Drain valve

A technology of drain valve and water valve, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as leakage, poor piston sealing, slow recovery speed of water valve piston, etc., to avoid leakage, The piston closes tightly and avoids the effect of reversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

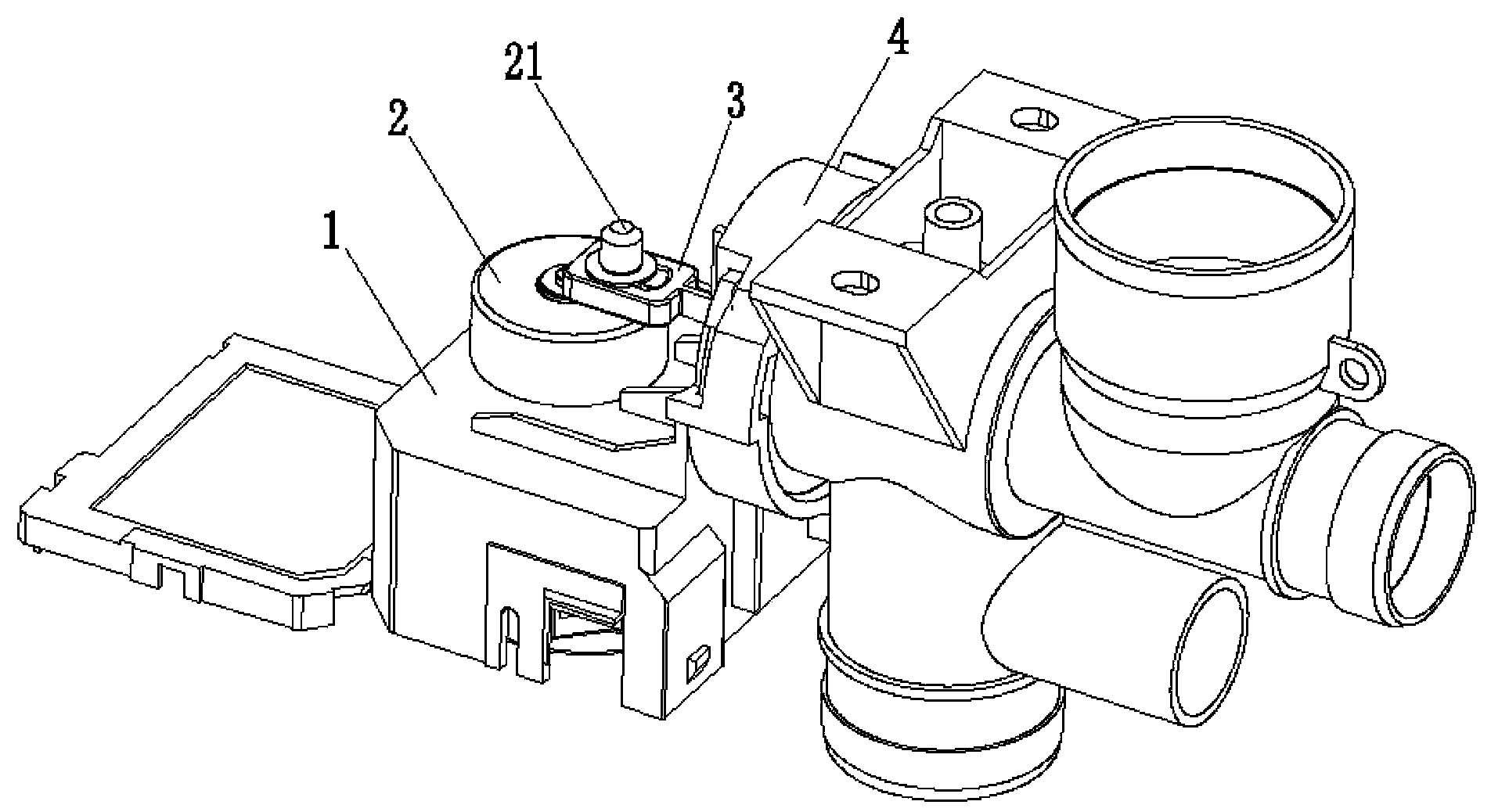

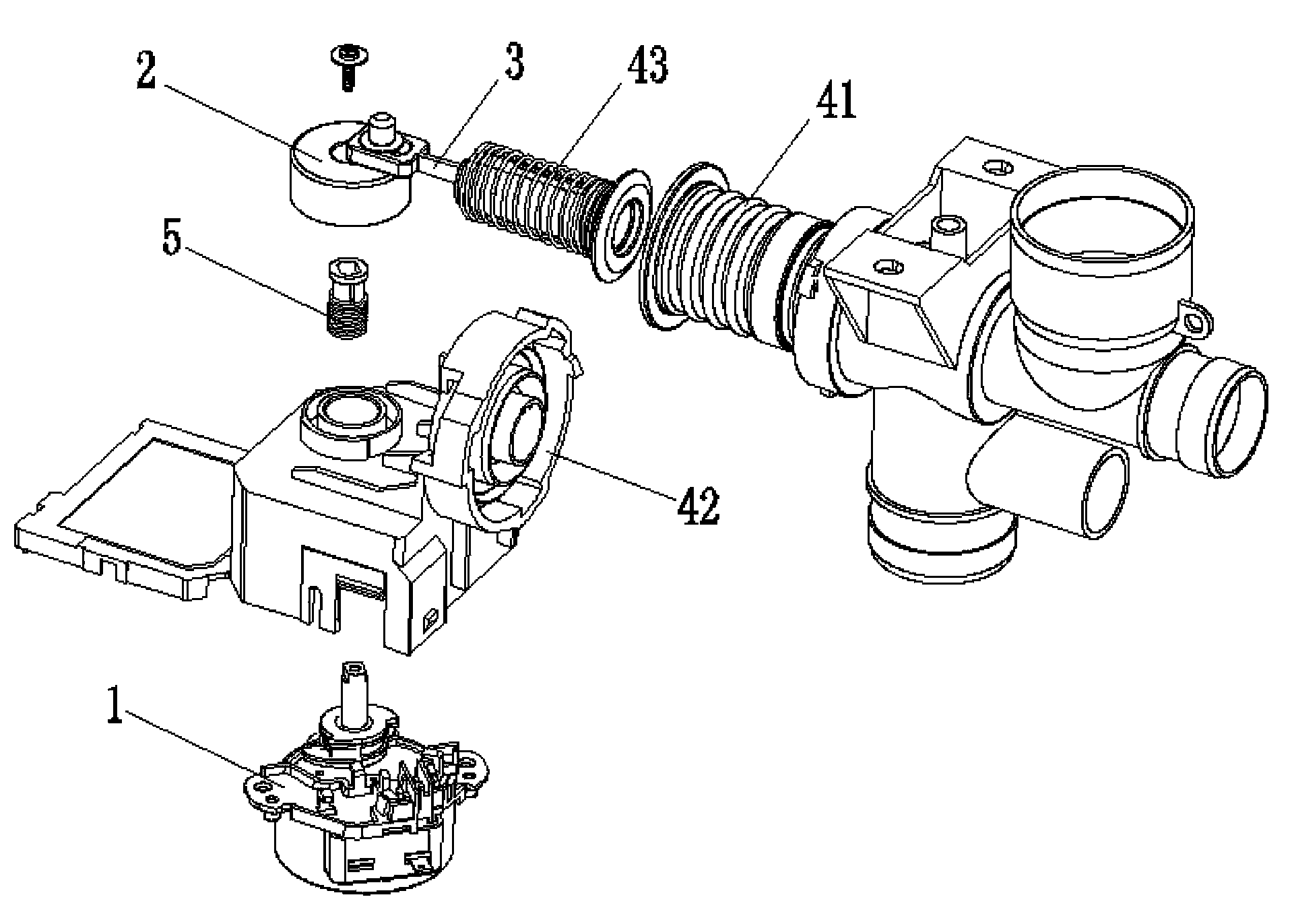

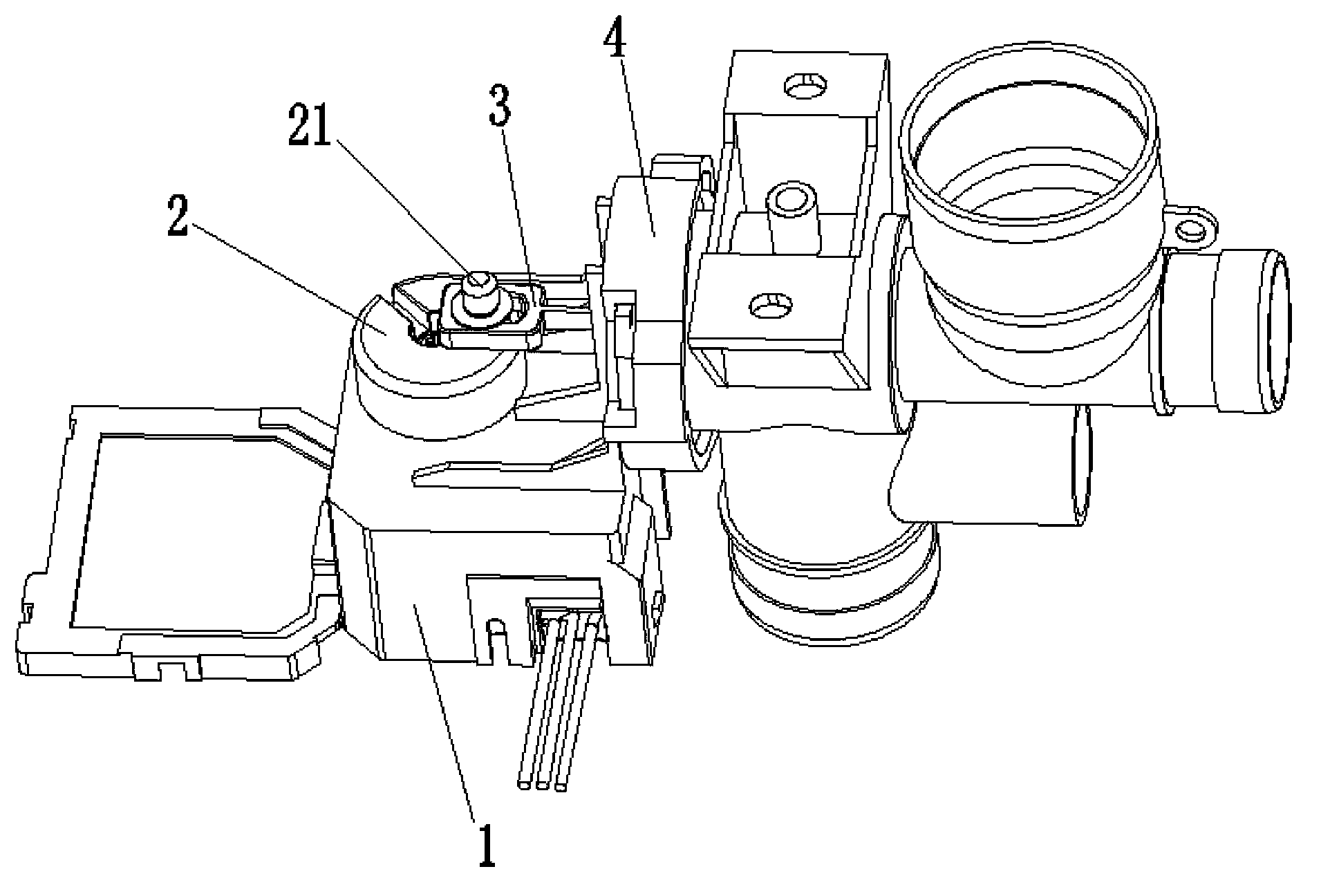

[0026] See figure 1 and figure 2 , The drain valve of this embodiment includes a motor 1, a cam 2, a connecting rod 3, a water valve 4 and an acceleration mechanism.

[0027] The cam 2 is installed on the output shaft of the motor 1, and the cam 2 is provided with a connecting rod shaft 21. One end of connecting rod 3 is installed on the connecting rod shaft 21, and the other