Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183results about How to "Close tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

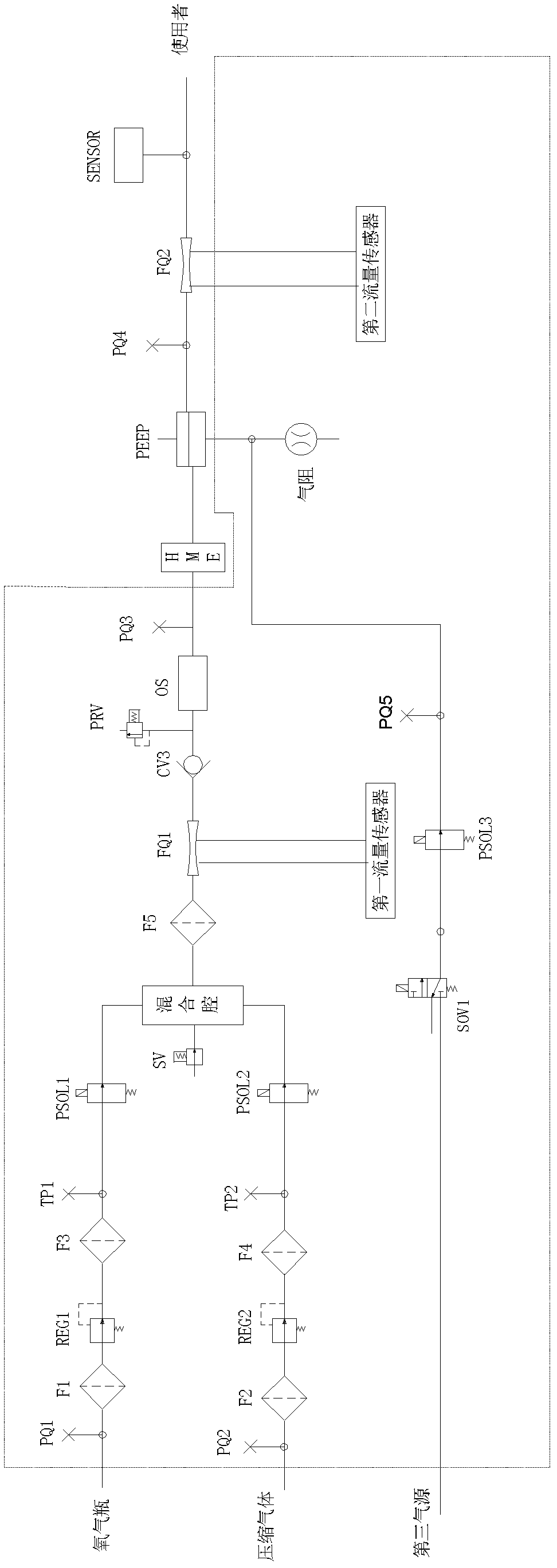

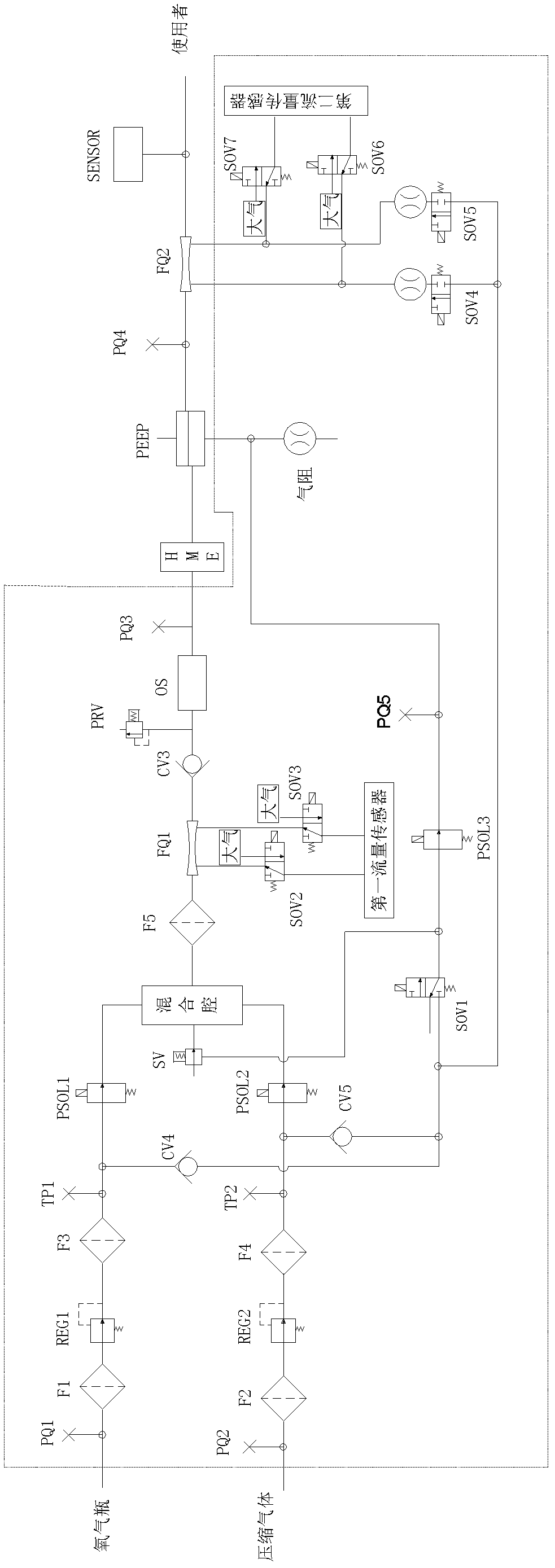

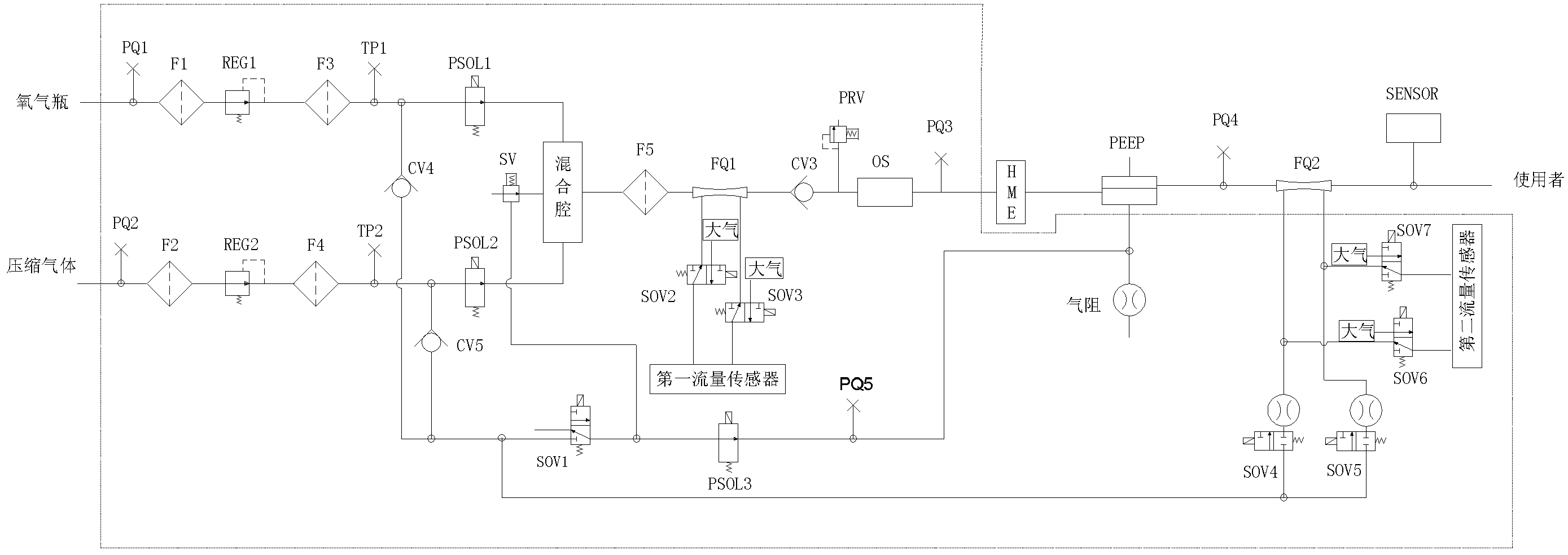

Air passage system of respirator

InactiveCN102500026AOxygen concentration is continuously adjustablePressure relief safetyRespiratorsRespiratorOxygen

The invention relates to an air passage system of a respirator. The air passage system comprises an oxygen communicating pipeline, as well as a pressure reducing valve (REG1) and a proportional valve (PSOL1), which are communicated on the oxygen communicating pipeline in series; a high-pressure air communicating pipeline, as well as the pressure reducing valve (REG2) and the proportional valve (PSOL2), which are communicated on the high-pressure air communicating pipeline in series; a mixing cavity and a free respiration valve (SV) communicated with the mixing cavity; a main pipeline, as well as a flow sensor probe (FQ1) and a one-way valve (CV3), which are communicated on the main pipeline in series; and a control air source, wherein the input end of the control air source is communicated with the oxygen communicating pipeline through an air passage beside a one-way valve (CV4), the air passage beside a one-way valve (CV5) is communicated with the high-pressure air communicating pipeline, and the output end of the control air source is communicated with the air inlet end of a two-position three-way valve (SOV1); the air outlet end of the SOV1 is communicated with the control end of the free respiration valve (SV) and a proportional valve (PSOL3), and the exhaust end is communicated with outside atmosphere; and the other end of the PSOL3 is communicated with an air lock and the pneumatic control end of a Peep valve.

Owner:于邦仲

Vacuum cup capable of cooling and heating instantly

InactiveCN102599783ADoes not affect appearanceSimple and beautiful structureDrinking vesselsEngineeringWater cooling

The invention relates to a vacuum cup capable of cooling and heating instantly, which is convenient in use, wherein air-cooling and air-heating speed of drinking water in the cup can be regulated in a stepless manner. The vacuum cup capable of cooling and heating instantly comprises a cup body and a cup cover, the cup body comprises an inner layer, a shell and a gap layer, the gap layer is arranged outside the inner layer and inside the shell, a bottom hole is arranged at the bottom of the cup body and is communicated with the bottom of the gap layer, an upper hole is arranged at a high position of the shell and is communicated with a high position of the gap layer, a ventilating notch or an air vent is arranged on a skirt, which is lower than the bottom hole, of the shell, the shell is provided with a concave bottom, the bottom hole is arranged on the concave bottom of the shell and provided with a bottom hole cover or a bottom hole switch, and the upper hole is provided with an upper hole switch. The vacuum cup can realize air cooling and air heating for the drinking water in the cup, the air-cooling or air-heating speed of the drinking water in the cup can be regulated in the stepless manner, the drinking water in the cup can be in water cooling or water heating rapidly, a thirsty person can drink the drinking water at the proper temperature rapidly, and furthermore, the vacuum cup can brew good tea and heat milk, and is convenient in use.

Owner:邢立天

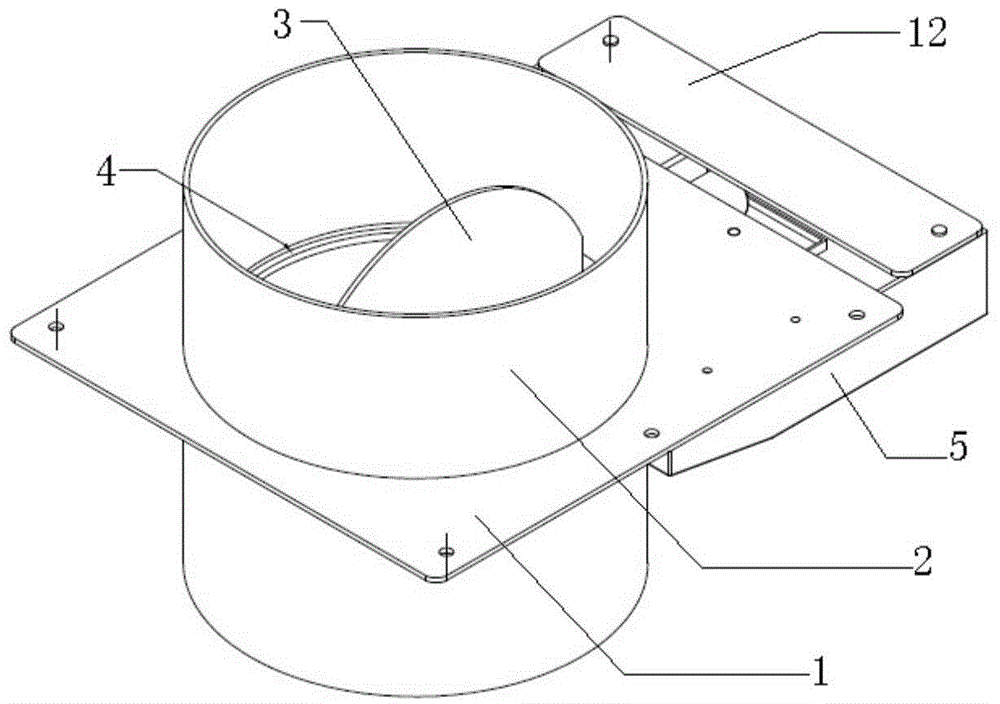

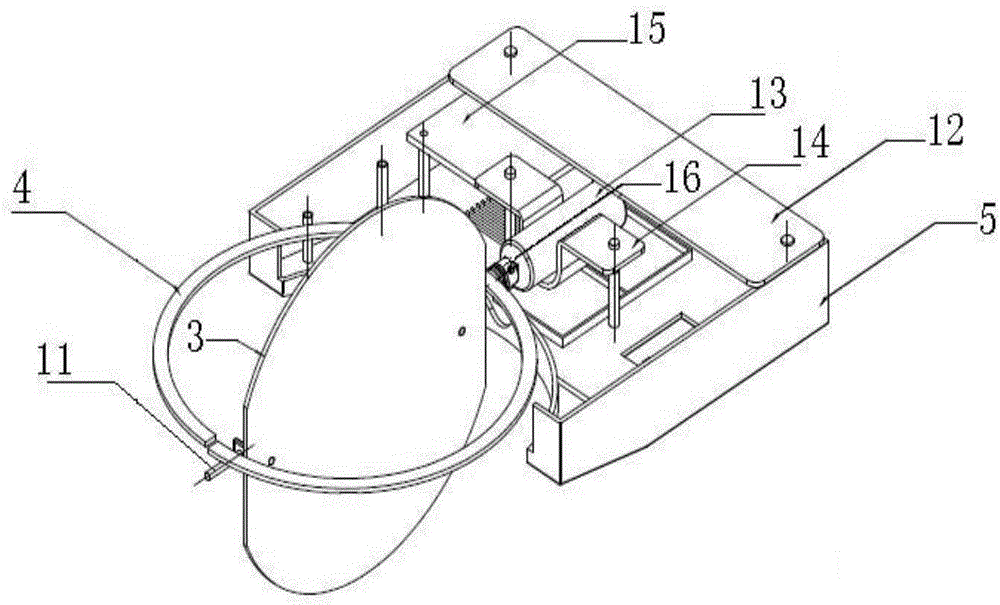

Intelligent electrically-operated check valve

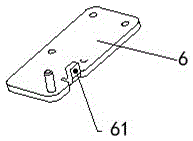

ActiveCN104482256ASignificant progressExtended service lifeDomestic stoves or rangesOperating means/releasing devices for valvesCouplingEngineering

The invention provides an intelligent electrically-operated check valve. The intelligent electrically-operated check valve comprises a check valve support, an air duct, a check valve plate, a magnetic seal ring and an intelligent controller, wherein the air duct is arranged on the check valve support; the check valve plate arranged in the air duct is perpendicular to the axis of the air duct; a pin roll enabling the check valve plate to rotate is arranged in the air duct; the magnetic seal ring fixedly arranged on the inner wall of the air duct consists of two half magnetic seal rings positioned on the upper and lower sides of the check valve plate, and is used for sealing a gap between the check valve plate and the inner cavity of the air duct; the intelligent controller is fixed on the check valve support, is connected with the pin roll through a coupling, and is used for controlling the rotation of the pin roll; micro switch sensors are arranged on the check valve support on two sides of the coupling; the coupling is provided with two mutually perpendicular contacts along the direction perpendicular to the axis of the coupling. The intelligent electrically-operated check valve adopts integrated arrangement, is simple in structure and convenient to use, and prevents a motor from starting at negative pressure or being blocked.

