Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Bite firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial teeth easily enabling bilateral balanced occlusion

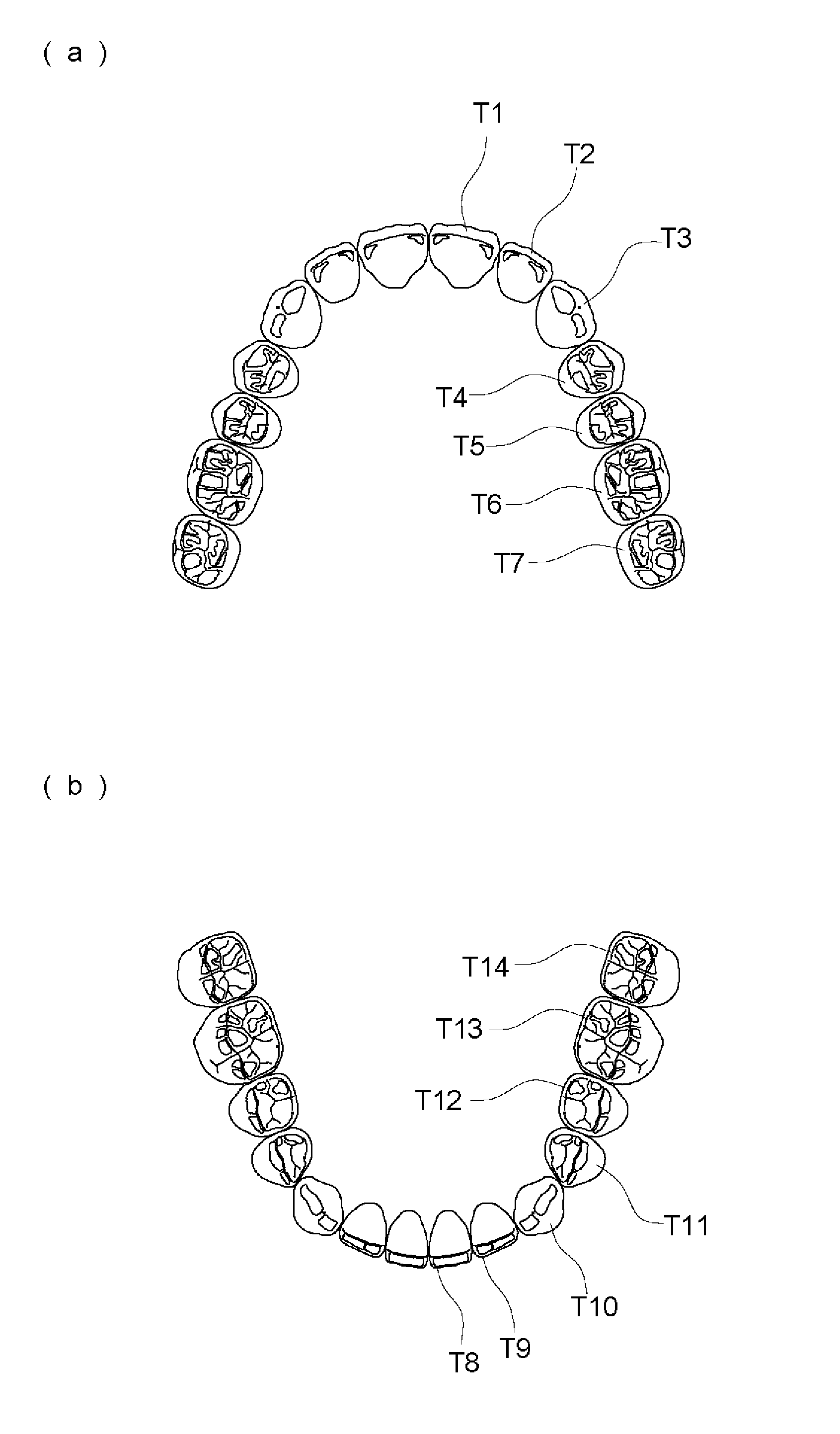

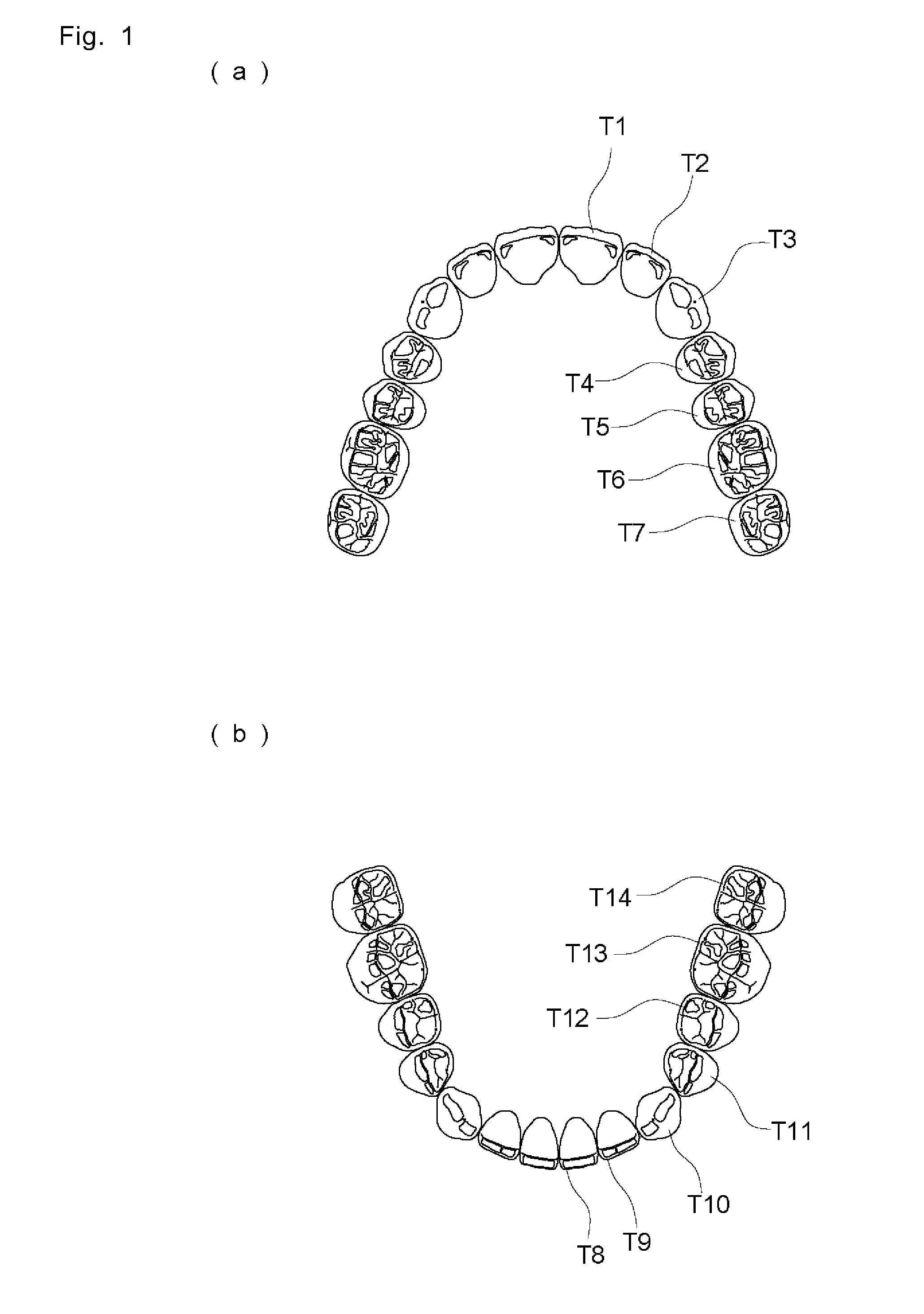

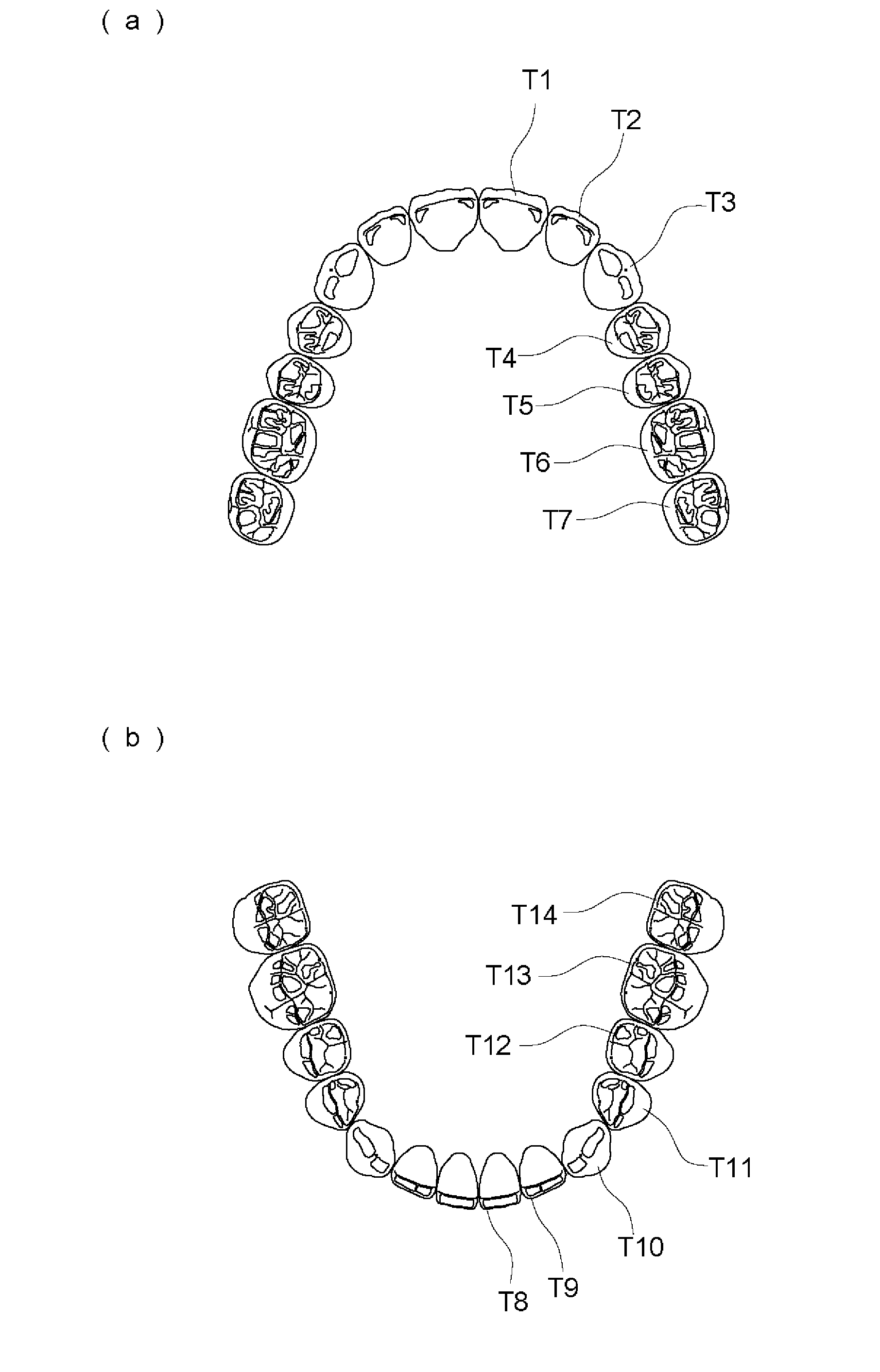

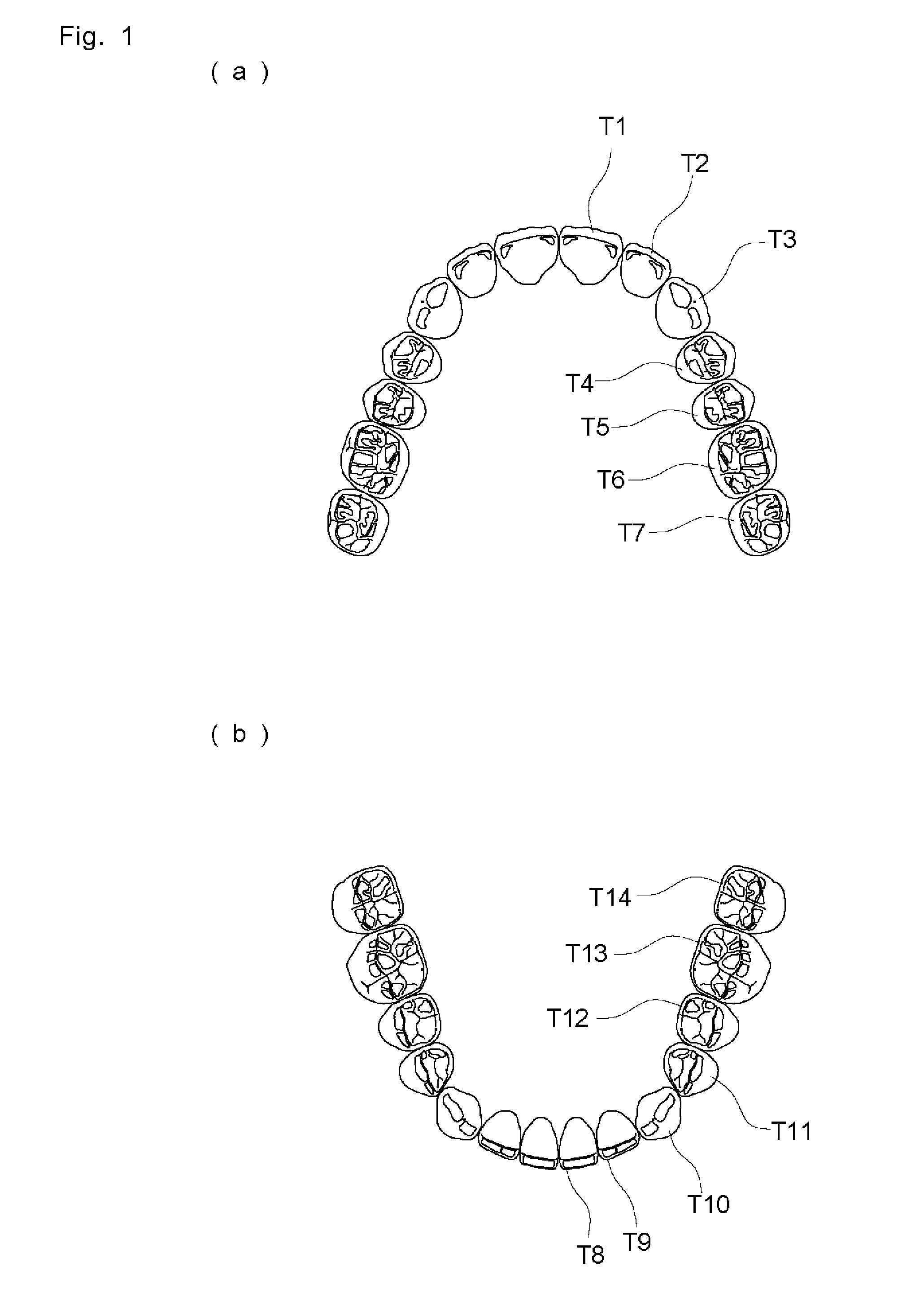

ActiveUS20100266988A1Less adjustment workBite firmlyTooth crownsArtificial teethSagittal planeCoronal plane

It is intended to provide artificial teeth designed to easily enable bilateral balanced occlusion with less grinding adjustment. According to the present invention, angles formed by occlusal facets of the artificial teeth with an occlusal plane are suitably set. An artificial tooth for maxillary central incisor, for example, has a protrusive facet and a retrusive facet on an incisal edge thereof. Of angles formed by the protrusive facet with the occlusal plane, the angle in cross section along a sagittal plane is 22.0° to 25.5°, and the angle in cross section along a coronal plane is 1.5° to 6.5°. Of angles formed by the retrusive facet with the occlusal plane, the angle in cross section along the sagittal plane is 20.5° to 23.0°, and the angle in cross section along the coronal plane is 1.5° to 6.5°.

