Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Control heat transfer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

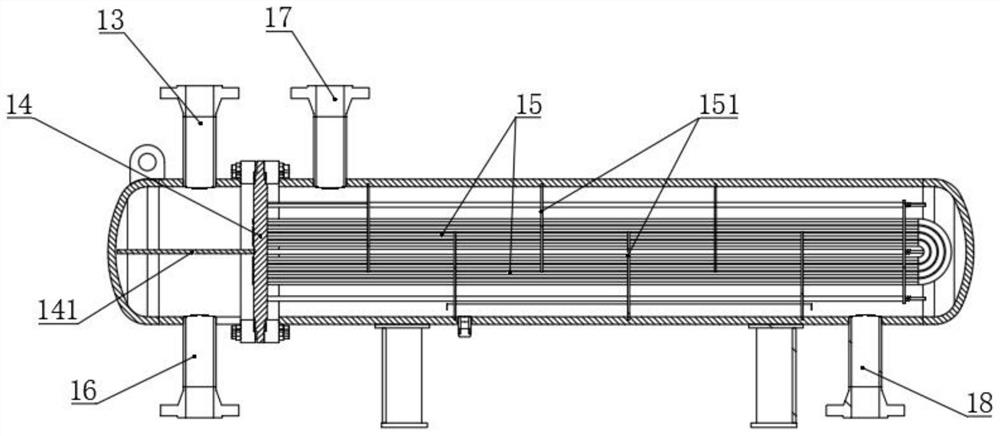

Pressure cooling process of segmented reinforcing type parts of hot forming steel pipe, and die hydraulic device

