Method and apparatus for treating a fibre web

A fiber web and equipment technology, applied in the field of fiber web processing, can solve problems such as difficult to control pits, and achieve the effect of avoiding web damage and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

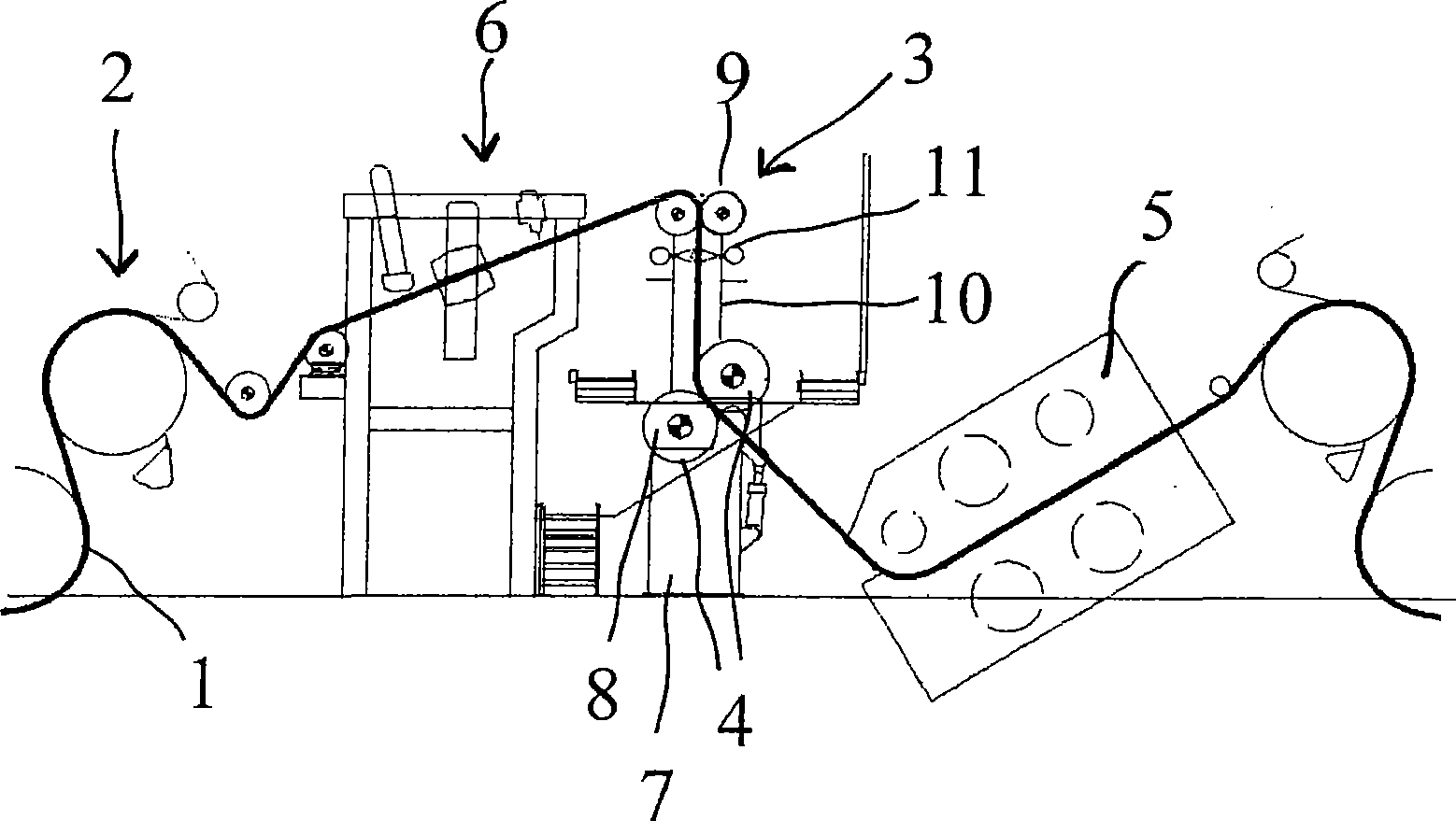

[0019] exist figure 1 In , a gluing station according to the invention is shown deployed in a production line. In the direction of movement of the web 1 , the first component is the dryer group 2 from which the web 1 is led directly to the coating device 3 . The coating apparatus 3 is followed by a press roll 4 and an air dryer 5 from which the web is led on for further processing. Between the dryer group 2 and the coating device 3 is a measuring instrument 6 for monitoring the web 1 .