Owner:SHOFU INC

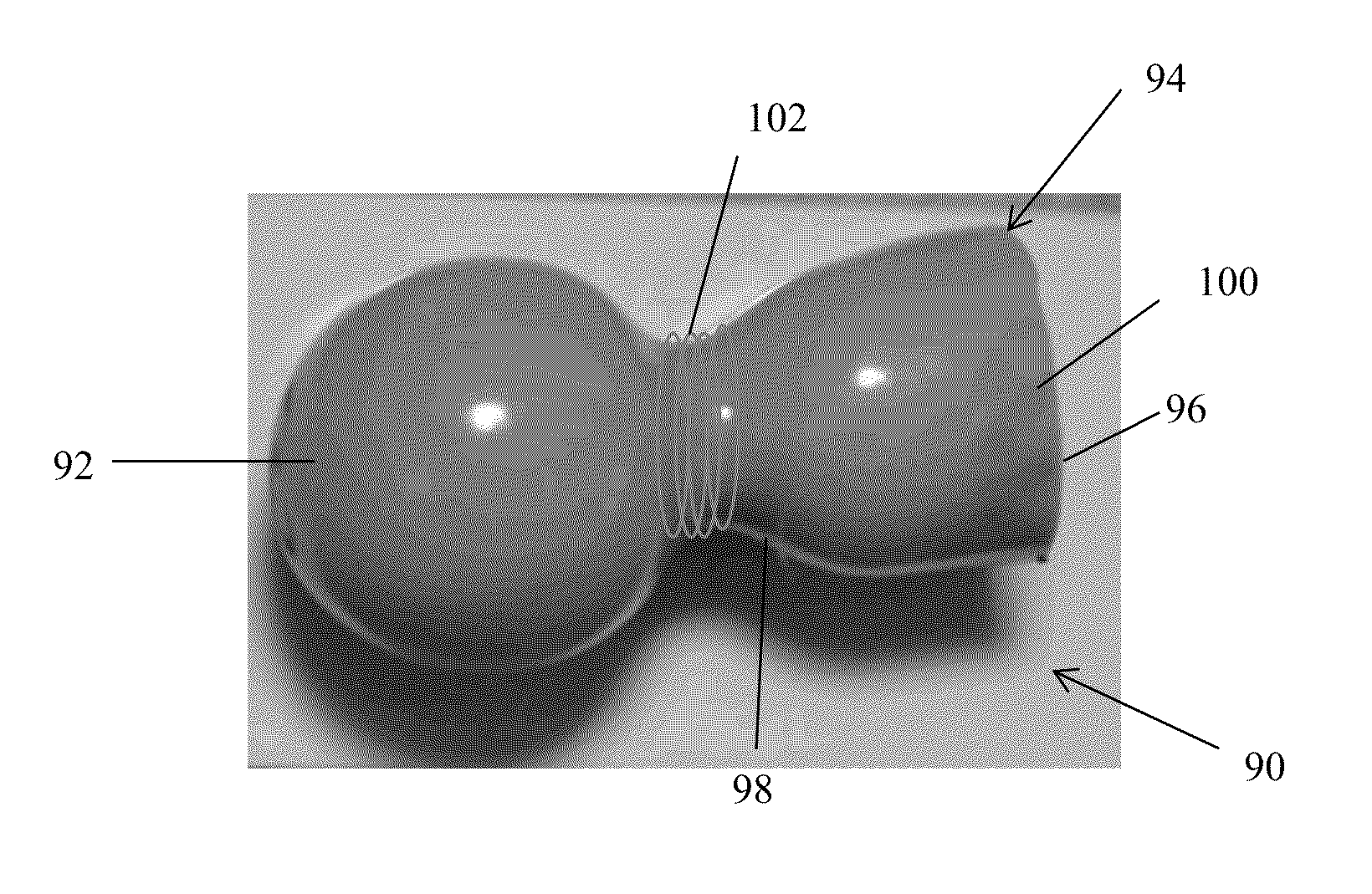

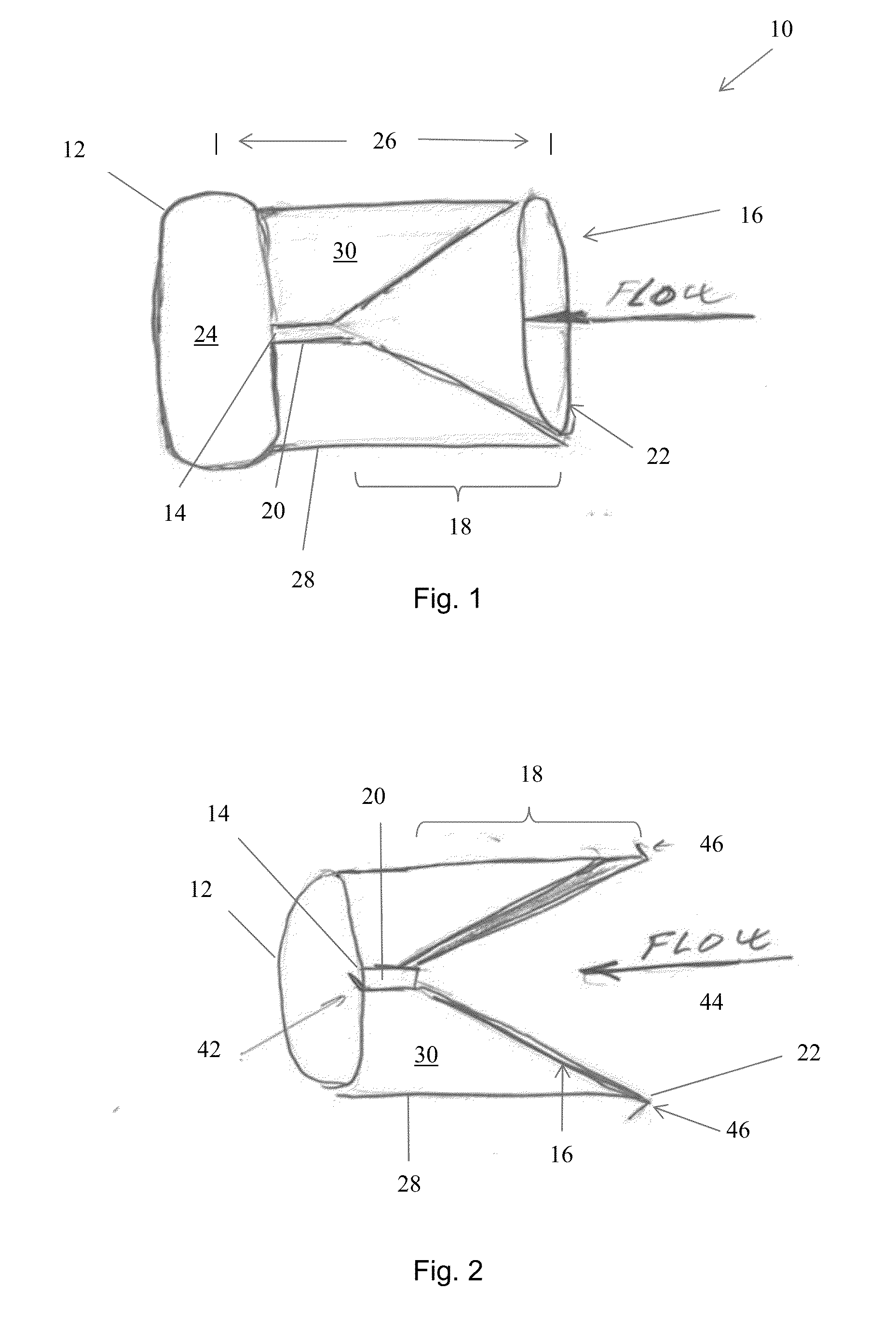

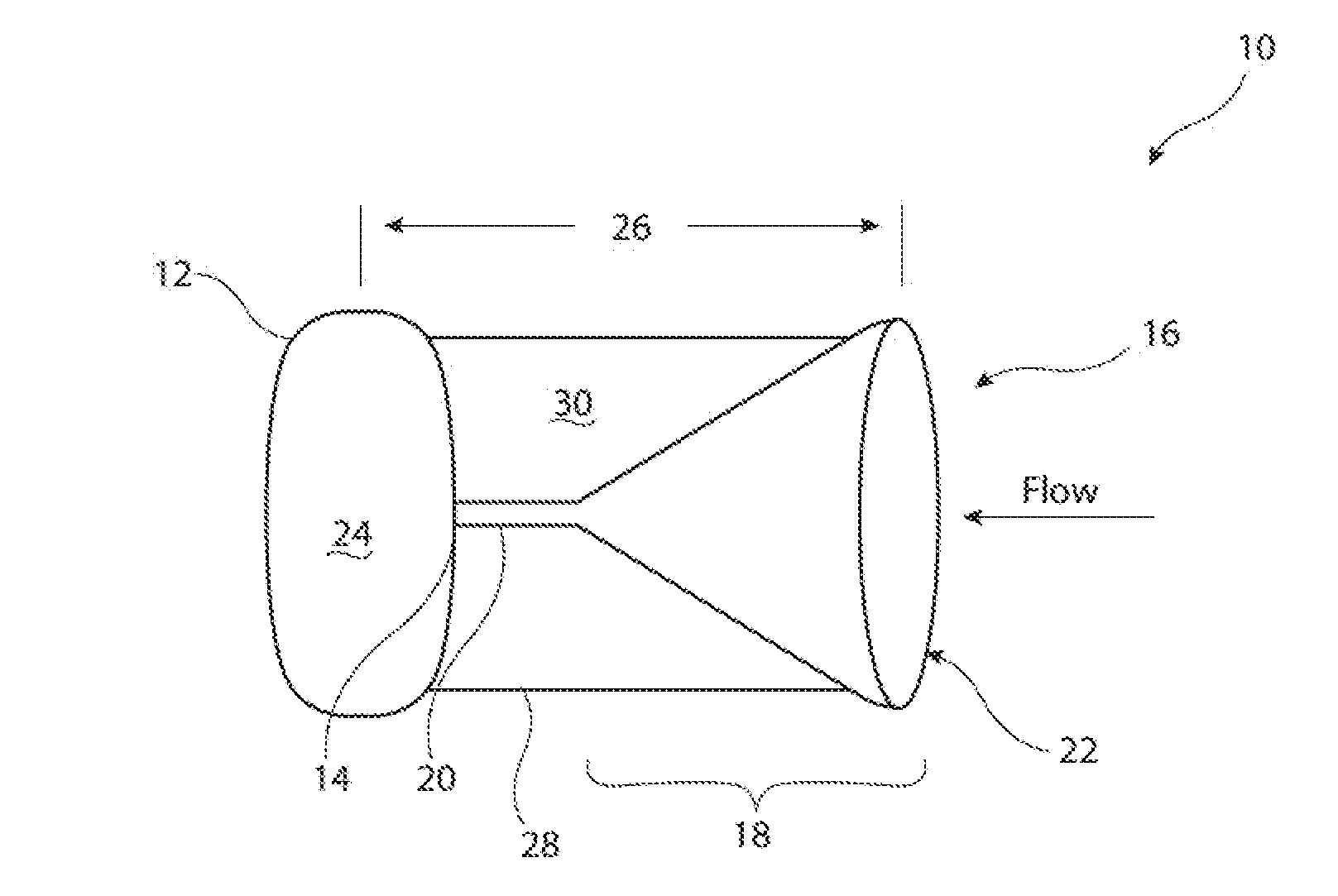

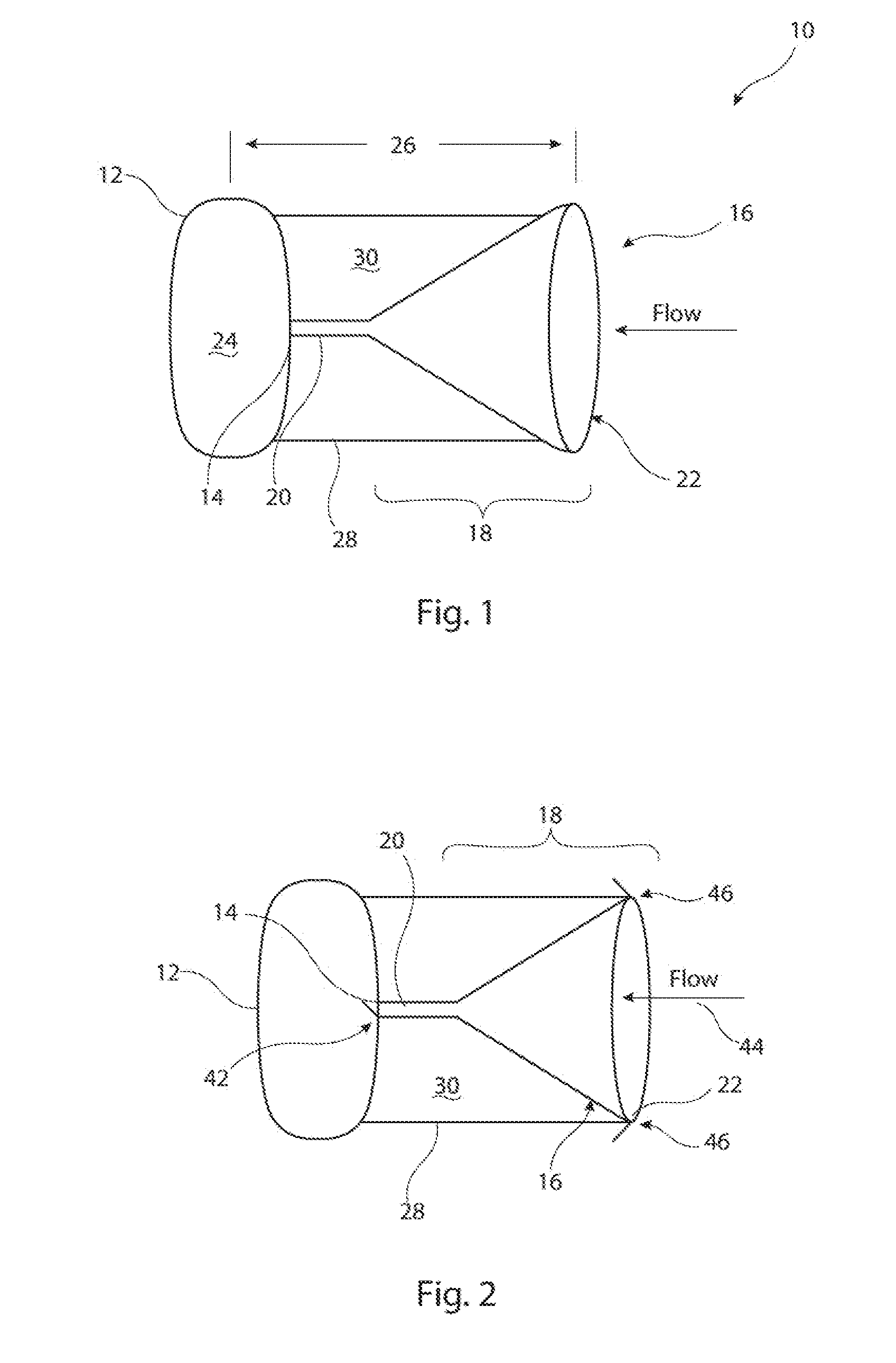

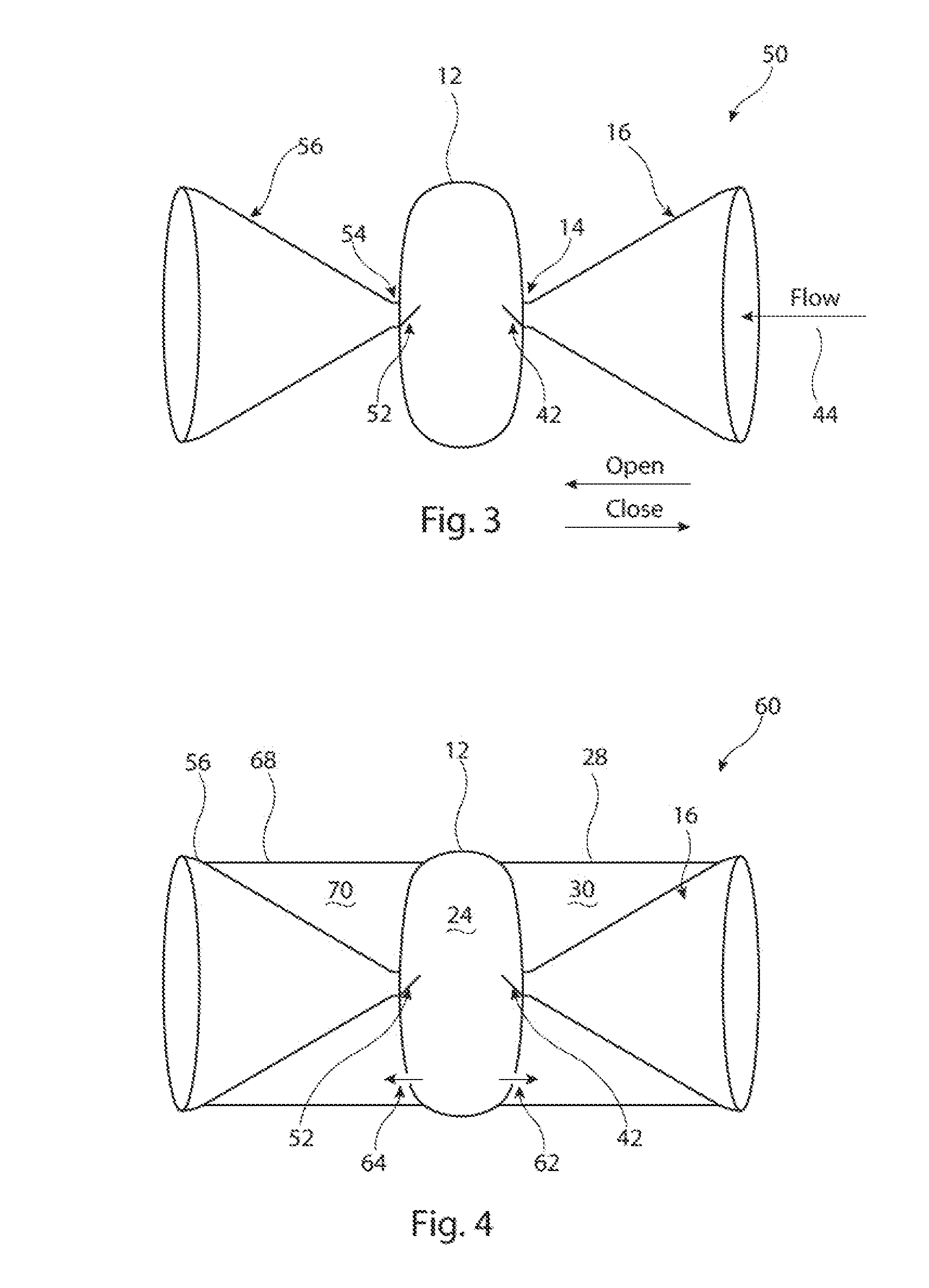

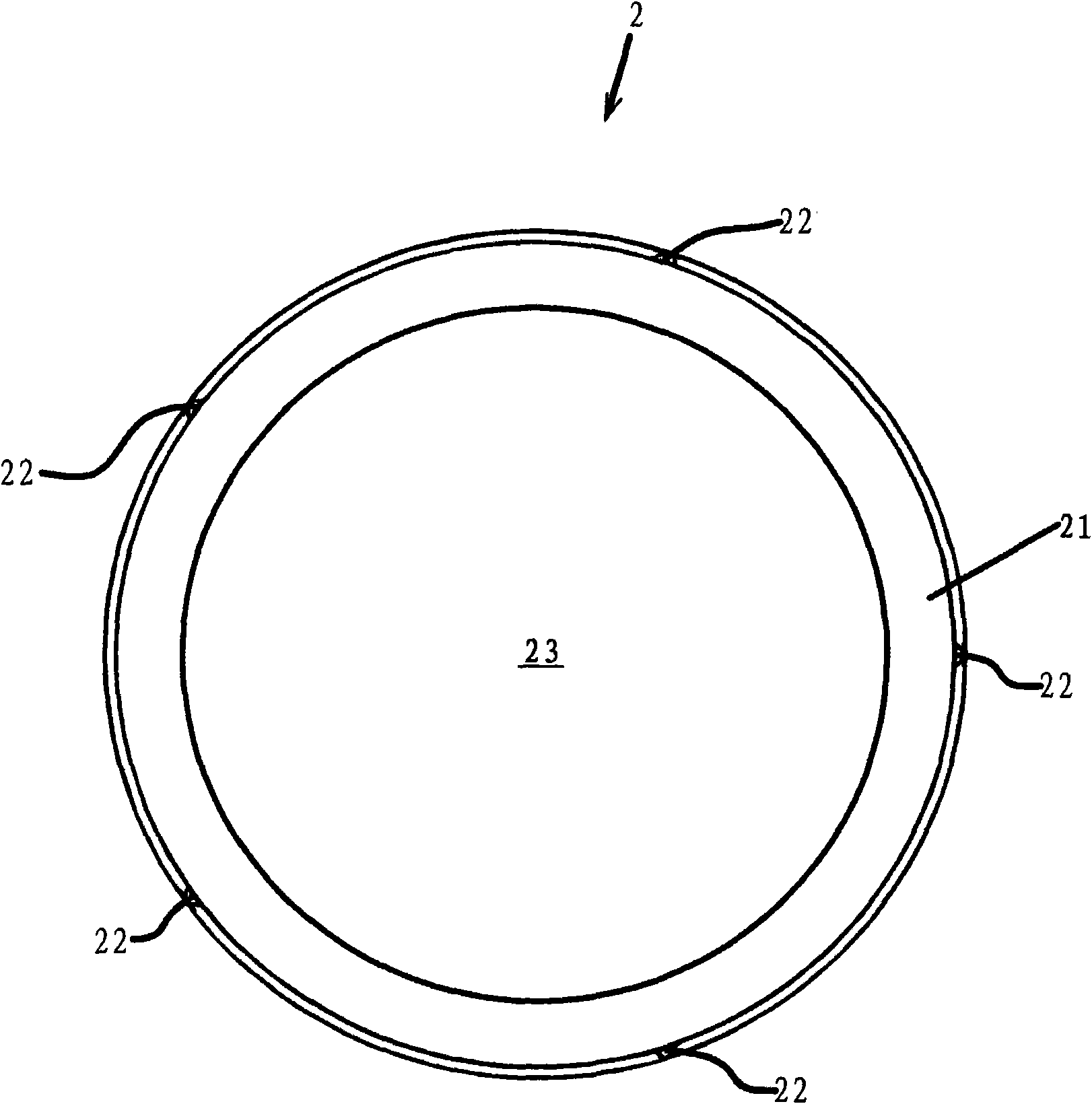

Vascular plug

A vascular plug for implantation into a patient's vessel includes an inflatable balloon and a flow accelerator. The flow accelerator includes a conical portion and a tubular coupling element which couples the conical portion to an aperture to the interior of the inflatable balloon. The flow accelerator will concentrate and therefore accelerate fluid flow into the inflatable balloon. Flow accelerator will increase the pressure of fluid thereby to cause the inflatable balloon to inflate even within a pressurised blood vessel. The plug may include a sleeve which provides a chamber between the flow accelerator and the balloon, into which blood may pass from the inflatable balloon or the flow accelerator to create additional blood statis and as a result thrombosis and a second occlusive barrier.

