Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Avoid clogging damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

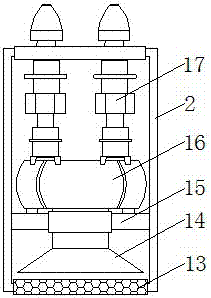

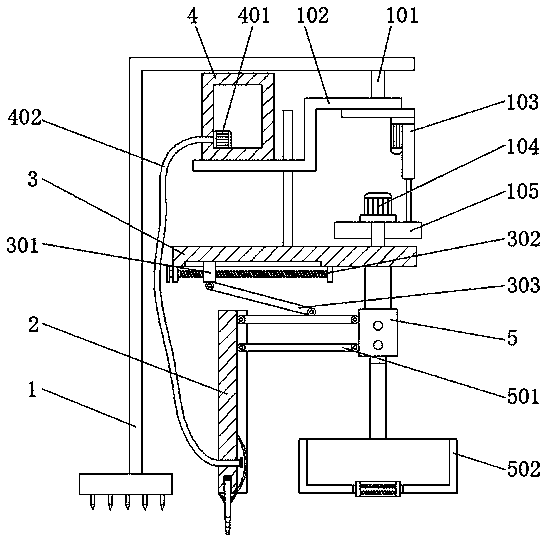

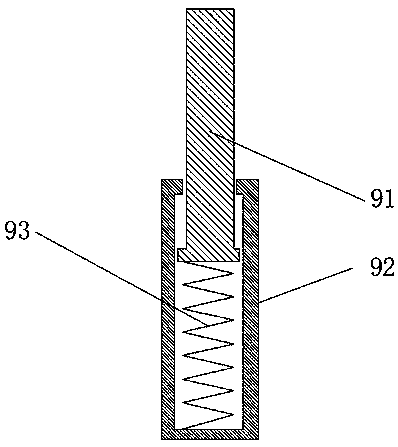

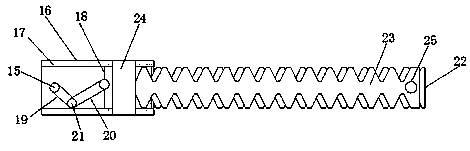

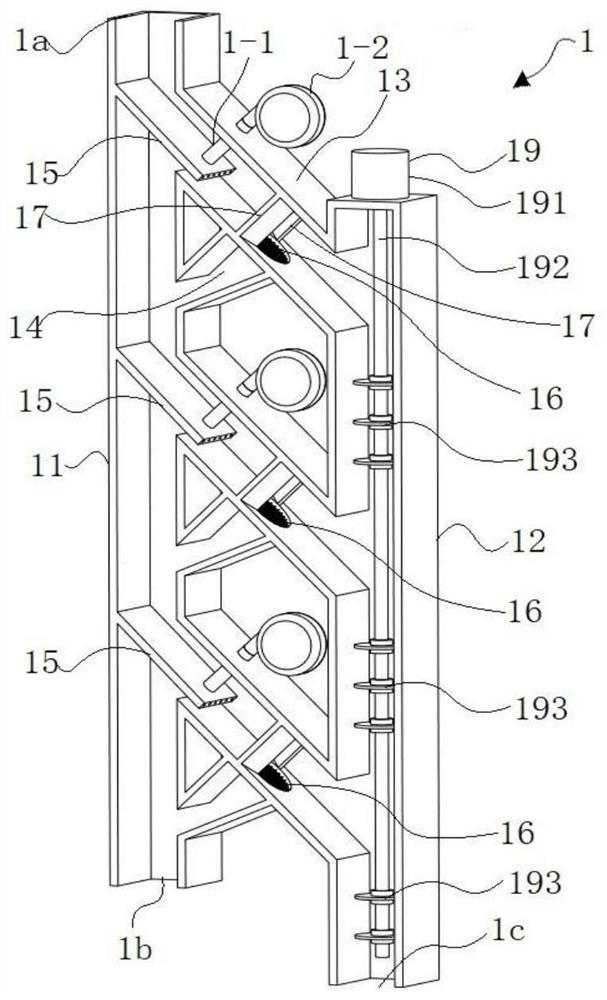

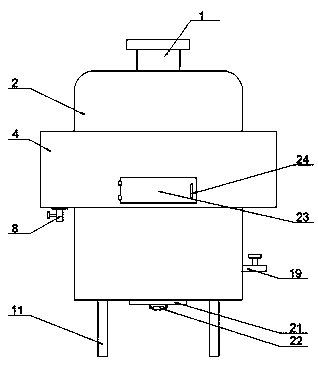

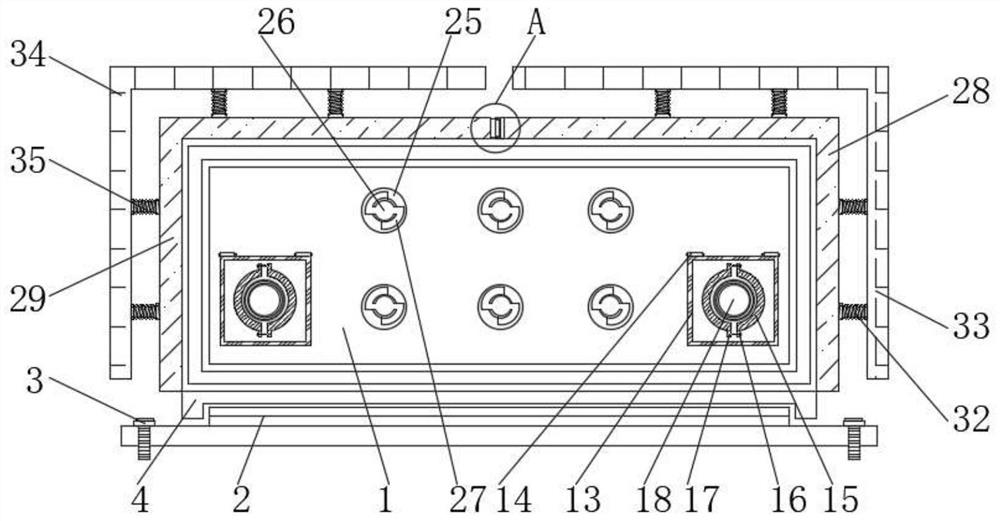

Movable landscape fountain device

InactiveCN107088493ACan control liftAvoid clogging damageLiquid spraying apparatusTransverse planeAgricultural engineering

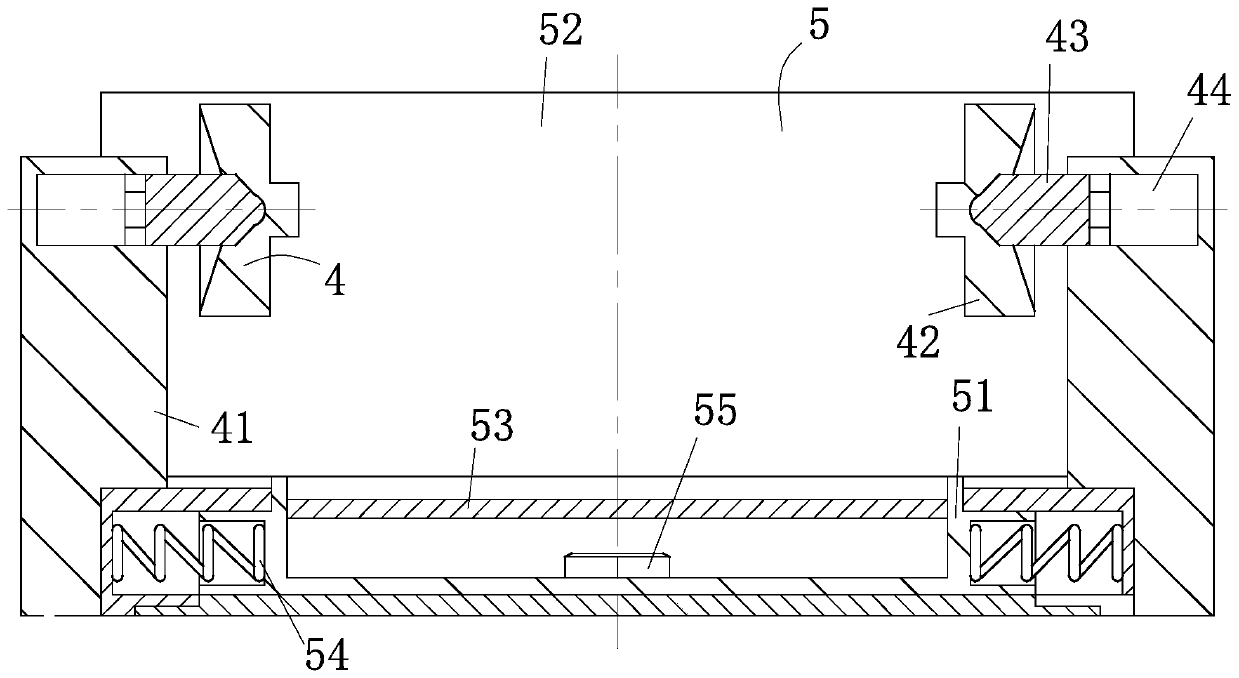

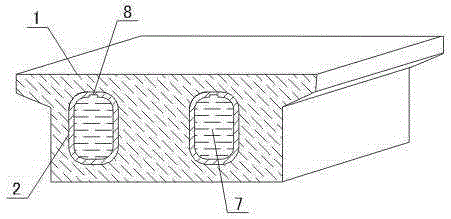

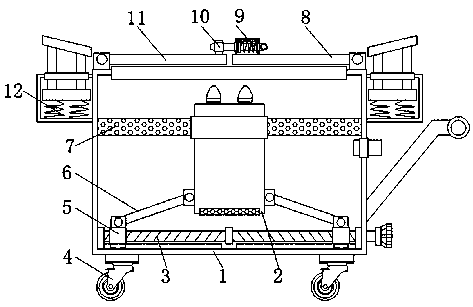

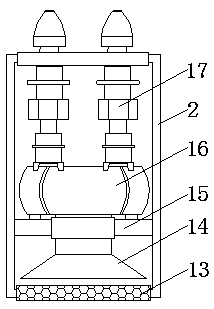

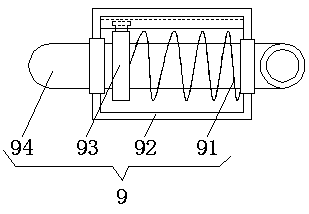

The invention discloses a movable landscape fountain device, and relates to the technical field of landscape fountains. The movable landscape fountain device comprises an outer frame. A filter plate is fixedly connected between the two sides of the inner wall of the outer frame. A lead screw is rotationally connected between the bottoms of the two sides of the inner wall of the outer frame. The two sides of the surface of the lead screw are in threaded connection with movable blocks. The tops of the movable blocks are rotationally connected with an inner frame through connecting rods. The top of the inner frame penetrates the filter plate and extends to the top of the filter plate. A transverse plate is fixedly connected between the two sides of the inner wall of the inner frame. The top of the transverse plate is fixedly connected with a booster pump. The movable landscape fountain device achieves the purpose that the fountain can move, fountain display can be achieved at any time and any place, and ascending and descending of a high-pressure sprayer can be controlled. When the movable landscape fountain device is not used, the high-pressure sprayer can be stored, the high-pressure sprayer is prevented from being blocked and damaged, water can be cyclically used, resources are saved, and impurities are prevented from blocking the high-pressure sprayer.