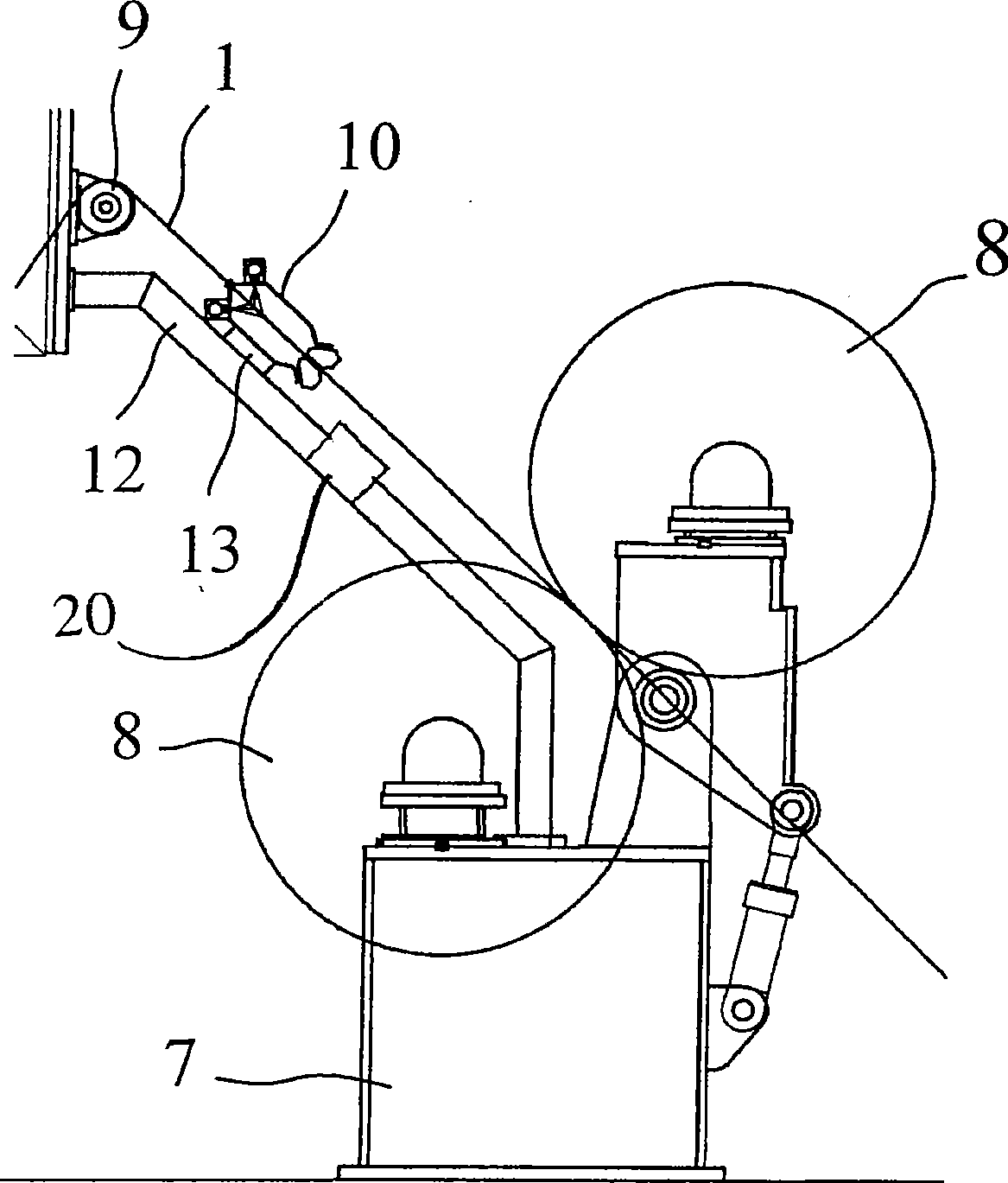

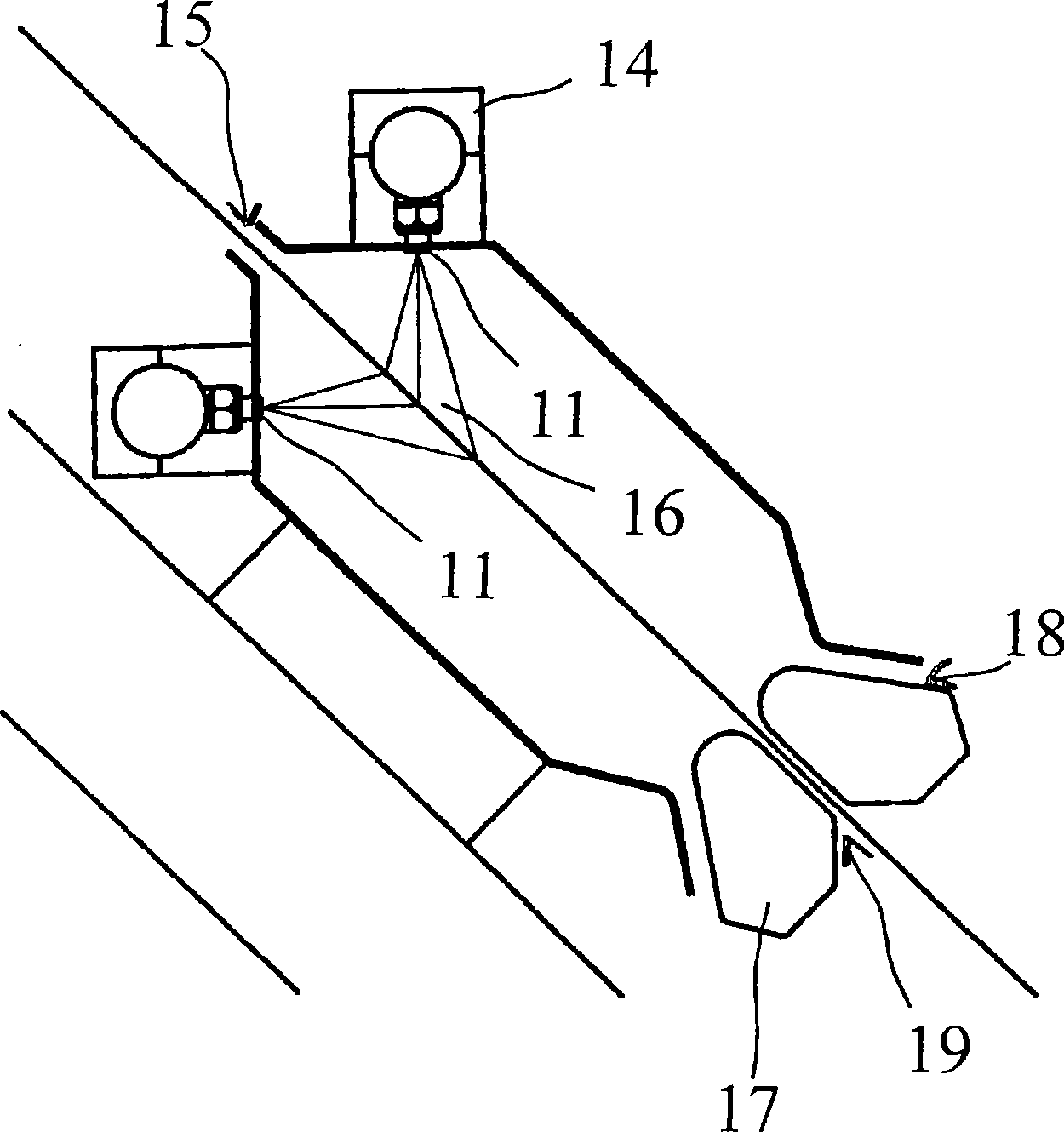

[0020]The coating apparatus 3 comprises a press roll 8 supported by bearings on a frame 7, said press roll forming a nip through which the treated web 1 passes. The press roll 8 and the frame 7 can be part of a conventional film transfer coating device, so in this solution the coating device corresponds to a film transfer coating device from which the press roll 8 of the coating device can transfer the coating. Remove from cloth equipment. The web 1 is guided to run directly down to a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com