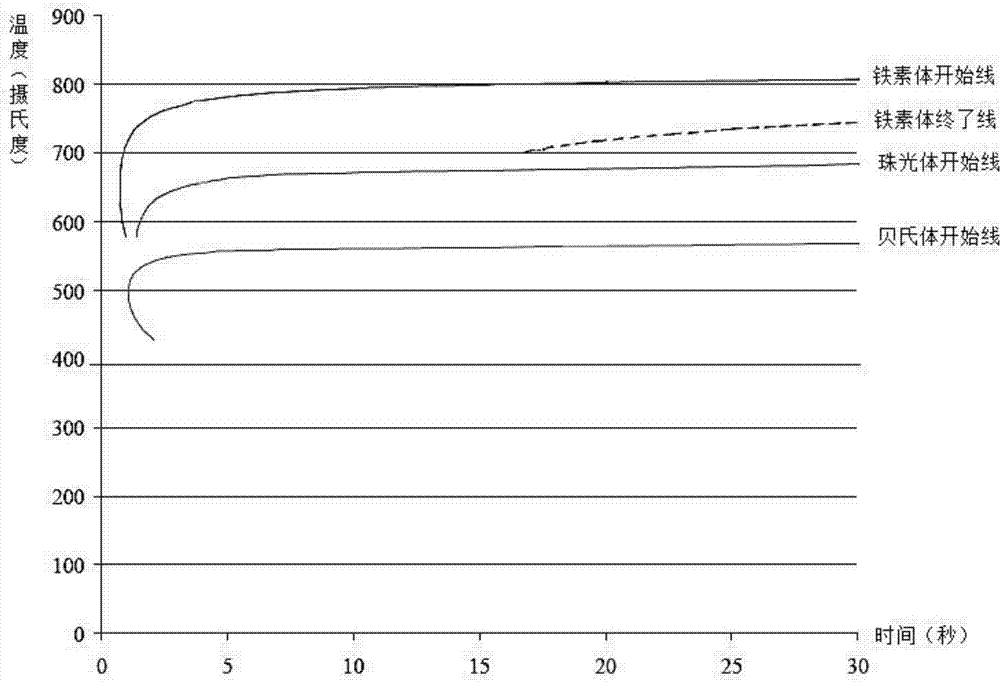

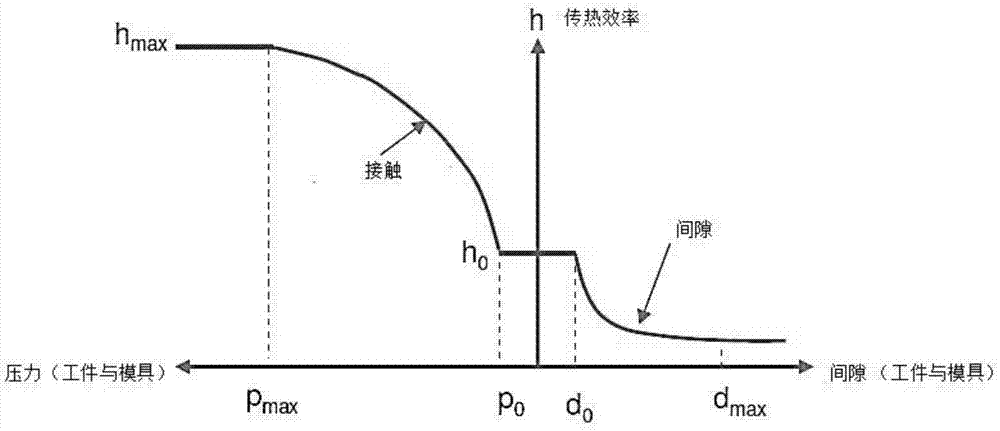

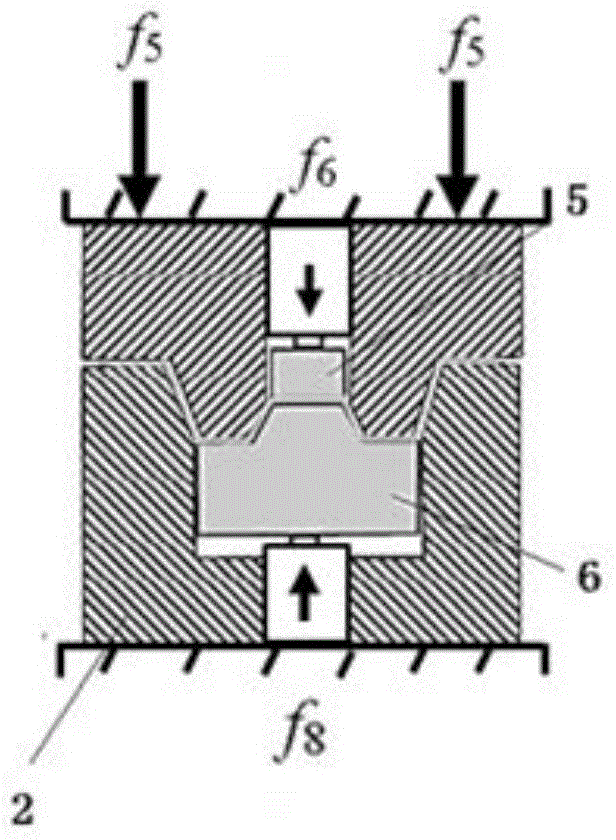

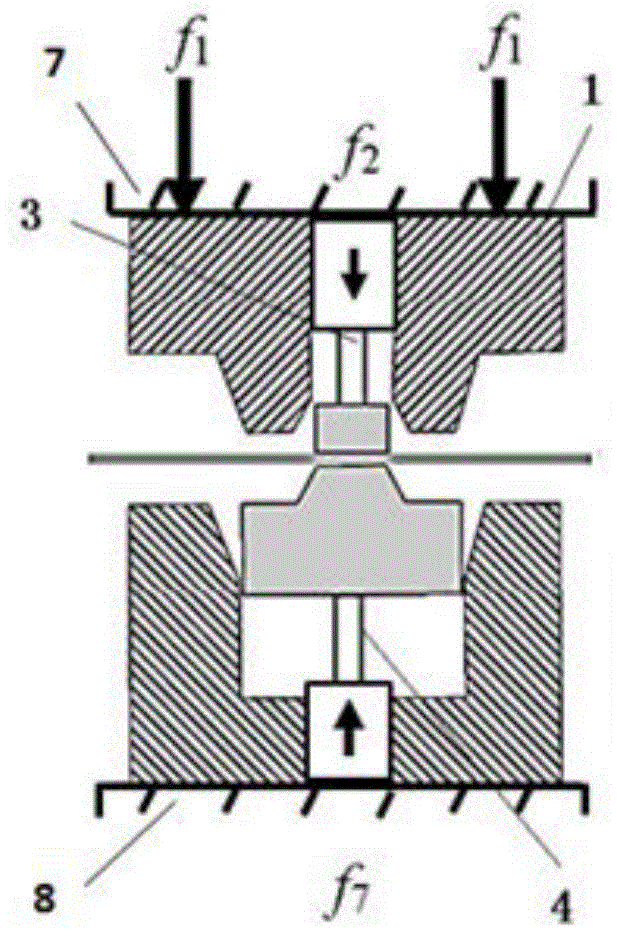

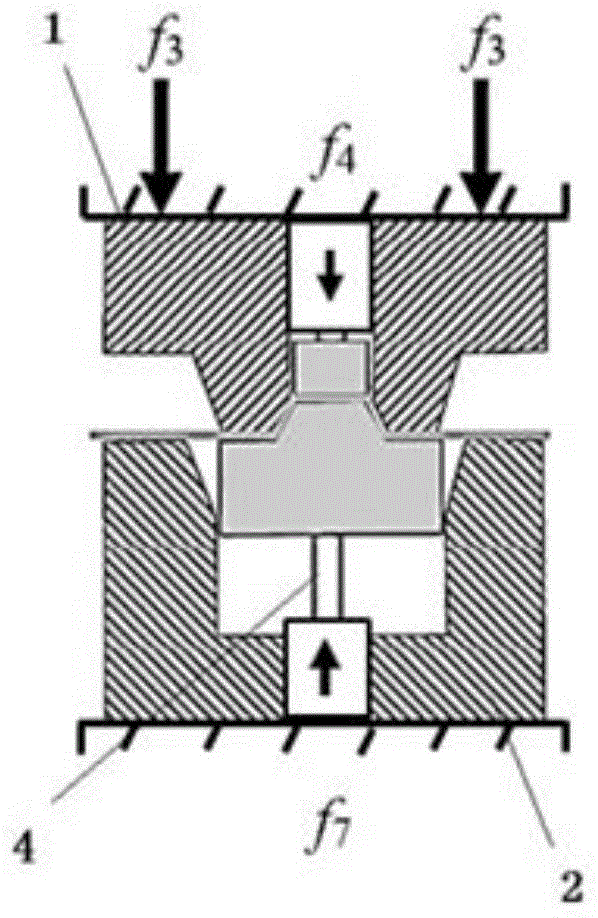

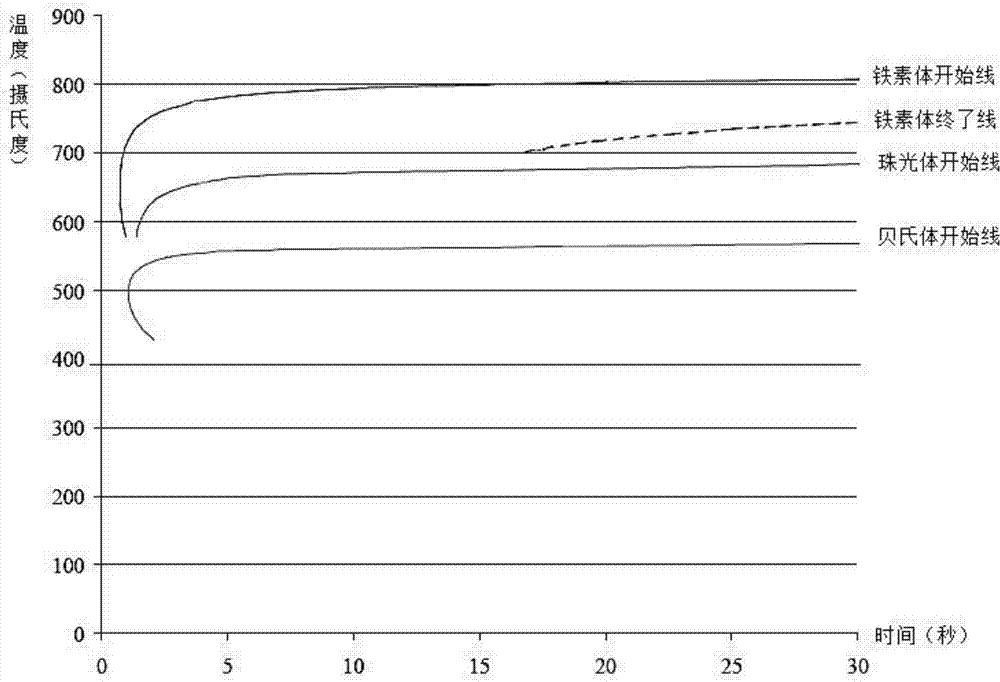

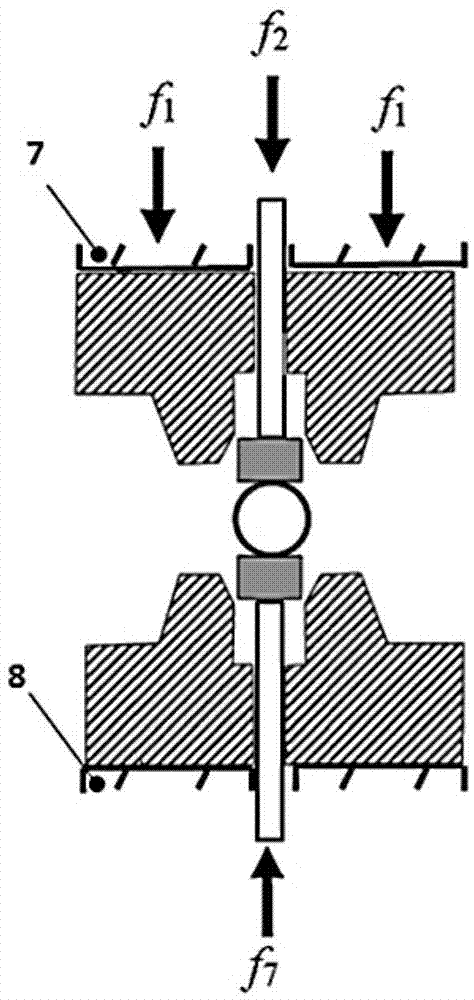

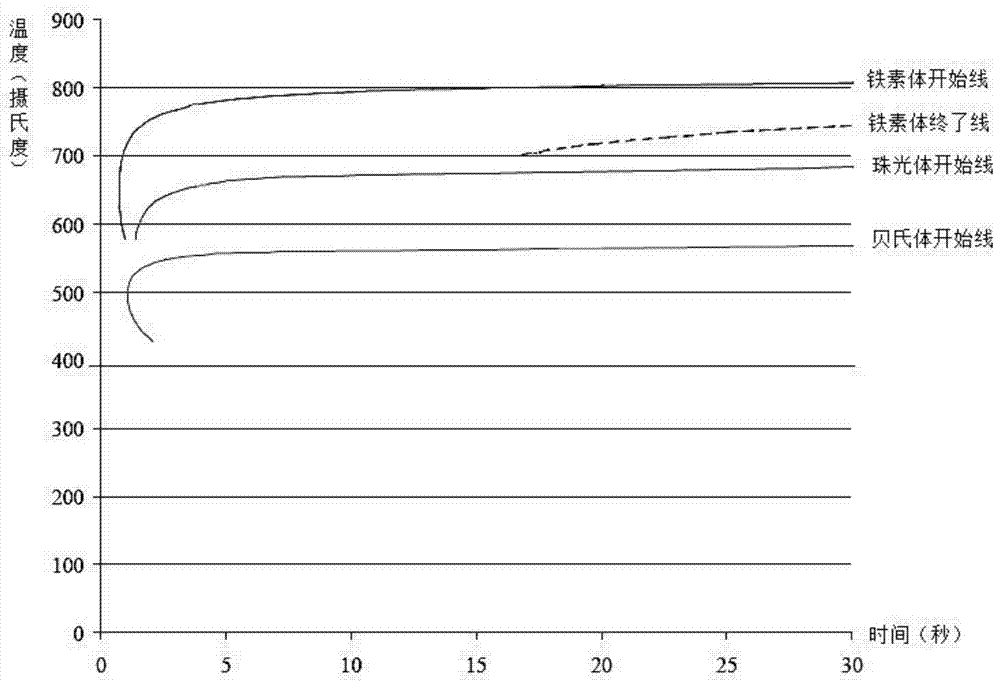

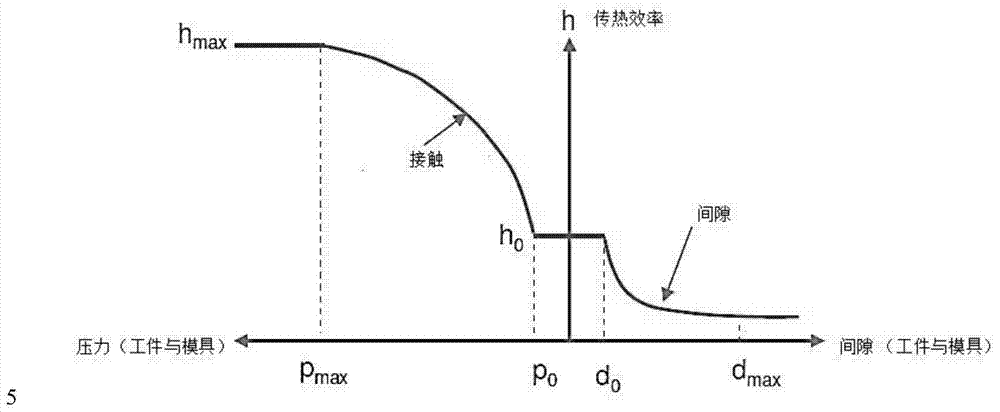

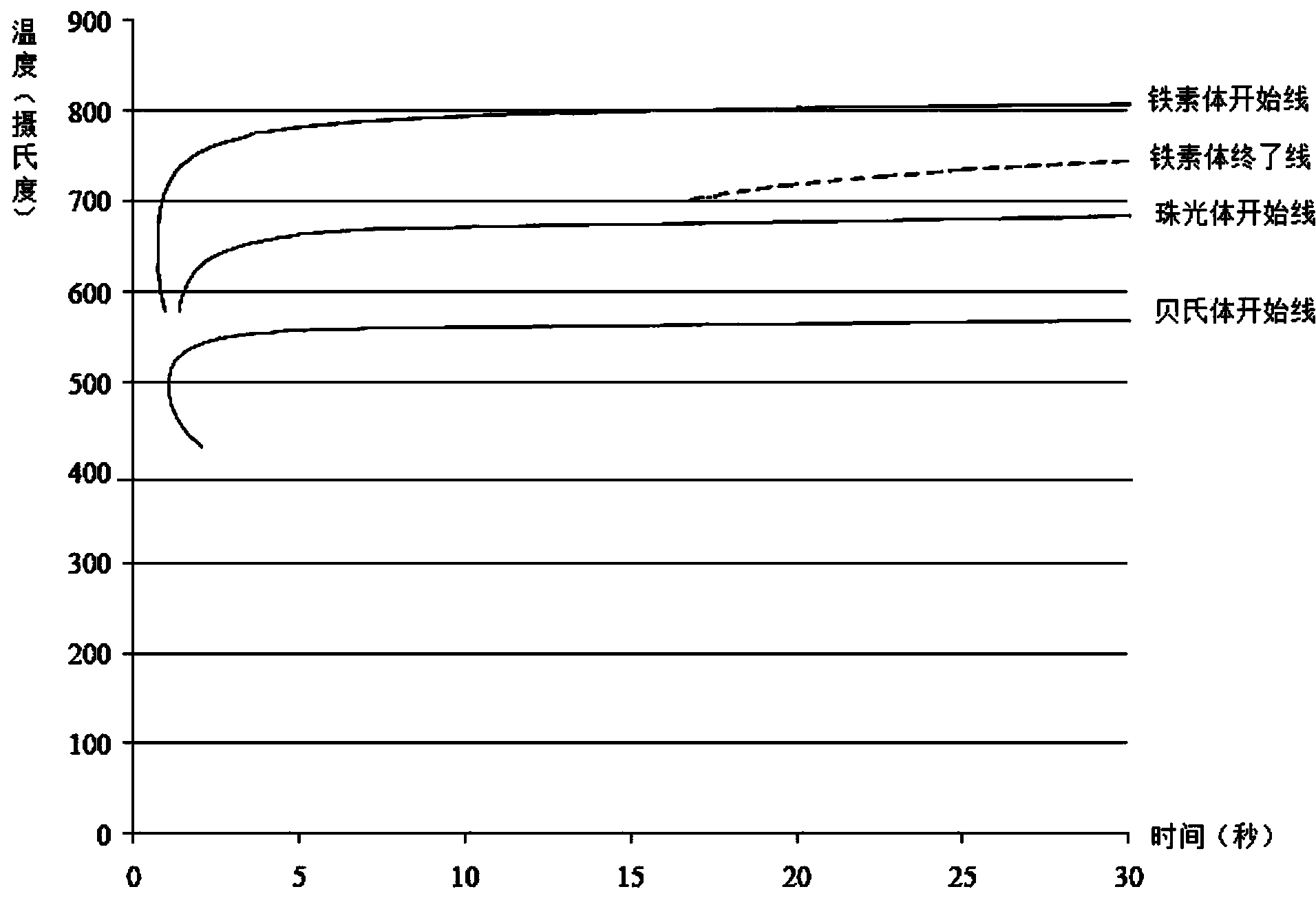

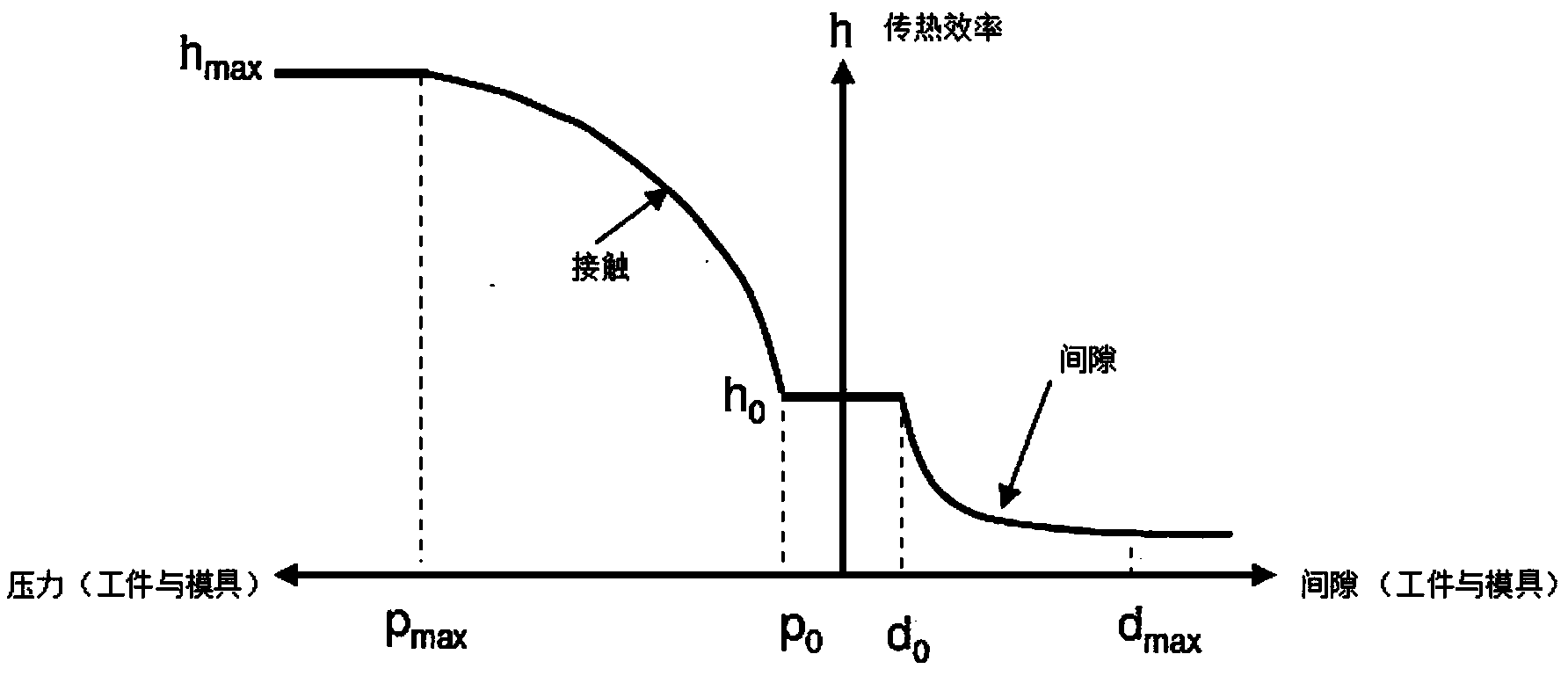

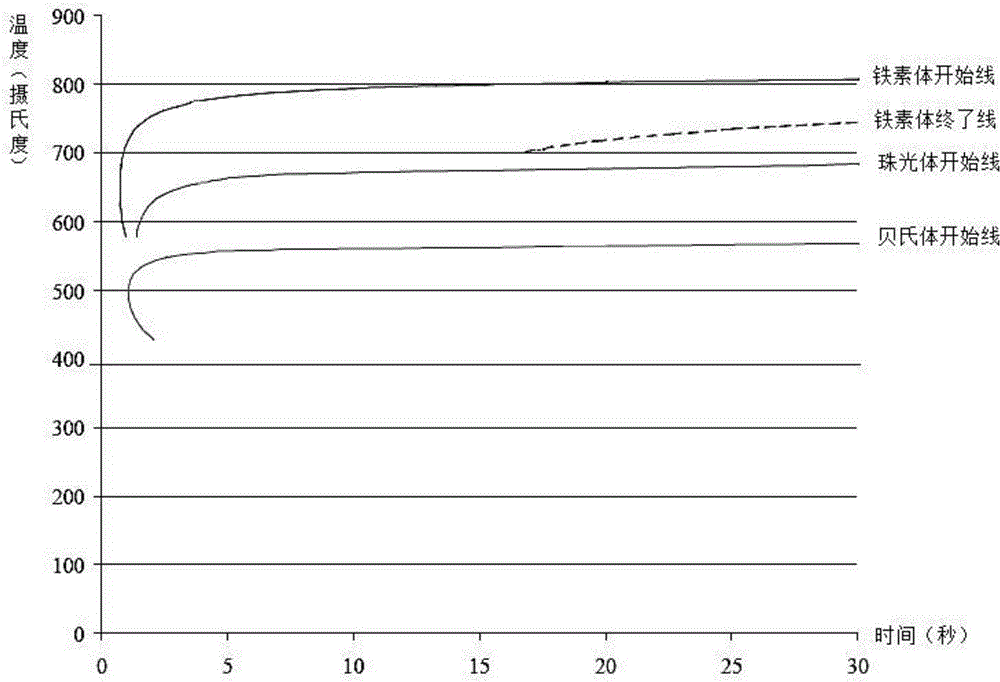

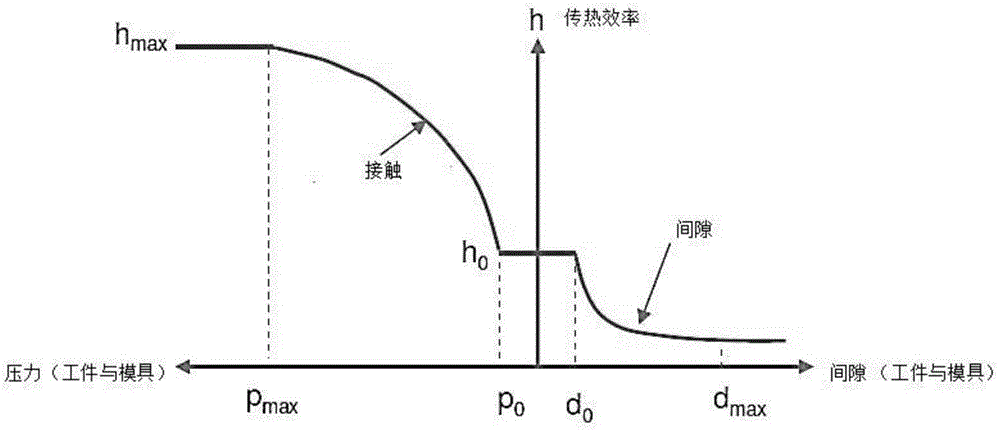

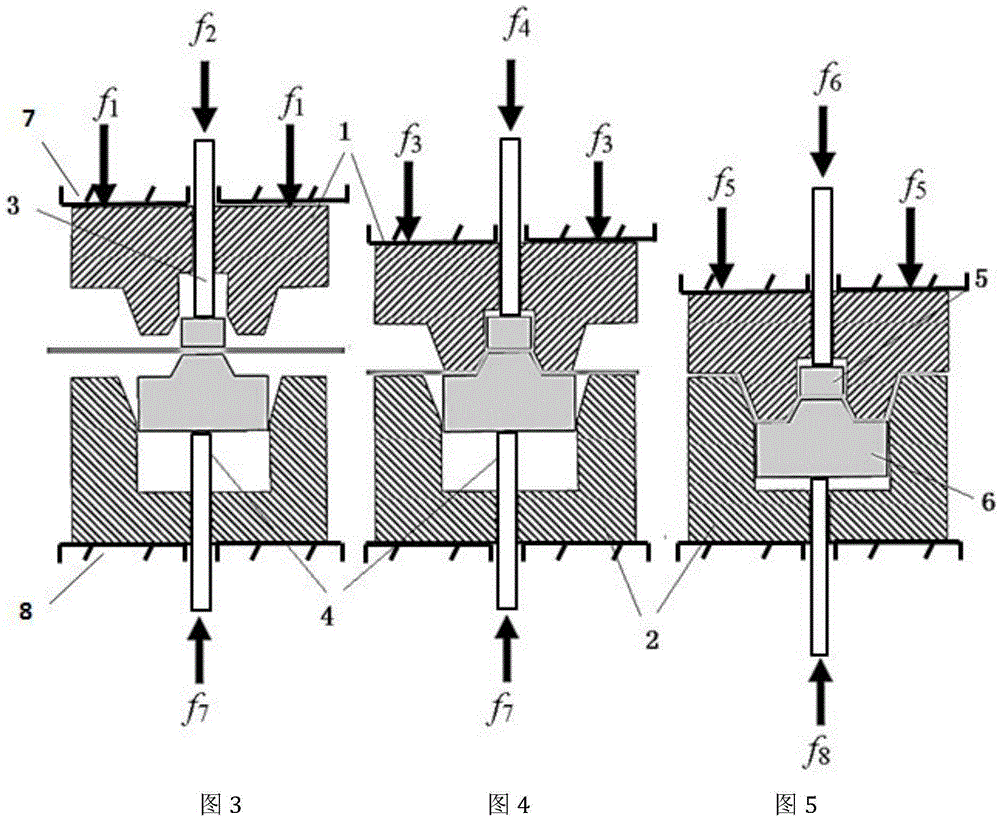

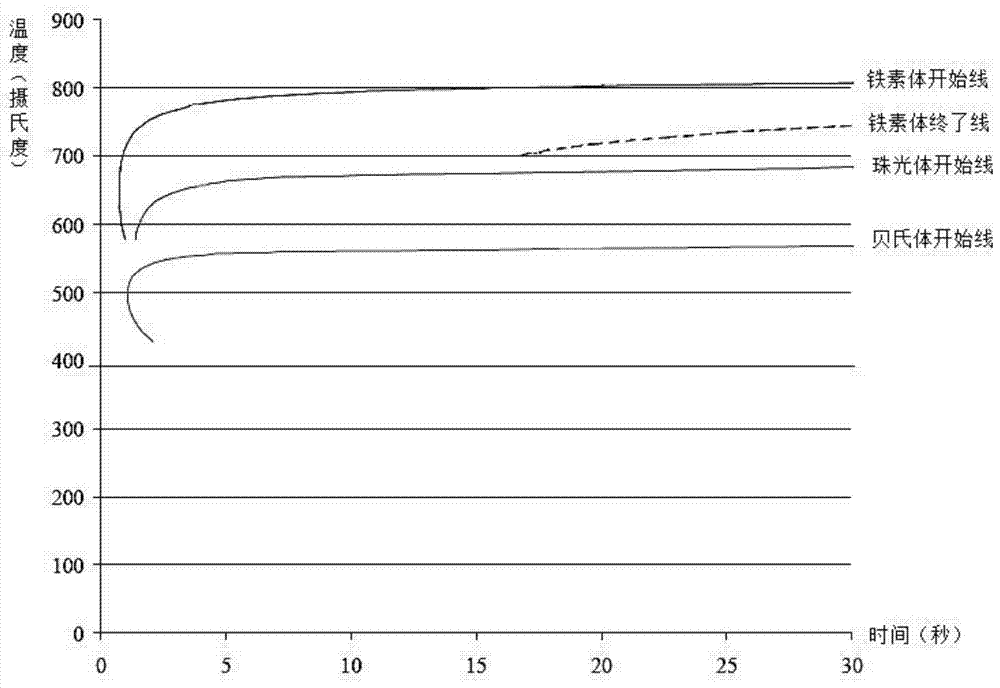

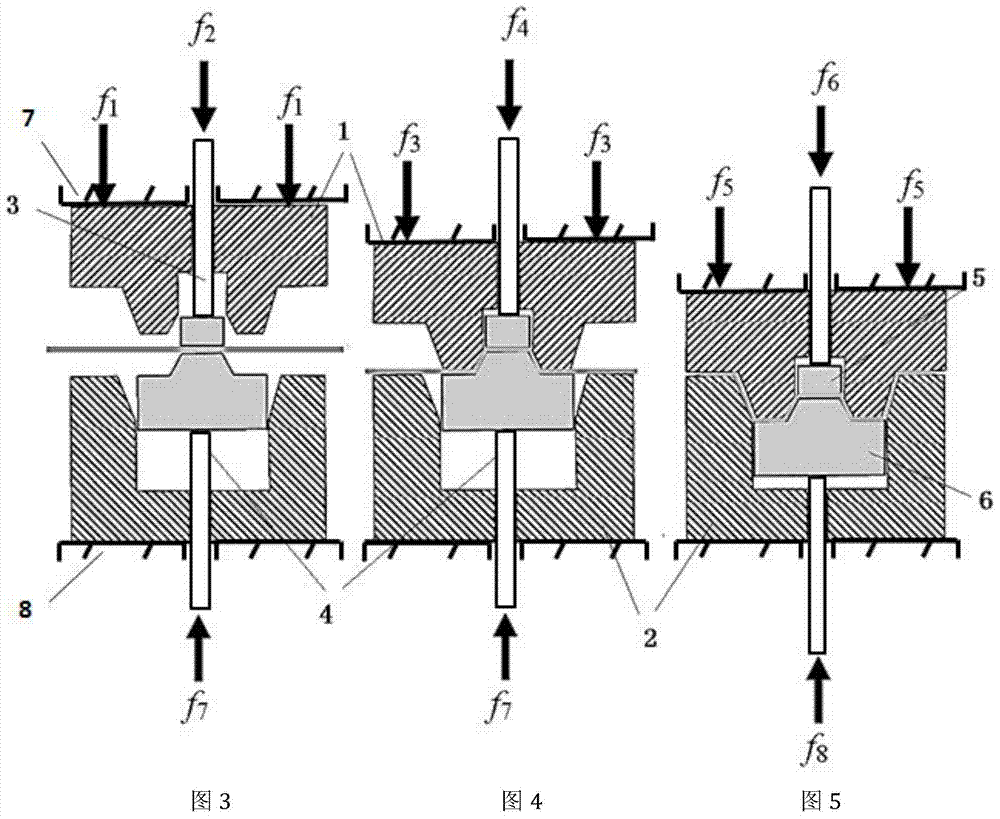

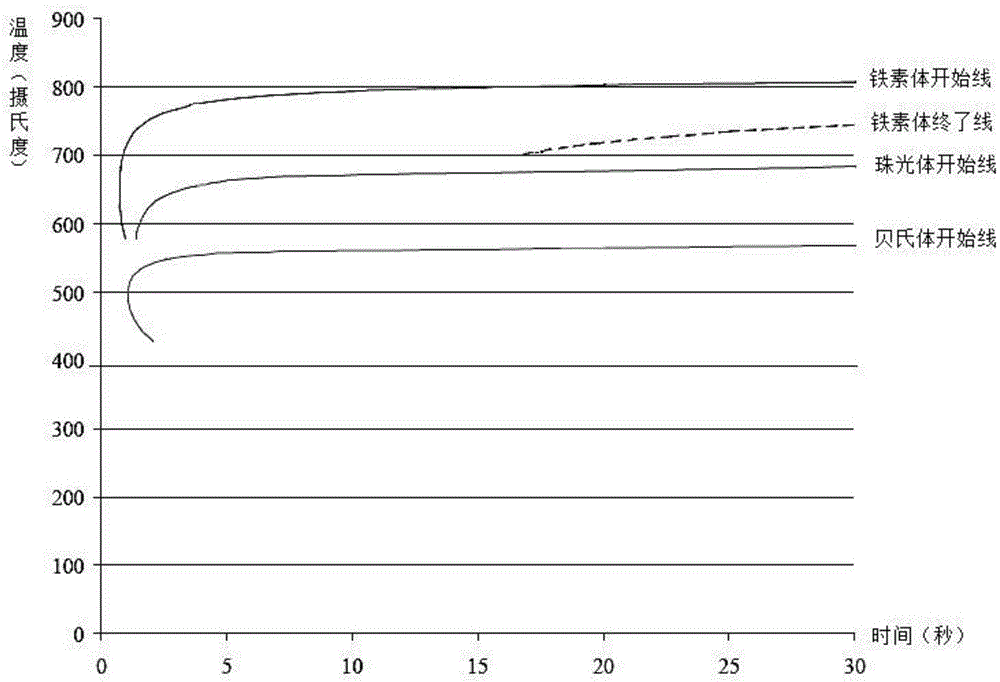

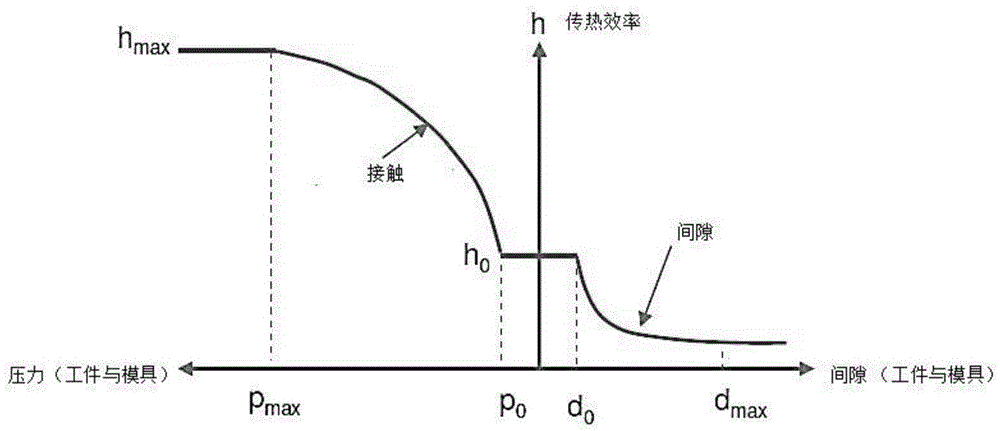

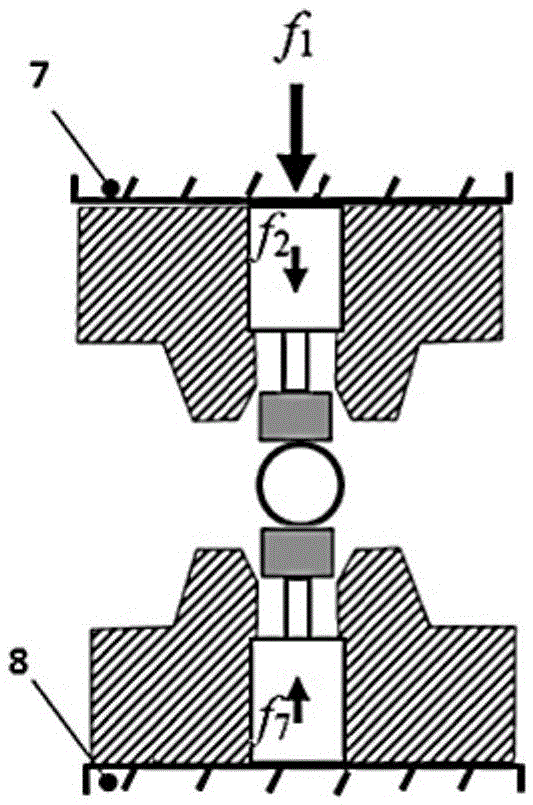

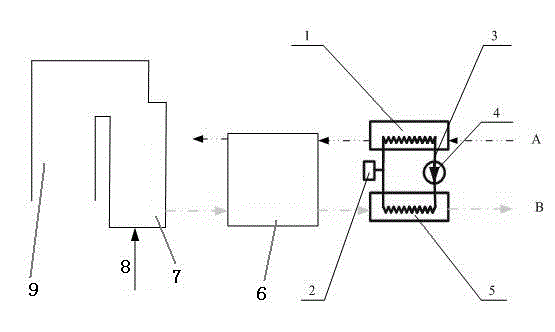

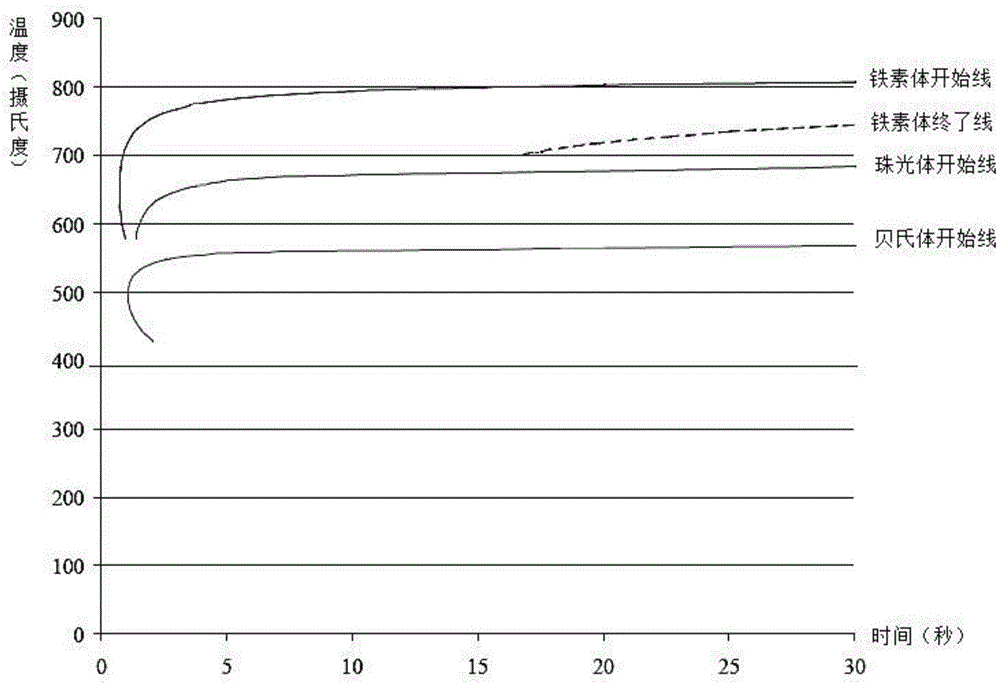

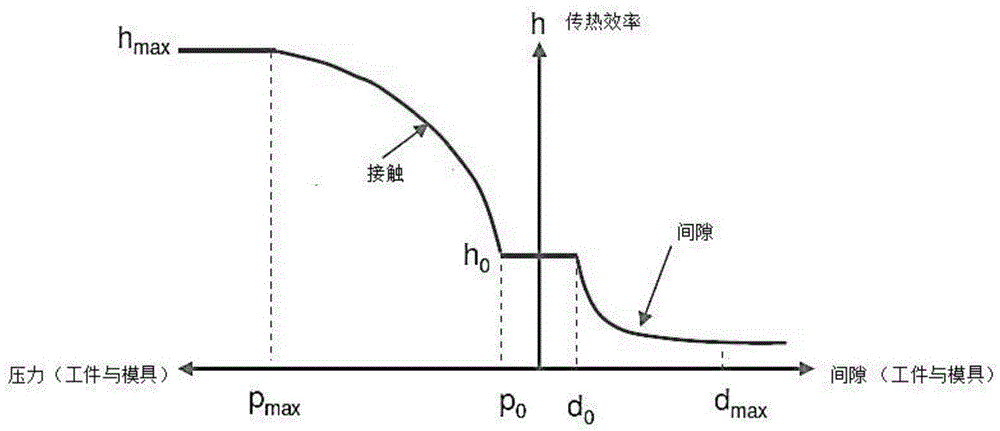

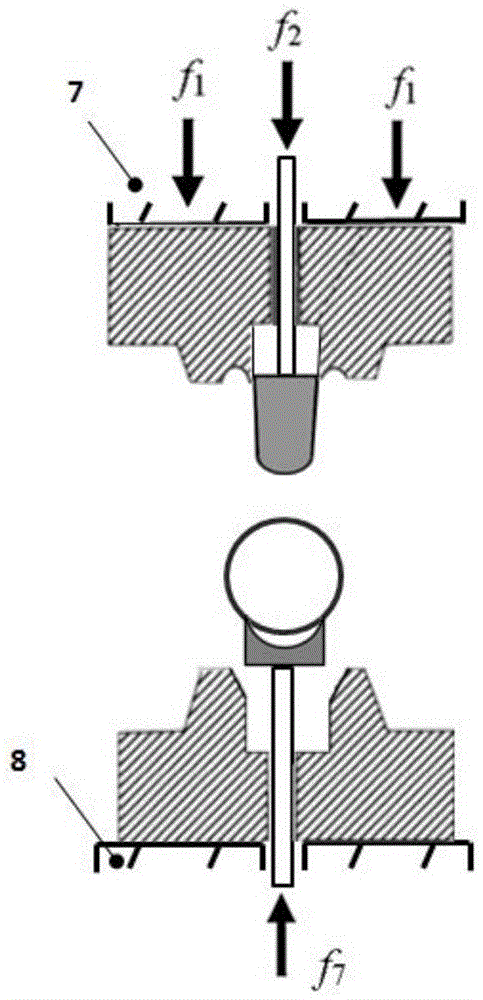

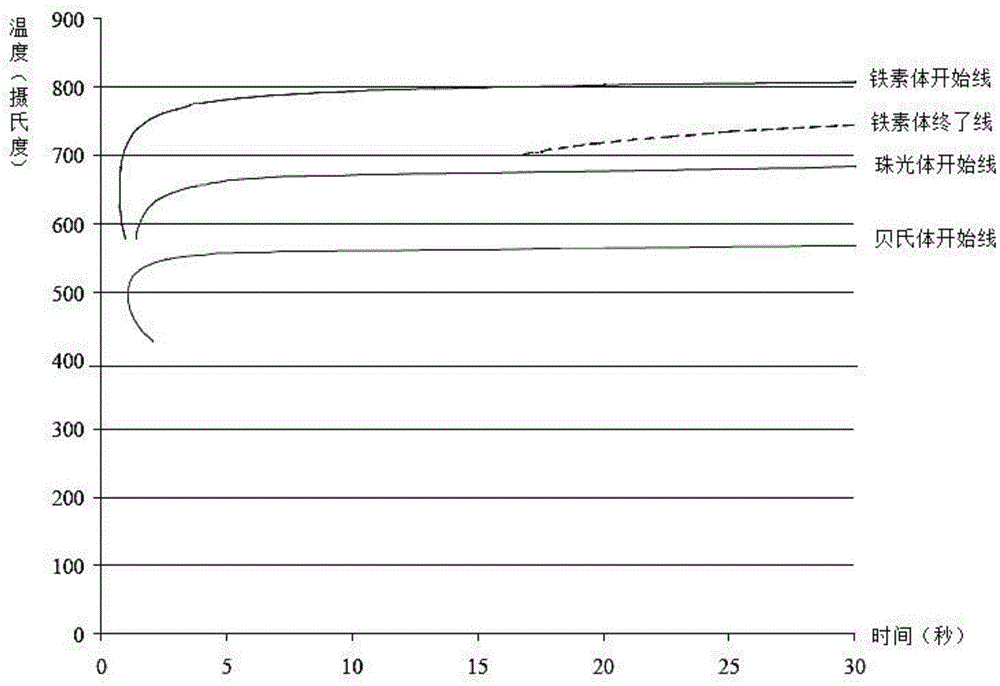

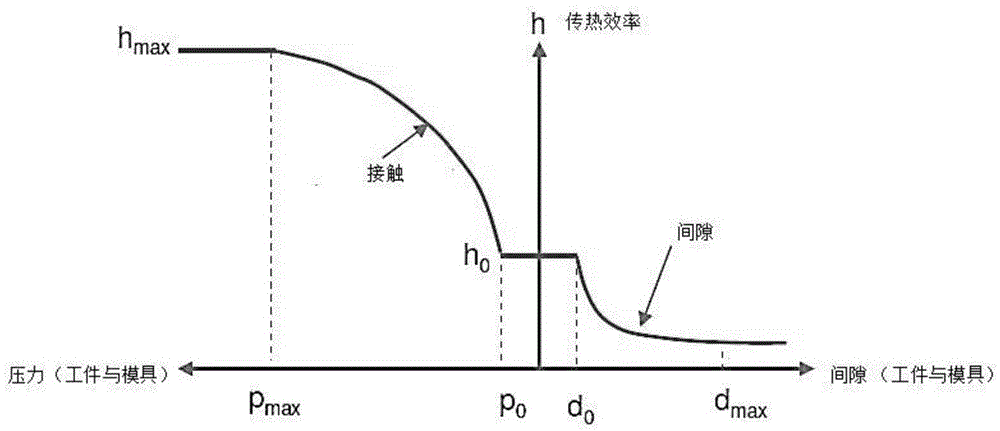

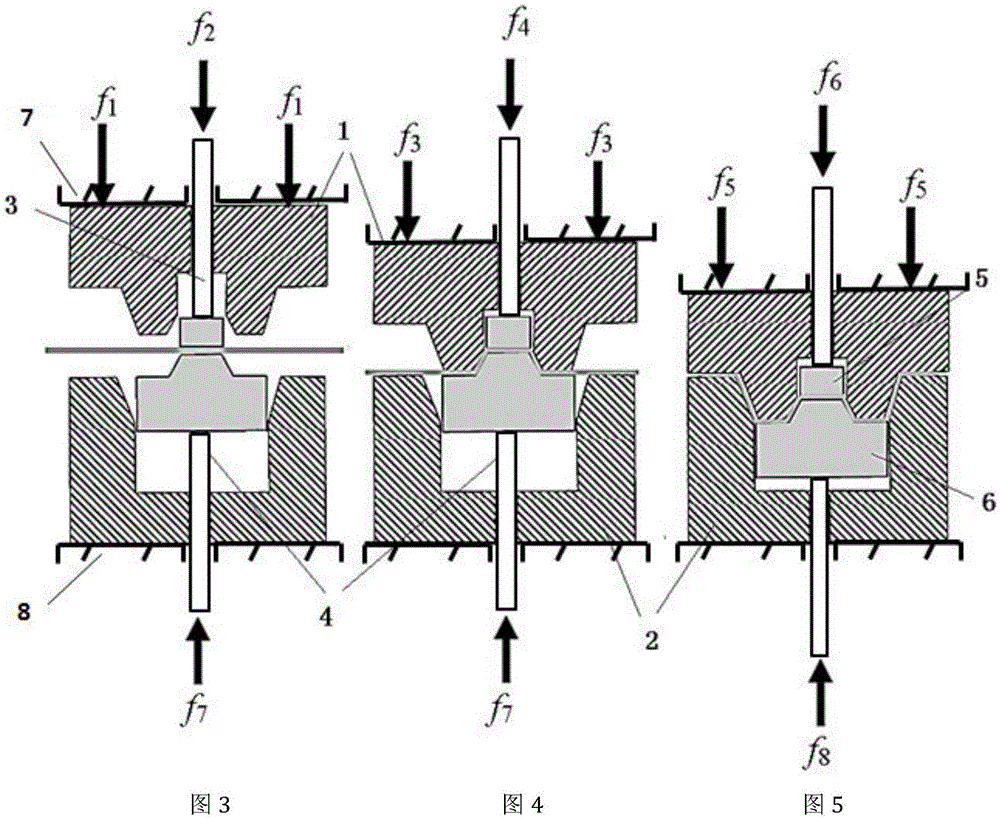

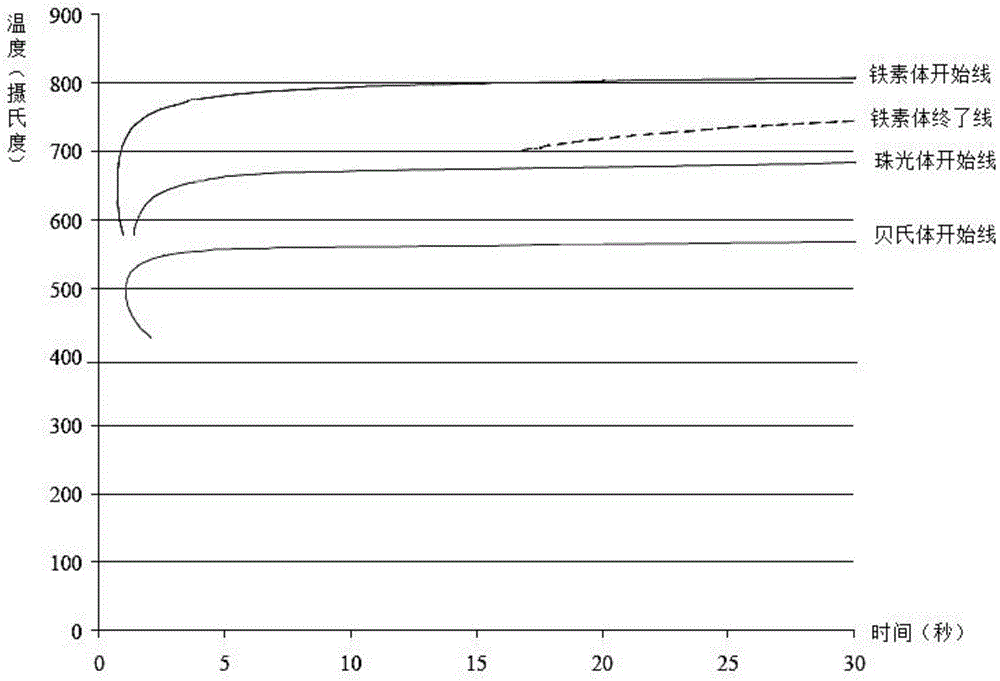

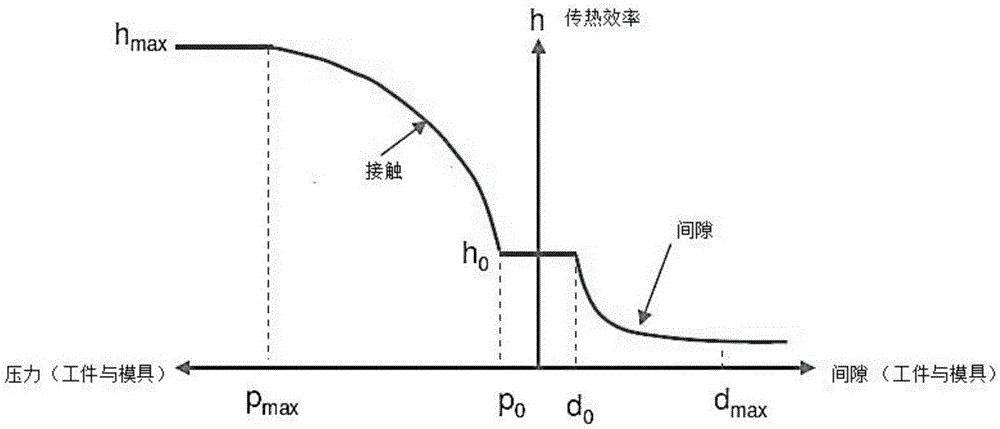