Owner:江西厨味洁消防设备有限公司

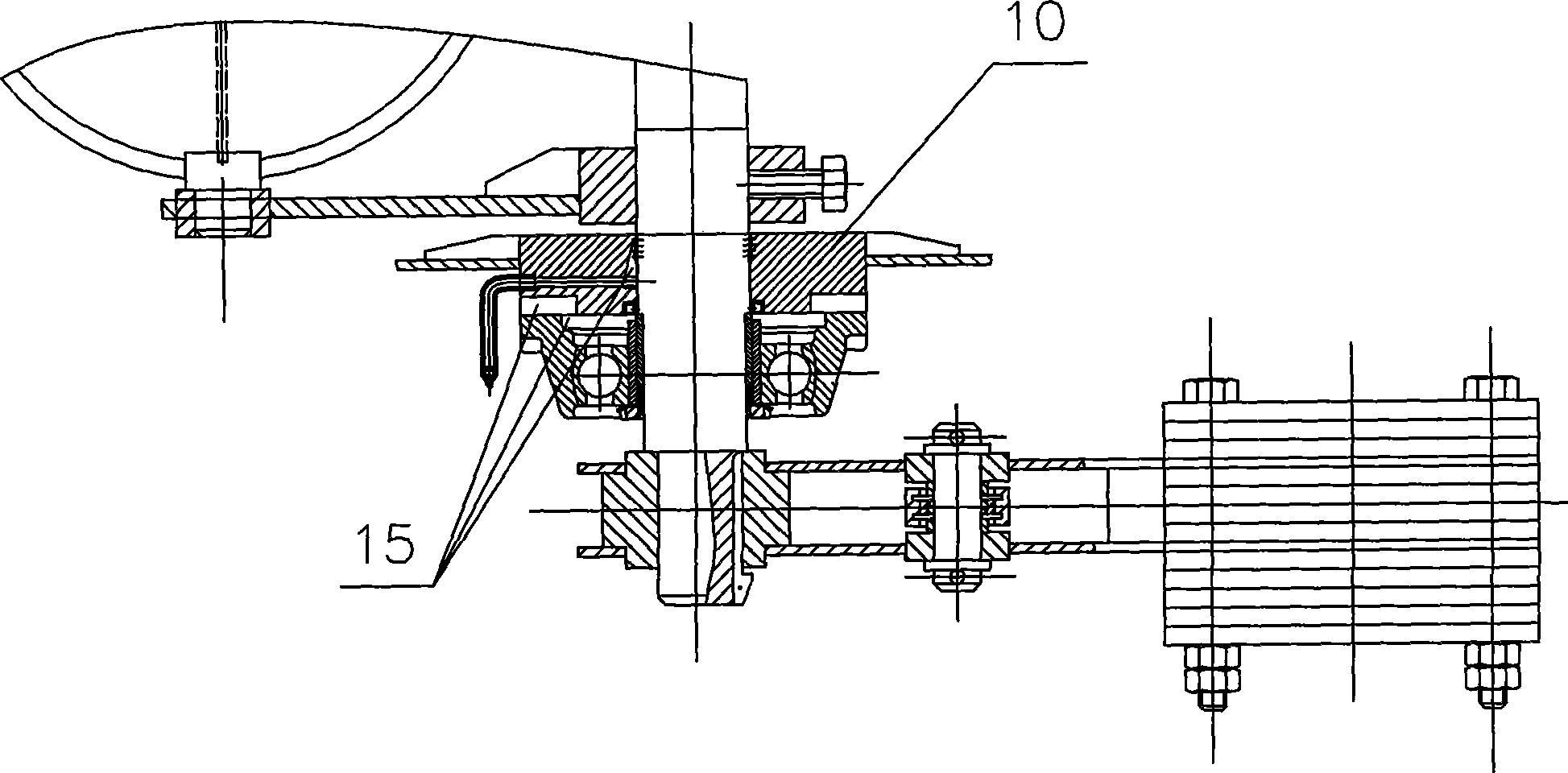

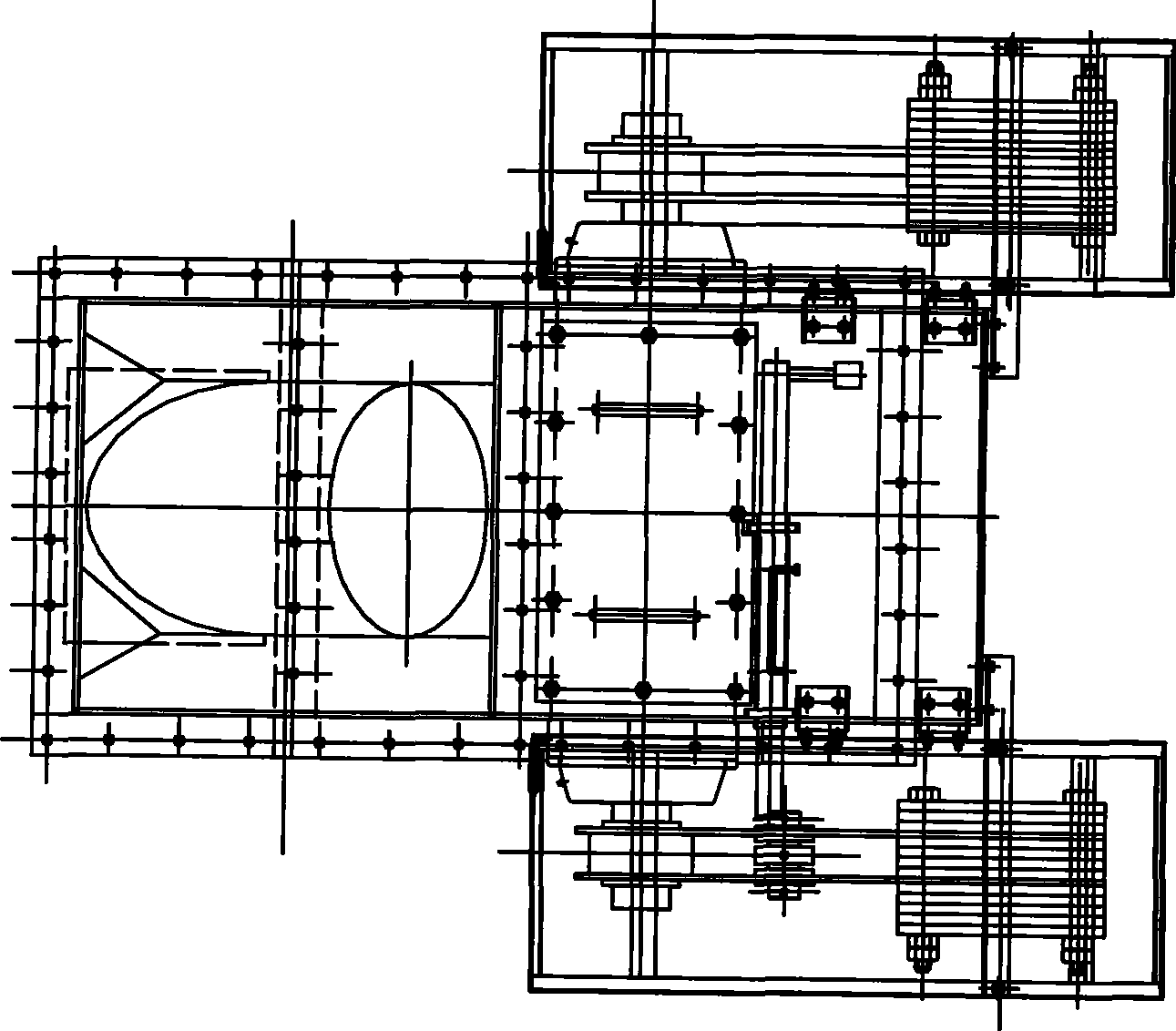

Tool for gravel fillup and bypass gravel fillup

InactiveCN101372888AEnsure security requirementsImprove bearing capacityFluid removalEngineeringMechanical engineering

A gravel-filling or a bypass gravel-filling tool comprises a filling assembly (1) and an exterior assembly (2). The tool is characterized in that the exterior assembly (2) comprises a switch short section (4) and a lower joint (17), both of which are arranged below an outer short section (3) and connected in sequence; a positioning lock spring (5) mounted inside the switch short section (4) and a sealing short section (6) below the positioning lock spring (5); a connecting lock spring (7), a lock ring (8), a conversion inner body (13), a uniflux valve (14) and a limiting short section (16) are connected in sequence under the sealing short section (6); a bypass filling sliding bush (9) and a filling bush (11) are mounted in the annular space between the switch short section (4) and the conversion inner body (13); a positioning ring (15) is arranged between the switch short section (4) and the limiting short section (16), and the filling assembly (1) is arranged inside the exterior assembly (2). The tool adopts the converting and filling structure and has the following characteristics: the tool can prevent blocking, sticking and filling interruption, and can be widely used in the technology of filling an oil well with gravel after oil exploitation.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

Reservoir for front end loaded infusion device

InactiveUS20060100581A1Close tightlyLarge volumeMedical devicesPressure infusionInfusion setEngineering

A medical reservoir for a front loaded infusion device including a housing, a chamber inside the housing for receiving the reservoir and a drive member. The reservoir includes a first end; an outlet disposed at the first end, the outlet having closable dispensing means; a second open end; an elongate body portion disposed between the first and second ends; and a piston slideably arranged within the elongate body portion and being connectable to the drive member.

Owner:UNOMEDICAL AS

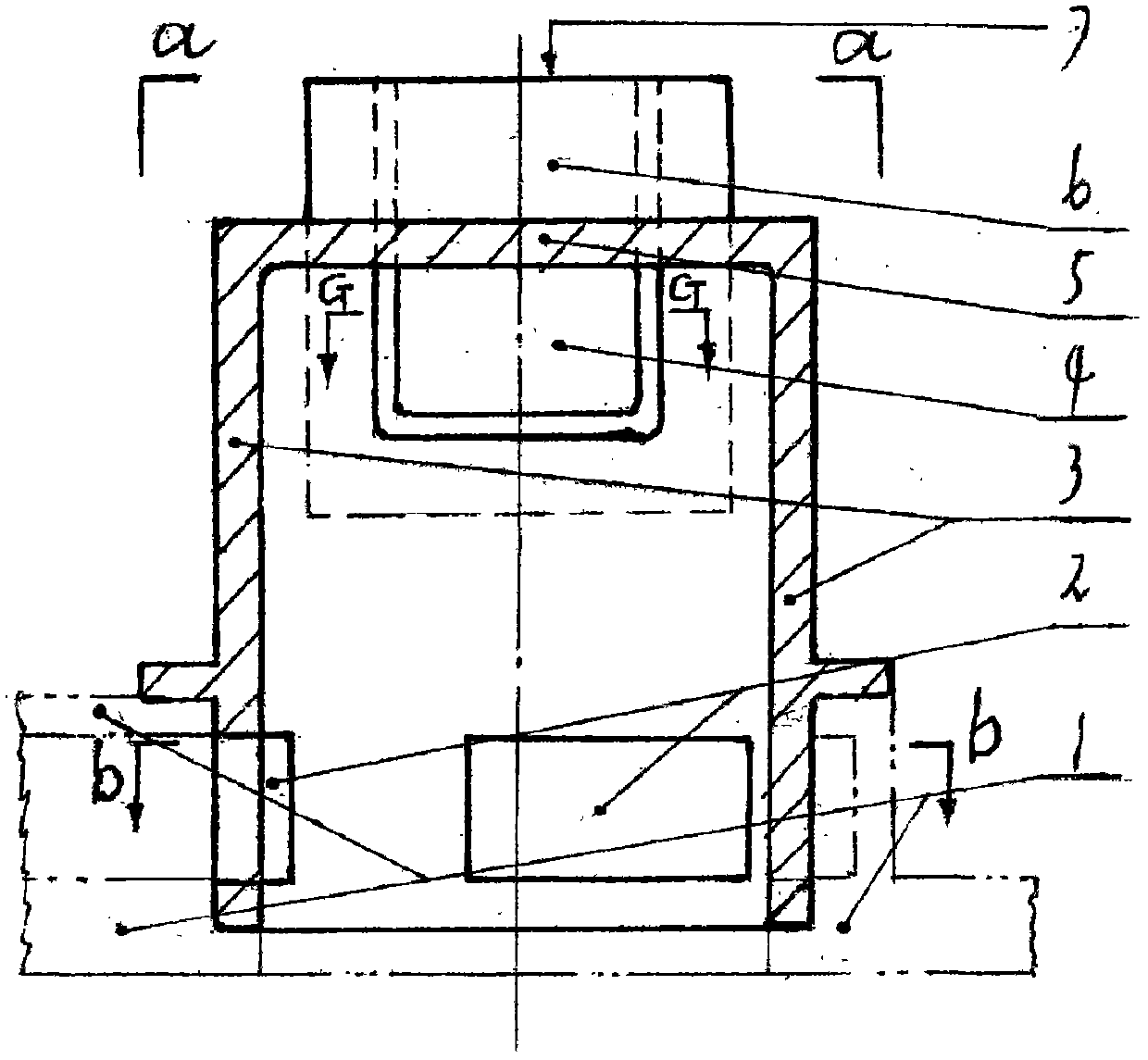

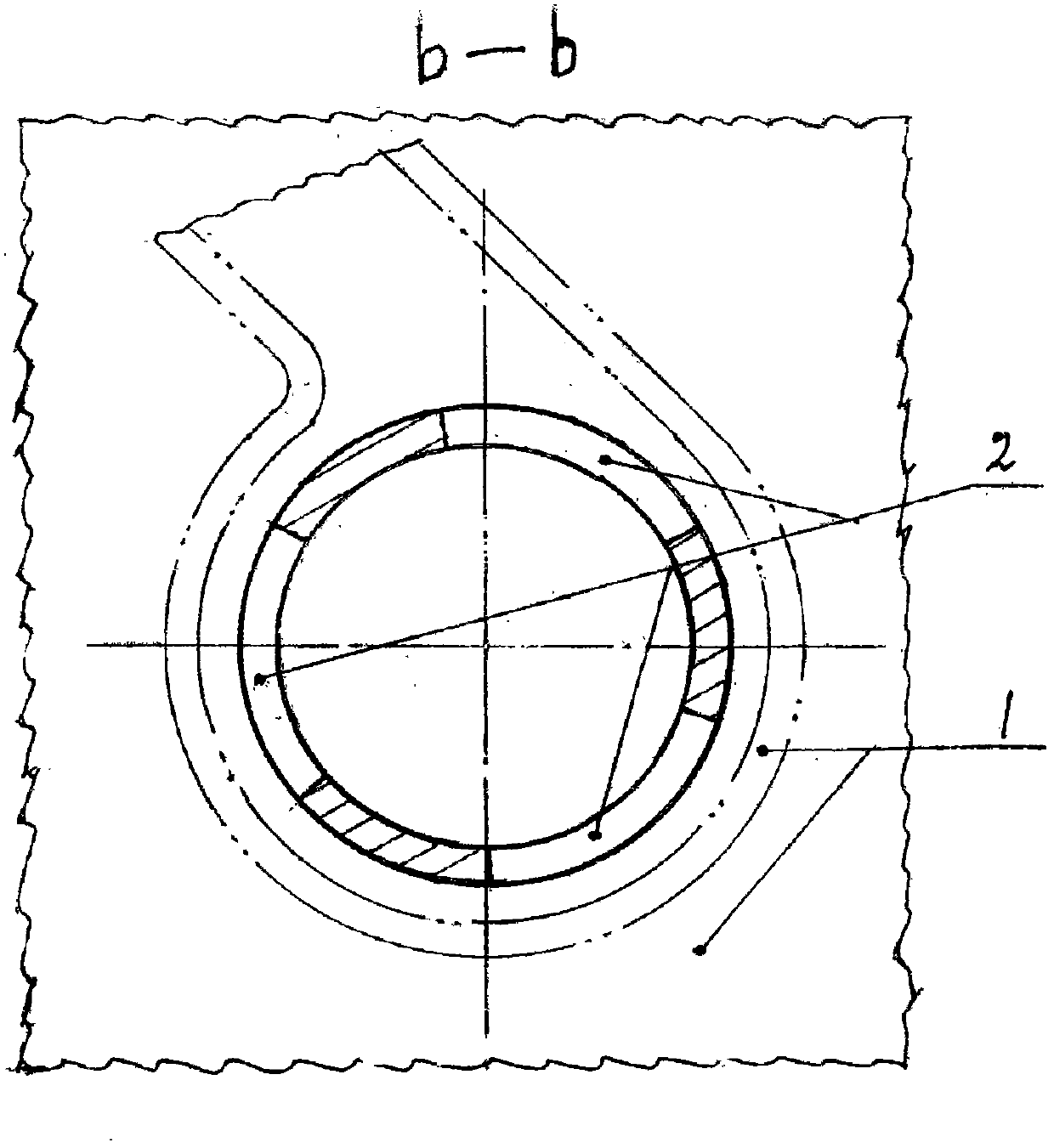

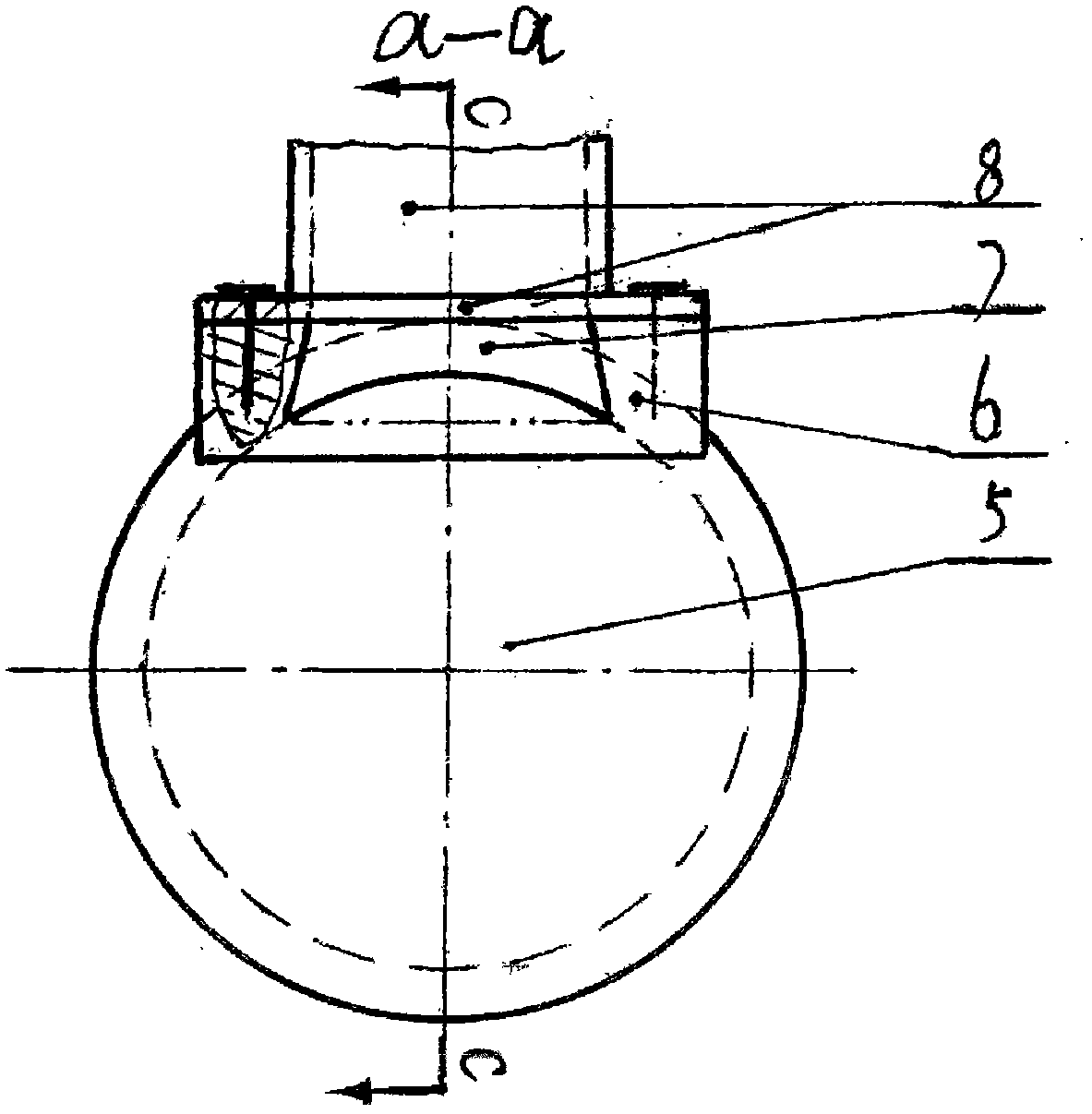

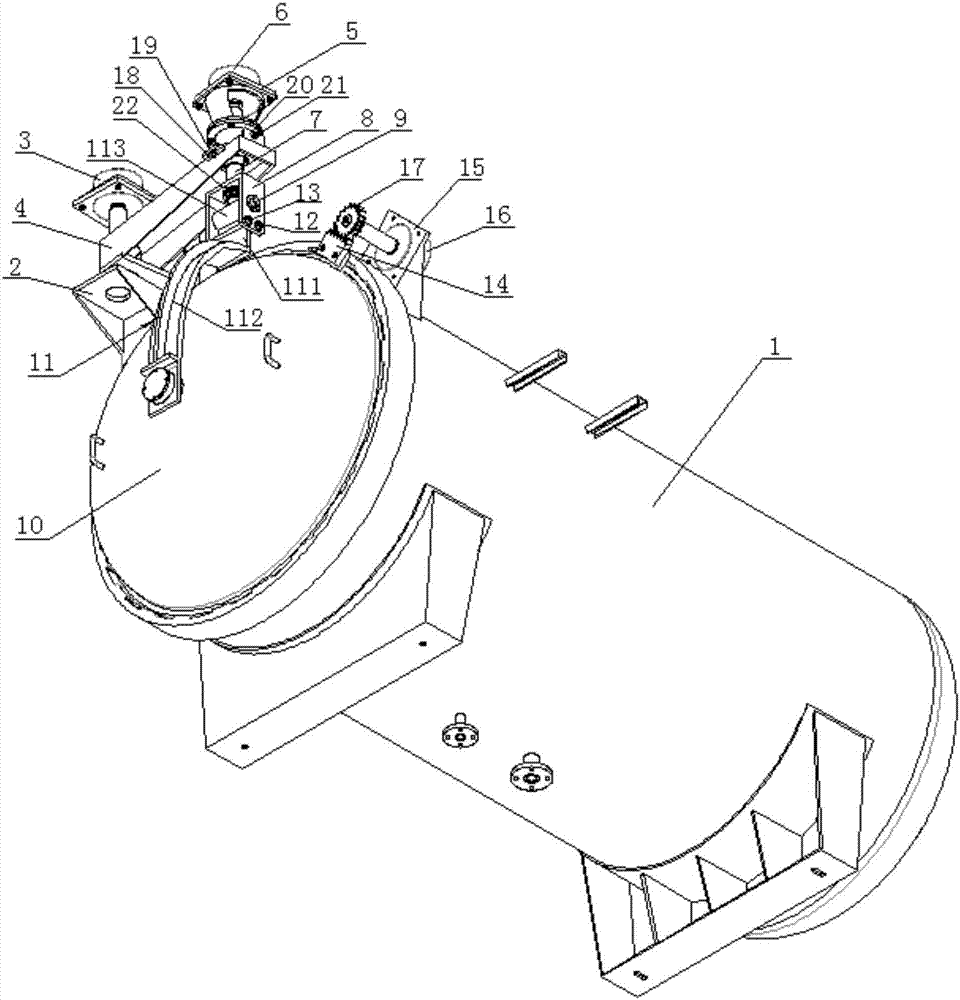

Starting cylinder of piston reciprocating internal combustion engine and air exhausting device of starting cylinder of piston reciprocating internal combustion engine

ActiveCN103993972AGood DC scavenging effectClose tightlyExhaust apparatusCylinder headsExternal combustion engineControl system

The invention discloses a starting cylinder of a piston reciprocating internal combustion engine and an air exhausting device of the starting cylinder of the piston reciprocating internal combustion engine. The starting cylinder and the air exhausting device are mainly characterized in that the mode that an air exhausting opening is formed in a starting cylinder cover plate, namely an engine cover plate, of an existing four-stroke or two-stroke direct current scavenging engine and connected with an air exhausting channel is changed into the mode that the air exhausting opening is formed in the side of a starting cylinder body and connected with the air exhausting channel, and meanwhile a mushroom-shaped vent valve is changed into a gate vent valve; in this way, the problem that a working mechanism must be arranged on the engine cover plate or multiple working parts are difficult to arrange is solved, damage, caused by air exhausting heat loads, to the engine cover plate and the arrangement on the engine cover plate is avoided, and indispensable conditions are particularly created for multiple overhead working systems and an overhead comprehensive regulating and control system which are invented in the ZL200710193939.4 invention with the publication patent number CN101205861B and a novel piston reciprocating internal combustion engine invented in the ZL200710193938.X invention with the publication patent number CN151289956B, wherein according to a pressurizing mechanism combination of the novel piston reciprocating internal combustion engine, energy is greatly saved, stains are greatly removed, and the specific weight of the engine is greatly reduced.

