Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Achieve labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

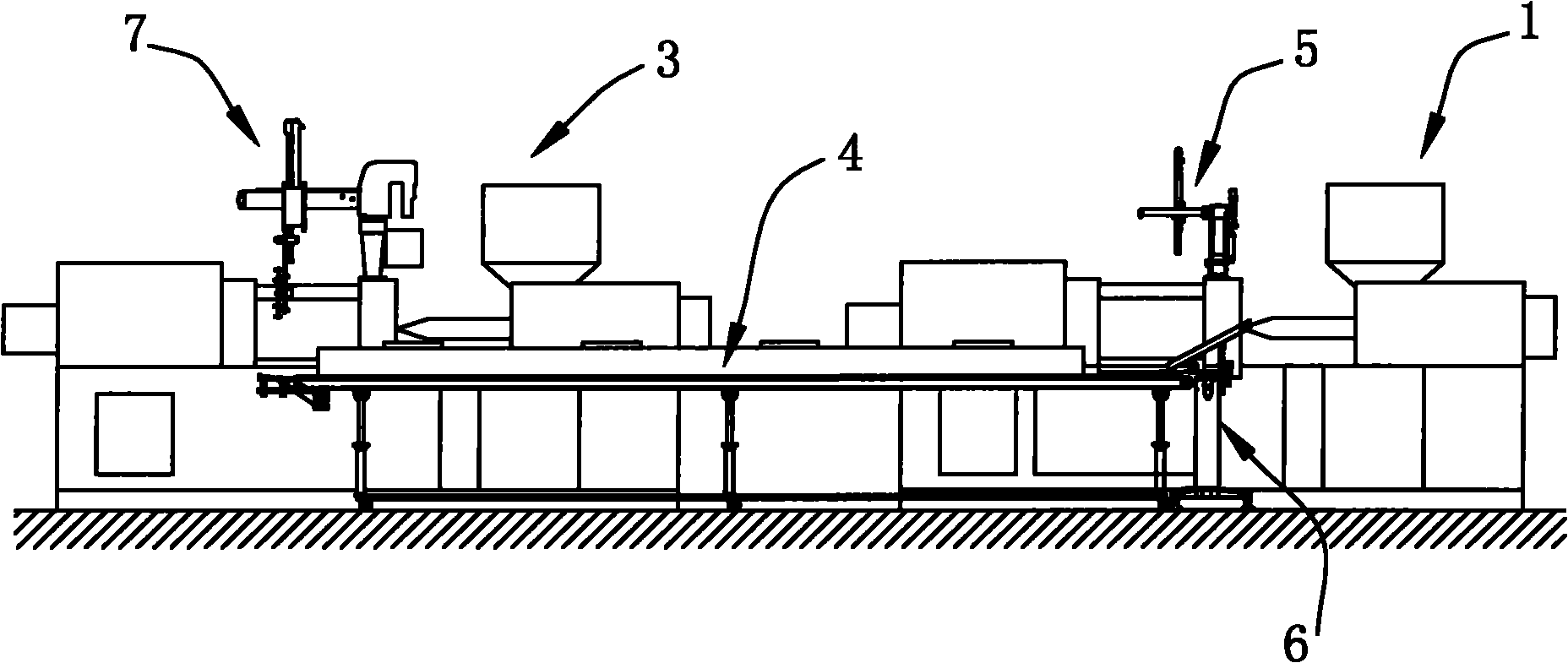

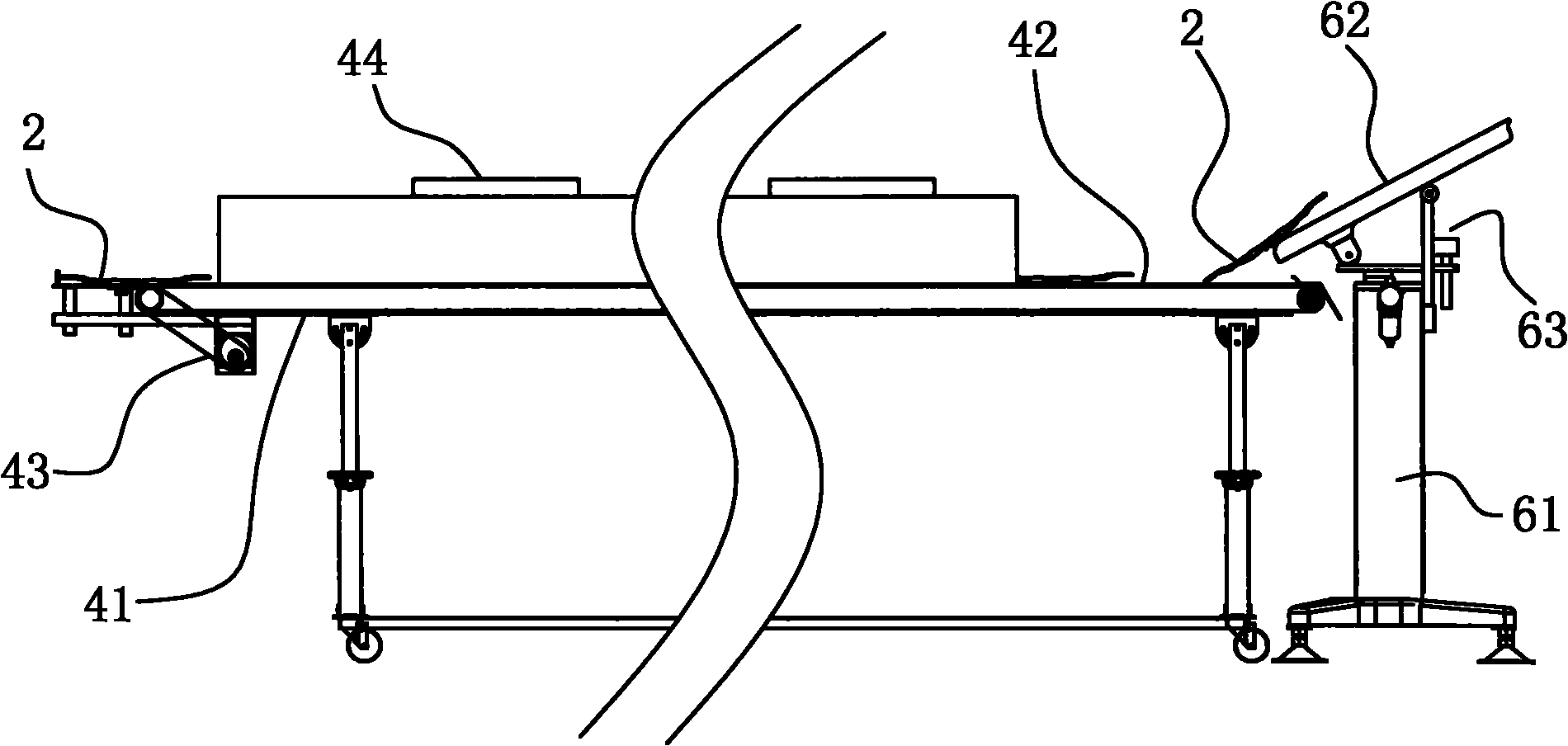

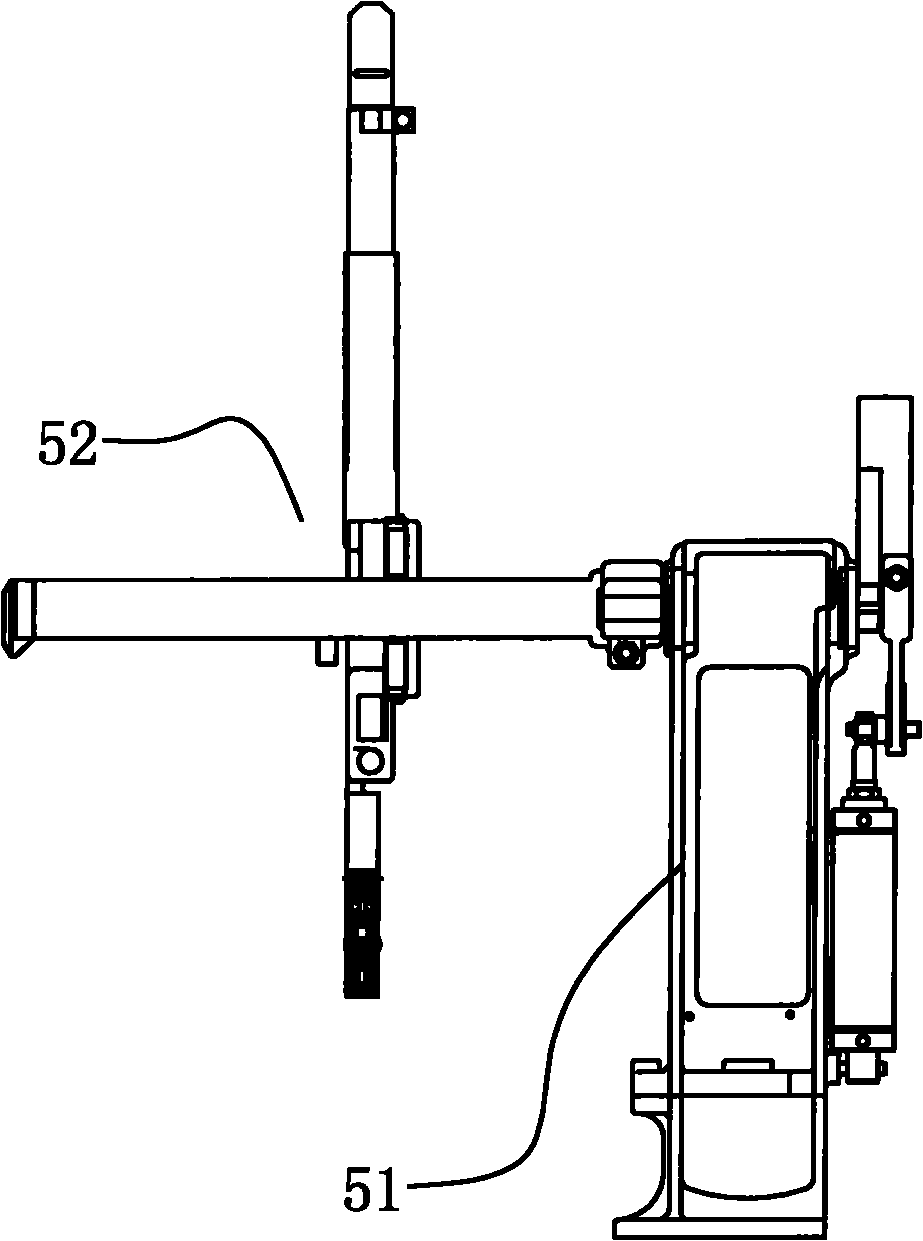

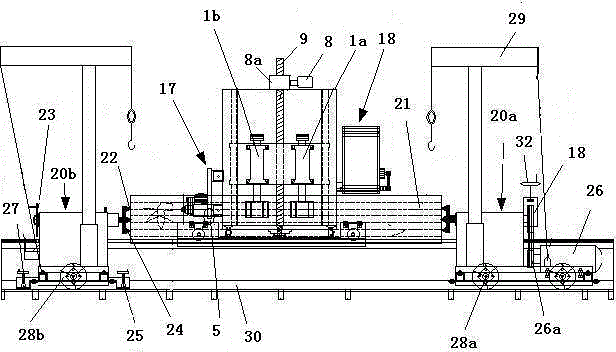

Secondary injection molding method for toothbrush handles and system for implementing same

InactiveCN102166807AReduce manufacturing costGood product qualityDomestic articlesEngineeringInjection moulding

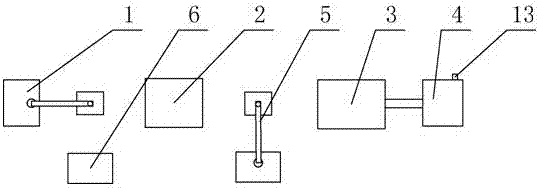

The invention discloses a secondary injection molding method for toothbrush handles, comprising the following steps of: (1) arranging a molding injection machine for performing injection molding of a toothbrush body; (2) arranging an encapsulating injection machine for performing secondary encapsulating injection on the toothbrush body to obtain the finished product; and (3) arranging a control system which is respectively connected with the molding injection machine and the encapsulating injection machine for controlling the operating modes thereof. The invention also discloses a system for implementing the method. The method provided by the invention can realize secondary injection molding on the basis of not changing the existing structure of the mold, so that the production cost is effectively reduced and the product quality is good. The system provided by the invention has a simple and reasonable structure, combines the molding injection machine and the encapsulating injection machine, realizes secondary injection molding, has high efficiency and quick speed, greatly improves the production efficiency and the product percent of pass, has high degree of automation, and greatly reduces the labor intensity.

Owner:东莞艾尔发自动化机械有限公司

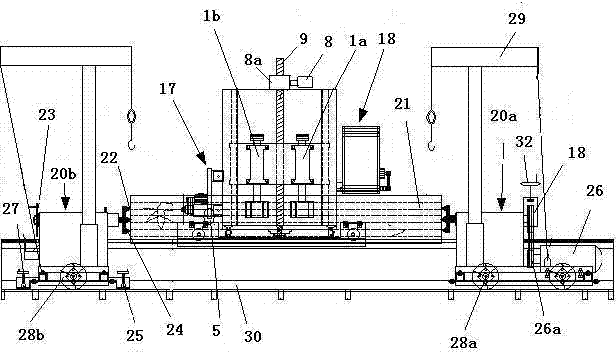

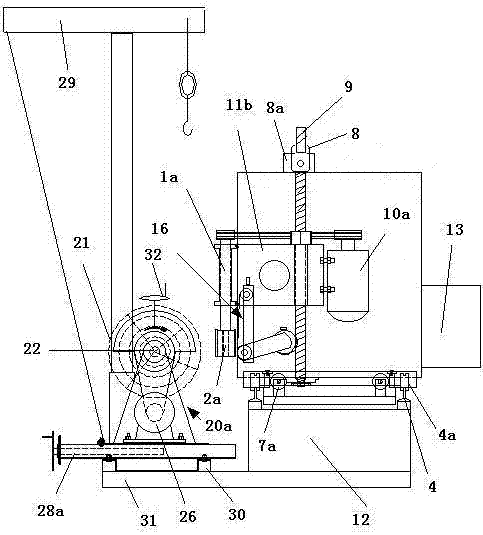

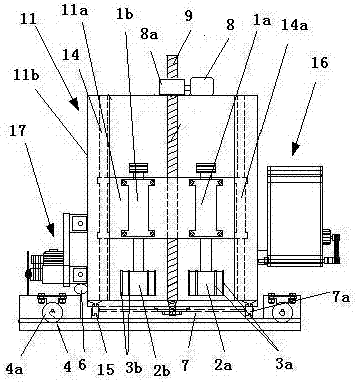

Multifunctional wood machining equipment

ActiveCN104890063AMove fastReduce resistance to movementMulti-purpose machinesBark-zones/chip/dust/waste removalWood machiningEngineering

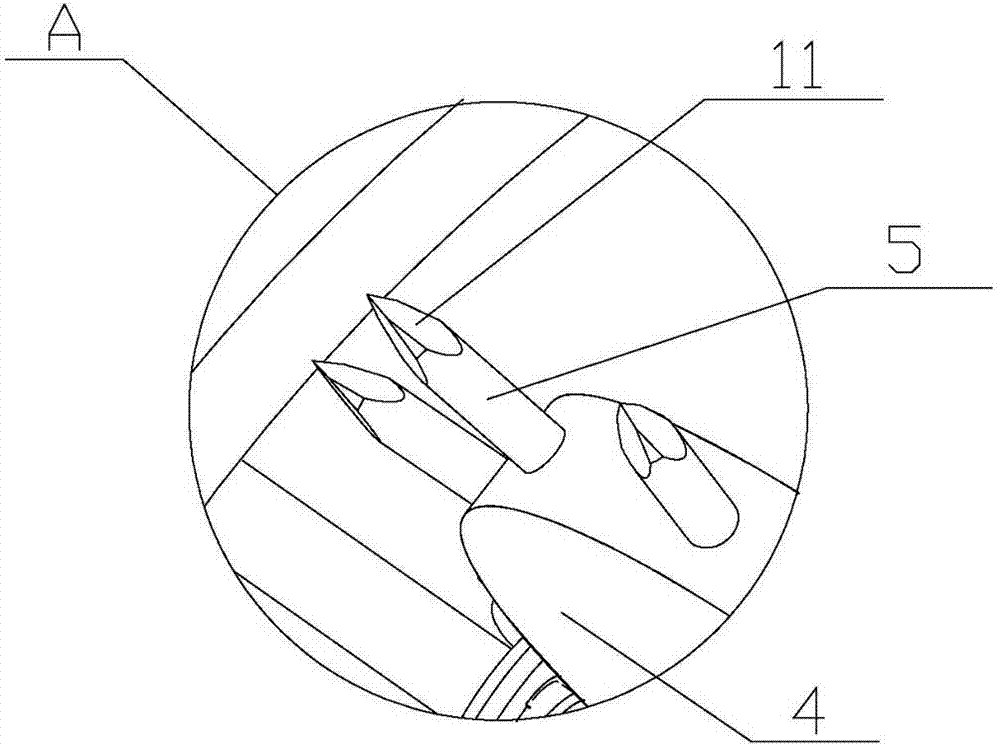

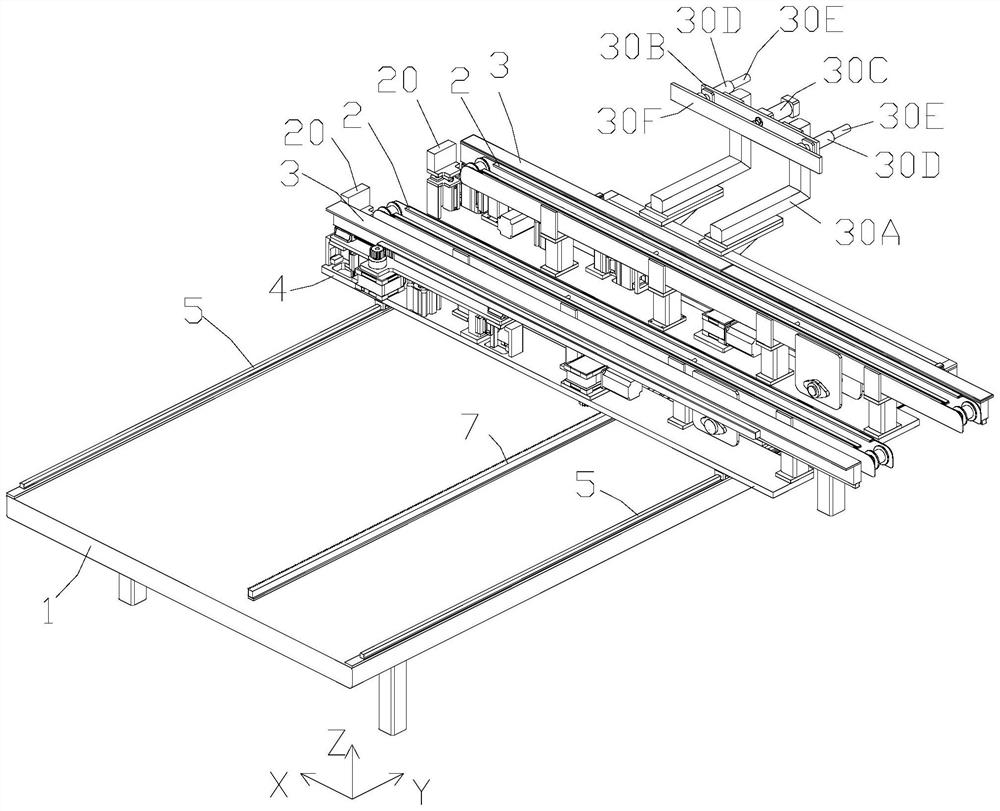

The invention discloses multifunctional wood machining equipment and belongs to the field of wood machining equipment. A running vehicle comprises a movement and driving devices moving along X-axis direction, Y-axis direction and Z-axis direction, at least two rotating spindles taking vertical direction as axis are arranged at the front end of the movement, a knife is arranged at the lower end of each spindle, and multiple rows of blades are arranged around each knife, distances between the blades on different spindles and cut wood are difference, the spindles are rotatably connected with a motor respectively, multiple top discs different in diameter are arranged on a top tip seat and a top tip of a tail seat, a rolling device along the X-axis direction is arranged on the lower portion of the tail seat, and a control panel is arranged on the multifunctional wood machining equipment. By the multifunctional wood machining equipment, production efficiency can be improved, labor intensity of operating personnel can be lowered, machining diameter can be expanded, machining variety can be increased, and sales market can be expanded.