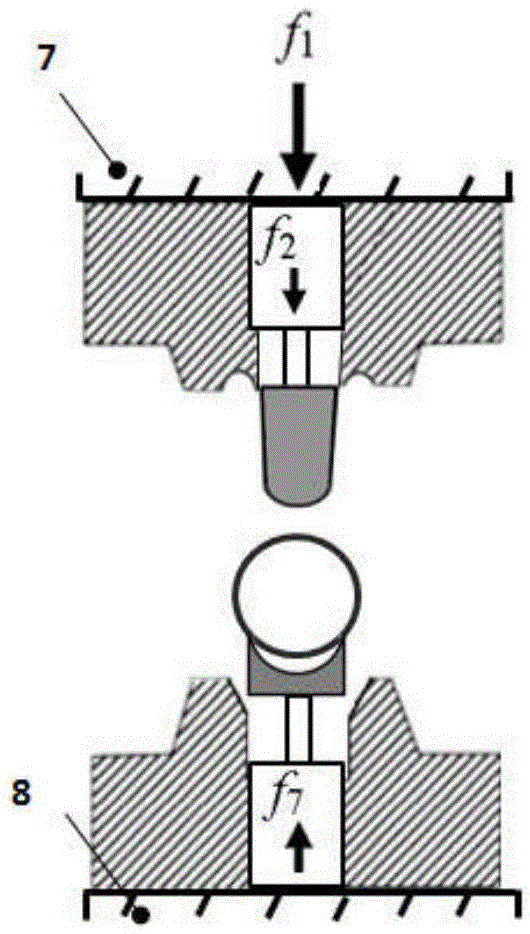

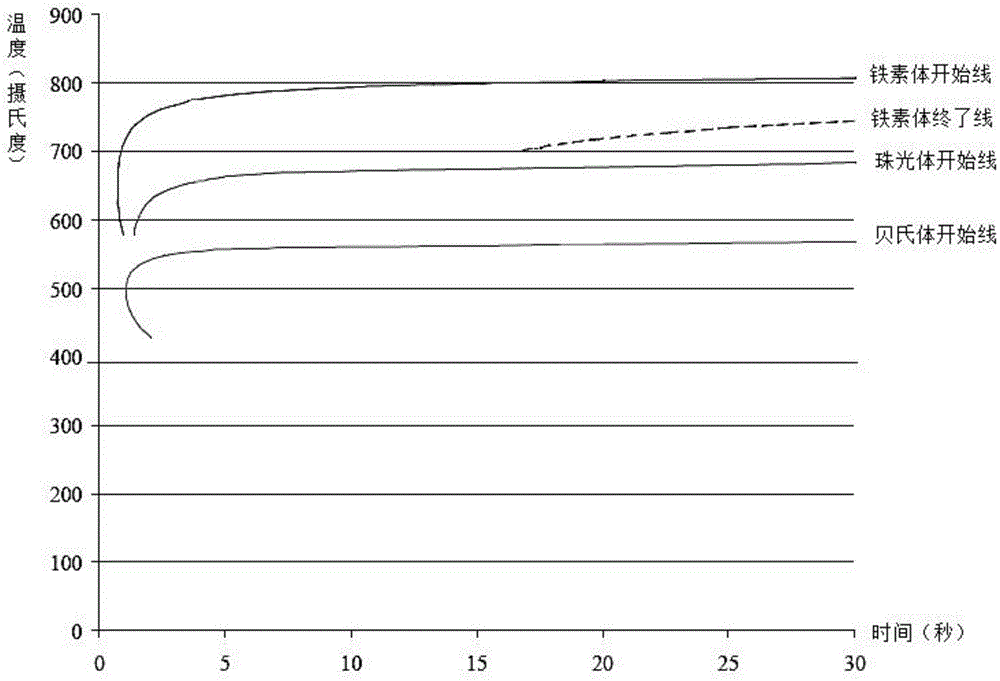

ActiveCN103785734AModes of Controlling Collision FailuresProtection securityShaping toolsPressesHydraulic cylinderMaterials science

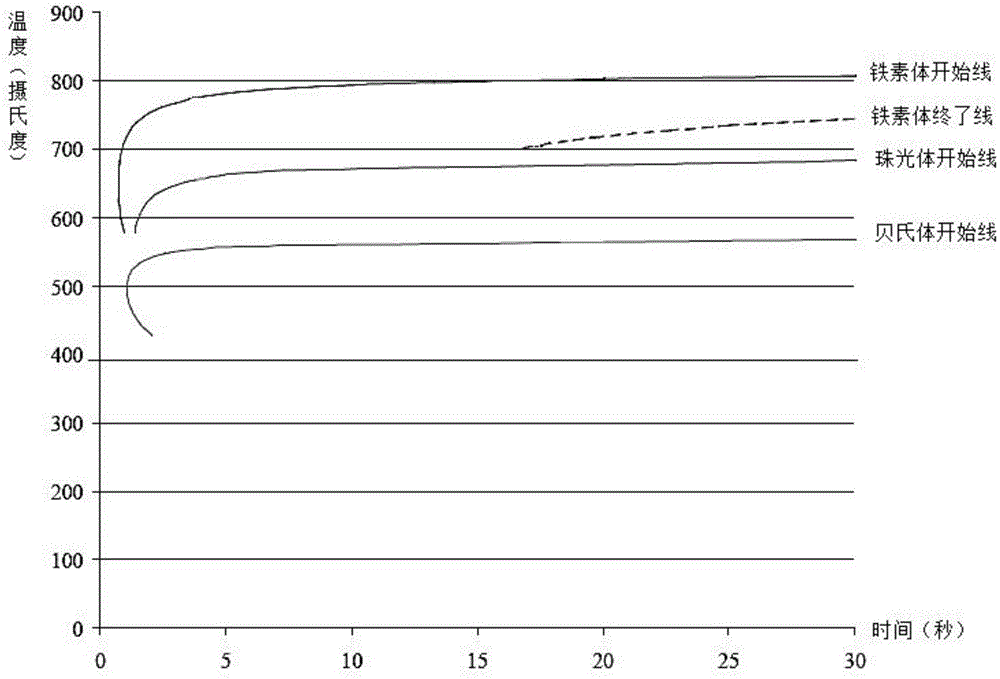

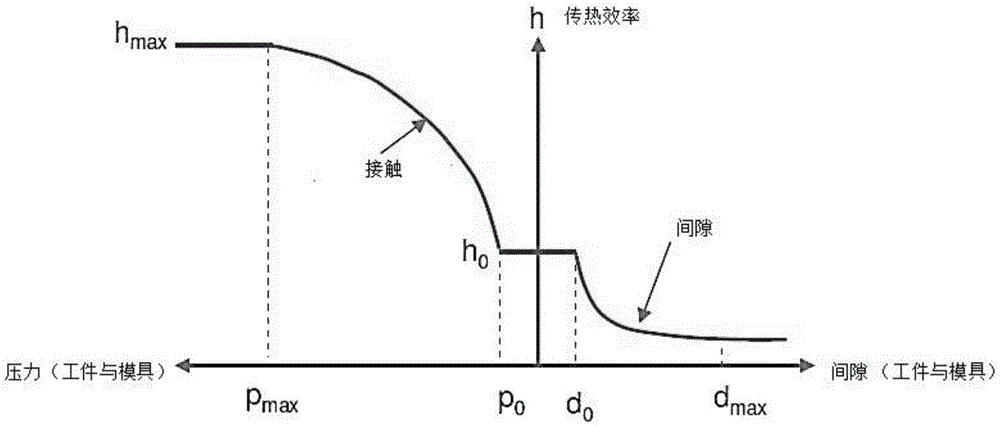

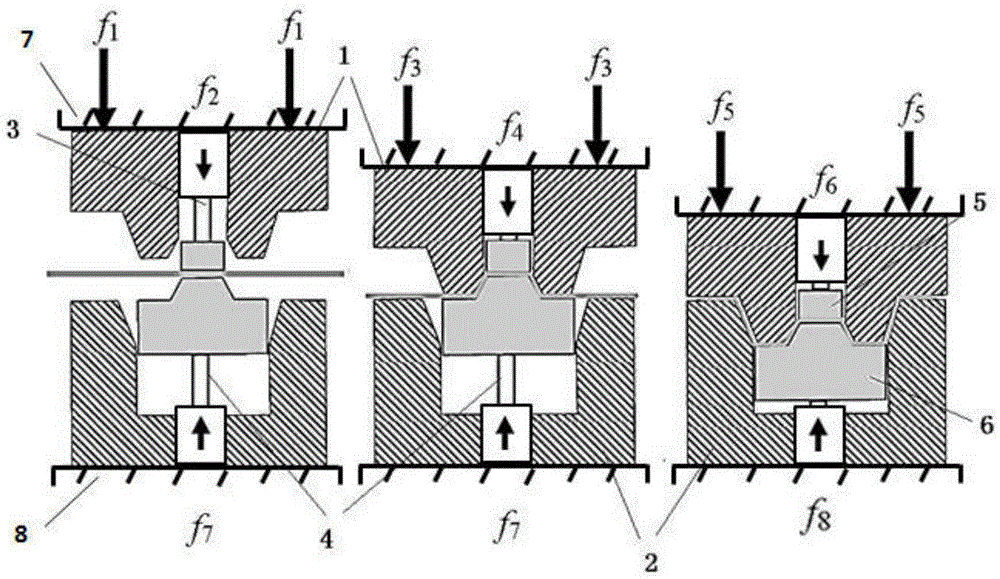

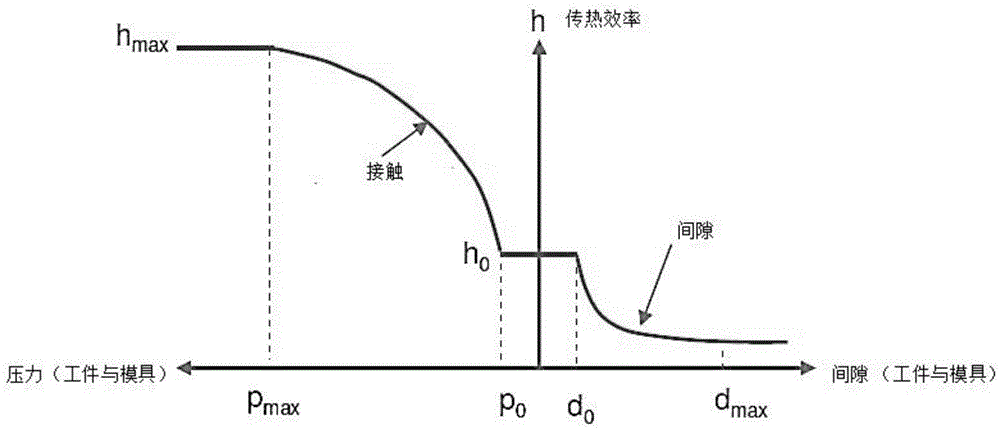

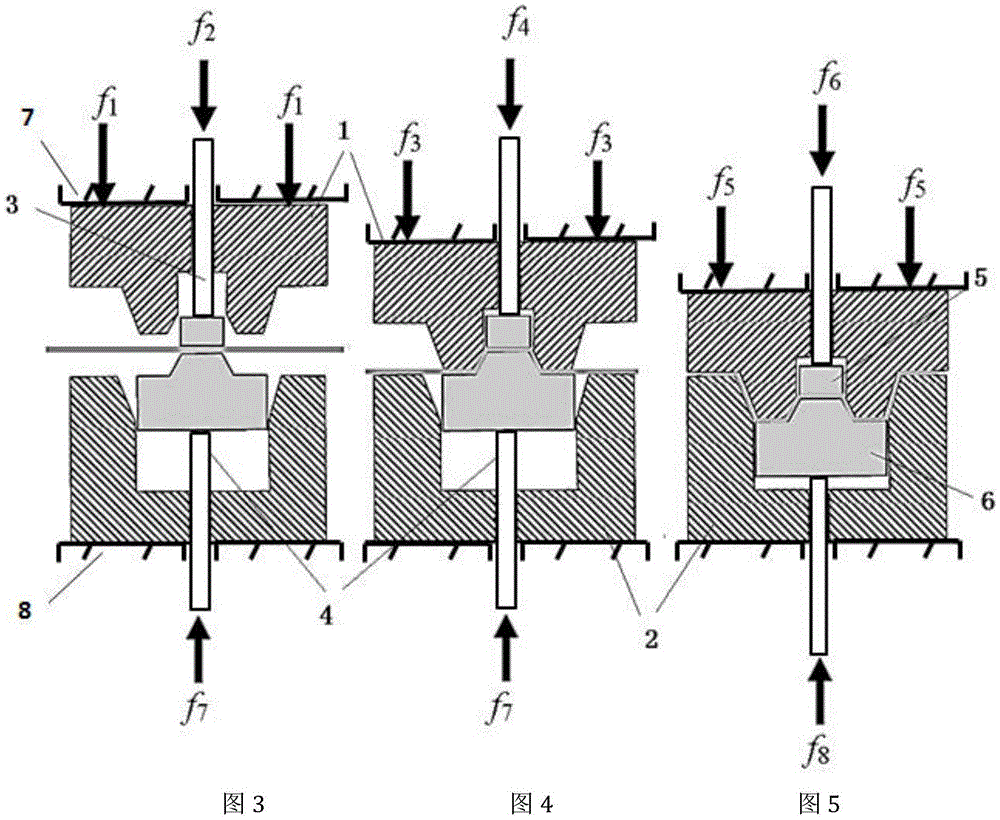

The invention discloses a pressure cooling process of segmented reinforcing type parts of a hot forming steel pipe, and a die hydraulic device. Through a hydraulic cylinder device in a die, existence of pressure keeping loading force borne by a workpiece is controlled according to the design requirements, and therefore the cooling speed of each sub-area is controlled, and different types of material mechanical performance of the sub-areas of a tubular product is obtained. Required material characteristics can be achieved for any area according to the design requirements, no additional die heating device needs to be arranged, and production cost and procedure complexity are greatly reduced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

