Numerical control rotation working table

A rotary table and working technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the indexing accuracy cannot reach very high rotation accuracy and positioning accuracy, and achieve the goal of overcoming the loss of accuracy and processing The effect of high precision and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

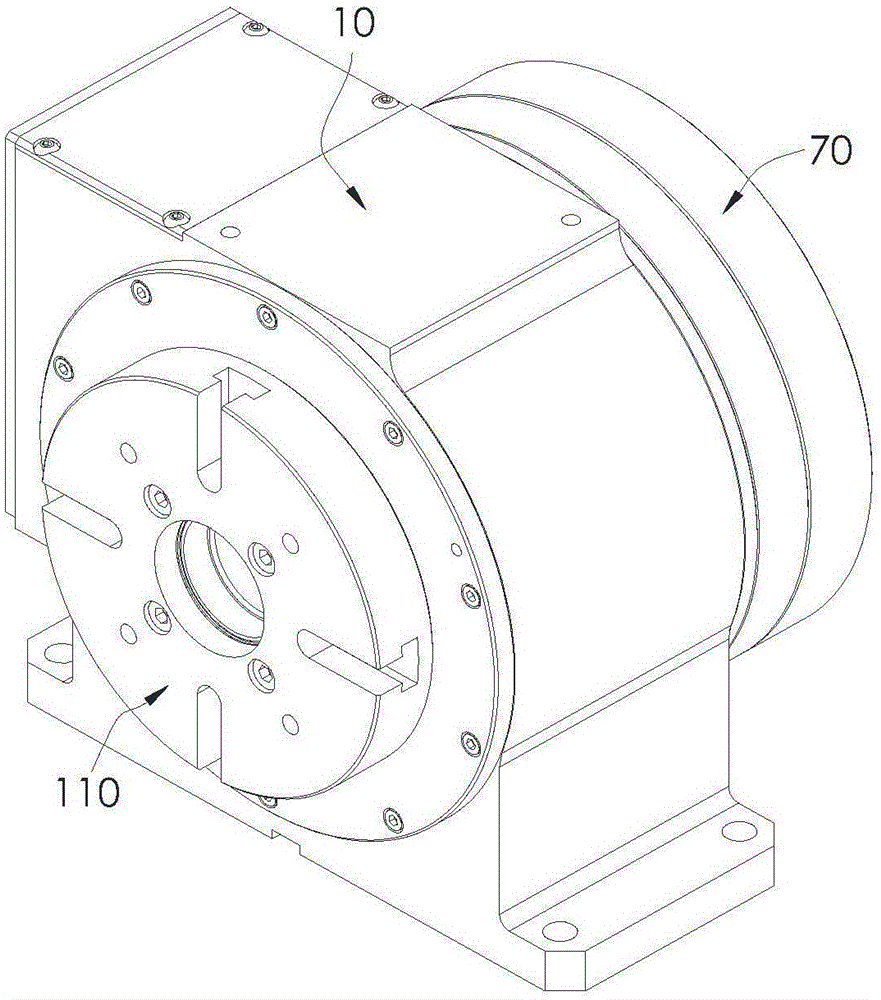

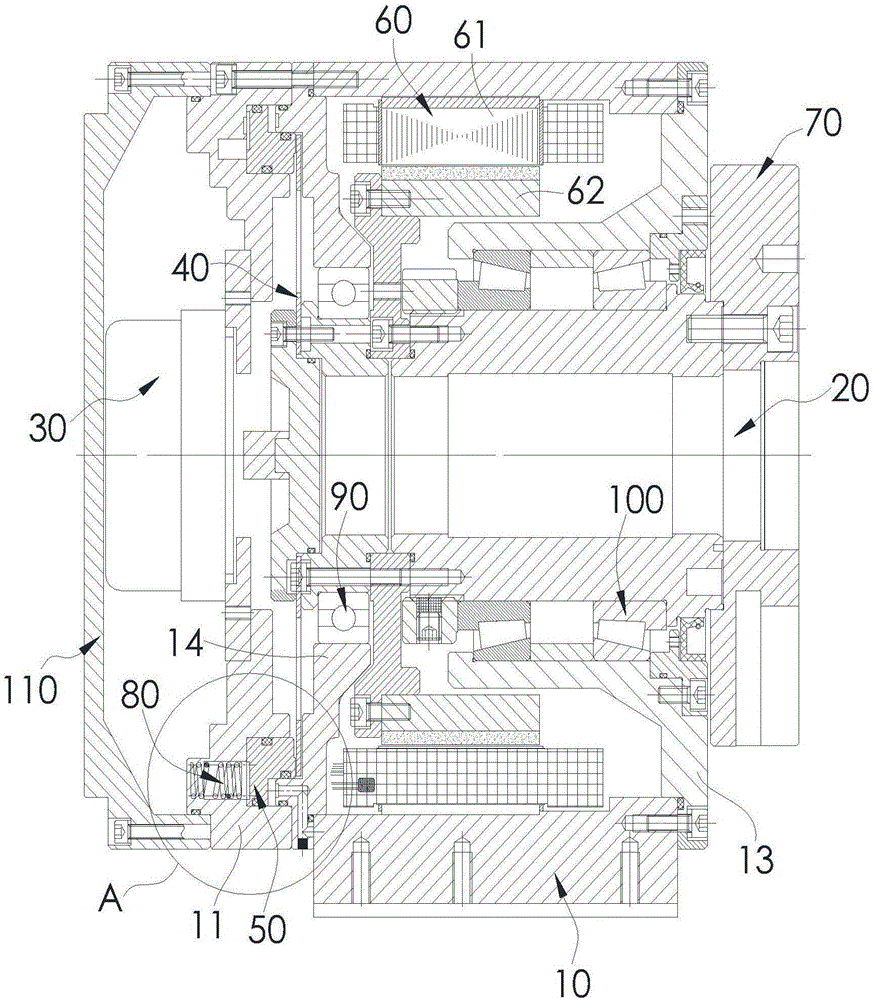

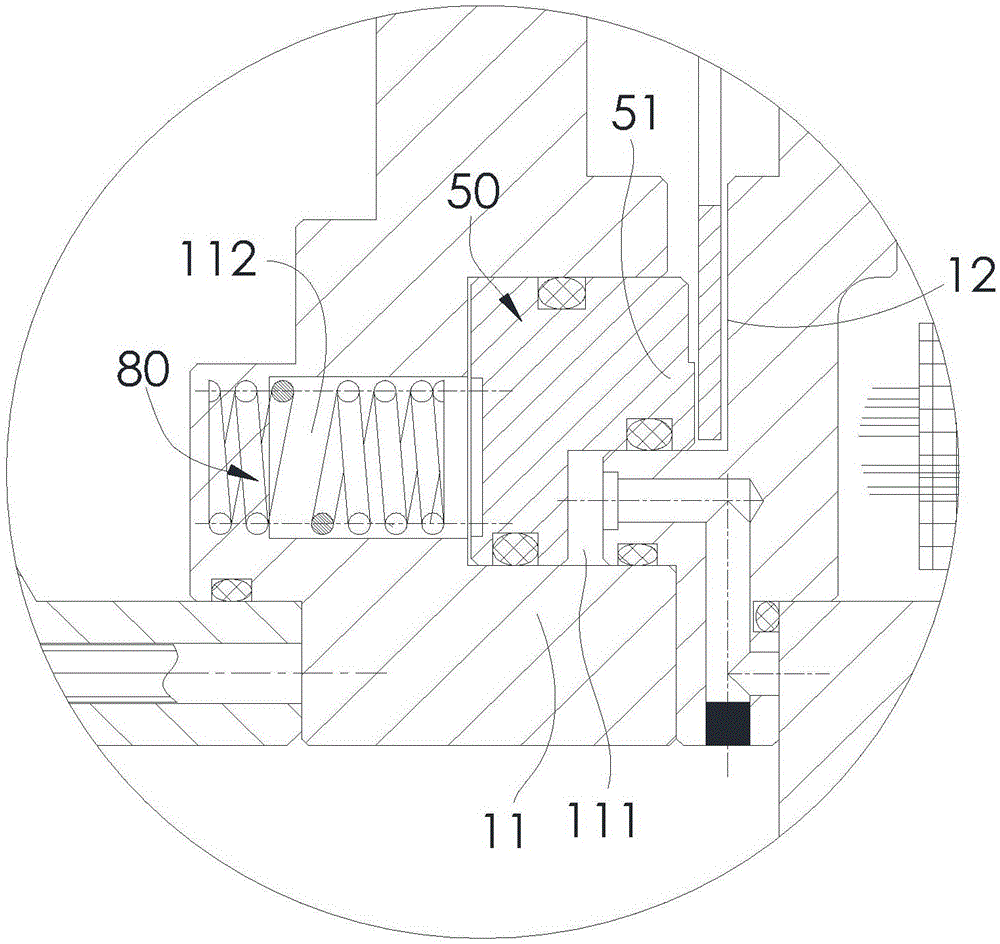

[0019] like Figure 1 to Figure 3 As shown, the numerically controlled rotary table of the present invention includes a machine body 10, a rotary shaft 20, a rotary encoder 30, a brake ring 40, a piston 50, a torque motor 60, and a work turntable 70 for installing workpieces. The cylinder body 11 and the rotary shaft 20 are pivotally connected to the body 10; the working turntable 70 is fixed at one end of the rotary shaft 20 and is located outside the body 10, the rotary encoder 30 is installed on the body 10, and the rotation of the rotary encoder 30 The shaft is coaxially connected with the rotary shaft 20; the piston 50 is movably installed in the cylinder body 11, and the end of the piston 50 located outside the cylinder body 11 forms a top end 51, which is connected to a top end 51 inside the body 10. A gap is formed between the side walls 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com