Owner:安阳市涵缘机械设备有限公司

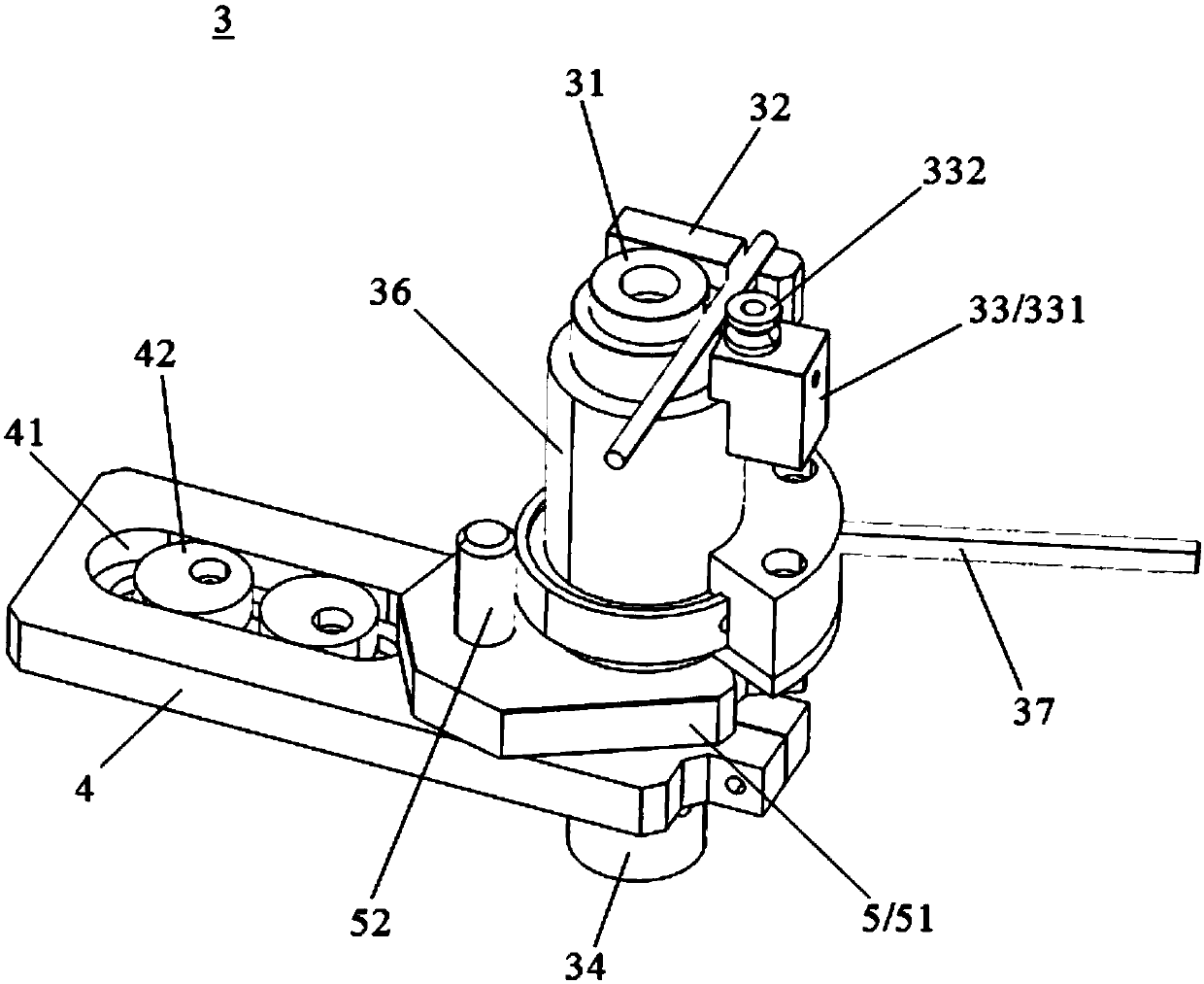

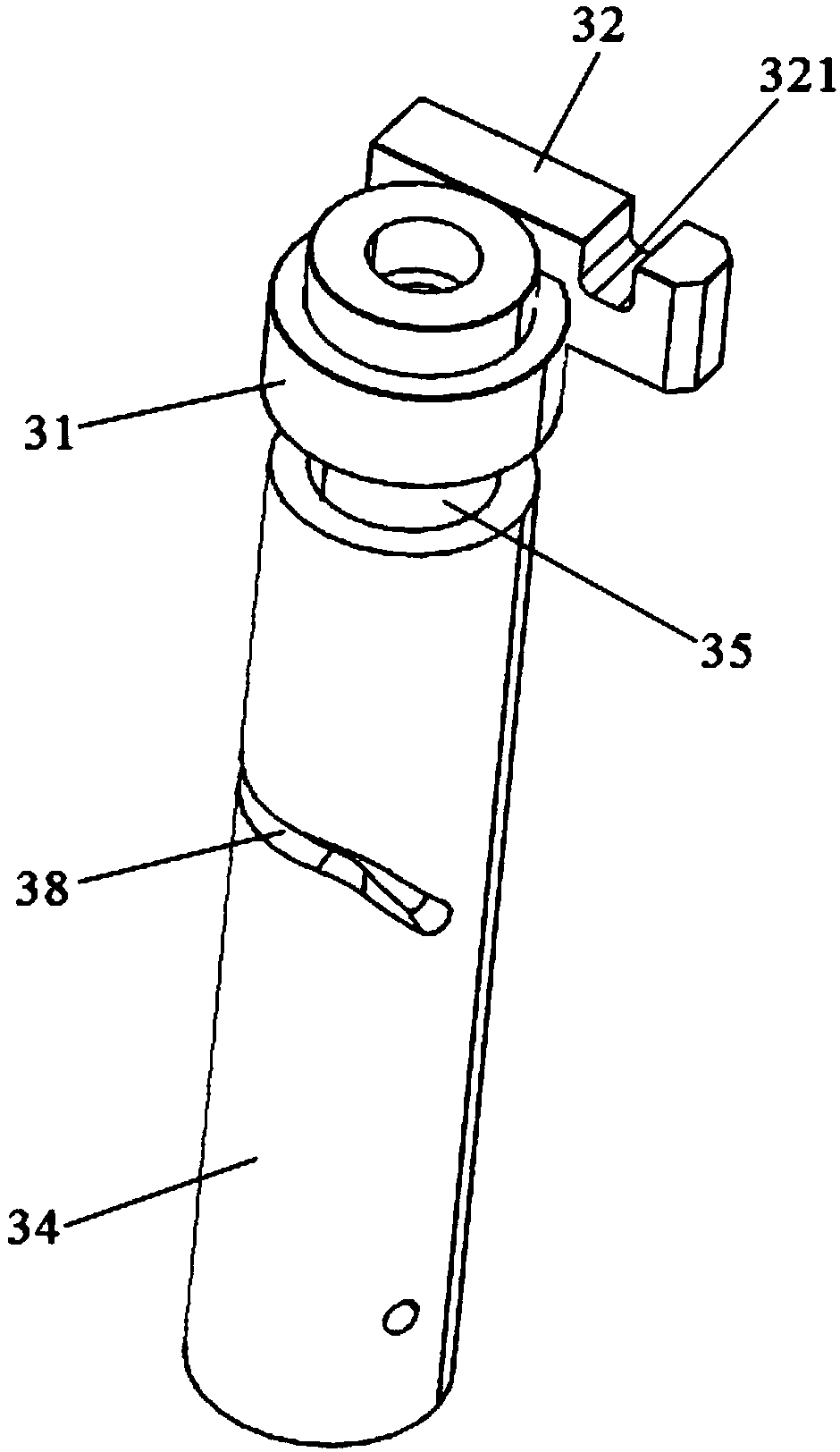

Manual pipe bending machine

PendingCN107639140AReduce the difficulty of productionImprove convenienceEngineeringMechanical engineering

The invention discloses a manual pipe bending machine. The manual pipe bending machine comprises a pipe bending unit which comprises a wheel mold, a stop block component blocking a bending edge of a pipe and a bending die cooperating with the wheel mold to bend the pipe, the pipe bending unit further comprises a rotating rising component which drives the bending die to rotate and simultaneously drives the bending die, the wheel mold and the stop block component to synchronously rise or fall. Accordingly, the pipe bending unit is modularized, the corresponding unit can be made rapidly and conveniently according to the pipe diameter and bending radius, the making efficiency of the pipe bending machine is improved, the making, disassembling and maintaining difficulties of the pipe bending machine are lowered, the pipe bending precision is high, the labor intensity is reduced, and the production efficiency is improved.

Owner:COOPER STANDARD AUTOMOTIVE SUZHOU CO LTD

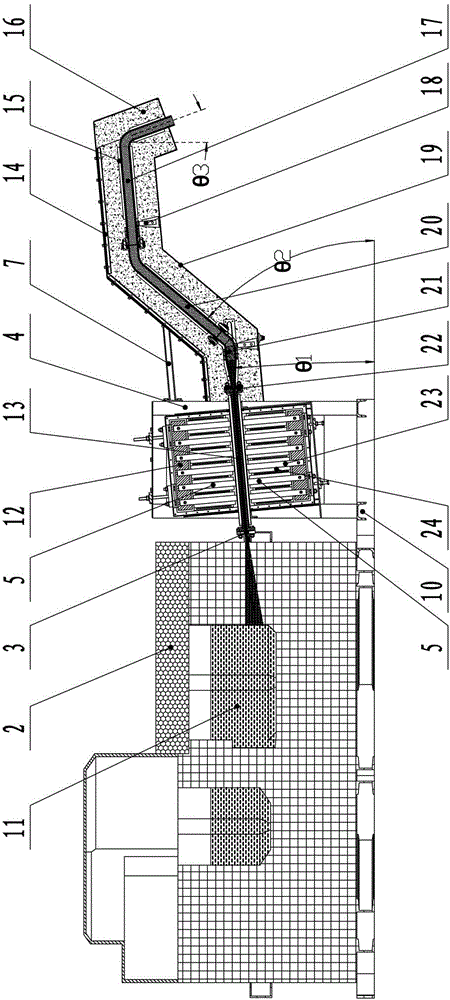

Method for low-pressure casting thin-wall long-sized castings and equipment used by same

The invention relates to a method for low-pressure casting thin-wall long-sized castings and equipment used by the same, wherein metal materials are firstly smelted, a furnace body is closed, a mould is prepared, dry compressed air is filled into an airtight container, under the action of gas pressure, liquid metal rises along a multitube and multi-sprue riser tube and stably enters a mould cavity through a sprue, and the gas pressure on the liquid level in a crucible is kept; and after the casting is completely solidified, the gas pressure on the liquid level is relieved to enable the unsolidified liquid metal in the riser tube to flow back into the crucible, and then the casting is taken out. The method for producing the thin-wall long-sized casting has the advantages that mold-filling is stable, a product is well molded, the mold-filling of liquid metal is carried out under the pressure, the liquid metal has good liquidity and is convenient to cast the thin-wall casting of the kind the casting is crystallized and solidified under the pressure and has a compact structure, so the mechanical property is improved, a pouring system is simple, casting heads are reduced, mechanization and automation are realized, the labor intensity of workers is reduced, a mould with multi-cavities is realized, the production efficiency is improved and the like.