Owner:肖光宇

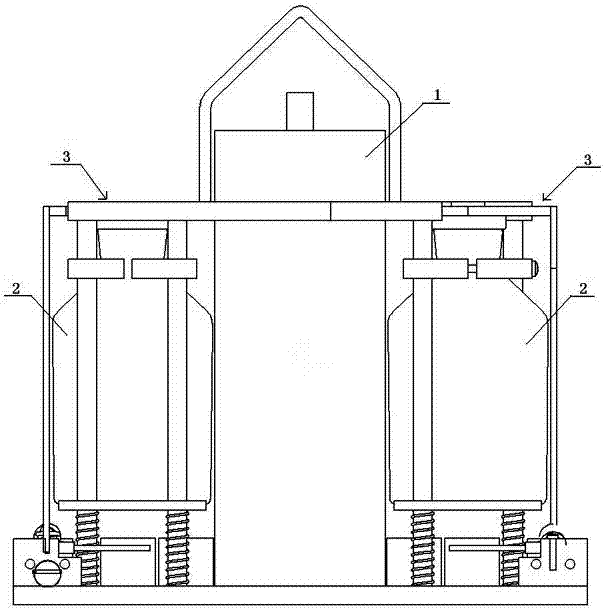

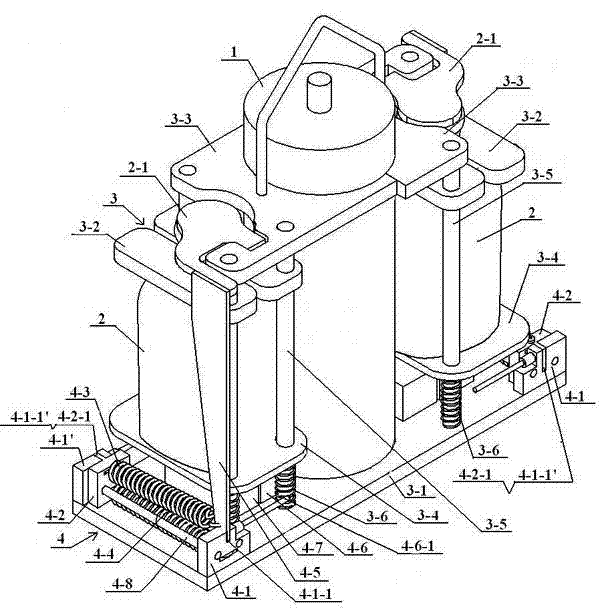

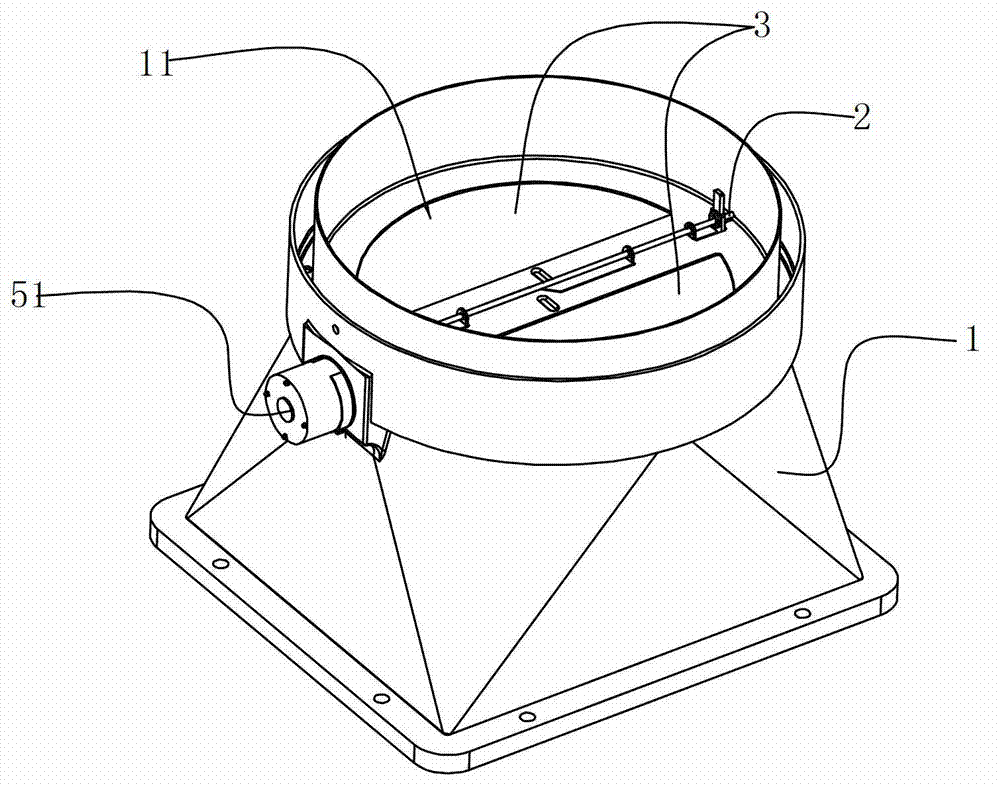

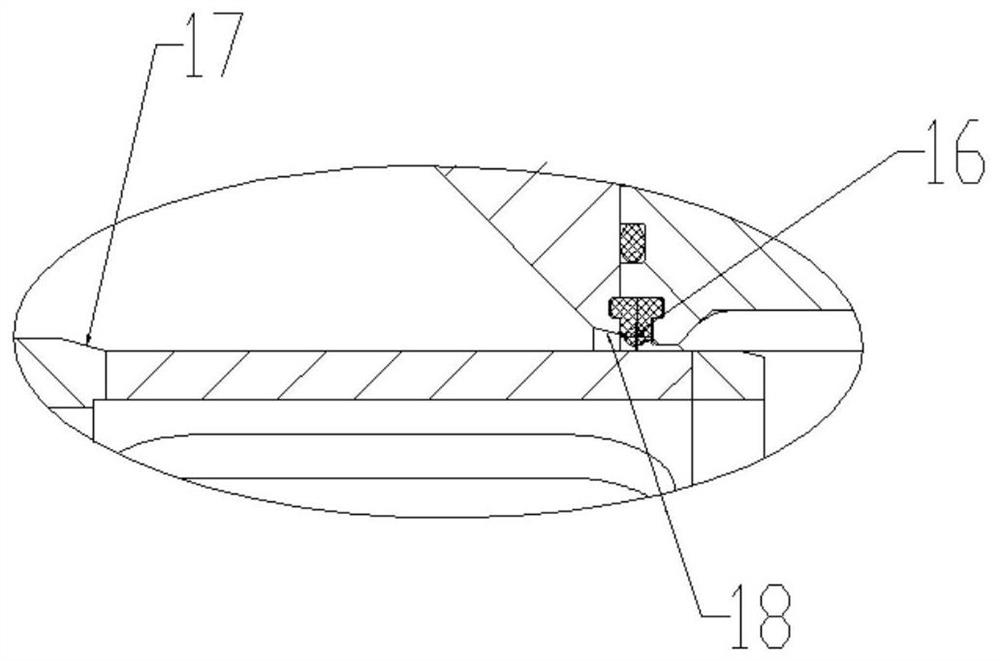

Current limiting closed exhaust valve used for aerostat and control method used for limiting same

InactiveCN105129067ASafe and reliable pneumatic shapeClose tightlyGas-bag arrangementsExhaust valveDrive wheel

The invention provides a current limiting closed exhaust valve used for an aerostat and a control method used for limiting the same. The exhaust valve comprises a motor, a screw, a valve cover, a seal ring, a column, a pedestal, an upper limiting member, a control circuit, a gear block, a support, a base, a driven wheel and a valve body, wherein the valve body covers on the seal ring and the valve port of the valve body. The control circuit is connected with the motor. The motor is connected with the valve cover and used for controlling the valve cover to move upwards and downwards along the screw. The upper limiting member is connected with the control circuit. The gear block is fixedly connected with the screw. When the motor rotates, the motor makes the gear block move upwards and downwards along the screw, the gear block contacts with the upper limiting member, the upper limiting member cuts off the control circuit, and the motor stops to make the valve cover be in a maximal opening state. When the motor rotates anticlockwise, the motor makes the gear block move downwards, the valve cover contacts with the seal ring to reach a preset compaction state, a pretightening force between the valve cover and the seal ring is kept, the current of the control circuit is limited to cut off the power supply to the motor, the valve cover can be automatically closed and in a sealed and closed state.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

In-situ water collecting device and method for underwater oil water sample

InactiveCN103115800AGuaranteed accuracyClosed tightlyWithdrawing sample devicesOil waterEnvironmental engineering

The invention provides an in-situ water collecting device and method for an underwater oil water sample to solve the problem that the normal use and a measured result are affected by defects on the aspect of an operating container cover switch existing in the prior art. The in-situ water collecting device for the underwater oil water sample comprises a container cover, a double-spring assembly and an electric magnet. When the in-situ water collecting device for the underwater oil water sample is used, a mechanism for opening the container cover is started through a control button of a deck unit after the device reaches a set depth. After an underwater electric control part receives an instruction, a power source of the electric magnet is started, a tensile force is provided by the electric magnet to pull a locking pin and generate displacement, a cover opening lever is pulled by a cover opening spring to break away from a locking position to move, water is collected through opening the container cover under the action of the lever, the electric magnet is started to act to close the container cover after the water is collected, an underwater part is lifted to a deck by pulling a rope, a container is taken out, and a water sample in the container is stored for analysis and research. The in-situ water collecting device has the advantages of simpliness and reliability in operation, accurate and reliable actions for opening and closing the cover, accurate measured result and the like.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI +1

Locking mechanism for door of garbage container

ActiveCN104495132AClose tightlyReduce usage timeWing fastenersLarge containersEngineeringLocking mechanism

The invention relates to a locking mechanism for a door of a garbage container. The locking mechanism comprises a straight shaft; a first fixed transverse shaft and a second fixed transverse shaft are parallel with each other; the straight shaft is located between the first fixed transverse shaft and the second fixed transverse shaft; the first fixed transverse shaft is glidingly matched with two shifting sliding sleeves; each shifting sliding sleeve is provided with a shifting block; one end of each of two active connecting rods is hinged to the corresponding shifting sliding sleeve; the other end of each of the two active connecting rods is hinged to a connection block at one end of the straight shaft; the second fixed transverse shaft is glidingly matched with a compression spring and two latch hook sliding sleeves; the compression spring is located between the two latch hook sliding sleeves; each latch hook sliding sleeve is provided with a latch hook; one end of each of two passive connecting rods is hinged to the corresponding latch hook sliding sleeve, and the other end of each of the two passive connecting rods is hinged to a connection block at the other end of the straight shaft to form a link gear. By adopting the locking mechanism for the door, disclosed by the invention, the shifting blocks are connected with a driving mechanism on the outside of a container body, and therefore the shifting blocks are driven to slide to be locked and separated from locking pins of the door to form the passive locking mechanism.

Owner:CHONGQING ENDURANCE & SHINMAYWA IND

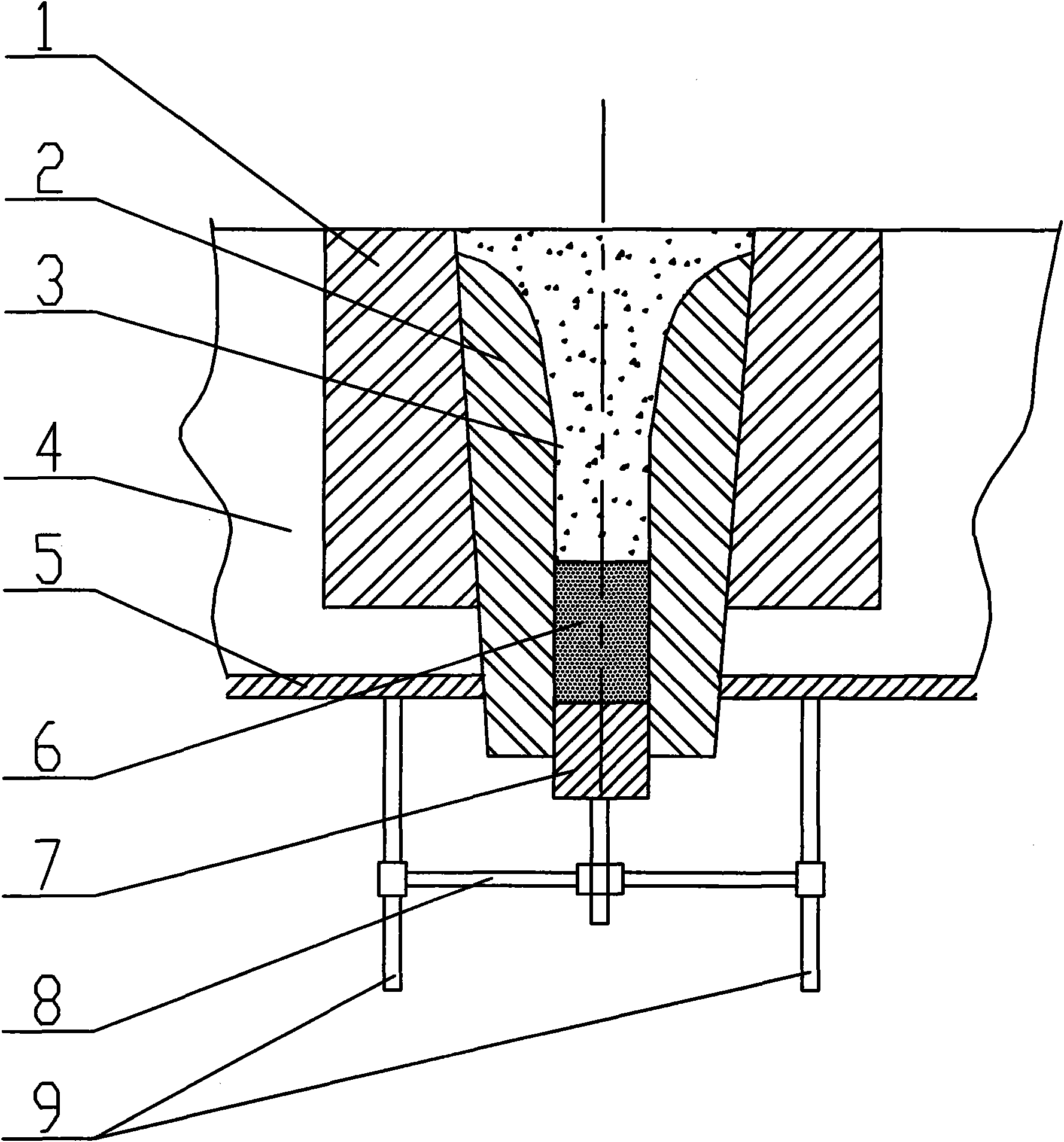

Nozzle structure at bottom of refining furnace and nozzle filling method

InactiveCN101579733AClose tightlyReduce the phenomenon of loose flow pouringMelt-holding vesselsBrickRefractory

The invention relates to a nozzle structure at the bottom of a refining furnace and a nozzle filling method. The nozzle structure at the bottom of the refining furnace comprises a seating brick, a nozzle brick, refractory lining, a refining furnace base, a plug, a rotatable bracket and a supporting frame, and is characterized in that: the nozzle brick is manufactured by adopting aluminum-carbon refractory material taking resin as bonding agent, and the chamfer angle of the upper mouth of an inner cavity of the nozzle brick is R58mm. The nozzle filling method comprises the following steps: in the situation that the lower mouth of the inner cavity of the nozzle brick is plugged and locked by the plug, cast-iron scrap is filled in the inner cavity of the nozzle brick to the height of 80-120mm and tamped, and then flow guiding sand is filled at the upper layer of the cast-iron scrap to the upper edge of the inner cavity of the nozzle brick and tamped so as to complete the plugging and filling of the nozzle, wherein the flow guiding sand adopts zirconium flow guiding sand. The invention has the advantages that: the aluminum-carbon refractory nozzle brick taking resin as bonding agent can meet the requirement of multi-box casting of the refining furnace, simultaneously the radian at the upper end of the inner cavity of the nozzle brick is changed from R90 to R58, the nozzle is tightly closed in the casting process, and the use of the zirconium flow guiding sand and the improvement of the filling method realize that multi-box casting molten steel of the refining furnace can automatically flow out along with the falling of the flow guiding sand, thus achieving the purpose of automatic casting.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