Owner:广东铭锦城园林景观设计工程有限公司

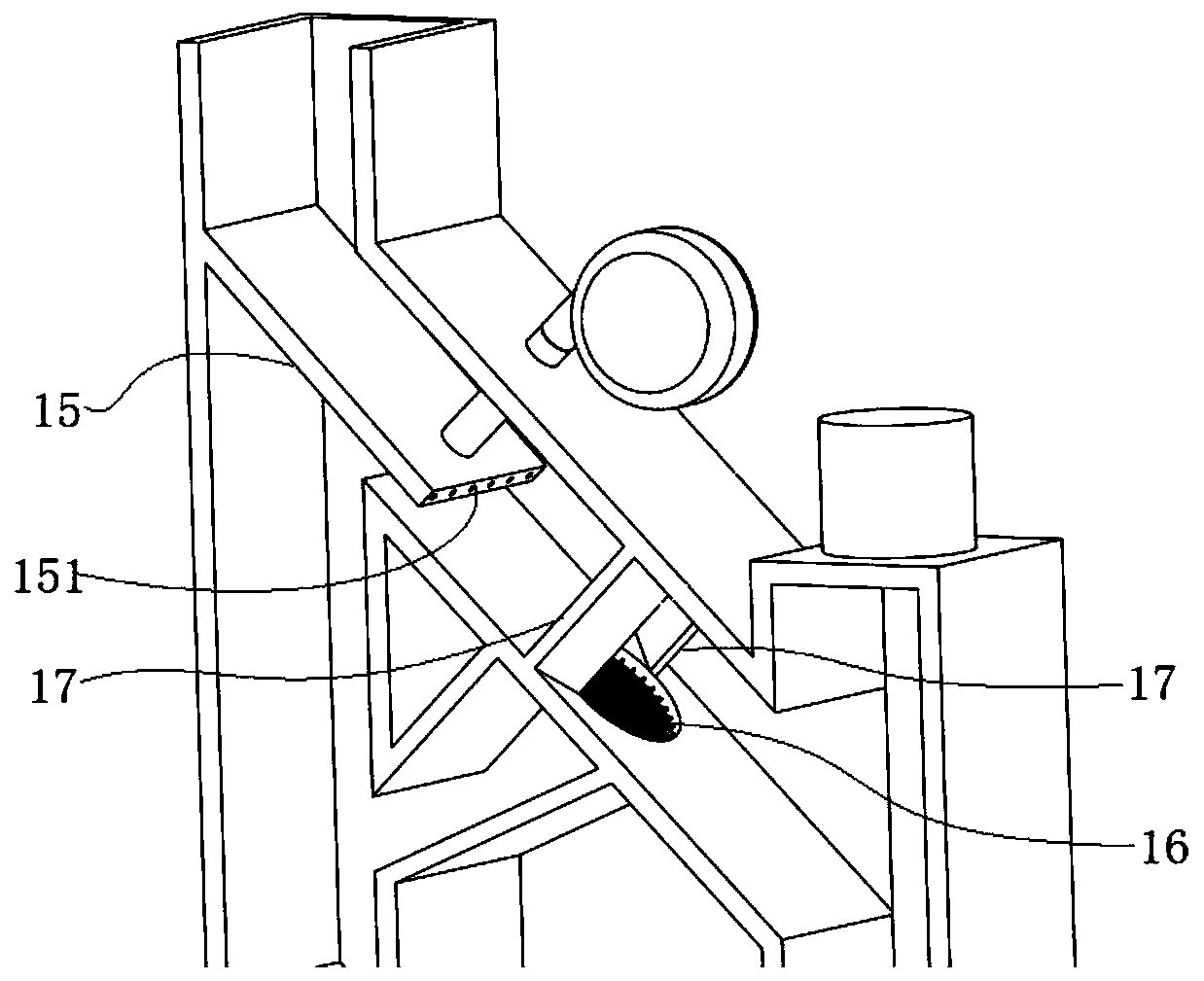

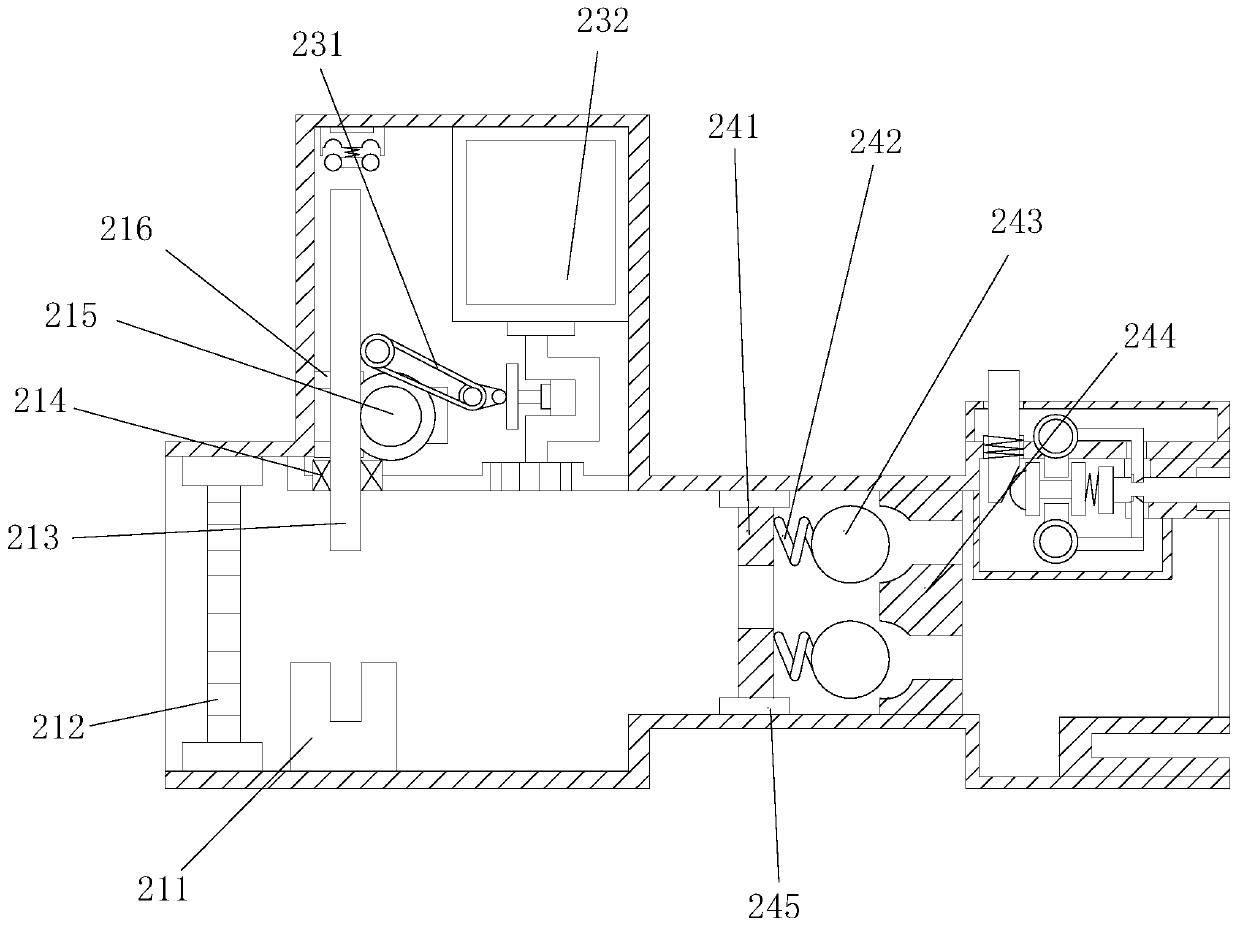

Mechanical equipment for preparing regenerated sand and stone materials by utilizing construction waste particles

The invention relates to the technical field of construction equipment, and in particular to mechanical equipment for preparing regenerated sand and stone materials by utilizing construction waste particles. The mechanical equipment comprises a storage structure, a storage chamber, a dust removal structure, a limiting structure, a discharging structure, a filtering structure and a driving structure; the driving structure is connected to the discharging structure on the storage structure, so that it is convenient for weight sensing through the discharging structure; when a cart is placed on thedischarging structure, the driving structure is used for driving the discharging structure to drive the cart to rotate for discharging, so that discharging is more convenient and faster, materials inthe cart can be completely discharged conveniently, and the discharging quality is greatly improved; the filtering structure is arranged, so that sewage can be conveniently filtered and recycled, itis convenient for pressure relieving on concrete blocks, broken stone blocks, and tile fragments; the dust removal structure used for removing dust of the concrete blocks, the broken stone blocks andthe tile fragments is connected to the driving structure, and the dust removal structure can be conveniently driven by the driving structure to conduct watering and dust removal on the concrete blocks, the broken stone blocks and the tile fragments in a multi-angle mode.

Owner:杭州欣禾工程管理咨询有限公司

Washing method for heavy metal contaminated soil

InactiveCN111589512AEasy to crushImprove the degree of purificationContaminated soil reclamationGrain treatmentsSoil scienceSoil washing

The invention discloses a washing method for heavy metal contaminated soil. According to the washing method, two stages of smashing devices are arranged, collected soil is preliminarily smashed through the first-stage smashing device, and then the soil is finally smashed through the second-stage smashing device; the soil is thoroughly smashed through the two stages of smashing devices, thus, the soil and a detergent are mixed conveniently, and the washing efficiency is greatly improved; the detergent is atomized through a spray head on a washing mixing mechanism, resources are saved, resourceconsumption is reduced, the purification and washing cost is reduced, the contact area of the detergent and the smashed soil is increased, and thus the washing efficiency is improved; the soil is guided into equipment in batches through a batch loading mechanism, and thus the equipment is prevented from being blocked and damaged; meanwhile, the soil is smashed more easily and purified more easily,the purification time is shortened, and the soil washing efficiency is improved; and when the soil is guided out of the equipment through a solid-liquid separation and conveying device, water stainsand chemical agents left after washing in the soil are separated from the soil, and thus secondary pollution of the soil is avoided.

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

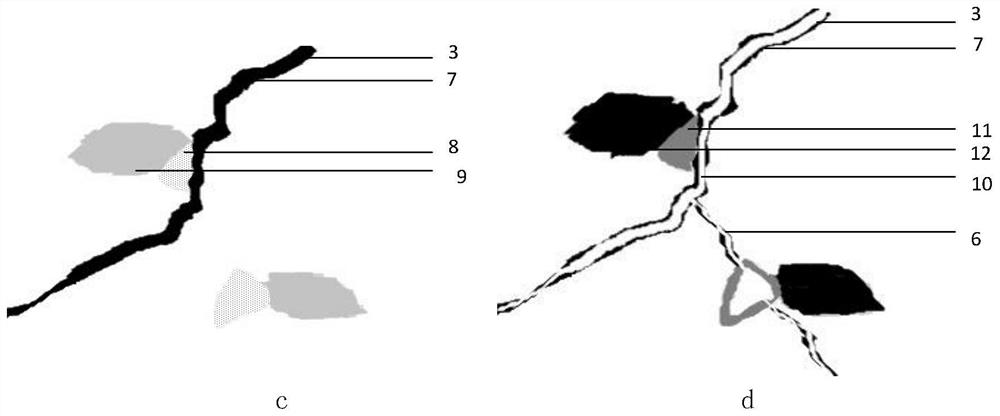

Method based on testing and assessment of sensitivity to alkali of hydrocarbon reservoir

InactiveCN107764971AAvoid clogging damageEarth material testingPermeability/surface area analysisClay mineralsSaline injection

The invention discloses a method based on testing and evaluating the alkali sensitivity of oil and gas layers. The preparation of brine with different pH values should start from the pH value of formation water and increase the pH value step by step according to the actual situation. The value can be set as 12. The selected core is evacuated and saturated with the first-stage brine, and soaked for 20-24 hours. Under the condition of lower than the critical flow rate, the stable permeability K1 of the core is measured with the first-stage brine, and injected into the second stage. Second-level brine, soak for 20~24h, under the condition of lower than the critical flow rate, use the second-level brine to measure the stable permeability K2 of the core, and change the level of injected brine until the last level of brine is used to measure the permeability of the core. Stable permeability Kn. The method obtains accurate values by testing the alkali sensitivity of the oil and gas layers, which can prevent the high pH value fluid from entering the oil and gas layers, which will cause structural damage of clay minerals and siliceous cement in the oil and gas layers, thereby causing blockage of the oil and gas layers The problem of damage occurs.