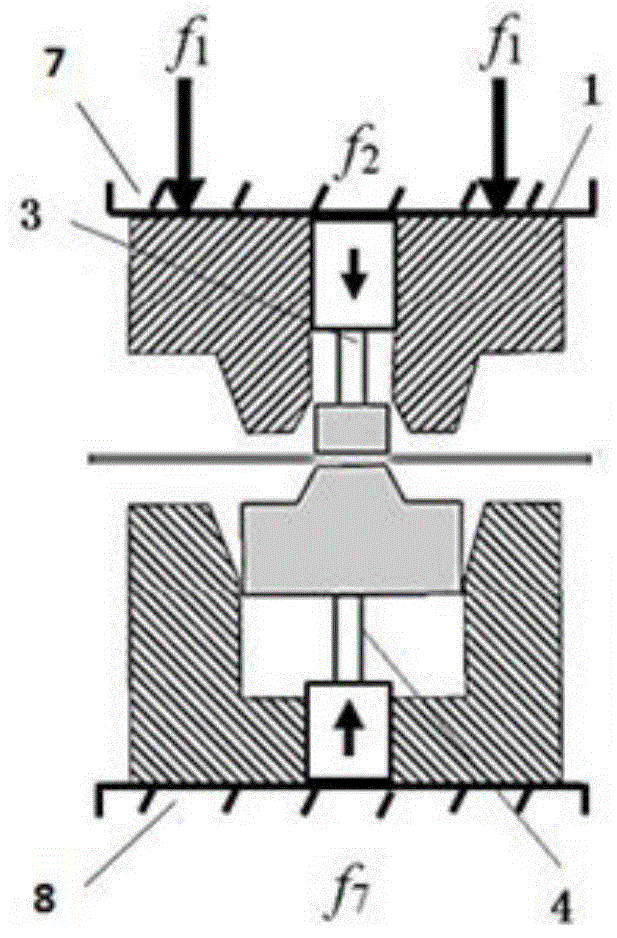

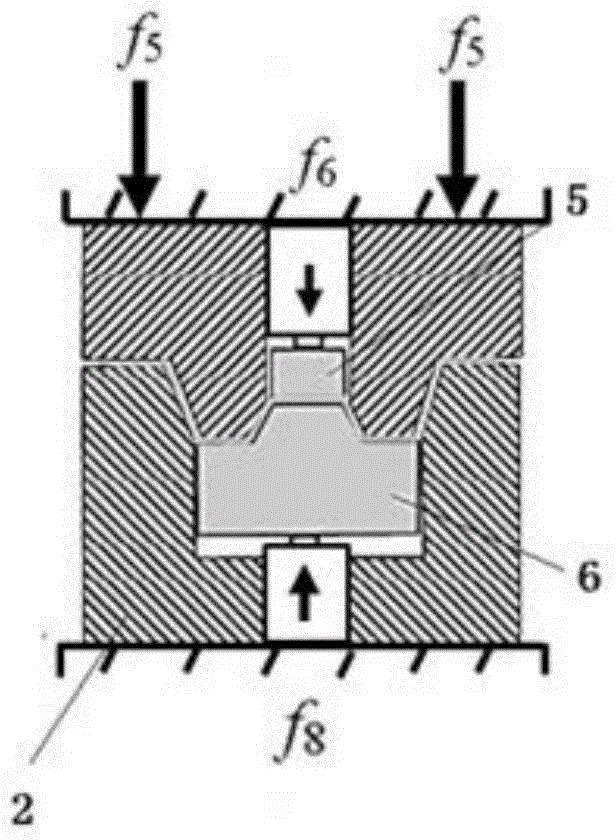

Pressure cooling process for thermally-formed steel plate sectionally-strengthen-type parts and die hydraulic device

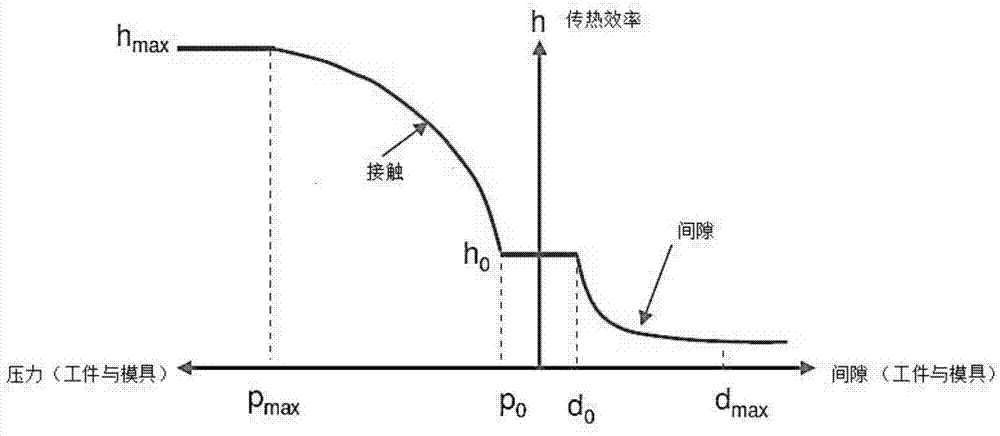

InactiveCN103817192AModes of Controlling Collision FailuresProtection securityShaping toolsPunchingSheet steel

Disclosed are a pressure cooling process for thermally-formed steel plate sectionally-strengthen-type parts and a die hydraulic device in the field of thermal-forming punching. Through a servo cylinder device in a die, existence of pressure-maintaining loading force applied on different regions of a workpiece is controlled according to design needs to control cooling speed of each sub-region so as to acquire mechanical performance of different materials of all sub-regions of a plate. By the pressure cooling process and the die hydraulic device, needed material characteristics can be realized at any region according to the design needs without additionally arranging a die heating device, so that production cost and process complexity are lowered remarkably.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

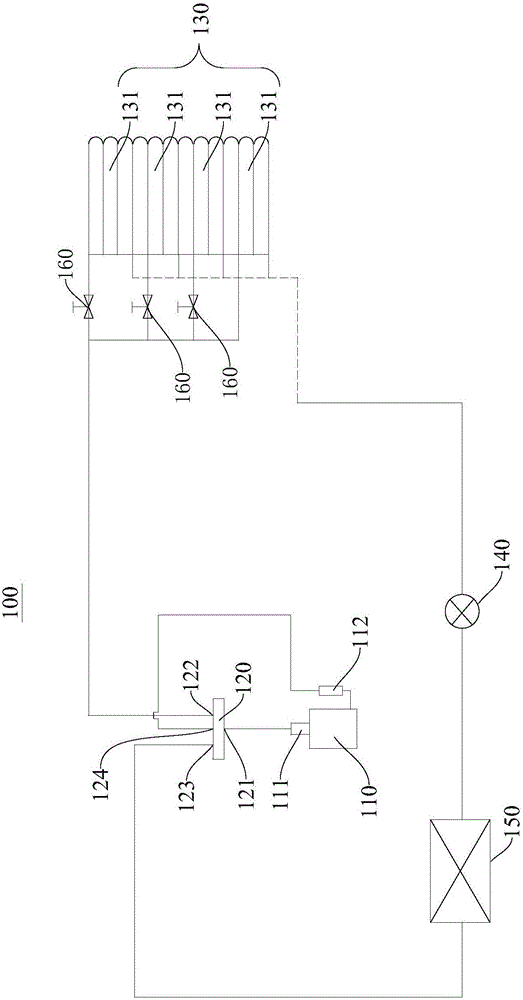

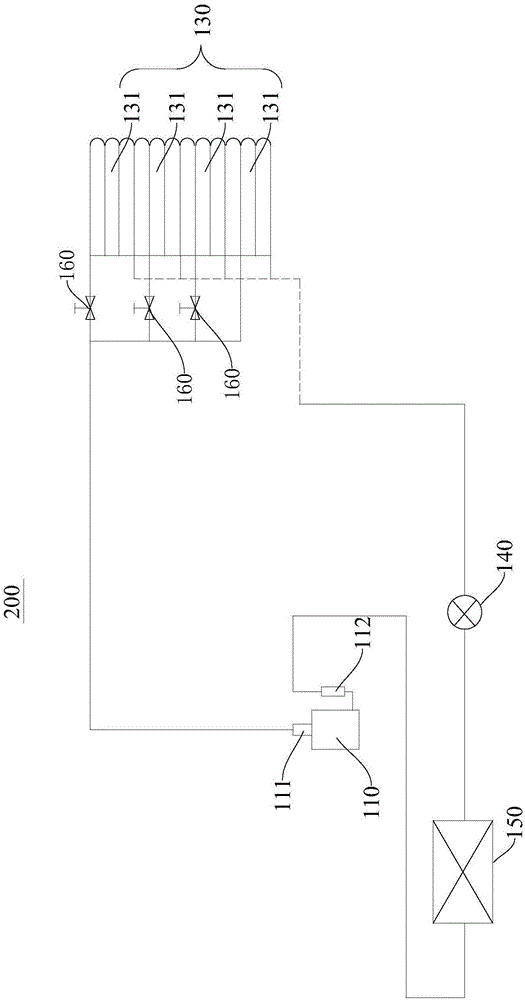

Cooling-heating type air conditioning system and cooling air conditioning system

InactiveCN105042738AControl heat transfer efficiencyGood cooling effect at low temperatureMechanical apparatusSpace heating and ventilation safety systemsCooling effectEngineering

The invention discloses a cooling-heating type air conditioning system and a cooling type air conditioning system. The cooling-heating type air conditioning system comprises a compressor, a reversing assembly, an outdoor heat exchanging assembly, an indoor heat exchanger, a controller and a temperature detection device; the reversing assembly comprises a first valve port, a second valve port, a third valve port and a fourth valve port; the outdoor heat exchanging assembly comprises n heat exchanging parts, the first end of each heat exchanging part is connected with the second valve port, and control valves are connected between the n-1 heat exchanging parts and the second valve port, wherein n is greater than or equal to 2; one end of the indoor heat exchanger is connected with the third valve port, the other end of the indoor heat exchanger is connected with one end of a throttling element, and the other end of the throttling element is connected with the second end of each heat exchanging part; the temperature detection device is used for detecting outdoor environment temperature, and the controller is connected with the temperature detection device, the reversing assembly and all the control valves and controls the opening number of the control valves according to the detection result of the temperature detection device. The cooling-heating type air conditioning system is good in low-temperature cooling effect.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