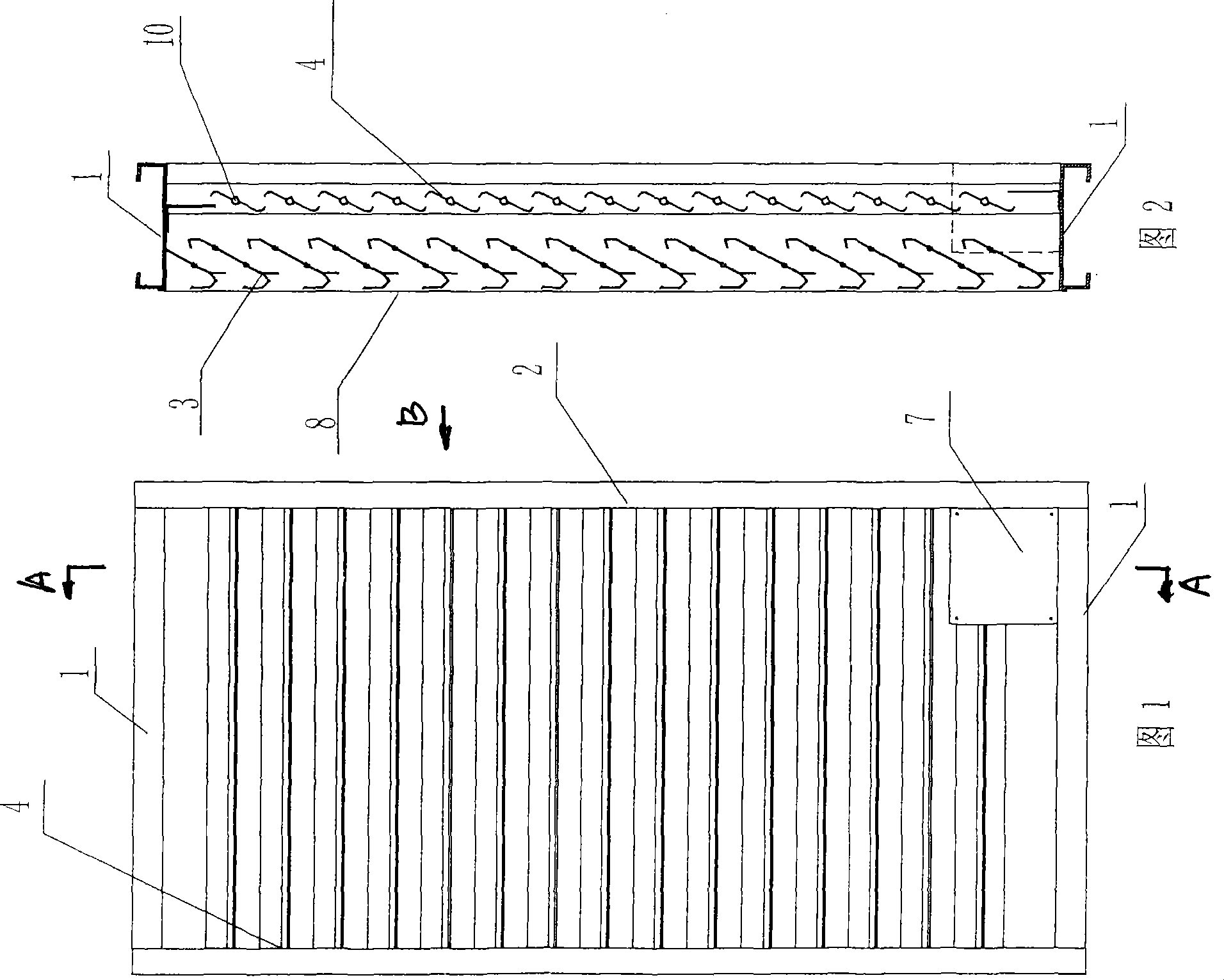

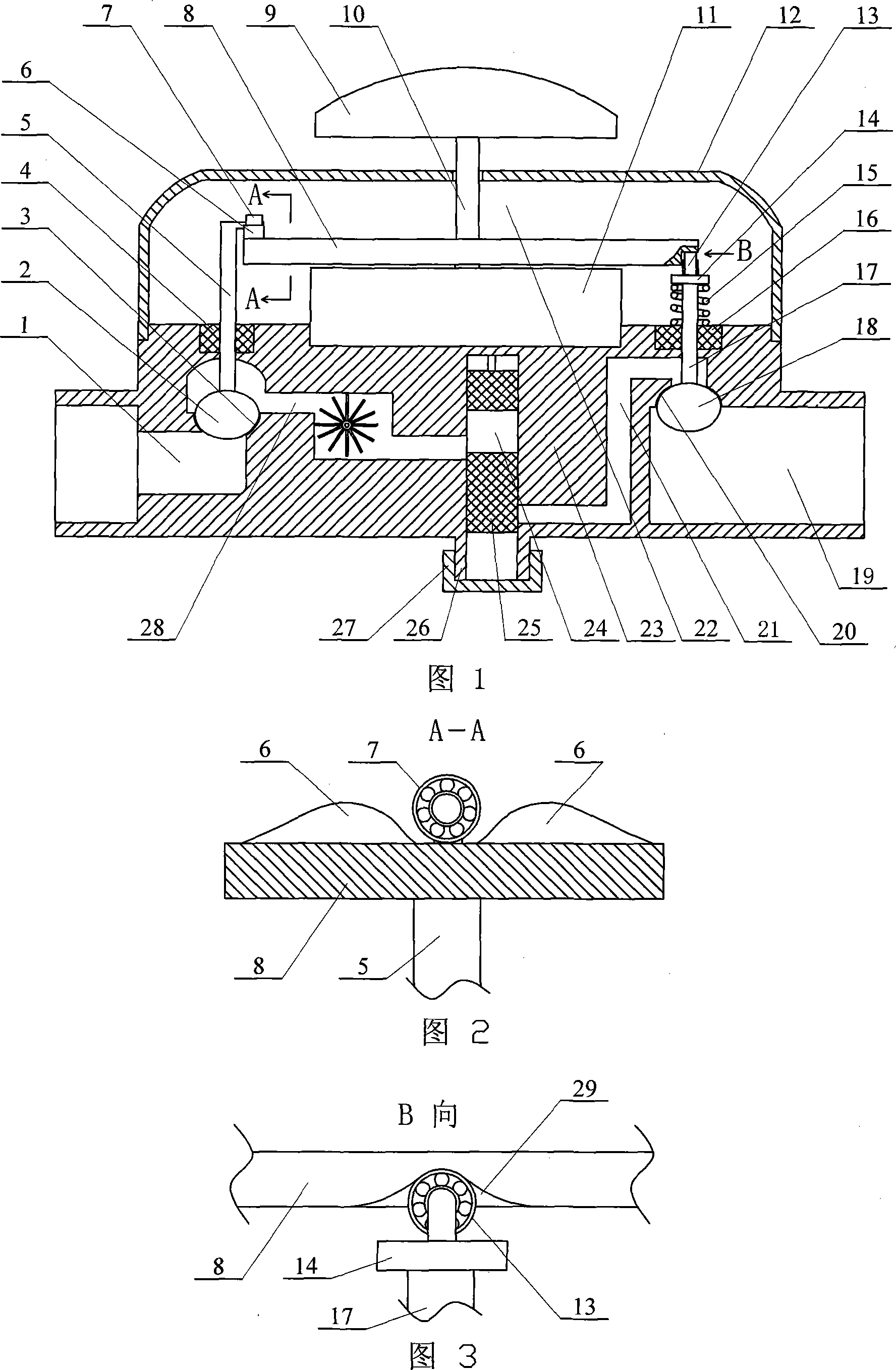

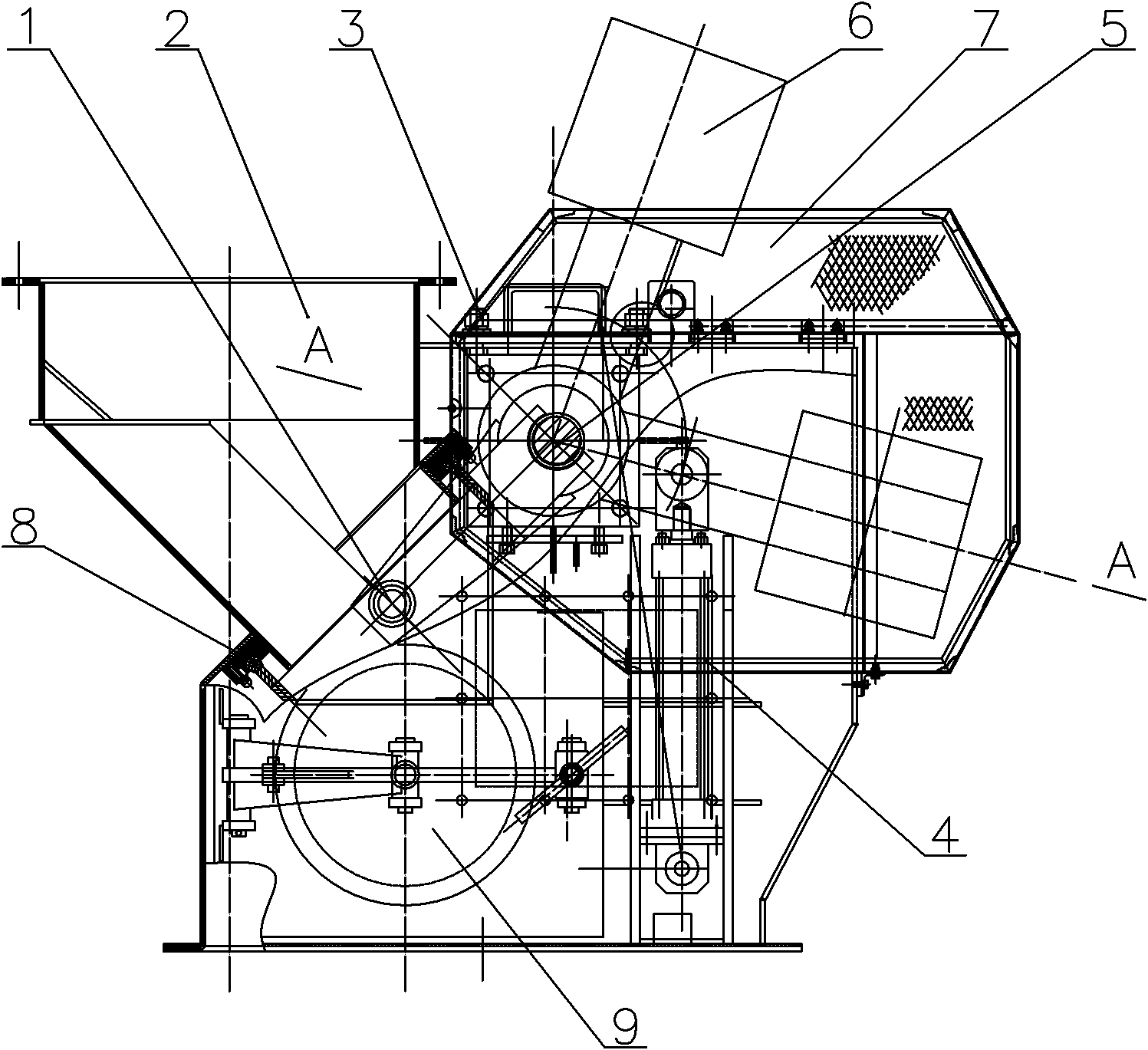

Electric stormproof louvre

InactiveCN101519944AFlexible opening and closingOvercome the fatal shortcoming of aging deformationSpecial door/window arrangementsManufacturing technologySteel ball

An electric stormproof louvre belongs to the manufacture technical field of ventilation facilities and mainly comprises an outer frame consisting of an upper and lower frame (1) and a side frame (2), a fixing stormproof blade (3) arranged at the inner part of the outer frame, an adjustable stormproof valve (4) provided with a rotating shaft (10), an electric executing mechanism (7) arranged at the bottom of the outer frame, a connecting bar drive device (6) arranged at the side of the side frame (2) and respectively connected with the electric executing mechanism (7) and one end of the rotating shaft (10), a full-closed type stainless steel ball bearing (5) arranged between the rotating shaft (10) and the side frame (2), a stainless steel protecting net (8) arranged outside the fixing stormproof blade (3), and the like. Two ends of the adjustable stormproof valve (4) are respectively provided with a 90-degree round hook structure. The invention has reasonable integral structure design and can effectively improve the rainproof property.

Owner:浙江浙风科技有限公司

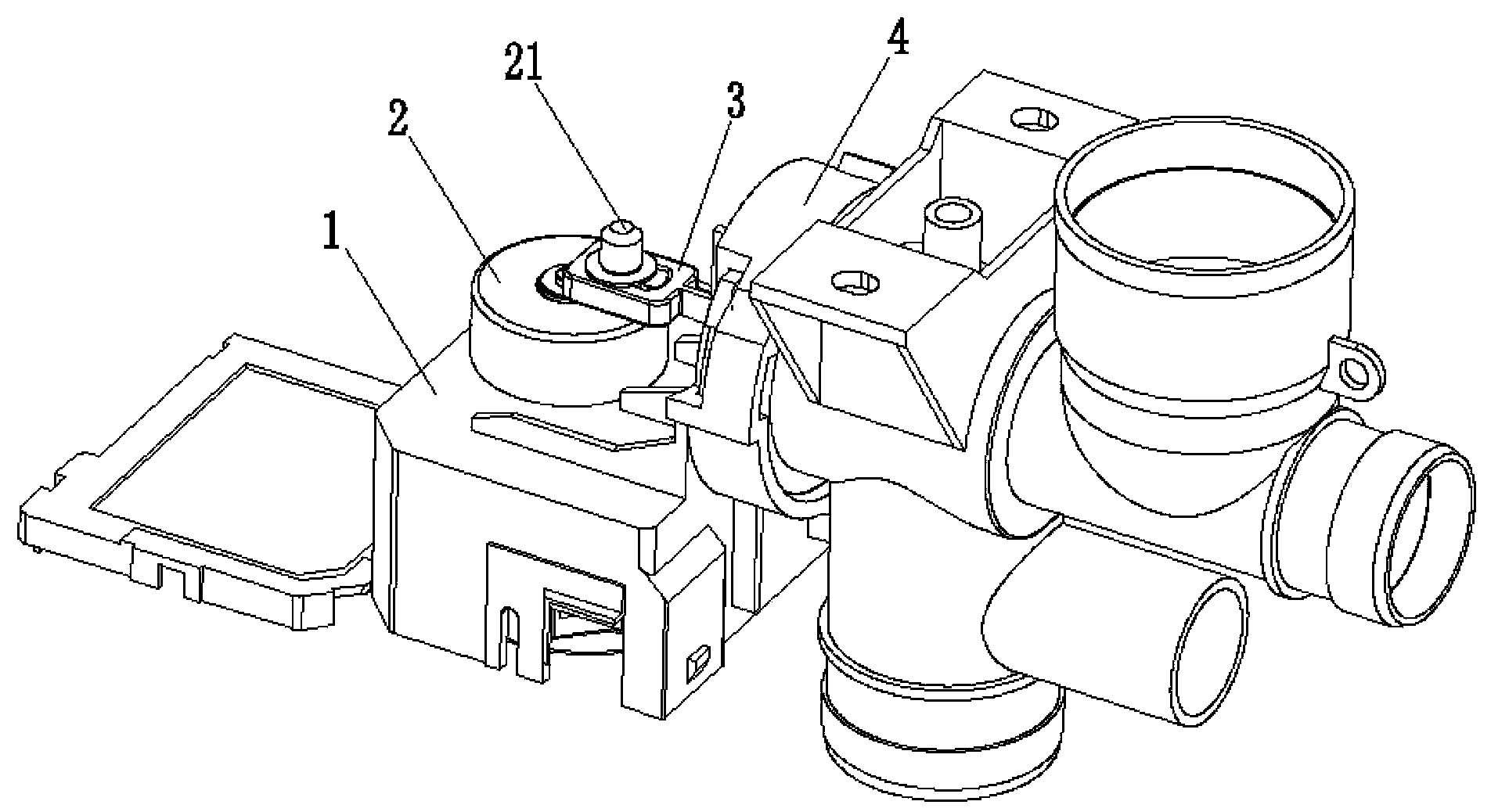

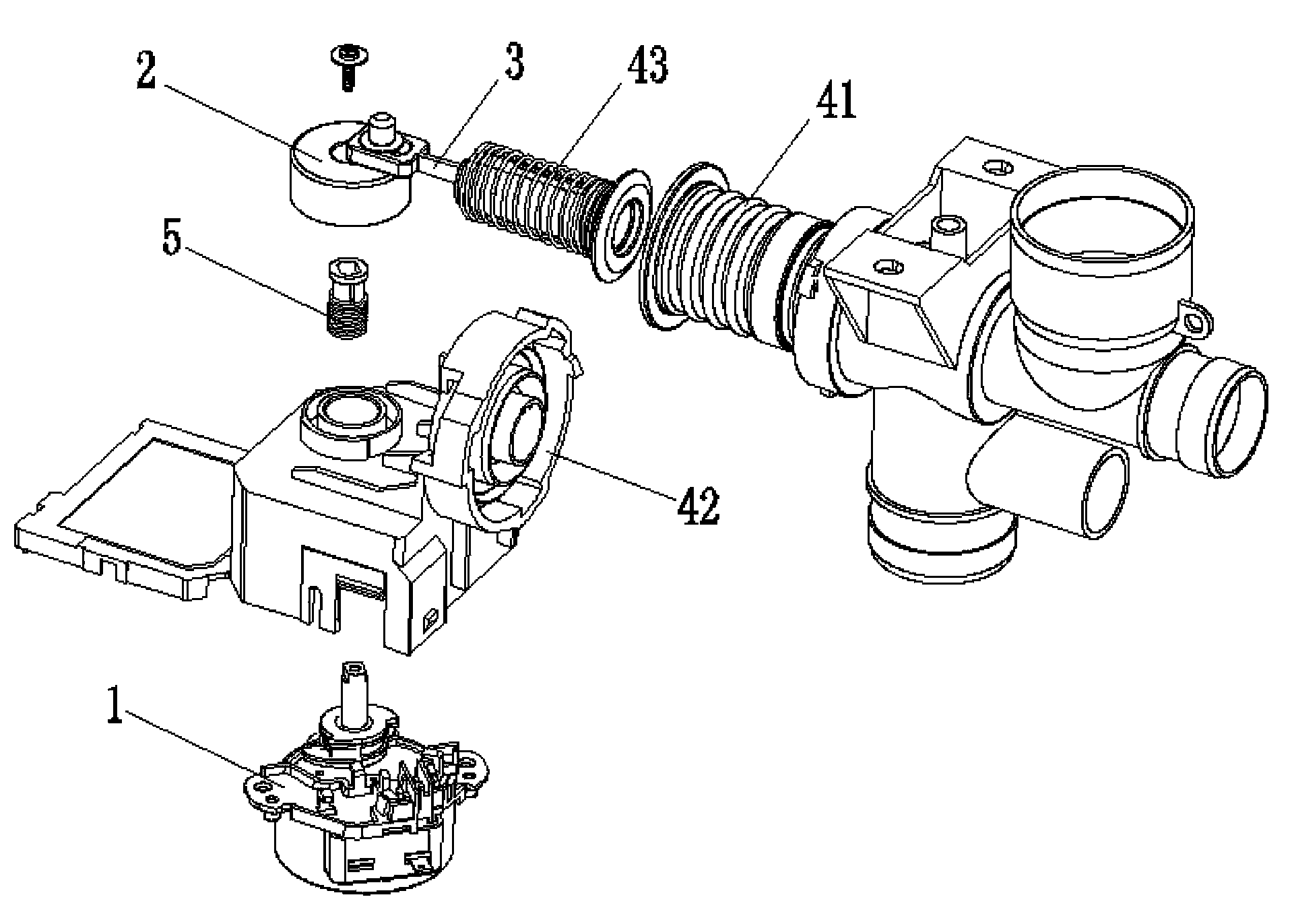

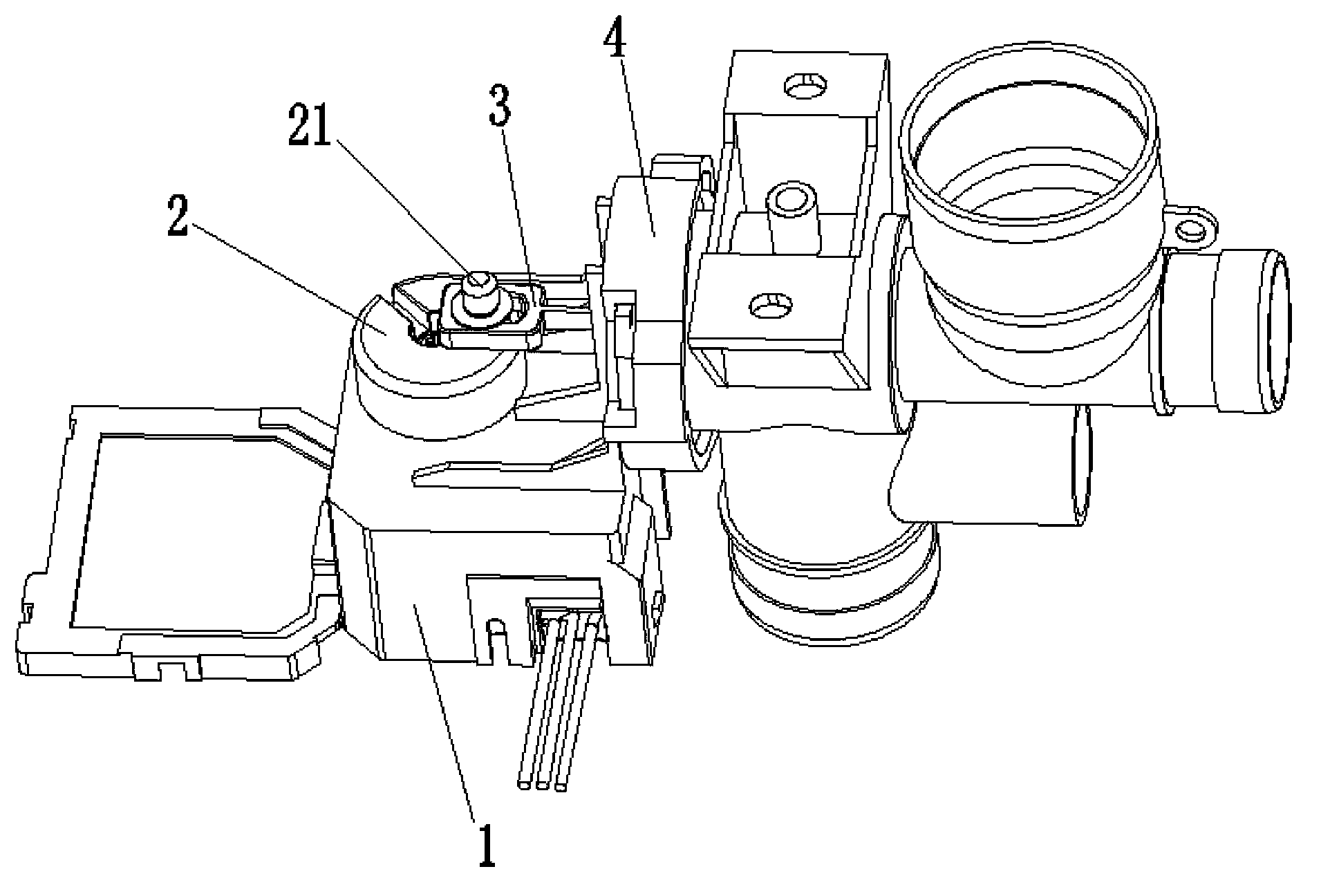

Drain valve

ActiveCN103511716ASpeed up closingClose tightlyOperating means/releasing devices for valvesEngineeringCam

The invention discloses a drain valve which comprises a motor, a cam, a connecting rod and a water valve. The cam is arranged on an output shaft of the motor, and a connecting rod shaft is arranged on the cam; one end of the connecting rod is arranged on the connecting rod shaft, and the other end of the connecting shaft is arranged on a piston of the water valve; a spring arranged on the connecting rod in a sleeved mode is arranged between the piston of the water valve and an end cover; the drain valve further comprises an accelerating mechanism which is arranged in the motor and is capable of accelerating the process that the cam pushes the piston of the water valve to be closed. According to the drain valve, through the fact that the accelerating mechanism is arranged in the motor to accelerate the closing of the piston, the piston is made to be closed more tightly, and the occurrence of the phenomenon of leakage is avoided effectively.

