Intelligent electrically-operated check valve

A technology of intelligent electric check and check valve, applied in functional valve type, valve details, control valve and other directions, can solve the lack of detection function, strong and weak electrical isolation function, anti-interference function and fault alarm function, valve cannot be opened , reduce the ventilation section and other problems, to increase the anti-fume backflow performance, prolong the service life, and prevent the transmission from being blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

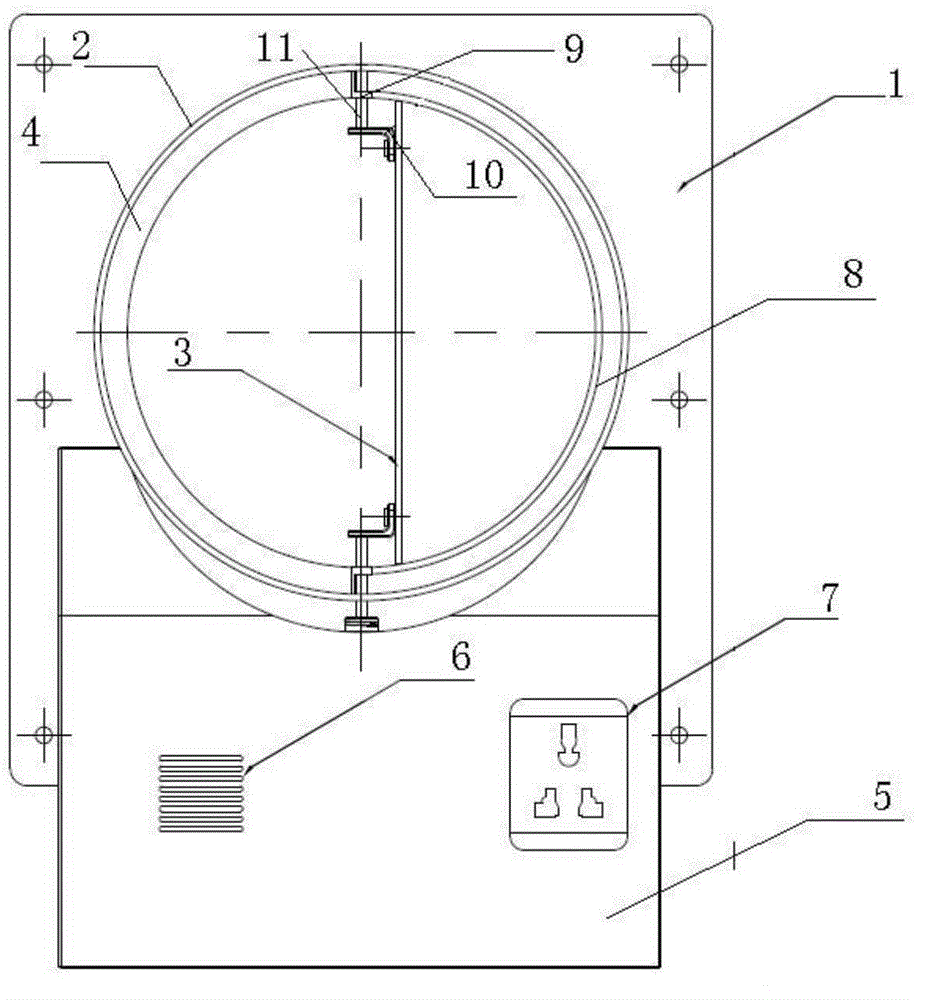

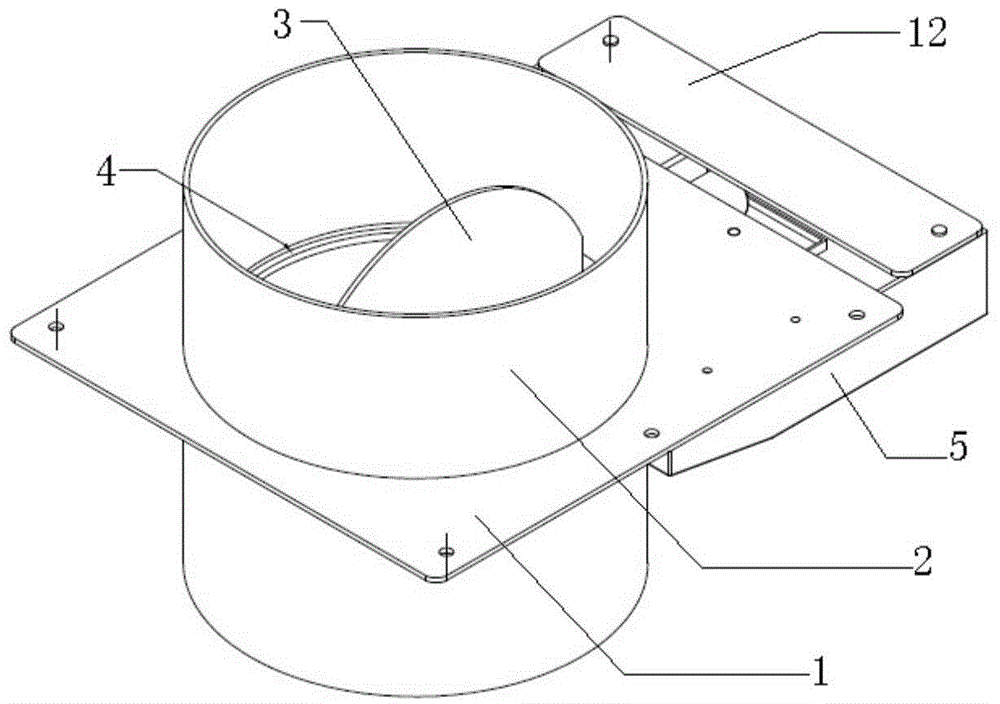

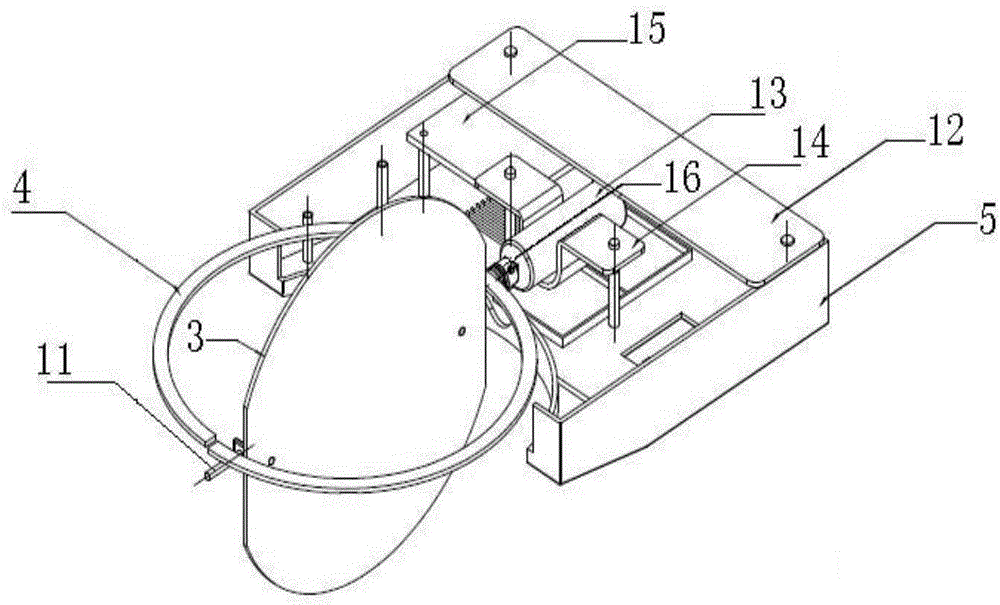

[0044] The invention provides an intelligent electric check valve, such as figure 1 As shown, the intelligent electric check valve is composed of an intelligent controller, a check valve bracket-1, an air duct-2, a check valve plate-3, a magnetic sealing ring-4 and a steel ring-8. Design, the air duct-2 is vertically fixed on the check valve bracket-1, the check valve plate-3 is set in the air duct-2, and the magnetic sealing ring-4 is set in the air duct-2 to seal the check valve The gap between sheet-3 and air duct-2; steel ring-8 is welded in air duct-2 to fix magnetic sealing ring-4; the intelligent controller is fixed on check valve bracket-1, through coupling The device-16 is connected with the pin shaft of the non-return valve plate-3, and is used to control the rotation of the non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com