Machining method for preventing inclined hole drilling of marine screw shaft 22 m long

A processing method and stern shaft technology, which are applied in the processing field of 22m long ship stern shaft anti-drilling drilling, can solve the problems of drilling deviation, difficult drilling deviation, short length, etc., to prevent the drilling deviation and deep drilling. The effect of uniform hole wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0020] The processing method of the anti-hole drilling deflection of the stern shaft of the 22m long ship in the present invention is realized through the following steps:

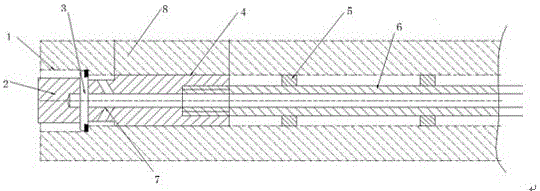

[0021] The first step, the stern shaft is fixed: first, the stern shaft 8 to be processed is fixed on the boring machine, such as figure 1 As shown, the boring machine includes a boring machine pull bar 6, and a guide bar 4 is installed at the front end of the boring machine pull bar 6, by setting the guide bar 4, it can be guided when boring, and at the front end of the boring machine pull bar 6 The middle position is equipped with a shockproof sleeve 5, through the setting of the shockproof sleeve 5, the bouncing phenomenon of the boring machine pull rod 6 can be avoided when the boring is pulled. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com