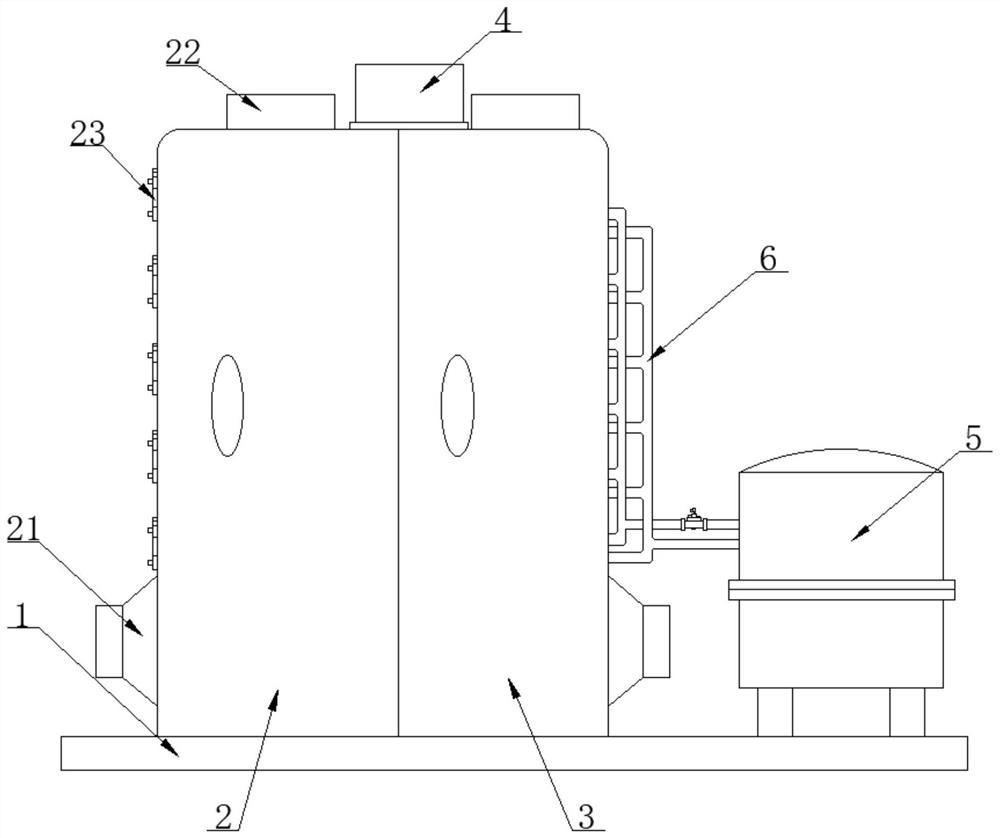

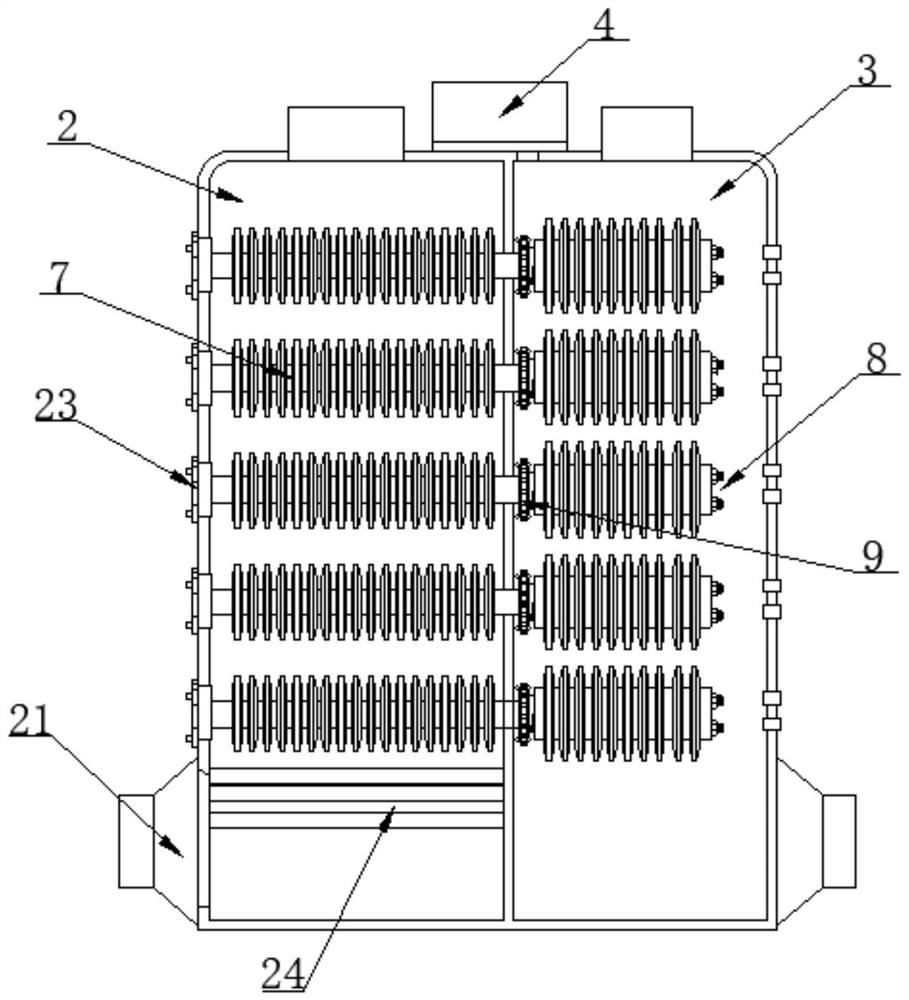

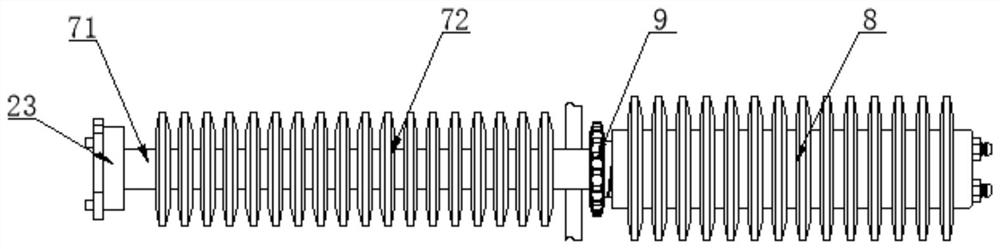

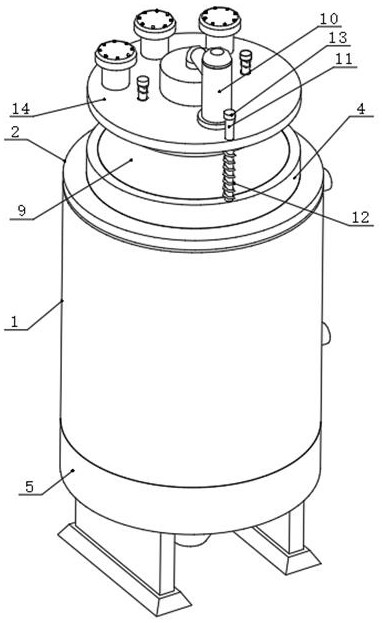

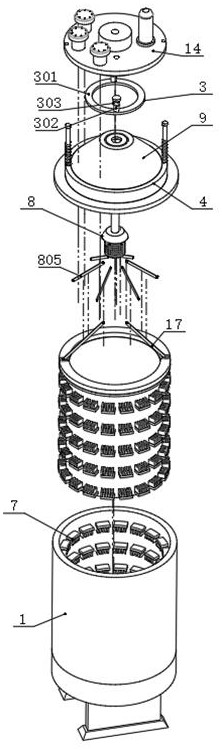

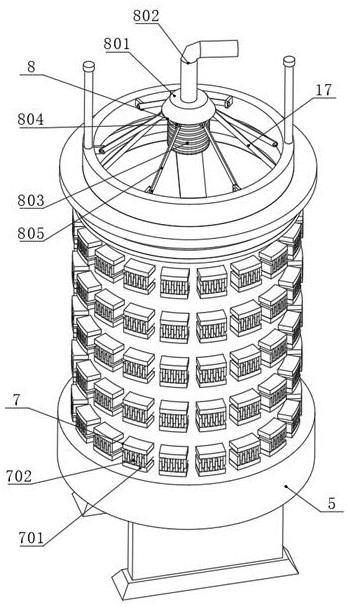

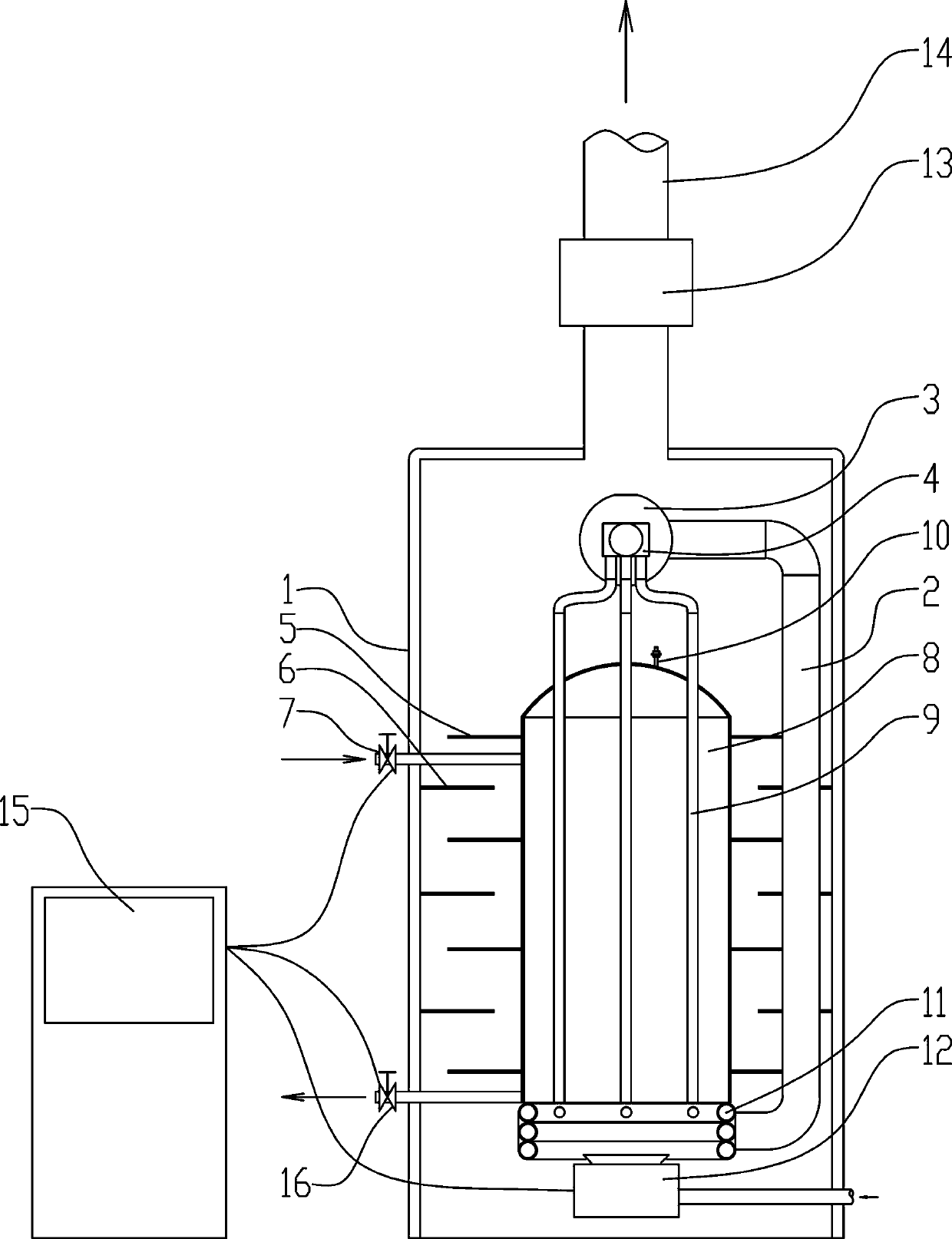

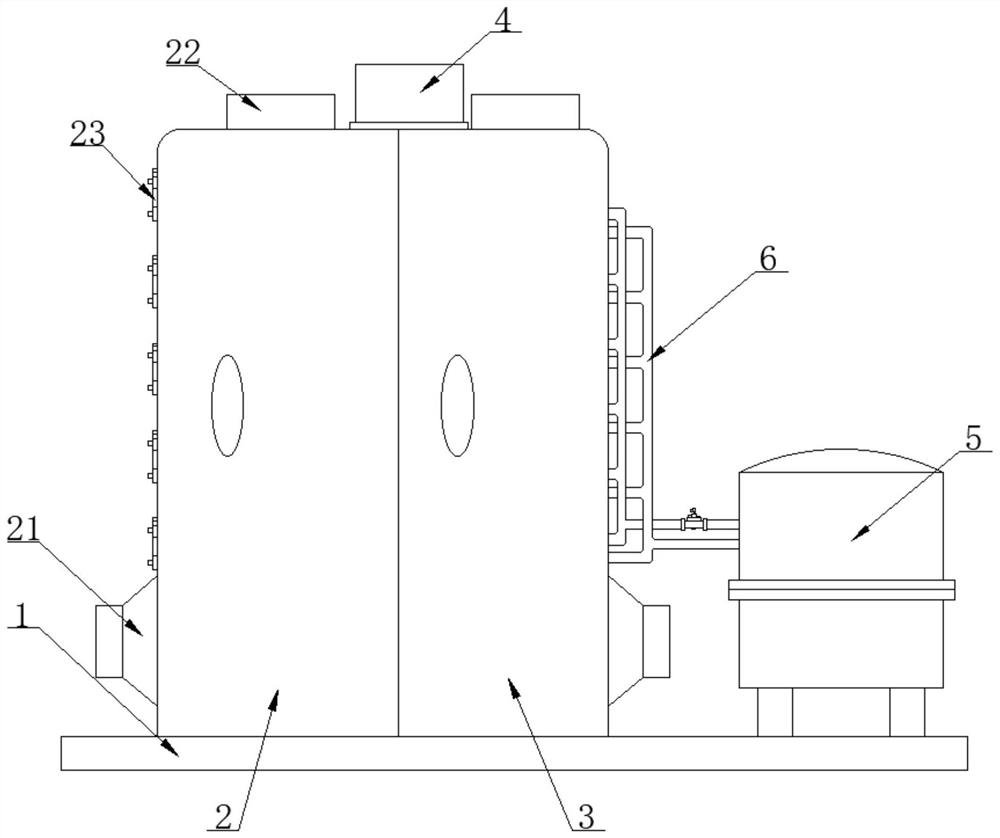

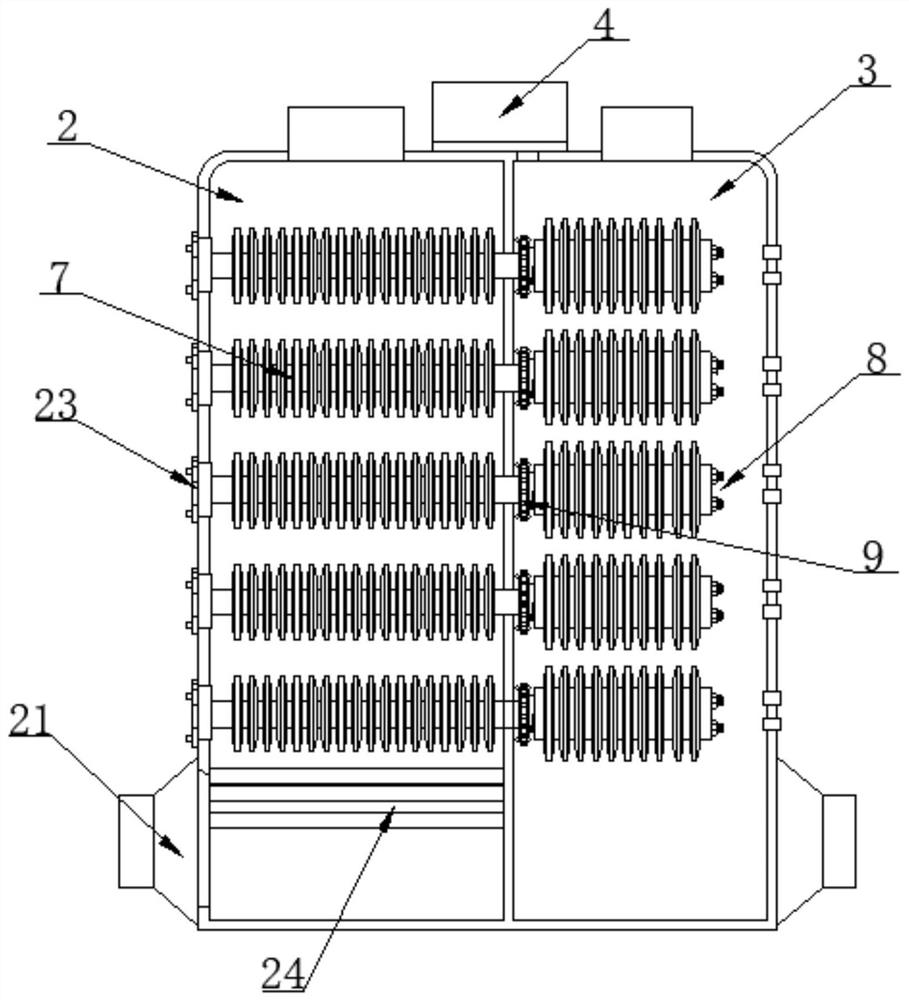

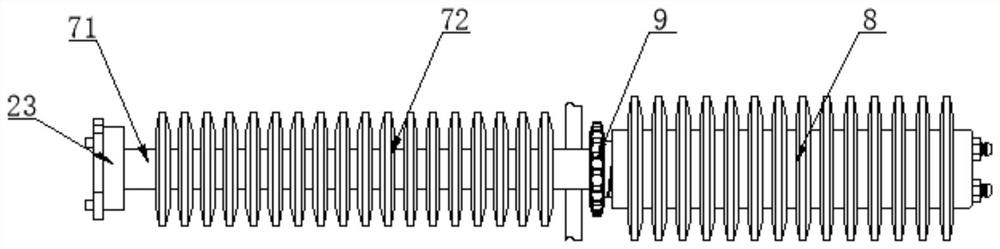

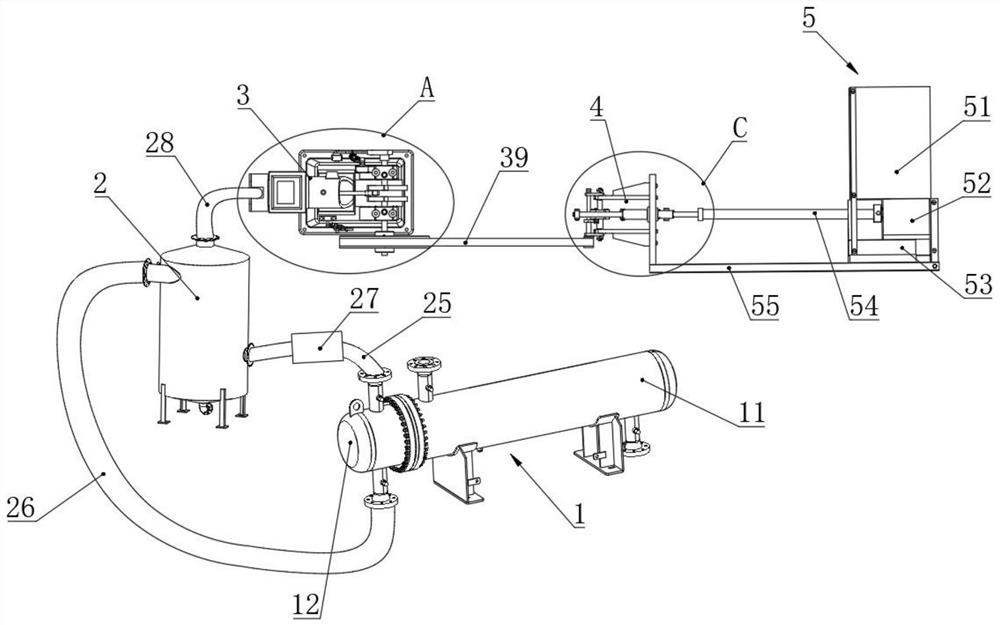

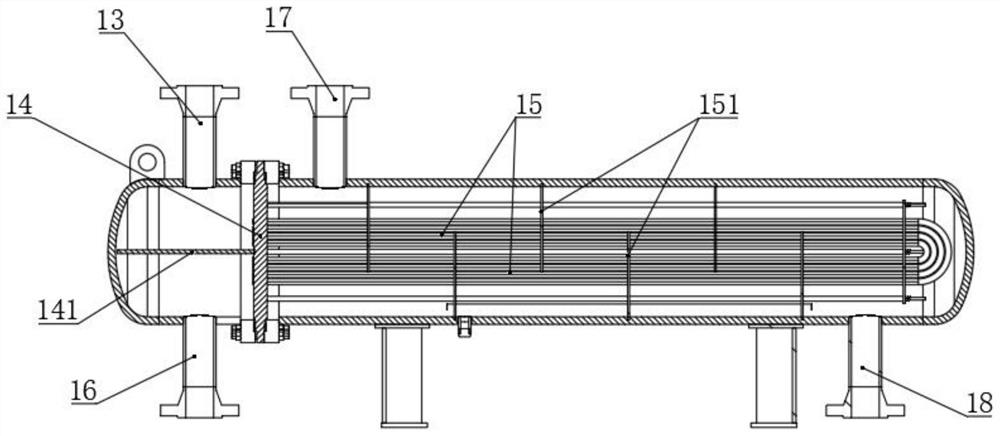

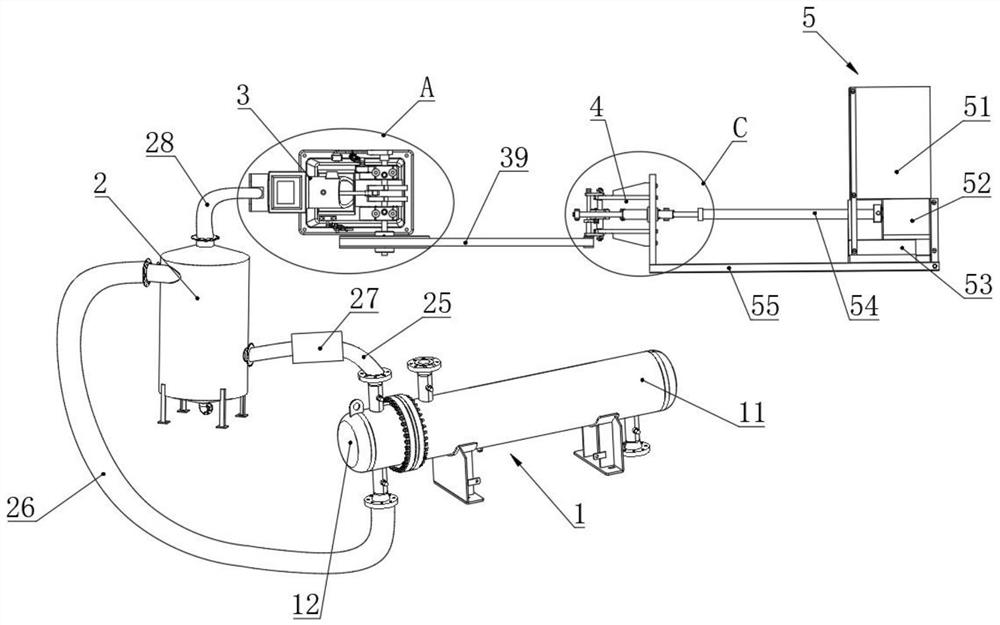

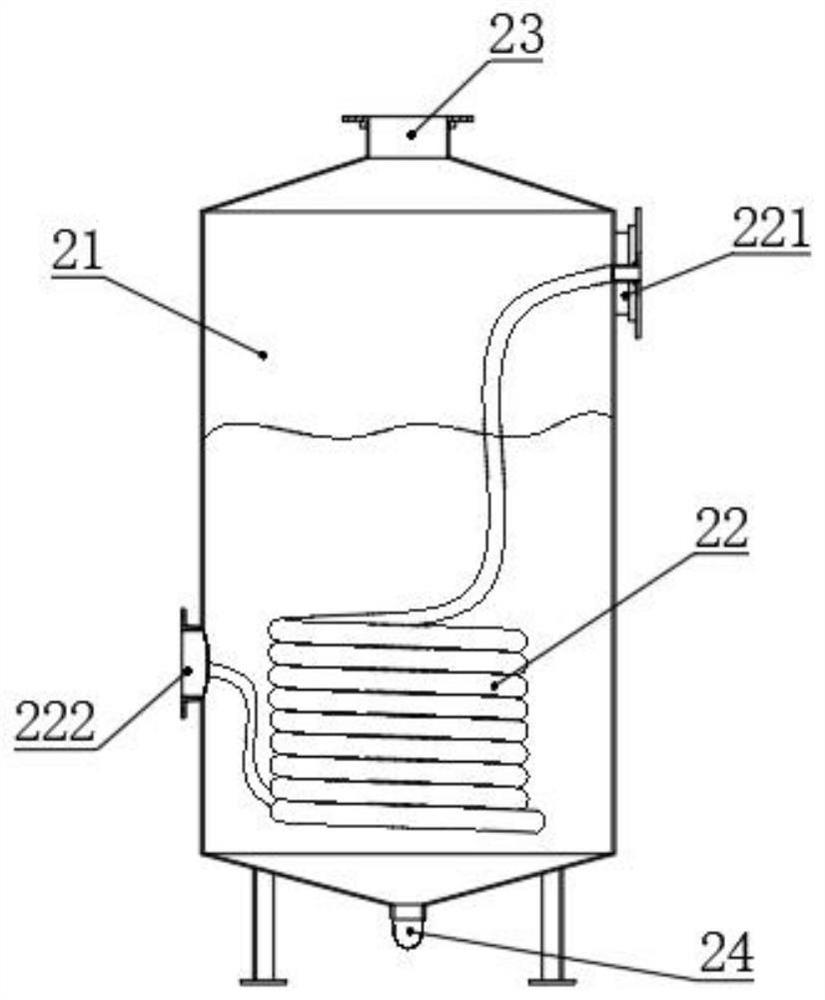

Thermal power plant combined type heat pipe smoke residual heat recycling device

ActiveCN111981880AAchieve temperature controlPrecise temperature controlCorrosion preventionIndirect heat exchangersProcess engineeringThermal recovery

The invention discloses a thermal power plant combined type heat pipe smoke residual heat recycling device and particularly relates to the field of residual heat recycling. The thermal power plant combined type heat pipe smoke residual heat recycling device comprises an installation seat, a smoke discharging bin and a residual heat recycling bin, wherein the top face of the installation seat is fixedly provided with a heat exchange water box, the smoke discharging bin and the residual heat recycling bin are fitted to each other on one side and are internally provided with combined type heat pipes in a running through manner, the surfaces of the combined type heat pipes are rotatably connected with screw thread driving sleeves located inside the smoke discharging bin in a sleeved manner, and the surfaces of the screw thread driving sleeves are movably connected with heat exchange pipe sleeve components in a sleeved manner. The thermal power plant combined type heat pipe smoke residual heat recycling device is provided with novel combined type heat pipe structures, the heat conduction fluid flow volume inside the heat exchange pipe sleeve components is actively changed by utilizing amechanical control component, and the bare lengths of the heat pipe ends inside the residual heat recycling bin are changed, heat exchange efficiency control is realized, the heat recycling airflow temperature is changed, precise temperature control is realized, use of recycled heat energy is facilitated, and the practicability of the residual heat recycling device is improved.

Owner:HUAINAN TIANJIAAN POWER GENERATION PLANT ANHUI ELECTRIC POWER CO LTD

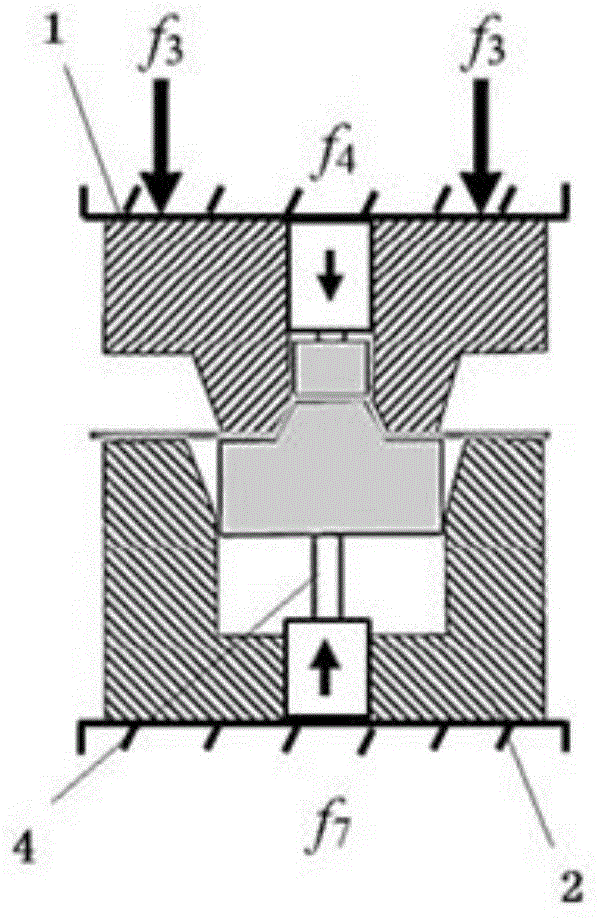

Pressure cooling process for thermally-formed steel plate sectionally-strengthen-type parts and die servo device

ActiveCN103817194AImprove product strength or elongationProtect personal safetyShaping toolsPressesSteel platesSub region

Disclosed are a pressure cooling process for thermally-formed steel plate sectionally-strengthen-type parts and a die servo device in the field of thermal-forming punching. Through a servo cylinder device in a die, strength and time of pressure-maintaining loading force applied on different regions of a workpiece are controlled according to design needs to control cooling speed of each sub-region so as to acquire different physical characteristics of all sub-regions of a plate. By the pressure cooling process and the die servo device, needed material characteristics can be realized at any region according to the design needs without additionally arranging a die heating device, so that production cost and process complexity are lowered remarkably.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

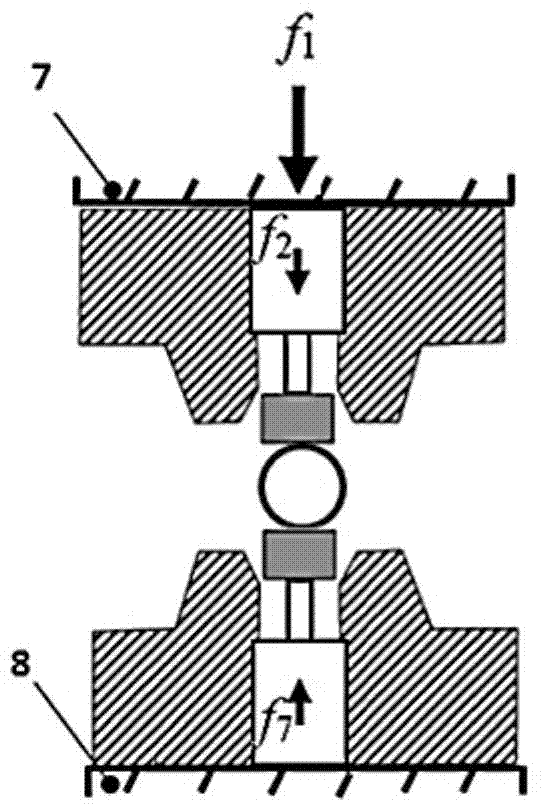

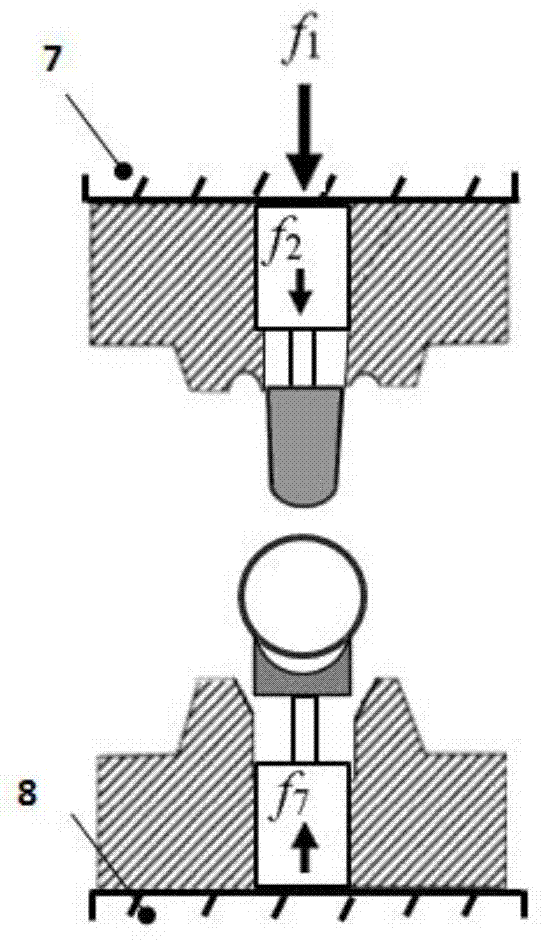

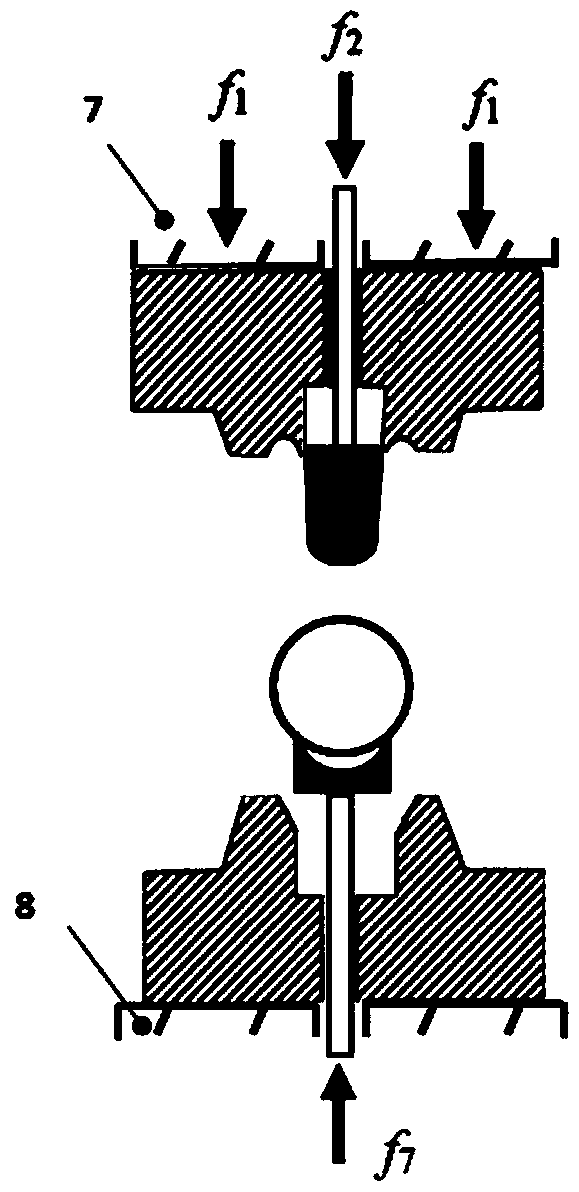

Pressure cooling process of segmented reinforcing type parts of hot forming steel pipe, and pressing machine hydraulic ejector rod devices

