Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Combustion hindrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alpha and beta two-phase magnesium lithium alloy with excellent casting performance and heat transfer performance

The invention discloses a dual-phase α+β magnesium-lithium alloy with excellent casting performance and heat transfer performance and a processing technology thereof. According to weight percentage, the composition of the alloy is: Li: 8.0‑10.0wt.%, Ge: 0.2‑0.8wt.%, Cd: 0.6‑0.8wt.%, Bi: 0.2‑0.5wt.%, Zr: 0.4‑ 0.8wt.%, Pd: 0.1‑0.2wt.%, Cu: 0.3‑0.5wt.%, Al: 1.8‑3.4wt.%, Fe: 0.2‑0.5wt.%, Mn: 0.1‑0.4wt.%, The balance is magnesium. The magnesium-lithium alloy for die-casting has high thermal conductivity that traditional magnesium-lithium alloys do not possess. This enables the alloy to have further specific applications in the occasions where the heat generation is large and the weight of the device is required, and it is convenient for large-scale industrial application.

Owner:GUANGZHOU YUZHI TECH CO LTD

Mg-Ca-In magnesium alloy for pressure casting and with high damping characteristic

InactiveCN108220723AImprove flame retardant performanceCombustion hindrancePressure castingMagnesium calcium

The invention discloses Mg-Ca-In magnesium alloy for pressure casting and with high damping characteristic as well as a processing process thereof. The alloy comprises the following components in percentage by weight: 0.6 to 1.5 percent of Ca, 1.6 to 3.2 percent of In, 3.0 to 4.5 percent of Sn, 0.8 to 1.5 percent of Sb, 0.4 to 0.8 percent of Zr, 0.2 to 0.5 percent of Be and the balance of magnesium. The magnesium calcium alloy has excellent pressure casting property and also has excellent damping property. The bottom layer property of the traditional magnesium for casing is expected to be innovated and optimized, so positive significance in development and improvement of the magnesium alloy pressure casting process, even the whole pressure casting industry and the technology thereof is achieved.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-wear-resistance high-thermal-conductivity zinc alloy containing strontium and sodium and machining process thereof

The invention discloses a high-wear-resistance high-thermal-conductivity zinc alloy containing strontium and sodium. The alloy comprises, by weight, 0.8-1.2wt% of Na, 0.2-0.3wt% of Sr, 4. 5-6.3wt% ofIn, 0.8-1.2wt% of Zr, 0.4-0. 8wt% of Si, 2.4-3.6wt% of Sn, 0.2-0.5wt% of Yb, 0.1-0.2wt% of Nd, 0.8-1.0wt% of S and the balance of zinc. Compared with a traditional zinc alloy, the high-wear-resistancehigh-thermal-conductivity zinc alloy containing strontium and sodium has excellent mechanical property and heat conduction performance.

Owner:GUANGZHOU YUZHI TECH CO LTD

High damping Ca and Mg containing aluminum alloy for pressure casting and processing technology thereof

InactiveCN108384995AImprove flame retardant performanceCombustion hindrancePressure castingAluminium alloy

The invention discloses high damping Ca and Mg containing aluminum alloy for pressure casting and a processing technology thereof. The alloy is prepared from the following components in percentage byweight: 0.8-1.5wt% of Ca, 2.0-8.0wt% of Mg, 3.0-5.0wt% of Sn, 0.5-1.2wt% of Y, 0.4-0.6wt% of Mo, 0.2-0.5wt% of Be and the balance of aluminum. The aluminum-calcium alloy has excellent pressure castingperform and excellent damping perform and is expected to have positive significance of development and promotion of an aluminum alloy pressure casting technology and even the whole pressure casting industry and a technology thereof.

Owner:GUANGZHOU YUZHI TECH CO LTD

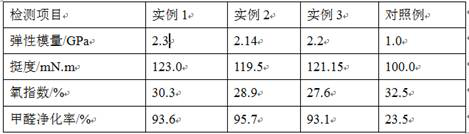

Preparation method of environment-friendly flame-retardant fiberboard

InactiveCN113580294AGood barrier effectImprove flame retardant performanceWood treatment detailsWood impregnation detailsOxideAluminum nitrate

The invention relates to a preparation method of an environment-friendly flame-retardant fiberboard, and belongs to the technical field of decorative materials. Magnesium nitrate and aluminum nitrate are used as raw materials, rare earth and diatomite are doped, diatomite with magnesium-aluminum hydroxide of a layered structure deposited is prepared through a coprecipitation method, the layered structure is bridged through the diatomite, the blocking effect is achieved, holes in the surface of a carbon layer formed in the combustion process are reduced, the better blocking effect is achieved, further entry and release of combustible gas and oxygen are inhibited, and at the same time, cooperation with the rare earth elements is adopted to achieve an effective smoke suppression effect, cooperation with a flame retardant is adopted to achieve flame retardance, the flame retardance of the fiberboard is effectively improved, the effects of reducing smoke and heat release in the combustion process are achieved, and meanwhile, the effects of dehumidification, deodorization, indoor air purification and the like by utilizing the diatomite are achieved. Diatomite is used as an additive to manufacture the fiberboard which is light in weight, flame-retardant and capable of reducing indoor toxic gas, and the artificial board is endowed with new functions of flame retardance, low formaldehyde release and capability of adjusting the indoor environment.

Owner:深圳市奥科杰环保材料科技有限公司

High-heat-conductivity Ba and Se including aluminum alloy for copper-clad aluminium conductor and processing process of high-heat-conductivity Ba and Se including aluminum alloy

InactiveCN108220702AReduce weightImprove flame retardant performanceCopper-clad aluminium wireHeat conducting

The invention discloses a high-heat-conductivity Ba and Se including aluminum alloy for a copper-clad aluminium conductor and a processing process of the high-heat-conductivity Ba and Se including aluminum alloy. The alloy is prepared from, by weight percent, 0.5-1.2 wt.% of Ba, 0.2-0.6 wt.% of Ge, 0.2-0.4 wt.% of Hf, 0.2-0.5 wt.% of Ru, 0.1-0.3 wt.% of Os, 0.4-0.8 wt.% of Se and the balance aluminum. The aluminum-barium alloy has the excellent mechanical property and heat conducting property failing to achieve on a traditional copper-clad aluminum conductor and has wide purposes in the electric appliance manufacturing industry, the electric wire industry and the radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

