Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Avoid loss of precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

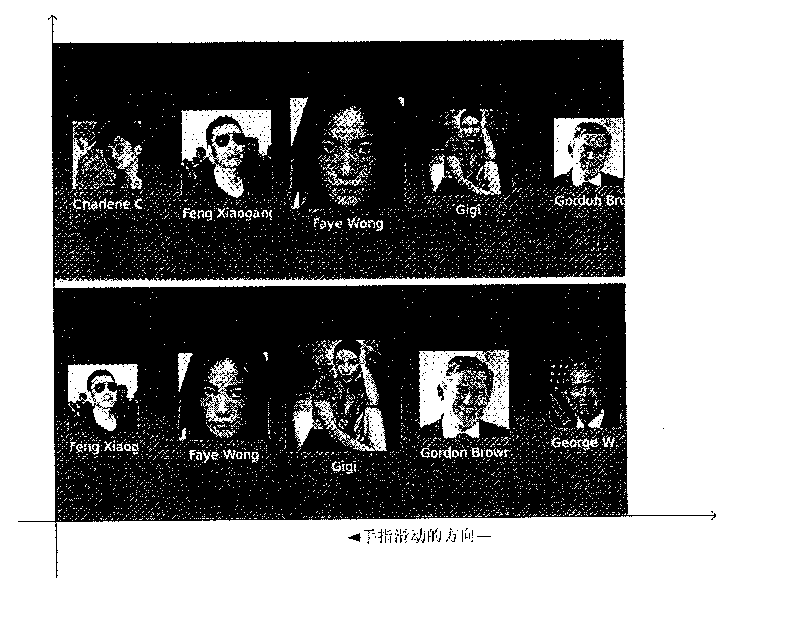

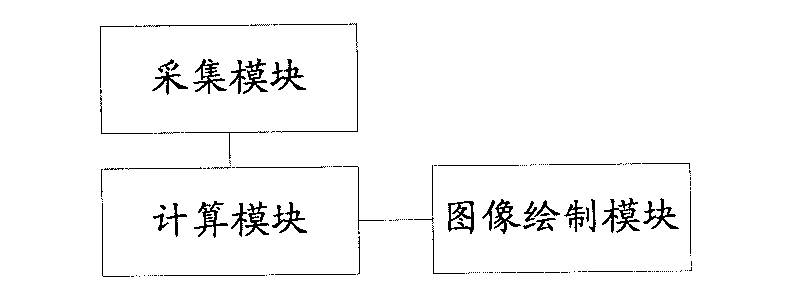

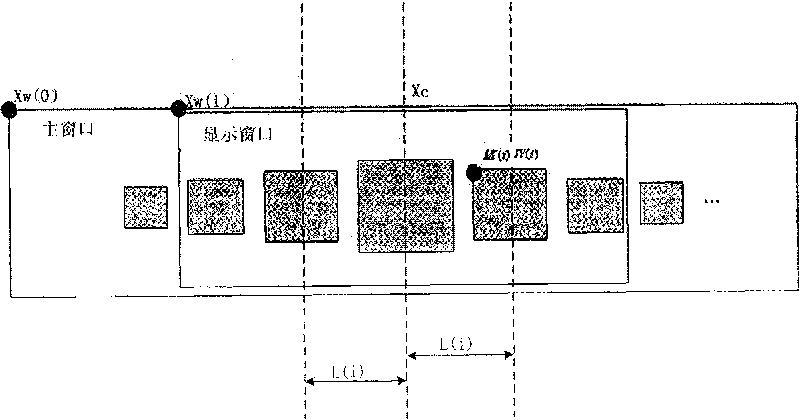

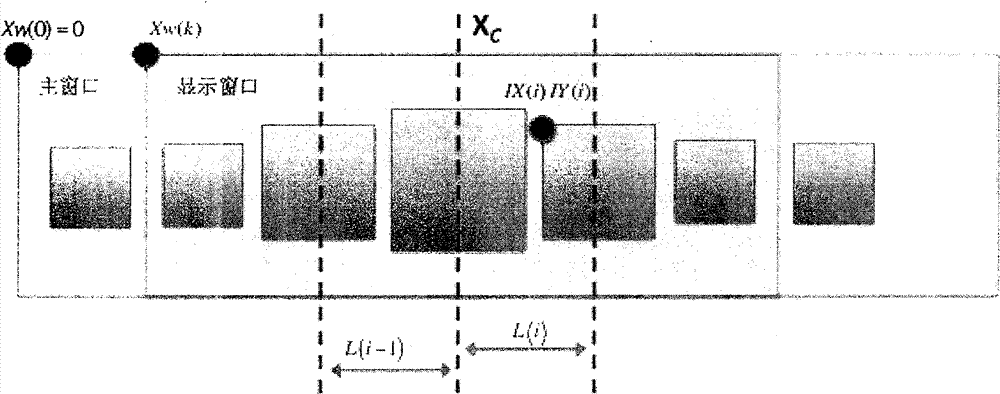

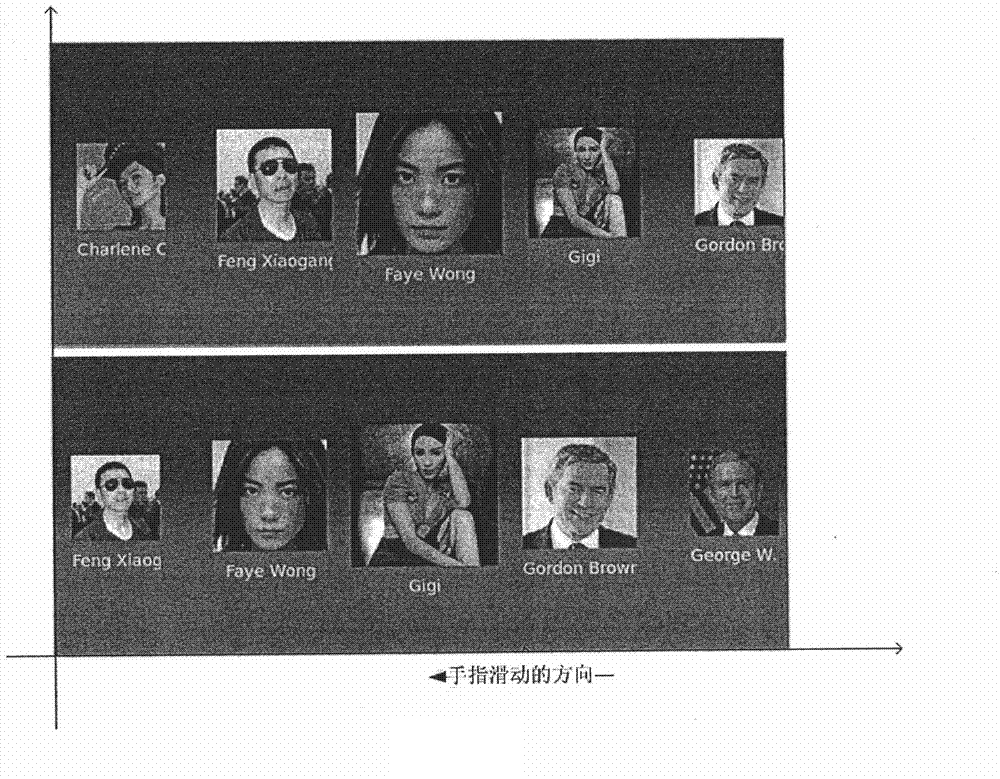

Method and device for realizing image container control with effect of convex lens

ActiveCN101727325AAvoid stackingAvoid loss of precisionSpecific program execution arrangementsInput/output processes for data processingComputer visionResource consumption

The invention provides a method and a device for realizing an image container control with the effect of a convex lens. The method comprises the following steps of: collecting the offset delta x of x-coordinate generated by moving figures on a touch screen at intervals per unit time using the top left corner of a main window as the origin of coordinate of the main window; calculating the X coordinate Xw(i) of the origin of coordinate of a display window according to the offset of the coordinate x generated by moving figures at intervals per unit time and calculating the zoom coefficient according to the X coordinate XC in the centre point of the display window and the X coordinate X(i) in the centre point of the subcontrol; obtaining the width W(i) of a new image and the height H(i) of a new image according to the zoom coefficient; calculating coordinate X at the top left corner of the new image according to the X coordinate X(i) in the centre point of the subcontrol, the width W(i) of the new image and the X coordinate Xw(i) of the origin of coordinate of the display window; calculating the coordinate Y at the top left corner of the new image according to the Y coordinate H in the centre point of the subcontrol and the height H(i) of the new image; and drawing the image according to the parameters. The invention realizes the image container control with the effect of the convex lens in a way of light-weight resource consumption in case of limited CPU and memory resources.