Owner:COOK MEDICAL TECH LLC

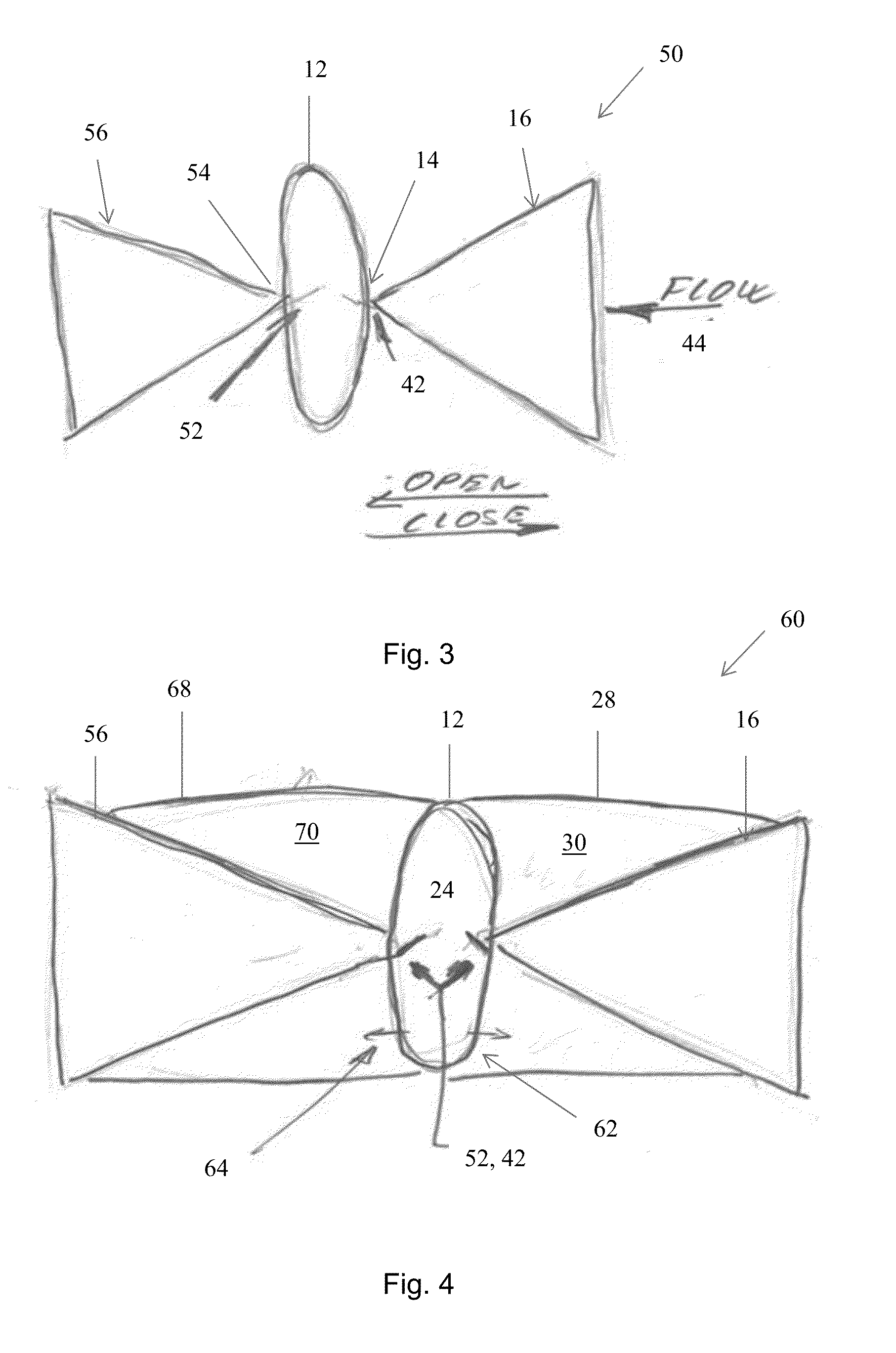

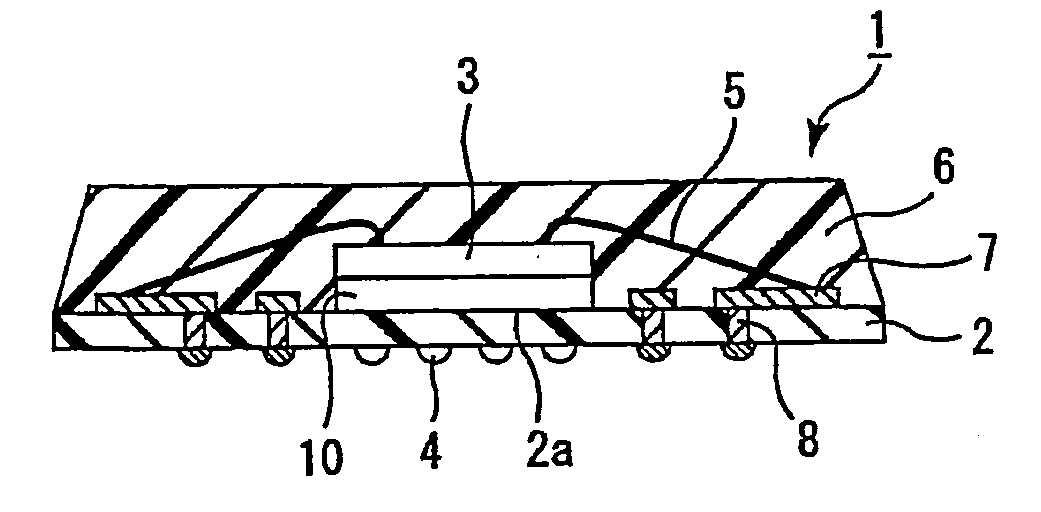

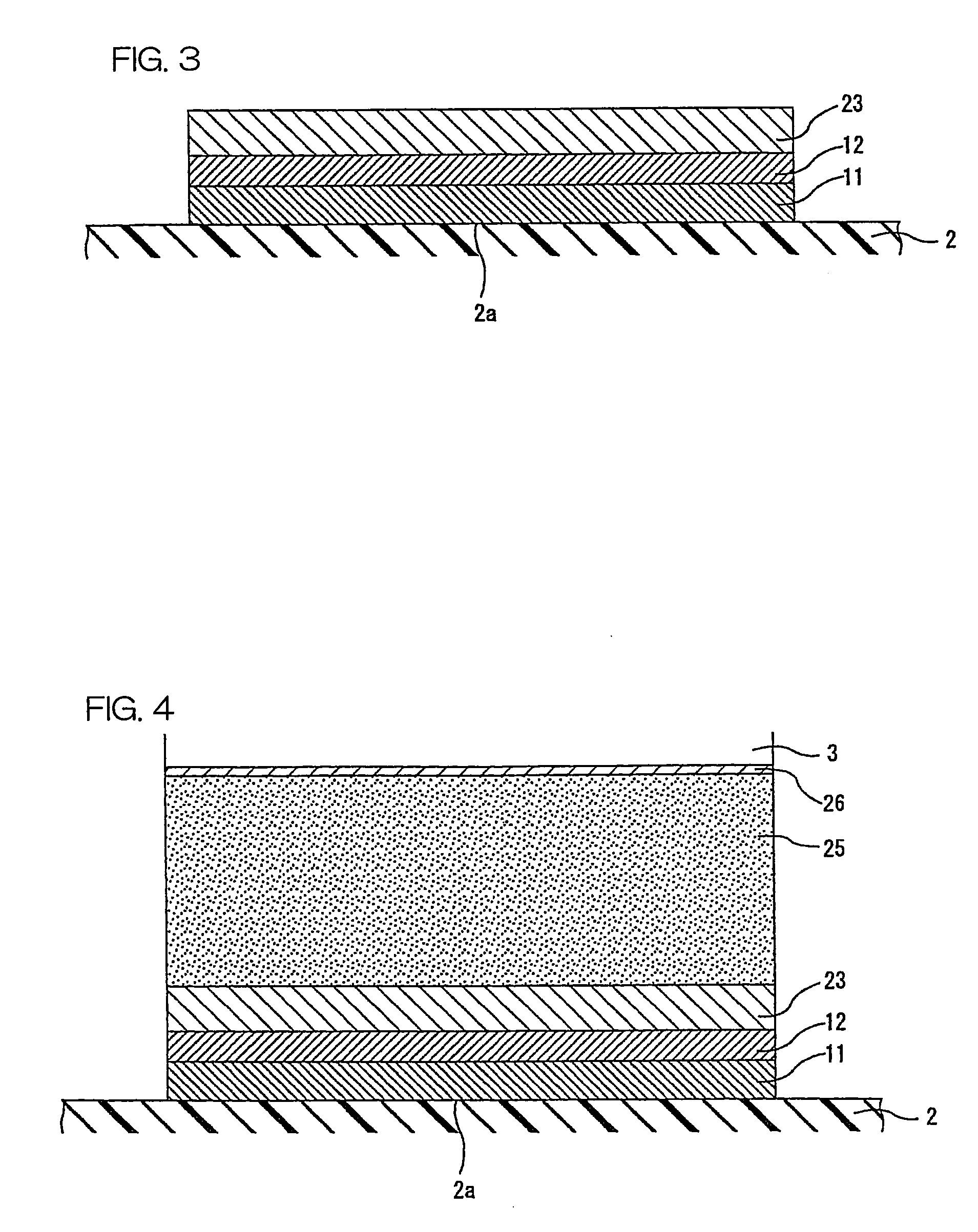

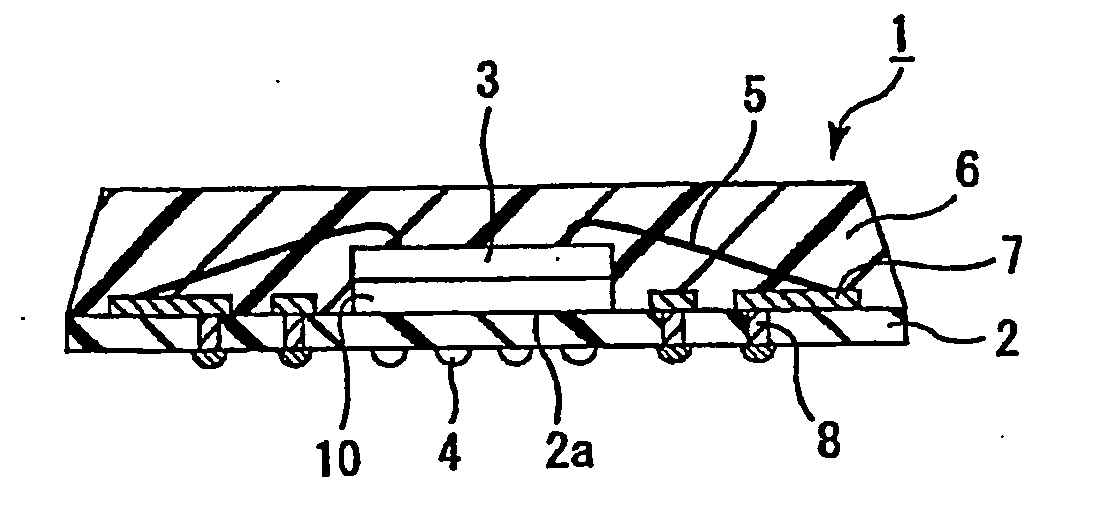

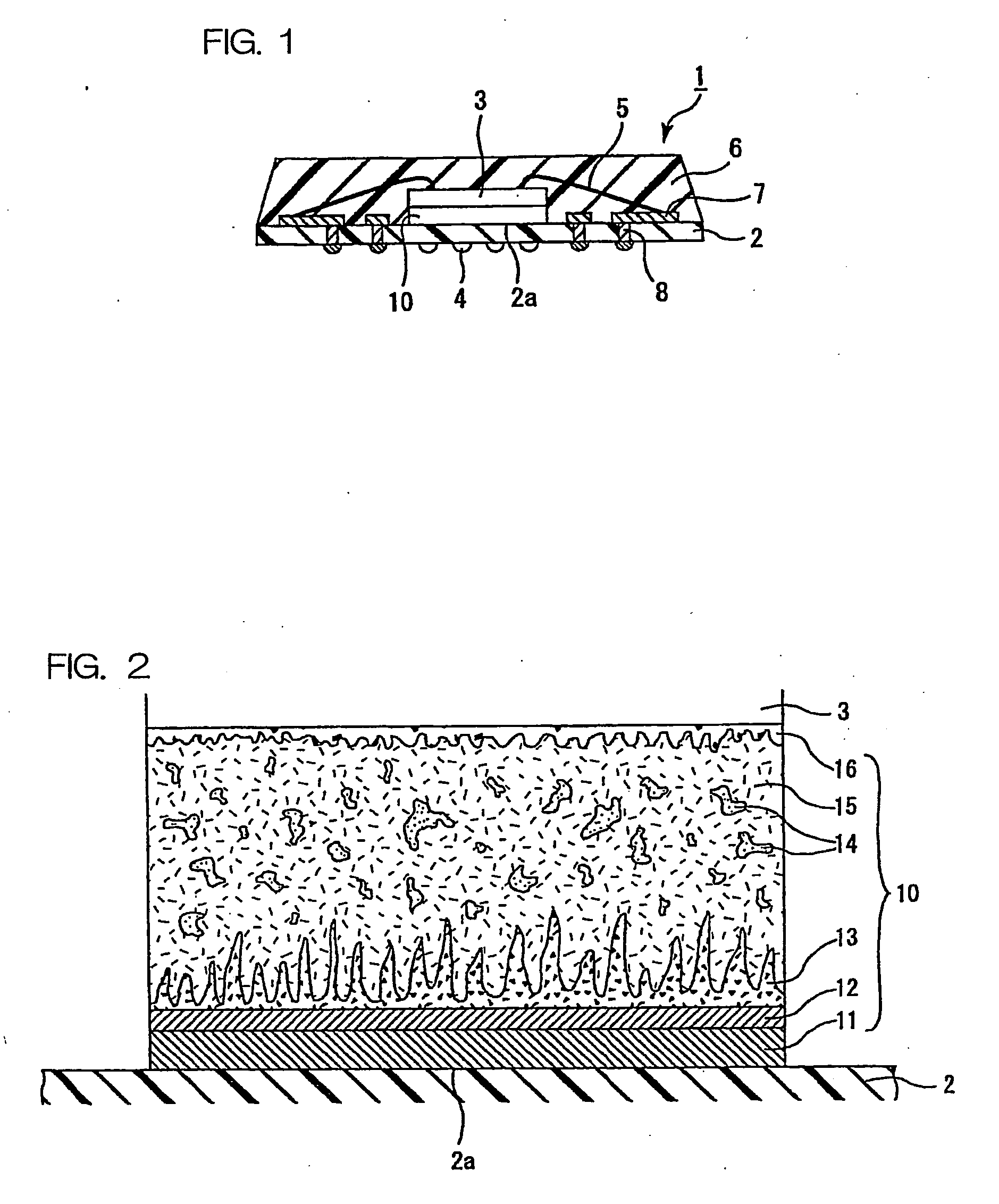

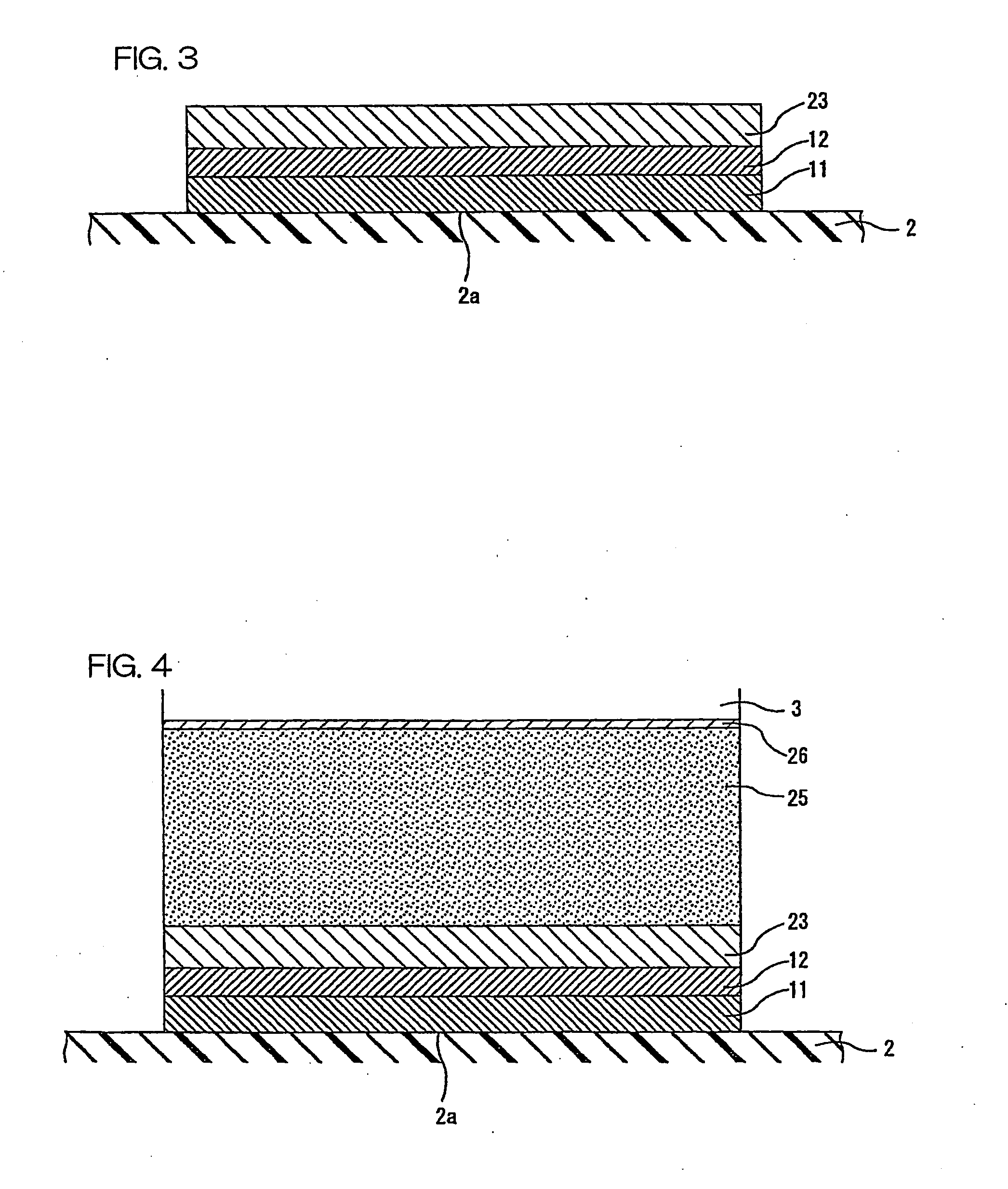

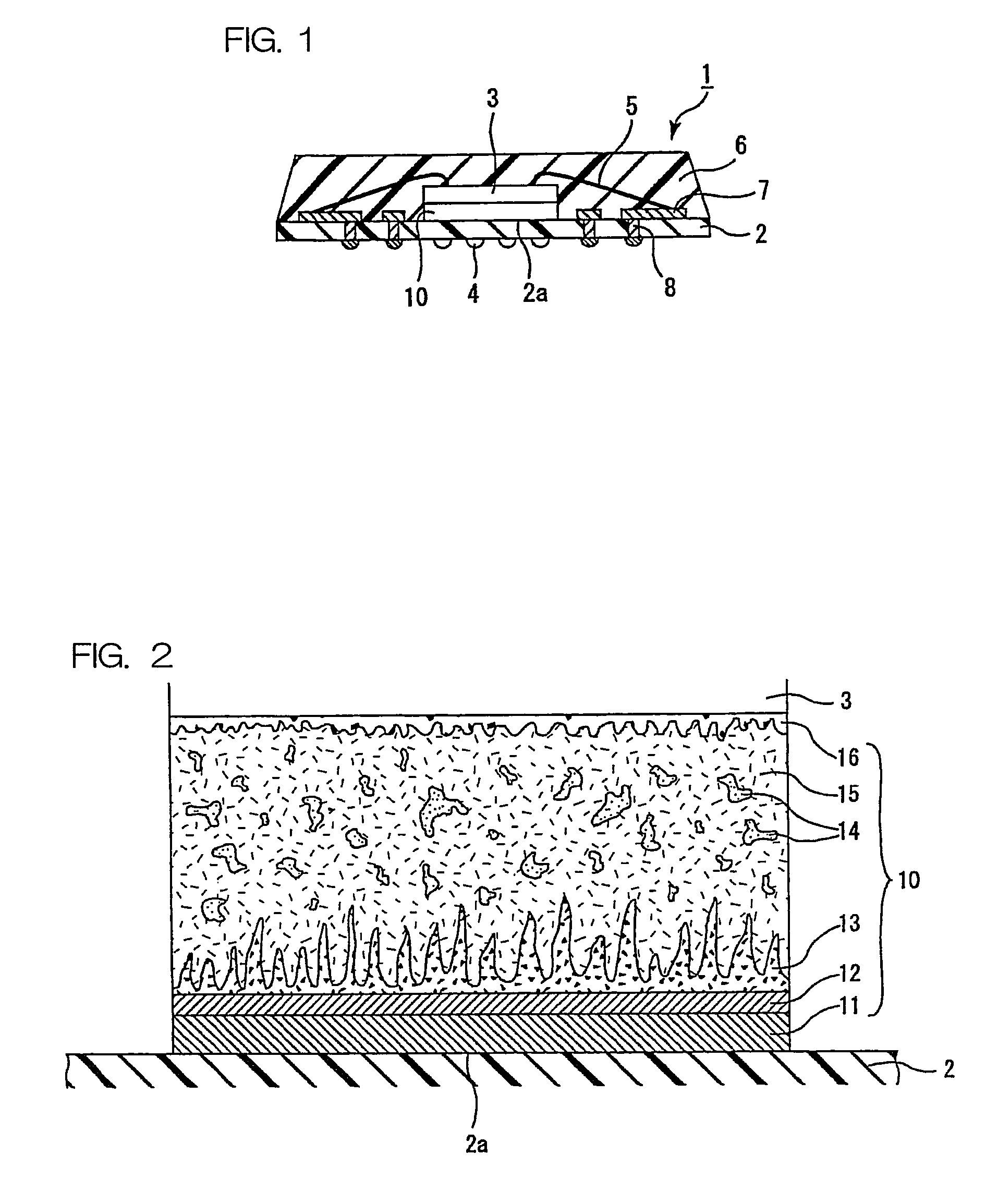

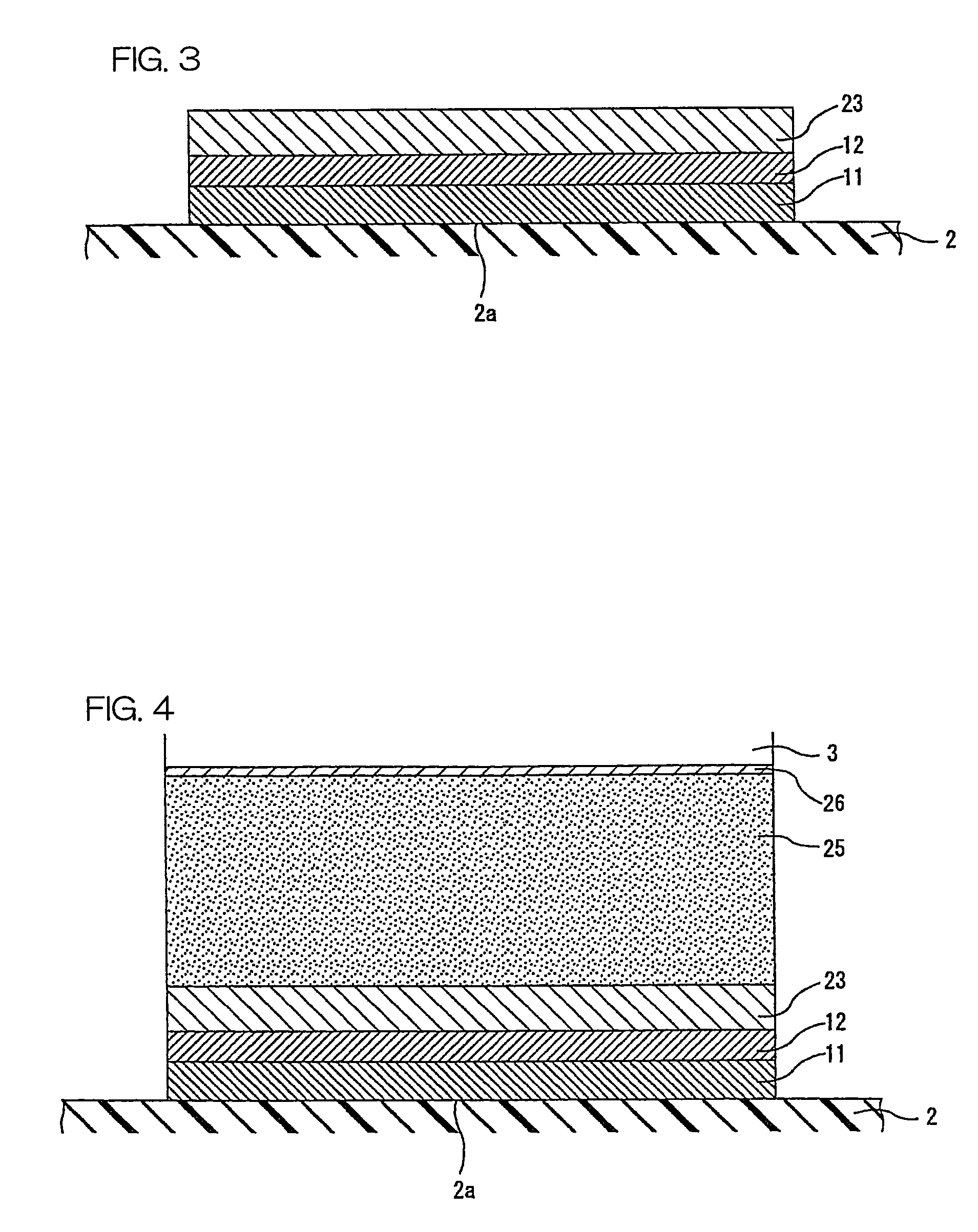

Semiconductor device, production method for the same, and substrate

ActiveUS20100013095A1High bonding strengthAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipAlloy

A semiconductor device is provided in which a semiconductor chip is bonded to a substrate with a sufficiently increased bonding strength and cracking is assuredly prevented which may otherwise occur due to heat shock, heat cycle and the like. The semiconductor device includes a semiconductor chip and a substrate having a bonding area to which the semiconductor chip is bonded via a metal layer. The metal layer includes an Au—Sn—Ni alloy layer and a solder layer provided on the Au—Sn—Ni alloy layer. Undulations are formed in an interface between the Au—Sn—Ni alloy layer and the solder layer.

Owner:ROHM CO LTD

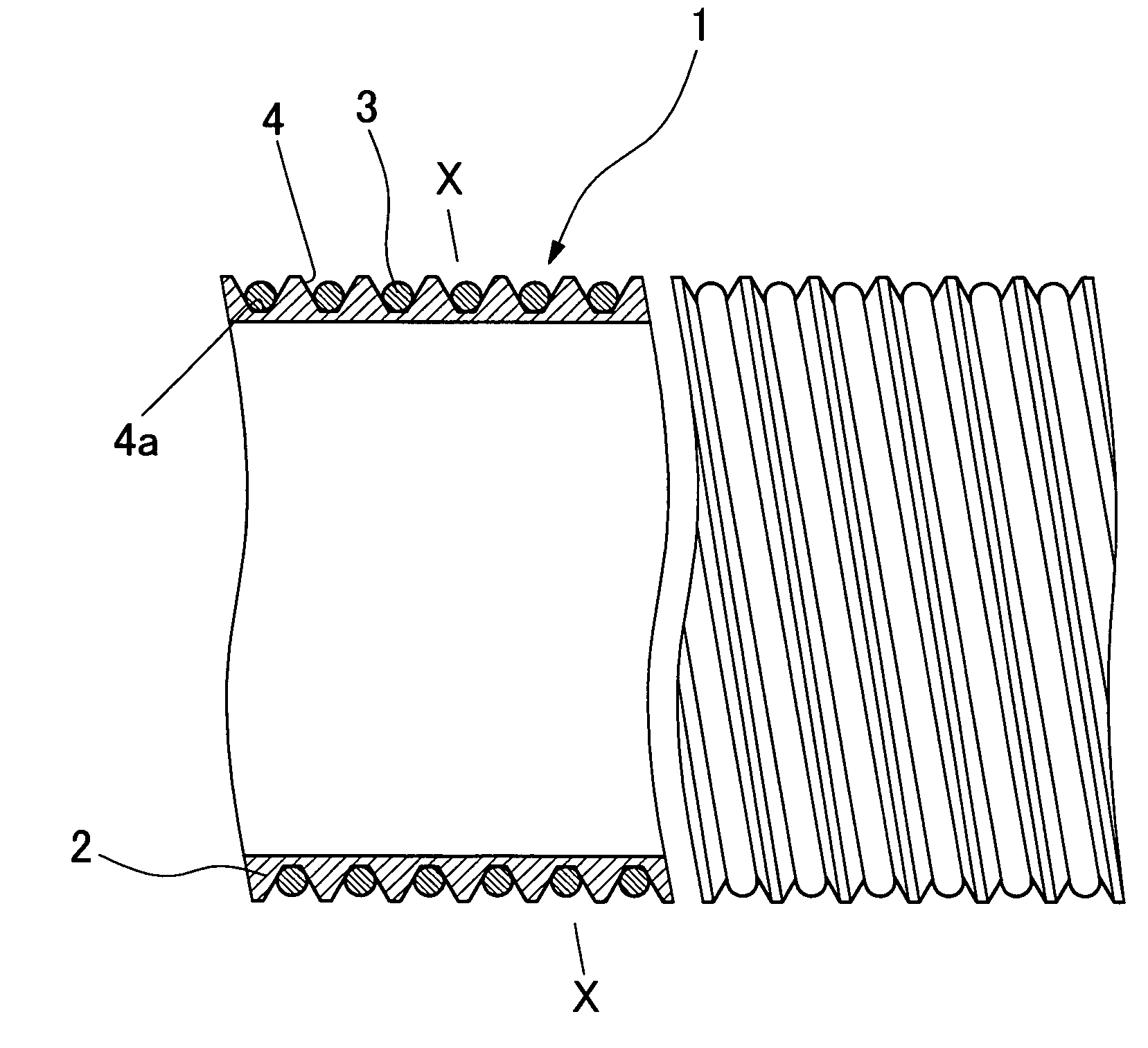

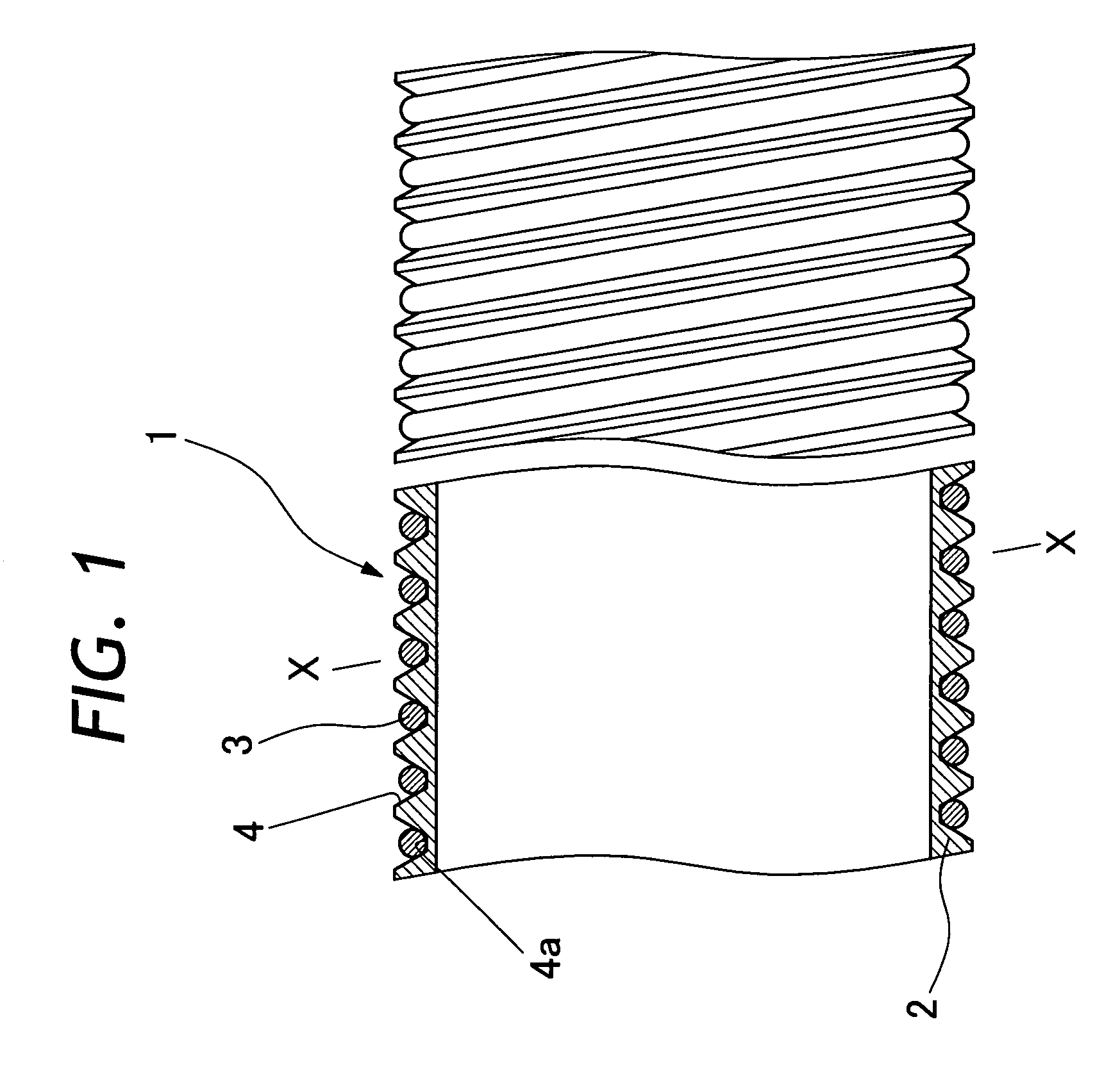

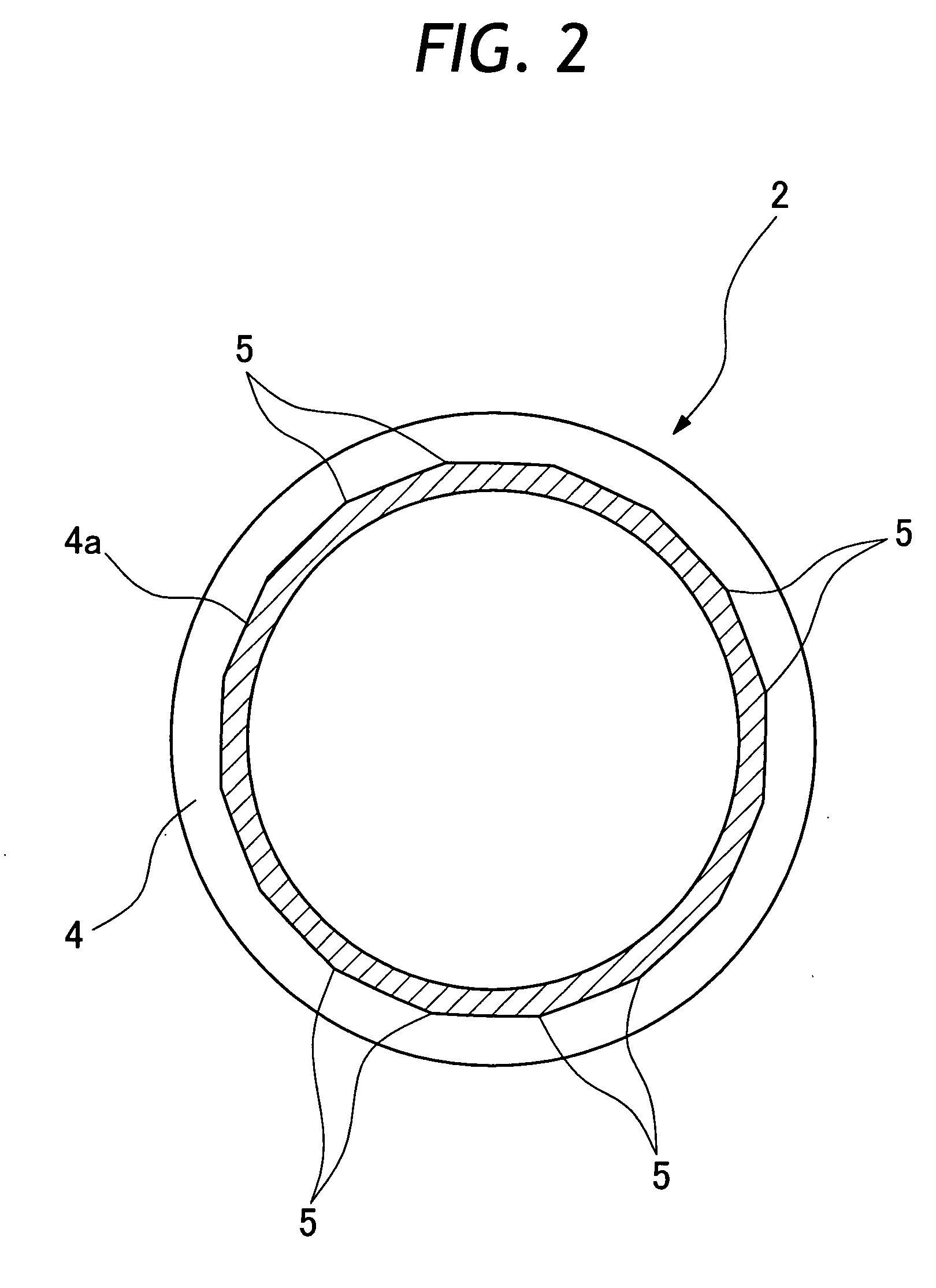

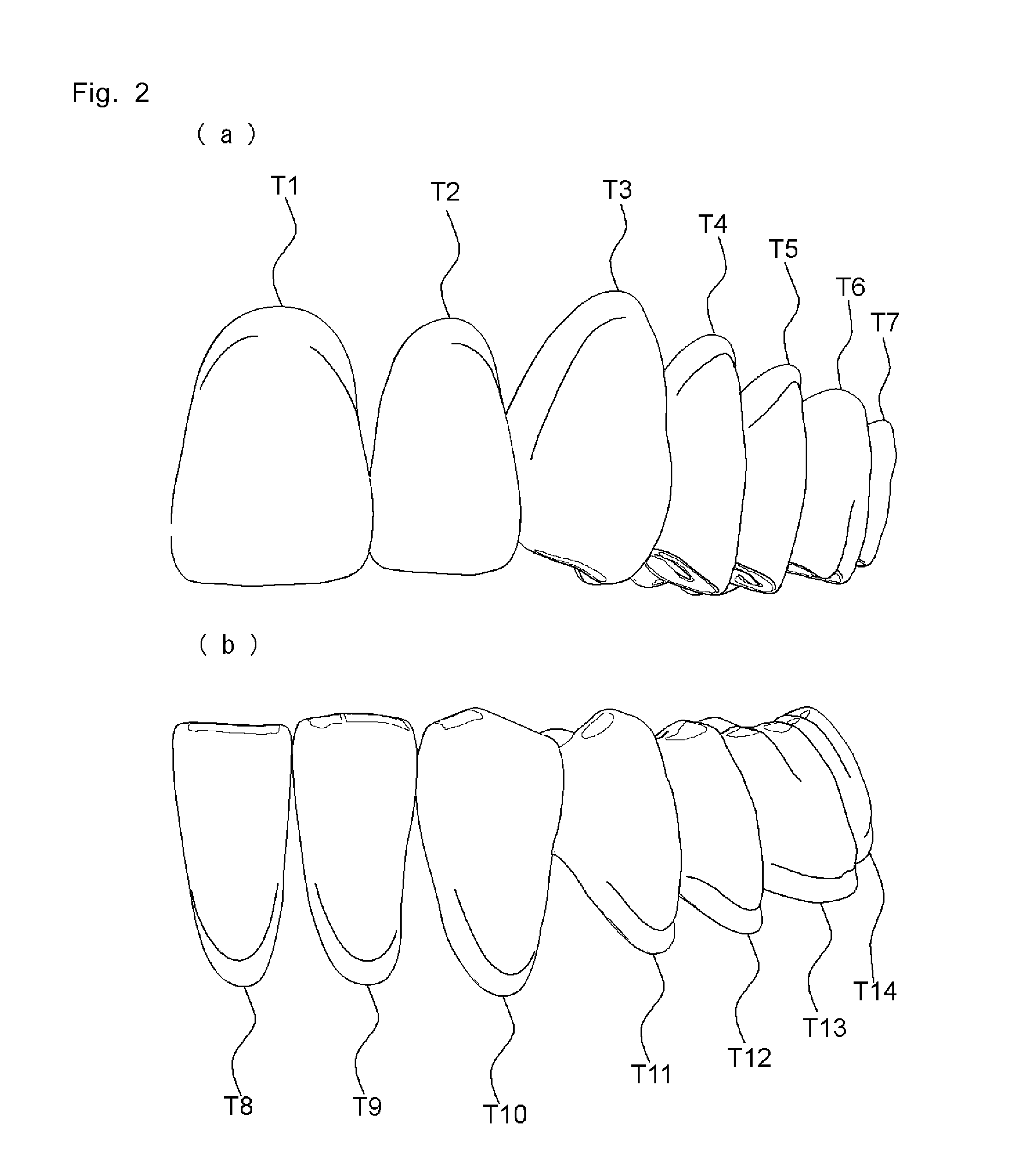

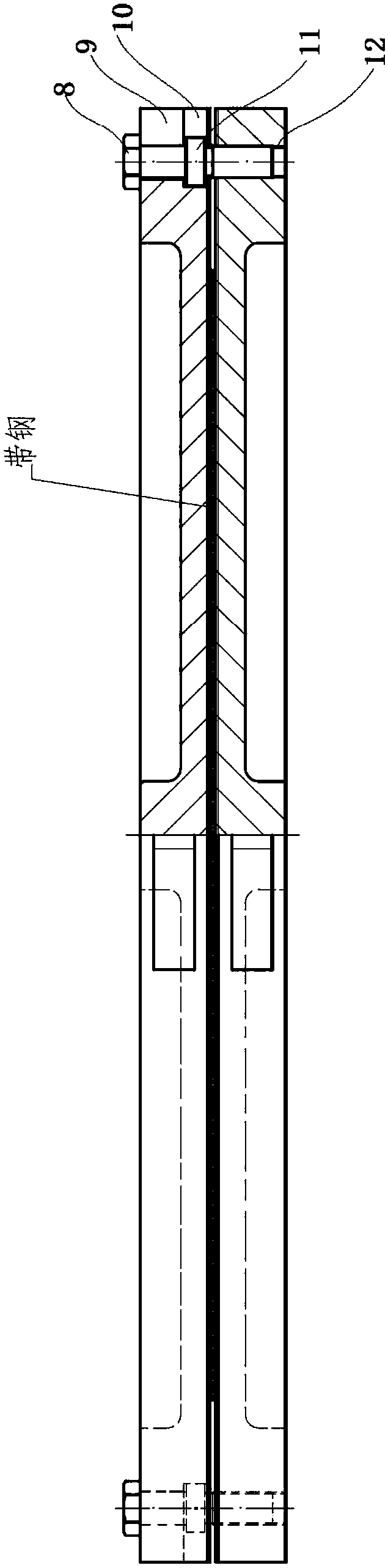

Flexible channel for use on endoscope

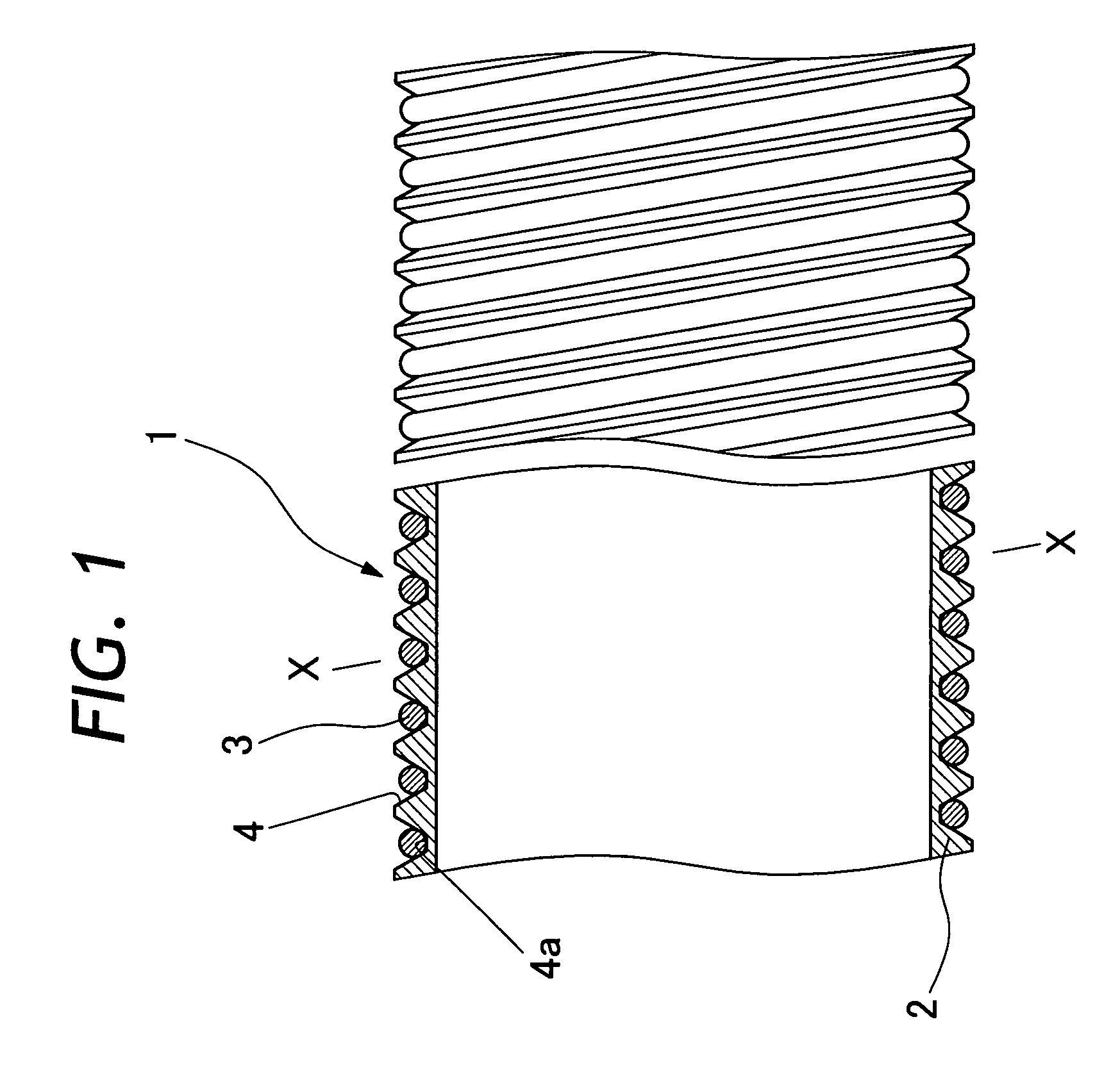

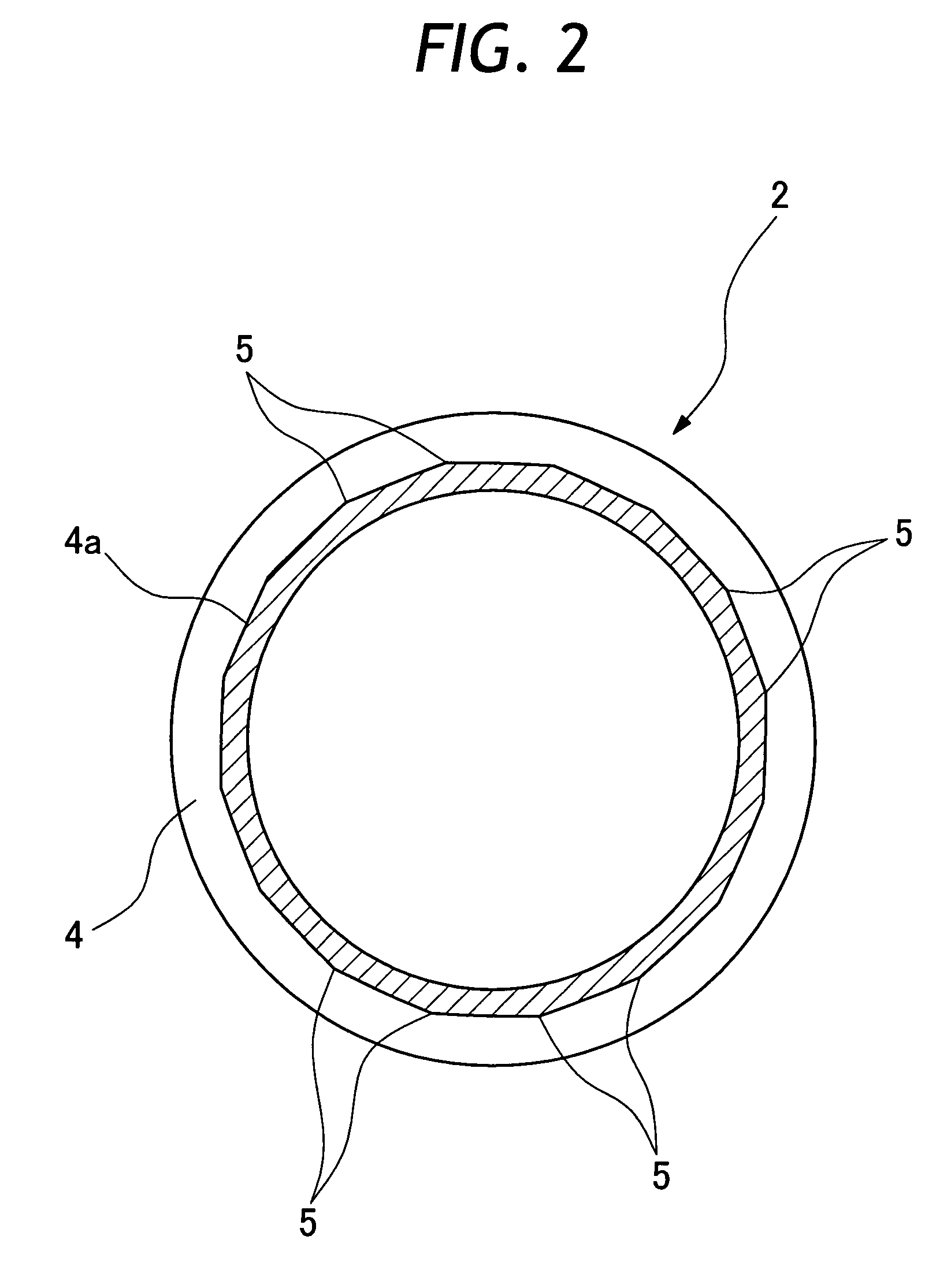

InactiveUS20070282304A1Maintain positional stabilitySmall diameterEndoscopesCatheterEngineeringMechanical engineering

A flexible channel to be incorporated into an endoscopic insertion portion having a flexible portion at least in part of its length, for the purpose of providing a flexible passage internally of the endoscopic insertion portion. The flexible channel is composed of a flexible tube with a helical groove on and around its outer periphery, and a reinforcing coil fitted in the helical groove on the flexible tube. At the root of the helical groove, angular projections are formed at intervals in the longitudinal direction and the reinforcing coil is tightly pressed tightly against the angular projections.