Owner:刘海峰

Expansion joint cutting equipment for bridge construction

InactiveCN111041956AAvoid breakage damageAvoid it happening againUsing liquid separation agentDirt cleaningCrushed stoneArchitectural engineering

The invention discloses expansion joint cutting equipment for bridge construction. According to the expansion joint cutting equipment for bridge construction, a water tank device is used for sprayingwater to a saw blade; fracture and damage of the saw blade caused by being in a high-temperature state for a long time are avoided, water is contacted with dust, flying dust is reduced, a dust collection device is used for collecting dust generated during cutting of the saw blade; the visibility of equipment line cutting is ensured; the body health damage caused by flying dust inhaled by workers is avoided; a large-diameter broken stone storage box is used for blocking and collecting large-diameter dust; large-diameter dust is prevented from entering the dust collection device to cause blockage and damage of the dust collection device; the dust collection device, the water tank device and a cutting turntable device are driven by a same motor; an extra motor is not needed, utilization of the motor is greatly improved, resources and cost are saved, two piston cylinders in opposite states of the dust collection device can enable a dust suction hood to continuously suck dust, the dust falling efficiency is improved, the front shovel cleans a bridge floor, and cutting is prevented from being affected by sundries on a cutting line.

Owner:季凤飞

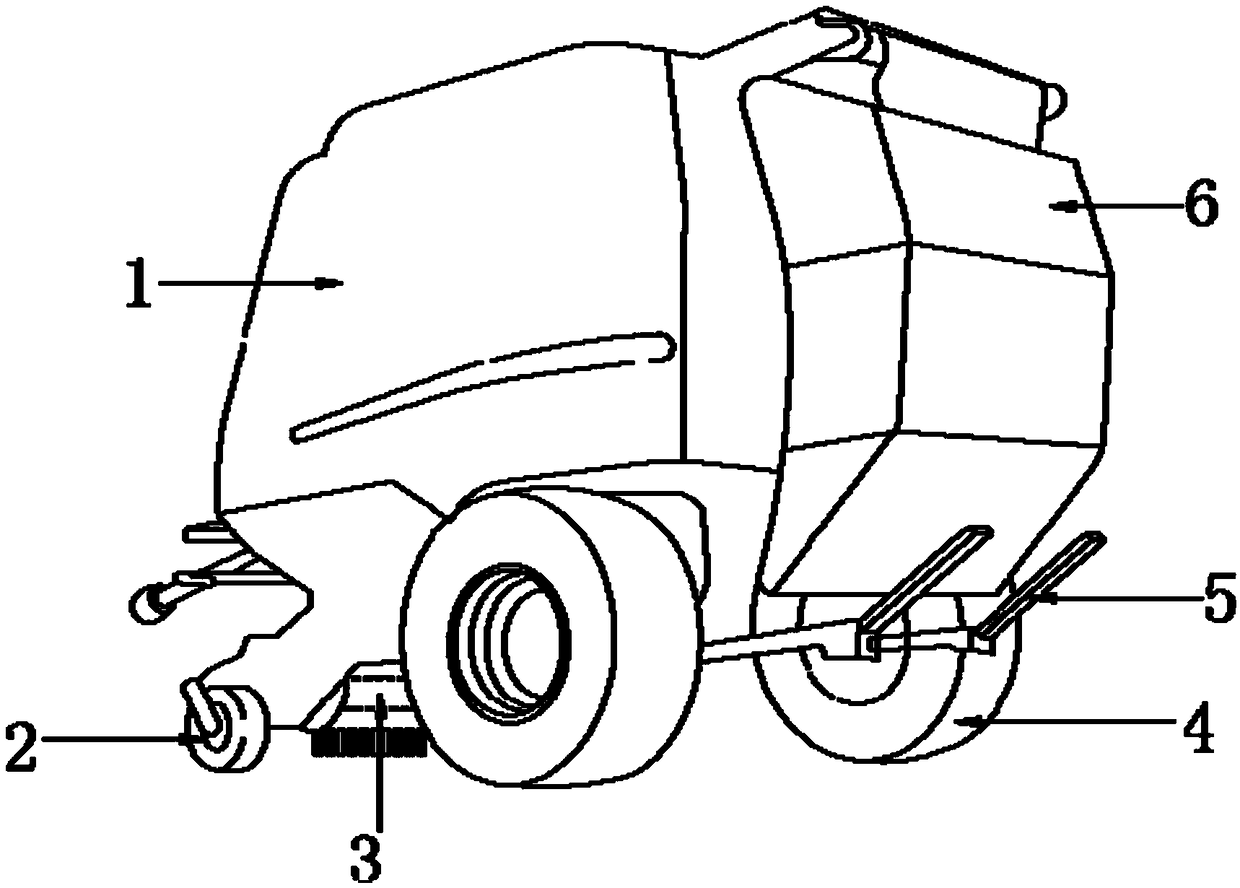

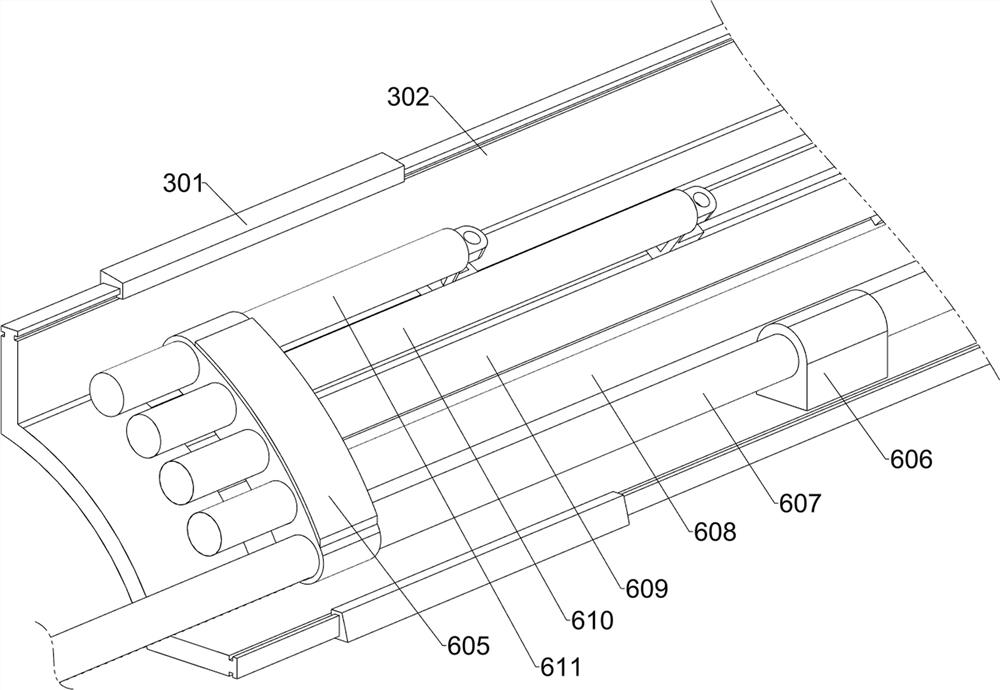

Self-propelled straw picking and binding integrated machine

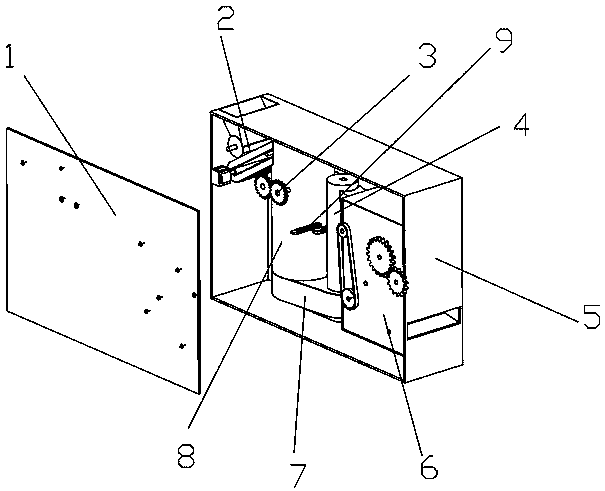

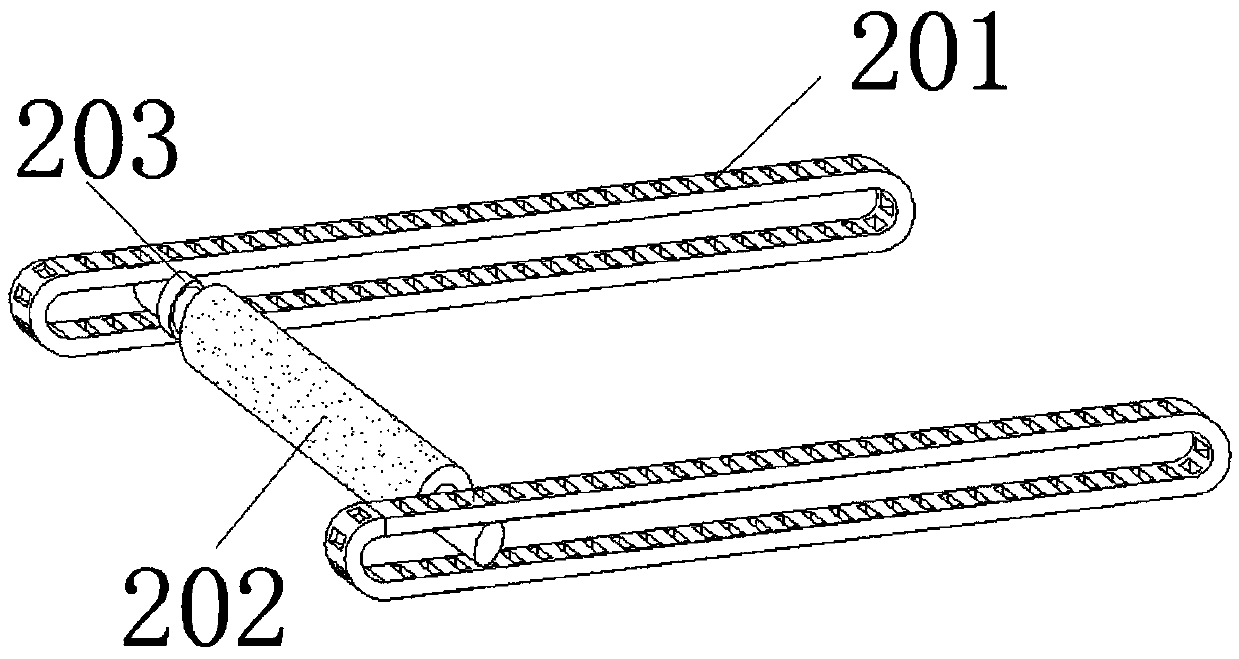

The invention discloses a self-propelled straw picking and binding integrated machine, which comprises a machine body, walking wheels, a picker, driving wheels, a grass remover and a hinge cover; twoends of the front side of the machine body are equipped with the walking wheels, and two ends of the rear side of the machine body are provided with the driving wheels; and the picker in transmissionconnection with the machine body is arranged between the two walking wheels. Compared with the prior art, the self-propelled straw picking and binding integrated machine has the beneficial effects that a round-bundle forming guide belt can conduct normal transmission and the contact area between the belt and a roller can be reduced, so that the round-bundle forming guide belt is prevented from being roughened, reduction of the friction coefficient of the round-bundle forming guide belt and the roller is facilitated, a phenomenon that the round-bundle forming guide belt is thinned and cracked is avoided, straw can be subjected to round bundling forming by means of centrifugal force under guiding and limiting action of the round-bundle forming guide belt, the straw is prevented from being not limited and flying out due to centrifugal force, a phenomenon of clogging and damage of the equipment is avoided, and maintenance cost is reduced.

