Novel stamping system suitable for oven

A new type of oven technology, applied in the stamping field, can solve the problems of stamping accident rate injury, complicated equipment structure, inconvenient operation, etc., and achieve the effect of high safety, high degree of automation, and low cost of production transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

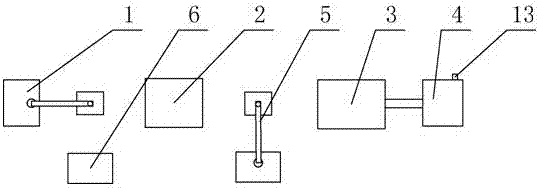

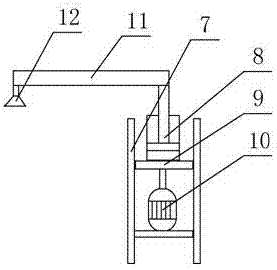

[0010] In the figure, 1. Stacking platform; 2. Punching press; 3. Forming press; 4. Stacker; 5. Feeding robot; 6. Turning table; 7. Support; 8. Lifting cylinder; ; 10, rotating motor; 11, mechanical arm; 12, sucker; 13, counter.

[0011] Such as figure 1 , figure 2 As shown, the stacking platform 1, the punching press 2, the forming press 3 and the stacker 4 are arranged in sequence, the forming press 3 is connected to the stacker 4, and the stacking platform 1 is connected to the punching machine. The feeding manipulator 5 is respectively arranged between the 2 presses, the punching press 2 and the forming press 3, and the turning table 6 is placed beside the feeding manipulator 5. The material manipulator 5 includes a support 7, a lifting cylinder 8. Rotating disk 9, rotating motor 10, mechanical arm 11 and suction cup 12, the rotating disk 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com