Manual pipe bending machine

A pipe bending machine and pipe bending technology, which is applied in the field of automobile pipe manufacturing, can solve the problems of inconvenient adjustment and maintenance, increased labor intensity, and limited pipe bending arm, so as to reduce manufacturing difficulty, reduce labor intensity, and increase pipe bending space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

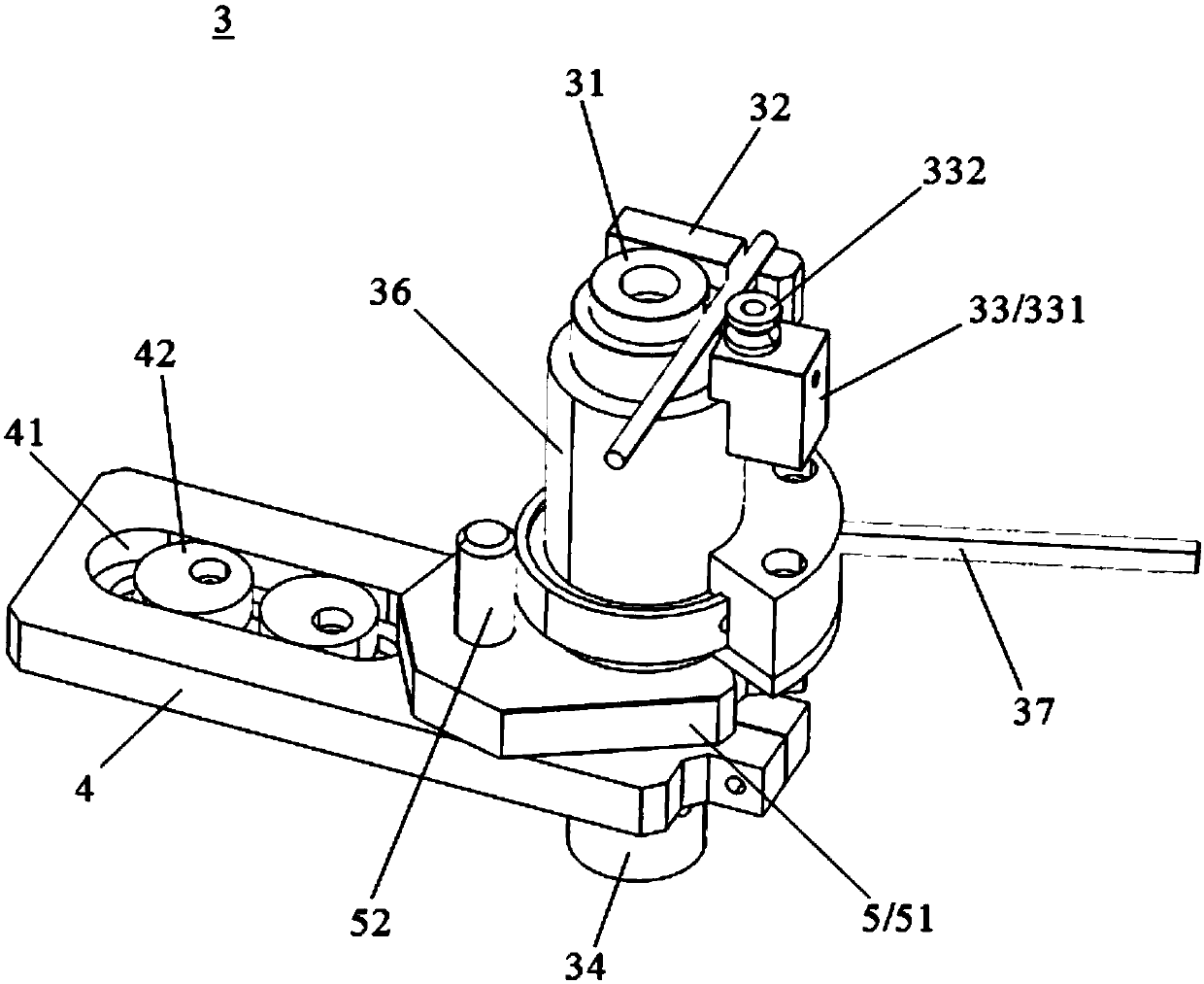

[0025] Please refer to Figure 1-Figure 5 , the present embodiment is a manual pipe bender 100, which includes a pipe bend base 1 made of aluminum alloy profiles, an end positioning device 2 installed at one end of the pipe bend base 1, and a module mounted on the pipe bend base 1 The curved pipe unit 3.