Owner:CHINA TELECOM CORP LTD

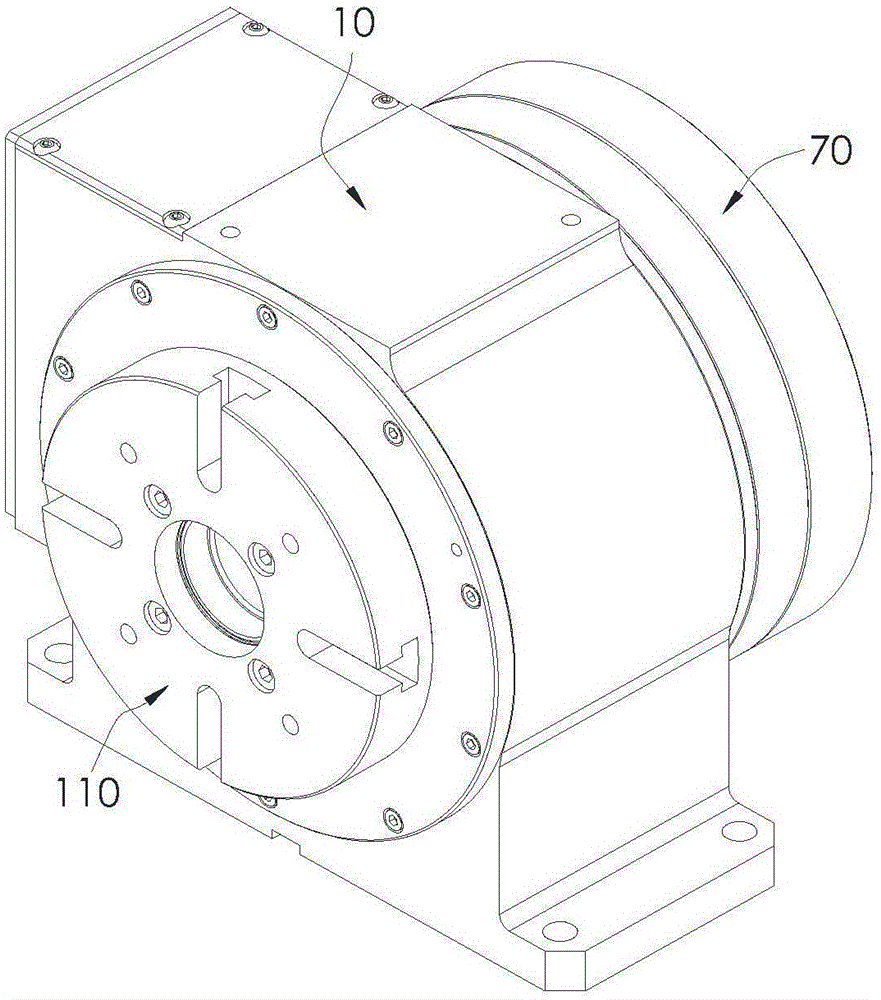

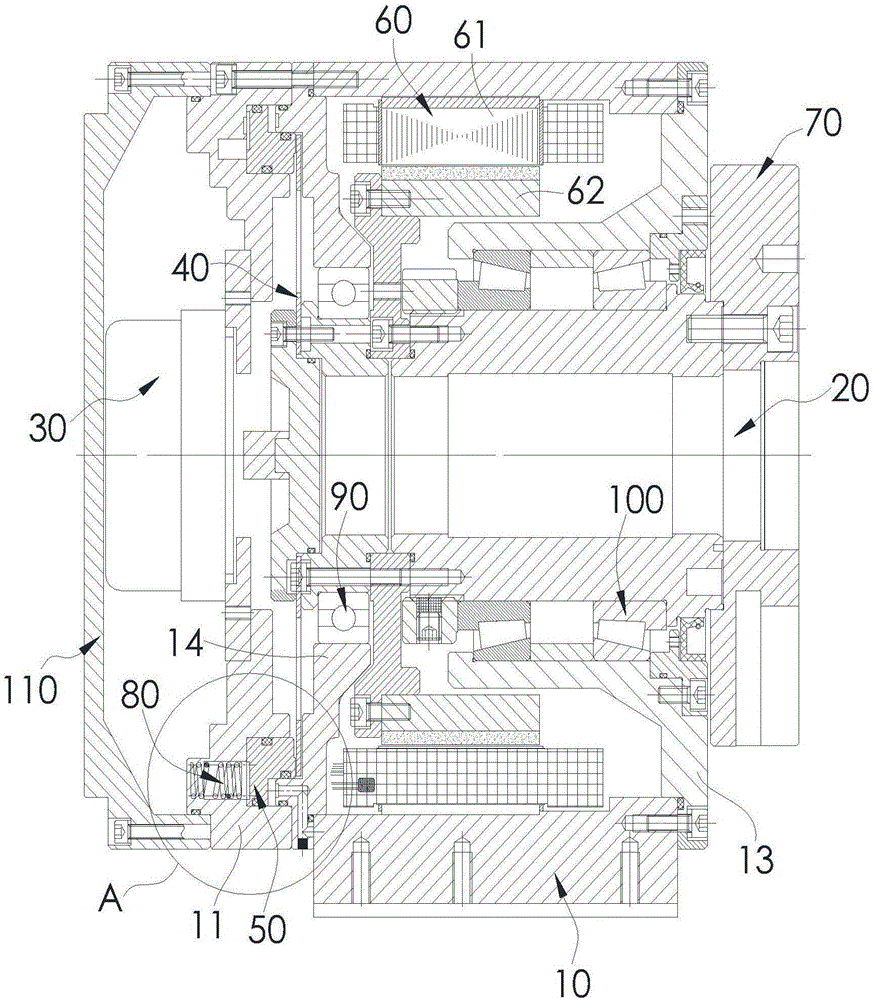

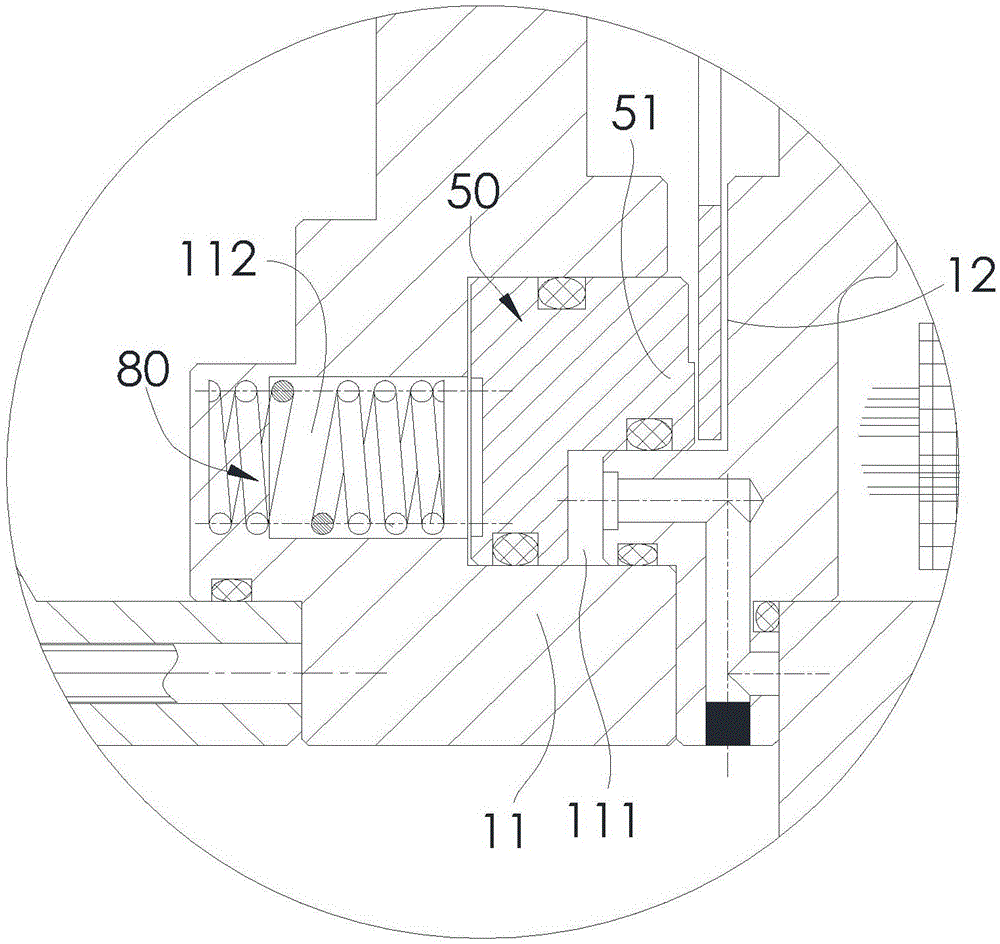

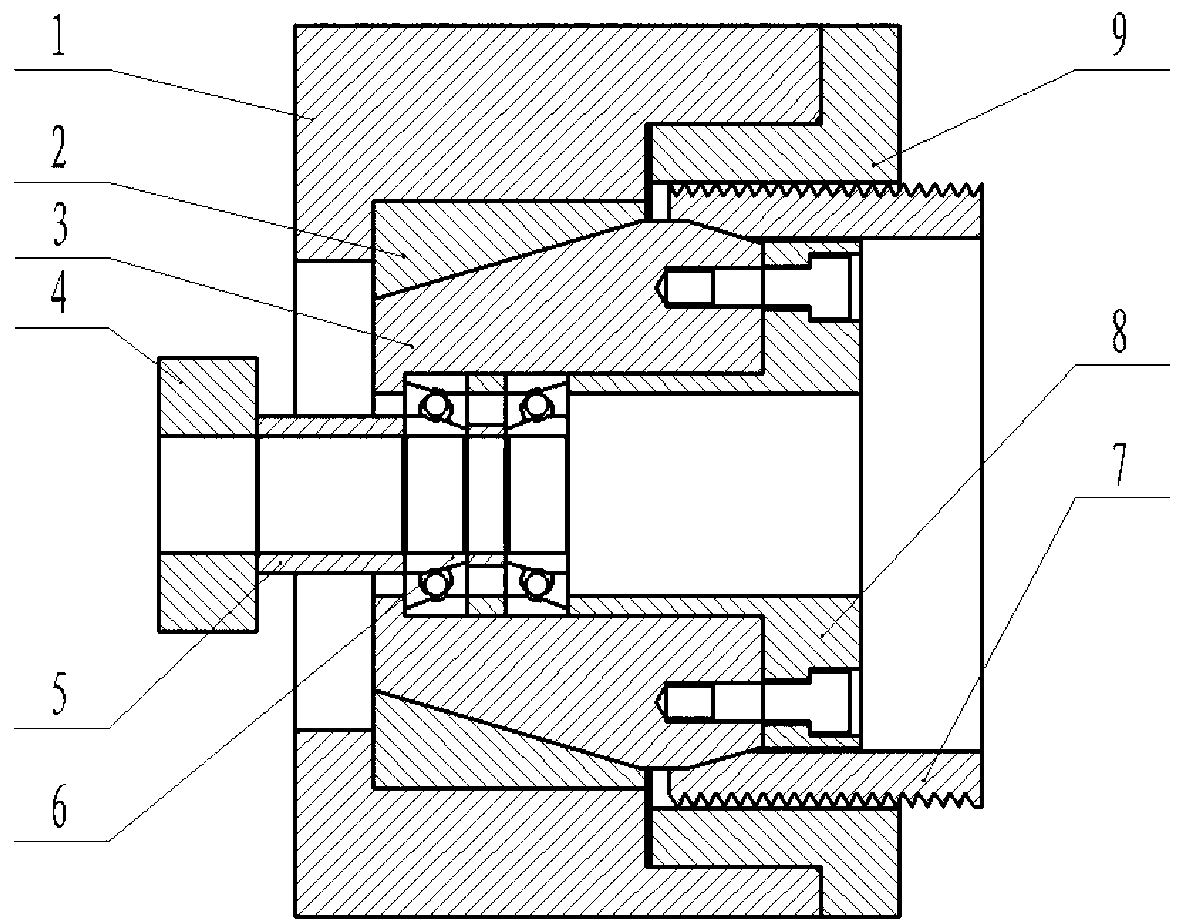

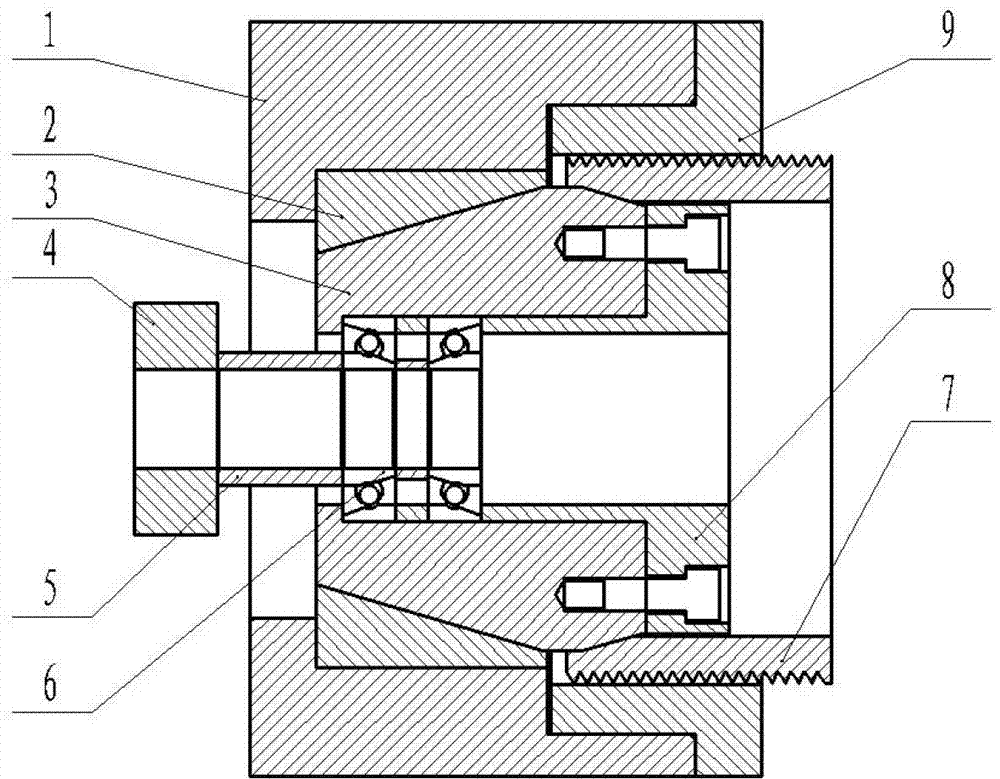

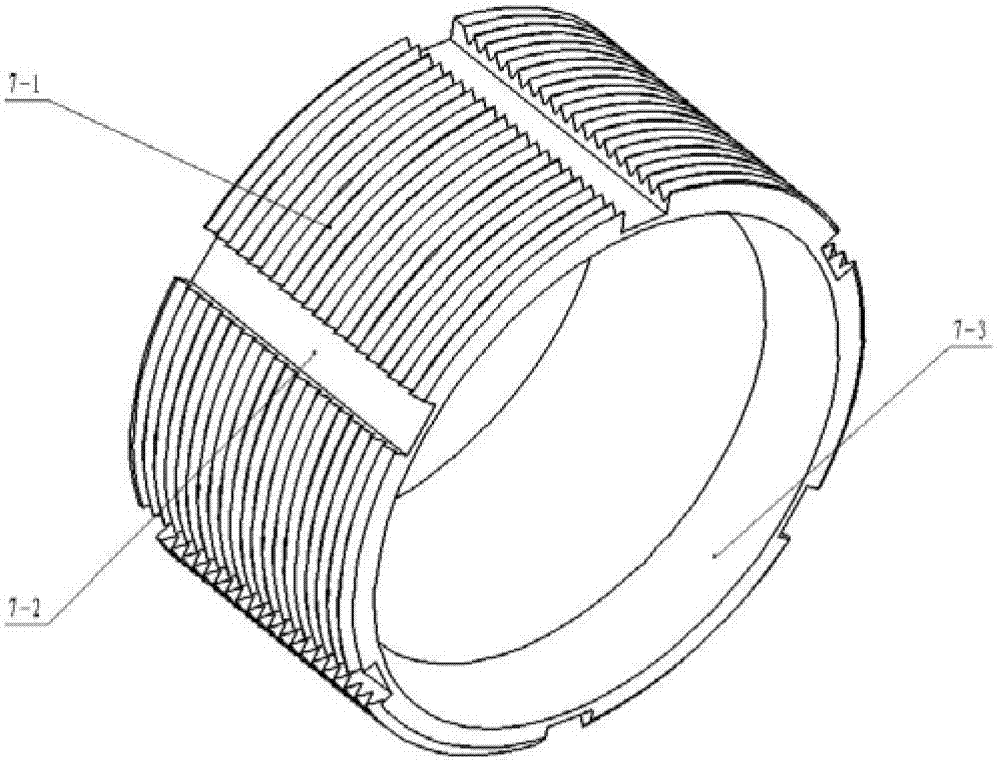

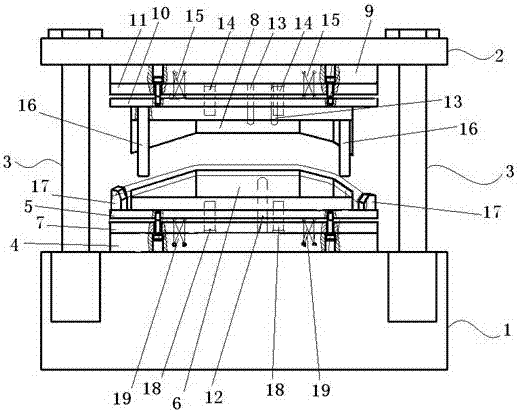

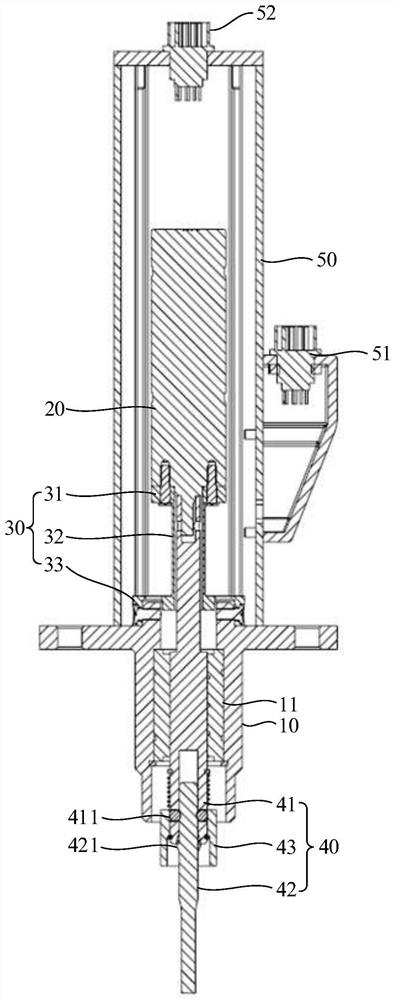

Numerical control rotation working table

InactiveCN105014480AImprove machining accuracyAvoid loss of precisionPrecision positioning equipmentNumerical controlTorque motor

A numerical control rotation working table comprises a machine body, a rotation shaft, a rotating encoder, a braking ring piece, a piston, a torque motor and a working rotating plate used for installing a workpiece. A cylinder is formed in the machine body. The rotation shaft is connected to the machine body in a pivoted mode. The rotating encoder is arranged on the machine body. The piston is movably arranged in the cylinder. The end, located on the outer side of the cylinder, of the piston forms an ejection end. The ejection rod is used for ejecting the braking ring piece and pressing the braking ring piece to the side wall of the machine body. According to the numerical control rotation working table, very high rotation accuracy and positioning accuracy can be output through direct drive of the torque motor and the cooperation with the high-precision encoder; in addition, linked machining and angle-fixed indexing machining can be achieved according to different machining requirements; in the linked machining process, stable machining can be conducted in the rotating process of the working rotating plate; and in the angle-fixed indexing machining process, by pressing the braking ring piece through the position and by means of the keeping torque of the torque motor, extremely high braking keeping torque can be generated so that the machining stability can be ensured.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

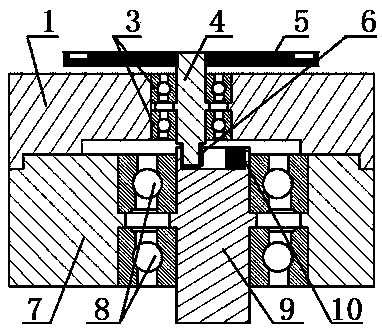

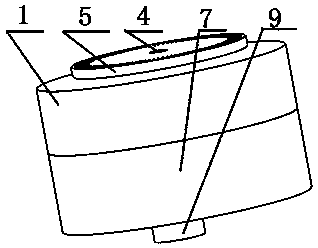

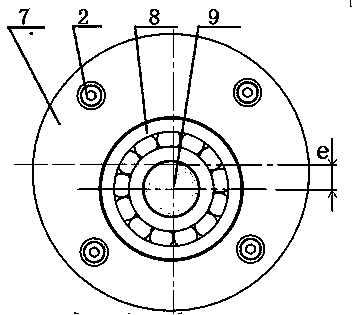

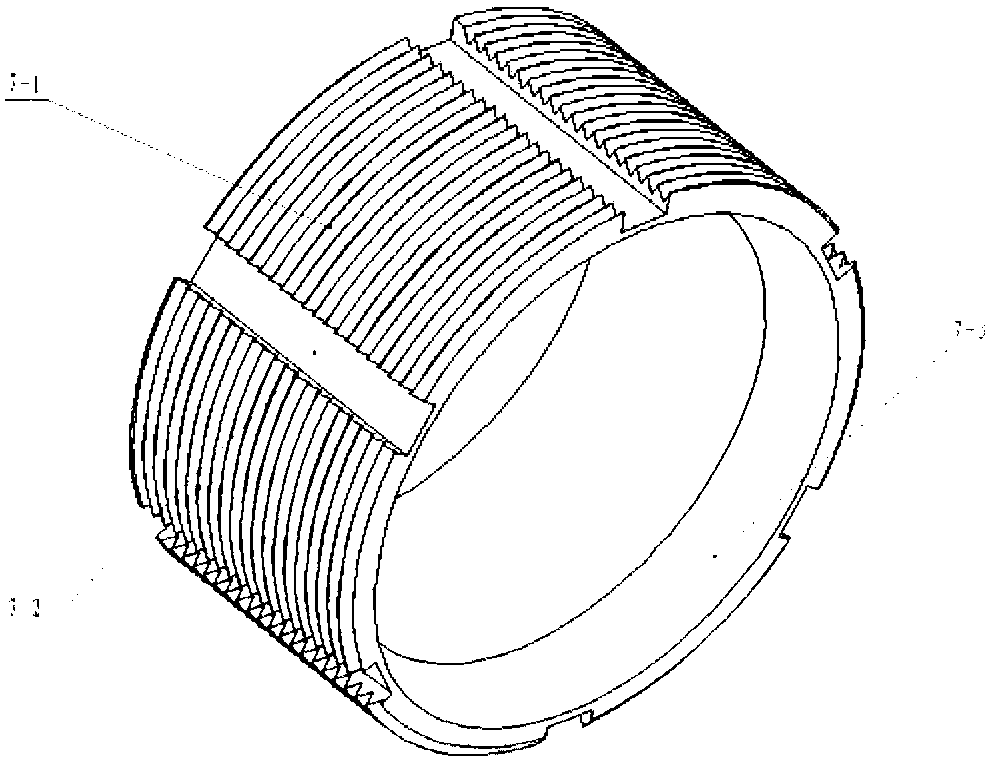

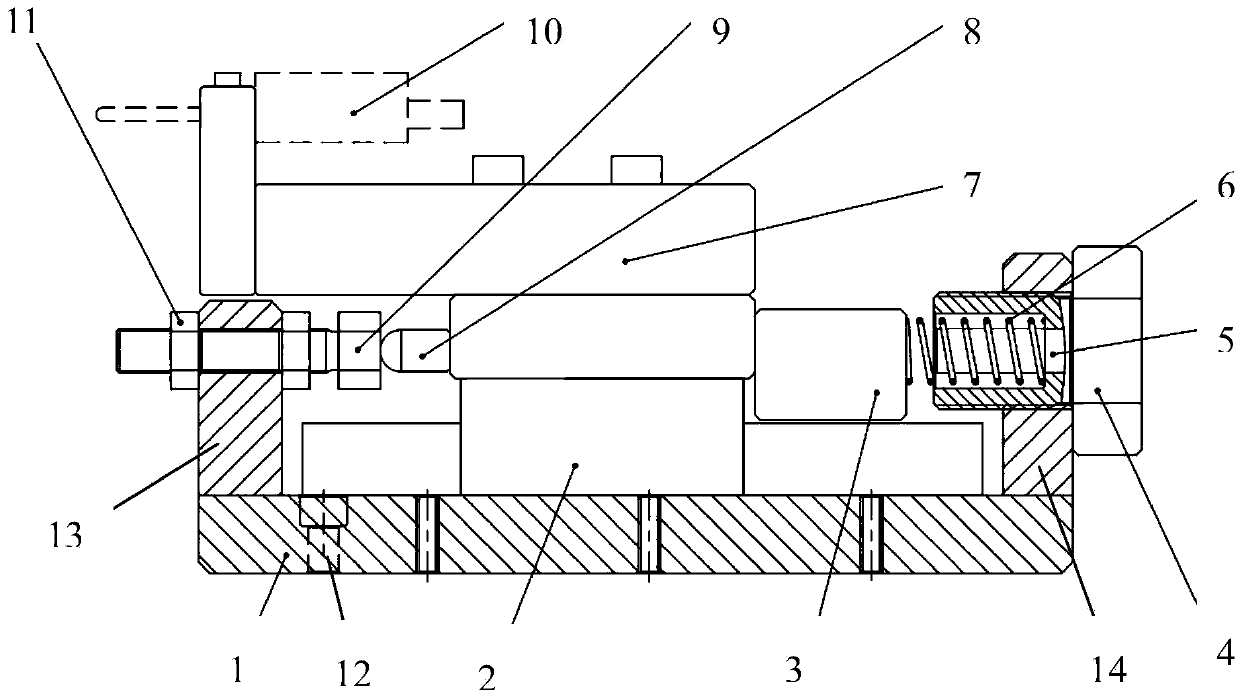

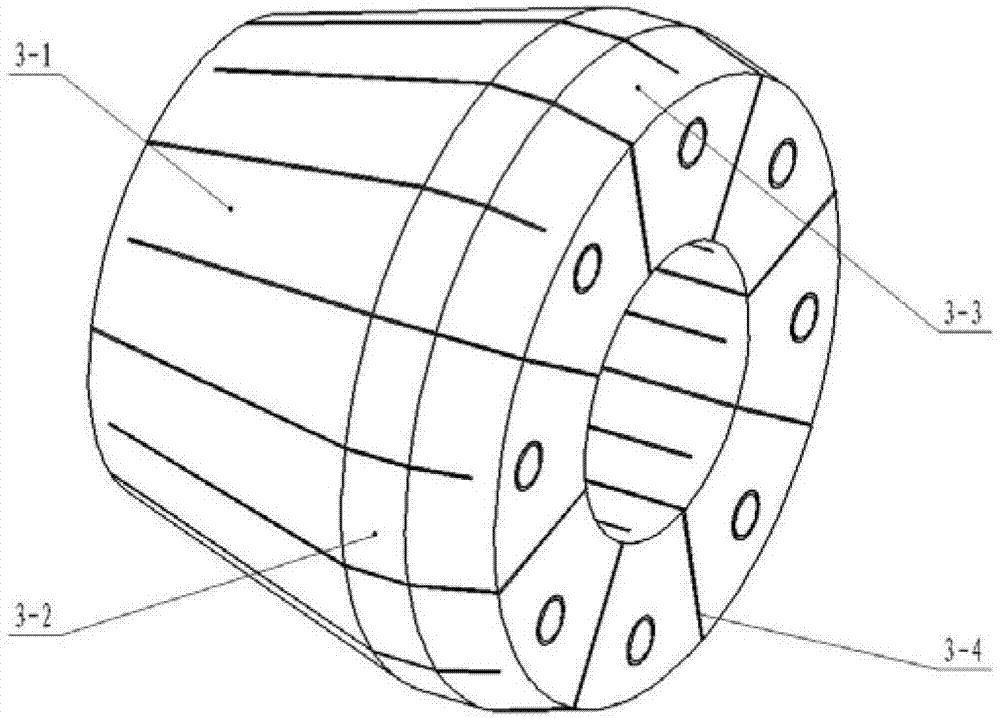

Machinery device for improving resolution of angle encoder and measurement precision

ActiveCN103644864AReduce design sizeHigh resolutionToothed gearingsUsing optical meansImage resolutionMechanical engineering

The invention relates to a machinery device for improving resolution of an angle encoder and measurement precision. The device comprises a connection coding disc rotating shaft bearing seat (1), connection coding disc rotating shaft bearings (3), a connection coding disc rotating shaft (4), a coding disc (5), a driven gear (6), an angle coder base seat (7), input shaft bearings (8), an input shaft (9) and a driving gear (10), wherein the input shaft (9) is mounted on the angle coder base seat (7) through the two input shaft bearings (8), the connection coding disc rotating shaft (4) is mounted on the connection coding disc rotating shaft bearing seat (1) through the two connection coding disc rotating shaft bearings (3), the connection coding disc rotating shaft bearing seat (1) is mounted on the angle coder base seat (7), the driving gear (10) is arranged on the input shaft (9), the driven gear (6) is arranged on the connection coding disc rotating shaft (4), the driven gear (6) and the driving gear (10) are engaged, the input shaft (9) is connected with a detected object, and the coding disc (5) is arranged on the connection coding disc rotating shaft (4). The machinery device greatly improves the resolution and measurement precision by adding a variable gear transmission device.

