Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Avoid drilling deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

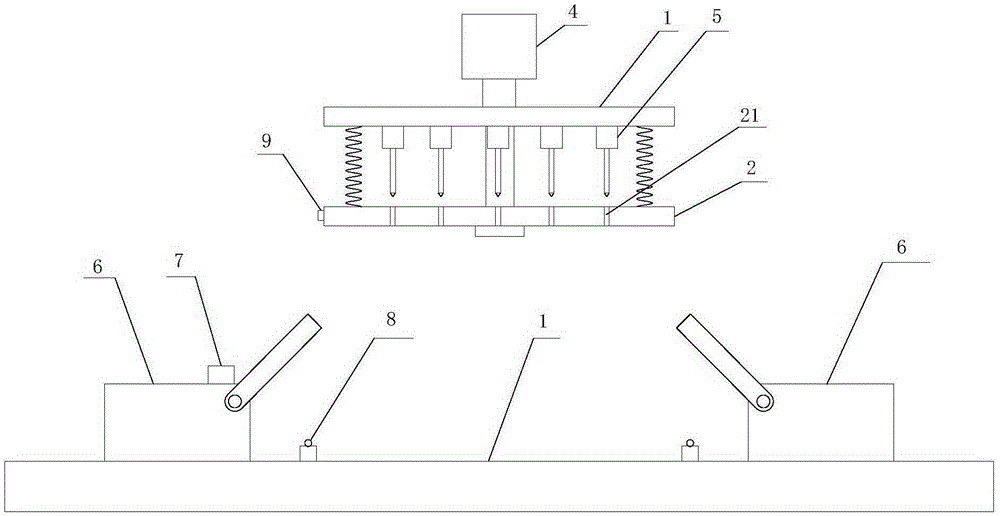

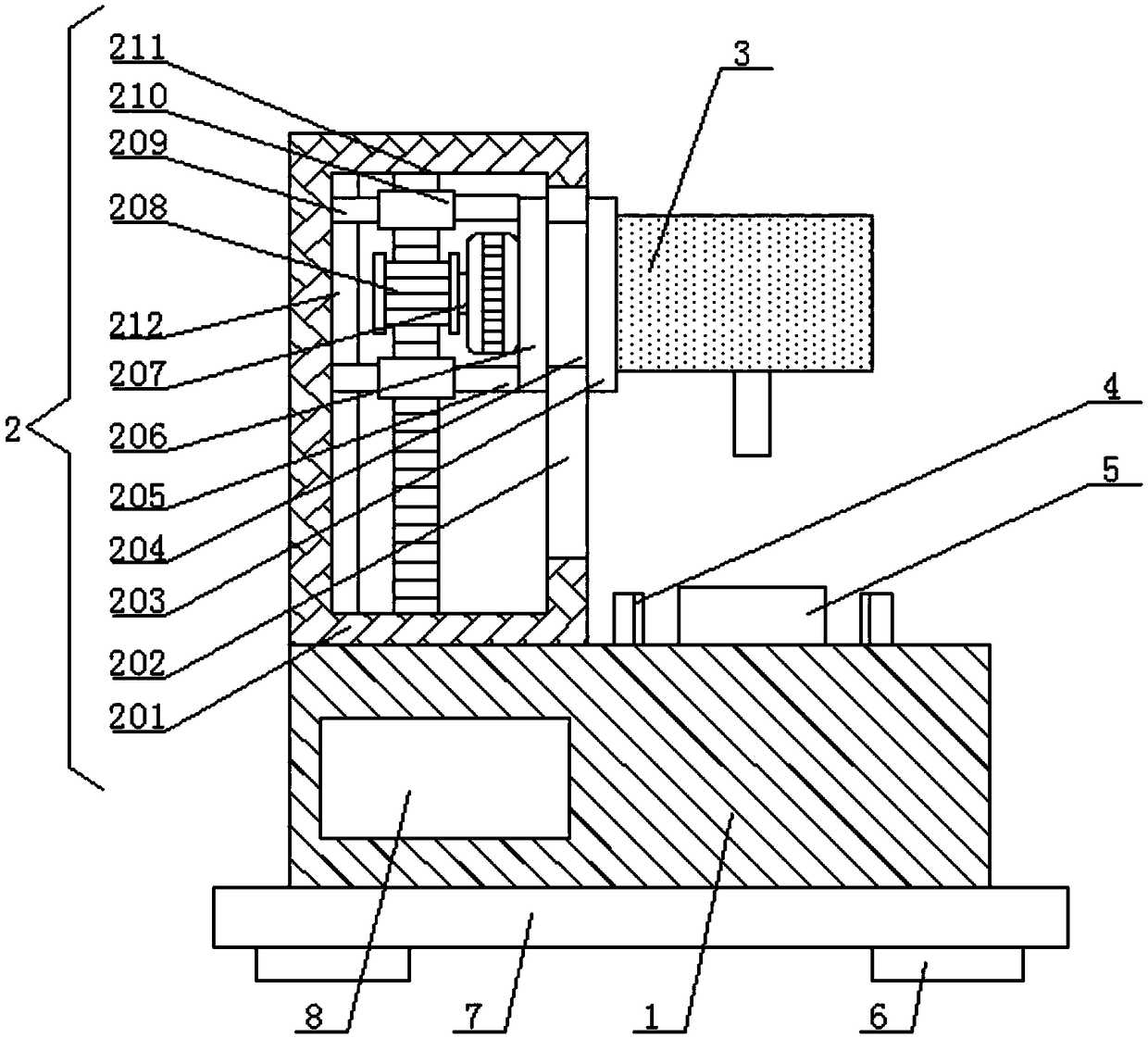

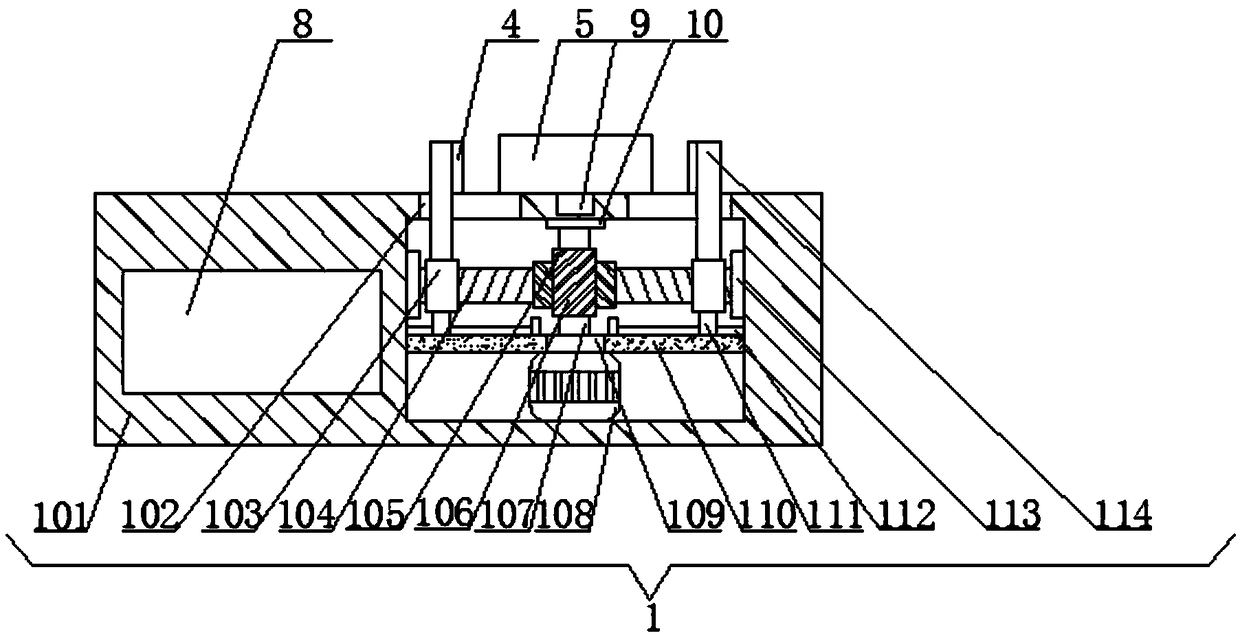

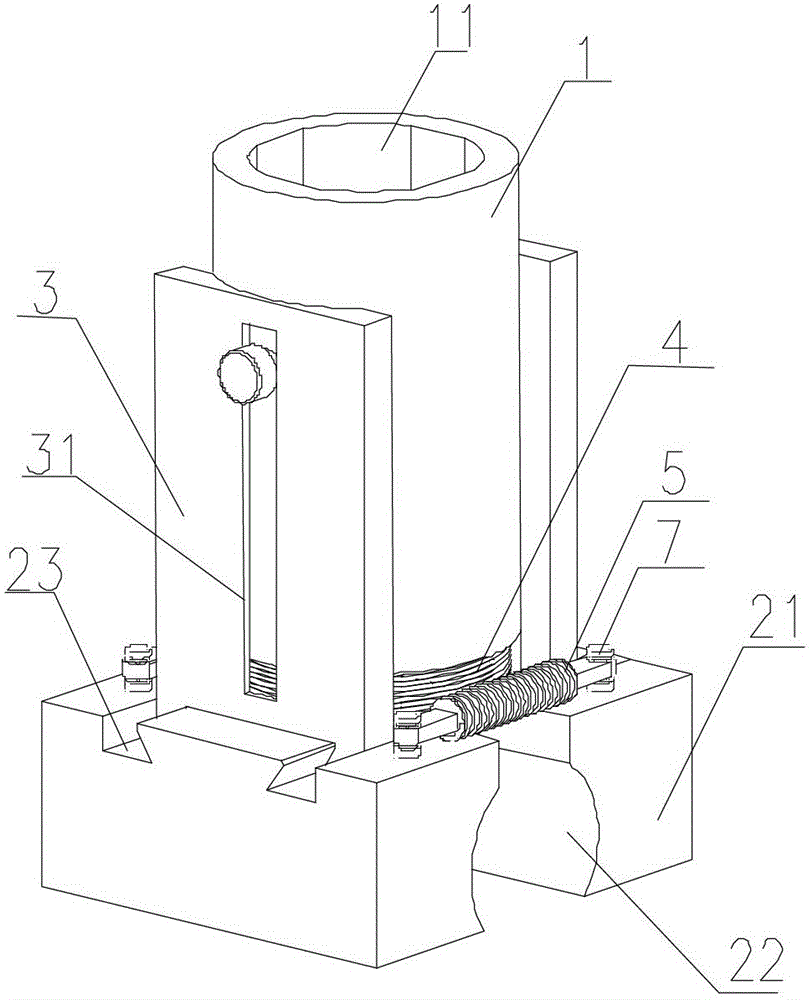

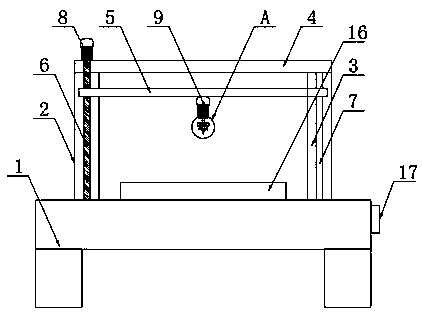

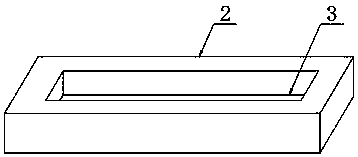

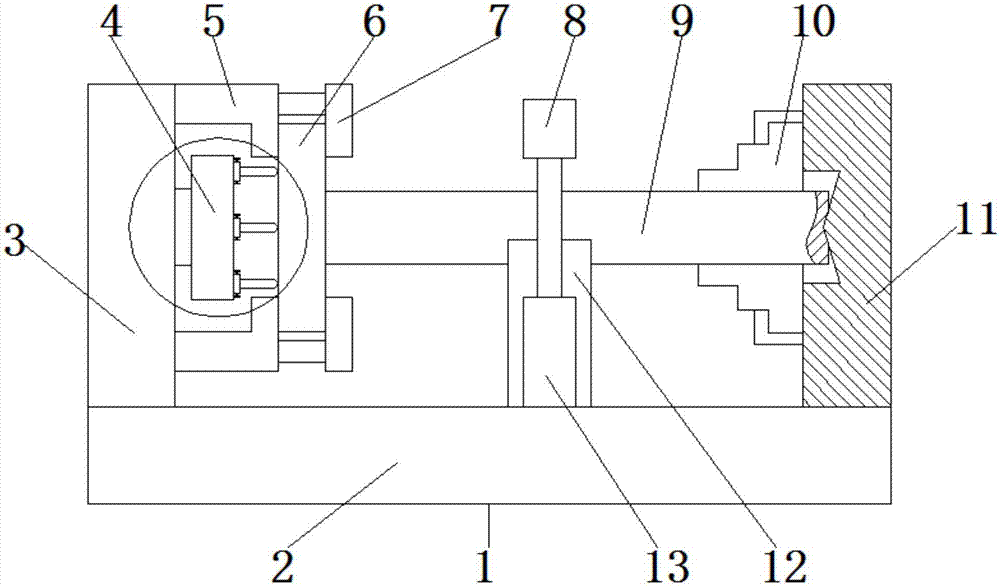

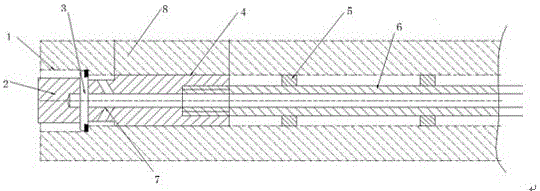

End hole machining device with prepressing function for diesel engine cylinder

InactiveCN105290456AAvoid drilling deviationImprove processing efficiencyDrilling/boring measurement devicesMeasurement/indication equipmentsData signalEngineering