Owner:FUJIFILM CORP

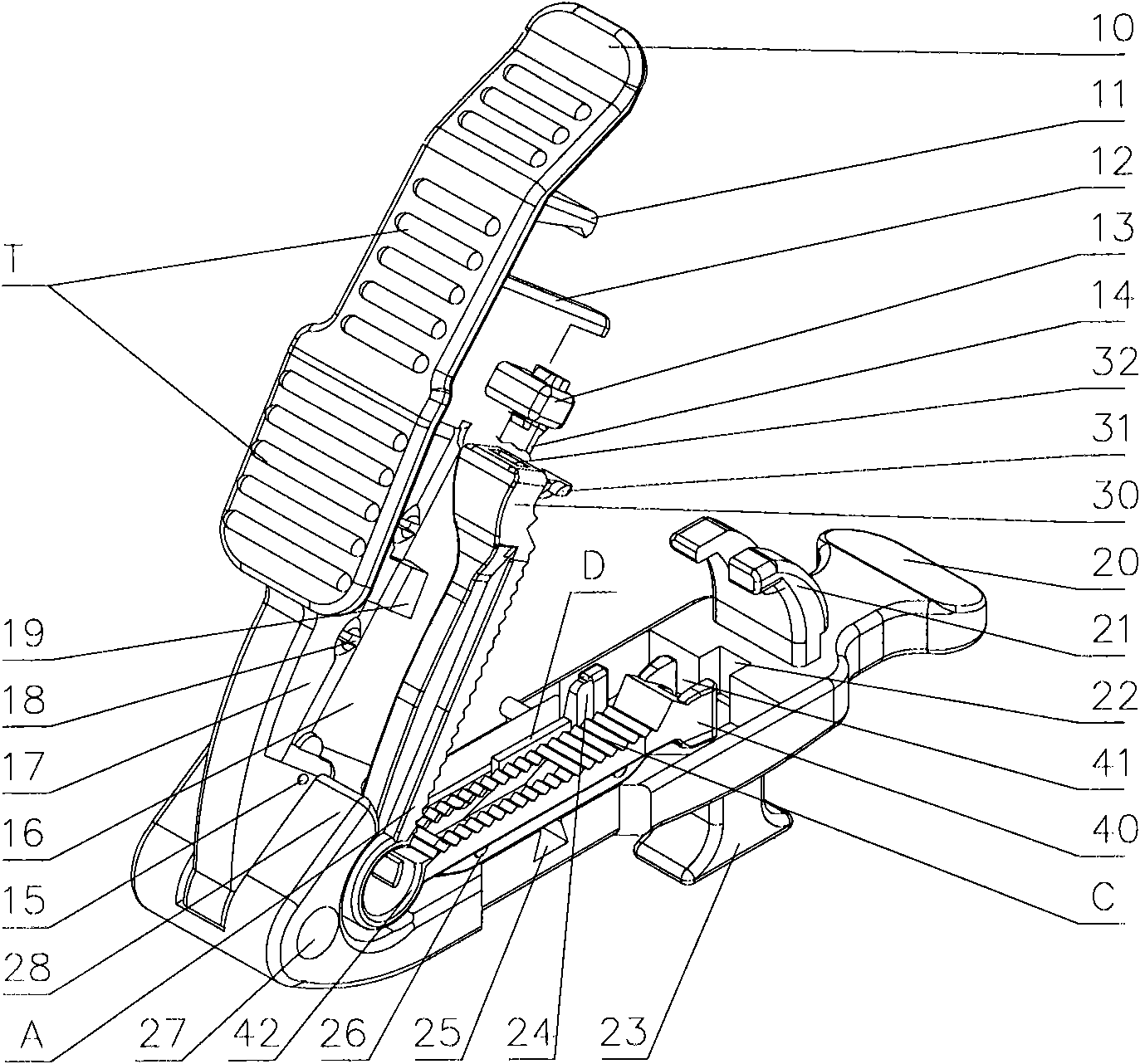

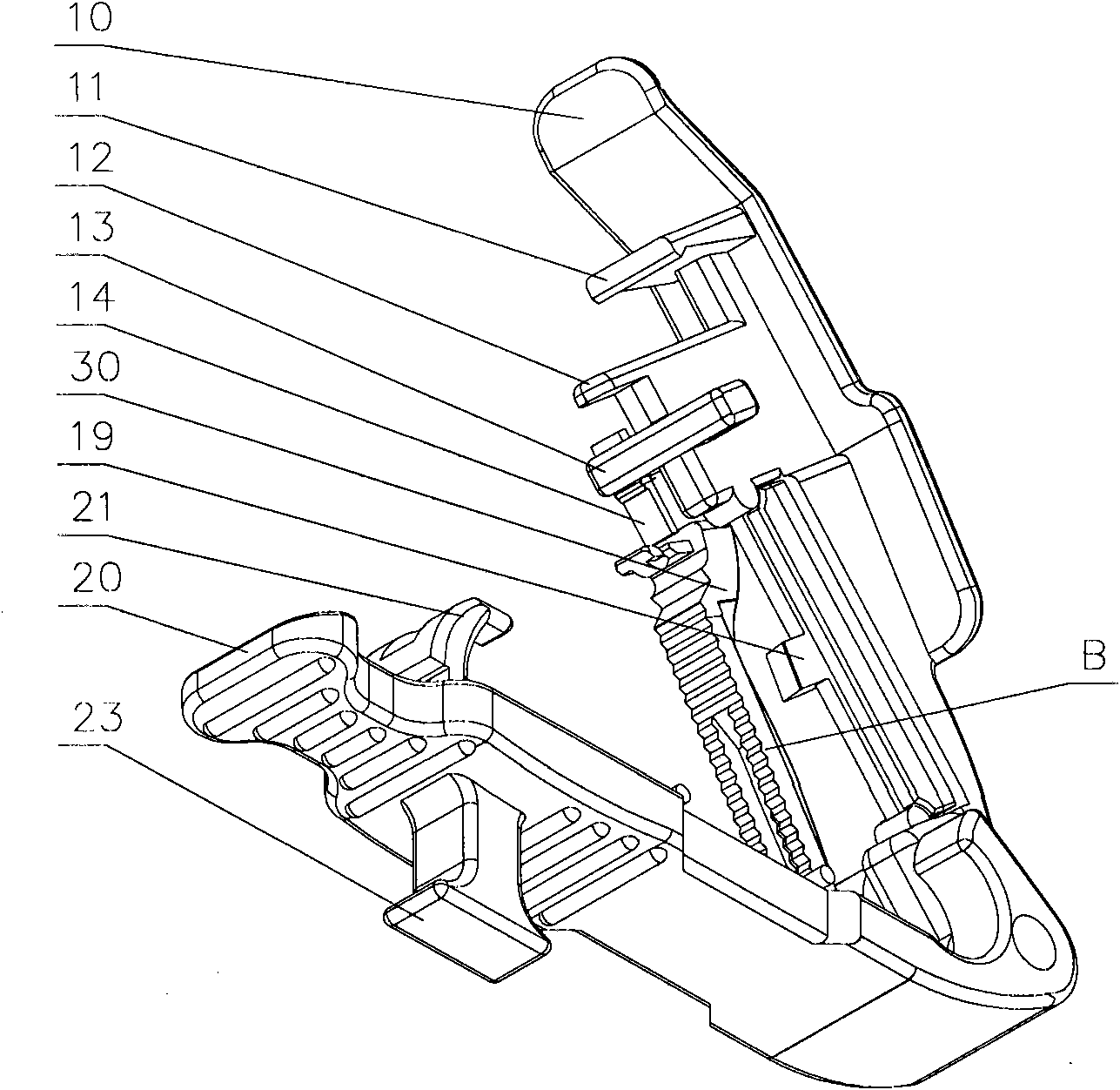

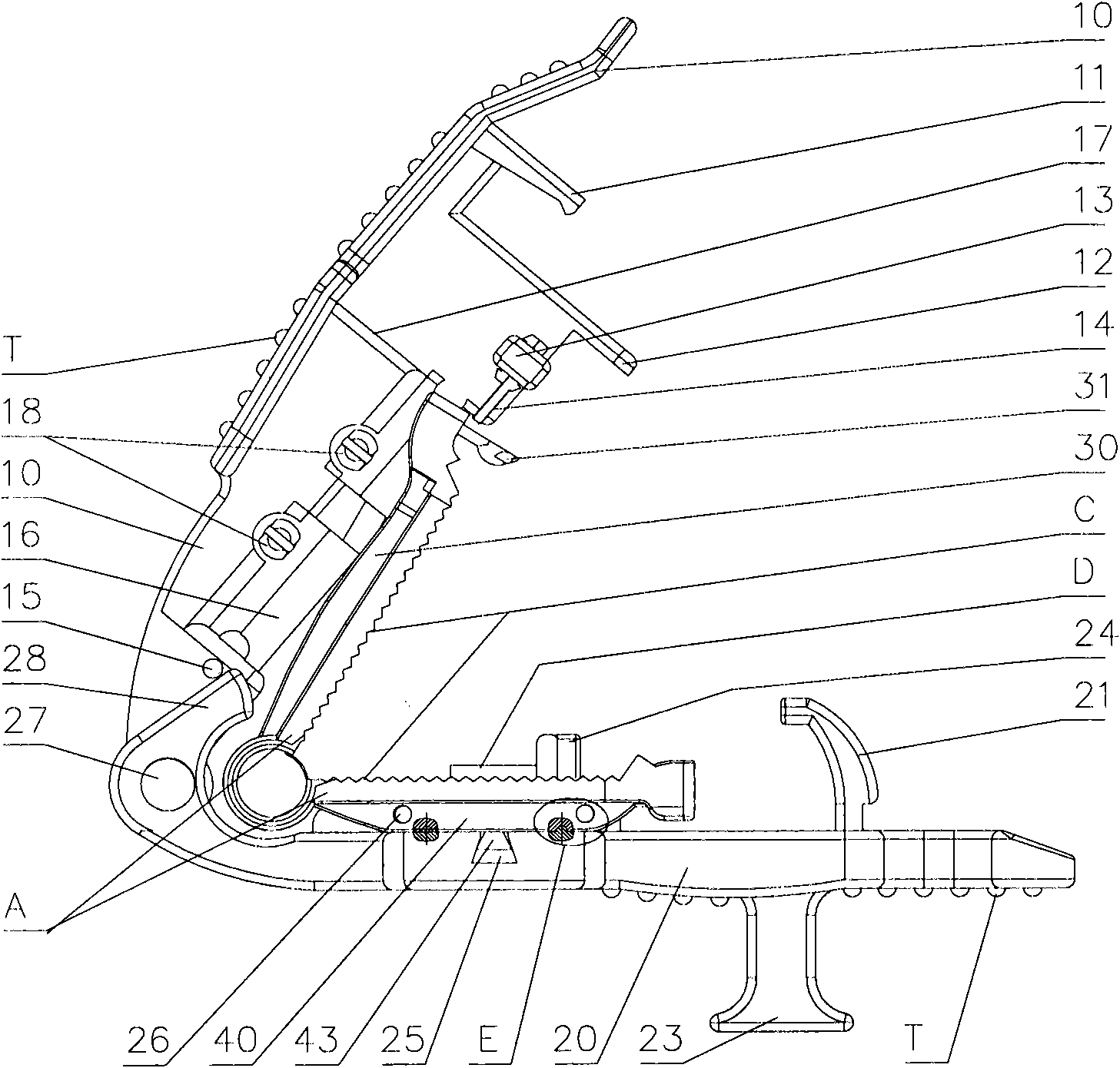

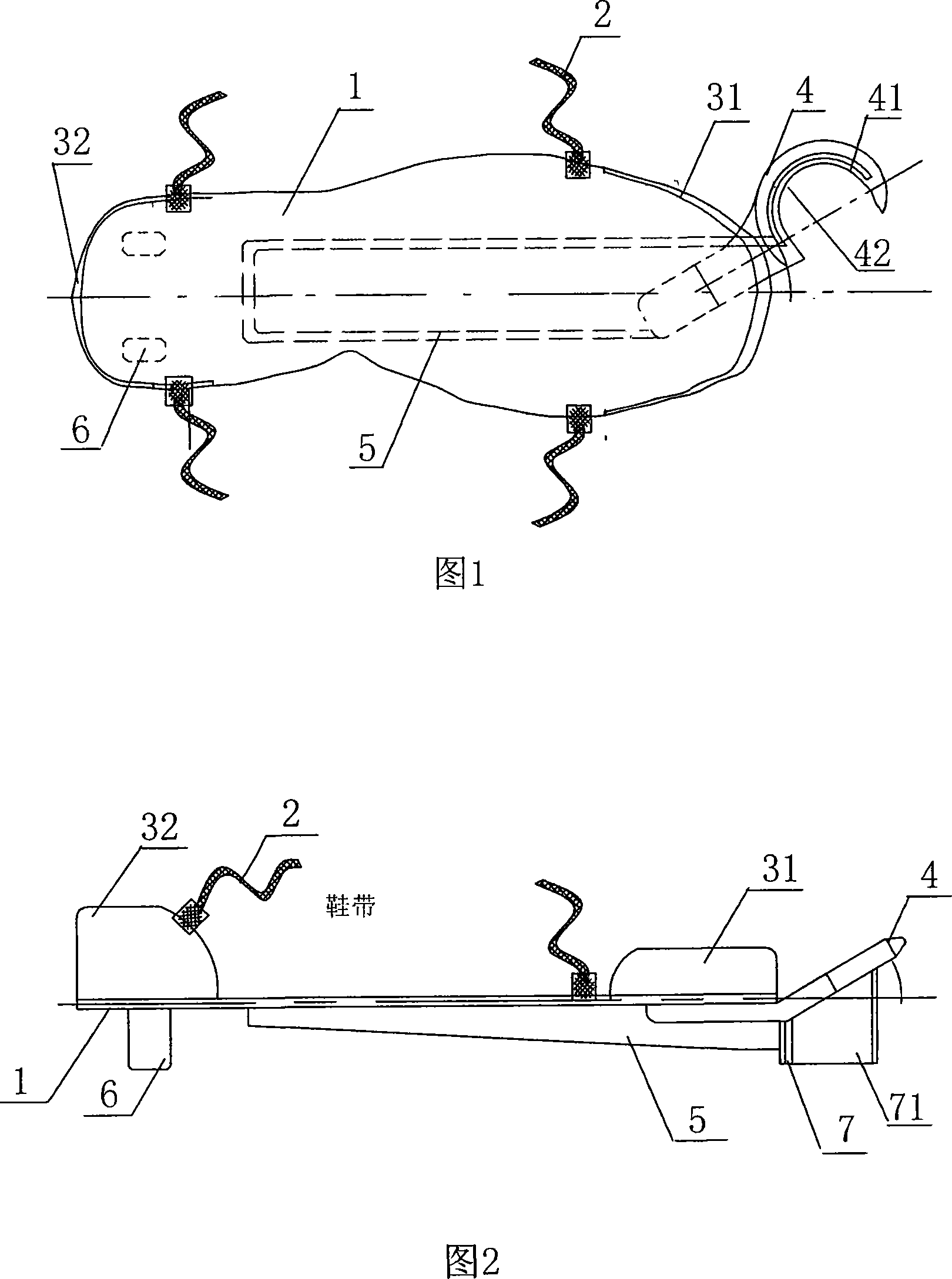

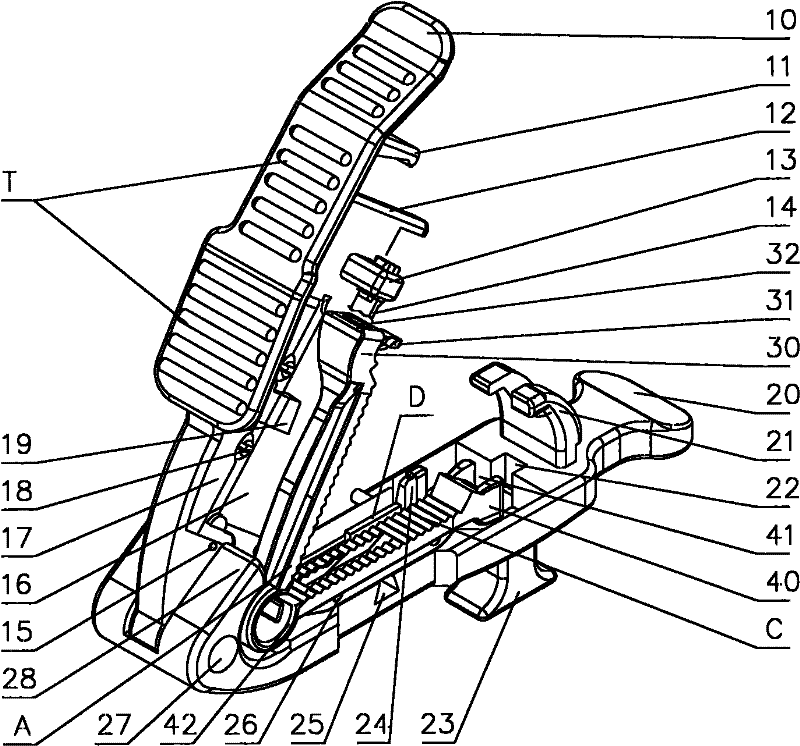

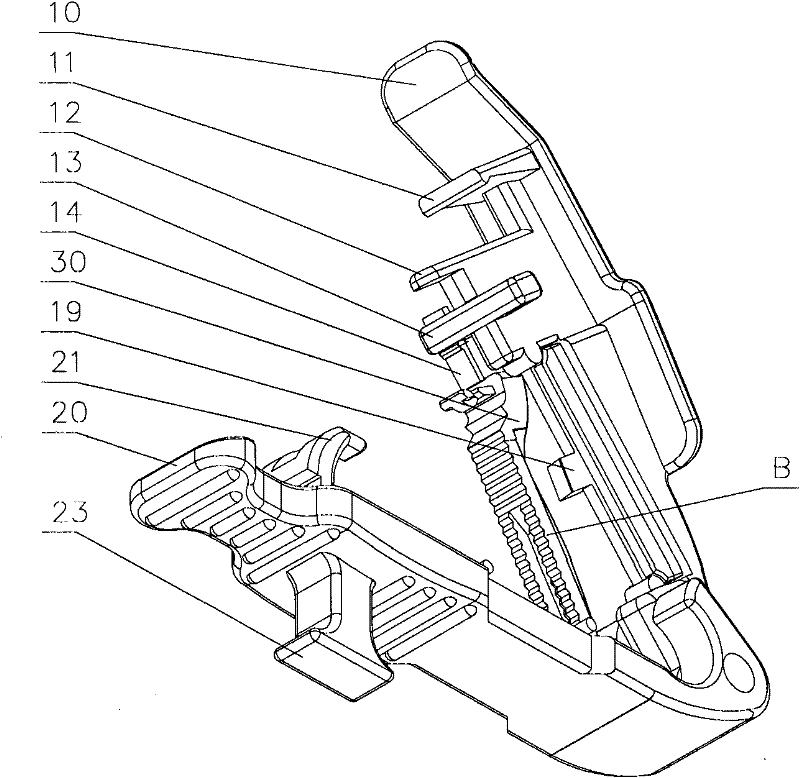

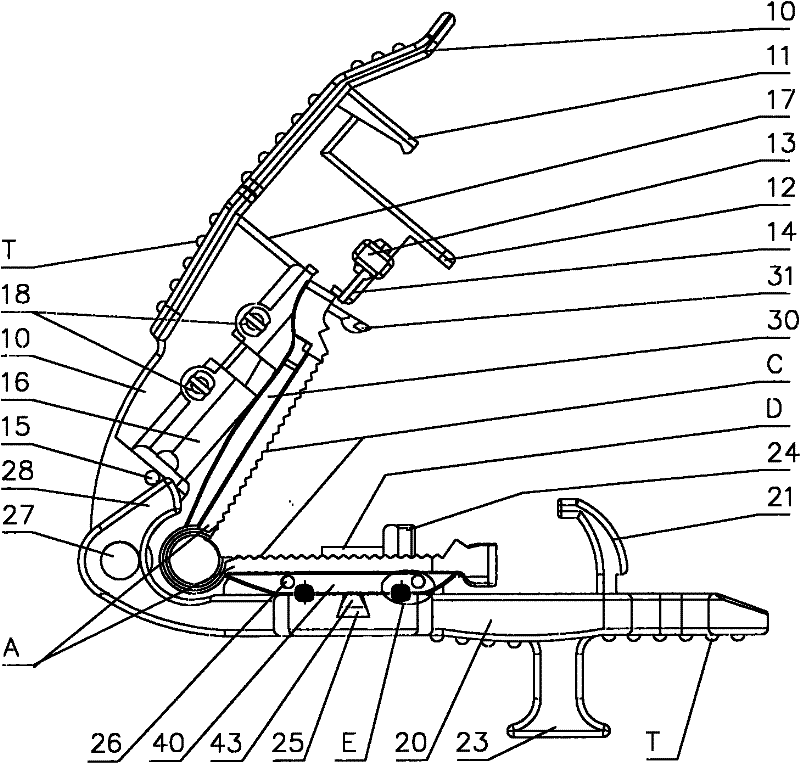

One-time bidirectional umbilical cord cutter

ActiveCN101856253AInconvenient to useBlock slide outObstetrical instrumentsEngineeringMechanical engineering

The invention provides an improvement on a conventional one-time bidirectional umbilical cord cutter. The one-time bidirectional umbilical cord cutter comprises that: an upper shell is provided with a side semi-convex sphere for preventing upper and lower shells from being closed upon a slight external force; one end of a stop body is provided with a stop lever for preventing the umbilical cord from sliding out of an open end of an umbilical clamp; the inner side of a convex pin of the lower shell is provided with an upright semi-convex sphere which is occluded with a spherical groove on the bottom surface of a lower clamping arm and used for preventing the umbilical clamp from transversely slipping; the bottom of the lower shell is provided with a handle for firmly gripping the umbilical cord cutter; the head of an upper clamping arm is provided with a longitudinal flat hole into which hold-down sheets at the two ends of a cross bar of the upper shell are inserted, so that the upper clamping arm and the hold-down sheets are more firmly positioned and occluded; a clamping hook of the upper clamping arm is firmly occluded with a concave platform in the clamping arm groove of the lower clamping arm, so that the upper clamping arm and the lower clamping arm are more firmly closed; a blade is movably arranged on a blade fixing frame through two conjoined elastic split convex pins and is convenient to separate; and when the blade is disassembled, the umbilical cord cutter is completely made of plastic, so the cutter can be recycled as waste plastic.