Owner:GUANGDONG UNIV OF TECH

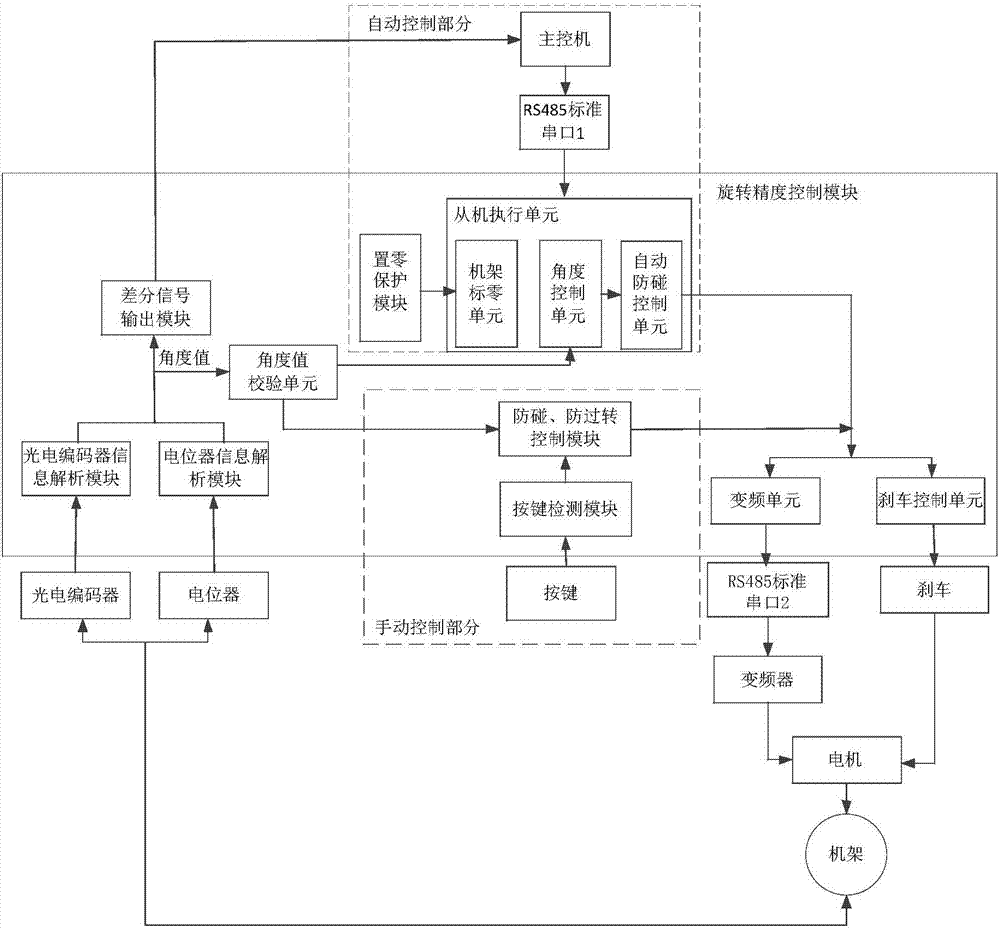

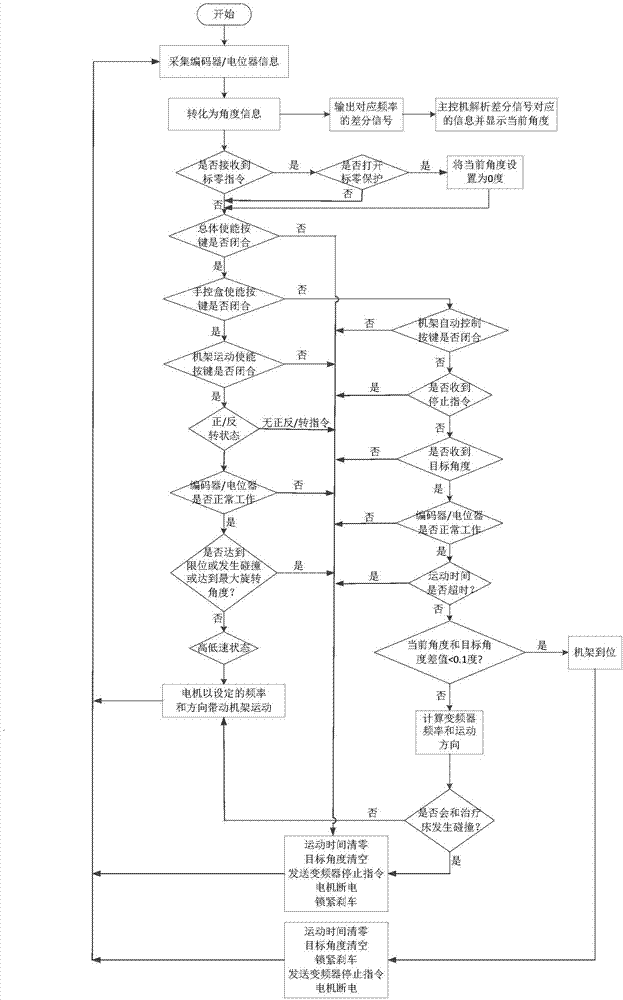

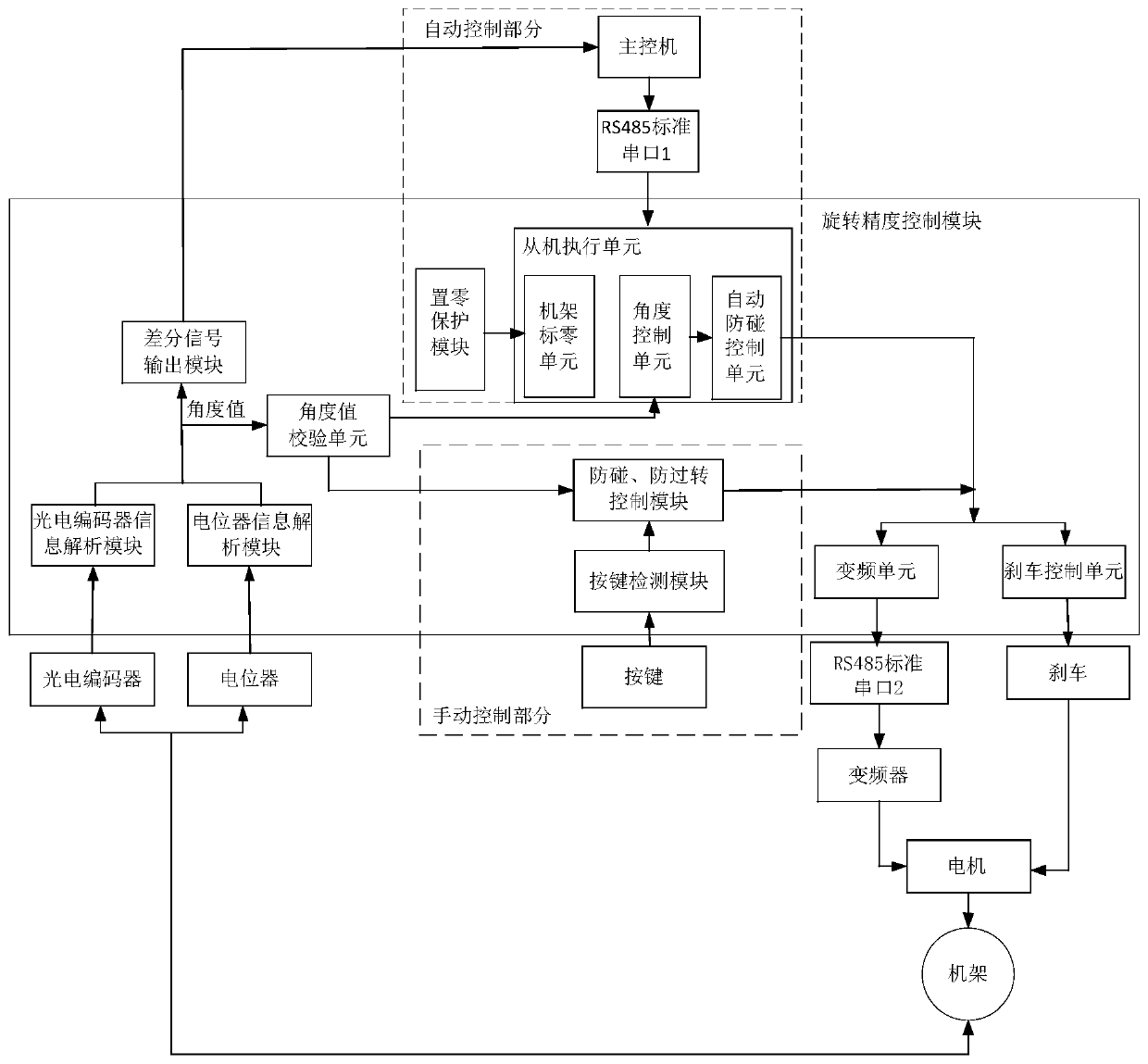

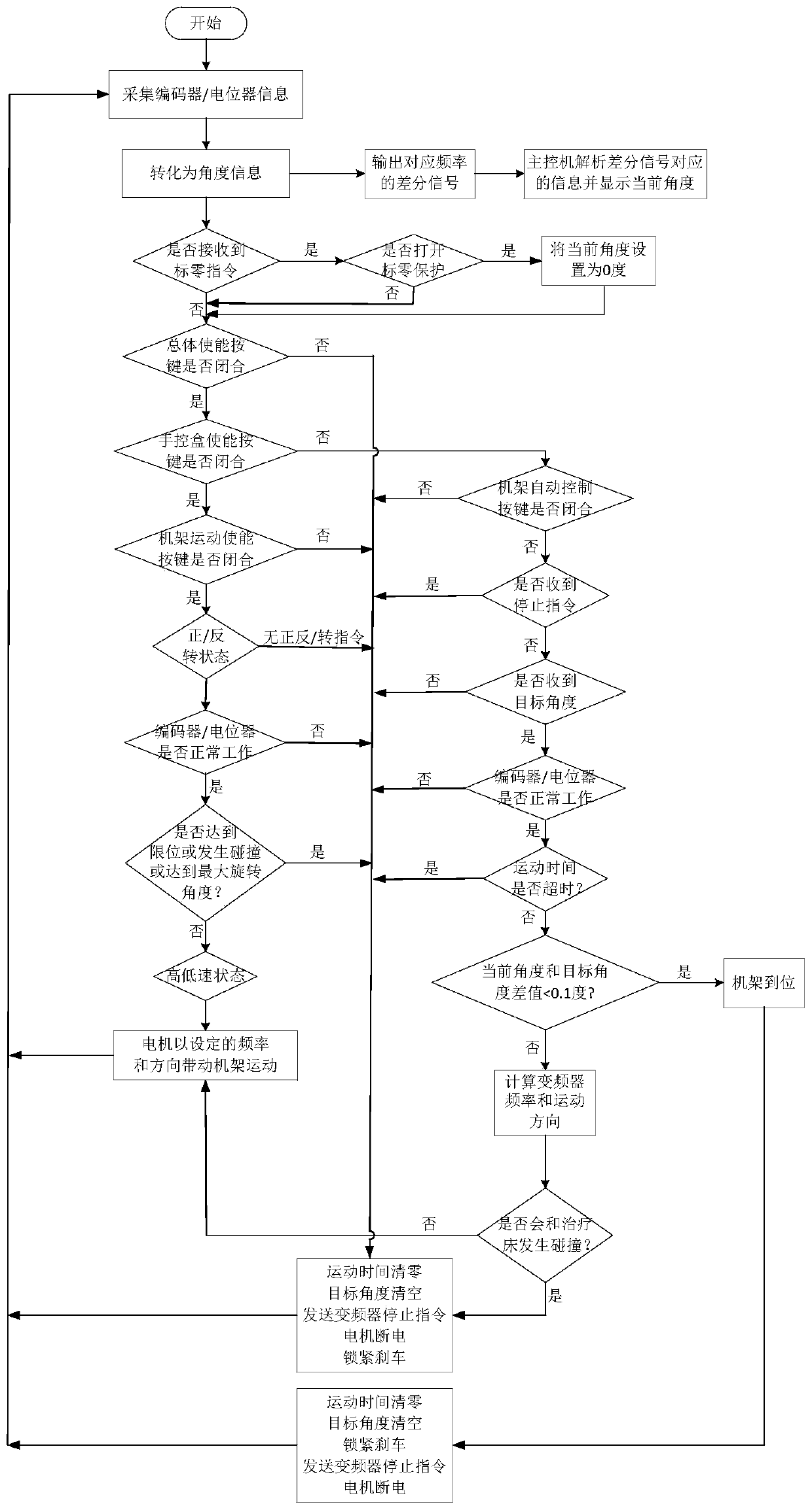

Control driving system for universal rack

ActiveCN106861055ARealize self-calibration functionAngular fault toleranceX-ray/gamma-ray/particle-irradiation therapyFrequency changerAutomatic control

The invention discloses a control driving system for a universal rack, which can realize stable and reliable rack rotation control and high control precision. A photoelectric encoder and a potentiometer are arranged on the rack and a motor respectively, two measurement angle values are calibrated through an angle calibration module, and thus, a self-calibration function is realized; in the case of automatic control, when the rack moves near a target angle, different operating frequencies are transmitted to a frequency converter according to the difference between the current angle and the target angle, the relationship between the angle difference and a motion speed can simulate a damped motion curve, the motion speed of the rack just reaches 0 when the rack moves to the target angle, and thus, zero overshoot control is realized, and the rotation precision is high; and through detecting the position of a treatment couch in real time through an automatic anti-collision control unit and an anti-collision and anti-over turning control module, collision between the rack and the treatment couch is automatically prevented.

Owner:江苏海明医疗器械有限公司

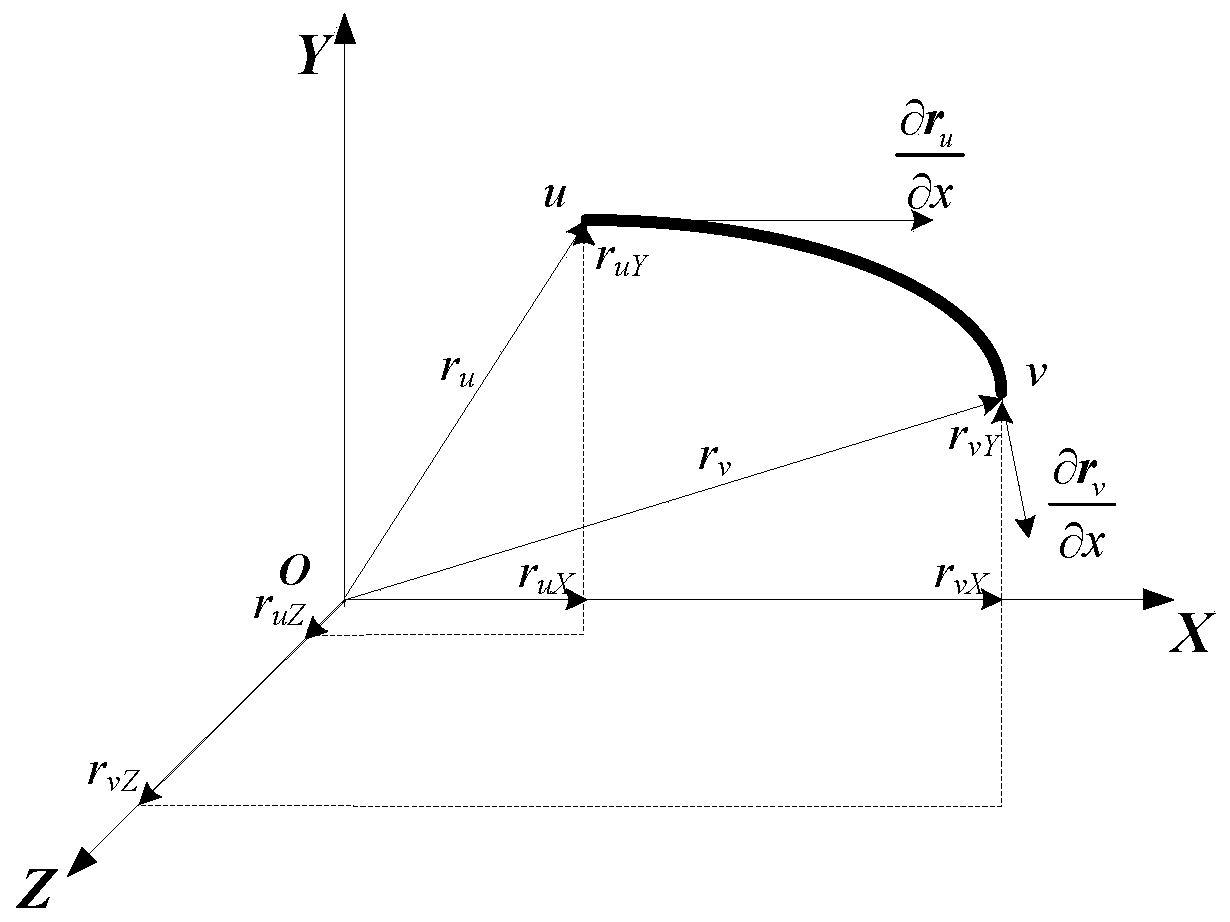

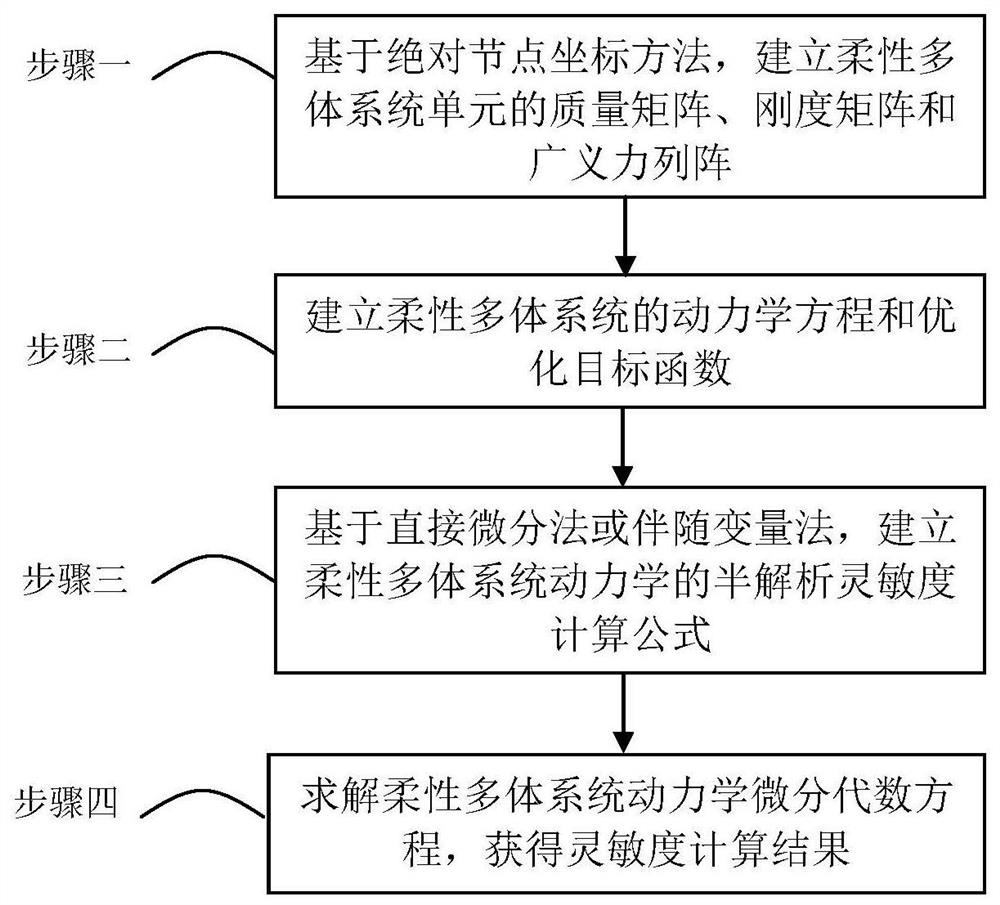

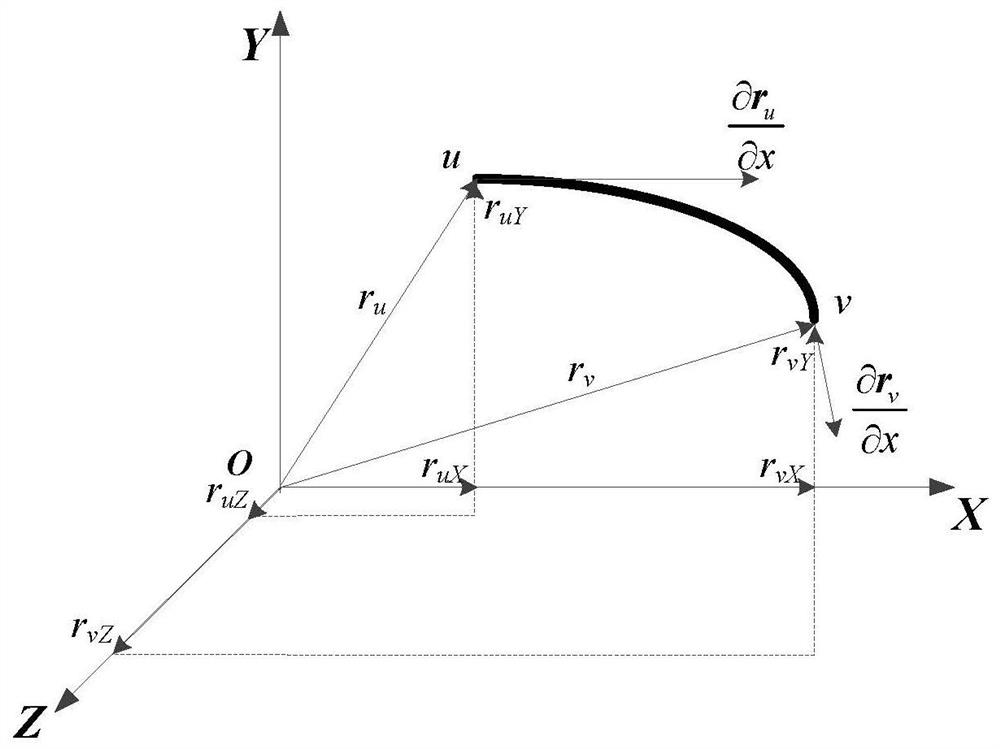

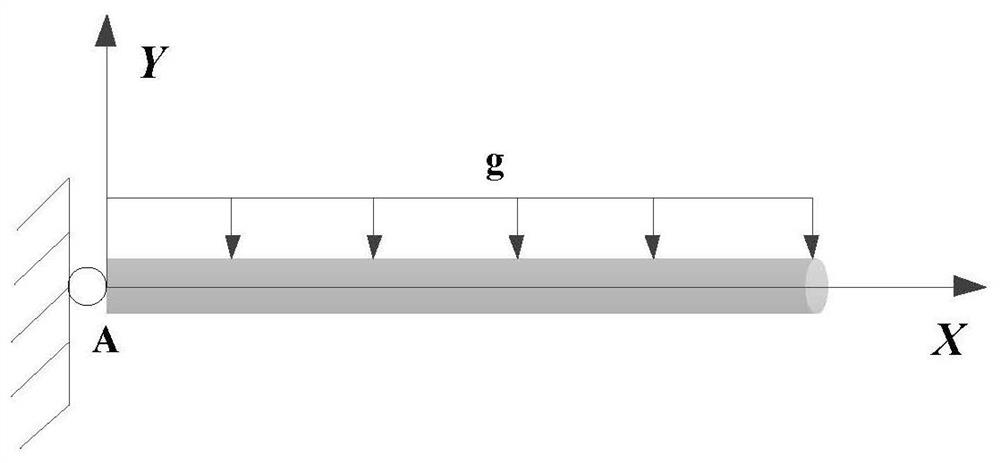

Flexible multi-body system dynamics semi-analytical sensitivity analysis method based on absolute node coordinate description

ActiveCN111159636AImprove computing efficiencyImprove calculation accuracyDesign optimisation/simulationComplex mathematical operationsAlgorithmAlgebraic equation

The invention relates to the technical field of dynamics system optimization, and provides a flexible multi-body system dynamics semi-analytical sensitivity analysis method based on absolute node coordinate description. The method comprises the following steps: firstly, establishing a mass matrix, a rigidity matrix and a generalized force array of the flexible multi-body system based on an absolute node coordinate method; secondly, establishing a kinetic equation and an optimization objective function of the flexible multi-body system; thirdly, based on a direct differential method or an adjoint variable method, establishing a semi-analytical sensitivity calculation formula of the flexible multi-body system dynamics; and finally, solving the dynamic differential algebraic equation of the flexible multi-body system to obtain a sensitivity calculation result. The method is based on an absolute node coordinate method and a multi-body system dynamics theory. A semi-analytical sensitivity calculation formula of the flexible multi-body system is established to solve the sensitivity analysis problem of dynamics of the flexible multi-body system, a set of new strategy for sensitivity analysis of the flexible multi-body system is provided, and convenience is provided for sensitivity calculation of the large-scale complex flexible multi-body system.

Owner:DALIAN UNIV OF TECH

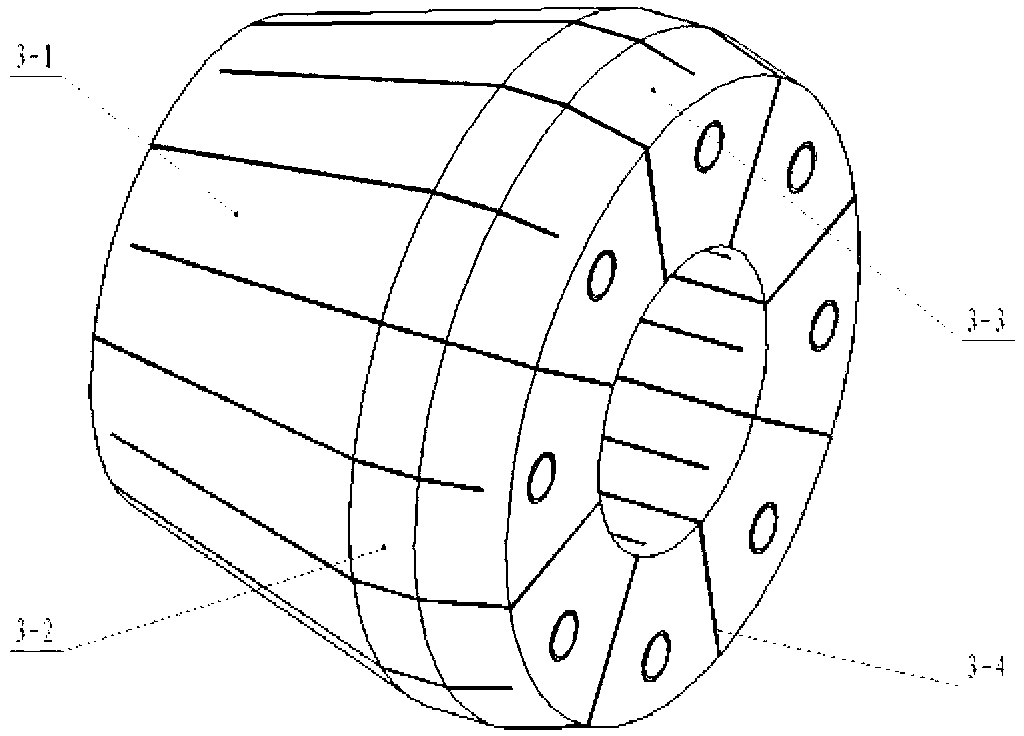

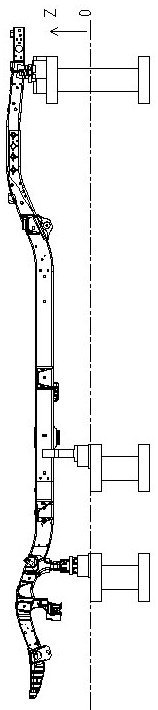

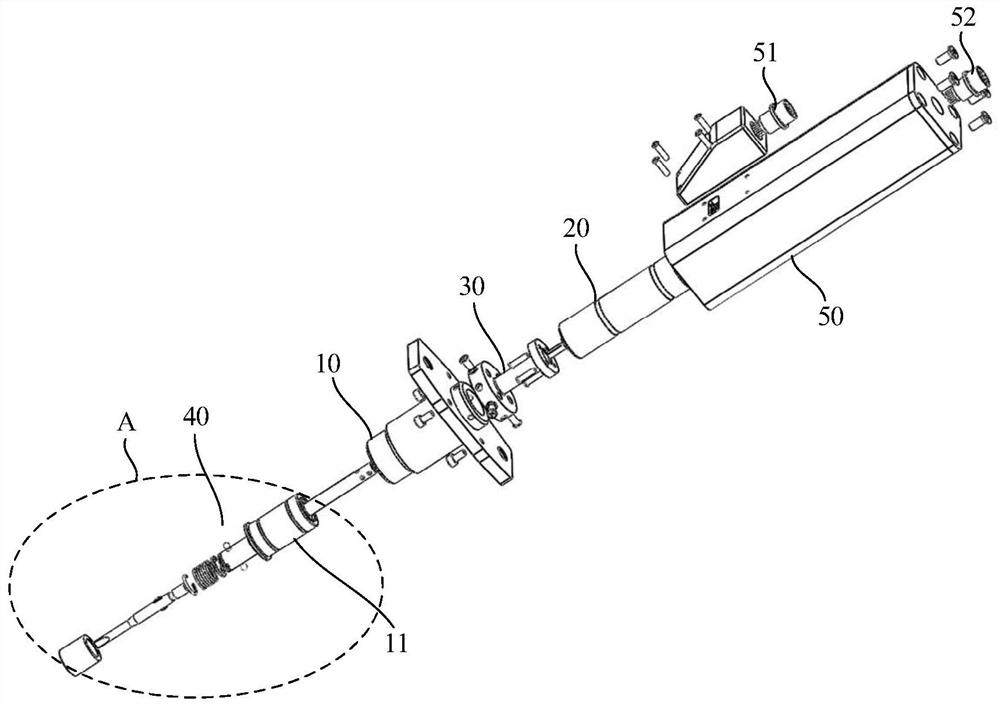

Supportive element capable of supporting ball screws with different shaft end size

ActiveCN103122981AEasy to processReassuring and reliableMachine gearing/transmission testingGearingBall screwEngineering

The invention discloses a supportive element capable of supporting ball screws with different shaft end size and particularly relates to the supportive element capable of supporting ball screws with different shaft end size. The supportive element mainly comprises a pressure nut, a threaded sleeve, an elastic retaining ring, a spring taper sleeve, a bearing, an inner taper sleeve, a supportive seat, an isolation sleeve and a locking nut and is characterized in that after ball screws with different size are replaced, the ball screws can be supported without detaching the supportive seat by replacing the spring taper sleeve, the bearing, the elastic retaining ring, the isolation sleeve and the locking nut. The supportive element capable of supporting ball screws with different shaft end size is compact in structure, high in centering precision, convenient to operate, low in cost and easy to machine.

