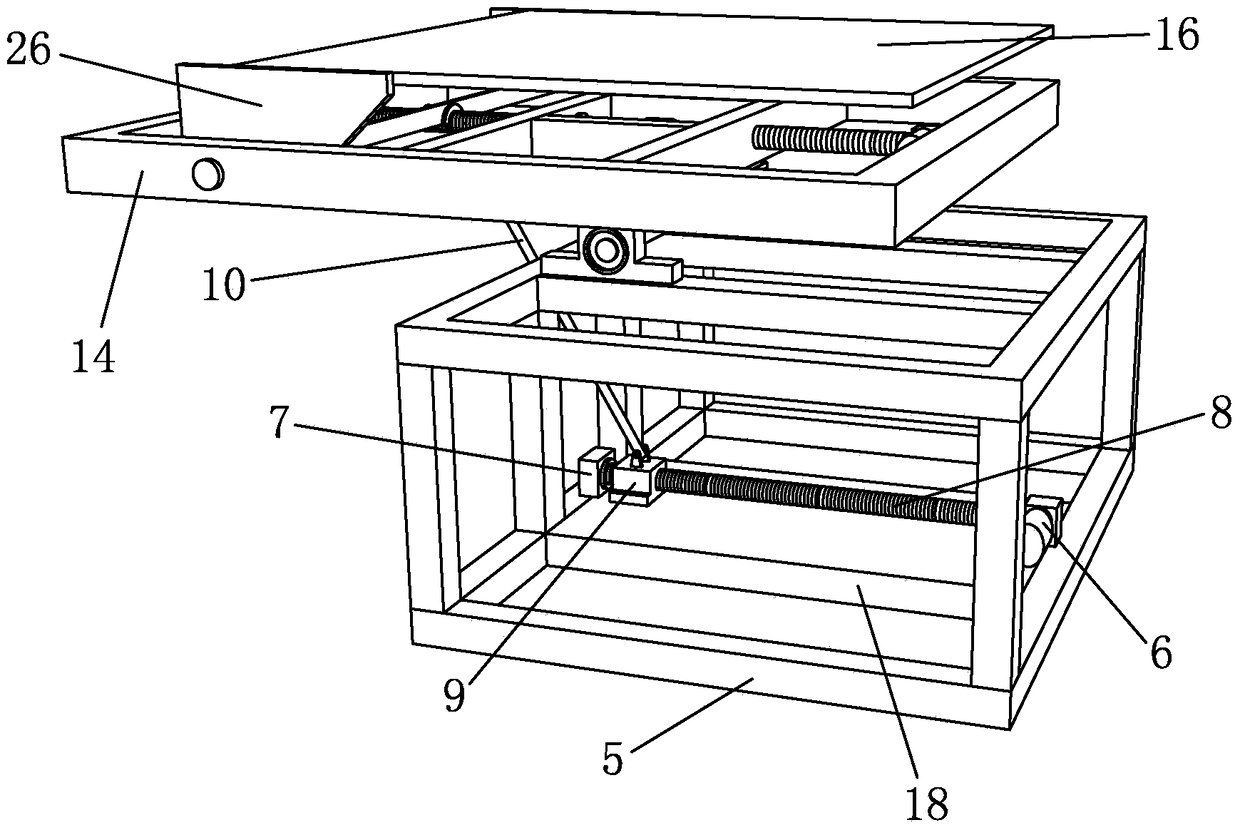

The invention discloses a tailoring machine for clothing production. The tailoring machine comprises a rack, a cloth feeding rack and a tailoring mechanism. The rack is provided with a conveying device. A discharging base is arranged in the rack and provided with a drive device. The drive device drives a sliding block to move on a sliding rod. A connecting rod is arranged on the sliding block. The discharging base is provided with a rotating base. A turnover panel is connected to the rotating base in a rotating mode and connected with the connecting rod. The turnover panel is provided with a U-type clamping base. A turnover outer frame is fixedly connected to the U-type clamping base. A leveling device is arranged on the turnover outer frame. A discharging panel is connected to the turnover outer frame in a rotating mode and connected with a conveyor belt on the conveying device. The discharging panel is provided with a locating plate clamped to the leveling device. According to the tailoring machine, tailored textiles can be picked up automatically, labor is reduced, the textiles can be collected into a collecting box at a higher speed, and prevented from absorbing dust, and the finished product quality of clothing production is improved.

Owner:SUZHOU GANNZ ELECTRONICS TECH CO LTD

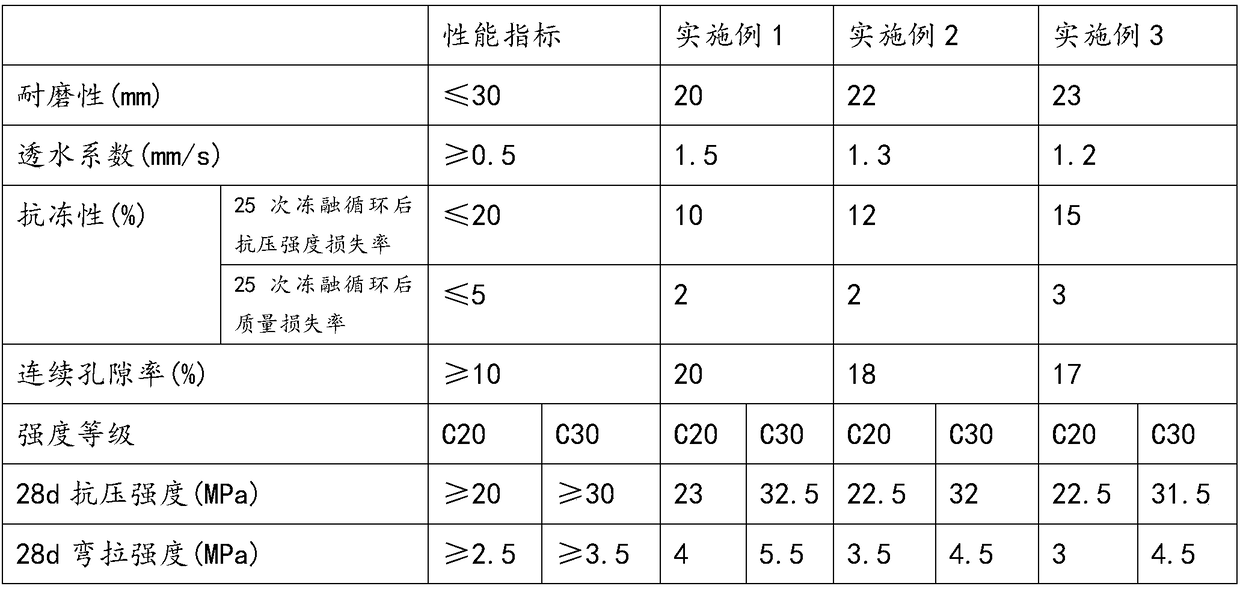

Special reinforcing agent for permeable concrete and preparation method thereof

The invention discloses a special reinforcing agent for permeable concrete and a preparation method thereof. The special reinforcing agent for the permeable concrete comprises the following ingredients in parts by weight: 40-50 parts of micro-silica fume, 1-2 parts of polyvinyl alcohol, 10-15 parts of a water-reducing agent, 30-40 parts of re-dispersible emulsion powder, and 1-2 parts of polypropylene fiber. According to the special reinforcing agent for the permeable concrete, the polypropylene fiber and the re-dispersible emulsion powder are used for enhancing strength of cement slurry as well as bond strength between the cement slurry and aggregate particles. Acetylation reaction initiates in virtue of hydroxyl radicals in the re-dispersible emulsion powder and the polypropylene fiber,so that, the polyvinyl alcohol cross-links to form a spatial reticular structure so as to promote formation of pores; and thus, permeability performance is enhanced so as to achieve the purpose of synchronously realizing high strength and permeability. Moreover, the polypropylene fiber with certain length is capable of enlarging size of the pores instead of causing blockage in the pores during formation process of the permeable concrete; and thus, mutual communication between the pores is facilitated so as to further improve permeability.

Owner:张顺林

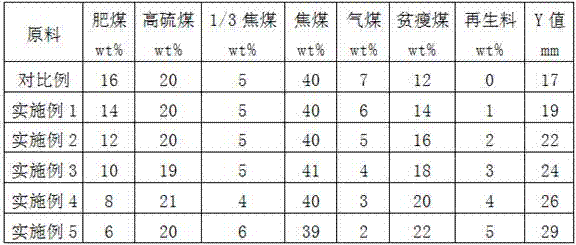

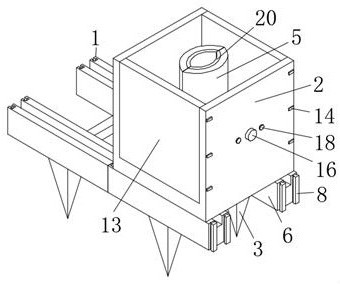

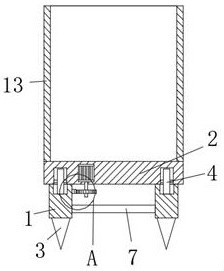

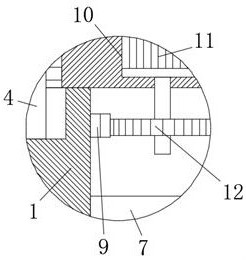

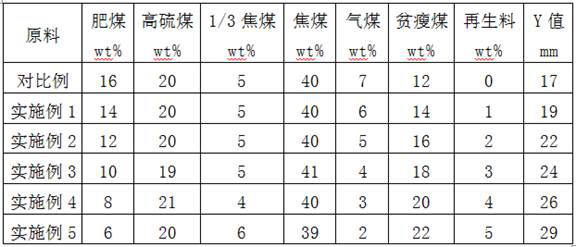

Coking mixed coal prepared via adding of reclaimed material, and coking coal blending method

The invention discloses a coking mixed coal prepared via adding of a reclaimed material, and a coking coal blending method. The coking mixed coal is composed of, by weight, (16-2N)% of fat coal, 19 to 21% of high-sulphur coal, 4 to 6% of 1 / 3 coking coal, 39 to 41% of coking coal, (7-N)% of meager lean coal, (12+2N)% of gas coal, and N% of the reclaimed material, wherein N<=5; the reclaimed material contains 21 to 24wt% of beta resin. According to the coking coal blending method, beta resin with adhesive effect is used for realizing combination of the coking mixed coal with coking coal blending technology, and is used for replacing a part of fat coal into coking coal to produce coke, so that coking coal source is widened, the using amount of expensive fat coal is reduced, and coal blending cost is reduced. The coking coal blending method is capable of widening the plastic temperature range of coking coal, realizing better connection of different kinds of coal, increasing cokeability in coking process, promoting anisotropic generation, ensuring that coke quality is capable of satisfying coke requirements of large blast furnaces, and at the same time increasing the using amount of low adhesive performance meager lean coal in coking coal blending, and reducing coal blending cost greatly.