Corrosion-resistant Pb-Li-Zr lead-lithium alloy with high-temperature thermostability

InactiveCN108251689AFix compatibility issuesSolve interface compatibility issuesShieldingLithiumNuclear reactor

The invention discloses a corrosion-resistant Pb-Li-Zr lead-lithium alloy with high-temperature thermostability and a processing technology thereof. The alloy comprises the ingredients of, by weight,1.2-2.5% of Li, 0.2-0.4% of Zr, 0.2-0.3% of Sm, 0.3-0.5% of In, 0.4-0.5% of Ni, 0.2-0.5% of Sn, and the balance lead. The lead-lithium alloy has the high-temperature thermostability which is not possessed by a lead alloy used for a traditional shielding material and has the high corrosion resistance; and the lead-lithium alloy is used for the fields such as nuclear pile, medical radioactive sourceshielding and nuclear waste disposal in the tropical environment, safe running of a nuclear reactor system can be effectively ensured, and the running life of the system is prolonged.

Owner:GUANGZHOU YUZHI TECH CO LTD

High thermal conductivity and damping silver-lithium electric contact alloy

The invention discloses an Ag-Li-Sn silver lithium electrical contact alloy with high thermal conductivity and damping and a processing technology thereof. By weight percentage, the chemical composition of the alloy is: Li:0.5‑3.0wt.%, Sn:1.0‑1.5wt.%, Zn:2.0‑4.0wt.%, Ba:0.5‑1.5wt.%, Sr:0.5‑ 1.2wt.%, Pd: 0.2‑0.4wt.%, Zr: 0.2‑0.3wt.%, Th: 0.1‑0.2wt.%, Ce: 0.5‑0.8wt.%, B: 0.5‑1.0wt.%, The balance is silver. Compared with silver alloys used in traditional electrical contact materials, this material has excellent mechanical properties, high electrical conductivity and high damping coefficient.

Owner:GUANGZHOU YUZHI TECH CO LTD

Cu-Li-Ge copper-lithium alloy replacing beryllium bronze

A Cu-Li-Ge copper-lithium alloy replacing beryllium bronze, the chemical composition of the alloy is: Li:0.2-1.6wt.%, Ge:2.0-3.0wt.%, Sr:2.0-3.0wt. .%, Ce: 0.2‑0.4wt.%, Ho: 0.2‑0.3wt.%, Pr: 0.2‑0.4wt.%, V: 0.6‑0.8wt.%, S: 0.8‑2.6wt.%, balance for copper. The material has excellent mechanical properties and electrical conductivity. Elastic modulus: 125‑138GPa; Yield strength: 950‑1080MPa; Tensile strength: 1100‑1200MPa; Elongation: 4‑10%; Conductivity (%IACS): 50‑80, while traditional beryllium copper is 18‑25 .

