Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Consistent extrusion speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester flax-like type different shrinkage composite yarn and preparation method thereof

ActiveCN108130624ASimple preparation processImprove fluffinessMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnPolyester

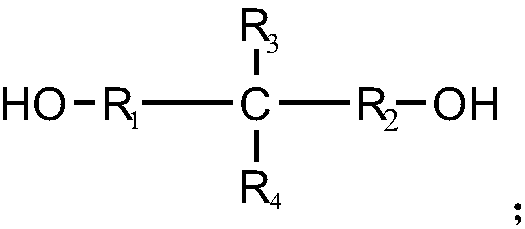

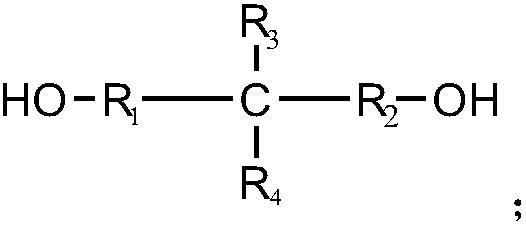

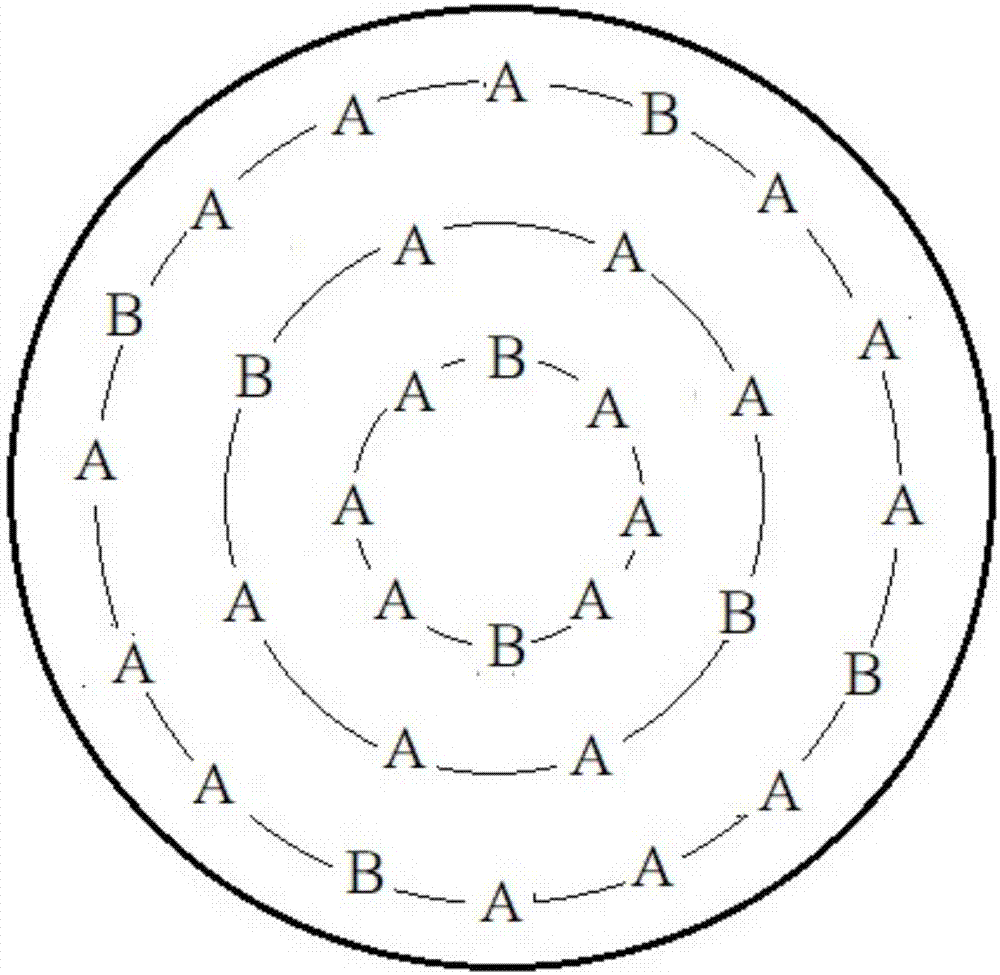

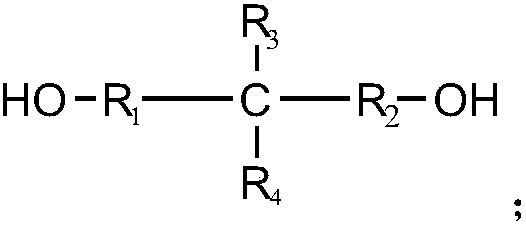

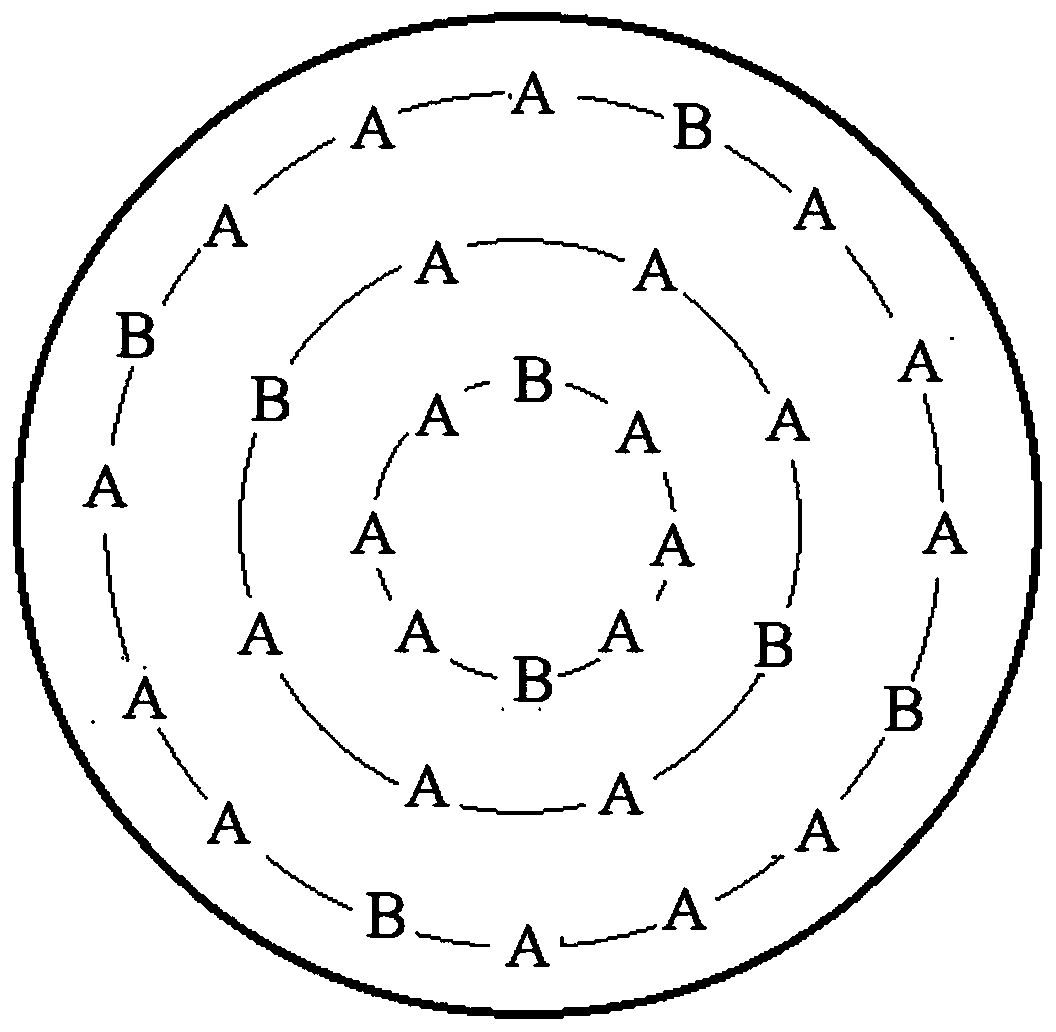

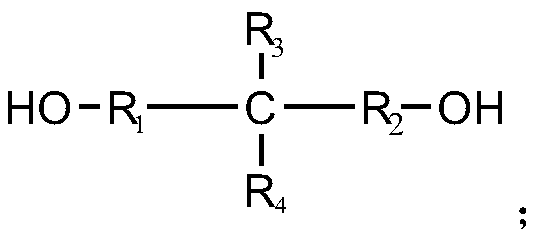

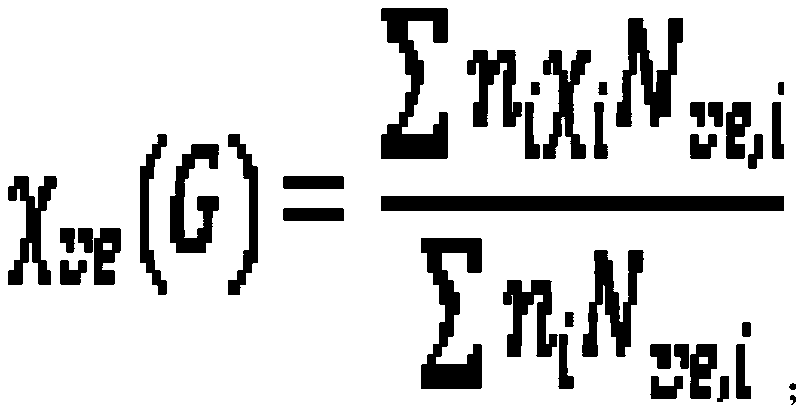

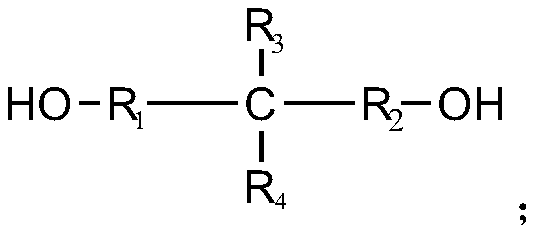

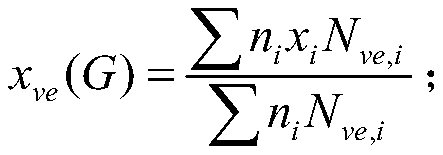

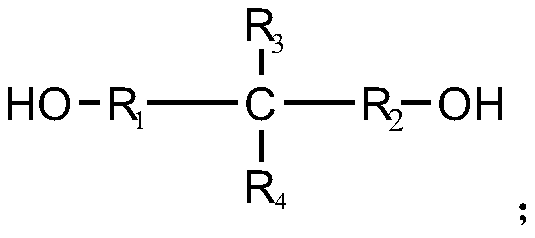

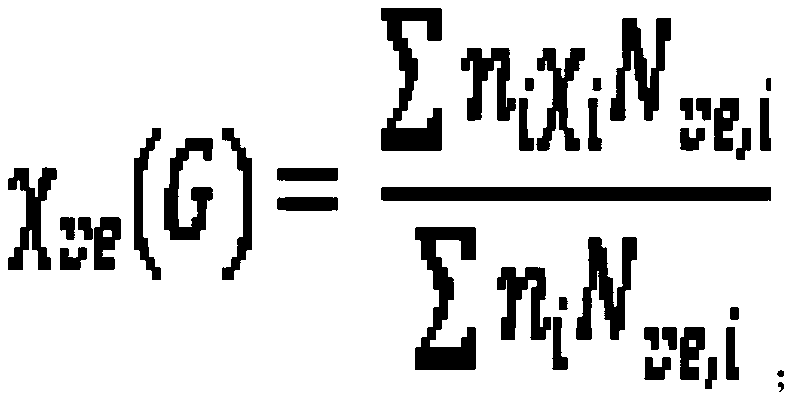

The invention relates to a polyester flax-like type different shrinkage composite yarn and a preparation method thereof. Firstly, a modified polyester yarn POY and a modified polyester yarn FDY are prepared respectively, then the modified polyester yarn POY and the modified polyester yarn FDY are compounded to prepare the polyester flax-like type different shrinkage composite yarn; the chromatic aberration [delta]E of the prepared polyester flax-like type different shrinkage composite yarn is less than 0.200; a bundle of the yarn POY or FDY extruded by a same spinneret plate contains a singleyarn shaped in a Chinese character 'wang' manner and a five-leaf single yarn; a molecular chain of modified polyester consists of a diol chain segment with a branched chain, and diol with the branchedchain has the structural formula defined in the specification, wherein R1 and R2 are straight-chain alkylene with the carbon atom number of 1-3 , R3 is alkyl with the carbon atom number of 1-5, and R4 is alkyl with the carbon atom number of 2-5. The method is simple and reasonable, and the prepared composite yarn has good fluffy property and moisture absorption and perspiration elimination properties.

Owner:JIANGSU HENGLI CHEM FIBER

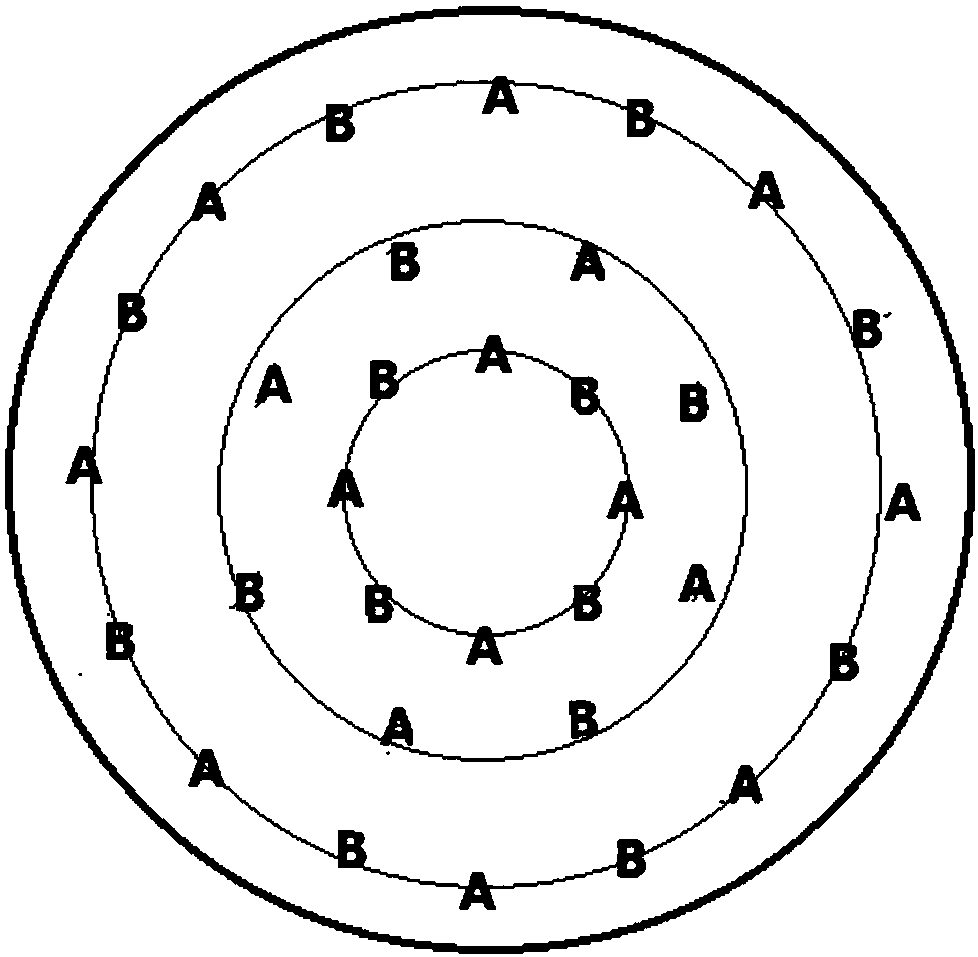

Polyester wool-like different-shrinkage composite wire and preparing method thereof

ActiveCN108130605AConsistent extrusion speedGood moisture wickingArtificial filament heat treatmentMelt spinning methodsPolyesterAlcohol

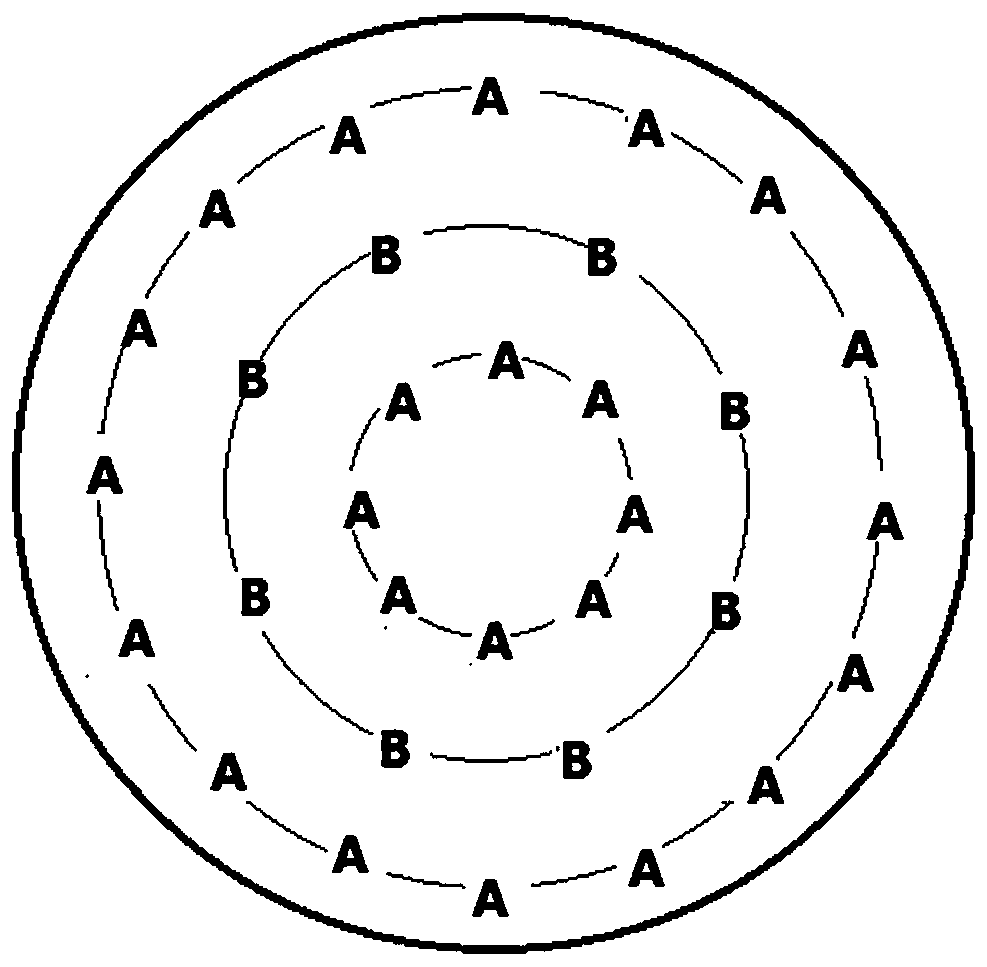

The invention relates to a polyester wool-like different-shrinkage composite wire and a preparing method thereof. The method comprises the steps of firstly, modified polyester POY and FDY wires are produced separately; then, the POY and FDY wires are compounded to produce the polyester wool-like different-shrinkage composite wire, wherein the chromatic aberration delta E of the produced compositewire is smaller than 0.200. A bunchof POY or FDY wires extruded through the same spinneret plate contain double-cross single wires and trilobal single wires simultaneously, a modified polyestermolecular chain contains a dihydric alcohol chain section with a branch chain, and the structural formula of the dihydric alcohol chain section with the branch chain is shown in the description, wherein R1 and R2 are straight chain alkylidenes of which the number of carbon atoms is 1-3, R3 is an alkyl of which the number of carbon atoms is 1-5, R4 is an alkyl of which the number of carbon atoms is 2-5, and a matt agent in modified polyester is a mixture of amorphous titanium dioxide and amorphous silicon dioxide or calcium carbonate and amorphous silicon dioxide. The preparing method is simple and reasonable, and the prepared composite wire has good fluffy and hygroscopic and sweat releasingperformance.