Owner:宣化钢铁集团有限责任公司

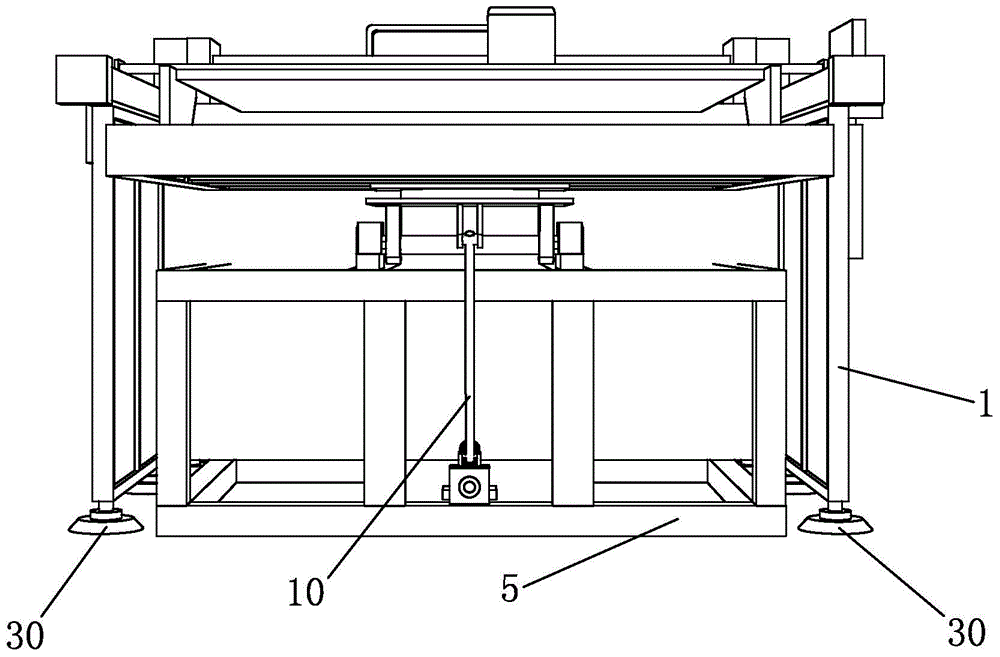

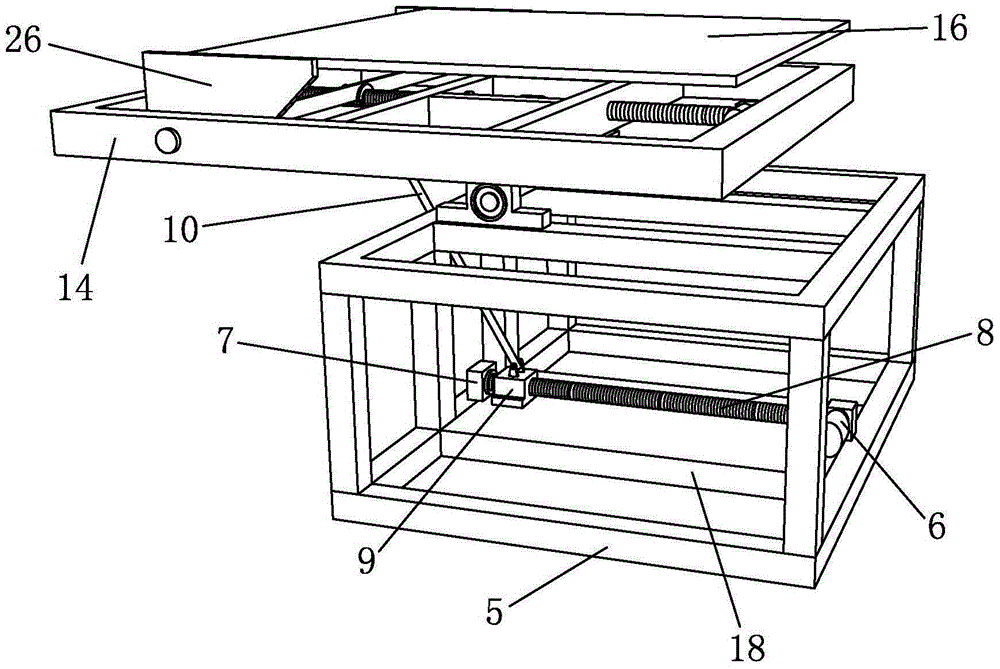

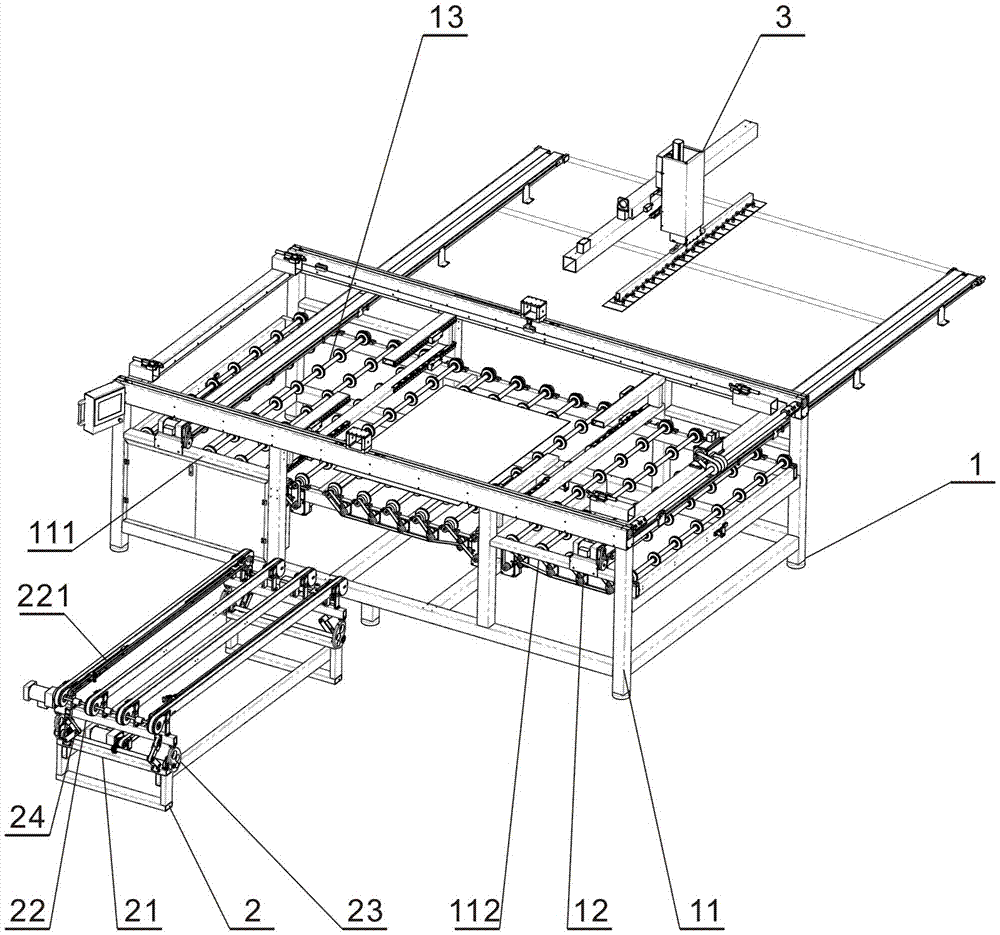

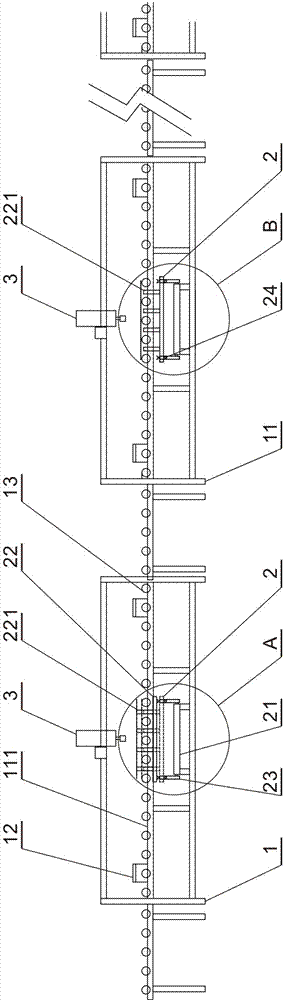

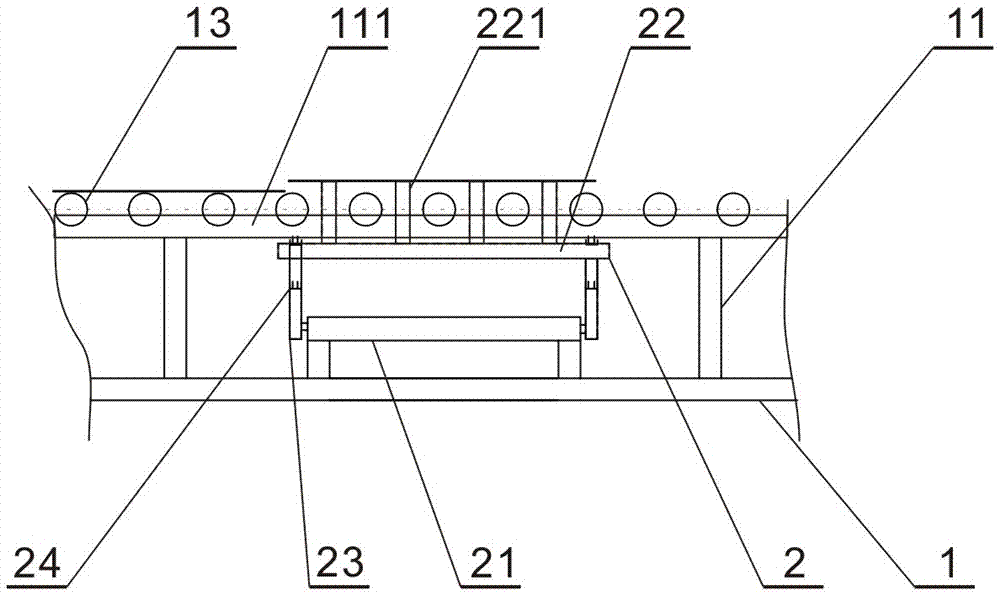

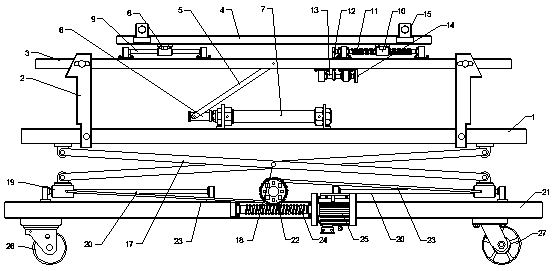

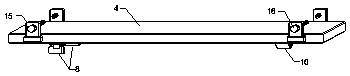

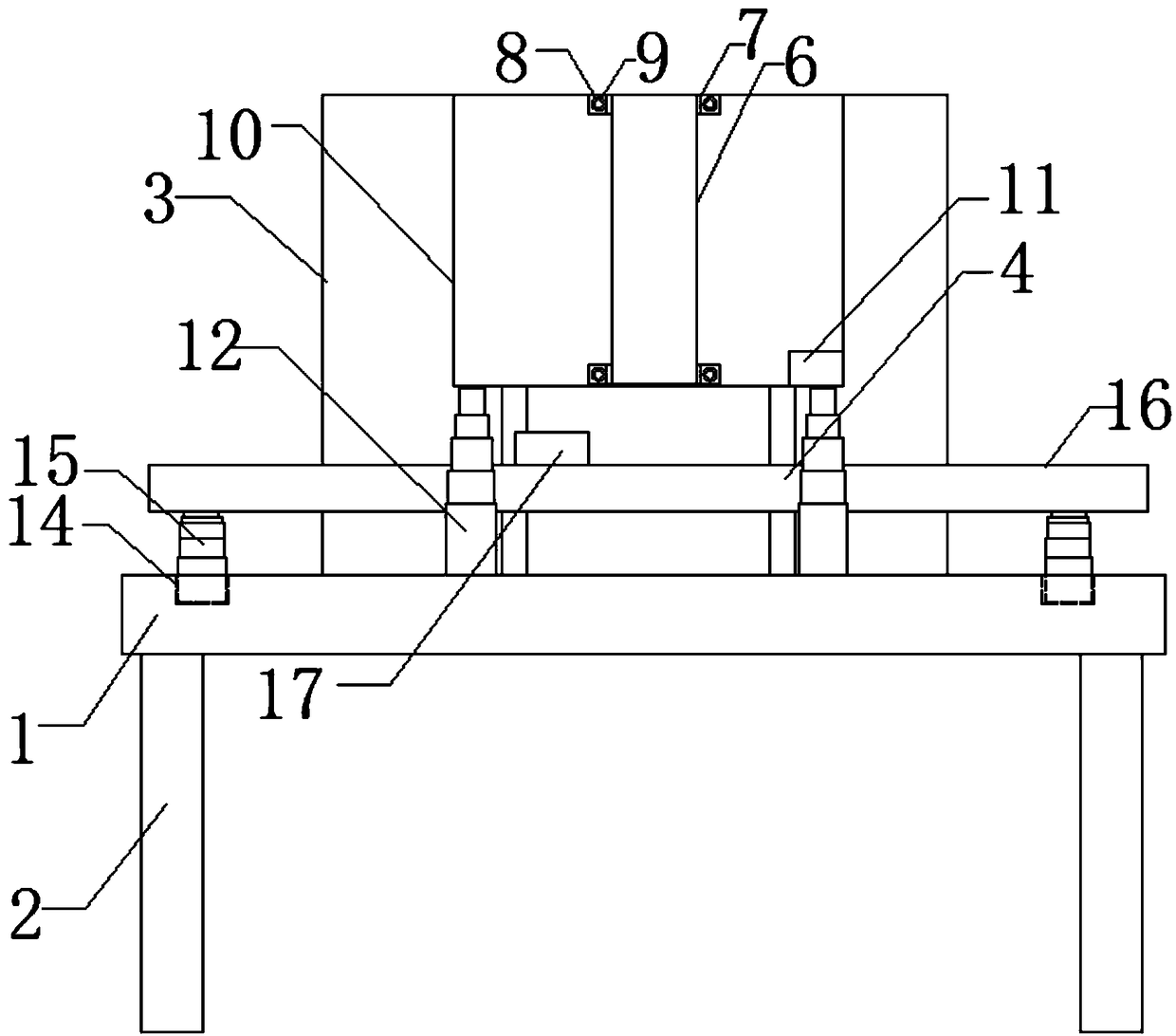

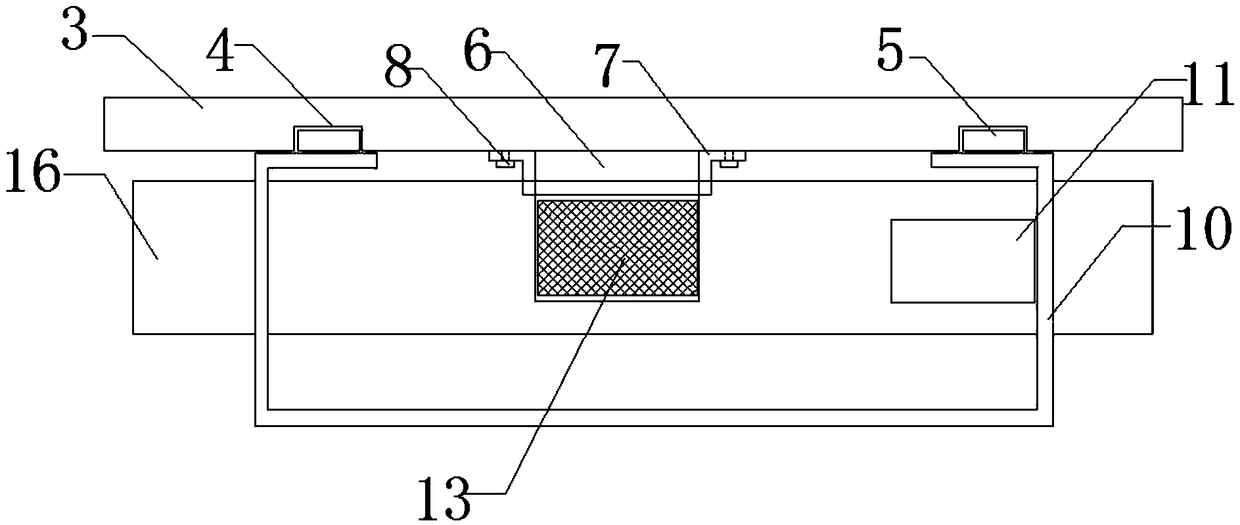

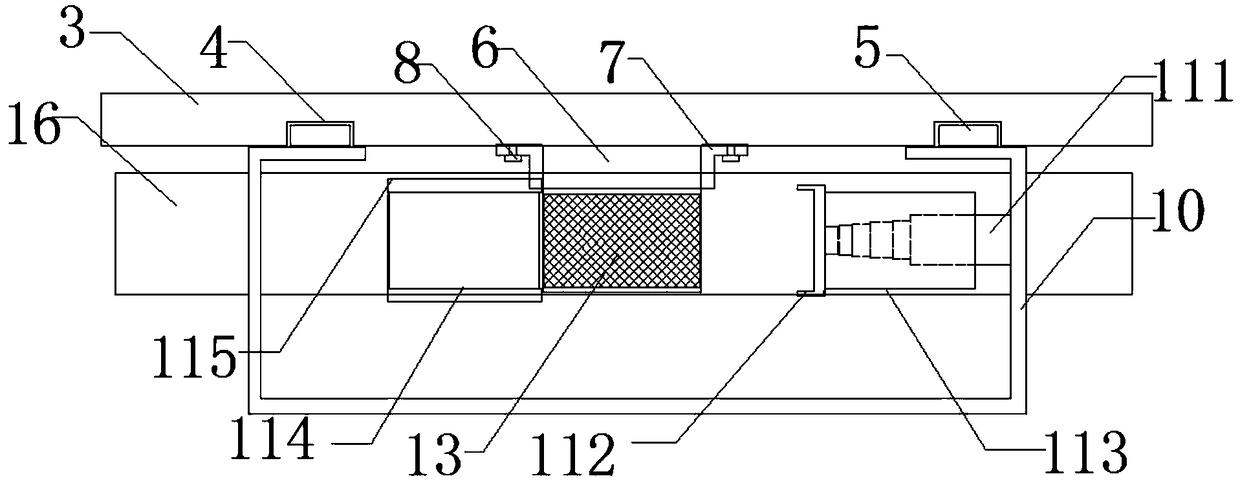

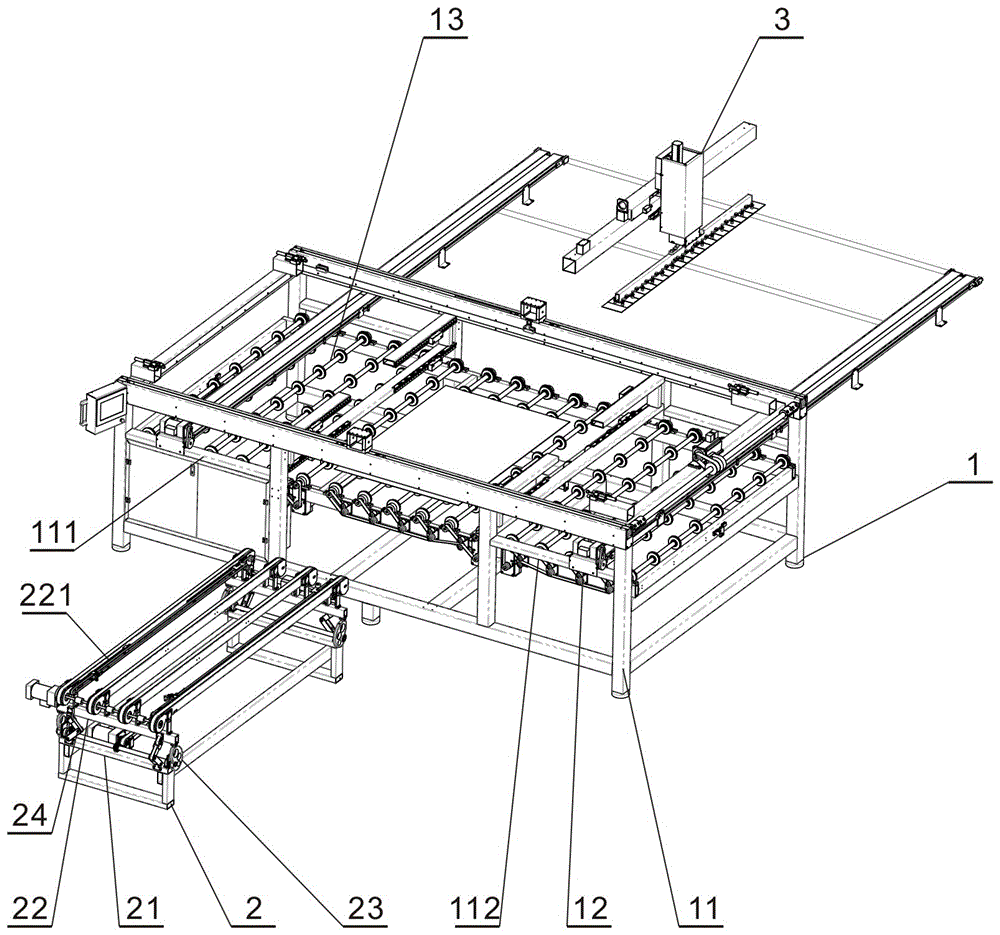

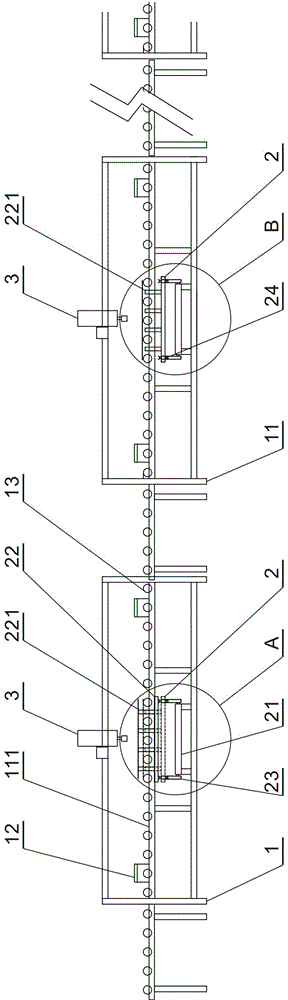

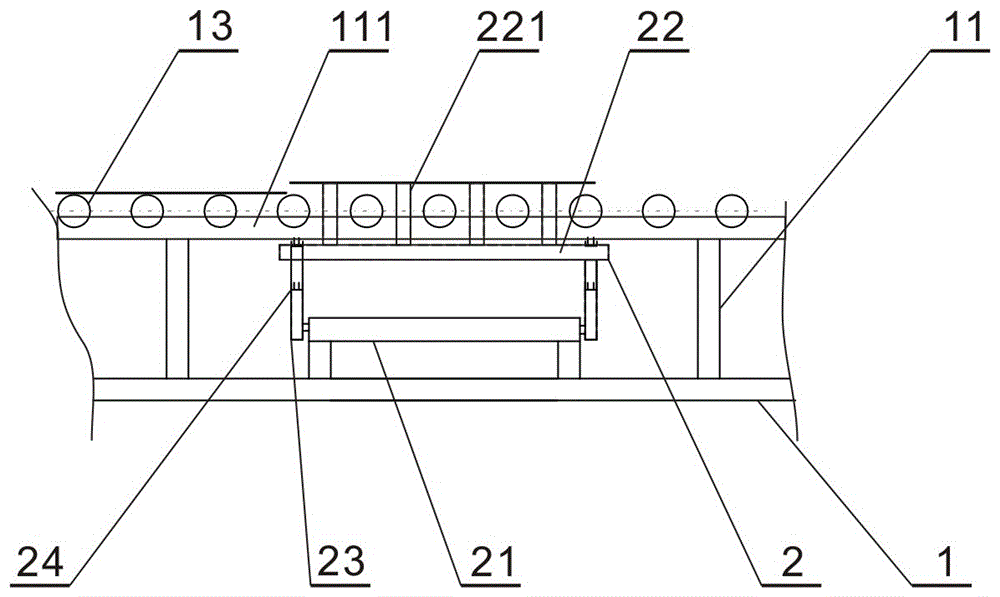

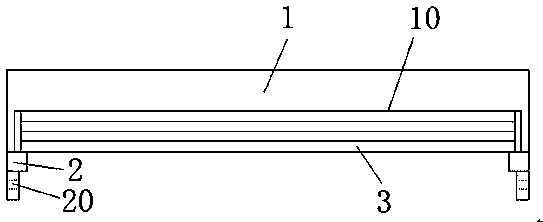

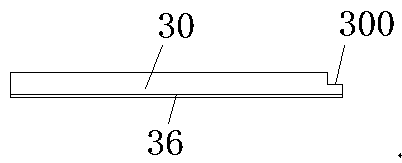

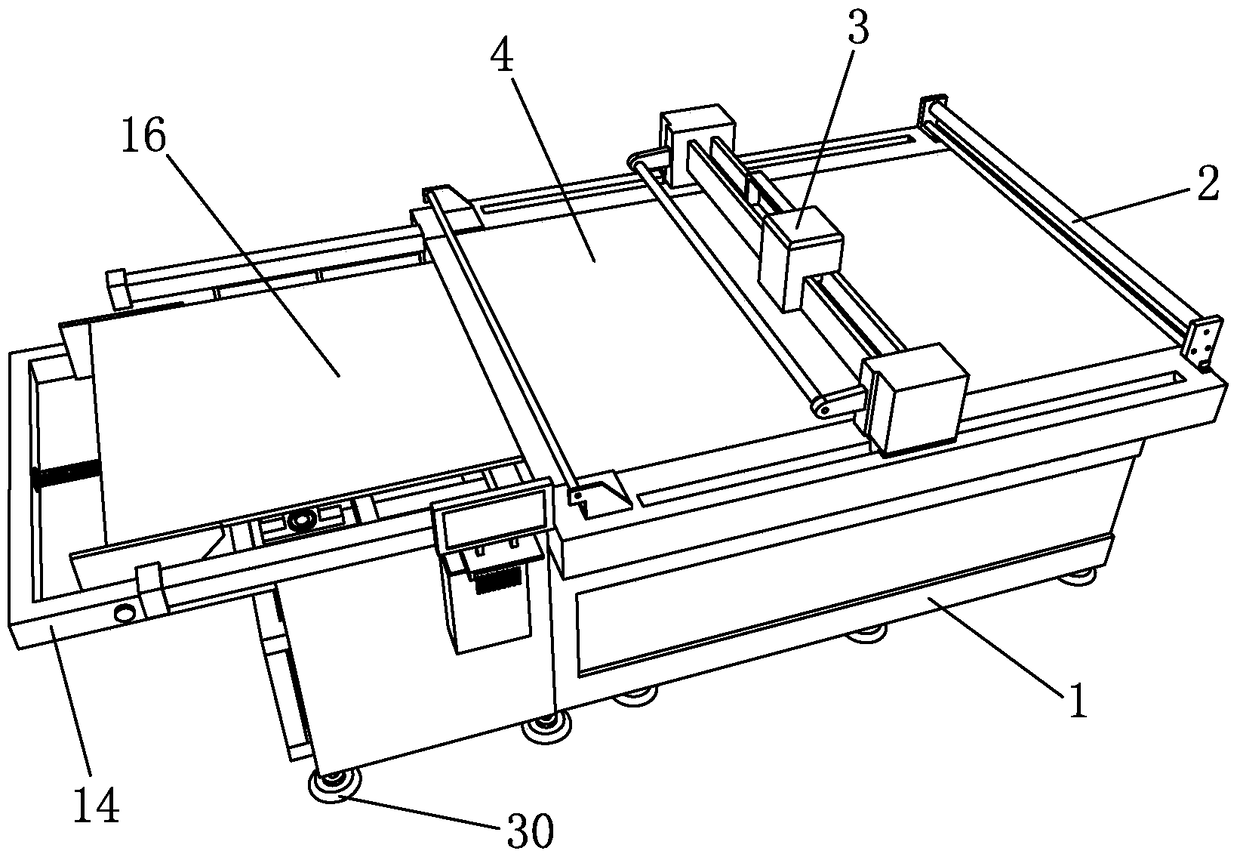

Three-dimensional conveying device for automatic photovoltaic cell string typesetter

ActiveCN105449049AEasy to connect and convertSmall footprintFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a three-dimensional conveying device for an automatic photovoltaic cell string typesetter. The three-dimensional conveying device comprises a longitudinal conveying line, a working platform and an automatic typesetter, wherein the working platform is arranged on any conveying machine frame in the longitudinal conveying line; and the automatic typesetter is arranged corresponding to the working platform, and is connected with the conveying machine frame. The working platform is embedded in the longitudinal conveying line, a synchronous belt on an upper platform can be higher or lower than a rolling wheel driving rod of the longitudinal conveying line via a lifting device, while impact on normal glass conveying of the longitudinal conveying line is avoided when the synchronous belt is at both the two working condition positions, so that the problem in arranging a plurality of working positions on the same longitudinal conveying line is solved, multiple positions can be connected and changed conveniently, the occupied space is small, the conveying speed is fast, and the production efficiency is high.