Owner:广州市海派科技有限责任公司

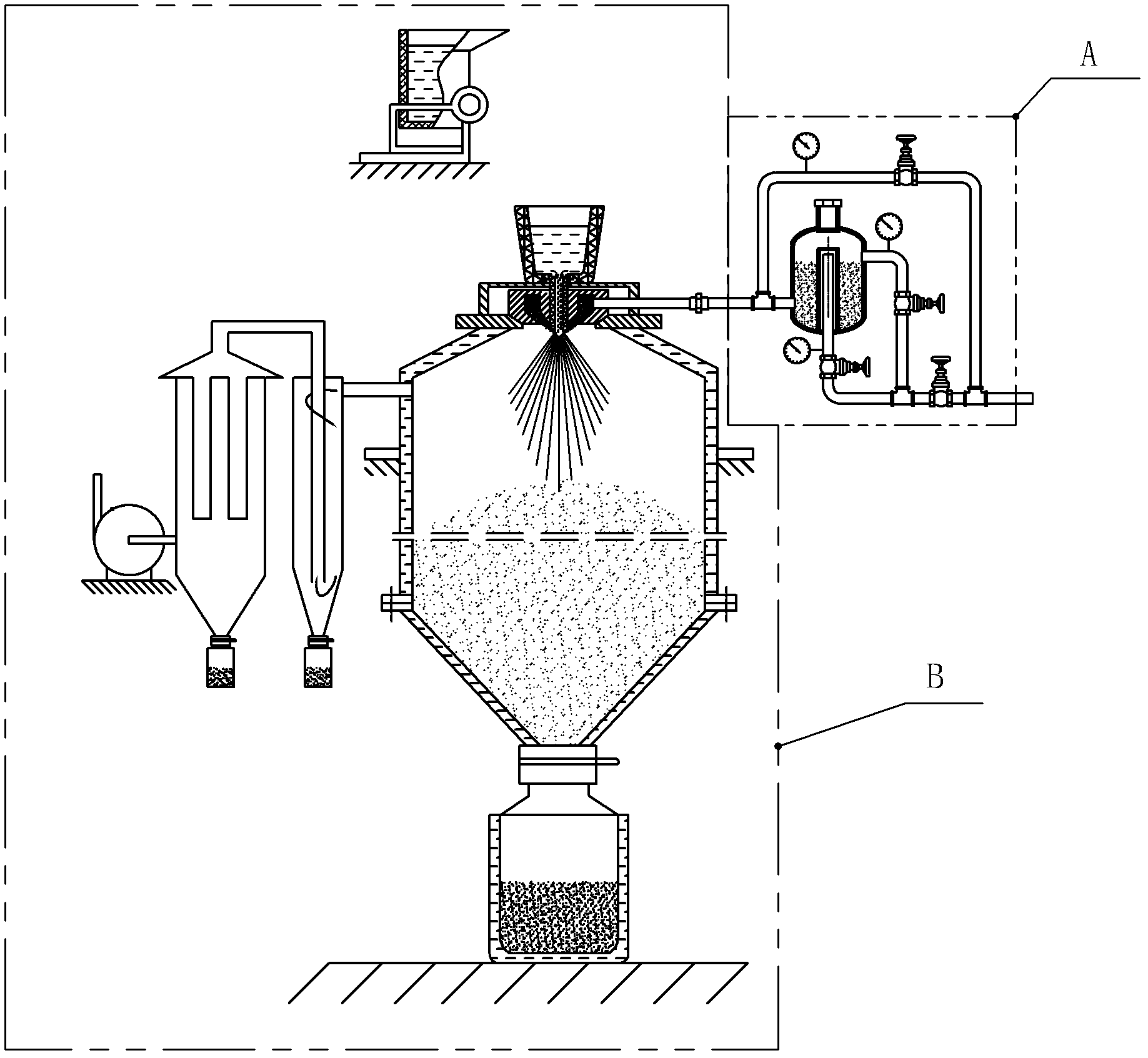

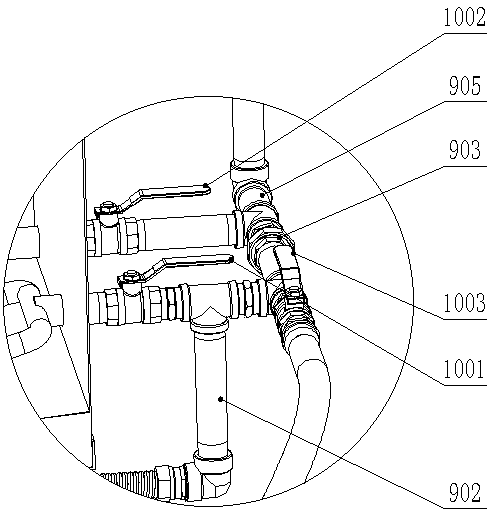

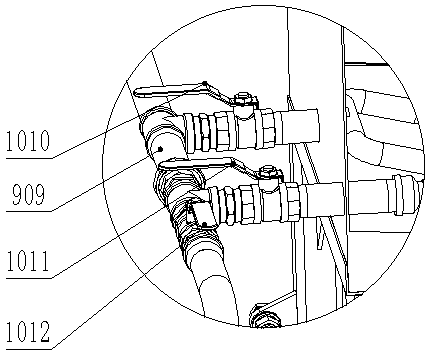

Equipment for preparing atomized quick-setting magnetic abrasive

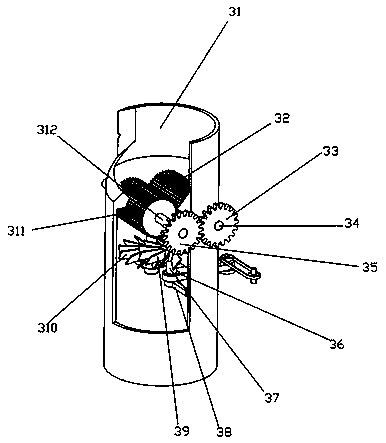

ActiveCN102250584BControl flowJet pressure can be controlledOther chemical processesHigh pressureControl valves

The invention discloses equipment for preparing atomized quick-setting magnetic abrasive, which consists of two parts: an atomizing part and an air flow powder feeding and mixing part. An atomizing device comprises a metal melting electric furnace, a crucible, a discharge spout, a jet nozzle, an atomizing chamber, cooling water, a powder collecting container and an exhausting and dedusting mechanism. An air flow powder feeding and mixing device comprises air flow powder feeding mechanism and an air flow powder mixing mechanism, wherein the powder mixing mechanism comprises a high-pressure air inlet pipe, a powder feeding mechanism, a discharging pipe, a jet pressure control valve, a jet pressure meter and a flow mixing pipe; and the powder feeding mechanism comprises a feed control valve, an air inlet, a balance air inlet pipe, a balance valve, a balance pressure meter, a feed tank, a spray valve, a spray air inlet pipe, a spray pressure meter, a round pipe casing, a jet pressure control valve, a balance valve, a spray valve, a round pipe casing, a spray air pressure meter, a balance air pressure meter and a jet pressure meter. By forcefully combining ferromagnetic metal with low compatibility and hard abrasive, high-performance magnetic abrasive which has high magnetoconductivity, high grinding force, controllable particle size, high structural strength, spherical structural form and long service life is prepared.

Owner:SHANDONG UNIV OF TECH

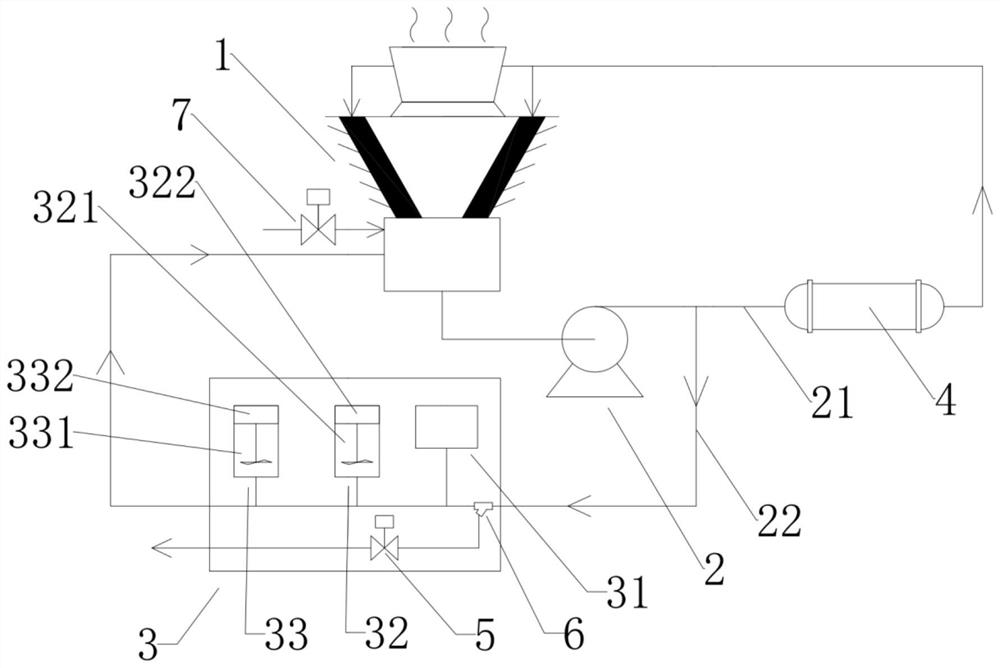

Closed water feeding process system for steel slag treatment

PendingCN107596780ARealize a sustainable green circular economyEasy to removeFiltration circuitsProcess systemsGeneration process

The invention discloses a closed water feeding process system for steel slag treatment. The closed water feeding process system comprises radial flow sedimentation device, a steel slag fine-grain press filtering device and the like, and can be used for rapidly and efficiently removing steel slag fine silt in a generation process of a steel slag treatment system; the problems that pump set equipment, a water spraying part, a pipeline system and the like in the steel slag treatment system are easy to block are solved and the efficient cyclic utilization of water resources in a steel slag treatment production process is also realized, so that the steel slag treatment production cost is reduced at maximum.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +2

Venturi reversing device and urea reversed pumping device based on device

ActiveCN108915829APrevent crystallizationAvoid clogging damageExhaust apparatusSilencing apparatusStopped workEngineering

The invention discloses a Venturi reversing device and a urea reversed pumping device based on the device. The Venturi reversing device comprises a Venturi pipe and a two-way valve, the Venturi pipe communicates with the two-way valve through one pipe in series, and the position of a throat of the Venturi pipe communicates with another pipe; and the urea reversed pumping device comprises a urea box, a Venturi pipe, a liquid outlet pipe, a jetting pipe, a first valve and a first liquid return pipe, the end of a gradually-shrinking section and the end of a gradually-expanding section of the Venturi pipe communicate with the urea box through the liquid outlet pipe and the first liquid return pipe, the first valve is arranged on the first liquid return pipe, one end of the jetting pipe communicates with the throat of the Venturi pipe, and the other end of the jetting pipe communicates with an urea nozzle. According to the Venturi reversing device and the urea reversed pumping device, the Venturi effect is used, when a urea injection system stops working, residual urea solutions in the jetting pipe and the urea nozzle can be reversely pumped into the urea box, the urea pump assembly structure is more compact, reliable and durable, and the manufacturing cost is lower.