Owner:烟台路通精密科技股份有限公司

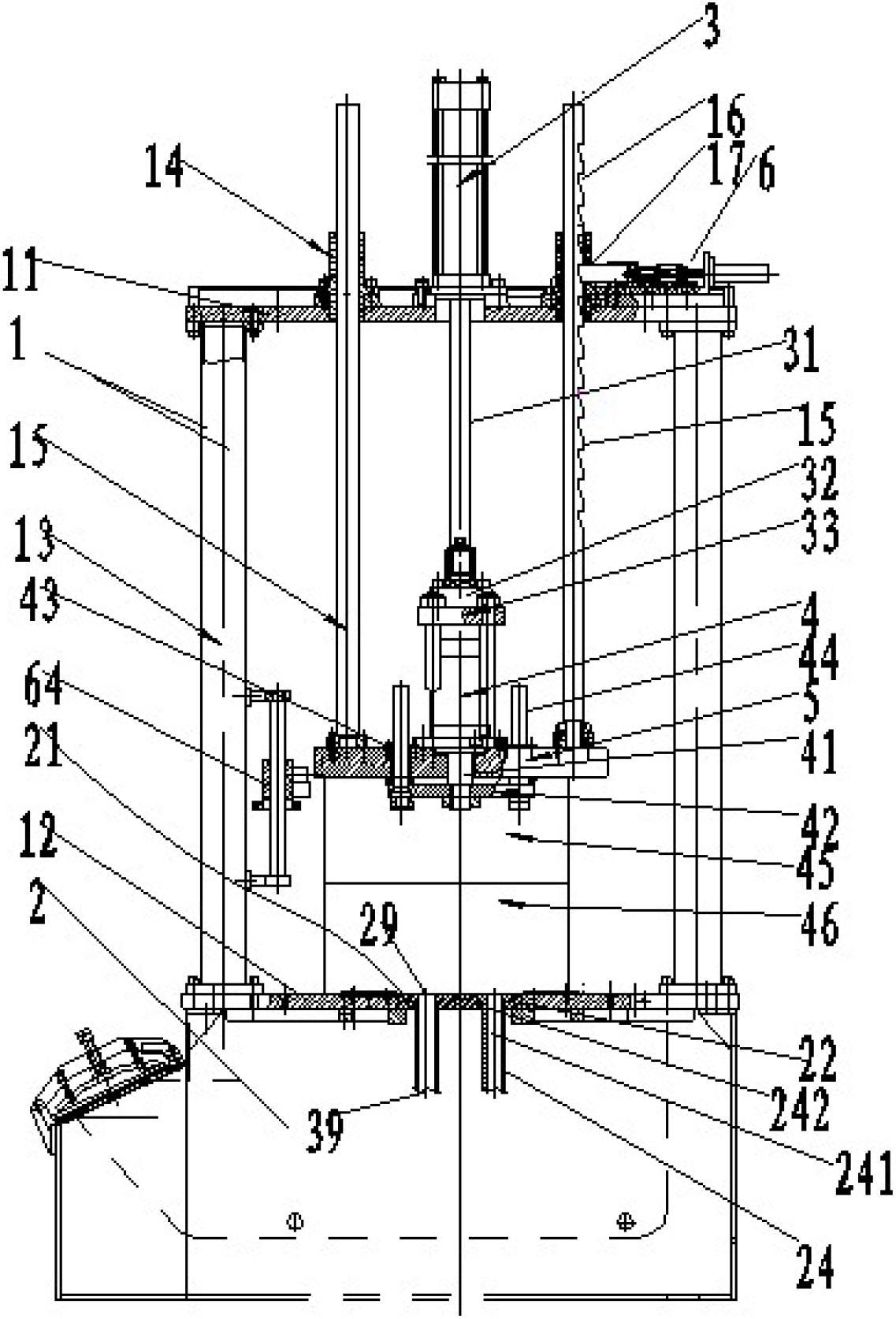

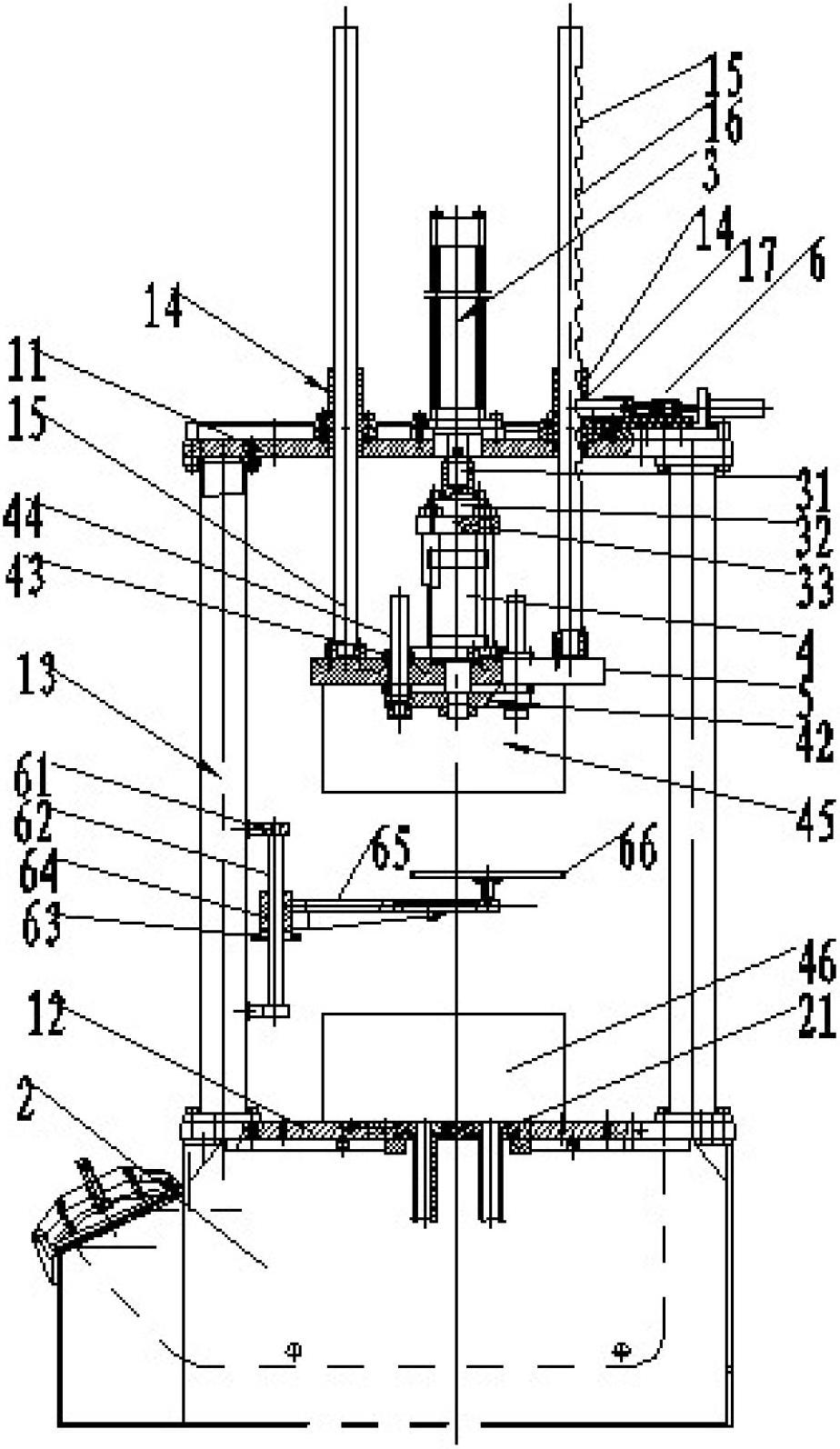

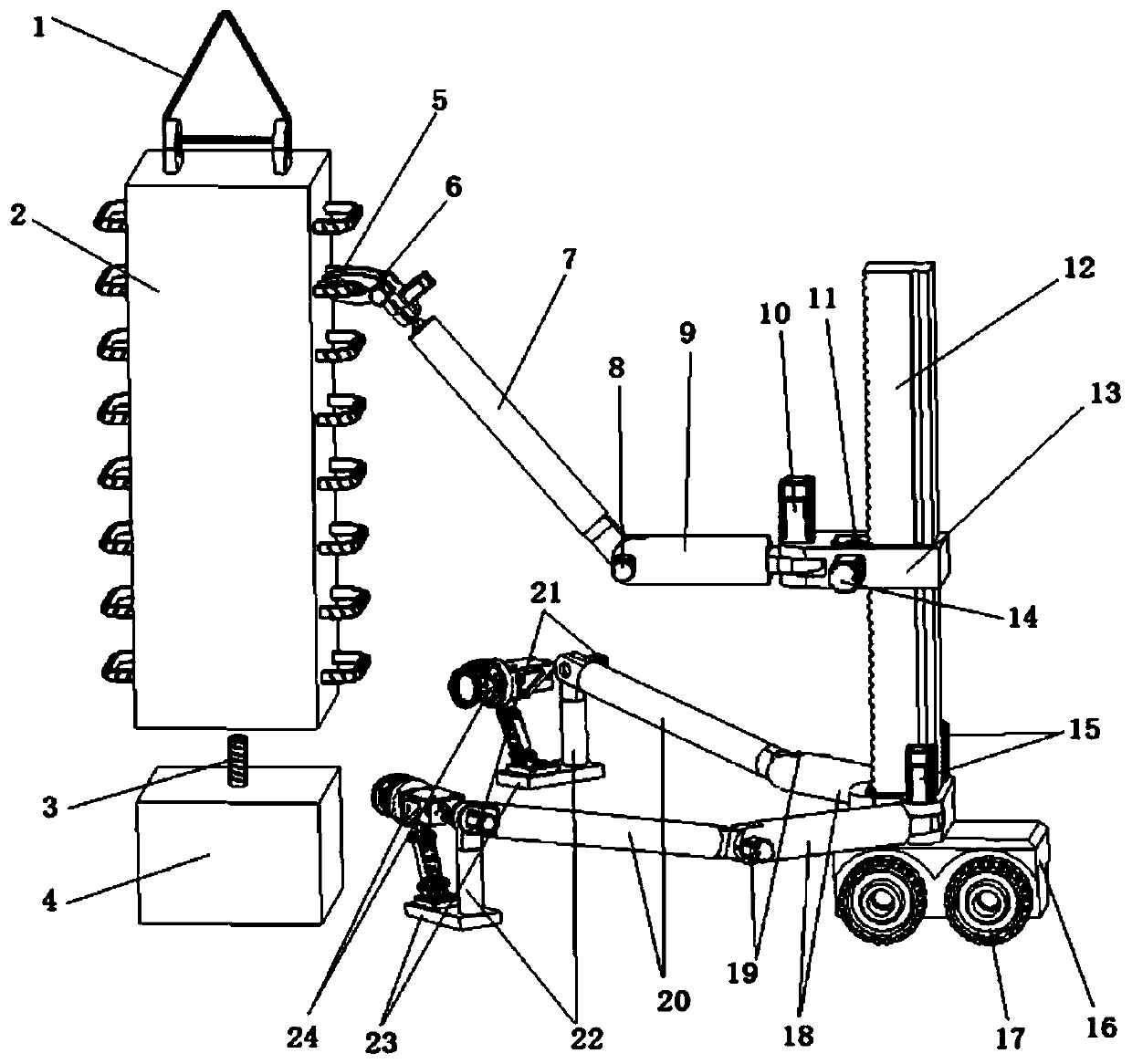

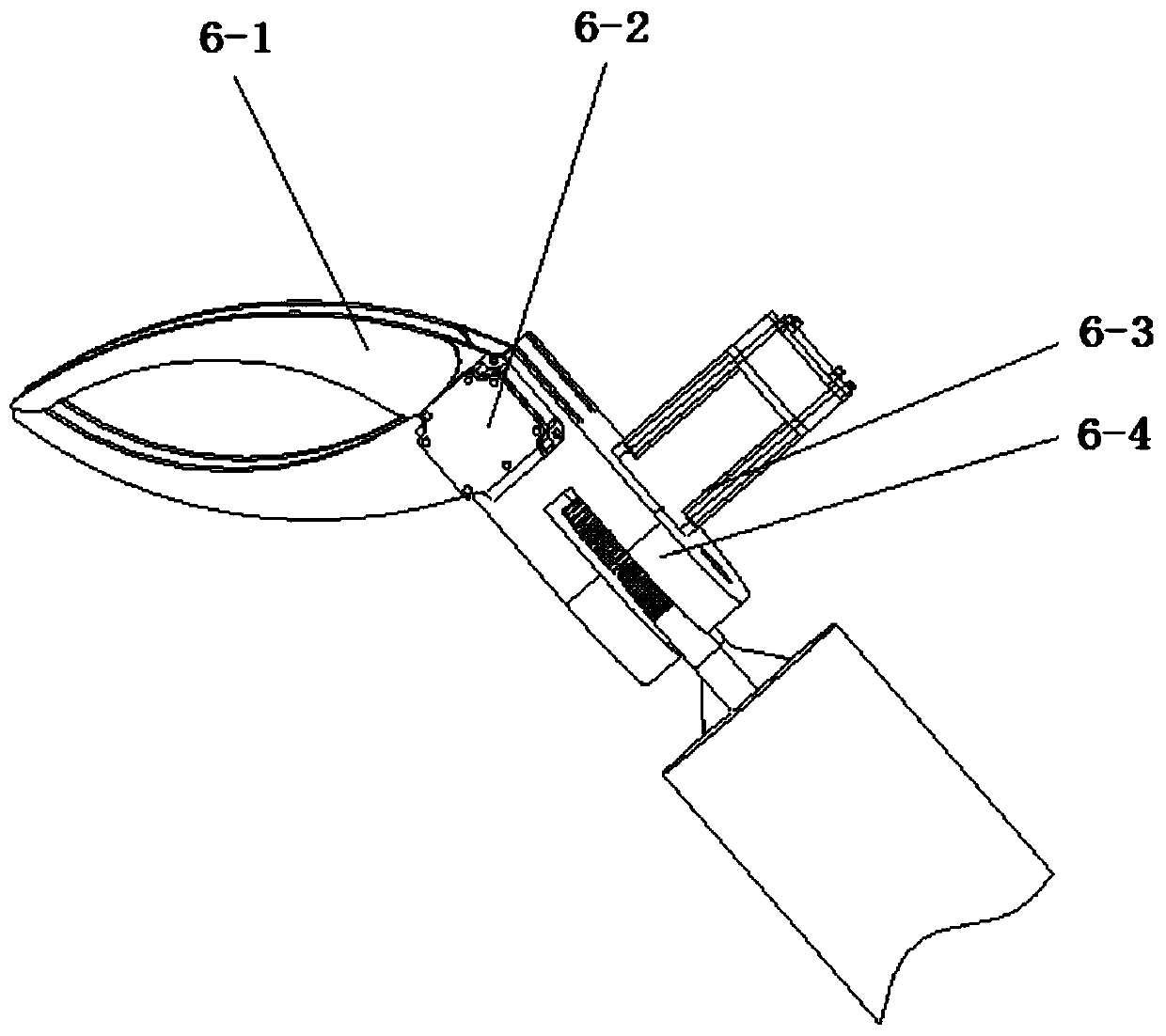

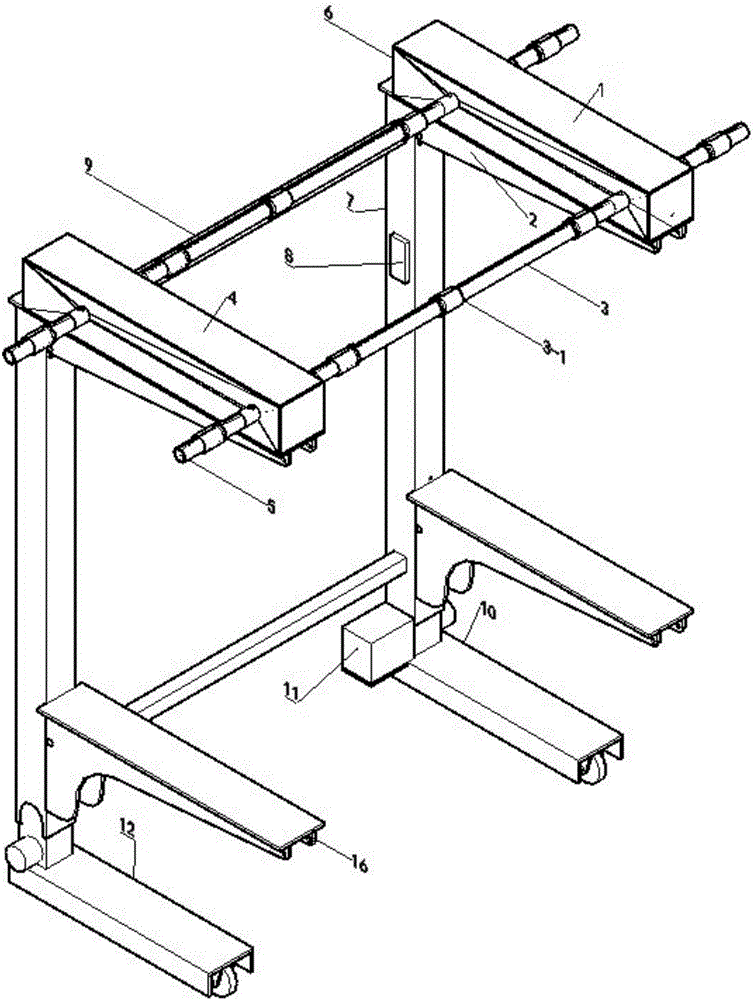

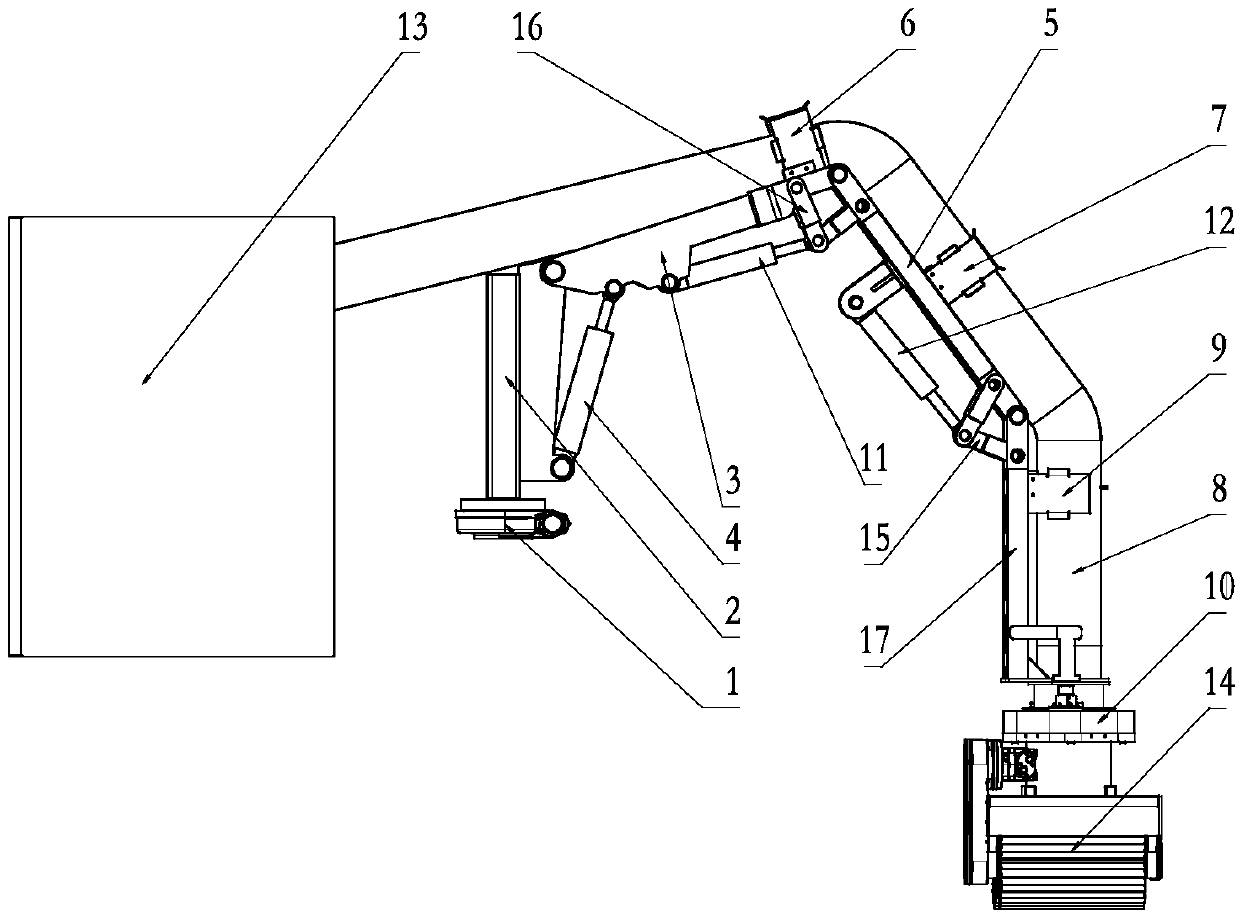

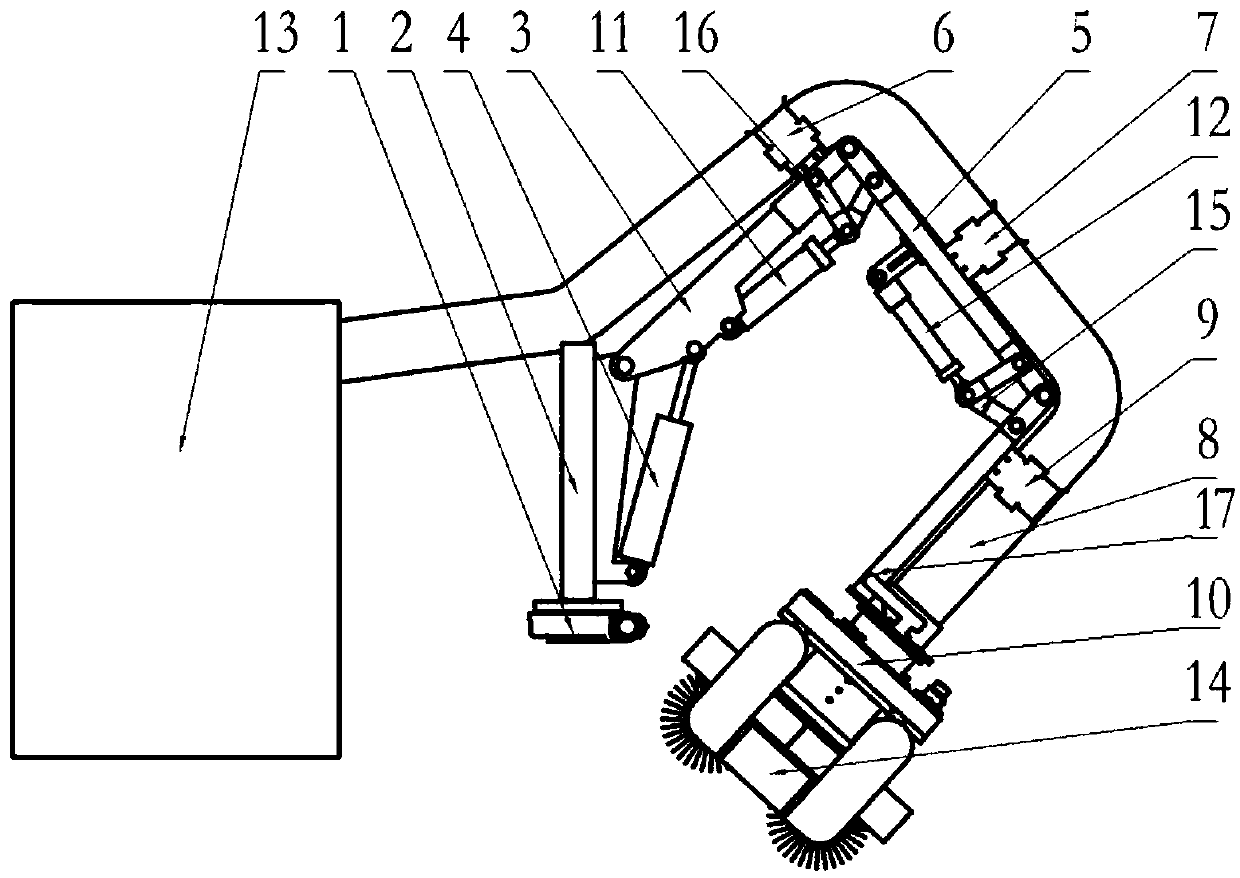

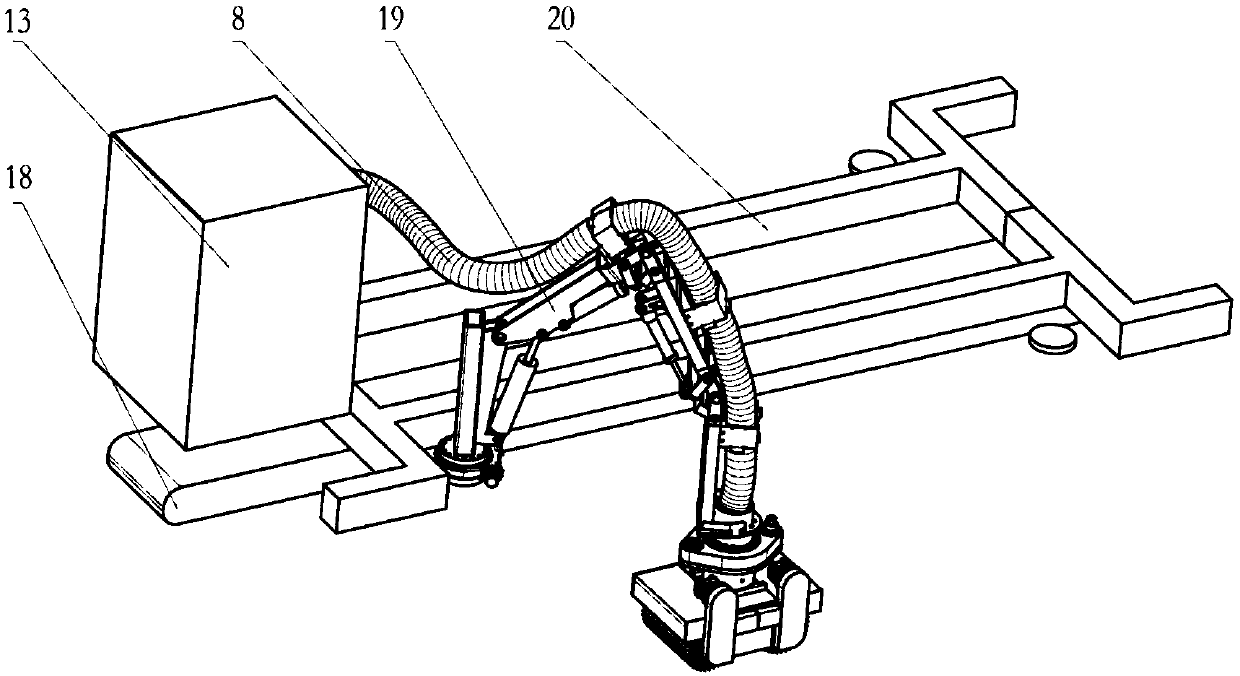

Accurate in-place robot for building prefabricated part based on machine vision

PendingCN110948507AAchieve labor intensityFull range of mobilityProgramme-controlled manipulatorGripping headsMachine visionEngineering

The invention relates to an accurate in-place robot for a building prefabricated part based on machine vision. The accurate in-place robot can achieve accurate in-place of box-shaped and columnar prefabricated parts on a fabricated building construction site. The robot is characterized in that a system platform serves as an overall frame support, and four universal wheel structures are installed on the two sides of the platform, so that all-directional movement of the robot device in a horizontal plane area can be achieved, and the operation area is enlarged; a toothed bar column is fixedly mounted on the system platform, and the toothed bar column is provided with a component clamping mechanical arm and two vision adjusting mechanical arms, so that free adjustment can be conducted withinthe space limit range, the operation flexibility is improved, and the operation precision is improved; cameras are installed on the two vision adjusting mechanical arms to form a binocular vision system, and position images of the prefabricated parts and the target installation points are obtained; and the clamping mechanical arms are controlled to clamp the prefabricated parts and adjust the positions of the prefabricated parts through the obtained position images, so that accurate positioning is achieved, and the automation degree and efficiency of prefabricated part installation are improved.

Owner:SHENYANG JIANZHU UNIVERSITY

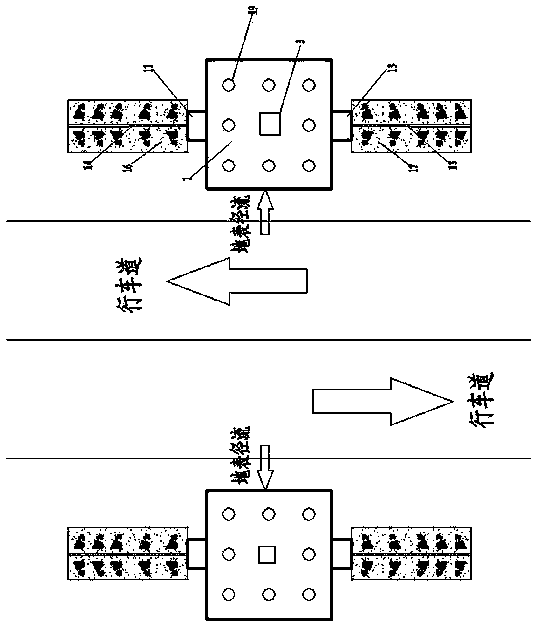

Pin shaft mistake proofing device used on automatic production line

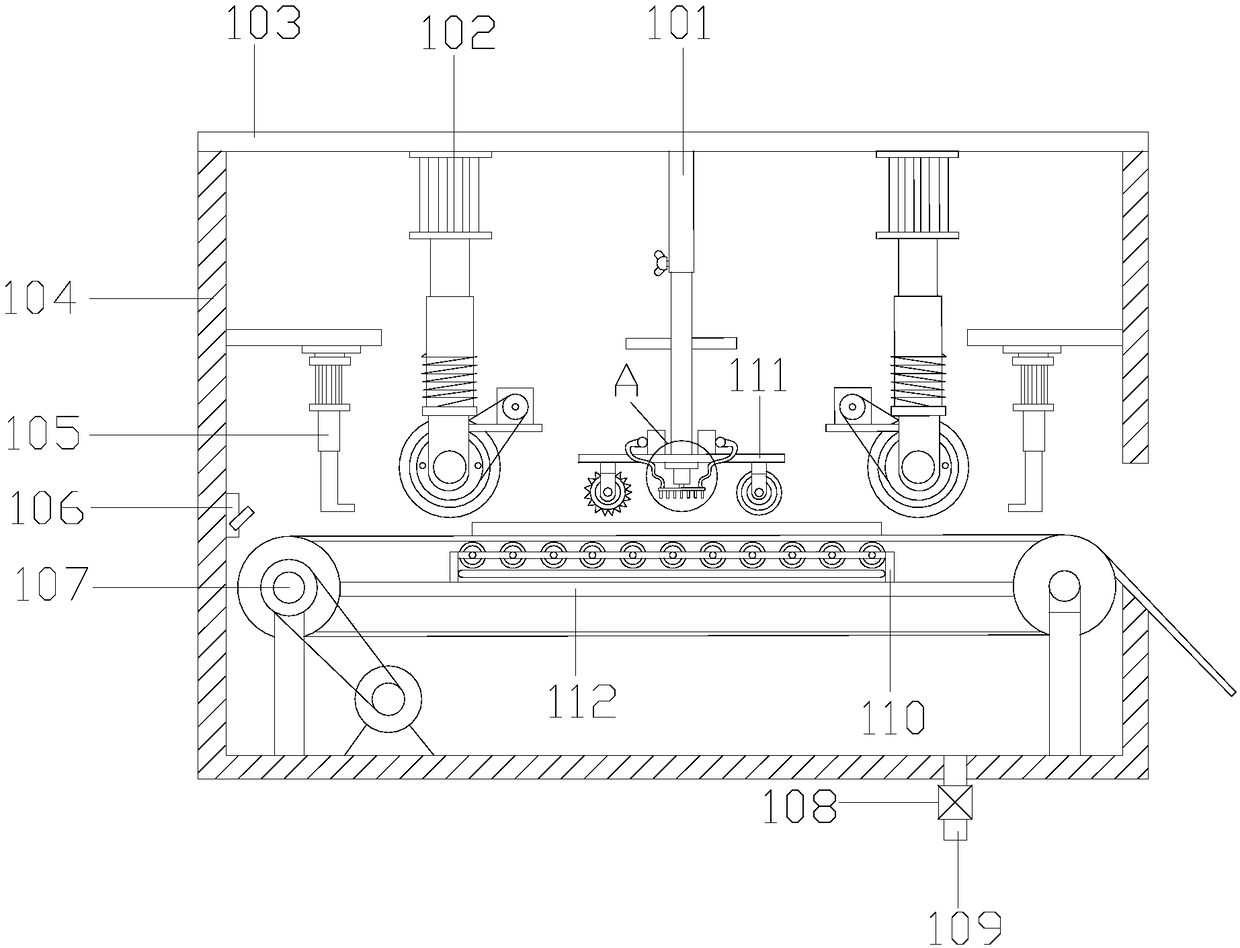

ActiveCN107244533AReduce labor intensityGuaranteed accuracyControl devices for conveyorsMechanical conveyorsEngineeringManufacturing line

The invention discloses a pin shaft mistake proofing device used on an automatic production line. The pin shaft mistake proofing device comprises a rack. A workpiece conveying device is arranged in the rack. Multiple accompanying tools evenly distributed at intervals are arranged on the workpiece conveying device. An axial centering positioning mechanism, a diameter detection mechanism and a ring groove position detection and correcting mechanism are sequentially arranged on the rack from the front end to the tail end. The accompanying tools on the workpiece conveying device sequentially pass through cavities of the axial centering positioning mechanism, the diameter detection mechanism and the ring groove position detection and correcting mechanism. The axial centering positioning mechanism can conduct clamping and centering on workpieces on the accompanying tools, and the types of the workpieces can be recognized according to the length dimension. The diameter detection mechanism can be used for detecting the diameters of the workpieces on the accompanying tools, and the types of the workpieces can be recognized according to the diameter dimension. The ring groove position detection and correcting mechanism can be used for conducting ring groove position detecting and correcting on the workpieces on the accompanying tools. The pin shaft mistake proofing device is used for replacing a traditional manual detection manner in the past, the detection accuracy is ensured, reliability is high, and the device conforms to accuracy and stability of the production line.