Owner:NANJING UNIV OF SCI & TECH

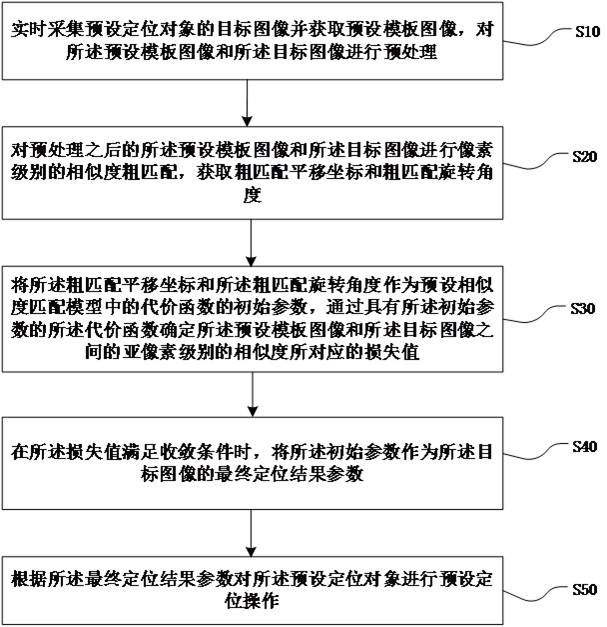

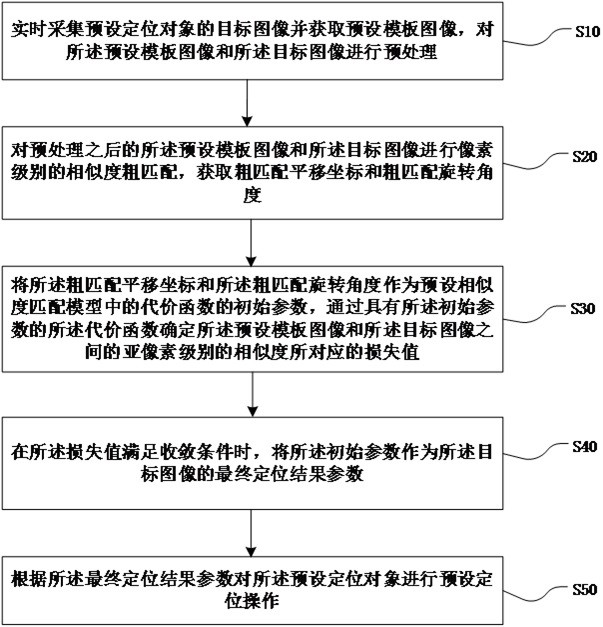

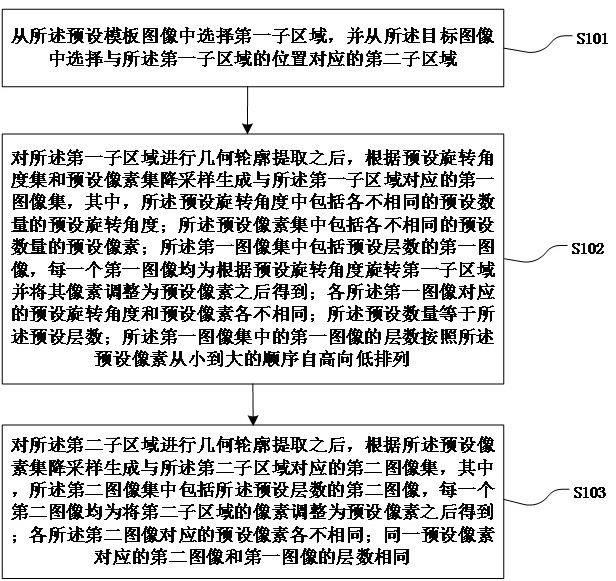

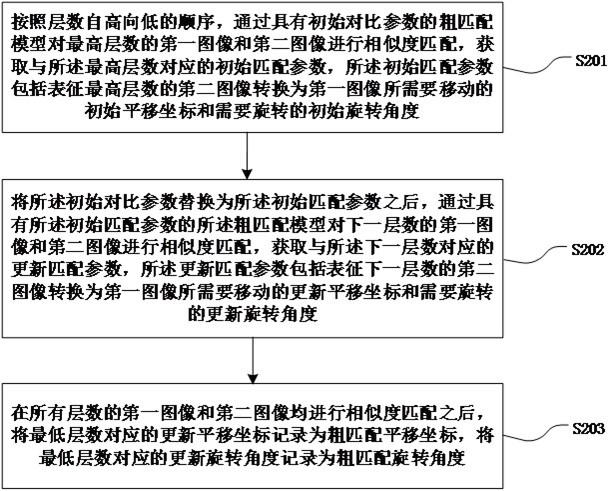

Image sub-pixel matching and positioning method and system, equipment and medium

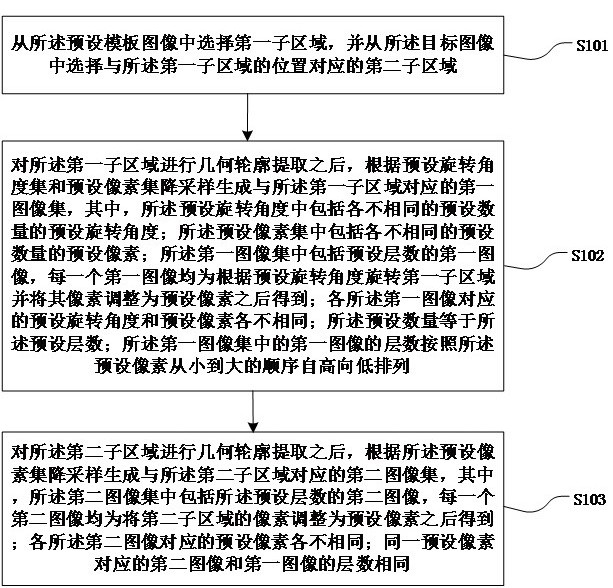

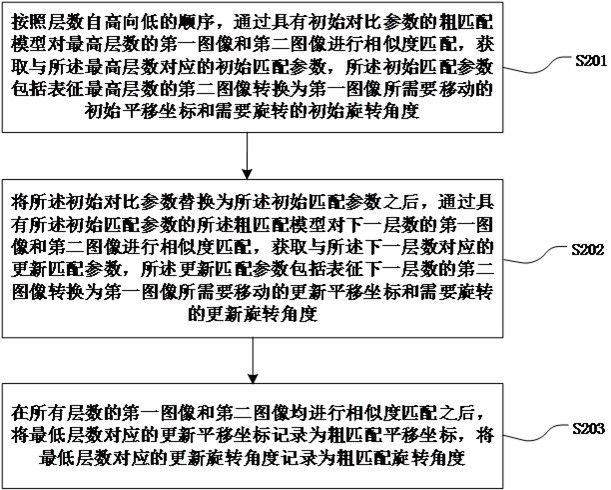

ActiveCN113850807AHigh positioning accuracyAvoid loss of precisionImage enhancementImage analysisEngineeringSimilarity matching

The invention discloses an image sub-pixel matching and positioning method and system, equipment and a medium. The image sub-pixel matching and positioning method comprises the steps: preprocessing a preset template image and a target image; carrying out pixel-level similarity rough matching on the pre-processed preset template image and the target image, and obtaining rough matching translation coordinates and a rough matching rotation angle; taking the coarse matching translation coordinates and the coarse matching rotation angle as initial parameters of a cost function in a preset similarity matching model, and determining a loss value corresponding to the similarity of the sub-pixel level between the preset template image and the target image through the cost function with the initial parameters; when the loss value meets a convergence condition, taking the initial parameter as a final positioning result parameter of the target image; and performing preset positioning operation on the preset positioning object according to the final positioning result parameter. According to the method and system, the problem of accuracy loss caused by discretization of translation coordinates and rotation angles can be effectively avoided, and the positioning accuracy is improved.

Owner:深圳市大族封测科技股份有限公司

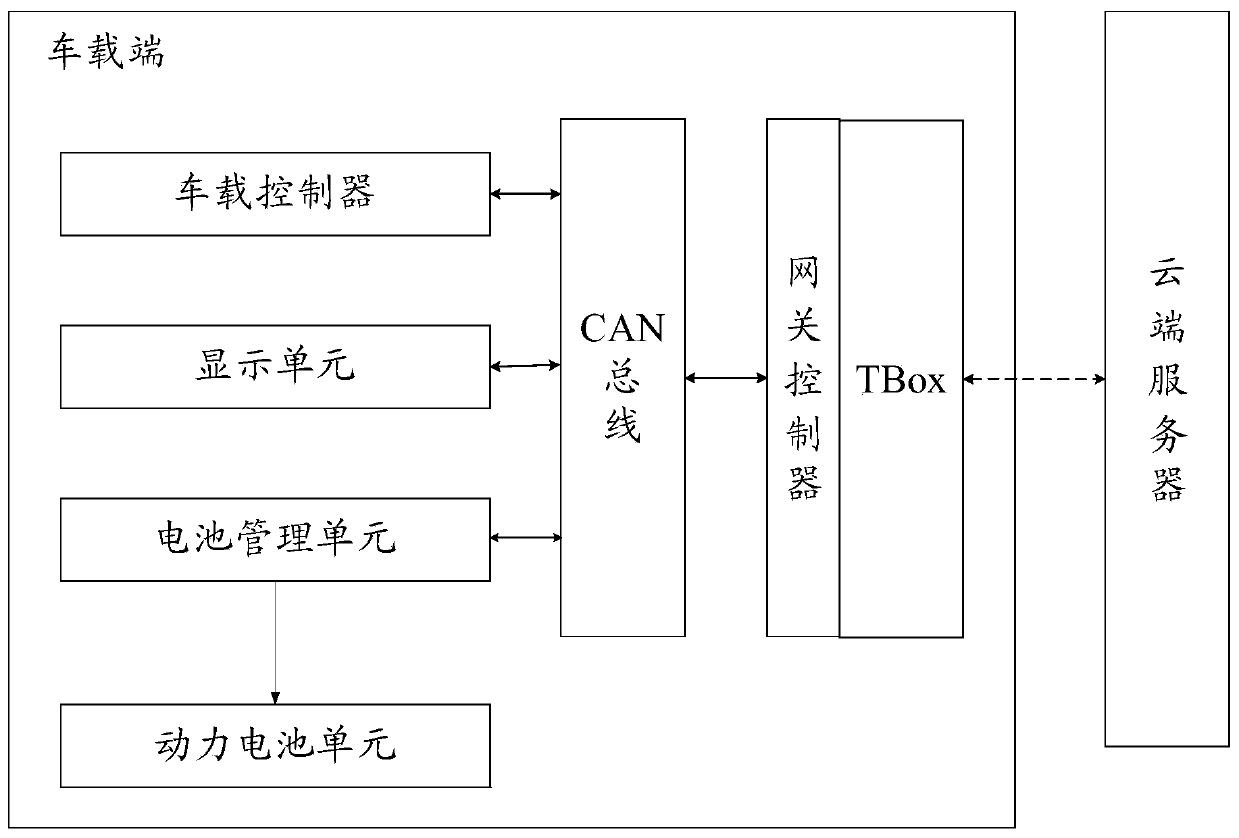

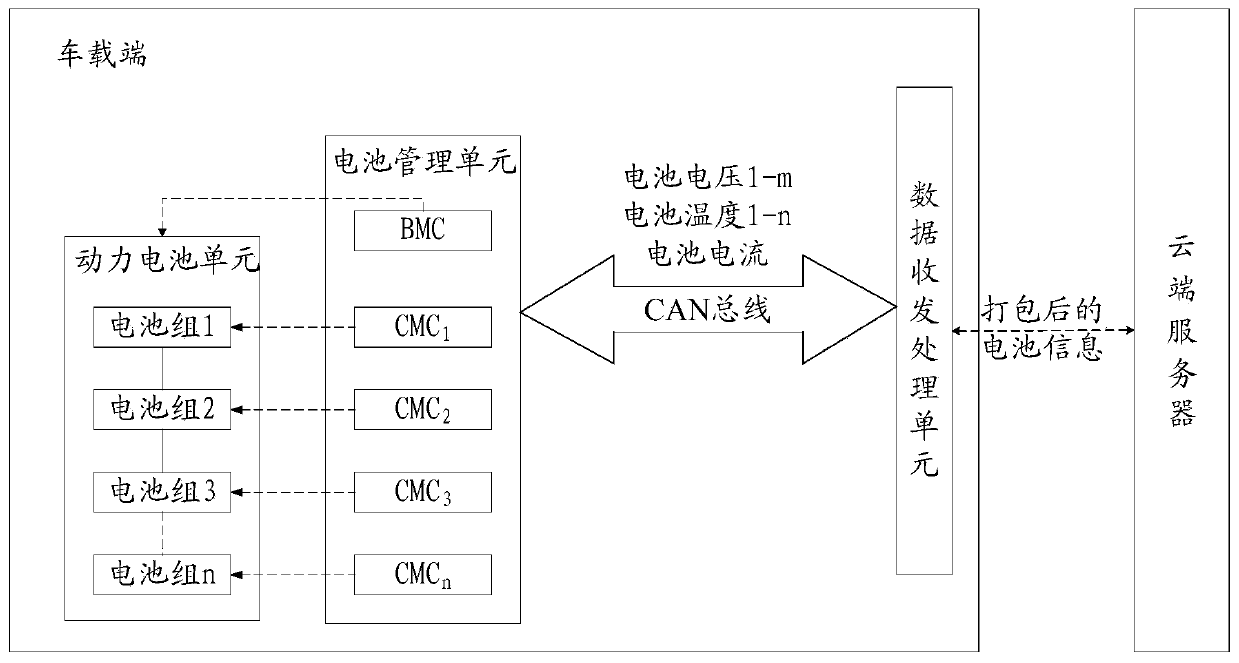

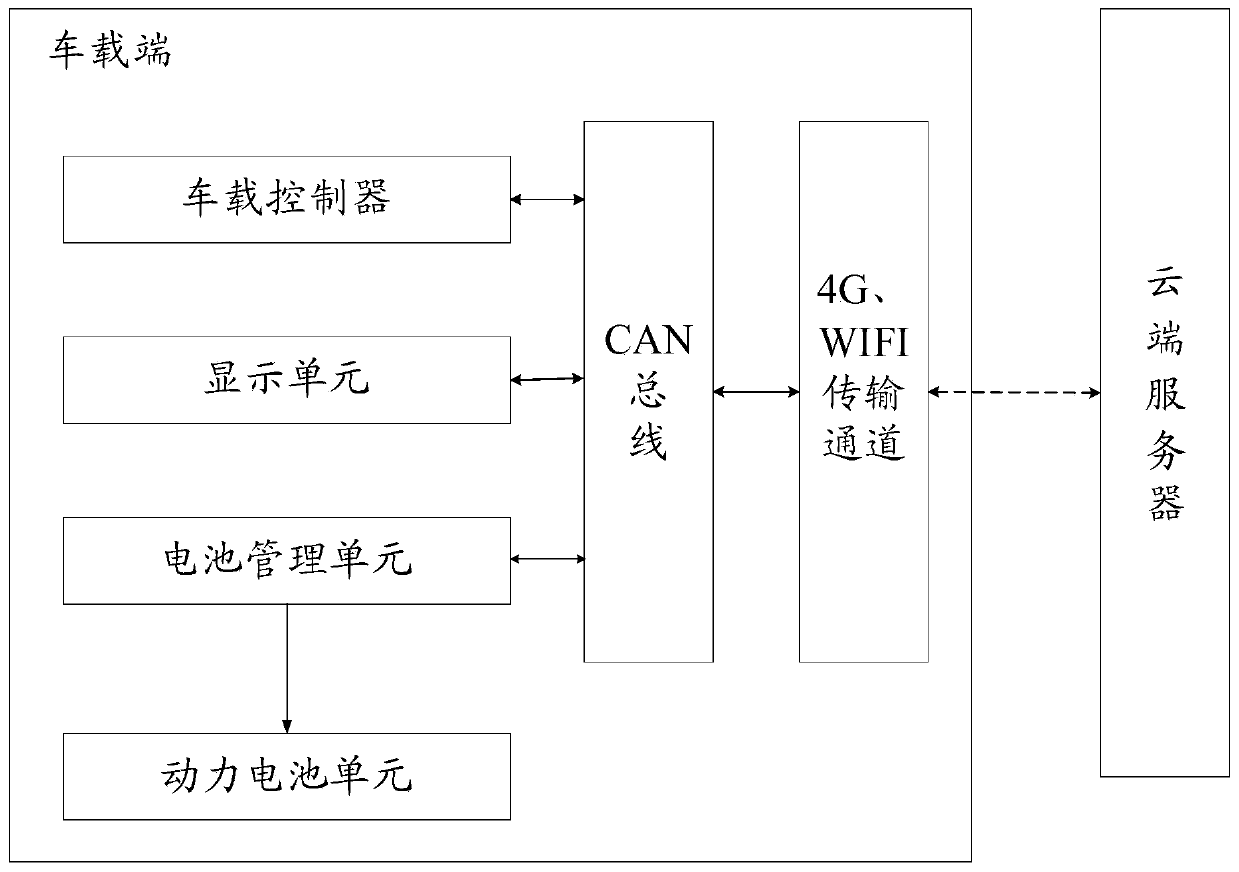

Networked automobile battery management system

PendingCN111262896AAvoid loss of precisionReal-time calculation of aging statusElectric signal transmission systemsElectrical testingAutomotive batteryInternal resistance

The invention provides a networked automobile battery management system. A networked automobile comprises an automobile battery for providing a power source for the networked automobile, and the networked automobile battery management system comprises a cloud server and a vehicle-mounted controller located at a vehicle-mounted end. Based on the networked automobile battery management system, the invention further provides an SOC and SOH combined estimation algorithm. The SOC and SOH combined estimation is carried out in a cloud server, so that the algorithm precision loss caused by fixed-pointnumber operation and index lookup approximation of the vehicle-mounted controller is avoided, and the SOC and SOH combined estimation algorithm based on cloud computing can improve the SOC estimationprecision by 2.5-4.5%. The SOH estimation algorithm provided by the invention not only can reflect the DC internal resistance of the battery, but also can calculate the aging state of the internal resistance of the battery under different frequency conditions in real time, characterizes the aging trend of the polarization characteristics of the battery, and can reflect the SOH of the battery morecomprehensively.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

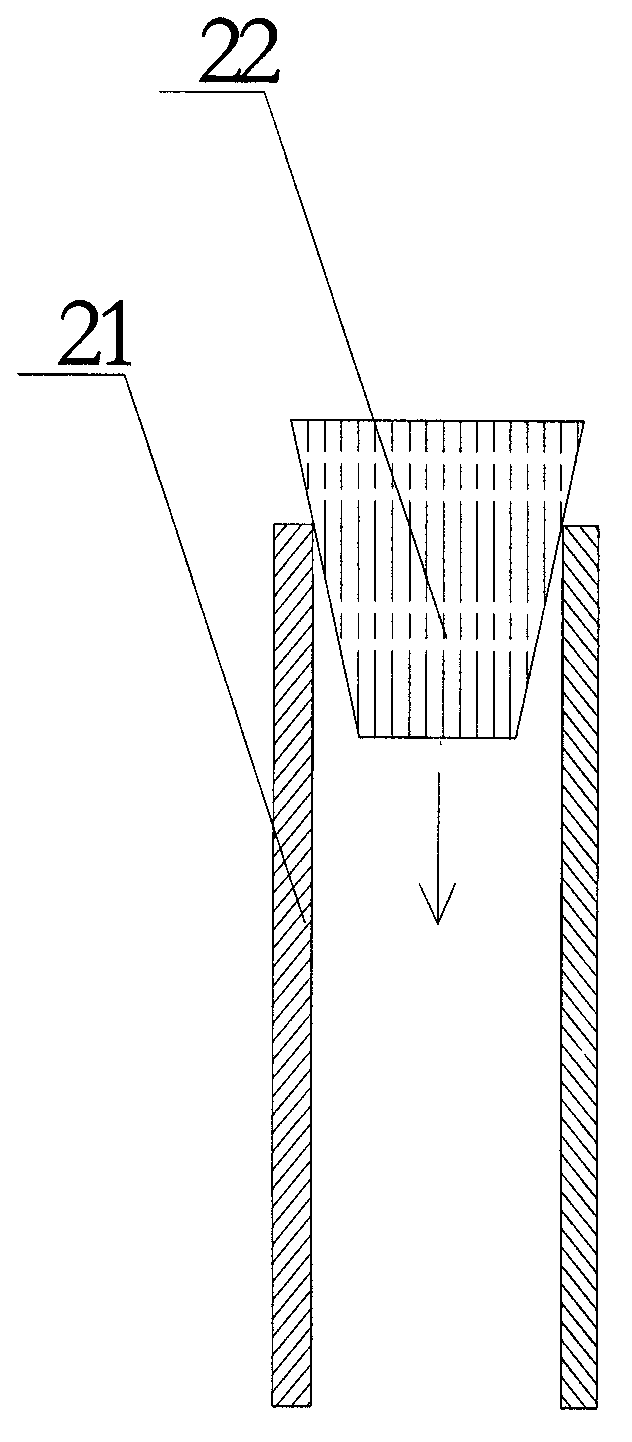

Multi-station punching machine

InactiveCN104043710AAvoid crackingMeet the needs of simultaneous processingPunch pressReciprocating motion

The invention provides a multi-station punching machine. The multi-station punching machine comprises a punching machine main body, wherein the punching machine main body is provided with a die stamping device, a stamping power device and a control device; the punching machine main body is also provided with at least two guide posts; the guide posts are perpendicularly arranged relative to the horizontal plane and are uniformly distributed; the power output end of the stamping power device is connected with the die stamping device; the die stamping device sleeves the guide posts in a sliding manner and is driven by the stamping power device to longitudinally reciprocate on the guide posts in a direction perpendicular to the horizontal plane; the die stamping device is provided with two or more punches; the punches are sequentially arranged according to stamping surface slopes of the punches; the punching machine main body is also provided with a lower die; the lower die is horizontally arranged and is opposite to the die stamping device; a workpiece to be machined is arranged in the lower die vertical to the horizontal plane.

