Energy-gathering heat conduction boiler

A kind of energy-gathering and boiler technology, applied in steam boilers, lighting and heating equipment, control systems, etc., can solve the problems of insufficient combustion waste heat recovery of burners, difficult boiler processing, and large boiler heat loss, etc., to reduce processing costs , Reduce processing difficulty, increase the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

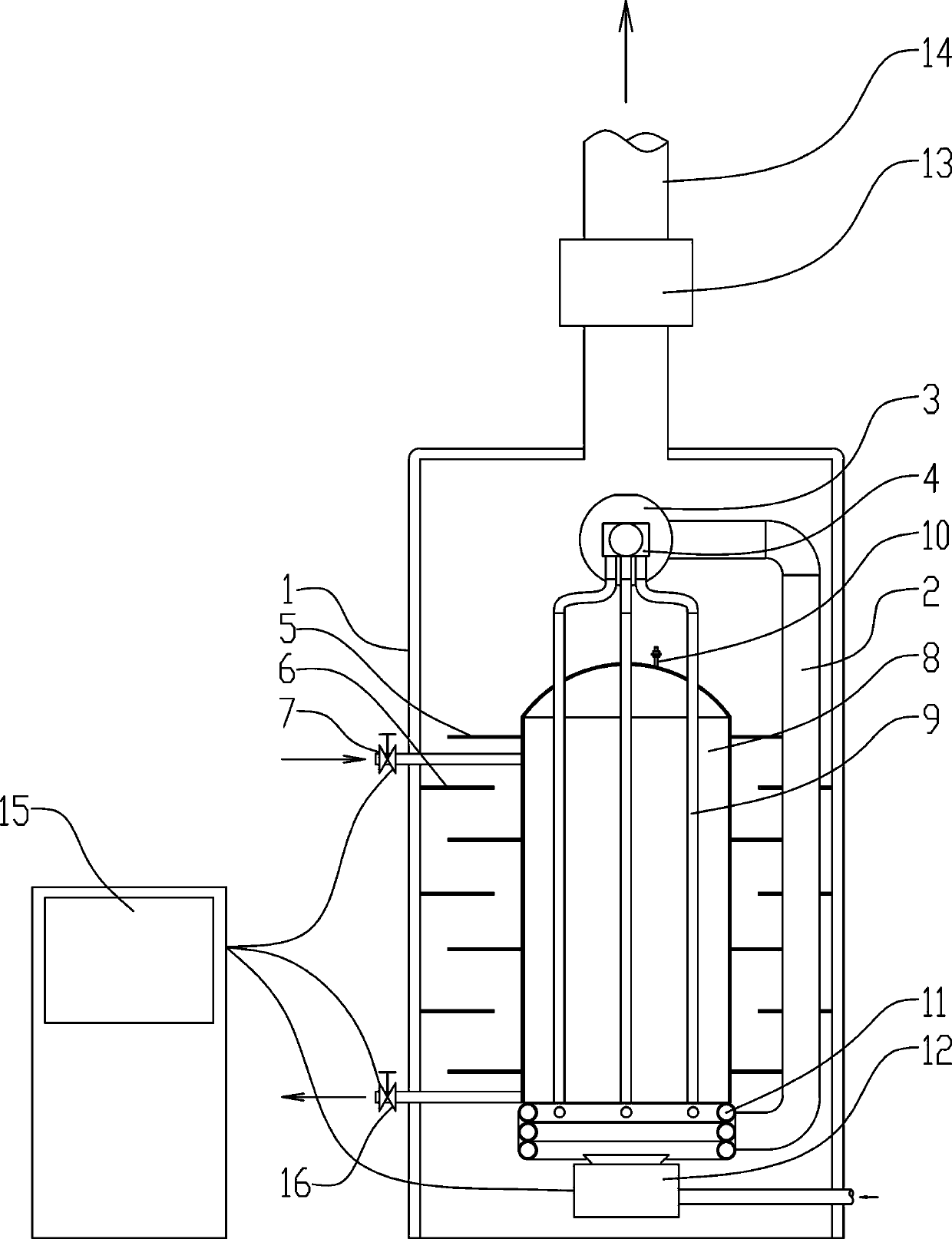

[0024] Such as figure 1 Among them, an energy-concentrating heat-conducting boiler includes a boiler body 8, at the bottom of the boiler body 8, above the heating device 12, a heat collecting cavity 11 is provided, and a heat-conducting medium is arranged in the inner cavity of the heat collecting cavity 11;

[0025] The heat collecting chamber 11 communicates with at least one heat exchange tube 9 , and the heat exchange tube 9 passes through the boiler body 8 and communicates with at least one circulation pipe 2 , and the circulation pipe 2 communicates with the heat collection chamber 11 . With this structure, the heating device 12 heats the heat conducting medium in the heat collecting chamber 11 while heating the bottom of the boiler body 8 , and the flow of the heat conducting medium transfers heat to the water. In this example, multiple heat exchange tubes 9 and circulation tubes 2 are preferably used. In this example, the heating device 12 adopts a gasification diesel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com