Owner:江西易通医疗器械有限公司

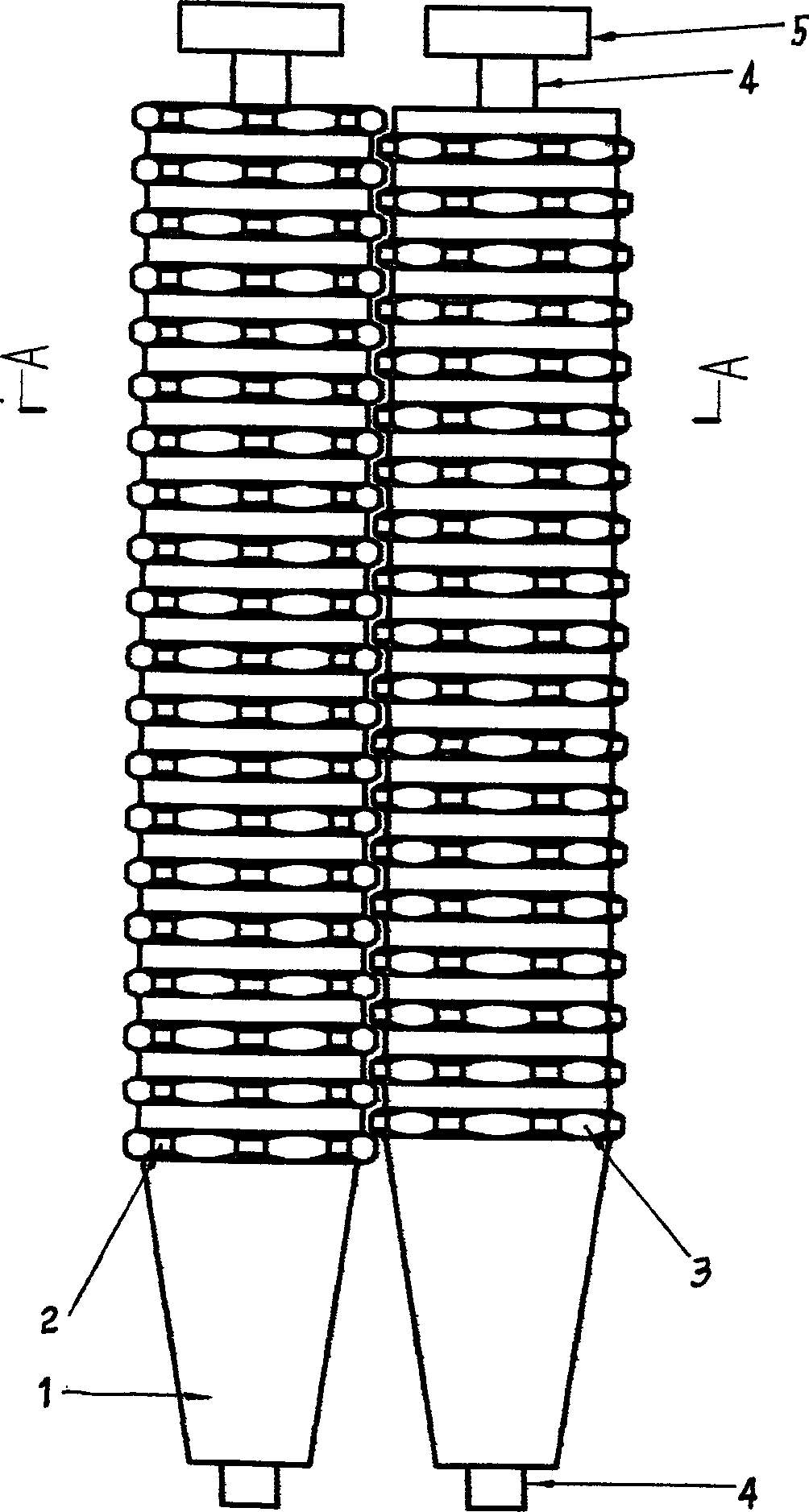

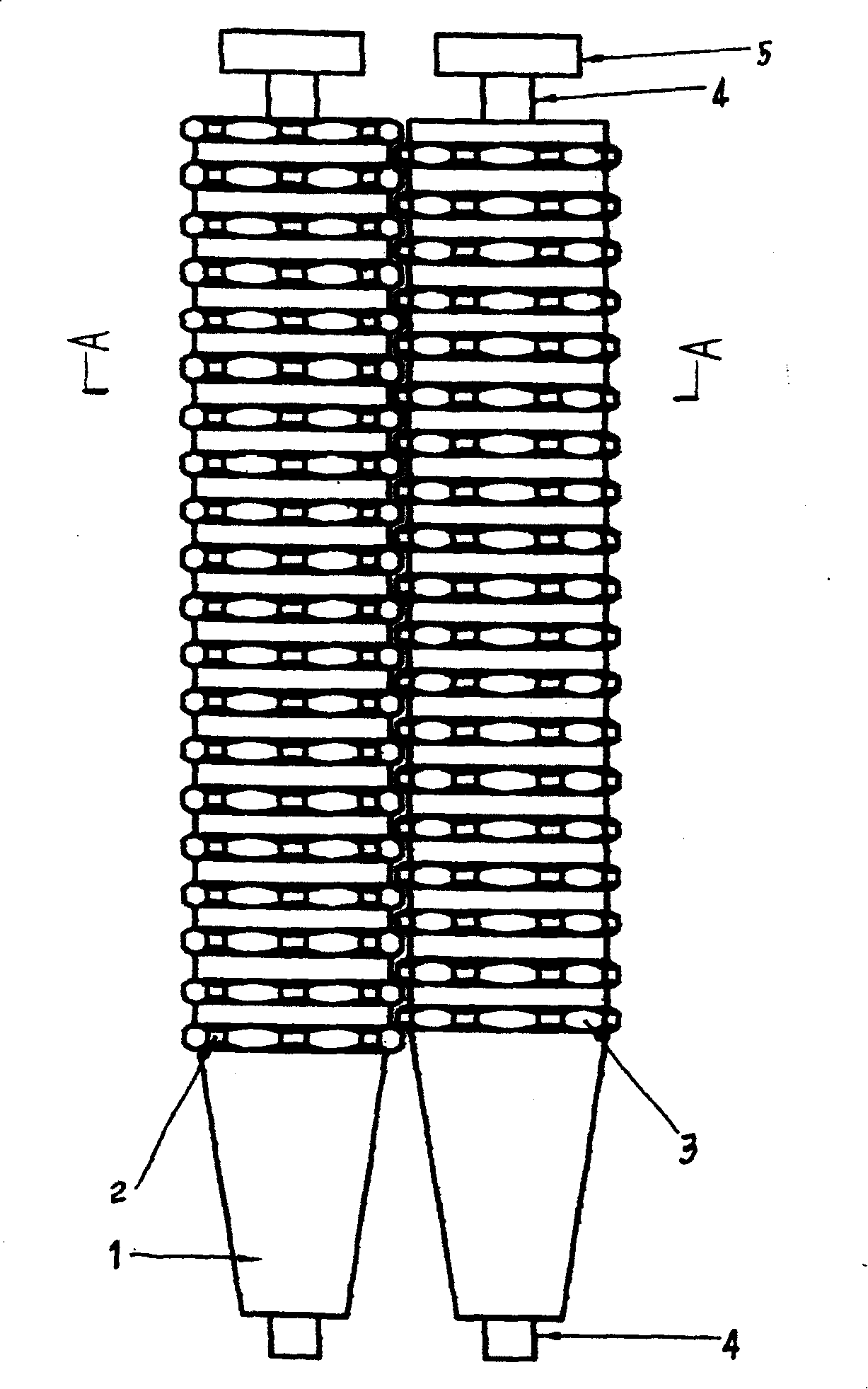

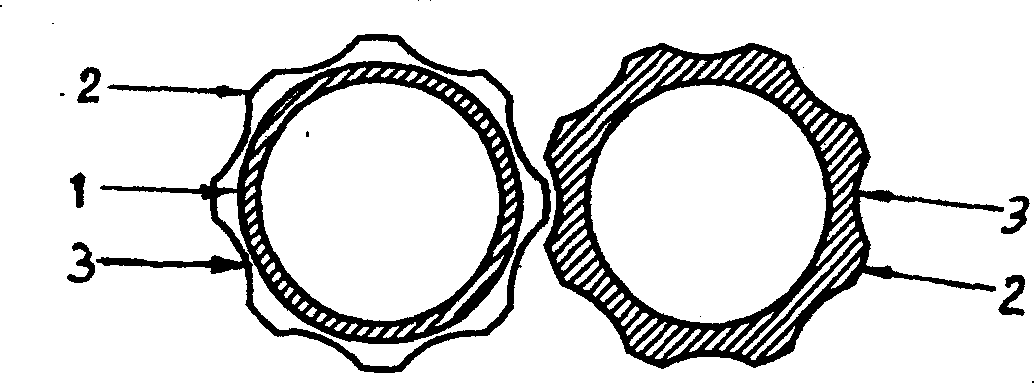

New-type core ear-picking roller

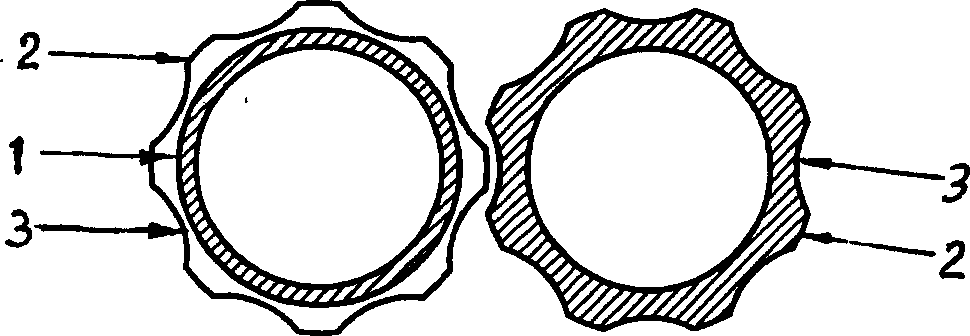

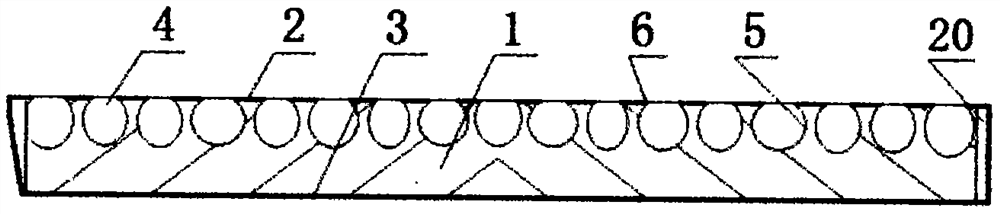

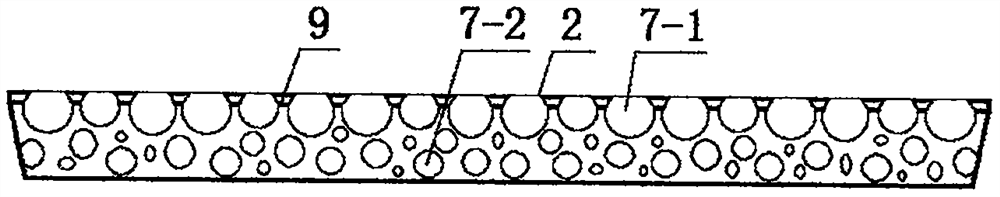

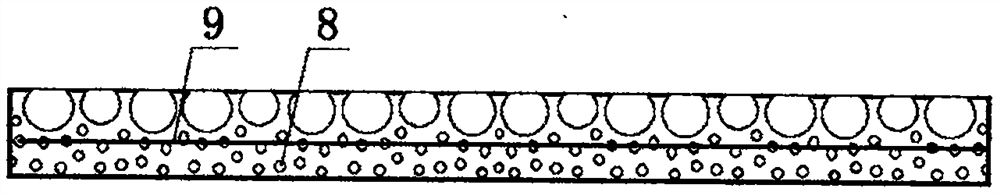

InactiveCN1774974AWon't get lostReduce loss rateHarvestersThreshersStructural engineeringMatrix Array

The present invention relates to a maize ear-picking roller. It is characterized by that on the surface of the ear-picking roller a dentation structure is set, i.e. the surface of every ear-picking roller has uniformly-distributed matrix array convex teeth which are arranged in the form of axial-lines and radial-columns and identical concave teeth. Two ear-picking rollers are combined together to form a pair of ear-picking roller to implement ear-picking operation. Said invention also provides their mounting method and concrete operation method.

Owner:山西信联集团实业有限公司

Method for engraving heel lifts

InactiveCN102343682ASatisfy preferencesBite firmlyDomestic footwearHigh volume manufacturingHardness

The invention relates to a method for engraving heel lifts. The method comprises the following steps of: pre-embedding the heads of lift nails into a heel-lift die cavity at certain intervals; respectively successively injecting or filling two or more types of mixtures different in strength, hardness and color into the die cavity by adopting two or more injection molding machines or filling machines so as to manufacture a single blank or a whole piece of blank plate; and then, engraving lifts into required shapes and sizes by using an engraving machine. The hardness and strength of a manufactured heel lift are good, and the heel lift can be articulated with a lift nail more firmly so as to prevent the heel lift from separating from the lift nail; the bottom layer of the heel lift is made of materials which are good in anticorrosive performance and flexibility, thereby improving the abrasion resistance and comfortableness of the heel lift; and through adding pigments of different colors, heel lifts with multiple types of different color combinations can be produced, thereby increasing the aesthetic property of the heel lift, enriching heel products and satisfying the favors of women. When a small batch of many types of heel lifts are produced, the method does not need to adopt many molds; and when a large batch of heel lifts are produced, the number of molds can be increased.

Owner:黎宏域

Artificial teeth easily enabling bilateral balanced occlusion

ActiveUS8128404B2Less adjustment workBite firmlyTooth crownsArtificial teethCoronal planeSagittal plane

It is intended to provide artificial teeth designed to easily enable bilateral balanced occlusion with less grinding adjustment. According to the present invention, angles formed by occlusal facets of the artificial teeth with an occlusal plane are suitably set. An artificial tooth for maxillary central incisor, for example, has a protrusive facet and a retrusive facet on an incisal edge thereof. Of angles formed by the protrusive facet with the occlusal plane, the angle in cross section along a sagittal plane is 22.0° to 25.5°, and the angle in cross section along a coronal plane is 1.5° to 6.5°. Of angles formed by the retrusive facet with the occlusal plane, the angle in cross section along the sagittal plane is 20.5° to 23.0°, and the angle in cross section along the coronal plane is 1.5° to 6.5°.

Owner:SHOFU INC

Flexible channel for use on endoscope

InactiveUS8663197B2Maintain positional stabilitySmall diameterSurgeryEndoscopesEngineeringMechanical engineering

A flexible channel to be incorporated into an endoscopic insertion portion having a flexible portion at least in part of its length, for the purpose of providing a flexible passage internally of the endoscopic insertion portion. The flexible channel is composed of a flexible tube with a helical groove on and around its outer periphery, and a reinforcing coil fitted in the helical groove on the flexible tube. At the root of the helical groove, angular projections are formed at intervals in the longitudinal direction and the reinforcing coil is tightly pressed tightly against the angular projections.

Owner:FUJIFILM CORP

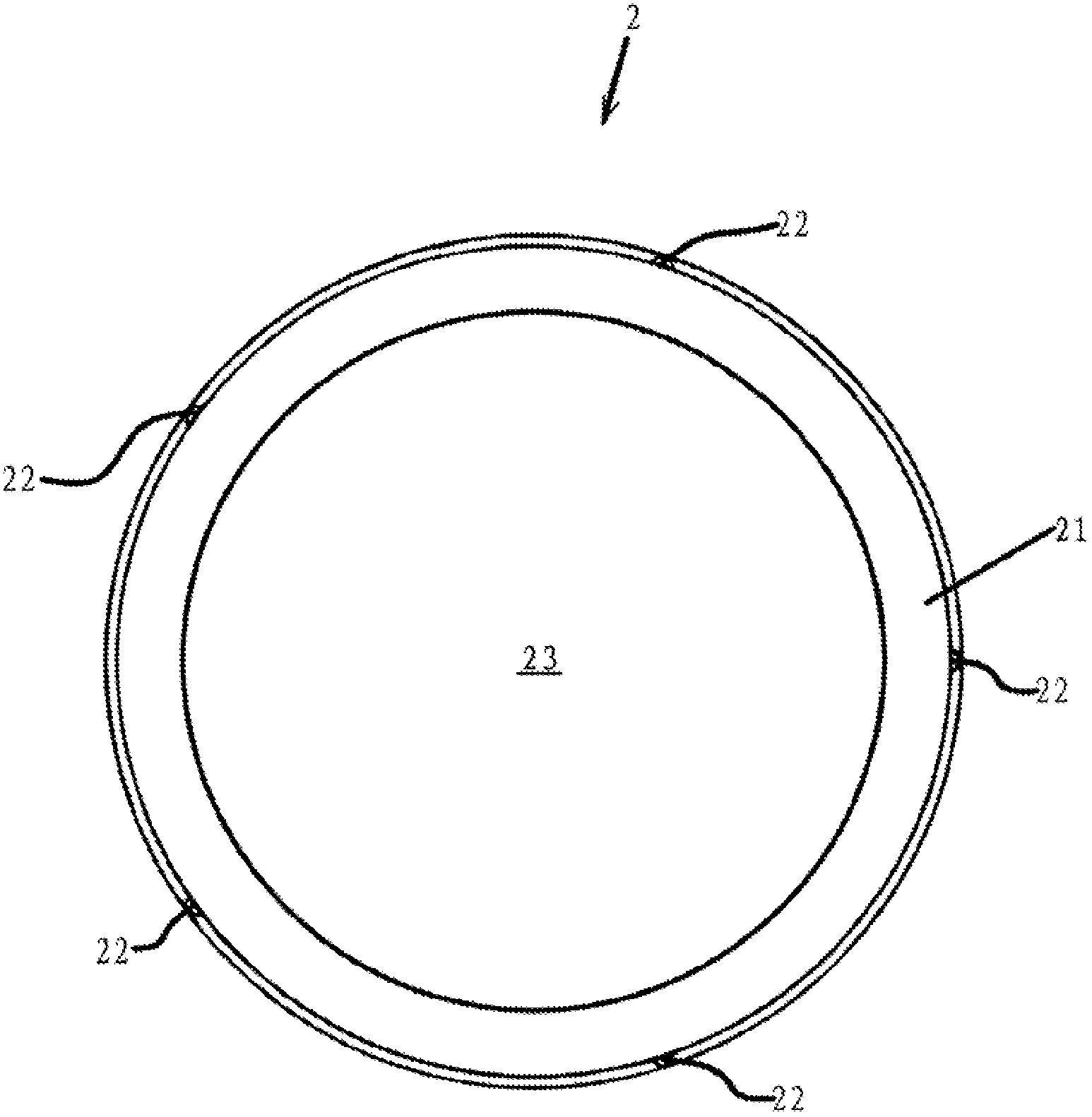

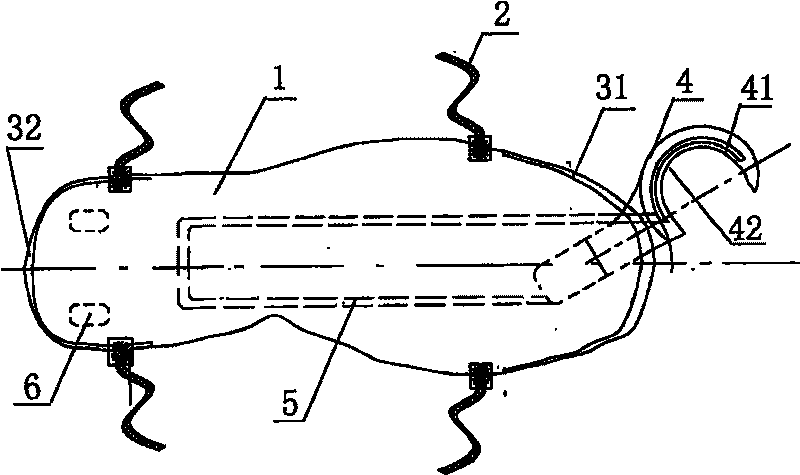

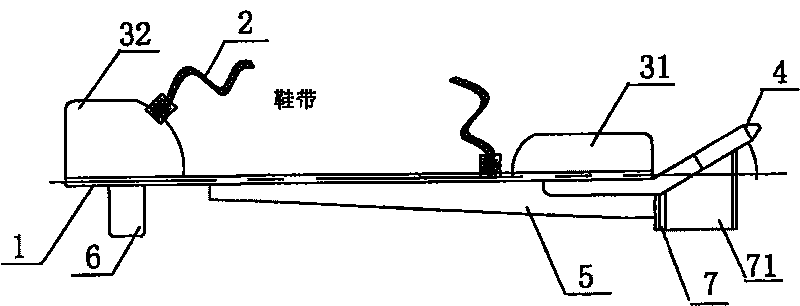

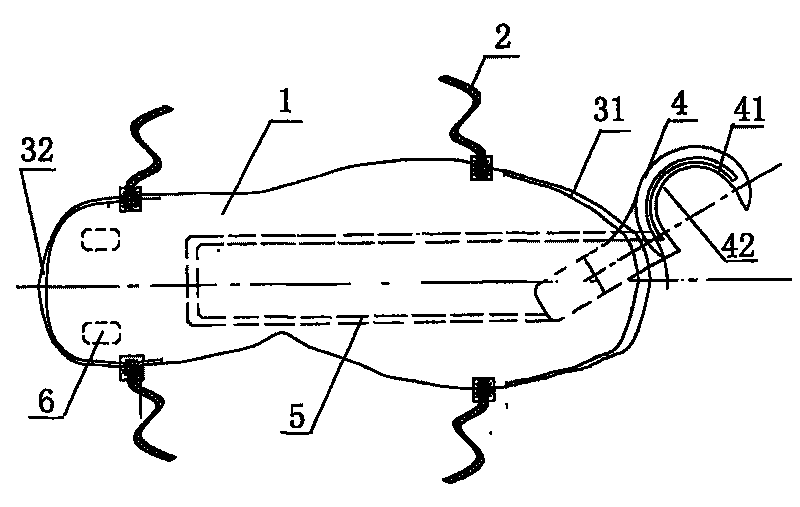

Container scrambling shoes

The present invention relates to clambering tool, and is especially one kind of container clambering boots for clambering container via seizing locking rod of container door. The container clambering boot includes a sole, a vamp and a boot string, and features that the sole is provided with one hook in the front end, one stabilizing block in the back of the hook and one or two supporting legs in the back part. The present invention has simple structure, use safety and low cost, and may be used in clambering container easily and safely.

Owner:NINGBO DAXIE CHINA MERCHANTS INT TERMINAL CO LTD

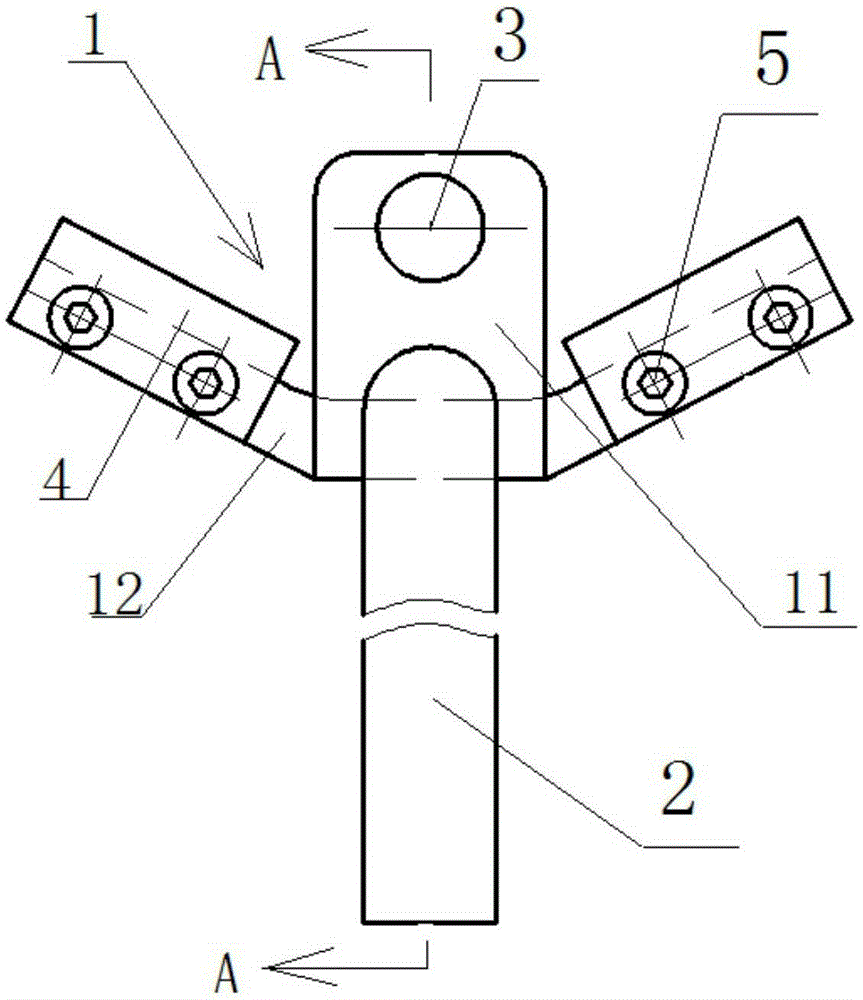

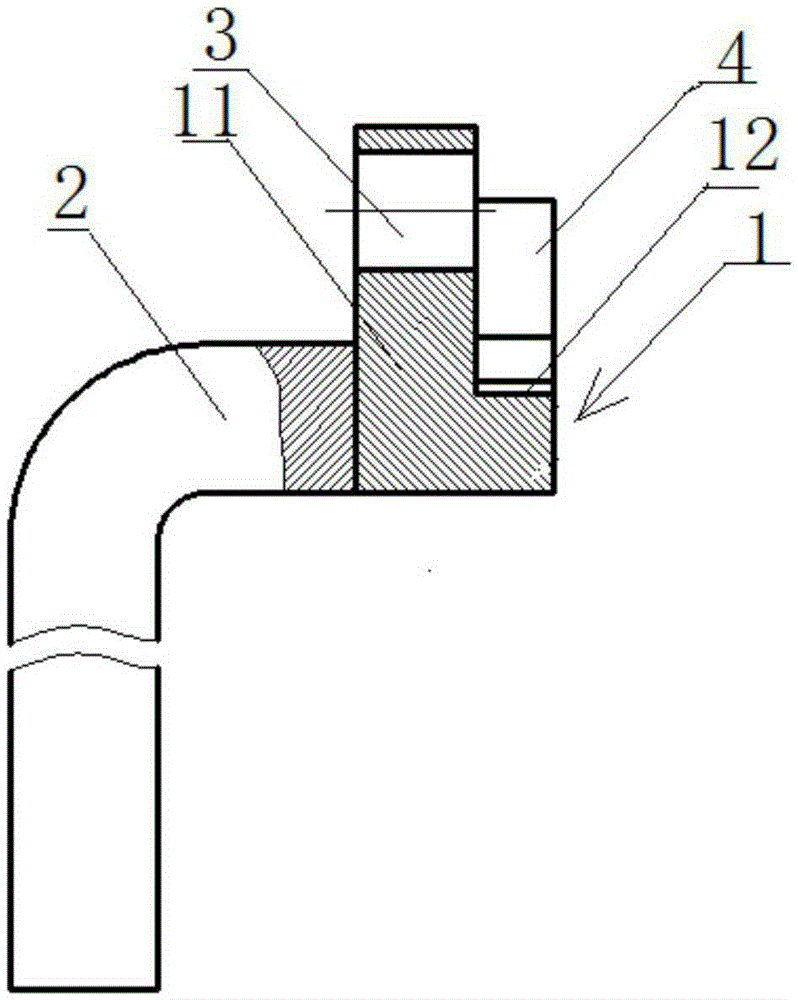

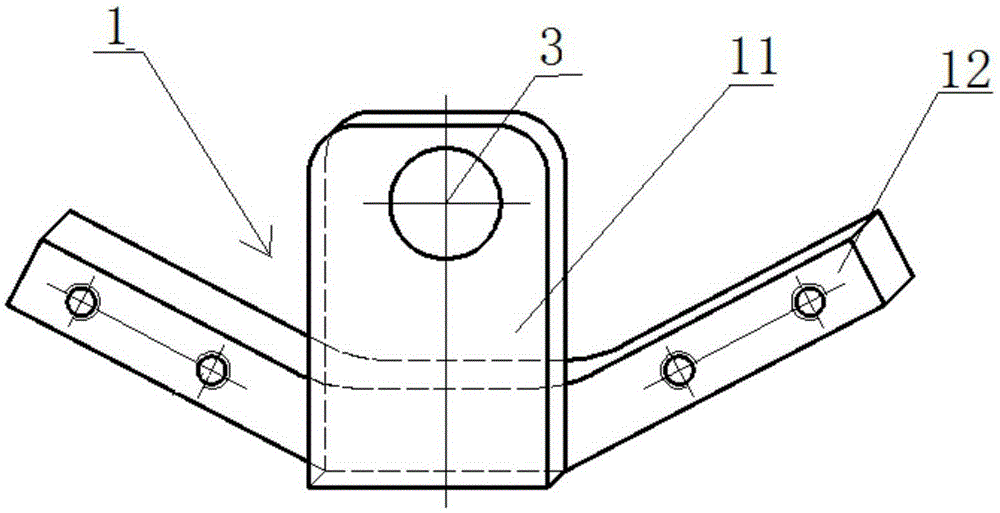

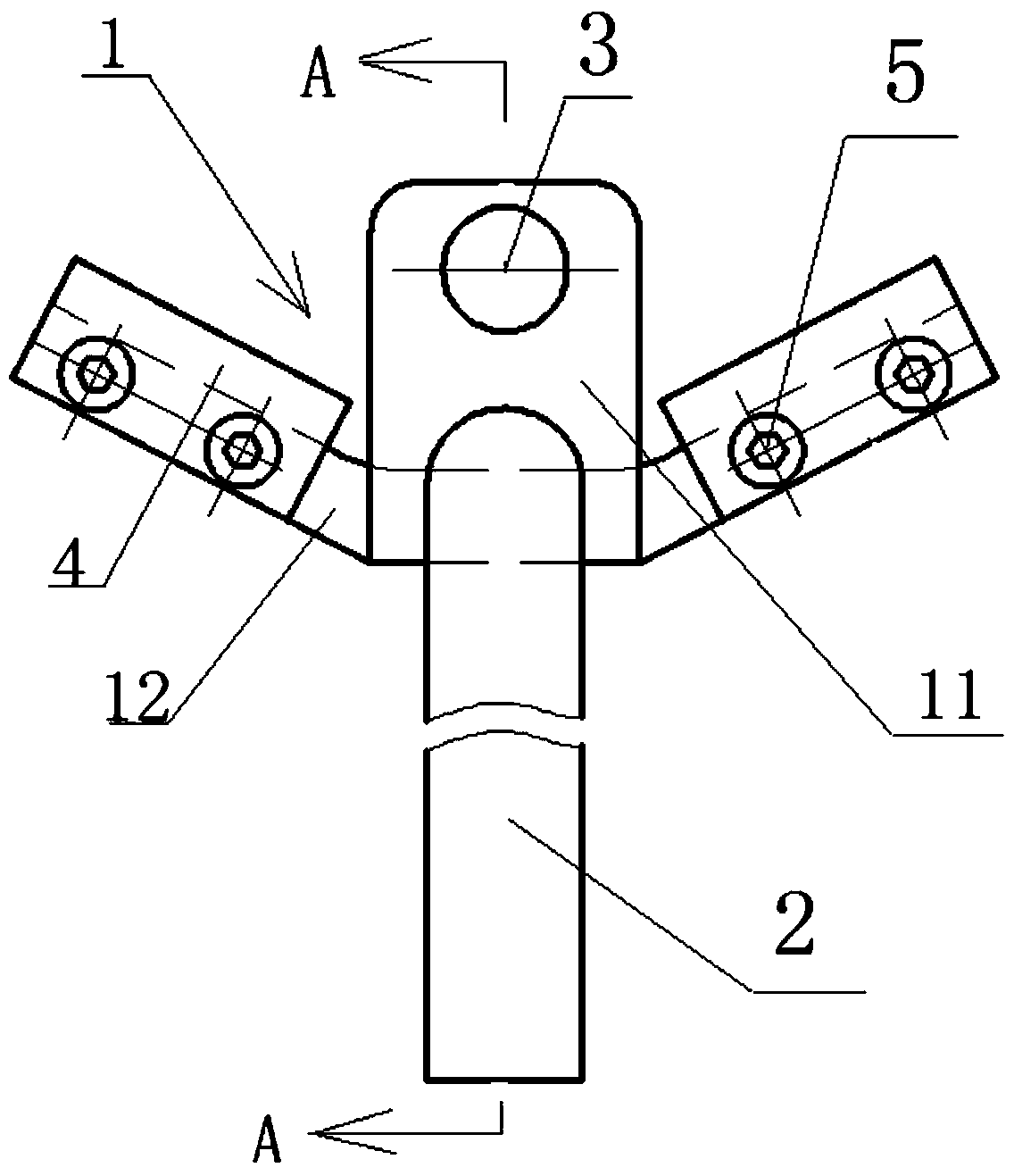

Crankshaft rotation tool and method for rotating crankshaft

ActiveCN105258667ASimple structureEasy to useMeasurement devicesReciprocating piston enginesElastic componentEngineering

The present invention discloses a crankshaft rotation tool, comprising a locating block and a handle connected with the locating block, wherein the locating block comprises a main locating block and two auxiliary locating blocks arranged at two sides of the main locating block, each auxiliary locating block is provided with an elastic component used for being tightly contacted with an excircle of a big end of a crankshaft, and the main locating block is provided with a locating hole used for cooperating with a locating pin at the end face of the big end of the crankshaft. The present invention aims to provide the crankshaft rotation tool which is simple in structure, convenient and reliable in use, and capable of forwards and reversely rotating the crankshaft, at the same time, the present invention also provides a method for rotating the crankshaft by adopting the crankshaft rotation tool.

Owner:GUANGXI YUCHAI MASCH CO LTD

Vascular plug

A vascular plug for implantation into a patient's vessel includes an inflatable balloon and a flow accelerator. The flow accelerator includes a conical portion and a tubular coupling element which couples the conical portion to an aperture to the interior of the inflatable balloon. The flow accelerator will concentrate and therefore accelerate fluid flow into the inflatable balloon. Flow accelerator will increase the pressure of fluid thereby to cause the inflatable balloon to inflate even within a pressurised blood vessel. The plug may include a sleeve which provides a chamber between the flow accelerator and the balloon, into which blood may pass from the inflatable balloon or the flow accelerator to create additional blood statis and as a result thrombosis and a second occlusive barrier.

Owner:COOK MEDICAL TECH LLC

Technology for inlaying aluminum alloy in magnesium alloy in pressure casting manner

InactiveCN110576291AImprove antioxidant capacityNo rust spotsDetails for portable computersPressure castingAluminum can

The invention discloses a technology for inlaying an aluminum alloy in a magnesium alloy in a pressure casting manner. The technology for inlaying the aluminum alloy in the magnesium alloy in the pressure casting manner includes the following steps that S1, pressure casting forming of the magnesium alloy is conducted; S2, local inlaying of the aluminum alloy is conducted; S3, CNC machining is conducted; S4, formation is conducted; S5, surface paint spraying is conducted; S6, drilling cutting highlighting is conducted; S7, salt spray testing is conducted; and S8, complete inspection packaging is conducted. By means of the technology for inlaying the aluminum alloy in the magnesium alloy in the pressure casting manner, due to the fact that the aluminum alloy is inlaid in a magnesium alloy shell and the antioxidant effect of the aluminum alloy is better than that of the magnesium alloy, it can be ensured that the highlighted part of a metal notebook computer face shell does not generate rust; due to the fact that a dovetail-shaped aluminum engaging structure is arranged, the aluminum alloy can be better engaged with the magnesium alloy firmly; and due to the fact that the aluminum engaging structure is made into a dovetail shape, the dovetail structure of aluminum can be completely wrapped by magnesium during pressure casting, and disengagement of the inlaid aluminum part is prevented.