Owner:GUANGZHOU YUZHI TECH CO LTD

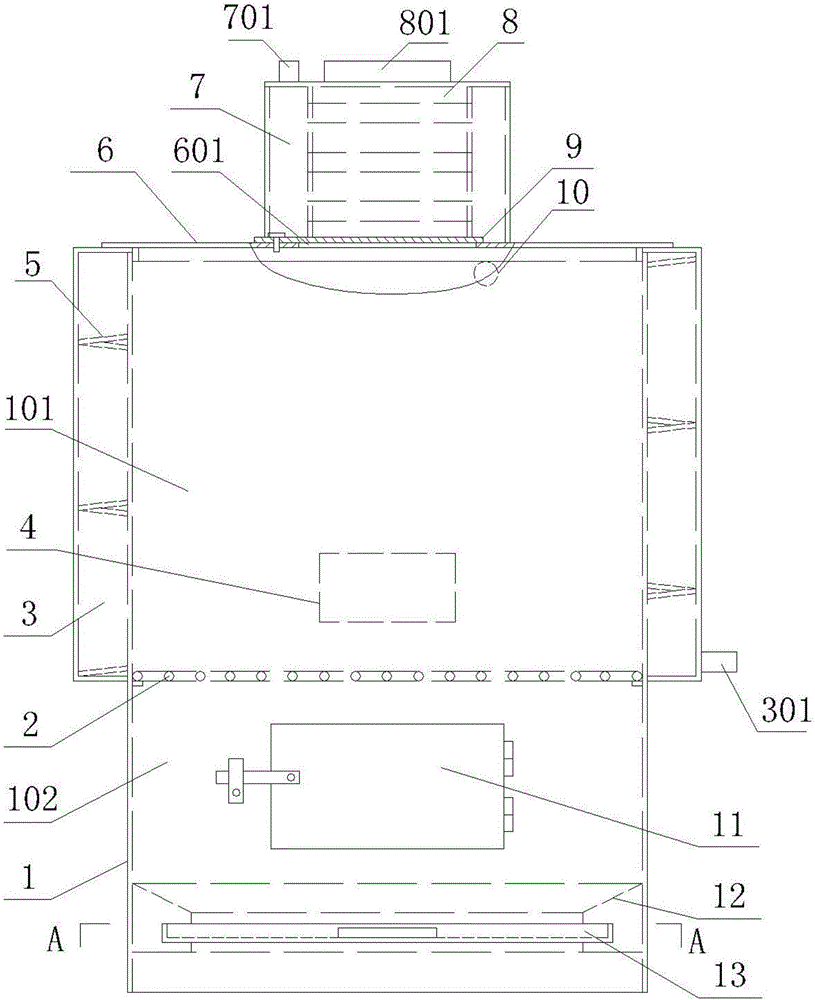

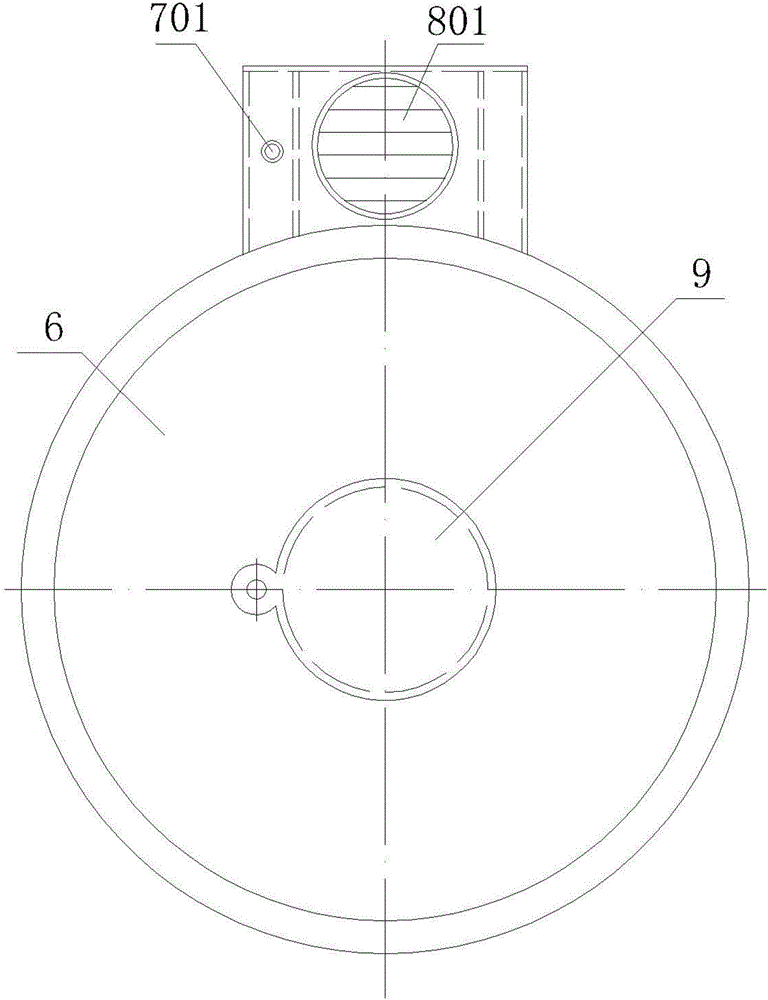

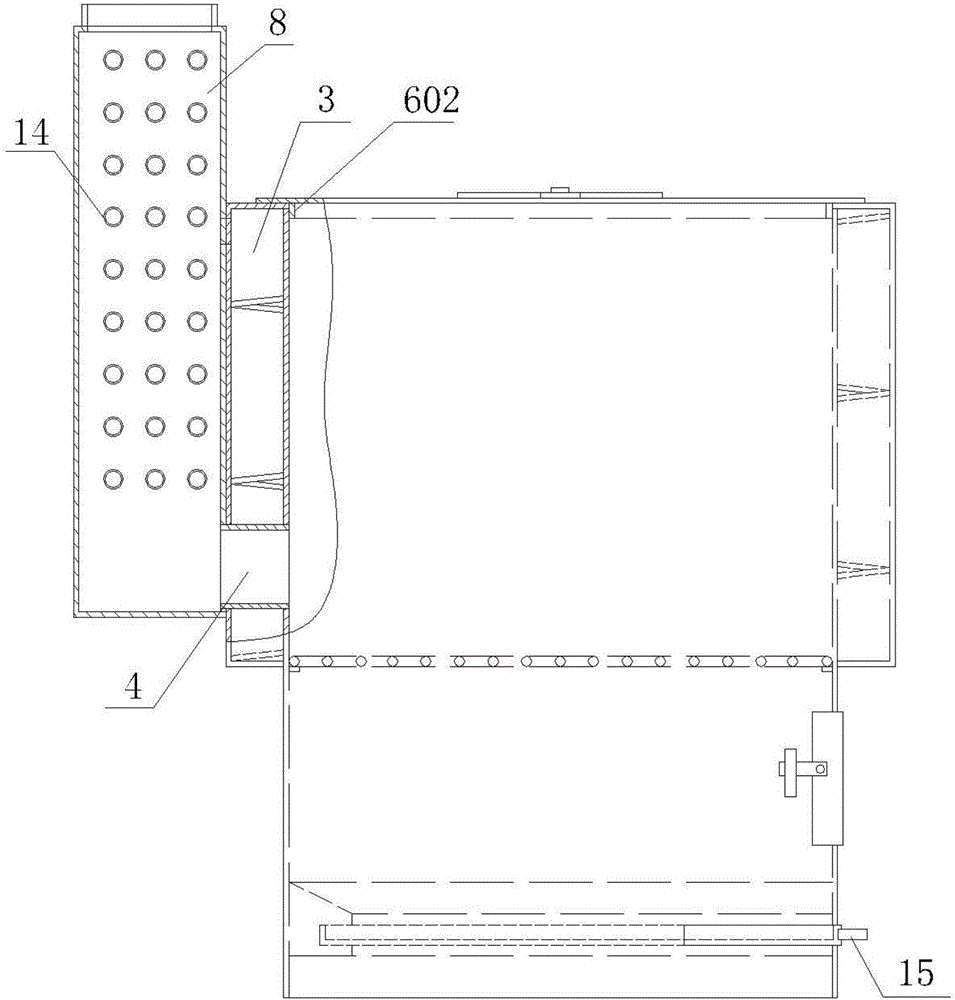

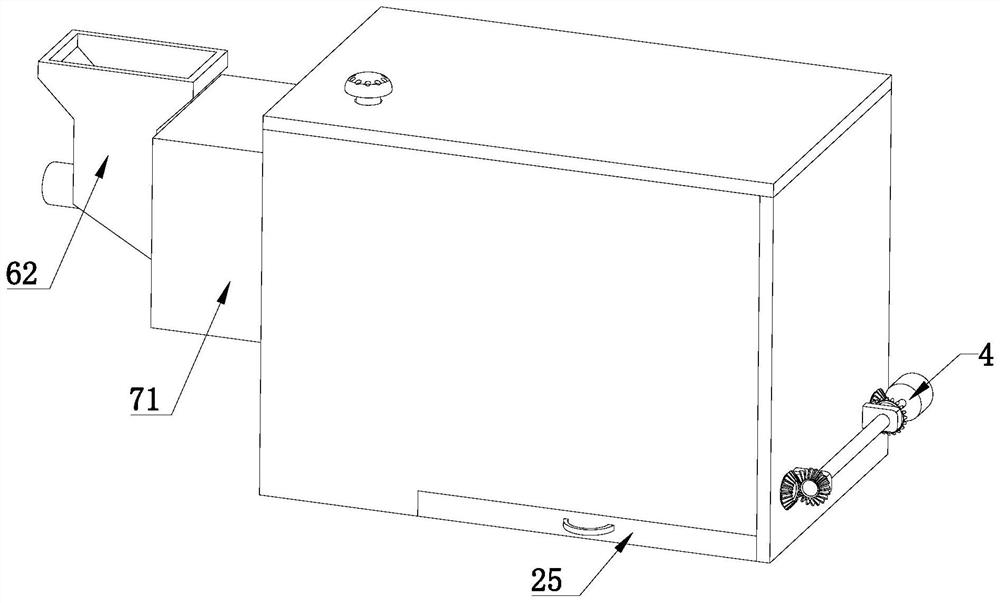

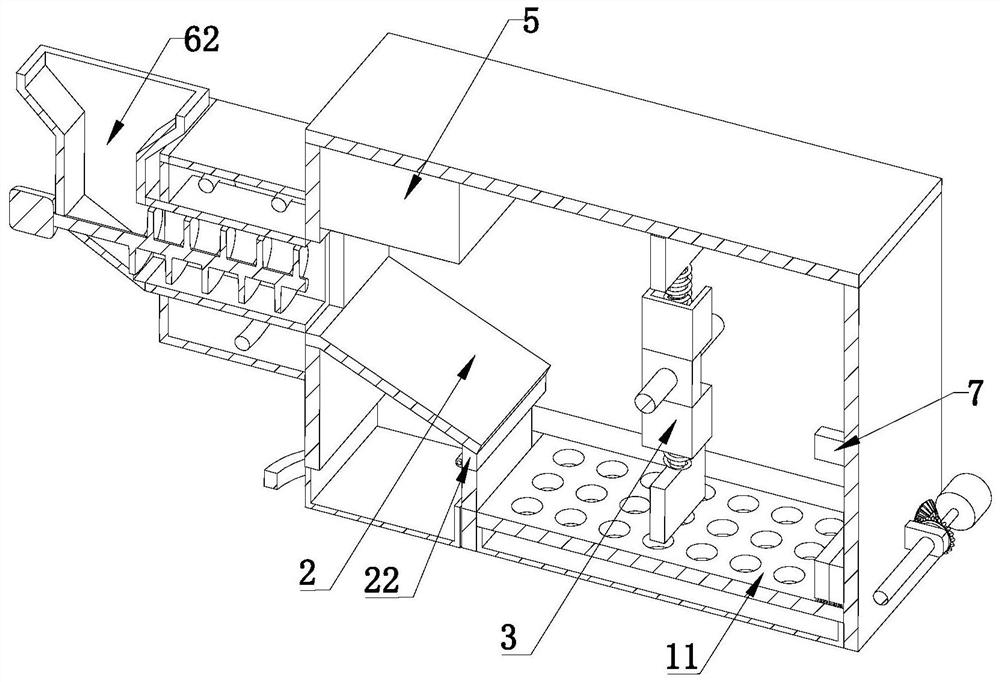

Top blowing and lower combustion type boiler

The invention discloses a top blowing and lower combustion type boiler. The top blowing and lower combustion type boiler comprises a boiler body, and a fire grate is arranged inside the boiler body; an inner cavity of the boiler body is divided into a hearth and an ash chamber through the fire grate; a water jacket interlayer is arranged in the position, on the edge of the hearth, on the boiler body; a water inlet is formed in the lower end of one side of the water jacket interlayer; an upper opening of the boiler body is provided with a boiler cover; an air inlet is formed in the center of the boiler cover; an adjusting cover used for adjusting the size of the air inlet is hinged to one side of the air inlet; a smoke exhaust tank and water tanks are connected on the back side of the boiler body; a smoke vent is formed in the upper end of the smoke exhaust tank; the lower end of the smoke exhaust tank and the lower part of the hearth communicate with each other through a smoke exhaust channel which penetrates through the water jacket interlayer; the upper end of the water jacket interlayer communicates with the water tanks; and a water outlet is formed in the upper end of one of the water tanks. The top blowing and lower combustion type boiler has the beneficial effects that warm water entering the water tanks can be heated again, the utilization rate of heat energy is high, the combustion is sufficient, coal is saved, the heating speed of cold water is high, the temperature in the hearth can be prevented from decreasing, and combustion of coal in the hearth can be prevented from being hindered.

Owner:王国新