ActiveCN103785760AModes of Controlling Collision FailuresProtection securityShaping toolsPressesEngineeringCooling speed

The invention discloses a pressure cooling process of segmented reinforcing type parts of a hot forming steel pipe, and pressing machine hydraulic ejector rod devices. By turning on and turning off the independent pressing machine hydraulic ejector rod devices, the magnitude of average loading force borne by a workpiece is adjusted, and the cooling speed of each sub-area of the workpiece is controlled, and therefore different types of material mechanical performance of the sub-areas of the workpiece are obtained. Required material characteristics can be achieved for any area according to the design requirements, no additional die heating device needs to be arranged, and production cost and procedure complexity are greatly reduced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Pressure cooling process of segmented reinforcing type parts of hot forming steel pipe, and die servo device

InactiveCN103785761AControl heat transfer efficiencyModes of Controlling Collision FailuresShaping toolsPressesEngineeringLoad force

The invention discloses a pressure cooling process of segmented reinforcing type parts of a hot forming steel pipe, and a die servo device. Through a servo cylinder device in a die, the magnitude of pressure keeping loading force borne by a workpiece and time for bearing the pressure keeping loading force by the workpiece are controlled according to the design requirements, and therefore the cooling speed of each sub-area is controlled, and the different physical properties of the sub-areas of a tubular product are obtained. Required material characteristics can be achieved for any area according to the design requirements, no additional die heating device needs to be arranged, and production cost and procedure complexity are greatly reduced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Pressure cooling technology for segmented and strengthened parts of hot-formed steel pipe and press servo top rod devices

ActiveCN103801605AModes of Controlling Collision FailuresProtection securityShaping toolsPressesEngineeringProcess complexity

A pressure cooling technology for segmented and strengthened parts of a hot-formed steel pipe and press servo top rod devices are characterized in that through the independent press servo top rod devices, the magnitude of loading force applied on workpieces and / or the length of time of stress and pressure applied on the workpieces can be adjusted, the each sub-regional cooling speed of the workpieces can be controlled, so that the mechanical performances of different materials in each sub-regional of the workpieces can be obtained. By means of the pressure cooling technology for the segmented and strengthened parts of the hot-formed steel pipe and the press servo top rod devices, the needed material performance can be achieved in any region according to a requirement of a design, an extra die heating device is not needed to be arranged, and production cost and process complexity can be reduced greatly.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

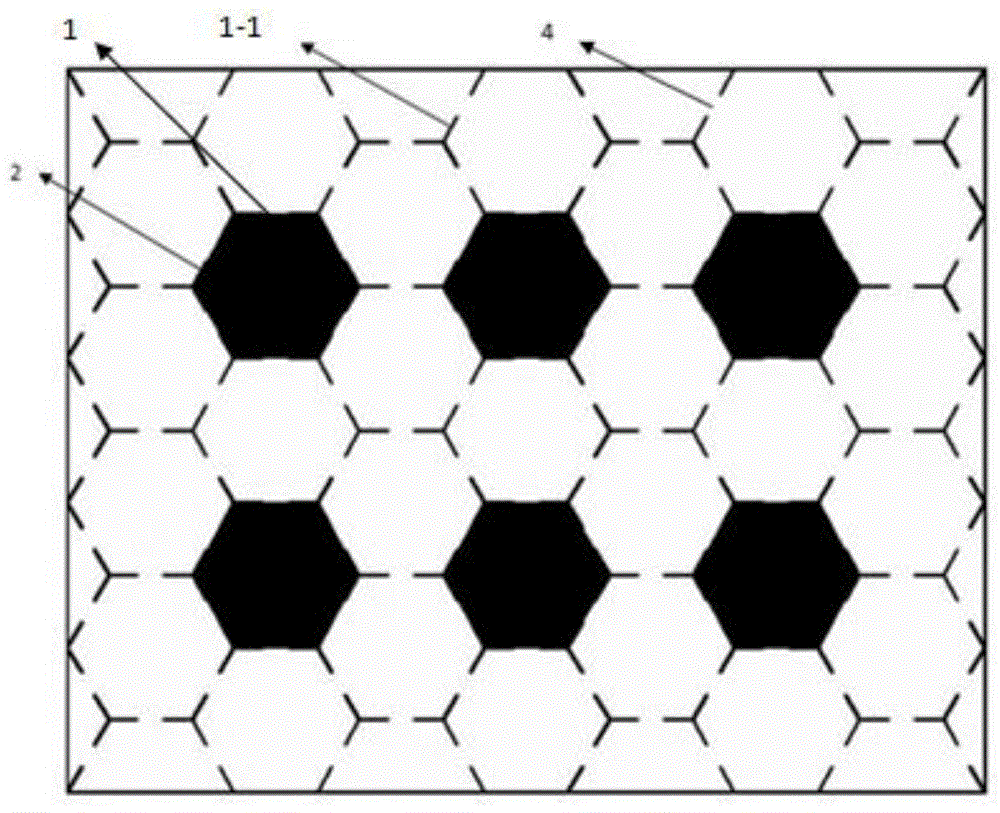

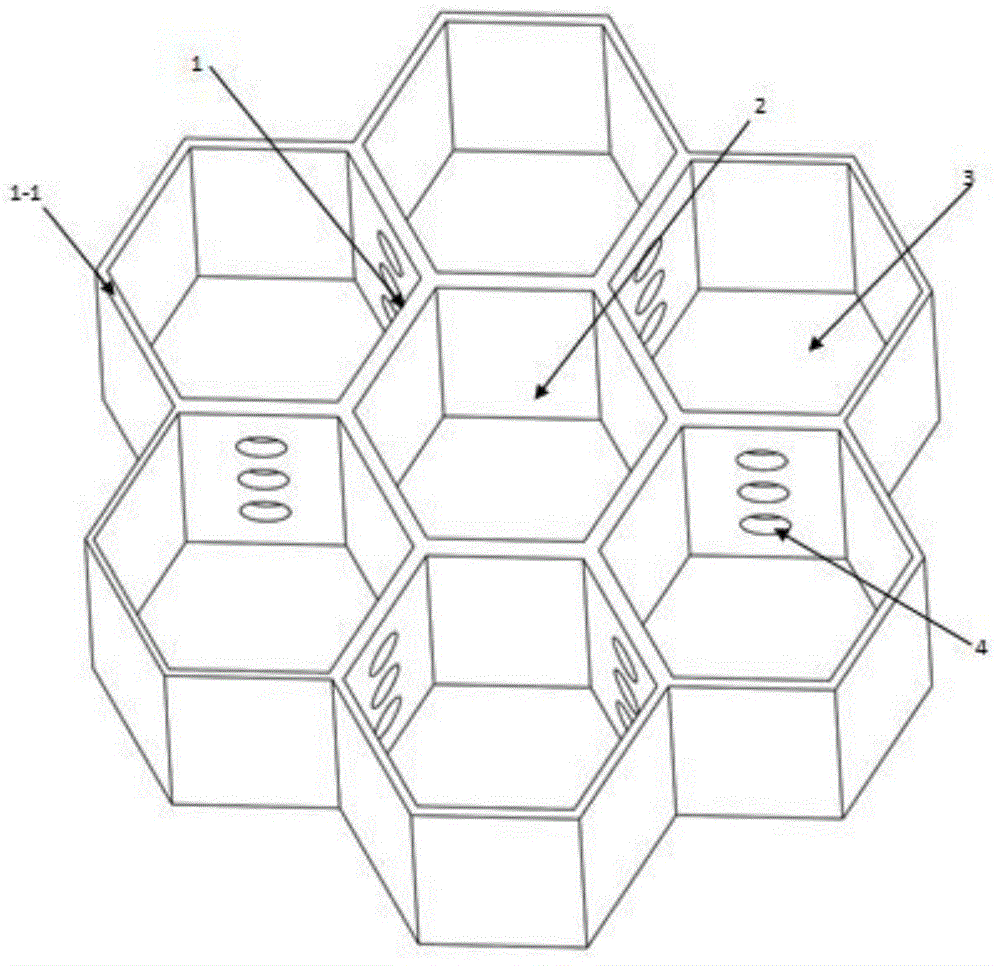

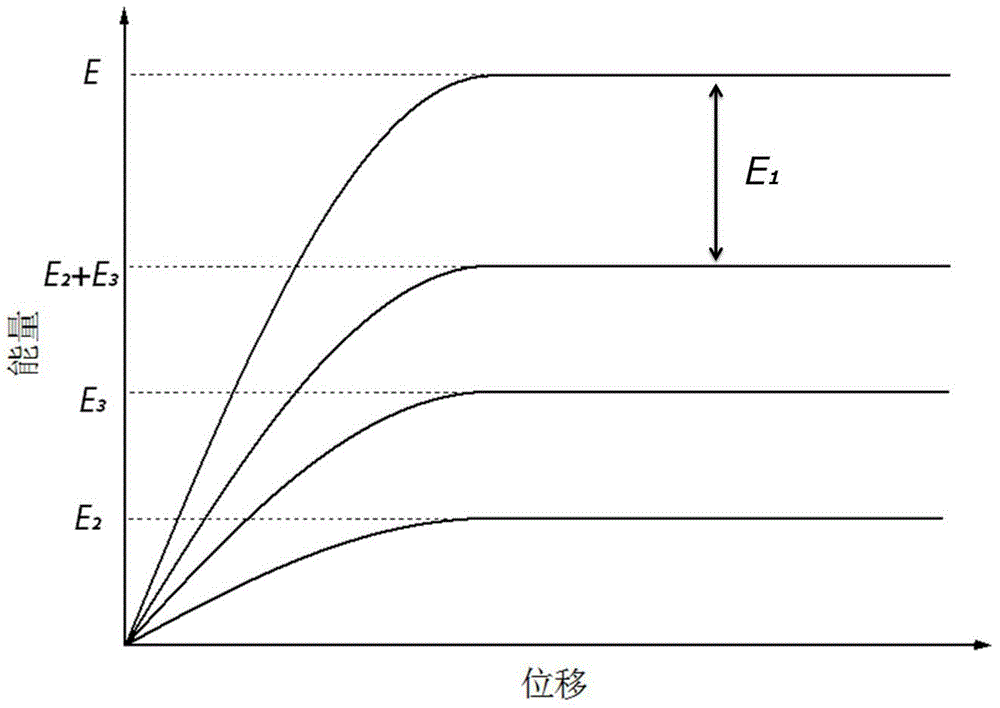

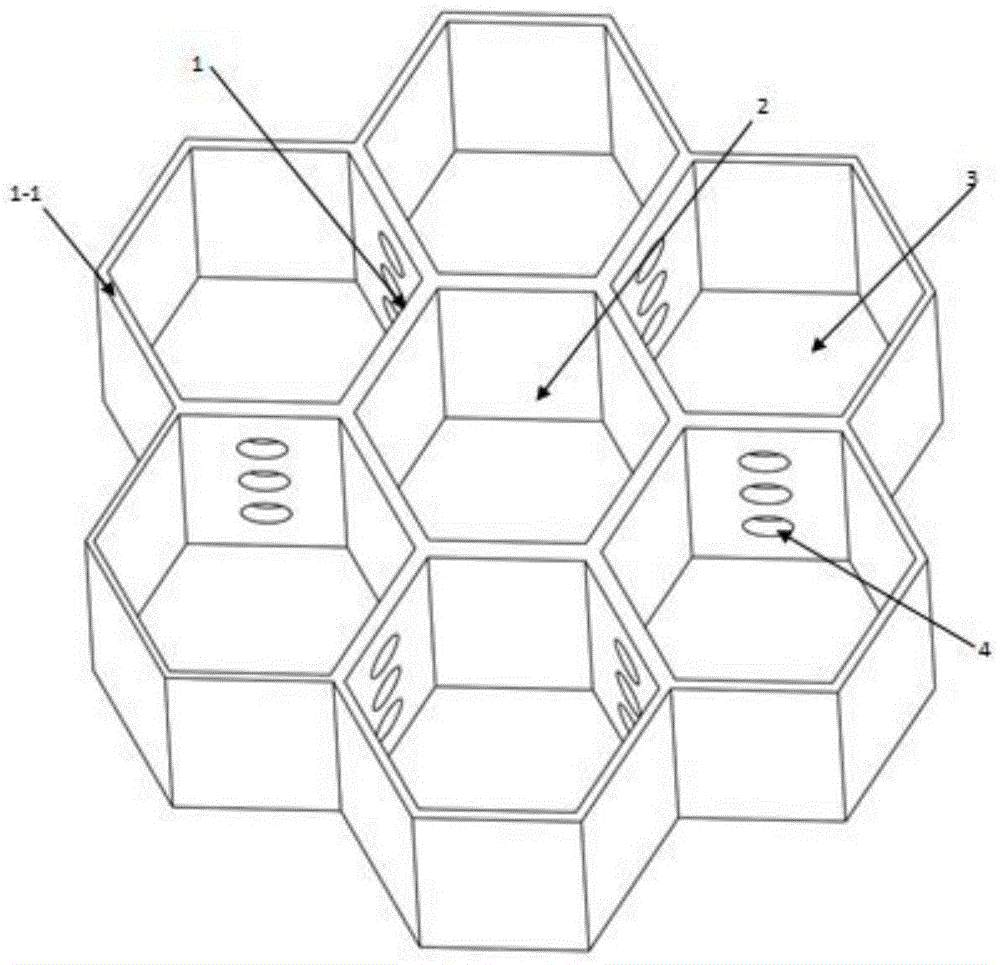

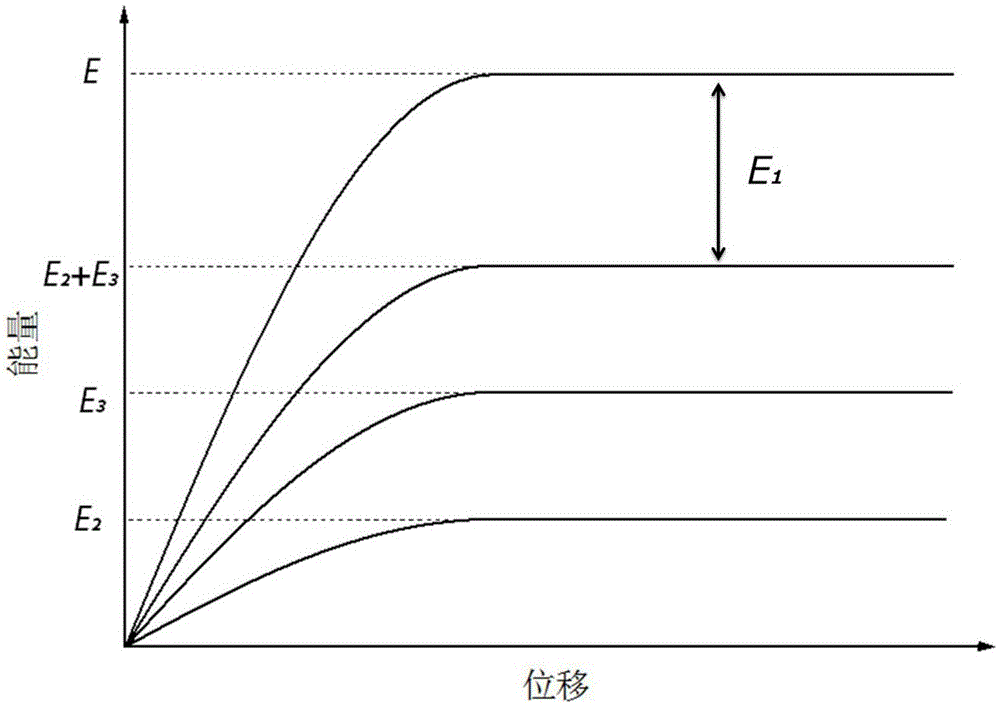

Multifunctional structure with heat absorption cooling effect and vibration reduction effect

ActiveCN104455151AEffective temperature controlMeet cooling needsElastic dampersShock absorbersCooling effectAbsorbed energy

The invention discloses a multifunctional structure with the heat absorption cooling effect and the vibration reduction effect. The multifunctional structure comprises center frameworks made of high-elasticity high polymer materials and peripheral frameworks which surround the center frameworks in a connected mode and are made of high-elasticity high polymer materials. The center frameworks and every other peripheral framework are filled with flowing fillers with the heat absorption cooling effect. One or more small holes are formed in the side walls of the peripheral frameworks which are not filled with the fillers. The multifunctional structure further comprises high polymer material packaging layers for packaging the fillers. The peripheral frameworks which are not filled with the fillers are provided with or are not provided with the high polymer material packaging layers in a packaged mode. When the temperature of the environment where the multifunctional structure is located is higher than certain threshold temperature, the fillers start to absorb heat to achieve the cooling effect; after losing the heat absorption cooling effect, the fillers are placed into the environment with the temperature lower than the threshold temperature, and the cooling effect will be automatically recovered. Meanwhile, in the vibration process, the multifunctional structure is the equal of an elastic damper, and the vibration reduction effect is achieved by absorbing energy generated during vibration.