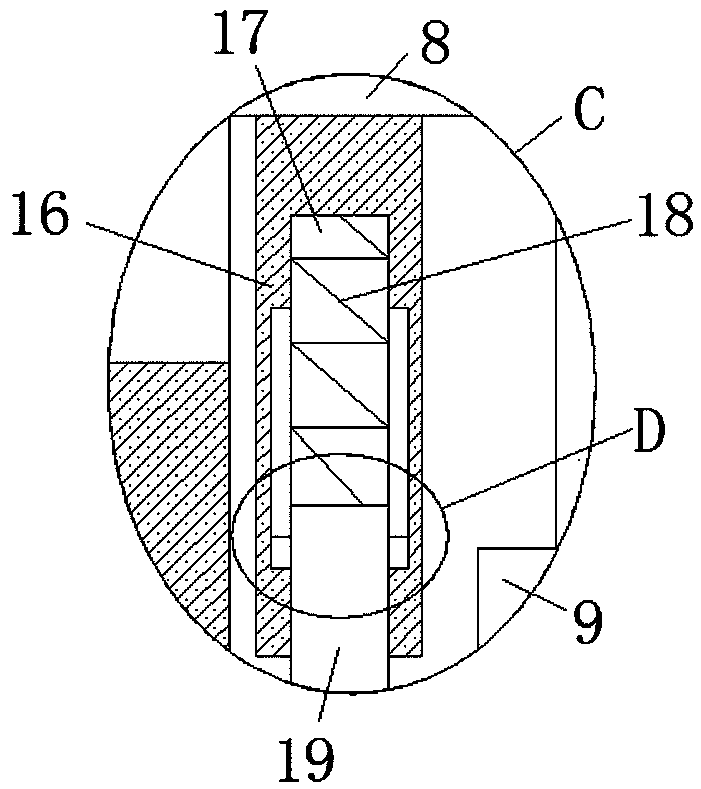

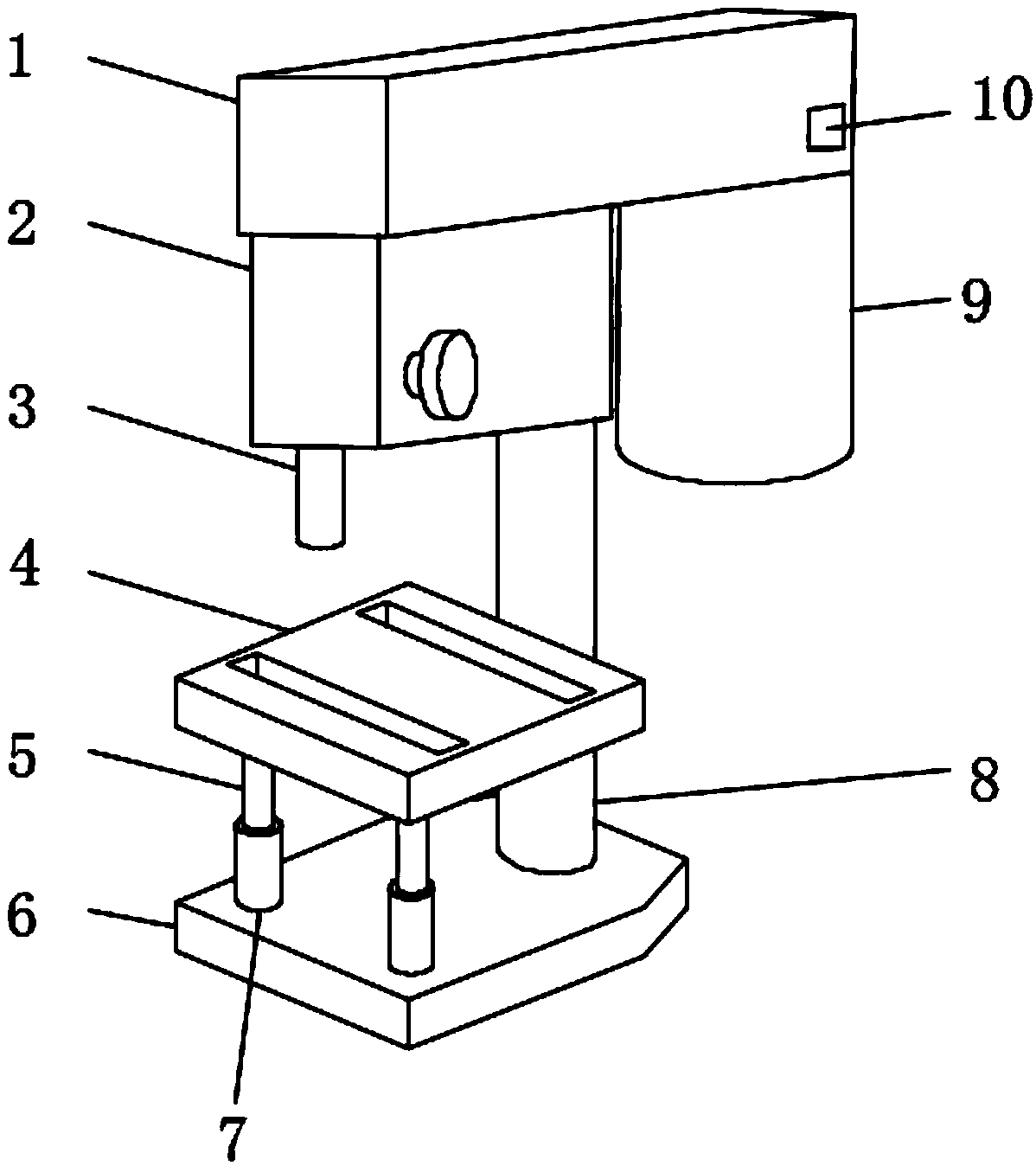

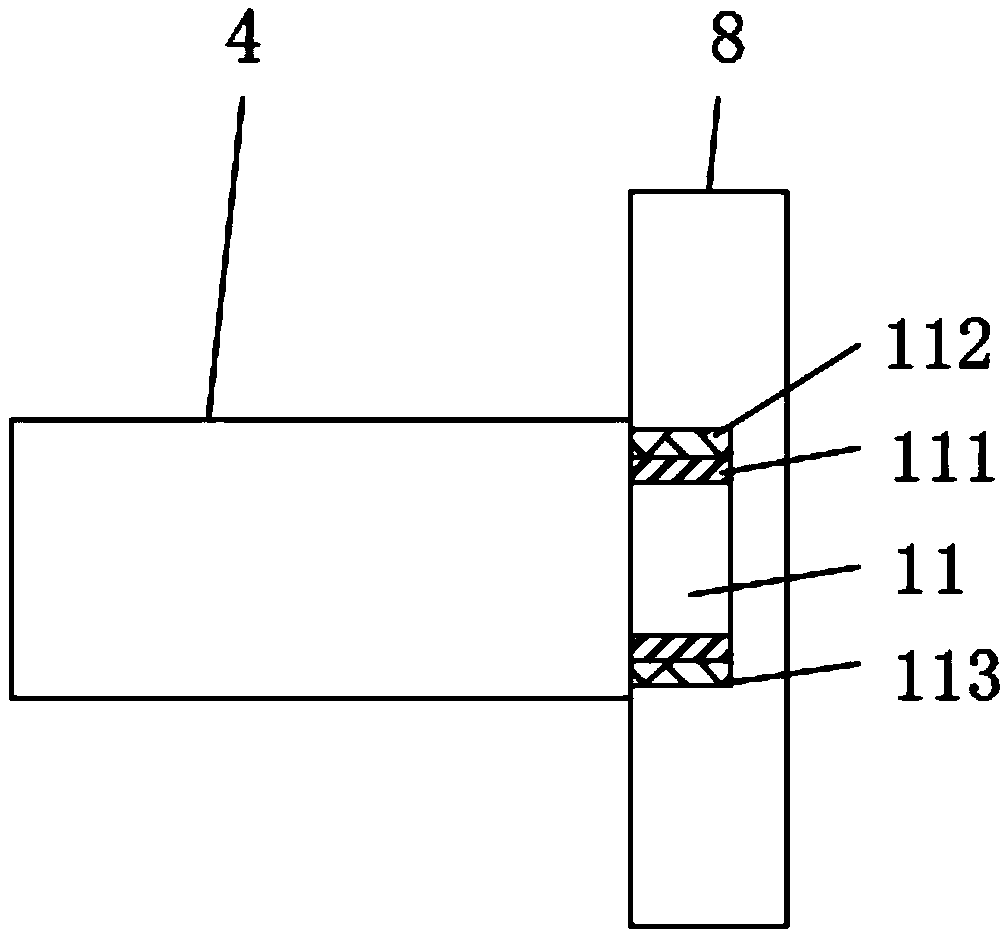

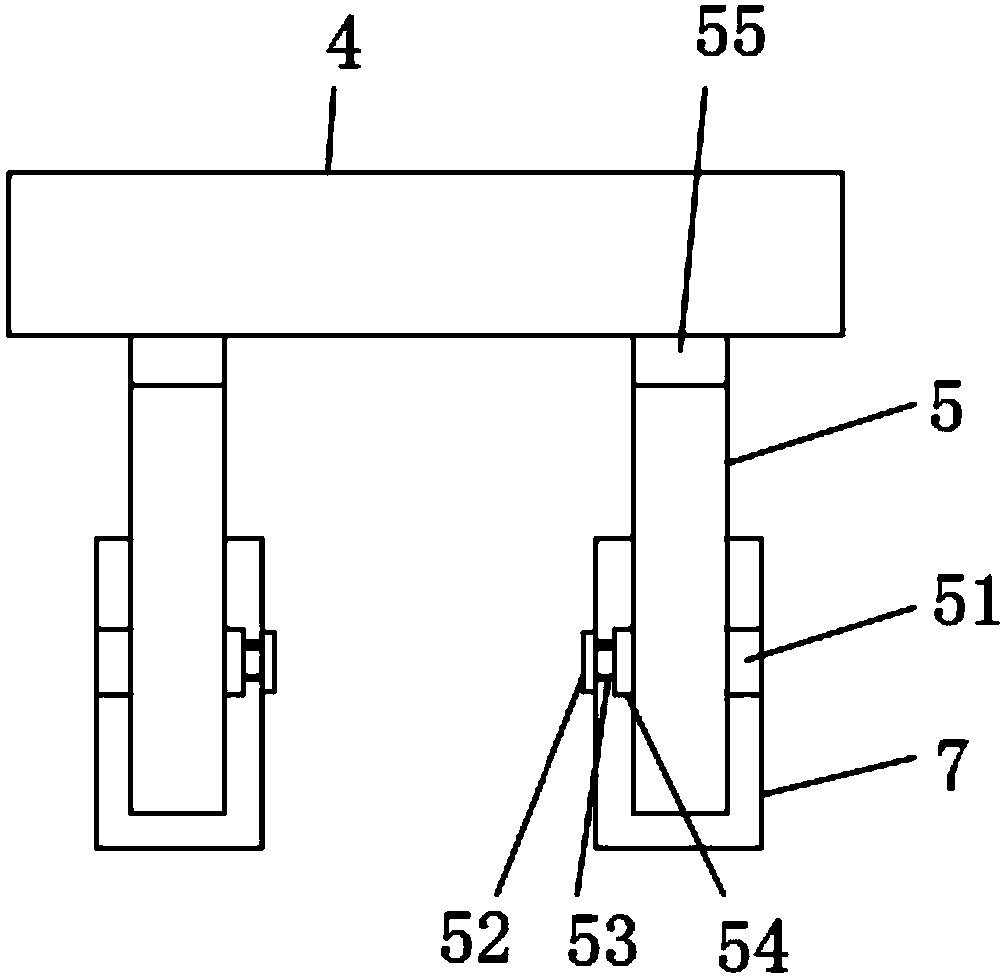

The present invention discloses an end hole machining device with prepressing function for diesel engine cylinder. The device comprises a fixing plate, a prepressing plate, a workbench and a driving mechanism. The fixing plate is located above the workbench and driven by the driving mechanism. A drilling mechanism is installed on the fixing plate. The prepressing plate is connected with the fixing plate through a spring set. A guide pillar is further disposed between the prepressing plate and the fixing plate. A guide hole is formed on the prepressing plate and located in the extension direction of a drill bit. The workbench is provided with at least two clamping mechanisms for fixing the cylinder. Each clamping mechanism is provided with a first sensor. The first sensor is connected with a prepressed control unit and is used for monitoring the spacing between the prepressing plate and the workbench and sending the monitored data signal to a control unit of each clamping mechanism. The control unit of each clamping mechanism controls the clamping mechanism to perform clamping or releasing action according to the data signal sent by the first sensor. The device of the present invention greatly improves the machining precision while improving the machining efficiency.

Owner:ANHUI QIFENG MACHINERY & EQUIP

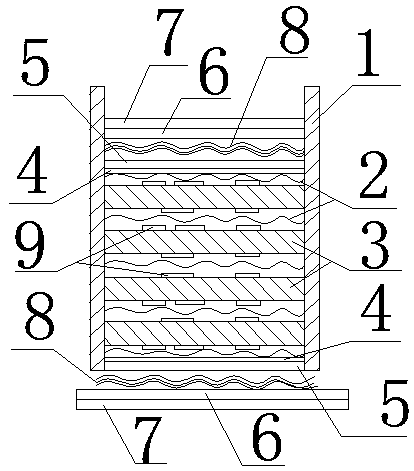

Multi-layer HDI circuit board blind hole windowing process

InactiveCN102036508AOptimize work processGuaranteed qualityPrinted element electric connection formationHigh densityInterconnector

The invention discloses a multi-layer high density interconnector (HDI) circuit board blind hole windowing process, which comprises the following steps of: manufacturing a target hole pattern on a PAD layer at the bottom of a laser blind hole; laminating by adopting a resin copper foil, drilling a target hole by adopting an X-RAY machine, and aligning and exposing by adopting an automatic exposure machine; and finally, developing, and etching for windowing. The process breaks through the conventional laser blind hole processing mode (positioning by adopting three tube holes and drilling the laser blind hole windowing and positioning hole through mechanical drilling), four target holes of a plate corner positioned on the same plane as the PAD layer at the bottom of the laser blind hole are accurately aligned, the target holes are drilled by an X-RAY precise drilling machine, repeated use and mechanical drilling error for outer tube holes are avoided, and the aim of accurately windowing the laser blind hole is fulfilled finally. The process is simple and the efficiency is high.

Owner:惠州中京电子科技股份有限公司

Method for improving multi-layer board borehole deviation

InactiveCN107580418AGuaranteed accuracyPrevent drilling deviationMultilayer circuit manufactureMicrometerX-ray

The invention relates to a method for improving multi-layer board borehole deviation. The method includes the steps: S1 performing X-RAY target drilling; S2 measuring actual expansion and contractiondata of boards, and calculating an expansion and contraction average value; S3 setting an X-RAY multi-layer board target drilling expansion and contraction range to be lower than or equal to 75 micrometers, and performing board running on the boards exceeding the expansion and contraction range in a pile dividing manner; S4 adjusting a drilling belt according to the expansion and contraction average value; S5 taking a standard value as an actual target drilling distance, and performing wire compensation equidistant target drilling; S6 dividing the boards into different piles, and transferringthe boards to a board edge routing process; S7 routing different number of V-shaped grooves in the board edges; S8 treating the expansion and contraction boards in a pile dividing manner; S9 manufacturing one standard board drilled target; S10 measuring an accuracy error by each target drilling machine per shift every day according to the standard board. According to the method, X-RAY and drillingparameters are strictly controlled, the target drilling machines measure accuracy by the aid of the standard board every day, so that the accuracy of the target drilling machines is within a controllable range, and borehole deviation caused by accuracy misalignment of the target drilling machines is prevented.

