Connecting structure of battery box and high-voltage connector shielding ring, battery box and automobile

A high-voltage connector and connection structure technology, which is applied in the direction of conductive connection, battery pack components, magnetic field/electric field shielding, etc., can solve the problems of reduced shielding effect, easy to cause accidents, electromagnetic interference of battery management system, etc., and achieve good shielding effectiveness , Electromagnetic interference reduction, good electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

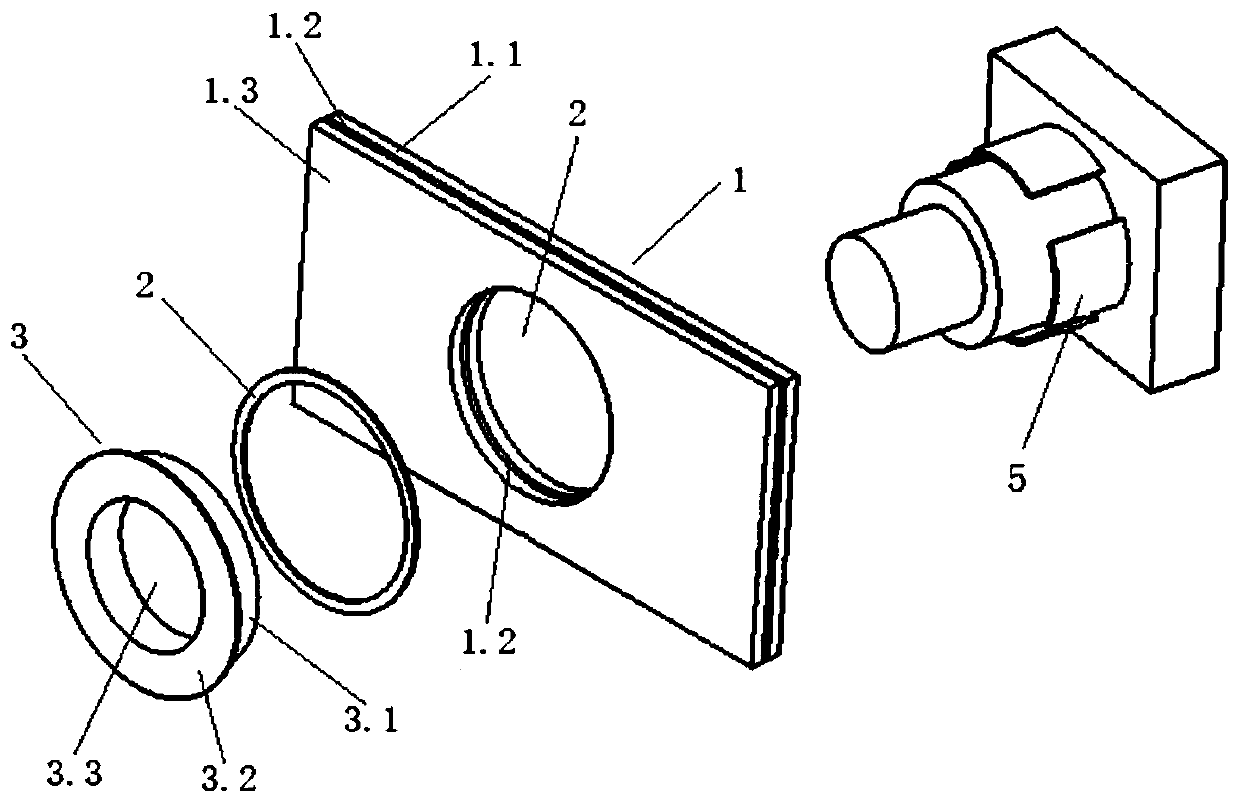

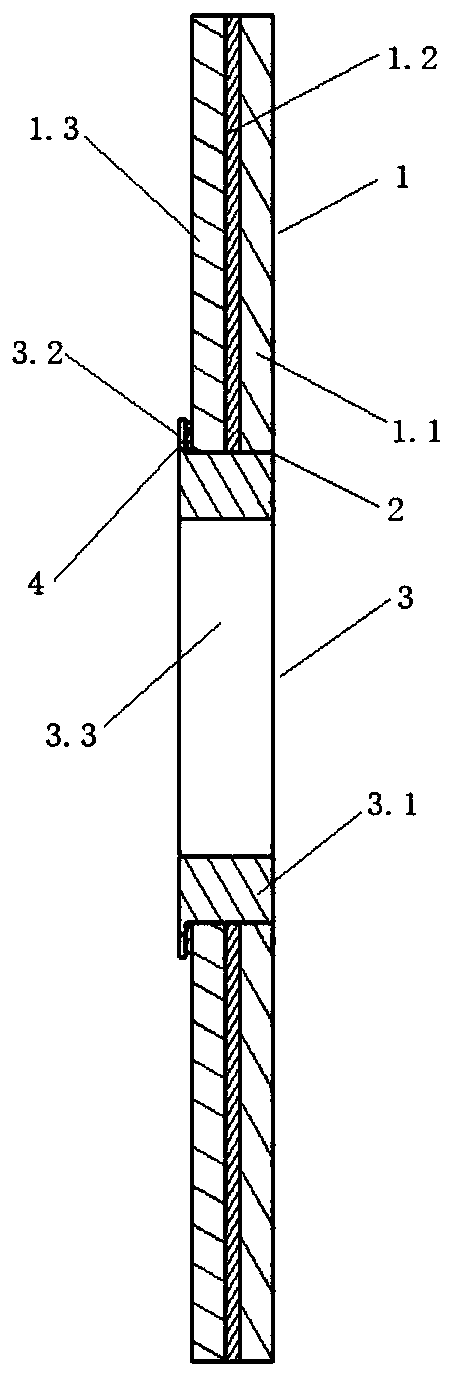

[0019] like figure 1 The connection structure between the battery box and the shielding ring of the high-voltage connector shown in the present invention includes a battery box body 1, and an installation hole 2 is opened on the battery box body 1. The battery box body 1 includes a carbon fiber inner layer 1.1, a metal The middle layer 1.2, the carbon fiber outer layer 1.3, and the battery box body 1 are formed by the existing HP-RTM process. The metal intermediate layer 1.2 is a metal mesh structure, preferably a metal copper mesh with good electrical conductivity, the specification is about 150g per unit area, about 0.1mm thickness of a single layer, and 200 mesh. A metal sleeve 3 is embedded in the installation hole 2, and the metal sleeve 3 is in contact with the metal intermediate layer 1.2. The interference fit between the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com