Owner:上海豪力起重机械有限公司

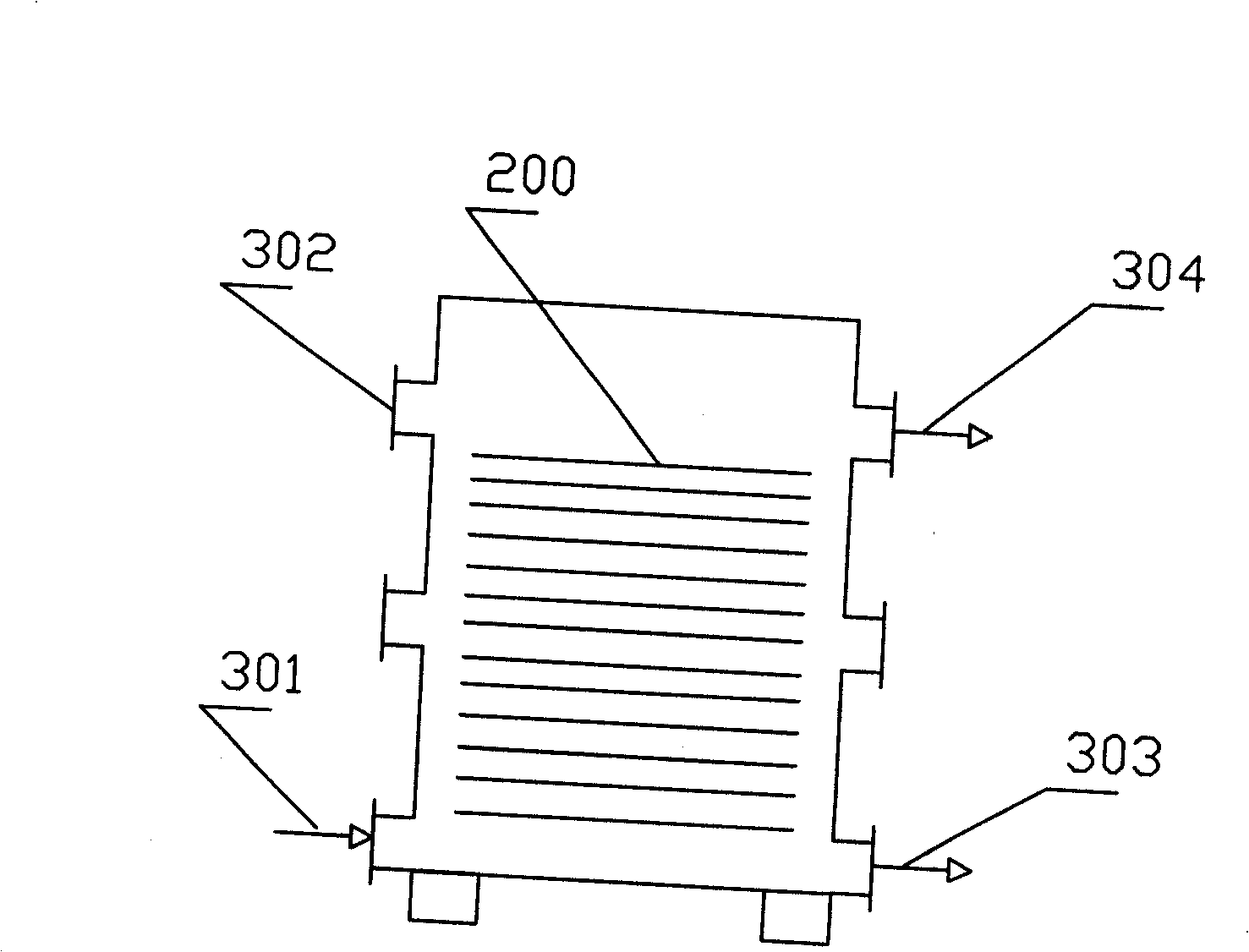

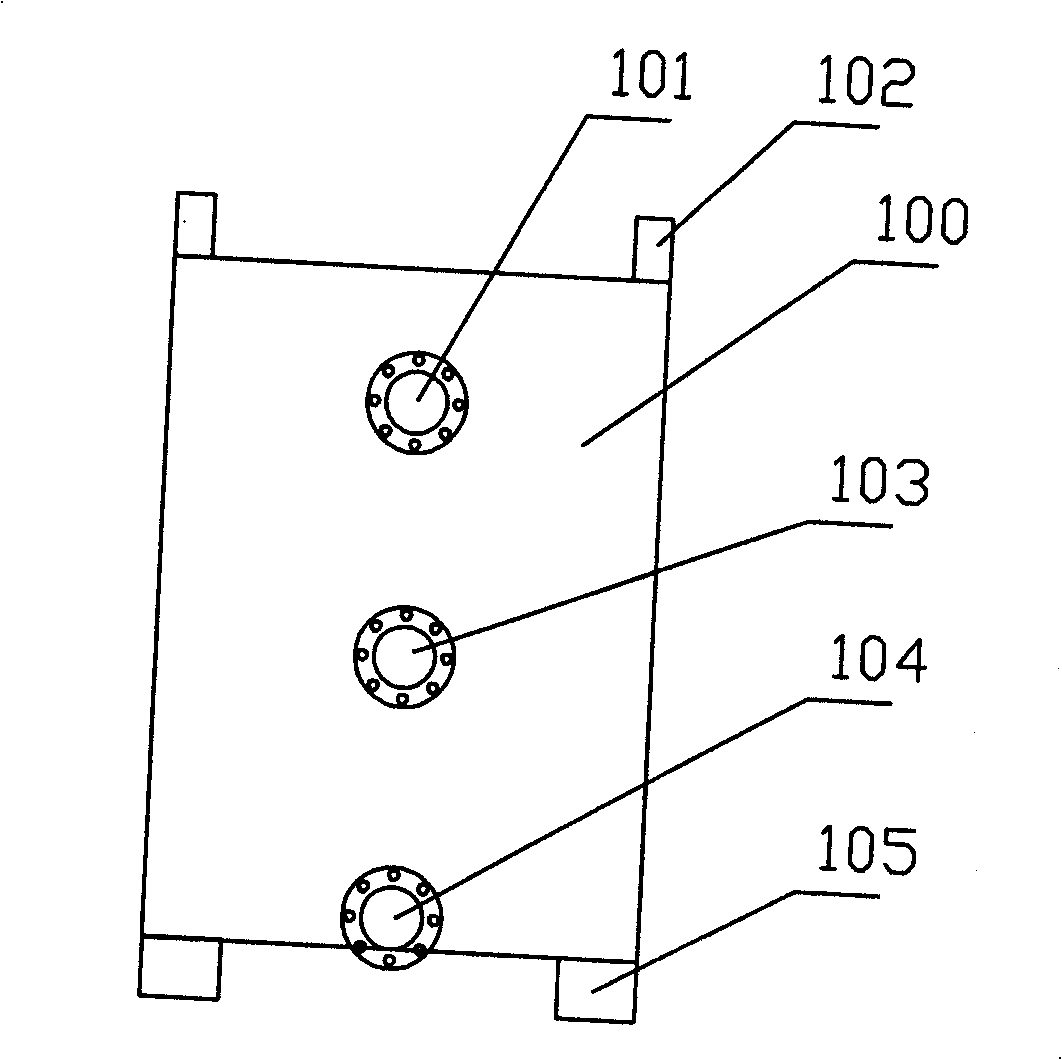

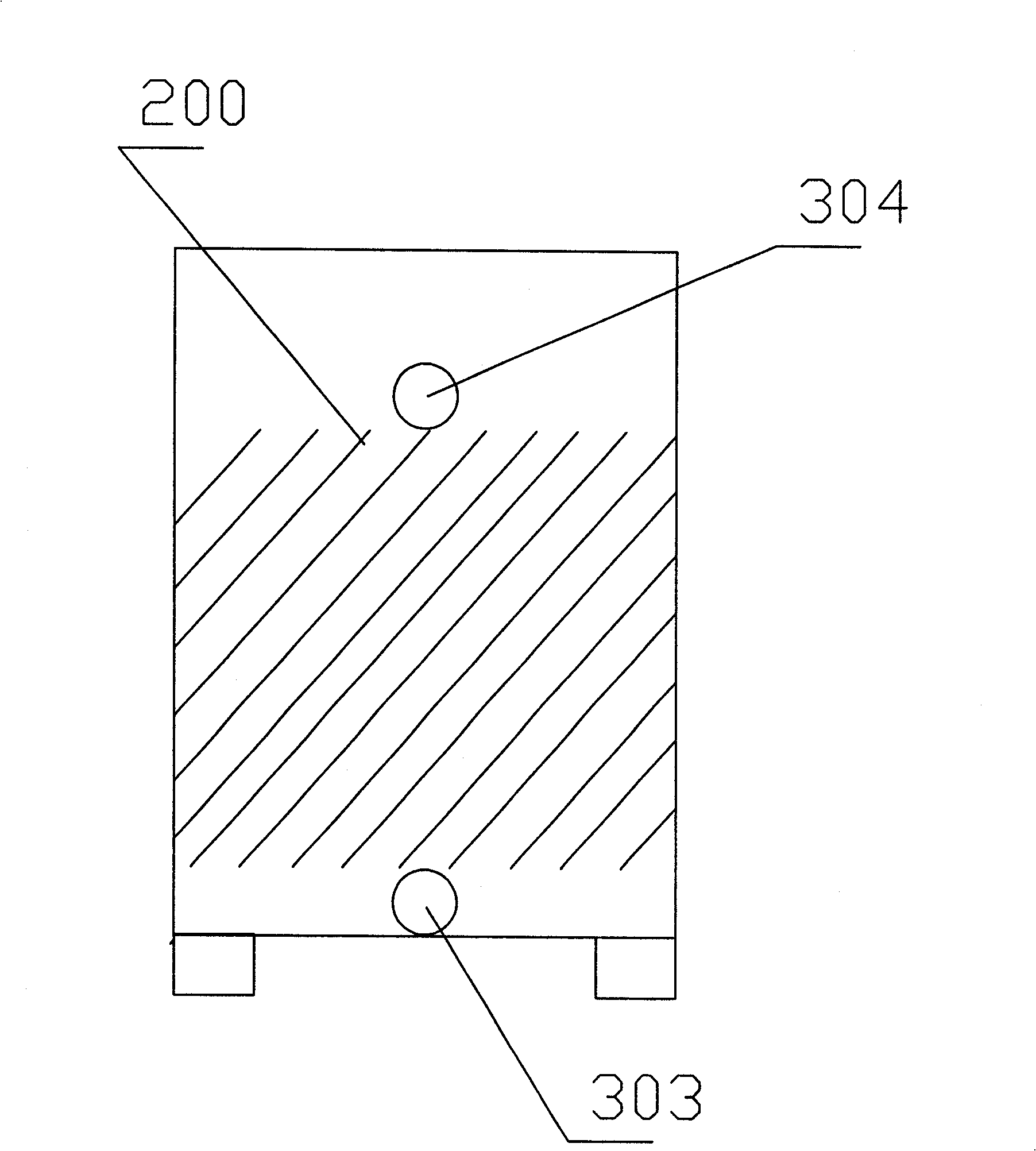

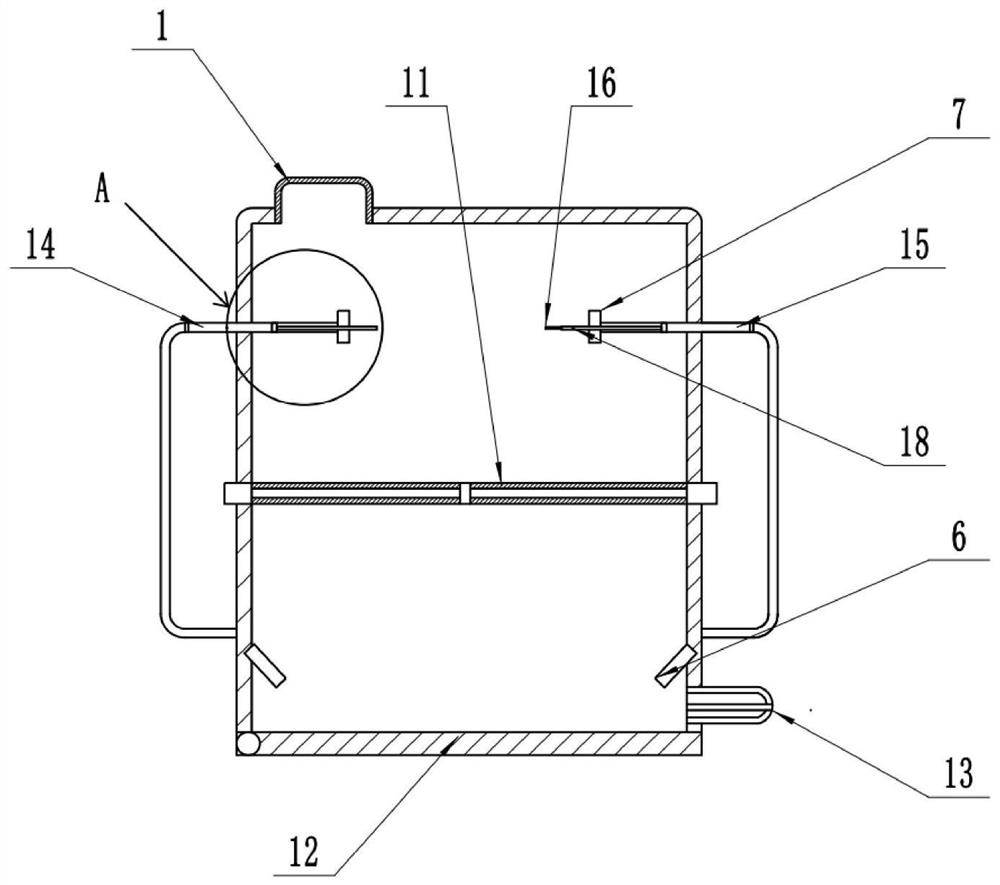

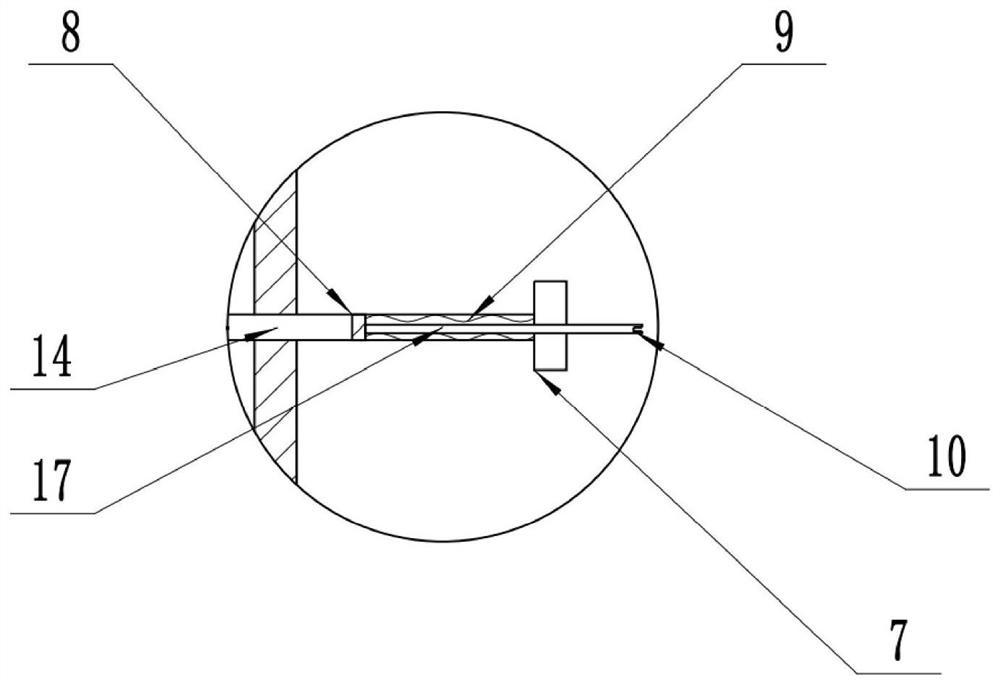

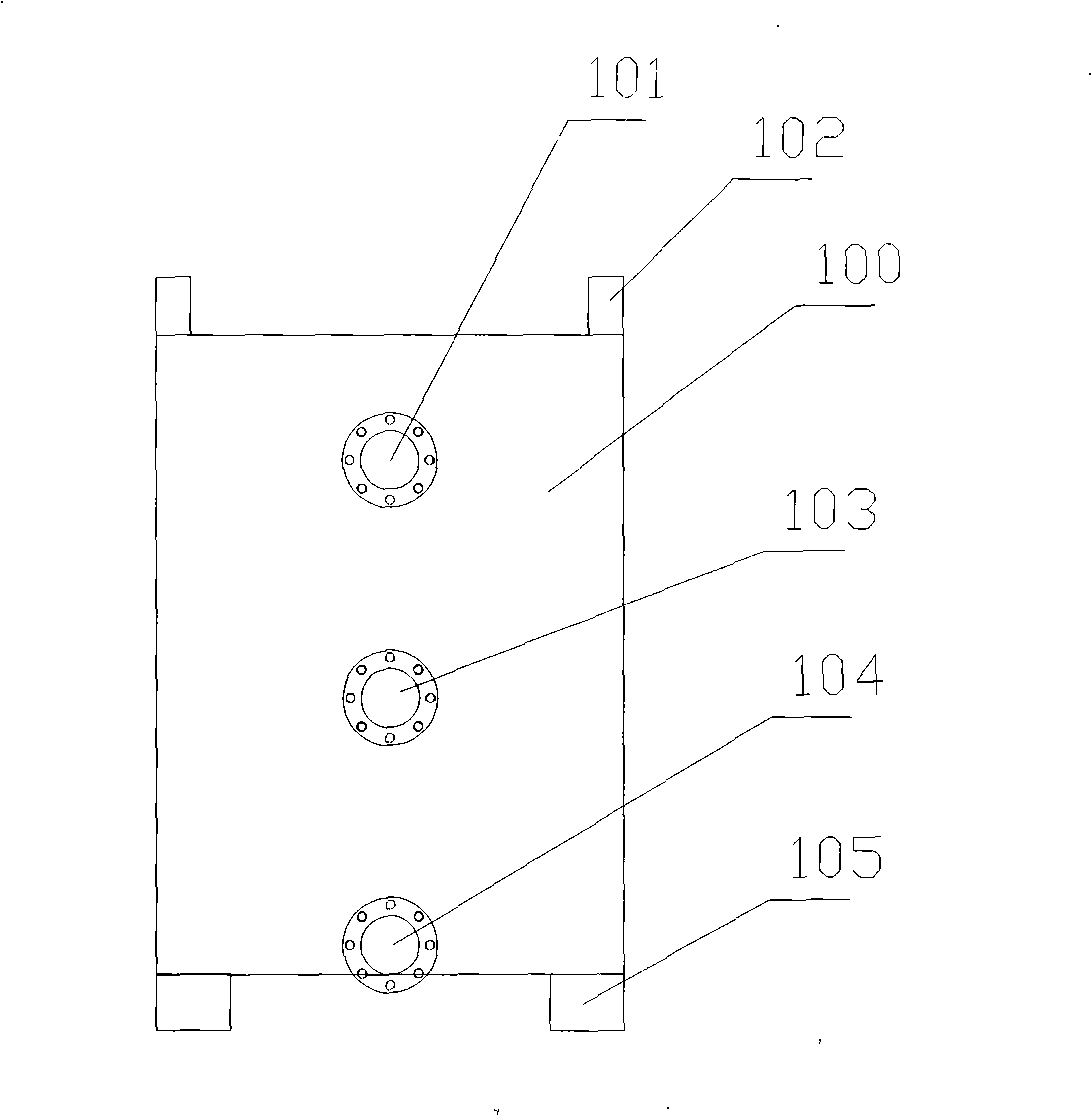

Side flow lamella using standard box body

InactiveCN101347688AEasy to connect with each otherEffective use of spaceWater/sewage treatmentSedimentation settling tanksTreatment effectEngineering

The invention relates to a sideward flow slanting board sedimentation pool which adopts a standardized box, including the standardized box; the box takes a shape of a rectangle, both ends of the box are respectively provided with three identical junction pipes which are arranged at the upper, middle and lower parts and are provided with flanges, and the junction pipes tilt from bottom to top and do not tilt along the water flow direction; the lower junction pipe at the front end of the box is a water inlet, while the upper junction pipe at the rear end of the box is a water outlet. The spacing which forms a water passage is left between the front end and rear end of the slanting board and the internal wall of the box, and the lower end and upper end thereof are respectively positioned below the upper junction pipe and above the lower junction pipe and form an included angle, which is not less than 45 degrees, with the horizontal plane. By adopting the sideward flow slanting boards, the passages between the slanting boards where the water currents which flow through the clearances among the slanting boards, are basically equal, thus being conducive to guarantee the overall effluent effect. The sedimentation pool of the invention can be assembled with other treatment equipment with the same box at will to build different treatment systems, thus reducing cost, simplifying installation and guaranteeing wastewater treatment effect.

Owner:BEIJING NENGTUO HI TECH

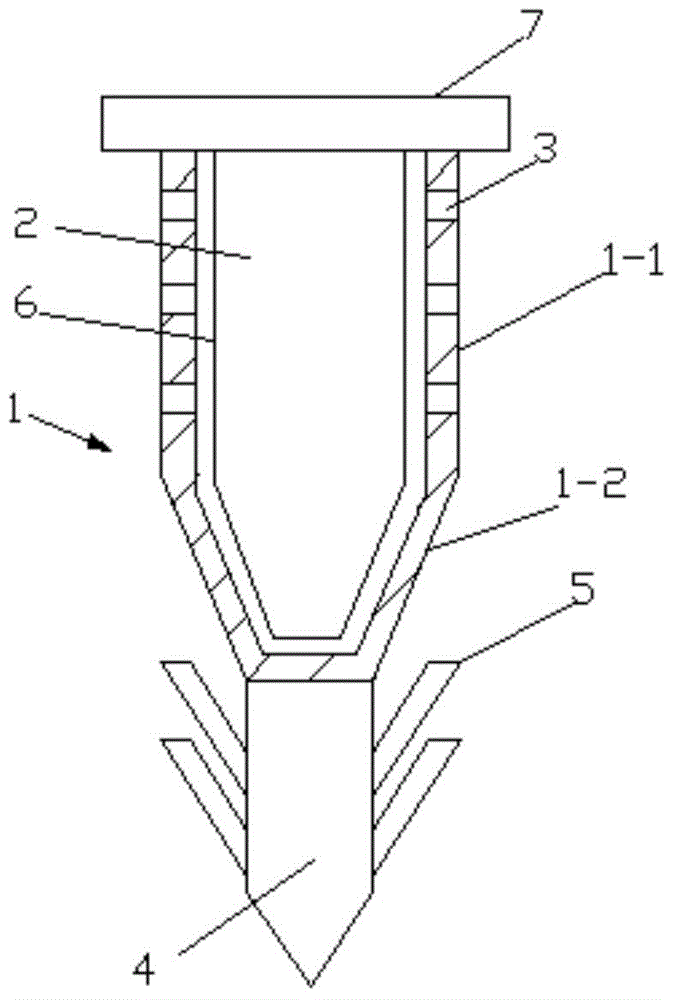

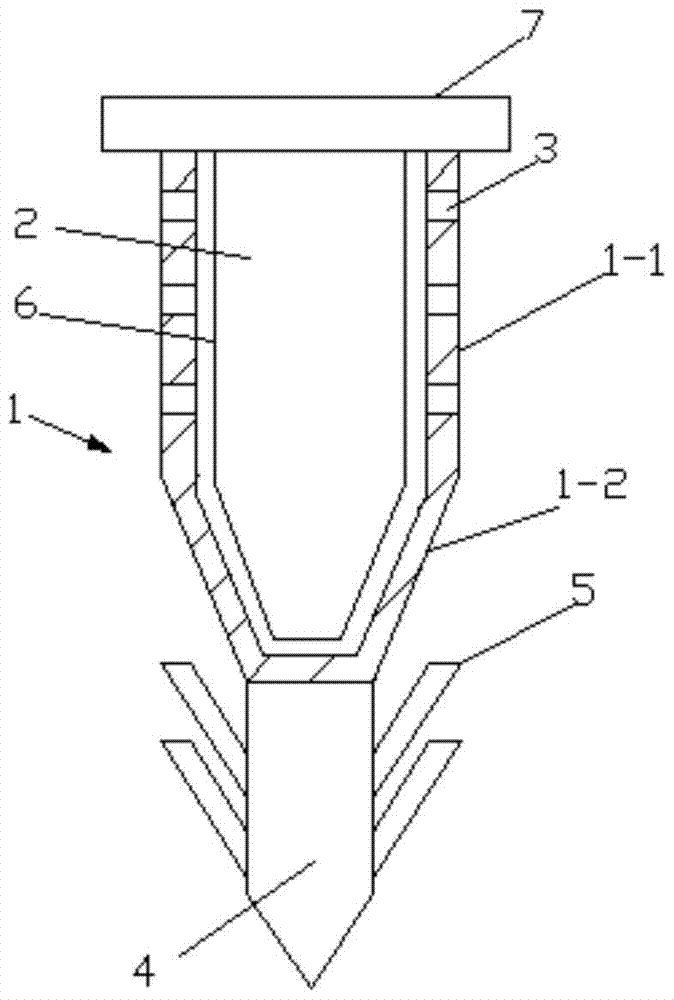

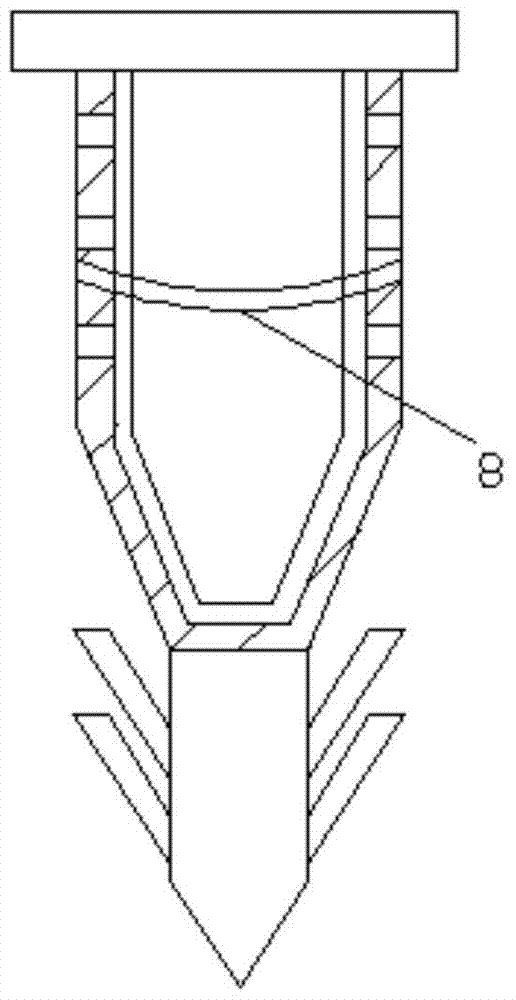

Blowdown device for aquaculture

The invention relates to a blowdown device for aquaculture. The blowdown device comprises a device body, wherein the device body is composed of a cylinder and a cone-shaped body arranged below the cylinder; the cylinder and the cone-shaped body are integrally arranged; a cavity is formed in the cylinder and the cone-shaped body; a plurality of water outlet through holes are formed in the side wall of the cylinder; an upright post is arranged below the cone-shaped body; the lower end of the upright post is in a shape of a needle tip; a plurality of barbs are formed on the side wall of the upright post; openings of the barbs are upward, and a filter screen is arranged in the device body. The blowdown device has the advantage of simple structure; when the blowdown device is used, only the upright post end is inserted into sludge, and then a blowdown pipe is inserted into the cavity, so that blowdown is realized; thus, the blowdown device is difficult to loosen when in use, and a handle is arranged, so that the blowdown device is convenient to lift after being used; in addition, a connecting joint is arranged, so that the blowdown device can be mutually butted with the blowdown pipe preferably.

