Method for preparing perilla oil powder through composite condensation microencapsulation

A technology of microencapsulation and perilla oil, applied in the field of food processing, can solve the problems of poor protein water solubility, complex process, easy coagulation, etc., and achieve the effects of low cost, simple process and improved permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

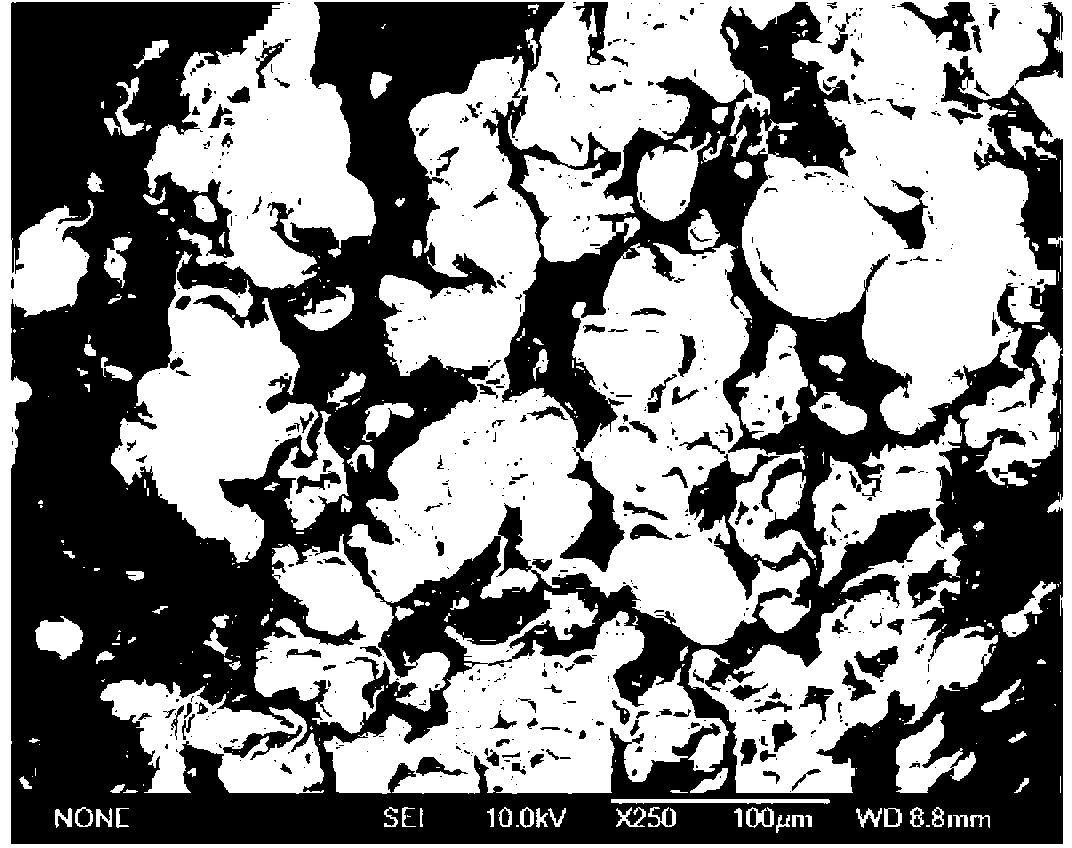

Image

Examples

Embodiment 1

[0036] (1) Soy protein isolate and sodium alginate were used as wall materials, and soybean protein isolate and sodium alginate were prepared into a 4% solution.

[0037] (2) Add emulsifier monoglyceride (0.1% of the total mass of the microcapsules) to the isolated soybean protein solution, stir and dissolve at 65°C.

[0038] (3) Adjust the pH value of the above solution to 9 with 10% sodium hydroxide solution.

[0039] (4) Add perilla oil to the above solution, and stir at a high speed of 1000r / min for 1min to obtain a uniform and stable emulsion. Add the sodium alginate solution obtained in step (1) dropwise to the above emulsion and stir evenly. Among them, the mass ratio of perilla oil to the mixed wall material is 1:1, and the mass ratio of soybean protein isolate to sodium alginate in the wall material is 4:1.

[0040] (5) Adjust the temperature of the system to 40°C in a water bath, and adjust the pH value to 3.5 with 10% acetic acid, keep the reaction in the water ba...

Embodiment 2

[0068] (1) Use soybean protein isolate and sodium alginate as wall materials, and prepare soybean protein isolate and sodium alginate into 3% solutions respectively.

[0069] (2) Add emulsifier Tween 80 (0.2% of the total mass of the microcapsules) to the isolated soybean protein solution, stir and dissolve at 65°C.

[0070] (3) Adjust the pH value of the above solution to 7 with 10% sodium hydroxide solution.

[0071] (4) Add perilla oil to the above solution, and stir at a high speed of 1000r / min for 1min to obtain a uniform and stable emulsion. Add sodium alginate solution dropwise to the above emulsion and stir evenly. Among them, the mass ratio of perilla oil to the mixed wall material is 1:1, and the mass ratio of soybean protein isolate to sodium alginate in the wall material is 3:1.

[0072] (5) Adjust the temperature of the system to 50°C in a water bath, and adjust the pH value to 3.5 with 10% acetic acid, keep the reaction in the water bath for 20 minutes, and for...

example 1

[0077] 1. The determination of microcapsule embedding rate is as follows: Weigh 2.000g of microcapsule product, shake and wash with 20mL petroleum ether, filter, repeat twice, put the combined filtrate into a weighing bottle that has been accurately weighed, and place it at 60°C Evaporate the solvent in an oven, place the weighing bottle in a desiccator to cool and weigh, and then obtain the surface oil mass of the microcapsules.

[0078] Weigh 2.000g microcapsule sample, grind repeatedly, use anhydrous diethyl ether as solvent and measure by Soxhlet extraction method to get the total oil content.

[0079]

[0080] Surface oil measurement data: the mass of the sample is 1.9994g, the mass of the weighing dish is 15.9972g, and the mass after evaporation of solvent and drying is 16.1101g.

[0081] Surface oil content=(16.1101-15.9972) / 1.9994=5.65%

[0082] Total oil content data: the mass of the sample is 1.9989g, the mass of the weighing dish is 16.3097g, and the mass after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com