Full-tailing damming method of damming machine

A technology for tailings and dam slopes, applied in the fields of botanical equipment and methods, dams, buildings, etc., can solve the problems of unsuitable tailings storage for dry discharge, underutilized tailings slurry, and slow dam construction. The effect of reducing construction cost, increasing speed and reducing construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

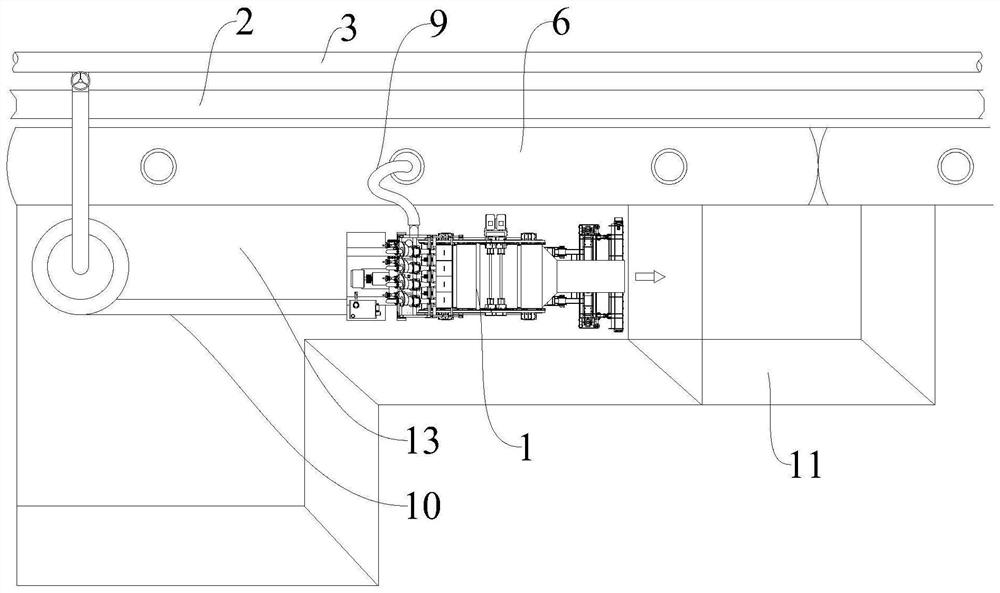

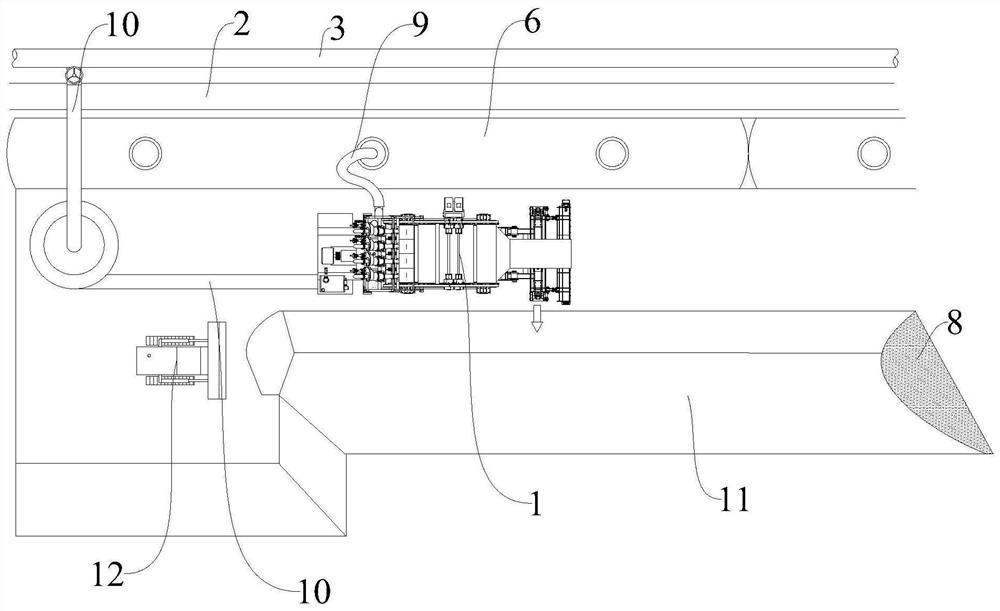

[0046] Please refer to Figure 1-Figure 3 , figure 1Shown is a lateral partial cross-sectional view of the dam building machine 1 provided by the embodiment of the present invention when building a dam; figure 2 Shown is a top view of the dam building machine 1 provided by the embodiment of the present invention when building a dam along the extension direction of the pre-built dam body 11; image 3 Shown is a top view of the dam building machine 1 provided by the embodiment of the present invention when building a stockpile.

[0047] The present embodiment provides a method for building a dam with all tailings of a dam building machine, comprising the following steps:

[0048] Dig the dam slope drainage ditch 2 along the dam building direction on one side of the pre-built dam body 11;

[0049] A leak-proof layer 4 is laid between one side of the pre-built dam body 11 and the dam slope drainage ditch 2, and a film bag 6 is placed above the leak-proof layer 4;

[0050] Bui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com