Velcro cavity type glass brocade brick and manufacturing method and equipment thereof

A production method and cavity technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve problems such as glass mosaic tiles are easy to fall off, and achieve crystal clear decorative effects, excellent quality, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

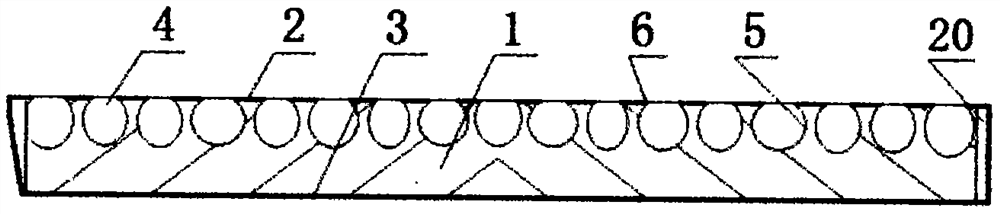

[0044] Embodiment one, such as Figure 1 , Figure four , Figure five , Figure six Shown:

[0045] 1. An adhesive cavity type glass mosaic tile, which is composed of a brick body (1), an adhesive surface (2), and a decorative surface (3), and is characterized in that: the adhesive surface (2) is provided with an adhesive cavity (4 ), the fastening cavity (4) is a structure with a large inner cavity (5) and a small opening (6), and the periphery of the brick body (1) is provided with an occlusal opening (20).

[0046] 2. When making, first put the glass raw material (11) into the mold (12);

[0047] 3. Place the mold (12) in a heating kiln or furnace (13), and gradually heat up to 600°C-850°C or 850°C-1000°C or 1000°C-1500°C, so that the glass raw material ( 11) hot melting is molten glass raw material (11-1);

[0048]4. Form a plurality of or Numerous bubbles (7);

[0049] 5. Control the viscosity of the molten glass raw material (11-1) by adjusting the temperature a...

Embodiment 2

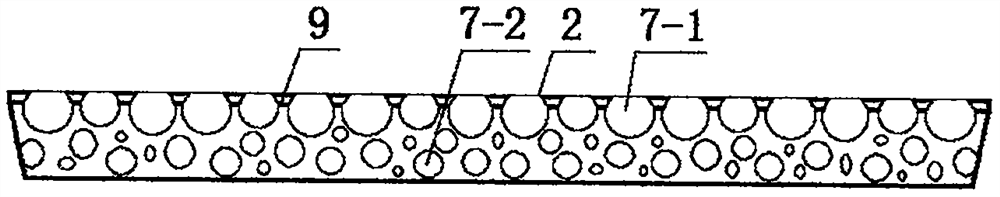

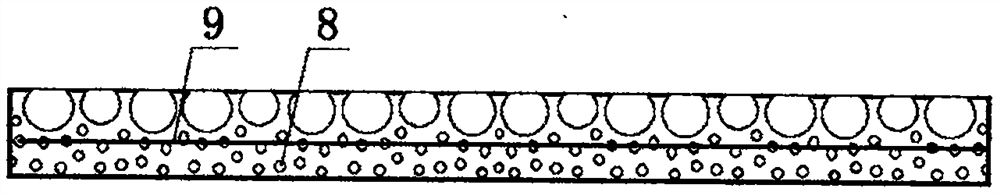

[0052] Embodiment two, such as Figure II , Figure three Shown, in conjunction with embodiment one:

[0053] 1. Air bubbles (7) or light particles (8) are distributed in the brick body (1), and the brick body (1) and / or the pasting surface (2) are equipped with reinforced anti-cracking nets and / or reinforced Crack-resistant fibers (9).

[0054] 2. During production, place reinforced anti-cracking mesh and / or reinforced anti-cracking fiber (9) on the lower part or middle part or upper part of the glass raw material (11) put into the mold (12);

[0055] 3. Place the mold (12) in a heating kiln or furnace (13), and gradually heat up to 600°C-850°C or 850°C-1000°C or 1000°C-1500°C, so that the glass raw material ( 11) Hot melting into molten glass raw material (11-1), through a substance that can generate bubbles at high temperature in the molten glass raw material (11-1), or through a process that can form bubbles in the molten glass raw material (11-1) , forming numerous ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com