end is installed on the piston 41 of water valve 4. A spring 43 sleeved on the connecting rod 3 is provided between the piston 41 of the water valve 4 and the end cover 42 . The acceleration mechanism is arranged in the motor 1, and can accelerate the speed at which the cam 2 pushes the piston 41 of the water valve 4 to close.

[0028] The acceleration mechanism includes a torsion spring 5 . The torsion spring 5 is sleeved on the output shaft of the motor 1 , and the outer wall of the torsion spring 5 is in close contact with the inner wall of the cam 2 .

[0029] The motor 1 rotates, drives the tor...

Embodiment 2)

[0031] See Figure 3 to Figure 7 , the present embodiment is basically the same as Embodiment 1, the difference is that the acceleration mechanism includes a slide bar 6, and coaxially arranged two wheel pieces 7 and two wheel shaft teeth 8 that can be separated and engaged, and are arranged on the output of the motor 1 Track groove 9 on the axle gear, and the stage clip that is arranged between two wheel pieces 7 and two axle teeth 8.

[0032] Cam 2 is fixed on the output shaft of motor 1. The slide bar 6 can rotate around the center, one end of the slide bar 6 is slidably connected with the track groove 8, and the other end controls the separation and engagement of the second wheel piece 7 and the second wheel axle tooth 8. The outer teeth of the two wheel blades 7 mesh with the rotor assembly of the motor 1 . The outer teeth of the two axle teeth 8 mesh with the first stage gear of the reduction gear set of the motor 1 .

[0033] See Figure 8 , The lower end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com