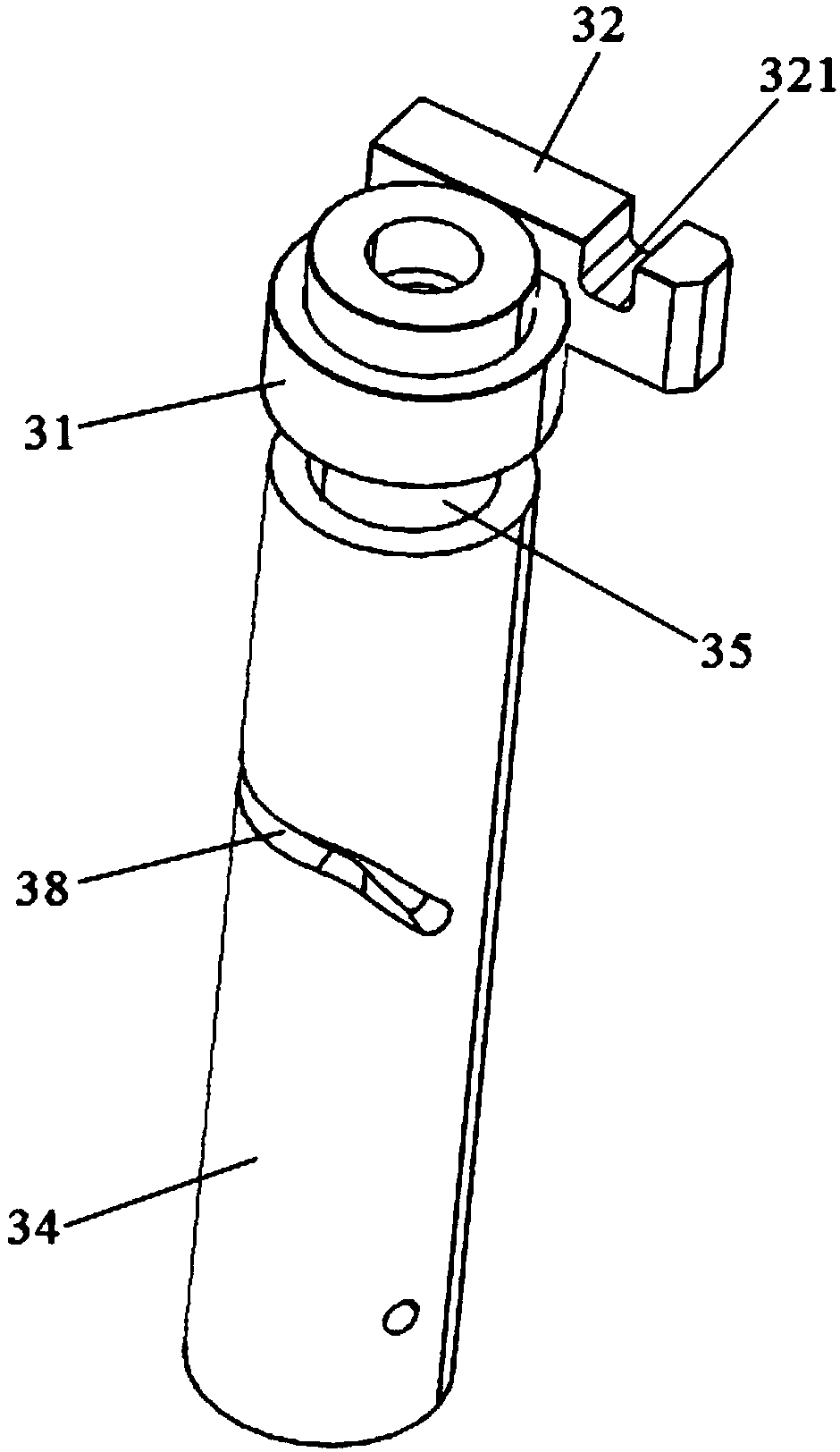

[0026] The pipe bending unit 3 includes a wheel mold 31, a block assembly 32 that blocks the pipe-bending edge, and a bending mold 33 that cooperates with the wheel mold 31 to bend the pipeline, and drives the bending mold 33 to rotate and simultaneously drives the bending mold 33 and the wheel. The mold 31 and the stopper assembly 32 are synchronously raised or lowered by rotating the rising assembly.

[0027] The rotating lifting assembly includes a guide cylinder 34, a guide rod 35 with gaps arranged inside the guide cylinder 34, a rotating sleeve 36 sleeved on the outer surface of the guide cylinder 34, a rotating handle 37 fixedly connected to the rotating sleeve 36, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com