Oxidation-resistant Pb-Li-V lead-lithium alloy with high thermal stability

The invention discloses an oxidation-resistant Pb-Li-V lead-lithium alloy with high thermal stability. The alloy comprises the following components in percentage by weight: 1.4-1.8% of Li, 0.2-0.5% ofV, 0.5-0.8% of Sm, 0.3-0.8% of B, 1.4-1.9% of Ge, 0.4-0.6% of Zn, and the balance lead. The lead-lithium alloy has the high thermal stability which is not realized by a traditional lead alloy for a shielding material; and moreover, the lead-lithium alloy is high in oxidation resistance; the lead-lithium alloy is applicable to the fields such as the fields of nuclear piles, medical radioactive source shielding, and nuclear waste treatment in a tropical environment; with the adoption of the lead-lithium alloy, a nuclear reactor system can effectively safely run, and the service life of the system can be prolonged.

Owner:GUANGZHOU YUZHI TECH CO LTD

A single-phase beta magnesium-lithium alloy having excellent castability and heat transfer performance

InactiveCN107893180AReduce usageGood casting performance and heat transfer performanceSingle phaseThermal conductivity

The invention discloses a single-phase β-magnesium-lithium alloy with excellent casting performance and heat transfer performance and a processing technology thereof. According to weight percentage, the composition of the alloy is: Li: 13.0‑18.0wt.%, Cu: 1.2‑2.3wt.%, Bi: 0.4‑0.6wt.%, Sb: 0.2‑0.5wt.%, V: 0.1‑ 0.2wt.%, W: 0.1‑0.2wt.%, Ag: 0.8‑1.2wt.%, Ge: 0.3‑0.6wt.%, Co: 0.1‑0.2wt.%, and the balance is magnesium. The magnesium-lithium alloy for die-casting has high thermal conductivity that traditional magnesium-lithium alloys do not have. This enables the alloy to have further specific applications in the occasions where the heat generation is large and the weight of the device is required, and it is convenient for large-scale industrial application.

