Coking coal blended with recycled materials and coking coal blending method

A technology of recycled materials and coal blending, applied in the field of coking technology, can solve problems such as difficult coke pushing, smoke and dust escape, and transportation difficulties, and achieve the effects of widening the plastic temperature range, reducing coal blending costs, and improving bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

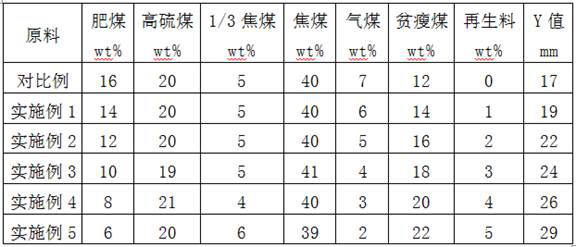

[0015] Examples 1-5 and Comparative Example: The following coking coal blending ratio and coking coal blending method are adopted for the coking coal blended with recycled materials.

[0016] (1) Coking coal blending method: each embodiment carries out coal blending according to the following method.

[0017] A. Premix lean coal and recycled materials in a weight ratio of 2:1 to obtain a premix. The recycled material is combustible domestic waste and / or industrial waste, such as a mixture of waste tires, plastics, clothing and other raw materials, wherein the content of β resin in the recycled material is 21-24wt%.

[0018] B. Feeding fat coal, high-sulfur coal, 1 / 3 coking coal, coking coal, lean coal, gas coal and premix according to the component distribution ratio of the product, the weight ratio of the components is: fat coal (16 -2N)%, high sulfur coal 19~21%, 1 / 3 coking coal 4~6%, coking coal 39~41%, gas coal (7-N)%, lean coal (12+2N)%, recycled material N %, said N≤5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com