Owner:奥士康精密电路(惠州)有限公司

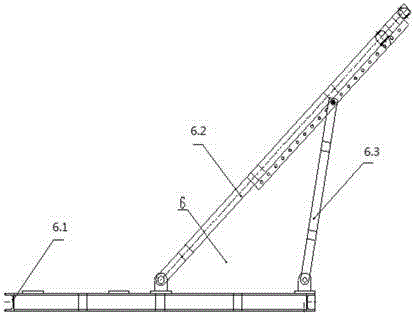

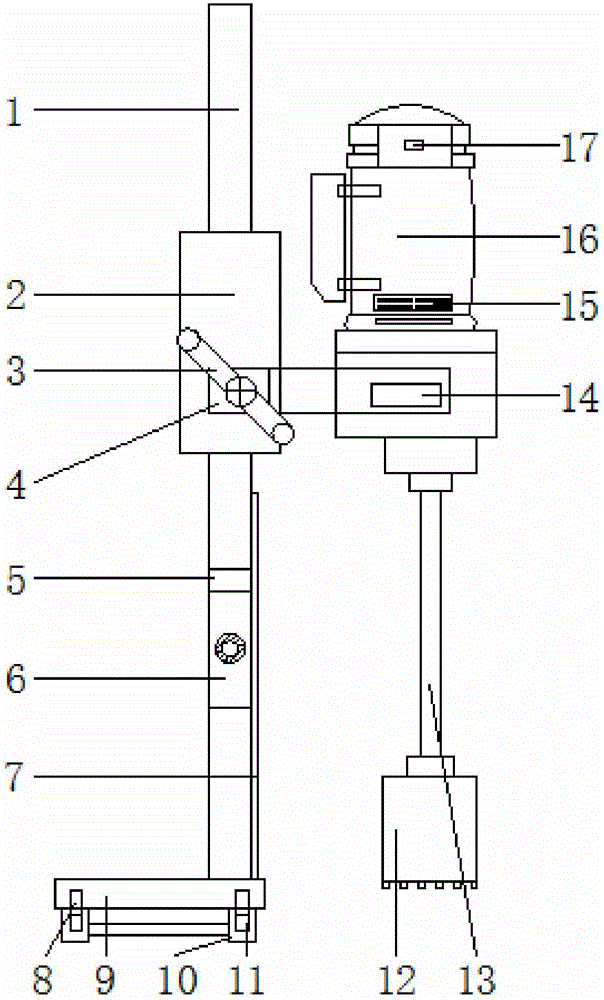

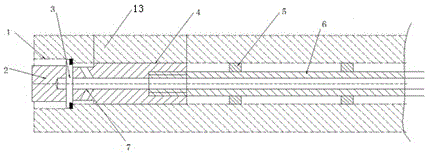

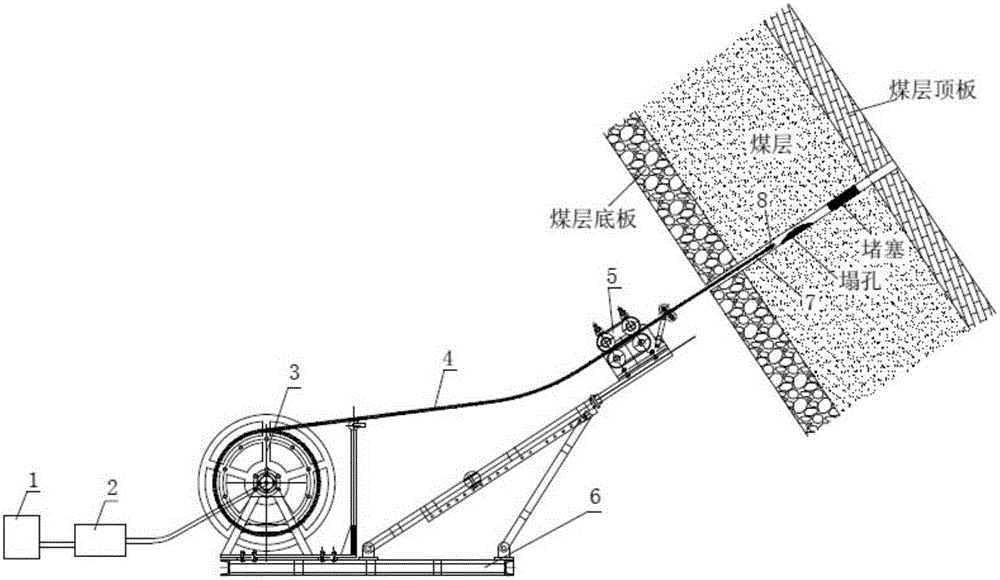

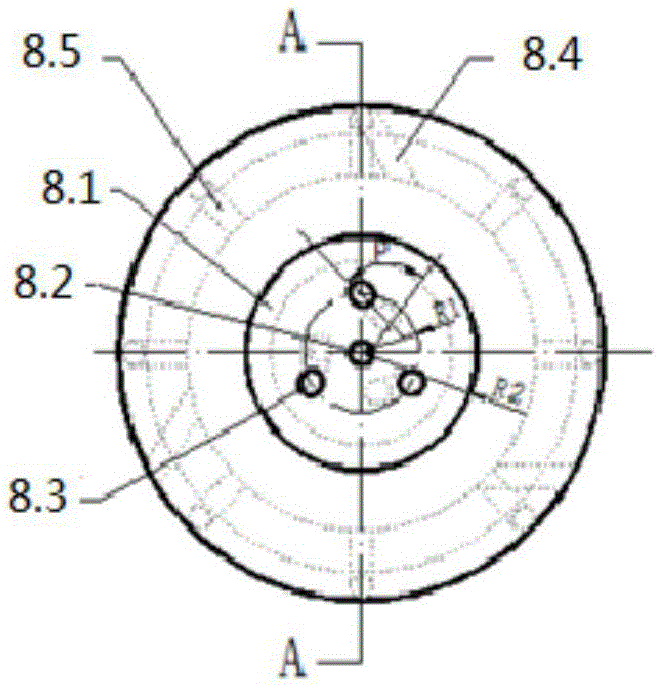

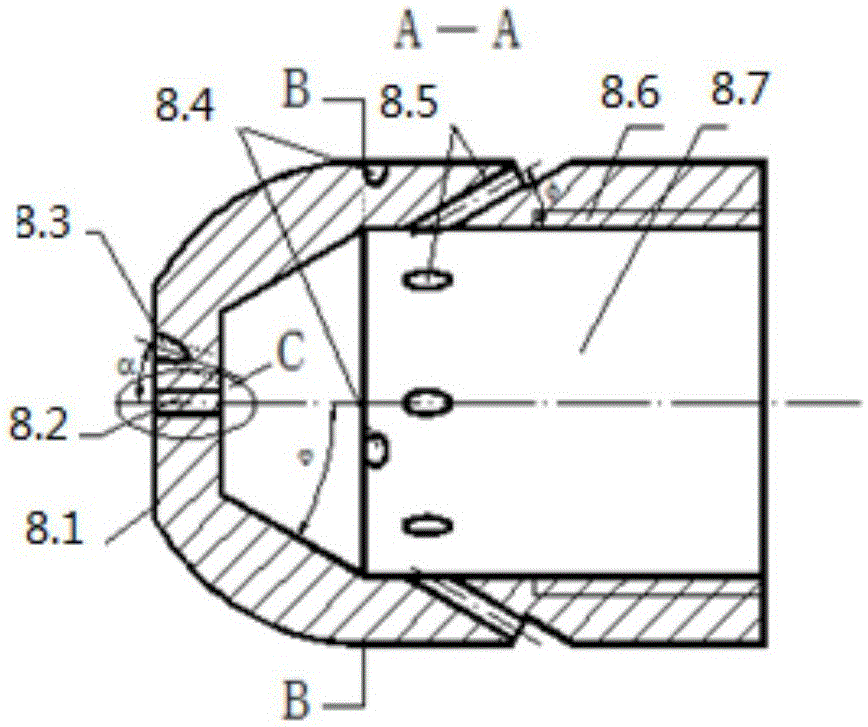

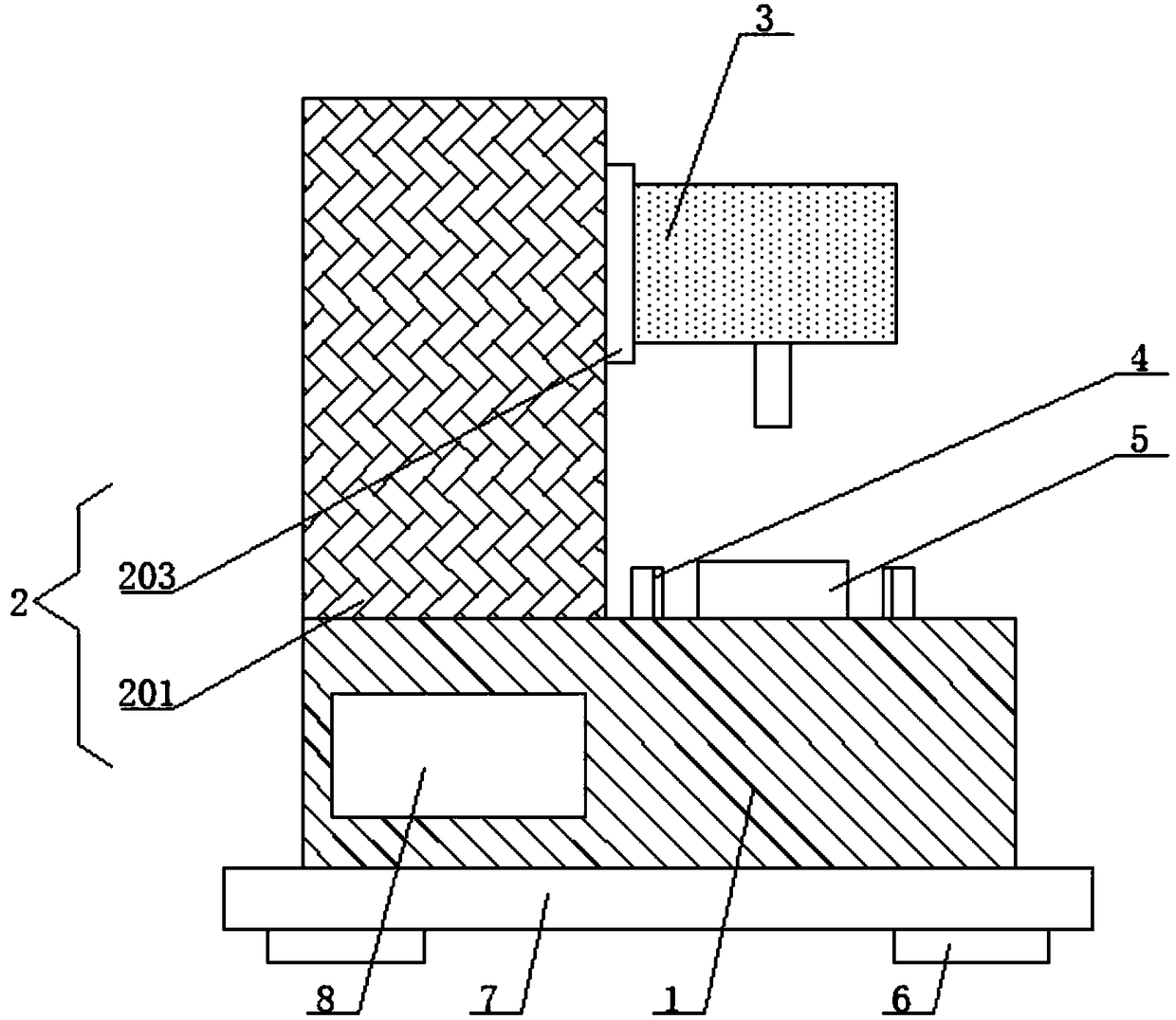

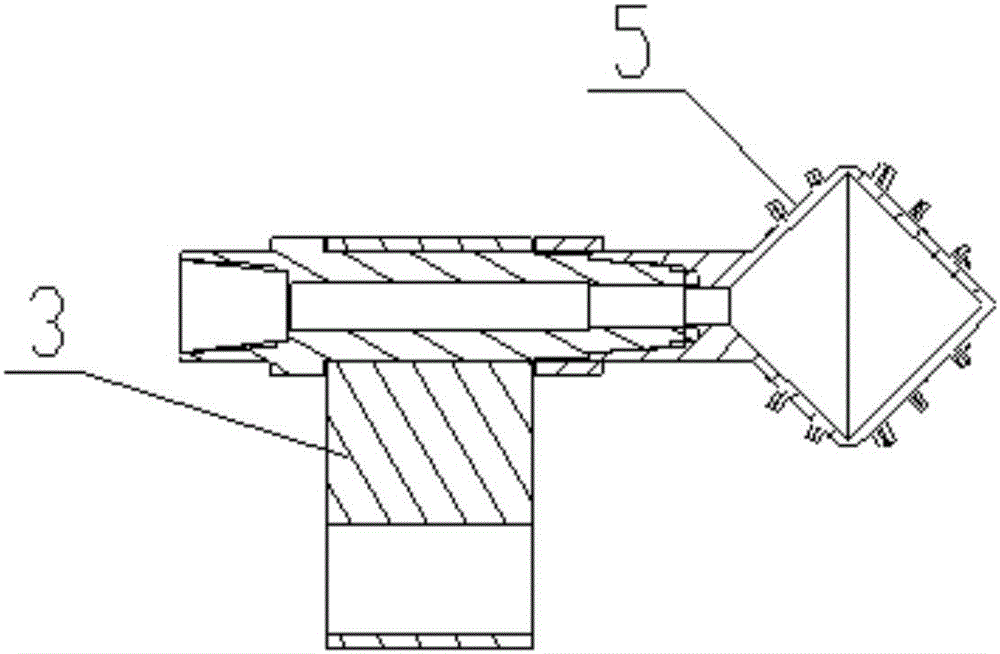

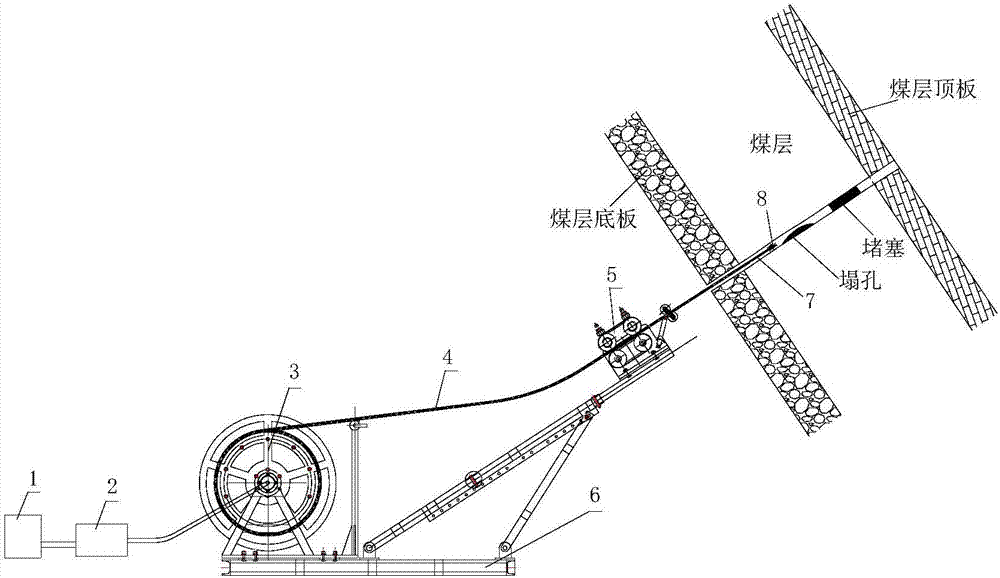

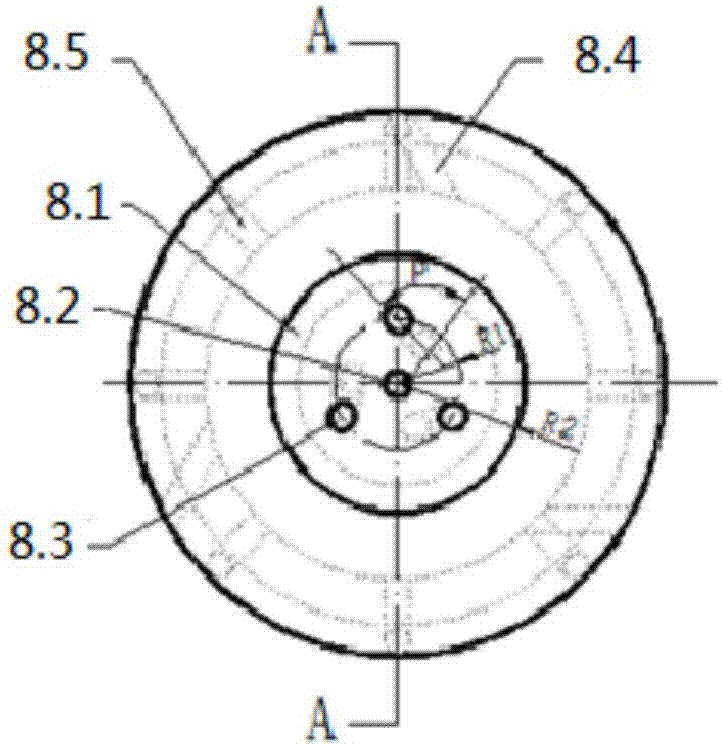

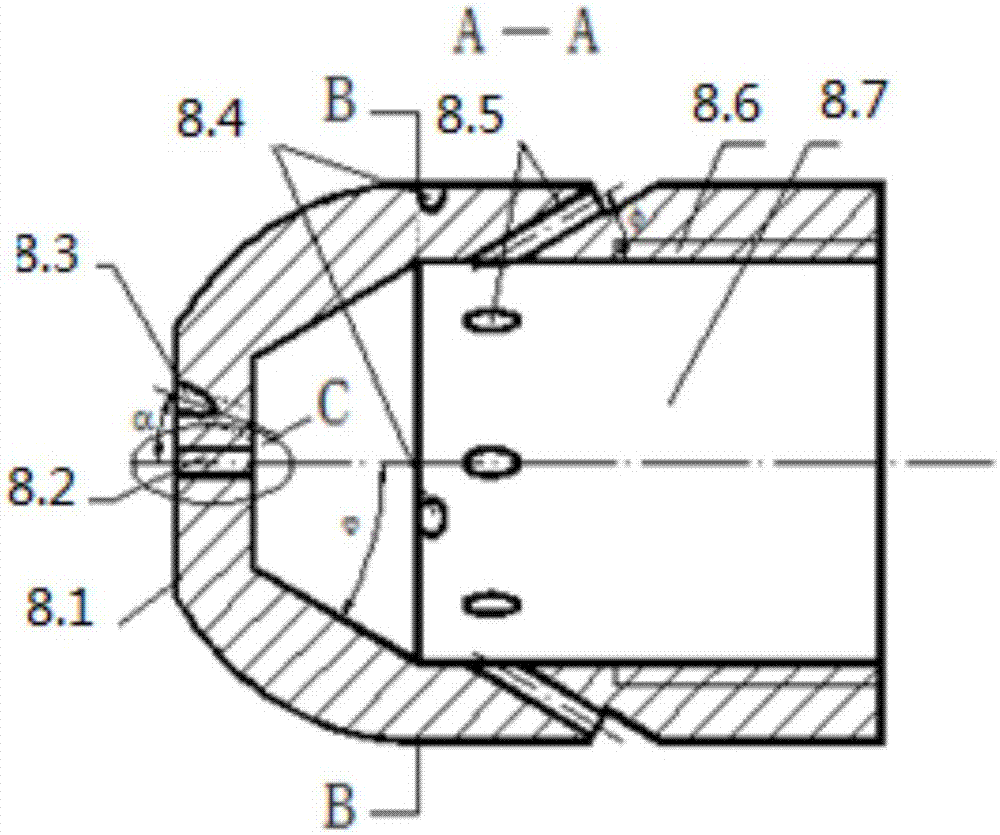

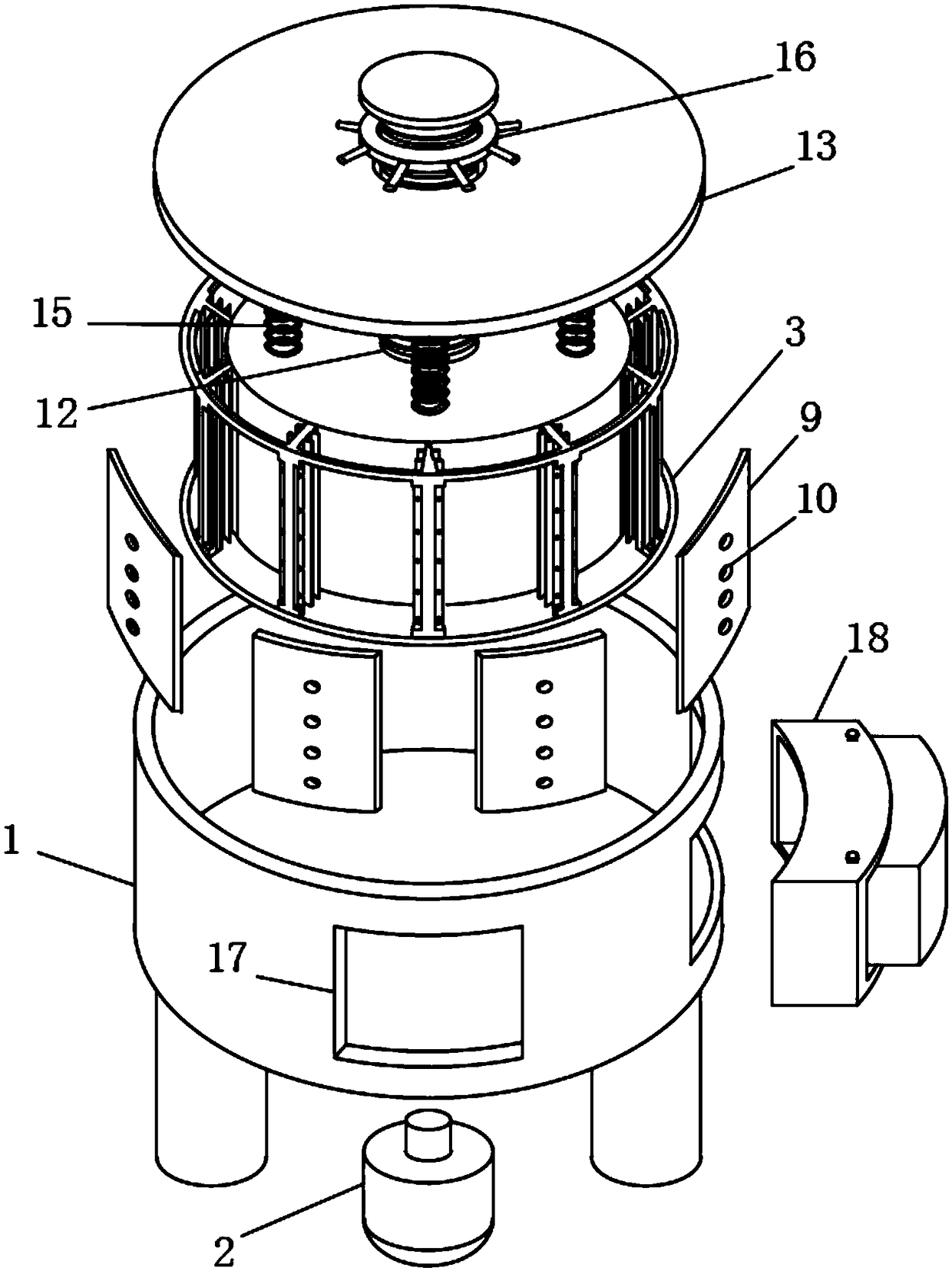

Hole flushing device for coal mine downhole gas extraction drill holes

ActiveCN105089525AImprove rock breaking efficiencyLarge self-propelled thrustDrill bitsDerricks/mastsHigh pressure waterHigh pressure

The invention provides a hole flushing device for coal mine downhole gas extraction drill holes. The hole flushing device comprises a water tank, a high-pressure pump, a high-pressure hard pipe, a high-pressure hose, a self-propelled drill bit, a base, a winch, a pushing mechanism and the like. The winch and the pushing mechanism are fixed to the base. The device can correspond to the drill holes in different positions and at different angles by adjusting all parts of the base. The high-pressure hard pipe can penetrate through the pushing mechanism before being fed into the drill holes. The high-pressure hard pipe can be conveyed forwards along the drill holes through pushing force provided by the pushing mechanism. When high-pressure water passes through the high-pressure hose at the front end of the high-pressure hard pipe and the self-propelled drill bit, high-pressure water jet is generated to conduct rock breaking dredging on collapsed and blocked portions, and self-propelling force is generated. The device is simple in structure, small in overall size and convenient to adjust, and can be conveniently used in coal mine downhole narrow working space. A whole power pipeline can be conveyed in long distance under joint acting force of pulling in front and pushing behind, and the pipeline can be prevented from being clamped. The hole flushing speed is high, efficiency is high, cost can be greatly reduced, and the gas extraction effect is improved.

Owner:CHONGQING UNIV +1

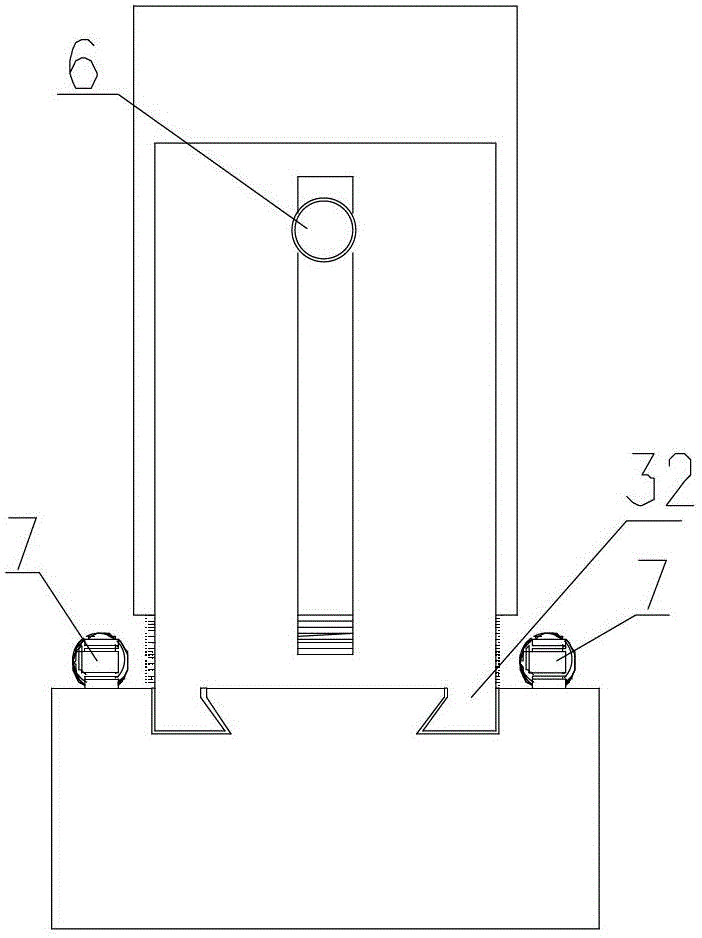

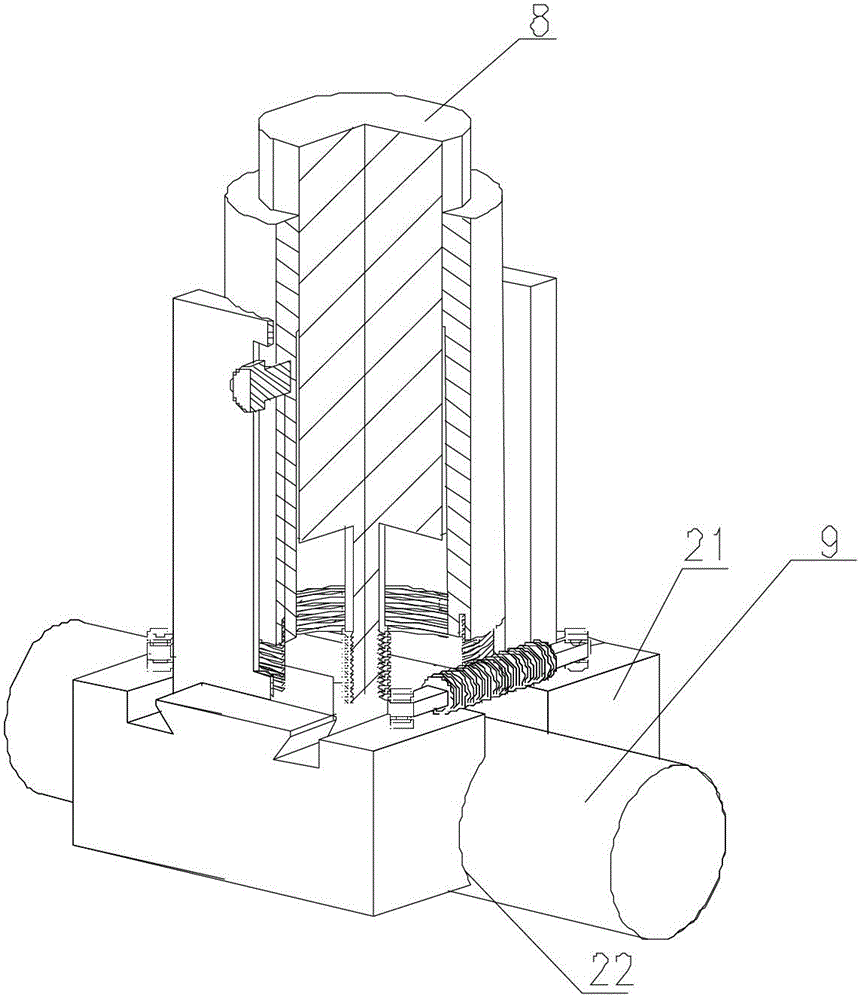

Drill hole positioning device

InactiveCN103658744AAvoid drilling deviationWork benchesPortable drilling machinesEngineeringMotion Mode

The invention provides a drill hole positioning device which comprises a positioning part, a guiding frame and a guiding cylinder. The positioning part is provided with a concave positioning area matched with the outer surface of a workpiece to the machined. The guiding frame is connected to the positioning part. The guiding cylinder is connected with the guiding frame in the guiding direction in a rectilinear motion mode, and is provided with an inner hole for being connected with an electric drill so that the drill bit of the electric drill can penetrate through the inner hole and extend towards the concave positioning area. The drill hole positioning device can effectively prevent the drill hole deviation caused by the sliding of the hand-operated electric drill in the process of pipeline part drilling, and the precision of a matched hole is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Novel wall drilling machine

InactiveCN106270645ASimple structureEasy to operateWork benchesPortable drilling machinesGyroscopeDrilling machines

The invention discloses a wall drilling machine comprising a fixed column, a slide cylinder, a rotary shaft, a gyroscope, a height adjuster, a pulley, a drill bit, a connecting rod, a fixing device, a radiator, an electric motor and a switch. The lower end of the fixed column is connected with the base and the slide cylinder is arranged on the upper end thereof. The slide cylinder is provided with the rotary shaft and the lower end is provided with horizontal air bubbles. The lower end of the base is provided with the pulley, the pulley is provided with a pulley lock, and the lower end of the pulley is provided with a rail. The drill bit and the motor are connected through the connecting rod. The electric motor is connected with the slide cylinder through the fixing device, and the electric motor is provided with the radiator and the switch. The drilling machine is innovatively designed in combination with the current drilling machine. The wall drilling machine is simple in structure, easy to use, reliable in wall drilling and capable of preventing drilling deviation, effectively protecting the wall and improving drilling efficiency.

Owner:石森龙

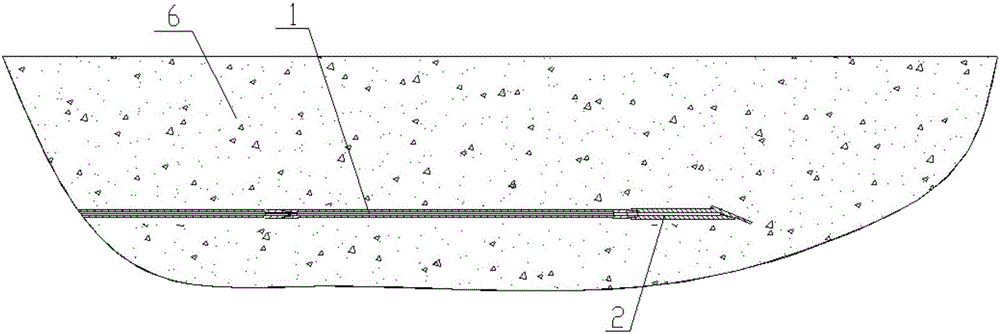

Machining process for marine propeller shaft with length of 22 metres and hollow middle

ActiveCN106002120AAvoid skewAvoid thermal deformation and bending during cuttingPropellerThermal deformation

The invention relates to a machining process for a marine propeller shaft with a length of 22 metres and a hollow middle. The machining process comprises the following steps: the propeller shaft to be machined is taken and fixed on a lathe and subjected to rough turning machining; then the propeller shaft to be machined is fixed on a boring machine and bored; a machining manner of reversely pulling a floating hole twice is adopted, and the middle-section position of the propeller shaft is sunken 1mm, and the parallelism degree of the axis of a pull rod of the boring machine and the axis of the propeller shaft is less than 0.5mm during a boring process; run-out and roundness of a transition sleeve, a central frame, a frame position gear and a machining frame position needing to be used during machining are controlled to be in set ranges, and then semi-finish machining and finish machining are carried out; the propeller shaft is hoisted and placed on a machining fixture through a crane; and a Y-axis direction and a Z-axis direction are verified, and then holes of a flange of the propeller shaft are drilled and bored by a boring die to complete machining. The machining process disclosed by the invention has the following advantages: the phenomena of deflection and cutting thermal deformation bending during drilling can be effectively avoided when the propeller shaft is machined by virtue of the process disclosed by the invention, thus the excircle roundness is ensured.

Owner:南通德玛瑞机械制造有限公司

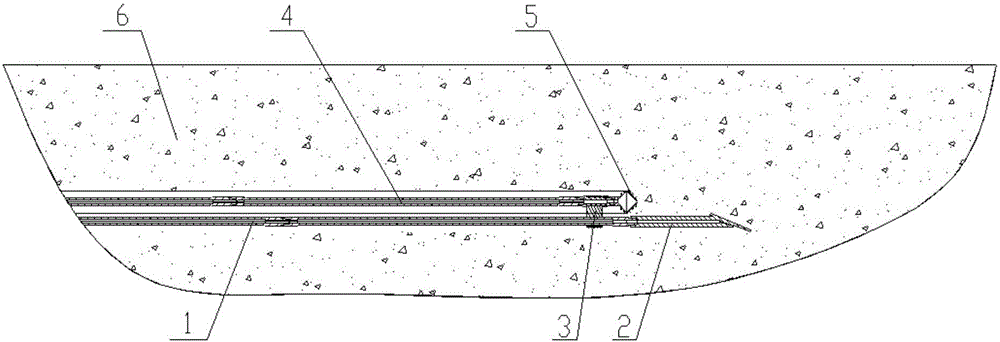

Hole-flushing method for gas extraction drilled hole under coal mine

ActiveCN105134112APrevent the drill bit from driftingImprove the effect of gas extractionDrill bitsDerricks/mastsDrill holeWater jet

The invention discloses a hole-flushing method for a gas extraction drilled hole under a coal mine. A hole-flushing device composed of a water tank, a high-pressure pump, a high-pressure hard pipe, a high-pressure hose, a self-propelled drill bit, a base, a winch and a pushing mechanism is adopted for crashing and flushing blocked and collapsed parts of the gas extraction drilled hole which blockage and collapse occur on under the coal mine through the rock-breaking capacity of self-propelled water jet, and the drilled hole is dredged and reamed; traction force provided by the self-propelled drill bit is utilized for moving the high-pressure hose forwards in a straightening mode; the characteristics that the resin pipe has certain rigidity and can transmit pushing force are utilized for moving the self-propelled drill bit forwards within a larger range. The hole-flushing method mainly has the effects of dredging and reaming the blocked and collapsed drilled hole under the coal mine so as to improve gas extraction efficiency. Compared with the prior art, the hole-flushing method has the advantages of being convenient to operate, capable of improving hole-flushing efficiency and the like and is mainly suitable for dredging the blocked extraction drilled hole in the process of gas extraction on a soft coal bed.