Owner:湖北芙源春贸易有限公司

Sampling and acquiring device for vegetation with soil for biological detection

InactiveCN110361220AReduce harmImprove the protection effectWithdrawing sample devicesFixed frameEngineering

The invention belongs to the technical field of biological sample acquisition, in particular to a sampling and acquiring device for vegetation with soil for biological detection. Aiming at the problemthat the vegetation is difficult to survive since the existing vegetation sampling and acquiring device has great damage to the vegetation roots, the invention proposes the sampling and acquiring device, which comprises a fixing frame, wherein a supporting column is welded to one side of the inner wall at the top part of the fixing frame, insertion nails are welded to the outer wall at the bottompart of the fixing frame, a Z-shaped frame sleeves one side outer wall of the supporting column, a push rod motor is fixed to the outer wall of the bottom part of the supporting column by means of screws, and a fixed stand is fixed to an output shaft of the push rod motor by means of screws. The sampling and acquiring device can reduce the damage to the vegetation roots, effectively improve the phenomenon that the vegetation root are cut when soil scarifying teeth move, is conductive to enhancing the protection efficiency of the soil scarifying teeth, improves the protection effect on the vegetation roots, can wash away soil on the outer wall of the soil scarifying teeth, keeps the outer wall of the soil scarifying teeth clean, helps to improve the scarifying efficiency, and can reduce rigid damage to the vegetation.

Owner:HUBEI UNIV

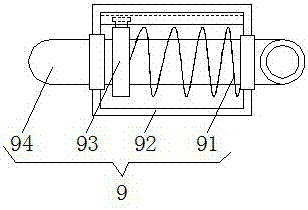

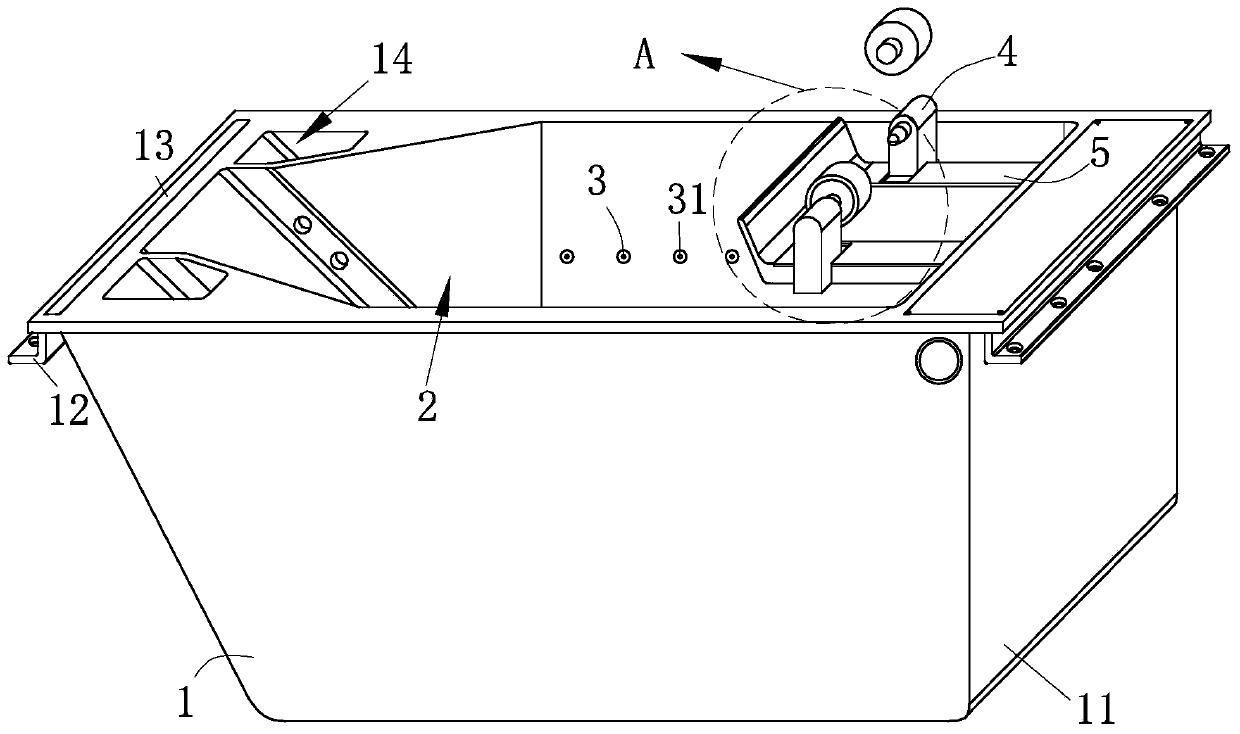

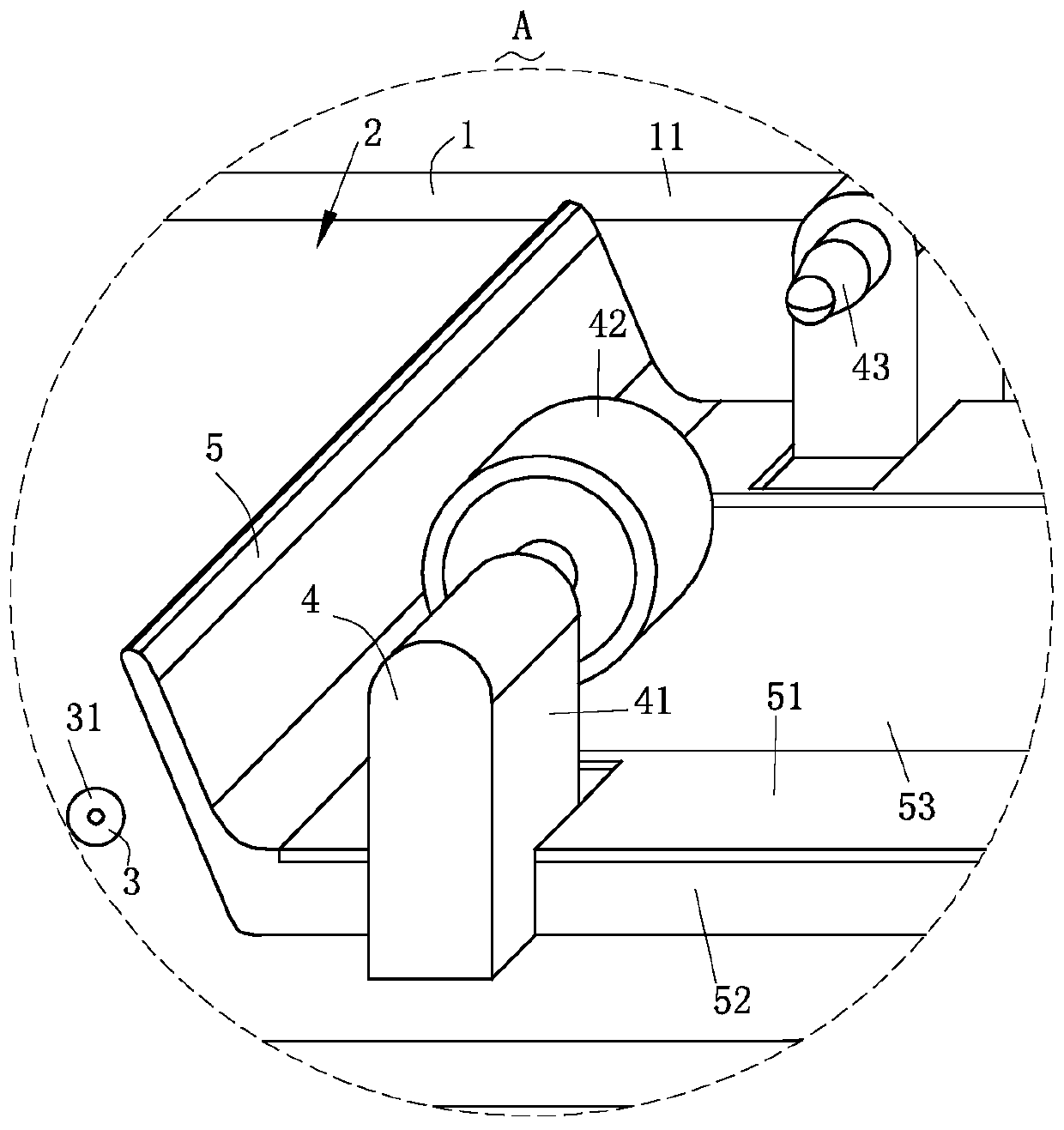

Spraying and irrigation device for agricultural machinery

InactiveCN108668854AAvoid cloggingAvoid clogging damageClimate change adaptationWatering devicesWater storage tankAgricultural engineering

The invention discloses a spraying and irrigation device for agricultural machinery, which comprises a base, a water storage tank, a water-proof pump, an irrigation device and a spraying device, wherein inverted L-shaped armrests are symmetrically arranged on the rear side of the upper end of the base; a placement platform is arranged on the side face of the water storage tank; the water-proof pump is arranged in the water storage tank; a water outlet is communicated with the exterior of the water storage tank through a pipeline; a three-way joint is arranged at the end part of the pipeline; the irrigation device comprises a water spraying pipe and a water receiving pipe; a plurality of water spraying holes are formed on the lower side of the water spraying pipe; the spraying device comprises an electric extension rod and a spraying head; the electric extension rod is arranged above the placement platform; the spraying head is arranged at the upper end of the electric extension rod; asecond connector of the three-way joint is connected with the water receiving pipe; and a third connector of the three-way joint is connected with the spraying head through a rubber hose. According tothe device, plant irrigation or spraying can be controlled unilaterally or simultaneously; the water compensation and wetting efficiency is improved; vibration generated by bump and inertia can be reduced; a service life of the device is prolonged; and the safety is improved.

Owner:杨静

Cracking-preventing bridge structure

InactiveCN104195937AReduce the temperature difference between inside and outsideAvoid crackingBridge structural detailsBridge materialsStructural engineeringSteel cylinder

The invention discloses a cracking-preventing bridge structure. The cracking-preventing bridge structure comprises a concrete bridge body and a steel cylinder arranged in the concrete bridge body. The steel cylinder is rectangular and hollow, the two ends of the steel cylinder are closed, the middle of the steel cylinder is a solid, the top of the solid is provided with a water inlet hole vertically extending downwards, the side face of the solid is provided with a water outlet hole which extends horizontally and is communicated with the water inlet hole and the hollow part of the steel cylinder at the same time, the upper end of the water inlet hole is provided with a thread blocking plug, and the hollow part of the steel cylinder is filled with water. The steel cylinder is filled with water, and due to the fact that the specific heat capacity of water is large, the difference between the temperature inside concrete and the temperature outside the concrete can be reduced very well, the temperature inside the concrete and the temperature outside the concrete is made to reach the balance state as much as possible, and the concrete is effectively prevented from cracking when the difference between the temperature inside concrete inside and the temperature outside the concrete is excessively large.

Owner:SICHUAN JINFENG CONSTR

Horizontal cement paste spraying device, paver with same and application thereof

PendingCN111119011APrevent grout from clumping and solidifyingEliminate time differenceRoads maintainenceManufacturing engineeringMechanical engineering

The invention provides a horizontal slurry spraying device, a paver with the same and application thereof. The horizontal slurry spraying device mainly comprises a cement box, a pipeline in the cementbox extends out of the box, surrounds the paver by a circle and returns into the cement box, the pipeline is composed of a pipeline body and a hose, the hose can be bent according to the spraying position, and the position of the hose located on the paver is adjusted so that the hose can be attached to the paver. The cement paste spraying device can be installed on the paver, cement paste is sprayed to a roadbed while paving is achieved, cement paste caking and solidification caused by paving after spraying are avoided, the time difference between paving and spraying is eliminated, and the adhesive force of a base layer structure is ensured. The stirrer in the cement box is matched with backflow scouring of the backflow pipe to form double stirring, mechanical rotary stirring of the stirrer and water flow scouring stirring of the backflow pipe are conducted at the same time, cement paste is continuously stirred, and the cement paste keeps the uniform mixing characteristic and is not bonded or solidified.