Owner:JIANGSU HENGLI CHEM FIBER

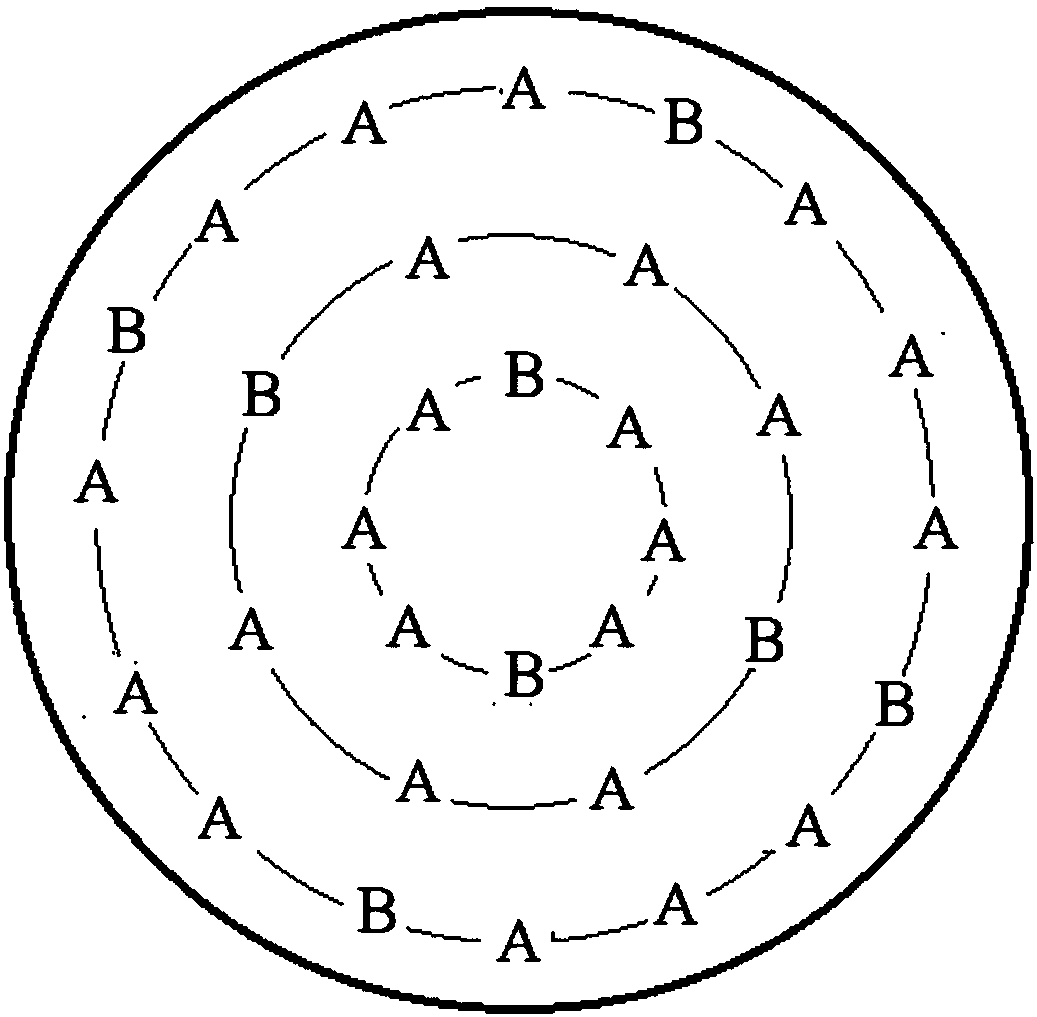

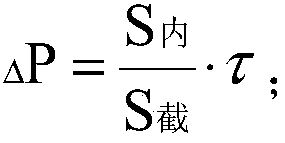

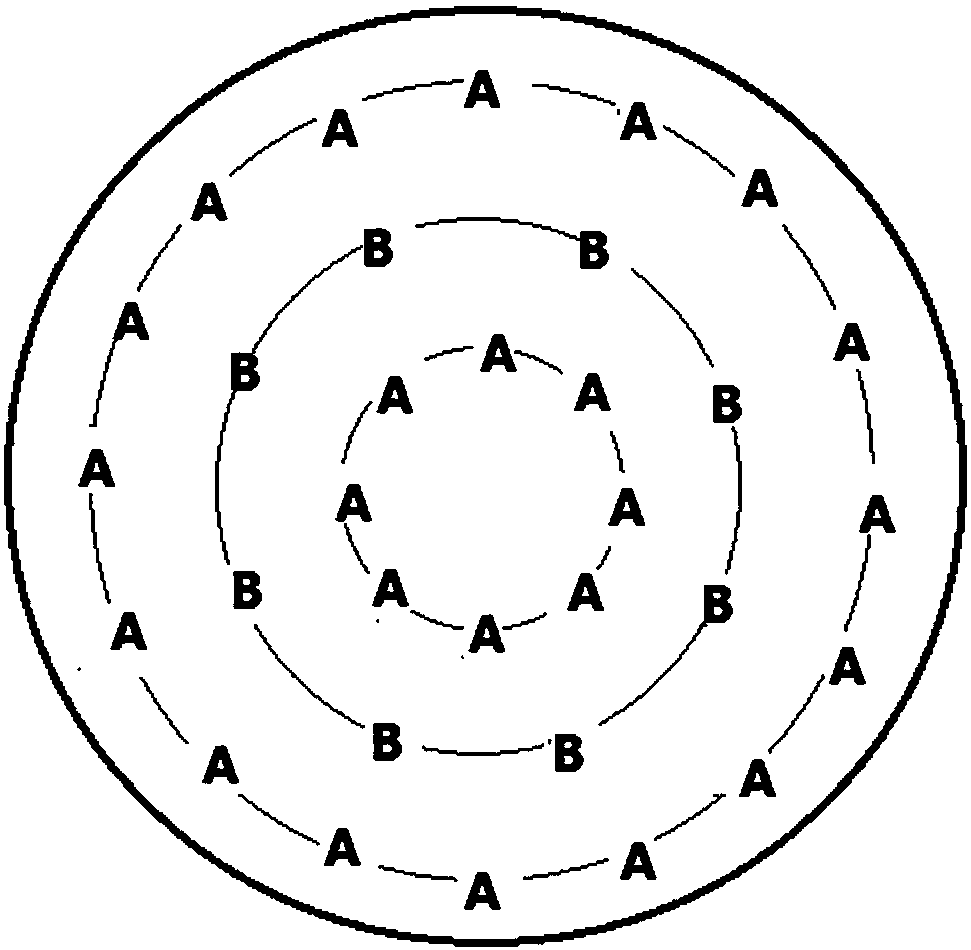

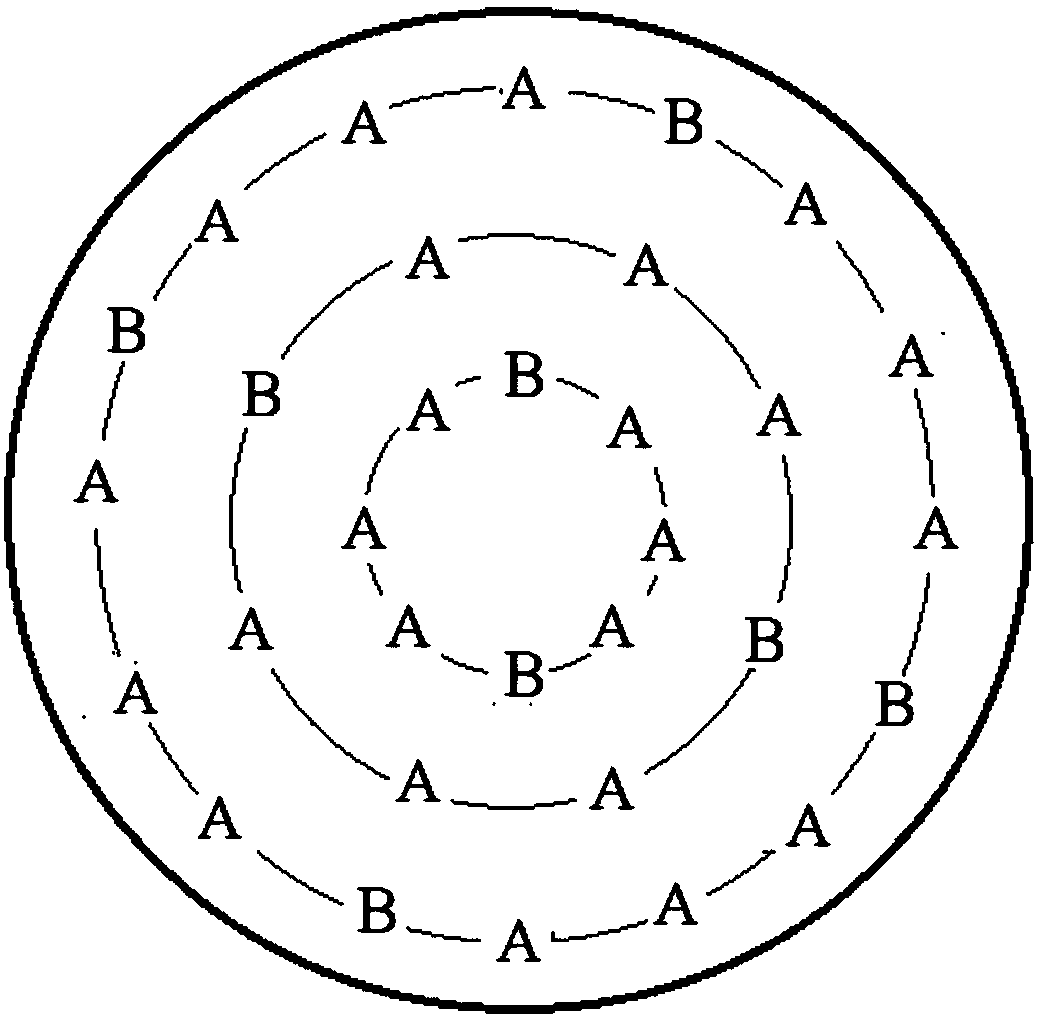

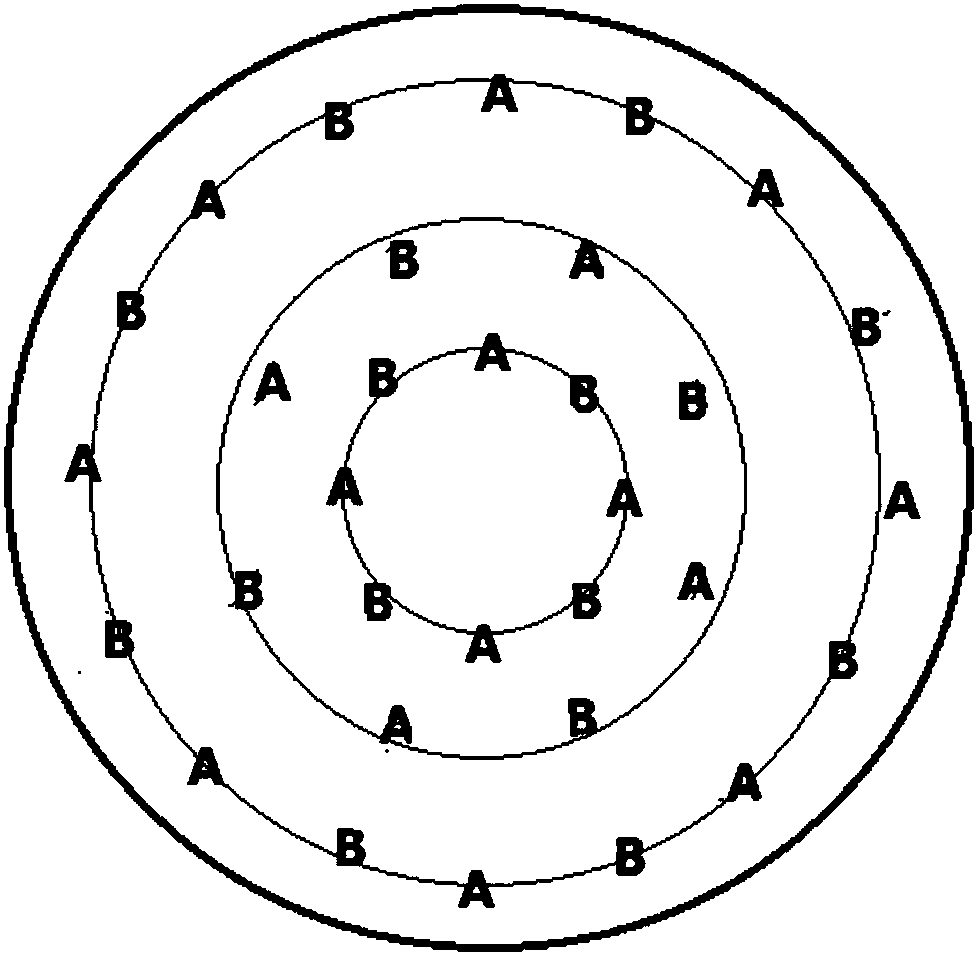

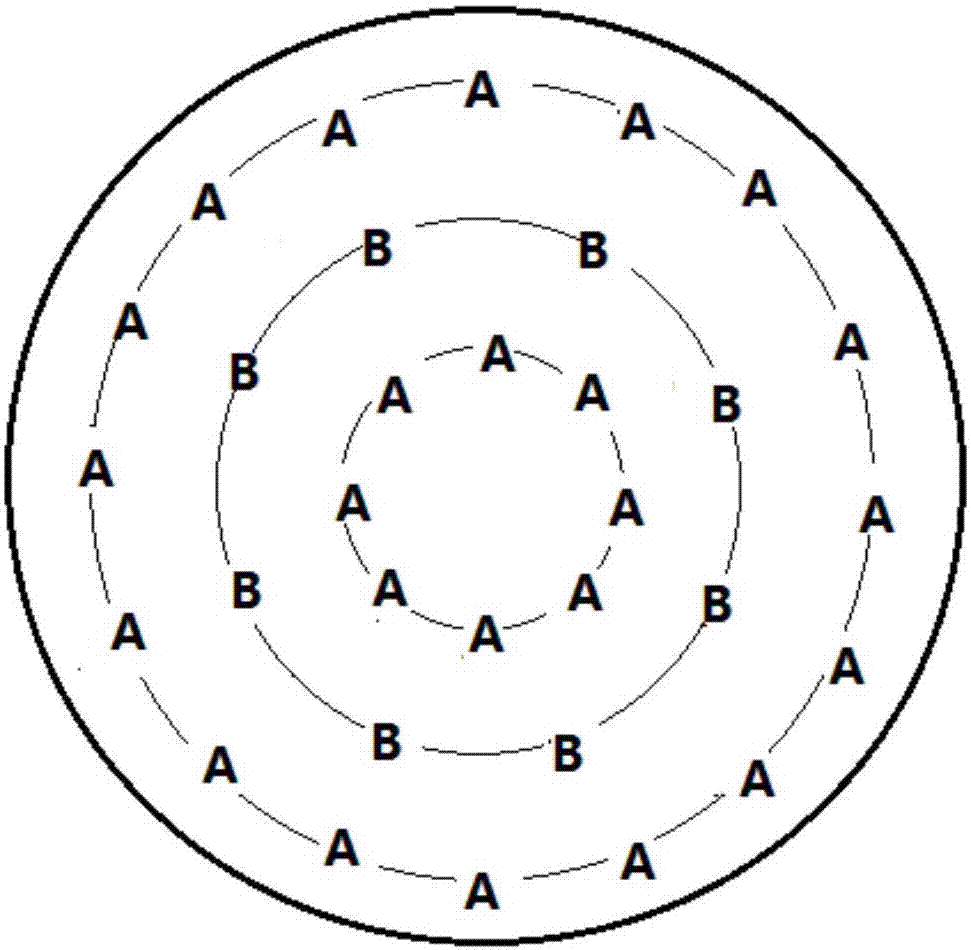

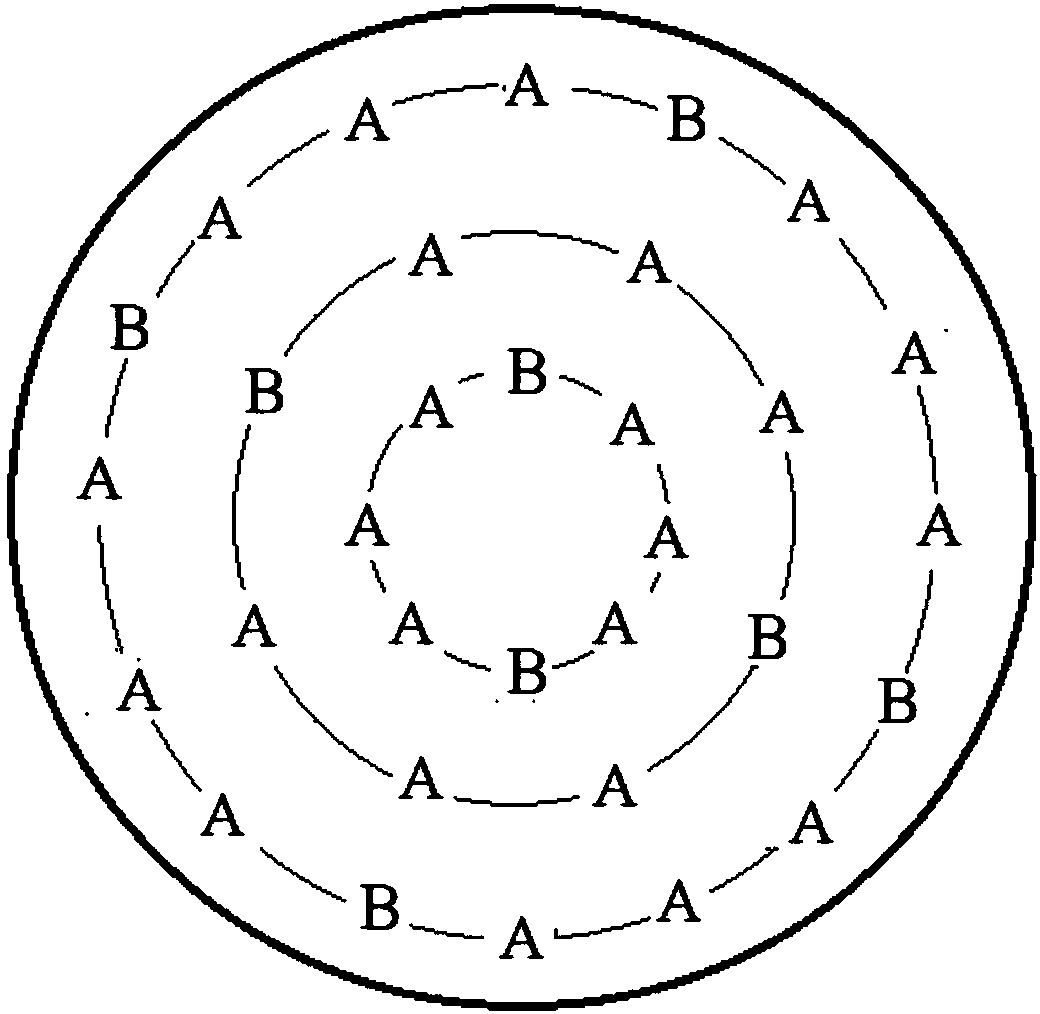

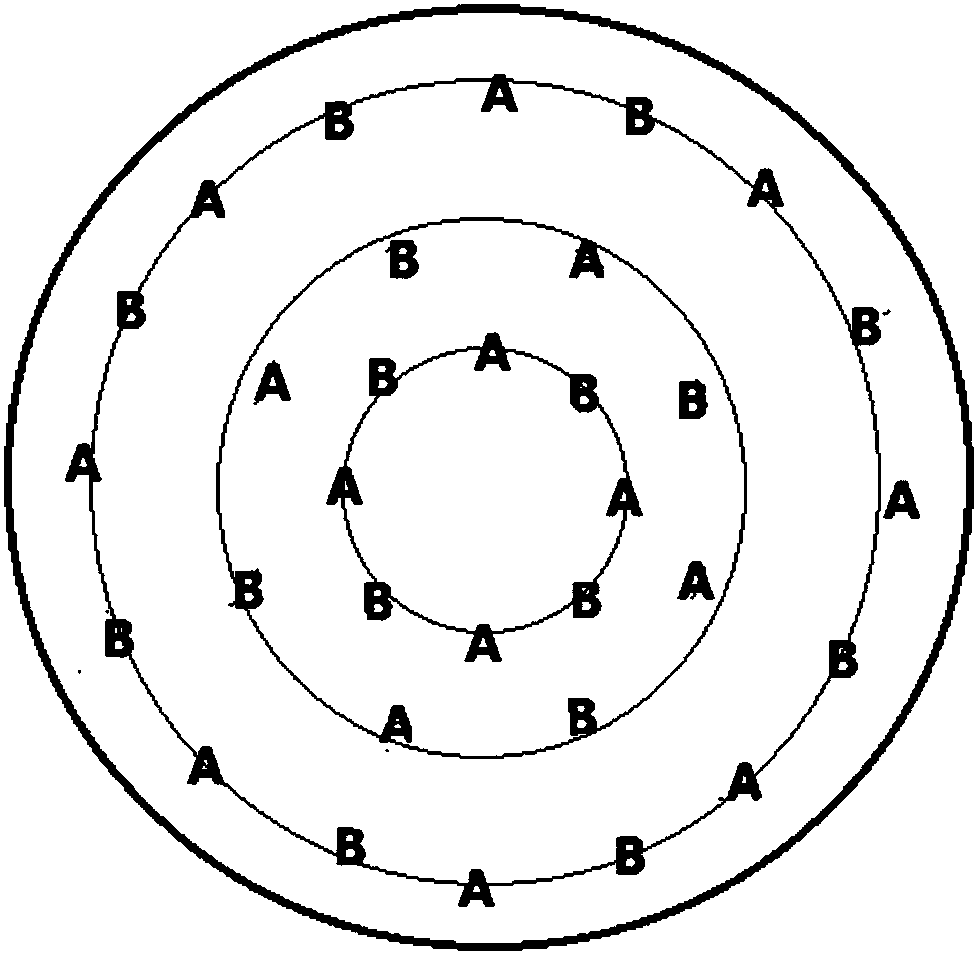

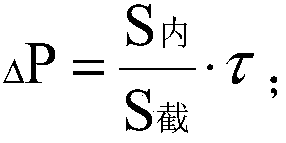

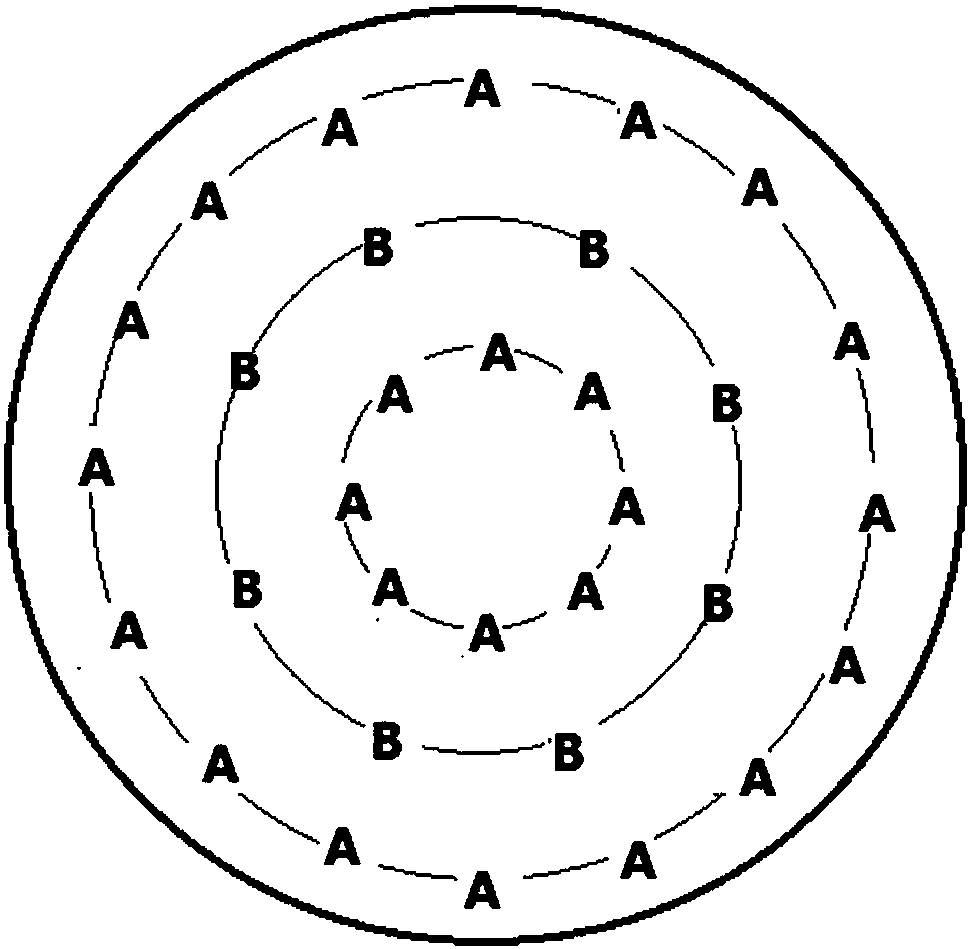

