A comprehensive recovery process of rare earth and strontium co-associated polymetallic ore

A polymetallic ore and rare earth technology, which is applied in the direction of improving process efficiency, can solve the problems of difficult rare earth separation, recovery and dispersion, and achieve the effect of simple equipment, easy operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

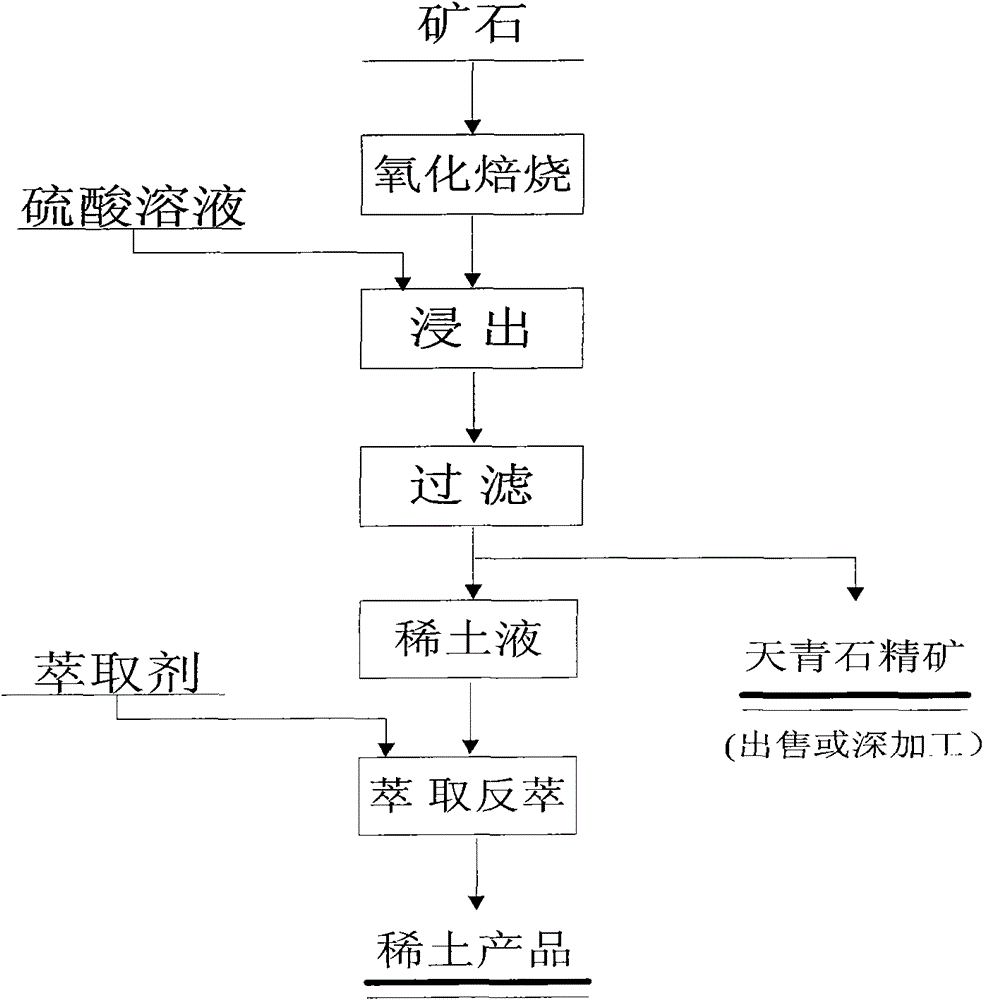

Method used

Image

Examples

Embodiment 1

[0035] Weigh 2000.0g of raw ore, after flotation and re-election, 434.5g of rare earth and strontium mixed ore can be produced. Weigh 100.0g of rare earth and strontium mixed ore (REO: 10.0wt%, SrO: 35.6wt%), roast at 550°C for 2.0h to obtain calcine 92.1g, use 150ml of hydrogen ion concentration to be 2.0mol / L sulfuric acid solution at 50 ℃ leaching for 3 hours, 70.0g of slag can be obtained, and the slag is the grade of celestite ore (SrSO 4 %) 84.6%. The recovery rate of strontium was 94.0%. The leaching solution is a mixed rare earth sulfuric acid solution, and the rare earth leaching rate is 96.2%, and a single rare earth product can be obtained by extracting and separating the mixed rare earth sulfuric acid solution.

Embodiment 2

[0037] Weigh 2000.0g of raw ore, after flotation and re-election, 438.0g of rare earth and strontium mixed ore can be produced. Weigh 100.0g rare earth and strontium mixed ore (REO: 20.2wt%, SrO: 20.0wt%), roast at 550°C for 2.0h to obtain calcine 86.1g, use 300ml hydrogen ion concentration to be 2.0mol / L sulfuric acid solution at 50 ℃ leaching for 3 hours, 39.4g of slag can be obtained, the slag is the grade of celestite ore (SrSO 4 %) 85.5%. The recovery rate of strontium was 95.0%. The leaching solution is a mixed rare earth sulfuric acid solution, and the rare earth leaching rate is 95.1%, and a single rare earth product can be obtained by extracting and separating the mixed rare earth sulfuric acid solution.

Embodiment 3

[0039] Weigh 2000.0g of raw ore, and after flotation and re-election, 435.0g of rare earth and strontium mixed ore can be produced. Weigh 100.0g rare earth and strontium mixed ore (REO: 16.7wt%, SrO: 25.4wt%), roast at 680°C for 1.0h to obtain calcine 88.2g, use 440.0ml hydrogen ion concentration to be 1.0mol / L sulfuric acid solution in After leaching at 45°C for 2 hours, 50.0g of slag can be obtained, which is the grade of celestite ore (SrSO4 %) 85.5%. The recovery rate of strontium was 95.0%. The leaching liquid is a mixed sulfuric acid rare earth solution, and the rare earth leaching rate is 98.0%, and a single rare earth product can be obtained by extracting and separating the mixed sulfuric acid rare earth solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com