Owner:CHONGQING UNIV

Drilling equipment for machining

InactiveCN109290599AAvoid damageImprove stabilityFeeding apparatusPositioning apparatusMotor driveFriction force

The invention discloses drilling equipment for machining, and relates to the technical field of machining. The drilling equipment comprises a clamping mechanism, and the bottom face of the clamping mechanism is fixedly connected with a fixed base. According to the drilling equipment for machining, by arranging an anti-sliding mat and anti-sliding grains, friction force between the bottom face of the fixed base and the ground can be effectively increased, the overall stability of the drilling equipment is improved, and it is avoided that in the use process, the drilling equipment topples due toexternal force, and consequently the drilling equipment is damaged. By arranging a second forward and backward rotating motor, a gear, a toothed bar, a movable plate, a second sliding block and a moving plate, the second forward and backward rotating motor drives the gear to rotate, and the second forward and backward motor drives the movable plate to move downwards; the movable plate drives themoving plate to move downwards through the second sliding block, so that a drilling machine body moves downwards, and automatic drilling work on a workpiece body is achieved; automatic drilling work of a mechanical accessory can be achieved overall, and the labor expenditure of workers is reduced

Owner:盐城新时代智能检测设备制造厂

Tracking boring crown

ActiveCN106437499AEasy to withdrawReduce concentrationDrill bitsDrilling machines and methodsEngineeringMechanical engineering

The invention relates to a tracking boring crown. The crown comprises a first boring stem, a first boring crown, a double hole tracking seat, a second boring stem and a second boring crown. An upper through hole and a lower through hole are placed on the double hole tracking seat. The upper through hole is located above the lower through hole. One side of the first boring stem is connected with a boring machine body. The other side of the boring stem passes through the lower through hole and is connected fixedly with the second boring crown. One side of the second boring stem is connected with the boring machine body. The other side of the second boring stem passes through the upper through hole and is connected fixed with the second boring crown. The boring machine body drives the first boring stem and the second boring stem respectively to rotate. The first boring stem drives the first boring crown to rotate. The second boring stem drives the second boring crown to rotate. Compared with the prior art, the boring crown can conduct boring operation in the areas with both sand and pebbles, accelerate the boring speed and boring depth, and make the boring crown recovery easier.

Owner:CANGZHOU GREAT DRILL

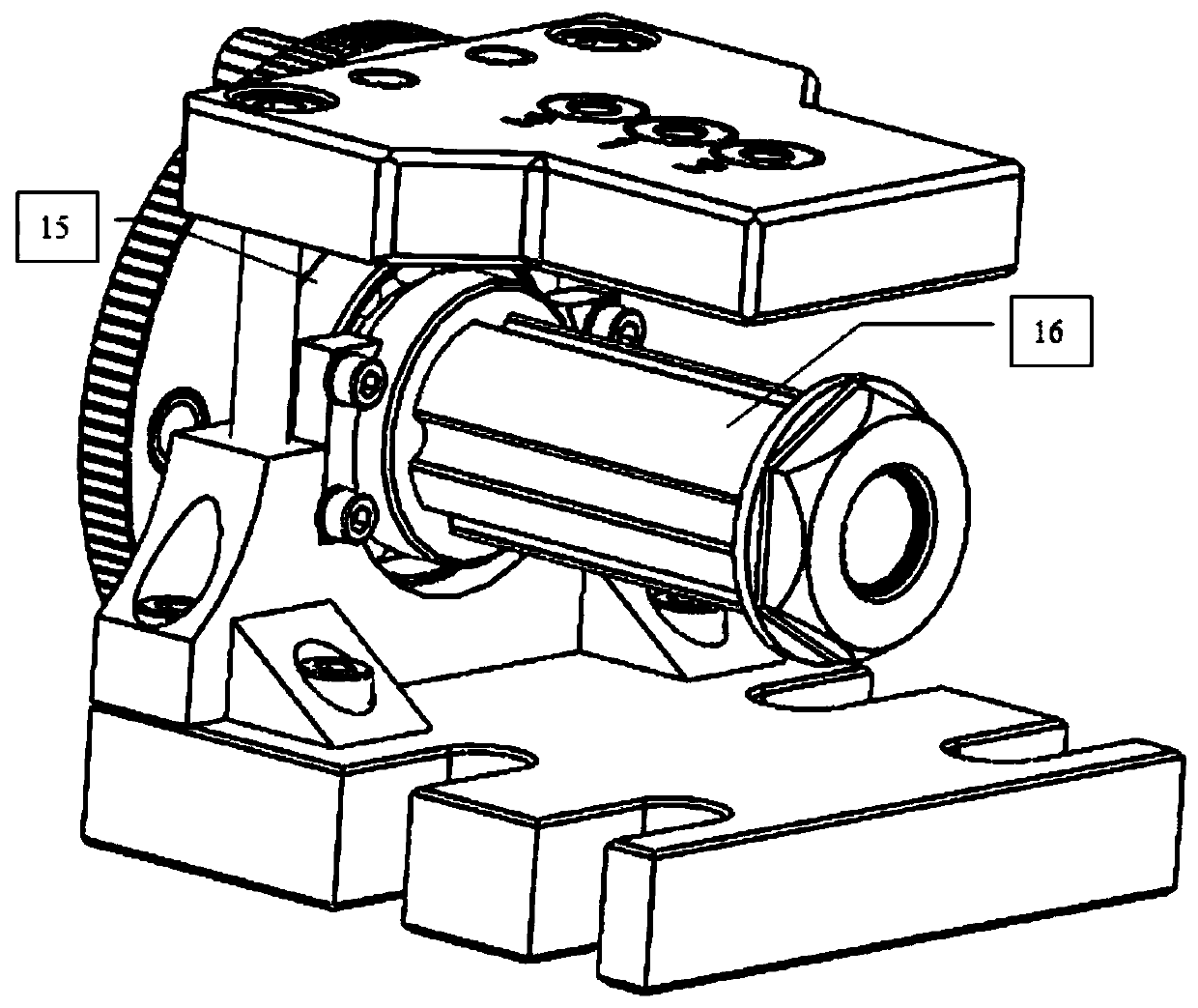

Fixture for conducting rough machining on water plugging holes of engine cylinder block

ActiveCN104959856AWon't shakeEasy loadingDrilling/boring measurement devicesWork clamping meansEngineeringCylinder block

The invention discloses a fixture for conducting rough machining on water plugging holes of an engine cylinder block. An engine cylinder block to be machined is placed on a supporting plate. The engine cylinder block can conduct slippage on a base along with the supporting plate, so that feeding and discharging of a cylinder block piece are facilitated. When machining is conducted, a clamping device clamps the engine cylinder block to the supporting plate, meanwhile a locking portion locks the supporting plate and the base, it is guaranteed that in the drilling process of a drill bit is guaranteed, the cylinder block cannot waggle, and drilling deviation is avoided. A guide device plays a guide function on the drill bit of a radial drilling machine, and drilling accuracy is guaranteed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

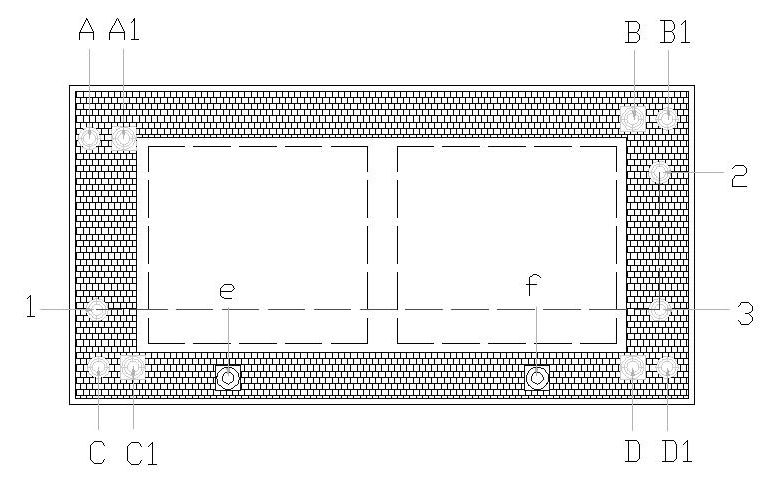

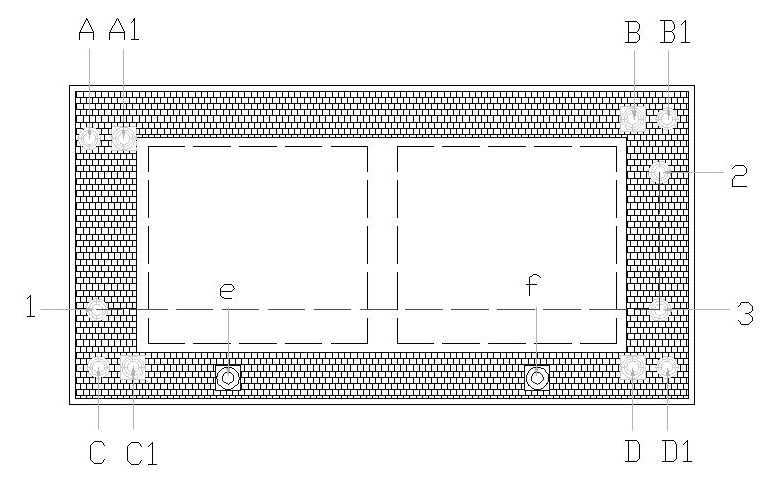

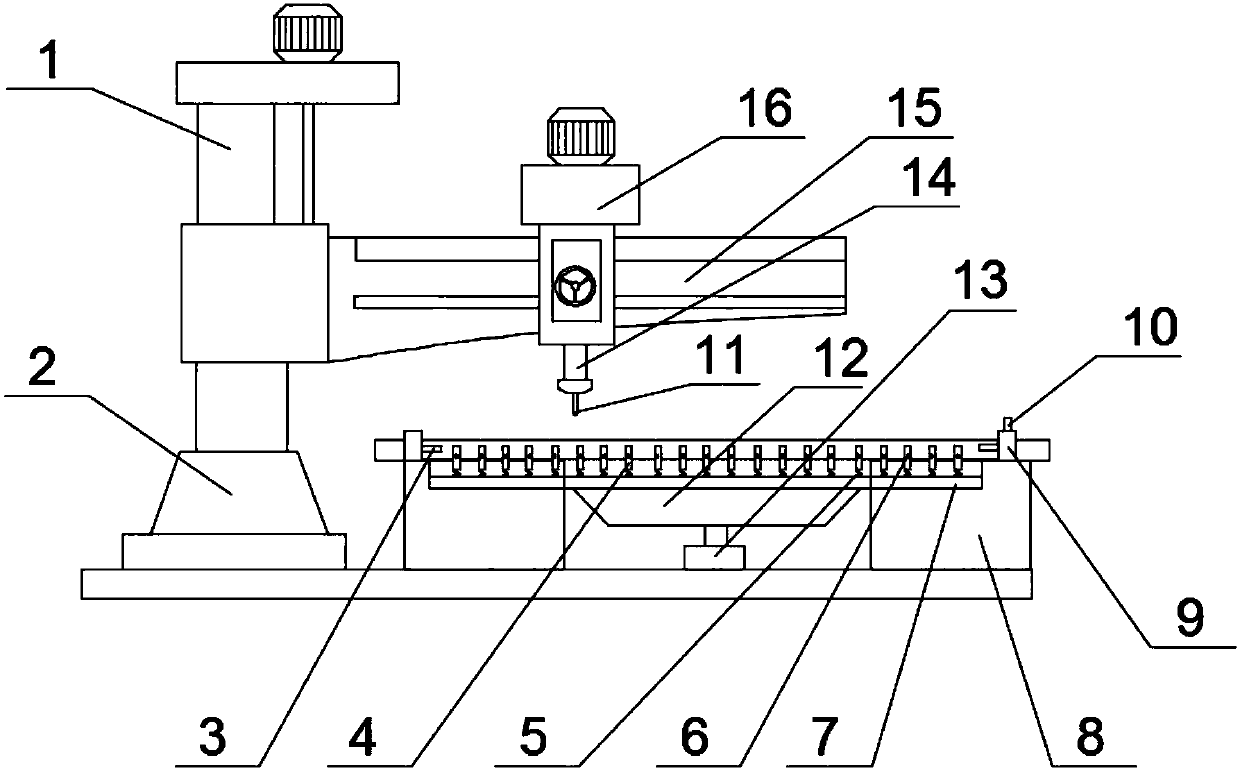

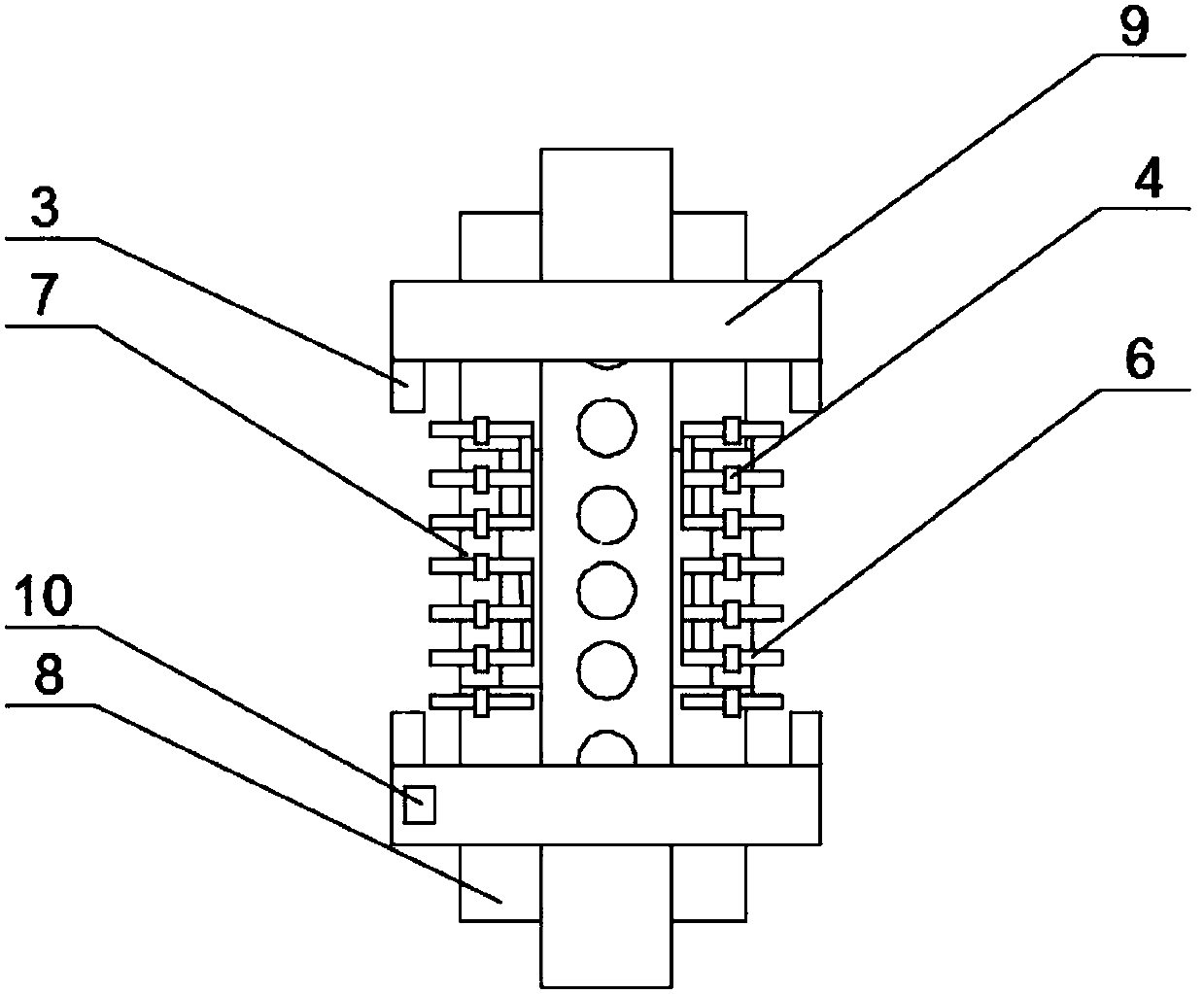

Radial drilling machine for pipe machining

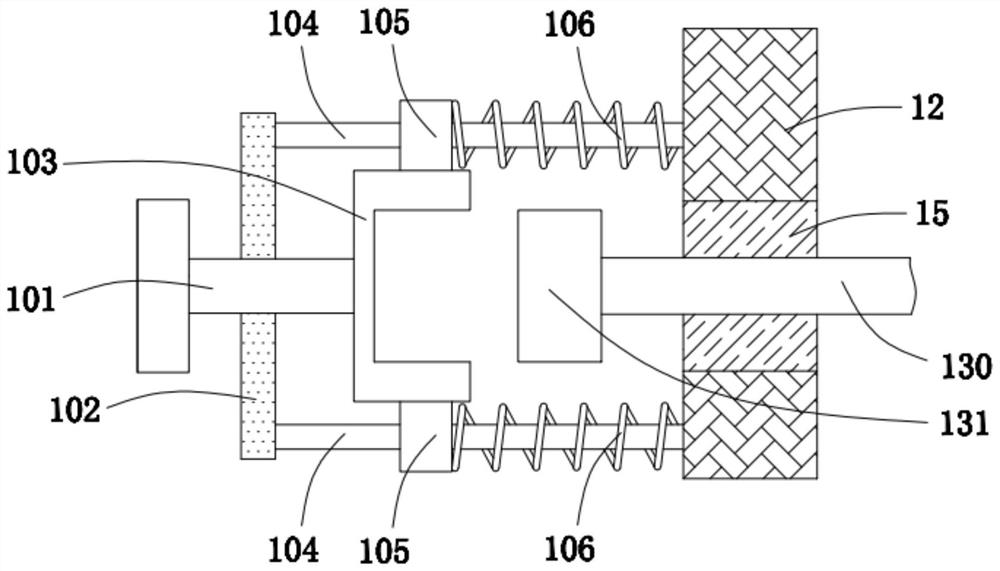

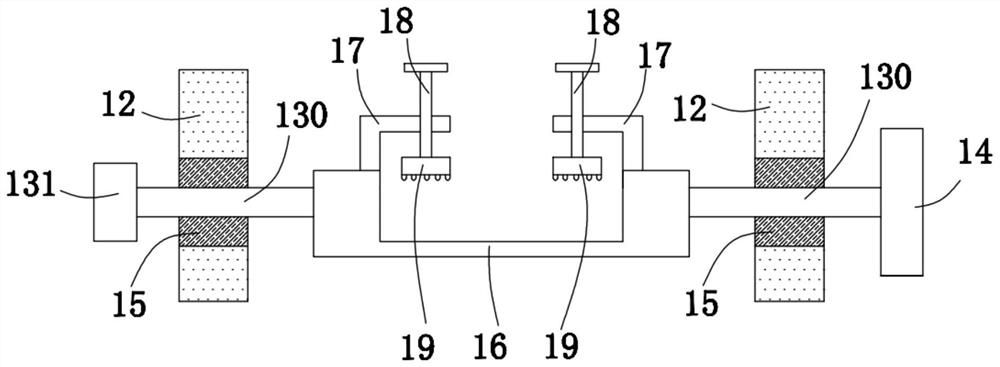

InactiveCN107716980AAvoid drilling deviationImprove the induction effectPositioning apparatusMaintainance and safety accessoriesMachiningPollution

The invention discloses a radial drilling machine for pipe machining, and relates to the technical field of drilling machine machining. The radial drilling machine is used for solving the technical problems that working efficiency is reduced due to the fact that an existing drilling machine is prone to skewing and the like. The radial drilling machine comprises a base, a stand column, a rocker arm, a spindle box, a spindle, a drill bit and a workbench; the stand column is arranged on the base, the rocker arm is arranged on the stand column, the spindle box is arranged on the rocker arm, the spindle is arranged below the spindle box, the drill bit is arranged at the bottom part of the spindle, the workbench is further arranged on the base, and the drill bit is located above the workbench; and workpiece locking blocks are arranged on the workbench, wherein a connecting plate is symmetrically arranged between the workbench, multiple springs are arranged on the connecting plate at intervals, and each spring is provided with a strip-shaped block; and the workpiece locking blocks are provided with infrared sensors. The radial drilling machine has the advantages that structure is simple,operation is convenient, drilling deviation is avoided, efficiency of the pipe machining is improved, and environmental pollution is small.

Owner:弘毅天承知识产权股份有限公司

Drilling positioning device

InactiveCN103658744BAvoid drilling deviationWork benchesPortable drilling machinesMotion ModePetroleum engineering

The invention provides a drill hole positioning device which comprises a positioning part, a guiding frame and a guiding cylinder. The positioning part is provided with a concave positioning area matched with the outer surface of a workpiece to the machined. The guiding frame is connected to the positioning part. The guiding cylinder is connected with the guiding frame in the guiding direction in a rectilinear motion mode, and is provided with an inner hole for being connected with an electric drill so that the drill bit of the electric drill can penetrate through the inner hole and extend towards the concave positioning area. The drill hole positioning device can effectively prevent the drill hole deviation caused by the sliding of the hand-operated electric drill in the process of pipeline part drilling, and the precision of a matched hole is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Building slate drilling device

InactiveCN110587828AImplement bufferingSo as not to damageWorking accessoriesStone-like material working toolsTransverse planeEngineering

The invention discloses a building slate drilling device, and particularly relates to the technical field of building slate drilling devices. The building slate drilling device comprises a worktable,wherein a drilling table is fixedly arranged at the top of the worktable, stand columns are fixedly arranged at two ends of the top of the worktable, a transverse plate is fixedly arranged at the topsof the stand columns, a support plate is arranged at the bottom of the transverse plate, a servo motor is fixedly arranged at the central position of the bottom of the support plate, a drill bit is fixedly connected with the end portion of an output shaft of the servo motor, a fixing plate is arranged on the exterior of the one end of the drill bit in a sleeving mode, and a bottom plate is arranged at the bottom end of the fixing plate. By arranging the fixing plate, a bottom plate, a pin shaft and a spring on the building slate drilling device, when the drill bit makes contact with stone inthe drilling process, the bottom of the bottom plate makes contact with the top of the stone, the bottom plate drives the pin shaft to move up and compresses the spring, thereby realizing buffering for the drill bit, and advantageously preventing the drill bit from being damaged, and then drilling efficiency is improved.

Owner:江苏金斗云新型材料科技有限公司

Technology applied to printed circuit board of electric power supply

ActiveCN109451668AShorten drilling timeReduce layer shiftLaminating printed circuit boardsEtchingSurface finishing

The invention discloses a technology applied to the printed circuit board of an electric power supply. The technology comprises the following steps that: S1: carrying out cutting; S2: obtaining an internal-layer graph; S3: carrying out internal-layer etching; S4: carrying out internal-layer AOI (Automated Optical Inspection); S5: carrying out lamination; S6: drilling a hole; S7: carrying out copper deposition; S8: carrying out full-plate electroplating; S9: manufacturing an external-layer circuit; S10: carrying out external-layer AOI; S11: carrying out screen printing and solder resisting; S12: carrying out surface treatment; and S13: forming. In the S5, a traditional rivet riveting process is omitted. In the S6, a magnetic workbench is adopted to lower hole drilling deviation, and therefore, the quality and the rate of finished products of the circuit board of the electric power supply are improved.

