Optimal waste heat utilization set for use at cold end of boiler of thermal power generating unit

A technology of thermal power units and boilers, applied in lighting and heating equipment, indirect carbon dioxide emission reduction, combustion methods, etc., can solve the problems of small power generation contribution of units, increase of heat transfer area, large loss of useful energy, etc., and achieve the reduction of exhaust gas temperature , Increase the air temperature and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

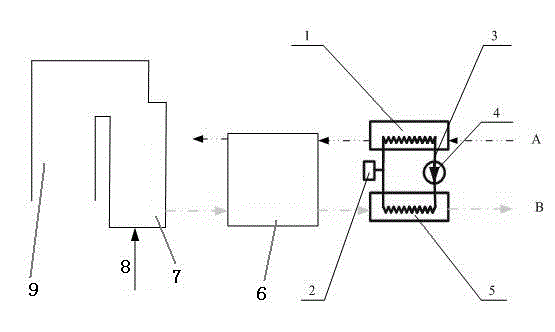

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

[0020] Thermal power unit boiler cold end optimized waste heat utilization device, after the air preheater 6, there are air-oil heat exchanger 1 and flue gas-oil heat exchanger 5, air-oil heat exchanger 1 and flue gas-oil heat exchanger The devices 5 are connected by a circulation pipeline 3, the circulation pipeline is filled with heat transfer medium and heat transfer oil, and the circulation pipeline is provided with an expansion tank 2 and a circulation pump 4; one end of the flue gas-oil heat exchanger 5 is preheated with the air One end of the air-oil heat exchanger 1 is connected to the air inlet of the air preheater, and the other end is provided with an air inlet A.

[0021] The shells of the air-oil heat exchanger 1 and the flue gas-oil heat exchanger 5 are provided with heat exchange tube bundles for accommodating heat-conducting oil. Air or flue gas runs outside the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com