Owner:JIANGSU LEILI MOTOR

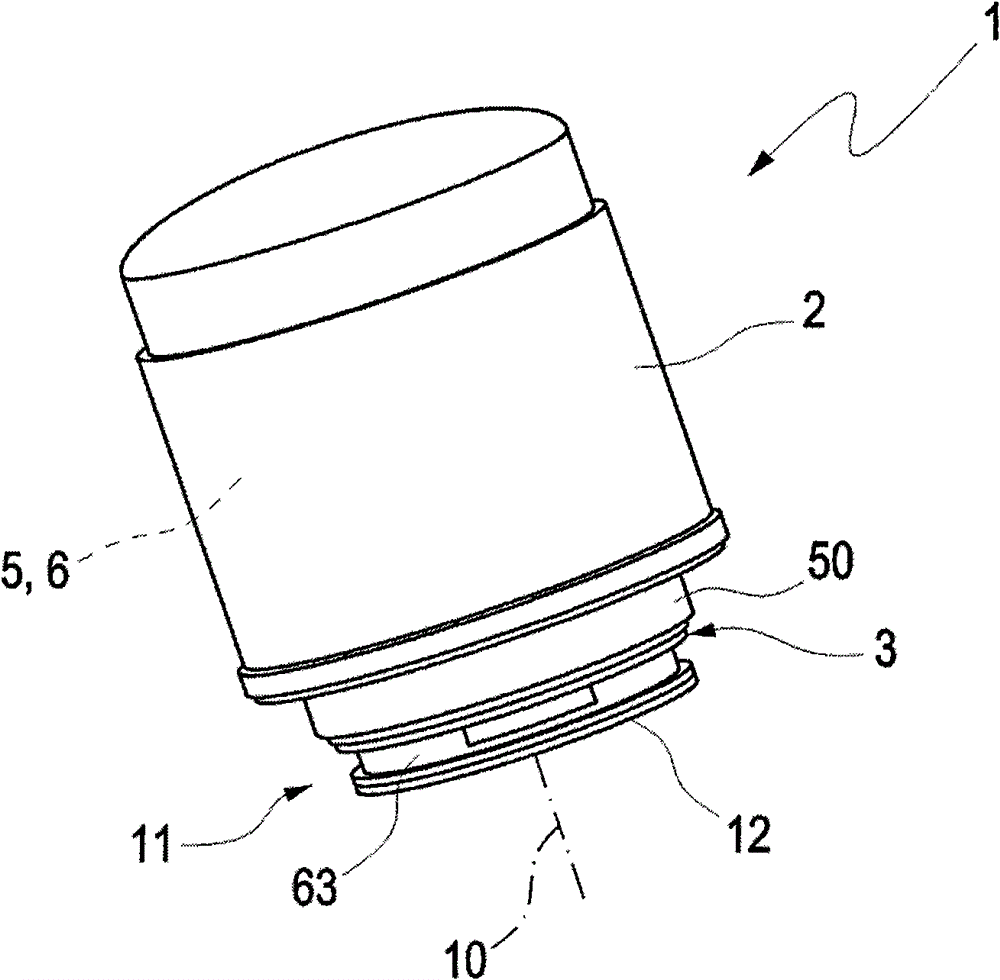

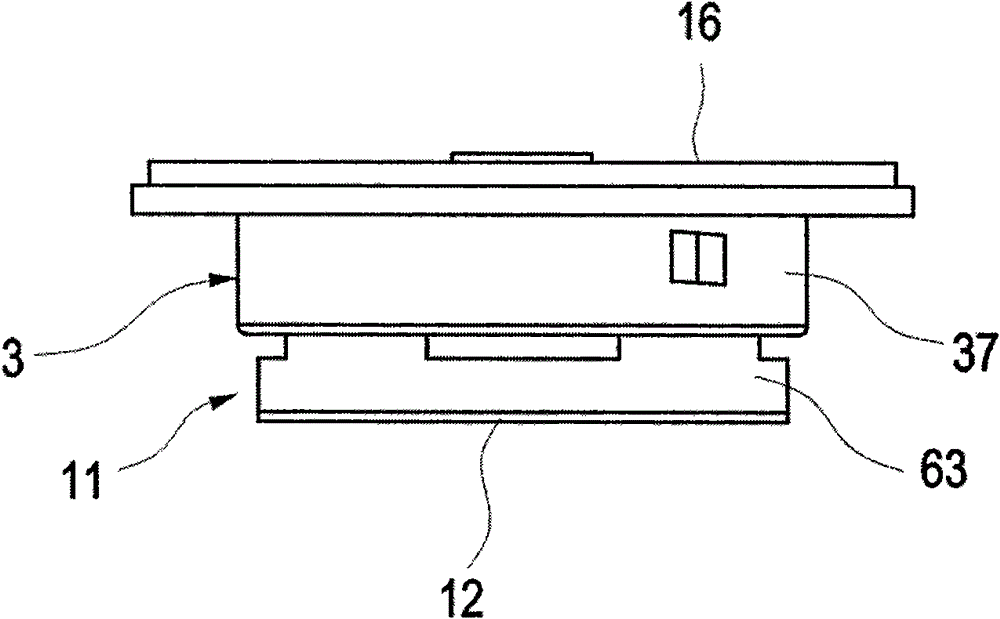

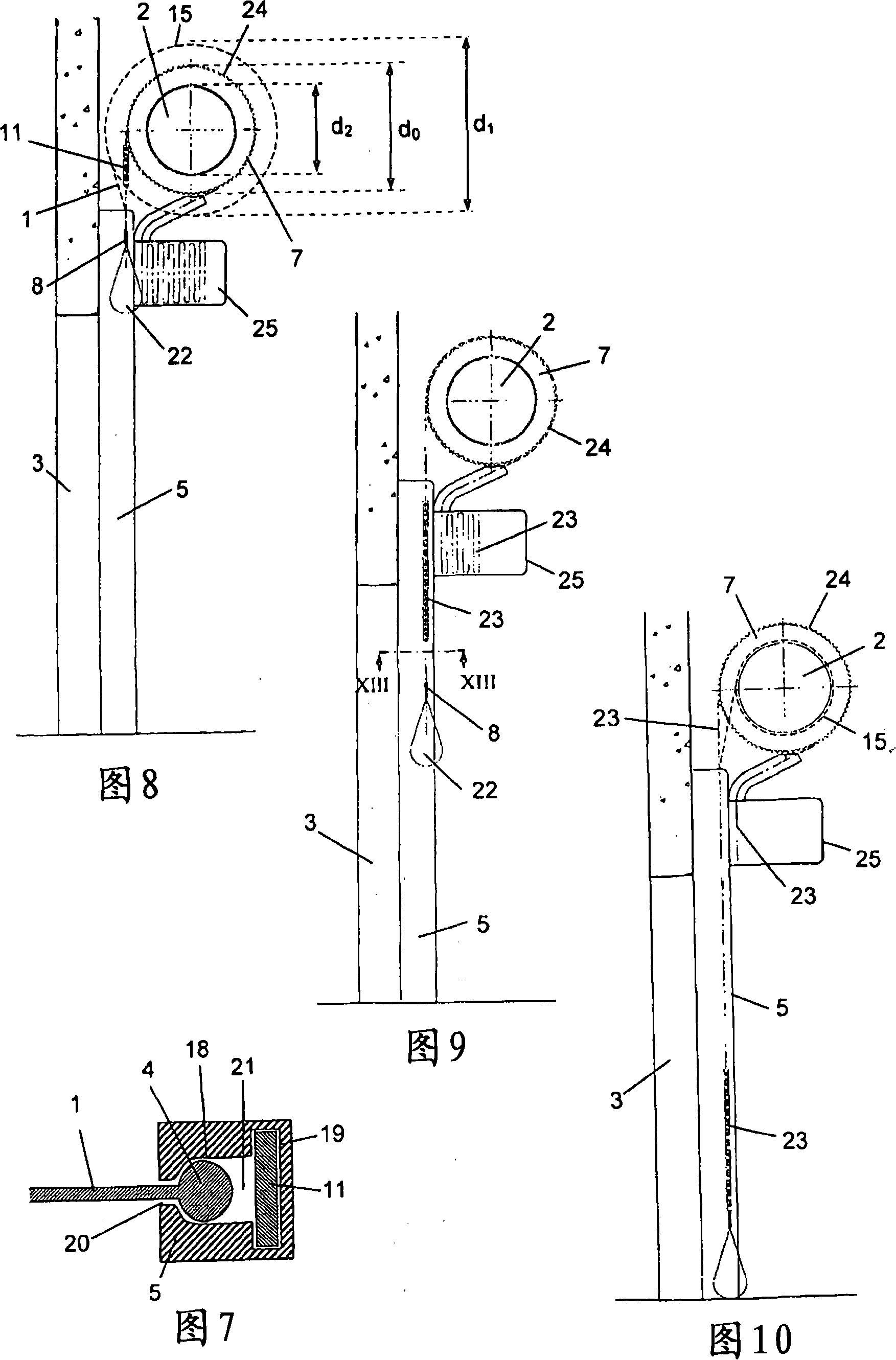

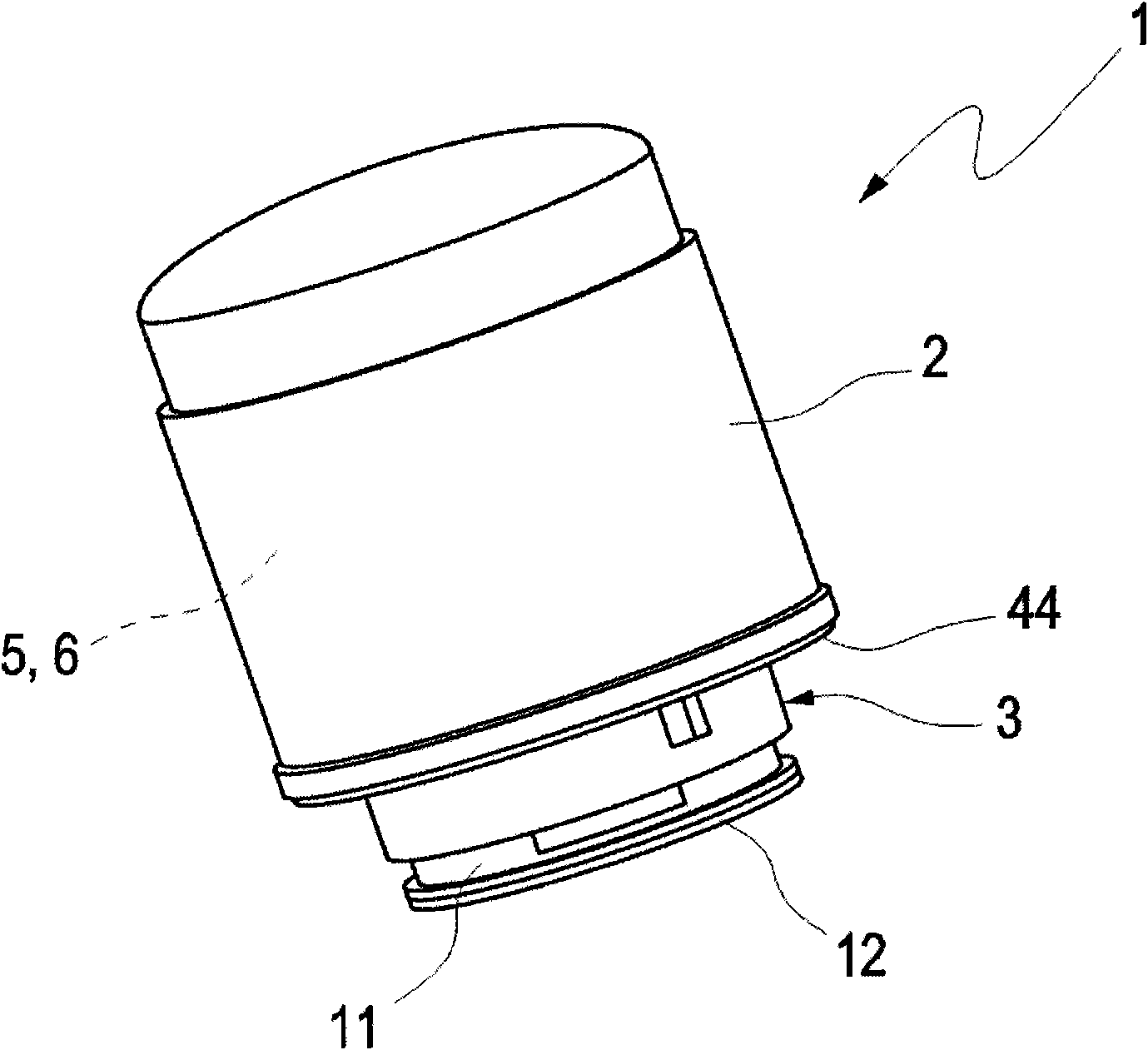

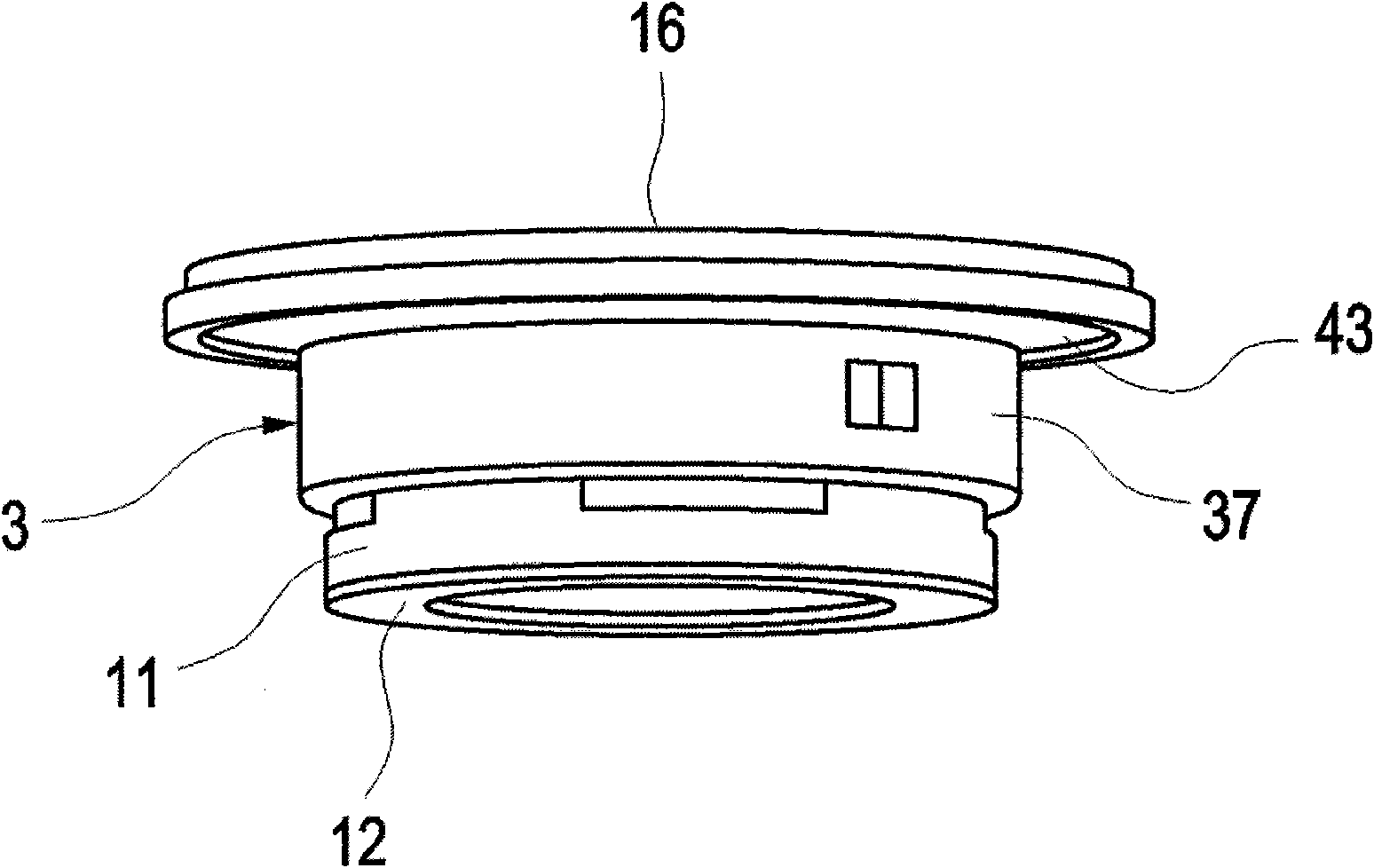

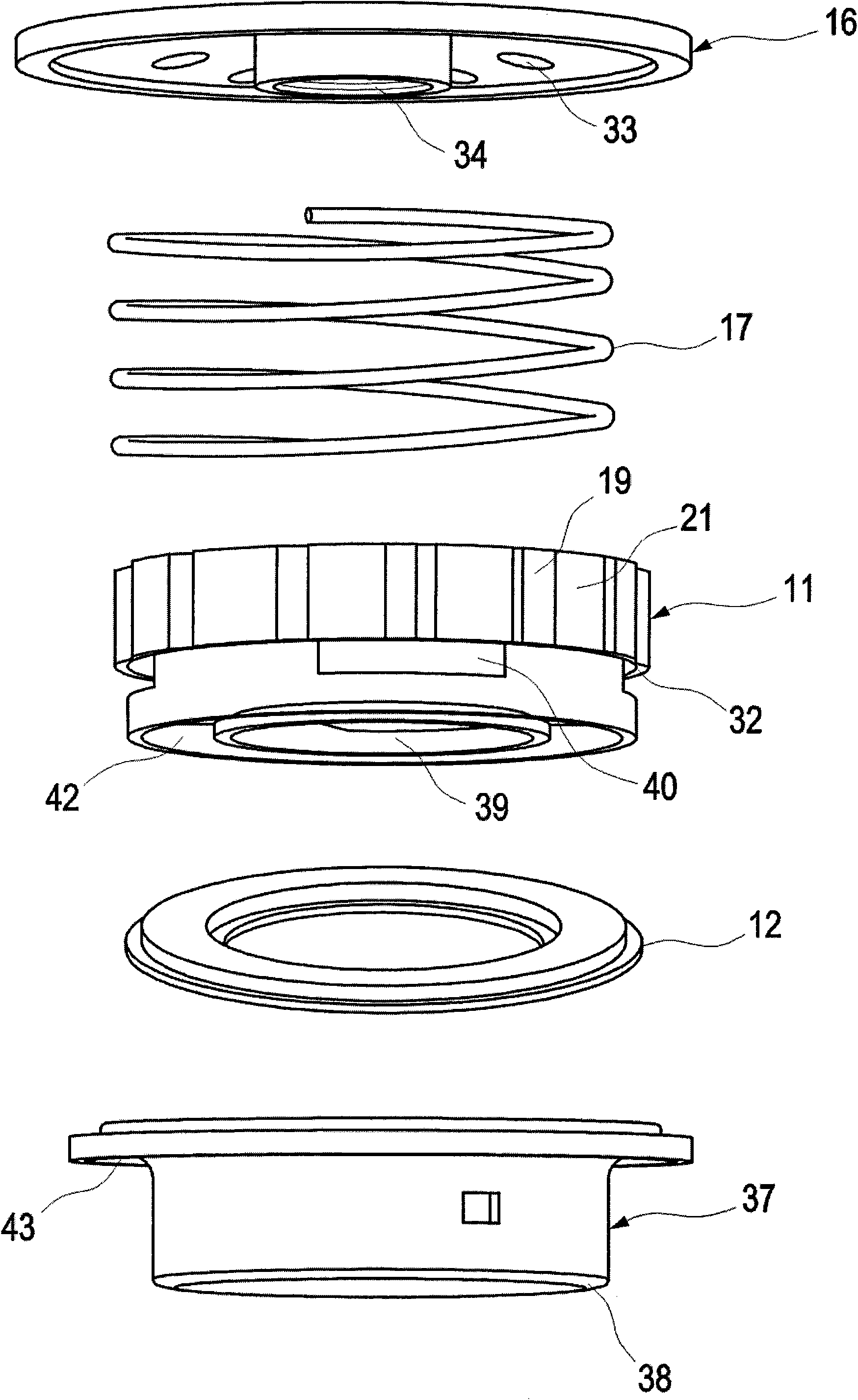

Filter device

ActiveCN102802753AEnsure closure functionOff stableMembrane filtersMachines/enginesFilter elementOil filter

The present invention relates to a filter device (1), in particular an oil filter, having a filter housing cover (2) which delimits a receiving chamber (5) and in which is arranged an annular filter element (6), having a housing (4) in which a dome (15) is arranged centrally and to which the filter housing cover (2) is screwed, having at least one intermediate piece (3) which is arranged between the filter housing cover (2) and the housing (4) when the filter housing cover (2) is screwed to the housing (4), having a housing-side inlet duct (7) which communicates with an untreated side of the annular filter element (6), and a housing-side outlet duct (8) which communicates with a clean side of the annular filter element (6), having a housing-side drainage duct (9) through which the receiving chamber (5) can be drained during the removal of the filter housing cover (2), having a closure device (11) which is arranged in the intermediate piece (3) so as to be rotatable about the filter axis (10) and which has a closure element (12) by means of which the drainage duct (9) can be closed off.