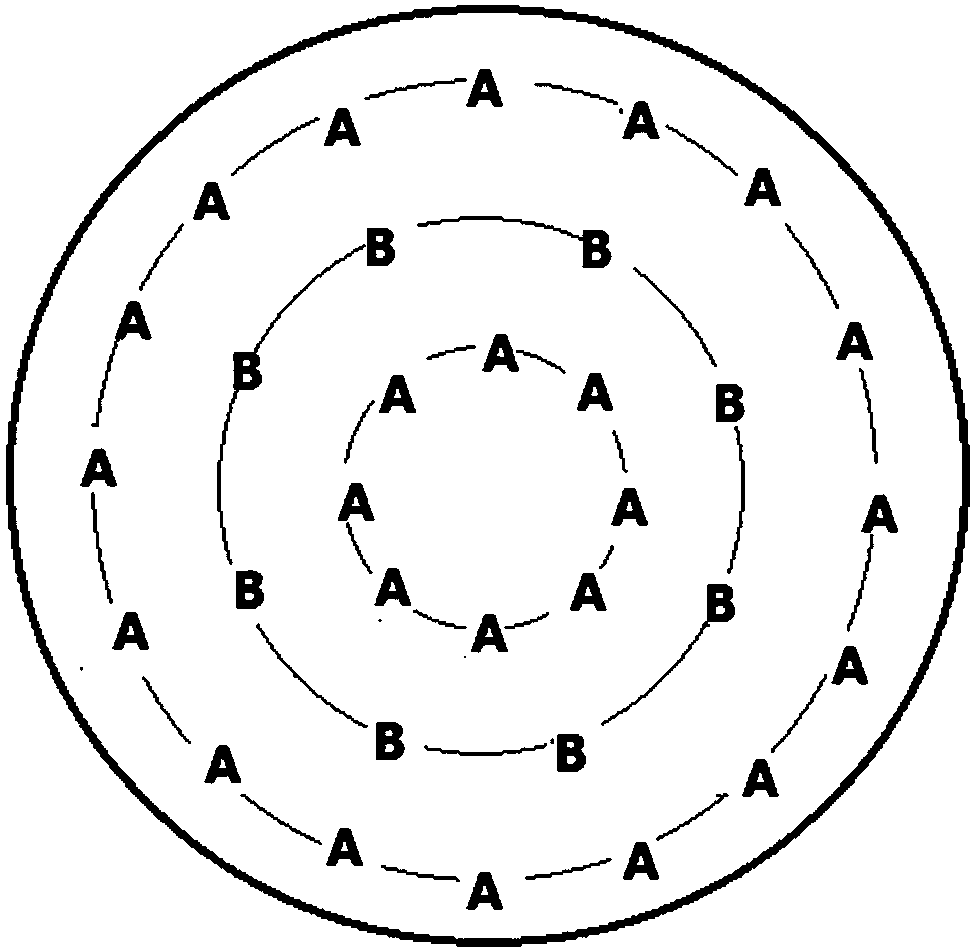

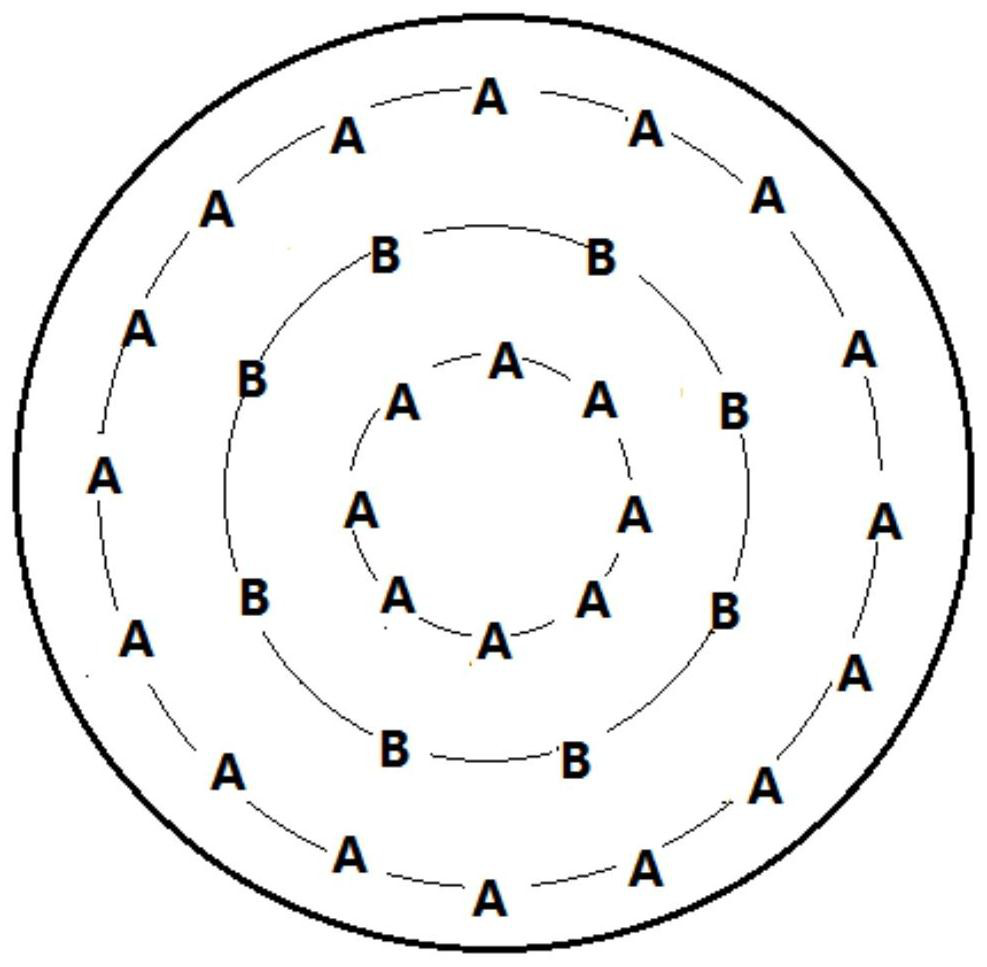

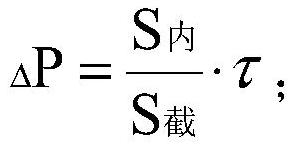

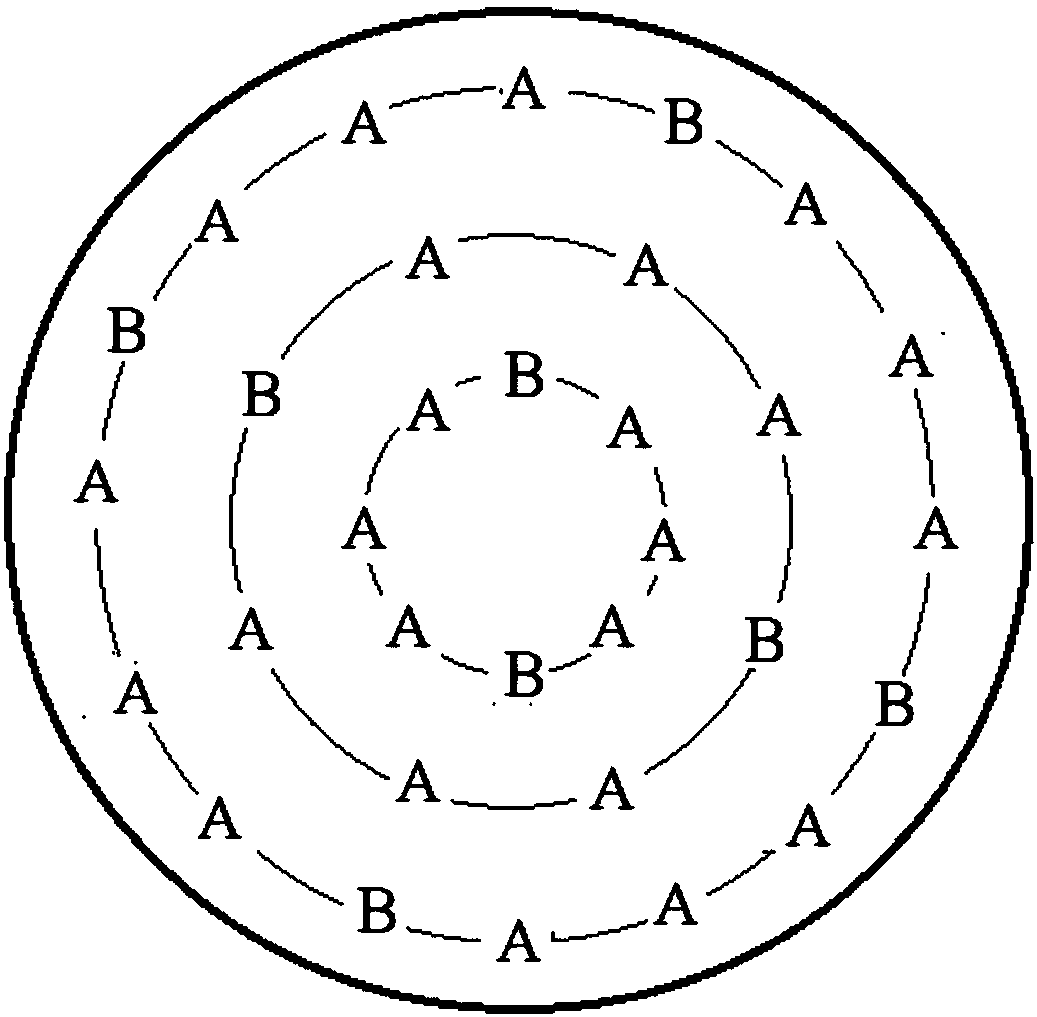

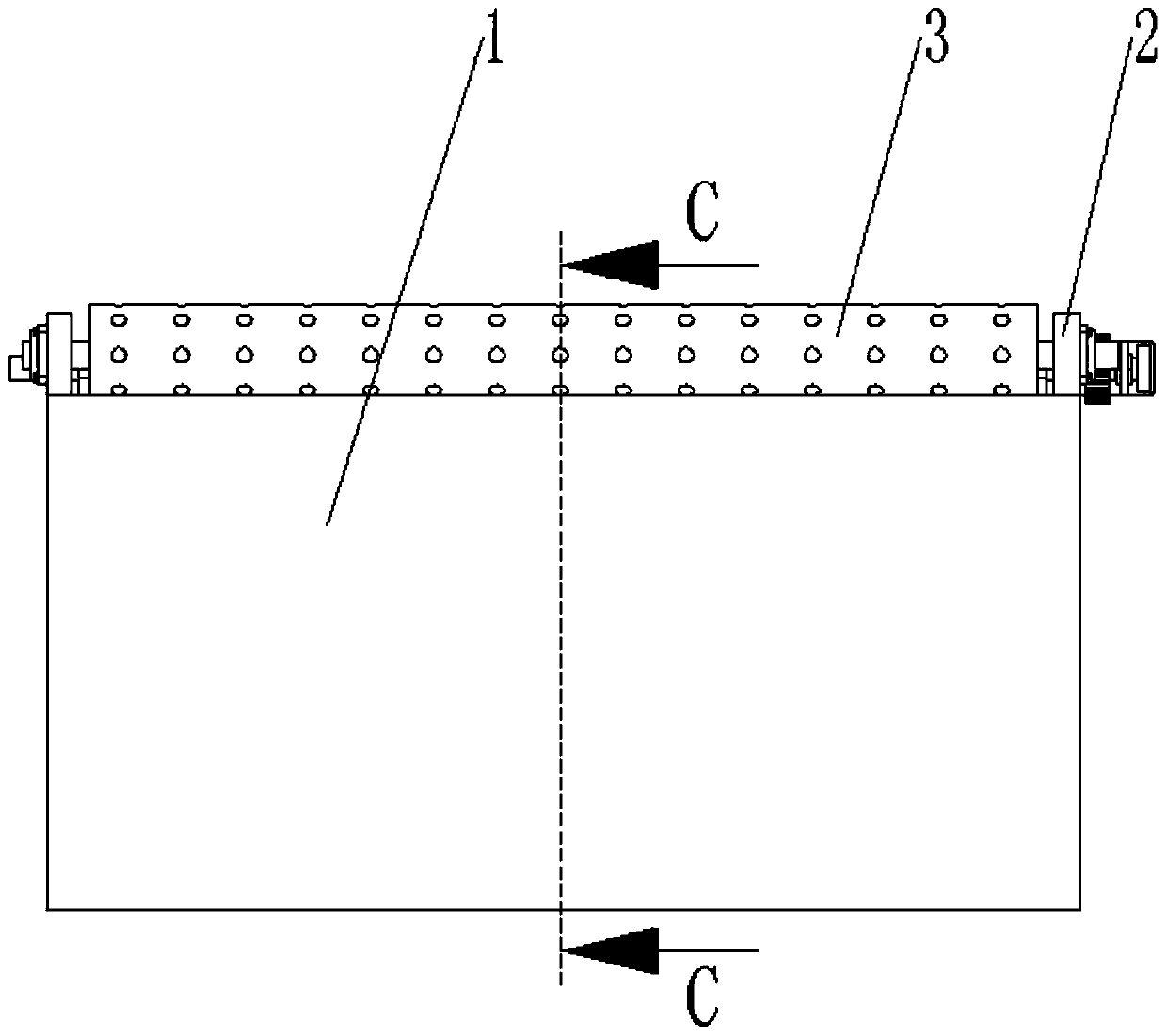

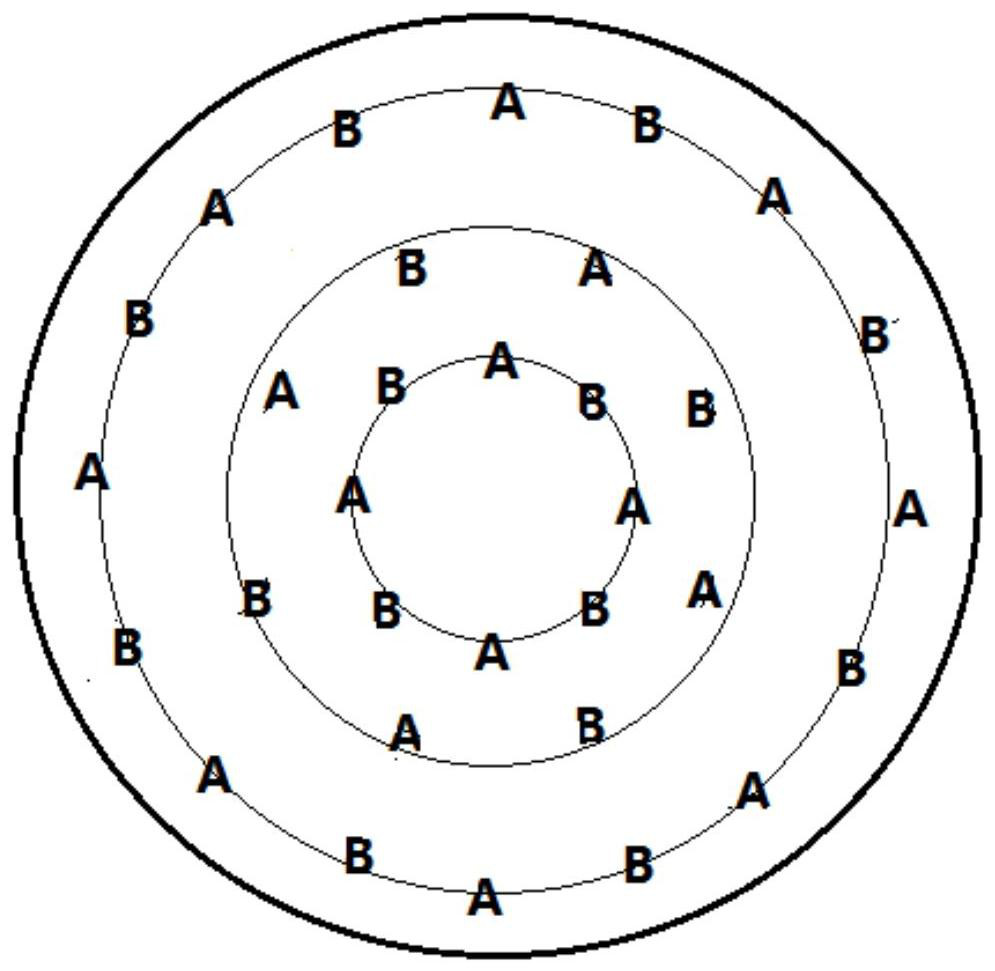

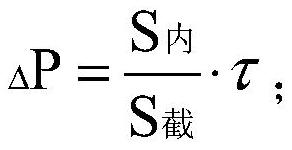

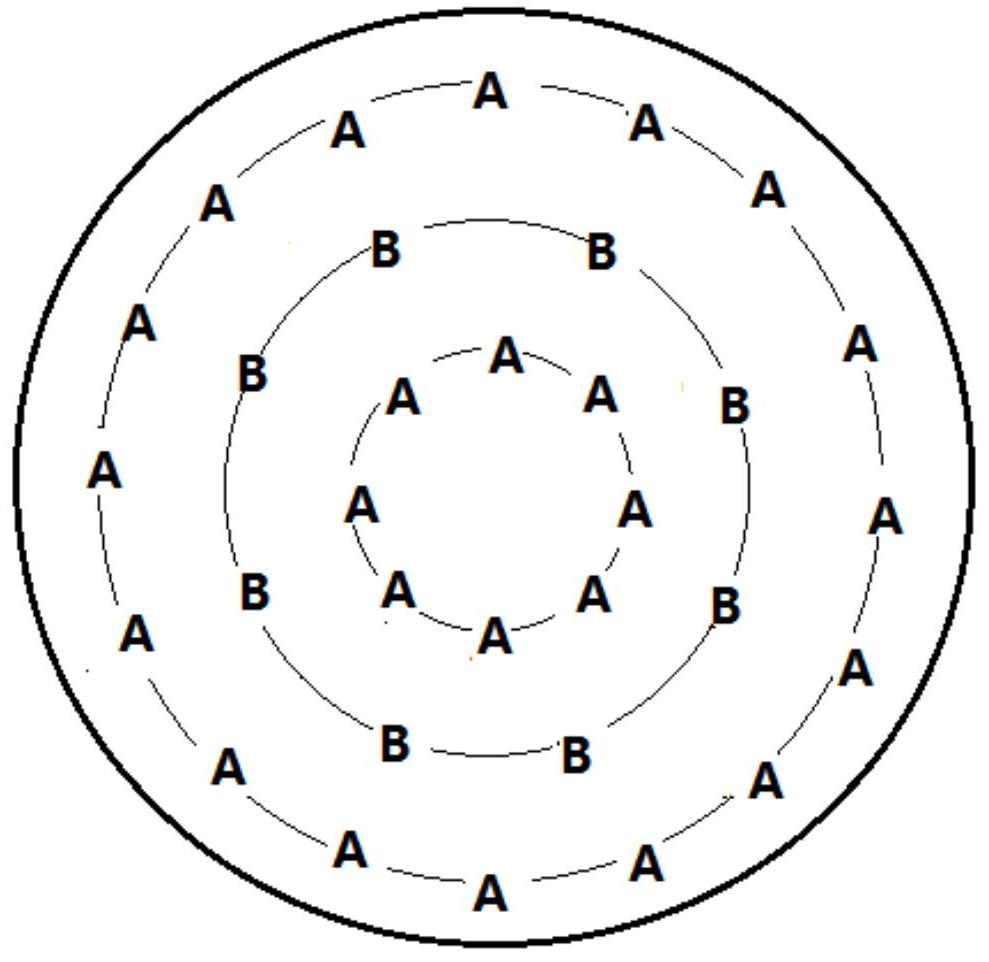

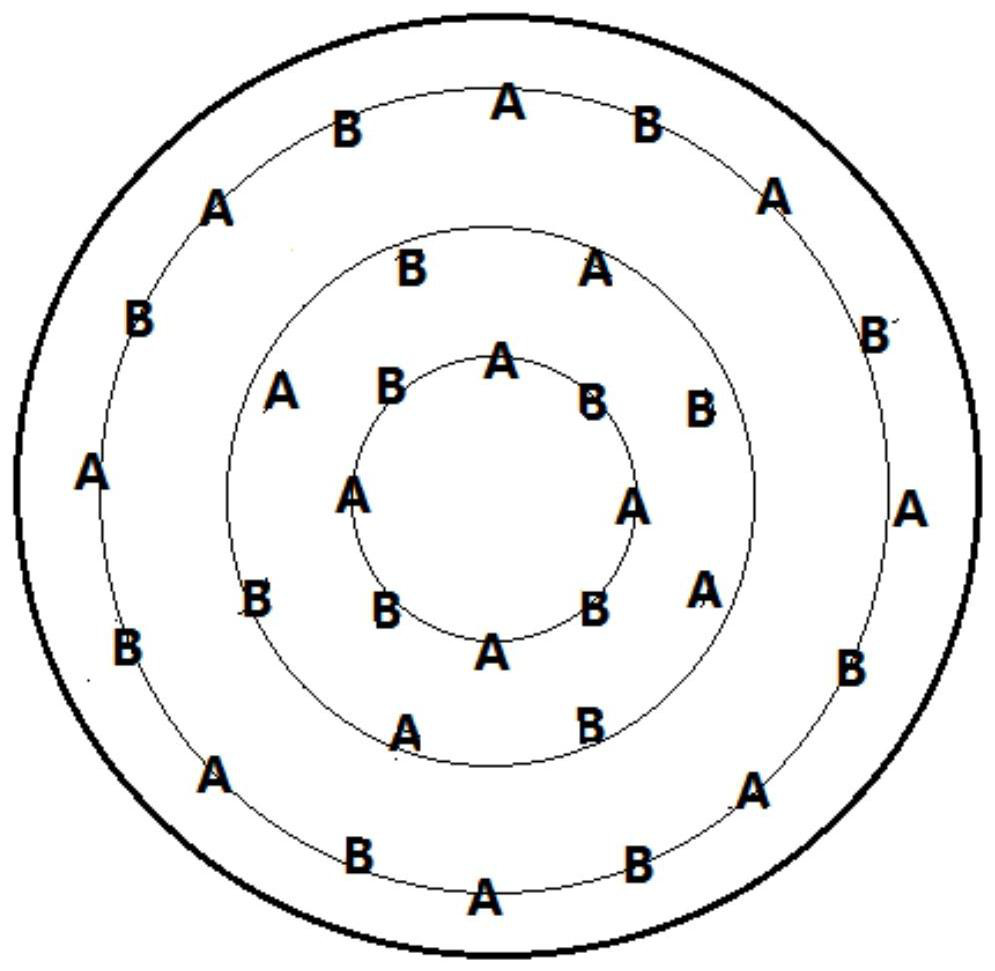

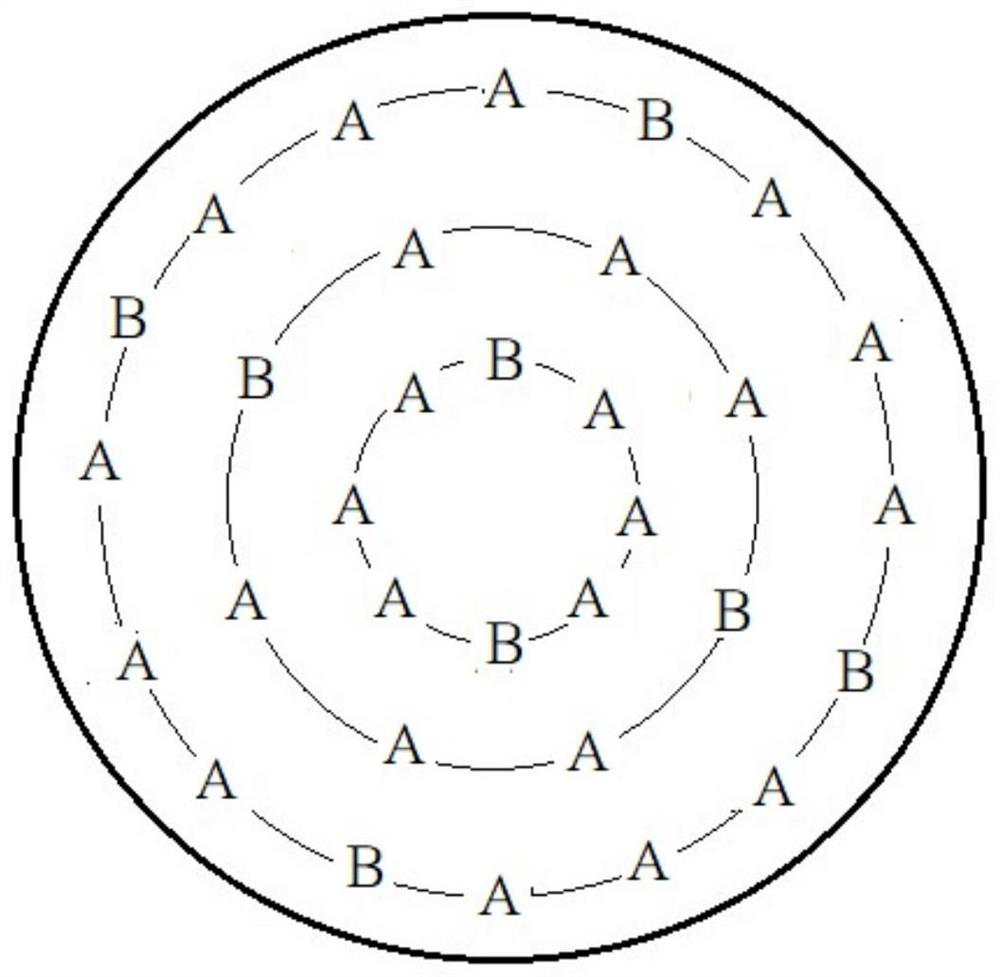

