Method for engraving heel lifts

A processing method and a technology of Tianpi, applied in the field of shoe material processing, can solve the problems of difficulty in improving the interest of female friends, and have no new ideas, and achieve the effects of increasing aesthetics, improving wear resistance, and firmly occluding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The present invention is a kind of heel top leather engraving processing method, and the steps are as follows:

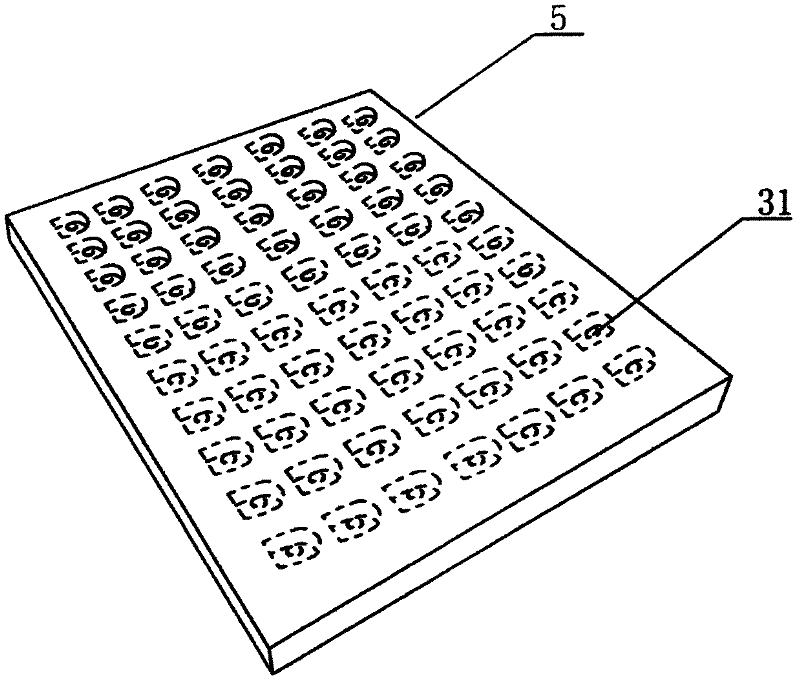

[0028] 1). The top skin nail caps 31 are pre-buried in the heel top skin mold cavity at a certain distance, and two or more mixtures of different strengths, hardnesses, and colors are poured in successively. Enter in the mold cavity, make the heel top blank, the heel top blank can be a single blank 4 that is larger than the size of the finished heel top 6,7, or a whole piece of blank plate 5;

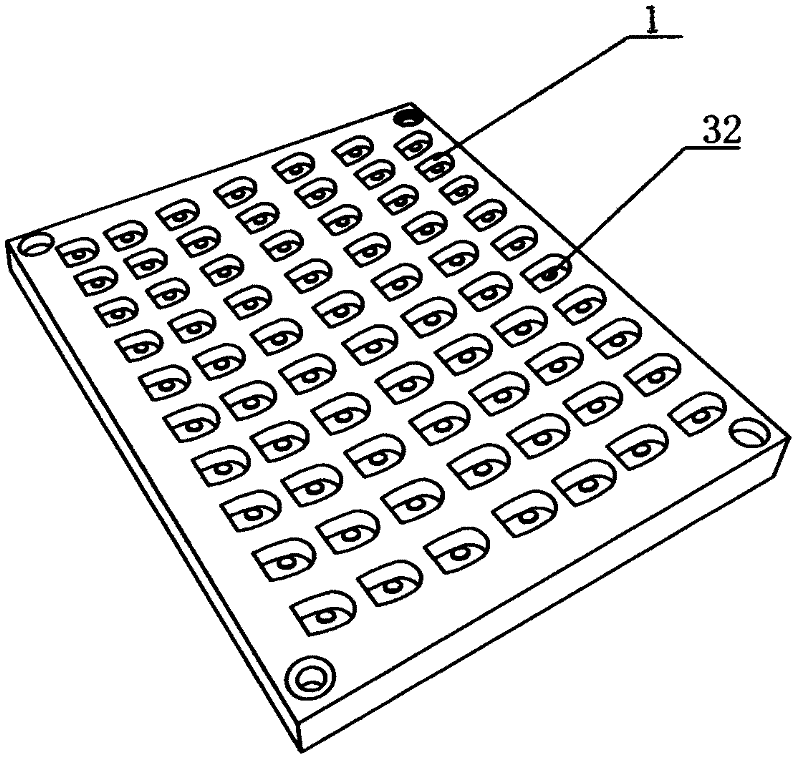

[0029] 2). The mold used can be as follows image 3 As shown, there are several open heel tops single cavity 1 arranged neatly arranged at certain intervals. The bottom of the cavity 1 is provided with a perforation, the nail rod 32 passes through the perforation, and the nail cap 31 is pre-embedded in the single cavity 1;

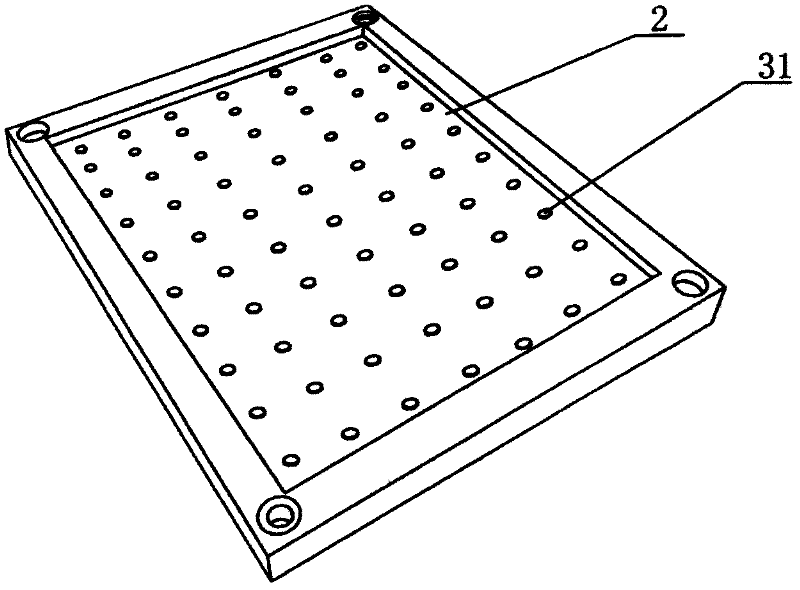

[0030] 3). The mold used can be as follows figure 1 As shown, an integral mold cavity 2 with a large area and an open mouth is pr...

Embodiment 2

[0035] Embodiment two: if adopt the mode of injection molding, 1). The top skin nail cap 31 is pre-buried in the heel top skin mold cavity at a certain interval, adopts the mode of injection molding successively, respectively puts two or more different Strength and hardness, and the mixture of different colors are injected into the mold cavity to make the heel top blank. The heel top blank can be a single blank 4 that is larger in size than the finished heel top 6, 7, or it can be A whole piece of blank plate 5;

[0036] 2). Two or more mixed raw materials are used, and each mixed raw material is first liquefied and processed in a reactor at high temperature, and then input into the barrel of the injection molding machine;

[0037] 3). Through the engraving method of the numerical control machine tool, the engraving knife engraves the heel top 6 and 7 of the required size and specifications on the single blank 4 of the heel top or the whole blank plate 5 around the top nail. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com