Owner:GUANGZHOU YUZHI TECH CO LTD

Sn-Li-Pt lithium tin alloy close to pure tin heat transmission performance

InactiveCN108103352AReduce usageGood heat transfer performanceTransmission performanceHeat transmission

The invention discloses Sn-Li-Pt lithium tin alloy close to pure tin heat transmission performance and a processing process of the Sn-Li-Pt lithium tin alloy. The Sn-Li-Pt lithium tin alloy comprisesthe components of, by weight, 1.8-2.4% of Li, 0.4-0.6% of Pt, 1.2-1.6% of Ge, 0.2-0.4% of V, 0.2-0.4% of Sc, 0.1-0.2% of Sm, and the balance tin. The lithium tin alloy has a high heat transmission performance not possessed by a traditional tin alloy. The melting point is 120-130 degrees. According to the Sn-Li-Pt lithium tin alloy close to pure tin heat transmission performance, the alloy has further specific application in the site that heating value is large, and device lightweight is needed; industrialize large-scale application is facilitated.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-thermal-conductivity Ge-containing magnesium alloy suitable for cold chamber die casting and processing technology thereof

InactiveCN108251728AImprove flame retardant performanceCombustion hindranceDie castingPromotion effect

The invention discloses high-thermal-conductivity Ge-containing magnesium alloy suitable for cold chamber die casting and a processing technology thereof. The alloy is prepared from the following components in percentage by weight: 0.5-1.2wt.% of Ca, 2.4-3.5wt.% of Ge, 1.0-2.5wt.% of Mn, 2.4-3.8wt.% of Ni, 0.5-1.2wt.% of Y, 0.2-0.6wt.% of Nb and the balance of magnesium. The magnesium-calcium alloy has excellent die casting properties and excellent thermal conductivity and is expected to have a promotion effect of enabling fine new materials independently researched and developed in China to occupy the market of international fine new materials.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-electric-conductivity Ba and Re-contained aluminum alloy for copper-clad aluminum conductor and machining process thereof

InactiveCN108300908AImprove flame retardant performanceCombustion hindranceConductive materialMetal/alloy conductorsRheniumMachining process

The invention discloses a high-electric-conductivity Ba and Re-contained aluminum alloy for a copper-clad aluminum conductor and a machining process thereof. The alloy comprises the following components in percentage by weight: 0.8-1.5 wt.% of Ba, 0.2-0.4 wt.% of Re, 0.2-0.3 wt.% of Zr, 0.5-0.8 wt.% of Zn, 0.1-0.2 wt.% of Pd, 0.5-0.8 wt.% of Te, and the balance of aluminum. The aluminum rhenium alloy achieves excellent mechanical performances and electric conductivity, which are not possessed by a traditional aluminum alloy for the copper-clad aluminum conductor. The alloy achieves wide purposes in the electric appliance manufacturing industry, the electric wire and cable industry and the radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

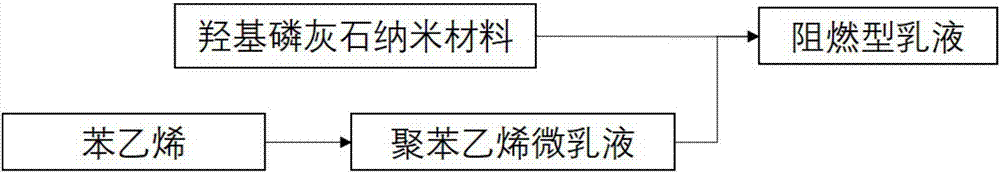

Flame-retardant emulsion and preparation method and application thereof

InactiveCN108003263AImplement Design for AssemblyCombustion hindranceFireproof paintsFiberMicrosphere

The invention belongs to the field of flameresistant materials, and discloses a flame-retardant emulsion and preparation method and application thereof. The preparation method of the flame-retardant emulsion is divided into two steps that firstly, flame-retardant nanoparticles with two-dimensional network structure are prepared; then, the flame-retardant nanoparticles are assembled on the surfacesof oil water emulsion microspheres, flame-retardant emulsion is prepared. The flame-retardant emulsion not only has good compatibility, can realize the assembly design of flame-retardant particles under nanometer size, but also can apply flame retardancy to materials, can be applied to the preparation of all kinds of flame-retardant materials, such as flame-retardant paper, flame-retardant film and flame-retardant fiber and other flame-retardant materials.

Owner:SOUTH CHINA UNIV OF TECH

High-strength high-conductivity Pb-Li-Sc lead-lithium alloy for shielding material

The invention discloses high-strength high-conductivity Pb-Li-Sc lead-lithium alloy for a shielding material and a processing technology thereof. The high-strength high-conductivity Pb-Li-Sc lead-lithium alloy comprises, by weight, 0.8-1.6wt.% of Li, 0.4-0.8wt.% of Sc, 0.2-0.5wt.% of Nb, 0.6-1.4wt.% of Co, 0.4-0.8wt.% of Sb, 0.1-0.2wt.% of Th, and the balance lead. The lead-lithium alloy has the high-strength high-conductivity performance which is not provided for traditional lead alloy for the shielding material. The high-strength high-conductivity Pb-Li-Sc lead-lithium alloy is applied to the fields of nuclear piles, medical radioactive source shielding, nuclear waste processing and the like, safe operation of a nuclear reactor system can be effectively ensured, and the system operationlife is prolonged.

