Combined type fast-assembling railway counter-rail apparatus

A combination and railway technology, applied in the direction of roads, tracks, rails, etc., can solve the problems of ineffective adjustment, heavy labor, hidden dangers, etc., and achieve the effect of mechanized operation, safe and reliable operation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

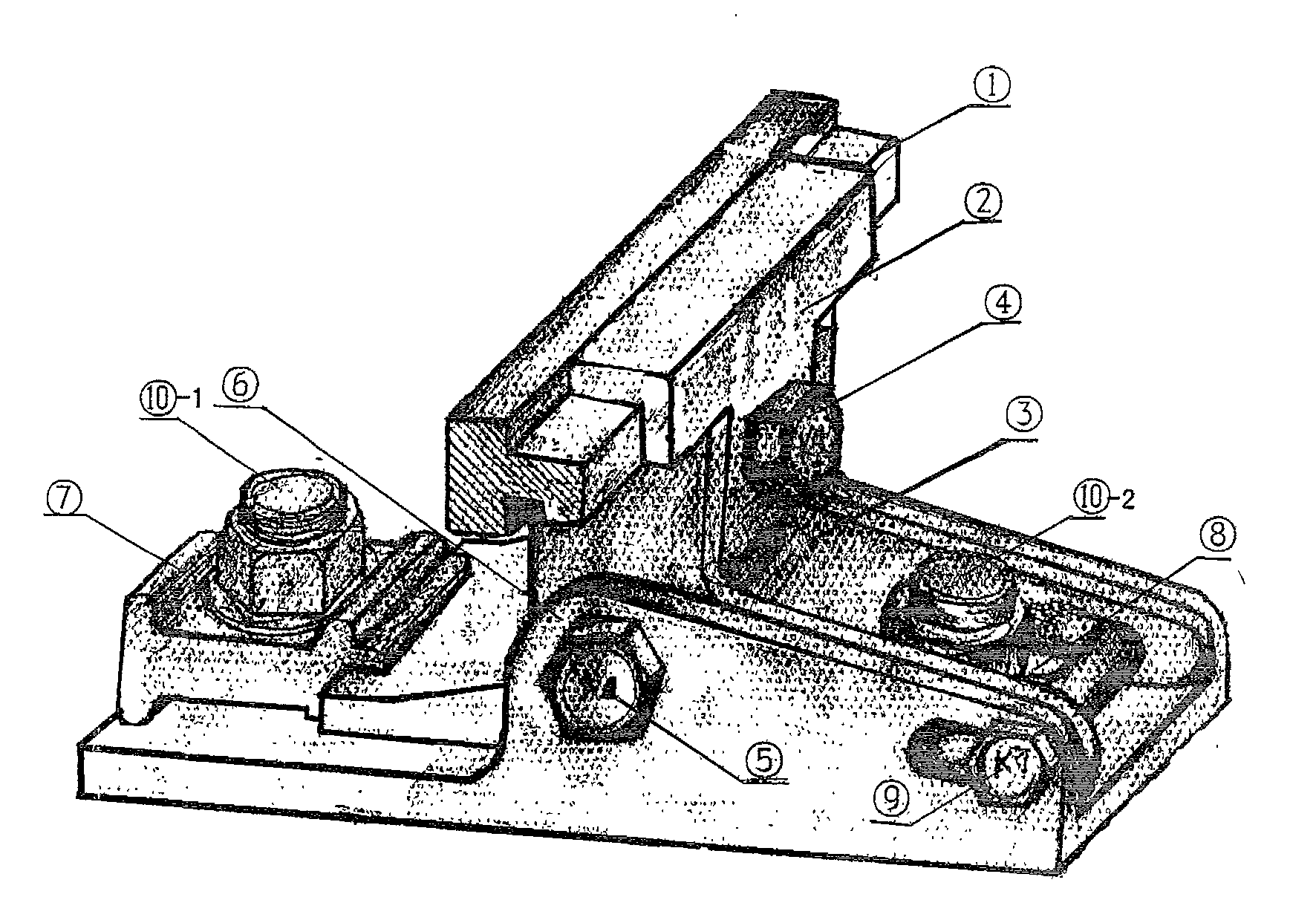

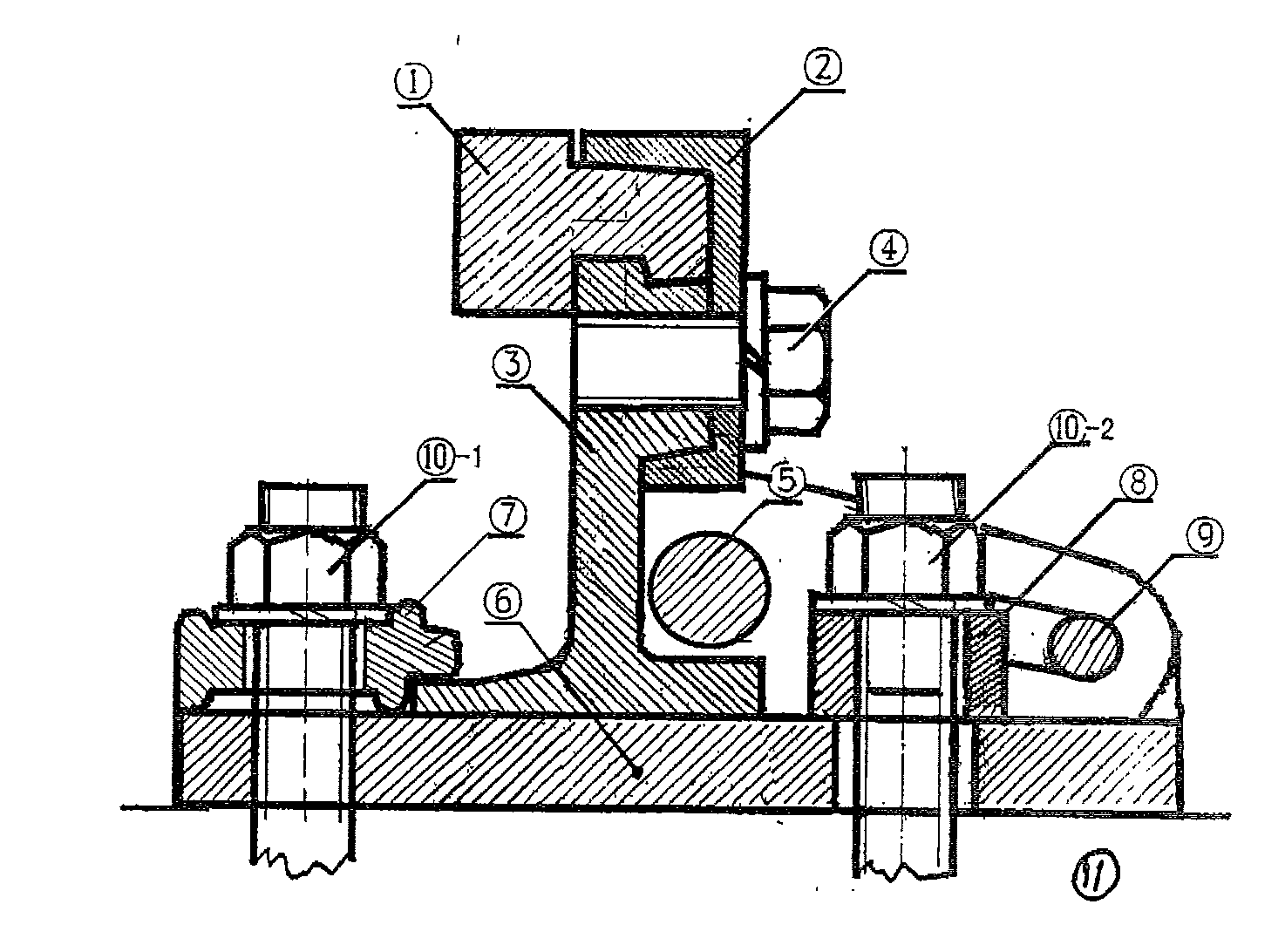

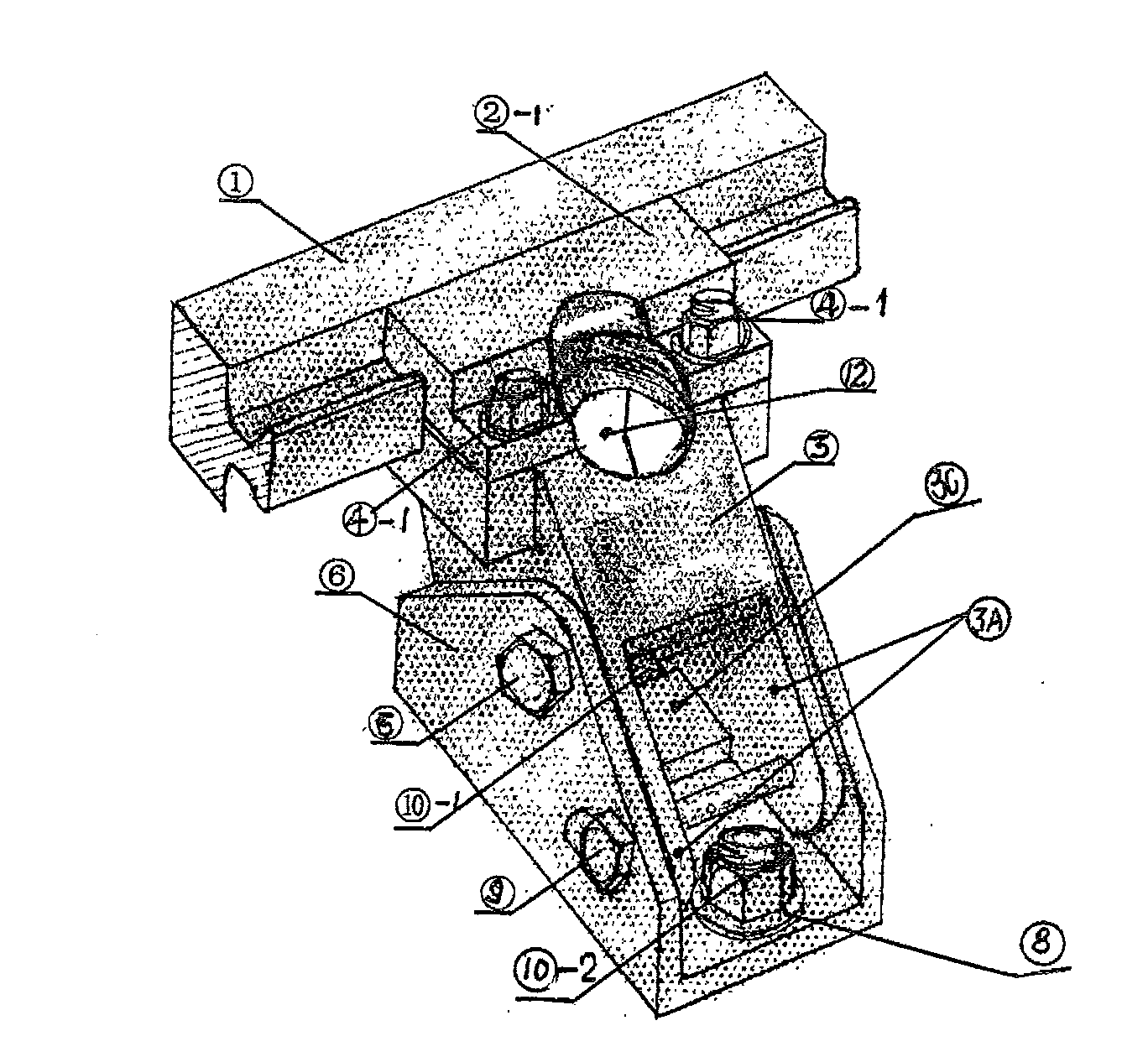

[0013] In combination with the given embodiments, it can be seen that the key design of the present invention includes the guard rail 1 and the positioning mechanism for fixing the guard rail 1 on the sleeper 11 so as to maintain a uniform distance from the side of the main rail. The key design is that the guard rail 1 is positioned on the support 3 with two turning flaps 3A by means of rail clips and positioning bolts. The support 3 can form a position by means of the slotted holes provided on the two turning wing plates 3A or the slotted holes on the slotted side 6A of the slotted base 6, the turning shaft 9 and the bracket base 6 with the slotted side 6A positioned on the sleepers. Adjustable hinge fit. Support 3 and support base 6 are combined into one by means of fixing bolt pin 5, two fixing bolts (10-1, 10-2) linking to each other with sleepers and supporting pressing plates (7, 8), and are fixed on corresponding sleepers 11.

[0014] Tighten the bolt pin 5 and two fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com