Owner:SHAANXI ZHONGDA LIDING TECH CO LTD +1

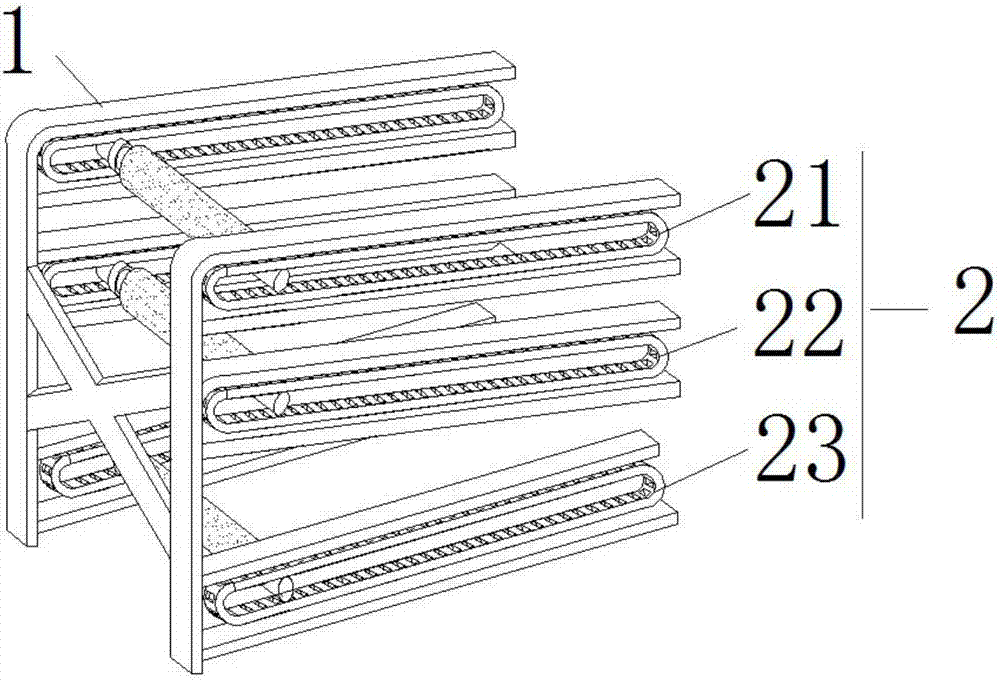

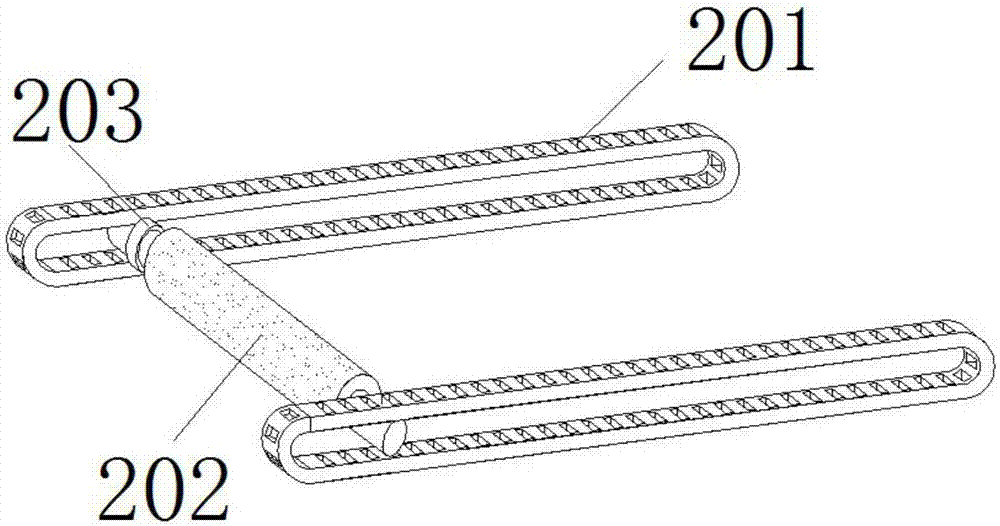

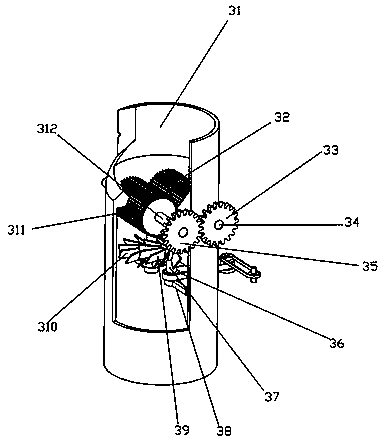

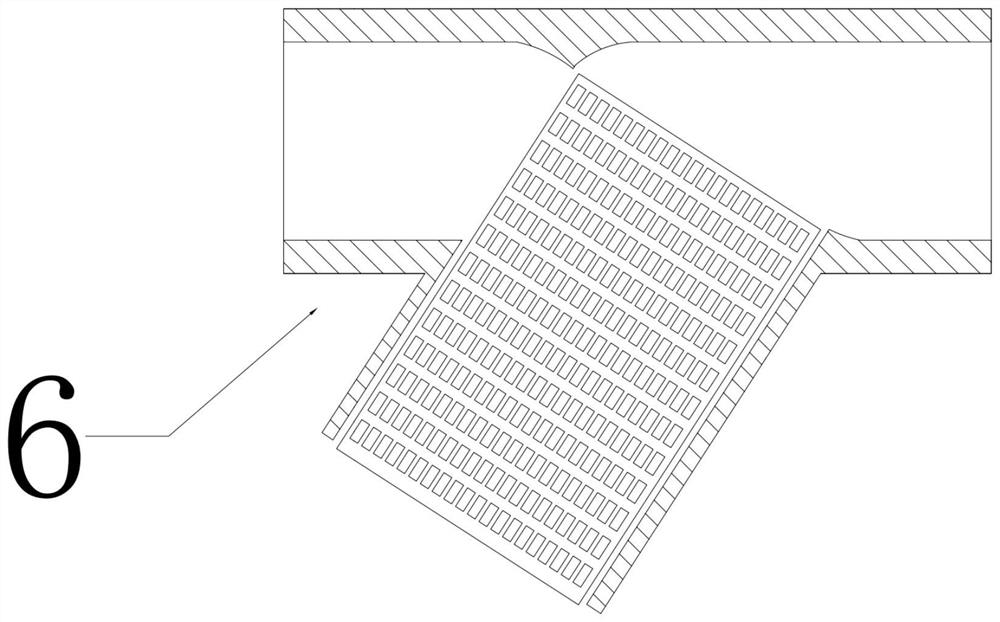

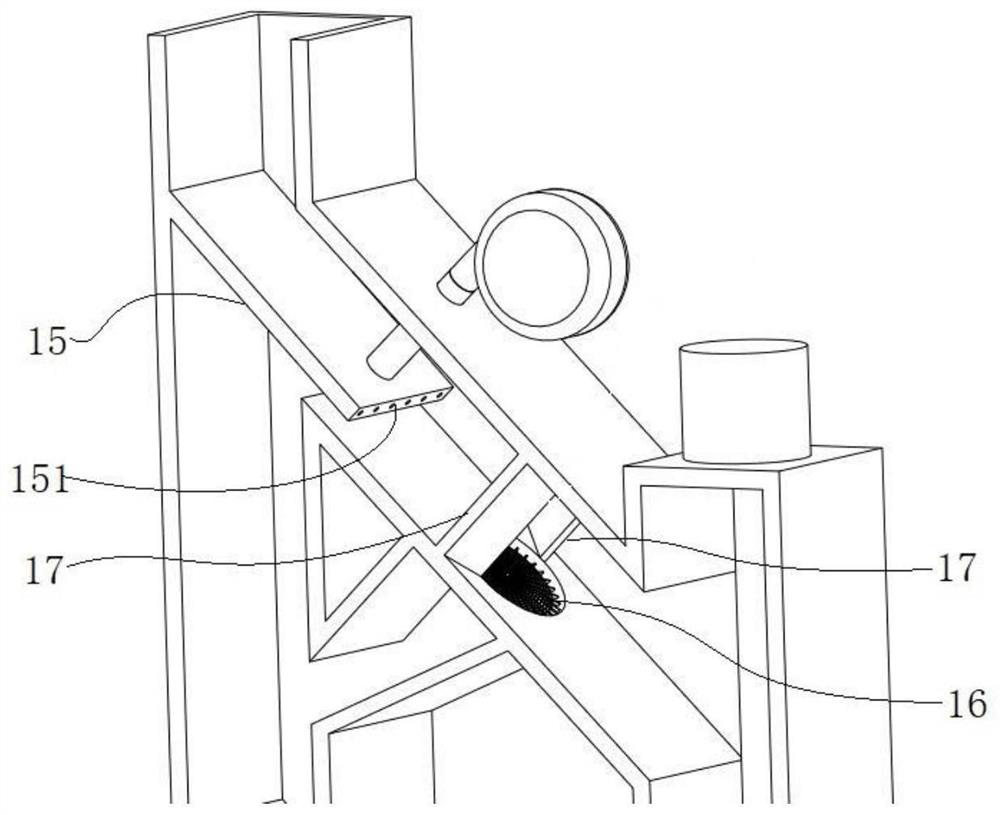

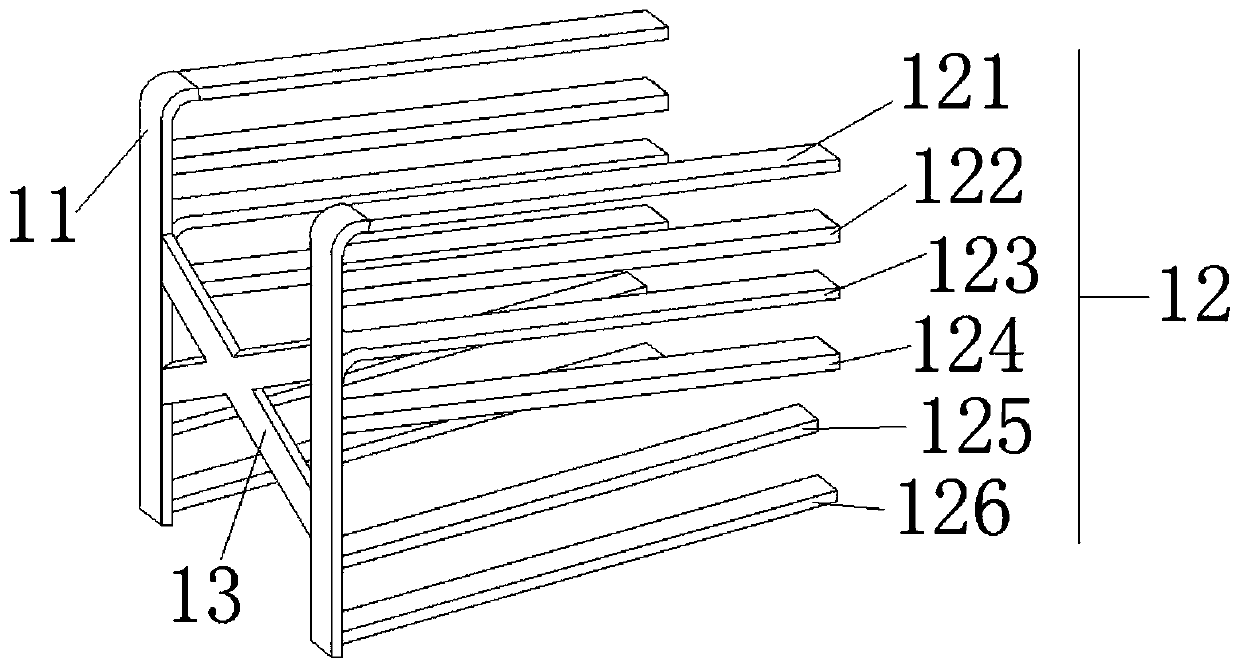

Cleaning device of dendrobium nobile shaking screen

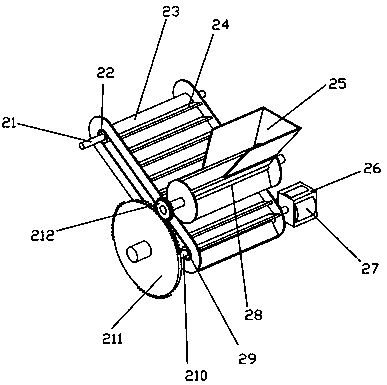

ActiveCN107243454AHigh degree of automationImprove efficiencySievingScreeningEngineeringMechanical engineering

The invention discloses a cleaning device of a dendrobium nobile shaking screen. The cleaning device comprises a bracket and driving rolling brushes; three-layer rail plates are arranged on the bracket; each three-layer rail plate is provided with a first driving rolling brush, a second driving rolling brush and a third driving rolling brush from the bottom up sequentially; and the third driving rolling brushes are arranged in the corresponding three-layer rail plates in an upward inclining manner. The cleaning device is simple in structure and convenient to use, and can clean a screen mesh rapidly, the working efficiency is ensured, a cleaning process is simple and rapid, and the cleaning device is high in practicability and is convenient for popularization.

