Top blowing and lower combustion type boiler

A combustion-type boiler technology, applied in the field of boilers, can solve the problems of low heat energy utilization rate, hinder coal combustion, reduce furnace temperature, etc., and achieve high heat energy utilization rate, fast heating speed and full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

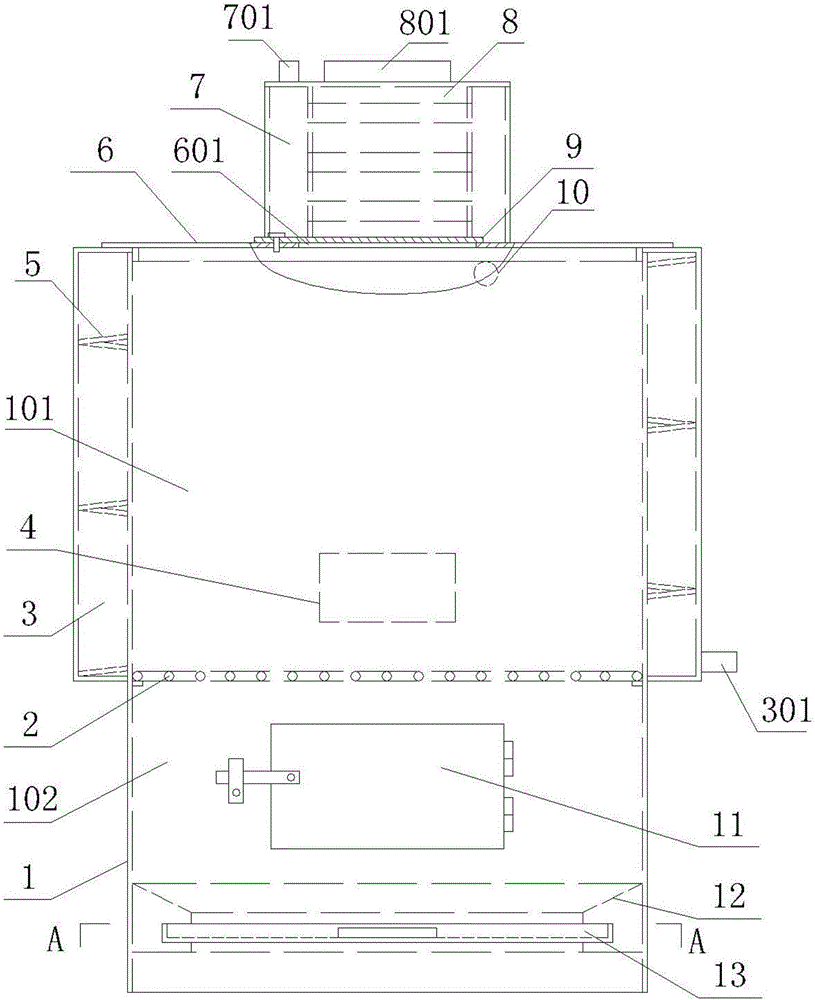

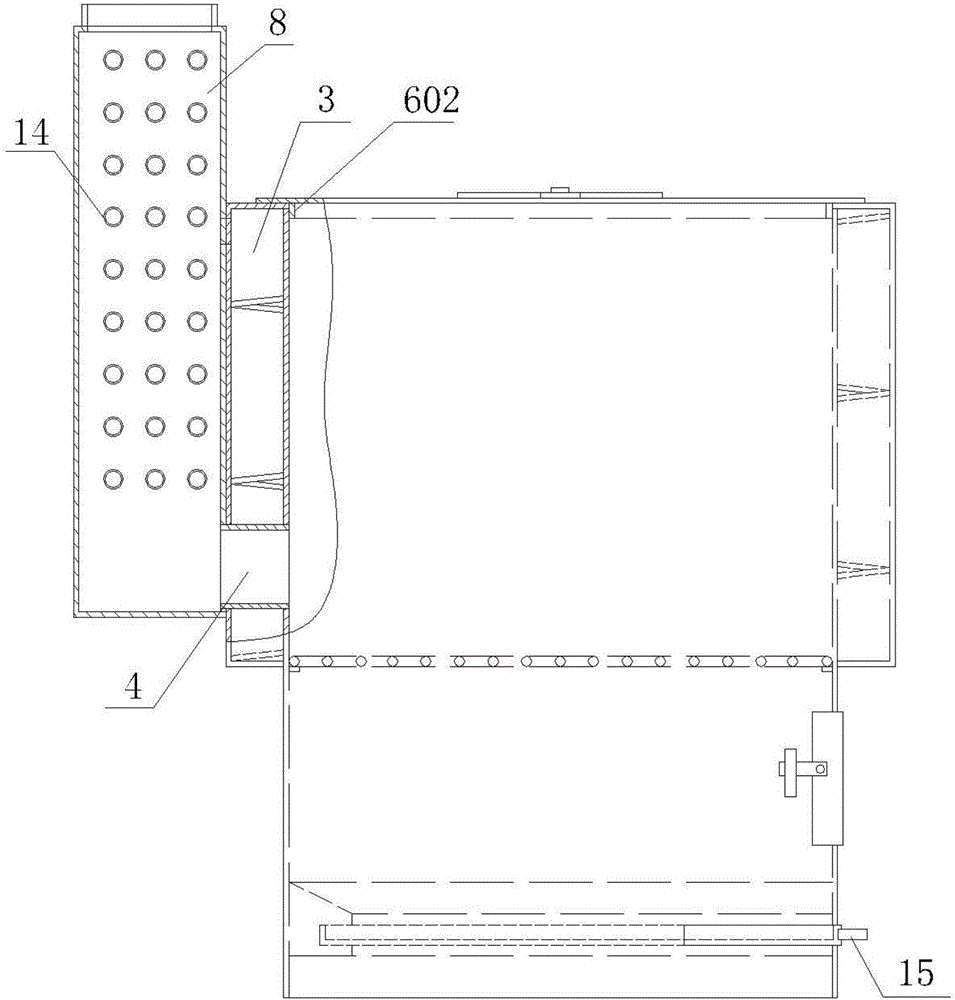

[0020] Such as Figure 1 ~ Figure 4 As shown, a top-blowing down-fired boiler related to the present invention includes a furnace body 1, the furnace body 1 is cylindrical, a grate 2 is supported in the middle of the furnace body 1, and the inner cavity of the furnace body 1 passes through the furnace The grate 2 is