Boiler circulation heat conduction structure

A heat-conducting structure and boiler technology, applied in steam boilers, lighting and heating equipment, steam generation, etc., can solve the problems of insufficient combustion waste heat recovery of burners, large boiler heat loss, and difficult boiler processing, etc., to reduce processing costs , increase the utilization rate, reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

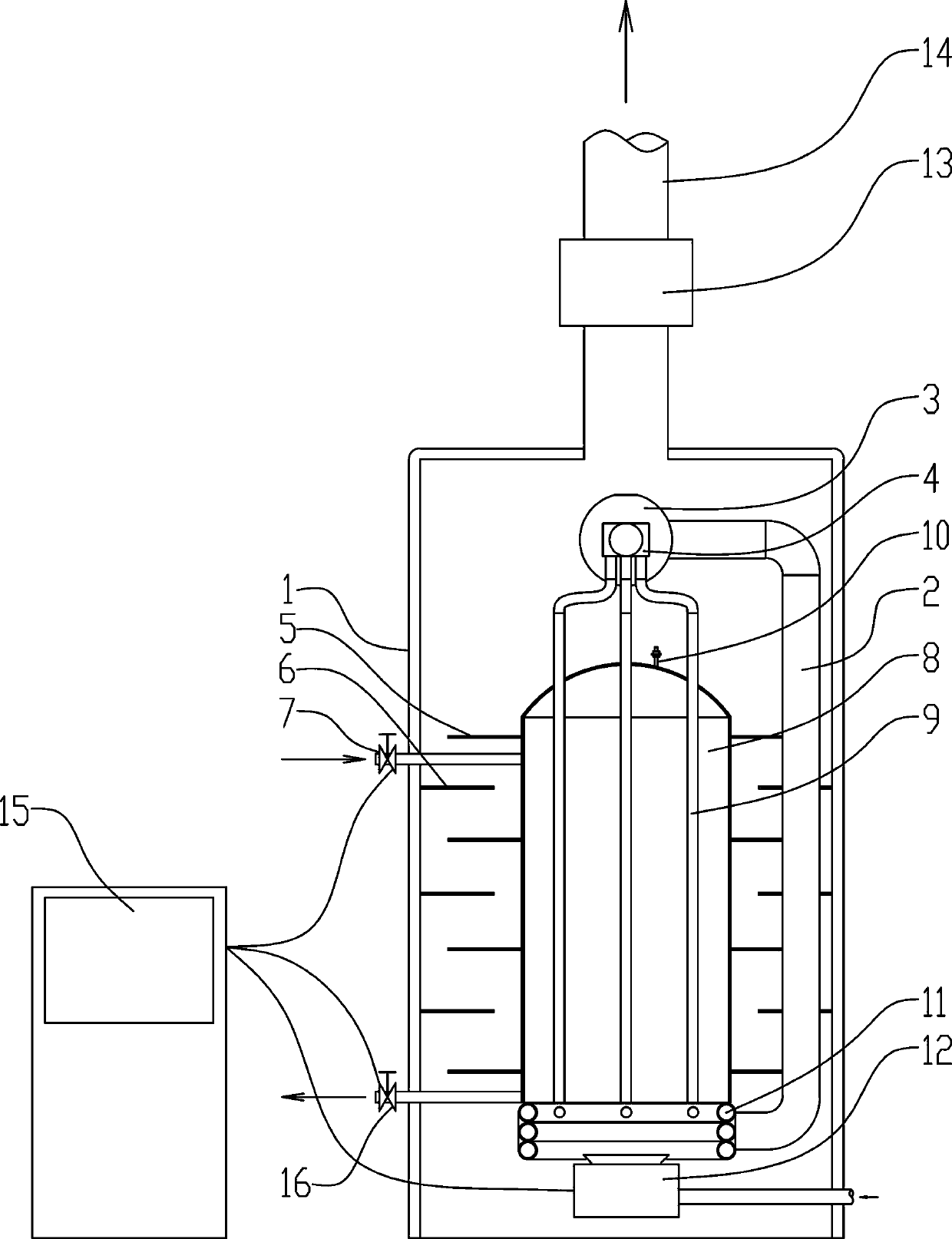

[0014] Such as figure 1 Among them, a boiler circulation heat conduction structure, including a heat collection chamber 11, a heat exchange tube 9 and a circulation pipe 2; at the bottom of the boiler body 8, above the heating device 12, a heat collection chamber 11 is provided, and the inner cavity of the heat collection chamber 11 The body is provided with a heat conducting medium; the heat collecting chamber 11 communicates with at least one heat exchange tube 9, the heat exchange tube 9 passes through the boiler body 8 and communicates with the circulation pipe 2, and the circulation pipe 2 communicates with the heat collection chamber 11, and the circulation pipe 2 is provided with There is a circular drive. With this structure, the heating device 12 heats the heat conducting medium in the heat collecting chamber 11 while heating the bottom of the boiler body 8 , and the flow of the heat conducting medium transfers heat to the water. In this example, the heating device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com