Owner:XI AN JIAOTONG UNIV

Pressure cooling process for thermally-formed steel plate sectionally-strengthen-type parts and press hydraulic ejector rod device

ActiveCN103817193AModes of Controlling Collision FailuresProtection securityShaping toolsPressesSheet steelPunching

Disclosed are a pressure cooling process for thermally-formed steel plate sectionally-strengthen-type parts and a press hydraulic ejector rod device in the field of thermal-forming punching. Through switching on and off of each independent press hydraulic ejector rod device, strength of average loading force applied on a workpiece is controlled to control cooling speed of each sub-region so as to acquire mechanical performance of different materials of all sub-regions of the workpiece. By the pressure cooling process and the press hydraulic ejector rod device, needed material characteristics can be realized at any region according to design needs without additionally arranging a die heating device, so that production cost and process complexity are lowered remarkably.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

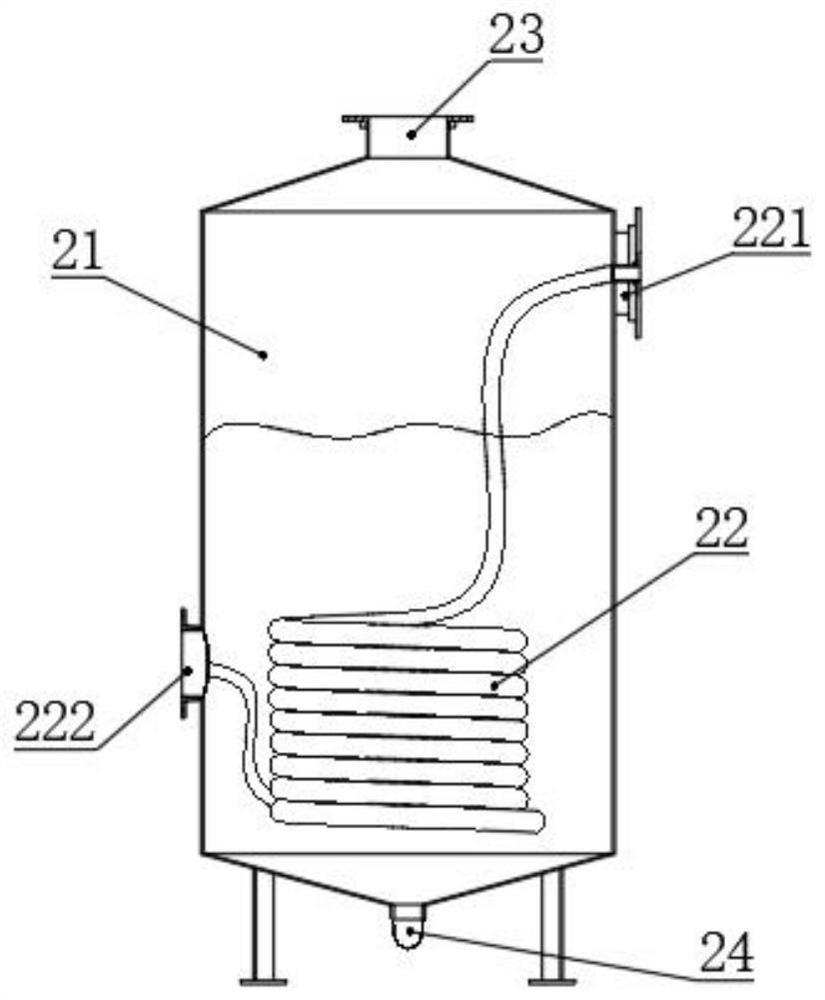

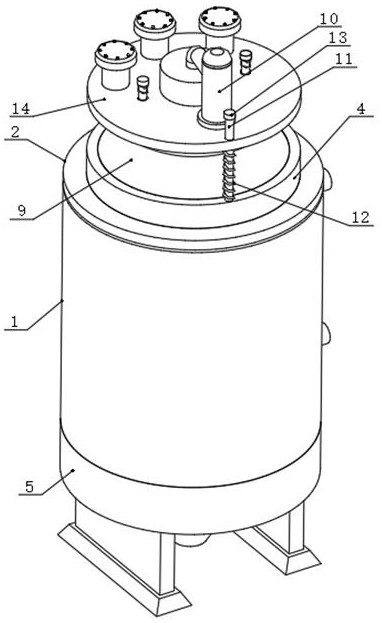

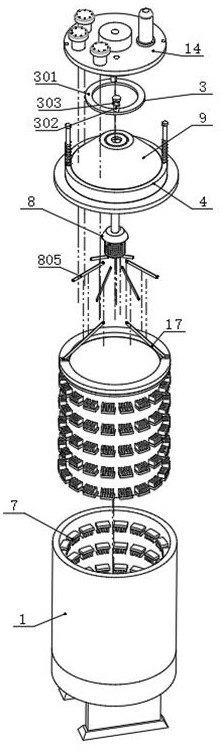

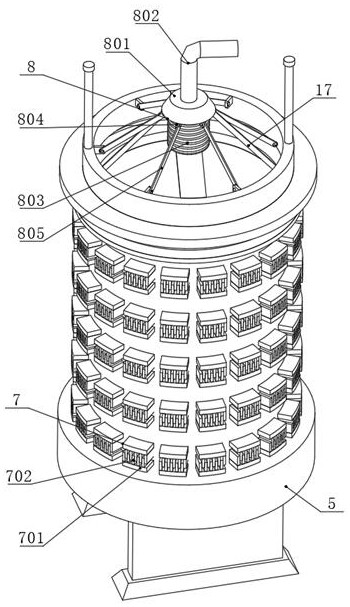

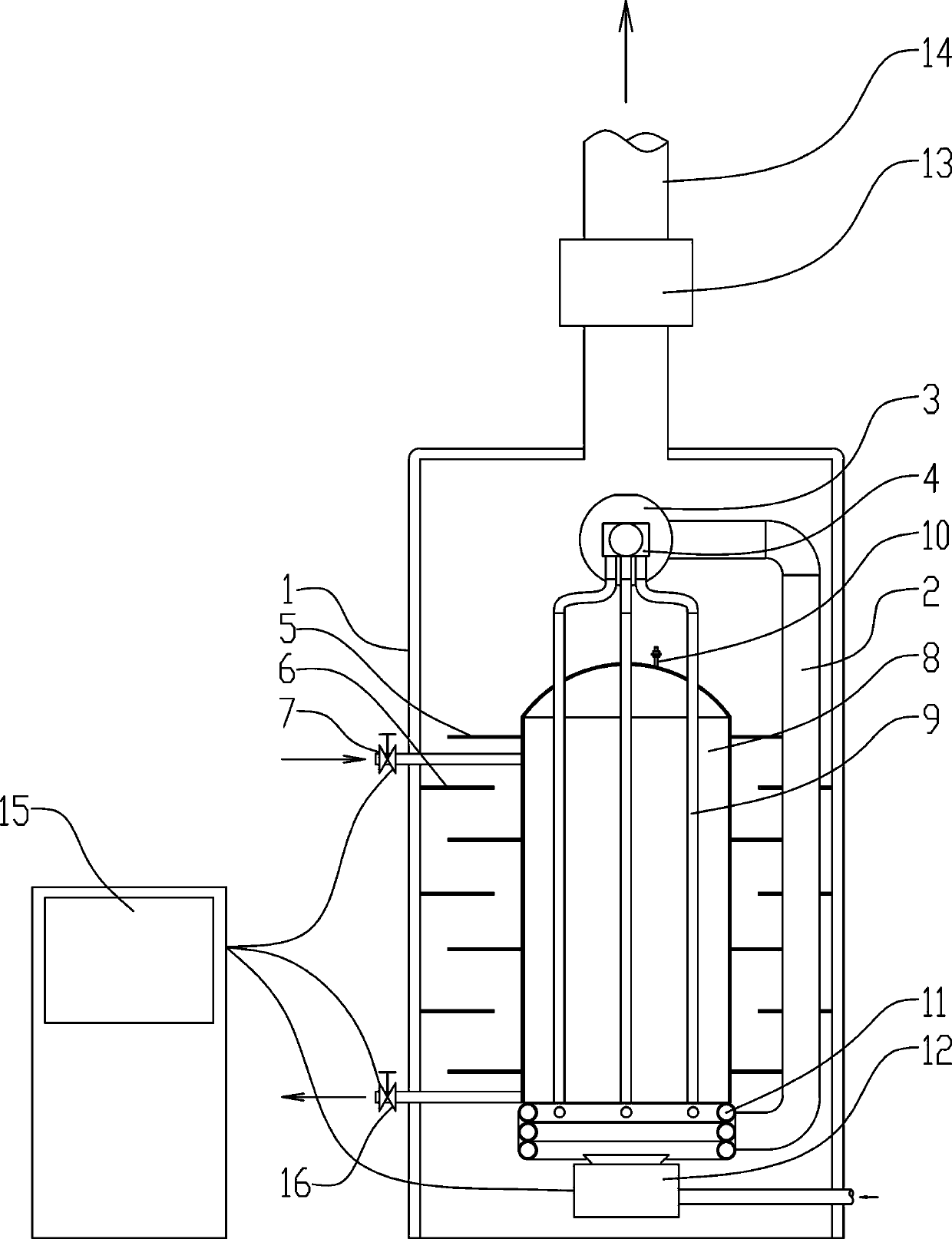

Resin production dehydration device

The invention discloses a resin production dehydration device, and belongs to the technical field of resin solid raw material dehydration, the resin production dehydration device comprises a dehydration kettle body, the bottom of the dehydration kettle body is fixedly provided with a kettle base, the inner cavity of the dehydration kettle body is slidably connected with an inner kettle body, and the outer side wall of the inner kettle body is fixedly connected with a jacket heat exchange mechanism. According to the device, an inflation pipe feeds gas into an expansion air bag, so that the expansion air bag is unfolded to push an abutting arc-shaped block to move upwards, and the abutting arc-shaped block moves upwards to pull a hinge block to rotate around one end of a first connecting rod to drive a top flexible unfolding cover to expand and unfold upwards; the distance between the flexible unfolding cover and the liquid level of a resin raw material in the inner kettle body can be adjusted, the situation that the resin raw material splashes and adheres to the interior of the flexible unfolding cover to affect the exhaust effect is avoided, meanwhile, when the flexible unfolding cover is unfolded and contracted, the pressure of the inner kettle body can be adjusted through the change of the space of the inner kettle body, and the pressure in the drying kettle during drying and heating is effectively controlled; the regulation and control treatment requirements of heating and drying are met.

Owner:山东永创材料科技有限公司

Pressure cooling process of segmented reinforcing type parts of hot forming steel plate, and pressing machine servo ejector rod devices

ActiveCN103785733AModes of Controlling Collision FailuresProtection securityShaping toolsSheet steelCooling speed

The invention discloses a pressure cooling process of segmented reinforcing type parts of a hot forming steel plate, and pressing machine servo ejector rod devices. Through the independent pressing machine servo ejector rod devices, the magnitude of loading force borne by a workpiece and / or force bearing and pressure keeping time for the workpiece are adjusted, and therefore the cooling speed of each sub-area of the workpiece is controlled, different types of material mechanical performance of the sub-areas of the workpiece are obtained. Required material characteristics can be achieved for any area according to the design requirements, no additional die heating device needs to be arranged, and production cost and procedure complexity are greatly reduced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Pressure cooling process and mold hydraulic device for hot-formed steel pipe segment strengthening parts

ActiveCN103785734BControl heat transfer efficiencyControl cooling rateShaping toolsPressesHydraulic cylinderEngineering

The invention discloses a pressure cooling process of segmented reinforcing type parts of a hot forming steel pipe, and a die hydraulic device. Through a hydraulic cylinder device in a die, existence of pressure keeping loading force borne by a workpiece is controlled according to the design requirements, and therefore the cooling speed of each sub-area is controlled, and different types of material mechanical performance of the sub-areas of a tubular product is obtained. Required material characteristics can be achieved for any area according to the design requirements, no additional die heating device needs to be arranged, and production cost and procedure complexity are greatly reduced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Optimal waste heat utilization set for use at cold end of boiler of thermal power generating unit

InactiveCN104421956AIncrease temperatureRealize comprehensive utilizationCombustion processIndirect carbon-dioxide mitigationExpansion tankAir preheater

The invention discloses an optimal waste heat utilization set for use at the cold end of a boiler of a thermal power generating unit. An air-oil heat exchanger and a flue gas-oil heat exchanger are provided behind an air preheater; the air-oil heat exchanger is connected with the flue gas-oil heat exchanger through a circulating pipeline; the circulating pipeline is filled with heat transfer medium, heat transfer oil; the circulating pipeline is provided with an expansion tank and a circulating pump. One end of the flue gas-oil heat exchanger is connected with a flue gas outlet of the air preheater; the other end of the flue gas-oil heat exchanger is provided with another flue gas outlet. One end of the air-oil heat exchanger is connected with an air inlet of the air preheater; the other end of the air-oil heat exchanger is provided with another air inlet. The optimal waste heat utilization set has the advantages that smoke emission temperature can be greatly lowered, utilization of flue gas waste heat is achieved, load of the air preheater is reduced, thermal deformation and air leakage are reduced for the air preheater, and energy consumption of the thermal power generating unit is reduced.

Owner:JINAN HIPOWER TECH

Pressure cooling process of hot-formed steel pipe segment strengthening parts and press servo ejector device

ActiveCN103801605BControl heat transfer efficiencyModes of Controlling Collision FailuresShaping toolsPressesEngineeringProcess complexity

A pressure cooling technology for segmented and strengthened parts of a hot-formed steel pipe and press servo top rod devices are characterized in that through the independent press servo top rod devices, the magnitude of loading force applied on workpieces and / or the length of time of stress and pressure applied on the workpieces can be adjusted, the each sub-regional cooling speed of the workpieces can be controlled, so that the mechanical performances of different materials in each sub-regional of the workpieces can be obtained. By means of the pressure cooling technology for the segmented and strengthened parts of the hot-formed steel pipe and the press servo top rod devices, the needed material performance can be achieved in any region according to a requirement of a design, an extra die heating device is not needed to be arranged, and production cost and process complexity can be reduced greatly.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

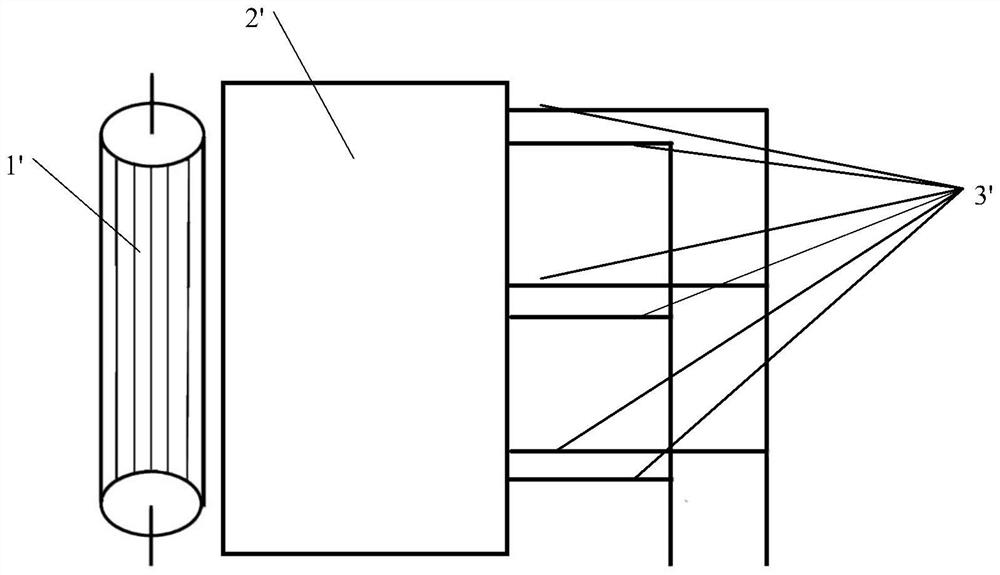

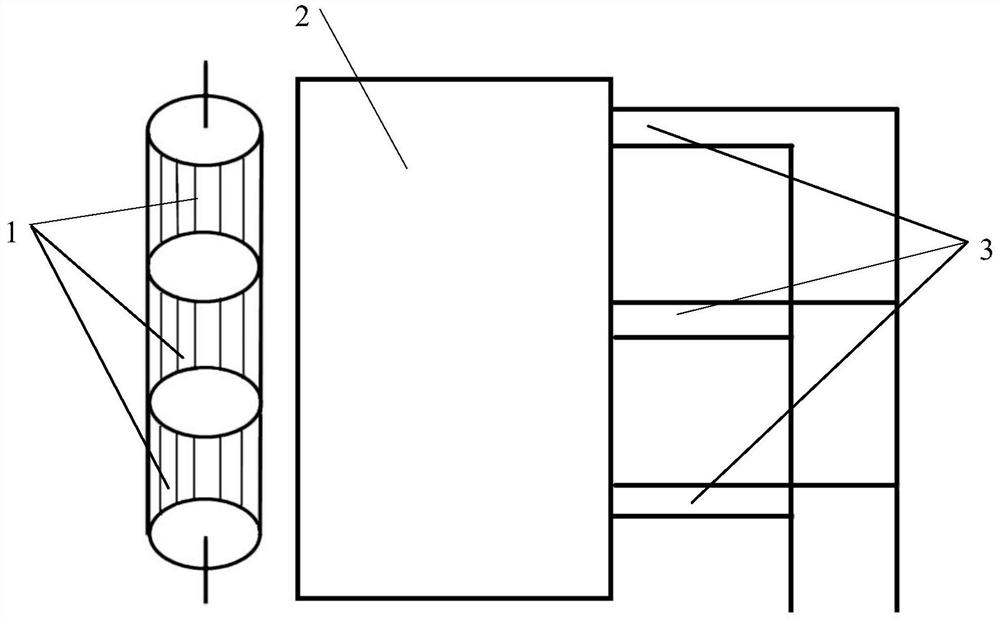

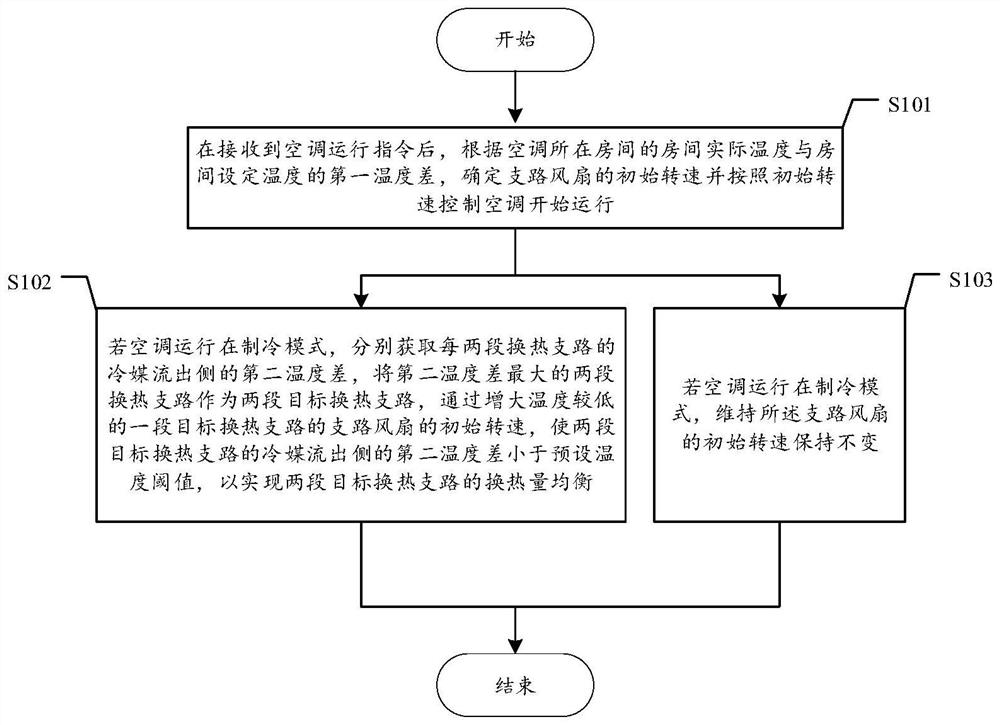

Control method, device and equipment for fan of air conditioner indoor heat exchanger and medium

PendingCN114811909AGuaranteed cooling effectWarranty or heating effectMechanical apparatusRefrigeration safety arrangementEngineeringRefrigeration

The invention relates to the technical field of air conditioners, in particular to a fan control method for an air conditioner indoor heat exchanger, and aims to solve the problems of non-uniform shunting of branches of an air conditioner, low utilization rate of an evaporator and serious resource waste. In order to achieve the purpose, the air conditioner indoor heat exchanger comprises a sectional type heat exchanger with multiple sections of heat exchange branches, and a first branch port and a second branch port of each section of heat exchange branch are connected with a first pipeline port and a second pipeline port of an air conditioner indoor refrigerant circulation pipeline correspondingly. The control method comprises the steps that after an air conditioner operation instruction is received, the initial rotating speed of the branch fans is determined according to the temperature difference between the actual room temperature and the set room temperature, and if the air conditioner operates in a refrigeration mode, the branch fans are started to rotate; if yes, the initial rotating speed of the branch fan of the lower section of heat exchange branch with the maximum temperature difference between the refrigerant outflow sides of every two sections of heat exchange branches is adjusted; and if the air conditioner operates in the heating mode, the initial rotating speed of the branch fan is kept unchanged.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

A multi-functional structure with heat-absorbing cooling and shock-absorbing effects

ActiveCN104455151BEffective temperature controlMeet cooling needsElastic dampersShock absorbersAbsorbed energyCooling effect

The invention discloses a multifunctional structure with the heat absorption cooling effect and the vibration reduction effect. The multifunctional structure comprises center frameworks made of high-elasticity high polymer materials and peripheral frameworks which surround the center frameworks in a connected mode and are made of high-elasticity high polymer materials. The center frameworks and every other peripheral framework are filled with flowing fillers with the heat absorption cooling effect. One or more small holes are formed in the side walls of the peripheral frameworks which are not filled with the fillers. The multifunctional structure further comprises high polymer material packaging layers for packaging the fillers. The peripheral frameworks which are not filled with the fillers are provided with or are not provided with the high polymer material packaging layers in a packaged mode. When the temperature of the environment where the multifunctional structure is located is higher than certain threshold temperature, the fillers start to absorb heat to achieve the cooling effect; after losing the heat absorption cooling effect, the fillers are placed into the environment with the temperature lower than the threshold temperature, and the cooling effect will be automatically recovered. Meanwhile, in the vibration process, the multifunctional structure is the equal of an elastic damper, and the vibration reduction effect is achieved by absorbing energy generated during vibration.

Owner:XI AN JIAOTONG UNIV

Boiler circulation heat conduction structure

InactiveCN109668138AImprove pressure bearing capacityControl burn timeSteam boilersCombustionEngineering

The invention provides a boiler circulation heat conduction structure. A heat gathering cavity, heat exchange pipes and a circulation pipe are included. The part, above a heating device, at the bottomof a boiler body is provided with the heat gathering cavity, and heat conduction media are arranged in an inner cavity of the heat gathering cavity. The heat gathering cavity communicates with at least one heat exchange pipe, the heat exchange pipes penetrate through the boiler body and communicate with the circulation pipe, and the circulation pipe communicates with the heat gathering cavity. The circulation pipe is provided with a circulation drive device. Through the arrangement of the structure of the heat gathering cavity, the structure of a double-layer water cavity in the prior art iseliminated, and the machining difficulty is lowered; by adoption of the common cylinder and circular-roof boiler structure, the pressure bearing capability of a boiler can be better improved, and themachining cost is greatly reduced. Through the arranged heat gathering cavity, flames of the heating device can be centralized at the bottom of the boiler body, and the fuel utilization rate is increased. In the preferable scheme, a circulation pump is arranged so that the heat exchange pipes can be rapidly utilized for conducting heat to water in the boiler body, and heat generated during combustion of the heating device is further sufficiently utilized.