Owner:GUANGZHOU YUZHI TECH CO LTD

High thermal conductivity Ca and Re containing aluminum alloy for pressure casting and machining technology thereof

The invention discloses a high thermal conductivity Ca and Re containing aluminum alloy for pressure casting and a machining technology thereof. The high thermal conductivity Ca and Re containing aluminum alloy for pressure casting is prepared from the components of, in percentage by weight, 0.6-1.5% of Ca, 1.6-3.2% of Re, 3.0-4.5% of In, 0.8-1.5% of Sc, 0.4-0.8% of Mn, 0.2-0.5% of Be, and the balance of aluminum. The kalzium metal has the excellent pressure casting property, and excellent thermal conductivity performance. The invention is predicted that the aluminum alloy has active meaning on the aluminum alloy pressure casting technology even the whole pressure casting industry and development and improvement of the technique of pressure casting.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-temperature-resisting Y containing lead-lithium alloy with extremely low machining hardening rate

The invention discloses a high-temperature-resisting Y containing lead-lithium alloy with an extremely low machining hardening rate and a machining technology of the high-temperature-resisting Y containing lead-lithium alloy. The high-temperature-resisting Y containing lead-lithium alloy comprises components including, by weight percent, 0.8 wt.%-1.5 wt.% of Li, 0.3 wt.%-0.5 wt.% of Y, 0.2 wt.%-0.4 wt.% of Nb, 0.5 wt.%-0.8 wt.% of Ge, 0.3 wt.%-0.5 wt.% of W, 0.2 wt.%-0.3 wt.% of Te and the balance lead. The lead-lithium alloy has the extremely low machining hardening rate and excellent high-temperature performance. The performance exceeds a traditional shielding material lead alloy, and the high-temperature-resisting Y containing lead-lithium alloy is widely applied to the military and civil fields.

Owner:GUANGZHOU YUZHI TECH CO LTD

High thermal conductive Pb-Li-Na alloy with excellent recovery performance

InactiveCN108251688AGood flame retardant performanceGood liquidityShieldingRadiation protectionLithium

The invention discloses a high thermal conductive Pb-Li-Na alloy with excellent recovery performance and a processing technology thereof. The high thermal conductive Pb-Li-Na alloy comprises, by weight, 0.6-1.5% of Li, 0.2-0.4% of Na, 1.2-2.8% of In, 0.3-0.8% of Zr, 0.5- 0.9% of Pd, 0.1-0.4% of W, and the balance lead. The high thermal conductive Pb-Li-Na alloy has excellent recovery performance which is not possessed by lead alloys for conventional shielding materials, and has high heat transfer performance. The high thermal conductive Pb-Li-Na alloy can be widely used in a variety of shielding conditions and has excellent radiation protection.

Owner:GUANGZHOU YUZHI TECH CO LTD

Flame-retardant high-strength high-conductivity Cu-Li-Ag copper-lithium alloy

The invention discloses a flame-retardant high-strength and high-conductivity Cu-Li-Ag copper-lithium alloy between 1200-1300 degrees and a processing technology thereof. In terms of weight percentage, the chemical composition of the alloy is: Li:0.8‑1.2wt.%, Ag:1.5‑3.0wt.%, Ca:1.5‑2.0wt.%, Sr:0.5‑1.0wt.%, In:0.1 ‑0.2wt.%, Hf: 0.2‑0.4wt.%, Pr: 0.1‑0.5wt.%, Er: 0.1‑0.2wt.%, B: 0.1‑0.2wt.%, and the balance is copper. The high-strength and high-conductivity copper-lithium alloy provided by this patent can be smelted in an atmospheric environment. Through the novel material science design, the alloying elements are screened out reasonably. By forming a layer of dense and durable protective film on the surface of copper-lithium melt, it can effectively prevent the burning of copper-lithium alloy in the atmospheric state. The material has a high tensile strength of 800-900MPa, and the electrical conductivity (%IACS) can be maintained at 94-96 (less than 80 for traditional copper alloys). And the material has an extremely excellent thermal conductivity (280-320W / m.K), and the thermal conductivity of general copper alloy materials is less than 200 W / m. K. The alloy is induction smelted under the atmosphere, the smelting and processing method is simple, and it is convenient for large-scale industrial application.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-strength die casting zinc alloy containing Ca and Be for ocean platform

The invention discloses a high-strength die casting zinc alloy containing Ca and Be for an ocean platform and a processing technology of the high-strength die casting zinc alloy. The zinc alloy is prepared from the following components by weight percent: 1.0 to 1.5 percent of Ca, 0.5 to 0.8 percent of Be, 1.5 to 2.0 percent of Cu, 0.5 to 0.9 percent of Sc, 1.5 to 2.8 percent of Co, 0.4 to 0.8 percent of Te, and the balance of zinc. The zinc-calcium alloy has excellent die casting performance and excellent mechanical performance. The high-strength die casting zinc alloy containing Ca and Be isexpected to be widely applied to the industry of novel ocean platforms.