Owner:李良有

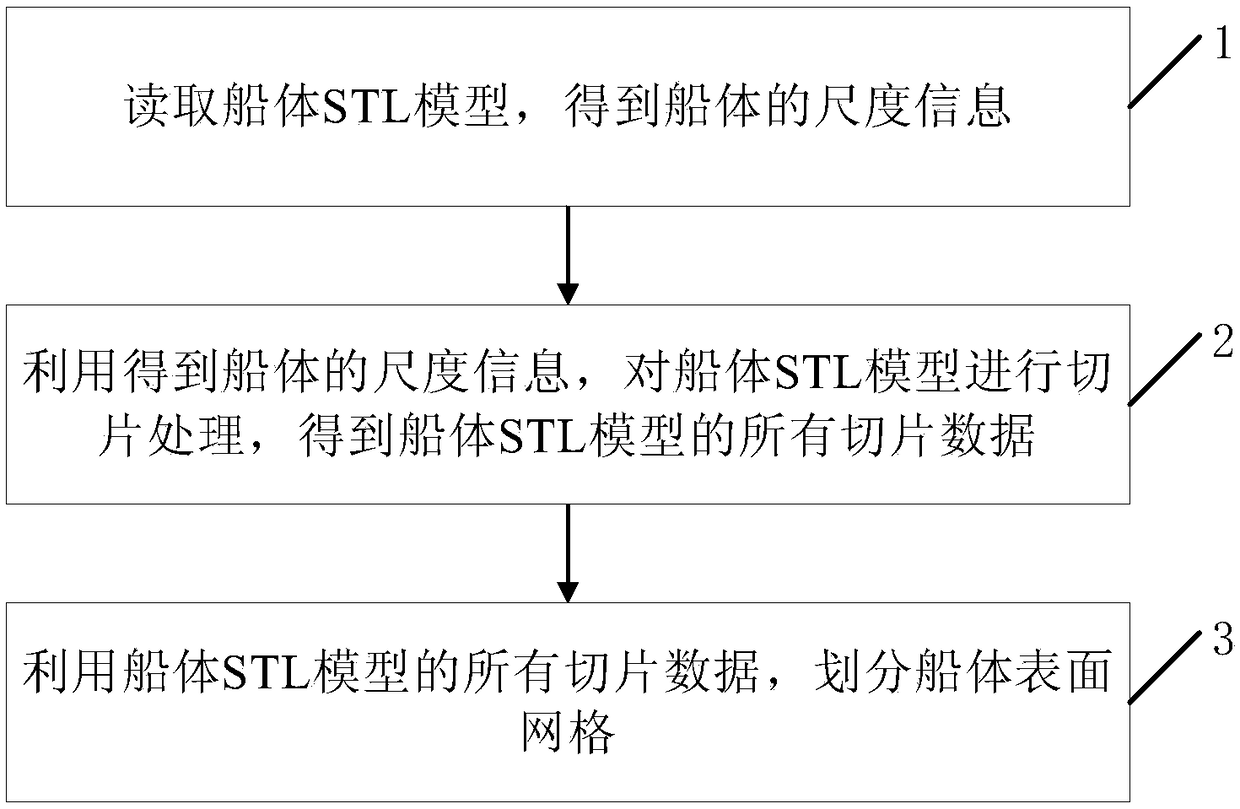

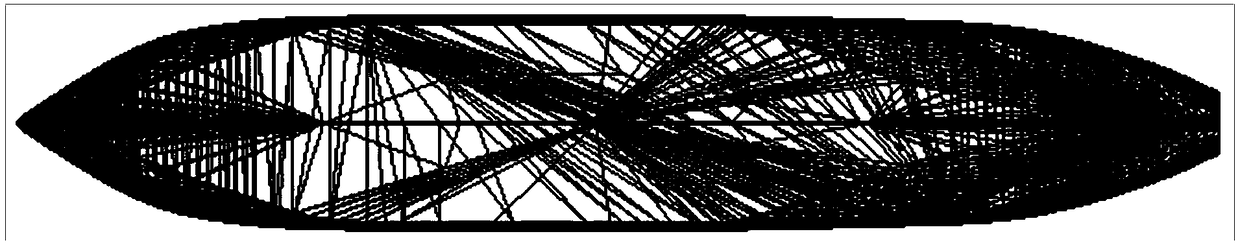

Boat body surface meshing method and device for hydrodynamic calculation

InactiveCN108694282AHigh precisionGuaranteed to be locatedGeometric CADSustainable transportationGeneration processCurve fitting

The invention relates to the technical field of a boat analog simulation technology, and provides a boat body surface meshing method and device for hydrodynamic calculation. The method comprises the following steps of 1, reading a boat body STL model to obtain the boat body scale information; 2, performing slicing processing on the boat body STL model by using the obtained boat body scale information to obtain all slice data of the boat body STL model; and 3, using all slice data of the boat body STL model to divide boat body surface lattices. The boat body surface lattices in the boat body hydrodynamic calculation can be fast generated; the generation process is simplified; the dense and precise boat body sectional line data can be accurately obtained; the errors due to three-dimensionalinterpolation and curve-fitting can be avoided; the real-time performance of the algorithm is good; and various complicated boat types difficult to be processed by the existing algorithm can be processed.

Owner:大连海驰科技有限公司 +1

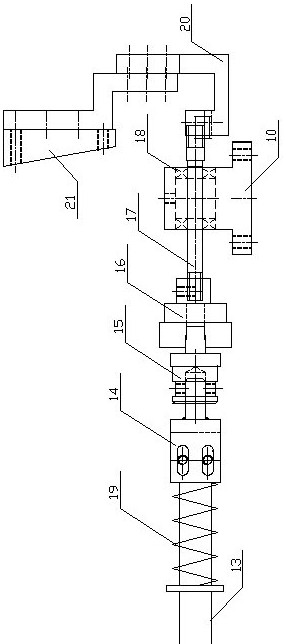

Gauge stand for repeated positioning detection

InactiveCN105371812AAvoid loss of precisionAdd lock nutMeasurement devicesMechanical engineeringPhase angle

The invention provides a gauge stand for repeated positioning detection. The gauge stand comprises a base, a front side wall, a rear side wall, a linear guide rail, a cushion block, a pre-tightening nut, a spring positioning pin, a pre-tightening spring, a dial indicator seat, a firing pin, an adjusting bolt, a dial indicator and a locking nut; the base is connected with the vertical front side wall and back side wall; 4 to 6 bolt holes are formed in on the base; the linear guide is located on the base and is fixedly connected with the base through the bolt holes; the spring positioning pin is located in the rear side wall; the pre-tightening spring sleeves the spring positioning pin; the pre-tightening nut is connected with the spring positioning pin; the dial indicator seat is located on the linear guide rail and is connected with the linear guide rail; the adjusting bolt is located in the front side wall; the locking nut is connected with the adjusting bolt; the firing pin is located at the side wall of the linear guide rail; the dial indicator is arranged on the dial indicator seat; and the cushion block is arranged on the linear guide rail. With the gauge stand for repeated positioning detection adopted, gear alignment detection accuracy of gear alignment phase angles of the same set of planetary gear assembly in a combined planetary gear alignment process can be improved.

Owner:TIANJIN TEEK TRANSMISSION

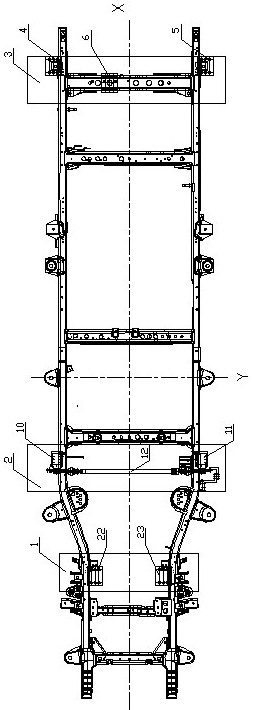

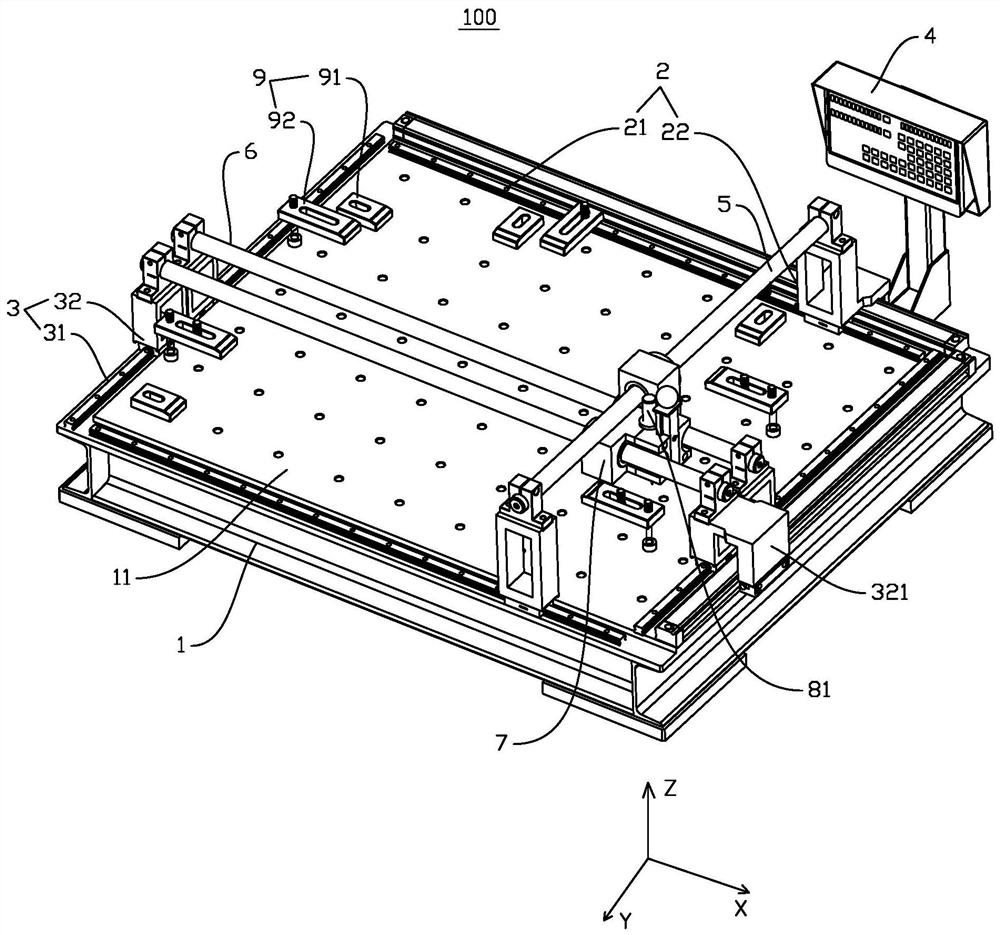

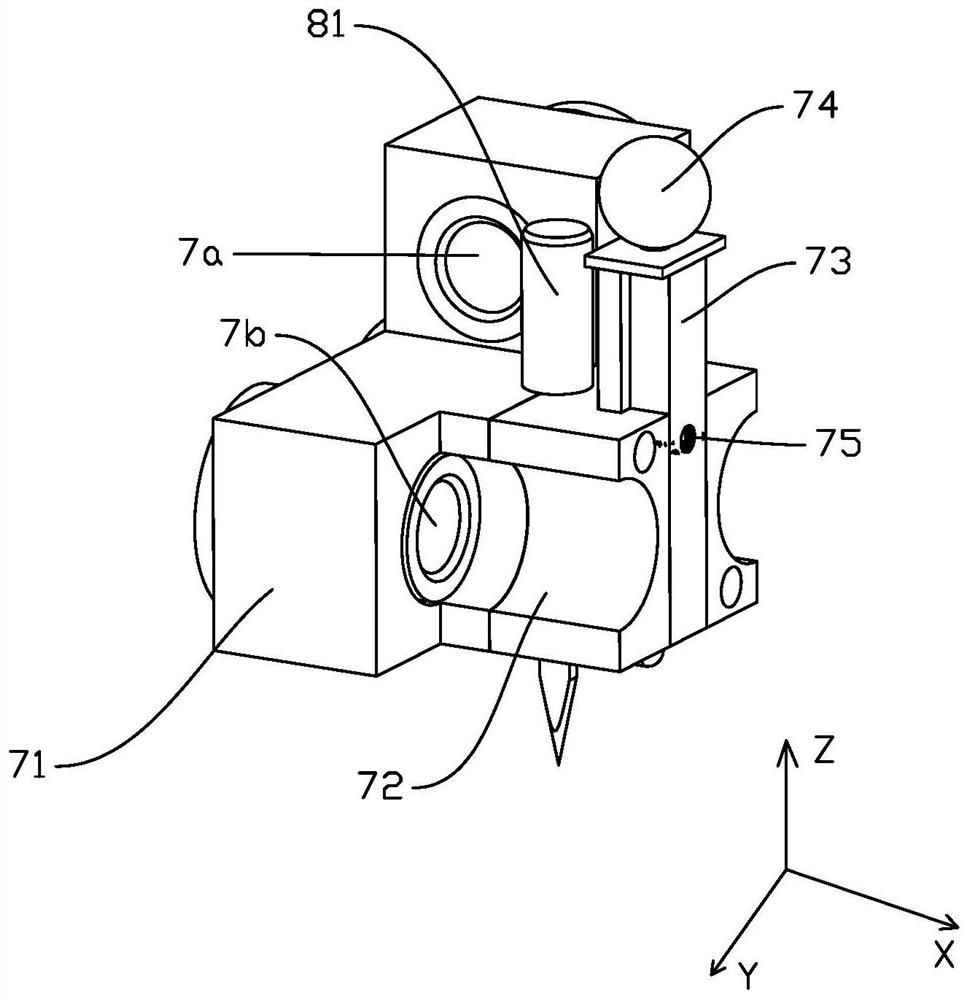

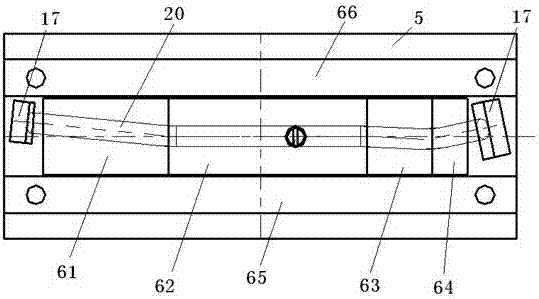

Automatic adjustment frame precision detection device and frame detection reference determination method

ActiveCN113494897AExtended service lifeEliminate the effects ofInternal combustion piston enginesMechanical measuring arrangementsVehicle frameDetent

The invention discloses an automatic adjustment frame precision detection device and a frame detection reference determination method. The automatic adjustment frame precision detection device comprises a front base, a middle base and a rear base which are sequentially arranged in the front-back direction of a frame; a left / right fixed supporting block and a middle adjusting positioner are mounted on the rear base; a left adjusting mechanism and a right adjusting mechanism are symmetrically arranged on the middle base and connected with the two ends of the flexible adjusting synchronizing shaft respectively; and a left / right rotary movable supporting table is mounted on the front base. The problem of detection precision distortion caused by detection reference deviation due to large frame welding deformation is solved, the consistency and accuracy of frame detection precision are greatly improved, the method can be applied to detection of frames with different widths, the work of replacement, adjustment, detection and positioning is reduced, and the detection efficiency is improved; and the device has the advantages of being high in detection accuracy, exquisite in mechanism, reliable in use and low in cost.

Owner:郑州日产汽车有限公司

High polymer material production equipment

InactiveCN111729633AAvoid loss of precisionFully contactedProcess control/regulationChemical/physical/physico-chemical stationary reactorsFrequency changerElectric machine

The invention discloses high polymer material production equipment which comprises a first reaction kettle body and a second reaction kettle body, wherein a transmission device is fixedly mounted at the top end of the second reaction kettle body; a display lamp is fixedly mounted on the upper surface of the transmission device; a motor is fixedly mounted on the upper surface of the transmission device; frequency converter fixedly connected with motor, the stirring frequency of the stirrer fan blades can be adjusted for sufficient stirring, so that the high polymer materials are in more sufficient contact; the stirring effect is improved, the raw materials are uniformly stirred, and the quality of finished products is improved; an enough space is formed between the stirring fan blades and the first reaction kettle body, so that the friction with the kettle body is reduced; the discharging pipe is fixedly mounted at the bottom end of the first reaction kettle body, so that high polymer materials can flow out uniformly, the labor intensity of workers is greatly reduced, the extruding device is fixedly mounted at the rightmost end of the discharging pipe, the stirred materials can be more uniformly accumulated together, and the product quality is effectively improved.

Owner:HANSHAN NORMAL UNIV

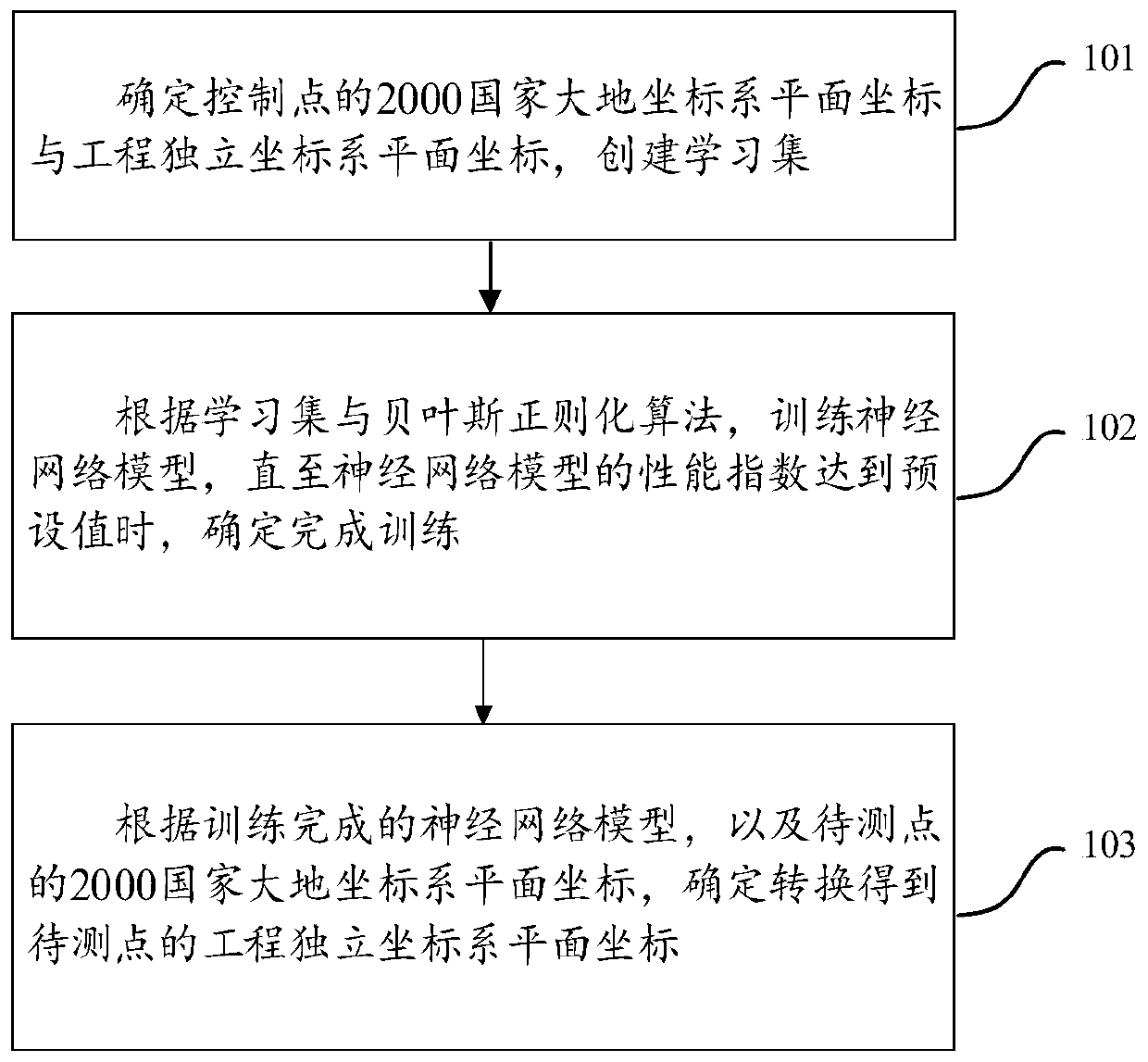

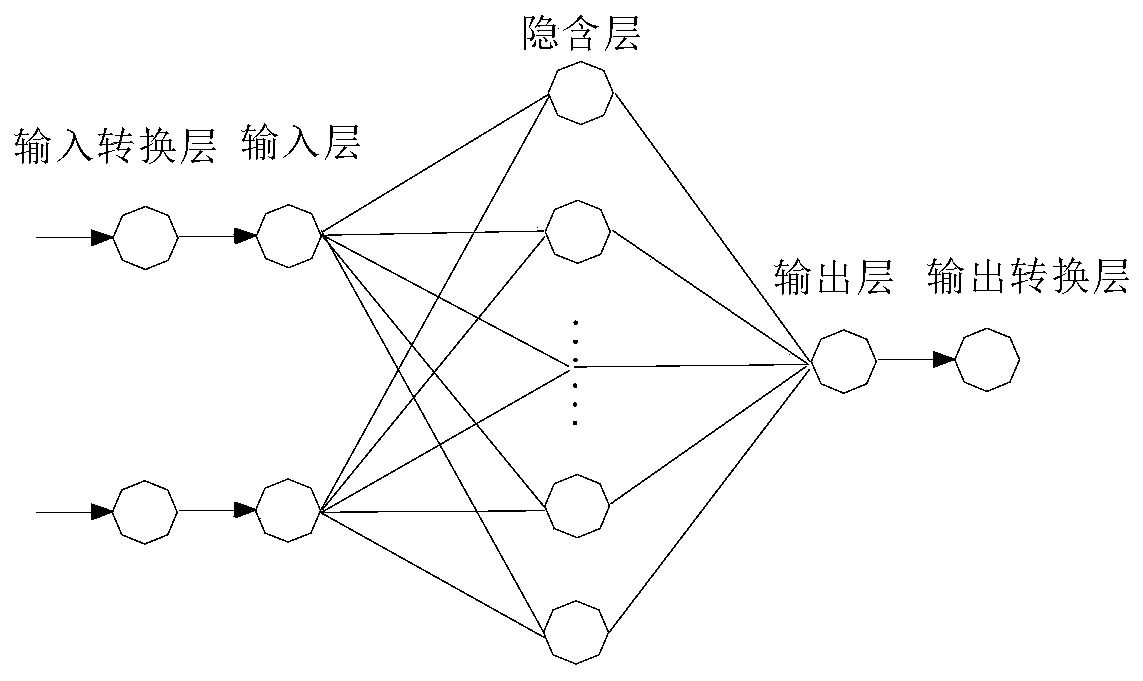

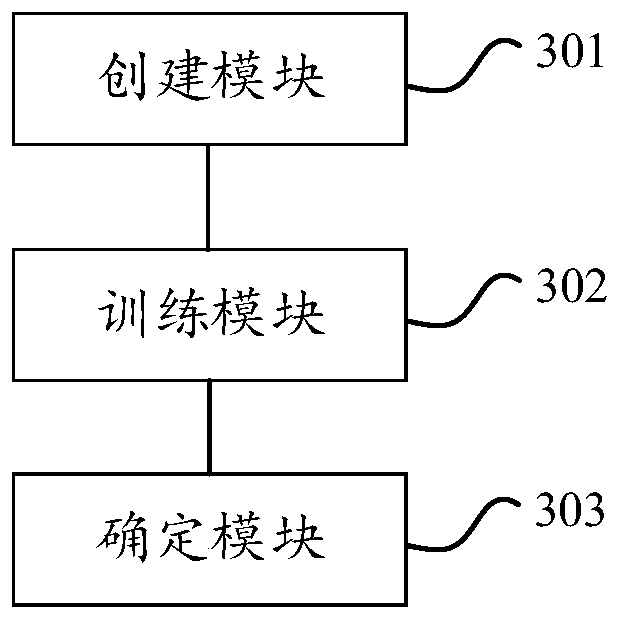

Bayesian regularization back propagation neural network coordinate conversion method and device