Owner:金寨智行知识产权运营有限公司

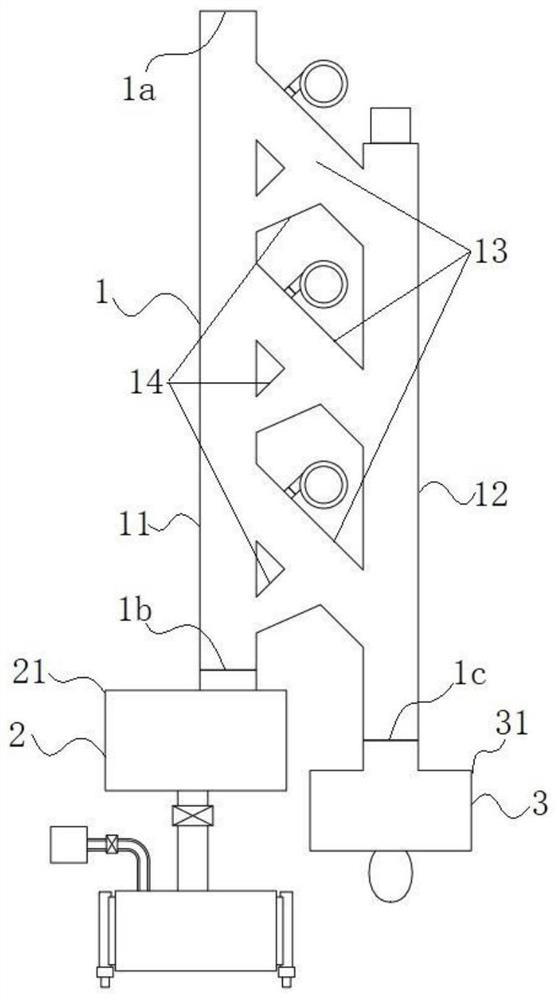

Rainwater recovering system for greenhouses

InactiveCN107178118AEasy maintenanceDoes not affect normal operationGeneral water supply conservationRoof drainageGreenhouseRainwater harvesting

A rainwater recovery system for greenhouses. A water collection tank is provided between the roofs of two adjacent greenhouses. A water outlet is provided at the bottom of the water collection tank. A water collection pool is installed, and a frequency conversion water pump is installed in the water collection pool. The outlet of the frequency conversion water pump is connected to the water supply main pipe, and the water supply main pipe is connected to multiple water supply branch pipes. A nozzle is installed at the end of each water supply branch pipe. The water supply branch pipe and the nozzle are located inside the greenhouse. The greenhouse rainwater recovery system of the present invention can fully utilize the roof area of a large-area greenhouse, and has a large amount of rainwater collection; effectively utilizes rainwater resources, and at the same time reduces the rainwater washing of nursery ridges.

Owner:HUBEI HUAYI BIOTECH CO LTD

Heavy metal contaminated soil washing equipment

InactiveCN111570496AImprove washing efficiencyImprove the degree of purification and the efficiency of purificationContaminated soil reclamationCleaning using liquidsMetal contaminationContaminated soils

The invention discloses heavy metal contaminated soil washing equipment. Two stages of crushing devices are arranged; collected soil is preliminarily crushed through the first-stage crushing device; the second-stage crushing device is used for finally crushing the soil; through the two-stage crushing devices, the soil is thoroughly crushed and thus the soil and the detergent can be conveniently mixed, so that the washing efficiency is greatly improved; a nozzle arranged on a washing and mixing mechanism atomizes the detergent, so that resources are saved, the resource consumption is reduced, and the purification washing cost is lowered; the contact area of the detergent and the crushed soil is increased, so that, the washing efficiency is improved; a batch loading mechanism guides soil into the equipment in batches, so that the equipment is prevented from being blocked and damaged; meanwhile, soil is easier to smash and purify, the purification time is shortened, and the soil washing efficiency is improved; water stains and chemical agents left by washing in the soil are separated from the soil when the soil is guided out of the equipment through a solid-liquid separation conveyingdevice, so that secondary pollution of the soil is avoided.

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

Domestic sewage processing equipment based on solid liquid separation technology, and processing method thereof

ActiveCN110498524AEnsure thoroughnessGuaranteed orderSpecific water treatment objectivesTreatment involving filtrationSeparation technologySewage

The invention discloses a domestic sewage processing equipment based on solid liquid separation technology, and a processing method thereof. The domestic sewage processing equipment comprises a stepwise solid liquid separator, a liquid sewage purifying processing unit, and a solid sewage compression recovery unit; the stepwise solid liquid separator is provided with a domestic water initial inlet,a liquid sewage final outlet, and a solid sewage final outlet, and is used for solid liquid stepwise separation of domestic sewage which is introduced into the stepwise solid liquid separator throughthe domestic water initial inlet; the liquid sewage purifying processing unit is arranged to be corresponding to the liquid sewage finial outlet of the stepwise solid liquid separator, and is used for purifying processing of liquid sewage; the solid sewage compression recovery unit is arranged to be corresponding to the solid sewage finial outlet of the stepwise solid liquid separator, and is used for compression and recovery of solid sewage. The domestic sewage processing equipment based on solid liquid separation technology and the processing method can be used for complete effective purifying processing of domestic sewage, processing effect is excellent, and environment pollution is prevented.

Owner:宁夏优智环保科技有限公司

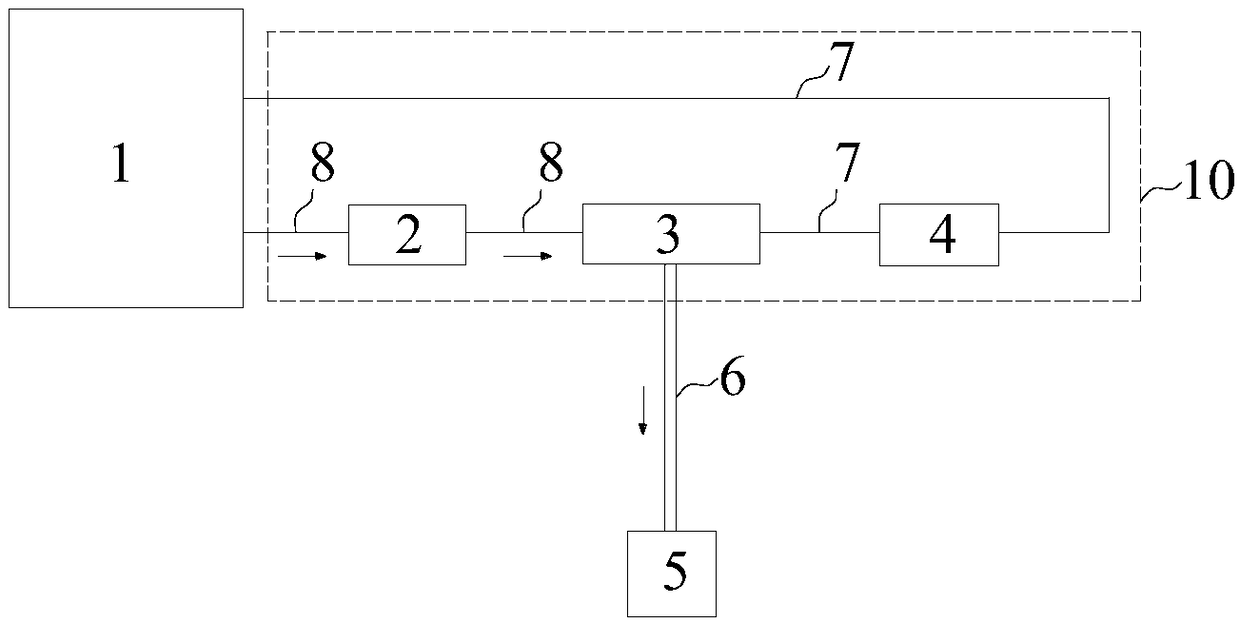

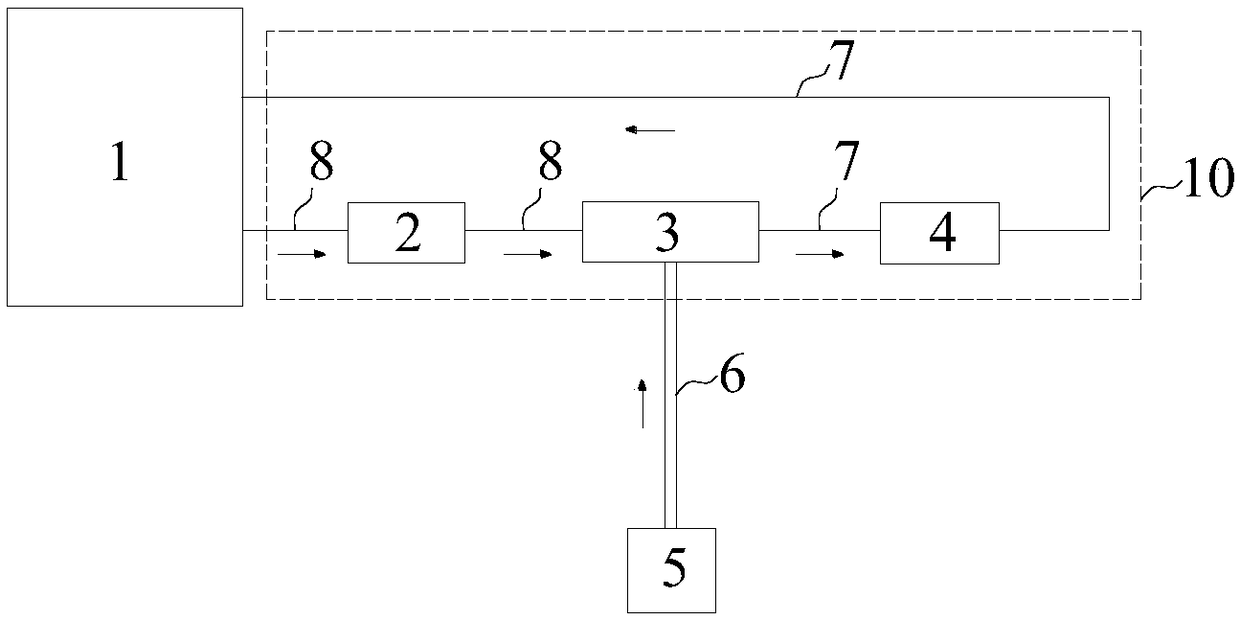

Automatic dosing system for water treatment

PendingCN114349184AAvoid damageImprove mixing efficiencyScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processWater storageCooling tower

The invention discloses an automatic dosing system for water treatment. The automatic dosing system comprises a cooling tower, a circulating pump, a dosing part and a water storage tank, the output end of the cooling tower, the first water outlet of the circulating pump, the water storage tank and the first input end of the cooling tower are sequentially communicated through a pipeline, the second water outlet of the circulating pump, the dosing part and the second input end of the cooling tower are sequentially communicated through a sampling pipeline, and the first water outlet and the second water outlet are connected in parallel. According to the automatic dosing system for water treatment, the dosage of the scale and corrosion inhibitor and the bactericide can be automatically calculated by monitoring the condition of the cooling water, so that the purposes of dynamically adjusting the water quality of the cooling water and reducing the labor cost are achieved.

