Pressure cooling technology for segmented and strengthened parts of hot-formed steel pipe and press servo top rod devices

A segmented strengthening and hot forming technology, applied in the field of high-strength steel stamping, can solve problems such as complex structure, achieve the effect of unifying processing technology, protecting human safety, and simplifying requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

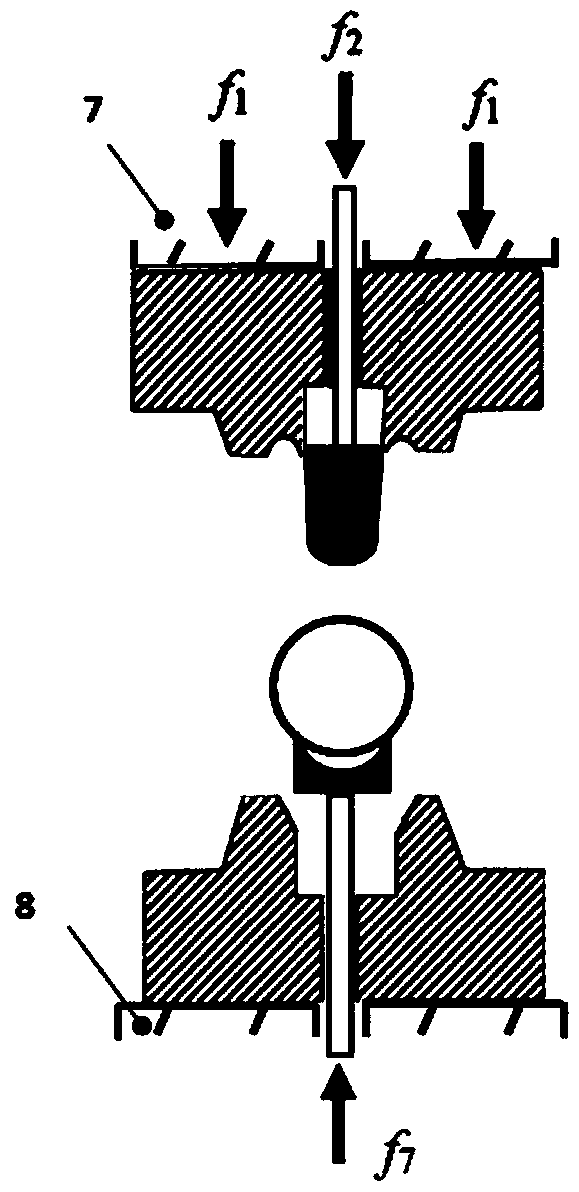

[0063] like Figure 3-Figure 5 As shown, the workpiece is 1.8mm thick, 80mm in diameter, 1000mm in length, and the schematic diagram of the cross-section forming and quenching of the hot-formed boron steel pipe workpiece. The workpiece product requirement is f 6 The corresponding product area is HS400 soft area, and the rest are hard area HS1150. A schematic diagram of the specific preparation process of this method, wherein:

[0064] figure 1 in the original state, according to figure 1 It can be seen that the device for realizing this method includes: an upper die 1, a lower die 2, a servo ejector pin 3 on the press, a lower servo ejector pin 4, an upper molding material core 5, a lower molding material core 6, and an upper sliding block 7 on the press , Press lower table 8, die mandrel 9.

[0065] The upper die 1 covers the product hard area HS1150, and the material is high-quality die steel SKD61;

[0066] The upper molding material core 5 covers the product soft are...

Embodiment 2

[0078] like Figure 3-Figure 5 As shown, the workpiece is 1.8mm thick, 80mm in diameter and 1000mm in length, the schematic diagram of cross-section forming and quenching of hot-formed boron steel workpiece. The workpiece product requirement is f 6 The corresponding product area is HS400 soft area, f 8 The area is the soft area HS700, and the rest of the product area is the hard area HS1150.

[0079] This method realizes the device such as figure 1 shown, where:

[0080] The upper die 1 covers all areas of the product hard zone HS1150, and the material is high-quality die steel SKD61;

[0081] The upper molding material core 5 covers all areas of the product soft area HS400, and the material is high-quality mold steel SKD61;

[0082] The lower molding material core 6 covers all areas of the product soft area HS700, and the material is high-quality mold steel SKD61;

[0083] The lower die 2 covers all areas of the product hard zone HS1150, and the material is high-quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com