Owner:SICHUAN HAIYING ELECTRONICS TECH

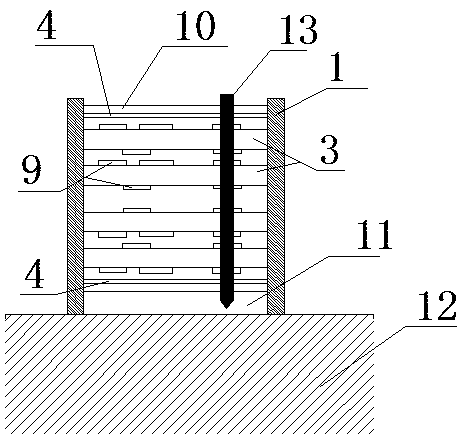

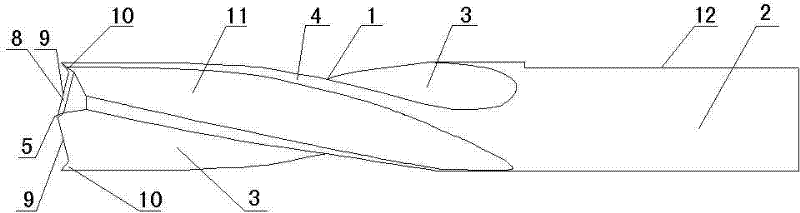

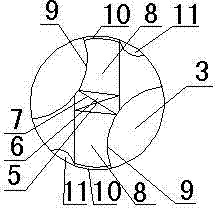

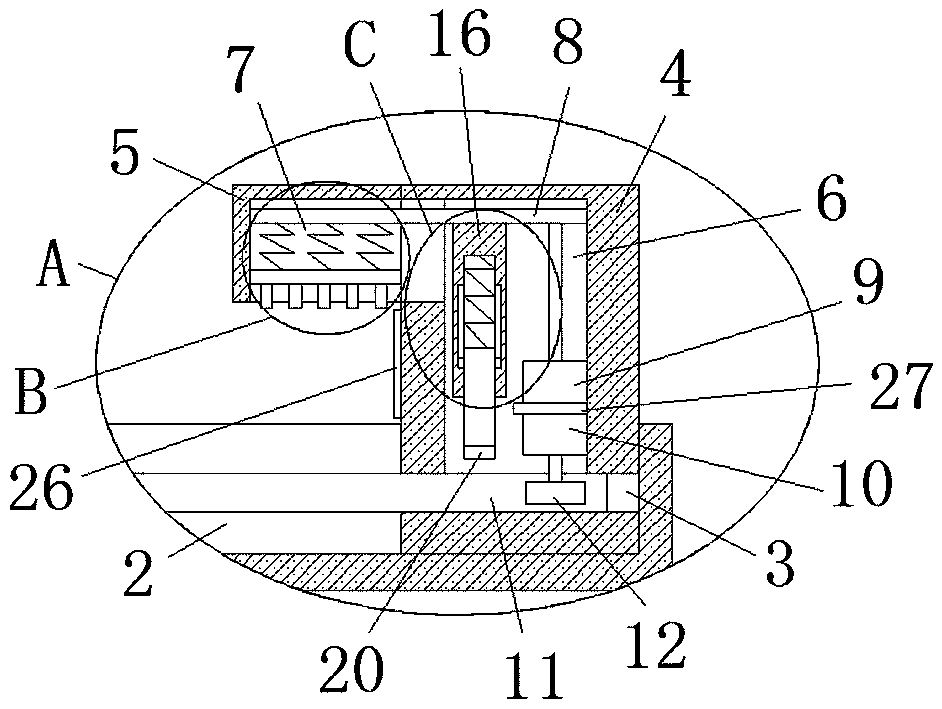

Four-groove gang drill

InactiveCN102490213AIncrease the effective cutting areaQuality improvementStationary drilling machinesWood turning toolsEngineeringDrill

The invention discloses a four-groove gang drill which comprises a cutting part (1) and a shank (2) that are connected in sequence. Two spiral chip grooves (3) are formed on the cutting part (1), the part between the spiral chip grooves (3) forms a cutter body (4), a positioning tip (5) is protruded from the center at the front end of the cutting part (1) and formed by four inclined positioning surfaces (6), the prismatic intersection of the four inclined positioning surfaces (6) forms a positioning edge (7), two downwardly sheer inclined surfaces (8) in outward symmetry are formed on the positioning tip (5), the inclined surfaces (8) and the groove bottoms of the spiral chip grooves (3) form end edges (9), the end edges (9) and the peripheral surface of the cutting part (1) form two outer side tips (10), and spiral auxiliary chip grooves (11) are formed on the cutter body (4). The invention has the following benefits: chip removal effect is good, and processing surface quality is improved; service life is prolonged; positioning is accurate, and drill offset is avoided; and assembly and disassembly are simple and convenient.

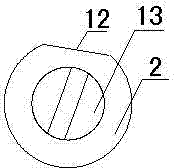

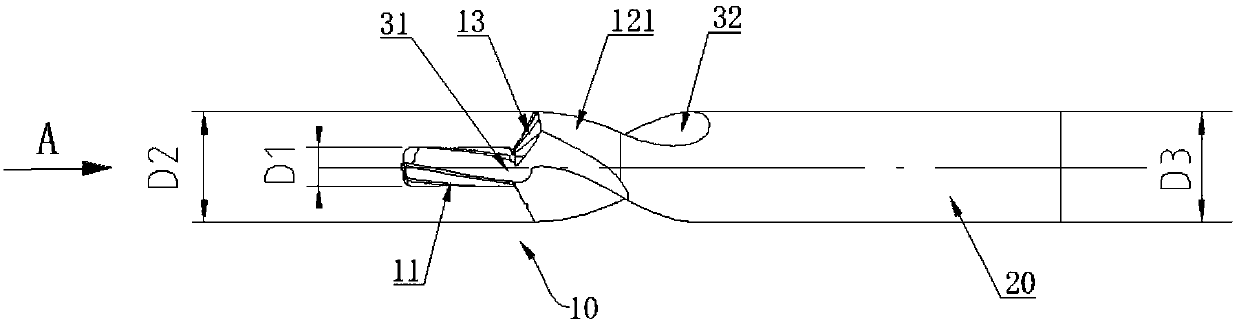

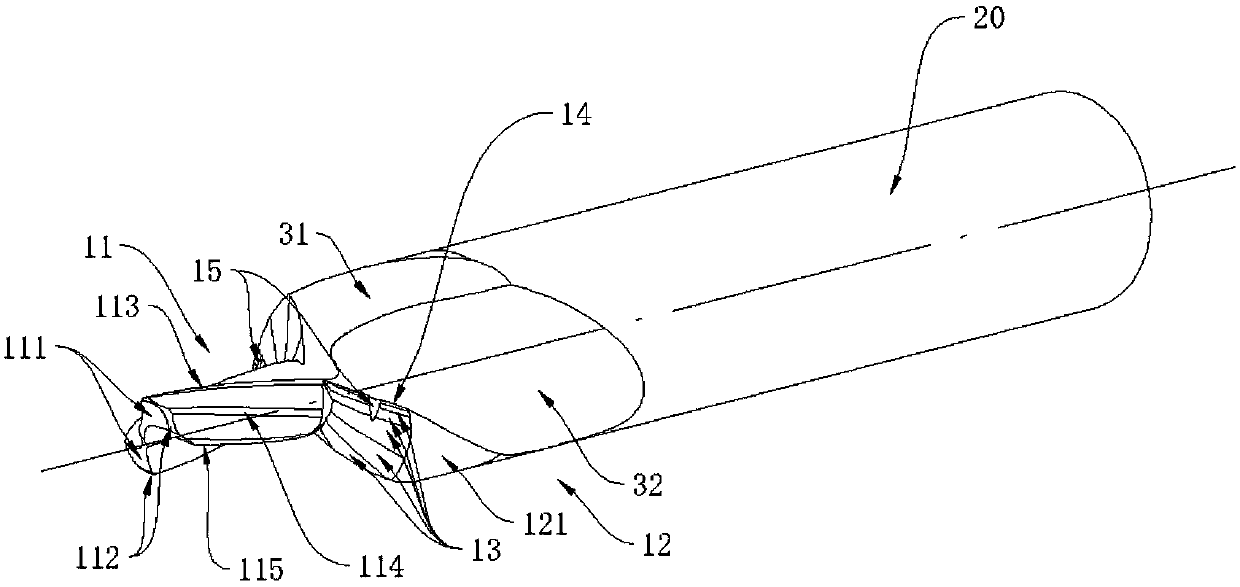

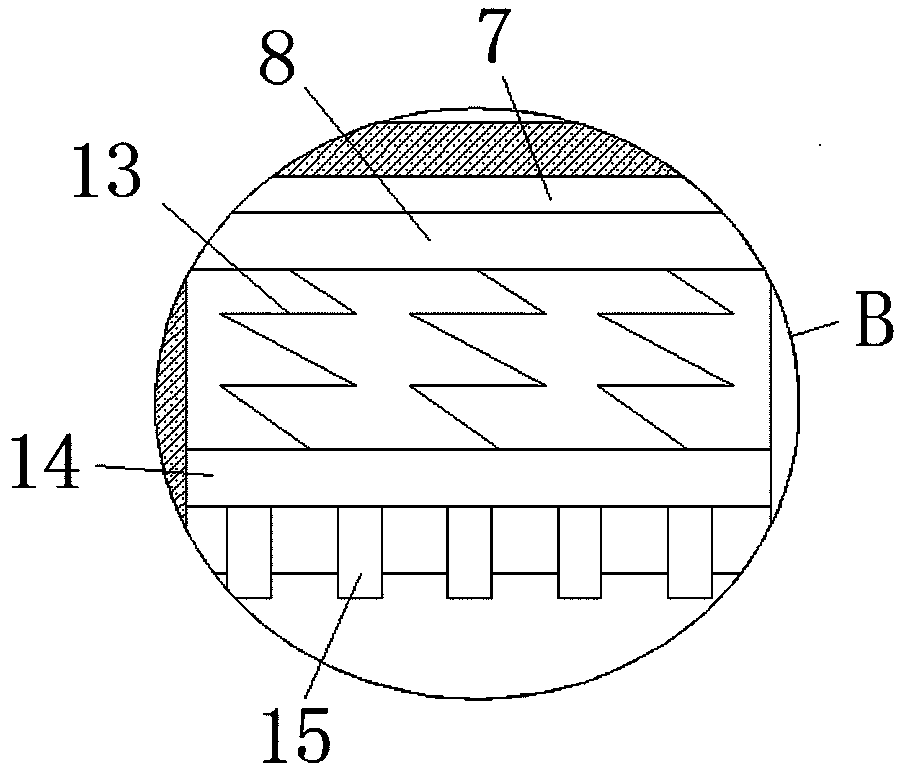

Stepped drill reamer for machining aircraft skin rivet holes

PendingCN107900421AReduce occupancyImprove processing timeTransportation and packagingStepped drillsReamerDrill

The invention provides a stepped drill reamer for machining aircraft skin rivet holes. The problems of a traditional method that machining efficiency is low; production cost is high; and machining quality cannot meet requirement can be solved. A reamer body comprises a first cylinder and a second cylinder which are concentrically connected into a whole from front to back; the diameter D1 of the first cylinder is smaller than the diameter D2 of the second cylinder; two first slag discharging grooves which are centrally symmetrical are formed in the periphery of the first cylinder, and two landsare formed on the periphery of the first cylinder; two second slag discharging grooves which are centrally symmetrical are formed in the periphery of the second cylinder; the two first slag discharging grooves in the periphery of the first cylinder both extend to the periphery of the second cylinder; the first slag discharging grooves and the second slag discharging grooves in the second cylinderare connected; the periphery of the second cylinder is divided to form two circumferential edges by the two first slag discharging grooves and the two second slag discharging grooves in the second cylinder; each land on the first cylinder is connected with the corresponding circumferential edge of the second cylinder in a transition mode through a stepped angle; the core thickness d1 of the firstslag discharging groove ranges from 0.25D1 to 0.35D1; the core thickness d2 of the second slag discharging groove ranges from 0.25D2 to 0.35D2; and d1 is smaller than d2.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

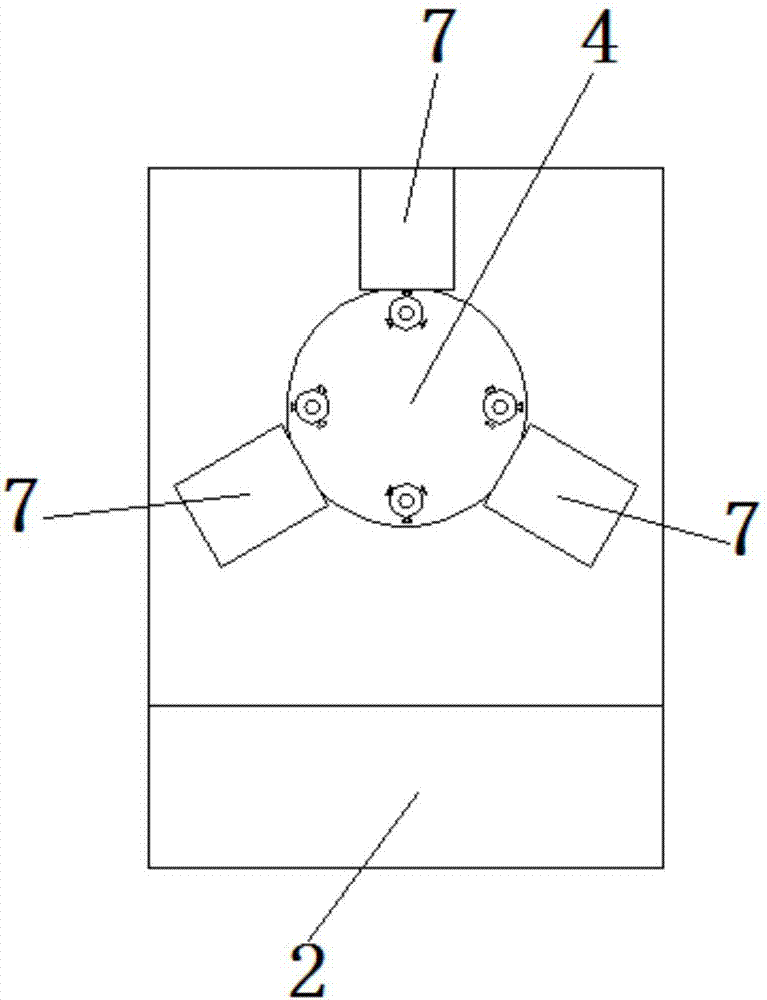

Four-hole drilling fixture for end-face gear of transmission shaft

InactiveCN106925811ASpeed upGuaranteed accuracyPositioning apparatusMetal-working holdersDrive shaftEngineering

A transmission shaft end face tooth drill four-hole tooling, including a device body and a drill bit, a base is provided at the bottom of the device body, and a support plate is connected to the right side of the top of the base by welding; the chuck is connected to the The left side of the support plate, and the drive shaft is installed inside the chuck; the left side of the chuck is provided with two hydraulic seats at the front and rear, and the bottom of the hydraulic seat is connected to the top of the base by welding; the top of the hydraulic seat is passed The hydraulic rod is connected with a locking plate, and the locking plate is connected with the hydraulic rod by welding; the fixed support block is installed between the front and rear hydraulic seats, and the middle part of the transmission shaft is placed in the fixed groove of the fixed support block . The setting of the motor box of the present invention is beneficial to the centerline of the motor box and the centerline of the end face gear on the same axis, and the method of drilling four holes at the same time ensures the accuracy of the required drilling and prevents drilling errors. The situation of drilling deviation and drilling crooked occurs.

Owner:十堰市劲鹰顺旺工贸股份有限公司

Machining method for preventing inclined hole drilling of marine screw shaft 22 m long

The invention relates to a machining method for preventing inclined hole drilling of a marine screw shaft 22 m long. The method comprises the steps that firstly, the screw shaft to be machined is fixed to a boring machine; then a guide hole with the depth of 120 mm is bored in the shaft end of the screw shaft through the boring machine; no floating blade is mounted on a boring machine pull rod at first, then the boring machine drives the boring machine pull rod to advance in an idle mode once, and it is confirmed that the boring machine pull rod can smoothly pass through the deep hole of the screw shaft; after it is confirmed that the boring machine pull rod can smoothly pass through the deep hole of the screw shaft, the floating blade is mounted on the boring machine pull rod, formal boring is started, the middle section of the screw shaft sinks for 1 mm in the boring process, and the parallelism of the axis of the boring machine pull rod and the axis of the screw shaft is within 0.5 mm. The machining method has the advantages that the middle section of the screw shaft sinks for 1 mm, it is ensured that the parallelism of the axis of the boring machine pull rod and the axis of the screw shaft is within 0.5 mm, and therefore it can be ensured that the phenomenon of inclined hole drilling is effectively avoided in the boring process.