Owner:珠海国业良种有限公司

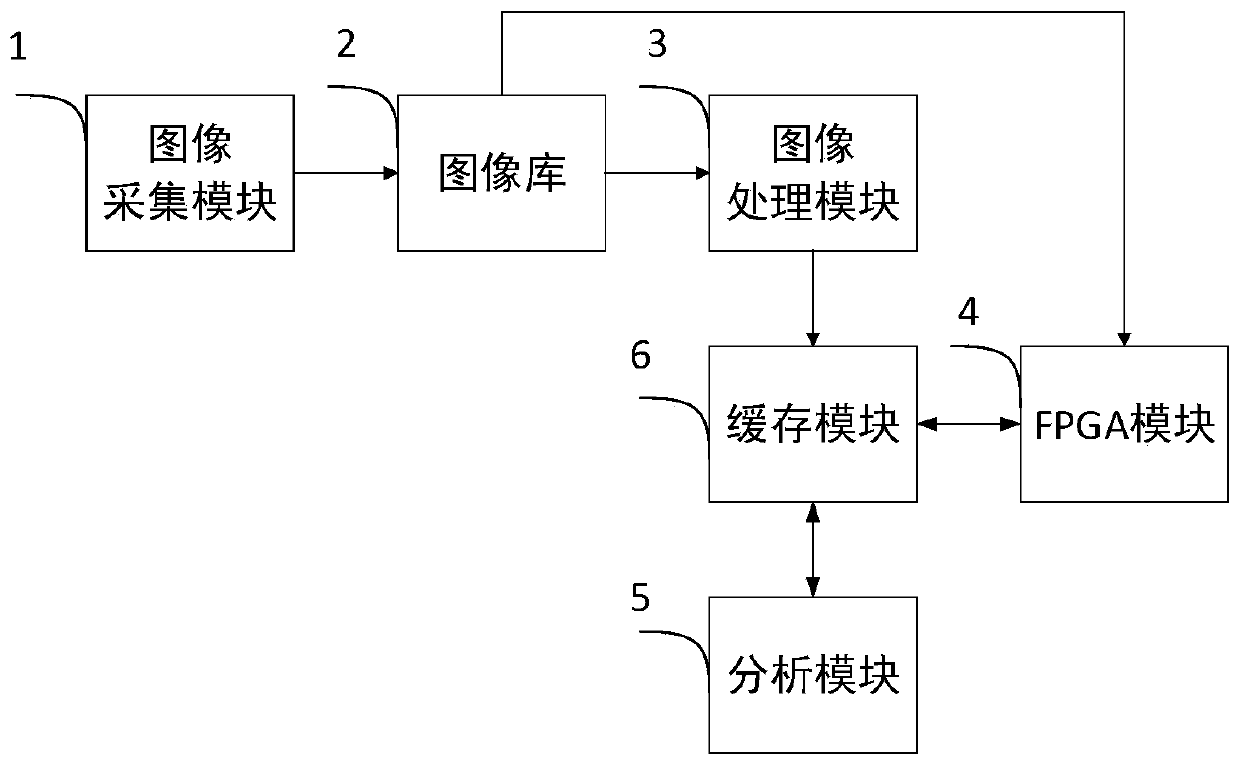

Dynamic target identification and real-time tracking system based on FPGA

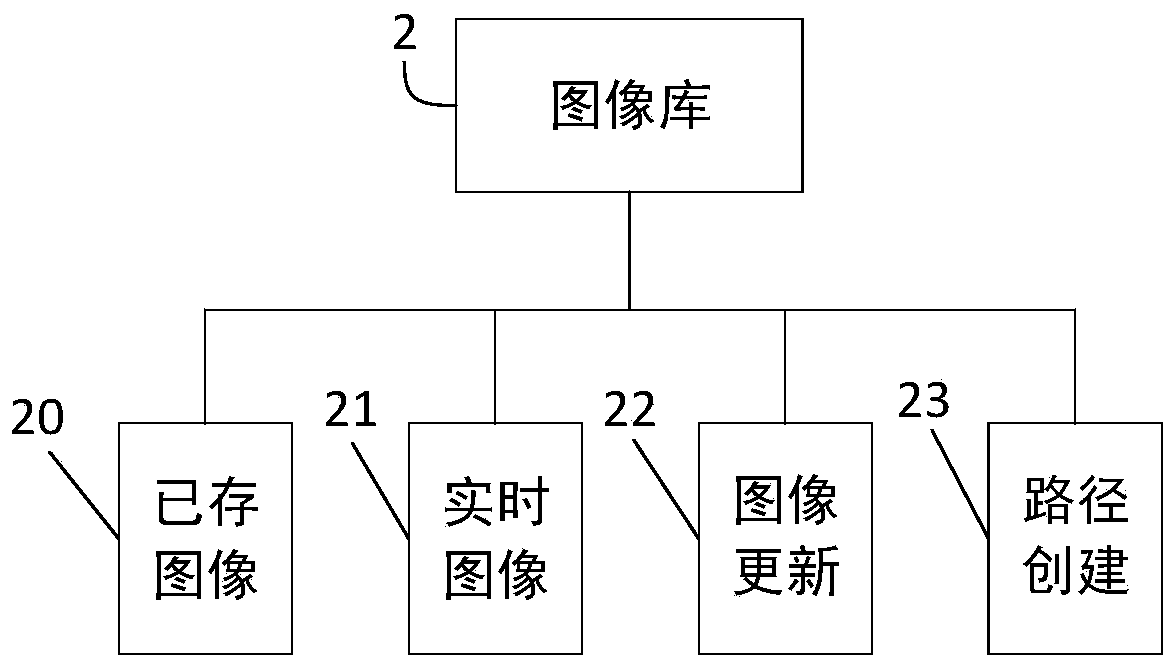

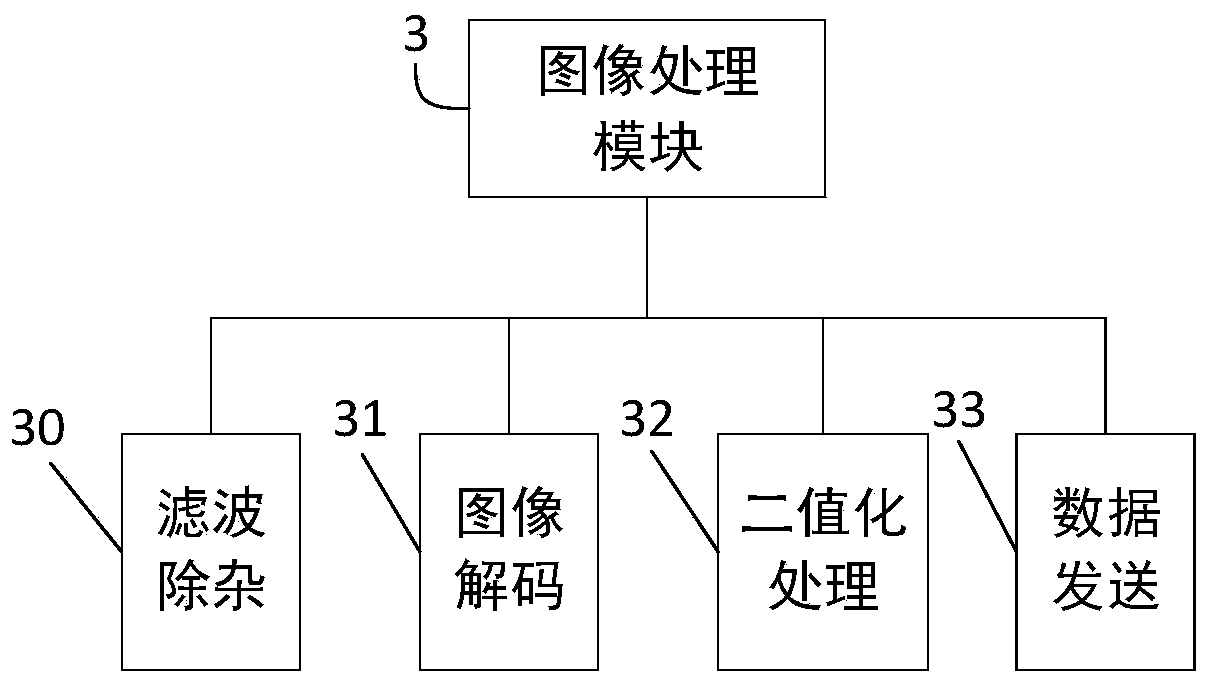

PendingCN110728617AEnhance real-time tracking capabilitiesSmall amount of calculationImage enhancementImage analysisImaging processingGoal recognition

The invention relates to a dynamic target identification and real-time tracking system based on an FPGA. The system comprises an image acquisition module used for acquiring images in real time, an image library used for updating and storing the images acquired in real time, an image processing module, an FPGA module, an analysis module and a cache module, and the image processing module is used for preprocessing the images acquired in real time to obtain processed real-time images; the FPGA module is used for performing target identification; the analysis module is used for performing target tracking and trajectory prediction; the cache module is used for caching data and providing mutual exchange between the data. Compared with the prior art, on the basis of the FPGA technology, filteringbinarization processing, cascading updating and distributed caching are adopted, and processing, target recognition, target tracking and trajectory prediction are carried out on images collected in real time, so that the recognition speed can be effectively increased, the recognition error is reduced, the recognition accuracy is improved, and the purpose of real-time target tracking can be achieved.

Owner:SHANGHAI DIANJI UNIV

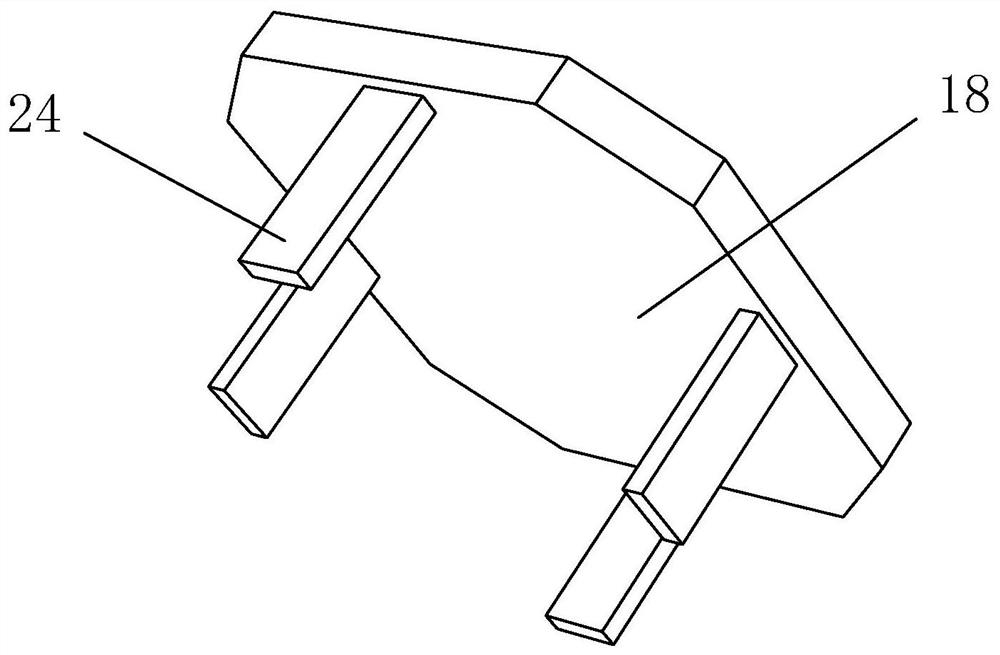

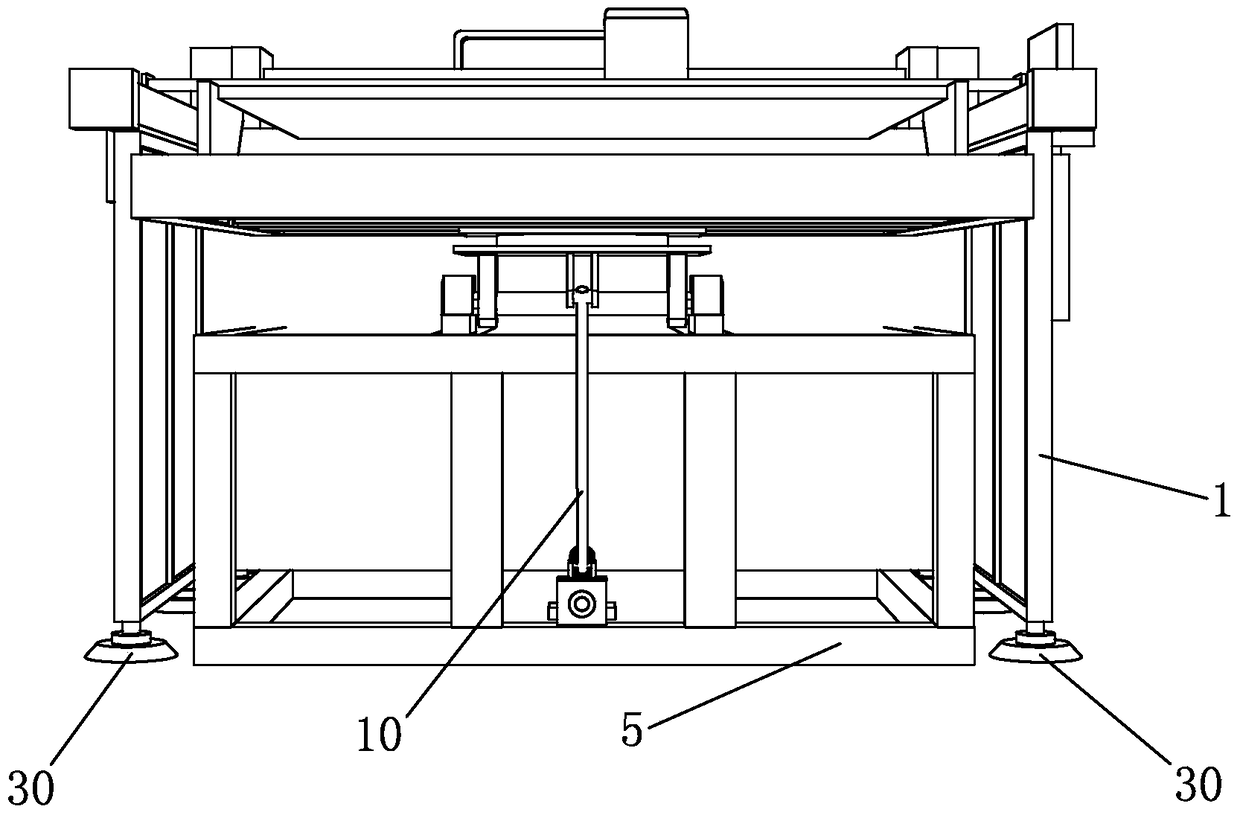

Subway station vertical face erecting connecting structure and installation component

PendingCN111576895AEasy to align and installEasy to connect with each otherBuilding material handlingStructural engineeringSubway station

The invention discloses a subway station vertical face erecting connecting structure and an installation component. A lifting part is installed above a bracket through a supporting arm in a parallel movement manner; a connecting frame is connected to the upper part of the lifting part through a horizontal movement component with a horizontal linear movement; a driving mechanism is installed on thebracket and connected to the lifting part; the installation component includes the vertical face erecting connecting structure; a scissor retractable component connects a base and the bracket; and anone-way transmission component is installed on the base and connected to the scissor retractable component through a pulling structure. The driving mechanism drives the lifting part to cooperate withthe supporting arm so that the connecting frame swings horizontally above the bracket to adjust the height up and down; while adjusting the height, the connecting frame is always kept in a horizontalposition, which finally drives the subway vertical face material fixed on the connecting frame to raise the height slightly; and the horizontal movement component drives the connecting frame to movehorizontally, thereby driving the vertical face material to follow the connecting frame to move in a short distance, which is convenient for materials in different positions to be connected to each other.