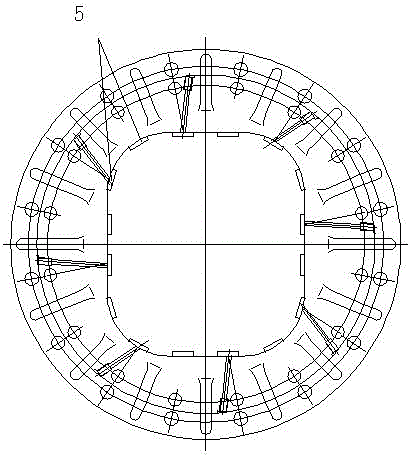

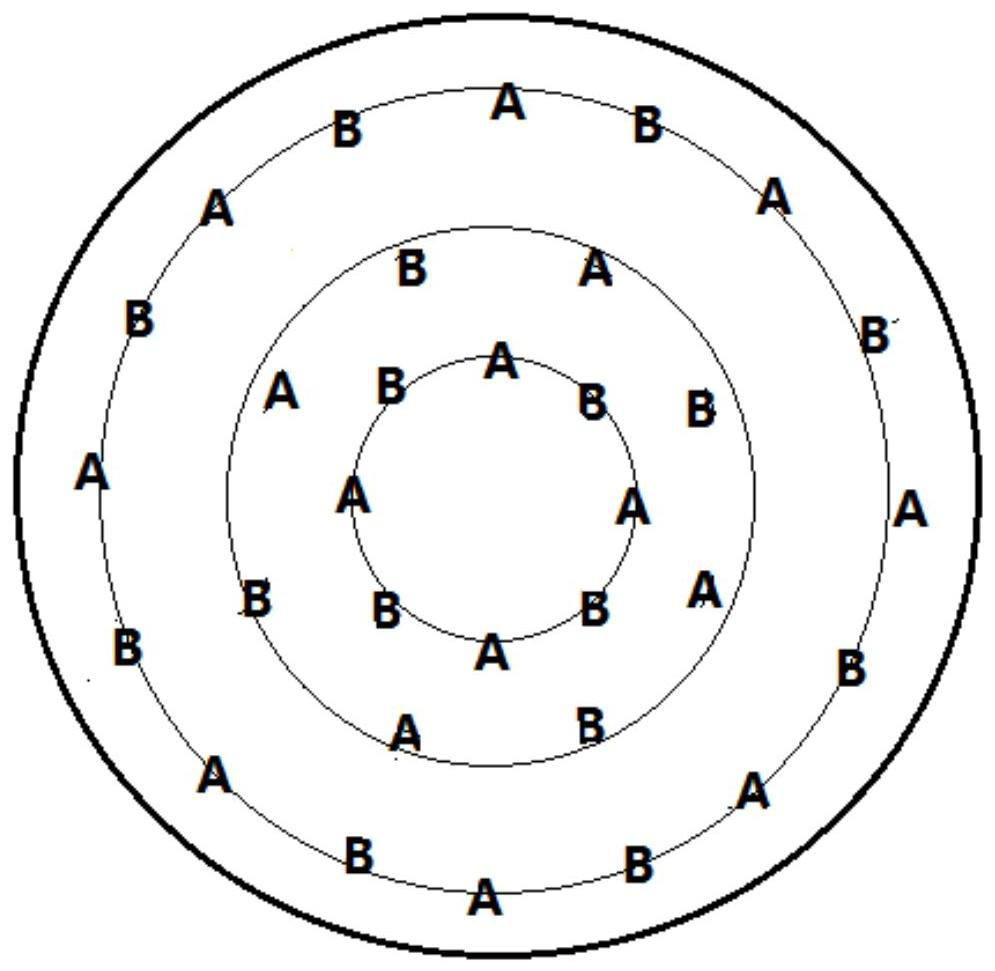

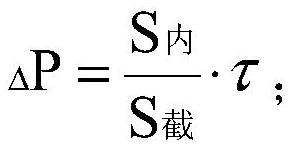

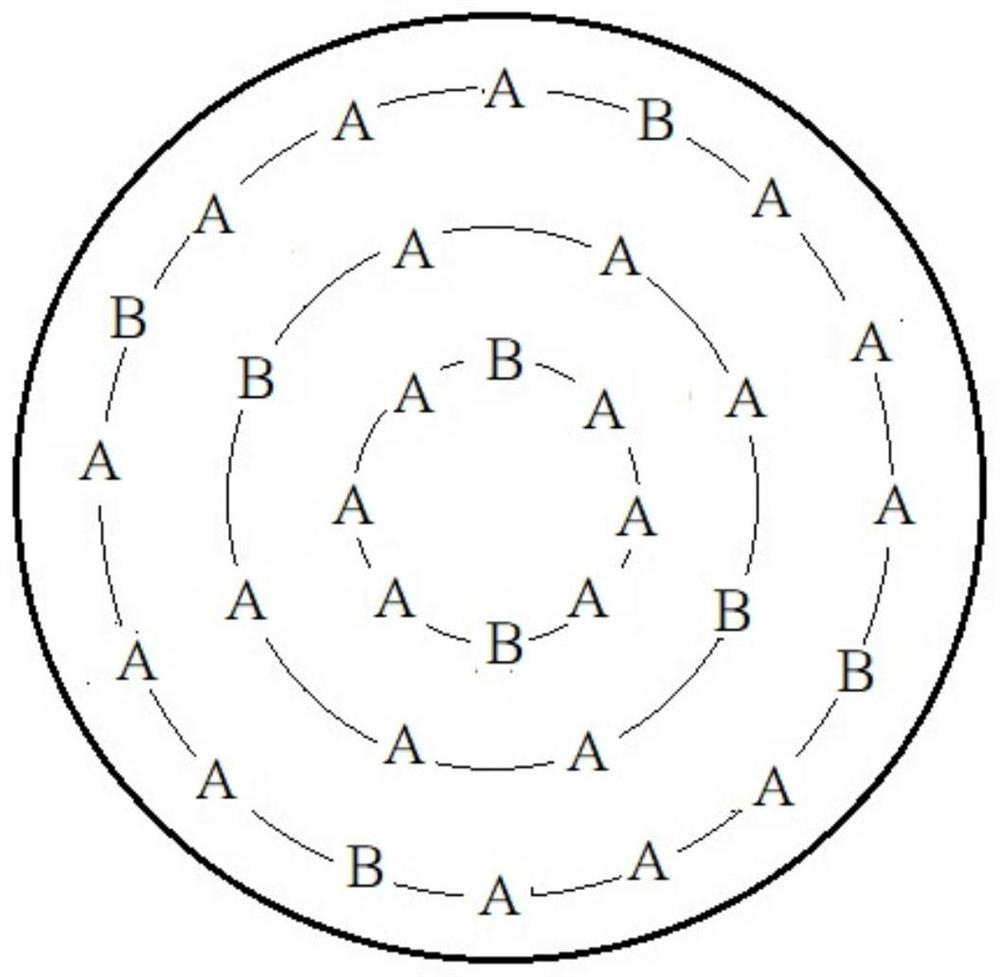

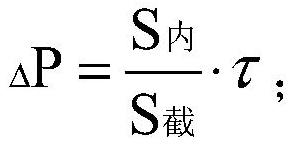

Composite spinneret plate

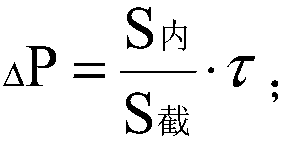

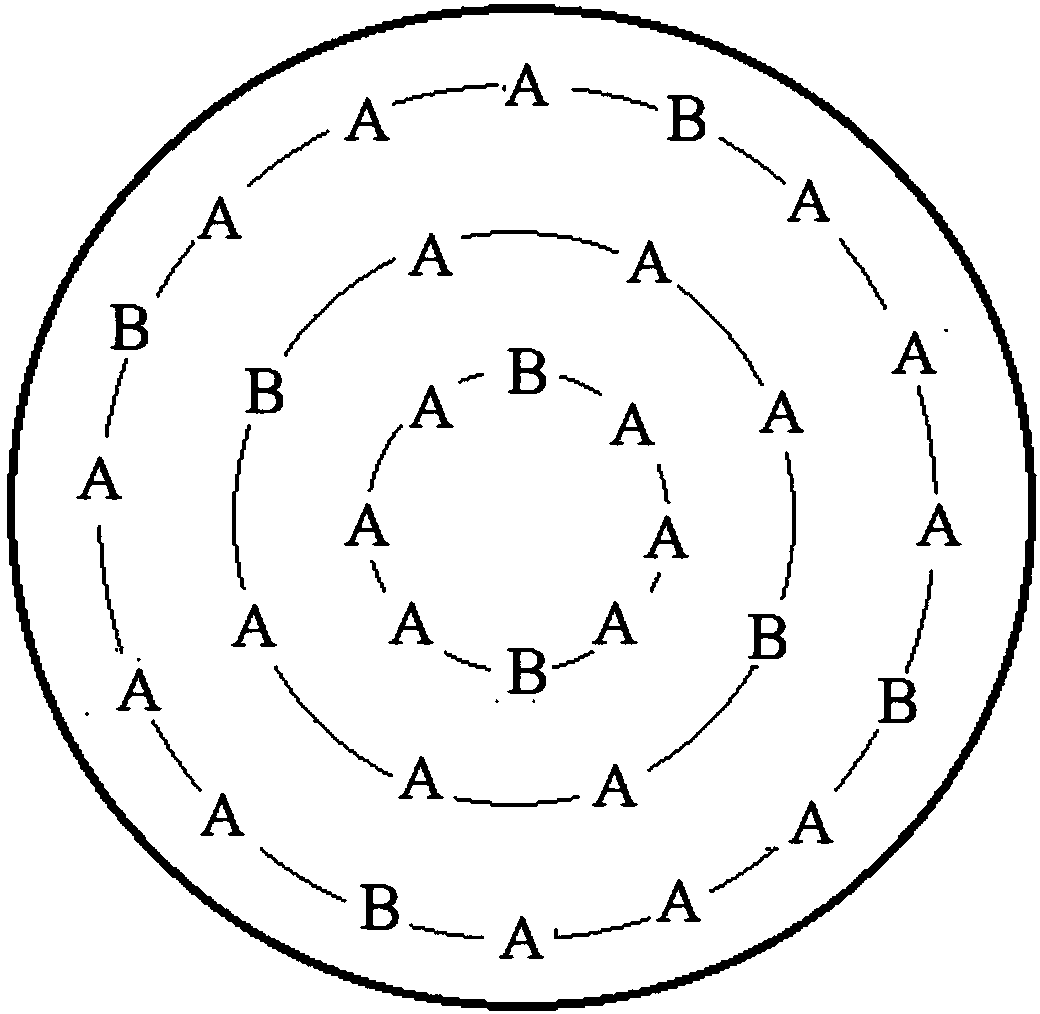

InactiveCN107794581AConsistent extrusion speedSmooth and stable spinningSpinnerette packsHollow filament manufactureDiameter ratioPolymer melt