Owner:三翔(十堰)汽车零部件有限公司

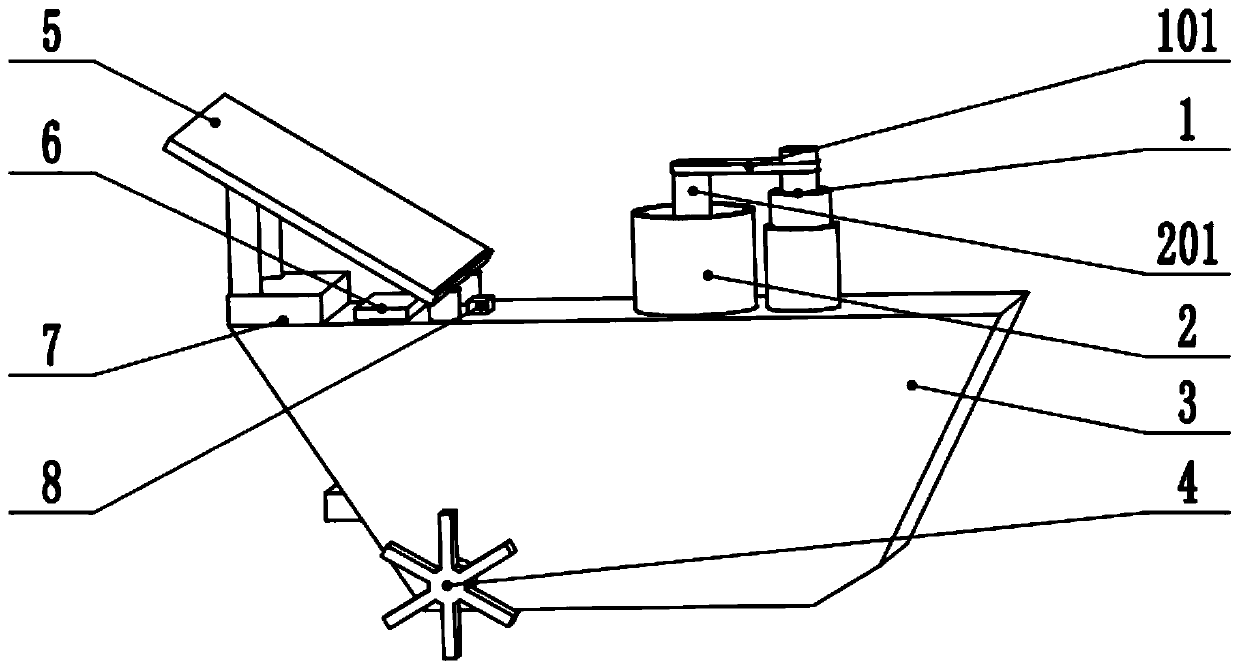

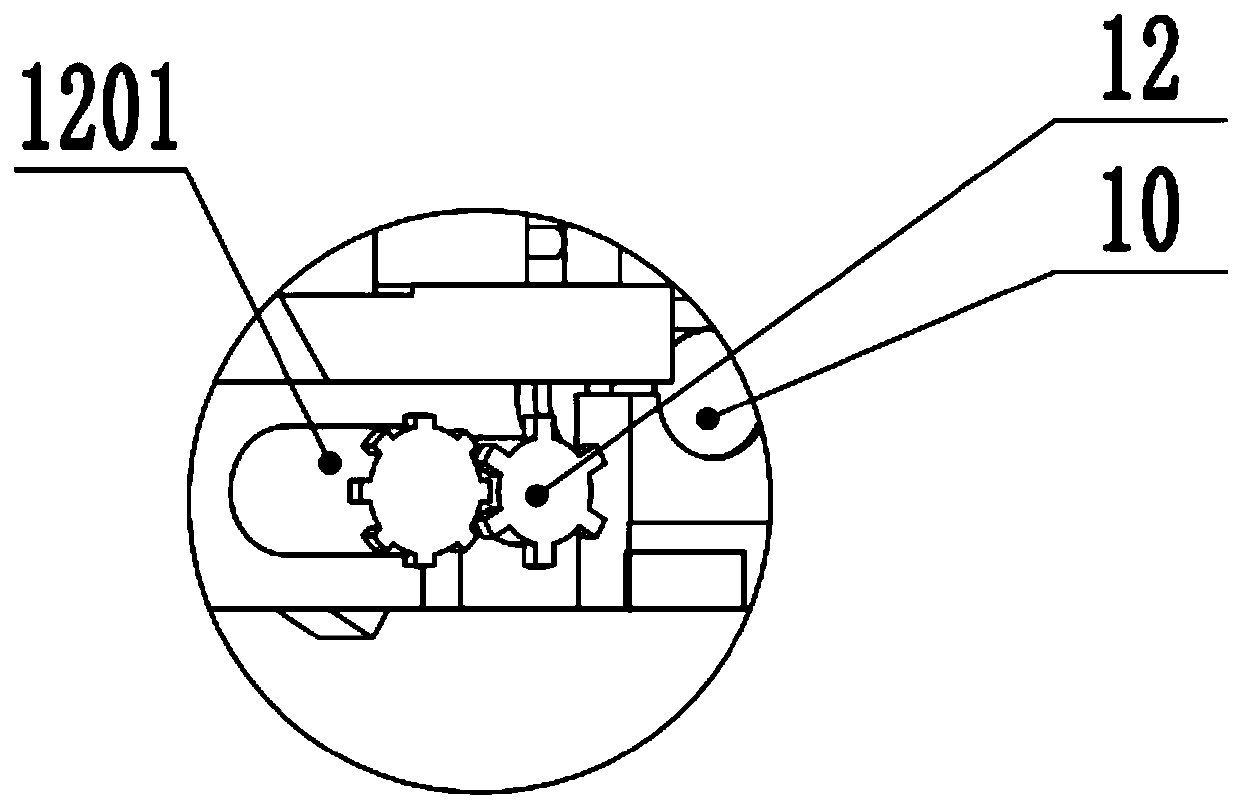

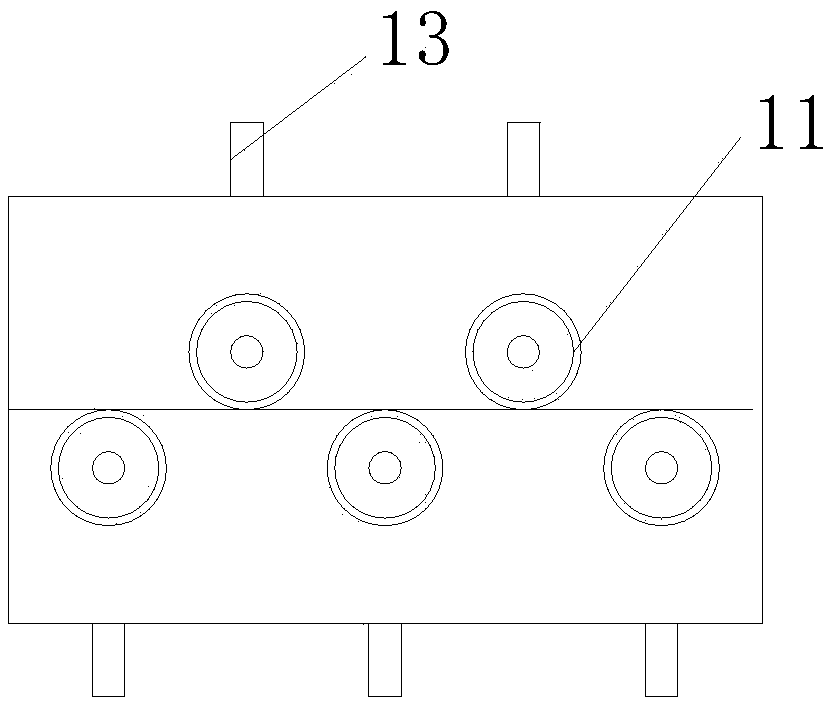

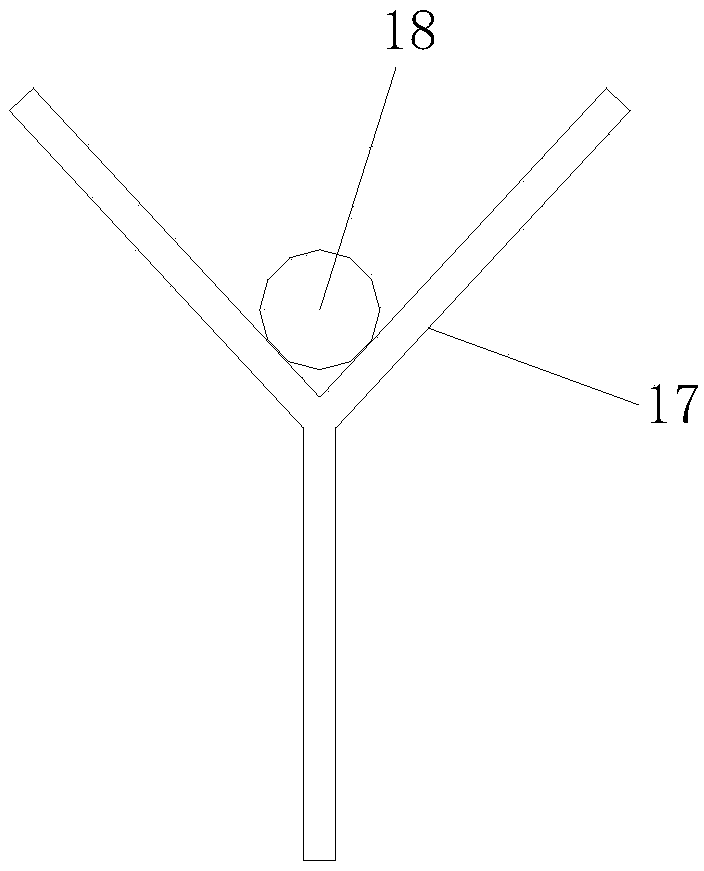

Fish feeding boat

ActiveCN109819924AAchieve labor intensityRealize multi-area feedingRotary propellersRotary stirring mixersPropellerEngineering

The invention discloses a fish feeding boat, and belongs to the field of fishery. The fish feeding boat is composed of a first motor, a stirring bucket, a boat outer shell, a propeller, a solar cell panel, a storage battery, an air pump, a controller, a feeding control device, a second motor, a feed put-in device and a third motor. The stirring bucket can contain various types of feed or medicines, the stirring shaft can evenly mix the feed and medicines, and the labor intensity of workers is well relieved; a feeding control plate can be moved left and right through an electromagnet and a spring, the feeding and stopping of the feed are realized, and the friction to the feeding control plate during moving can be relieved through a rolling body; a first cylinder moves to compress the feed,the compressed feed is located in a compression blocking hole, then a second cylinder moves, the compressed feed is projected to a far place with aid of the movement of a second piston rod, the compressed feed can enlarge the projection area, and multi-area feeding is realized.

Owner:山东同其数字技术有限公司

Metal wire drawing, shearing and bending integrated machine and machining process thereof

PendingCN109175151AIncrease productivityReduce labor intensityMetal working apparatusEngineeringMachining process

The invention belongs to the technical field of integrated machines and particularly relates to a metal wire drawing, shearing and bending integrated machine. The metal wire drawing, shearing and bending integrated machine comprises shearing equipment, drawing equipment and bending equipment which are installed on a frame in sequence, wherein the drawing equipment comprises a wire feeding structure, a positioning device, drawing devices and a rolling compaction straightening device, the drawing devices comprise the first drawing device and the second drawing device, and the first drawing device comprises a bottom plate, upper and lower two sets drawing idler wheel sets which are in misalignment arrangement and installed on the bottom plate and adjusting screw rods adjusting positions of drawing idler wheels correspondingly. By means of a machining process of the metal wire drawing, shearing and bending integrated machine disclosed by the invention, shearing, drawing and bending are integrated into a whole, full automation and integration are realized, straightening of metal wires is realized by integrating drawing deformation and plastic deformation, then the shearing and bending are performed on the metal wires through the shearing equipment and the bending equipment, the product qualified rate is high, and the technical benefits are obvious.

Owner:浙江步丹工贸有限公司

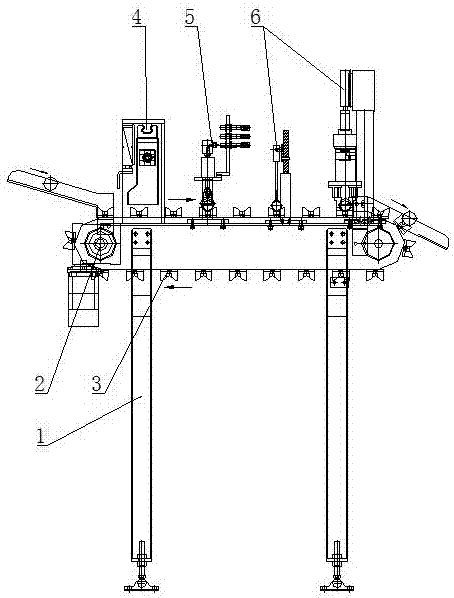

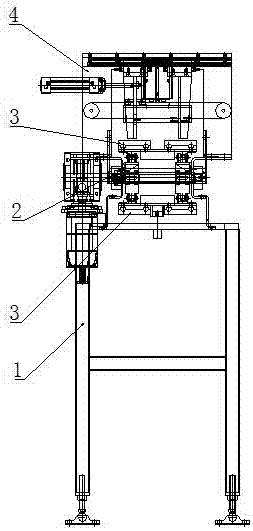

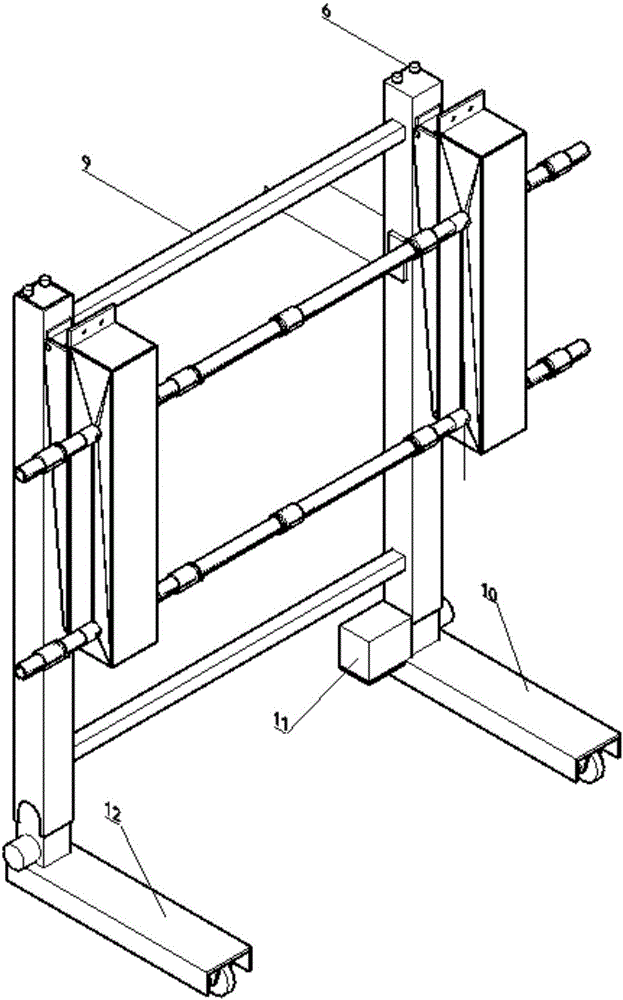

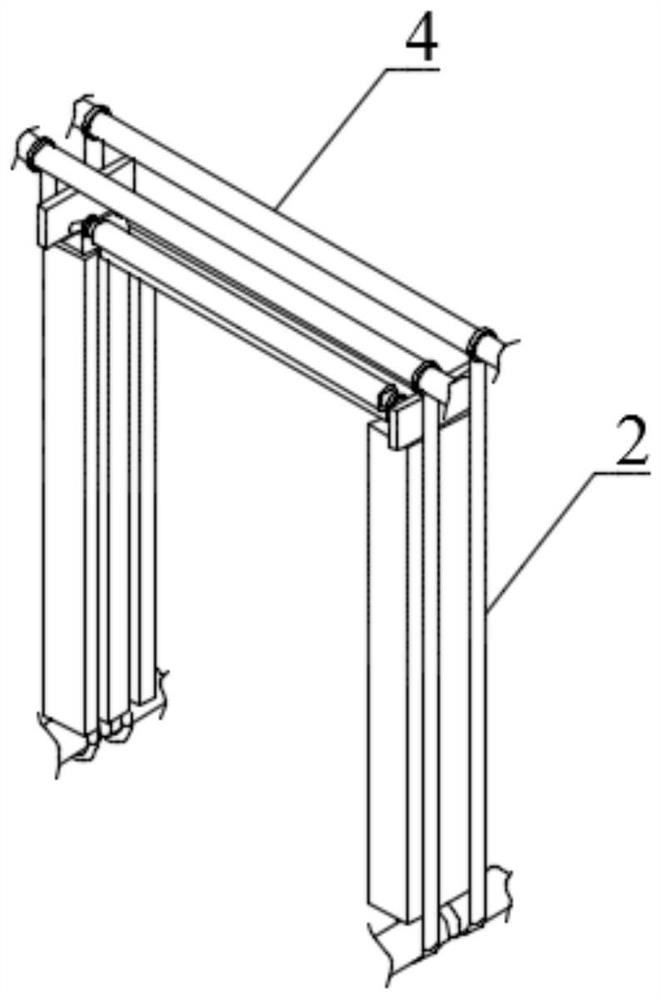

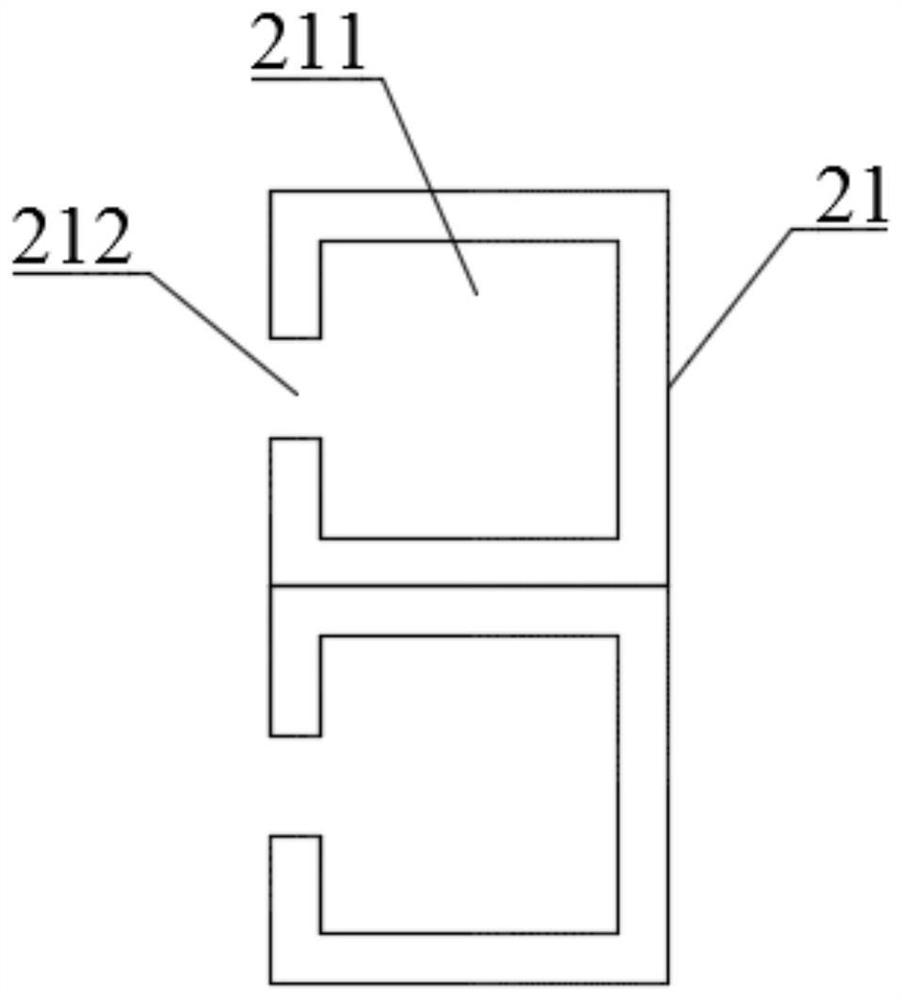

Multi-purpose mobile nursing rack

InactiveCN106038136AMeet different needsAchieve labor intensityNursing bedsAmbulance serviceNursing facilityEngineering

The invention provides a multi-purpose mobile nursing rack. The multi-purpose mobile nursing rack comprises a rack body composed of two support posts and a fixing cross beam arranged between the two support posts, wherein a support arm is hinged to the top of each support post, a power box and a driven box are arranged on the two support arms respectively, two hollow shafts are mounted between the power box and the driven box, a power box motor is mounted in the power box, a force transmission mechanism with two opposite output ends is further arranged in the power box, an input shaft of the force transmission mechanism is connected with the output end of the power box motor, two output shafts of the force transmission mechanism are respectively connected with the two hollow shafts, at least three groups of T-shaped clamp groove structures are arranged on each hollow shaft, each group of T-shaped clamp groove structure comprises a small groove and a large groove which are arranged on the hollow shaft and connected with each other, and a sealing ring arranged on the hollow shaft, the sealing ring is provided with an open slot with the shape the same as that of the large groove, and a nursing facility with a flexible belt is mounted in the corresponding T-shaped clamp groove structure through a T-shaped head arranged at the end part of the flexible belt. The multi-purpose mobile nursing rack is simple in structure, low in cost, and high in reliability.