Owner:MAHLE INT GMBH

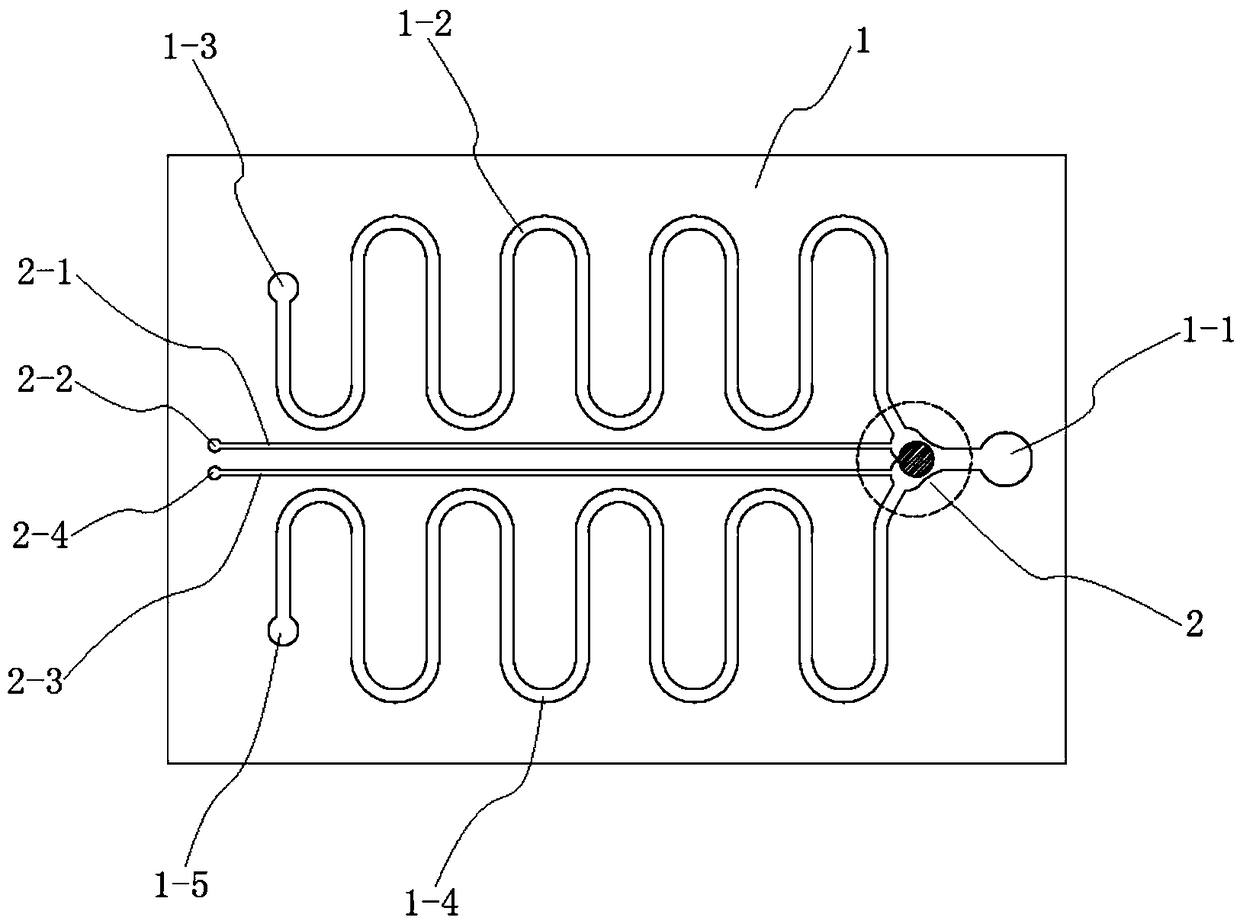

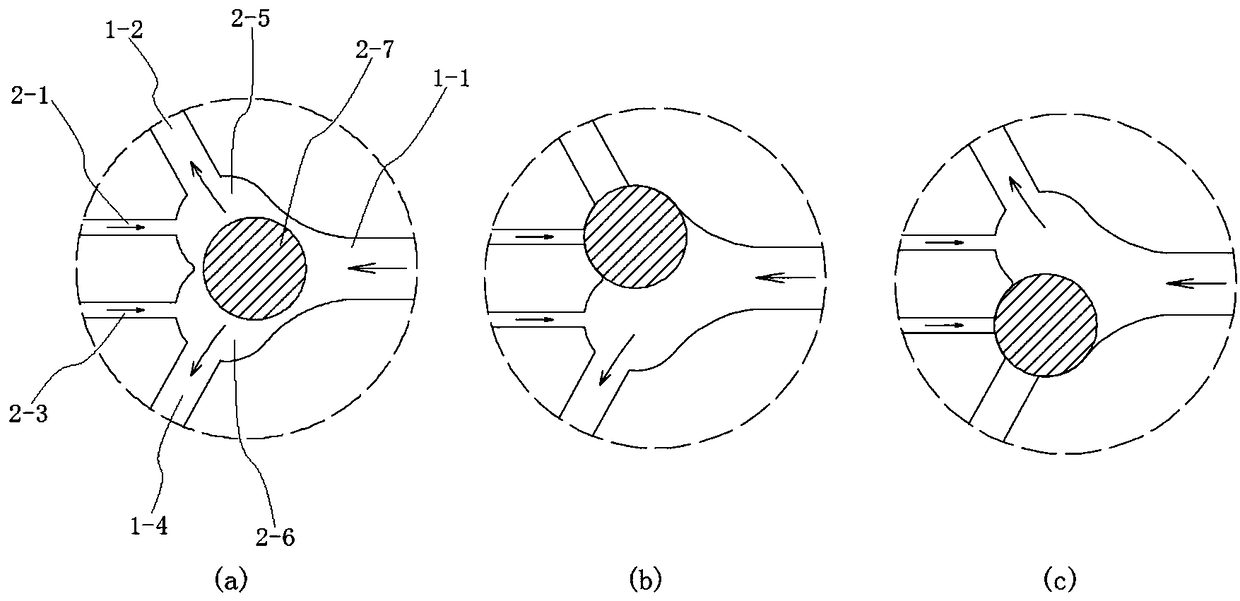

Flow channel switching micro-valve structure for micro-fluidic chip and switching control method thereof

ActiveCN109296823AQuick switchThe switching action is stable and reliableValve arrangementsLaboratory glasswaresInlet channelEngineering

The invention discloses a flow channel switching micro-valve structure for a micro-fluidic chip and a switching control method thereof, and belongs to the field of microfluidics. The flow channel switching micro-valve structure for the micro-fluidic chip comprises the micro-fluidic chip and a switching micro-valve arranged in the micro-fluidic chip, wherein the switching micro-valve comprises a first valve cavity, a second valve cavity, a middle switching valve cavity and a switching ball valve, the switching ball valve is arranged in the middle switching valve cavity, and can enter the firstvalve cavity to block a first flow channel or enter the second valve cavity to block a second flow channel, the first valve cavity communicates with a first air inlet channel capable of blowing out the switching ball valve from the first valve cavity, and the second valve cavity communicates with a second air inlet channel capable of blowing out the switching ball valve from the second valve cavity. According to the provided novel mechanical type micro-valve structure, an air channel is used for blowing the switching ball valve arranged in the valve cavity to achieve rapid switching of the flow channels in the micro-fluidic chip, the structure is simple, machining and manufacturing are convenient, the manufacturing cost is low, moreover, the micro-valve switching action is stable and reliable, and the operation is simple and convenient.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

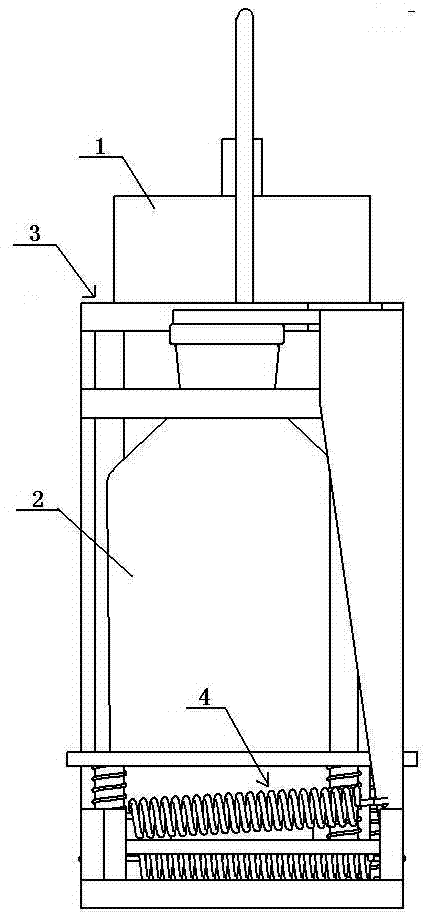

Self-holding solenoid valve

ActiveCN104676078AExtended service lifeSave powerOperating means/releasing devices for valvesLift valveSolenoid valveEngineering

The invention provides a self-holding solenoid valve and relates to a solenoid valve. The self-holding solenoid valve comprises a valve body, a valve element, a sliding connecting rod and an electromagnetic coil, wherein a connecting rod slide way, a piston slide way and a valve cavity are arranged in the valve body; a fluid outlet output is arranged on a wall body of the piston slide way and a fluid inlet input is arranged on a wall body of the valve cavity; the valve element is in a hollow piston structure; a through hole is formed in the side wall of the upper part of the piston structure; an upper sealing ring and a lower sealing ring are arranged on the outer side of the middle wall body of the piston structure and on the outer side of the lower part wall body of the piston structure; an iron magnet is arranged in the upper end body of the sliding connecting rod; the sliding connecting rod is connected with the upper end of the valve element; the valve element is arranged in the piston slide way; the sliding connecting rod stretches into the connecting rod slide way; an isobaric cavity is formed by a piston slide way space above the upper sealing ring; the valve cavity is communicated with the isobaric cavity by a fluid channel and a through hole in the valve element; the electromagnetic coil is mounted at the periphery of the wall body of the connecting rod slide way. According to the self-holding solenoid valve, valve switching-on / off operation can be smoothly carried out without overcoming the pressure of fluid; a valve seat is not arranged in the valve body so that the structure of the solenoid valve is simple.

Owner:NINGBO JLT ELECTRIC CO LTD

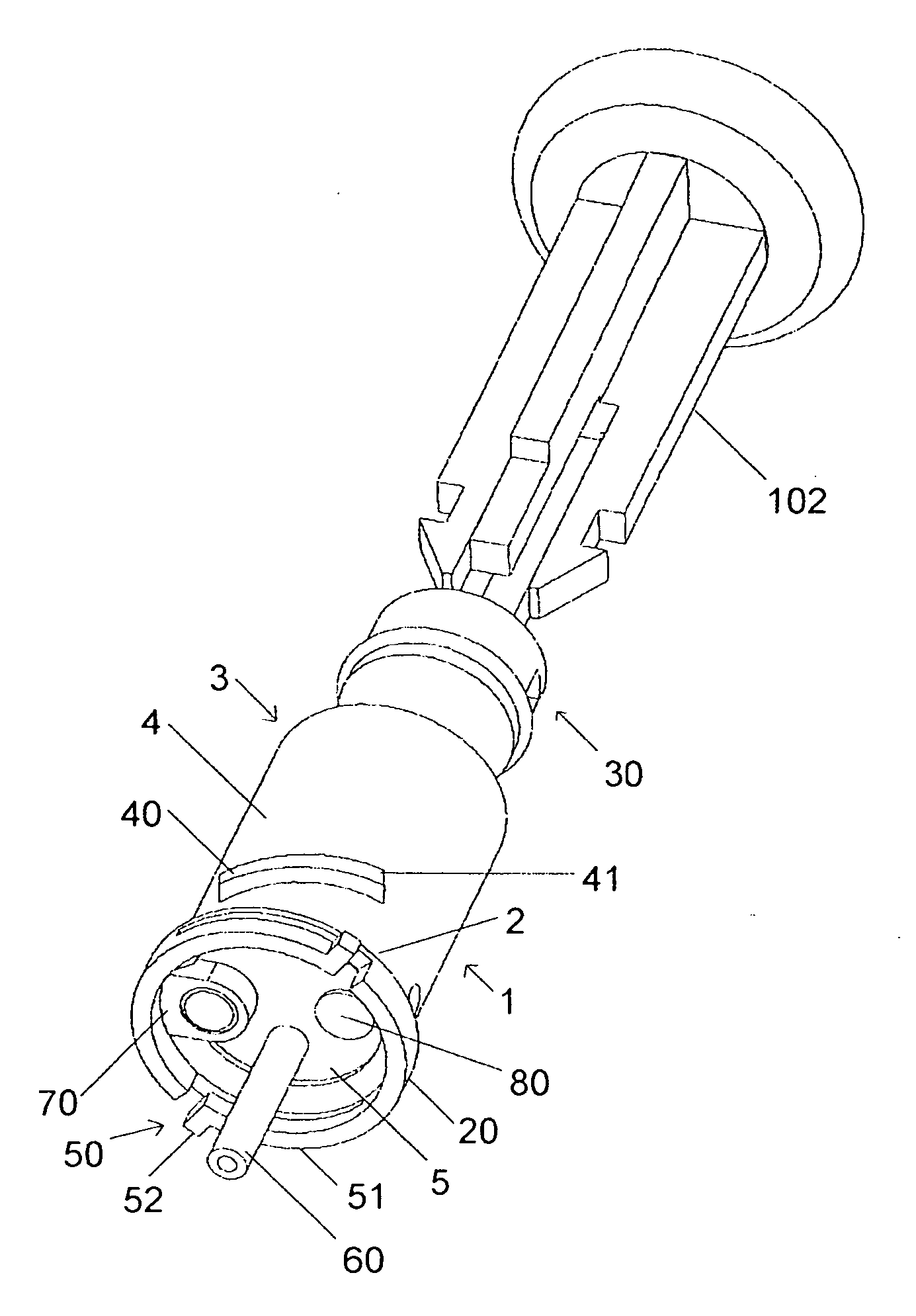

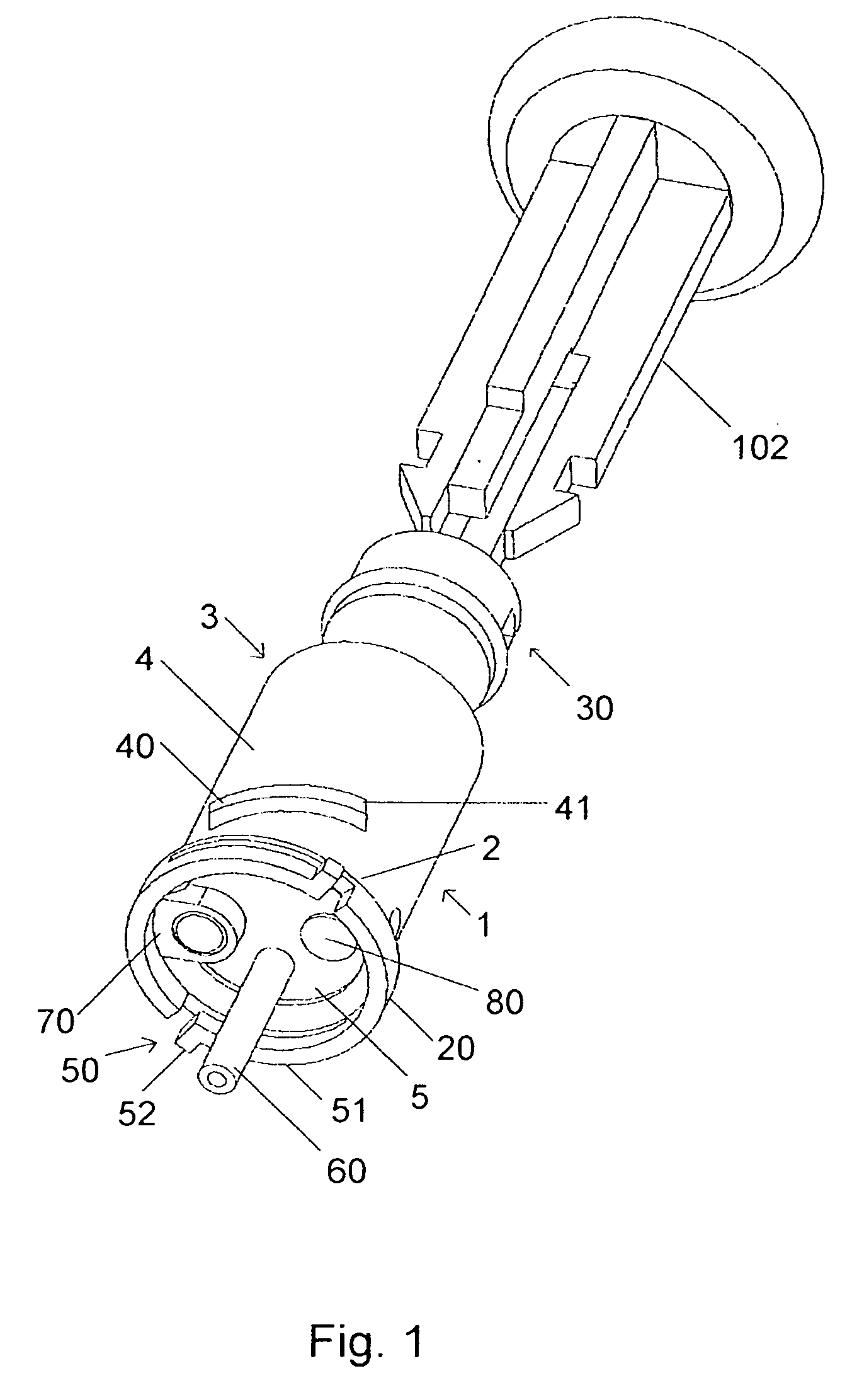

Valve ball control device for timing, quantitative, water-stopping self-closing water tap

InactiveCN101235922AClose tightlySimple structureOperating means/releasing devices for valvesFluid-delivery valvesWater leakageEngineering

A valve ball controlling device for a tap capable of timing, amount fixing and self-closing when water supply is cut off relates to a tap. The invention aims at resolving the problems that structure of control device of existing water-stopping self-closing tap is complex, sensibility is influenced, and incompletely closure of tap caused by stopped water, and water leakage after water is re-supplied. The upper portion of the main valve ball connecting rod of the invention is provided with a spring support shield, the main valve ball connecting rod between the spring support shield and the valve body is equipped with a support spring, a second bearing is arranged at the top end of the main valve ball connecting rod, the lower end of an auxiliary valve ball connecting rod is fixedly connected with upper end of an auxiliary valve ball, upper section of the auxiliary valve ball connecting rod passes through the valve body and is arranged in a cavity of a valve cover. The valve ball controlling device for a tap adapts to that the tap does not automatically close when running water stops after the tap is opened, the tap automatically stops when running water stops after the tap is opened, the water is timed and has fixed amount after the tap is opened, the tap automatically closes when time and amount are adequate and the tap automatically closes once water stops. The valve ball controlling device has the advantages of simple structure, high sensibility, and tight closure of tap when water supply is cut off.