Owner:重庆百钰顺科技有限公司

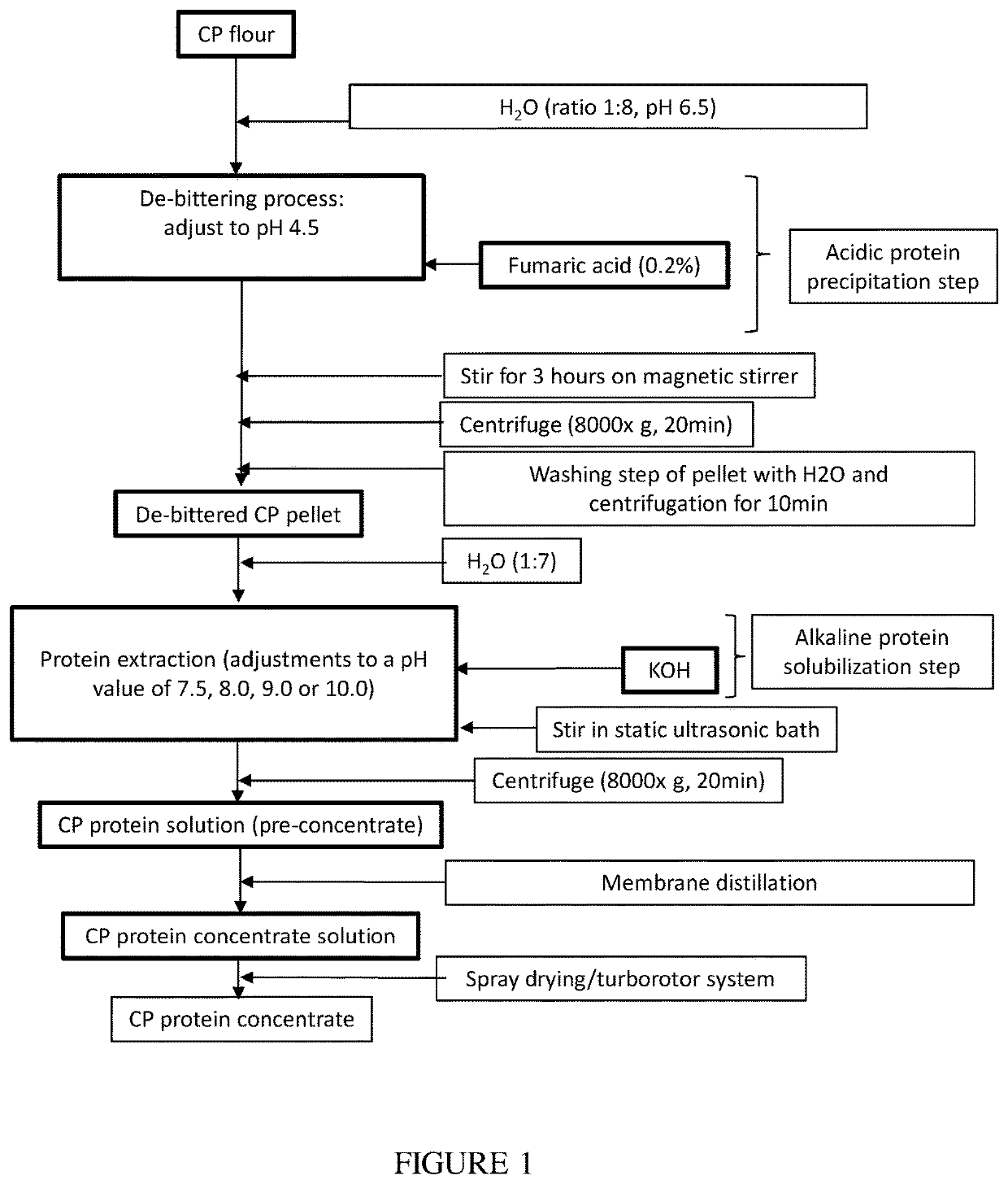

Chickpea protein concentrate

PendingUS20200390131A1Less bitternessBite firmlyProtein composition from vegetable seedsCheese manufactureBiotechnologyConcentration protein

Provided are debittered chickpea based protein concentrates, methods of manufacturing thereof and food products comprising the protein concentrates.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Bulge forming apparatus for producing canned product, and canned product

InactiveCN103052568AEasy costNot easy to jump coverRemovable lids/coversClosures to prevent refillingBiomedical engineeringEngineering

Owner:AKZO NOBEL SWIRE PAINTS SHANGHAI +1

Container scrambling shoes

The present invention relates to clambering tool, and is especially one kind of container clambering boots for clambering container via seizing locking rod of container door. The container clamberingboot includes a sole, a vamp and a boot string, and features that the sole is provided with one hook in the front end, one stabilizing block in the back of the hook and one or two supporting legs in the back part. The present invention has simple structure, use safety and low cost, and may be used in clambering container easily and safely.

Owner:NINGBO DAXIE CHINA MERCHANTS INT TERMINAL CO LTD

New-type core ear-picking roller

InactiveCN100397974CWon't get lostReduce breakageHarvestersThreshersStructural engineeringMatrix Array

The present invention relates to a maize ear-picking roller. It is characterized by that on the surface of the ear-picking roller a dentation structure is set, i.e. the surface of every ear-picking roller has uniformly-distributed matrix array convex teeth which are arranged in the form of axial-lines and radial-columns and identical concave teeth. Two ear-picking rollers are combined together to form a pair of ear-picking roller to implement ear-picking operation. Said invention also provides their mounting method and concrete operation method.

Owner:山西信联集团实业有限公司

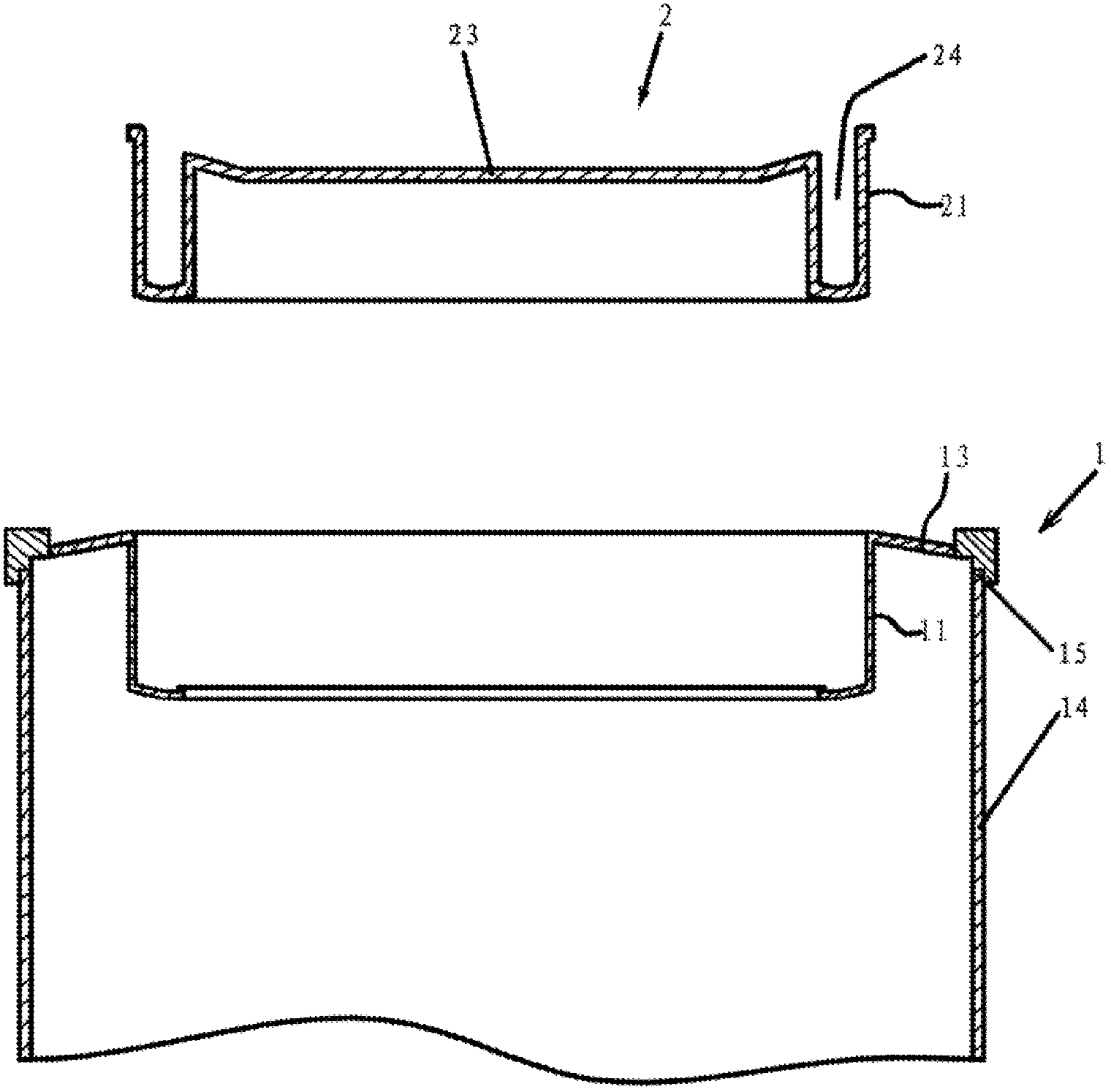

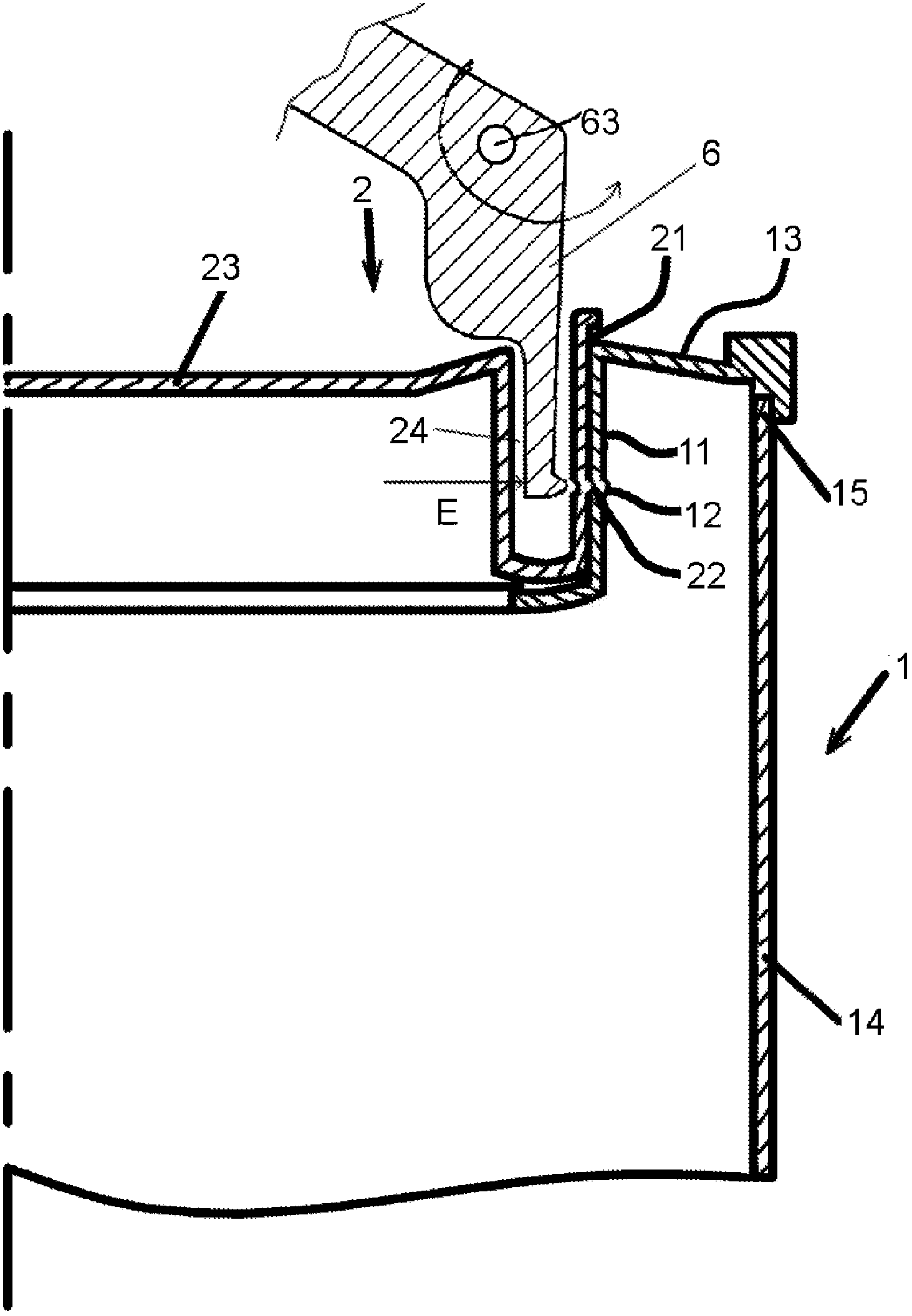

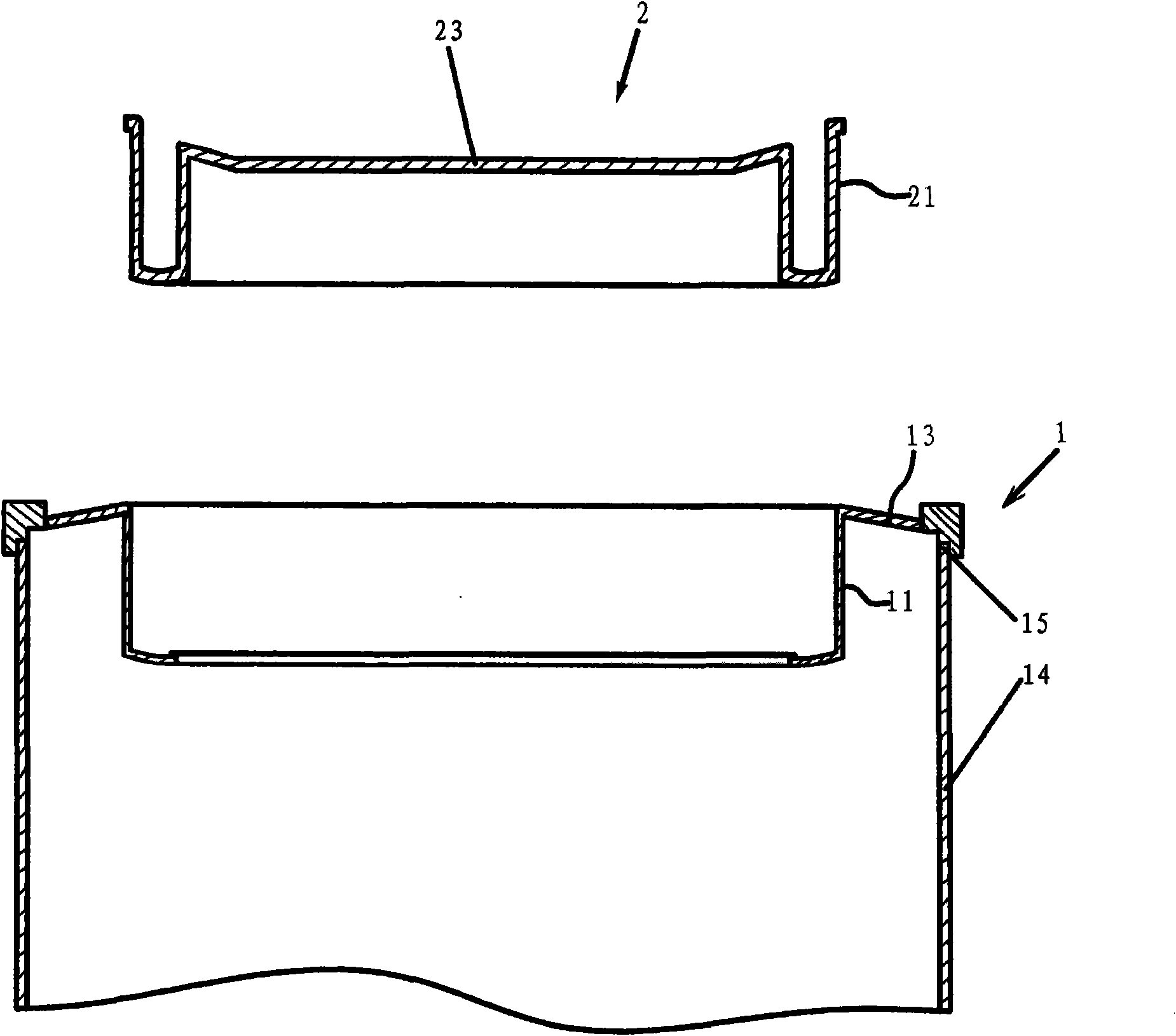

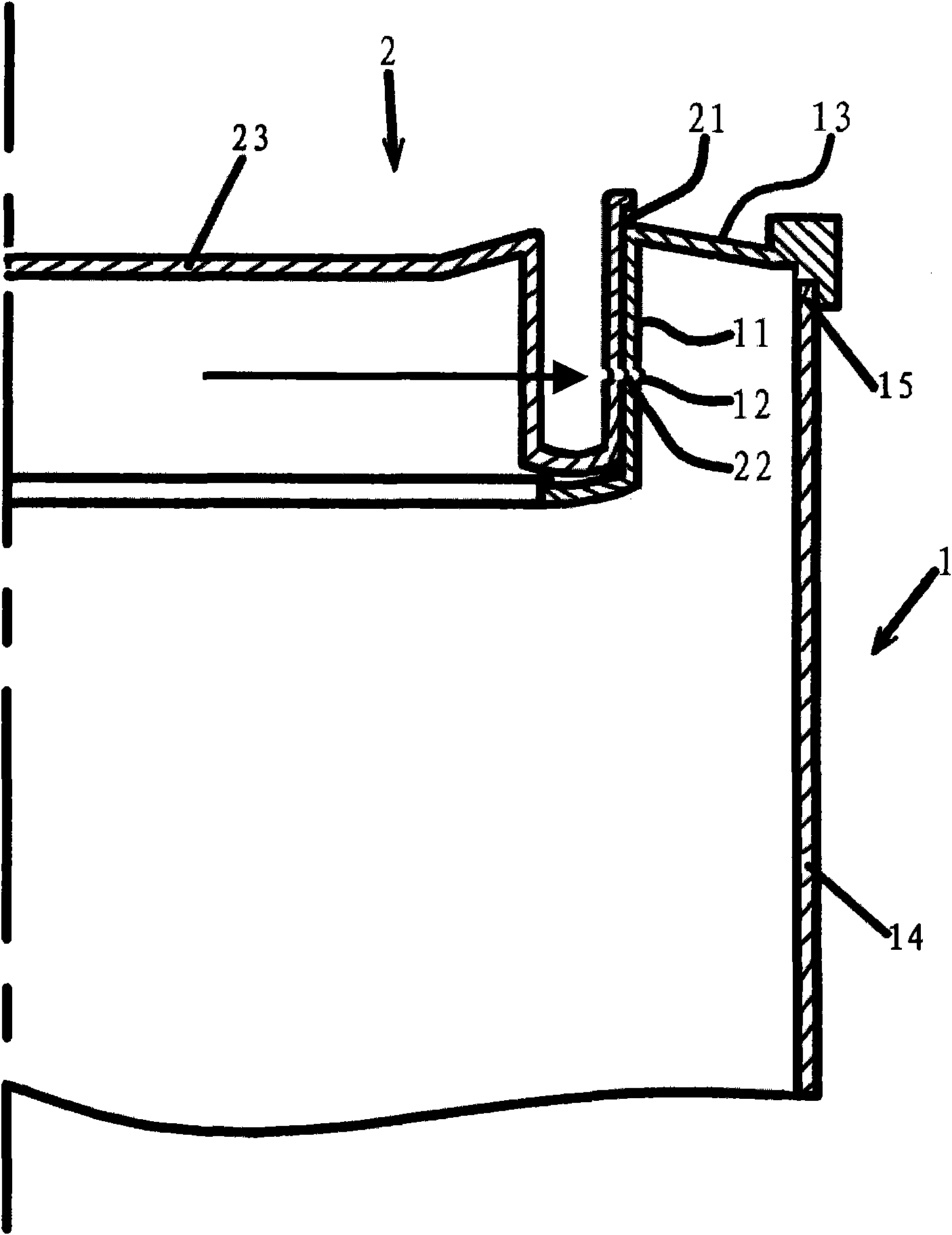

Method for preparing barreled product and barreled product

InactiveCN101992882AReliable jointBite firmlyRemovable lids/coversLidsEngineeringMechanical engineering

The invention relates to a method for preparing a barreled product, comprising the following steps of: providing a packing barrel, a barrel cover and articles, wherein the articles are contained in the packing barrel, the packing barrel is provided with an opening part, the barrel cover is provided with an extending part which can be matched with the opening part to seal the packing barrel; loading the articles in the packing barrel; and assembling the barrel cover into the opening part of the packing barrel so that the extending part of the barrel cover is matched with the side wall of the opening part. The method is characterized by also comprising the following steps of: after assembling the barrel cover into the opening part of the packing barrel, forming at least one convex part on one of the extending part of the barrel cover and the side wall of the opening part, and combining the convex surface of the at least one convex part and the other of the extending part of the barrel cover and the side wall of the opening part when the barrel cover is opened to destroy the extending part and / or the side wall. The invention also relates to a barreled product prepared by the method.

Owner:AKZO NOBEL SWIRE PAINTS SHANGHAI

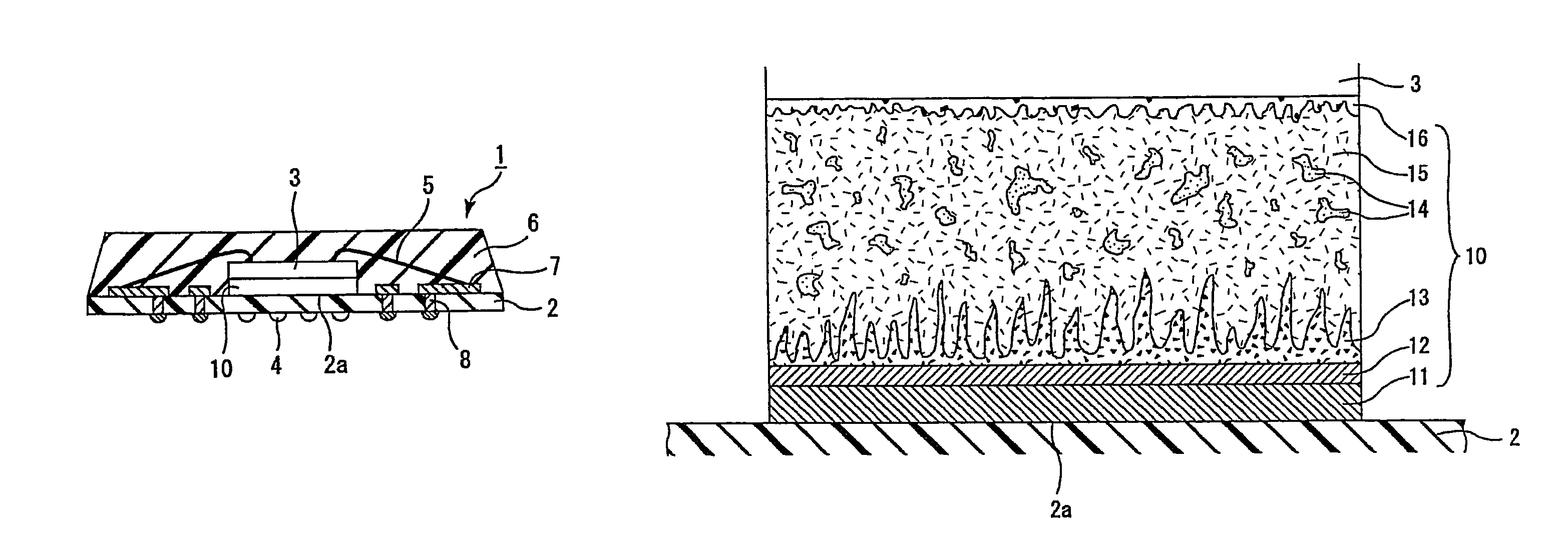

Semiconductor device, production method for the same, and substrate

ActiveUS20110115089A1High bonding strengthAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipAlloy

A semiconductor device is provided in which a semiconductor chip is bonded to a substrate with a sufficiently increased bonding strength and cracking is assuredly prevented which may otherwise occur due to heat shock, heat cycle and the like. The semiconductor device includes a semiconductor chip and a substrate having a bonding area to which the semiconductor chip is bonded via a metal layer. The metal layer includes an Au—Sn—Ni alloy layer and a solder layer provided on the Au—Sn—Ni alloy layer. Undulations are formed in an interface between the Au—Sn—Ni alloy layer and the solder layer.