Owner:GUANGXI POLYTECHNIC

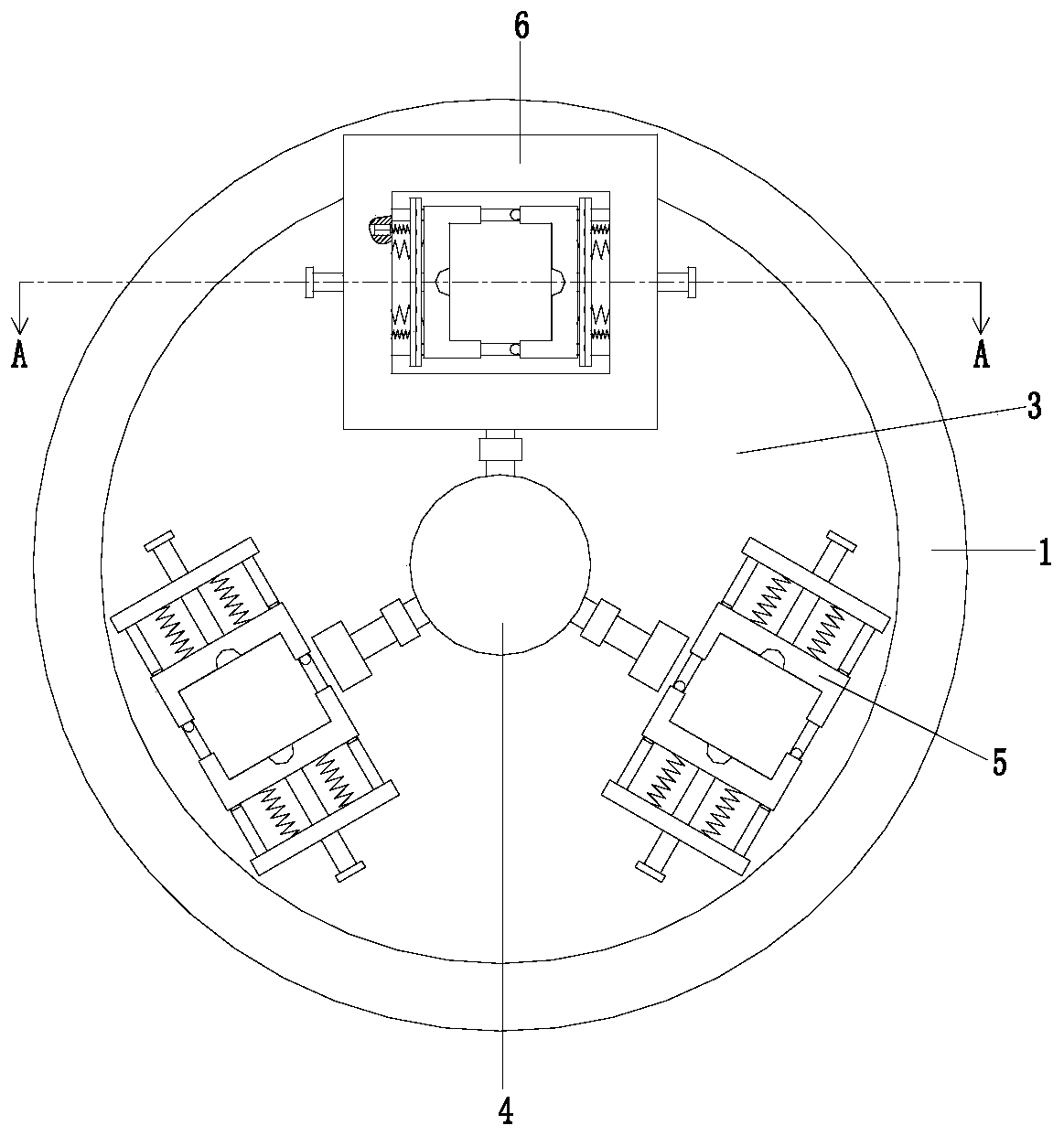

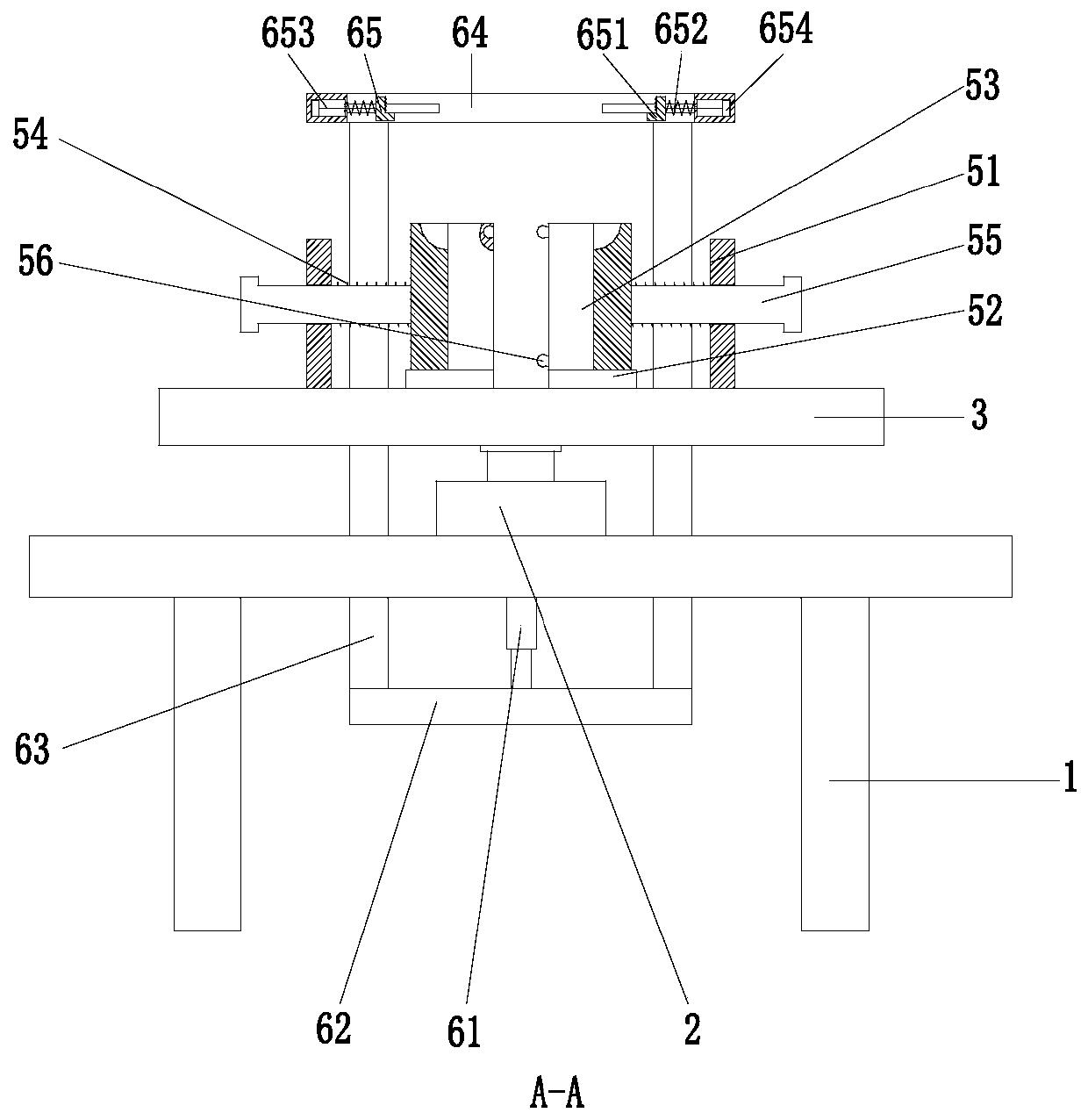

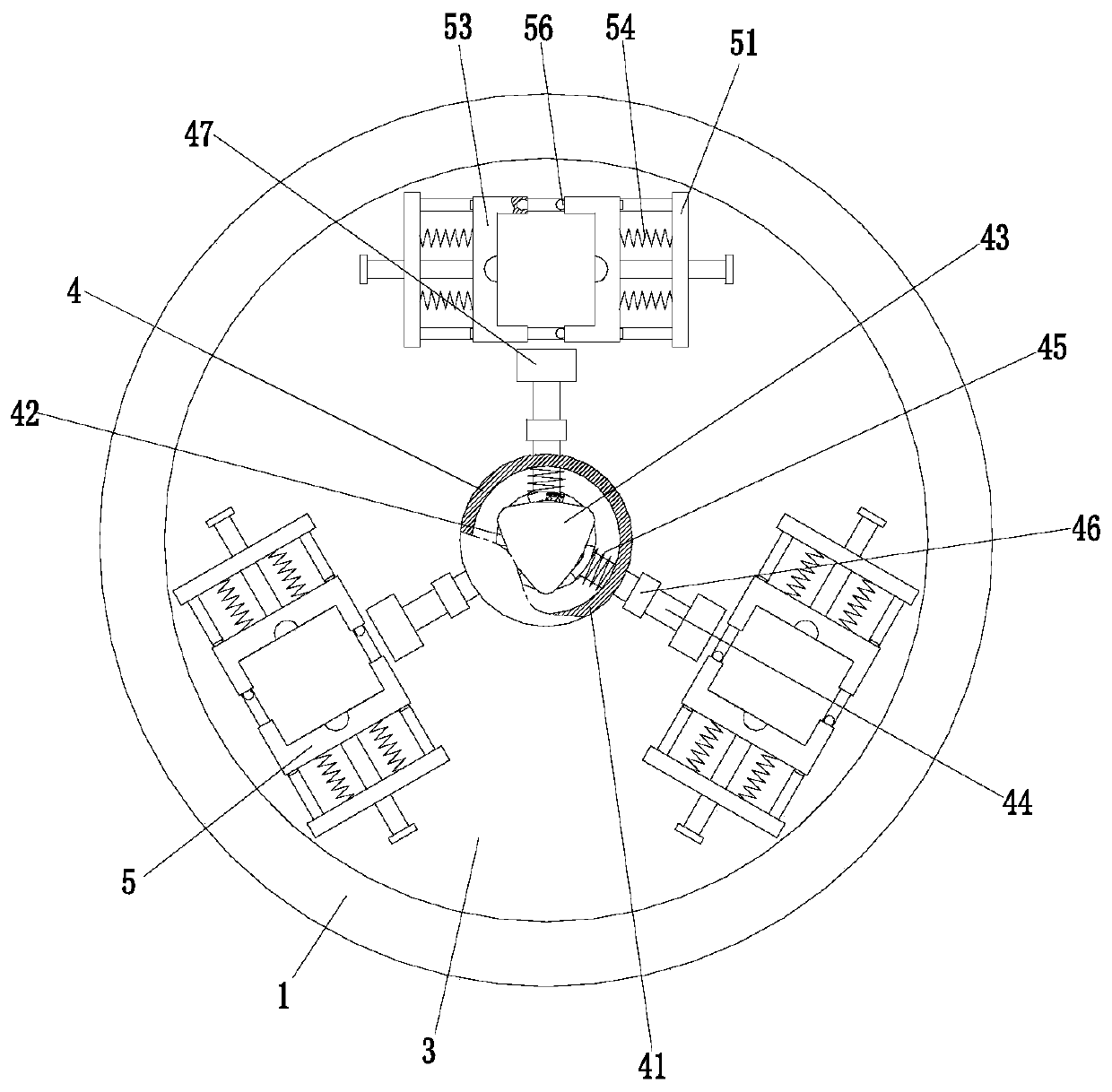

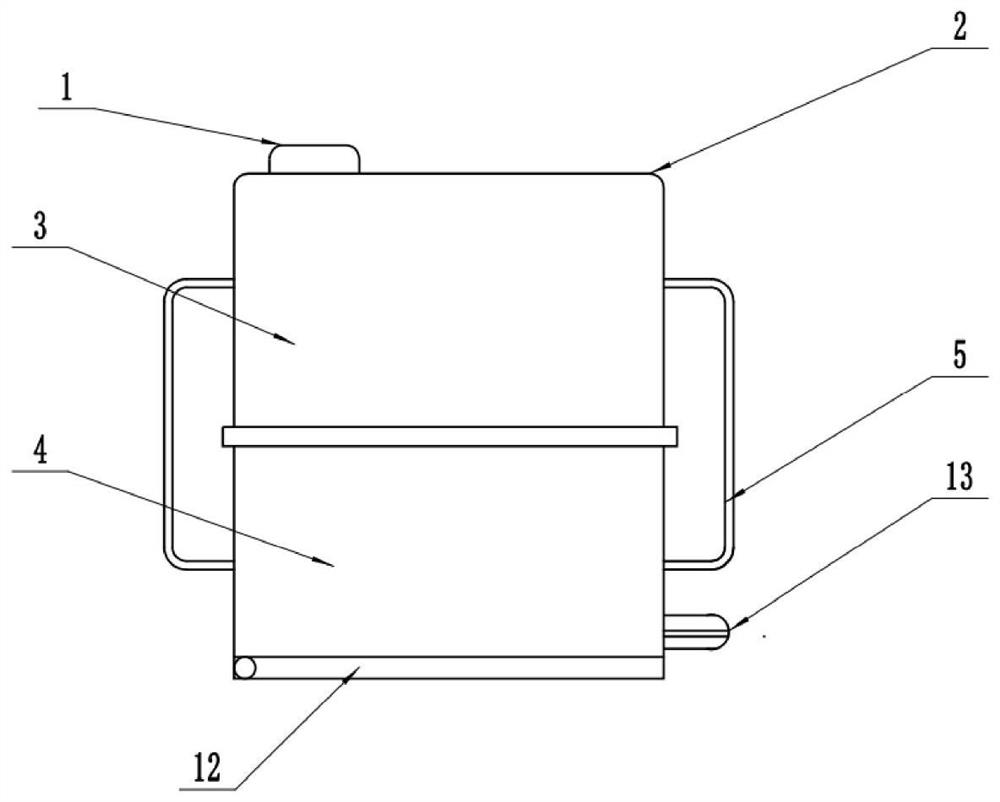

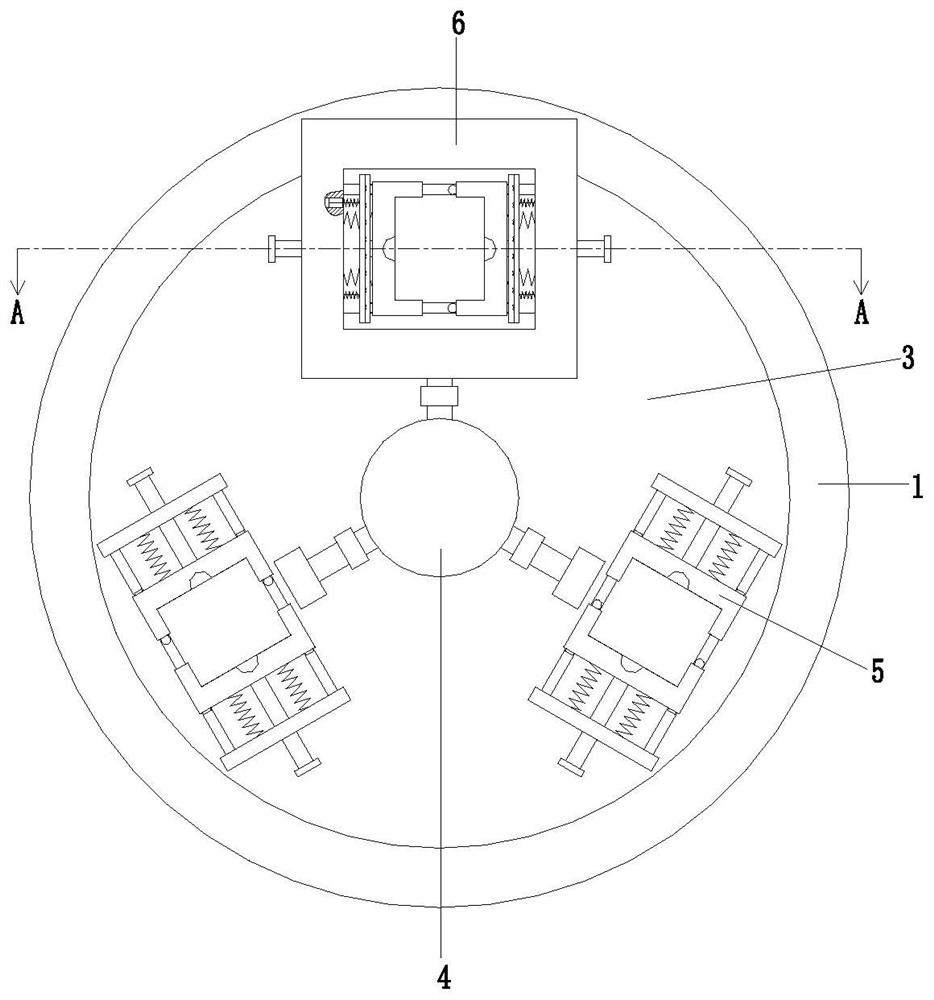

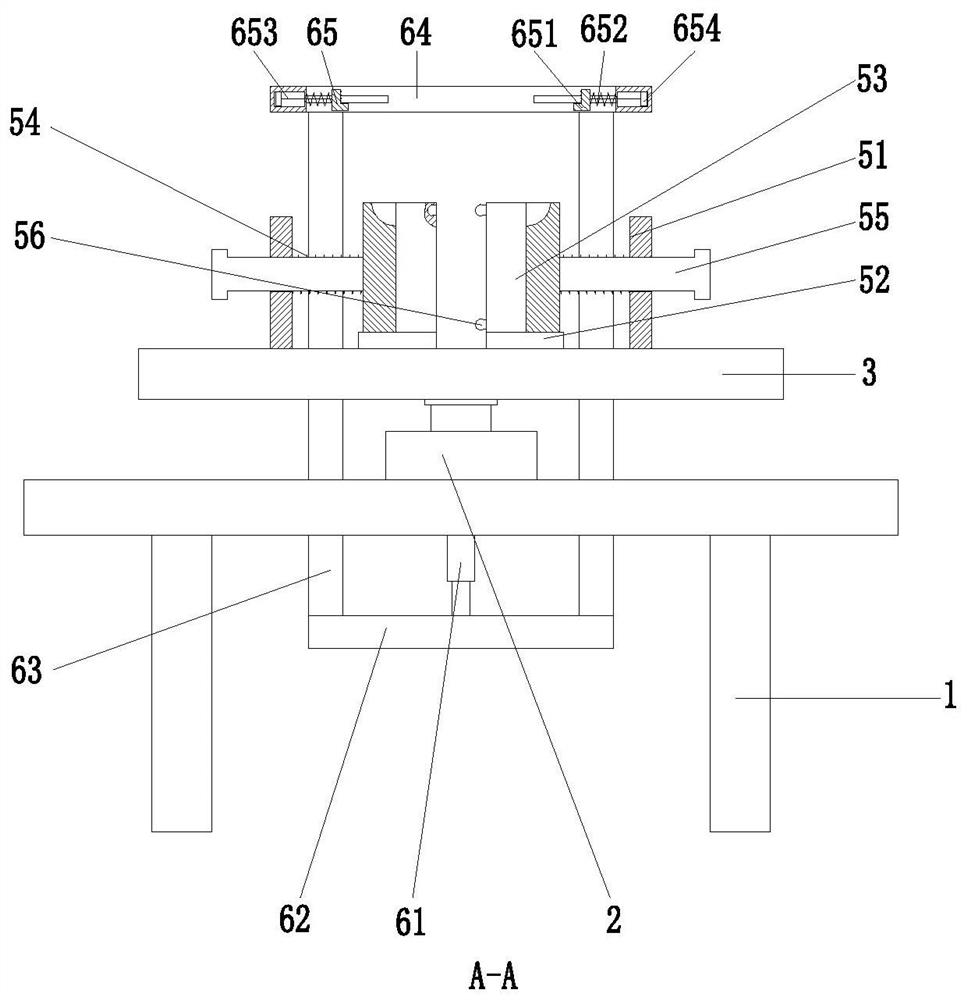

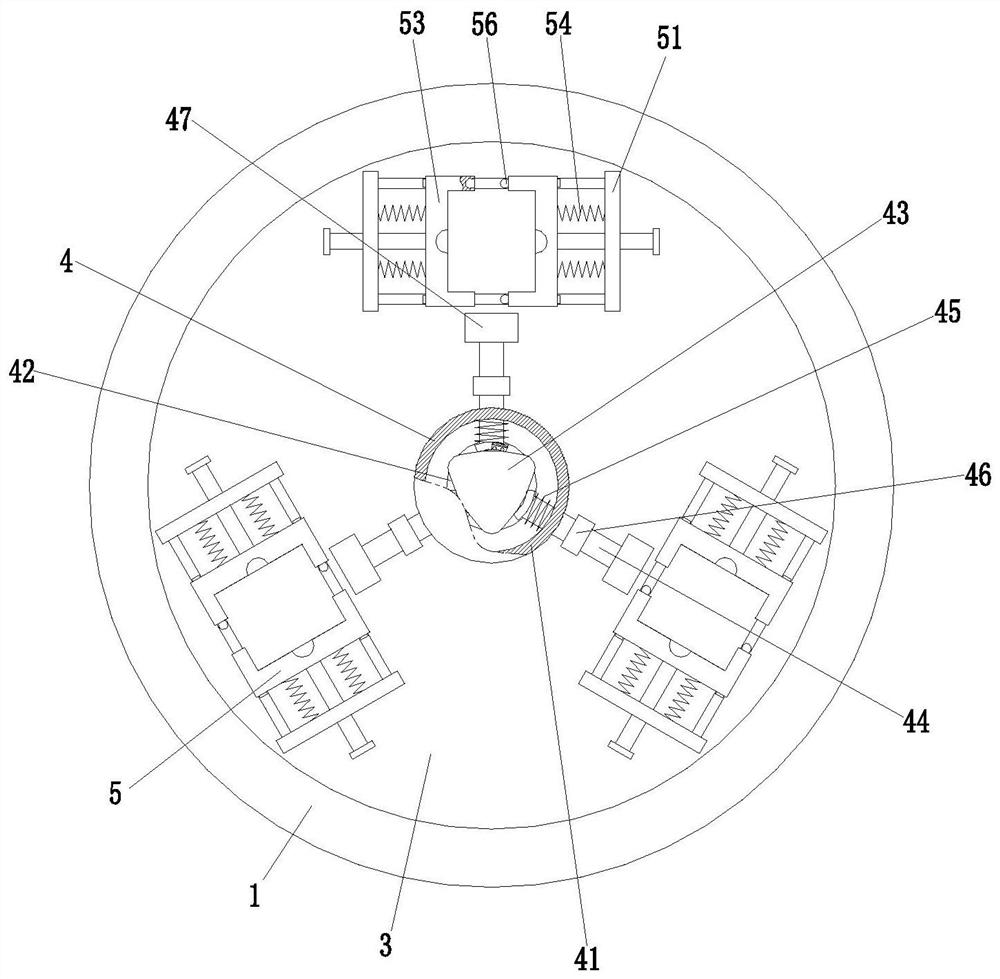

Air circuit breaker assembling machine

ActiveCN110340633ASimple organizationImprove production and assembly efficiencyMetal working apparatusProduction lineElectric machine

The invention provides an air circuit breaker assembling machine. A workbench, a drive motor, a fixing table, an executing device, fixing devices and an auxiliary device are included. The upper end ofthe workbench is provided with the drive motor through a motor base. An output shaft of the drive motor is connected with the fixing table through a flange. The executing device is arranged at the middle portion of the fixing table, and the fixing devices are evenly arranged at the upper end of the fixing table around the circumference direction of the fixing table in a sliding fit manner. The auxiliary device is arranged on the workbench and located above the fixing devices. The air circuit breaker assembling machine can solve the problems that in the process that an operation handle of a circuit breaker is manually pushed up and then is sleeved with a ceramic shell, the manual operation efficiency is low, inner components in the incompletely-assembled circuit breaker are not completelyfixed, and disengaging of the inner components is likely to be caused by manual operation handle carrying; and meanwhile, the manual installing efficiency is low, and the work efficiency of a production line is influenced.

Owner:泰州亿丰达电器有限公司

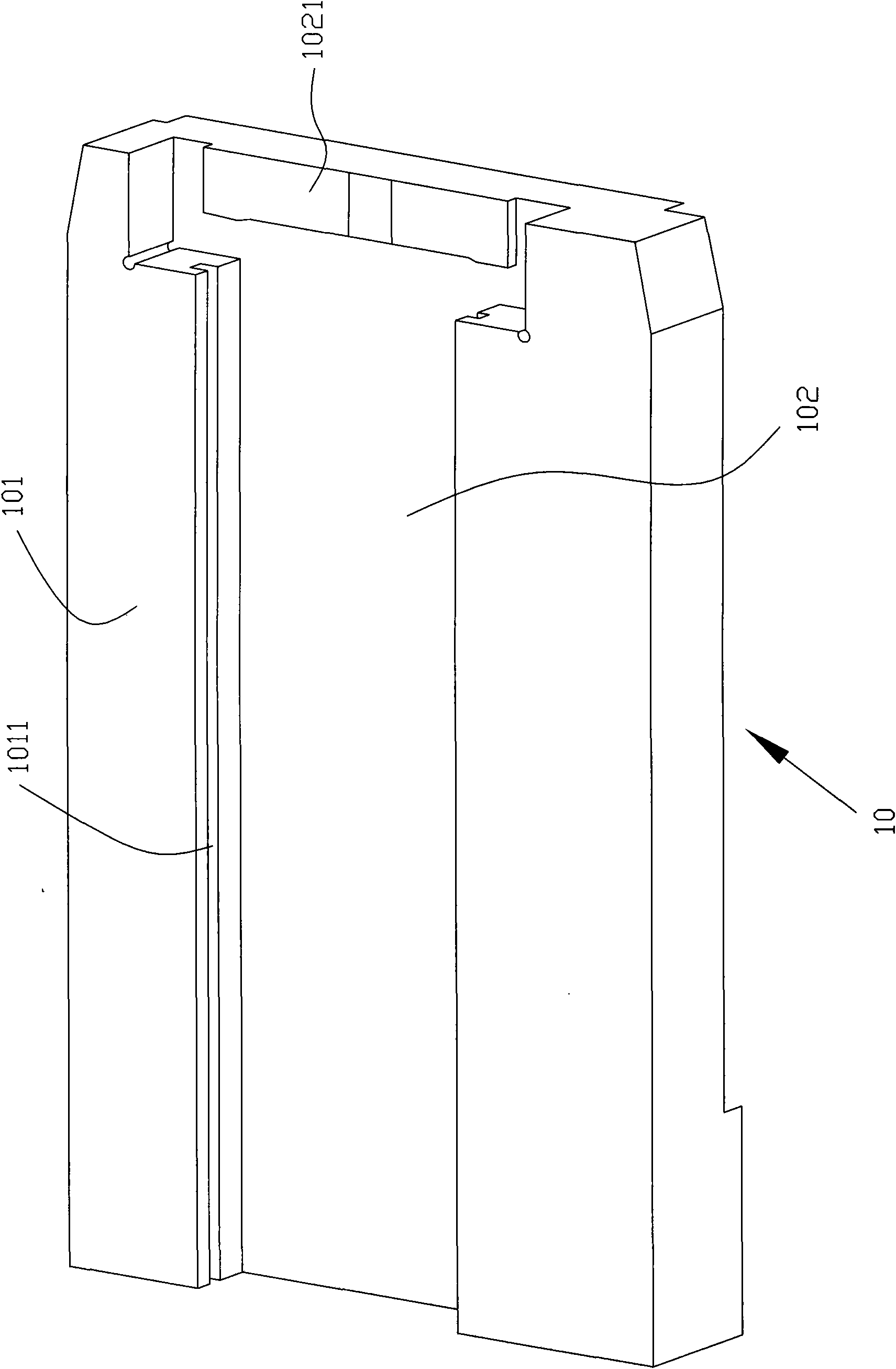

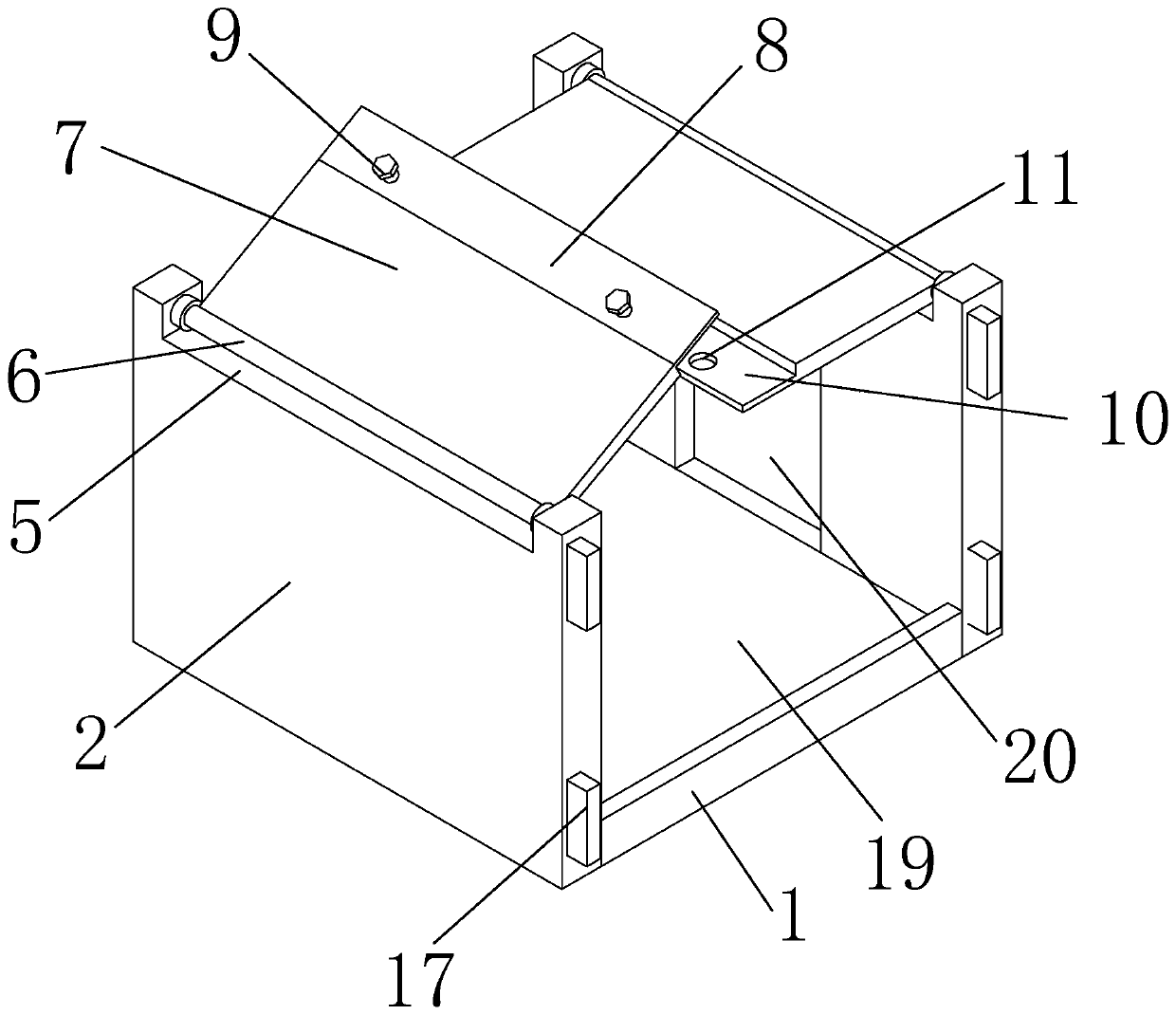

Test-aiding bracket

InactiveCN101576455AEasy to connect with each otherGuaranteed test resultsStrength propertiesSoftware engineeringMotherboard

The invention provides a test-aiding bracket which mainly comprises a body. A fixed groove, i.e. a T-shaped groove for fixing an interface of an extending line, is dug at one side of the body; both opposite inner sides of the T-shaped groove are respectively provided with a guide rail for a panel to slide, and one end of the T-shaped groove is provided with a convex seat for placing the interface of the extending line. The extending line is aided in an HALT test and fixed on the test-aiding bracket so as to connect the interface at one end of the extending line with a mainboard interface of a machine to be tested and ensure test results.

