Novel structural closed type unloading mechanism and use thereof

A technology of unloading device and new structure, applied in the field of unloading device, can solve the problems of unsuitable star-shaped ash extractor and poor sealing performance, and achieve the effects of increasing shear stress, reducing extrusion and shortening replacement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure and use method of a new type of sealed unloading device will be described in detail below through specific embodiments.

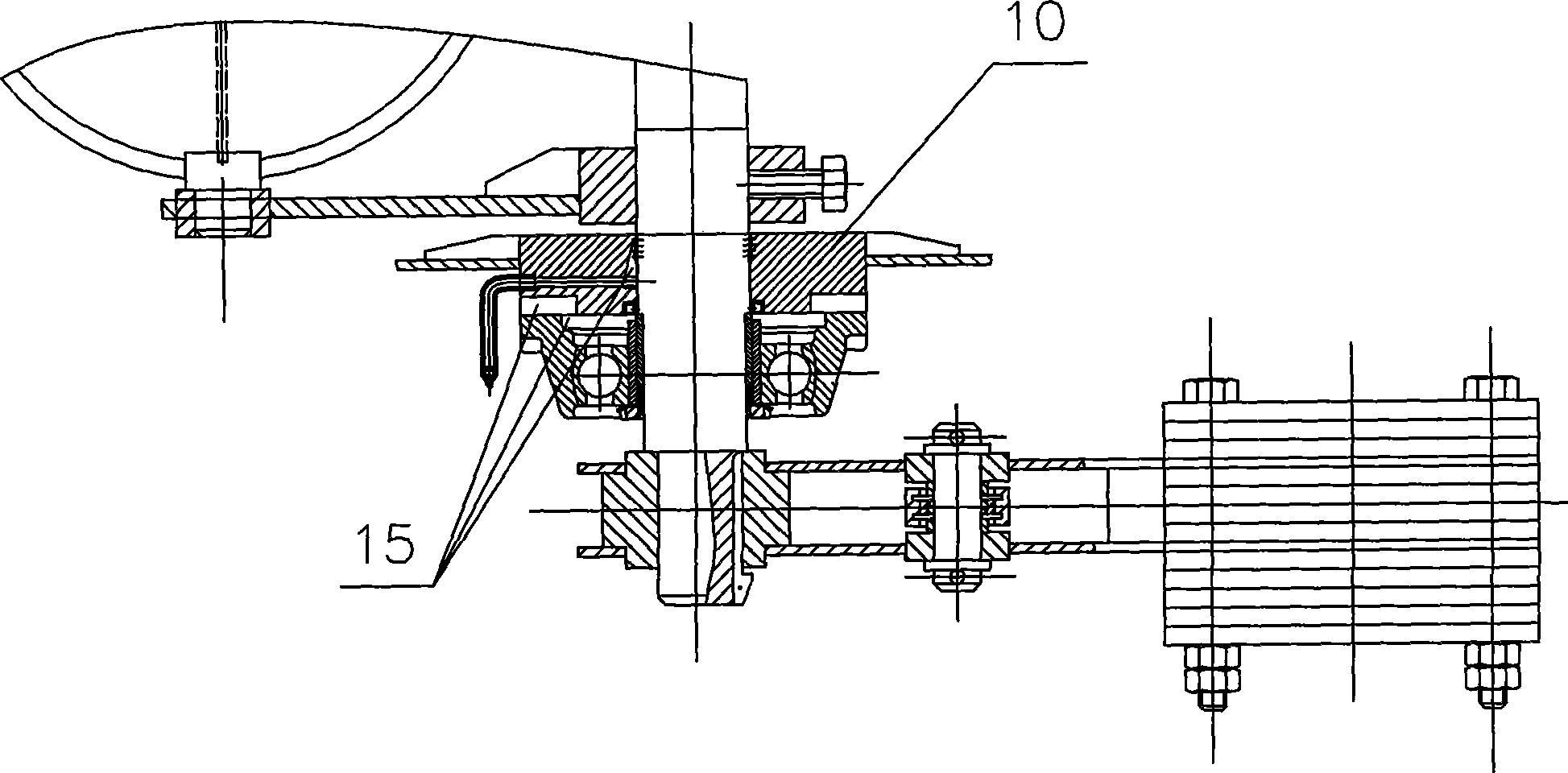

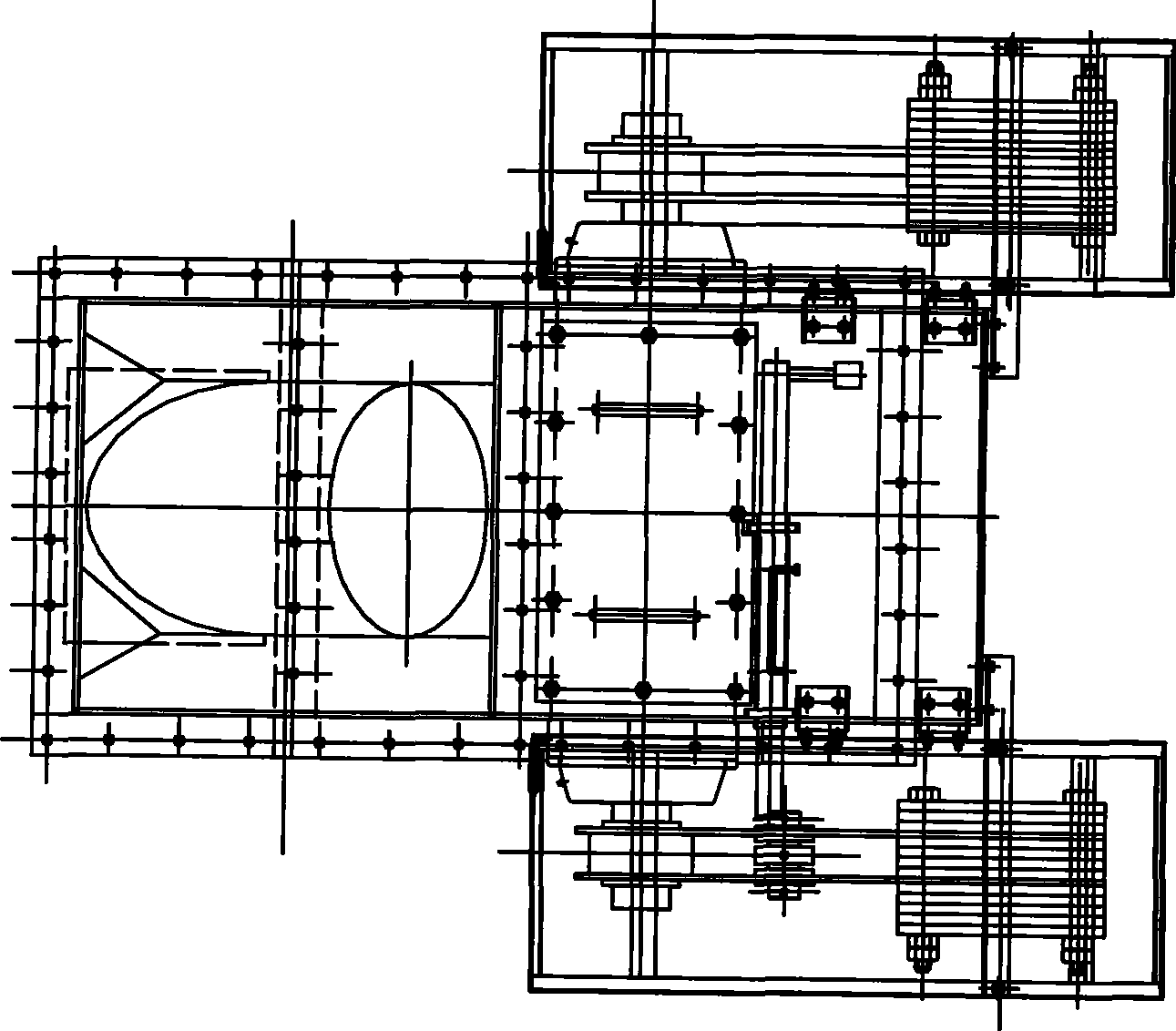

[0027] See figure 1 , figure 2 , image 3 , a sealed unloading device with a new structure, including a discharge spout door 1, a box body 2, a cover plate 3, an oil cylinder 4, a bearing with a seat 5, a counterweight rod 6, a protective cover 7, a sealing ring 8, a rotating unit The door 9, the isolation seat 10, and the integral bearing are arranged on the outside of the box body 2 and are isolated with the isolation seat 10 between the box body, and the isolation seat 10 is provided with a dust discharge channel 15. This structure allows the leaked dust to be discharged through this channel without entering into the bearing. A labyrinth sealing structure and a sealing ring are adopted between the isolation seat 10 and the rotating shaft. A silicone rubber sealing ring 8 is provided at the contact portion between the blanking sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com