Owner:GUANGZHOU YUZHI TECH CO LTD

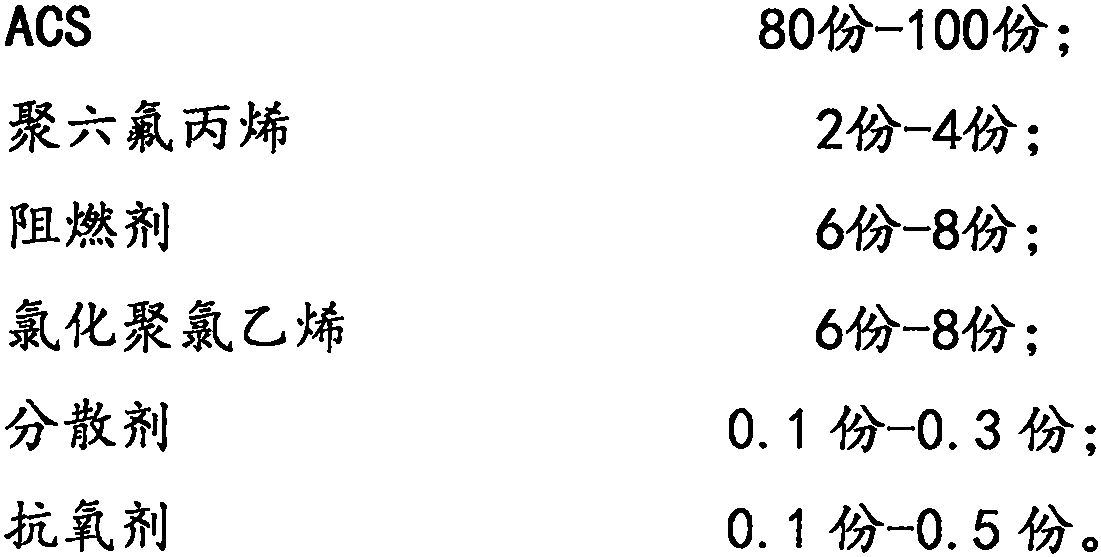

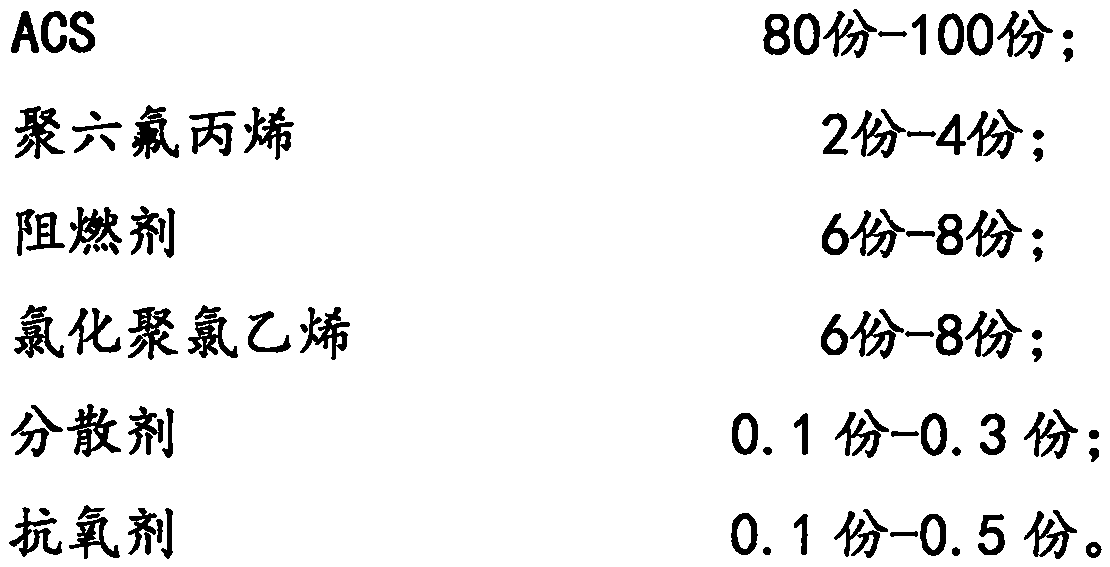

Flame-retardant ACS (acrylonitrile-vinyl chloride-styrene) composite material

InactiveCN109666242ASelf-extinguishingImprove flame retardant performanceChlorinated polyvinyl chlorideHexafluoropropylene

The invention relates to a flame-retardant ACS composite material. The flame-retardant ACS composite material is composed of, by weight part, 80-100 parts of ACS, 2-4 parts of polyhexafluoropropylene,6-8 parts of flame retardant, 6-8 parts of chlorinated polyvinyl chloride, 0.1-0.3 part of dispersant and 0.1-0.5 part of antioxidant. According to the flame-retardant ACS composite material, the chlorinated polyvinyl chloride achieves self-extinguishment and can produce HCl during combustion, which can shield and dilute combustible gas and block further combustion and accordingly enhance the flame retardance of the flame-retardant ACS composite material; through certain flame retardance of the ACS as well as self-extinguishment of the chlorinated polyvinyl chloride, the flame retardant rating of the ACS can reach V-0 only by adding in a small amount of phosphorous-nitrogen fire retardant of WRO3.

Owner:虞海盈

Ba-Pt-Cr aluminum alloy applied to corrosion-resistant copper-clad aluminum wire

InactiveCN108165838AGood flame retardant performanceGood liquidityCopper-clad aluminium wireCorrosion resistant

The invention discloses Ba-Pt-Cr aluminum alloy applied to a corrosion-resistant copper-clad aluminum wire and a machining process of the Ba-Pt-Cr aluminum alloy. The Ba-Pt-Cr aluminum alloy comprisesthe following components in percentage by weight: 0.5-0.8 wt% of Ba, 0.2-0.4 wt% of Pt, 0.5-0.6 wt% of Cr, 0.2-0.4 wt% of Sn, 0.8-1.2 wt% of Y, 0.1-0.3 wt% of Th and the balance of aluminum. The aluminum-barium alloy has excellent mechanical properties and corrosion resistance which the traditional aluminum alloy applied to the copper-clad aluminum wire does not have. The Ba-Pt-Cr aluminum alloyis widely applied to the electric appliance manufacturing industry, the electric wire and cable industry and the radio industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

Flexible In-Li-Re indium lithium alloy with corrosion resistance, high thermal conductivity and high conductivity

The invention discloses a flexible In-Li-Re indium lithium alloy with corrosion resistance, high thermal conductivity and high conductivity. The flexible In-Li-Re indium lithium alloy consists of thefollowing components in percentage by weight: 1.6-2.1wt% of Li, 0.3-0.5wt% of Re, 0.6-0.8wt% of Ni, 0.2-0.3wt% of Se, 0.1-0.3wt% of Pd, 0.1-0.2wt% of La and the balance of indium. The indium lithium alloy has high thermal conductivity, high conductivity and corrosion resistance which are not provided in a conventional indium alloy, has flexibility of pure lithium, and has a melting point of 120-140 DEG C. The alloy is great in calorific value, is further applied specifically in an occasion which needs a light apparatus, and is convenient for industrial large-scale application.

Owner:GUANGZHOU YUZHI TECH CO LTD

High thermal conductivity and electrical conductivity silver-lithium electric contact alloy

The invention discloses an Ag-Li-Sm silver-lithium alloy with high thermal conductivity and electrical conductivity and a processing technology thereof. In terms of weight percentage, the chemical composition of the alloy is: Li:0.5‑2.5wt.%, V:1.0‑1.8wt.%, Pt:0.2‑0.4wt.%, Nb:0.3‑0.8wt.%, Sr:1.0‑ 1.6wt.%, Ca: 0.2‑0.4wt.%, Sm: 0.2‑0.5wt.%, Ho: 0.1‑0.2wt.%, S: 0.5‑0.8wt.%, B: 0.5‑0.9wt.%, The balance is silver. Compared with silver alloys used in traditional electrical contact materials, this material has excellent mechanical properties, high electrical conductivity and high heat transfer coefficient.