PendingCN111598235APrevent overfittingSimple structureGeometric image transformationCharacter and pattern recognitionBack propagation neural networkAlgorithm

The invention discloses a Bayesian regularization back propagation neural network coordinate conversion method and device, which are used for solving the problems that in the coordinate conversion process, a set of coordinate conversion parameters is adopted in the whole area, so that the precision of the local area is lost in the coordinate conversion process, and the accuracy of the converted coordinates is influenced. The Bayesian regularization back propagation neural network coordinate conversion method comprises the following steps: determining plane coordinates of a 2000 country geodetic coordinate system and plane coordinates of an engineering independent coordinate system of a control point, and creating a learning set; training a neural network model according to the learning setuntil the performance index of the neural network model reaches a preset value, and determining that the training is completed; and according to the trained neural network model and the 2000 countrygeodetic coordinate system plane coordinates of the to-be-measured point, determining engineering independent coordinate system plane coordinates of the to-be-measured point obtained through conversion. According to the Bayesian regularization back propagation neural network coordinate conversion method, the network weight of the back propagation neural network is limited through the Bayesian regularization algorithm, and the network structure is effectively improved, and the accuracy of coordinate conversion is improved.

Owner:SHANDONG JIAOTONG UNIV

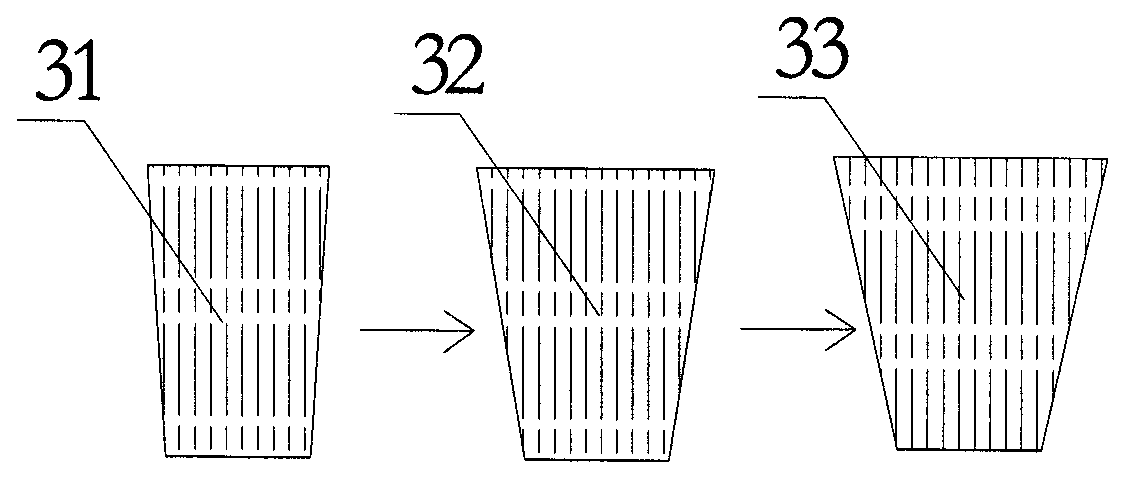

Automatic feeding and automatic turning-round magnetic material punching machine

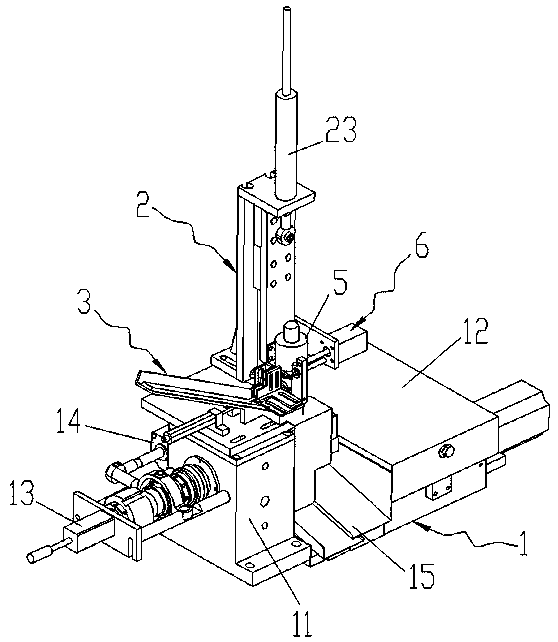

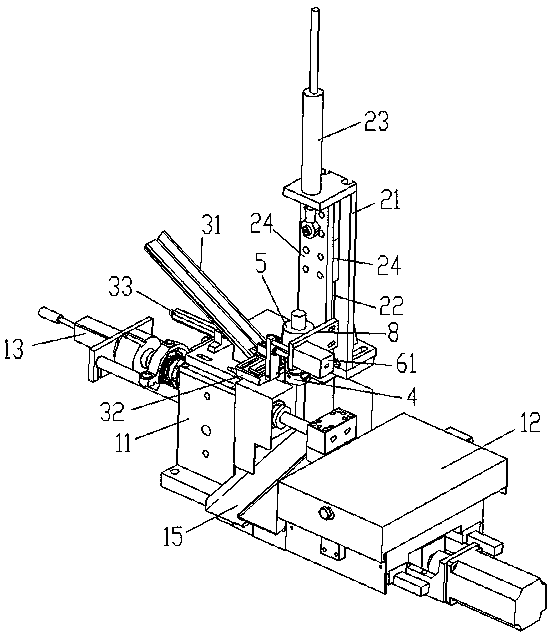

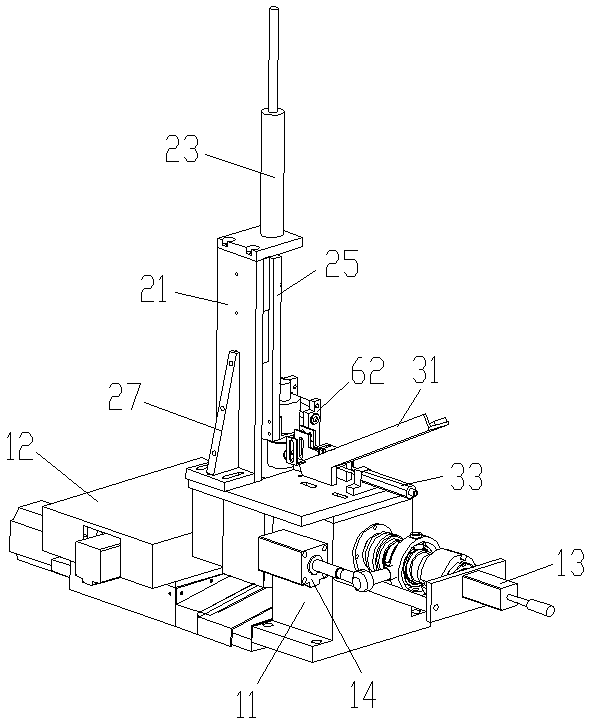

PendingCN111318736AImprove machining accuracyAvoid loss of precisionMetal working apparatusBoring/drilling machinesPunchingRobot hand

The invention discloses an automatic feeding and automatic turning-round magnetic punching machine. The automatic feeding and automatic turning-round magnetic punching machine comprises a punching machine main body composed of a clamping workpiece and rotating main shaft device, a cross worktable, a discharging air cylinder and a clamping air cylinder, and a lifting device and an automatic feedingdevice used for pushing a to-be-machined material into a rotating mechanical arm are arranged on the upper plate surface of the clamping workpiece and rotating main shaft device; and the rotating mechanical arm is fixedly installed on a rotator, the rotator rotates to drive the rotating mechanical arm to rotate so as to achieve the automatic turning-round of the to-be-machined material, the rotator is installed on the lifting device, the lifting device drives the rotator to achieve the conveying of the to-be-machined material to a position with a predetermined height, a material ejecting device is further installed on the lifting device, and the material ejecting device moves horizontally to push the to-be-machined material in the rotating mechanical arm to a clamping position of the clamping workpiece and rotating main shaft device. The automatic feeding and automatic turning-round magnetic punching machine is high in punching efficiency and low in production cost, and twice machining of the material can be conducted in the same environment.

Owner:宁波市江北宁科金创机械制造有限公司

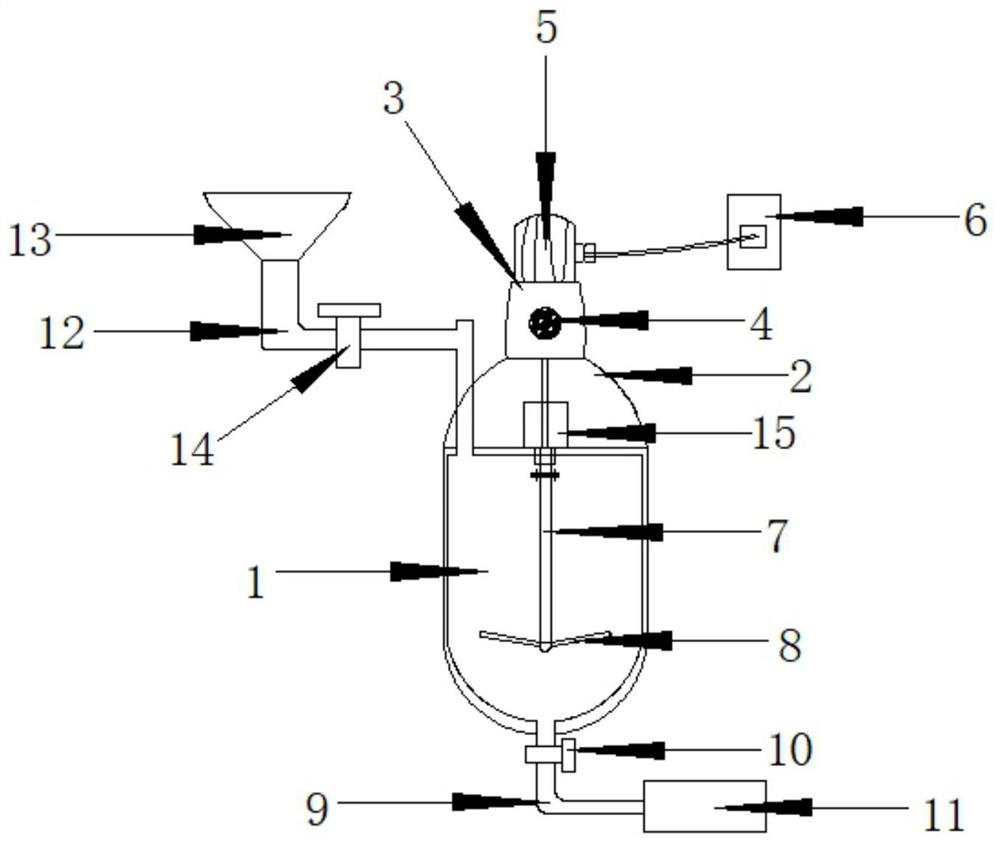

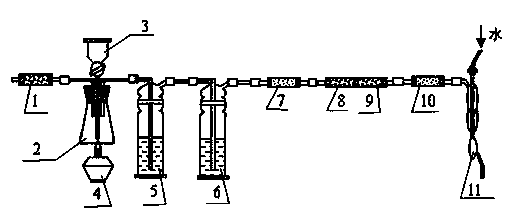

Carbon dioxide content determination apparatus

InactiveCN103091194BGuaranteed accuracyLow market pricePreparing sample for investigationWeighing by absorbing componentCo2 absorptionChloride

The invention relates to a carbon dioxide content determination apparatus. The apparatus comprises a reaction device, the reaction device comprises a reaction bottle, the reaction bottle is provided with a separating funnel having a piston, an alcohol burner is arranged under the reaction bottle, a device for absorbing carbon dioxide in air is arranged in front of the reaction bottle, and an impurity removal device, a carbon dioxide absorbing device and a water absorbing device are sequentially arranged behind the reaction bottle. The apparatus has the advantages of simplicity, easy operation, realization of the assembling completion in most laboratories, and wide application range. The carbon dioxide content result determined through using the apparatus is stable and reliable, and has a good precision and a good accuracy; and simultaneously anhydrous calcium chloride is used to substitute anhydrous magnesium perchlorate, so the measure cost is effectively reduced, and the apparatus is economic and practical.

Owner:武汉钢铁有限公司

A Control and Drive System for a Universal Rack

ActiveCN106861055BRealize self-calibration functionAngular fault toleranceX-ray/gamma-ray/particle-irradiation therapyFrequency changerAutomatic control

The invention discloses a control driving system for a universal rack, which can realize stable and reliable rack rotation control and high control precision. A photoelectric encoder and a potentiometer are arranged on the rack and a motor respectively, two measurement angle values are calibrated through an angle calibration module, and thus, a self-calibration function is realized; in the case of automatic control, when the rack moves near a target angle, different operating frequencies are transmitted to a frequency converter according to the difference between the current angle and the target angle, the relationship between the angle difference and a motion speed can simulate a damped motion curve, the motion speed of the rack just reaches 0 when the rack moves to the target angle, and thus, zero overshoot control is realized, and the rotation precision is high; and through detecting the position of a treatment couch in real time through an automatic anti-collision control unit and an anti-collision and anti-over turning control module, collision between the rack and the treatment couch is automatically prevented.

Owner:江苏海明医疗器械有限公司

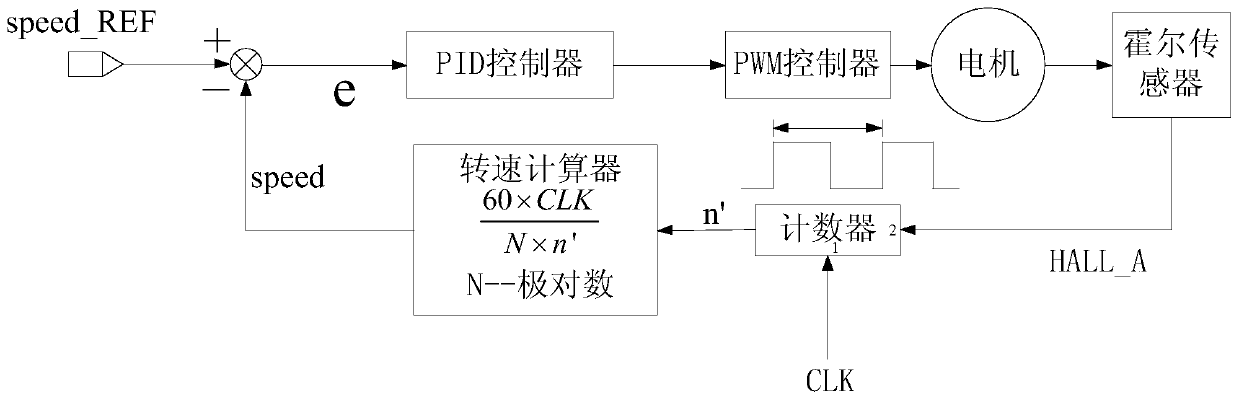

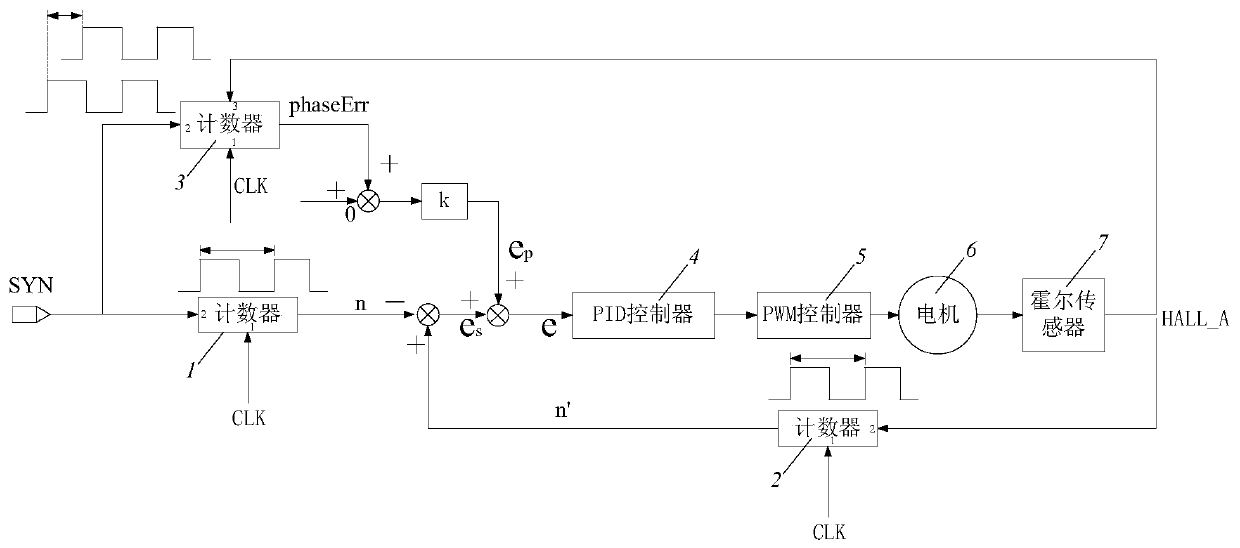

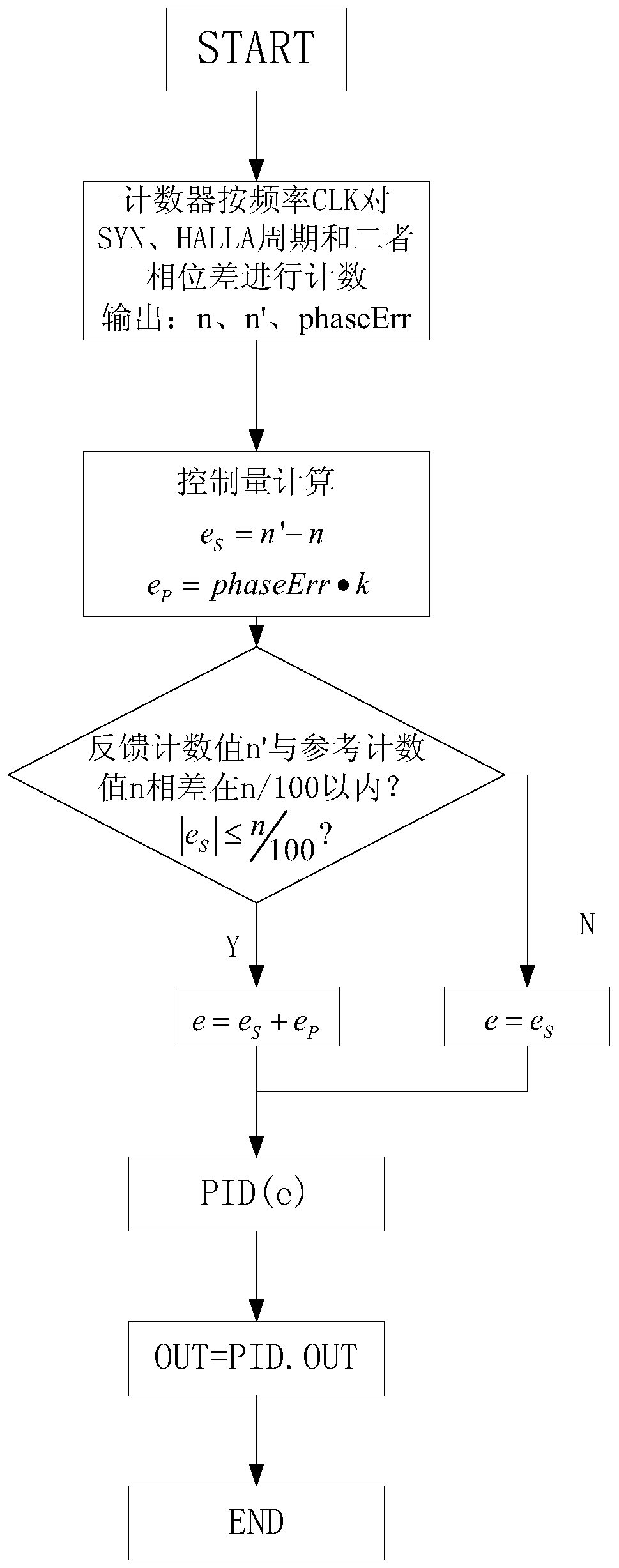

High-precision phase-locked motor speed controller

ActiveCN107592039BHigh speed accuracySolve the problem that the angular error becomes larger over timeSingle motor speed/torque controlElectronic commutatorsMotor speedProportion integration differentiation

