Hole-flushing method for gas extraction drilled hole under coal mine

A gas extraction and coal mine technology, which is applied to gas discharge, drill bits, mining equipment, etc., can solve the problems of easy collapse and blockage of gas extraction boreholes, and threaten the safety production of coal mines, so as to improve the gas extraction effect and prevent drill bits. The effect of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

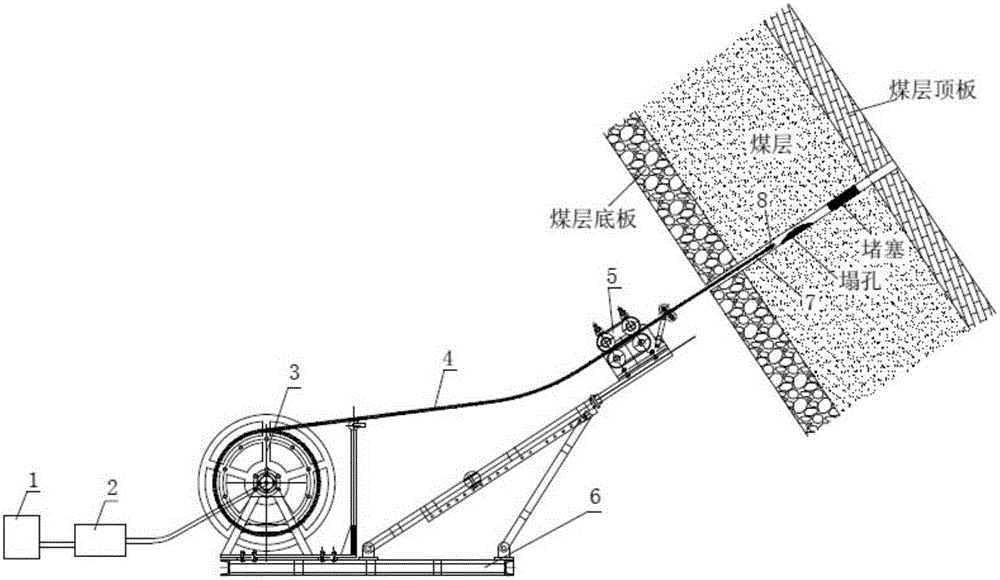

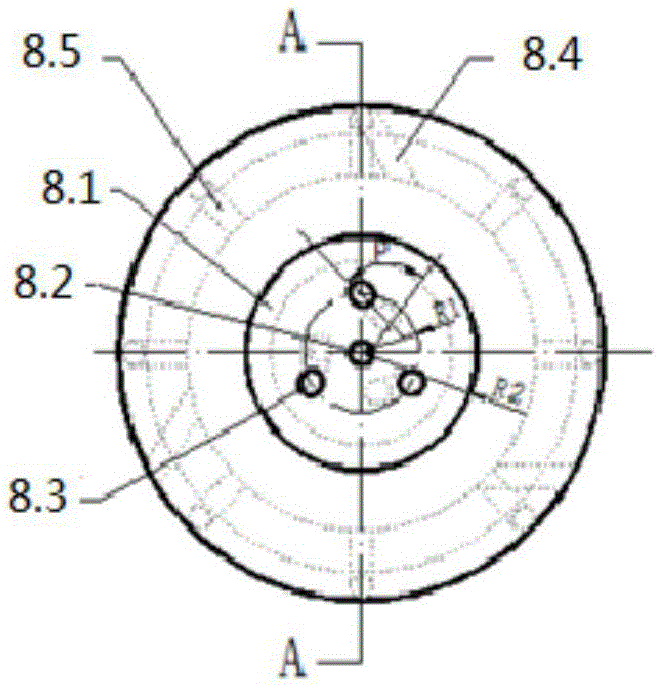

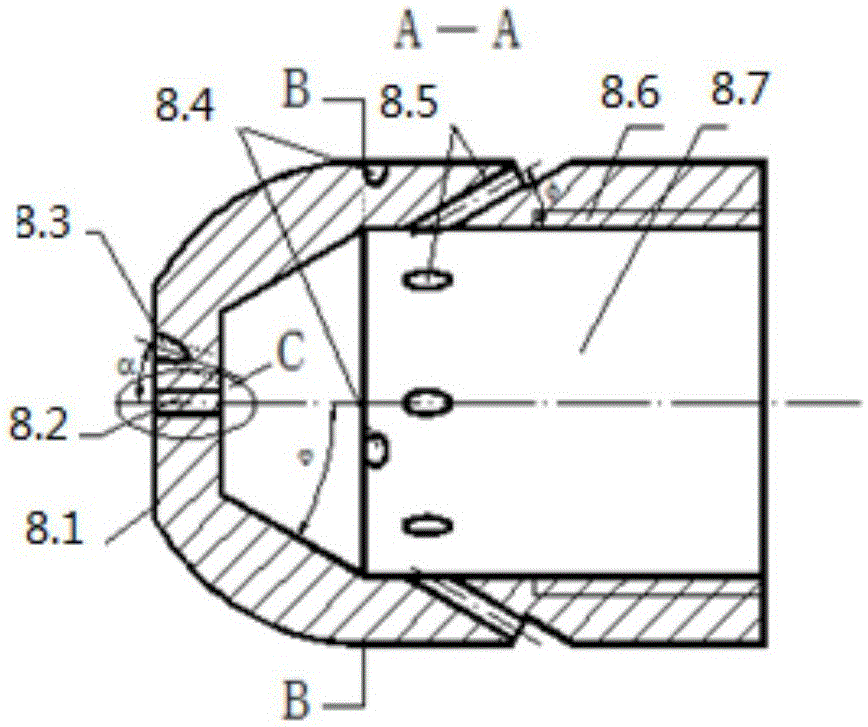

[0049] The method of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] The main function of the invention is to dredge and expand the clogged and collapsed boreholes in coal mines, so as to improve the efficiency of gas drainage. The technical principle of the drilling and washing method for underground gas drainage in coal mines described in the present invention is as follows: high-pressure resin pipes, high-pressure hoses, self-advancing drill bits, high-pressure water jet generating devices, and resin pipe winding and pushing devices cooperate in the hole washing process. use. For the clogged and collapsed gas drainage boreholes in coal mines, the rock-breaking ability of the self-propelled water jet is used to break and flush the clogged and collapsed parts to dredge and ream the boreholes; the self-propelled drill bit provides The traction force of the high-pressure hose makes the high-pressure hose stretch str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com