Method for connecting wedged cone shaped tooth block combination locking pipe

A connection method and tooth block technology, which is applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems of high price, difficulty in popularization and application, complex processing technology of snap ring, etc., and achieve low price , good locking effect and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

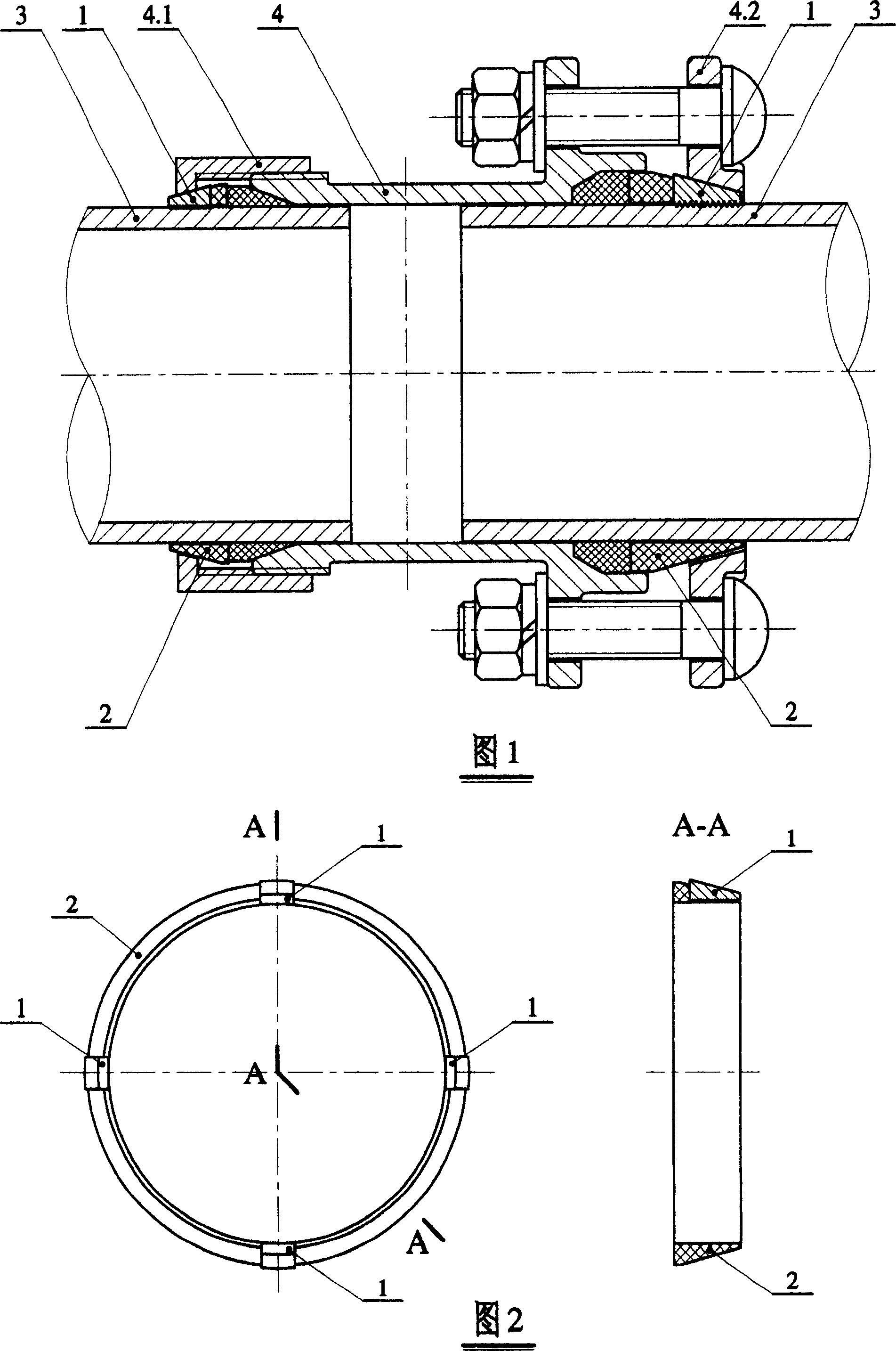

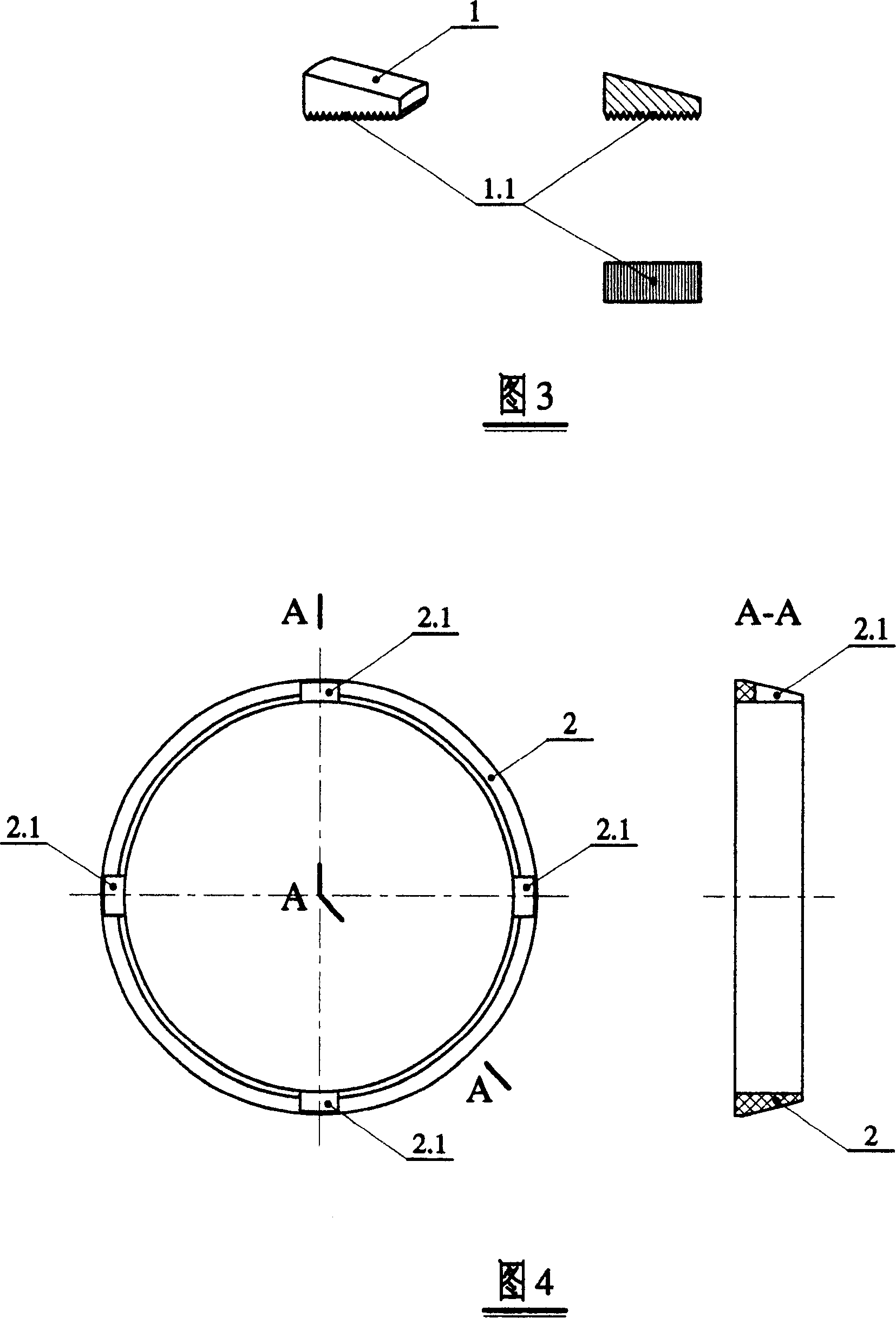

[0027] The specific implementation, structure, features and effects of the method for connecting wedge-conical tooth blocks combined locking pipelines according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0028] Please refer to Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the connection method of the wedge-conical tooth block combined locking pipeline of the present invention mainly includes the wedge-conical tooth block 1, the tooth block bracket 2, the pipe 3 and the fast Pipe fitting 4, the several wedge-shaped tooth blocks 1 are embedded in the reserved gap 2.1 of the tooth block bracket 2, and then the ring-shaped tooth block bracket 2 inlaid with wedge-shaped tooth blocks 1 is set on the pipe 3, As the locking part of the fast fitting pipe 4, the outer skin of the pipe 3 is bitten to realize the locking connection between the fast fitting pipe 4 and the pipe 3.

[0029] The above-mentioned we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com