Owner:ROHM CO LTD

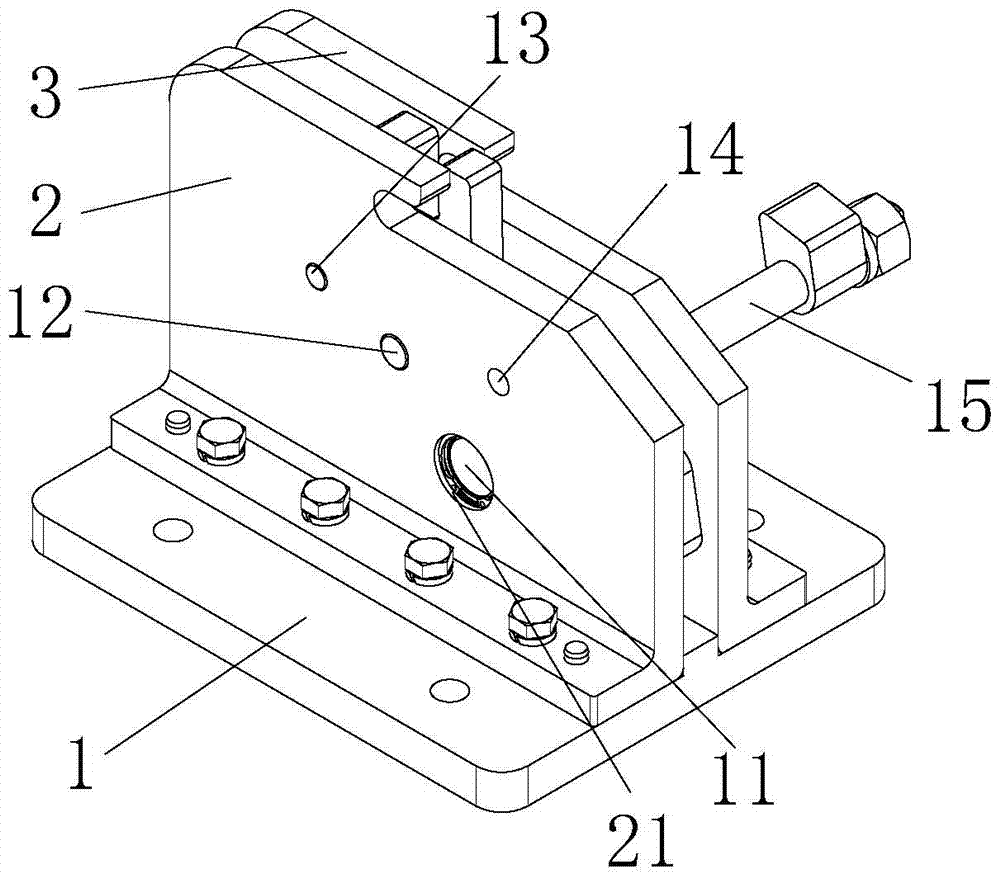

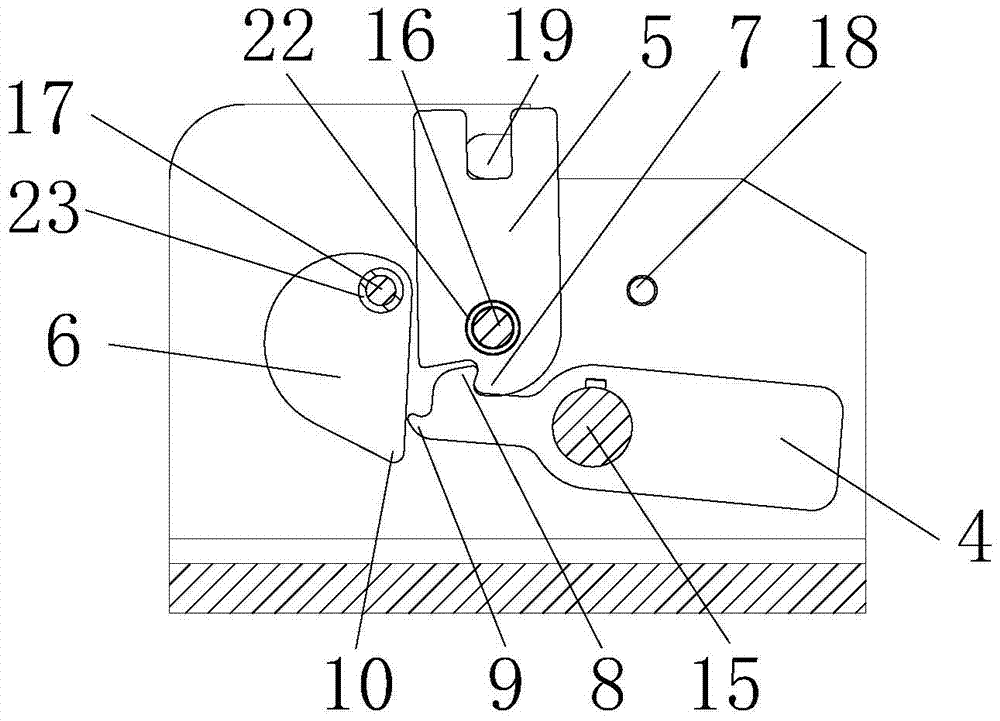

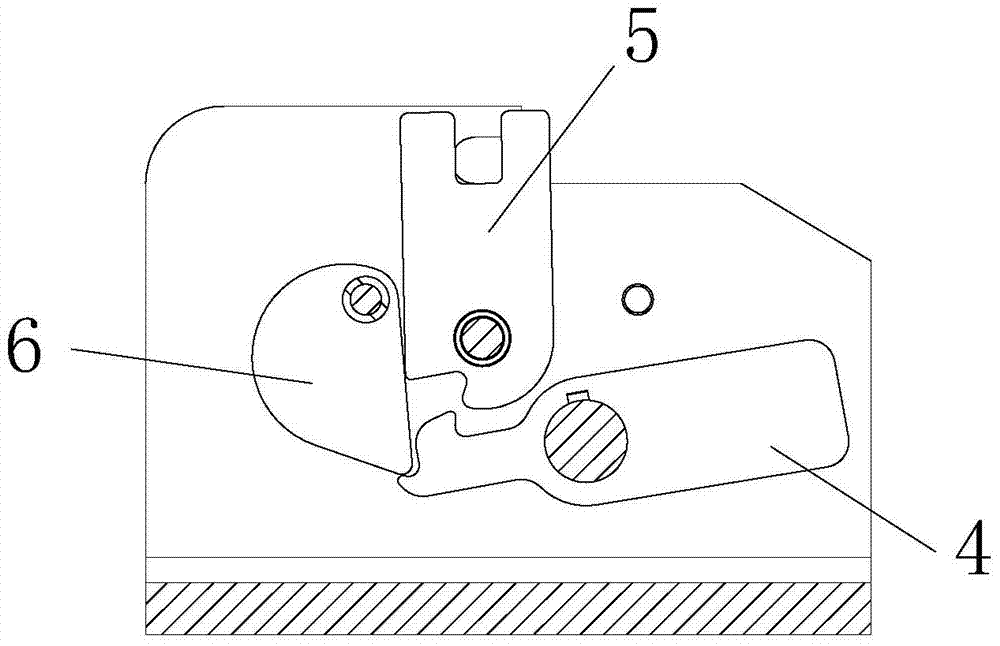

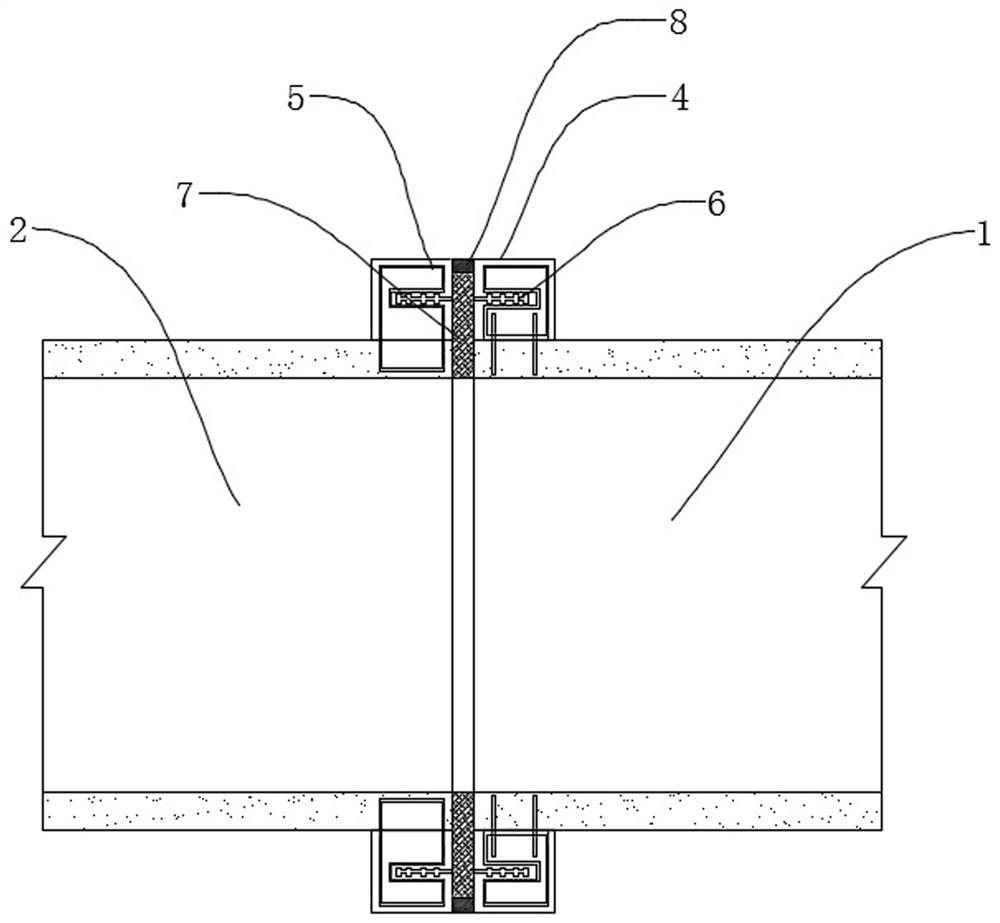

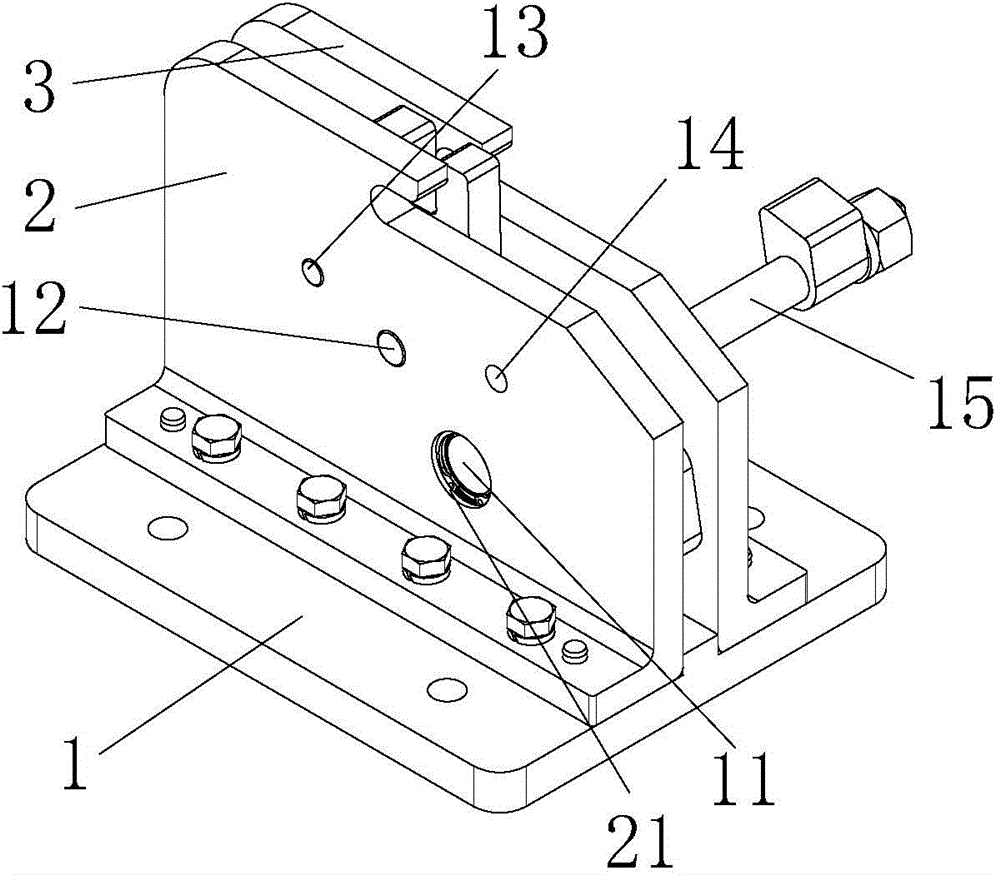

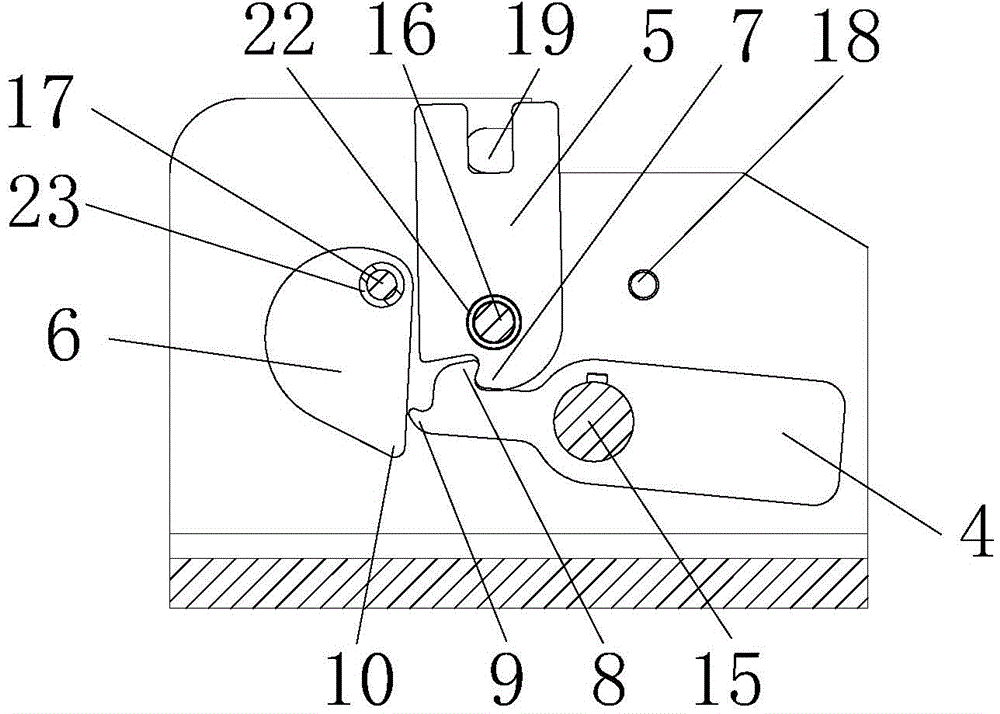

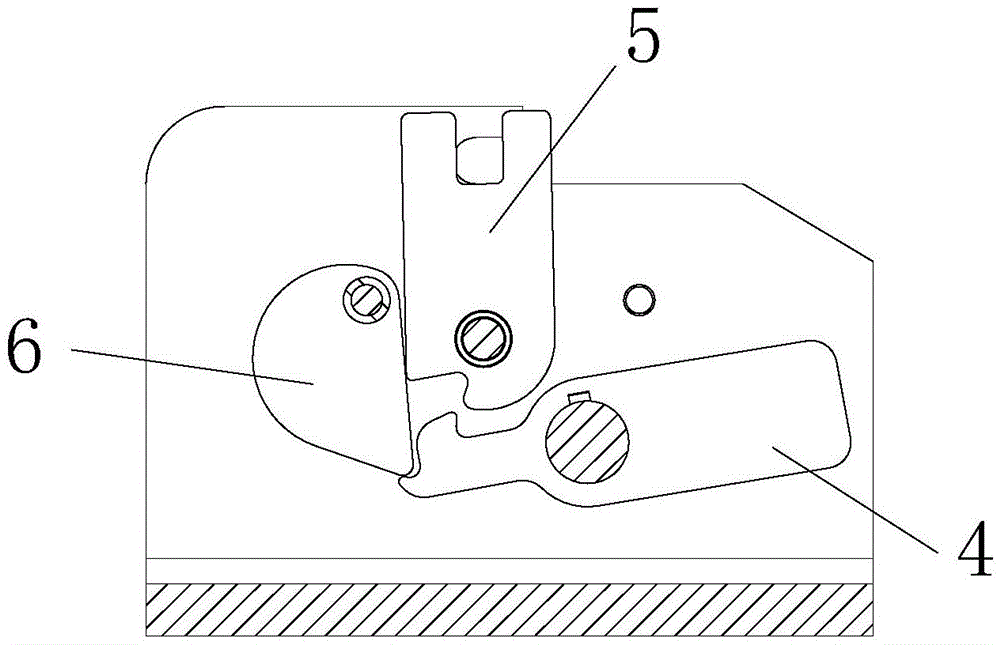

A self-locking mechanical lock relying on gravity

The invention discloses a gravity-based self-locking mechanical lock, which includes a base (1), a housing A (2), a housing B (3), a main lock hook (4), a lock block (5) and an auxiliary lock hook. (6), shell A (2) and shell B (3) are symmetrically arranged on the base (1), and the main lock hook (4), lock block (5) and auxiliary lock hook (6) are all installed on the shell Between A (2) and housing B (3); the bottom of the lock block (5) is provided with a first hook (7), and one end of the main lock hook (4) is provided with a second hook (8) and a third hook. (9), the auxiliary lock hook (6) is provided with a fourth hook (10), the first hook (7) matches the second hook (8), the third hook (9) matches the fourth hook (10) Cooperate. The invention can realize locking and unlocking within a small stroke range, has the advantages of simple structure and convenient unlocking, and greatly improves the stability of the mechanical lock.

Owner:NORTHEASTERN UNIV LIAONING

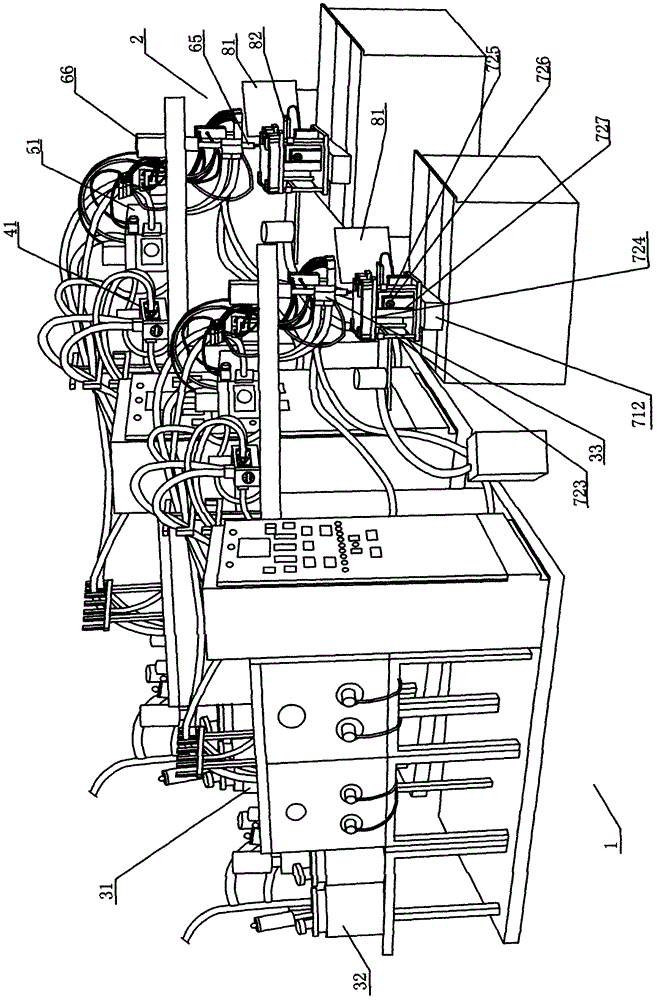

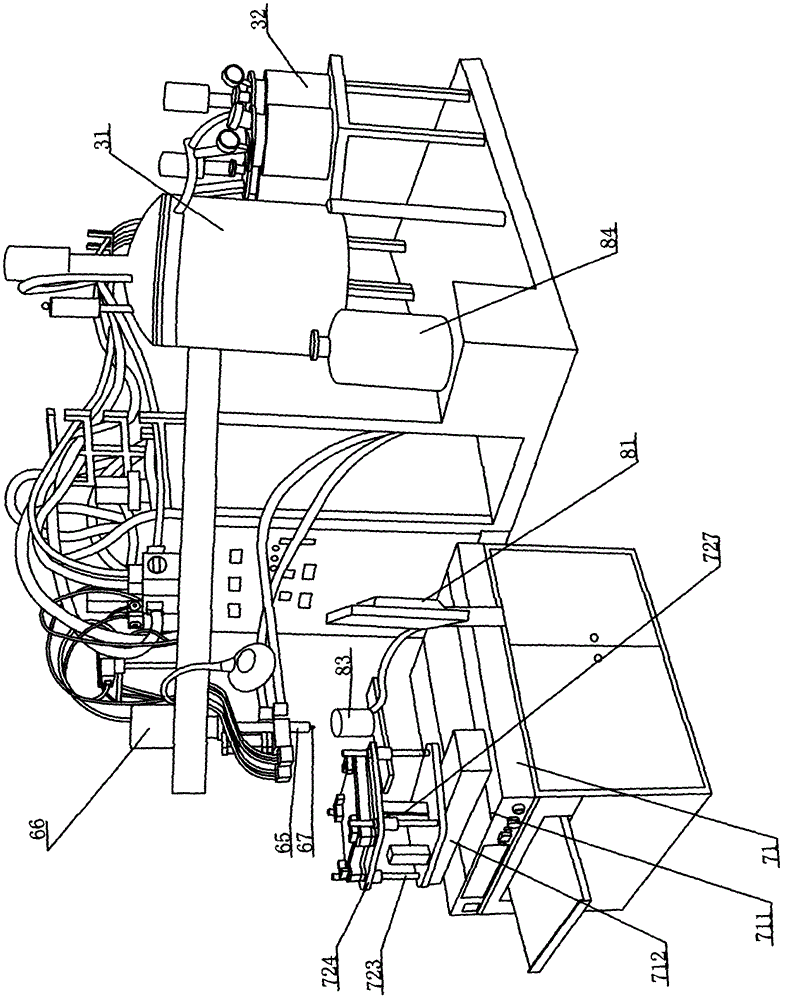

Color paste switching device of micro-scale polyurethane elastomer pouring machine

ActiveCN102653118BAvoid separationSolve the lack of hardnessDomestic articlesNumerical controlPolyurethane elastomer

Owner:海盐县于城丝绸印染股份有限公司

Crankshaft turning tool and method of turning a crankshaft

ActiveCN105258667BSimple structureEasy to useMeasurement devicesReciprocating piston enginesElastic componentEngineering

The present invention discloses a crankshaft rotation tool, comprising a locating block and a handle connected with the locating block, wherein the locating block comprises a main locating block and two auxiliary locating blocks arranged at two sides of the main locating block, each auxiliary locating block is provided with an elastic component used for being tightly contacted with an excircle of a big end of a crankshaft, and the main locating block is provided with a locating hole used for cooperating with a locating pin at the end face of the big end of the crankshaft. The present invention aims to provide the crankshaft rotation tool which is simple in structure, convenient and reliable in use, and capable of forwards and reversely rotating the crankshaft, at the same time, the present invention also provides a method for rotating the crankshaft by adopting the crankshaft rotation tool.

Owner:GUANGXI YUCHAI MASCH CO LTD

Semiconductor device, production method for the same, and substrate

ActiveUS7902681B2High bonding strengthAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSemiconductor chip

Owner:ROHM CO LTD

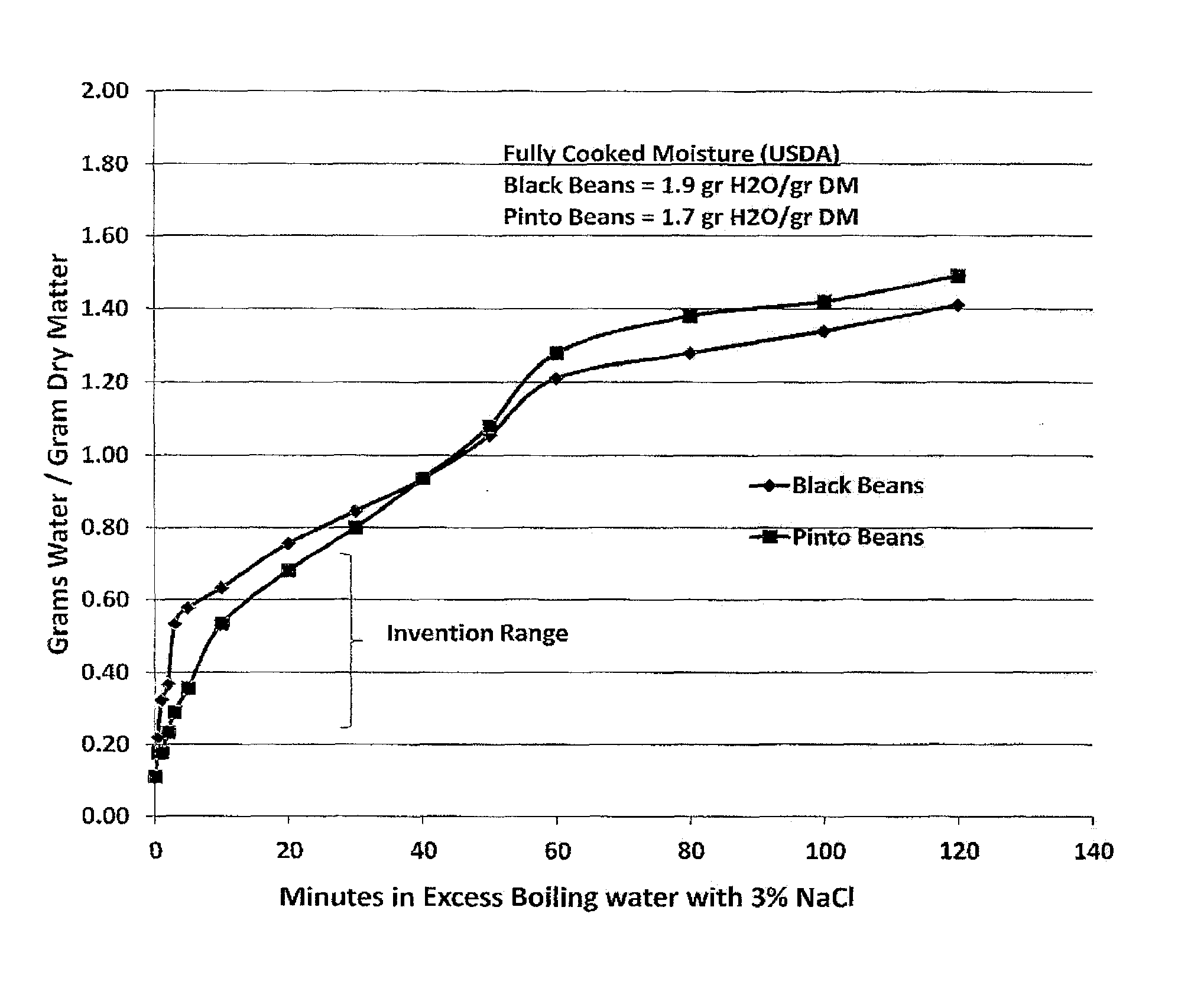

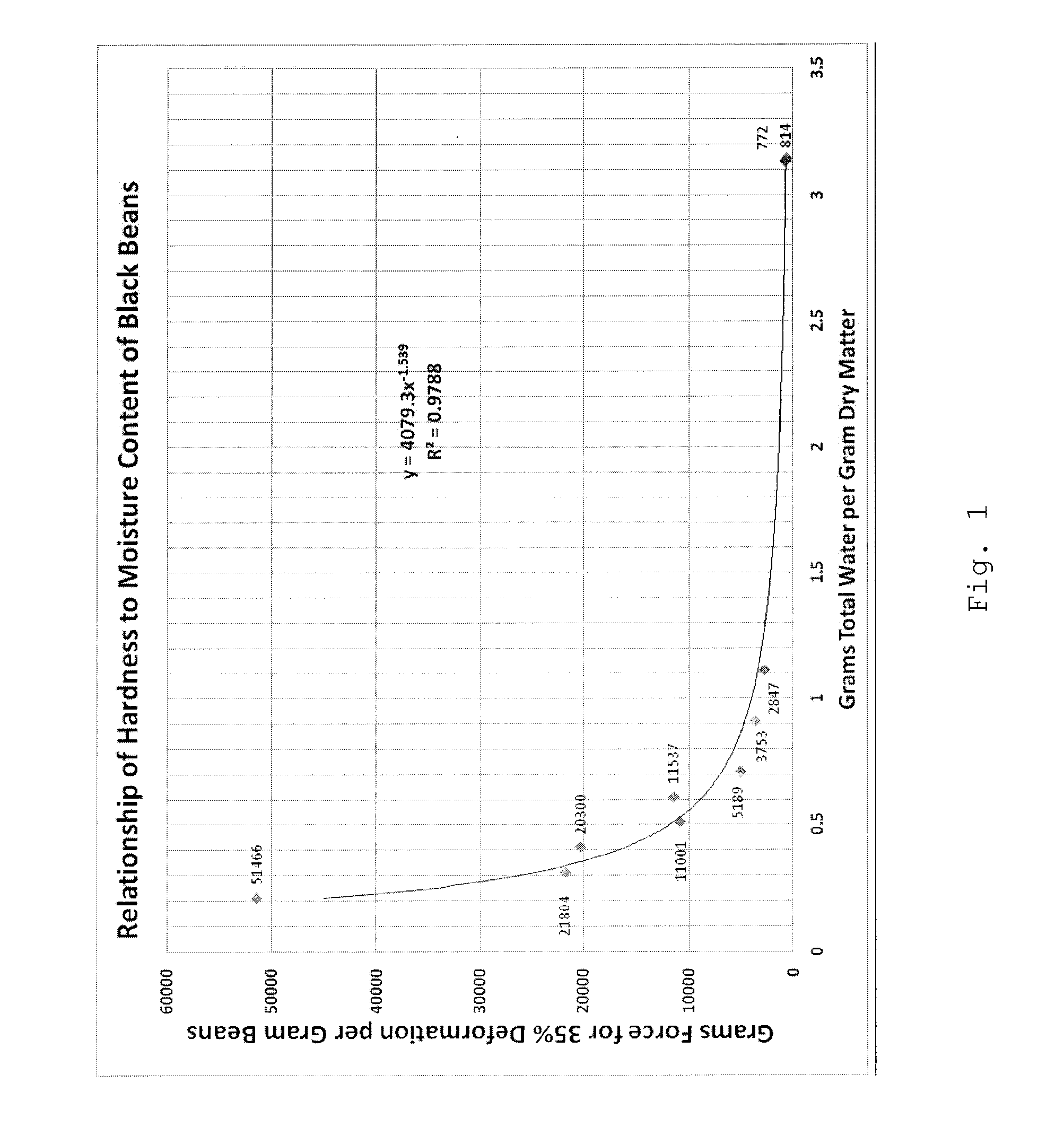

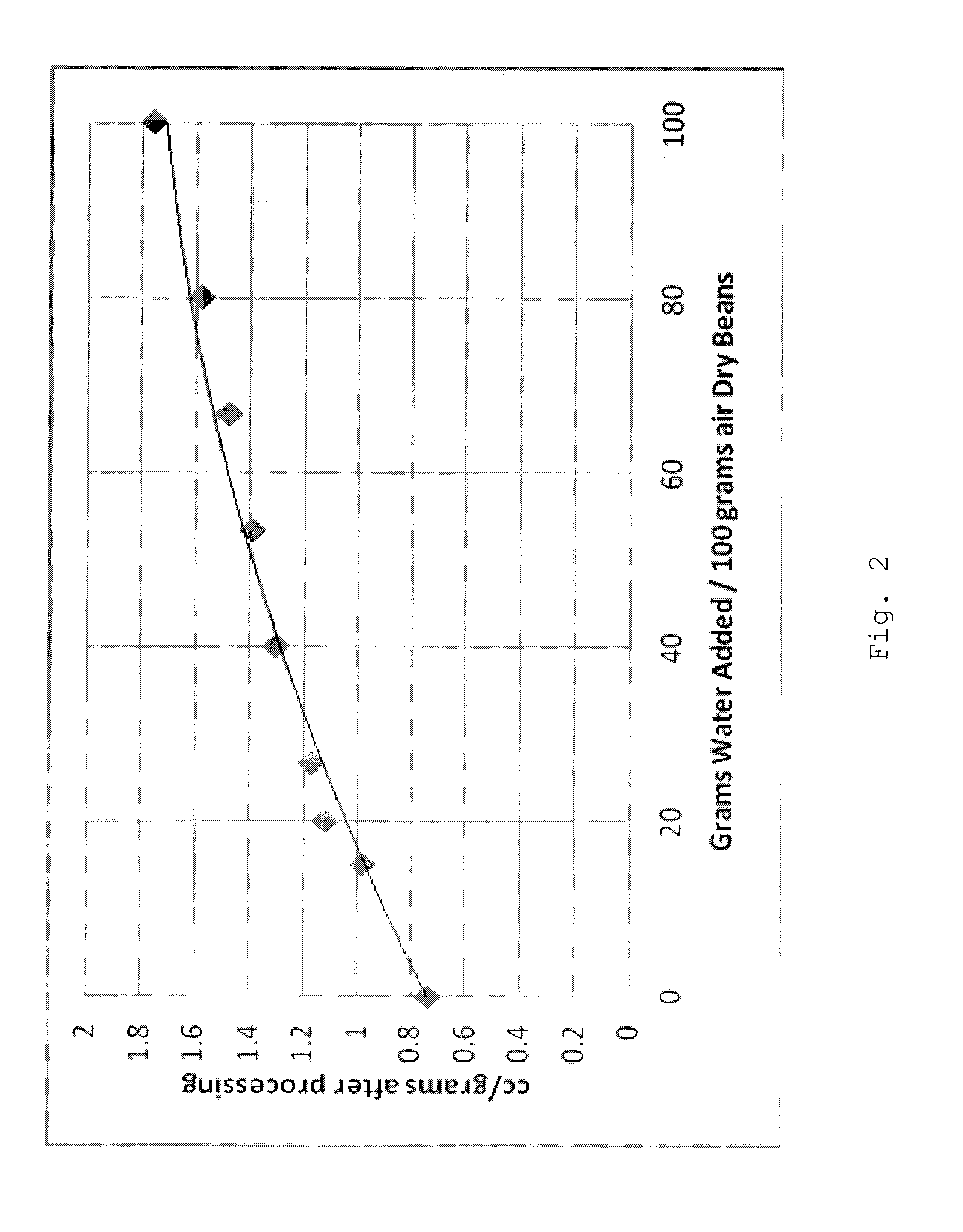

Thermally processed seed product and method

A food product and method are provided. The food product includes a pulse having a total water content below that of a fully hydrated pulse and a chewier texture. It is formed from a dry pulse and is hydrated, but only partially, resulting in a total water content in the range of between about 0.25 grams water / gram dry matter and about 0.75 grams water per gram dry matter. The pulse is in an intact form and has not been fully hydrated after harvest.