Owner:南通德玛瑞机械制造有限公司

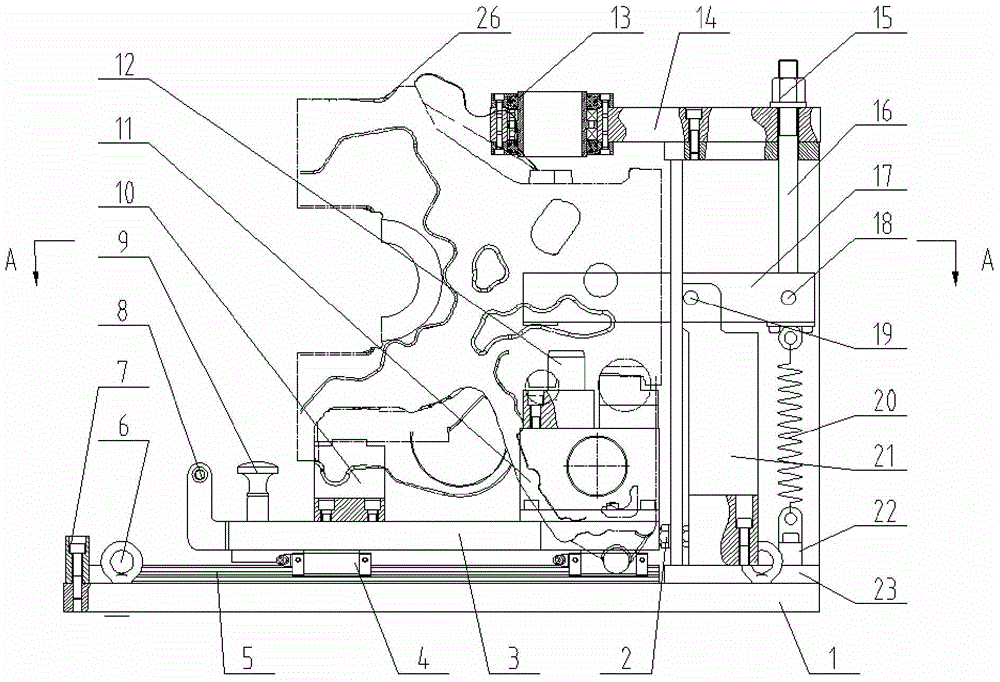

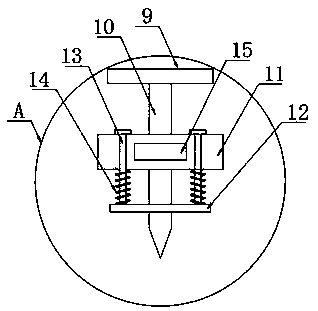

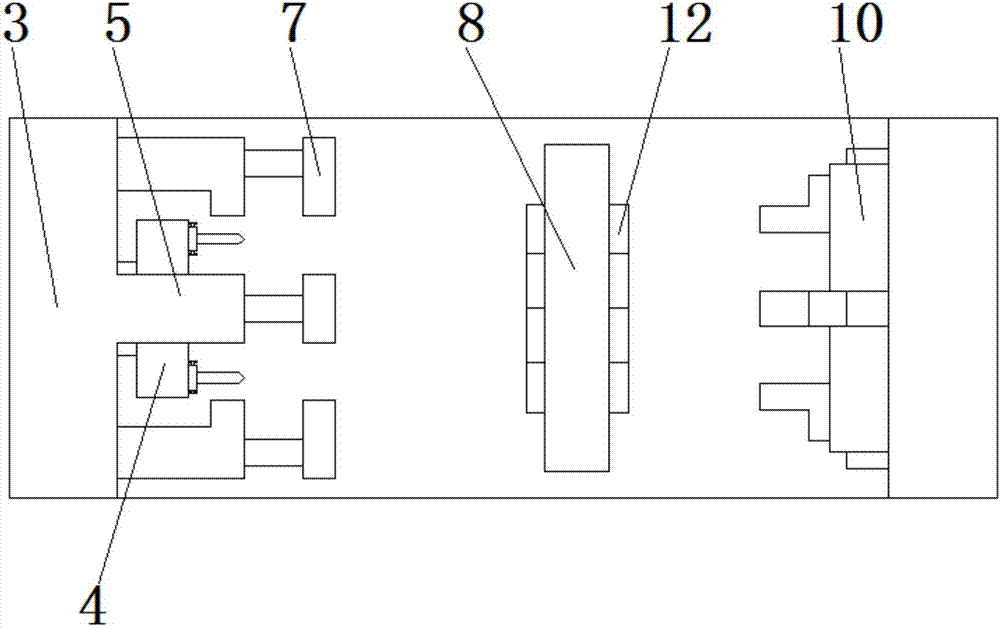

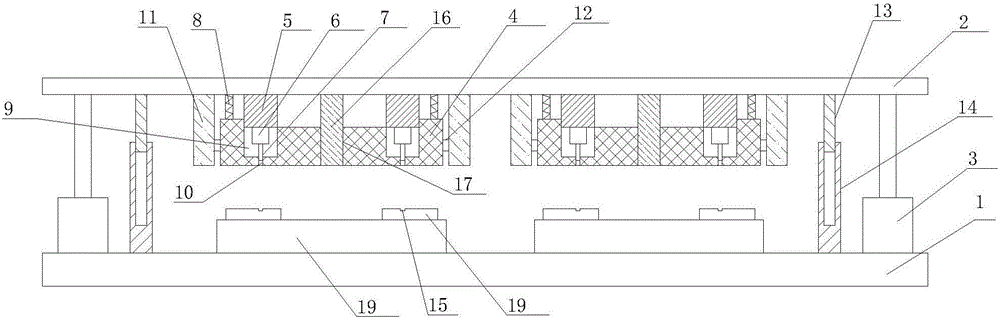

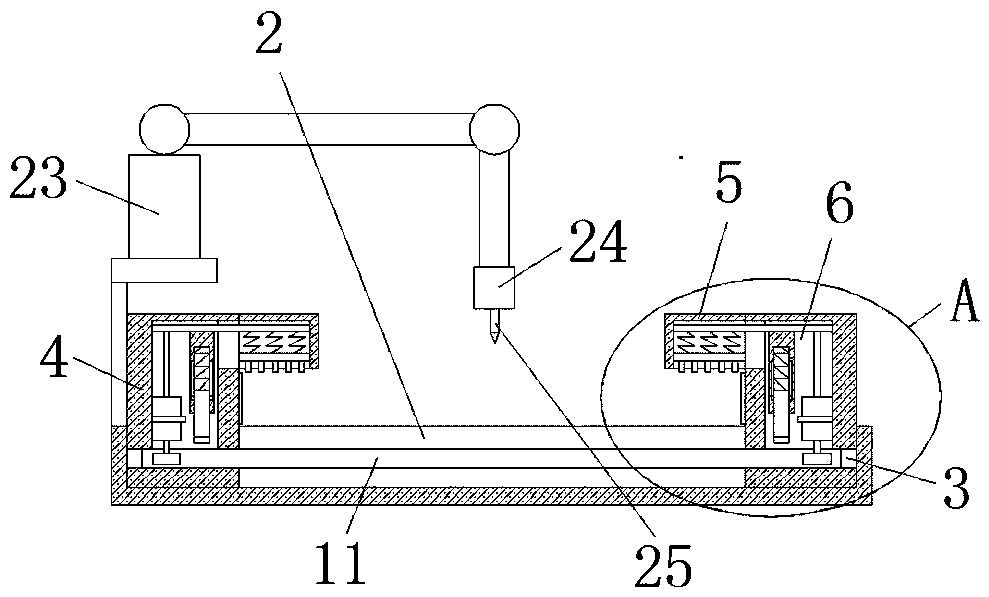

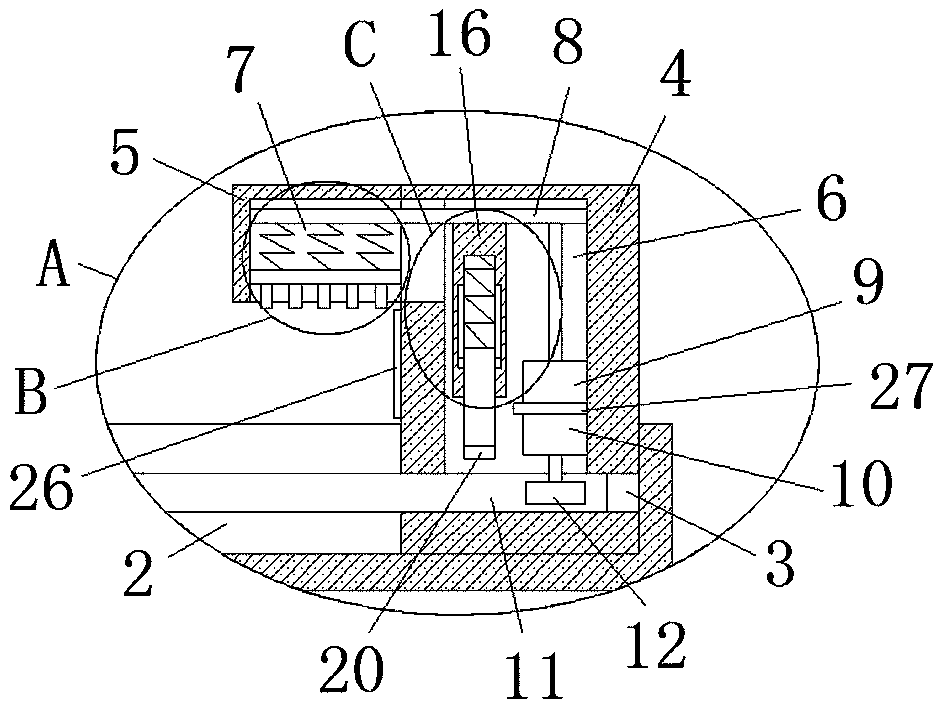

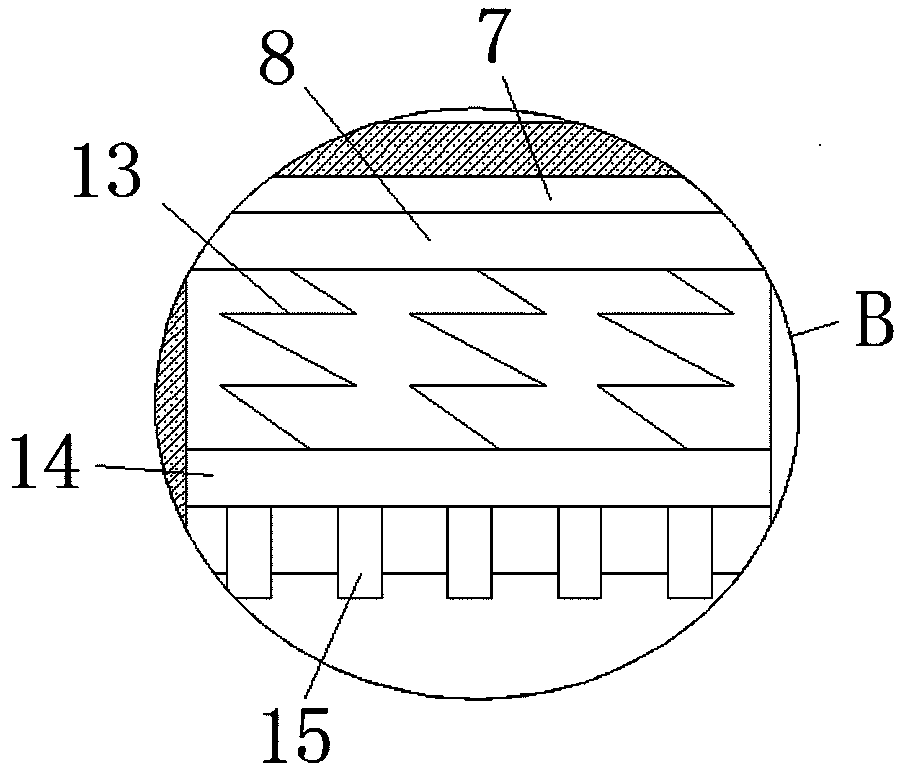

High-precision charger shell end face drilling machining device

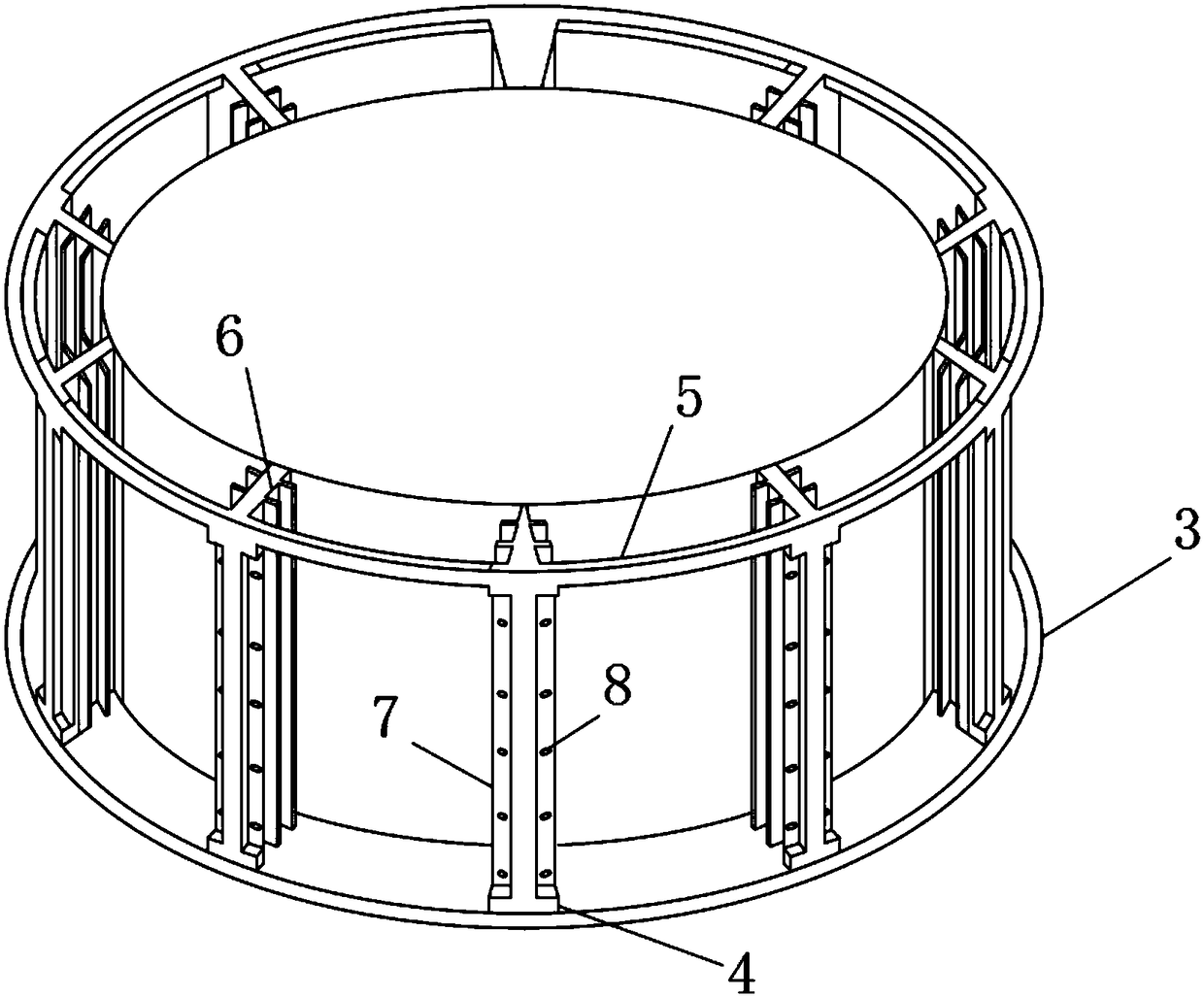

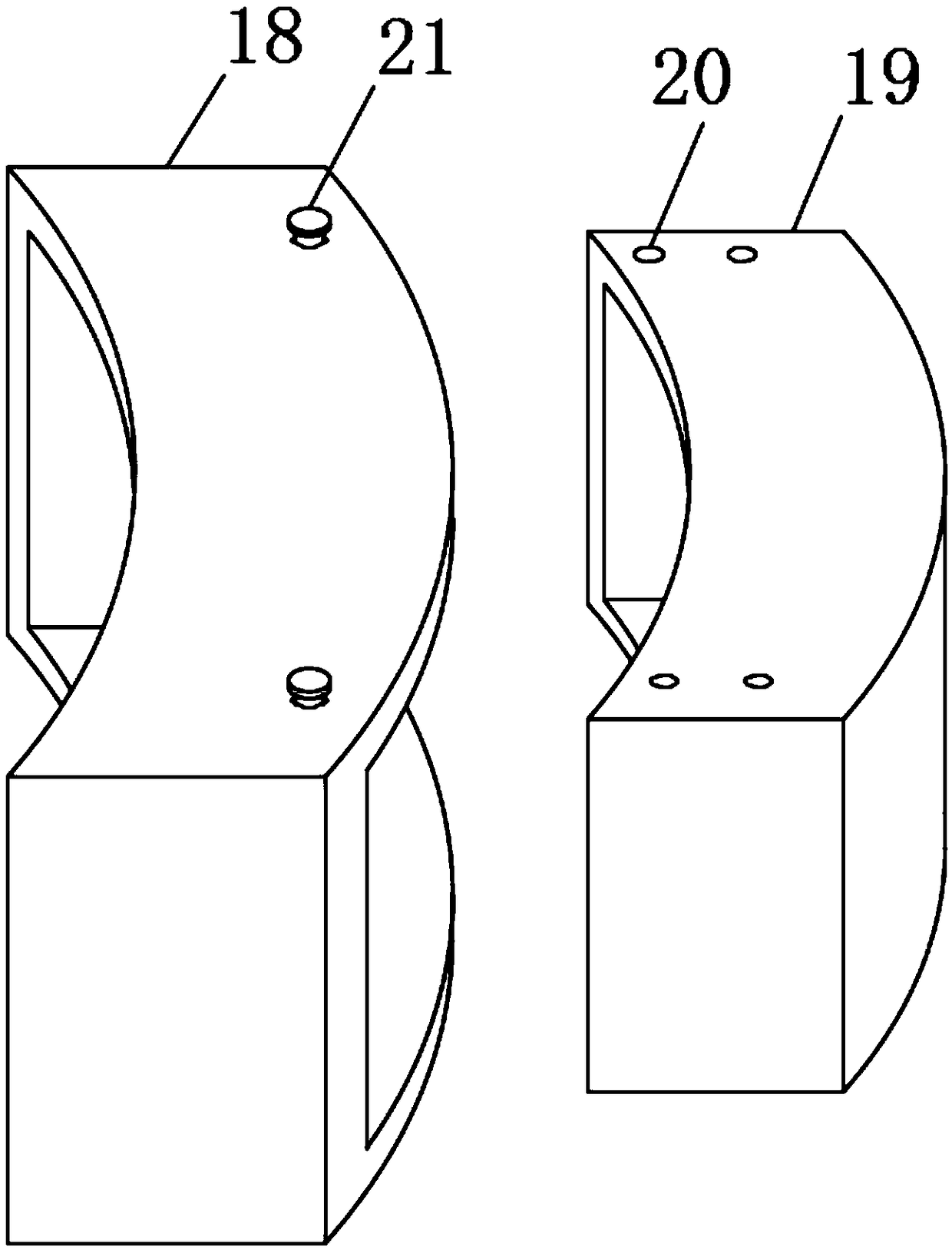

InactiveCN106624033AAvoid shakingAvoid drilling deviationMeasurement/indication equipmentsLarge fixed membersEngineeringMachining