Owner:刘文国

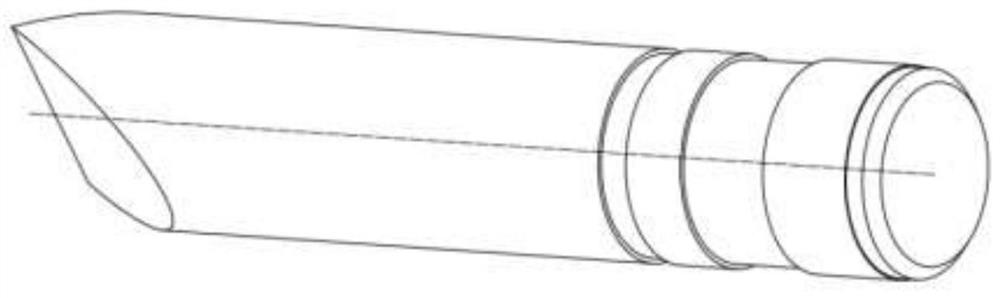

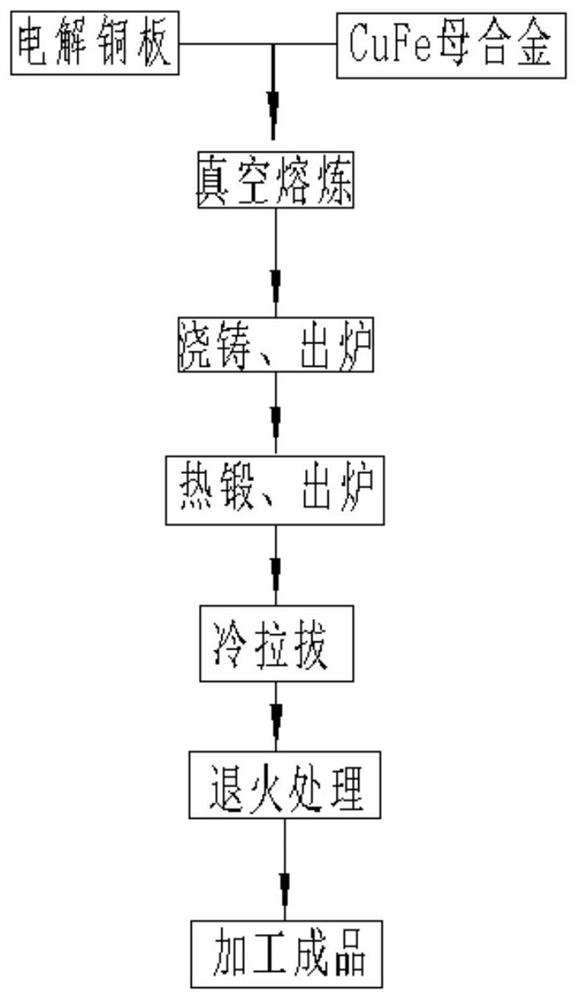

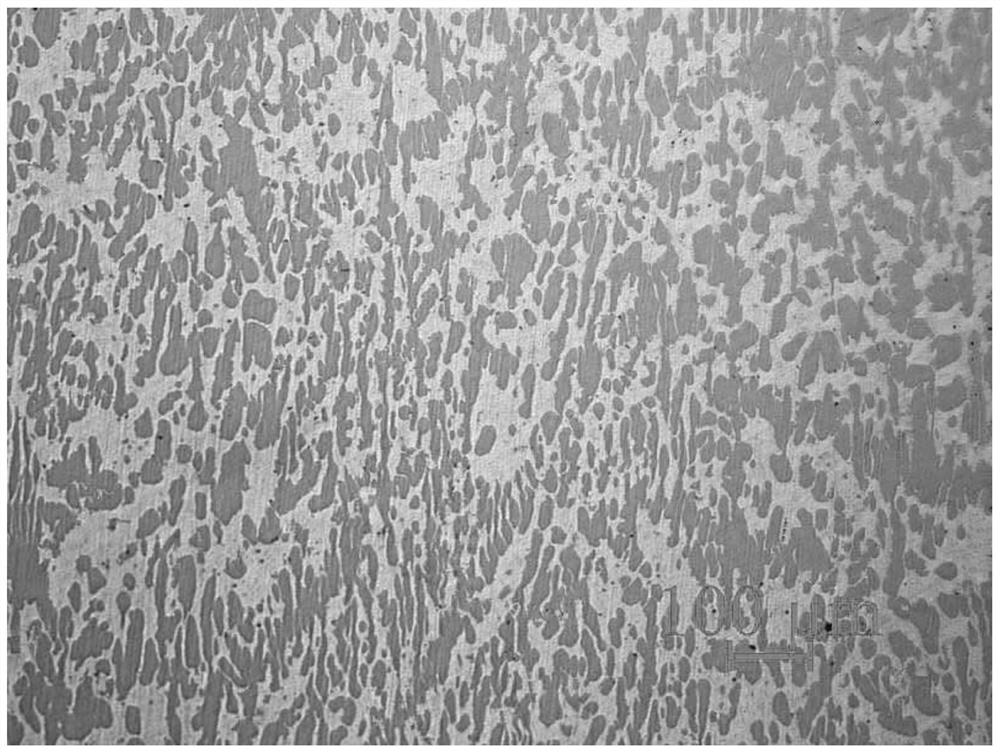

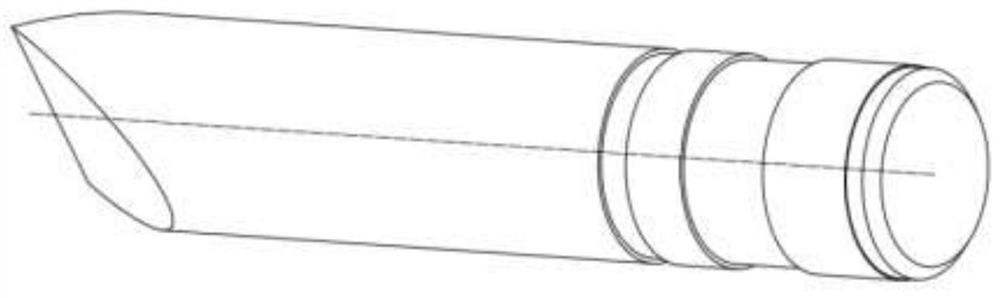

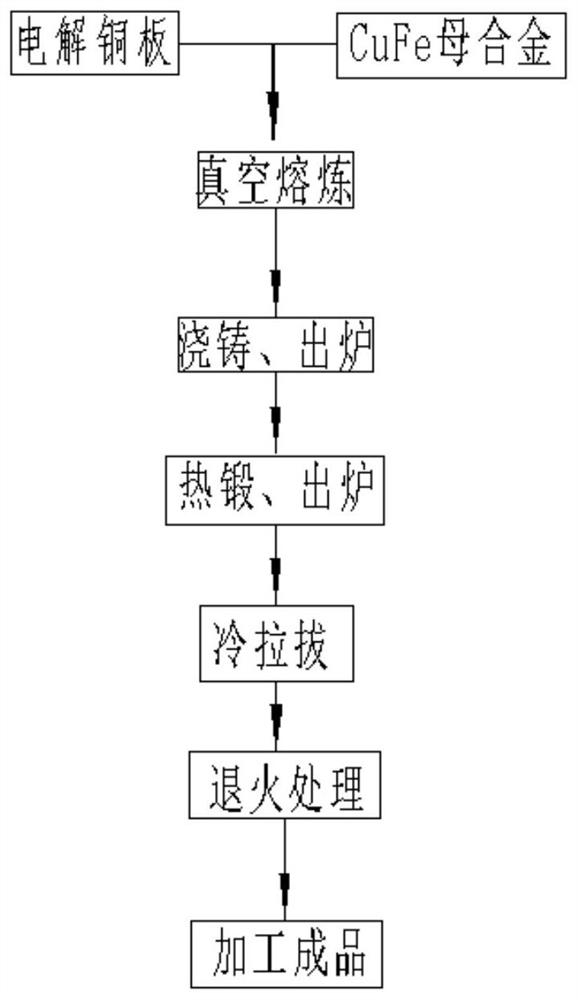

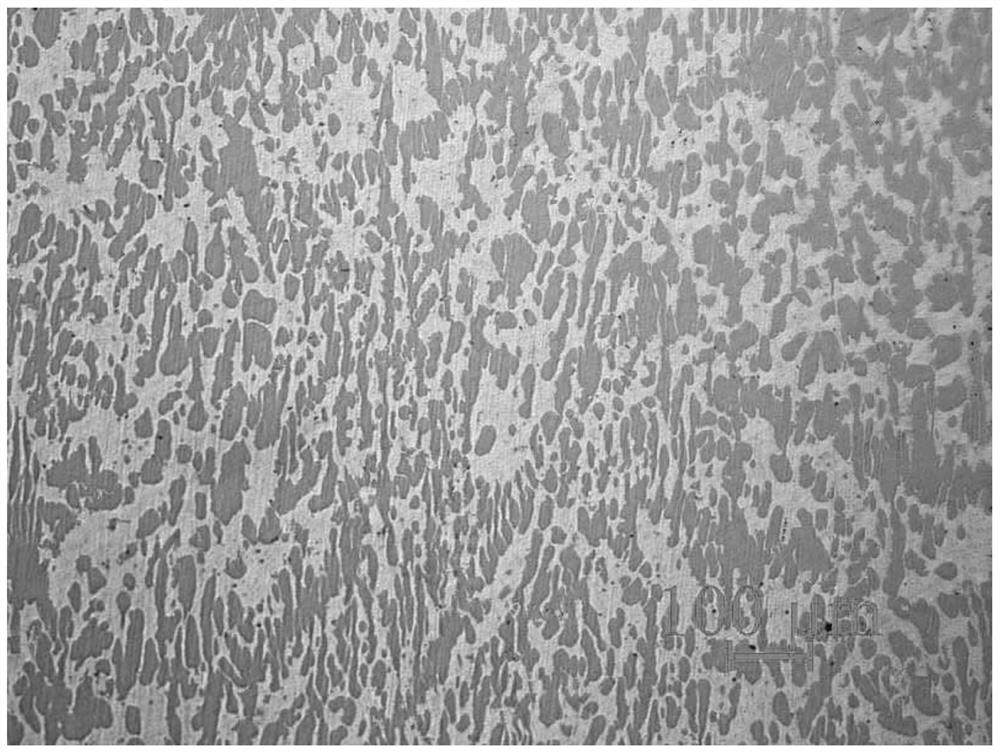

A preparation method of a long-life, low-cost soldering iron tip

The invention discloses a preparation method of a long-life and low-cost soldering iron tip, including S1: batching, S2: vacuum melting, S3: casting, S4: hot forging, turning the outer circle, S5: drawing and intermediate annealing, S6: Machining, the soldering iron tip prepared by the present invention is prepared by the CuFe alloy material, has long service life, strong corrosion resistance, low production cost, and can control the heat conduction of the soldering iron tip by adjusting the ratio of copper and iron content Efficiency, more widely used occasions.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

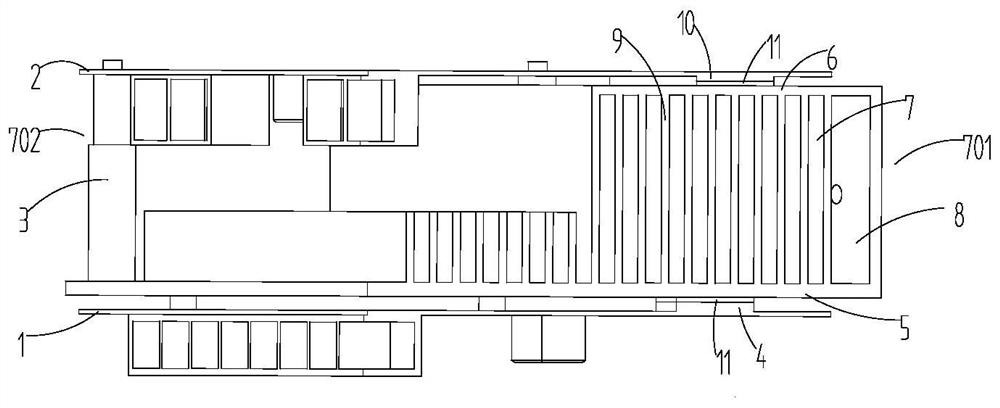

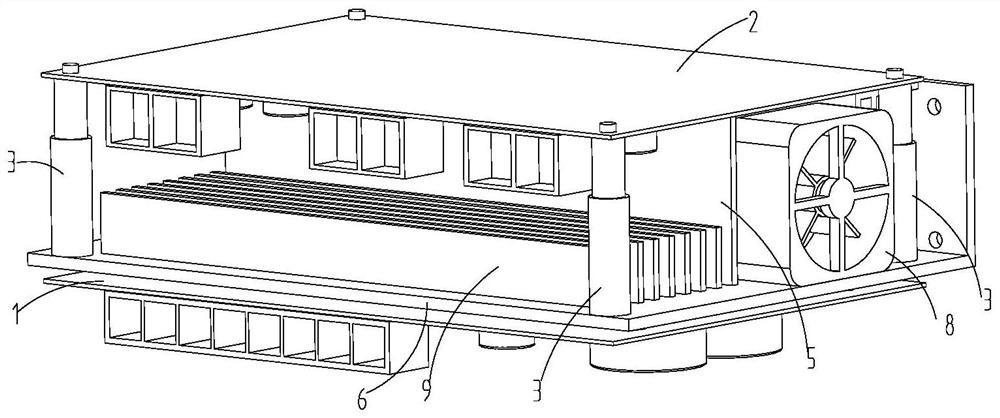

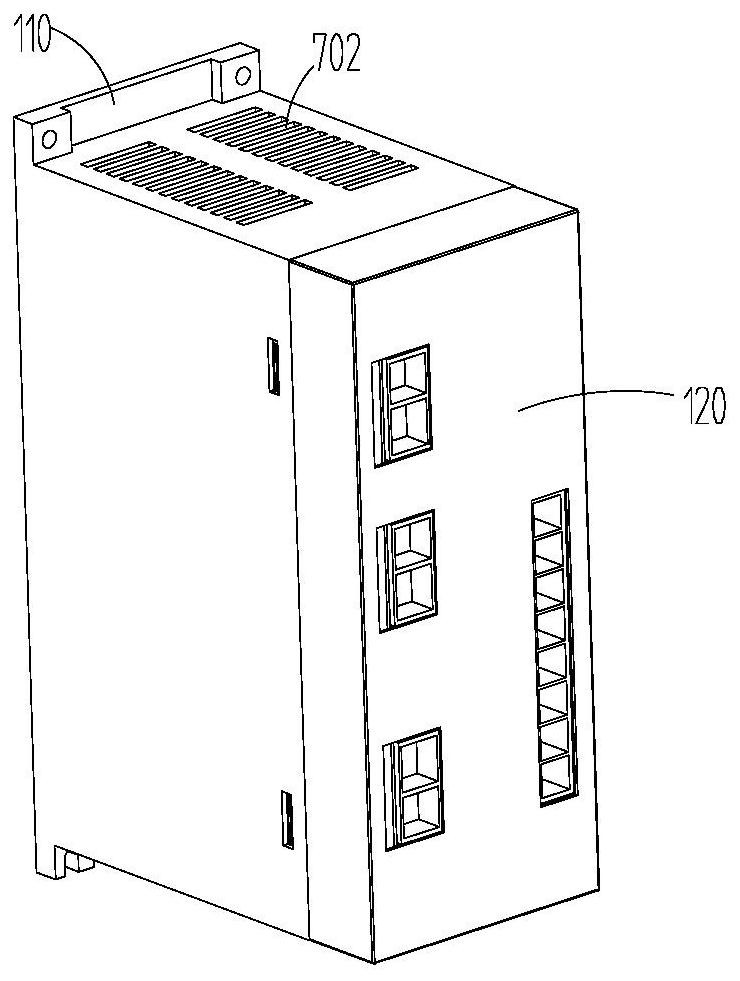

A driver, an electronic device and a control method for the driver

ActiveCN112165768BIncrease cooling spaceRealize self-balancing of working temperaturePrinted circuits structural associationsPrinted circuit non-printed electric components associationEngineeringHigh electron

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method of soldering bit with long service life and low cost

The invention discloses a preparation method of a soldering bit with long service life and low cost. The preparation method comprises the following steps of S1, material preparation, S2, vacuum melting, S3, casting, S4, hot forging, turning of an outer circle, S5, drawing and intermediate annealing, and S6, machining. According to the preparation method of the soldering bit with long service lifeand low cost, the soldering bit is prepared from a CuFe alloy material and has the advantages of being long in service life, high in corrosion resistance and low in production cost, the heat conduction efficiency of the soldering bit can be controlled by adjusting the proportion of the copper content to the iron content, and the application occasion is wider.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Pressure cooling process of hot-formed steel plate segment strengthening parts and press servo ejector device

ActiveCN103785733BControl heat transfer efficiencyControl cooling rateShaping toolsSheet steelEngineering

The invention discloses a pressure cooling process of segmented reinforcing type parts of a hot forming steel plate, and pressing machine servo ejector rod devices. Through the independent pressing machine servo ejector rod devices, the magnitude of loading force borne by a workpiece and / or force bearing and pressure keeping time for the workpiece are adjusted, and therefore the cooling speed of each sub-area of the workpiece is controlled, different types of material mechanical performance of the sub-areas of the workpiece are obtained. Required material characteristics can be achieved for any area according to the design requirements, no additional die heating device needs to be arranged, and production cost and procedure complexity are greatly reduced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

A thermal power plant combined heat pipe flue gas waste heat recovery device

ActiveCN111981880BTemperature controlChange temperatureCorrosion preventionIndirect heat exchangersTemperature controlFlue gas

The invention discloses a thermal power plant combined heat pipe flue gas waste heat recovery device, specifically relates to the field of waste heat recovery, including a mounting seat, a flue gas discharge bin and a waste heat recovery bin. One side of the discharge bin and the waste heat recovery bin are attached to each other, and a combined heat pipe is installed through the inside of the flue gas discharge bin and the waste heat recovery bin. , the surface of the threaded drive sleeve is movably socketed with a heat exchange sleeve assembly. The invention sets a new combined heat pipe structure, uses mechanical control components to actively change the volume of the heat transfer liquid flow inside the heat exchange pipe sleeve assembly, and changes the exposed length of the heat pipe end inside the waste heat recovery chamber, so as to realize the control of heat exchange efficiency and change the heat recovery air flow The temperature can achieve precise temperature control, facilitate the use of recovered heat energy, and improve the practicability of the waste heat recovery device.

Owner:HUAINAN TIANJIAAN POWER GENERATION PLANT ANHUI ELECTRIC POWER CO LTD

Online hot plate furnace hazardous waste co-processing device and using method

ActiveCN112728545AImprove quality and efficiencyImprove work efficiencyStationary tubular conduit assembliesSteam engine plantsCombustionProcess engineering

The invention belongs to the technical field of solid waste treatment, and particularly relates to an online hot plate furnace hazardous waste co-processing device which comprises a heat exchange device and further comprises a steam generation unit, a steam engine, a power conversion unit and a grinding unit, wherein one end of the heat exchange device is connected to a hot plate furnace, and the other end of the heat exchange device is connected to a decomposition furnace; pulverized coal is filled in the grinding unit; and one part of the pulverized coal processed by the grinding unit is fed into the hot plate furnace, and the other part of the pulverized coal is fed into the decomposition furnace. The invention further provides a using method of the device, the using method comprises the steps of collecting heat, generating steam, generating torque through a steam engine and the like. The heat released by reducing the temperature of combustion gas in the hot plate furnace is collected through the heat exchange device, pulverized coal is levigated, energy is fully utilized, cost is reduced, and the combustion quality of the online hot plate furnace is improved.

Owner:蓝天众成环保工程有限公司 +1

A resin production dehydration device

The invention discloses a dehydration device for resin production, which belongs to the technical field of resin solid raw material dehydration, and comprises a dehydration kettle body. The outer wall of the inner kettle body is fixedly connected with a jacket heat exchange mechanism. In the present invention, the inflatable tube sends gas into the inflatable airbag so that the inflatable airbag expands and pushes the abutting arc-shaped block to move upward, and the upward movement of the abutting arc-shaped block can pull the hinge block to rotate around one end of the first connecting rod to drive the top flexible deployment cover upward. Expansion and expansion can adjust the distance between the flexible expansion cover and the internal resin raw material liquid surface of the inner kettle body, so as to prevent the resin material from splashing and adhering in the flexible expansion cover and affecting the exhaust effect. At the same time, when the flexible expansion cover expands and shrinks, it can The change of the space of the kettle body adjusts the pressure of the inner kettle body, effectively controls the pressure in the drying kettle during drying and heating, and meets the needs of the regulation and treatment of heating and drying.

Owner:山东永创材料科技有限公司

Pressure cooling process and mold servo device for hot-formed steel plate segmentally strengthened parts

ActiveCN103817194BControl heat transfer efficiencyModes of Controlling Collision FailuresShaping toolsPressesPunchingControl theory

Disclosed are a pressure cooling process for thermally-formed steel plate sectionally-strengthen-type parts and a die servo device in the field of thermal-forming punching. Through a servo cylinder device in a die, strength and time of pressure-maintaining loading force applied on different regions of a workpiece are controlled according to design needs to control cooling speed of each sub-region so as to acquire different physical characteristics of all sub-regions of a plate. By the pressure cooling process and the die servo device, needed material characteristics can be realized at any region according to the design needs without additionally arranging a die heating device, so that production cost and process complexity are lowered remarkably.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

On-line hot plate furnace co-processing device and method for co-processing hazardous waste

ActiveCN112728545BImprove quality and efficiencyImprove work efficiencyStationary tubular conduit assembliesSteam engine plantsCombustionProcess engineering

The invention belongs to the technical field of solid waste treatment, and in particular relates to an on-line hot plate furnace for co-processing hazardous wastes, including a heat exchange device, one end of the heat exchange device is connected to the hot plate furnace, the other end is connected to a decomposition furnace, and also includes steam A generating unit, a steam engine, a power conversion unit and an abrasive unit, the abrasive unit is equipped with pulverized coal, part of the pulverized coal processed by the abrasive unit is sent to the hot plate furnace, and the other part of the pulverized coal is sent to the decomposition furnace. The invention also provides a method for using the device, which includes steps of heat collection, steam generation, and torque generation by the steam engine. The method of the invention collects the heat released by reducing the temperature of the combustion gas in the hot plate furnace through the heat exchange device. , the pulverized coal is ground and processed, the method makes full use of energy, saves costs, and improves the combustion quality of the on-line hot plate furnace.

Owner:蓝天众成环保工程有限公司 +1

Pressure cooling process and mold servo device for hot-formed steel pipe segment strengthening parts

InactiveCN103785761BControl heat transfer efficiencyModes of Controlling Collision FailuresShaping toolsPressesProcess engineeringPipe

The invention discloses a pressure cooling process of segmented reinforcing type parts of a hot forming steel pipe, and a die servo device. Through a servo cylinder device in a die, the magnitude of pressure keeping loading force borne by a workpiece and time for bearing the pressure keeping loading force by the workpiece are controlled according to the design requirements, and therefore the cooling speed of each sub-area is controlled, and the different physical properties of the sub-areas of a tubular product are obtained. Required material characteristics can be achieved for any area according to the design requirements, no additional die heating device needs to be arranged, and production cost and procedure complexity are greatly reduced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Pressure cooling process of hot-formed steel plate section strengthened parts and press hydraulic ejector device

ActiveCN103817193BControl heat transfer efficiencyControl cooling rateShaping toolsPressesPunchingSheet steel

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Energy-gathering heat conduction boiler

PendingCN107654991AImprove pressure bearing capacityControl burn timeBoiler controlSteam boilersEngineeringHeat transfer tube

The invention provides an energy-gathering heat-conducting boiler, which includes a boiler body, a heat collecting cavity is provided at the bottom of the boiler body and above the heating device, and a heat-conducting medium is arranged in the cavity inside the heat collecting cavity; the heat collecting cavity is connected with at least one The heat exchange tube is connected, the heat exchange tube passes through the boiler body and communicates with the circulation pipe, and the circulation pipe communicates with the heat collecting chamber. The heat collecting chamber is composed of a plurality of ring-shaped or spiral metal tubes, the top of the heat collecting chamber is the bottom of the boiler body, and the bottom of the heat collecting chamber is open. Through the structure of the heat collecting chamber, the structure of the double-layer water chamber in the prior art is canceled, which reduces the difficulty of processing, and adopts the commonly used boiler structure with a columnar shape and a round top, which is also conducive to increasing the pressure bearing capacity of the boiler. , and also greatly reduce the processing cost. The set heat collecting chamber can make the flame of the heating device be concentrated at the bottom of the boiler body, thereby increasing the utilization rate of the fuel.

Owner:刘文国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com