Owner:MITAC COMP (SHUN DE) LTD

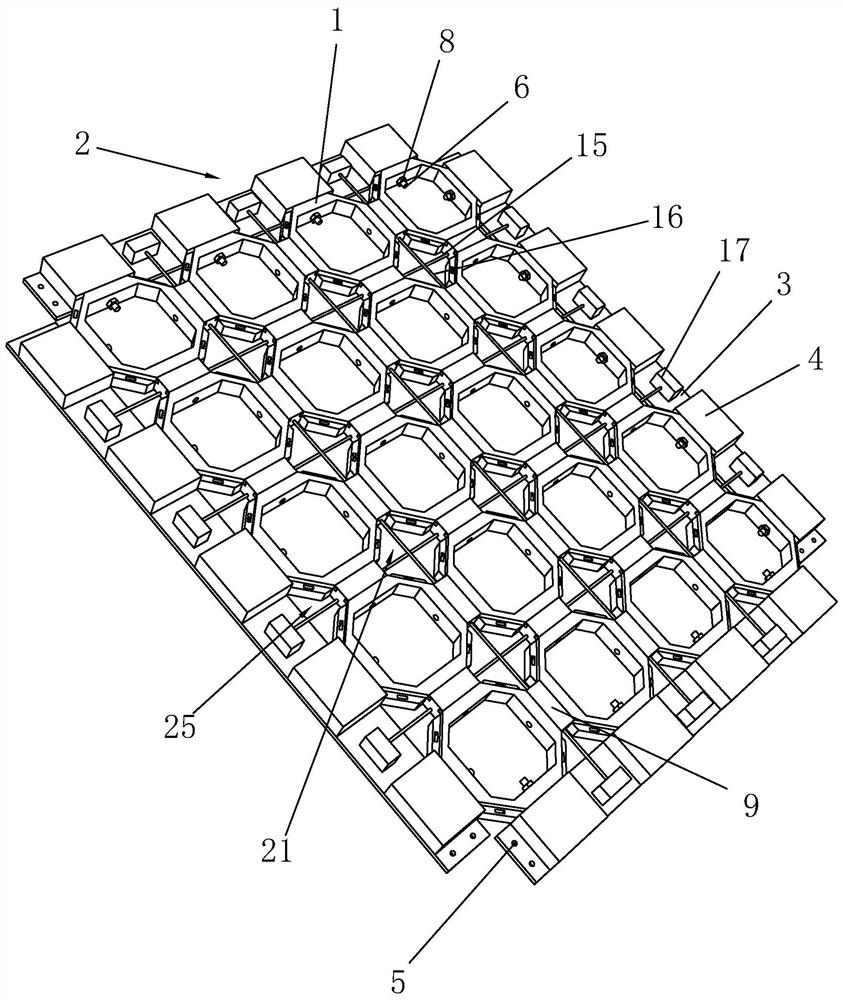

Construction method of ecological revetment block structure

ActiveCN112575741AEnsure the firmness of the installationEnsure support limit functionCoastlines protectionReceptacle cultivationEnvironmental resource managementWater flow

The invention discloses a construction method of an ecological revetment block structure. The construction method comprises the following steps of 1) construction preparation, 2) preparation of reinforcing edge strips, 3) construction of an ecological revetment, and 4) plant planting. According to the construction method, the reinforcing edge strips are arranged on the four sides of the ecologicalrevetment, reinforcing and supporting are conducted from the four sides of the ecological revetment simultaneously, the stability of the whole ecological revetment is effectively improved, thus ecological blocks are not prone to falling off, and the ecological revetment can resist scouring of water flow better; the adjacent ecological blocks are mutually clamped through positioning blocks, the positioning blocks in the same row or the same column are connected and fixed through connecting rods, indirect connecting and fixing between the transverse ecological blocks and the longitudinal ecological blocks are achieved, thus the ecological blocks are mutually combined and restrained, the structural strength of the revetment structure is improved, the ecological revetment is not prone to deforming, and the ecological blocks do not fall off; and through further reinforcing and positioning arrangement of auxiliary blocks, the structure of the whole ecological revetment is more compact and firmer.

Owner:宁波龙元盛宏生态建设工程有限公司

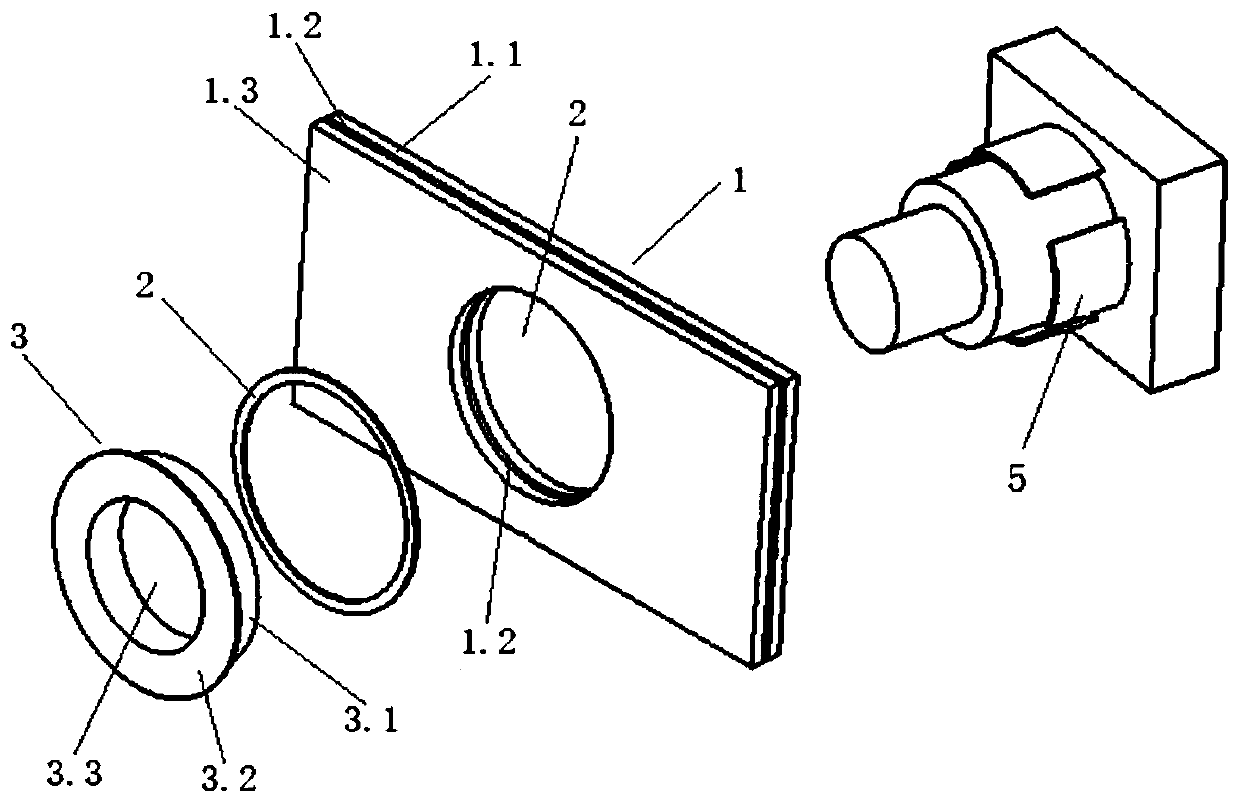

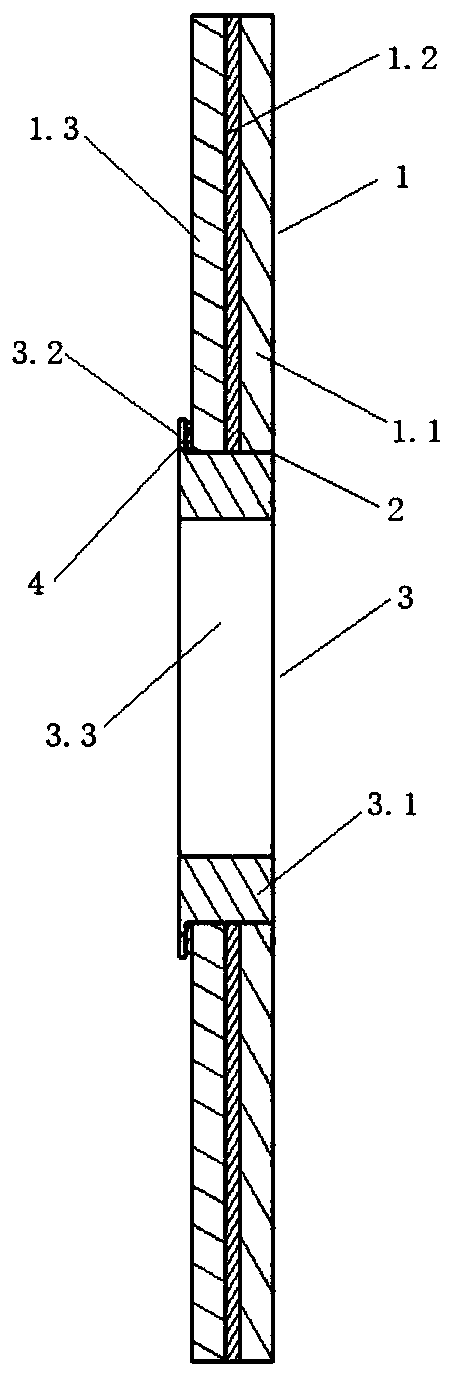

Connecting structure of battery box and high-voltage connector shielding ring, battery box and automobile

ActiveCN111525061AGood shielding effectGood electromagnetic shielding effectMagnetic/electric field screeningCurrent conducting connectionsIn vehicleAutomotive engineering

The invention discloses a connecting structure of a battery box and a high-voltage connector shielding ring, a battery box and an automobile. The connecting structure of the battery box and the high-voltage connector shielding ring comprises a battery box body, a mounting hole is formed in the battery box body, and the connecting structure is characterized in that the battery box body comprises acarbon fiber inner layer, a metal middle layer and a carbon fiber outer layer; and a metal sleeve is embedded in the mounting hole and is in contact connection with the metal middle layer. Good conductor mutual communication is achieved, it is guaranteed that the contact resistance of the high-voltage connector shielding ring and the carbon fiber box body is greatly reduced, the electromagnetic shielding effect is good, and therefore it is guaranteed that a battery management system and other vehicle-mounted electronic components are not subjected to electromagnetic interference, and the accident occurrence probability is reduced.

Owner:DONGFENG MOTOR CORP HUBEI

Waste gas heat energy recycling device for centralized treatment of kitchen waste

PendingCN112856436AEasy to use and return to the next timeAchieve first useIncinerator apparatusExhaust fumesWaste treatment

The invention discloses a waste gas heat energy recycling device for centralized treatment of kitchen waste in the field of waste treatment and aims to increase the utilization rate of waste gas heat energy in the kitchen waste combustion process. In order to achieve the purpose, the waste gas heat energy recycling device for centralized treatment of kitchen waste comprises an incinerator with an inlet and an outlet; the incinerator is provided with a drying layer and an incineration layer in sequence from an inlet to an outlet; a heat conduction pipe is communicated between the bottom of the incineration layer and the drying layer; and the junction of the heat conduction pipe and the drying layer communicates with a heat energy utilization device. According to the technical scheme of the waste gas heat energy recycling device for centralized treatment of the kitchen waste, the integrated incinerator seals the drying layer and the incineration layer, so that heat of the incineration layer is transferred to the drying layer to achieve the material drying effect, the situation that wastes cannot be fully burnt due to too high water content is avoided, and waste gas heat energy utilization is achieved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

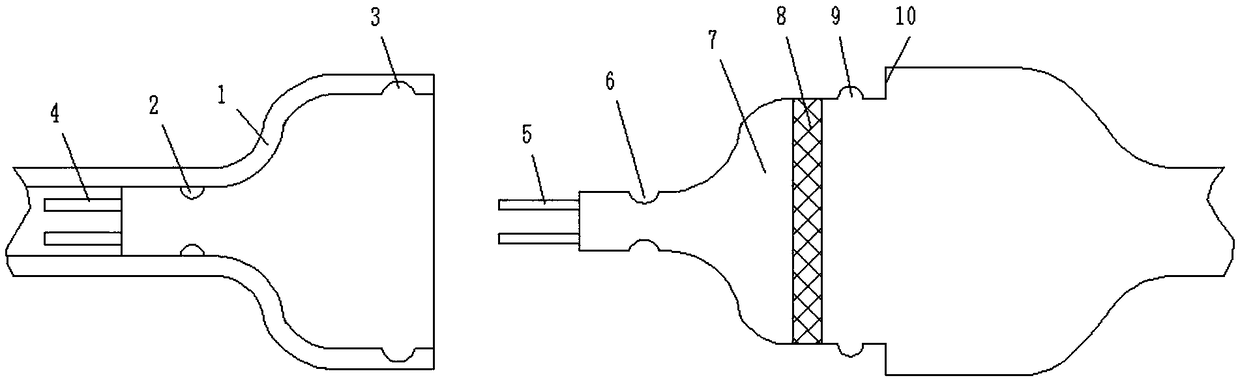

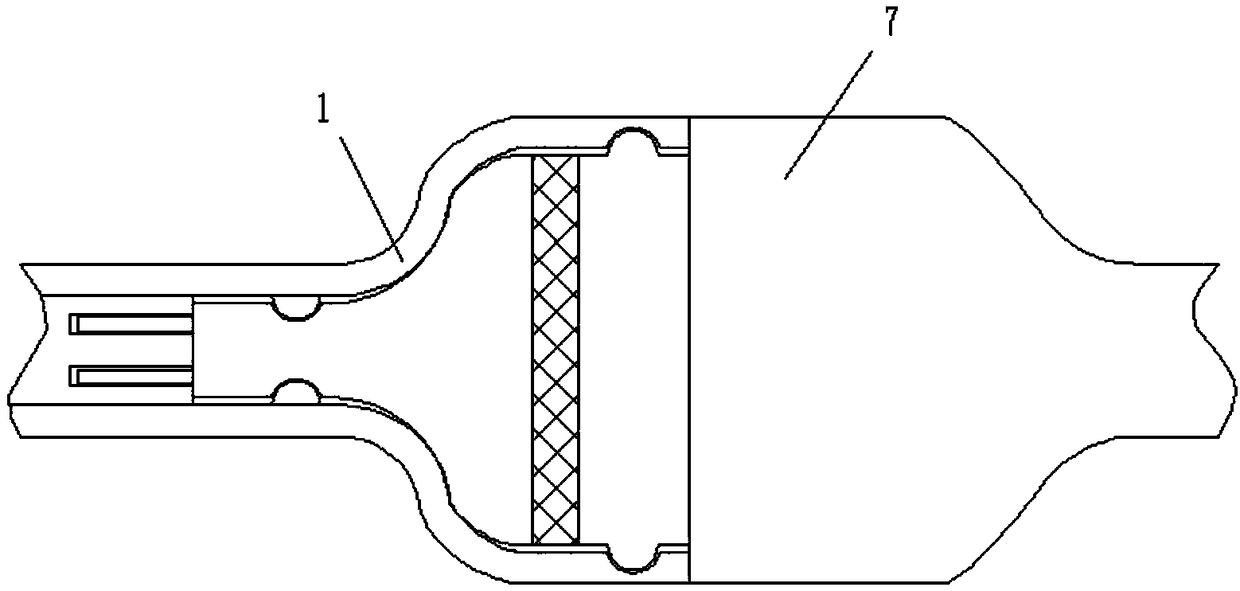

Waterproof connecting line joint

InactiveCN108183352AImprove sealingImprove fastnessCoupling contact membersCouplings bases/casesMating connectionRubber material

The invention discloses a waterproof connecting line joint, and the joint comprises a socket and a plug, which are connected closely and cooperatively, thereby improving the fastening performance andsealing performance. Moreover, the butt joint and disassembly of the socket and the plug are very convenient, and the socket and the plug are made of rubber materials, and the rubber materials are good in sealing performance. The front end of the socket consists of two hollow tubes with different diameters, wherein the inner wall of a big end is provided with a socket groove, and the interior of asmall end is provided with a socket convex block. The front end of the plug is provided with two solid tubes with different diameters, wherein the exterior of the small end is provided with a circular plug groove, and a big end is provided with a plug convex block. The plug is provided with a circular drying agent groove, and a drying agent is placed in the drying agent groove, and absorbs the moisture entering from a gap, thereby improving the waterproof performance of the interior of the joint. The drying agent can be replaced regularly, thereby guaranteeing the waterproof quality. A plug box has the same excircle diameter as the big end of the socket, and the sealing performance is improved after the cooperative connection. The joint is not liable to be scraped by a foreign object.

Owner:颍上贝斯特电子科技有限公司

A sewage discharge device for aquaculture

Owner:珠海国业良种有限公司

Tray loading device for biscuit packaging

InactiveCN108792002AImprove loading efficiencyPlay a supporting rolePackaging biscuitsBiochemical engineeringSemi automatic

The invention discloses a tray loading device for biscuit packaging, and relates to the technical field of biscuit production packaging equipment. The tray loading device comprises a first fixing andsupporting plate, fixing and supporting rods are fixedly connected to the 90-degree corners of the bottom of the outer surface of the first fixing and supporting plate, a second fixing and supportingplate is fixedly connected to the portion, close to the middle of one side of the reverse side of the first fixing and supporting plate, of the surface of the top of the first fixing and supporting plate, first fixing sliding grooves are formed in the portions, close to the two sides of the middle of the second fixing and supporting plate, of the obverse side of the second fixing and supporting plate, and fixing sliding blocks are slidably connected to the surfaces of the first fixing sliding grooves. According to the tray loading device for biscuit packaging, the purpose of effectively improving the whole tray loading efficiency is achieved; the whole device is simple in structure and principle and convenient to manufacture, and therefore the device is low in cost and convenient to operate; and complete artificial tray loading is replaced with semi-automatic tray loading, therefore, the whole tray loading efficiency is greatly improved, manpower and material resources are saved, and the whole production cost can be reduced.

Owner:ANHUI NONG ANKANG FOODS LTD CO

A three-dimensional conveying device of a photovoltaic battery string automatic typesetting machine

ActiveCN105449049BDoes not affect normal deliverySolve puzzlesFinal product manufactureSemiconductor/solid-state device manufacturingMechanical engineeringPhotovoltaics

The invention discloses a three-dimensional conveying device for an automatic photovoltaic cell string typesetter. The three-dimensional conveying device comprises a longitudinal conveying line, a working platform and an automatic typesetter, wherein the working platform is arranged on any conveying machine frame in the longitudinal conveying line; and the automatic typesetter is arranged corresponding to the working platform, and is connected with the conveying machine frame. The working platform is embedded in the longitudinal conveying line, a synchronous belt on an upper platform can be higher or lower than a rolling wheel driving rod of the longitudinal conveying line via a lifting device, while impact on normal glass conveying of the longitudinal conveying line is avoided when the synchronous belt is at both the two working condition positions, so that the problem in arranging a plurality of working positions on the same longitudinal conveying line is solved, multiple positions can be connected and changed conveniently, the occupied space is small, the conveying speed is fast, and the production efficiency is high.

Owner:上海豪力起重机械有限公司

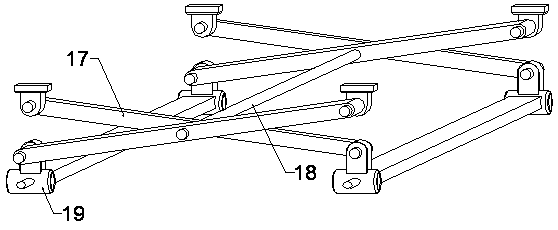

Track type transfer vehicle for nursery stock to transfer with soil

InactiveCN111776647AEasy to connect with each otherEasy to disassemble and replaceMechanical conveyorsTrackwayAgricultural engineering

Owner:安徽绿泉生态农业股份有限公司

Coking coal blended with recycled materials and coking coal blending method

The invention discloses a coking blending coal blended with recycled materials and a coking coal blending method. The weight ratio of the components is: fat coal (16-2N)%, high-sulfur coal 19-21%, 1 / 3 coking coal 4~6%, coking coal 39~41%, lean coal (7-N)%, gas coal (12+2N)%, recycled material N%, said N≤5; the content of β resin in said recycled material is 21~24wt%. This blended coal uses β resin with caking effect and combines it with coking coal blending technology to replace part of fat coal and add it to coking coal to produce coke, which can not only expand coking coal resources, but also reduce high-priced fat coal blending. Ratio, reduce coal blending cost. This coal blending method widens the plastic temperature range of coking coal, so that various coal types can better connect and overlap each other, improve the coking performance of the coking process, and promote the anisotropy generation technology; in ensuring the quality of coke to meet the requirements of large-scale Under the condition of blast furnace coke demand, the proportion of lean and weak coal with weak cohesion can be maximized in coking coal blending, so as to greatly reduce the cost of coal blending.

Owner:宣化钢铁集团有限责任公司

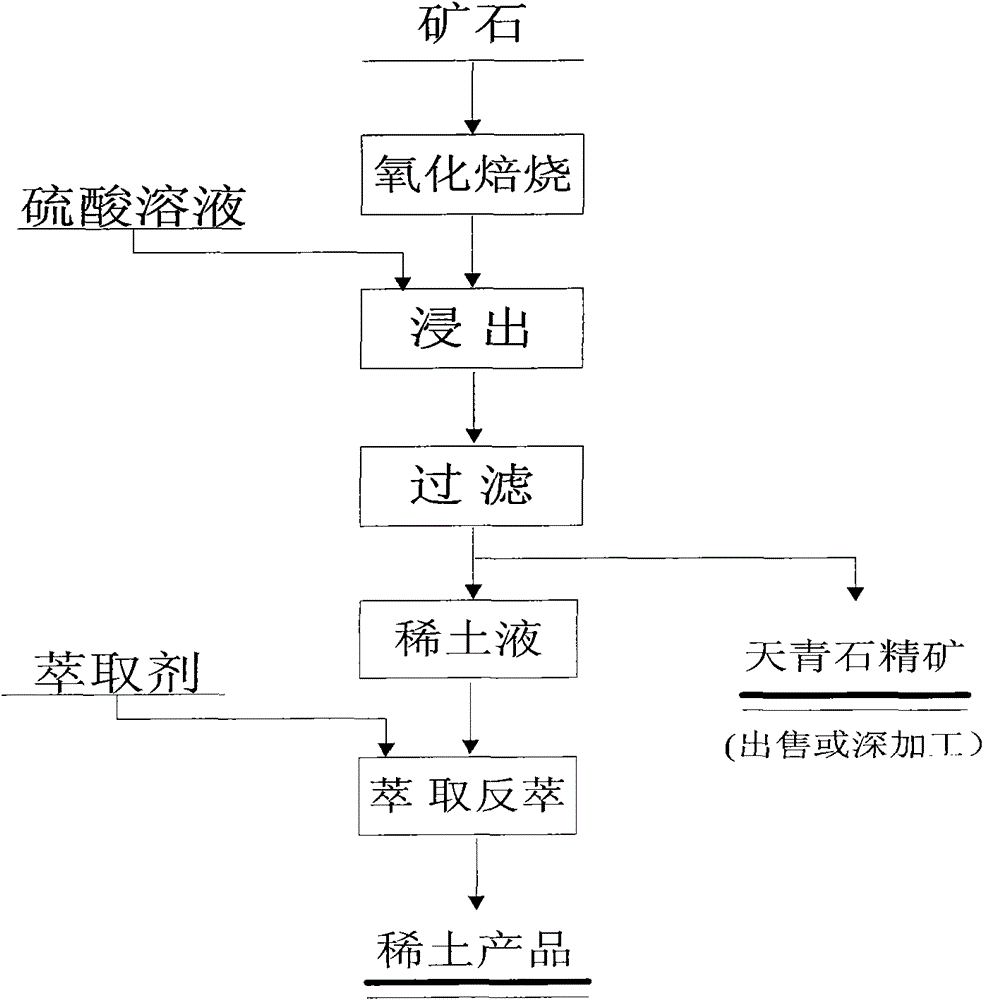

A comprehensive recovery process of rare earth and strontium co-associated polymetallic ore

ActiveCN102399999BEfficient separationSimple processProcess efficiency improvementAir atmosphereHydrogen-Ion Concentrations