Owner:王振琦 +2

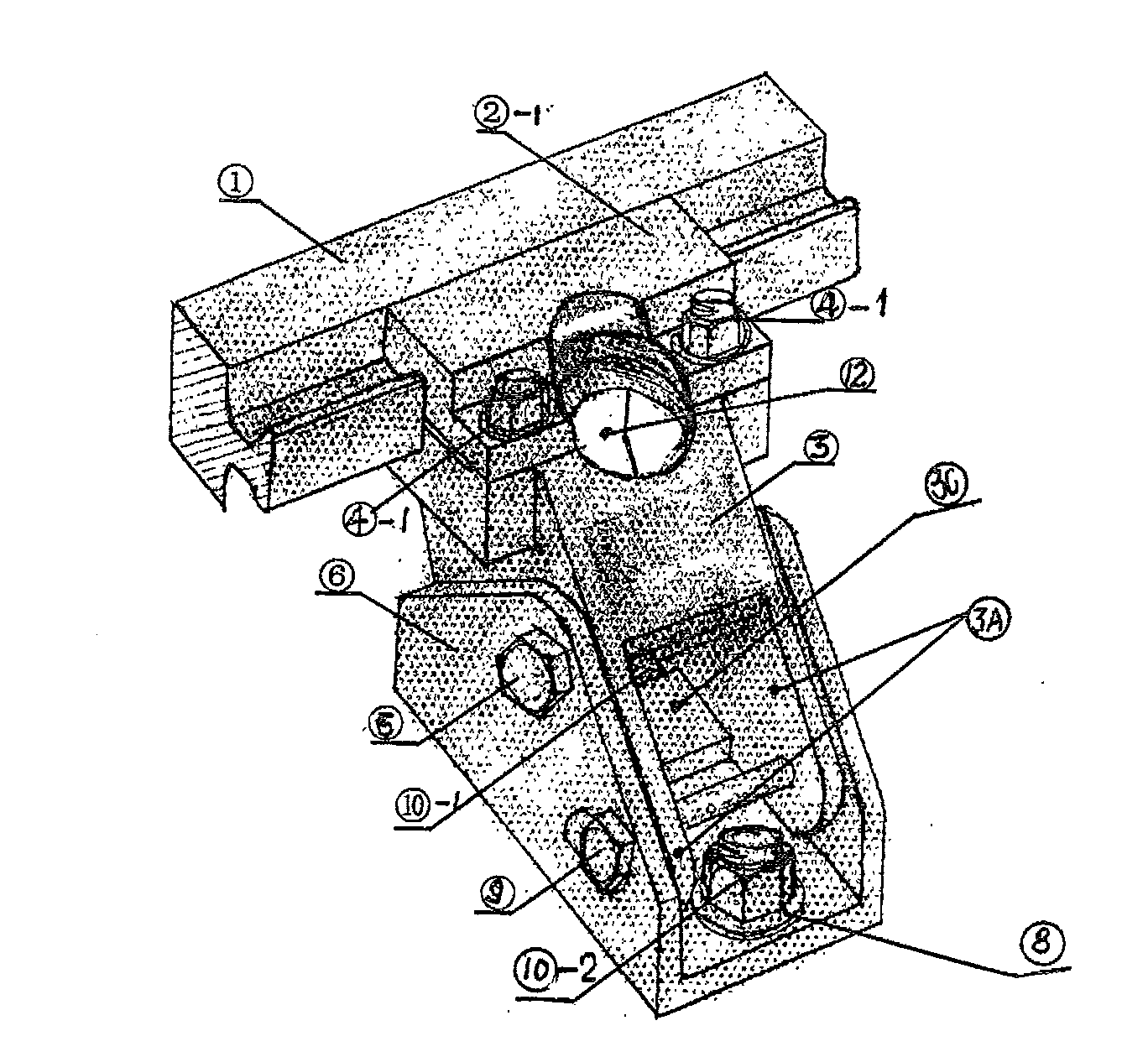

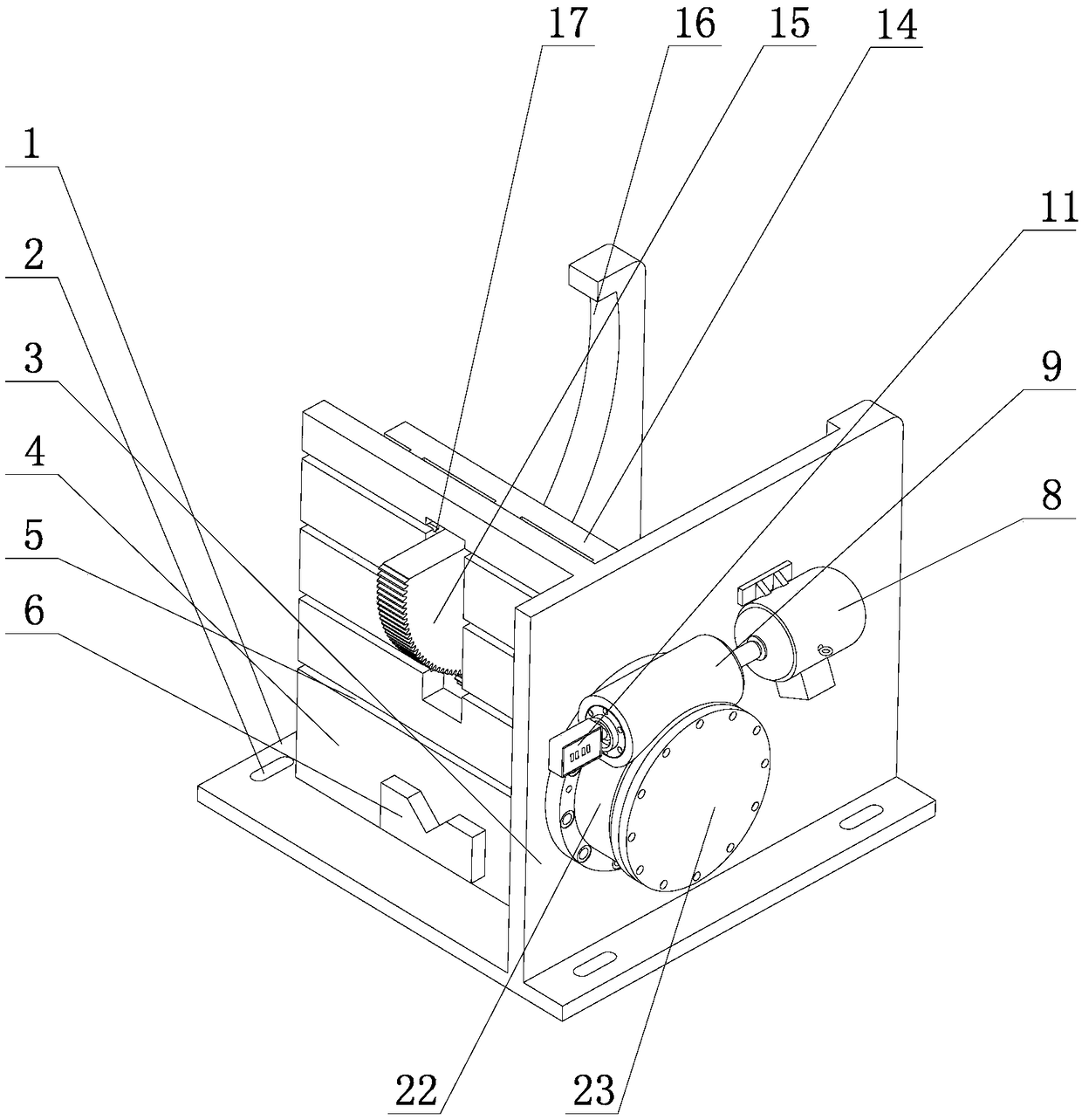

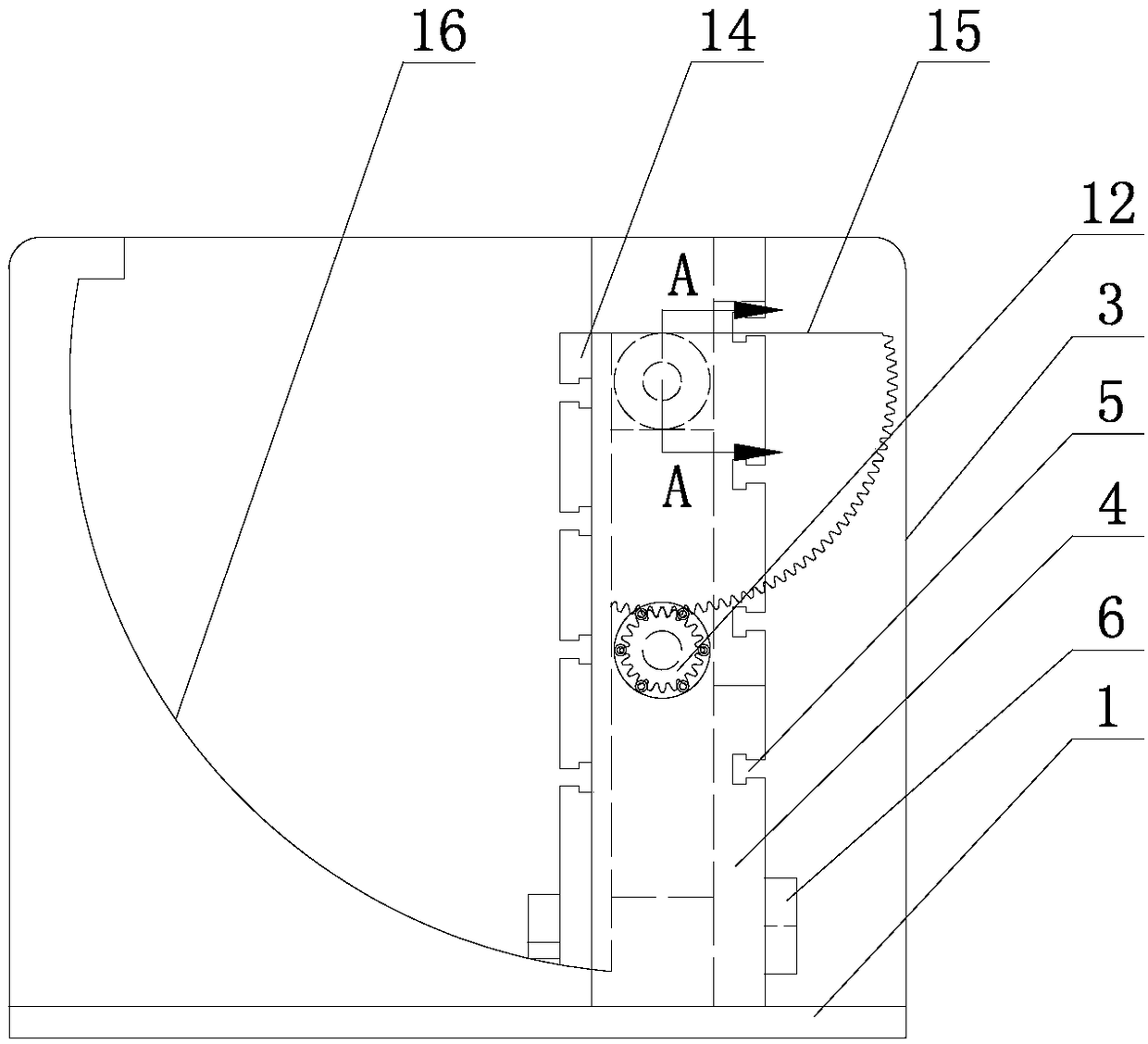

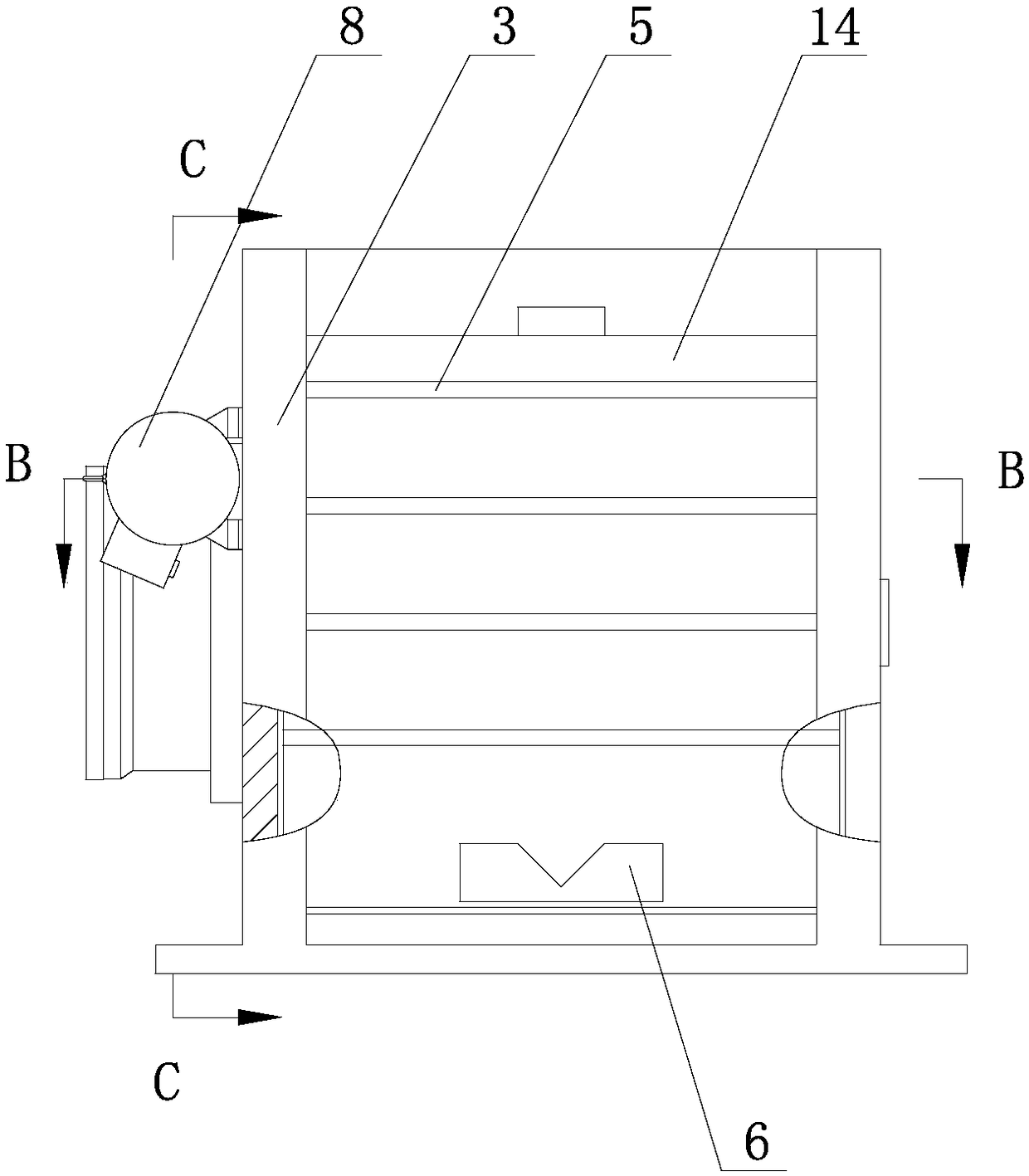

Mechanical bent-plate-type slope adjusting clamp and method

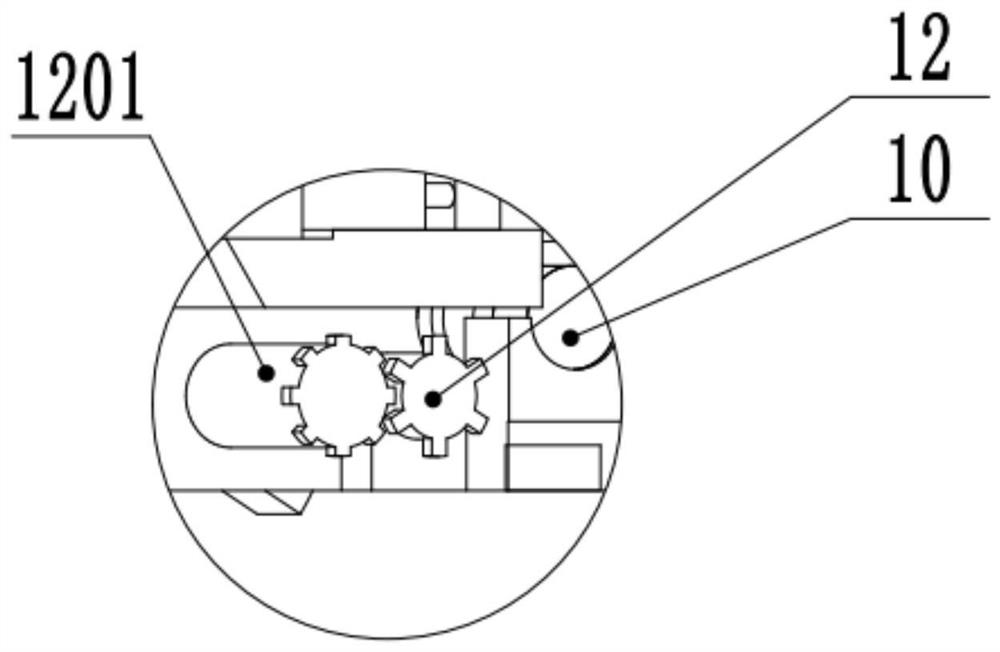

ActiveCN107745266AAchieve verticalImprove quality and efficiencyPositioning apparatusMetal-working holdersEngineeringGear wheel

The invention provides a mechanical bent-plate-type slope adjusting clamp and method. The mechanical bent-plate-type slope adjusting clamp comprises a clamp base, wherein a side vertical plate and a middle vertical plate are arranged on the clamp base; a plurality of T-shaped grooves are formed in the outer side surface of the middle vertical plate from top to bottom in a spacing manner; a V-shaped positioning block is arranged at the bottom of the middle vertical plate; two raised brackets are horizontally arranged on the inner side surface of the middle vertical plate in a spacing manner; aservo motor is arranged on the outer side surface of the side vertical plate and connected with a worm; the worm is connected with a worm gear; an angle displayer is arranged at the tail end of the worm; one end of a gear shaft is mounted on the worm gear; the other end of the gear shaft penetrates through the side vertical plate and is mounted on the clamp base; the raised brackets are in hingedconnection with a rotating table plate through a hinge shaft; a fan-shaped gear is arranged on the reverse side of the rotating table plate and in meshed connection with the gear shaft; the T-shaped grooves are formed in the obverse side of the rotating table plate from top to bottom; and the V-shaped positioning blocks are arranged at the bottom of the rotating table plate. The mechanical bent-plate-type slope adjusting clamp and method have the advantages that the structure is stable, the rigidity is high, the operation is simple, the labor intensity is reduced, the working efficiency is improved, and the clamped part slope adjusting and positioning precision is high.

Owner:荣成远海滑动轴承有限公司

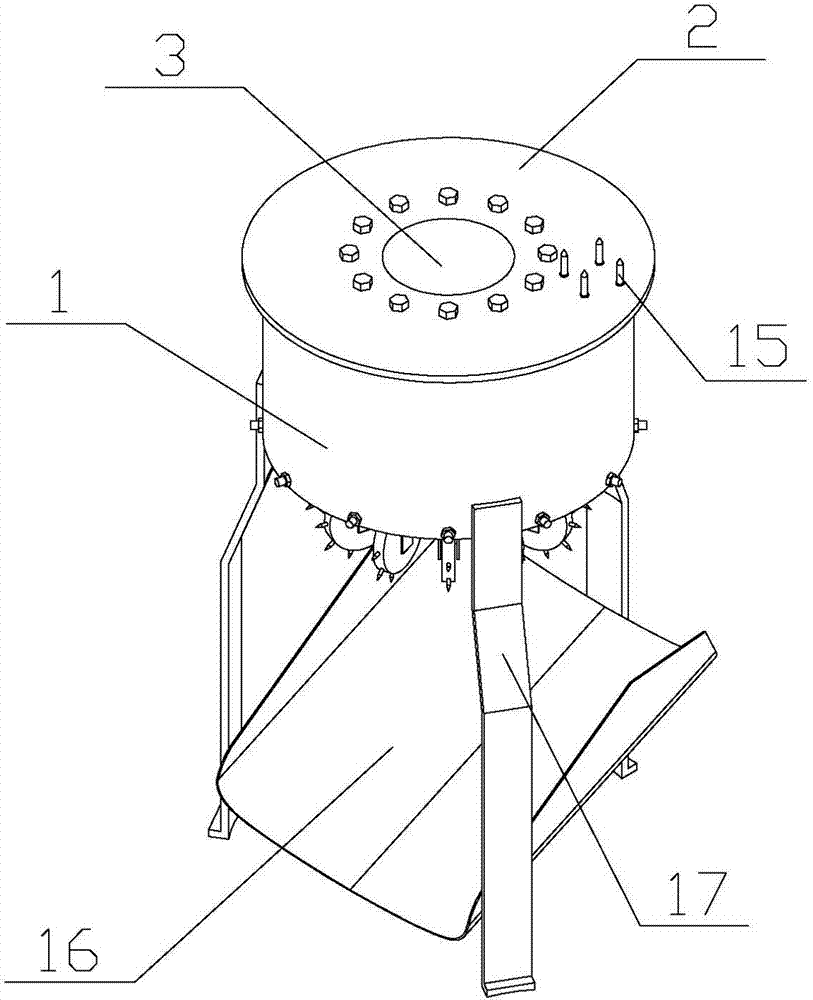

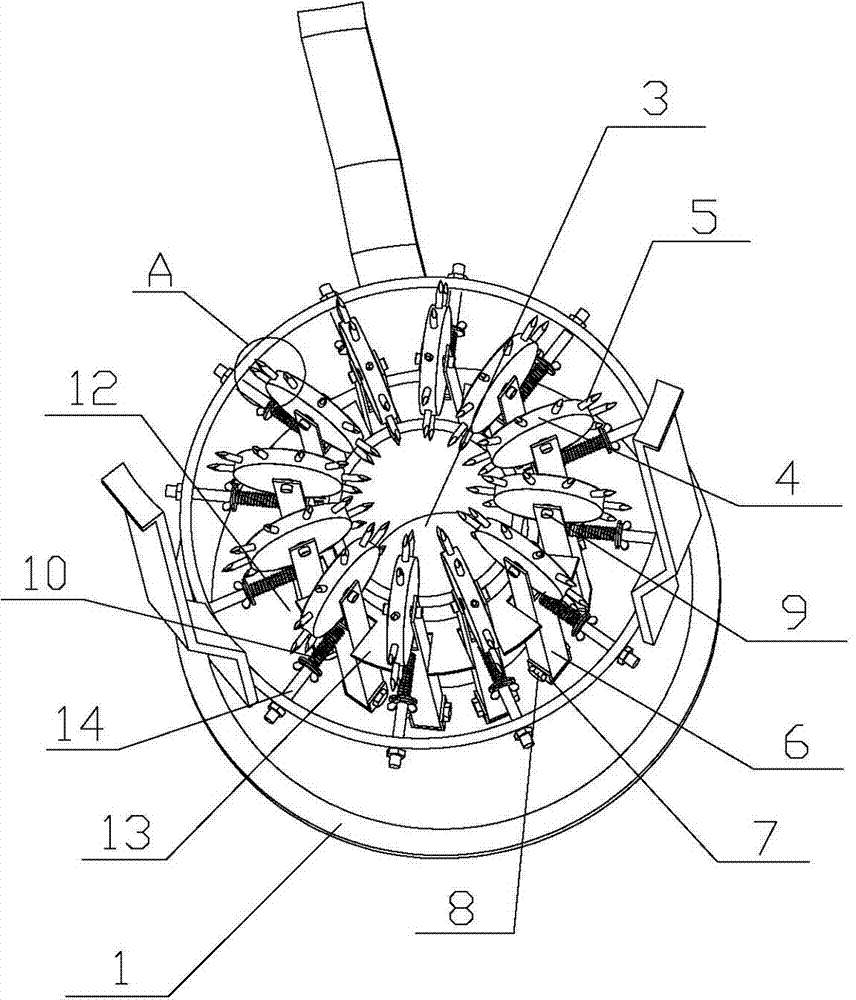

Bacteria stick quick perforating machine

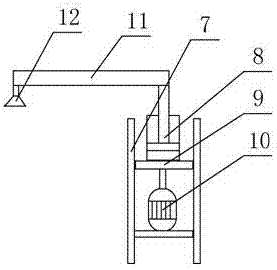

A bacteria stick quick perforating machine comprises a machine frame, wherein a circular table is arranged on the machine frame, a bacteria stick channel is formed in the circular table, piercing blocks are arranged at an outlet of the bacteria stick channel, stings are arranged on the piercing blocks, a support is arranged on the bottom face of the circular table, and the support is connected with the circular table through springs. The bacteria stick quick perforating machine has the advantages that the structure is reasonable, using is convenient, installing and maintaining are convenient, automation of bacteria stick perforating is achieved, work efficiency is improved, labor intensity of workers for perforating operation is lowered, production cost is lowered, perforated bacteria stick holes can be evenly distributed, mycelia in bacteria sticks can normally grow, yield of mushrooms can be improved, income of bacteria growers can be improved, accidental injuries of workers can not occur in the automatic bacteria stick perforating process, personal safety of the workers is protected, the using effect is good, and popularization is facilitated.

Owner:李明

Drilling and planting machine

The invention discloses a drilling and planting machine for drilling on mountains. The drilling and planting machine is arranged on an agricultural vehicle frame. According to the drilling and planting machine, a speed reducer drives a square-interior round-exterior tube penetrating a twist drill lifting frame to operate. The upper half of a twist drill penetrates an inner cavity of a feed screw nut, and ascends and descends during operation; the middle of the twist drill penetrates an inner cavity of the square-interior round-exterior tube, and is clamped by the square-interior round-exterior tube for operation; the lower portion of the twist drill is a spiral drill which can drill into soil to form a round pit, and seedlings are planted conveniently. The labor intensity of holding shovels to dig holes on hillsides to plant the seedlings is replaced by the machine.

Owner:刘清海

Novel stamping system suitable for oven

InactiveCN107486497ASimple structureReduce labor intensityMetal-working feeding devicesPositioning devicesProduction linePunching

The invention discloses a novel stamping system suitable for an oven. The forming press is connected to the stacker, and the stacking table and the punching press, and between the punching press and the forming press are respectively provided with The feeding manipulator, the turning table is placed on the side of the feeding manipulator, the rotating disk is located on the support, the rotating motor is located below the rotating disk and connected to it, and the lifting cylinder is fixed on the rotating and connected to one end of the mechanical arm, and the other end of the mechanical arm is provided with the suction cup. The invention realizes the automation of the stamping production line on the left side of the oven, the equipment is simple and easy to operate, reduces the labor intensity of workers, and is suitable for small and medium-sized stamping enterprises. Personal safety, and low cost of production transformation, has broad market prospects.