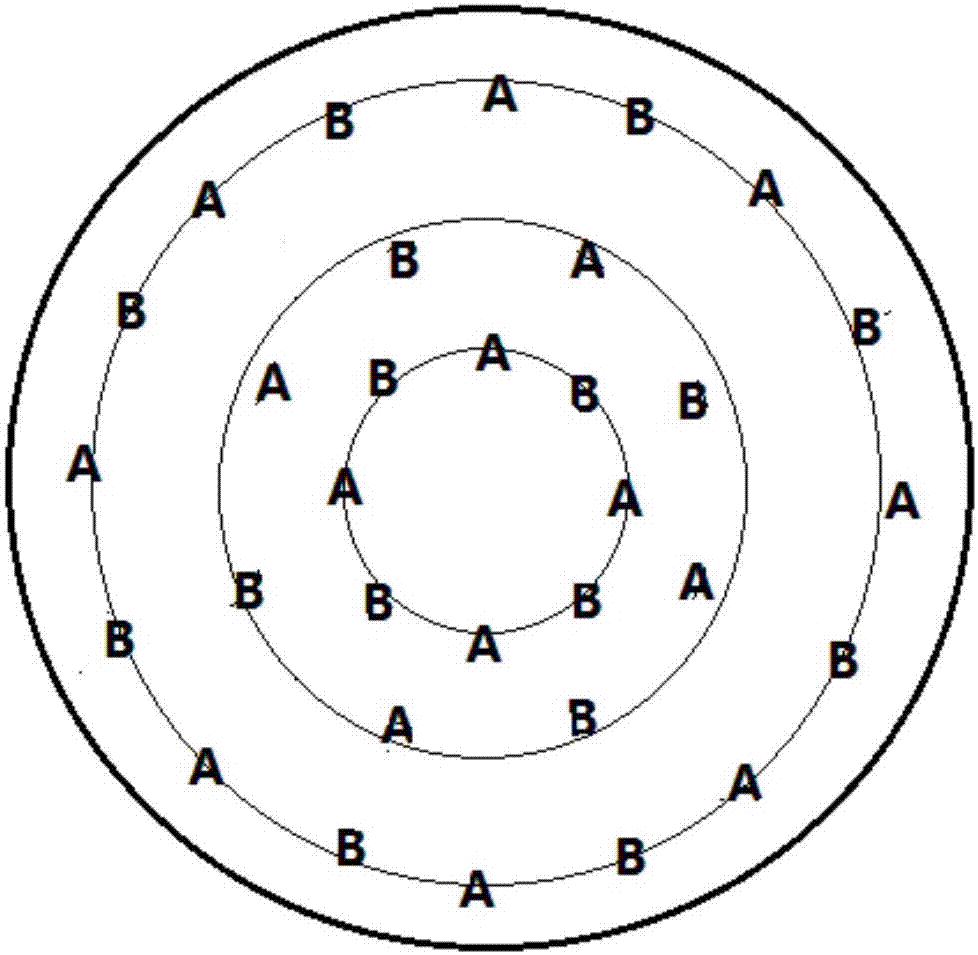

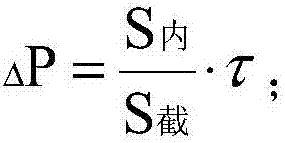

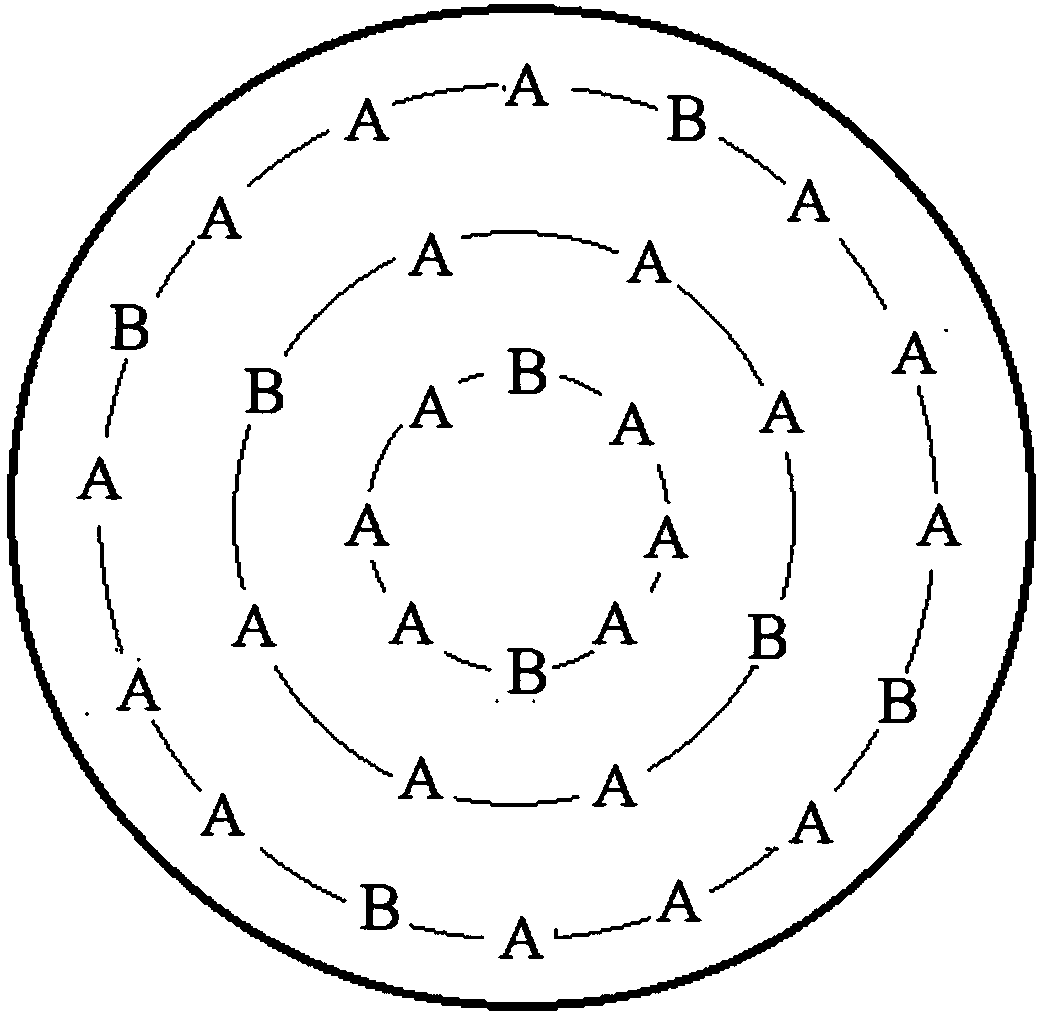

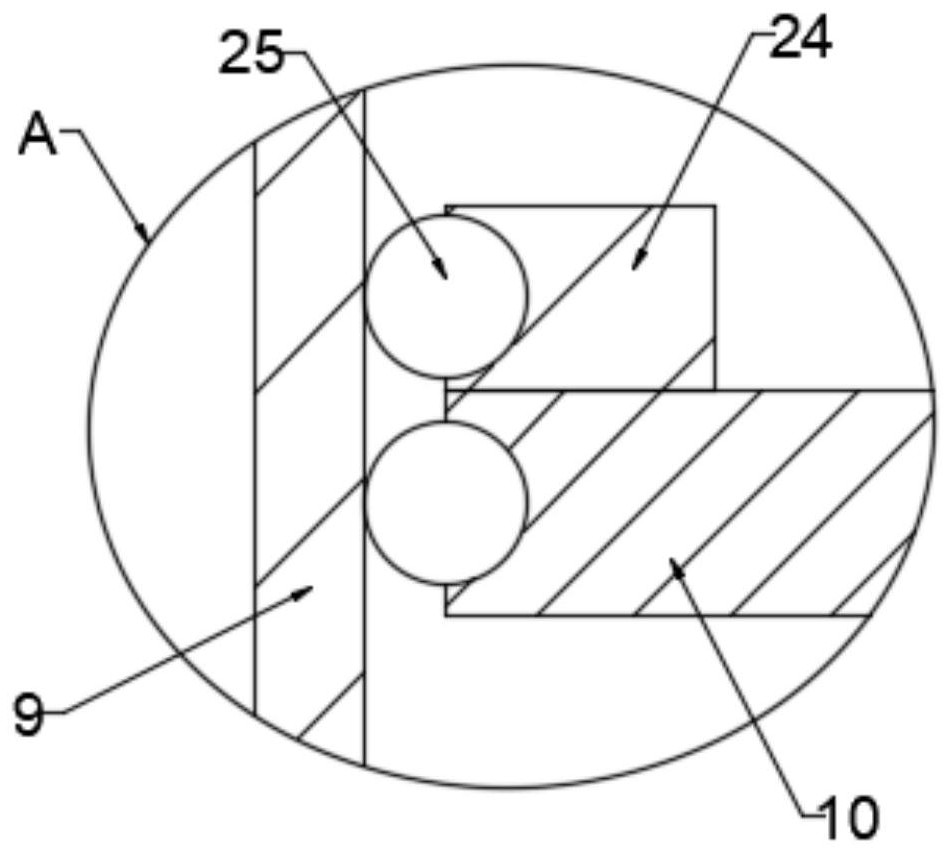

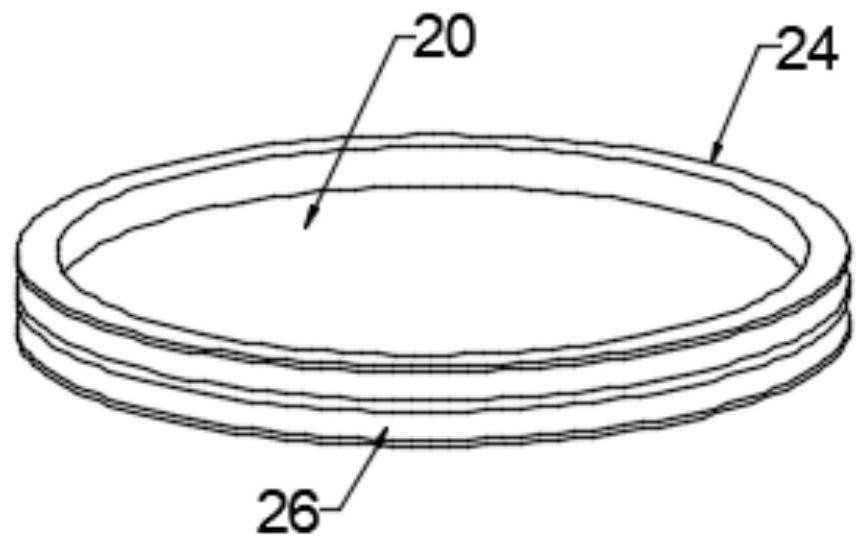

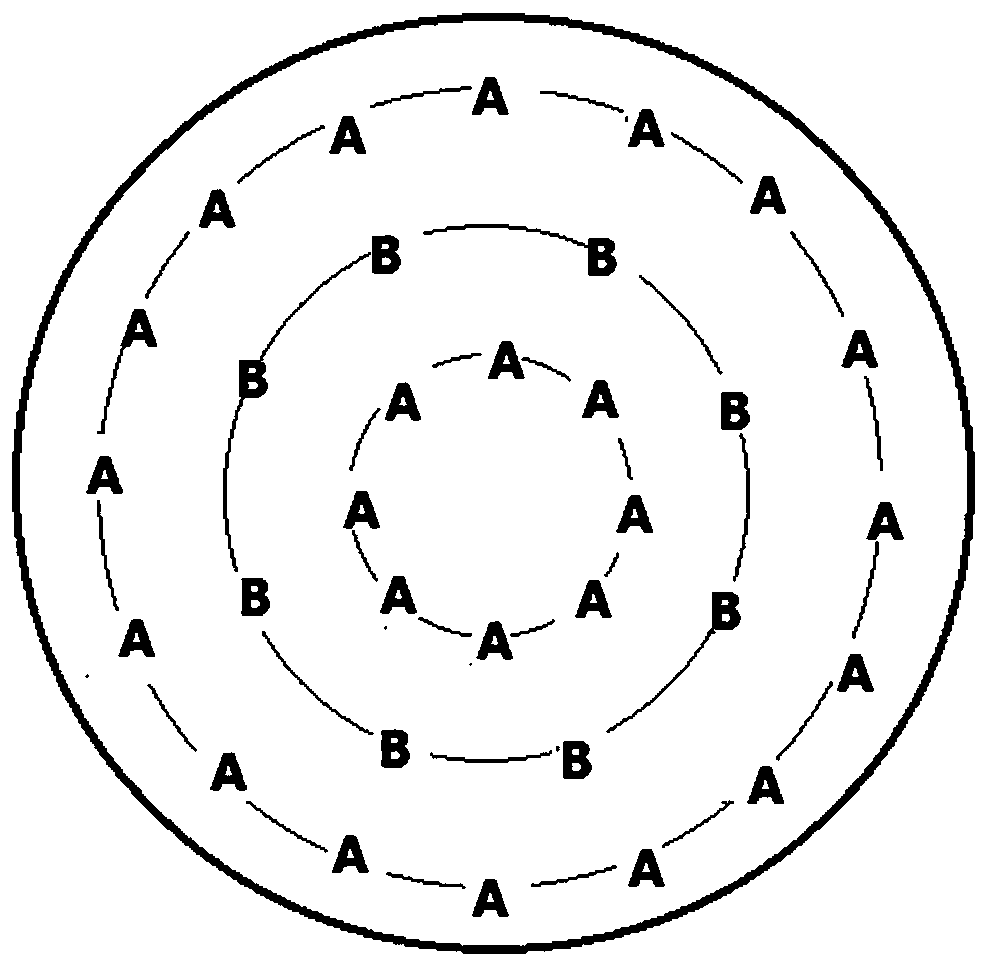

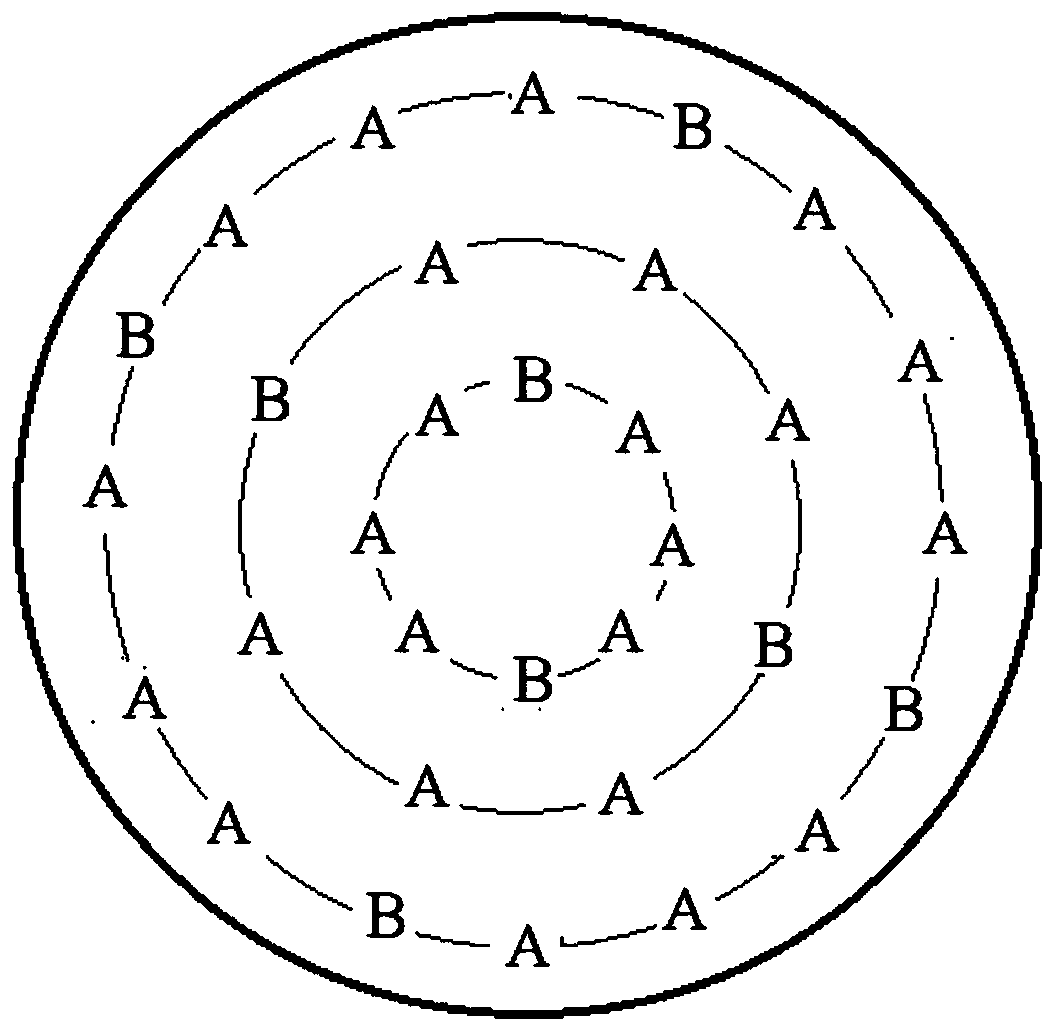

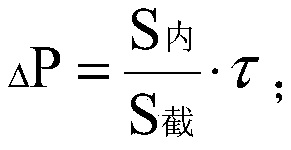

The invention relates to a composite spinneret plate. Two different spinneret orifices A and B are formed in the spinneret plate, the micropore length ratio of the spinneret orifices A and B is equalto the arithmetic product of the equivalent diameter ratio of the spinneret orifices A and B, the coefficient K and the consistency coefficient ratio of materials flowing through the spinneret orifices B and A, the equivalent diameter is the ratio of the cross-sectional area of the spinneret orifices to the cross-sectional perimeters of the spinneret orifices, the coefficient K is 0.97-1.03, the micropore length of the spinneret orifices A or B is 0.30-2.08mm, and the equivalent diameter is 0.15-0.52mm. According to the composite spinneret plate, by setting the micropore lengths, the cross-sectional area and the cross-sectional perimeters of the two spinneret orifices and establishing a certain relationship among the sizes of the two spinneret orifices and the consistency coefficient of the materials flowing through the two spinneret orifices, the pressure drop of polymer melts passing different spinneret orifices of the same spinneret plate is basically the same, so that the extrusionspeed of the melts from the spinneret orifices is basically consistent, and smooth spinning can be realized.

Owner:JIANGSU HENGLI CHEM FIBER

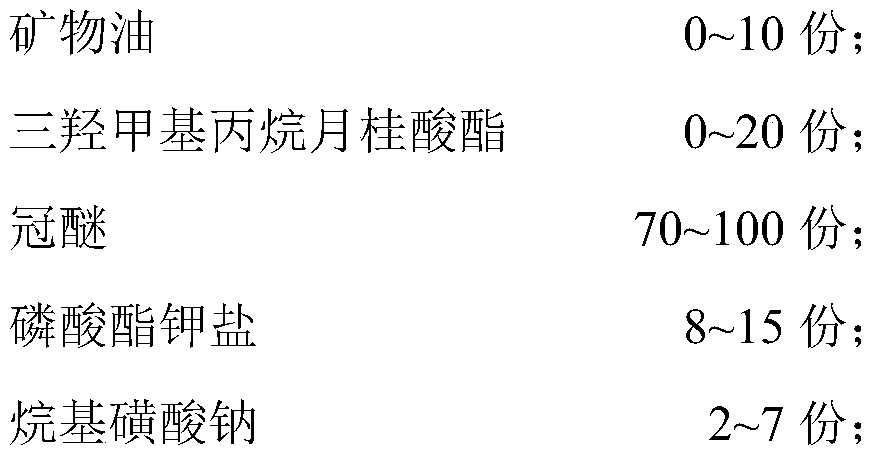

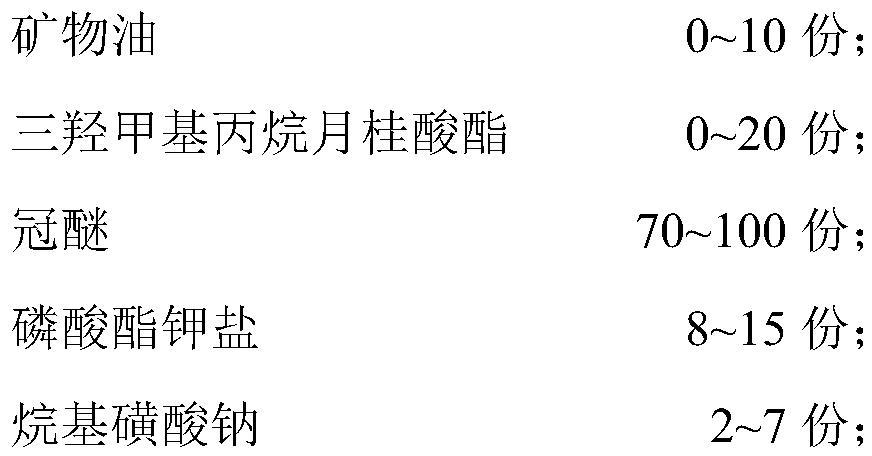

Hot and humid and comfortable polyester fiber FDY silk for winter and preparation method thereof

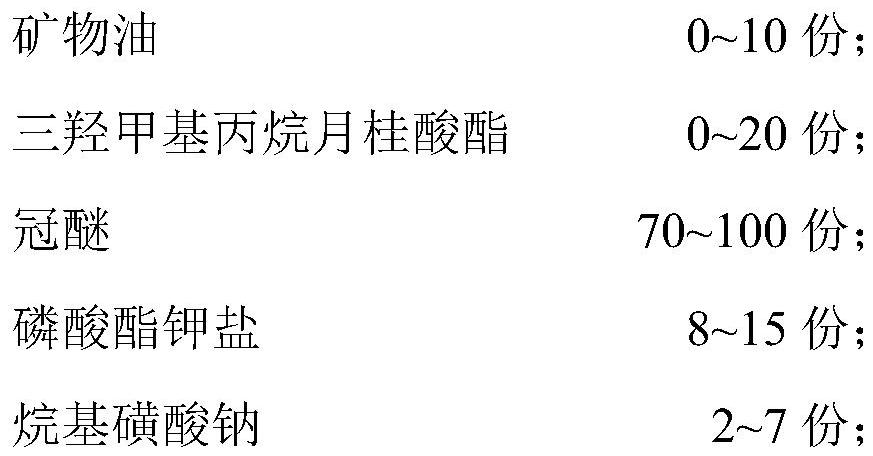

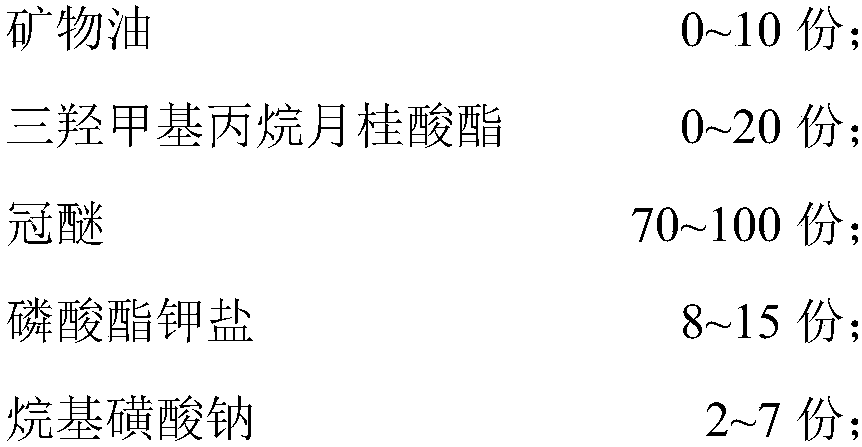

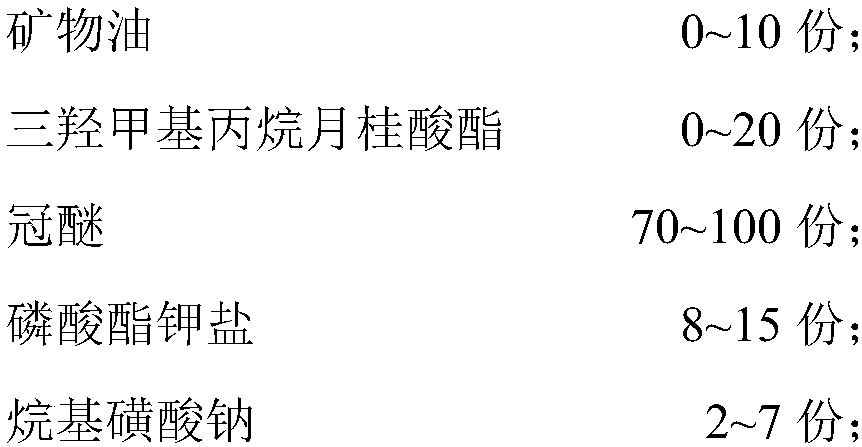

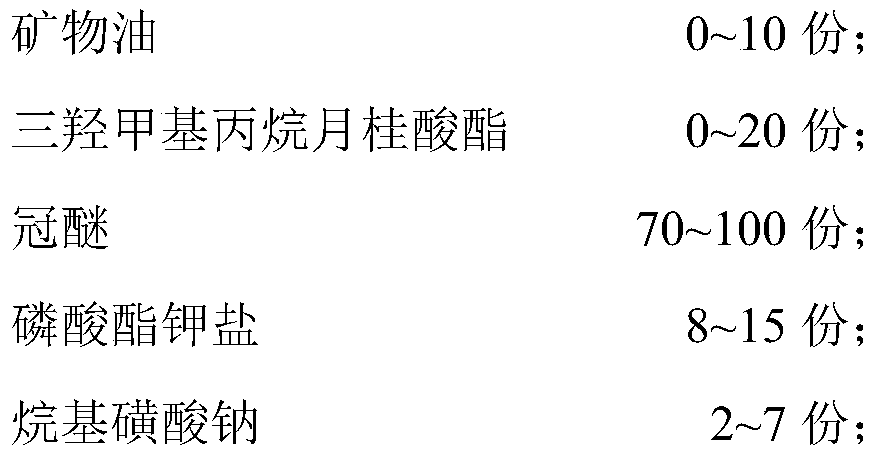

ActiveCN108035009AGood thermal and humidity comfortEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber

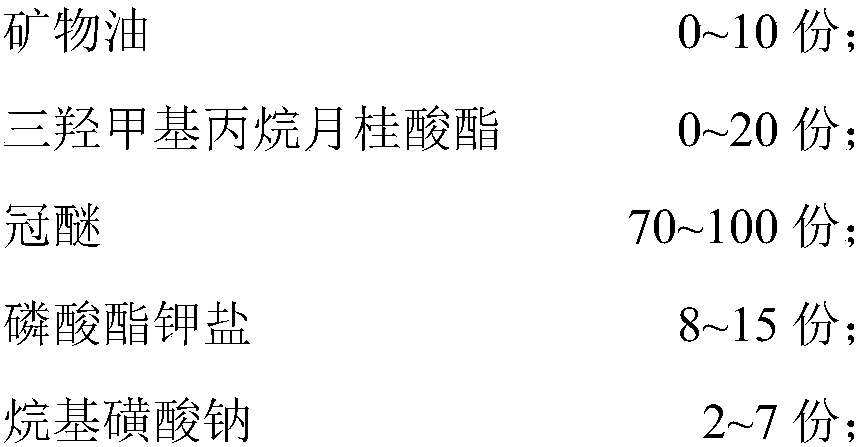

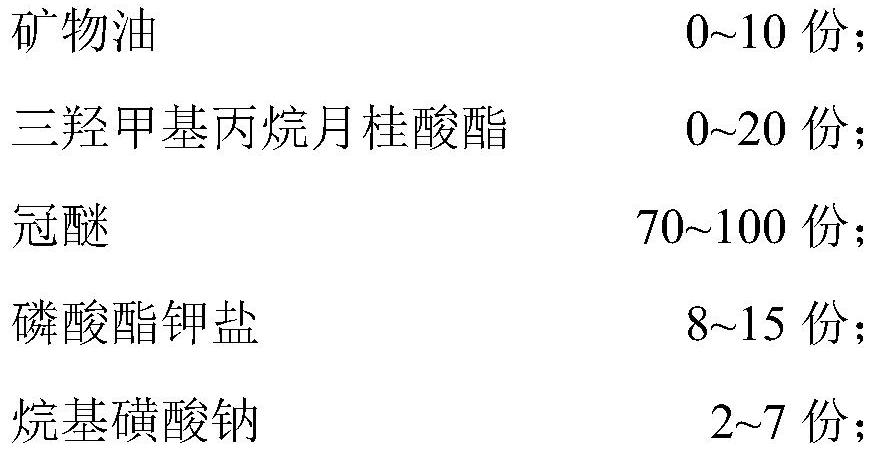

The invention relates to a hot and humid and comfortable polyester fiber FDY silk for winter and a preparation method thereof. The preparation method comprises the following steps that the hot and humid and comfortable polyester fiber FDY silk for winter is prepared by conducting weighing, extrusion by a composite spinneret plate, cooling, oiling, stretching, heat shaping and winding on a spinningmelt, the texture of the silk is polyester with a matte agent being dispersed, the thermal resistance of the obtained woven fabric is higher than or equal to 0.18m<2>. DEG C / W, the moisture vapor resistance of the woven fabric is lower than or equal to 14 Pa.m<2> / W, cross-shaped spinneret orifices and double-cross-shaped spinneret orifices are formed in the composite spinneret plate simultaneously, the micropore length ratio of the cross-shaped spinneret orifices and the double-cross-shaped spinneret orifices is equal to product of the equivalent diameter ratio and the coefficient K, the value range of the coefficient K is between 0.97 and 1.03, an oiling agent used in the oiling contains crown ether, and the content of crown ether is 67.30-85.58wt%. The preparation method is simple, theobtained polyester fiber FDY is excellent in thermal-wet comfort, and has considerable application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

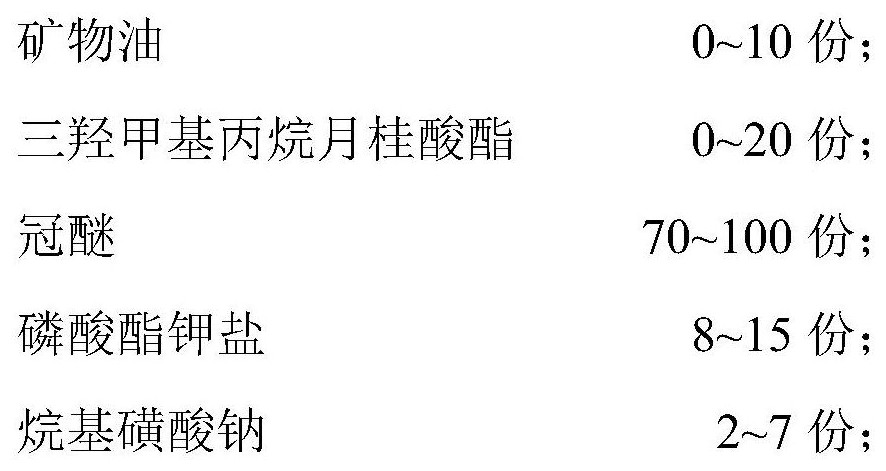

Full-dull polyester and polyester composite yarn and preparation method thereof

ActiveCN107988635ASoft lusterSoft touchSpinnerette packsFibre typesYarnPolyethylene terephthalate glycol

The invention relates to a full-dull polyester and polyester composite yarn and a preparation method thereof. According to the preparation method, dull PET (polyethylene terephthalate) melts and super-bright PET melts are metered, extruded by a composite spinneret plate, cooled, coated with oil and wound to prepare POYs (polyester pre-oriented yarns); the POYs are heated, drawn, falsely twisted, shaped in a heating manner and wound to prepare DTYs (draw texturing yarns) through a yarn guide pipe and a network, namely, the full-dull polyester and polyester composite yarn. An oil agent for oiling contains crown ether, the content of the crown ether is 67.30-85.58wt%, a full-dull polyester and polyester composite yarn extruded by the same composite spinneret plate simultaneously contain dullPET monofilaments dispersed matt agents and super-bright PET monofilaments dispersed matt agents, the matt agents are mixture of unformed titanium dioxide and unformed silicon dioxide or mixture of calcium carbonate and unformed silicon dioxide, and the composite yarn gloss is lower than 20%. The preparation method is simple, the smooth spinning of fibers is achieved in the preparation process, and fabrics prepared by the method are excellent in performance and has great application values.

Owner:JIANGSU HENGLI CHEM FIBER

Hot-wet comfortable polyester fiber FDY filament for summer and preparation method of hot-wet comfortable polyester fiber FDY filament

ActiveCN108035010AGood thermal and humidity comfortEasy to processNew-spun product collectionFibre typesChemistryPolyester

The invention relates to a hot-wet comfortable polyester fiber FDY filament for summer and a preparation method of the hot-wet comfortable polyester fiber FDY filament. The preparation method comprises the following steps: measuring spinning melt, extruding by a composite spinneret plate, cooling, oiling, stretching, thermally shaping and coiling, thus obtaining the hot-wet comfortable polyester fiber FDY filament for summer which is made of polyester dispersed with a matt agent, a core absorption height of a prepared woven fabric is greater than or equal to 135 mm, an evaporation rate of thewoven fabric is greater than or equal to 0.22g / h, the composite spinneret plate is simultaneously provided with a cross spinneret hole and a circular spinneret hole, a length ratio of micropores of the cross spinneret hole and the circular spinneret hole is equal to a product of an equivalent diameter ratio and a coefficient K, a valuing range of the coefficient K is 0.97 to 1.03, an oiling agentcomprises crown ether, and the content of the crown ether is 67.30 to 85.58 percent by weight. The preparation method is simple, and the obtained fiber is excellent in hot-wet comfortability and remarkable in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Hot-wet comfortable polyester-fiber draw texturing yarns (DTYs) for winter, and preparation method of DTYs

ActiveCN107988648AGood thermal and humidity comfortEasy to processFibre typesFilament/thread formingYarnPolyester

The invention relates to hot-wet comfortable polyester-fiber draw texturing yarns (DTYs) for winter, and a preparation method of the DTYs. The preparation method comprises the steps of metering spinning melt, extruding by using a composite spinneret, cooling, oiling and winding to obtain polyester pre-oriented yarns (POYs); enabling the POYs to pass through a yarn guide pipe and a network, stretching under the condition of heating, carrying out false twisting and heat-setting, and molding by winding so as to obtain the hot-wet comfortable polyester-fiber DTYs; the material of the DTYs is polyester with a dispersed matting agent; the thermal resistance and moisture resistance of knitted fabric made from the DTYs are respectively more than or equal to 0.16m<2>.DEG C / W and less than or equalto 12Pa.m<2> / W; the composite spinneret is provided with a cross-shaped spinneret orifice and a double-cross shaped spinneret orifice; the ratio of the micropore length of the cross-shaped spinneret orifice to the micropore length of the double-cross shaped spinneret orifice is equal to a product of the ratio of the equivalent diameter and a coefficient K, wherein the value range of the coefficient K is 0.97-1.03; an oiling agent for oiling contains crown ether, and the content of the crown ether is 67.30-85.58wt%. The preparation method provided by the invention is simple, and the obtained hot-wet comfortable polyester-fiber DTYs are excellent in hot-wet comfort performance.

Owner:JIANGSU HENGLI CHEM FIBER

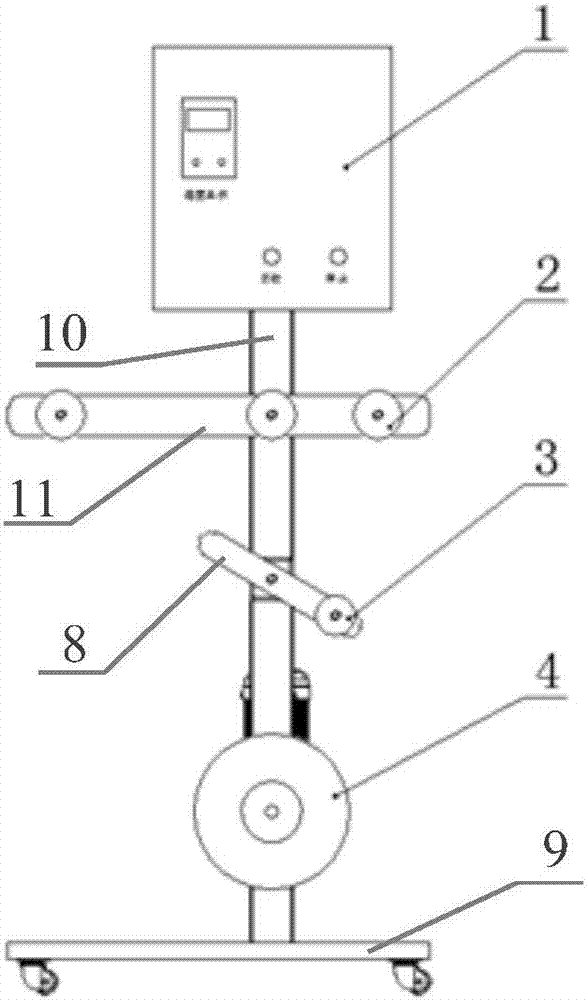

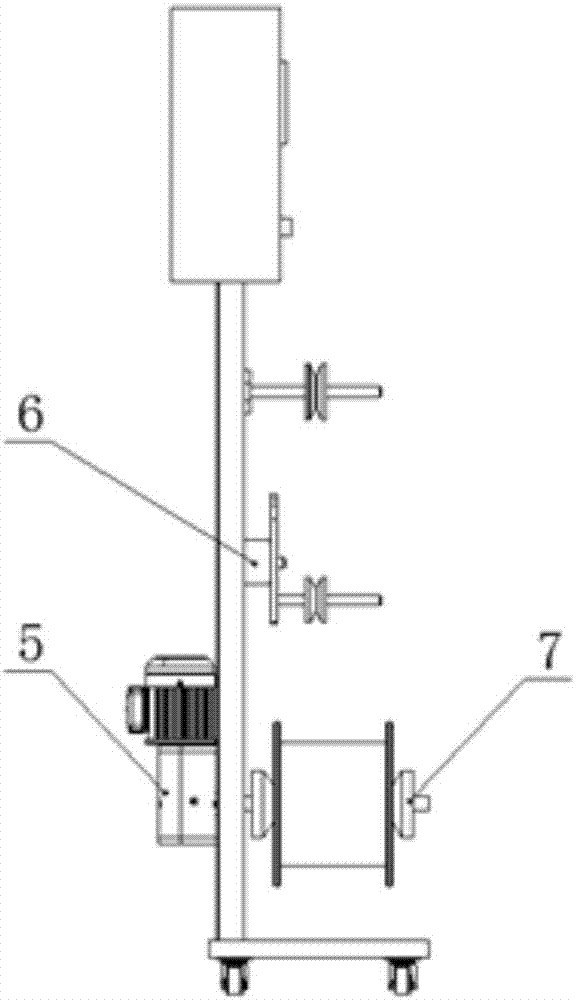

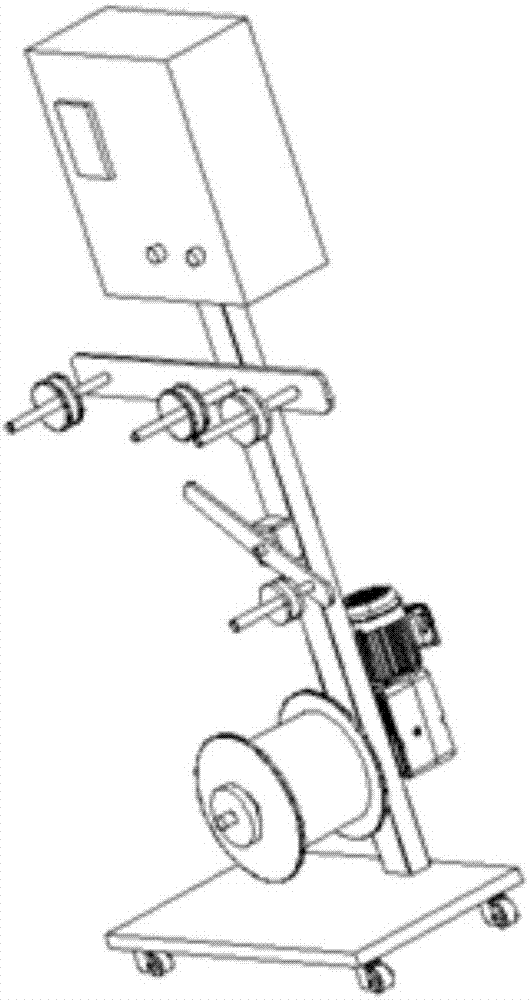

Copper wire unwinding machine

PendingCN107265189AConsistent extrusion speedEliminate stretching tensionFilament handlingCopper wireEngineering

The invention provides a copper wire unwinding machine. A copper wire needs to be clamped into a rubber sealing strip for an automobile in the extrusion process, and due to the fact that the shrinkage ratio and rigidity of the copper wire are higher than those of rubber, length contraction of the rubber sealing strip due to environment temperature change can be avoided. In an existing rubber sealing strip extrusion technology process, the copper wire is forcefully pulled into an extruding machine, the copper wire is stretched to generate tension before entering the extruding machine and is further clamped into the sealing strip with the tension, and bending deformation of a final product can be caused. The copper wire unwinding machine provided by the invention is provided with a copper wire speed adjusting unit, so that the unwinding speed of the copper wire is consistent with the extruding speed of the rubber sealing strip, stretching tension of the copper wire is removed, and the condition that the rubber strip is subjected to bending deformation and cannot be used due to the speed or tension difference of the rubber strip and the copper wire is effectively avoided.

Owner:TIANJIN MINCHI AUTOMOBILE PARTS

Polyester cotton-like type differential shrinkage composite yarns and preparation method thereof

ActiveCN108385226AHigh molecular weightNarrow molecular weightFilament/thread formingYarnYarnPolyester

The invention relates to polyester cotton-like type differential shrinkage composite yarns and a preparation method thereof. The preparation method comprises the following steps: respectively preparing modified polyester POY (Pre-Oriented Yarn) and FDY (Fully Drawn Yarn) wires, and then compounding the POYs with the FDYs to prepare the polyester cotton-like type differential shrinkage composite yarns, wherein the color difference delta E of the prepared composite yarns is less than 0.200, a beam of POYs or FDYs extruded by the same yarn spraying plate simultaneously contains crossed single yarns and trefoiled single yarns; a molecular chain of the modified polyester comprises a branched diol chain segment, a structural formula of the branched diol is as follows: the formula (1) is shown inthe description; in the formula, R1 and R2 are straight-chain alkylene with carbon atomic number 1-3, R3 is alkyl with carbon atomic number 1-5, R4 is alkyl with carbon atomic number 2-5, and a matteagent dispersed in the modified polyester is amorphous titanium dioxide and amorphous silicon dioxide or a mixture of calcium carbonate and the amorphous silicon dioxide. The method disclosed by theinvention is simple and reasonable, and the prepared composite yarns have good fluffy, moisture absorption and perspiration performance.

Owner:JIANGSU HENGLI CHEM FIBER

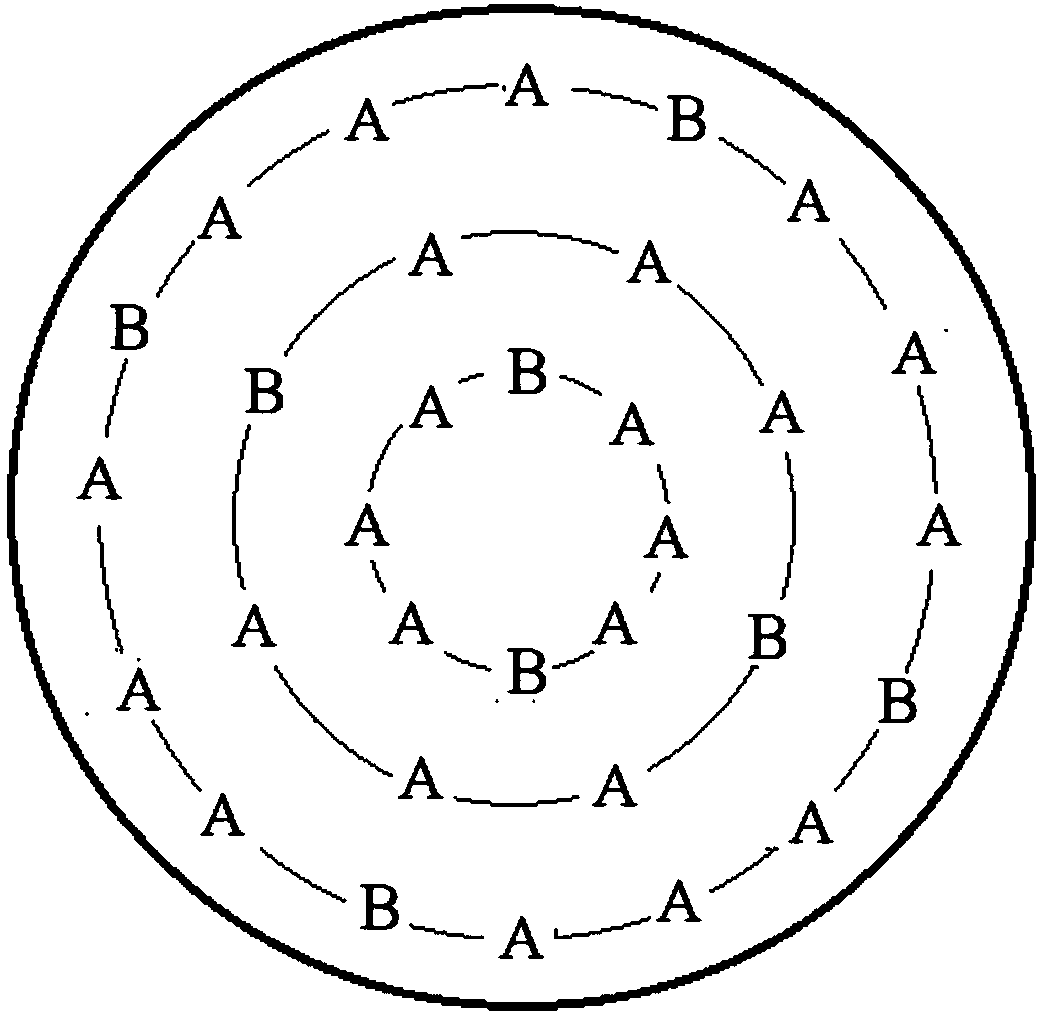

Moisture absorption and perspiration fiber and preparation method thereof

ActiveCN108035006ALow viscosityHigh viscosityArtificial filament heat treatmentMelt spinning methodsPolyesterFiber

The invention relates to a moisture absorption and perspiration fiber and a preparation method thereof. The moisture absorption and perspiration fiber is prepared by measuring polyester melt, extruding by a compositing spinneret plate, cooling, oiling, stretching, thermally shaping and coiling, wherein the composite spinneret plate is provided with a cross spinneret hole and a spinneret hole shaped like the Chinese character Wang, a length ratio of micropores of the cross spinneret hole and the spinneret hole shaped like the Chinese character Wang is equal to a product of an equivalent diameter ratio of the cross spinneret hole and the spinneret hole shaped like the Chinese character Wang and a coefficient K, the equivalent diameter is a ratio of an area and perimeter of a cross section ofthe spinneret hole, the valuing range of the coefficient K is 0.97 to 1.03, an oiling agent comprises crown ether, the content of the crown ether is 67.30 to 85.58 percent, and a capillary parameterof the prepared moisture absorption and perspiration fiber is greater than or equal to 0.16. The preparation method is simple and reasonable in method, and the prepared fiber has excellent moisture absorption and perspiration performance and has good popularization value.