Owner:哈尔滨兴言科技发展有限公司

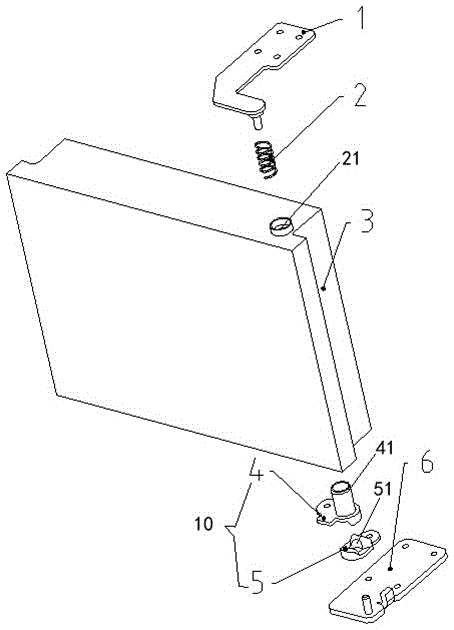

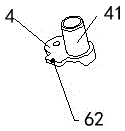

Refrigerator and self-locking structure of door body thereof

InactiveCN105135800AClose tightlyReduce churnDomestic cooling apparatusLighting and heating apparatusSelf lockingEngineering

The invention discloses a refrigerator and a self-locking structure of a door body thereof. The self-locking structure of the door body of the refrigerator comprises an upper hinge and a lower hinge which are arranged at the upper end and the lower end of the door body of the refrigerator respectively and used for connecting the door body of the refrigerator to a refrigerator body in a hinged mode; one end of the upper hinge is fixedly connected to the refrigerator body, and the other end of the upper hinge is hinged to the edge side of the upper end of the door body of the refrigerator through an automatic return spring; one end of the lower hinge is fixedly connected to the refrigerator body, and the other end of the lower hinge is hinged to the edge side of the lower end of the door body of the refrigerator through a jacking structure rotating upwards. The refrigerator and the self-locking structure of the door body thereof are fast to use and reliable and have the advantages that the structure is simple, machining and manufacturing are convenient, the door body can be automatically locked, and closer closing is achieved, and therefore convenience is supplied to a user.

Owner:ANHUI KONKA TONGCHUANG HOUSEHOLD APPLIANCES

Floating ball valve

ActiveCN1975219AClose tightlyIncrease the lengthOperating means/releasing devices for valvesLift valveEngineeringBall valve

Owner:杨召泽

Door closer

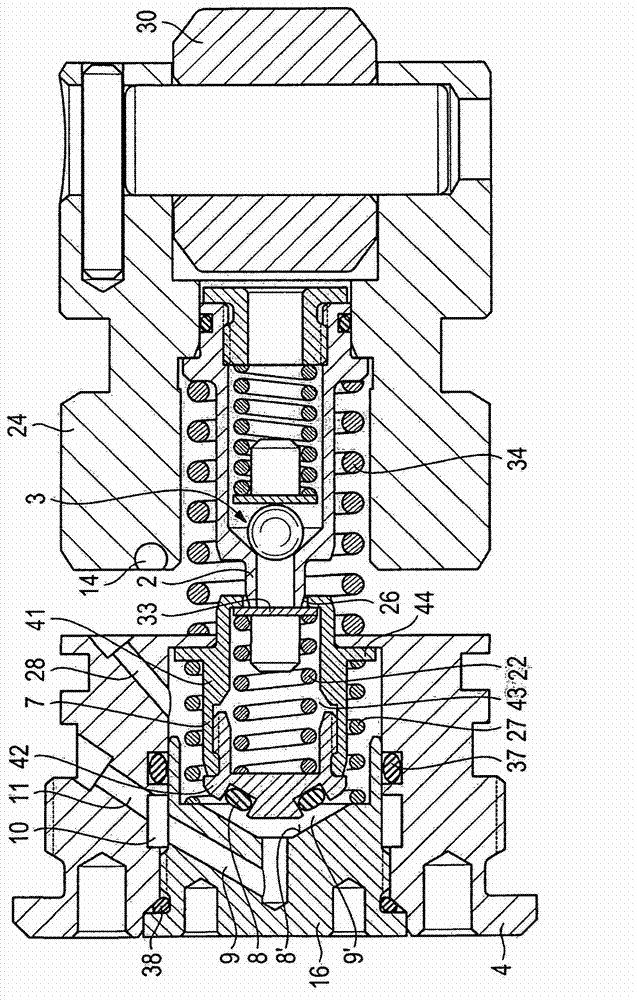

InactiveCN102959168AClose tightlyHigh shock pressureBuilding braking devicesWing accessoriesEngineeringPiston

The invention relates to a door closer, comprising a door closer housing, a drive unit which can be coupled to a door by means of a door closer shaft and a linkage and is disposed in the door closer housing, and a hydraulic damping unit, which has a damping piston which is guided in a damping cylinder of the door closer housing and is operatively connected to the drive unit. Said damping piston cooperates with a first oil discharge channel associated with a rapid door closing movement and a second oil discharge channel associated with a slow door closing movement, wherein the first and second discharge channels are disposed one after the other and wherein the first discharge channel, as seen looking in the direction of movement of the damping piston, is disposed downstream of the second discharge channel.

Owner:DORMAKABA DEUT GMBH

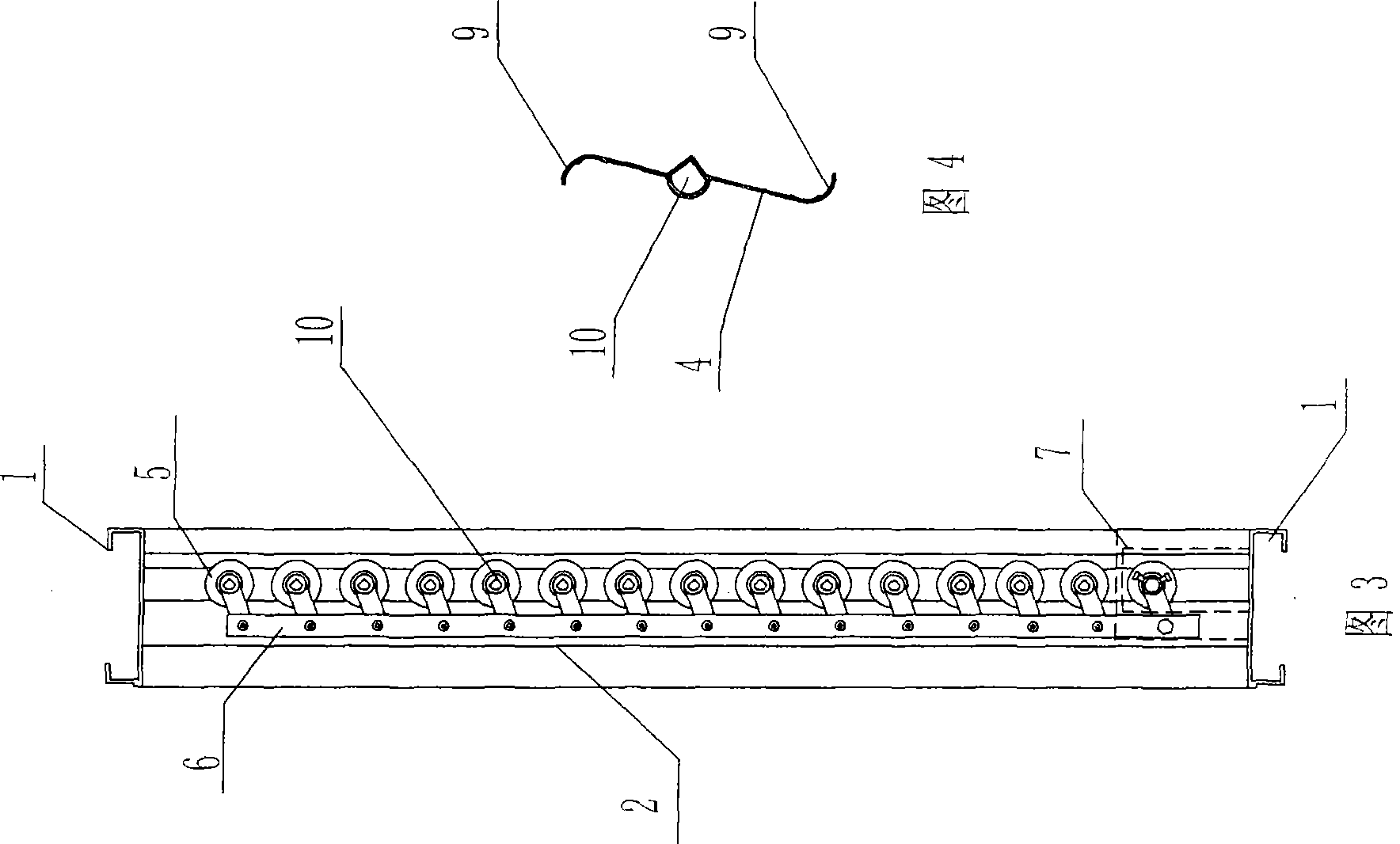

Roller curtain device

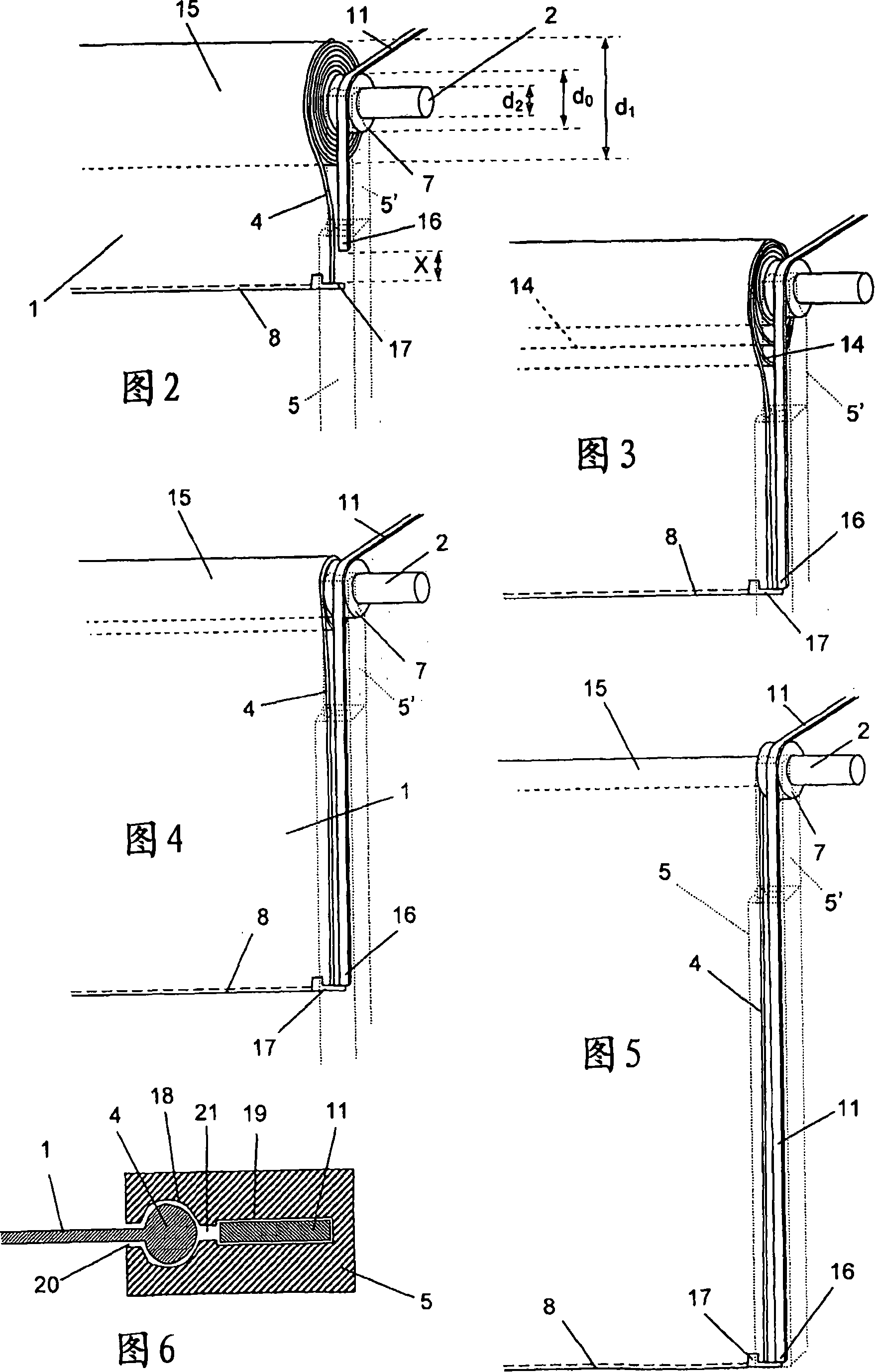

ActiveCN101124373AWon't interfere with operationSimple designSunshadesLighting and heating apparatusDrive wheelControl theory

The invention relates to a curtain device mounted on a shaft (2) about which said curtain (1) can be wound to an open position and unwound into a closed position, a drive wheel (7) fixed coaxially to said shaft (2) and cooperating with said curtain (1) such as to displace the latter between said two positions. The device comprises an oblong flexible control body (11), cooperating with the drive wheel (7), said body (11) being embodied to permit the displacement of the curtain (1) between the open position and the closed position thereof, independently of the slack formed in the curtain (1) and to be able to be displaced along at least one of the lateral edges (4) of the curtain (1) and act upon the region (8) of the latter as opposed to that arranged on the shaft (2).

Owner:DYNACO EURO

Filter device

InactiveCN102458598AOff stableGuaranteed functionSeparation devicesMembrane filtersInlet channelEngineering

The present invention relates to a filter device (1), particularly an oil filter, having a filter housing cover (2) bounding a receiving chamber (5), in which a ring filter element (6) is disposed, having a housing (4) in which a dome (15) is centrally disposed, and onto which the filter housing cover (2) can be threaded, having at least one intermediate piece (3) disposed on the filter housing cover (2) threaded onto the housing (4) between the filter housing cover (2) and the housing, having an inlet channel (7) on the housing side communicating with an unfiltered side of the ring filter element (6) and an outlet channel (8) on the housing side communicating with a clean side of the ring filter element (6), having an idler channel (9) on the housing side, through which the receiving chamber (5) can be emptied when the filter housing cover (2) is removed, having a closure device (11); rotatably disposed about the filter axis (10) comprising a closure element (12) by means of which the idler channel (9) can be closed off.

Owner:MAHLE INT GMBH

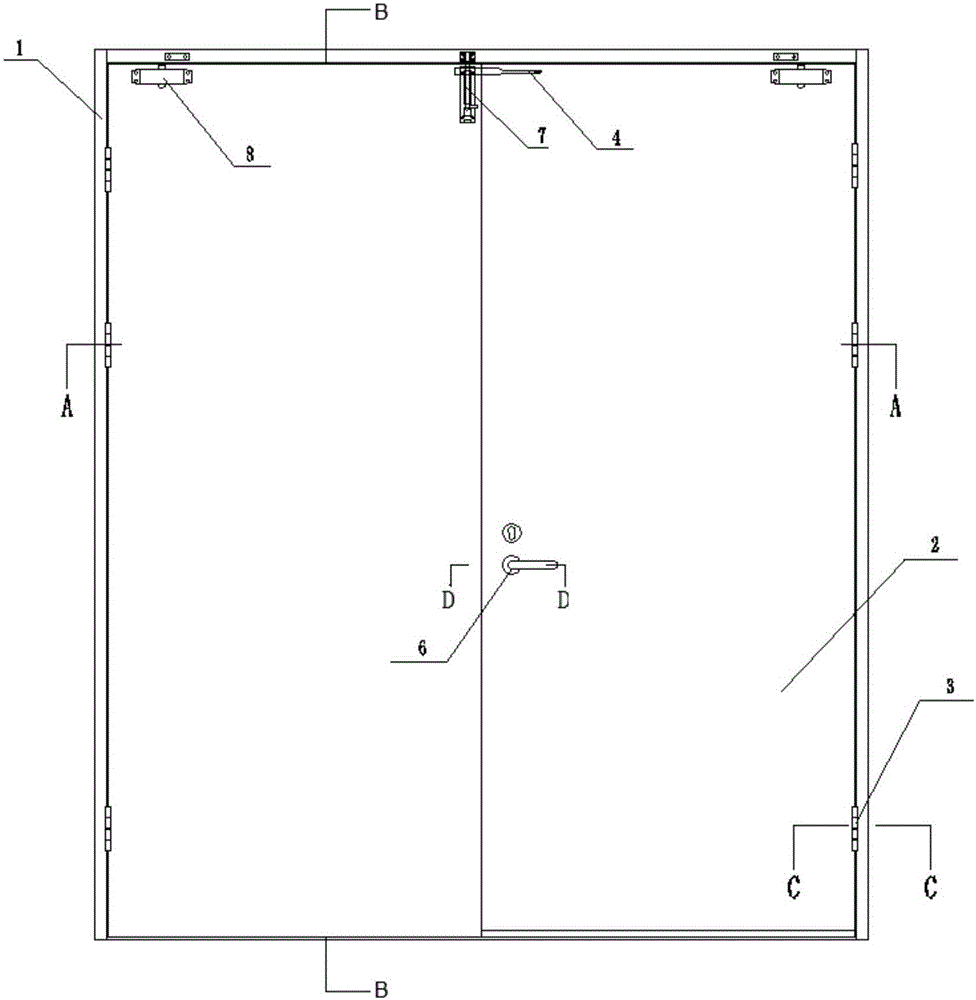

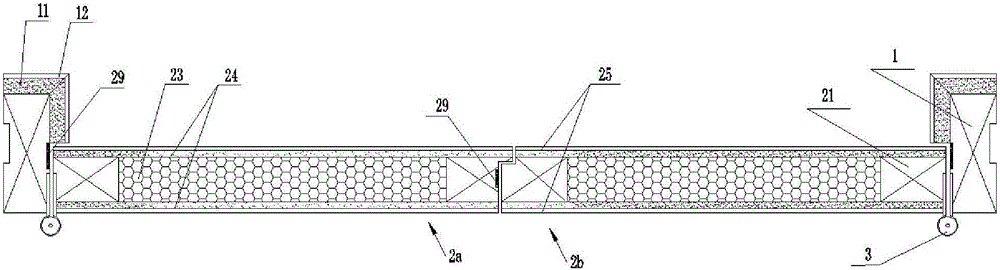

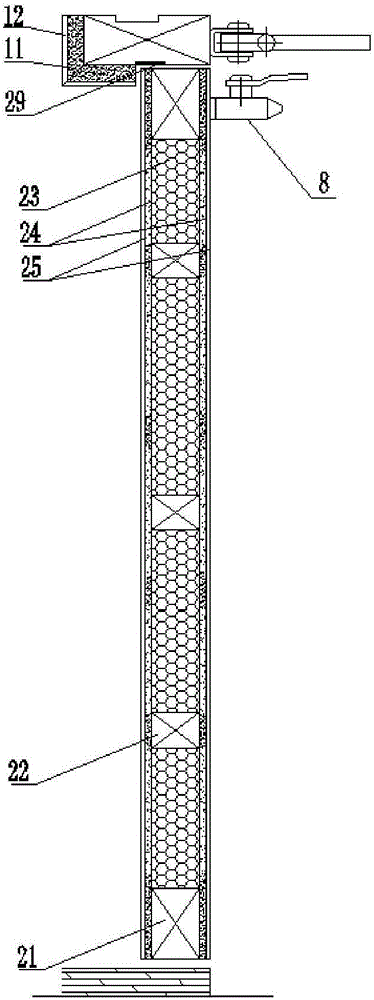

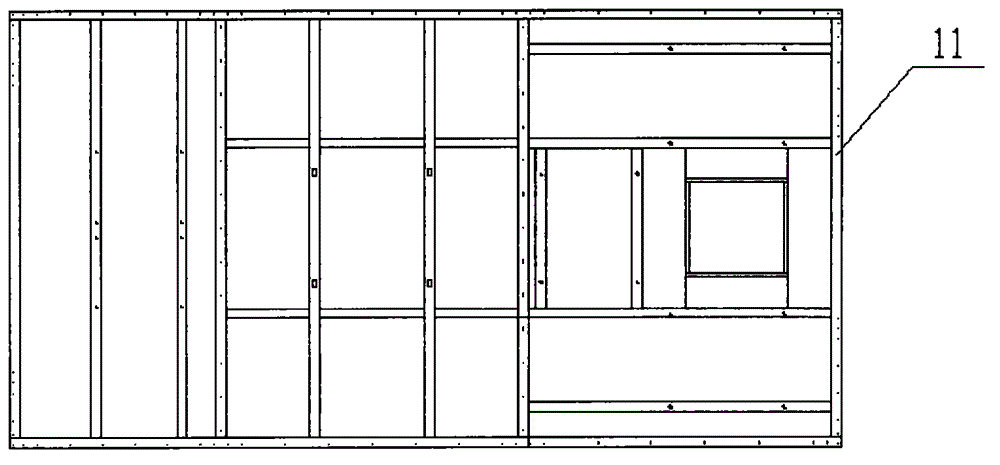

Double-side opening type wooden heat insulation fireproof door

InactiveCN105927126AHigh strengthImprove impact resistanceFireproof doorsWindow/door framesEngineeringTongue and groove