Owner:GRIREM ADVANCED MATERIALS CO LTD

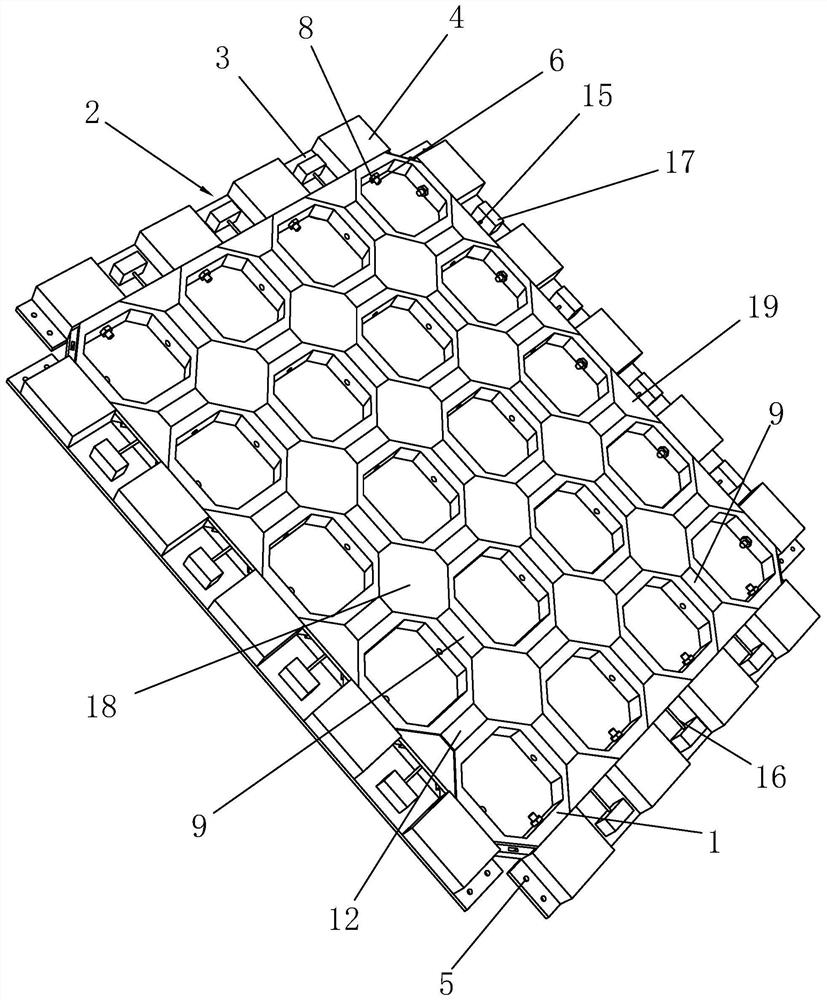

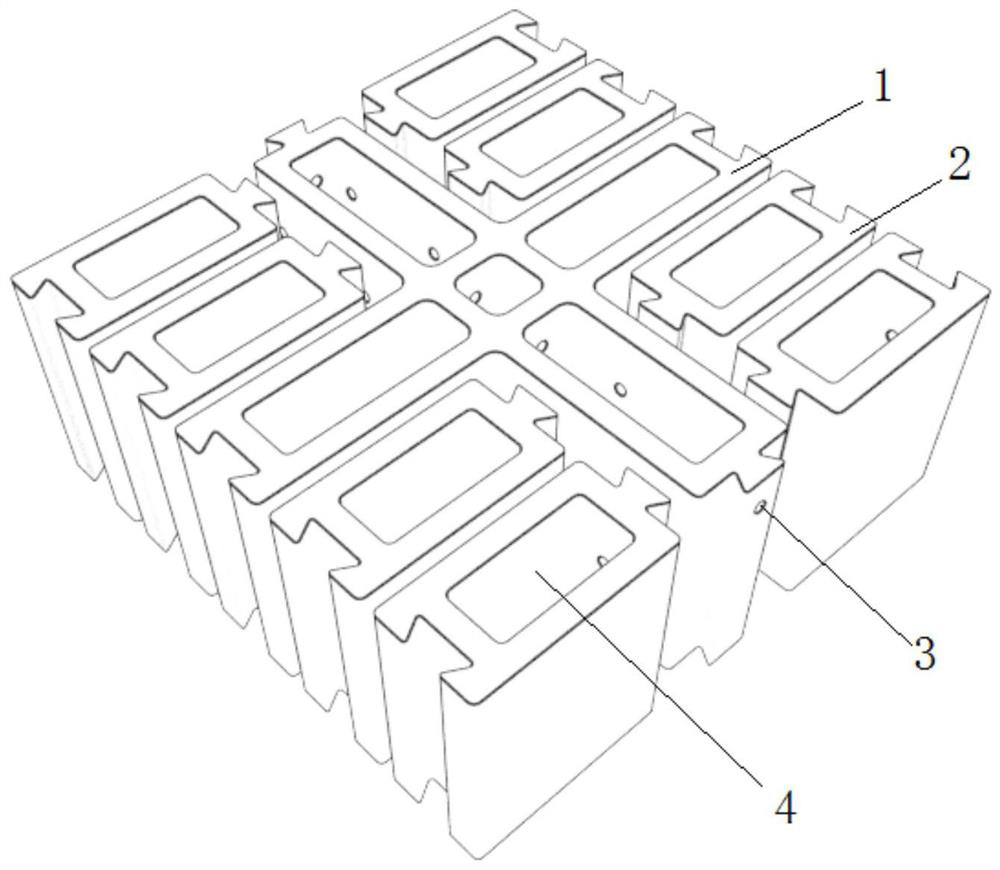

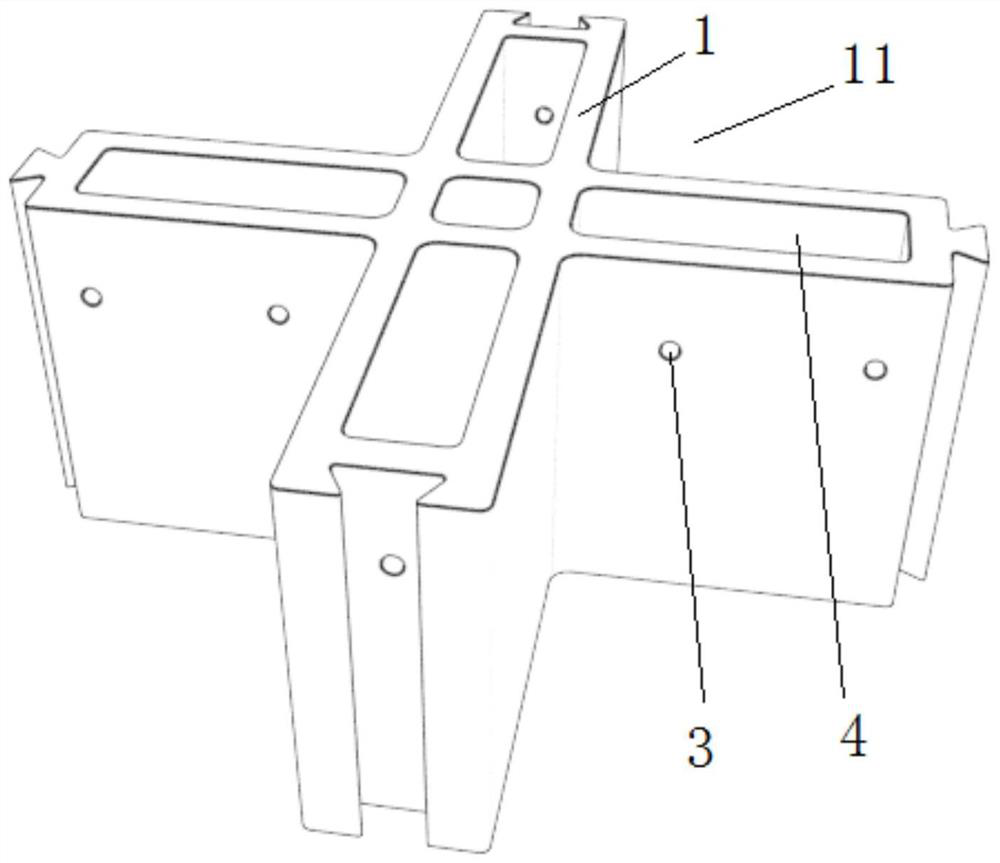

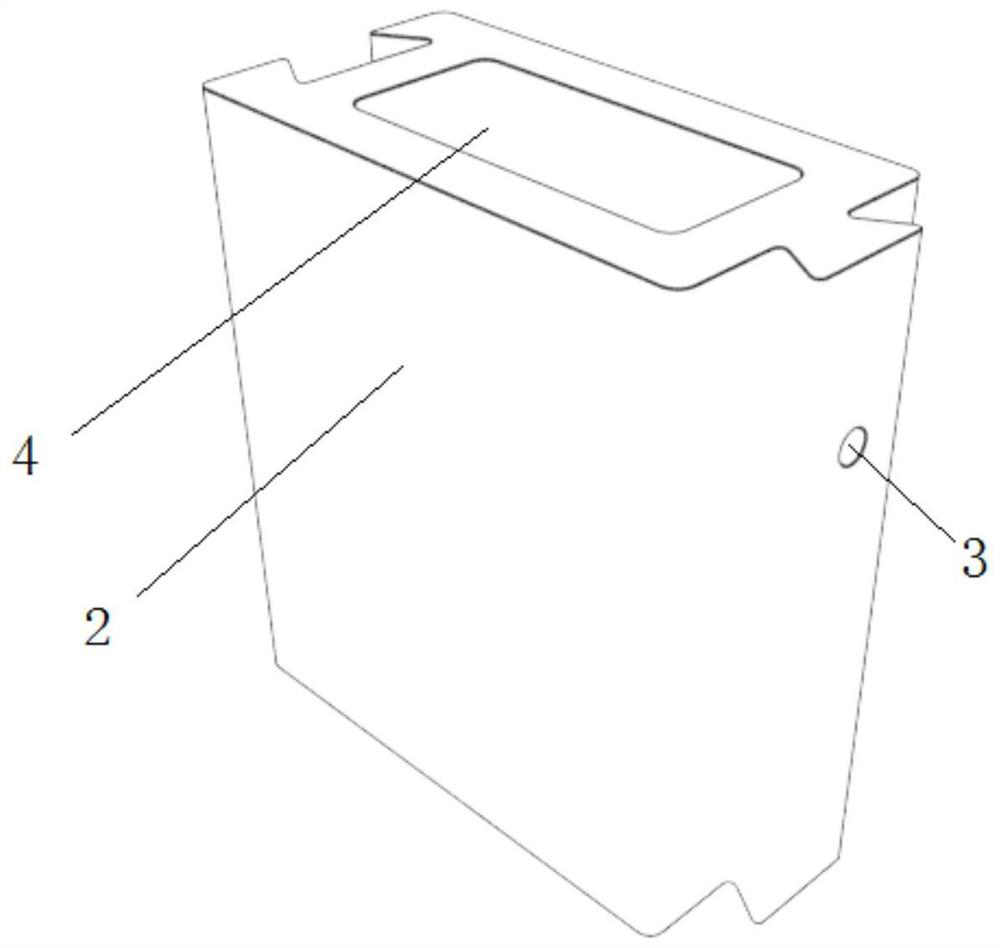

Snap-in block unit and revetment

PendingCN111636376ANot easy to dumpIncrease productivityCoastlines protectionExcavationsArchitectural engineeringStructural engineering

The invention discloses a snap-in block unit and a revetment. The snap-in block unit and the revetment aim to solve the technical problems existing in the prior art that an entire block is liable to fall down and is liable to damage when impacted by heavy storms and rain. According to the snap-in block unit, protrusions or grooves are arranged on central blocks, and protrusions or grooves are respectively arranged on the two opposite side faces of clamping blocks, therefore, during laying, the central blocks are connected and buckled with the clamping blocks in a clamping mode through the protrusions and the grooves, so that the whole snap-in block unit is not liable to fall down and can withstand impact. According to the revetment, the central blocks are regularly distributed in rows andlines, and the clamping blocks are arranged between adjacent central blocks, so that the coverage area of blocks produced each time is increased, and the revetment is more beautiful compared with therevetment distributed by the blocks with a single shape.

Owner:西安景兴祥环境科技有限公司

Pre-forming device for textile semi-finished products

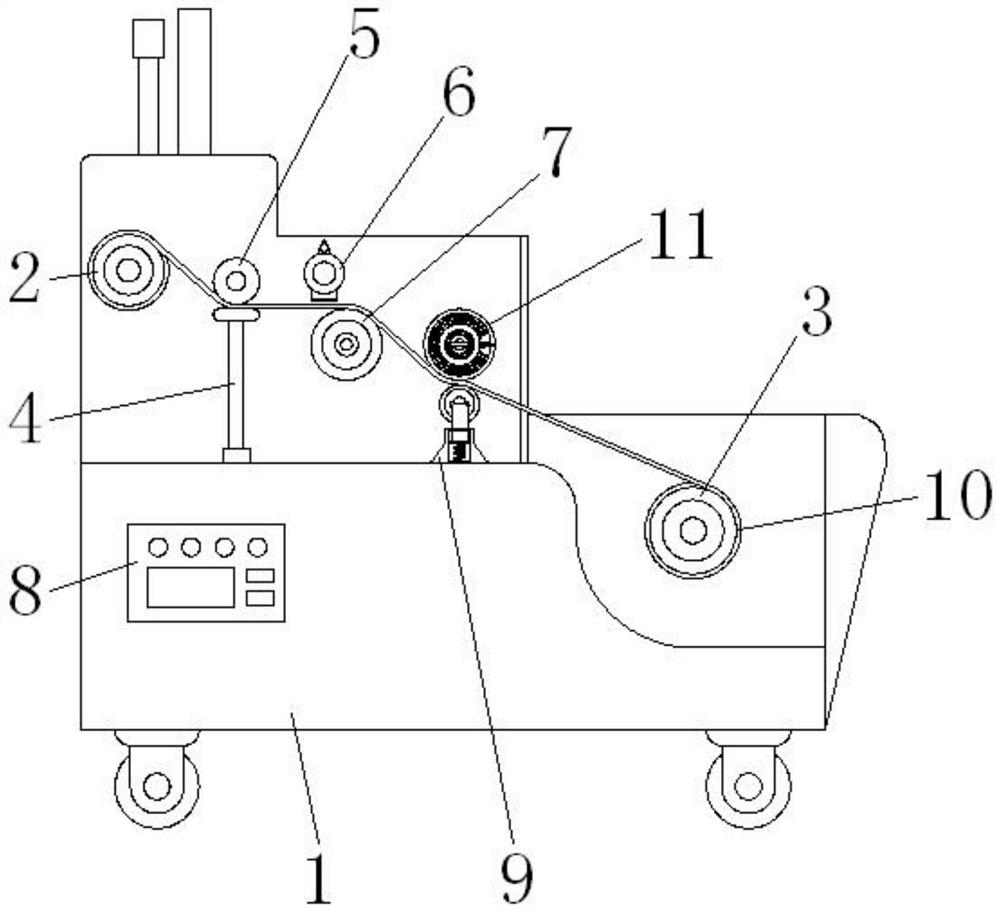

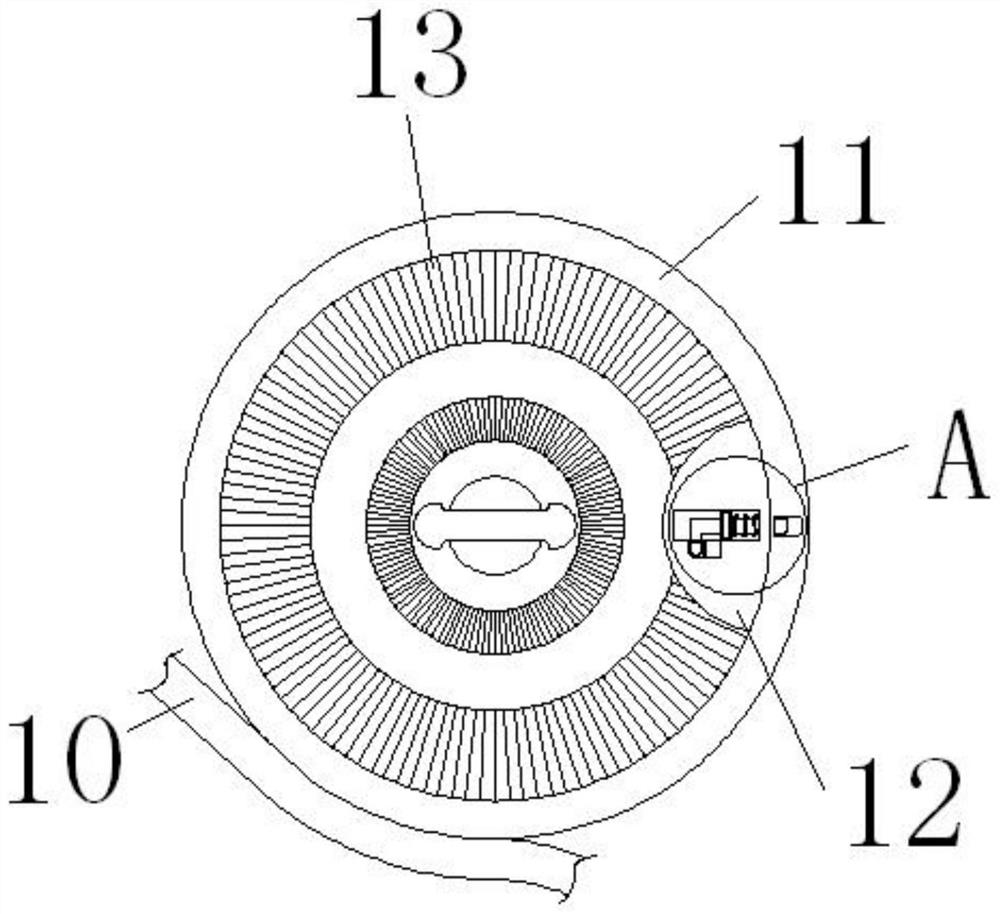

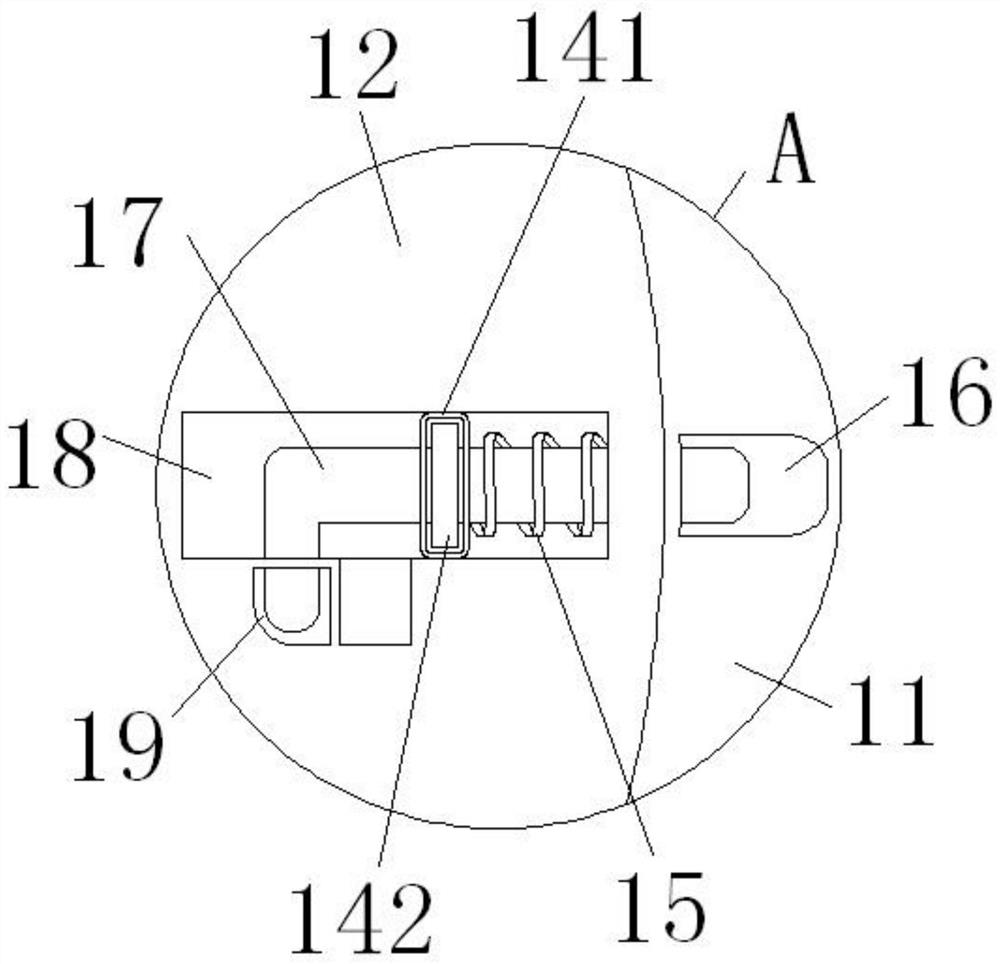

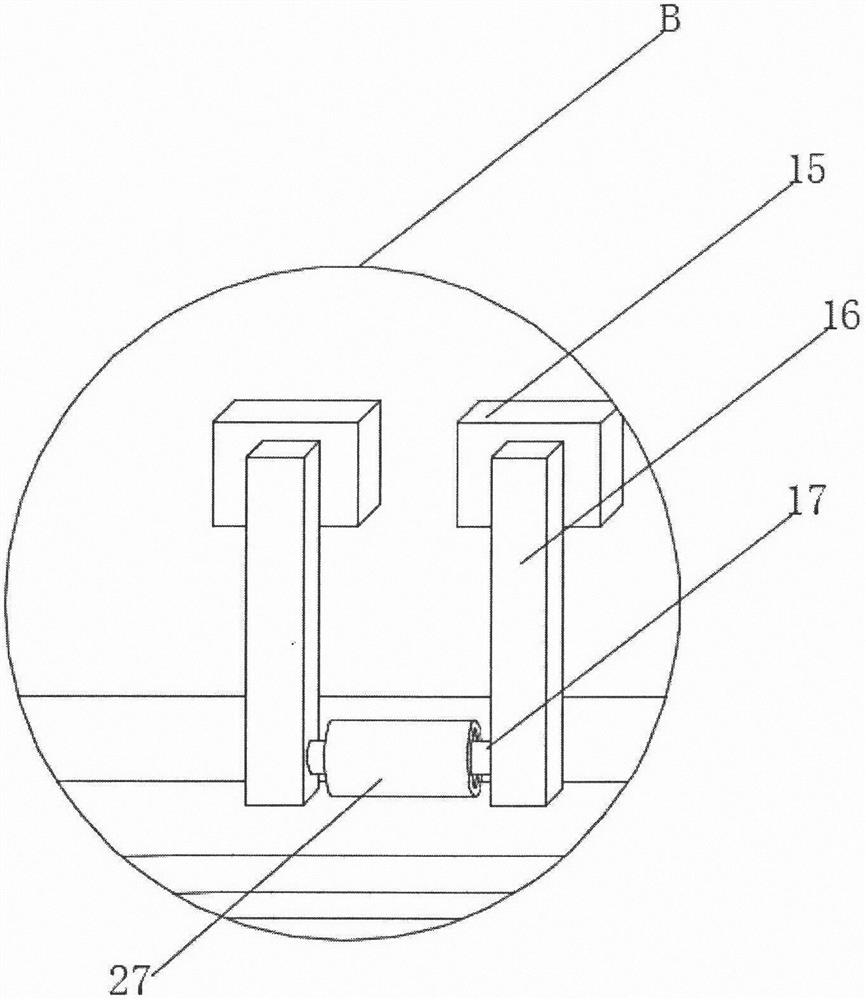

InactiveCN111850894AEasy to connect with each otherKeep dryLiquid/gas/vapor removalFiber bundleMechanical engineering

The invention relates to the technical field of textile pre-forming equipment, and discloses a pre-forming device for textile semi-finished products. The pre-forming device comprises a processing machine body, wherein a rotating cylinder is movably connected to the left side of an inner cavity of the processing machine body in a sleeving mode; a vertical supporting rod is fixedly connected to thebottom of the inner cavity of the processing machine body; a linkage cylinder is movably connected to the front surface of the inner cavity of the processing machine body in a sleeving mode; and a printing and dyeing device is fixedly connected to the front surface of the inner cavity of the processing machine body and is positioned on the right side of the linkage cylinder. According to the pre-forming device for the textile semi-finished products, through the cooperation of compression springs, limiting holes and L-shaped rods, a qualitative roller and an arc-shaped plate on a heat dissipation annular cylinder can be conveniently clamped with each other, so that the uniformity of the movement between the qualitative roller and the heat dissipation annular cylinder is ensured; and uniformheat dissipation fins are installed inside the heat dissipation annular cylinder, so that textile cloth after printing and dyeing can be conveniently dried, meanwhile, the color painted on the textile cloth can be conveniently combined, bonded and fixed with fiber bundles, and the dyeing effect of the formed textile cloth and the quality of the dyed textile cloth are improved.