Owner:茂名华粤华源气体有限公司

Weeding device for planting of juicy peaches

The invention discloses a weeding device for planting of juicy peaches. The weeding device comprises a box body, the box body is of a cavity structure, several jacks are arranged at the bottom of thebox body, jacking rods are sleeved with the jacks respectively, mounting bases are arranged at the bottoms of the jacks respectively, vehicle wheels are sleeved with the mounting bases respectively, and fixed rods which are of a cylindrical cavity structure are symmetrically arranged at the top of one side of the box body; several limiting holes are formed in the fixed rods in sequence, movable rods are sleeved with cavities of the fixed rods and are of a U-shaped cavity structure, through holes are formed in the movable rods, limiting pins are sleeved with the through holes, and one ends of the limiting pins penetrate through the limiting holes and extend to the outer sides of the fixed rods. The weeding device has the advantages that the device is simple and reasonable in overall design,convenient to operate and high in weeding efficiency, the problem that cutting sheets are easily clogged is solved, and the device is suitable for different people and different geographical factors,and has certain practicability.

Owner:明光市丰润家庭农场

Domestic sewage treatment equipment and treatment method based on solid-liquid separation technology

ActiveCN110498524BEnsure thoroughnessGuaranteed orderSpecific water treatment objectivesTreatment involving filtrationLiquid wasteSeparation technology

The invention discloses domestic sewage treatment equipment and a treatment method based on solid-liquid separation technology, comprising a step-by-step solid-liquid separator, a liquid waste purification treatment unit and a solid waste compression recovery unit; the step-by-step solid-liquid separator has domestic sewage The initial inlet, the final outlet of liquid waste and the final outlet of solid waste; the step-by-step solid-liquid separator is used to separate the domestic pollution from the initial import of domestic sewage into the solid and liquid step by step; the liquid waste purification treatment unit corresponds to The final outlet of liquid dirt set in the step-by-step solid-liquid separator is used to purify the liquid dirt; the solid dirt compression recovery unit is correspondingly set in the final outlet of solid dirt in the step-by-step solid-liquid separator for cleaning Solid waste is compressed and recycled. The domestic sewage treatment equipment and treatment method based on the solid-liquid separation technology provided by the present invention can thoroughly and effectively purify domestic sewage with good treatment effect and avoid pollution to the environment.

Owner:宁夏优智环保科技有限公司

Energy-saving building type water energy storage system

PendingCN112268475AAvoid clogging damageImprove filtering effectHeat storage plantsCorrosion preventionWater storageWater storage tank

The invention relates to an energy-saving building type water energy storage system. The system comprises a water storage tank body and a heat preservation shell, the heat preservation shell is fixedly installed at the periphery of the outer side of the upper end of the water storage tank body, and the energy-saving building type water energy storage system has a very good filtering effect througha novel water inlet connector structure. The system can be well connected and installed with an external water inlet pipeline through threaded connecting holes at the periphery of the upper end of around steel disc, bolts penetrate through the threaded connecting holes in an inserting manner and are rotationally fixed, and a honeycomb net plate is inserted into the upper end of the inner side ofthe round steel disc, so that the system is fixedly connected and installed in an inserted manner, and installation is more convenient; and similarly, an impurity filter screen is inserted into the rear end of the honeycomb net plate, and when external water flow enters, the honeycomb net plate and the impurity filter screen are mutually staggered and matched for use, so that impurities such as silt, metallic oxide or hydroxide in the water flow can be filtered out to the greatest extent, a water inlet connector is cleaned periodically, and the problem of blockage and damage in equipment canbe avoided.

Owner:上海中如智慧能源集团有限公司

New agricultural water-saving regulator device for irrigation

ActiveCN109519572BAvoid clogging damageAvoid damageOperating means/releasing devices for valvesWatering devicesAgricultural scienceAgricultural engineering

Owner:海南乾碳行环境科技有限公司

A crack-proof bridge structure

InactiveCN104195937BReduce the temperature difference between inside and outsideAvoid crackingBridge structural detailsBridge materialsStructural engineeringEngineering

The invention discloses a cracking-preventing bridge structure. The cracking-preventing bridge structure comprises a concrete bridge body and a steel cylinder arranged in the concrete bridge body. The steel cylinder is rectangular and hollow, the two ends of the steel cylinder are closed, the middle of the steel cylinder is a solid, the top of the solid is provided with a water inlet hole vertically extending downwards, the side face of the solid is provided with a water outlet hole which extends horizontally and is communicated with the water inlet hole and the hollow part of the steel cylinder at the same time, the upper end of the water inlet hole is provided with a thread blocking plug, and the hollow part of the steel cylinder is filled with water. The steel cylinder is filled with water, and due to the fact that the specific heat capacity of water is large, the difference between the temperature inside concrete and the temperature outside the concrete can be reduced very well, the temperature inside the concrete and the temperature outside the concrete is made to reach the balance state as much as possible, and the concrete is effectively prevented from cracking when the difference between the temperature inside concrete inside and the temperature outside the concrete is excessively large.

Owner:SICHUAN JINFENG CONSTR

A mobile landscape fountain device

InactiveCN107088493BCan control liftAvoid clogging damageMovable spraying apparatusLiquid spraying apparatusSprayerTransverse plane

The invention discloses a movable landscape fountain device, and relates to the technical field of landscape fountains. The movable landscape fountain device comprises an outer frame. A filter plate is fixedly connected between the two sides of the inner wall of the outer frame. A lead screw is rotationally connected between the bottoms of the two sides of the inner wall of the outer frame. The two sides of the surface of the lead screw are in threaded connection with movable blocks. The tops of the movable blocks are rotationally connected with an inner frame through connecting rods. The top of the inner frame penetrates the filter plate and extends to the top of the filter plate. A transverse plate is fixedly connected between the two sides of the inner wall of the inner frame. The top of the transverse plate is fixedly connected with a booster pump. The movable landscape fountain device achieves the purpose that the fountain can move, fountain display can be achieved at any time and any place, and ascending and descending of a high-pressure sprayer can be controlled. When the movable landscape fountain device is not used, the high-pressure sprayer can be stored, the high-pressure sprayer is prevented from being blocked and damaged, water can be cyclically used, resources are saved, and impurities are prevented from blocking the high-pressure sprayer.

Owner:广东铭锦城园林景观设计工程有限公司

Segmented convergent type plugging machine for piping emergency rescue

ActiveCN114108545AReduce disturbanceUniform and stable exitHydro energy generationHydraulic engineering apparatusEmergency rescueArchitectural engineering

The invention relates to the field of water conservancy, in particular to a segmented convergent type plugging machine for piping emergency rescue. The invention solves the technical problem that a single high polymer is difficult to tightly block a piping channel. According to the technical scheme, the segmented collection type plugging machine for piping emergency rescue comprises a first mounting rack, a collection assembly and a feeding pipe; the right part of the first mounting rack is provided with a binding assembly, and the binding assembly binds a cloth bag in sections; a feeding pipe is arranged in the first mounting rack and prevents water flow from flowing back into the steel pipe. By arranging the bundling assembly, segmented bundling, staged expansion and automatic strap shearing of the geotechnical cloth bag are achieved, and workers do not need to enter a piping channel for operation.

Owner:重庆艺锦陶瓷有限公司

Garbage treatment equipment for primary purification of sewage

PendingCN109224553ANovel structureScientific and reasonable designGrain treatmentsStationary filtering element filtersEngineeringSewage

The invention belongs to the technical field of sewage purification and in particular relates to garbage treatment equipment for primary purification of sewage. The garbage treatment equipment comprises a treatment box, wherein a water inlet is formed in the top of the treatment box; a supporting cushion disc is fixedly mounted in the treatment box; a bottom disc is arranged at the top of the supporting cushion disc in a rotary manner; the bottom disc is provided with a plurality of filtering screens and filtering holes; the filtering screens and the filtering holes are distributed in an annular shape; a machine case is fixedly welded with the inner part of the treatment box through a bracket; the machine case is internally provided with a motor; a rotary shaft is fixedly connected with anoutput shaft of the motor; the upper end of the rotary shaft is fixedly connected with the bottom disc; a plurality of rotary propelling devices, which are distributed in the annular shape, are fixedly arranged at the top of the bottom disc through screws; a plurality of grinding rings, which are distributed in the annular shape, are fixedly mounted on an inner wall of the treatment box; throughholes are formed among the grinding rings. The garbage treatment equipment provided by the invention is novel in structure and scientific and reasonable in design; floating matters in the sewage are sufficiently filtered and the purification effect of a purifier is further improved.

Owner:湖州欧汇再生资源科技有限公司

Dredging equipment for water conservancy project

InactiveCN112726720ASide turnFree runWind motor with solar radiationWind motor controlStructural engineeringHydraulic engineering

The invention discloses dredging equipment for a water conservancy project. A ship body is included, a cabin is fixedly installed at the rear end of the right side in the ship body, a power generation mechanism is fixedly installed at the top of the cabin, a diesel generator is fixedly installed on the front section of the right side of the bottom of the ship body, and a power storage box is fixedly installed on the right side of the upper end of the cabin. An insulating rubber sleeve is fixedly installed in the power storage box, a storage battery is fixedly installed in the insulating rubber sleeve, a cabin door is hinged to the right side of the front face of the cabin, a control console is arranged on the left side in the cabin, a DSP controller is fixedly installed in the control console, and a seat is fixedly installed at the bottom of the right side in the cabin. A buzzer is fixedly installed at the upper end of the front face of the cabin, and a storage mechanism is fixedly installed on the left side in the ship body. The equipment is high in dredging capacity, convenient to use, capable of achieving automatic endurance, good in environmental protection performance, high in practicability, wide in application prospect and worthy of application and popularization.

Owner:张春晓

An environmentally friendly oxidation-imbibition method for enhanced oil recovery with zero flowback of fracturing fluid in shale gas wells

Owner:SOUTHWEST PETROLEUM UNIV

A kind of cleaning device of dendrobium vibrating screen

ActiveCN107243454BHigh degree of automationImprove efficiencySievingScreeningMechanical engineeringSieve

Owner:金寨智行知识产权运营有限公司

A communication management machine system device for a communication base station

ActiveCN112055495BImprove stabilityPrevent fallingCasings/cabinets/drawers detailsWireless communicationHeat sinkBase station

The present invention belongs to the communication-related technical field, and is especially a communication management machine system device for a communication base station, including a base provided under the outer wall of the housing, and first fixing bolts penetrate through the outer walls on both sides of the base, and the base The top of the outer wall of the outer wall is installed in cooperation with the first card slot, and the first card slot is opened on the lower outer wall surface of the shell, and a plurality of temperature sensors are installed under the inside of the shell, and heat dissipation fins are installed above the temperature sensors, so A fan cover is installed above the cooling fins, and cooling fans are installed on both sides of the inside of the fan cover, a plurality of weight sensors are installed above the fan cover, and an alarm is installed on the outer upper side of the weight sensor . The present invention can fix the shell by screwing the fixing bolt through the threaded hole and the wall to be connected to the shell by setting the threaded hole, avoiding the inconvenient installation and fixing of the shell, thereby effectively improving the performance of the device. Effect.

Owner:中屹技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com