Owner:GUANGZHOU YUZHI TECH CO LTD

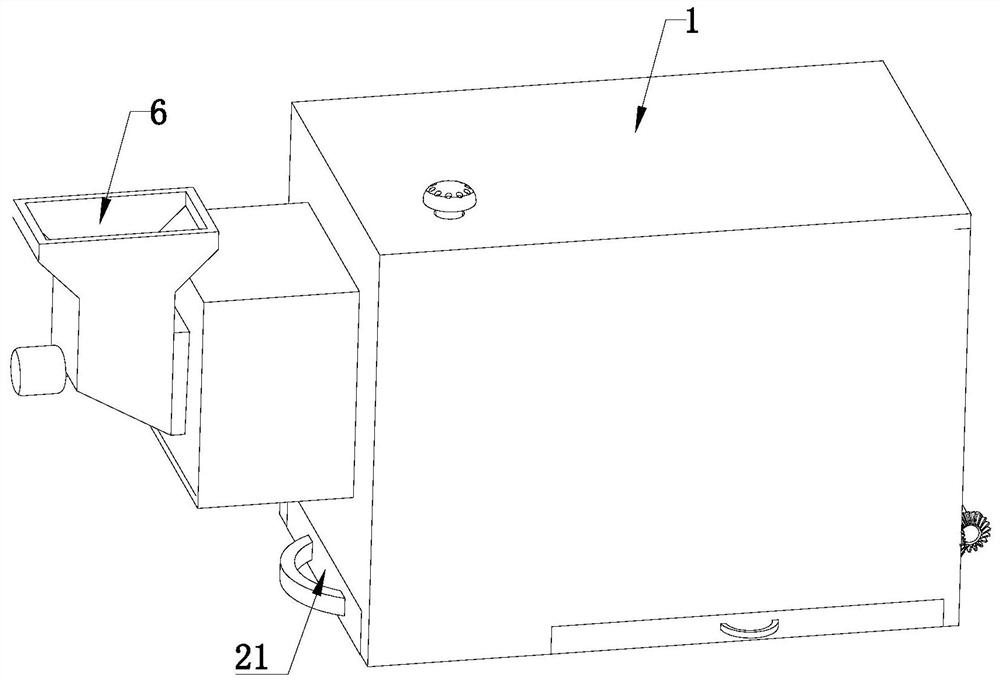

Heat insulation hearth suitable for biomass gas combustion

PendingCN113251409APromote combustionBurn fullySolid fuel combustionLump/pulverulent fuel feeder/distributionThermodynamicsEngineering

The invention discloses a heat insulation hearth suitable for biomass gas combustion, and belongs to the technical field of biomass combustion equipment.The heat insulation hearth comprises a furnace body, a bearing pore plate, a stirring mechanism, an ash scraping mechanism, an exhaust mechanism and a feeding mechanism, a feeding port is formed in the side wall of the furnace body, and an ignition module is further arranged on the side wall of the furnace body. The feeding mechanism is arranged at a feeding port in the side wall of the furnace body, the bearing pore plate is welded in the furnace body, the stirring mechanism is rotationally installed in the furnace body, the ash scraping mechanism is installed in the furnace body, one end of the ash scraping mechanism penetrates through the furnace body, and the exhaust mechanism is installed at the inner top of the furnace body. According to the heat insulation hearth suitable for biomass gas combustion, raw materials at the bottom of the bearing pore plate are stirred to make contact with the ignition module and air, combustion is promoted, meanwhile, ash generated after combustion on the bearing pore plate is removed, and the situation that following combustion is hindered is prevented.

Owner:广东宝杰环保科技有限公司

Flexible corrosion-resistant high-heat-conduction Sn-Li-Au tin-lithium alloy

The invention discloses flexible corrosion-resistant high-heat-conduction Sn-Li-Au tin-lithium alloy and a processing process thereof. The flexible corrosion-resistant high-heat-conduction Sn-Li-Au tin-lithium alloy is prepared from the following components in percentage by weight: 1.2-1.6wt% of Li, 1.5-3.6wt% of Au, 0.2-0.4wt% of Sc, 0.2-0.4wt% of Ge, 0.2-0.4wt% of Si, 0.1-0.2wt% of Sm and the balance of tin. The tin-lithium alloy has high heat conduction and corrosion resistance, which are not possessed by conventional tin alloy, has softness of pure tin, and has a melting point of 120-140 DEG C. The alloy is further applied specifically on occasions that the calorific value is great, and an apparatus needs to be light, and is convenient for industrial large-scale application.

Owner:GUANGZHOU YUZHI TECH CO LTD

Al-Li-Ba aluminum lithium alloy with higher conductivity than pure aluminium and with high thermal conductivity

The invention discloses an Al-Li-Ba aluminum-lithium alloy with higher electrical conductivity than pure aluminum and high thermal conductivity. In terms of weight percentage, the chemical composition of the alloy is: Li:2.0‑4.0wt.%, Ba:0.2‑0.6wt.%, Cu:1.5‑2.5wt.%, Ag:0.5‑1.5wt.%, Sr:1.0‑ 1.5wt.%, Pt: 0.2‑0.3wt.%, Zr: 0.2‑0.5wt.%, Nb: 0.1‑0.4wt.%, Gd: 0.1‑0.2wt.%, B: 0.5‑1.0wt.%, The balance is aluminum. Compared with traditional aluminum alloys for cables, this material has excellent mechanical properties, high electrical conductivity and high thermal conductivity.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-strength low-temperature-resistant Pb-Li-Mn lead-lithium alloy for shielding material

The invention discloses a high-strength low-temperature-resistant Pb-Li-Mn lead-lithium alloy for a shielding material and a processing technology thereof. The alloy comprises the following components, by weight percentage: 0.8-2.4wt% of Li, 0.6-1.8wt% of Mn, 0.2-0.4wt% of Se, 0.6-1.5wt% of Cr, 0.2-0.4wt% of Ba, 0.6-0.9wt% of In and the balance Pb. The lead-lithium alloy has the high strength which a traditional lead alloy for a shielding material does not have, and excellent plasticity can be achieved at extremely low temperature. The lead-lithium alloy is applied to the fields of nuclear reactor polar environment, medical radioactive source shielding, nuclear waste treatment and the like in the polar environment, safe operation of a nuclear reactor system can be effectively guaranteed, and the service life of the system can be prolonged.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com