Owner:天津市斯佳琦机械有限责任公司

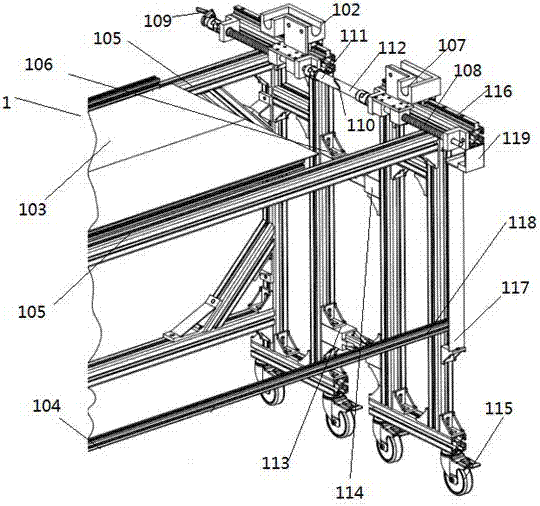

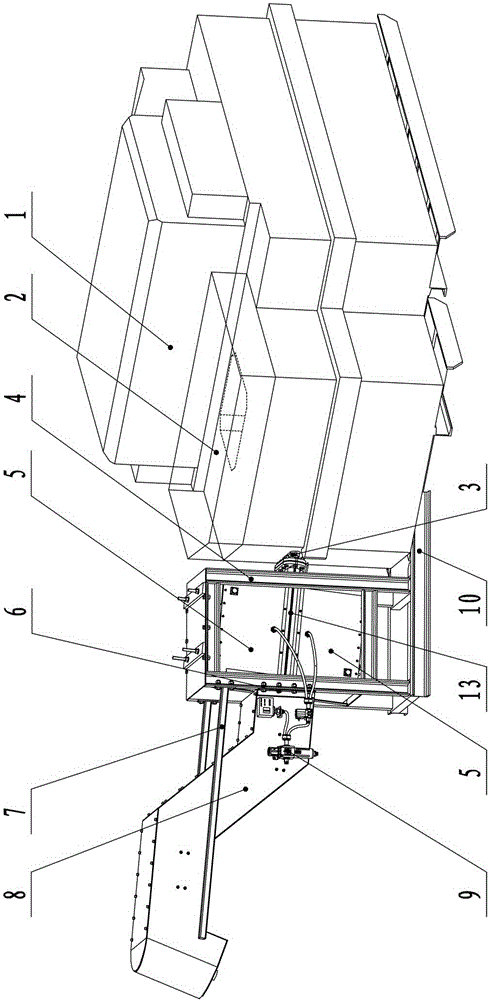

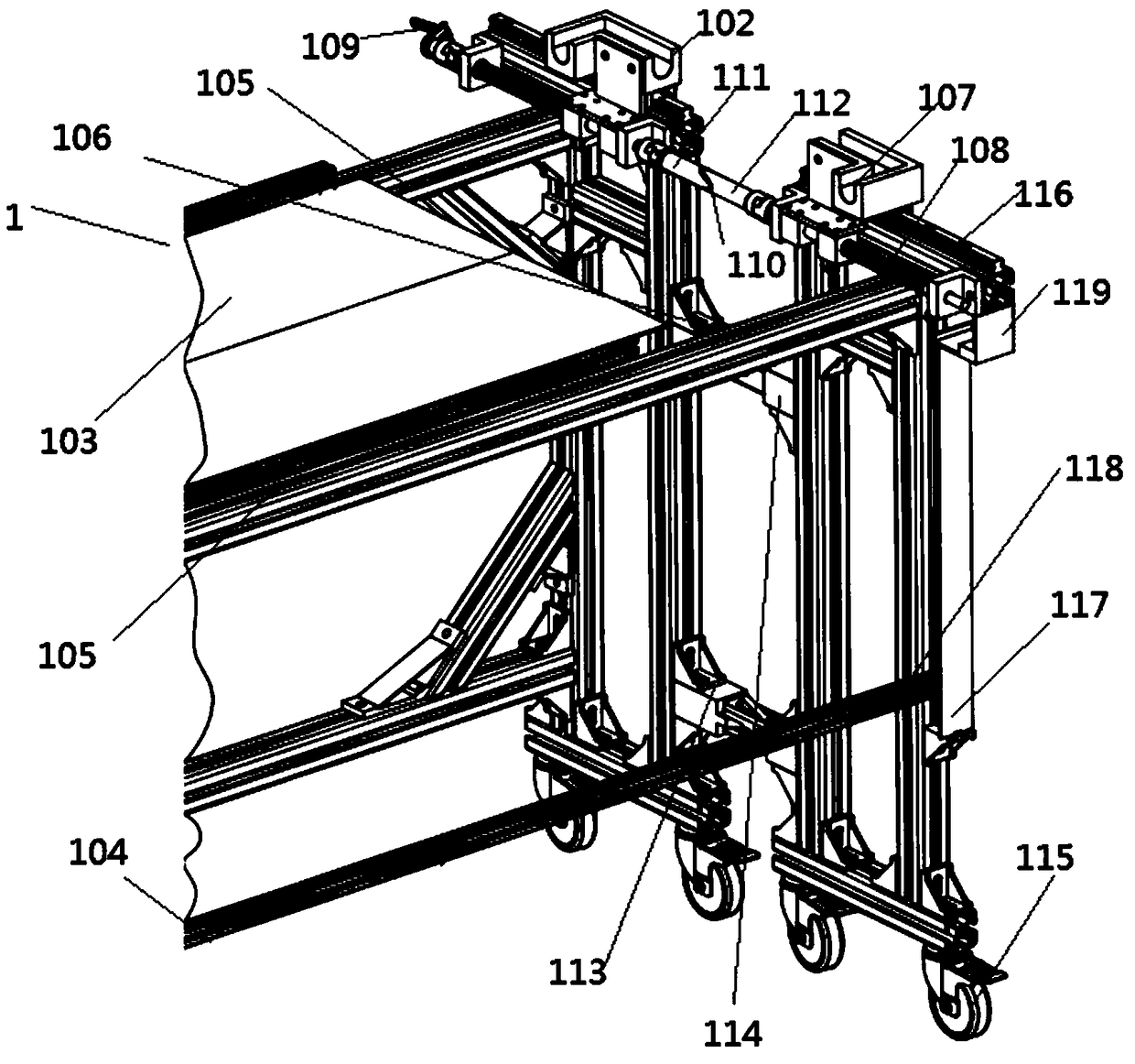

Stretcher cart for transfer of postoperative patient

The invention discloses a stretcher cart for transfer of a postoperative patient. The stretcher cart comprises a transfer cart (1) with a telescopic-rotary stretcher (2). The transfer cart (1) comprises a cart frame (101), the upper end of which is provided with a slideway locking unit (102) and a canvas folding unit (103). The lower end of the cart frame (101) is provided with movable wheels (115). The side surface of the cart frame (101) is provided with a mobile rod moving unit (104). The telescopic-rotary stretcher (2) comprises a frame (201) matching the slideway locking unit (102). Two ends of the frame (201) are provided with frame clutch units (202). The frame (201) is internally provided with a hip plate (203) and a push board telescopic-rotary unit (204). The frame (201) is further provided with a frame telescopic unit (205). The stretcher cart for transfer of a postoperative patient has the following beneficial effects: carrying efficiency is increased; labor intensity of medical staff is reduced; carrying stability and reliability are improved; and the impact on patients is lessened.

Owner:WENZHOU UNIVERSITY

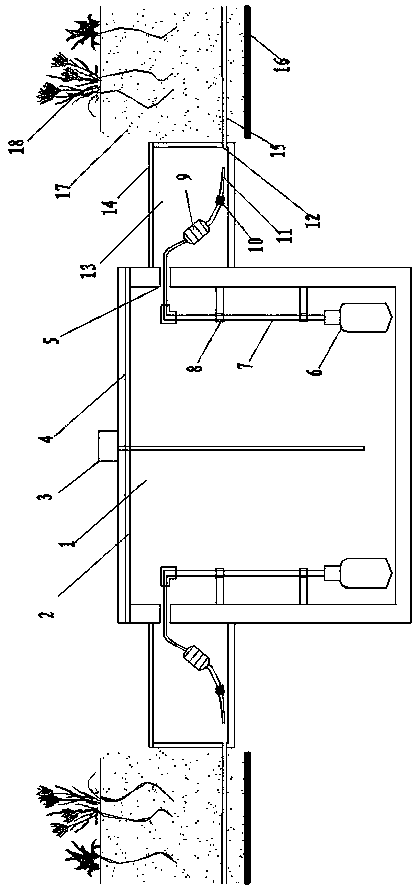

Irrigation system and method of road green belts in arid and semi-arid regions

The invention relates to an irrigation system and method of road green belts in arid and semi-arid regions. The system comprises a water storage pond and two irrigation ponds which are respectively located on the two sides of the water storage pond; a filtering net arranged horizontally is arranged at the upper part of the water storage pond; a liquid level sensor is arranged in the water storagepond; the water storage pond is located below the irrigation pond; a siphon is arranged between the water storage pond and the irrigation pond; a water permeable pipe is arranged above the irrigationpond in the running direction of the road; a waterproof separation layer is arranged below the water permeable pipe; and the upper part of the water-proof layer is provided with planting soil. According to the system and method disclosed by the invention, the construction cost is low, the use and the later maintenance are convenient, the labor cost is saved, and the feasibility is high.

Owner:王一达

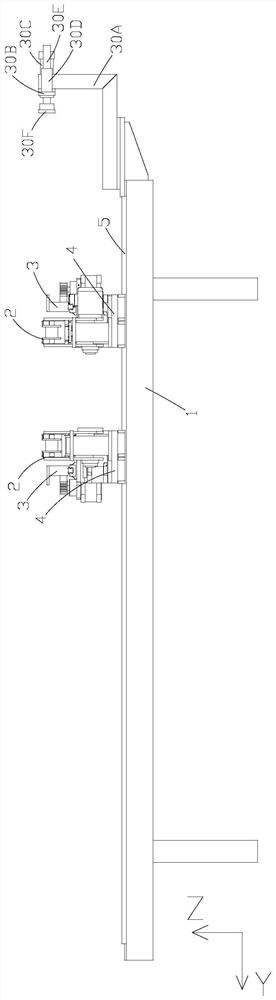

Feeding mechanism of heat exchanger bending machine and bending machine applying feeding mechanism

PendingCN112547866ASmall footprintReduce frictionMetal-working feeding devicesHeat exchange apparatusPhysicsEngineering

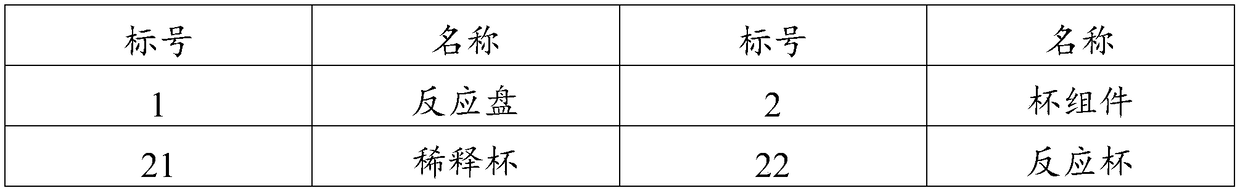

The invention discloses a feeding mechanism of a heat exchanger bending machine and the bending machine applying the feeding mechanism. The feeding mechanism comprises a feeding rack, wherein a conveying unit is arranged on the feeding rack, and comprises a conveying assembly and a carrying assembly; the conveying assembly is used for bearing and conveying workpieces; the carrying assembly is located on one side of the conveying assembly and used for bearing a workpiece to be bent on the conveying assembly and carrying the workpiece to a bending station or taking out the bent workpiece from the bending station and carrying the bent workpiece onto the conveying assembly; and the feeding mechanism can achieve feeding conveying of the workpiece to be bent and taking-out conveying of the bentworkpiece, so that the workpiece can be carried without other carrying devices after being bent, the whole mechanism of the bending machine is more compact, the occupied space of the bending machine is reduced, the feeding mode is simple and convenient, friction force borne by the workpiece in the conveying process is reduced, surface scratches are reduced, the bent workpiece is ensured to be evenly stressed in the conveying process, and the yield is increased.

Owner:OMS MASCH CO LTD

Detecting analyzer and using method thereof

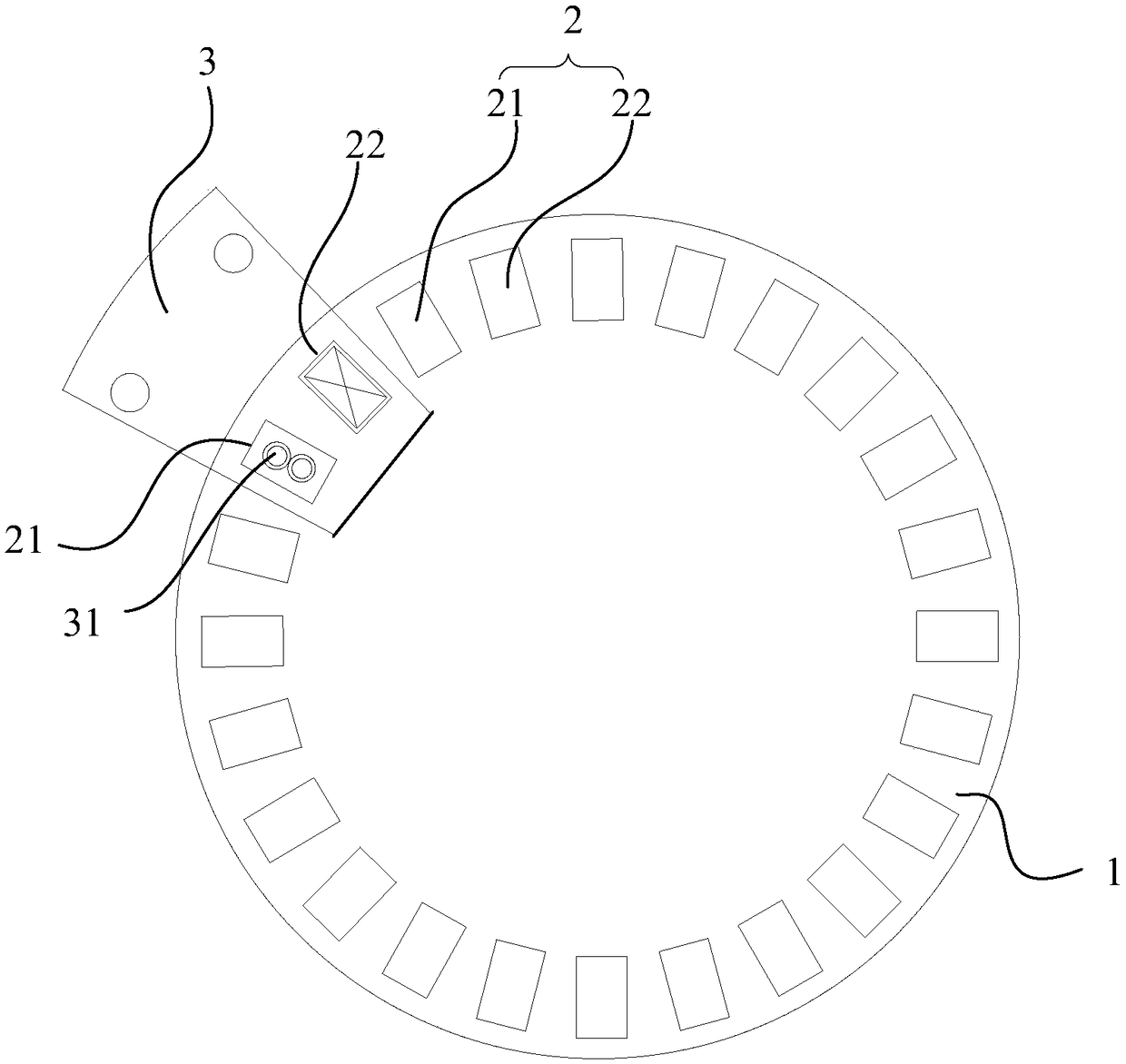

The invention discloses a detecting analyzer and a using method thereof. The detecting analyzer is used for analyzing and detecting in-vitro samples, and comprises a reaction plate, a cup assembly andan automatic cleaning mechanism; the cup assembly is arranged on the reaction plate; the cup assembly consists of a diluting cup and a reaction cup which are spaced from each other adjacently; the reaction plate is rotatable, and is provided with a detecting position for detecting the in-vitro samples and a cleaning position for cleaning the cup assembly; the cup assembly can move to the cleaningposition from the detecting position along with rotation of the reaction plate; and the automatic cleaning mechanism is adjacent to the reaction plate, and is used for thoroughly cleaning the diluting cup and the reaction cup which are located at the cleaning position. By the technical scheme, the types of consumables can be reduced, the labor intensity of operators is reduced, and the instrumenttesting speed is increased.

Owner:SHENZHEN GOLDSITE DIAGNOSTICS

Full-tailing damming method of damming machine

The invention provides a full-tailing damming method of a damming machine, and relates to the technical field of mine tailing pond damming processes. The method comprises the following steps: digging a dam slope drainage ditch; a leakage-proof layer is laid, and a film bag is placed on the leakage-proof layer; a construction platform is built, an ore pulp conveyor and a damming machine are driven to the construction platform and communicated with a pulp discharge pipe, the ore pulp conveyor and the damming machine, and a wake flow pulp discharge pipe of the damming machine is communicated with a material injection opening of the film bag; the damming machine advances on the construction platform in the damming direction for damming, the dry ore sand is used for damming after the damming machine rotates, the high-water-content fine ore mortar is injected into the film bag from the injection port, and the damming machine retreats to the heightened construction platform after damming is conducted to the specified length; and after the first layer is built, a second layer of film bags are laid on the original film bags, and the steps are repeated till the pre-built dam body reaches the designed height. By the adoption of the method, local materials can be used, full tailing sand is reasonably used for damming, the damming efficiency is improved, the damming construction period is shortened, the damming cost is reduced, and meanwhile zero emission of tailing slurry is achieved.

Owner:吉林省华冶环境治理有限公司

Railway sewage suction truck side suction working device and operation method thereof

PendingCN111042044ASolve storage problemsAchieve storageRailway cleaningAgricultural engineeringDust control

The invention discloses a railway sewage suction truck side suction working device which comprises a dust removal system, the outer side of the dust removal system is connected with a sweeping and sucking device (14) through a suction pipe (8); the sweeping and sucking device comprises a rotary supporting box body (27) connected to the tail end of a sucking pipe (8); a rotary support driving motor(30) is arranged on the rotary supporting box body (27); the rotary support driving motor (30) is used for driving the rotary supporting box body (27) to rotate to a required operation position; a side suction device cover body (29) is further connected to the lower portion of the rotary supporting box body (27), a motor (26) is arranged above the side suction device cover body (29), a rolling brush (25) is arranged below the side suction device cover body (29), and the upper portion of the rotary supporting box body (27) is communicated with the suction pipe (8). According to the technical scheme, operators can be greatly reduced, the manual labor intensity is reduced, and the health level of the operators is improved.

Owner:CRCC HIGH TECH EQUIP CORP LTD

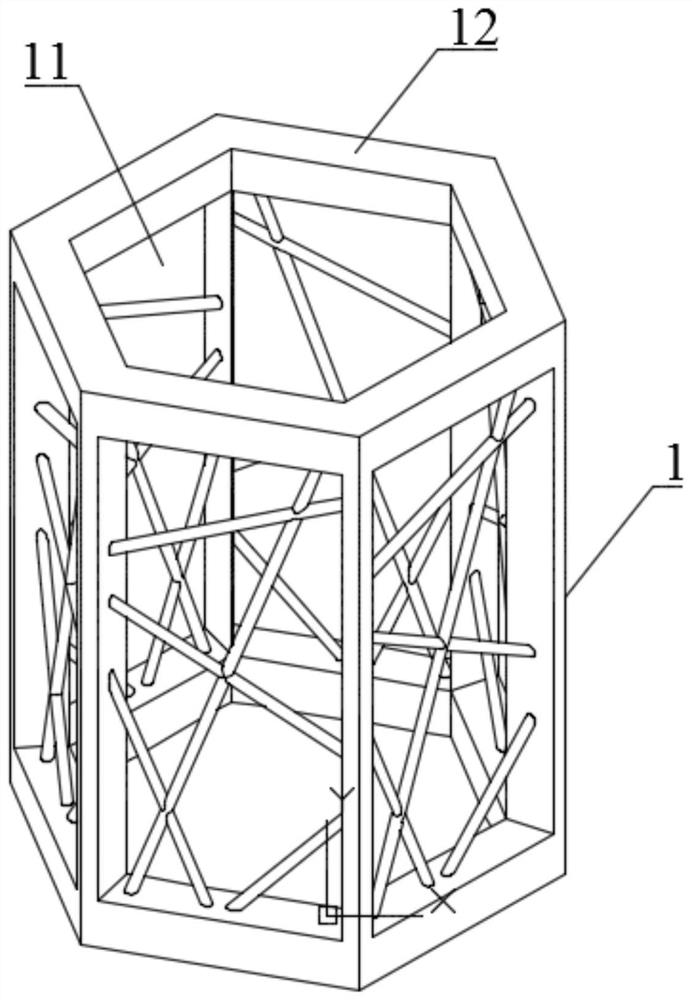

Deepwater net cage capable of quickly replacing netting gear

PendingCN112167136AEasy to replaceReduce unit weightClimate change adaptationPisciculture and aquariaMarine engineeringStructural engineering

The invention discloses a deepwater net cage capable of quickly replacing a netting gear. The net cage comprises a net cage framework, mounting assemblies, netting assemblies and winding devices, thenet cage framework forms an internal culture space, and the bottom netting gear is fixedly arranged at the bottom of the net cage framework; a plurality of sets of mounting assemblies are tightly arranged on the net cage framework along the outer edge of the internal culture space; each mounting assembly is provided with at least two pairs of sliding supports, and each pair of sliding supports isconnected with the corresponding netting assembly in a sliding manner; and at least one winding device is arranged at the corresponding position of each mounting assembly, and each winding device is detachably connected with the netting assembly in the corresponding mounting assembly so as to drive the netting assembly to be wound. The labor intensity of netting gear replacement and netting gear carrying can be reduced, netting gear replacement is facilitated, the large-scale net cage is achieved, and therefore the problem of existing netting gear replacement is solved.