The invention provides a double-side opening type wooden heat insulation fireproof door, comprising a door frame and two door leaves, wherein the two door leaves are symmetrically fixed on side frames at the two sides of the door frame respectively by fireproof hinges; each door leaf comprises a framework; each framework is internally filled with an expanded perlite fire prevention board, and a first magnesium-silicon fire prevention board and a flame-retardant plywood are sequentially fixed on the surface of each expanded perlite fire prevention board; a fire-proof expansion sealing element is arranged between the door frame and each door leaf; a second magnesium-silicon fire prevention board is fixed at the inner side of a surface, exposed to fire, of the door frame; the two door leaves are closed in a tongue-and-groove way. The expanded perlite fire prevention boards are arranged in the door leaves, so that a fireproof effect is improved; the magnesium-silicon fire prevention boards are arranged, so that the strength and impact resistance of the door leaves are improved while the fireproof effect is further improved. The fire-proof expansion sealing elements are reasonably installed on the door frame, so that a sealing fire prevention effect is improved.

Owner:ANHUI ANWANG DOOR IND

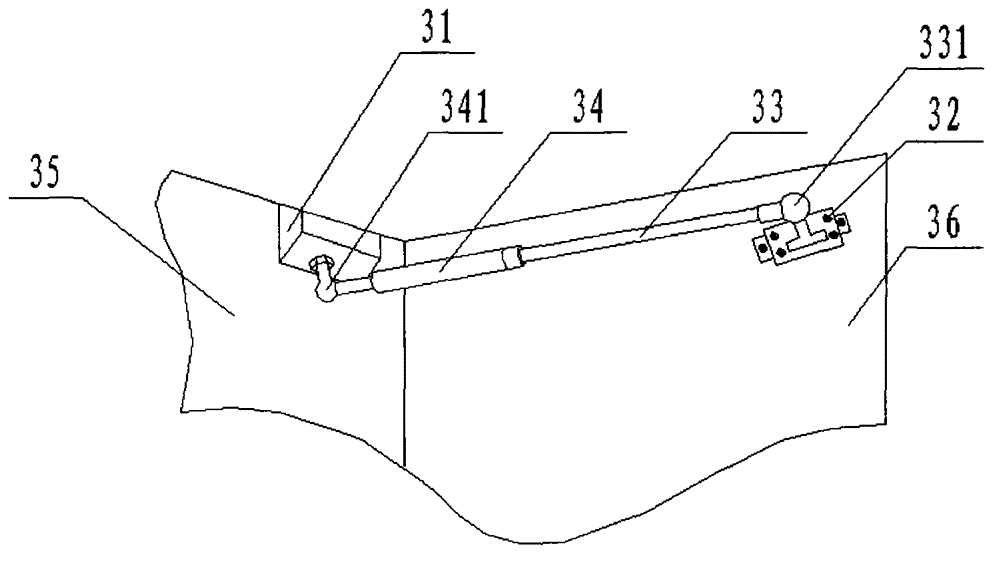

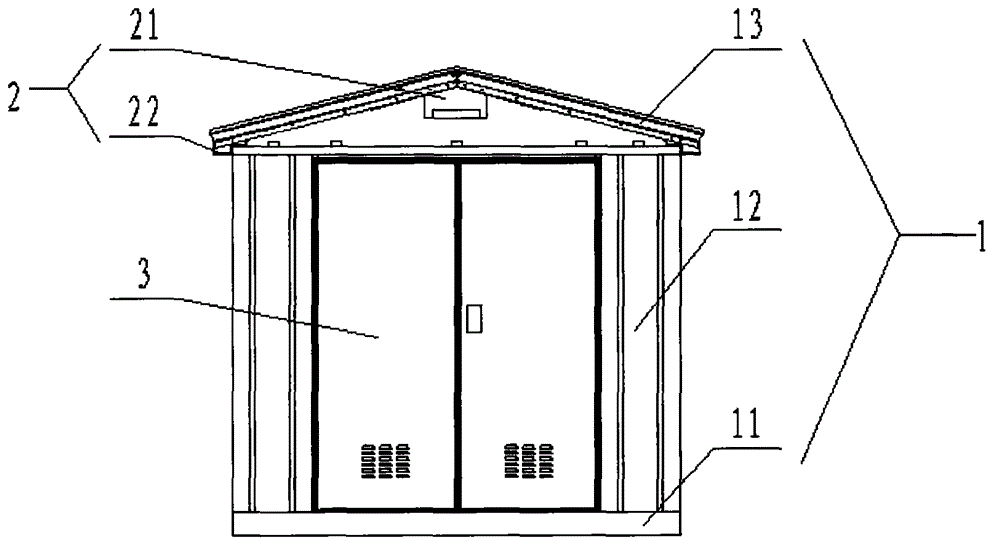

Prefabricated power transformation box with automatic opening and shutting door

InactiveCN104701766ARealize assemblyRealize standardized productionSubstation/switching arrangement cooling/ventilationHydraulic cylinderEngineering

The invention belongs to the technical field of a prefabricated power transformation box structure and especially relates to a prefabricated power transformation box with an automatic opening and shutting door. The prefabricated power transformation box comprises a box body, a ventilating device, and the automatic opening and shutting door, wherein the automatic opening and shutting door comprises a first fixing part, a second fixing part, and a hydraulic rod; the hydraulic rod is sleeved with a hydraulic cylinder, one end of the hydraulic rod is in extensible connection with one end of the hydraulic cylinder, the other end of the hydraulic cylinder is provided with a first spherical connector which is moveably connected the inside of a door frame through the first fixing part, and the other end of the hydraulic rod is provided with a second spherical connector which is moveably hinged to the upper door beam of the automatic opening and shutting door leaf through the second fixing part. The prefabricated power transformation box is convenient to install, safe and reliable, and high in production efficiency.

Owner:SUNRISE GRP CO LTD

Air outlet device for range hoods

ActiveCN102927601AExtended service lifeOpen smoothlyDomestic stoves or rangesLighting and heating apparatusAutomatic controlEngineering

The invention discloses an air outlet device for range hoods. The air outlet device comprises a cover body and a valve block component which is arranged at an air outlet of the cover body, wherein the valve block component comprises a rotation shaft which is arranged along the symmetry axis of the air outlet and two symmetric valve blocks which are hinged on the rotation shaft; the total area of the two valve blocks is matched with the air outlet; and the valve blocks are capable of rotating around the rotation shaft to open or close the air outlet. The air outlet device for range hoods is characterized in that a control device which is used for controlling the two valve blocks to be automatically opened and closed is arranged below the valve block component. The air outlet device is not only capable of automatically controlling the opening and the closing of the valve clocks to ensure the smooth opening and the tight closing of the valve blocks, ensure the unobstructed air exhaust during the use of the range hoods and prevent the backflow of lampblack when the range hoods are closed, but also capable of ensuring the synchronous opening and closing of the two valve blocks to ensure the unobstructed air exhaust of the range hoods and reduce the noise of the range hoods.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Using method of closed-type discharging device

The invention relates to a using method of a closed-type discharging device. The device comprises a discharging sprout door, a bearing and a box body, wherein the bearing is arranged outside the box body and is separated from the box body by a separating seat provided with a dust discharging channel. The discharging process is accomplished by two discharging gates and a middle translational section, a material falls into the discharging gate I through a receiving port and then enters into the translational section after the discharging sprout door of the discharging gate I is opened via a hydraulic oil cylinder, afterwards, the discharging sprout door of the discharging gate I is closed and the discharging gate II is opened, the material in the translational section enters into the discharging gate II and is delivered to a belt conveyor via a vibrating feeder, the discharging gate II is closed and then the discharging sprout door of the discharging gate I is opened, followed by the circulation of the above steps. The external leakage of the air in kiln can be effectively prevented through the cooperative use of the device and the two discharging gates.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

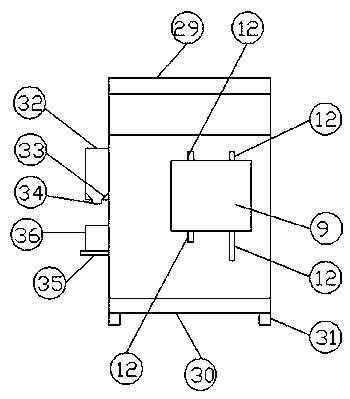

Novel structural closed type unloading mechanism and use thereof

The invention relates to a discharging device and application thereof, and particularly to a sealing type discharging device with a novel structure which is used to prevent air leakage of a kiln in the discharging process of a lime shaft kiln. The device comprises a discharging sprout door, a bearing and a box body, wherein the bearing is arranged outside the box body and separated from the box body by a separating seat provided with a dust discharging channel; a maze type sealing structure and a sealing ring are utilized between the separating seat of the box body and a rotating shaft; the contacting part between the discharging sprout door and the box body is provided with a sealing ring; and the device is arranged on a material receiving opening below a discharging machine of the lime shaft kiln to prevent the air leakage of the kiln, and has the advantages of having good sealing effect, discharging materials without stopping wind and having the action of stopping flow, along with simple structure, light weight and few easily-damaged parts.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

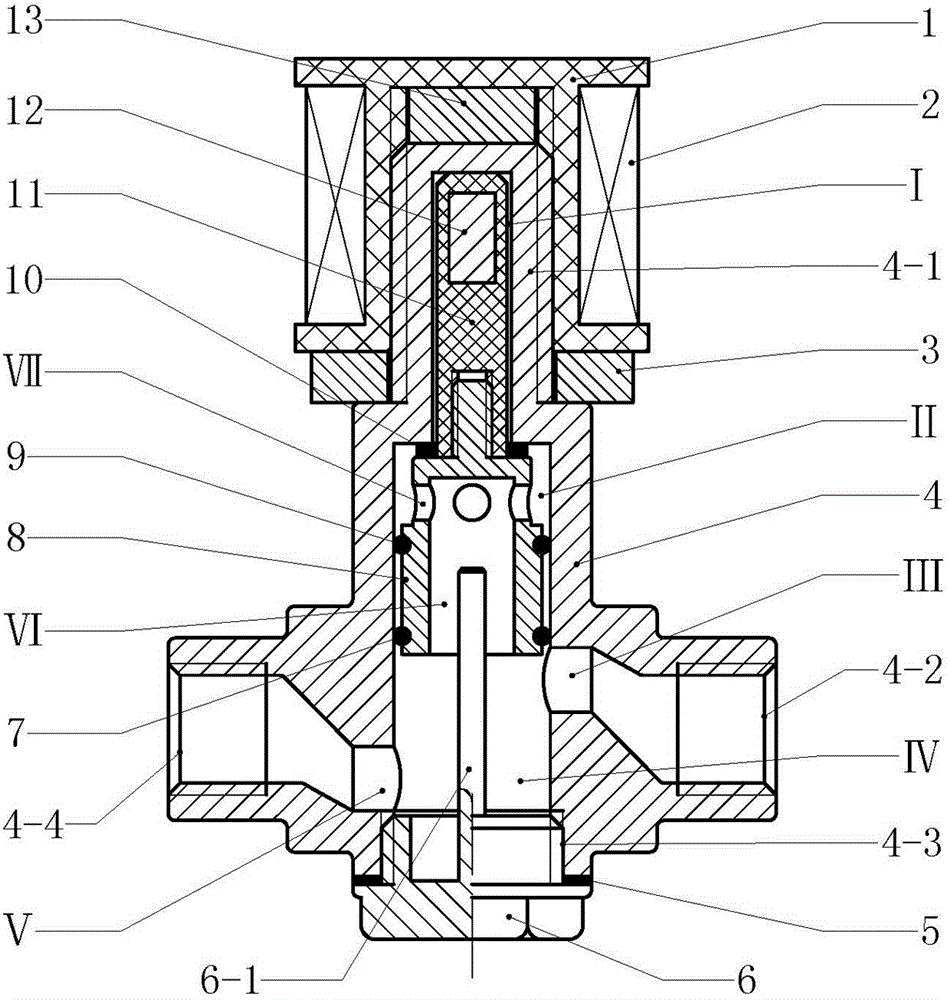

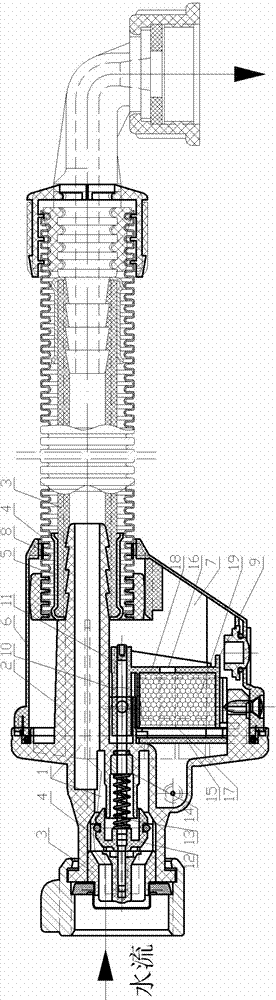

Piston-driven straight-through type pressure and flow regulating valve

PendingCN111795190AImprove liquidityWith pressure regulating functionOperating means/releasing devices for valvesValve members for absorbing fluid energyWater flowEngineering

The invention provides a piston-driven straight-through type pressure and flow regulating valve. The piston-driven straight-through type pressure and flow regulating valve comprises a main valve and apilot valve connected with the main valve, an outer shell and an inner shell of a valve body of the main valve are coaxially arranged, a valve cavity is formed between the outer shell and the inner shell, and a driving device is installed in the inner shell in a sliding mode in the axial direction; an end cover with a spherical structure is arranged on the side, facing a first port, of the innershell; and the inner walls of the two ends of the shell are each of an arc-shaped structure, the inner diameter of each arc-shaped structure is gradually reduced from inside to outside, long grooves are formed in the axial direction of a pup joint, and the outlet side pressure of the valve body is adjusted through the length of the long grooves in a pressure reduction opening-closing piece extending into the valve cavity. A pressure reducing valve provided by the straight-through type pressure and flow regulating valve has high distribution capacity, water flow energy counteracts each other atthe arc-shaped structure at the outlet of the valve body, cavitation and vibration can be effectively avoided, and due to the fact that the pressure reducing opening and closing piece is subjected tothe effect of control pressure of the guide valve, the valve has a pressure regulating function, water head loss is very small during opening and closing, and resistance is small during complete opening; and meanwhile, the valve is closed tightly and is good in sealing performance.

Owner:TIANJIN TANGGU NO 1 VALVE FACTORY

Inclined setpoint closing container complete side door opening device

The invention belongs to the technical field of container door opening devices, and in particular relates to a complete side door opening device for a container which can be closed at an inclined selection point, comprising a cantilever mounting seat arranged on the container body, and a cantilever mounting seat is rotatably mounted on the cantilever mounting seat driven by a first driving mechanism. A cantilever, the end of the cantilever far away from the cantilever mounting seat is equipped with a rotating shaft mounting seat, and a rotating shaft driven by a second driving mechanism is rotatably installed on the rotating shaft mounting seat, and the rotating shaft is connected to the cover connecting seat, and the cover The connecting seat of the body is hingedly connected with a crank arm for connecting the cover, and the connecting seat of the cover is provided with a position-limiting structure that limits the movement range of the crank arm. The complete side door opening device for containers with inclined point selection and closure provided by the present invention can fully open the cover and place it behind the opening of the container body, providing enough space for automatic operation, which is conducive to improving production efficiency, and the cover is naturally inclined due to gravity Realize point-selected closing, tight closing, and less wear on the sealing ring.

Owner:诸城市金泰食品机械有限公司

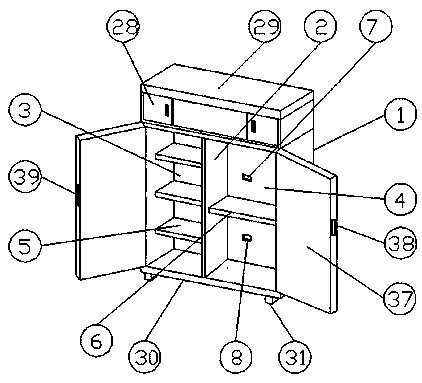

Shoe cabinet with drying deodorizing functions

The invention discloses a shoe cabinet with drying deodorizing functions. The shoe cabinet with drying deodorizing functions comprises a cabinet body; the back surface of the cabinet body is providedwith a drying deodorizing device; a heating chamber and a deodorizing chamber are arranged in a housing; a motor is arranged in the heating chamber; the motor is used for driving blades to rotate; theblades are used for driving air to flow, and cold wind is heated in passing by an electric heating wire; the heated air is introduced into a gas outlet through a first pipeline for drying of shoes inthe drying chamber; a gas pump is arranged in the deodorizing chamber; under the effect of a gas suction port and a second pipeline, the air in the drying chamber is sucked into the deodorizing chamber, is filtered using a graphene filter screen and an active carbon filter screen, and is discharged through a gas exhaust pipe, so that deodorizing effect is achieved. The beneficial effects are that: the shoe cabinet is simple in structure, can be used for drying shoes got wet in rainy days, and removing peculiar smell generated in drying process, ensuring the freshness of indoor air, promotingair circulation, and preventing bacteria breeding.

Owner:安徽爱就爱家具制造有限公司

Expansion member of leak-proof water inlet pipe component

ActiveCN103032614ARapid responseLow costEqualizing valvesSafety valvesPolyvinyl chlorideCentral pressure

The invention provides an expansion member of a leak-proof water inlet pipe component. The expansion member has the advantages of quick response of a valve mechanism, tight cut-off and closing, low raw material cost and convenience in material taking. The expansion member comprises a central pressure pipeline, an external shell, a PVC (Polyvinyl Chloride) pressure hose and a corrugated pipe, wherein the central pressure pipeline is externally wrapped by the external shell and the PVC pressure hose; the junctions of the external shell and the PVC pressure hose are buckled and firmly connected through an aluminum sealing pipe; the corrugated pipe is sleeved on an outer annular surface of the PVC pressure hose; a fixing member is sleeved outside the external shell; one end of the fixing member is packaged in the outer annular surface of the corrugated pipe; a cavity is enclosed by the fixing member and the external shell; and an inner interlayer cavity of the corrugated pipe is communicated with the cavity.

Owner:WUXI JINHUA YIYUAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com