Clamping device for band penetration

A clamping device and belt threading technology, used in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of time-consuming, high noise, waste, etc., and achieve the effect of broad market prospects and huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments.

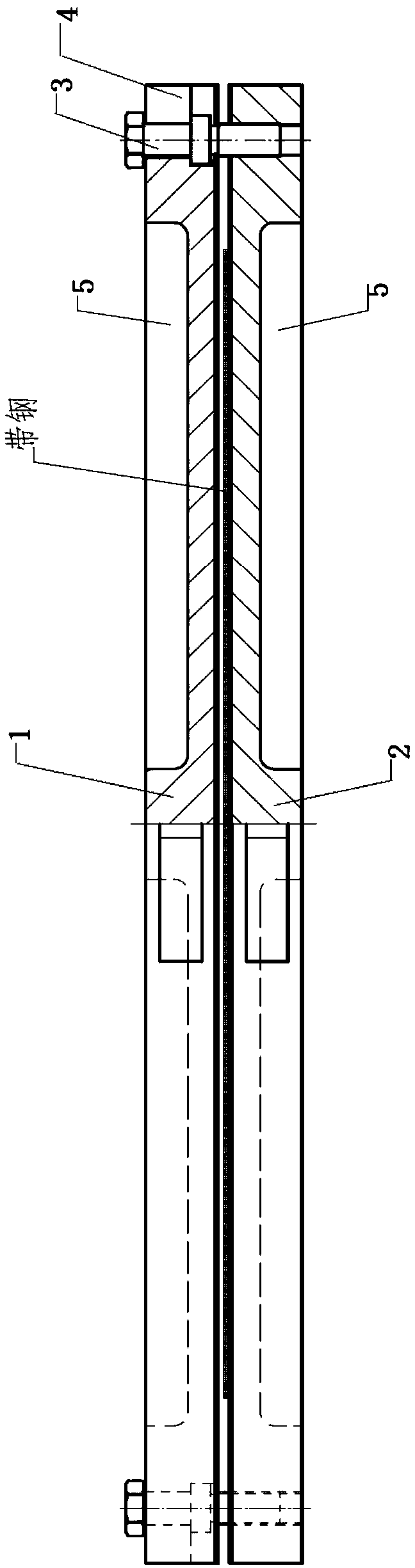

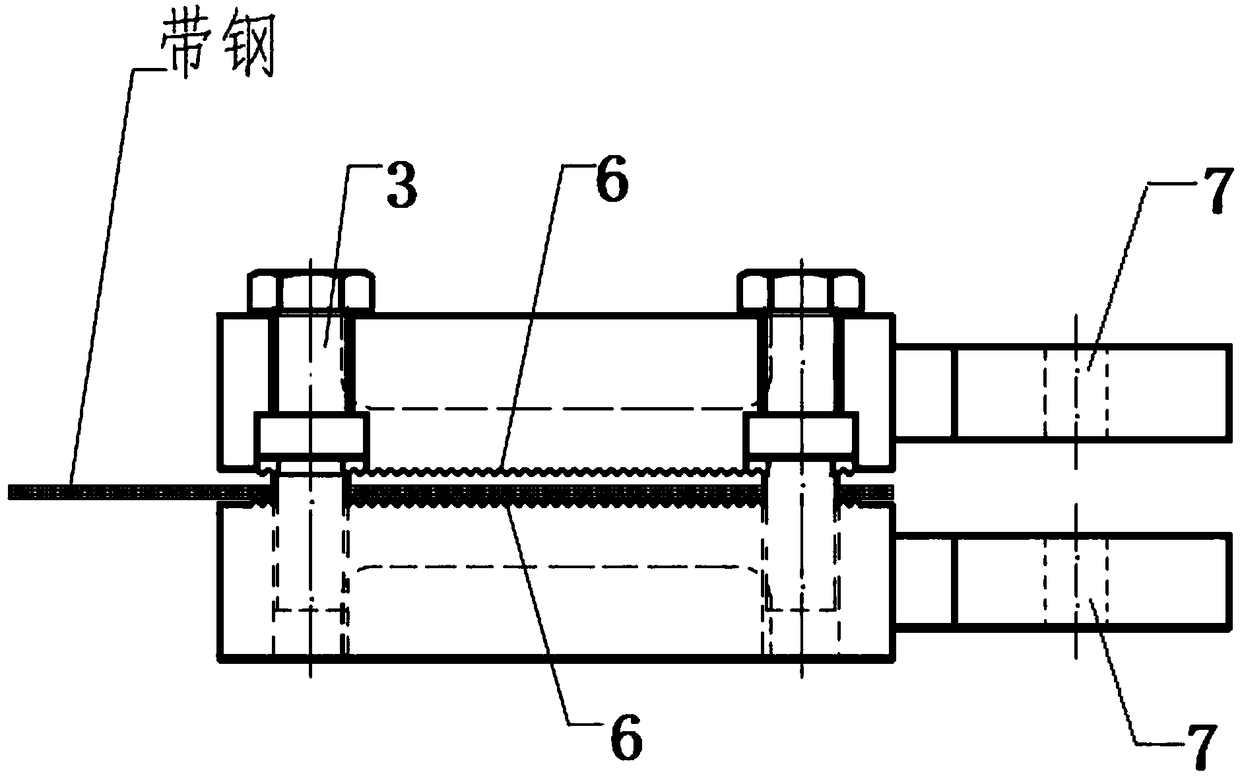

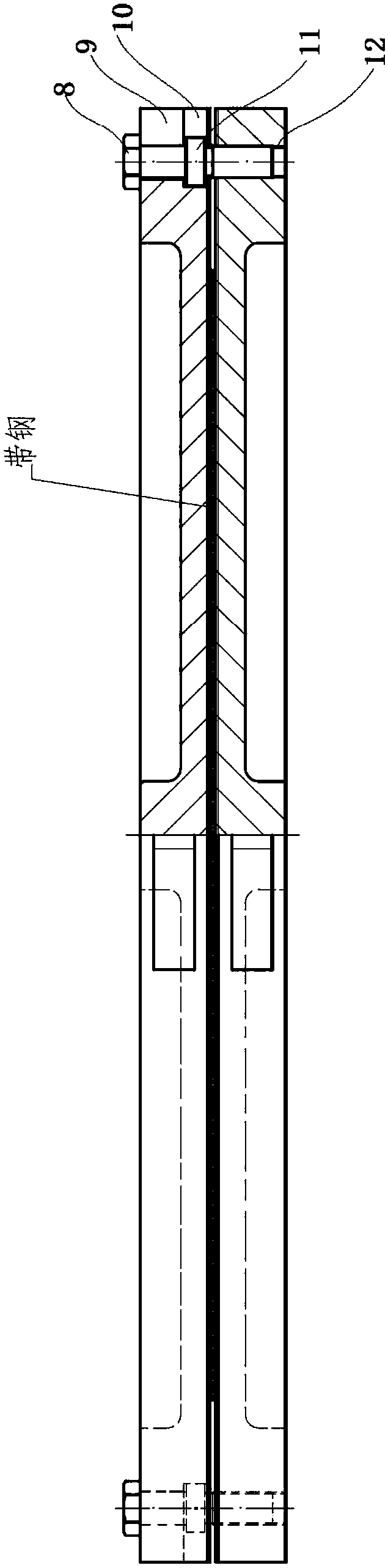

[0022] like Figure 1 to Figure 6 As shown, a belt clamping device includes an upper clamp 1, a lower clamp 2 and an adjustment bolt 3, the clamping surfaces of the upper clamp 1 and the lower clamp 2 are provided with mutually staggered anti-skid teeth 6, the upper clamp 1 and the lower clamp The front part of the splint 2 is provided with the connecting holes 7 facing each other, the left and right end surfaces of the upper splint 1 are respectively provided with two U-shaped grooves 4, front and rear, and the lower splint 2 is provided with a one-to-one correspondence with the U-shaped grooves 4. The threaded hole 12, the U-shaped groove 4 is in the shape of a second step and the upper part 9 is narrower than the lower part 10; The bolt head 8 partially covers the top surface of the upper splint 1, and the flange 11 is in clearance fit with the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com