Owner:黄芳

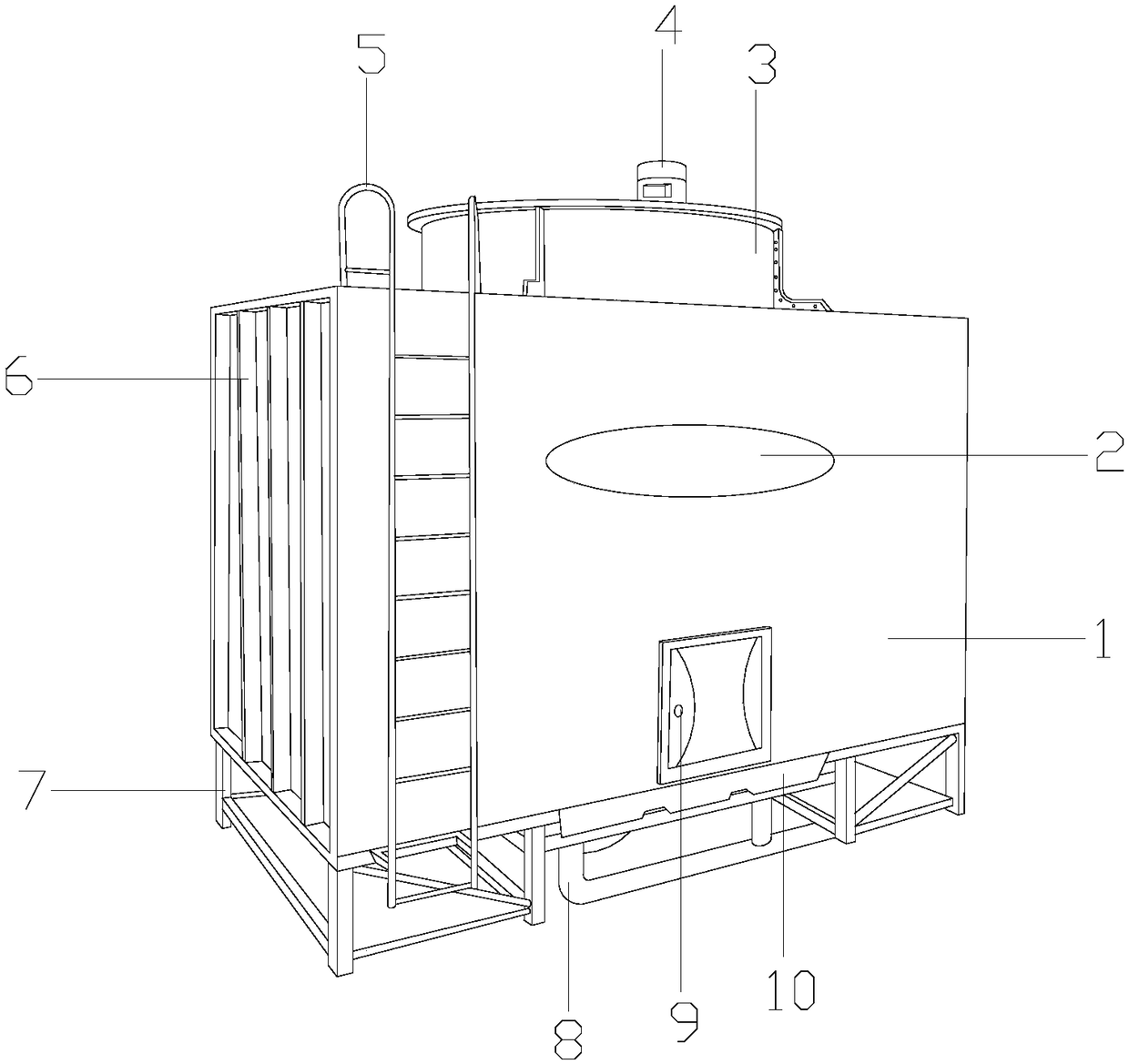

High-efficiency cooling equipment for metallurgy

InactiveCN108444208AImprove cooling efficiencyStrong cooling abilityDomestic cooling apparatusLighting and heating apparatusWater pipeArchitectural engineering

The invention discloses high-efficiency cooling equipment for metallurgy. The high-efficiency cooling equipment for metallurgy structurally comprises a high-efficiency cooling mechanism, a LOGO, an air feeder, a motor, an escalator, an air inlet window, more than two fixed column feet, a main water pipe, an access door and a water collecting sump, wherein the more than two fixed column feet are respectively welded at the four corners of the bottom of the high-efficiency cooling mechanism; the air inlet window is fixedly fastened at the left side of the high-efficiency cooling mechanism and isfixedly connected through locating pins; and the escalator is fixedly welded at the front end of the high-efficiency cooling mechanism and is reinforced and connected by bolts. The high-efficiency cooling equipment for metallurgy has the beneficial effects that the lifting operation of L-shaped lifting plates on a metallurgical body is realized through the matching of a sliding block and a slidingrail; meanwhile, the high-efficiency cooling equipment for metallurgy begins working by starting a lifting cylinder; the height of main temperature reduction sliding mechanisms can be adjusted in real time; the high-efficiency cooling equipment for metallurgy has a stroke limit function on the metallurgical body, ensures the left and right movement of the metallurgical body for work, realizes omnibearing temperature reduction so as to enbale operation to be relatively convenient and can reduce labor intensity.

Owner:黄乞珠

A liquid aluminum alloy electromagnetic conveying equipment

ActiveCN103900386BPrevent oxidationReduce heat lossCharge manipulationMolten metal conveying equipmentsLiquid stateAir cooling system

The invention relates to a liquid-state aluminum alloy electromagnetic conveying device which is composed of a molten aluminum heat-maintaining furnace part and a molten aluminum conveying part. The molten aluminum heat-maintaining furnace part comprises a heat-maintaining furnace and a heat-maintaining furnace cover, and a furnace side opening is formed in one side of the heat-maintaining furnace; the molten aluminum conveying part comprises a flat pump groove connected with the furnace side opening, a conveying pipe connected with the flat pump groove, an electromagnetic pushing device arranged at the section, where the flat pump groove is formed, of the conveying pipe and an air cooling system; the electromagnetic pushing device comprises two electromagnetic pump bodies, traveling wave magnetic fields are generated by magnet yokes, iron cores and coils, the magnet yokes, the iron cores and the coils are arranged in the electromagnetic pump bodies, and the traveling wave magnetic fields are interacted with induced currents excited by the traveling wave magnetic fields in molten aluminum in the flat pump groove to generate electromagnetic pushing force to push the molten aluminum in the flat pump groove to flow; a magnetic gap between the two electromagnetic pump bodies can be adjusted. By means of the liquid-state aluminum alloy electromagnetic conveying device, the heat-maintaining furnace is sealed by the heat-maintaining furnace cover, and molten aluminum alloy is conveyed through the sealed conveying pipe; meanwhile, the molten aluminum alloy is processed by the electromagnetic fields in the conveying process, and the automation level, the production efficiency and the casting quality are improved.

Owner:TSINGHUA UNIV +1

A kind of multifunctional wood processing equipment

ActiveCN104890063BMove fastReduce resistance to movementMulti-purpose machinesBark-zones/chip/dust/waste removalWood machiningMechanical engineering

The invention discloses multifunctional wood machining equipment and belongs to the field of wood machining equipment. A running vehicle comprises a movement and driving devices moving along X-axis direction, Y-axis direction and Z-axis direction, at least two rotating spindles taking vertical direction as axis are arranged at the front end of the movement, a knife is arranged at the lower end of each spindle, and multiple rows of blades are arranged around each knife, distances between the blades on different spindles and cut wood are difference, the spindles are rotatably connected with a motor respectively, multiple top discs different in diameter are arranged on a top tip seat and a top tip of a tail seat, a rolling device along the X-axis direction is arranged on the lower portion of the tail seat, and a control panel is arranged on the multifunctional wood machining equipment. By the multifunctional wood machining equipment, production efficiency can be improved, labor intensity of operating personnel can be lowered, machining diameter can be expanded, machining variety can be increased, and sales market can be expanded.

Owner:安阳市涵缘机械设备有限公司

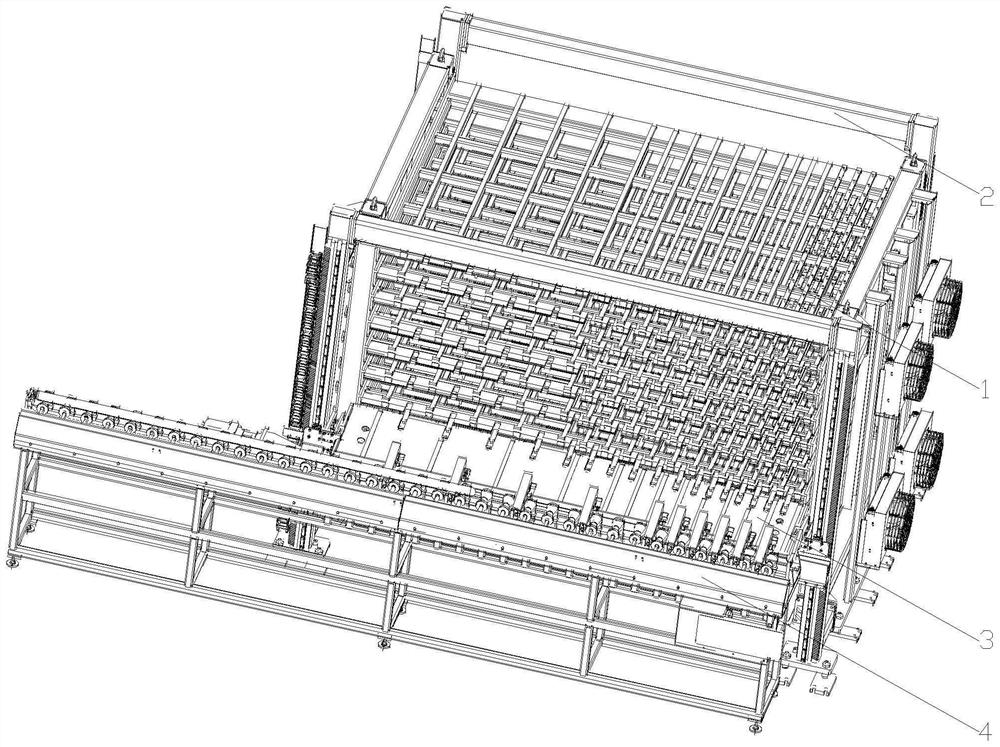

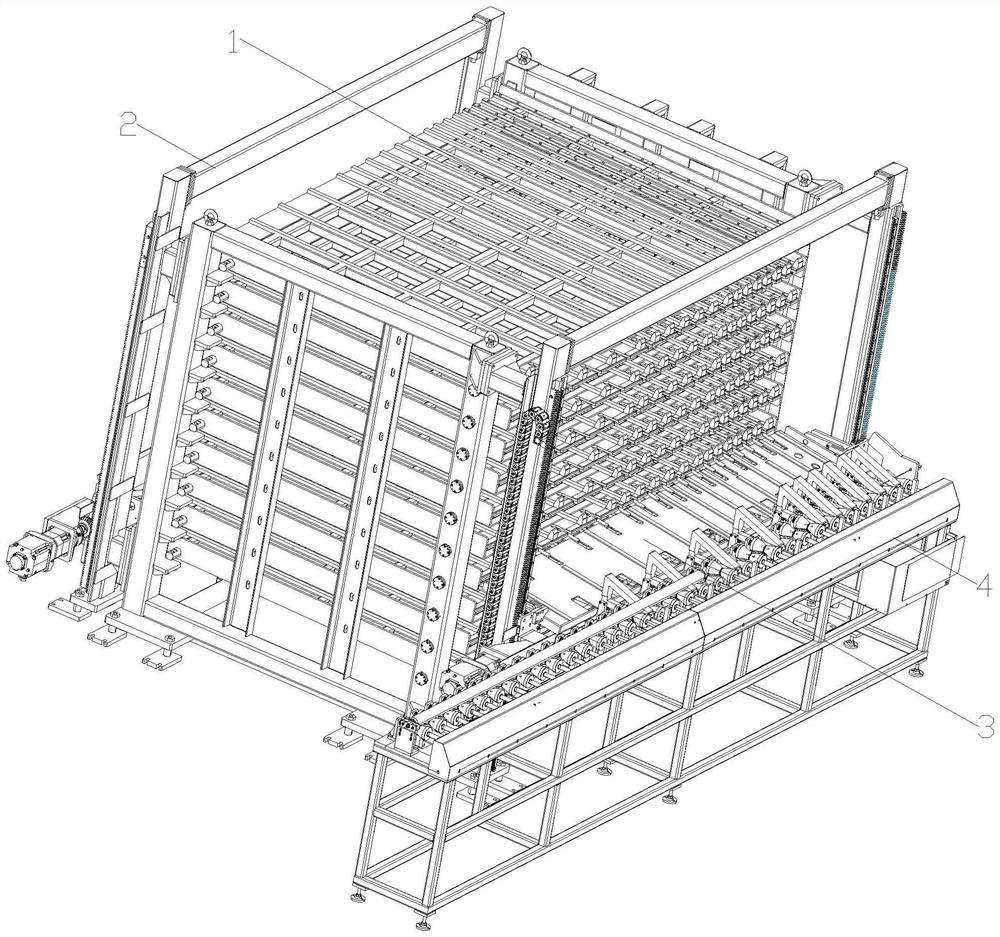

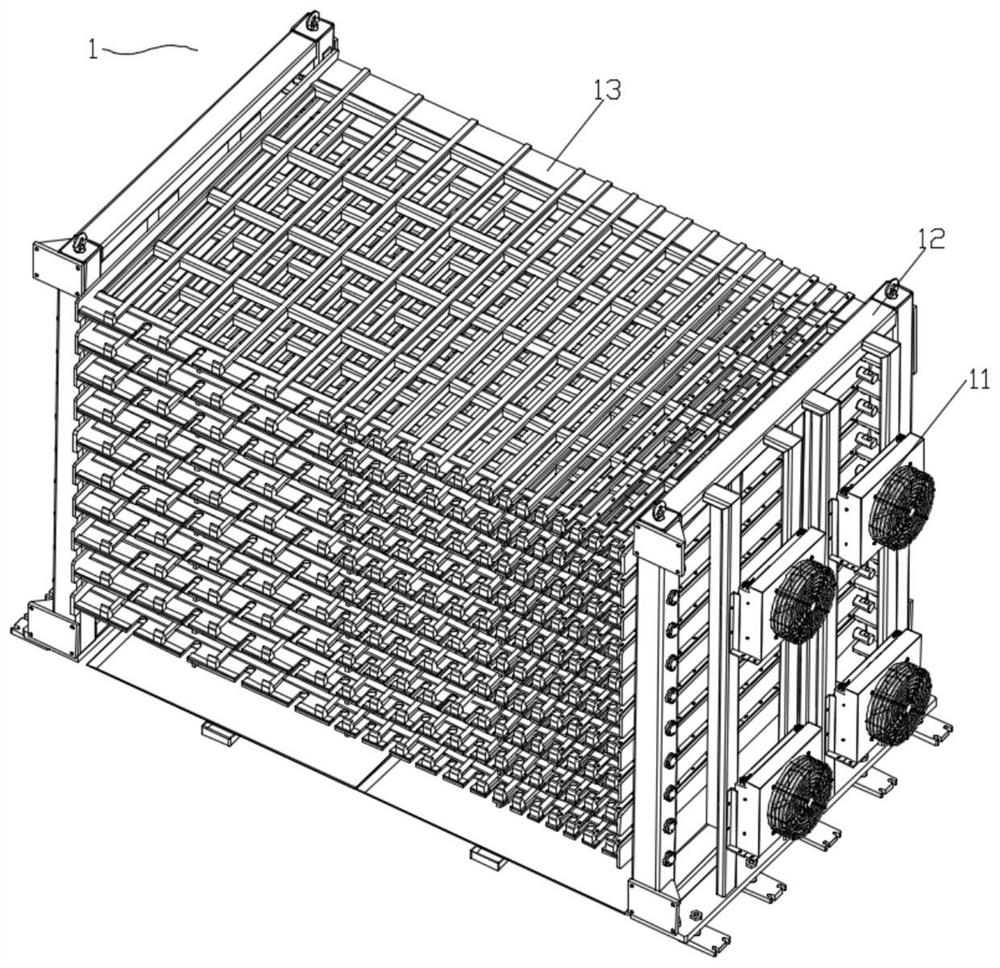

Full-automatic buffering feeding and discharging device for header long pipe and bent pipe

The full-automatic buffering feeding and discharging device comprises a buffering frame used for stacking and placing pipe joints, the buffering frame comprises two supporting frames, a plurality of material storage partition plates and a plurality of draught fans used for accelerating cooling of the pipe joints, and the two supporting frames are arranged in the left-right direction; the multiple material storage partition plates are obliquely arranged between the two supporting frames, the multiple material storage partition plates are arranged in the vertical direction, and the multiple draught fans are installed on the same supporting frame; the device further comprises a feeding mechanism used for conveying the pipe joints to the temporary storage frame and a discharging mechanism used for taking the pipe joints out of the temporary storage frame, the feeding mechanism is arranged on the rear side of the temporary storage frame, and the discharging mechanism is arranged on the front side of the temporary storage frame. In this way, the pipe joints are temporarily stored on the material storage partition plates of the three-dimensional temporary storage frame, air cooling is conducted on the pipe joints through the draught fan, and the cooling rate of the pipe joints is increased; automatic storing and taking of the pipe joints are achieved through the feeding mechanism and the discharging mechanism, and the circulation efficiency of the pipe joints is improved.

Owner:ZHEJIANG KING MAZON MACHINERY +1

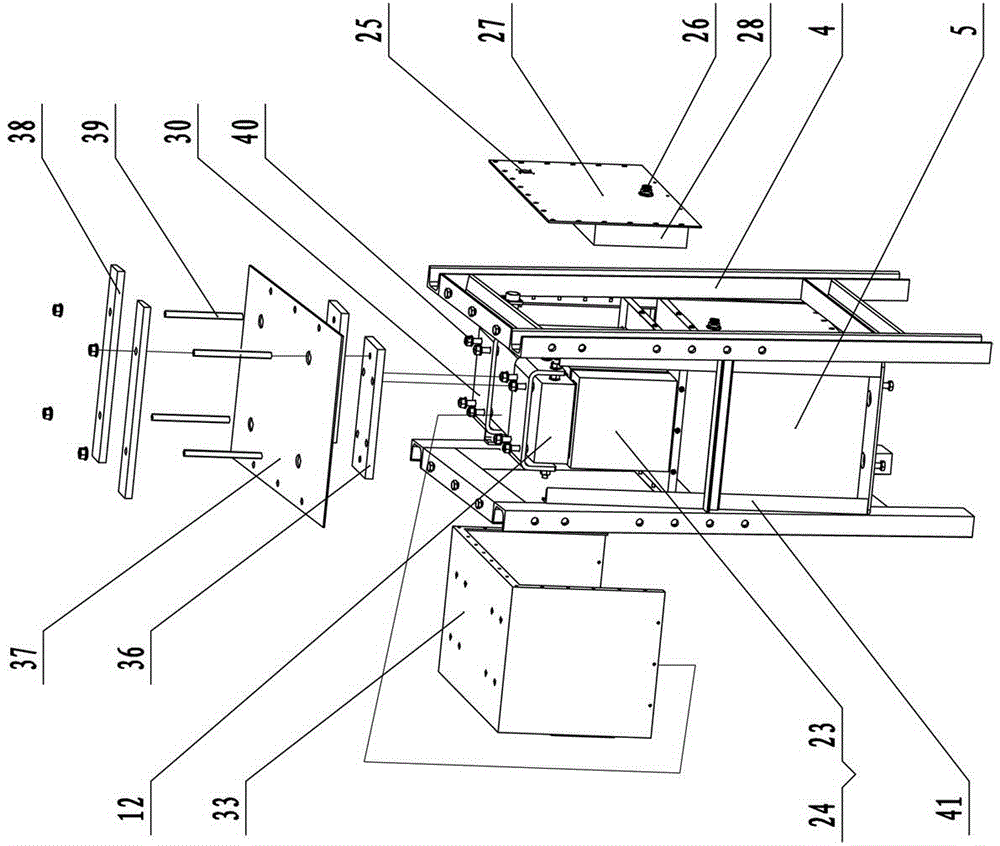

A multifunctional load simulation test bench

InactiveCN103558050BSimple structureReasonable designStructural/machines measurementRolling-element bearingEngineering

A multifunctional load stimulation test stand comprises a base, a load steering engine, a load steering engine fixing lug base, a load steering engine front-and-back position adjusting wedge block, a load steering engine left-and-right position adjusting block, a pull pressure sensor, a connecting flange, a load steering lug ring shaft, a middle inertia block, a measured steering engine output shaft, a measured steering engine, a measured steering engine installing plate, a rack, a gear, a gear shaft, a gear shaft support, a rolling bearing, a middle bracket, an inertia disc, an anti-rotation cross, a threaded end cap, a lateral force prevention guide wheel, a load steering engine output shaft, an adaptor, a dowel, a guide wheel baffle, a gear shaft support bearing, a load steering engine left-and-right position adjusting screw and a measured steering engine lug ring shaft. By the adoption of the test stand, the performance of the measured steering engine is accurately and reliably tested through the simplest structure and operation most convenient to conduct and at lowest using cost. The multifunctional load stimulation test stand has the advantages of being convenient to demount and mount and high in universality of an installing conversion structure, and can also be suitable for other equipment needing loading.