Owner:JIANGSU HENGLI CHEM FIBER

Lightweight warmth retention fiber and preparation method thereof

ActiveCN107988640ALow viscosityHigh viscosityNew-spun product collectionHollow filament manufacturePolyesterDiameter ratio

The invention relates to a lightweight warmth retention fiber and a preparation method thereof. Polyester melts are metered, extruded by a composite spinneret plate, cooled, coated with oil, stretched, thermoformed and wound to prepare the lightweight warmth retention fiber, a hollow spinneret hole and a circular spinneret hole are formed in the composite spinneret plate, the ratio of the hollow spinneret hole to the micro-hole length of the circular spinneret hole is equal to the product of the equivalent diameter ratio of the hollow spinneret hole to the circular spinneret hole and a coefficient K, the equivalent diameter is the ratio of cross-sectional areas of the spinneret holes to cross-sectional area perimeters, value range of the coefficient K is 0.7-1.03, an oil agent for oiling contains crown ether, the content of the crown ether is 67.30-85.58wt%, the heat conductivity coefficient of a knitting fabric prepared from the prepared lightweight warmth retention fiber is smaller than or equal to 0.150W / m*K, and the weight of the knitting fabric is 100g / m<2>. The method is simple and reasonable, and the prepared fiber has good lightweight warmth retention, moisture absorption and sweat-releasing performances and has excellent popularization values.

Owner:JIANGSU HENGLI CHEM FIBER

Elastic cotton-linen-like polyester fiber and preparation method thereof

ActiveCN107904682ASimple preparation processGood moisture permeabilityMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention relates to an elastic cotton-linen-like polyester fiber and a making method thereof. POY are made through polyester melt metering, composite spinneret extrusion, cooling, oiling and winding and are made into DTY, namely the elastic cotton-linen-like polyester fiber, through a yarn guiding tube, a network, heating and stretching, false twisting, thermal setting and winding formation,wherein a matting agent is dispersed in a polyester melt, and the composite spinneret is provided with spinneret orifices which are in two special shapes and have a certain relation in micro-void length, cross section area and cross section perimeter size. A bundle of made elastic cotton-linen-like polyester fiber contains round polyester DTY monofilaments and cross-shaped polyester DTY monofilaments, the crimp shrinkage rate of the elastic cotton-linen-like polyester fiber is 35.0+ / -5.0%, and the crimp stability is 80% or above. The method is simple and reasonable, and the made elastic cotton-linen-like polyester fiber has the advantages of high elasticity and wrinkle resistance and has a great popularization value.

Owner:JIANGSU HENGLI CHEM FIBER

Double-abnormal-shape fiber and preparation method thereof

ActiveCN108130613AExcellent performanceLow viscosityFibre typesFilament/thread formingEthylene glycolPolymer science

The invention relates to double-abnormal-shape fibers and a preparation method thereof. A spinning melt is subjected to metering, composite spinneret plate extrusion, cooling, oiling, stretching, heatsetting and winding to obtain the double-abnormal-shape fibers; a bunch of the prepared double-abnormal-shape fibers contain a two-barred cross monofilament and a round monofilament at the same time;the fibers are made of modified polyester, and a matte agent is dispersed in the modified polyester; a molecular chain of the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3, R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5; the matte agent is a mixture of amorphous titanium dioxide and amorphous silicon dioxide or a mixture of calcium carbonate and amorphous silicon dioxide. The method is simple and reasonable, and the prepared fibers have stiff and smooth performance and softness.

Owner:JIANGSU HENGLI CHEM FIBER

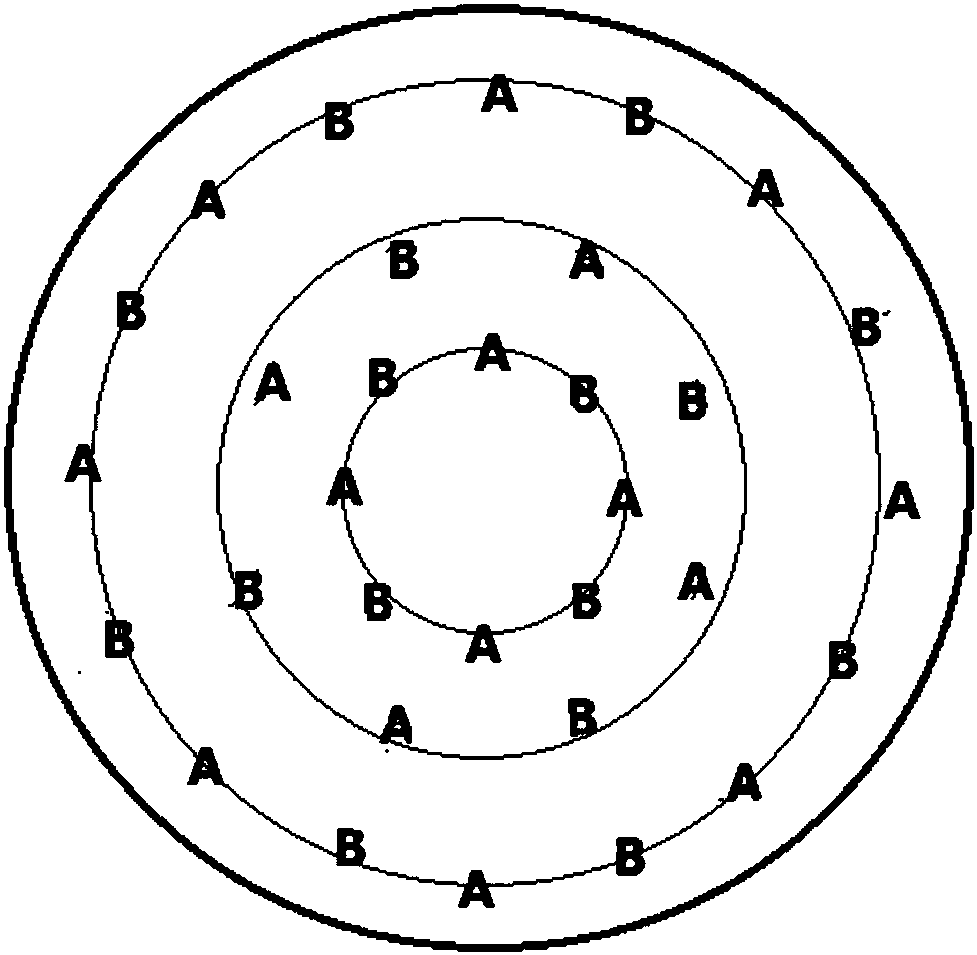

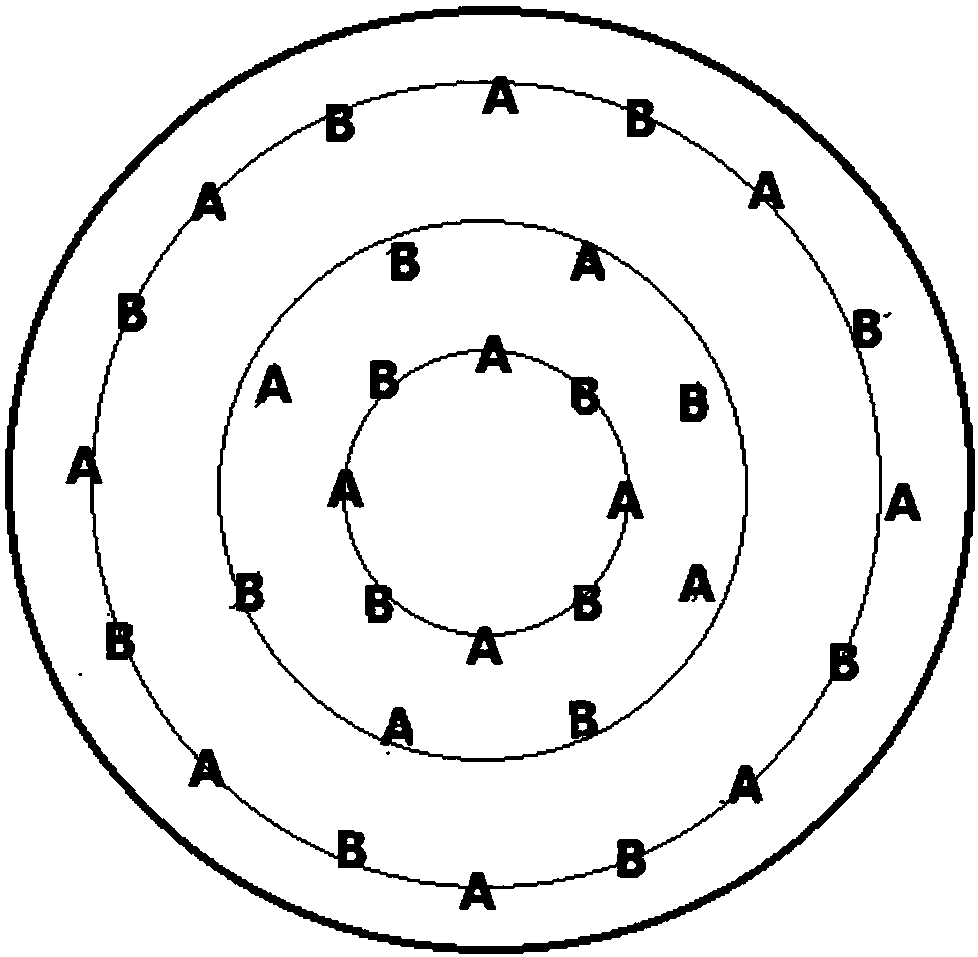

Polyester-nylon composite yarn and preparation method thereof

InactiveCN108035025AGood hygroscopicityRich in colorSpinnerette packsFilament/thread formingYarnPolyester

The invention relates to polyester-nylon composite yarn and a preparation method thereof. The polyester-nylon composite yarn is prepared by conducting measurement, composite spinneret extrusion, cooling, oil applying, stretching, heat shaping and winding on PET flux and PA flux, a composite spinneret is provided with a spinneret hole A and a spinneret hole B different from the spinneret hole A atthe same time, and the microporous length ratio of the spinneret hole A to the spinneret hole B is equal to the product of the equivalent diameter ratio of the spinneret hole A to the spinneret hole B, a coefficient K and the consistency coefficient ratio of a material flowing through the spinneret hole B to a material flowing through the spinneret hole A, wherein the equivalent diameter is the radio of the cross sectional area of one spinneret hole to the cross sectional perimeter of the spinneret hole, and the coefficient K is 0.97-1.03; composite spinneret extrusion means that the PET fluxis extruded from the spinneret hole A, and the PA flux is extruded from the spinneret hole B, or the PET flux is extruded from the spinneret hole B, and the PA flux is extruded from the spinneret holeA. The method is simple and reasonable, the prepared polyester-nylon composite yarn not only has the advantages of a good moisture absorption performance and good dimensional stability at the same time, but also has rich color and lustre, and has an excellent promotion value.

Owner:JIANGSU HENGLI CHEM FIBER

PVC floor formula and floor processing technology using same

InactiveCN103819848AConsistent extrusion speedConsistent pulling speedAluminium hydroxidePolyvinyl chloride

The invention provides a PVC floor formula and a floor processing technology using the same. The objective of the invention is to overcome the problems that individual usage of tribasic lead sulfate and dibasic lead sulfate as a stabilizing agent poses great harm to a human body and that individual usage of calcium ricinoleate as a stabilizing agent leads to poor floor stability. The PVC floor formula comprises, by mass, 54 to 58% of a PVC resin, 26 to 30% of a softener dioctyl phthalate, 12 to 16% of calcium carbonate, 0.05 to 0.15% of an antistatic agent SN, 0.5 to 0.7% of a fire retardant aluminum hydroxide, 0.2 to 0.4% of glitter, 0.3 to 0.7% of tribasic lead sulfate and dibasic lead sulfate and 0.3 to 0.7% of calcium ricinoleate. The floor processing technology mainly comprises the following steps: batching; feeding; extrusion; press polish; cooling; rolling; and warehousing. According to the invention, a mixture of tribasic lead sulfate, dibasic lead sulfate and calcium ricinoleate is used as a stabilizing agent, so harm of lead in tribasic lead sulfate and dibasic lead sulfate to the human body is reduced, and floor stability is guaranteed.

Owner:浙江通达塑业有限公司

Porous ultra-bright polyester fiber and preparation method thereof

ActiveCN107938000AUneven solutionSolve the strength problemFilament/thread formingSynthetic polymer filament chemical after-treatmentBreaking strengthPolyester

The invention relates to a porous ultra-bright polyester fiber and a preparation method thereof. The preparation method comprises the steps that polyester melt undergoes metering, composite spinneretextruding, cooling, oiling, stretching, heat setting and winding, wherein a composite spinneret is provided with a triangular spinneret hole and a --shaped spinneret hole, the ratio of micropore lengths of the triangular spinneret hole and the --shaped spinneret hole is equal to the product of the equivalent diameter ratio and the coefficient K, the equivalent diameter is the ratio of the cross sectional area of the spinneret hole to the perimeter of the cross section, and the value range of the coefficient K is 0.97 to 1.03; an oiling agent for oiling contains crown ether, and the crown ethercontent is 67.30-85.58wt%. The preparation method is simple and reasonable, and the smooth spinning of the fiber is achieved. The prepared porous ultra-bright polyester fiber has a fineness of 75-150dtex, a breaking strength larger than or equal to 3.8 cN / dtex and an oil content of 0.90+ / -0.20%, a glossiness larger than or equal to 80% and a full-package rate larger than or equal to 99%.

Owner:JIANGSU HENGLI CHEM FIBER

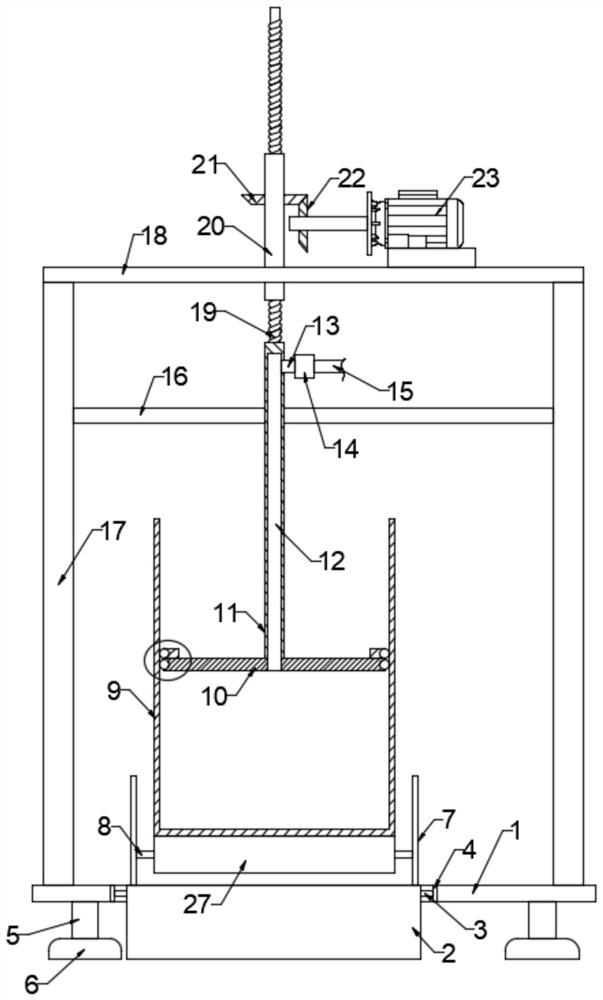

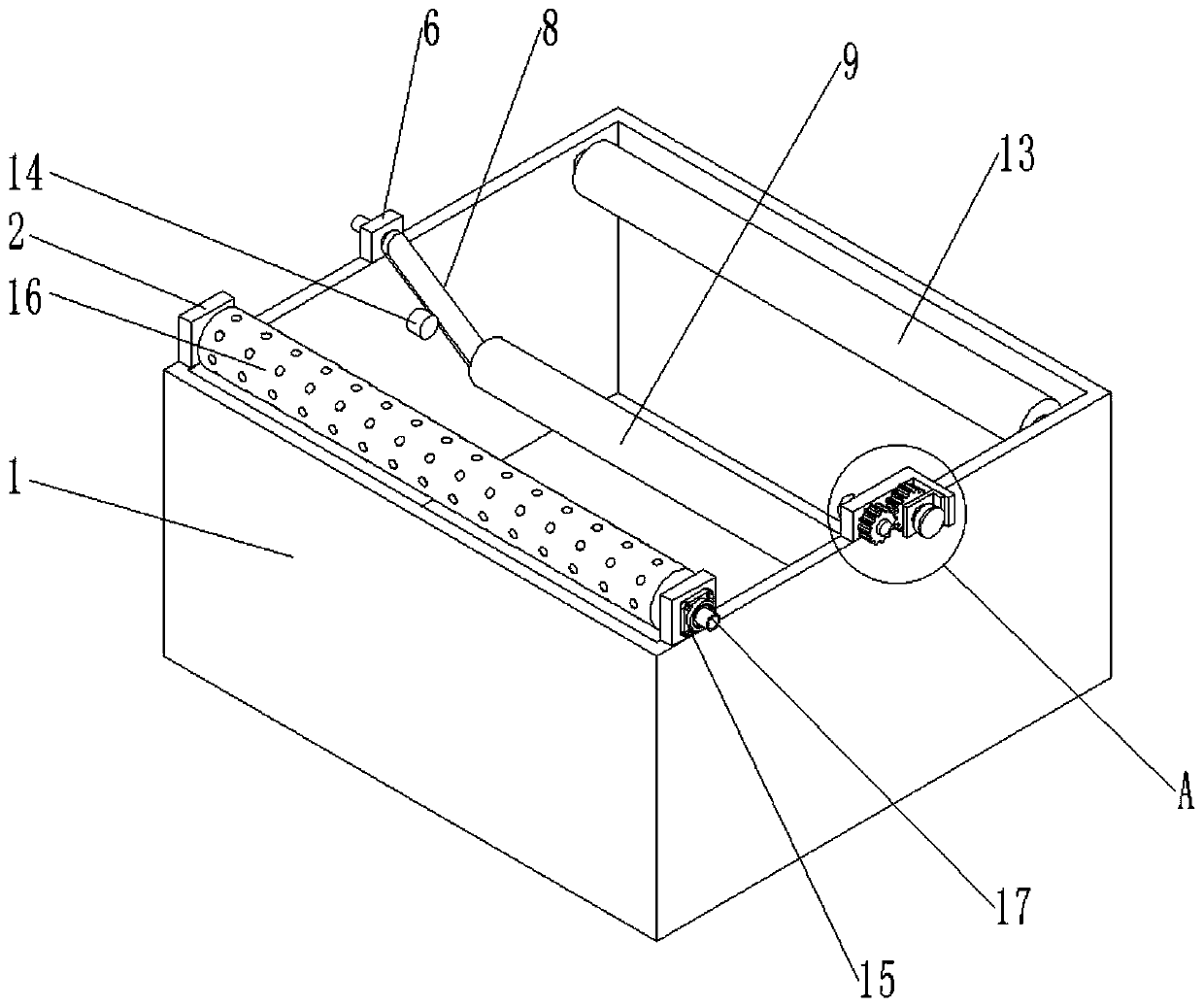

Uniform grease adding equipment for feed production

InactiveCN112644948ASave storage spaceUniform output speedConveyorsFeeding-stuffOil and greaseWorking environment

The invention relates to the technical field of feed processing, and discloses uniform grease adding equipment for feed production. The uniform grease adding equipment comprises a base, wherein a grease barrel filled with grease is arranged above the base, the grease barrel is positioned through a positioning assembly, the grease barrel is also connected with an auxiliary carrying assembly for facilitating replacement of the grease barrel, and an extrusion piston plate is nested in the grease barrel; the extrusion piston plate and a grease barrel inner wall assembly are provided with sealing assemblies, the axis of the extrusion piston plate is fixedly connected with a prismatic extrusion rod, the prismatic extrusion rod is connected with an extrusion mechanism driving the prismatic extrusion rod to ascend and descend, and a grease channel is formed in the prismatic extrusion rod and communicated with the grease barrel cavity below the extrusion piston plate; and the other end of the grease channel is communicated with a connecting oil pipe which is provided with a connector, and the connector is provided with a hose. The uniform grease adding equipment is ingenious in structure, capable of adding grease evenly, low in labor intensity, high in working efficiency, neat and attractive in working environment and convenient to maintain.

Owner:无锡市昌顺科技有限公司

A kind of lightweight thermal fiber and preparation method thereof

ActiveCN107988640BImprove stabilityEasy to processNew-spun product collectionHollow filament manufacturePolyesterPolymer science

The invention relates to a lightweight heat-preserving fiber and a preparation method thereof. The polyester melt is measured, extruded through a composite spinneret, cooled, oiled, stretched, heat-set and wound to obtain a lightweight heat-preserving fiber. The spinneret plate is equipped with hollow spinneret holes and circular spinneret holes at the same time, and the ratio of the micropore length of the hollow spinneret holes to the round spinneret holes is equal to the equivalent diameter of the hollow spinneret holes and the round spinneret holes The product of the ratio and the coefficient K, the equivalent diameter is the ratio of the cross-sectional area of the spinneret hole to the circumference of the cross-section, the value range of the coefficient K is 0.97 to 1.03, the oil used for oiling contains crown ether, and crown The content of ether is 67.30-85.58wt%, and the weight of the prepared lightweight thermal fiber is 100g / m 2 The thermal conductivity of the knitted fabric is ≤0.150W / m·K. The method of the invention is simple and reasonable, and the prepared fiber has good light-weight, heat-retaining and moisture-absorbing and perspiration-releasing performances, and has excellent popularization value.