Owner:桐乡市顺洪针织厂

Router with wireless charging function

PendingCN113270947AAvoid mutual equivalenceAvoid offsetBatteries circuit arrangementsCasings/cabinets/drawers detailsUSBEmbedded system

The invention discloses a router with a wireless charging function, and the router comprises a device body; the outer wall of the device body is provided with a USB connection port, the interior of the USB connection port is clamped with an antenna, the interior of the other side of the device body is provided with a data line interface, the interior of the data line interface is clamped with a data line, the bottom of the data line is fixedly connected with a charging receiving module, and a driving fan is fixedly installed at the bottom of one side of the device body. By designing a movable mounting block and a movable extension rod, the left side of the device body can be limited through the movable mounting block, the situation that the tops of the charging receiving module and the charging module cannot be equal to each other is avoided, and a connecting rod can extend according to the size of the charging module in the pushing process; one side of the device body can be guided through the movable mounting block, then the two sides of the device body are limited through the movable extension rods, deviation is avoided, and therefore the working efficiency can be improved.

Owner:MICRONET UNION TECH (CHENGDU) CO LTD

An adjustable anti-jump cover

The invention discloses an adjustable material splash-prevention cover plate. The adjustable material splash-prevention cover plate comprises a cover plate shell and an L-shaped mounting fixed plate;a cover plate comprises a fixed cover plate and a plurality of sliding cover plates; an upper L-shaped clamping groove I is formed in the top side edge of the fixed cover plate; upper L-shaped clamping grooves II are formed in the top side edges of the sliding cover plates; and clamping position grooves are formed in two ends of the upper clamping grooves II. The adjustable material splash-prevention cover plate is novel in structure, is capable of realizing the storage and unfolding of cover plates, and is convenient to mount and dismount so as to facilitate the using of people; by utilizinga sliding chute, sliding, on the fixed cover plate, of the sliding cover plates is realized; by utilizing the clamping position grooves and clamping position through holes, clamping of clamping position rods is convenient, gaps between the cover plates during the clamping are decreased, so that zero-splash of materials is ensured; by utilizing the L-shaped clamping grooves II and lowe-shaped clamping grooves, the adjacent sliding cover plates can be mutually matched and clamped, so as to ensure that no gaps exist between the sliding cover plates; and by utilizing threaded holes and threaded rods, the cover plates can be fixed on sliding rails when being unfolded, so that the cover plates can be conveniently mounted and fixed.

Owner:ANHUI JIETAI INTELLIGENT TECH

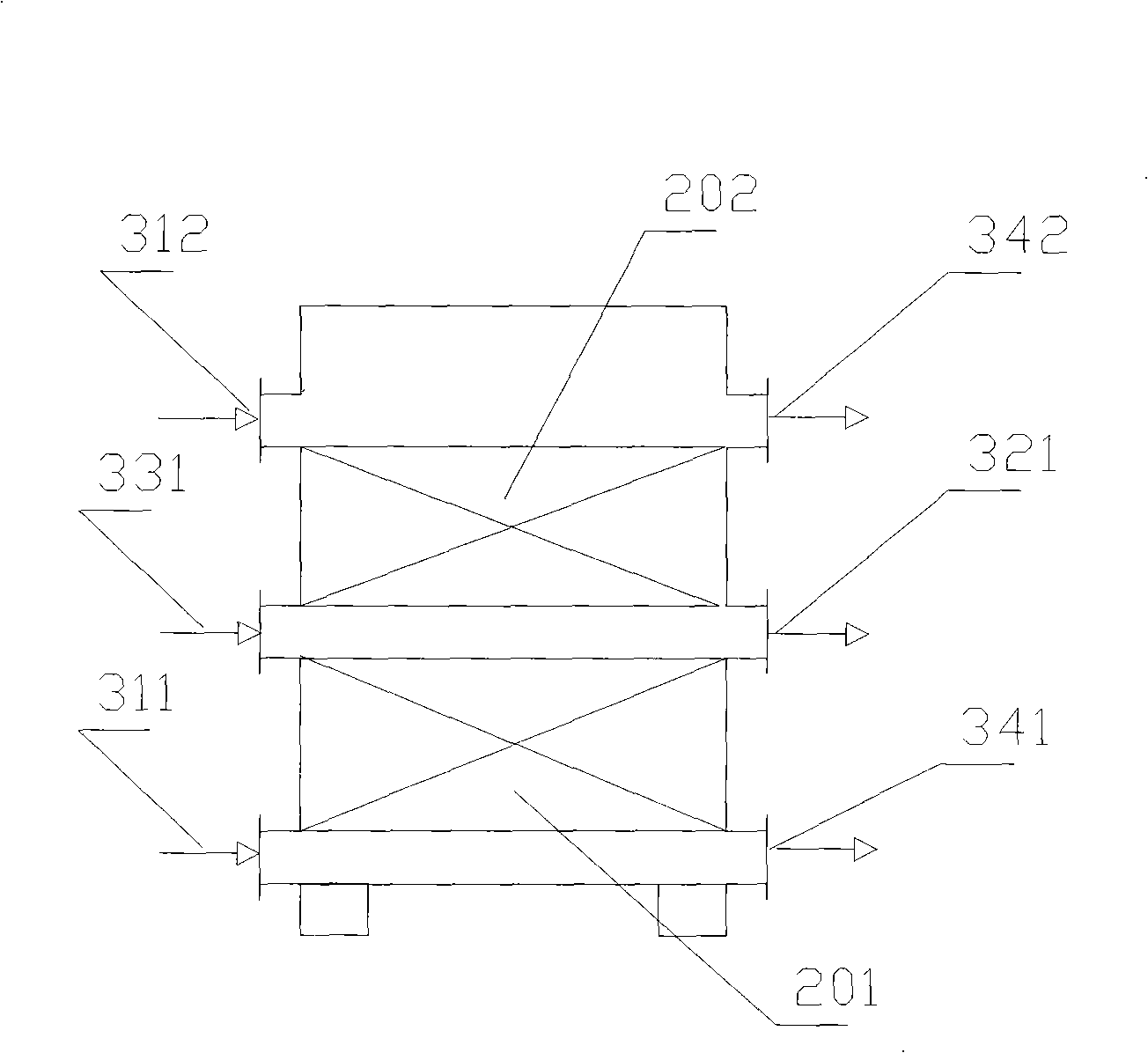

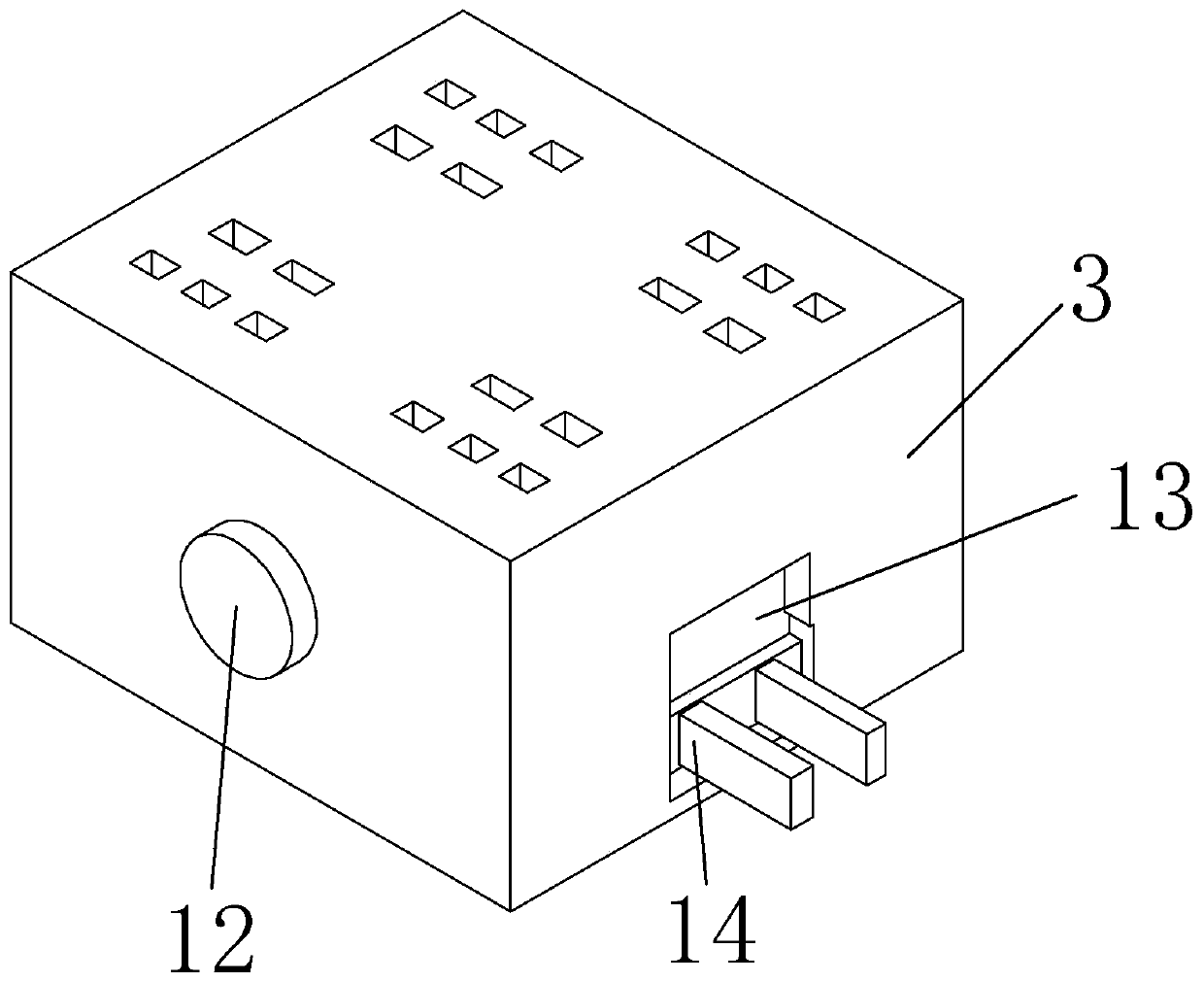

Modularized double-bed ionic exchange apparatus

InactiveCN101318721AEasy to connect with each otherEffective fieldWater/sewage treatment by ion-exchangeIon exchangeTreatment effect

The invention discloses a modular double fluidized bed ion exchange device, which comprises a standardized box body, wherein, the box body is of a rectangle, both ends of the box body are respectively and vertically provided with three identical connecting short pipes with flanges, a fixed upper ion exchange resin bed and a fixed lower ion exchange resin bed are arranged in the box body, the upper ion exchange resin bed is positioned between the upper connecting short pipes and the intermediate connecting short pipes, the lower ion exchange resin bed is positioned between the intermediate connecting short pipes and the lower connecting short pipes, the intermediate connecting short pipe on the front end of the box body is an inlet of water to be treated, the upper connecting short pipe and the lower connecting short pipe on the rear end of the box body are water outlets after ion exchange, the upper connecting short pipe and the lower connecting short pipe on the front end of the box body are inlets of backwashing water, and the intermediate connecting short pipe on the rear end of the box body is an outlet of the backwashing water. The device can be arbitrarily assembled with treatment devices of other box bodies with the same specification, which contributes to reducing cost, being convenient for installation, guaranteeing the treatment effect of water, and performing backwashing. The device can be used for sewage treatment in the environmental protection field or water purification in the chemical field.

Owner:BEIJING NENGTUO HI TECH

A universal circuit breaker assembly machine

ActiveCN110340633BSimple organizationImprove production and assembly efficiencyMetal working apparatusProduction lineElectric machine

The invention provides an air circuit breaker assembling machine. A workbench, a drive motor, a fixing table, an executing device, fixing devices and an auxiliary device are included. The upper end ofthe workbench is provided with the drive motor through a motor base. An output shaft of the drive motor is connected with the fixing table through a flange. The executing device is arranged at the middle portion of the fixing table, and the fixing devices are evenly arranged at the upper end of the fixing table around the circumference direction of the fixing table in a sliding fit manner. The auxiliary device is arranged on the workbench and located above the fixing devices. The air circuit breaker assembling machine can solve the problems that in the process that an operation handle of a circuit breaker is manually pushed up and then is sleeved with a ceramic shell, the manual operation efficiency is low, inner components in the incompletely-assembled circuit breaker are not completelyfixed, and disengaging of the inner components is likely to be caused by manual operation handle carrying; and meanwhile, the manual installing efficiency is low, and the work efficiency of a production line is influenced.

Owner:泰州亿丰达电器有限公司

Combined socket with retractable socket surface

ActiveCN110233389AAdjustable installation angleEasy to shrinkCoupling device detailsPulp and paper industry

Owner:ZHEJIANG HUAYAN ELECTRIC CO LTD

A cutting machine for garment production

The invention discloses a cutting machine for garment production, which comprises a frame, a cloth upper frame and a cutting mechanism, a conveying device is arranged on the frame, a discharge base is provided in the frame, and a driving device is provided on the discharge base , the driving device drives the slider to move on the slider; the slider is provided with a connecting rod, the unloading base is provided with a rotating base, and the rotating base is connected with a flip panel, and the flip panel is connected with the connecting rod; There is a "U"-shaped deck, the "U"-shaped deck is fixedly connected with a flip frame, and a leveling device is installed on the flip frame; the flip frame is rotatably connected with a discharge panel, the discharge panel and the conveying device The conveyor belts on the top are connected to each other, and the unloading panel is provided with a positioning plate, which is engaged with the leveling device. The invention realizes automatic picking up of the cut textiles, reduces labor force, and at the same time can collect the textiles into the collecting box at a relatively fast speed, prevents the textiles from absorbing dust, and improves the quality of finished garments.

Owner:SUZHOU GANNZ ELECTRONICS TECH CO LTD

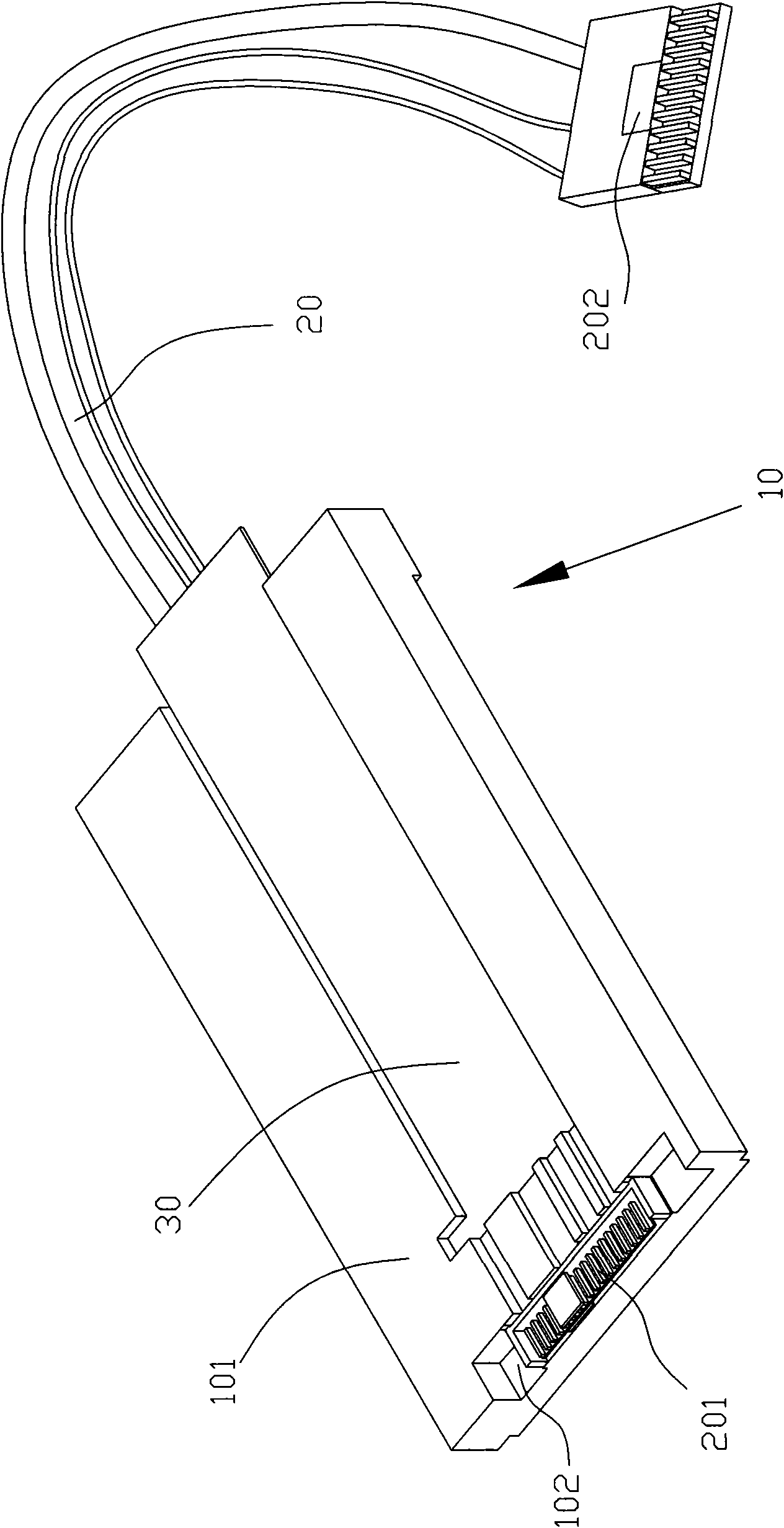

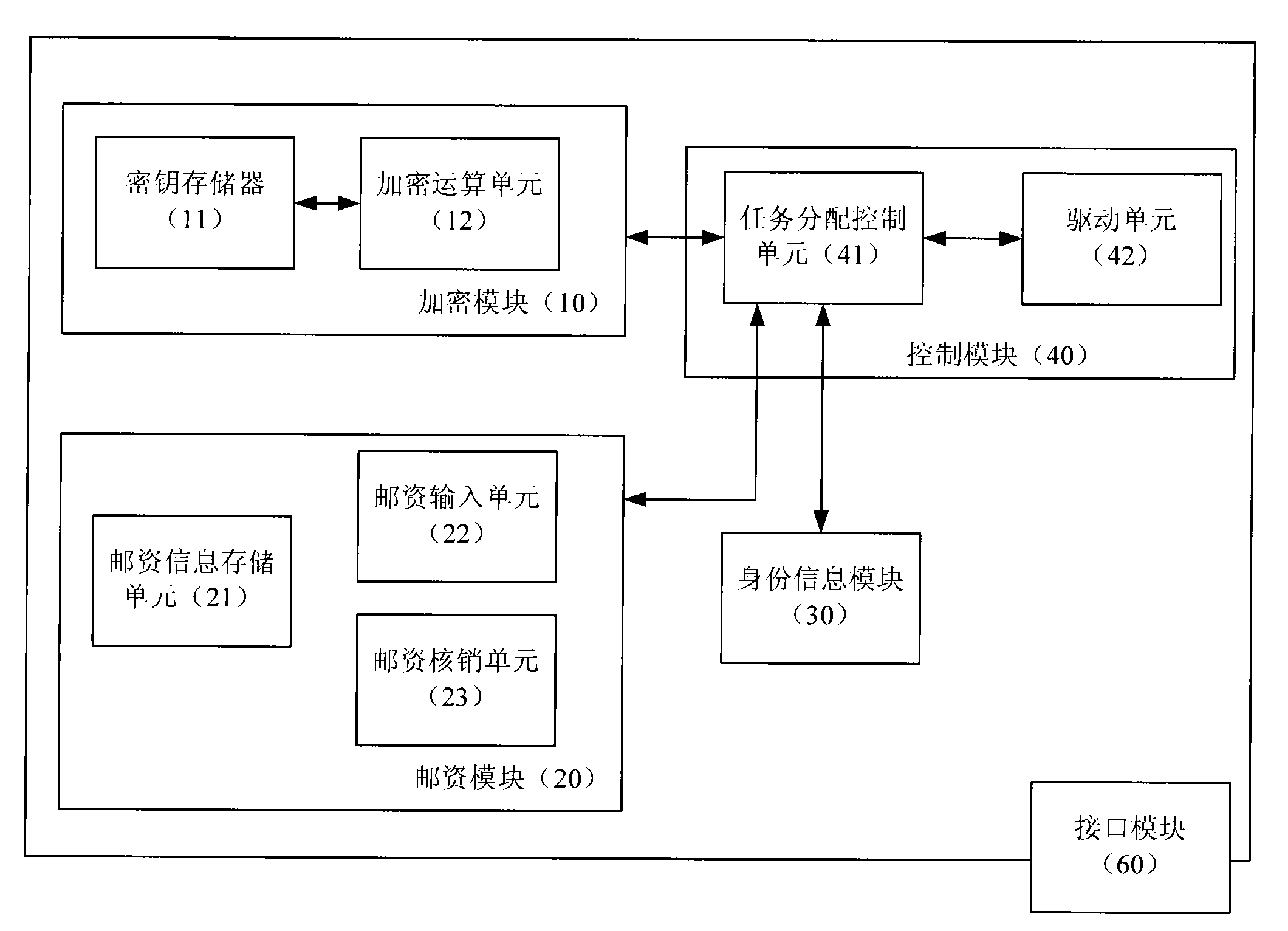

Digital postage black box and method for processing digital postage thereof

ActiveCN101661636AFirmly connectedCapable of encryption and anti-counterfeitingFranking apparatusInformation processingComputer module

The invention discloses a digital postage black box and a method for processing a digital postage thereof. The digital postage black box is used for controlling output postage information, and comprises an encryption module (10) used for outputting a postage check code, a postage module (20) used for processing postage information, an identity information module (30) used for storing the identityinformation on the digital postage black box, an interface module (60) used for exchanging data with the outside, and a control module (40) used for exchanging the data with the interface module (60)and controlling other modules. The method for processing the digital postage comprises four steps of initializing, postage information input, postage output and postage information processing. The method and the device have the advantages that the method can separately process the postage information and also has the capacities of encrypting and anti-counterfeiting, and the device is convenient tocarry and convenient for mutual plug connection with external printing equipment to drive printing the postage information.

Owner:SHENZHEN ROUTDATA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com