Owner:BEIHANG UNIV

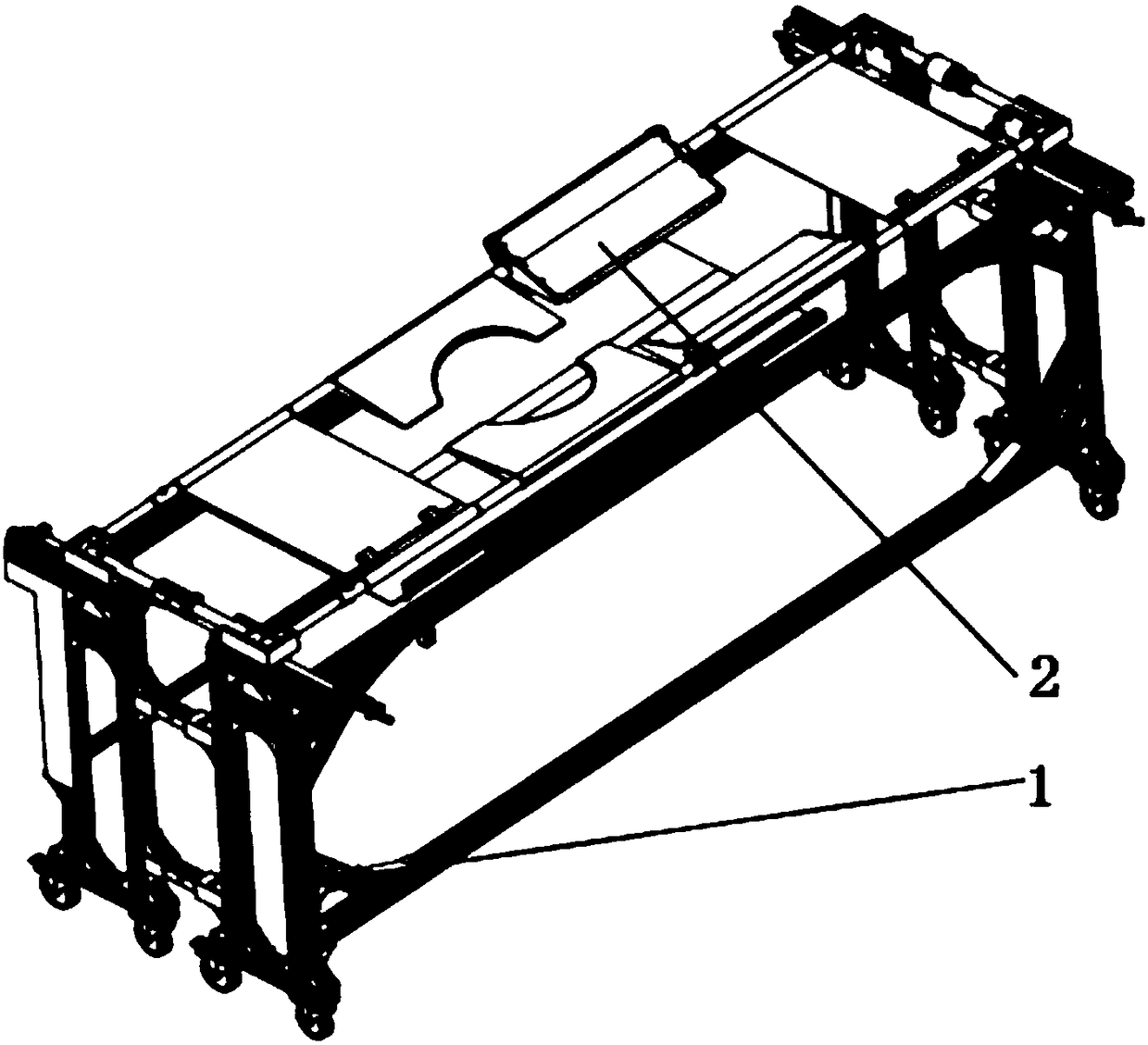

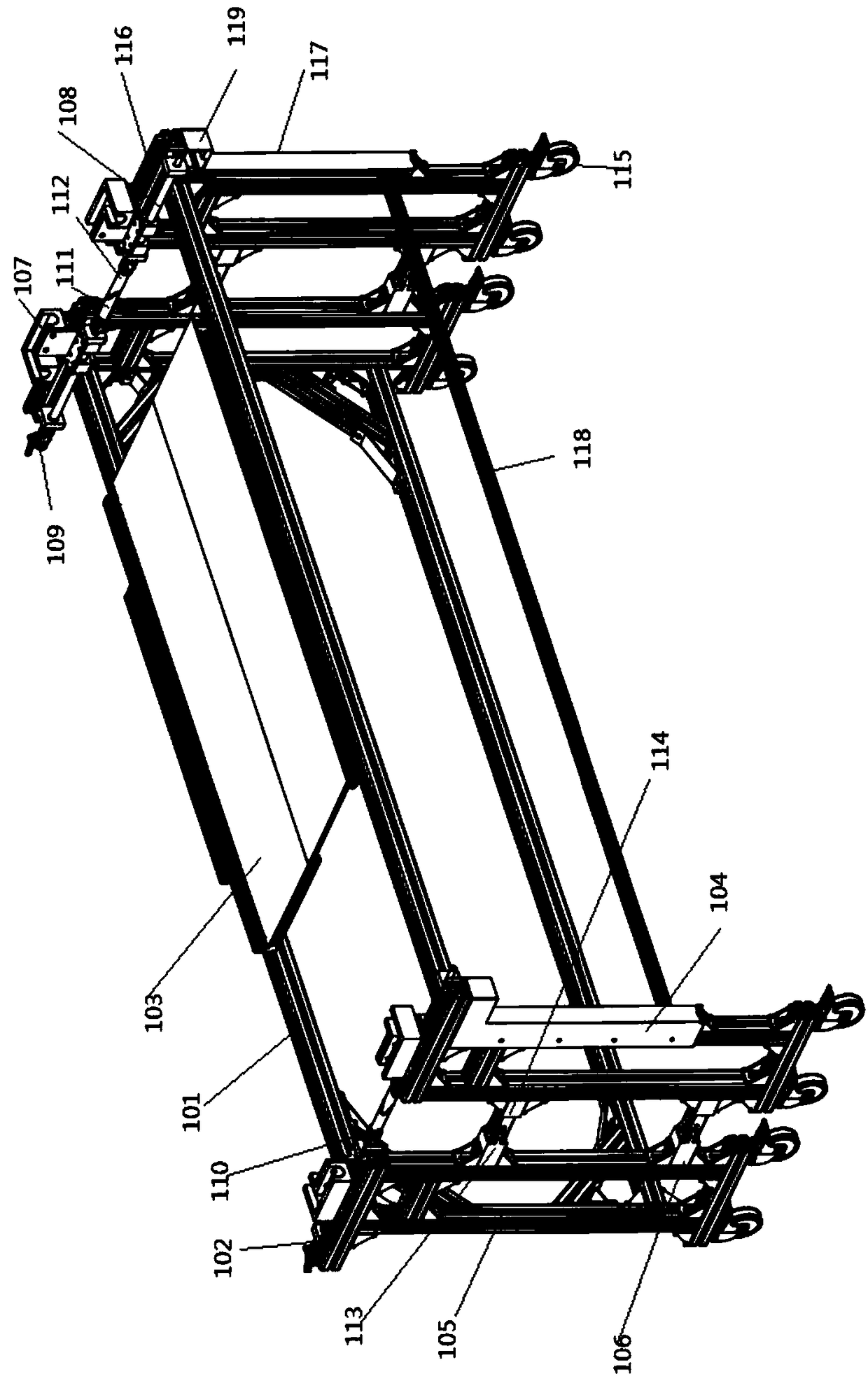

Stretcher trolley for postoperative patient transfer

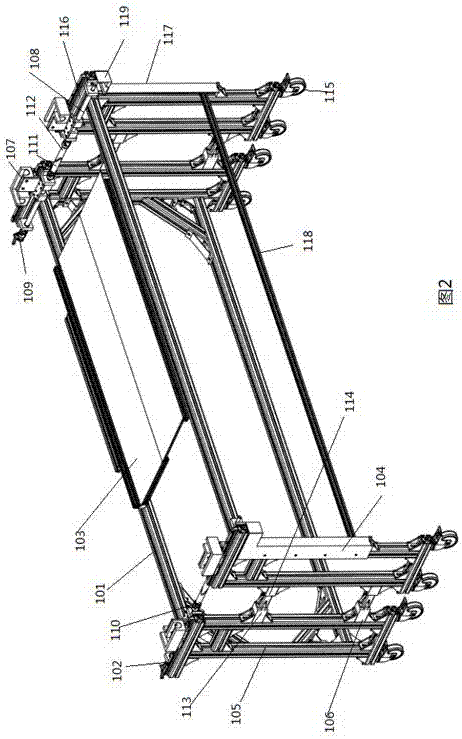

InactiveCN106943246BEasy transferQuickly shovel inStretcherPhysical medicine and rehabilitationVehicle frame

The invention discloses a postoperative patient transfer stretcher cart, which comprises a transfer cart (1), on which a telescopic rotating stretcher (2) is arranged; the transfer cart (1) includes a frame (101), The upper end of the vehicle frame (101) is provided with a slideway locking unit (102) and a canvas folding unit (103), the lower end of the vehicle frame (101) is provided with moving wheels (115), and the side of the vehicle frame (101) is provided with a movable rod The mobile unit (104); the telescopic rotary stretcher (2) includes a frame (201) matched with the slideway locking unit (102), and a frame clutch unit (202) is provided at both ends of the frame (201), and the frame ( 201) is provided with a buttock plate (203) and a push plate telescopic rotation unit (204), and the frame (201) is also provided with a frame telescopic unit (205). The invention has the characteristics of improving the transport efficiency, reducing the labor intensity of medical personnel, improving the stability and reliability of transport and reducing the impact on patients.

Owner:WENZHOU UNIVERSITY

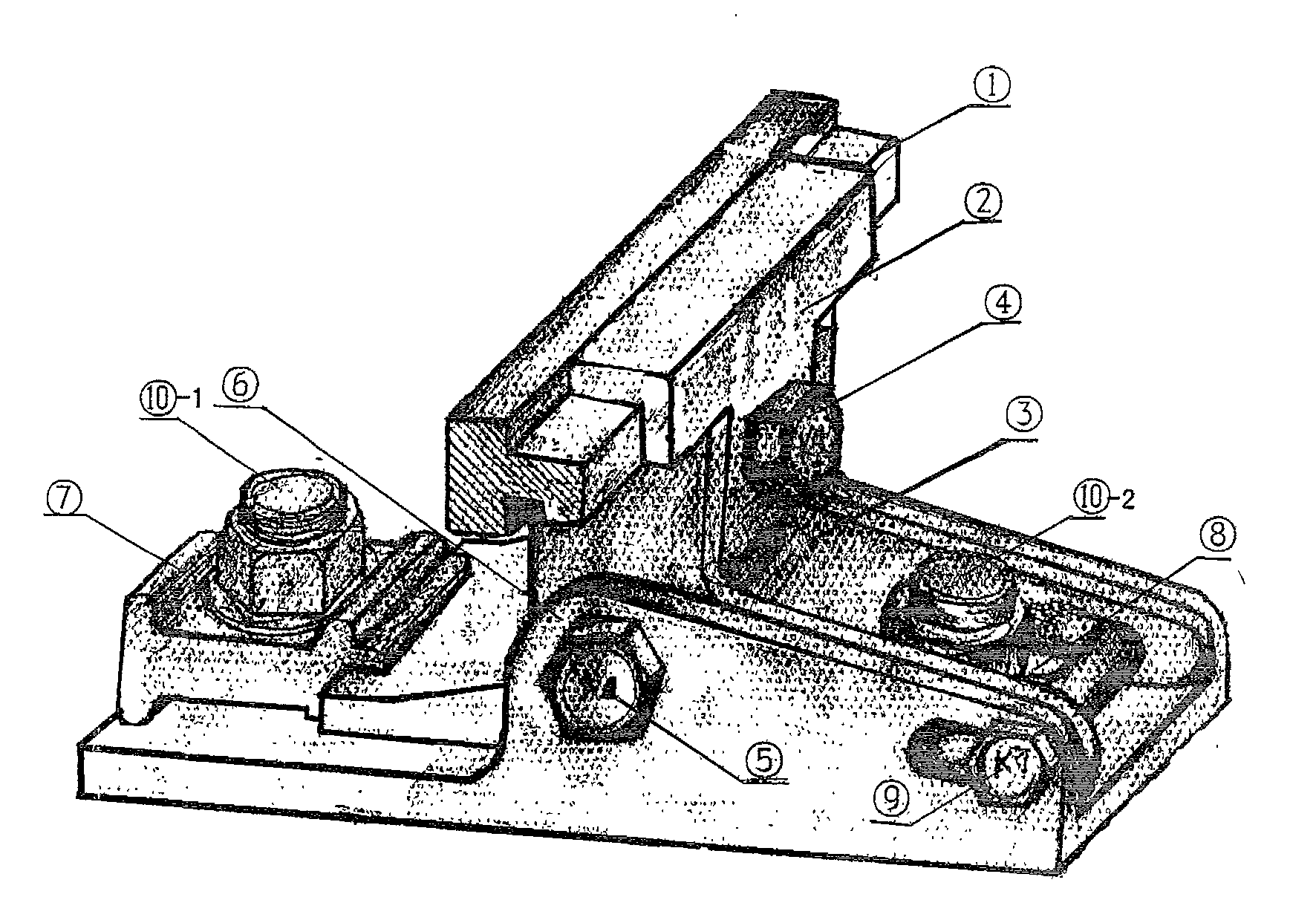

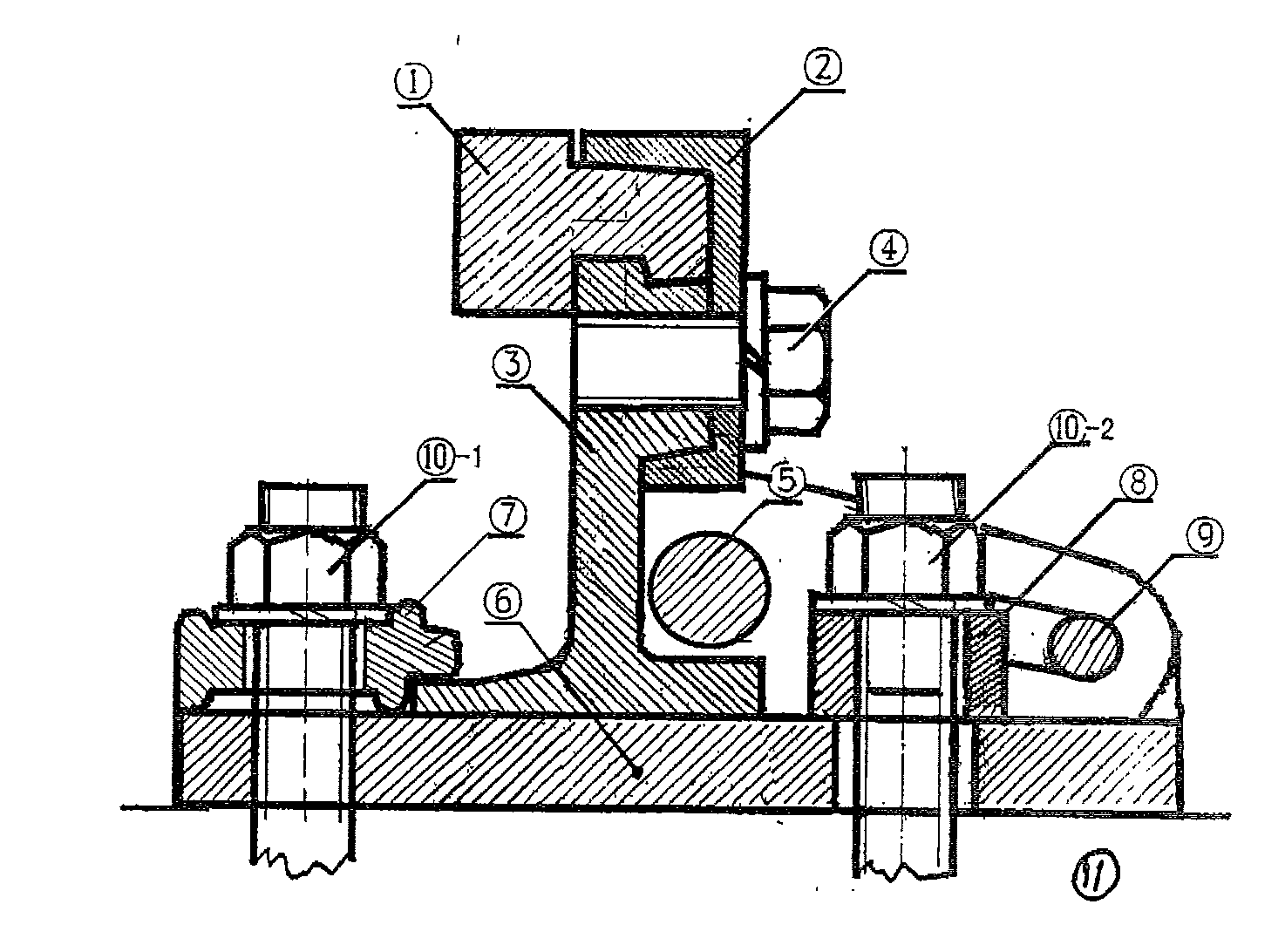

Combined type fast-assembling railway counter-rail apparatus

The invention relates to an improvement of a guard rail device in the railway rail equipment, which is particularly suitable for an erection of dangerous segments in a rail traffic. The structure of the guard rail device consists of guard rails and a positioning device which is used for fixing the guard rail on a timber so as to lead the guard rail to keep an even distance from a lateral side of a main rail. The key improvement lies in that the guard rail is positioned on a bracket with two turnover wing plates by a rail clamp and a locating bolt; with the assistance of groove-shaped holes and rotating axle of the groove-shaped holes on a groove edge of a groove-shaped base arranged on the two turnover wing plates, the bracket and a bracket base positioned on the timber with groove edges can form a hinge coordination, the position of which can be adjusted. The bracket and the bracket base can be combined with a corollary pressure plate as a whole by a fixed bolt pin and two fixed bolts to be fixed on the corresponding timber.

Owner:杨金福

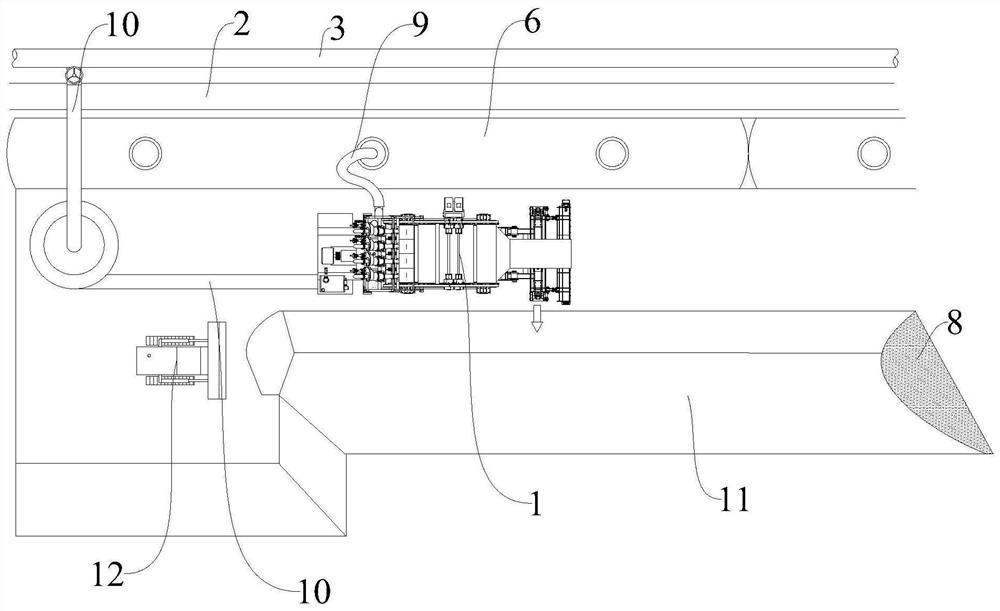

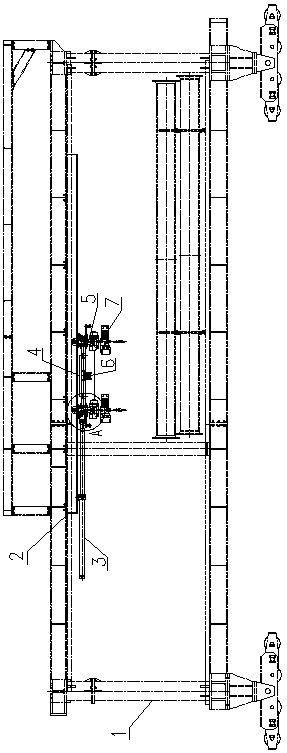

A muddy water shield fully automatic pipe changing crane

ActiveCN106744341BAchieve labor intensitySafe and stable transferTravelling cranesTravelling gearSlurryUltimate tensile strength

Disclosed is a slurry shield full-automatic pipe replacement crane. The slurry shield full-automatic pipe replacement crane comprises a trailer and a pipe replacement crane mechanism. The pipe replacement crane mechanism is installed on the trailer, and a pipe storage mechanism is arranged on the trailer. The pipe replacement crane mechanism comprises a pipe replacement crane longitudinal beam, wherein the pipe replacement crane longitudinal beam is connected with the trailer. A longitudinal translation oil cylinder is arranged on the pipe replacement crane longitudinal beam, and a travelling frame is connected to the stretching and drawing end of the longitudinal translation oil cylinder. A crane transverse beam frame and a transverse translation oil cylinder are arranged on the travelling frame, one end of the transverse translation oil cylinder is connected with the crane transverse beam frame, and the other end of the transverse translation oil cylinder is connected with the travelling frame. An electric hoist is arranged on the crane transverse beam frame, and moves along the crane transverse beam frame. A tank chain groove is formed in the top of the travelling frame, a tank chain groove is also installed in the lower surface of a platform on the top of the trailer, and the two tank chain grooves are connected through a tank chain. The slurry shield full-automatic pipe replacement crane is simple in structure and high in practicability, is successfully put into use, reduces the labor intensity of workers in the slurry pipe replacement process, and greatly improves the working efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A Mechanical Bending Plate Slope Adjusting Fixture and Method

ActiveCN107745266BAchieve verticalImprove quality and efficiencyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides a mechanical bent-plate-type slope adjusting clamp and method. The mechanical bent-plate-type slope adjusting clamp comprises a clamp base, wherein a side vertical plate and a middle vertical plate are arranged on the clamp base; a plurality of T-shaped grooves are formed in the outer side surface of the middle vertical plate from top to bottom in a spacing manner; a V-shaped positioning block is arranged at the bottom of the middle vertical plate; two raised brackets are horizontally arranged on the inner side surface of the middle vertical plate in a spacing manner; aservo motor is arranged on the outer side surface of the side vertical plate and connected with a worm; the worm is connected with a worm gear; an angle displayer is arranged at the tail end of the worm; one end of a gear shaft is mounted on the worm gear; the other end of the gear shaft penetrates through the side vertical plate and is mounted on the clamp base; the raised brackets are in hingedconnection with a rotating table plate through a hinge shaft; a fan-shaped gear is arranged on the reverse side of the rotating table plate and in meshed connection with the gear shaft; the T-shaped grooves are formed in the obverse side of the rotating table plate from top to bottom; and the V-shaped positioning blocks are arranged at the bottom of the rotating table plate. The mechanical bent-plate-type slope adjusting clamp and method have the advantages that the structure is stable, the rigidity is high, the operation is simple, the labor intensity is reduced, the working efficiency is improved, and the clamped part slope adjusting and positioning precision is high.

Owner:荣成远海滑动轴承有限公司

a fish feeding boat

ActiveCN109819924BAchieve labor intensityRealize multi-area feedingRotary propellersRotary stirring mixersAnimal scienceAir pump

A fish feeding boat, belonging to the field of fishery, is composed of a first motor, a mixing tank, a hull, a propeller, a solar panel, a storage battery, an air pump, a controller, a feeding control device, a second motor, a feed projection device and a first Composed of three motors, the mixing tank in this invention can hold a variety of feeds or medicines, and the stirring shaft can realize the uniform mixing of feeds and medicines, which greatly reduces the labor intensity of workers; the electromagnet and spring in this invention can realize The left and right movement of the blanking control plate realizes the lowering and stopping of the feed. The rolling body can reduce the friction of the blanking control plate when it moves; the first cylinder moves to compress the feed, and the compressed feed is located in the compressed block hole, and then With the movement of the second cylinder, the compressed feed can be projected far away by means of the movement of the second piston rod, and the compressed feed can expand the projection area, thereby realizing multi-area feeding.

Owner:山东同其数字技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com