divided into a furnace 101 and an ash chamber 102 arranged up and down. A water jacket interlayer 3 is provided on the outer edge of the furnace 101 on the furnace body 1, and a water inlet 301 is provided on the furnace body 1 at the lower end of the water jacket interlayer 3 side.

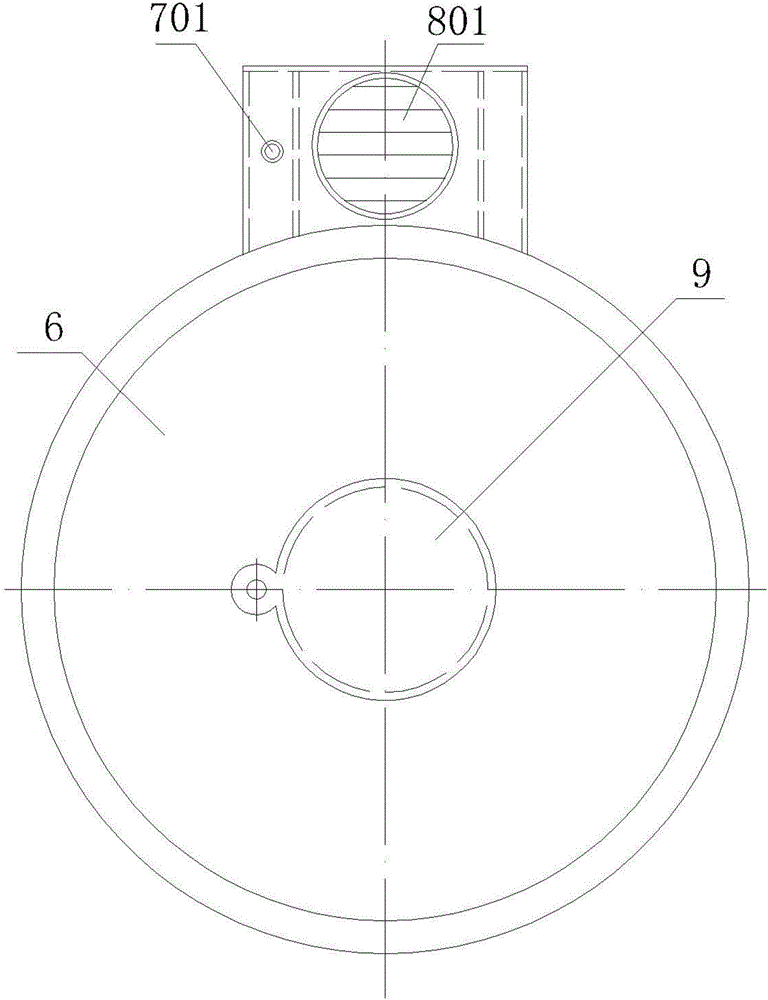

[0021] There is a circular furnace cover 6 on the upper mouth of the furnace body 1, and a ring of annular positioning bosses 602 are provided on the lower surface of the furnace cover 6. The positioning bosses 602 are inserted into the upper mouth of the furnace body 1 through clearance fit to ensure that the furnace cover and the furnace The coaxiality of the body. An air inlet 601 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com