Owner:VISTA INNOVATION

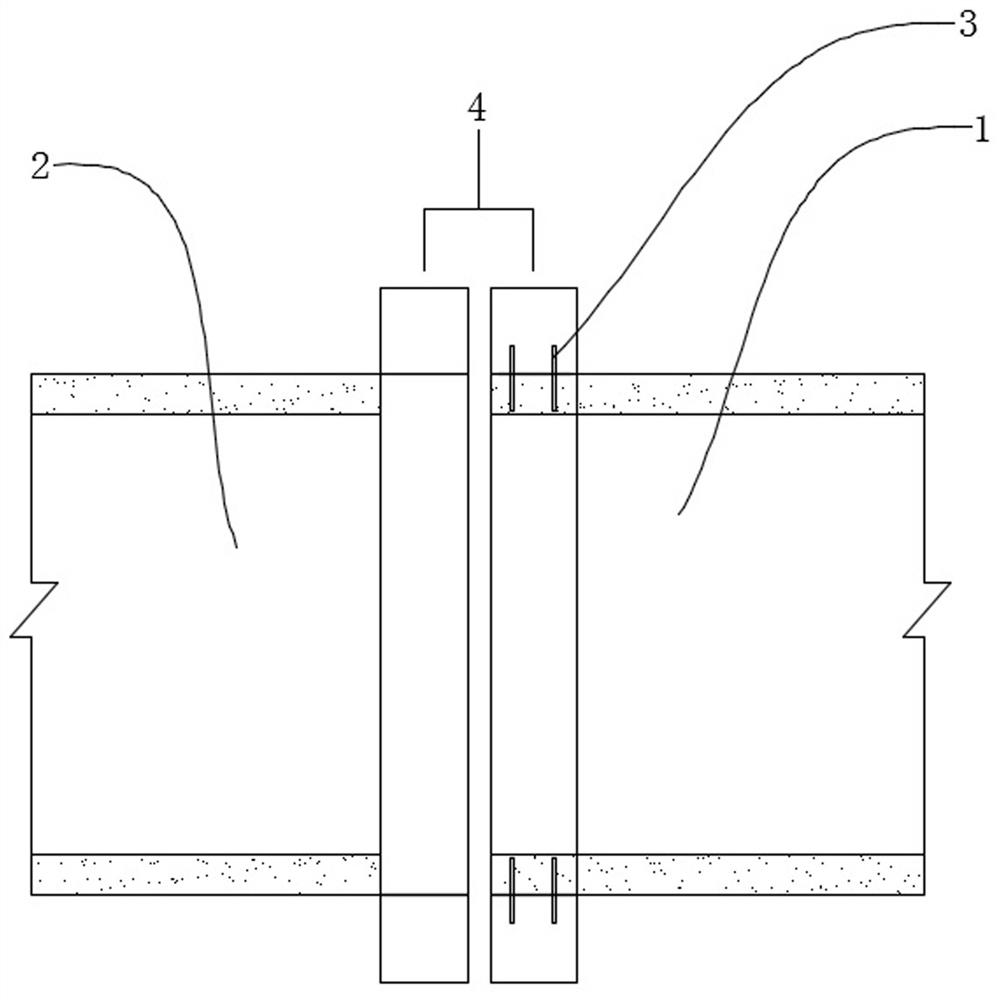

Connecting method for waterproof settlement joint at junction of new box culvert and old box culvert

PendingCN114059459ABite firmlyEasy to placeArtificial islandsGround-workReinforced concreteArchitectural engineering

The invention discloses a connecting method for a waterproof settlement joint at the junction of a new box culvert and an old box culvert, the connecting method is applied to connecting an old box culvert channel with a new box culvert, and embedded steel bars are arranged in the old box culvert through chiseling; the end of the new box culvert is arranged to be of a protruding structure, newly-built reinforced concrete ring walls are arranged at the protruding position of the new box culvert and the scabbled position of the old box culvert through embedded steel bars, a settlement joint is formed between the two newly-built reinforced concrete ring walls, framework steel bars are bound between the two newly-built reinforced concrete ring walls, and a middle-buried type rubber water stop belt and a foam board of the settlement joint are arranged in the framework steel bars. A gap is reserved between the two newly-built reinforced concrete ring walls, the newly-built reinforced concrete ring walls are subjected to concrete pouring and maintenance, and the old box culvert is subjected to chiseling and rebar planting treatment, so that the newly-poured reinforced concrete ring walls and the old box culvert are firmly engaged to form a stress whole. The reinforced concrete ring wall is arranged on the periphery of the old box culvert, and the ring wall is arranged at the end of the new box culvert in a protruding mode, so that connection of the new box culvert and the old box culvert can be effectively converted into connection of the new box culverts.

Owner:HUALAN DESIGN GRP CO LTD

One-time bidirectional umbilical cord cutter

ActiveCN101856253BInconvenient to useBlock slide outObstetrical instrumentsEngineeringUmbilical cord

The invention provides an improvement on a conventional one-time bidirectional umbilical cord cutter. The one-time bidirectional umbilical cord cutter comprises that: an upper shell is provided with a side semi-convex sphere for preventing upper and lower shells from being closed upon a slight external force; one end of a stop body is provided with a stop lever for preventing the umbilical cord from sliding out of an open end of an umbilical clamp; the inner side of a convex pin of the lower shell is provided with an upright semi-convex sphere which is occluded with a spherical groove on the bottom surface of a lower clamping arm and used for preventing the umbilical clamp from transversely slipping; the bottom of the lower shell is provided with a handle for firmly gripping the umbilicalcord cutter; the head of an upper clamping arm is provided with a longitudinal flat hole into which hold-down sheets at the two ends of a cross bar of the upper shell are inserted, so that the upper clamping arm and the hold-down sheets are more firmly positioned and occluded; a clamping hook of the upper clamping arm is firmly occluded with a concave platform in the clamping arm groove of the lower clamping arm, so that the upper clamping arm and the lower clamping arm are more firmly closed; a blade is movably arranged on a blade fixing frame through two conjoined elastic split convex pins and is convenient to separate; and when the blade is disassembled, the umbilical cord cutter is completely made of plastic, so the cutter can be recycled as waste plastic.

Owner:江西易通医疗器械有限公司

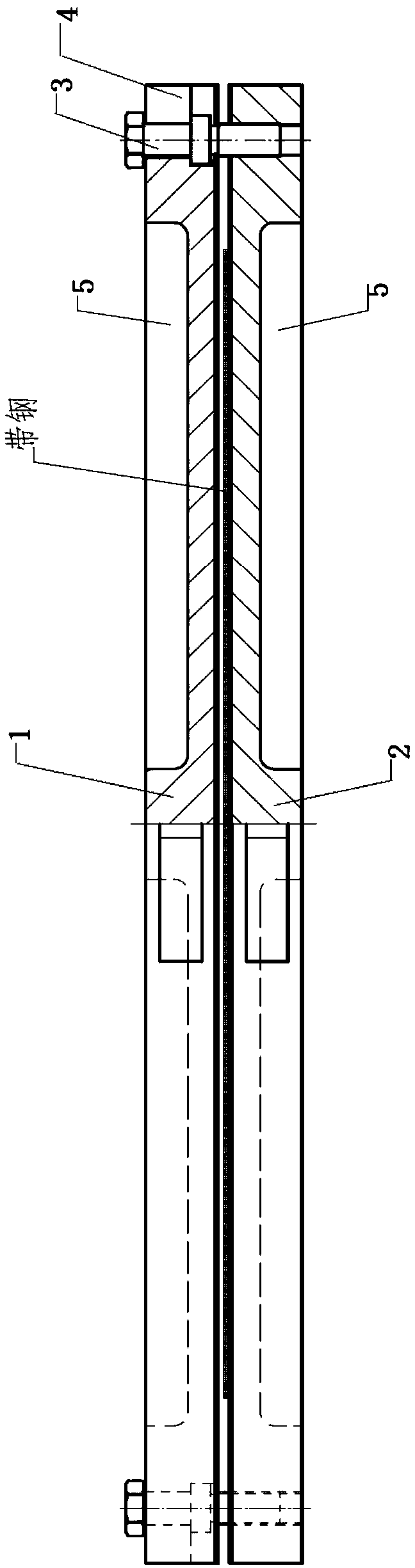

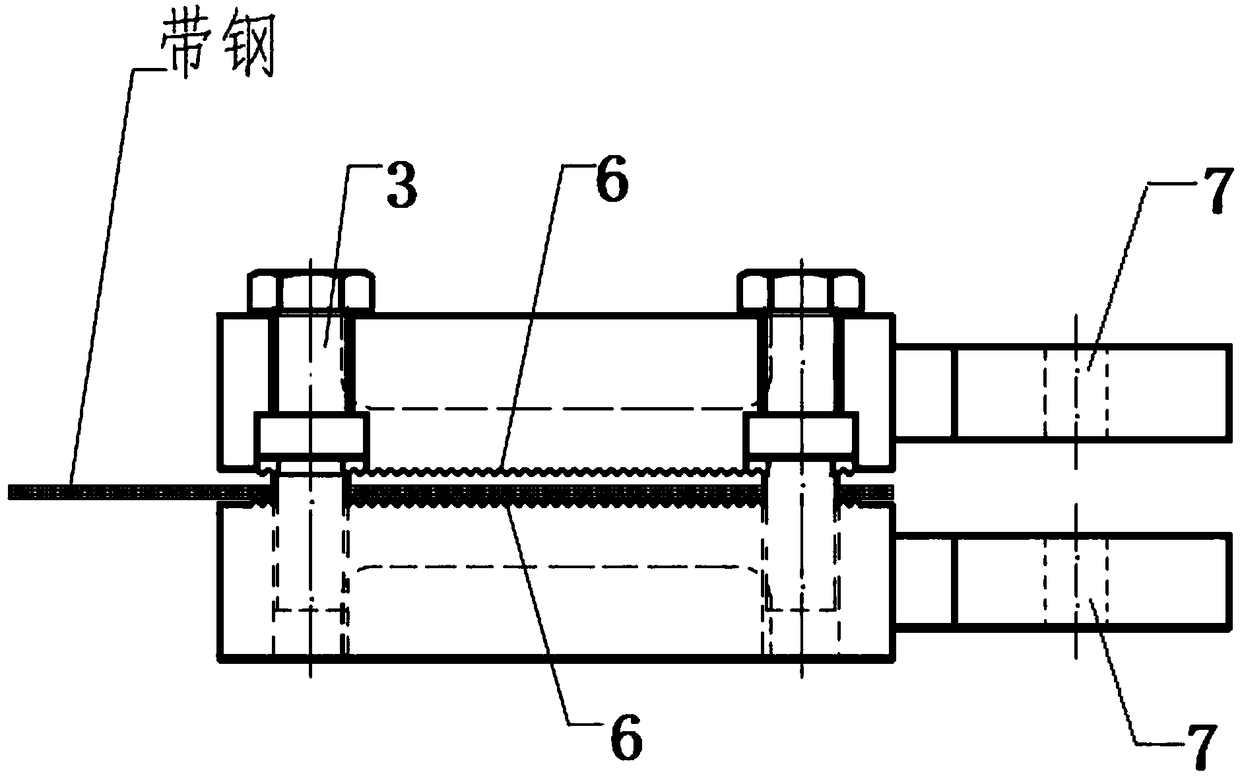

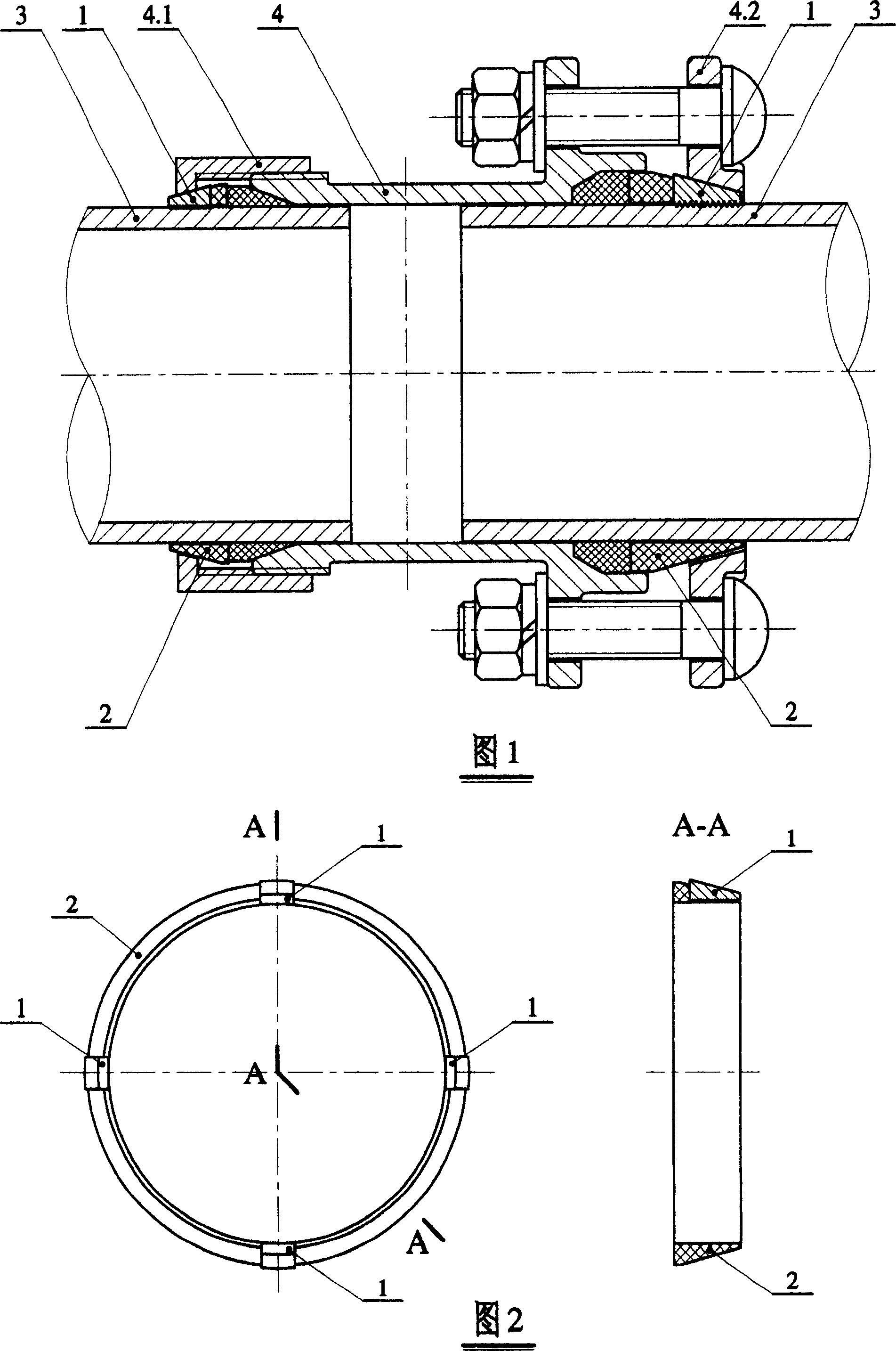

Clamping device for band penetration

PendingCN108435805AShorten the lengthBite firmlyMetal rolling arrangementsArchitectural engineeringEngineering

The invention relates to a clamping device for band penetration. The clamping device for band penetration comprises an upper clamping plate, a lower clamping plate and adjusting bolts. Antiskid teethare arranged on the clamping surface of the upper clamping plate. Antiskid teeth are arranged on the clamping surface of the lower clamping plate. The antiskid teeth of the upper clamping plate and the antiskid teeth of the lower clamping plate are arranged in a mutually staggered manner. A band penetration rod connecting hole is formed in the front of the upper clamping plate. A band penetrationrod connecting hole is formed in the front of the lower clamping plate. The band penetration rod connecting holes are formed in a mutually opposite manner. A front U-shaped groove and a rear U-shapedgroove are formed in each of the left end face and the right end face of the upper clamping plate. Threaded holes corresponding to the U-shaped grooves one to one are formed in the lower clamping plate. Each U-shaped groove is in the shape of a two-step stair, and the upper step part of the U-shaped groove is narrower than the corresponding lower step part. Each adjusting bolt is provided with a bolt head on the upper part and a convex edge in the middle, and the lower part of the adjusting bolt is matched with the corresponding threaded hole. The bolt head part of each adjusting bolt covers the top surface of the upper clamping plate. The convex edge of each adjusting bolt is in clearance fit with the lower step part of the corresponding U-shaped groove. When each bolt head is tightened,the bolt head drives the upper clamping plate to move downwards to clamp band steel, and when each bolt head is turned reversely, the corresponding convex edge drives the upper clamping plate to moveupwards so as to release the band steel. The clamping device for band penetration is high in efficiency, higher in yield, free of noise, low in cost and convenient to use.

Owner:WISDRI ENG & RES INC LTD

Gravity-based self-locking type mechanical lock

Owner:NORTHEASTERN UNIV

Velcro cavity type glass brocade brick and manufacturing method and equipment thereof

InactiveCN112142300AImprove performanceSuitable for flexibilityConstruction materialGlass shaping apparatusFiberBrick

The invention relates to a Velcro cavity type glass brocade brick and a manufacturing method and equipment. The Velcro cavity type glass brocade brick comprises a brick body, a sticking surface and adecorative surface, and is characterized in that the sticking surface is provided with a Velcro cavity, the Velcro cavity is of a structure with a large inner cavity and a small opening, and bubbles or light particles and reinforced anti-cracking nets and / or reinforced anti-cracking fibers are distributed in the brick body. The material is glass or a mixed material taking glass as a cementing material or microcrystalline glass. The glass brocade brick has the advantages that during construction, the adhesive mortar is embedded into the Velcro cavity of the sticking surface, just like a plurality of or a plurality of anchor bolts are formed on the sticking surface, so that the glass brocade brick is firmly and reliably embedded and occluded on a wall surface. The bonding mortar embedded into the Velcro cavity has high strength, proper flexibility and toughness, can effectively release the thermal expansion stress and deformation stress of the glass brocade brick, and provides conditionsfor selecting a flexible caulking material, thereby thoroughly solving the industry stubborn problem that similar products are easy to fall off. Especially, the weight per square meter of a light product is about 5Kg / m<2> to 8Kg / m<2> and is only about half of the weight of a glazed tile, and the excellent quality of the glass brocade brick is better manifested when used for bonding a basic soft external wall thermal insulation surface.

Owner:许浒

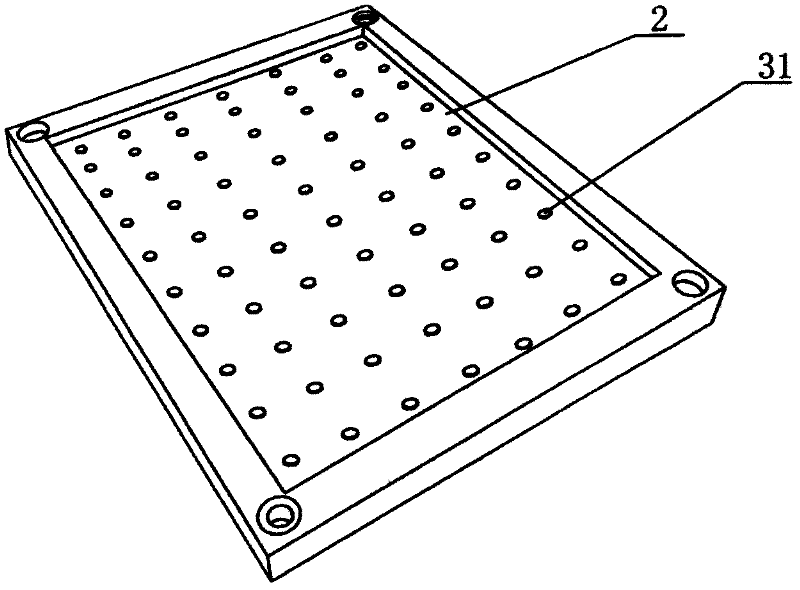

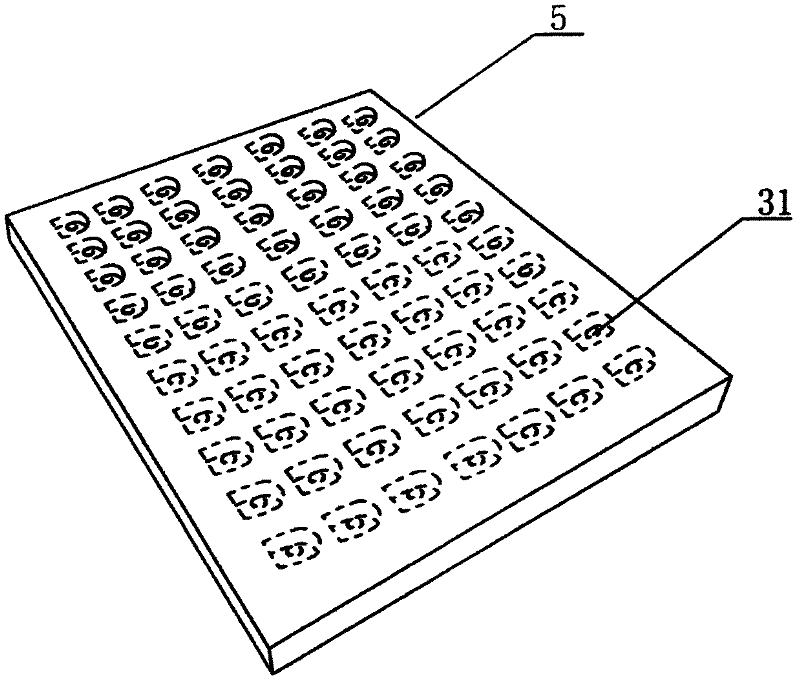

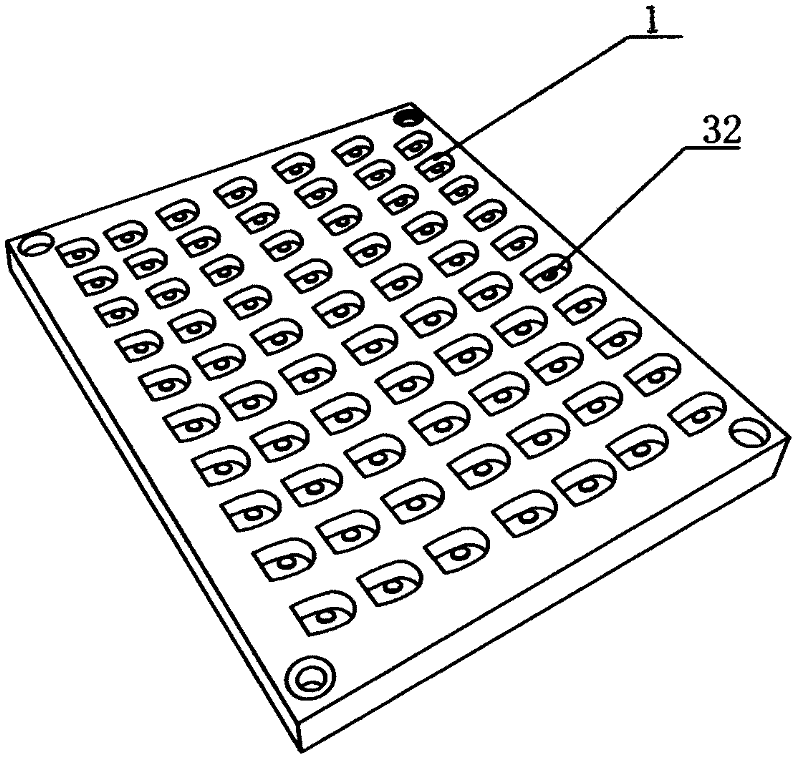

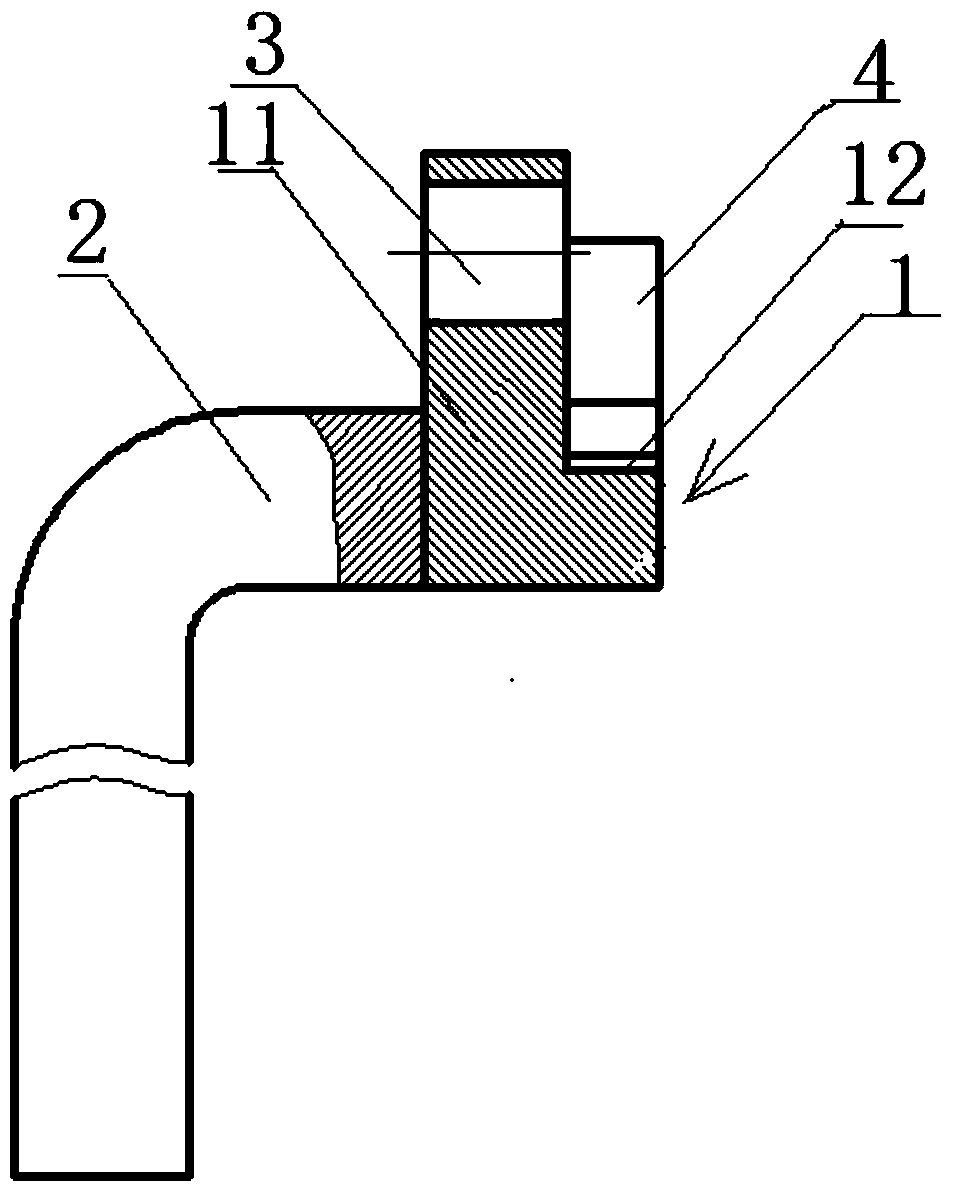

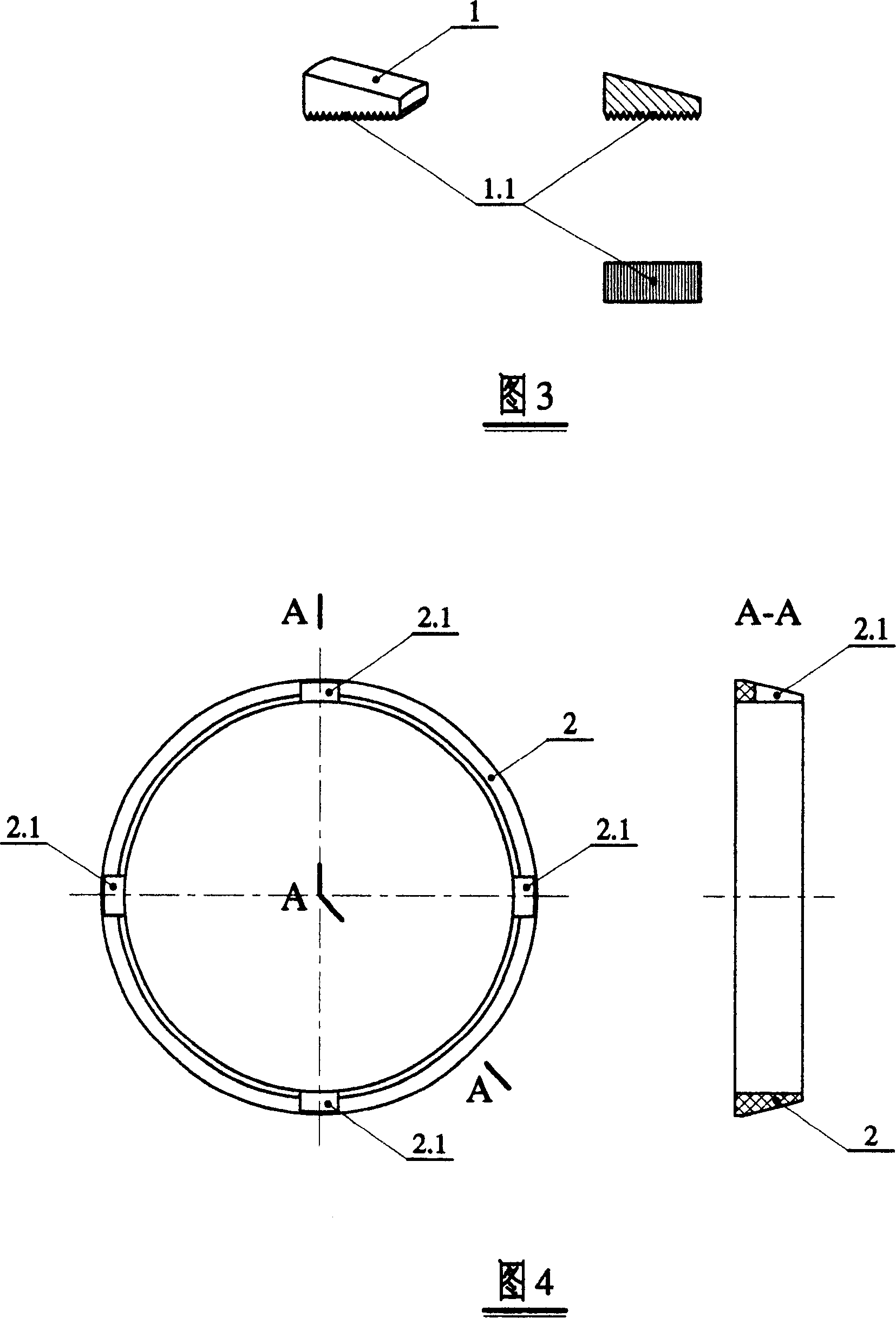

Method for connecting wedged cone shaped tooth block combination locking pipe

InactiveCN1333196CRealize locking connectionEasy to processSleeve/socket jointsCone-shaped teethPipe fitting

The invention relates to a connection method of wedge taper shaped tooth block combination lock pipeline. It realizes the lock connection function between the fast install pipe fitting and the pipeline by the tooth inside the wedge taper shaped tooth block biting the out surface of the pipeline. The connection component includes wedge taper shaped tooth block, tooth block supporting, pipeline, and fast install pipeline component. Several wedge taper shaped tooth blocks are embedded into the break that is obligated in the tooth block pipeline. Covering the circle tooth block supporting onto the pipeline as the lock component matched to the fast install pipeline component and biting the out surface of the pipeline, the lock connection function would be realized between the fast install pipeline component and the pipeline. The invention is easy to machine, and cost low.

Owner:葛文宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com