Borehole washing device for gas drainage drilling in coal mine

A gas extraction and coal mine technology, which is applied in the field of underground coalbed methane extraction in coal mines, can solve the problems of hole collapse, high hardness of winding steel pipes, and need to re-sealing holes, etc., to reduce pressure loss, increase hole washing depth, and advance distance. far effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the specific embodiment of this hole washing device is further described:

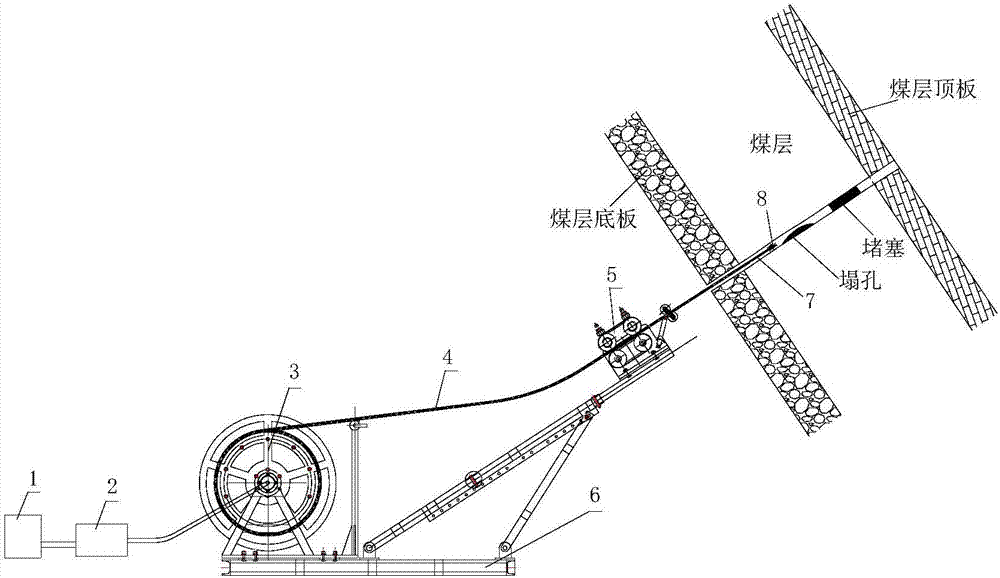

[0051] Such as figure 1 As shown, the hole washing device of the gas drainage drilling proposed by the present invention mainly consists of water tank (1), high-pressure pump (2), high-pressure hard pipe (4) and high-pressure flexible pipe (7), self-advancing drill bit (8 ), base (6), capstan (3), propulsion mechanism (5) and other components. The water outlet of the water tank (1) is connected to the high-pressure pump (2), and the high-pressure pump is connected to the capstan (3) through the high-pressure pipe, and the high-pressure water is delivered to the high-pressure hard pipe (4) wound on the capstan (3) through the high-pressure sealing water tail, The high-pressure hard pipe (4) passes through the propulsion mechanism (5) before being sent into the borehole, and the high-pressure hard pipe is conveyed forward along the borehole through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com