Owner:JIANGSU HENGLI CHEM FIBER

Hot-wet comfortable polyester fiber DTY silk used in summer and preparation method thereof

ActiveCN108035001AGood thermal and humidity comfortEasy to processFilament/thread formingSynthetic polymer filament chemical after-treatmentPolyesterFiber

The invention relates to hot-wet comfortable polyester fiber DTY silk used in summer and a preparation method thereof. The method comprises the steps that spinning melt is measured, extruded through acomposite spinneret plate, cooled, oiled and wound to prepare POY silk, and the POY silk is guided through a silk guide pipe, meshed, heated, stretched, subjected to false twisting and hot shaping and wound to prepare the hot-wet comfortable polyester fiber DTY silk used in summer. The material is polyester dispersed with a matting agent, the core absorption height of prepared knitted fabric is larger than or equal to 160 millimeters, the evaporation rate is larger than or equal to 0.24 g / h, cross spinneret holes and circular spinneret holes are formed in the composite spinneret plate, the specific value of the micropore lengths of the cross spinneret holes and the circular spinneret holes is equal to the product of the proportion of equivalent diameters and the coefficient K, the value range of the coefficient K is between 0.97 and 1.03, an oiling agent which is used for oiling contains crown ether, and the content of crown ether is 67.30-85.58%. The preparation method is simple, andthe obtained fiber is excellent in hot-wet comfortable performance.

Owner:JIANGSU HENGLI CHEM FIBER

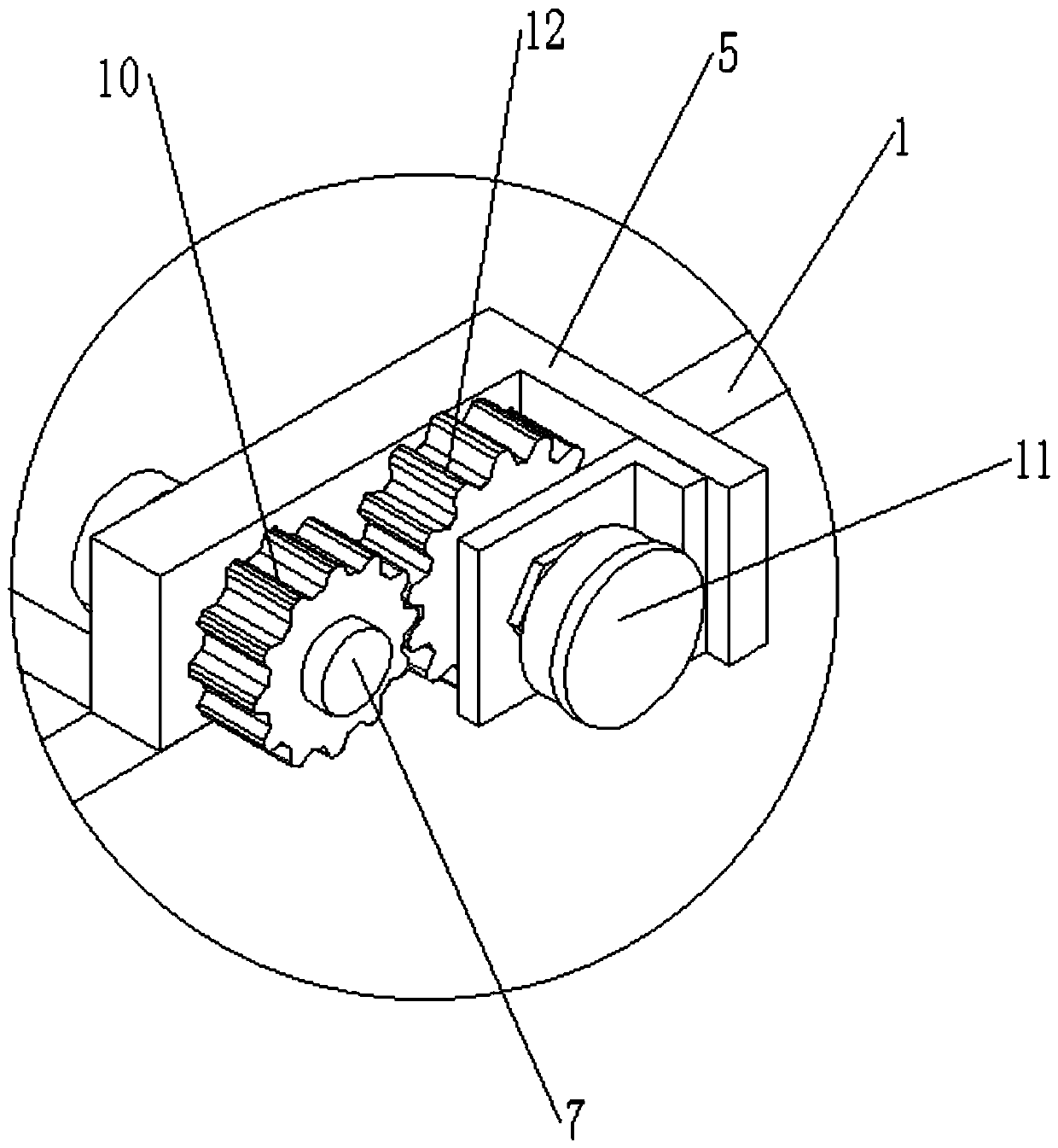

Thin film extruding speed control device for plastic extruding and drawing machine

The invention discloses a thin film extruding speed control device for a plastic extruding and drawing machine. The thin film extruding speed control device for the plastic extruding and drawing machine comprises a cooling water tank; a guide roller is mounted at the left upper end of the cooling water tank; a first supporting roller is arranged in the cooling water tank; a front mounting frame and a rear mounting frame are respectively arranged on the front side wall and the rear side wall of the upper end in the middle of the cooling water tank; each of the front mounting frame and the rearmounting frame is connected with a rotating shaft; each of the two rotating shafts is connected with a connecting mounting plate; a second supporting roller is mounted on the two connecting mounting plates; a first gear is mounted on a shaft body, positioned outside the cooling water tank, of the rotating shaft connected to the front mounting frame; a potentiometer is mounted on the front mountingframe; the potentiometer is electrically connected to a control frequency converter of a driving motor of a screw of the plastic extruding and drawing machine; a second gear is mounted on a rotatingadjusting shaft of the potentiometer; and the second gear is engaged with the first gear. According to the thin film extruding speed control device for the plastic extruding and drawing machine, the extruding speed of a thin film can be automatically adjusted and controlled so that the extruding speed of the thin film is kept consistent with the traction speed of a tractor.

Owner:浙江亚设塑业有限公司

A kind of hot and humid comfortable polyester fiber fdy yarn for winter and its preparation method

ActiveCN108035009BGood thermal and humidity comfortEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention relates to a hot and humid and comfortable polyester fiber FDY silk for winter and a preparation method thereof. The preparation method comprises the following steps that the hot and humid and comfortable polyester fiber FDY silk for winter is prepared by conducting weighing, extrusion by a composite spinneret plate, cooling, oiling, stretching, heat shaping and winding on a spinningmelt, the texture of the silk is polyester with a matte agent being dispersed, the thermal resistance of the obtained woven fabric is higher than or equal to 0.18m<2>. DEG C / W, the moisture vapor resistance of the woven fabric is lower than or equal to 14 Pa.m<2> / W, cross-shaped spinneret orifices and double-cross-shaped spinneret orifices are formed in the composite spinneret plate simultaneously, the micropore length ratio of the cross-shaped spinneret orifices and the double-cross-shaped spinneret orifices is equal to product of the equivalent diameter ratio and the coefficient K, the value range of the coefficient K is between 0.97 and 1.03, an oiling agent used in the oiling contains crown ether, and the content of crown ether is 67.30-85.58wt%. The preparation method is simple, theobtained polyester fiber FDY is excellent in thermal-wet comfort, and has considerable application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

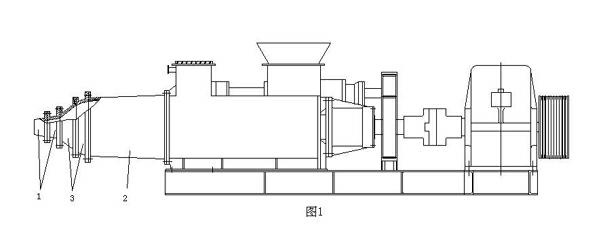

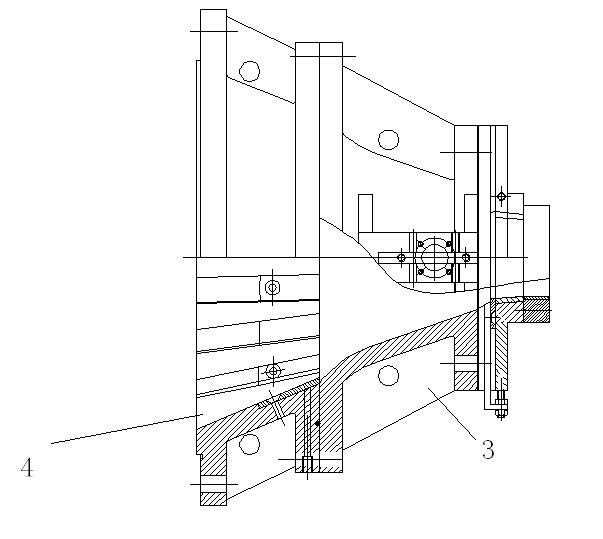

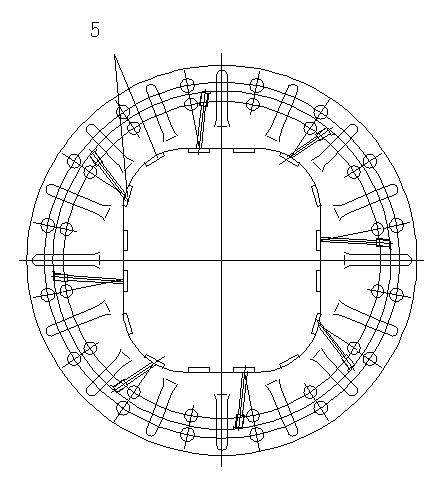

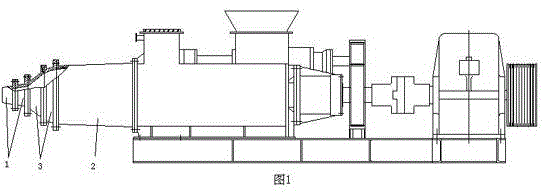

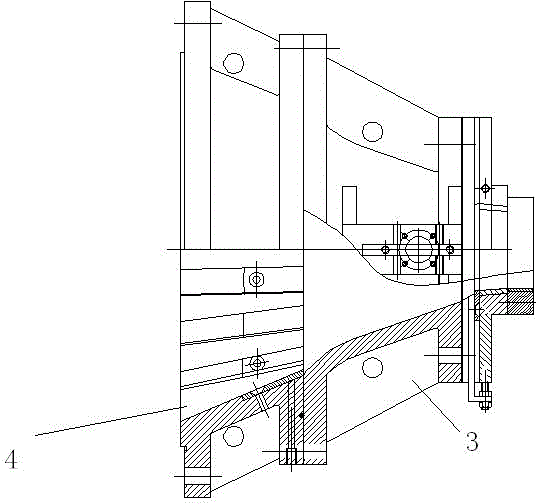

Machine neck of vacuum brick extruding machine

The invention discloses a machine neck of a vacuum brick extruding machine, and the machine neck provided by the invention is arranged between the machine head and mud cylinder of the vacuum brick extruding machine. The machine neck is in a two-section structure, and the interior of a transition machine neck arranged at the upstream of the machine neck is provided with a lubrication mechanism forcarrying out partitioned lubrication on mud materials. The transition machine neck is equipped with a plurality of guide mechanisms, so that under the interference of the guide mechanisms, the rotarymotion of the mud materials which enter into the transition machine neck from the mud cylinder is converted into a linear motion.

Owner:赵培龙

A kind of porous ultra-bright polyester fiber and its preparation method

ActiveCN107938000BFluffy goodConsistent extrusion speedFilament/thread formingSynthetic polymer filament chemical after-treatmentPolyesterPolymer science

The invention relates to a porous ultra-bright polyester fiber and a preparation method thereof. The preparation method comprises the steps that polyester melt undergoes metering, composite spinneretextruding, cooling, oiling, stretching, heat setting and winding, wherein a composite spinneret is provided with a triangular spinneret hole and a --shaped spinneret hole, the ratio of micropore lengths of the triangular spinneret hole and the --shaped spinneret hole is equal to the product of the equivalent diameter ratio and the coefficient K, the equivalent diameter is the ratio of the cross sectional area of the spinneret hole to the perimeter of the cross section, and the value range of the coefficient K is 0.97 to 1.03; an oiling agent for oiling contains crown ether, and the crown ethercontent is 67.30-85.58wt%. The preparation method is simple and reasonable, and the smooth spinning of the fiber is achieved. The prepared porous ultra-bright polyester fiber has a fineness of 75-150dtex, a breaking strength larger than or equal to 3.8 cN / dtex and an oil content of 0.90+ / -0.20%, a glossiness larger than or equal to 80% and a full-package rate larger than or equal to 99%.

Owner:JIANGSU HENGLI CHEM FIBER

Machine neck of vacuum brick extruding machine

InactiveCN102152388BConsistent extrusion speedUniform structureCeramic shaping apparatusLinear motionBrick

The invention discloses a machine neck of a vacuum brick extruding machine, and the machine neck provided by the invention is arranged between the machine head and mud cylinder of the vacuum brick extruding machine. The machine neck is in a two-section structure, and the interior of a transition machine neck arranged at the upstream of the machine neck is provided with a lubrication mechanism for carrying out partitioned lubrication on mud materials. The transition machine neck is equipped with a plurality of guide mechanisms, so that under the interference of the guide mechanisms, the rotary motion of the mud materials which enter into the transition machine neck from the mud cylinder is converted into a linear motion.

Owner:赵培龙

A kind of warm and humid comfortable polyester fiber dty yarn for winter and its preparation method

ActiveCN107988648BGood thermal and humidity comfortEasy to processFibre typesFilament/thread formingPolyesterYarn

The invention relates to hot-wet comfortable polyester-fiber draw texturing yarns (DTYs) for winter, and a preparation method of the DTYs. The preparation method comprises the steps of metering spinning melt, extruding by using a composite spinneret, cooling, oiling and winding to obtain polyester pre-oriented yarns (POYs); enabling the POYs to pass through a yarn guide pipe and a network, stretching under the condition of heating, carrying out false twisting and heat-setting, and molding by winding so as to obtain the hot-wet comfortable polyester-fiber DTYs; the material of the DTYs is polyester with a dispersed matting agent; the thermal resistance and moisture resistance of knitted fabric made from the DTYs are respectively more than or equal to 0.16m<2>.DEG C / W and less than or equalto 12Pa.m<2> / W; the composite spinneret is provided with a cross-shaped spinneret orifice and a double-cross shaped spinneret orifice; the ratio of the micropore length of the cross-shaped spinneret orifice to the micropore length of the double-cross shaped spinneret orifice is equal to a product of the ratio of the equivalent diameter and a coefficient K, wherein the value range of the coefficient K is 0.97-1.03; an oiling agent for oiling contains crown ether, and the content of the crown ether is 67.30-85.58wt%. The preparation method provided by the invention is simple, and the obtained hot-wet comfortable polyester-fiber DTYs are excellent in hot-wet comfort performance.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of polyester hemp-like different shrinkage composite yarn and its preparation method

ActiveCN108130624BSimple preparation processImprove fluffinessMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterPolymer science

The invention relates to a polyester flax-like type different shrinkage composite yarn and a preparation method thereof. Firstly, a modified polyester yarn POY and a modified polyester yarn FDY are prepared respectively, then the modified polyester yarn POY and the modified polyester yarn FDY are compounded to prepare the polyester flax-like type different shrinkage composite yarn; the chromatic aberration [delta]E of the prepared polyester flax-like type different shrinkage composite yarn is less than 0.200; a bundle of the yarn POY or FDY extruded by a same spinneret plate contains a singleyarn shaped in a Chinese character 'wang' manner and a five-leaf single yarn; a molecular chain of modified polyester consists of a diol chain segment with a branched chain, and diol with the branchedchain has the structural formula defined in the specification, wherein R1 and R2 are straight-chain alkylene with the carbon atom number of 1-3 , R3 is alkyl with the carbon atom number of 1-5, and R4 is alkyl with the carbon atom number of 2-5. The method is simple and reasonable, and the prepared composite yarn has good fluffy property and moisture absorption and perspiration elimination properties.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of hot and humid comfortable polyester fiber fdy yarn for summer and its preparation method

ActiveCN108035010BGood thermal and humidity comfortEasy to processNew-spun product collectionFibre typesPolyesterHeat setting

The invention relates to a summer heat and humidity comfortable polyester fiber FDY yarn and a preparation method thereof. The preparation method is as follows: measuring the spinning melt, extruding through a composite spinneret, cooling, oiling, stretching, heat setting and Summer hot and humid comfortable polyester fiber FDY yarn is obtained by winding, the material is polyester dispersed with a matting agent, the wicking height of the woven fabric made by it is ≥ 135 mm, and the evaporation rate of the woven fabric is ≥ 0.22 g / Hours, the composite spinneret is equipped with cross-shaped spinneret holes and circular spinneret holes at the same time, and the ratio of the micropore length of the cross-shaped spinneret holes to the circular spinneret holes is equal to the product of the ratio of the equivalent diameter and the coefficient K, and the coefficient The value range of K is 0.97-1.03, and the oil agent for oiling contains crown ether, and the content of crown ether is 67.30-85.58wt%. The preparation method of the invention is simple, the obtained fiber has excellent heat and moisture comfort performance, and has promising application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of polyester imitation cotton type differential shrinkage composite yarn and preparation method thereof

ActiveCN108385226BImprove fluffinessGood moisture wicking effectFilament/thread formingYarnPolyesterPolymer science

The invention relates to polyester cotton-like type differential shrinkage composite yarns and a preparation method thereof. The preparation method comprises the following steps: respectively preparing modified polyester POY (Pre-Oriented Yarn) and FDY (Fully Drawn Yarn) wires, and then compounding the POYs with the FDYs to prepare the polyester cotton-like type differential shrinkage composite yarns, wherein the color difference delta E of the prepared composite yarns is less than 0.200, a beam of POYs or FDYs extruded by the same yarn spraying plate simultaneously contains crossed single yarns and trefoiled single yarns; a molecular chain of the modified polyester comprises a branched diol chain segment, a structural formula of the branched diol is as follows: the formula (1) is shown inthe description; in the formula, R1 and R2 are straight-chain alkylene with carbon atomic number 1-3, R3 is alkyl with carbon atomic number 1-5, R4 is alkyl with carbon atomic number 2-5, and a matteagent dispersed in the modified polyester is amorphous titanium dioxide and amorphous silicon dioxide or a mixture of calcium carbonate and the amorphous silicon dioxide. The method disclosed by theinvention is simple and reasonable, and the prepared composite yarns have good fluffy, moisture absorption and perspiration performance.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of polyester wool-like different shrinkage composite yarn and its preparation method

ActiveCN108130605BConsistent extrusion speedMoisture wickingArtificial filament heat treatmentMelt spinning methodsYarnPolyester

The invention relates to a polyester wool-like different-shrinkage composite wire and a preparing method thereof. The method comprises the steps of firstly, modified polyester POY and FDY wires are produced separately; then, the POY and FDY wires are compounded to produce the polyester wool-like different-shrinkage composite wire, wherein the chromatic aberration delta E of the produced compositewire is smaller than 0.200. A bunchof POY or FDY wires extruded through the same spinneret plate contain double-cross single wires and trilobal single wires simultaneously, a modified polyestermolecular chain contains a dihydric alcohol chain section with a branch chain, and the structural formula of the dihydric alcohol chain section with the branch chain is shown in the description, wherein R1 and R2 are straight chain alkylidenes of which the number of carbon atoms is 1-3, R3 is an alkyl of which the number of carbon atoms is 1-5, R4 is an alkyl of which the number of carbon atoms is 2-5, and a matt agent in modified polyester is a mixture of amorphous titanium dioxide and amorphous silicon dioxide or calcium carbonate and amorphous silicon dioxide. The preparing method is simple and reasonable, and the prepared composite wire has good fluffy and hygroscopic and sweat releasingperformance.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of hot and humid comfortable polyester fiber dty yarn for summer and its preparation method

ActiveCN108035001BGood thermal and humidity comfortEasy to processFilament/thread formingSynthetic polymer filament chemical after-treatmentPolyesterYarn

The invention relates to a DTY yarn of hot and humid polyester fiber for summer use and a preparation method thereof. The preparation method is as follows: measuring the spinning melt, extruding it through a composite spinneret, cooling, oiling and winding to obtain a POY yarn , POY yarn is made of hot and humid comfortable polyester fiber DTY yarn for summer through wire guide tube, network, heating stretching, false twisting, heat setting and winding molding. The material is polyester dispersed with matte agent. The wicking height of the knitted fabric is ≥160 mm, the evaporation rate is ≥0.24 g / hour, and the composite spinneret is equipped with cross-shaped spinneret holes and circular spinneret holes at the same time. The micropore length ratio is equal to the product of the equivalent diameter ratio and the coefficient K, and the value range of the coefficient K is 0.97-1.03. The oil agent for oiling contains crown ether, and the crown ether content is 67.30-85.58wt%. The preparation method of the invention is simple, and the obtained fiber has excellent heat and moisture comfort performance.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com