Method for preparing barreled product and barreled product

A product and drum packaging technology, which is applied in the direction of preventing repeated filling of containers, tanks/barrels/barrels, packaging, etc., can solve problems such as external environmental pollution, detachment of drum lids, and technical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

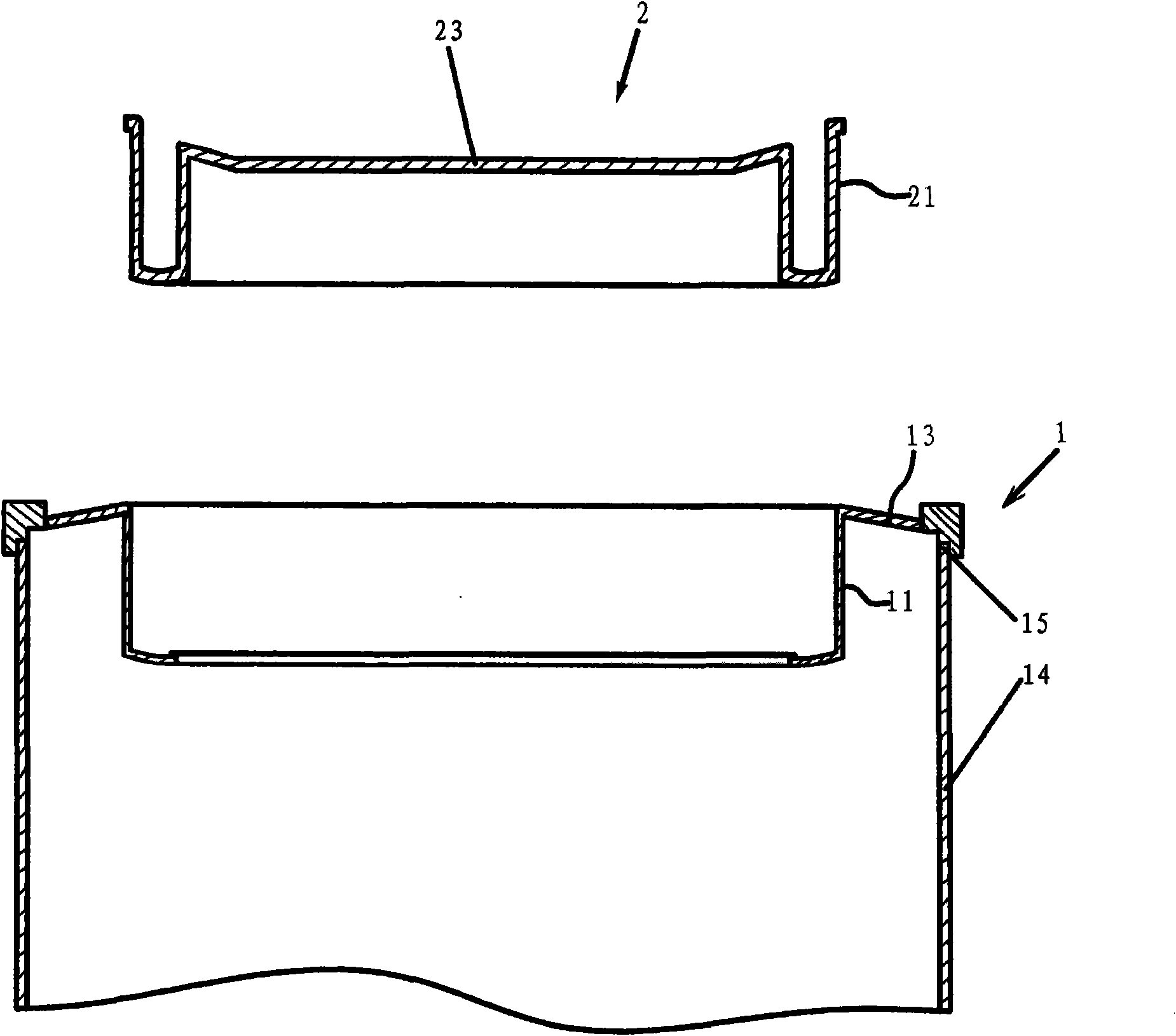

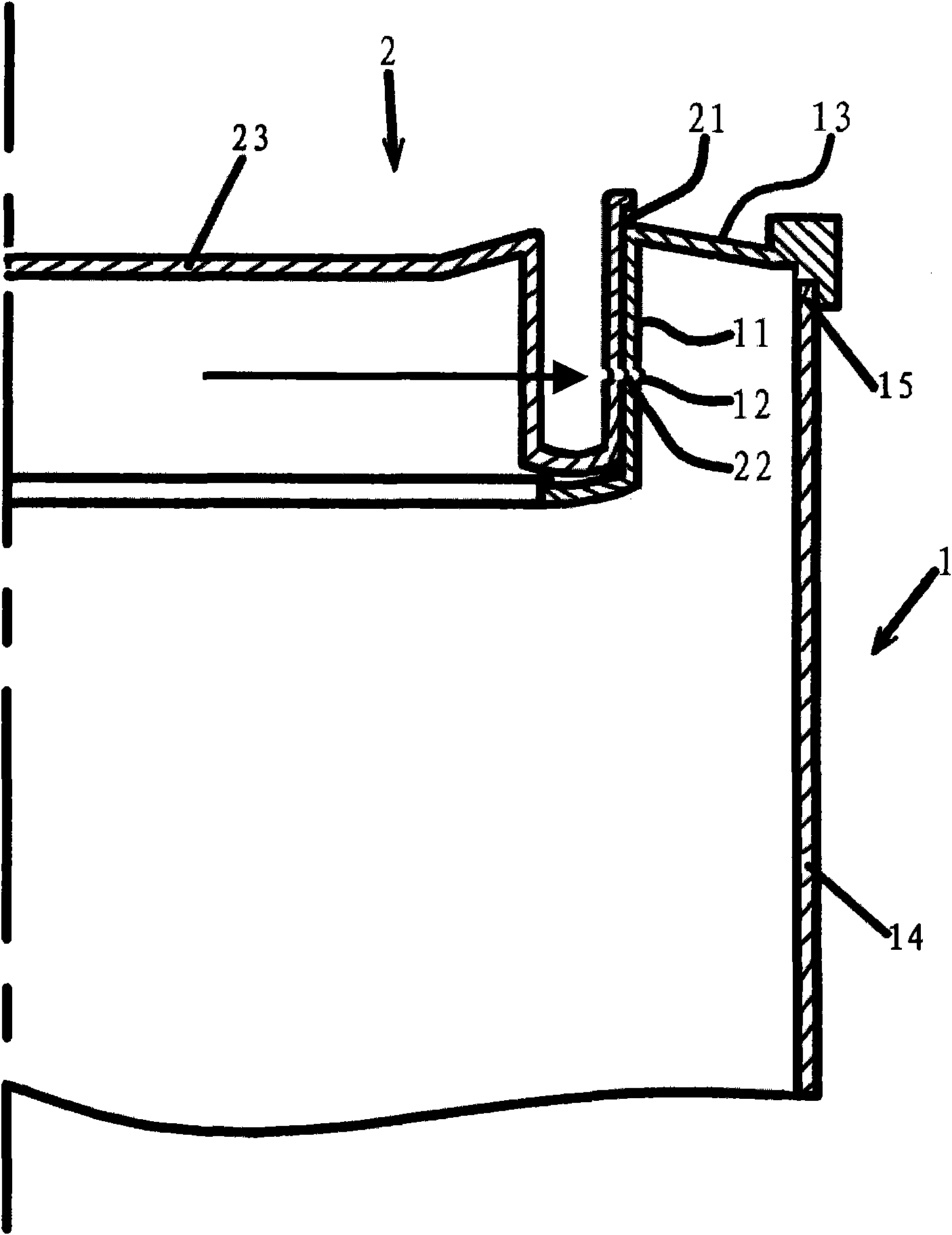

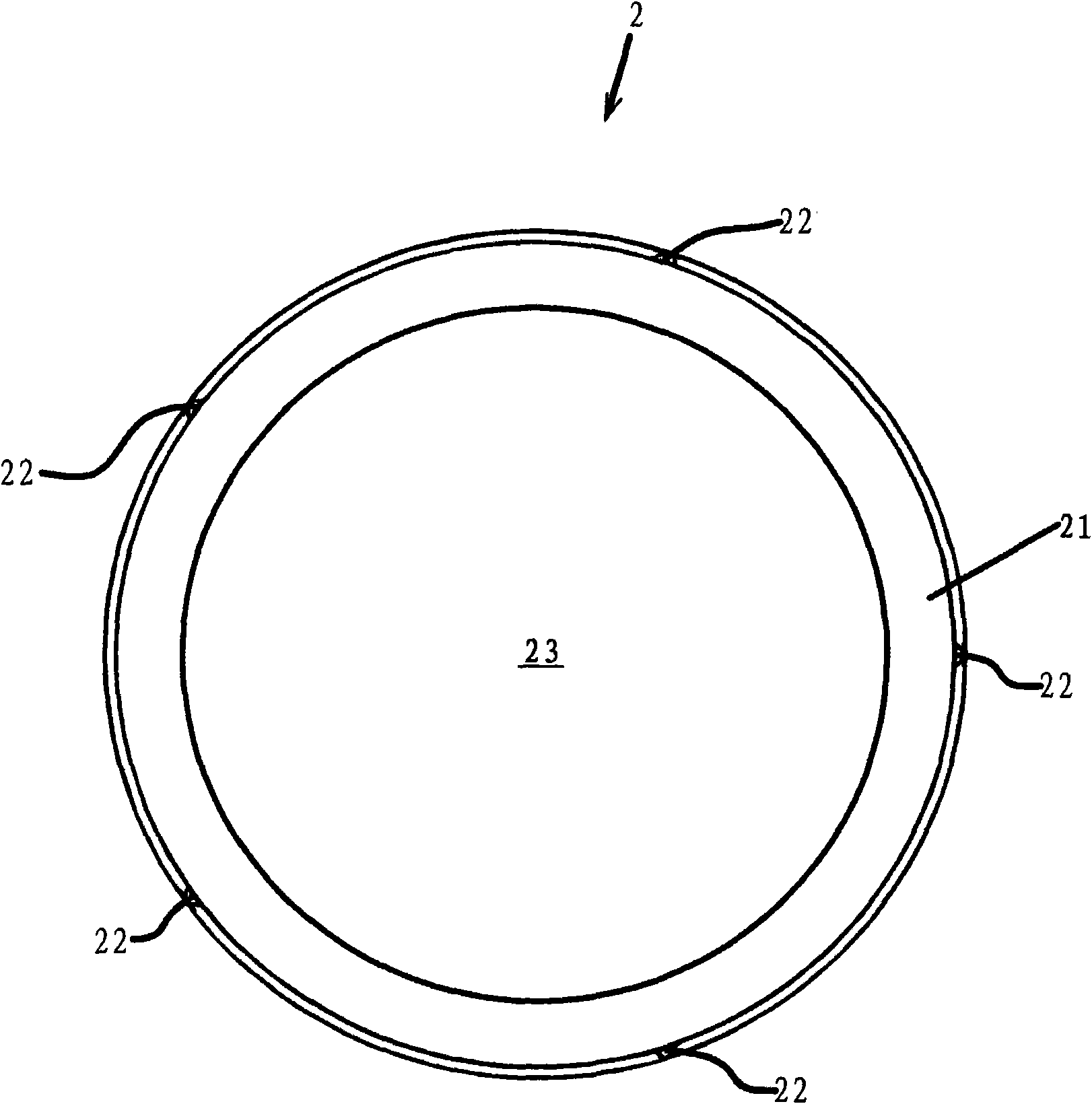

[0020] figure 1 An exploded view showing a bucket cover and a packaging bucket of a bucket product (such as a bucket paint product) according to an embodiment of the present invention. In this embodiment, the bung is circular, and the packaging bucket is cylindrical. figure 1 Shown is a cross-sectional view taken along a plane through the center axis of the lid and tub. Those skilled in the art should understand that the cross section of the bucket lid and the bucket is not limited to a circle, but can also be in any other shape, such as a square, a rectangle, and the like. Such as figure 1 As shown, the partially shown packaging bucket 1 has an opening 13 for the paint to be loaded and to cooperate with the bucket lid. The opening 13 may be a part integrally formed with the same material (for example, the same metal) as the barrel body 14 of the packaging barrel 1; The means are fixedly arranged on the barrel body 14 and adopt the same or different materials as the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com