Owner:NO 24 RES INST OF CETC

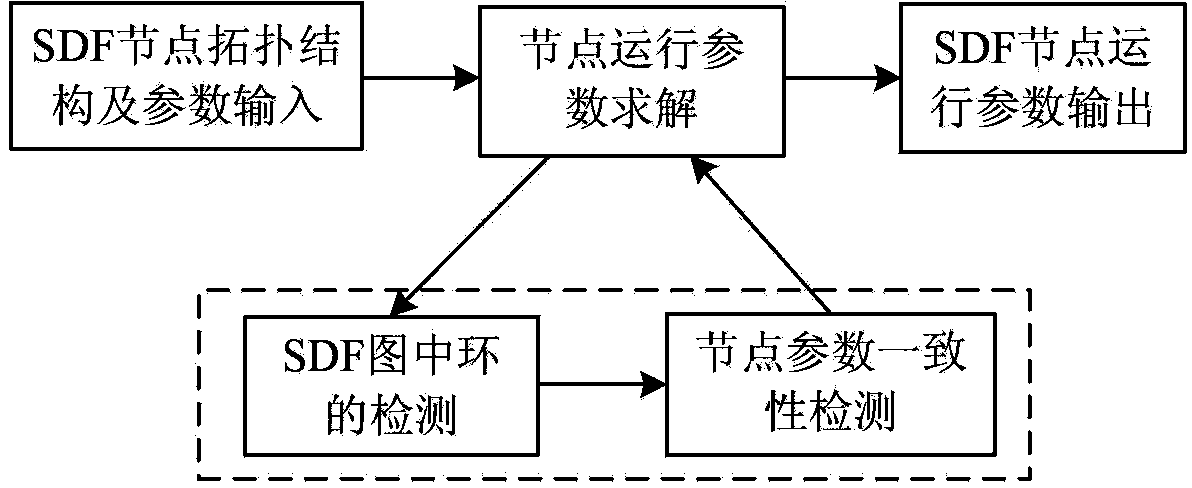

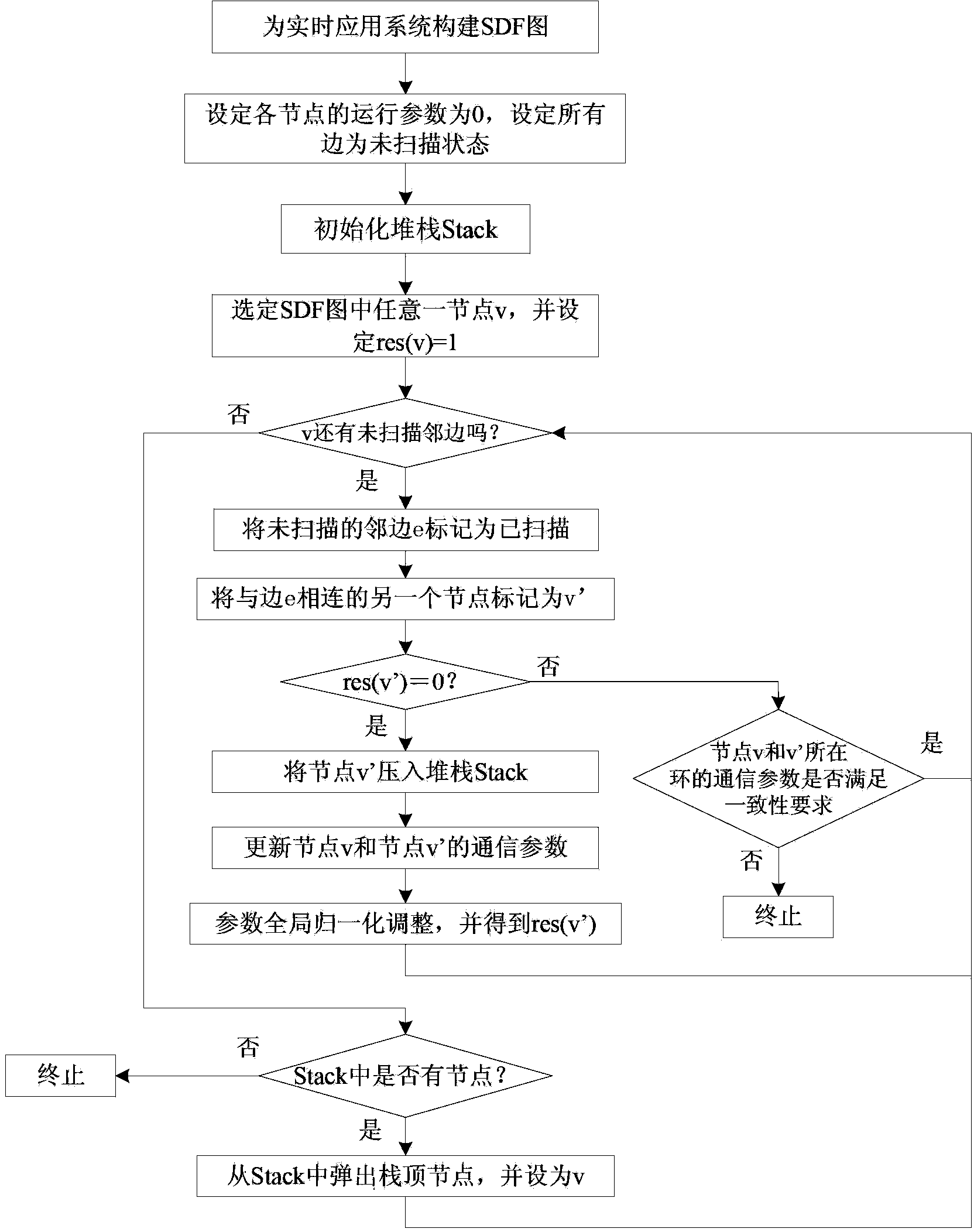

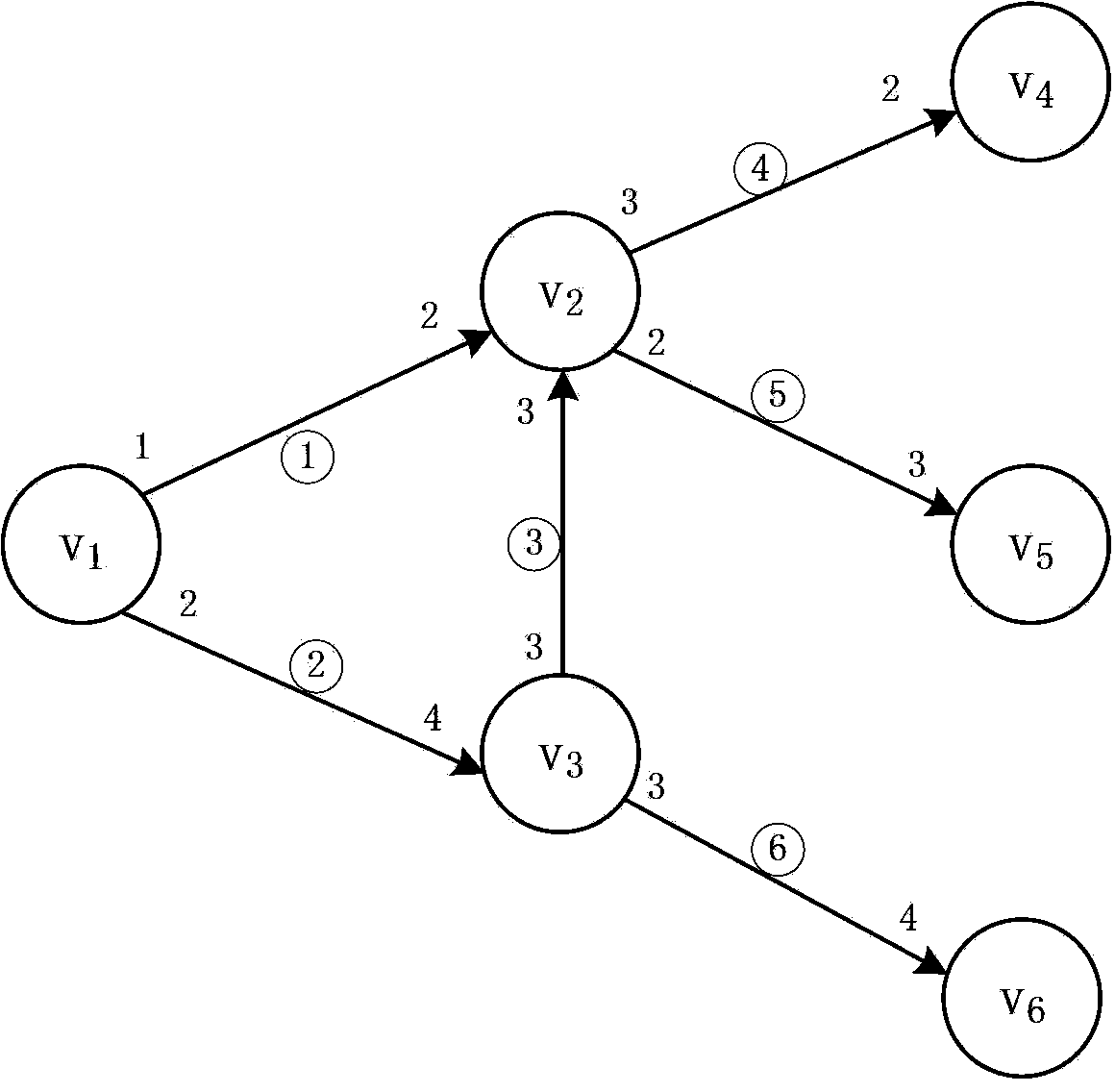

Fast processing method of ergodic synchronous data flow system node parameter based on graphs

InactiveCN103136334BGeneralizedAvoid calculationSpecial data processing applicationsData streamParallel computing

The invention discloses a fast ergodic synchronous data flow (SDF) system node parameter processing method based on graphs. The fast ergodic synchronous data flow system node parameter processing method includes that an SDF graph is built for a real-time system, communication parameters of nodes connected at two ends on the side are marked at the two ends of each side in the graph, a node needed to be temporarily stored in the SDF graph stacking and storing ergodic process is built, any one node in the SDF is selected and operation parameters of the selected node are initialized, scanning is started, whether rings exist in the graph can be judged when each node is scanned, operation parameter consistency judgment is performed on yes judgment, otherwise, the operation parameters of the node are determined on the basis of communication parameters of the node, and the operation parameters of the scanned nodes in the graph are subjected to overall normalized adjustment. The fast ergodic synchronous data flow system node parameter processing method is few in processing steps, small in calculating amount, high in efficiency and accurate in calculating result, has the universalizaion advantage of being capable of processing parameters in different attributes, and improves speed and efficiency of computers for processing real-time SDF system node operation parameters.

Owner:BEIHANG UNIV

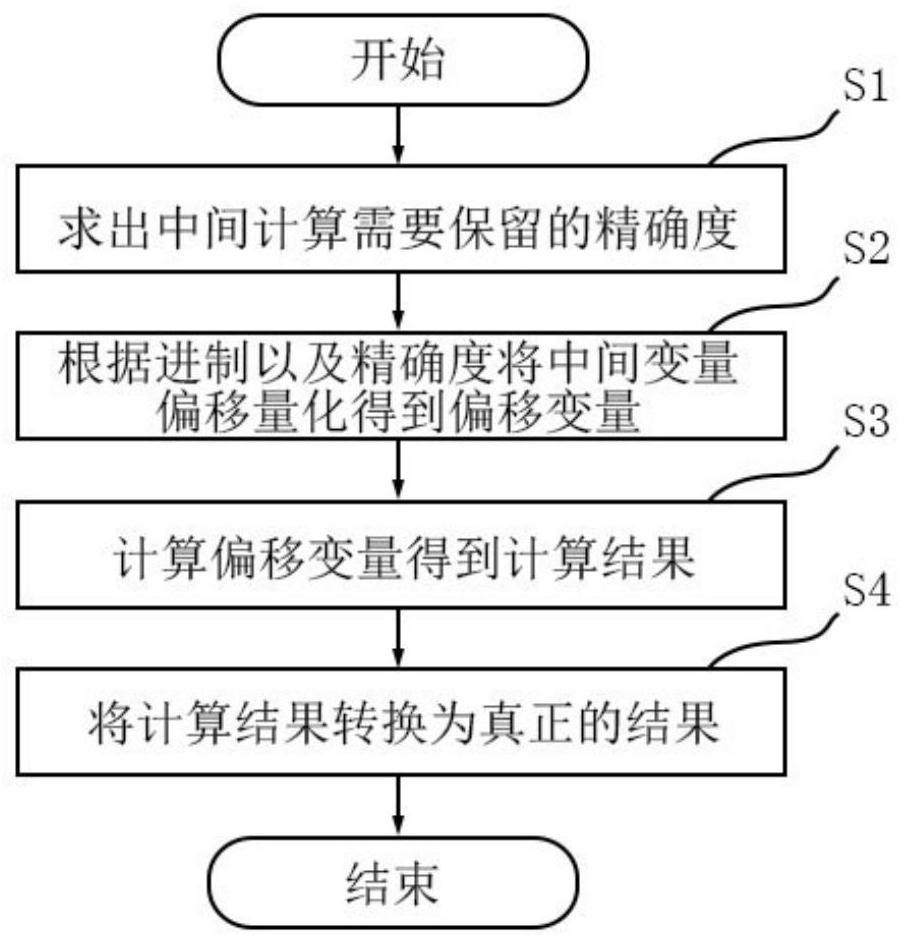

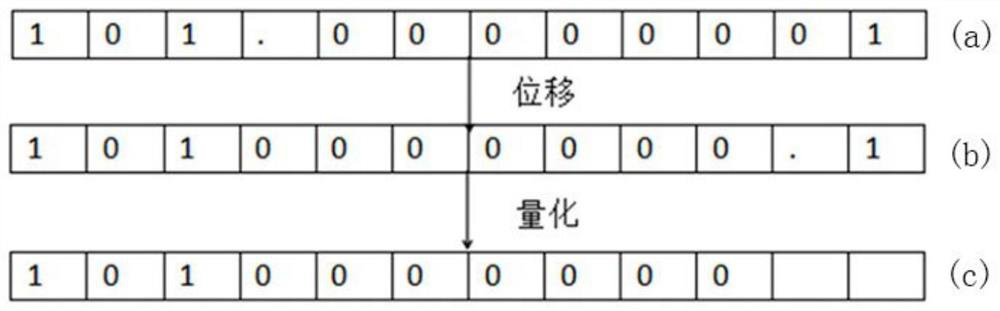

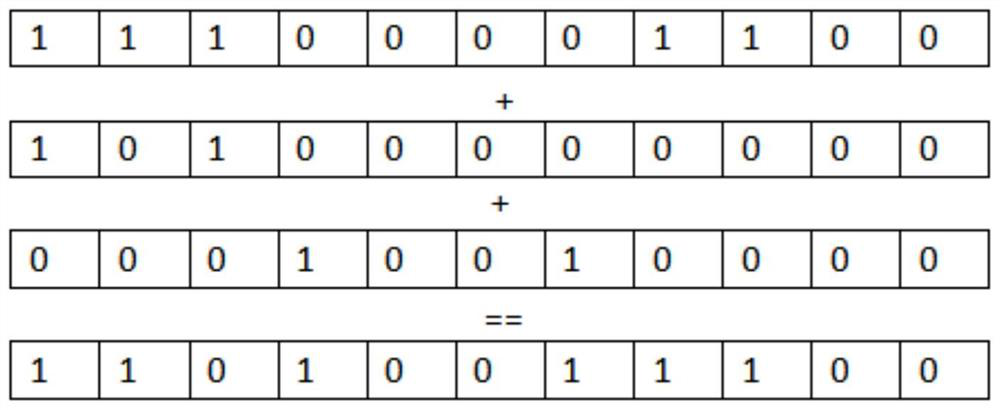

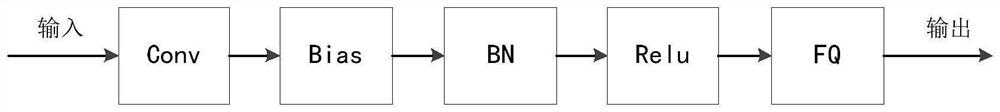

High-precision quantization acceleration method for ultra-high-resolution image analysis

ActiveCN110213582BAccuracy impactGuaranteed accuracyDigital video signal modificationImaging analysisUltrahigh resolution

The present invention provides a high-precision quantitative acceleration method for ultra-high resolution image analysis, which is used to improve a large amount of intermediate data calculation process in the ultra-high resolution image analysis process through quantization, and is characterized in that it includes the following steps: Step S1, obtain the accuracy α required for the final result, and obtain the accuracy β that needs to be retained in the intermediate calculation; step S2, obtain the intermediate variable X, and perform the intermediate variable X according to the accuracy β that needs to be retained in the intermediate calculation through the current calculation system γ Quantize to get the offset variable X 1 ;Step S3, based on the offset variable X 1 Carry out the calculation operation, obtain the calculation result Y1, and reserve the calculation process queue Q in the calculation process; step S4, by the calculation result Y 1 , the accuracy β that needs to be preserved in the intermediate calculation, and the calculation process queue Q to get the final result Y of the final base.

Owner:FUDAN UNIV

Image sub-pixel matching and positioning method, system, device and medium

ActiveCN113850807BHigh positioning accuracyAvoid loss of precisionImage enhancementImage analysisPattern recognitionComputer graphics (images)

The invention discloses an image sub-pixel matching and positioning method, system, equipment and medium. The image sub-pixel matching and positioning method includes: preprocessing a preset template image and a target image; preprocessing the preset template image Carry out rough matching of pixel-level similarity with the target image, and obtain the rough matching translation coordinates and rough matching rotation angles; use the rough matching translation coordinates and rough matching rotation angles as the initial parameters of the cost function in the preset similarity matching model, by having The cost function of the initial parameters determines the loss value corresponding to the sub-pixel similarity between the preset template image and the target image; when the loss value satisfies the convergence condition, the initial parameters are used as the final positioning result parameters of the target image; according to the final The positioning result parameter performs a preset positioning operation on the preset positioning object. The present invention can effectively avoid the problem of lack of precision caused by discretization of translation coordinates and rotation angles, and improves positioning precision.

Owner:深圳市大族封测科技股份有限公司

A support unit capable of supporting ball screws of different shaft end sizes

ActiveCN103122981BEasy to processReassuring and reliableMachine gearing/transmission testingGearingBall screwRetaining ring

The invention discloses a supportive element capable of supporting ball screws with different shaft end size and particularly relates to the supportive element capable of supporting ball screws with different shaft end size. The supportive element mainly comprises a pressure nut, a threaded sleeve, an elastic retaining ring, a spring taper sleeve, a bearing, an inner taper sleeve, a supportive seat, an isolation sleeve and a locking nut and is characterized in that after ball screws with different size are replaced, the ball screws can be supported without detaching the supportive seat by replacing the spring taper sleeve, the bearing, the elastic retaining ring, the isolation sleeve and the locking nut. The supportive element capable of supporting ball screws with different shaft end size is compact in structure, high in centering precision, convenient to operate, low in cost and easy to machine.

Owner:NANJING UNIV OF SCI & TECH

Method and device for realizing image container control with effect of convex lens

ActiveCN101727325BAvoid stackingAvoid loss of precisionSpecific program execution arrangementsInput/output processes for data processingPartition of unityResource consumption

The invention provides a method and a device for realizing an image container control with the effect of a convex lens. The method comprises the following steps of: collecting the offset delta x of x-coordinate generated by moving figures on a touch screen at intervals per unit time using the top left corner of a main window as the origin of coordinate of the main window; calculating the X coordinate Xw(i) of the origin of coordinate of a display window according to the offset of the coordinate x generated by moving figures at intervals per unit time and calculating the zoom coefficient according to the X coordinate XC in the centre point of the display window and the X coordinate X(i) in the centre point of the subcontrol; obtaining the width W(i) of a new image and the height H(i) of a new image according to the zoom coefficient; calculating coordinate X at the top left corner of the new image according to the X coordinate X(i) in the centre point of the subcontrol, the width W(i) of the new image and the X coordinate Xw(i) of the origin of coordinate of the display window; calculating the coordinate Y at the top left corner of the new image according to the Y coordinate H in the centre point of the subcontrol and the height H(i) of the new image; and drawing the image according to the parameters. The invention realizes the image container control with the effect of the convex lens in a way of light-weight resource consumption in case of limited CPU and memory resources.