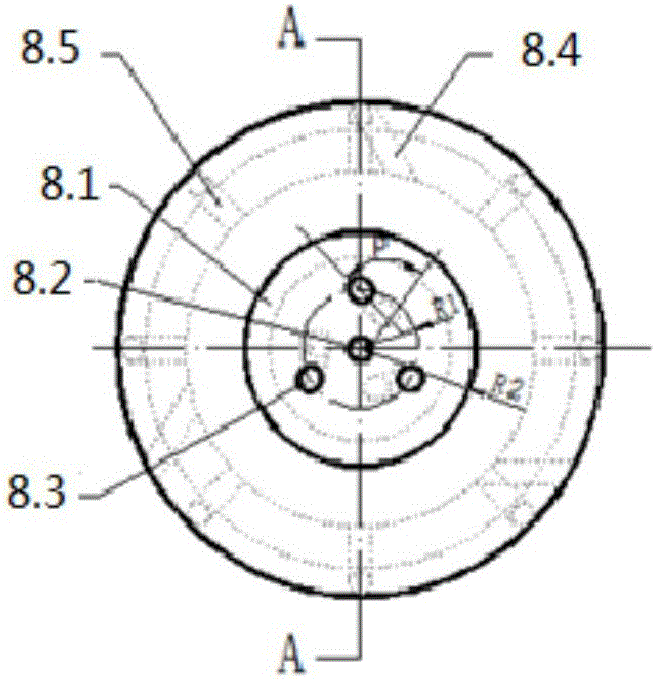

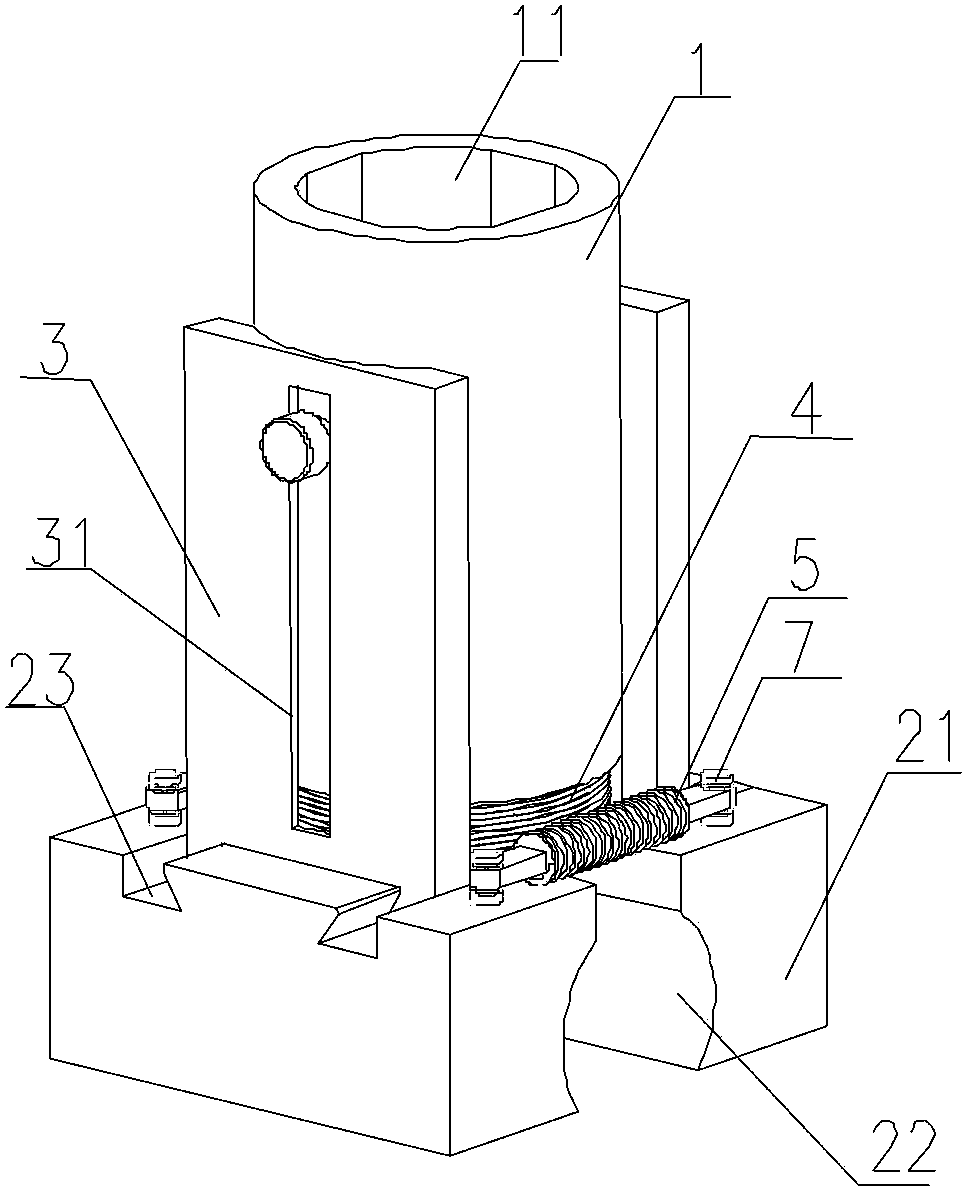

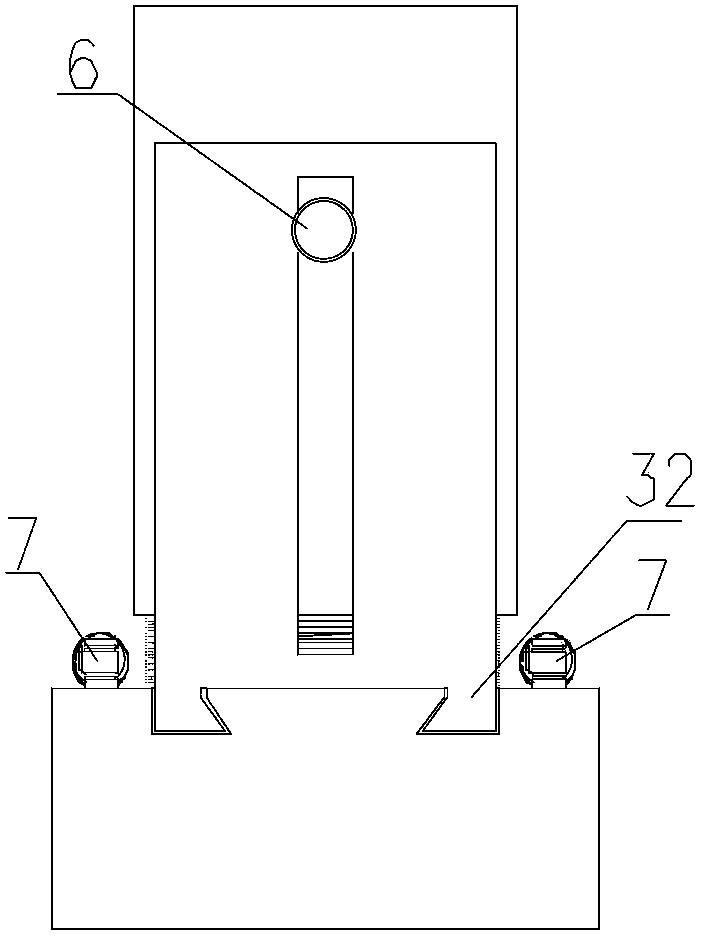

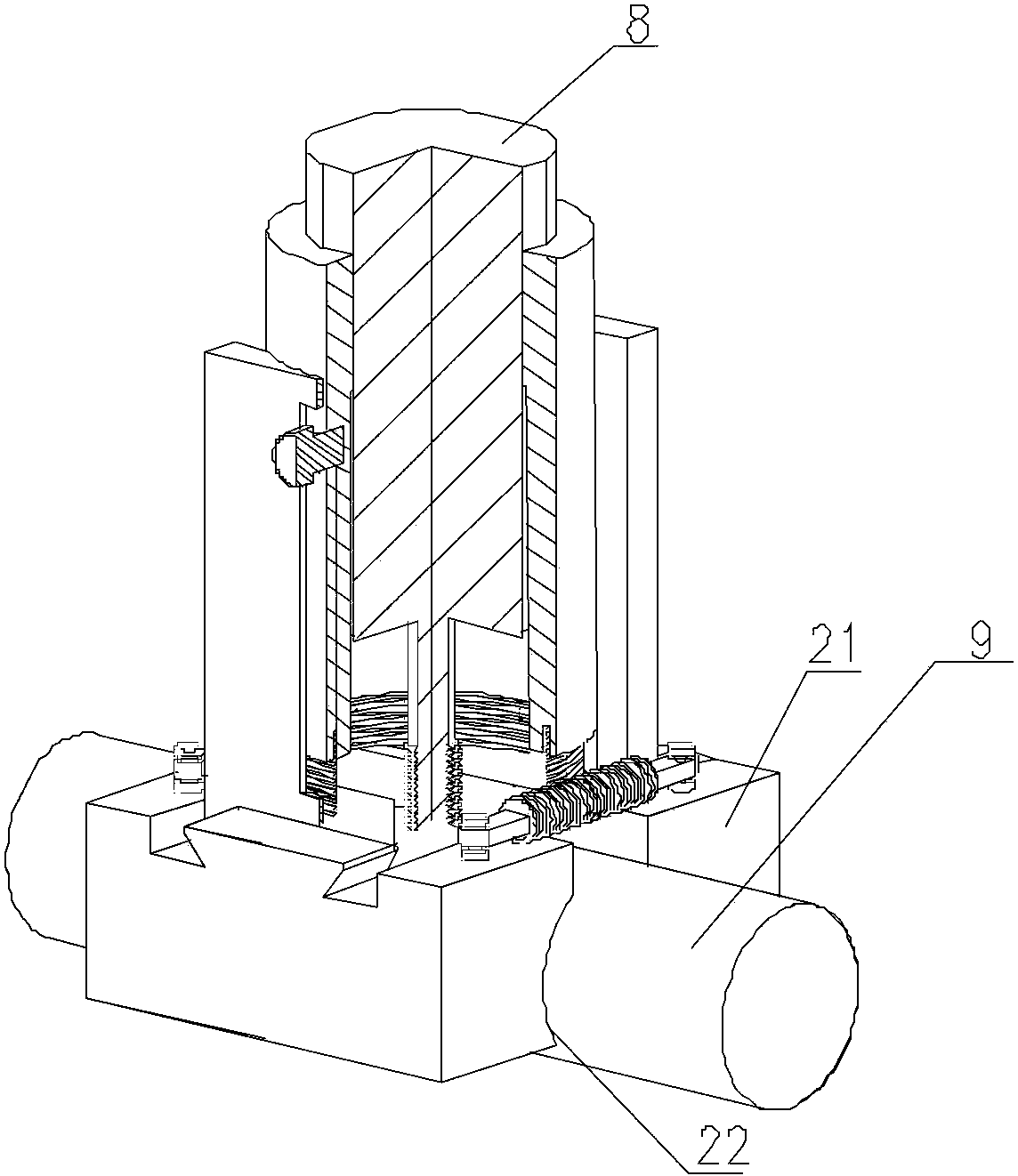

The invention provides a high-precision charger shell end face drilling machining device. The device comprises a workbench, an installing frame, a first driving mechanism, N drilling mechanisms, N fixing mechanisms and a controller; the installing frame is provided with a distance measuring sensor used for detecting a distance value between the installing frame and the workbench in real time; each drilling mechanism comprises M drilling components and prepressing sleeves, wherein the M drilling components are all installed on the installing frame and circumferentially distributed, drill bits of all the drilling components face the workbench, the prepressing sleeves are located under the installing frame, connected with the installing frame through multiple reset springs and provided with M guiding grooves, and a first guiding hole used for allowing the corresponding drill bit to penetrate through is formed in each guiding groove in the extending direction of the drill bit; M fixing platforms used for fixing a charger shell are arranged at the end, close to the installing frame, of a fixing base, and the controller is connected with the first driving mechanism and the distance measuring sensor. The high-precision charger shell end face drilling machining device is accurate in drilling and positioning performance, high in precision and drilling efficiency, good in machining effect and high in product quality.

Owner:天长市优信电器设备有限公司

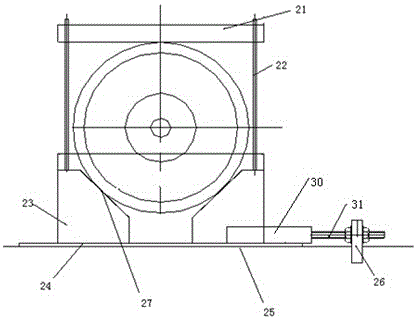

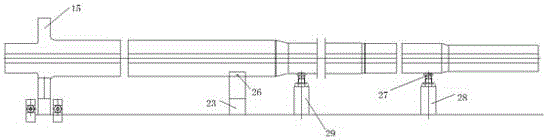

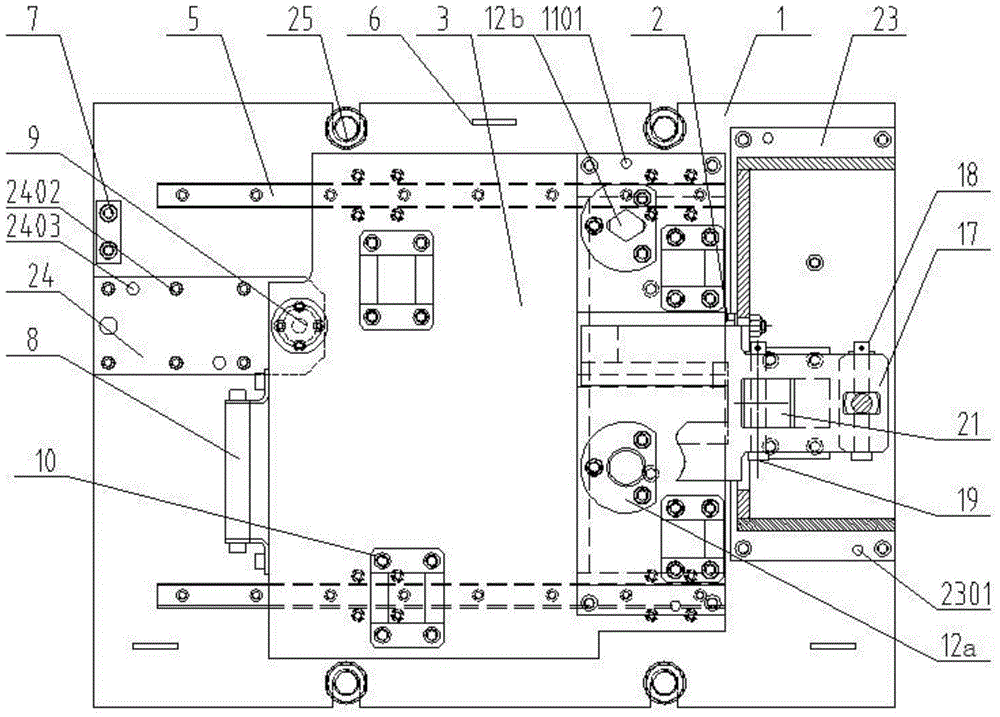

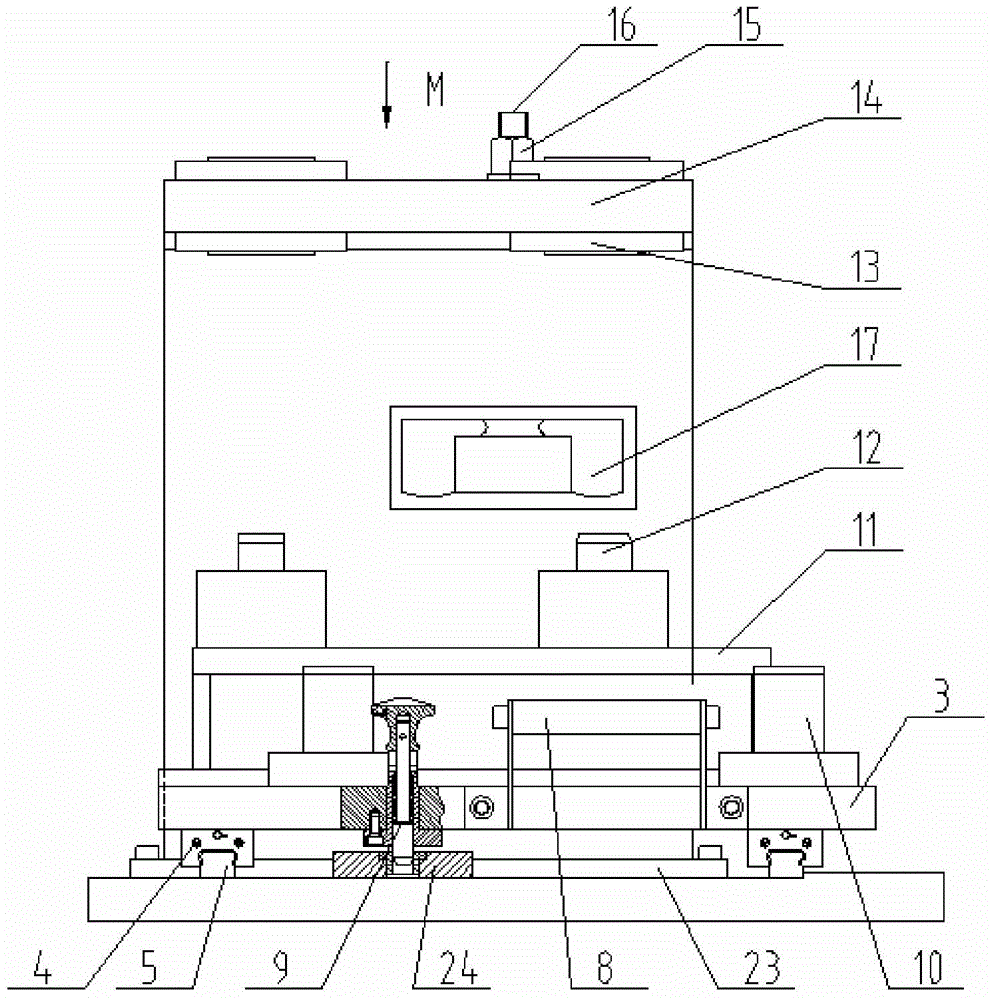

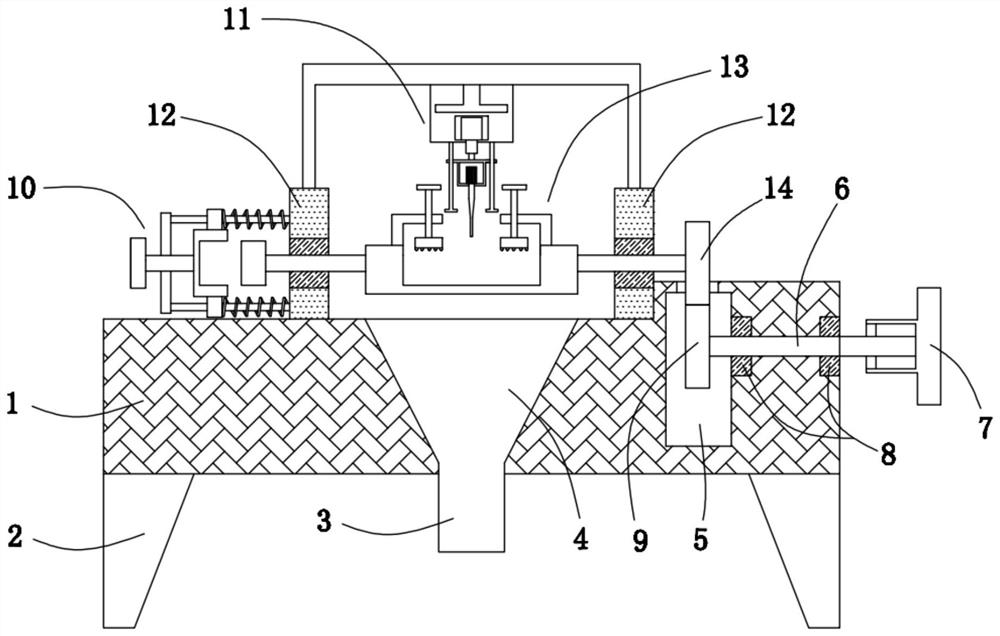

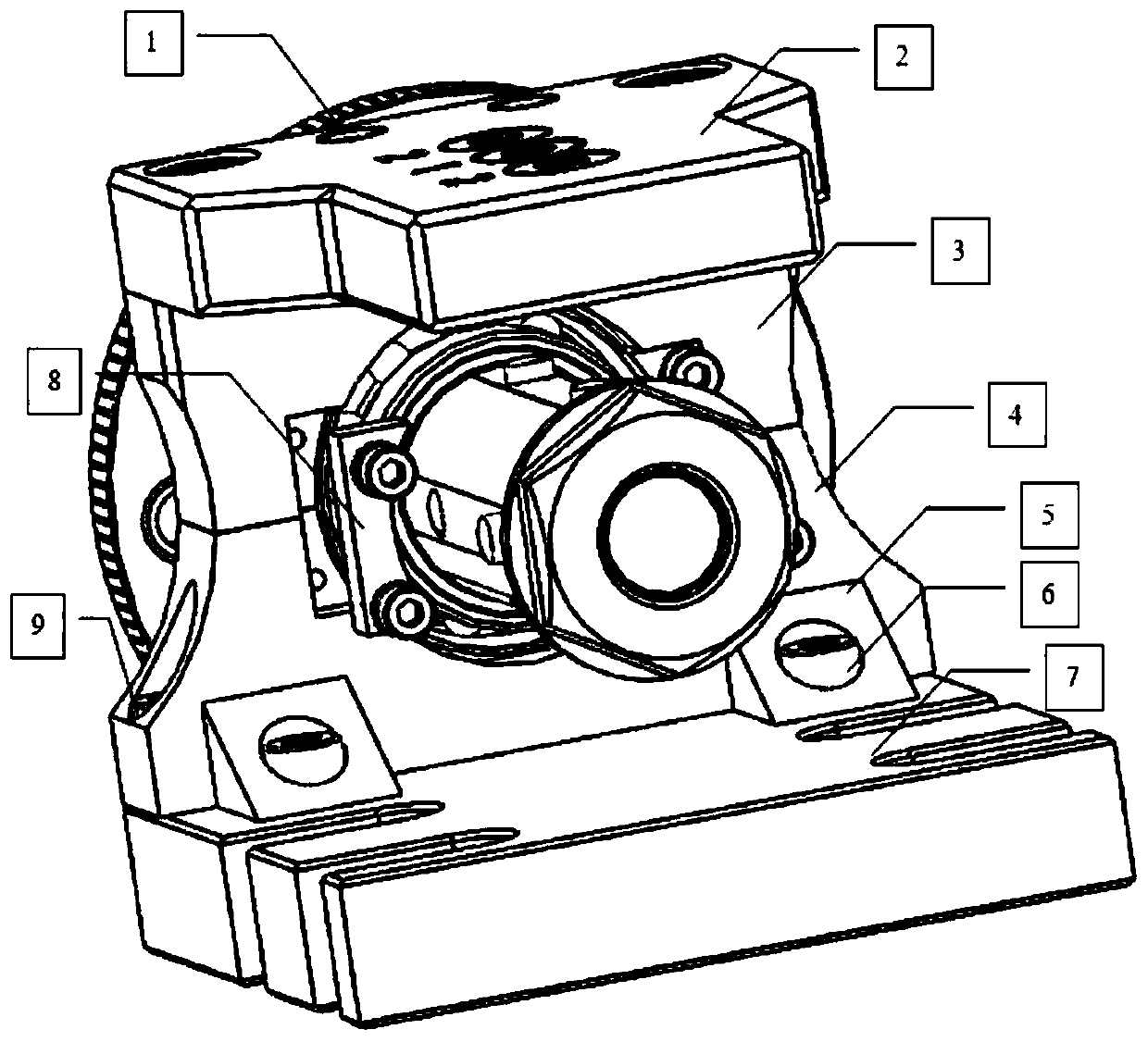

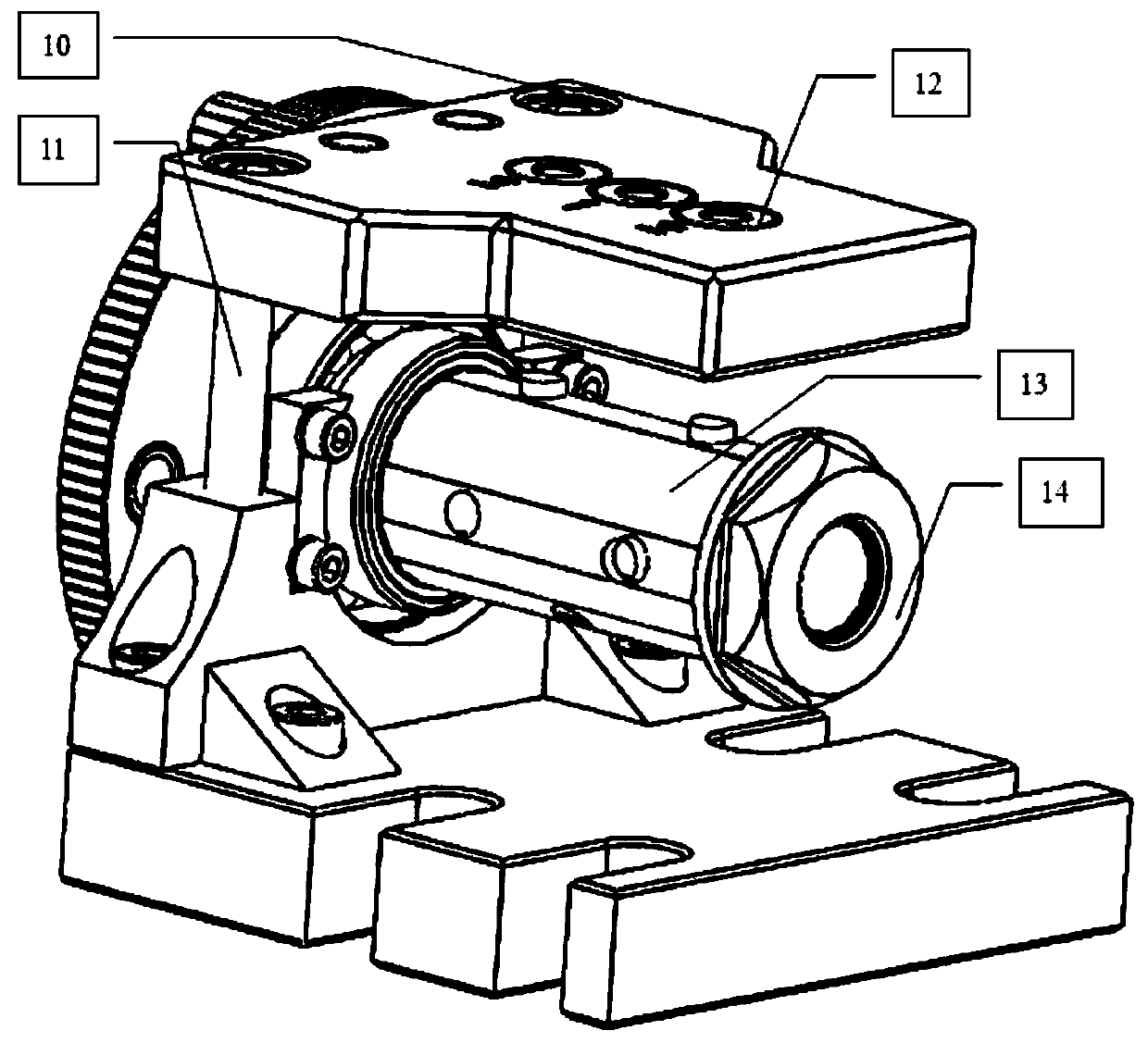

Automatic punching machine for pantograph sliding plate aluminum bracket and punching method thereof

ActiveCN108890348BAchieve initial positioningAchieve repositioningPositioning apparatusMetal-working holdersPunchingEngineering

The invention discloses an automatic punching machine for a pantograph slide plate aluminum support and a punching method of the machine. The automatic punching machine for the pantograph slide platealuminum support comprises a base, a sliding groove is formed in the top of the base, a same limiting rod is welded to the inner walls of the two sides of the sliding groove, two symmetrical clampingplates slidingly sleeve the limiting rod, two pressing plates are welded to the sides, close to each other, of the two clamping plates and located above the base, two limiting holes matched with the limiting rod are formed in the sides, close to each other, of the two clamping plates and slidingly connected with the limiting rod, a groove is formed in the inner wall of the top of each limiting hole, and a first groove is formed in the bottom of each pressing plate. The machine is reasonable in design and simple in structure, the pantograph slide plate aluminum support can be stably and fixedlyclamped and positioned, when the pantograph slide plate aluminum support is punched, the position deviation is prevented, the punching position deviation is prevented accordingly, and the accuracy ofthe punching position is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Vertical bench drill for bearing machining

InactiveCN109079523AEasy to drillHeight adjustableLarge fixed membersBoring/drilling componentsEngineeringDrill bit

The invention discloses a vertical bench drill for bearing machining. The bench drill comprises a box cover; a control box and a motor are fixedly connected to the outer surface of the lower end of the box cover; the control box is located in front of the motor; a power outlet is formed in the outer surface of one side of the box cover; a drill bit is movably connected to the outer surface of thelower end of the control box; a stand column is inserted in the position, close to the back side of the drill bit, of the outer surface of the lower end of the control box; a base is fixedly connectedto the outer surface of the lower end of the stand column; and fixing pipes are fixedly connected to the positions, close to the front, of the outer surface of the upper end of the base. According tothe bench drill, a series of structures are arranged, the placing angle of a workbench can be adjusted during use of the bench drill, the inner surfaces of bearings can be drilled conveniently by thebench drill, the workbench can be fixed when inclined, and thus drilling deviation caused by interference of external force can be avoided; and the height of the drill bit can be adjusted, so that relatively small bearings can be drilled conveniently by the bench drill.

Owner:WUXI SANLI BEARINGS

Automatic punching machine for pantograph slide plate aluminum support and punching method of machine

ActiveCN108890348AReliable positioning and clampingAvoid position shiftPositioning apparatusMetal-working holdersPunchingSlide plate

The invention discloses an automatic punching machine for a pantograph slide plate aluminum support and a punching method of the machine. The automatic punching machine for the pantograph slide platealuminum support comprises a base, a sliding groove is formed in the top of the base, a same limiting rod is welded to the inner walls of the two sides of the sliding groove, two symmetrical clampingplates slidingly sleeve the limiting rod, two pressing plates are welded to the sides, close to each other, of the two clamping plates and located above the base, two limiting holes matched with the limiting rod are formed in the sides, close to each other, of the two clamping plates and slidingly connected with the limiting rod, a groove is formed in the inner wall of the top of each limiting hole, and a first groove is formed in the bottom of each pressing plate. The machine is reasonable in design and simple in structure, the pantograph slide plate aluminum support can be stably and fixedlyclamped and positioned, when the pantograph slide plate aluminum support is punched, the position deviation is prevented, the punching position deviation is prevented accordingly, and the accuracy ofthe punching position is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Multi-angle drilling device and multi-angle drilling method for auto spare parts manufacturing

PendingCN111922375AAdjust the drilling angleAvoid drilling deviationFeeding apparatusPositioning apparatusProcess engineeringDrill hole

The invention discloses a multi-angle drilling device for auto spare parts manufacturing. The device comprises a workbench, two sides of an upper end of the workbench are provided with a bracket, a clamping mechanism is connected between the two sets of brackets, the bracket at a left side is connected with a brake mechanism, and upper ends of the two sets of brackets are further connected with adrilling mechanism; the device can adjust a drilling angle of auto spare parts before a drill bit performs drilling; the device can keep the auto spare parts subjected to angle adjustment motionless,and can prevent drilling deviation; a piston of an air cylinder stretches out, thus, a box body and a servo motor in the box body move downwards, the servo motor works and makes the drill bit at an output end thereof perform high-speed rotation, until the drill bit contacts a surface of the auto spare parts on a clamping base and completes a drilling operation, then, by sliding of a sliding base on a sliding rail, a drilling point of the drill bit on the surface of the auto spare parts can be adjusted, and thus, working efficiency of the drilling operation can be improved.

Owner:WUHAN UNIV OF TECH

Special clamp used for circular hollow pipe drilling

PendingCN110405495ASimple structureEasy to operatePositioning apparatusMetal-working holdersEngineeringBolt connection

The invention discloses a special clamp used for circular hollow pipe drilling. The special clamp comprises a fixing bottom plate and a top plate. The upper portion of the fixing bottom plate is connected with a bearing supporting base through first bolts. The upper portion of the bearing supporting base is connected with a bearing supporting upper plate through second bolts. A bearing is arrangedin the middle of the bearing supporting base. The upper portion of the bearing supporting upper plate is connected with a top plate through third bolts. A pipe fixing pipe socket is arranged on the inner race of the bearing in a sleeving manner. The outer side of one end of the pipe fixing pipe socket is sleeved with a to-be-drilled circular hollow pipe, and the end is locked by means of a nut. The other end of the pipe fixing pipe socket is connected with a rotating plate through linkage bolts. A plurality of positioning holes are formed in the outer side of the rotating plate. The interiorof the positioning hole in the top is fixed to the top plate through a positioning bolt. The special clamp is simple in structure, small in investment, small in size, high in measuring degree and lowin using and maintenance charge, the purpose of using can be fast achieved, the product quality accuracy is improved, and a good using effect is achieved.

Owner:CHERY & WANDA GUIZHOU BUS

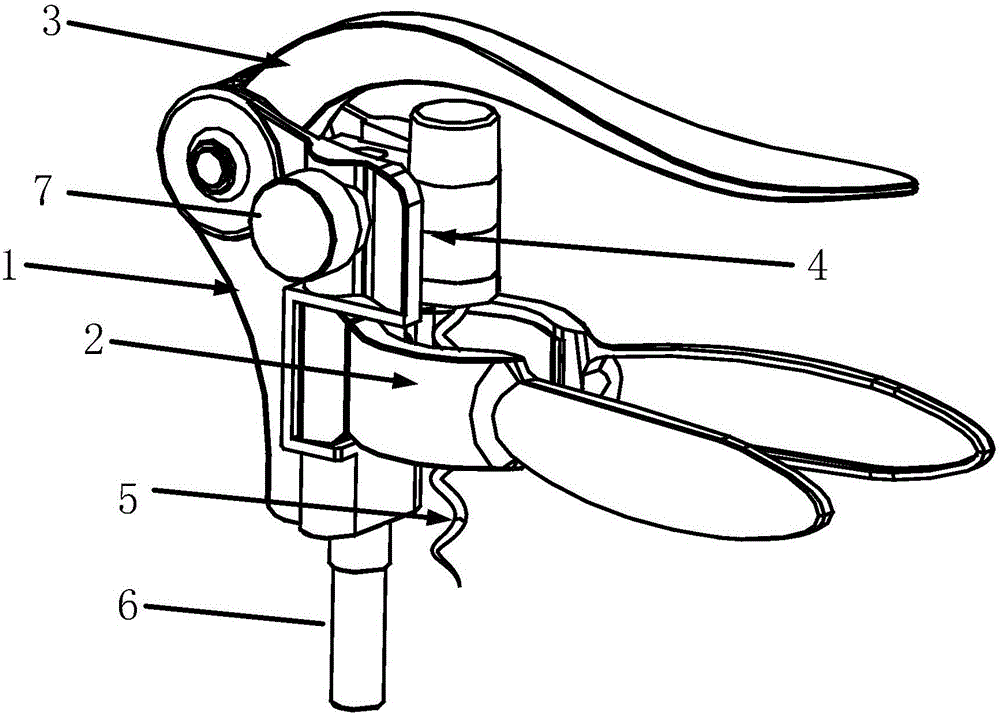

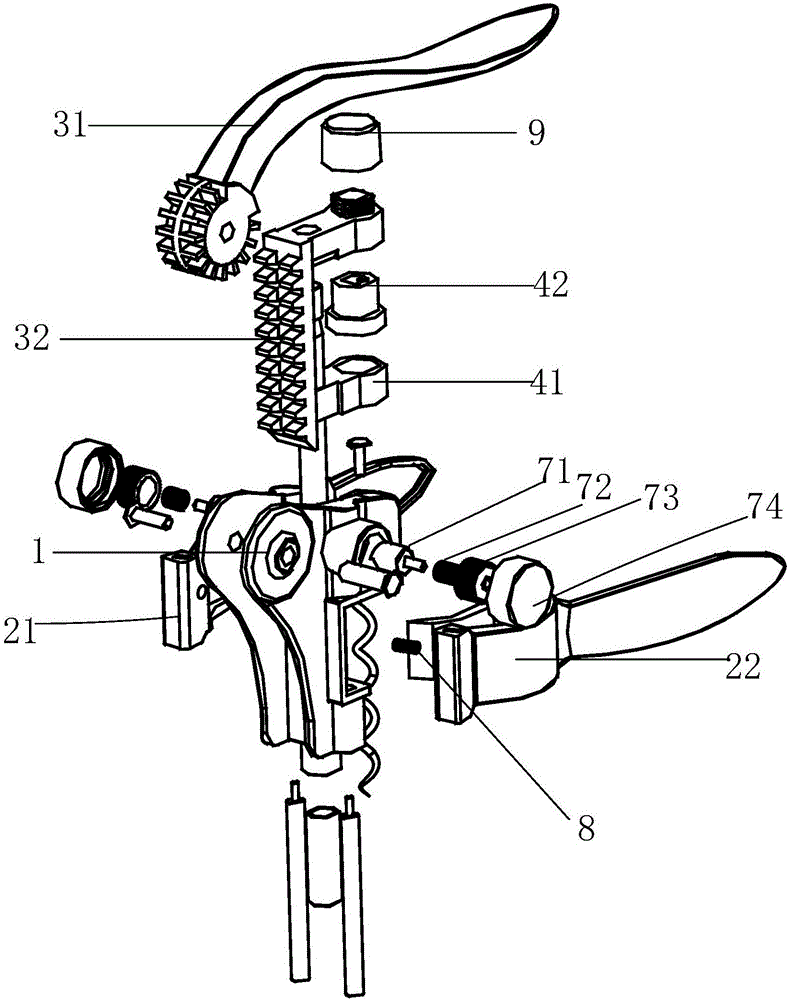

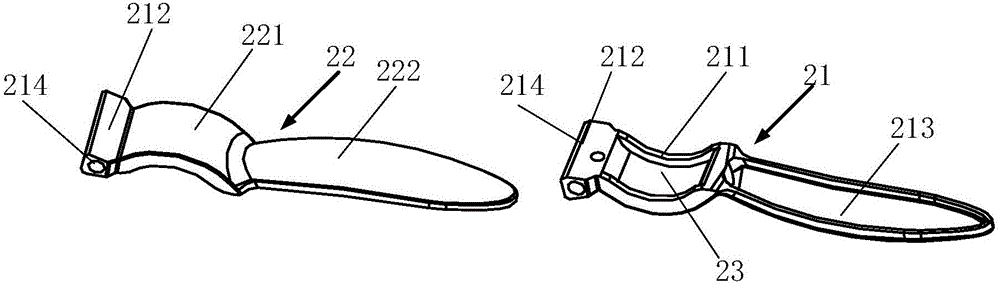

Corkscrew guiding structure and corkscrew

The invention discloses a corkscrew guiding structure. The corkscrew guiding structure comprises a main body and a threaded rod. A threaded guiding seat is arranged on the main body by being clamped and comprises a placing hole and a positioning pin hole. A threaded guiding part is arranged on the placing hole. A positioning pin is mounted in the positioning pin hole. The threaded rod is movably arranged in the threaded guiding part and the placing hole. The threaded rod and the positioning pin are fixed on a pressing plate. The invention provides the corkscrew guiding structure capable of avoiding deviation drilling and a corkscrew.

Owner:邢皓宇

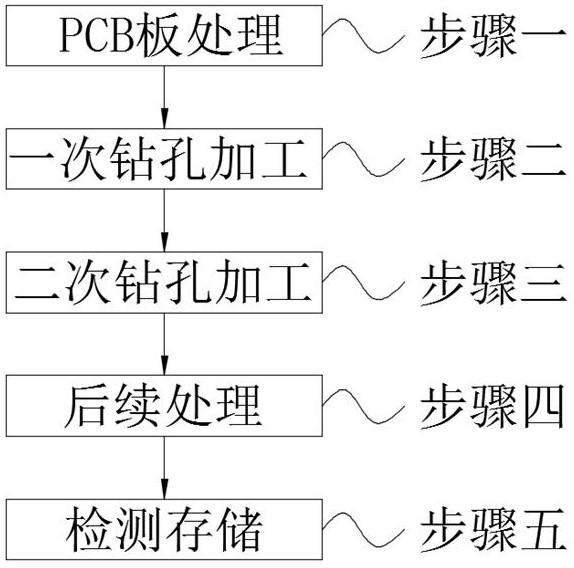

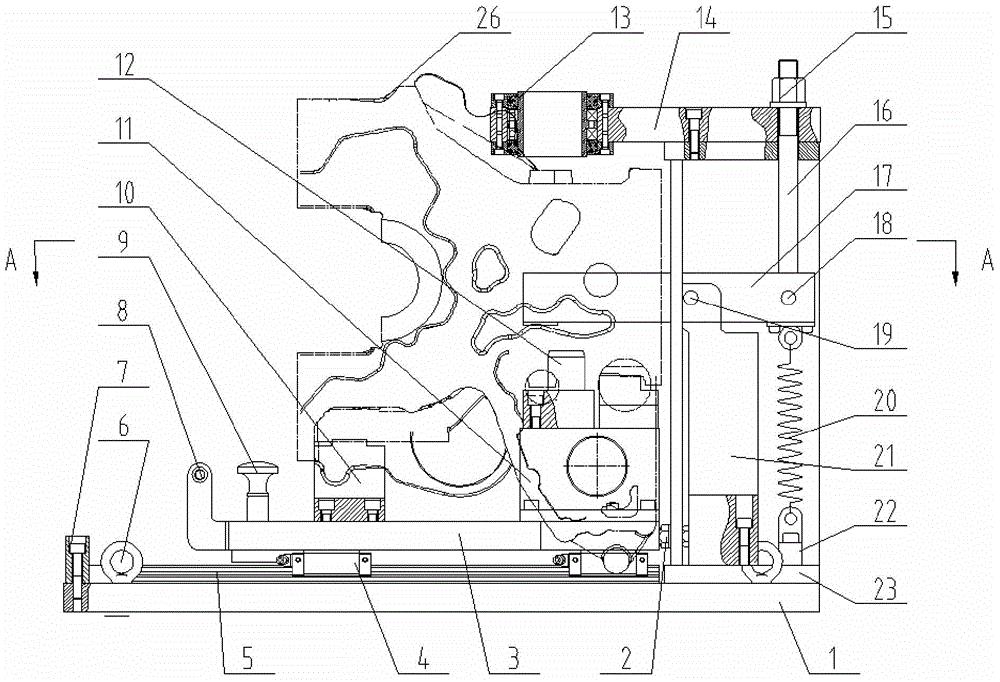

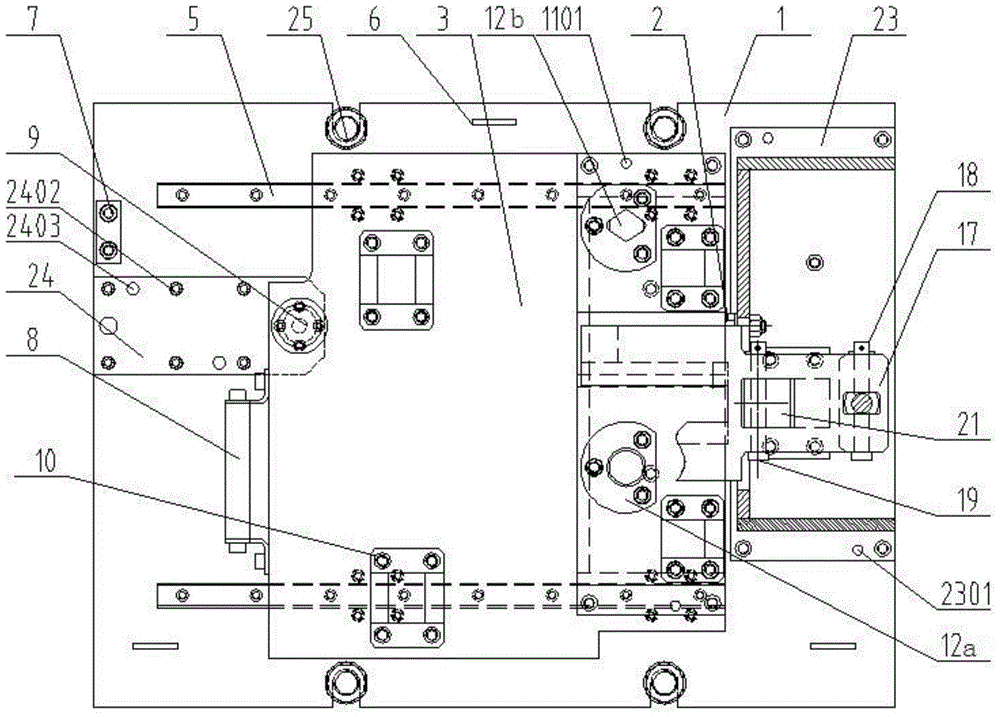

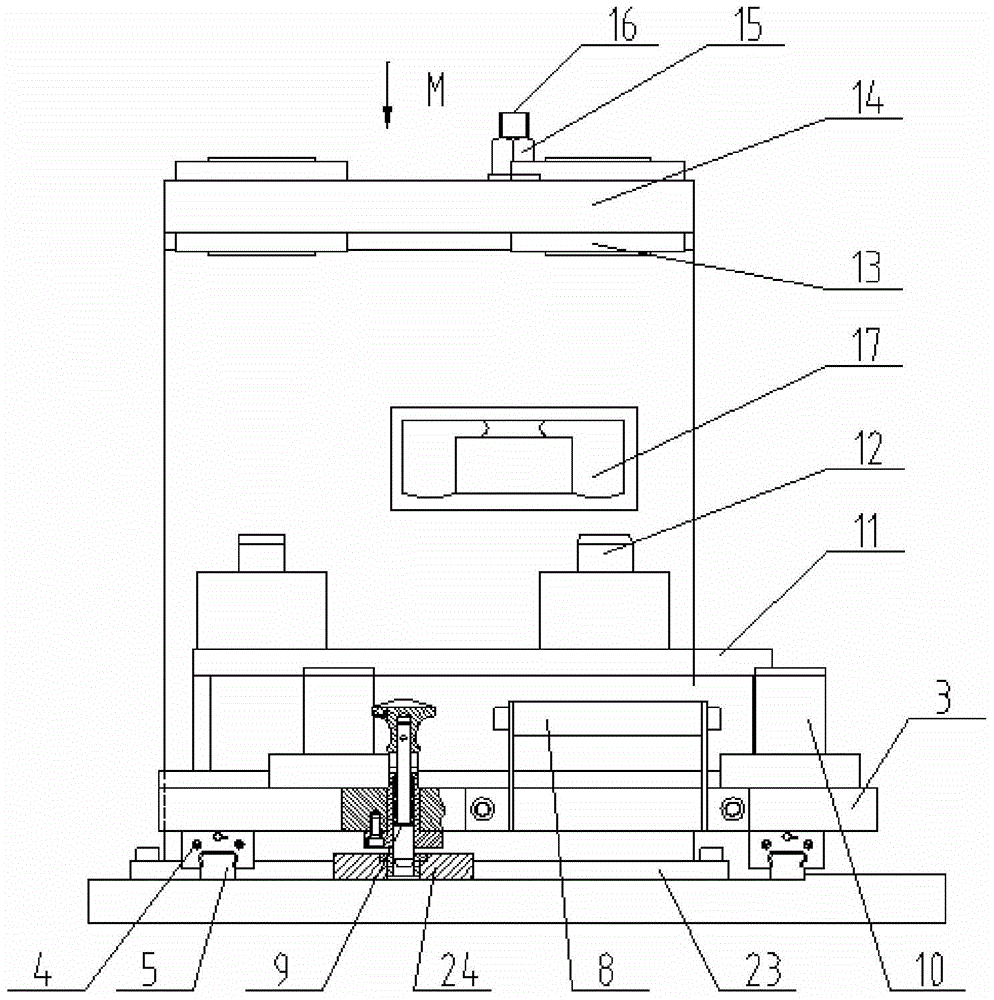

Efficient drilling method for multi-layer PCB

InactiveCN112087871AEasy to operateIncrease PCB board thicknessPrinted circuit manufactureCopper foilProcess engineering

The invention discloses an efficient drilling method for a multi-layer PCB. The efficient drilling method comprises: firstly, processing the PCB; 2, conducting primary drilling machining; 3, conducting secondary drilling machining; and 4, performing subsequent treatment; 5, detecting and storing; wherein in the step 1, the elasticity, the expansion and shrinkage conditions, the air permeability and the surface lines of the PCB are manually detected, and the PCB is cleaned and dried; the copper foil liquid is poured on the PCB, the copper foil liquid is manually smeared to increase the amount of the PCB, and then the PCB is dried and stored. The efficient drilling method for the multi-layer PCB is easy to operate, the thickness of the PCB is increased through copper foil liquid, drilling machining is facilitated, positioning is conducted through a small drill bit firstly, then drilling machining is conducted through a round spiral drill bit, machining deviation is avoided, the PCB drilling speed is increased, the efficient drilling method is efficient and convenient, time and labor are saved, layered drilling is conducted, and PCB drilling deviation caused by scrap accumulation is avoided; and the scheme is provided according to different processing problems, is suitable for different production conditions and modes, and is convenient for users to process.

Owner:深圳市联创电路有限公司

Fixture for rough machining of water plugging hole in engine block

ActiveCN104959856BWon't shakeEasy loadingDrilling/boring measurement devicesWork clamping meansEngineeringCylinder block

The invention discloses a fixture for conducting rough machining on water plugging holes of an engine cylinder block. An engine cylinder block to be machined is placed on a supporting plate. The engine cylinder block can conduct slippage on a base along with the supporting plate, so that feeding and discharging of a cylinder block piece are facilitated. When machining is conducted, a clamping device clamps the engine cylinder block to the supporting plate, meanwhile a locking portion locks the supporting plate and the base, it is guaranteed that in the drilling process of a drill bit is guaranteed, the cylinder block cannot waggle, and drilling deviation is avoided. A guide device plays a guide function on the drill bit of a radial drilling machine, and drilling accuracy is guaranteed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Borehole washing device for gas drainage drilling in coal mine

ActiveCN105089525BImprove rock breaking efficiencyLarge self-propelled thrustDrill bitsDerricks/mastsEngineeringHigh pressure water

Owner:CHONGQING UNIV +1

Circular arc surface drilling machining tool applied to numerical control machine tool

InactiveCN109108323AHigh precisionAdjustable distanceBoring/drilling machinesNumerical controlMachine tool

The invention discloses a circular arc surface drilling machining tool applied to a numerical control machine tool. The circular arc surface drilling machining tool comprises a supporting frame body,a placement frame, an auxiliary buckle plate, a lower pressing plate and a drilling device. A motor is fixedly connected to the bottom surface of the supporting frame body, and a rotating shaft of themotor penetrates through the bottom surface of the supporting frame body and is fixedly connected to the bottom surface of the placement frame. A plurality of partition plates are fixedly connected to the surface of the placement frame, connecting rings are fixedly connected between every two adjacent partition plates, and limiting sliding grooves are formed in the surfaces of the partition plates. Butting grooves are formed in the side walls of the partition plates, inserting-connecting holes are formed in the surfaces of the butting grooves, and the inserting-connecting holes connected withinserting-connecting rods arranged on the plate surface of the auxiliary buckle plate in an inserting mode. According to the circular arc surface drilling machining tool applied to the numerical control machine tool, circular arc plates are arranged and placed in a front-and-back aligned mode, drilling treatment of three circular arc plates when a drill bit drills at a time is realized, and the opening efficiency of the circular arc plates is greatly improved.

Owner:杨祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com