Owner:CHINA TELECOM CORP LTD

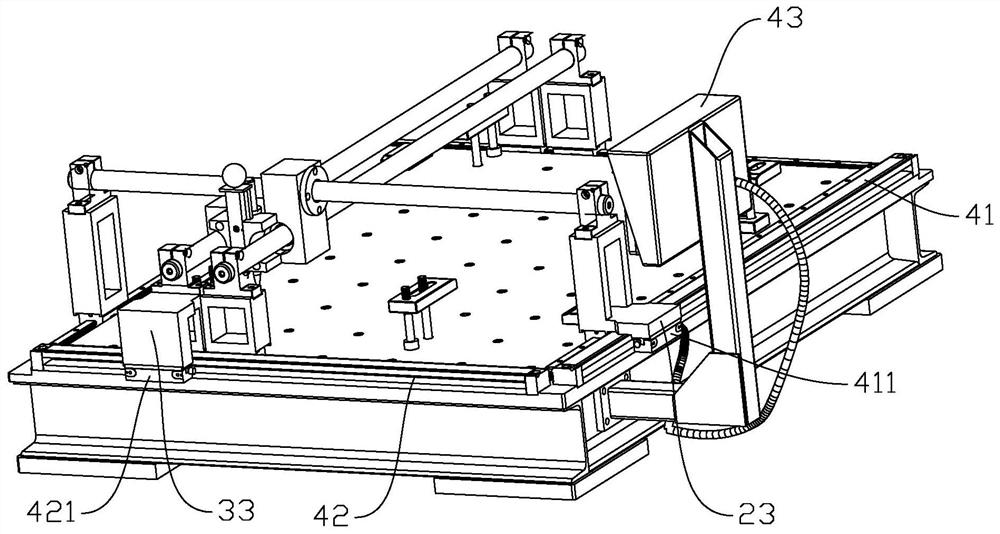

Drilling and marking device

PendingCN114131573ASimple structureReduce manufacturing costOther workshop equipmentControl theoryMechanical engineering

The invention relates to a drilling and marking device. The drilling and scribing device comprises a base; the first sliding assembly comprises a first sliding rail and a first sliding block, the first sliding rail is arranged on the top face of the base, and the first sliding block is arranged on the first sliding rail in a sliding mode; the second sliding assembly comprises a second sliding rail and a second sliding block, the second sliding rail is arranged on the top face of the base, the second sliding block is arranged on the second sliding rail in a sliding mode, and the first sliding rail is perpendicular to the second sliding rail; the measuring unit is used for measuring the sliding distance of the first sliding block and the sliding distance of the second sliding block; a first slide bar and a second slide bar; the supporting seat comprises a first through hole and a second through hole, the supporting seat is arranged on the first sliding rod in a sliding mode through the first through hole, and the supporting seat is arranged on the second sliding rod in a sliding mode through the second through hole; the first scribing needle is arranged on the supporting seat, and the axis of the first scribing needle is perpendicular to the top surface of the base. According to the drilling lineation device, the lineation and drilling efficiency and precision are improved.

Owner:CETC WUHU DIAMOND AIRCRAFT MFG +1

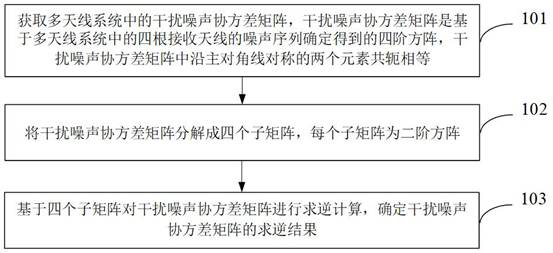

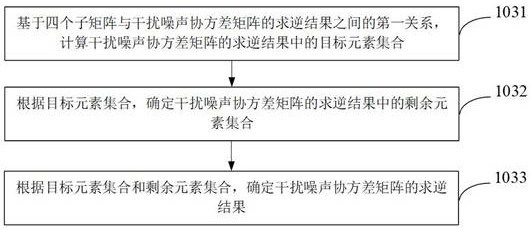

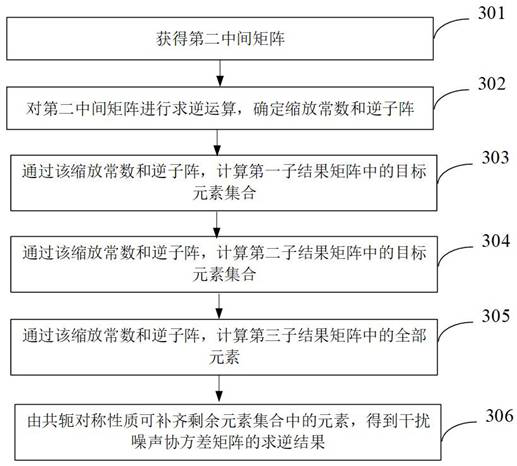

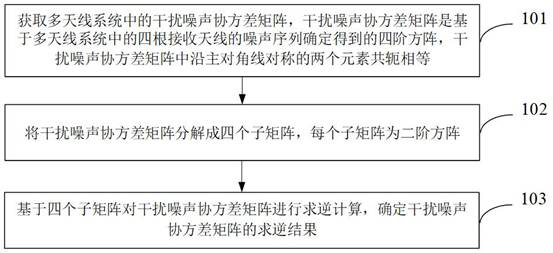

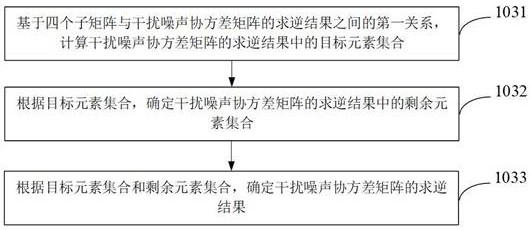

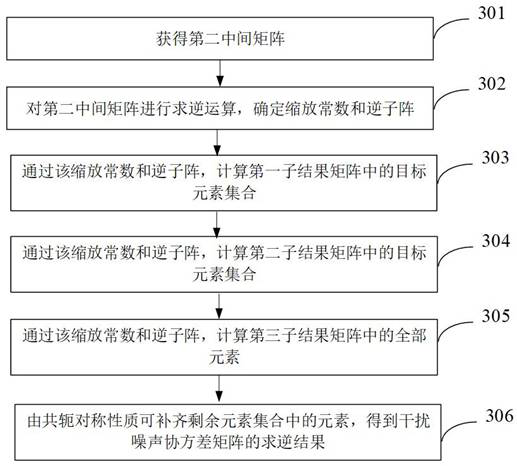

Matrix inversion method, device and equipment for multi-antenna system and storage medium

ActiveCN113708817AAvoid Iteration ErrorsReduce bit error rateSpatial transmit diversityChannel estimationMain diagonalInterference (communication)

The invention relates to a matrix inversion method, device and equipment for a multi-antenna system and a storage medium, and relates to the technical field of wireless communication, and the method comprises the steps: obtaining an interference noise covariance matrix in the multi-antenna system, wherein the interference noise covariance matrix is a four-order square matrix determined based on noise sequences of four receiving antennas in the multi-antenna system, and two elements symmetrical along a main diagonal in the interference noise covariance matrix are conjugated and equal; decomposing the interference noise covariance matrix into four sub-matrixes, wherein each sub-matrix is a second-order square matrix; and performing inversion calculation on the interference noise covariance matrix based on the four sub-matrixes, and determining an inversion result of the interference noise covariance matrix. In this way, decomposition and order reduction can be carried out on the four-order interference noise covariance matrix, and the inversion result can be directly obtained by omitting the layer-by-layer iteration process, so that the precision loss in the iteration process can be avoided, the bit error rate in the multi-antenna system is reduced, and meanwhile, the operand is reduced.

Owner:GUANGZHOU HUIRUI SITONG INFORMATION SCI & TECH CO LTD

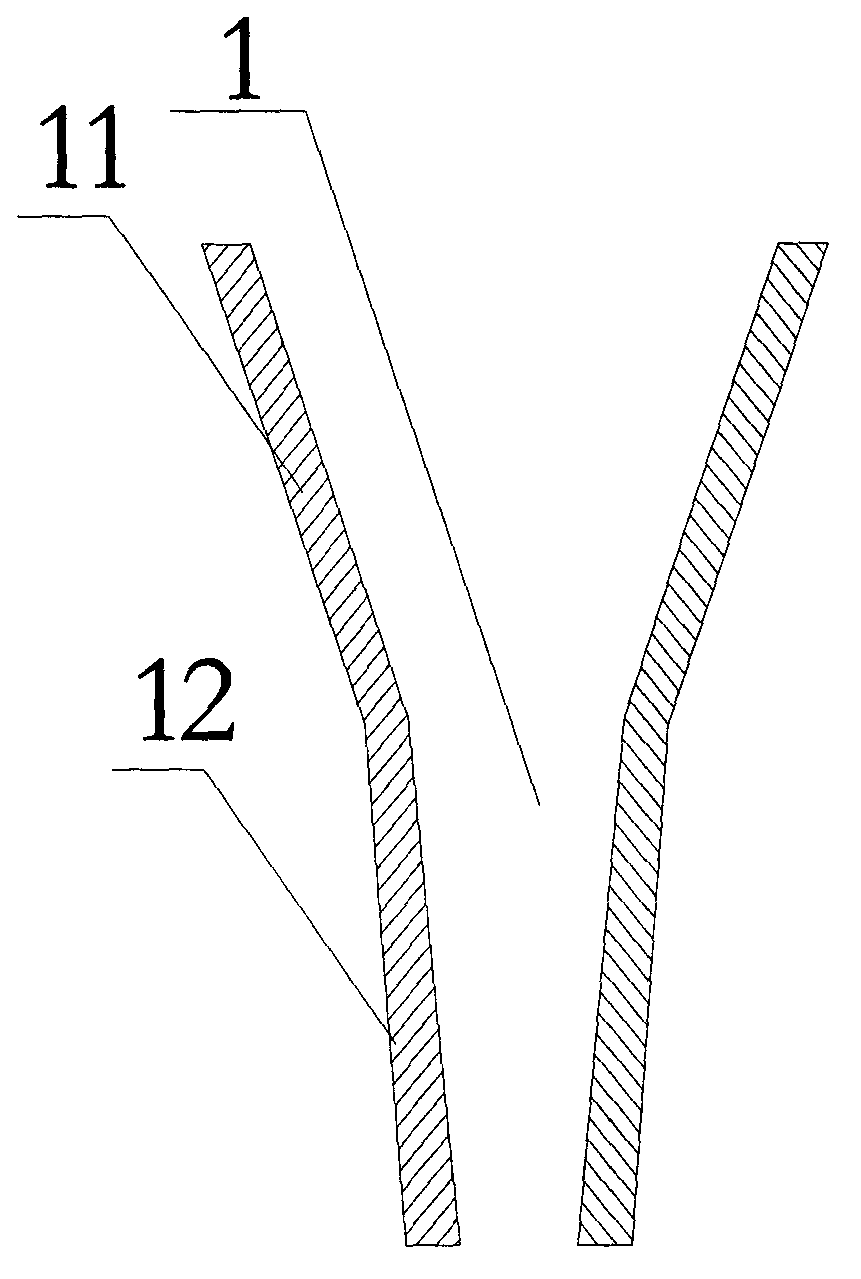

A pipe forming device

ActiveCN104607513BReduce investmentShorten the timeShaping toolsMetal-working feeding devicesEngineeringSingle station

The invention discloses a pipe fitting forming device, which comprises a workbench and an upper base plate arranged sequentially from top to bottom, a lifting mechanism is arranged between the workbench and the upper base plate, and the upper base plate moves up and down through the lifting mechanism; the top surface of the workbench The lower mold assembly, the lower stripping plate and the lower mold base are arranged in sequence from top to bottom; the upper mold base, the upper stripping plate and the upper mold group are arranged in sequence from top to bottom on the bottom surface of the upper base plate opposite to the top surface of the workbench pieces. Compared with the single-station, single-process processing mode, the present invention saves the time spent on re-clamping pipe fittings between processing processes, has high processing efficiency, avoids the loss of precision caused by multiple clamping, and effectively improves the processing accuracy. , fully meet the quality requirements.

Owner:ZHENJIANG MINGCHENG PIPE IND CO LTD

A semi-analytical sensitivity analysis method for dynamics of flexible multibody systems

ActiveCN111159636BImprove computing efficiencyImprove calculation accuracyDesign optimisation/simulationComplex mathematical operationsAlgorithmDynamic equation

The invention relates to the technical field of dynamic system optimization, and proposes a semi-analytical sensitivity analysis method for flexible multi-body system dynamics based on absolute node coordinate description. First, based on the absolute nodal coordinate method, the mass matrix, stiffness matrix and generalized force array of the flexible multi-body system are established; secondly, the dynamic equations of the flexible multi-body system and the optimization objective function are established; thirdly, based on the direct differential method or accompanying variable The semi-analytic sensitivity calculation formula of the flexible multi-body system dynamics is established by using the method; finally, the differential algebraic equation of the flexible multi-body system dynamics is solved to obtain the sensitivity calculation results. According to the absolute node coordinate method and the multi-body system dynamics theory, the present invention establishes a semi-analytical sensitivity calculation formula of the flexible multi-body system to solve the sensitivity analysis problem of the flexible multi-body system dynamics, and aims to provide a set of flexible multi-body system sensitivity A new strategy for analysis that facilitates sensitivity calculations for large-scale complex flexible multibody systems.

Owner:DALIAN UNIV OF TECH

Matrix inversion method, device, equipment and storage medium for multi-antenna system

ActiveCN113708817BAvoid Iteration ErrorsReduce bit error rateSpatial transmit diversityChannel estimationMain diagonalInterference (communication)

The disclosure relates to a matrix inversion method, device, device and storage medium for a multi-antenna system, and relates to the field of wireless communication technology. The method includes: obtaining the interference noise covariance matrix in the multi-antenna system, the interference noise covariance matrix is a fourth-order square matrix determined based on the noise sequences of four receiving antennas in a multi-antenna system. The two elements in the interference noise covariance matrix that are symmetrical along the main diagonal are conjugate equal; the interference noise covariance matrix is decomposed into Four sub-matrices, each sub-matrix is a second-order square matrix; based on the four sub-matrices, the inverse calculation of the interference noise covariance matrix is performed to determine the inversion result of the interference noise covariance matrix. In this way, the fourth-order interference noise covariance matrix can be decomposed and reduced. Since the process of layer-by-layer iteration is omitted and the inversion result can be obtained directly, the loss of accuracy in the iterative process can be avoided, making the bit error in the multi-antenna system The rate is reduced, and the amount of calculation is reduced at the same time.

Owner:GUANGZHOU HUIRUI SITONG INFORMATION SCI & TECH CO LTD

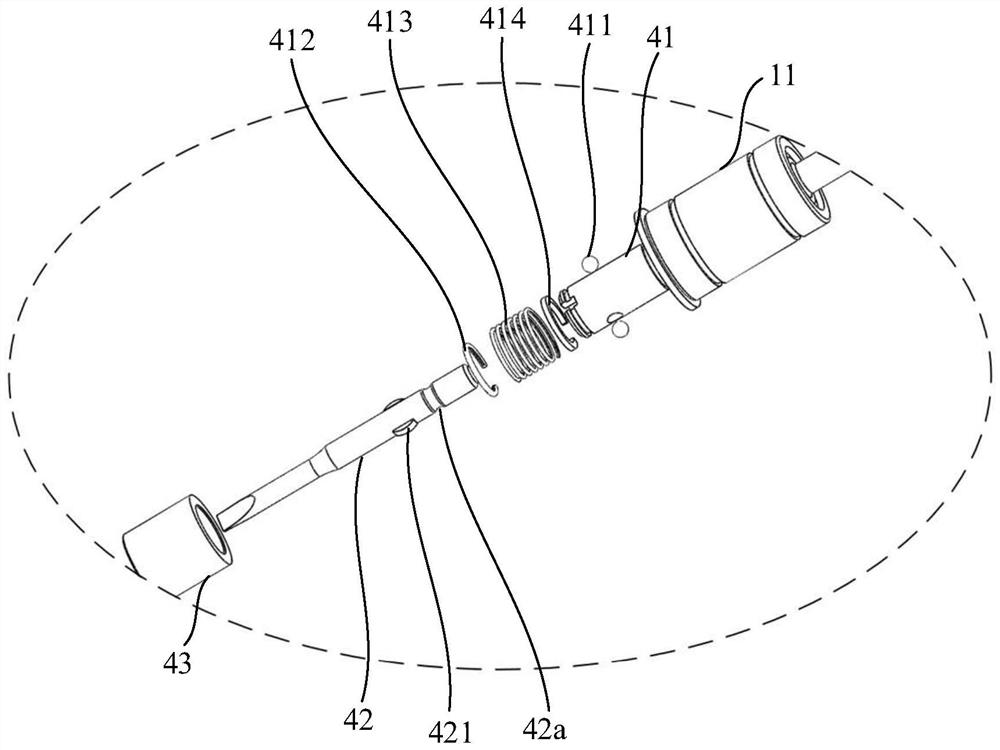

Automatic intelligent electric screwdriver based on torque and pressure composite force sensor

PendingCN114559393AImprove consistencyAvoid Loss of PrecisionPower driven toolsMotor shaftElectrical and Electronics engineering

The invention relates to the technical field of electric screwdrivers, and provides an automatic intelligent electric screwdriver based on a torque and pressure composite force sensor and a control method of the automatic intelligent electric screwdriver. The automatic intelligent electric screwdriver based on the torque and pressure composite force sensor comprises a base; a motor; one end of the torque and pressure composite force sensor is fixed on the base, and the other end of the torque and pressure composite force sensor is connected with the motor; the screwdriver head structure comprises an electric screwdriver core shaft and a screwdriver head, and the two ends of the electric screwdriver core shaft are coaxially connected with the motor shaft and the screwdriver head respectively; and a sensor aviation plug and a motor aviation plug are arranged on the fuselage shell. According to the automatic intelligent electric screwdriver based on the torque and pressure composite force sensor, tightening torque and assembly pressure data in the screw locking process can be collected and monitored in real time, and the consistency and reliability of operation quality and the controllability of assembly pressure are greatly improved while ultrahigh tightening precision is guaranteed.

Owner:北京力优科技有限公司

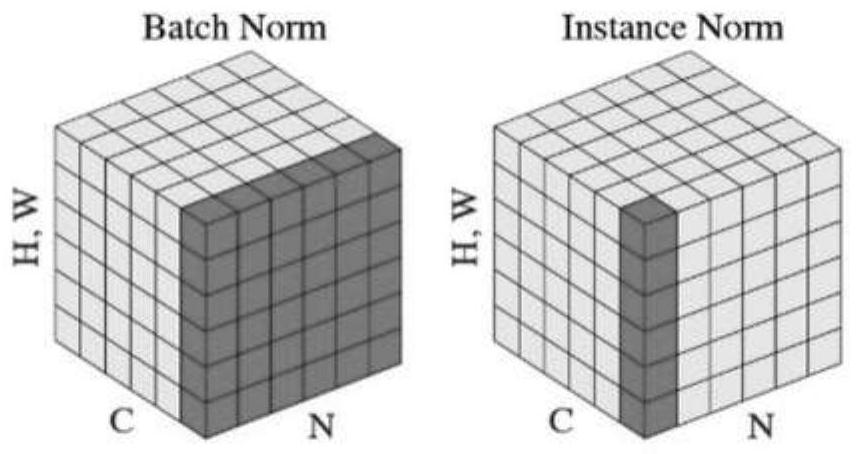

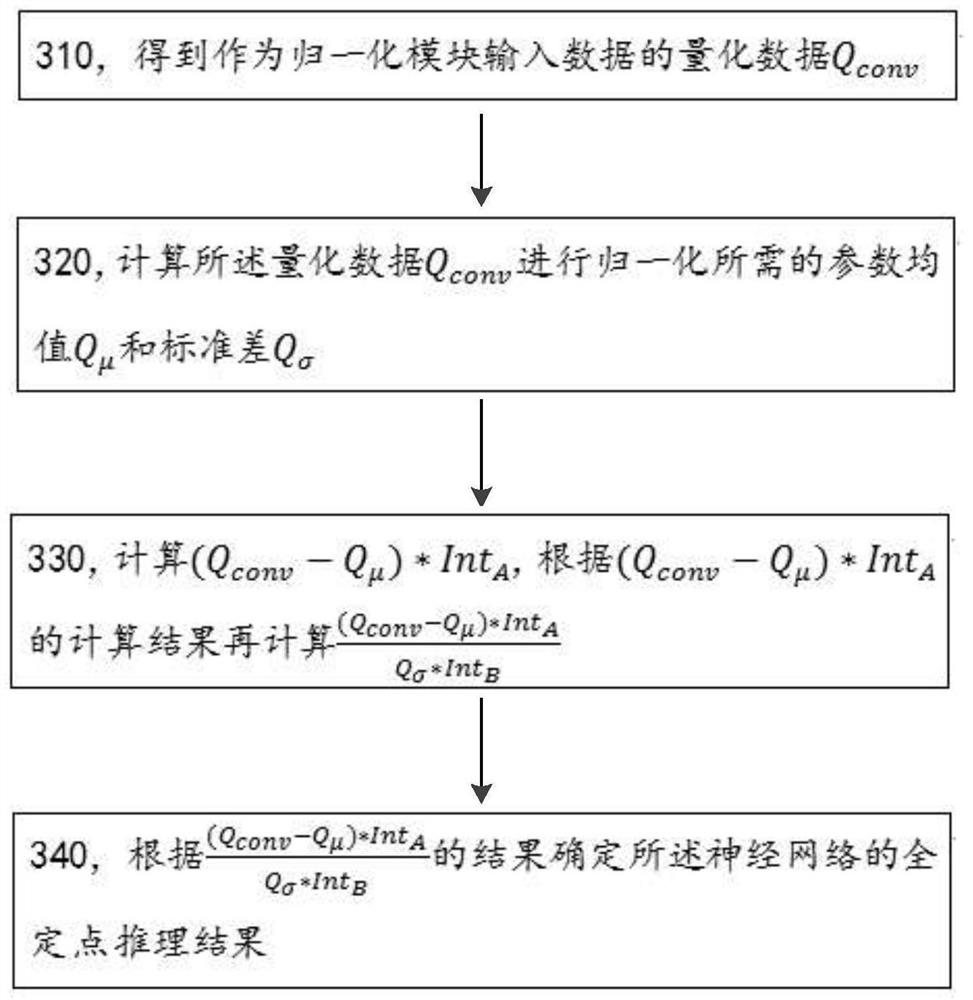

Normalization quantification method and device, electronic equipment and storage medium

PendingCN114330655AImprove inference speedAvoid loss of precisionNeural architecturesInference methodsAlgorithmTheoretical computer science

The embodiment of the invention provides a normalization quantification method and device, electronic equipment and a storage medium. The method comprises the following steps: obtaining quantized data Qconv serving as input data of a normalization module; calculating a parameter mean value Q [mu] and a standard deviation Q [sigma] required by normalization of the quantized data Qconv; (Qconv-Qmu) * IntA is calculated, SR is calculated again according to a calculation result of the (Qconv-Qmu) * IntA, and the SR is determined according to a re-scaling parameter of the normalization module and a parameter of a subsequent module of the normalization module; and determining a full-fixed-point reasoning result of the neural network according to the result. According to the normalization quantification method provided by the embodiment of the invention, the problem of precision loss caused by normalization in a fixed-point calculation process is avoided by utilizing a thought of first calculation of (Qconv-Qmu) * IntA, so that full fixed-point reasoning of a neural network model with an INGNLN module becomes possible, the reasoning speed of the neural network model is improved, and the reasoning efficiency of the neural network model is improved. And the power consumption of model reasoning is effectively reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com