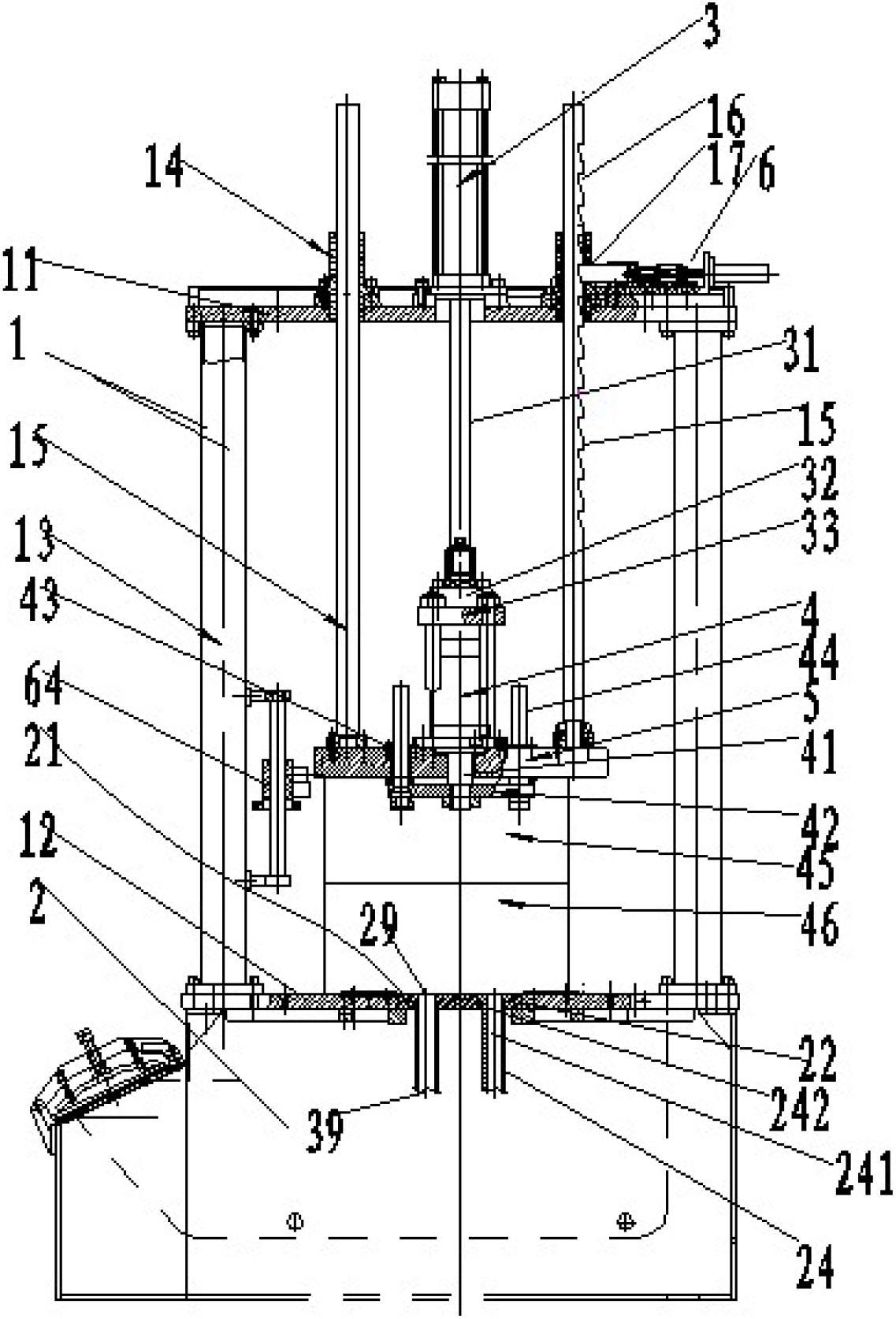

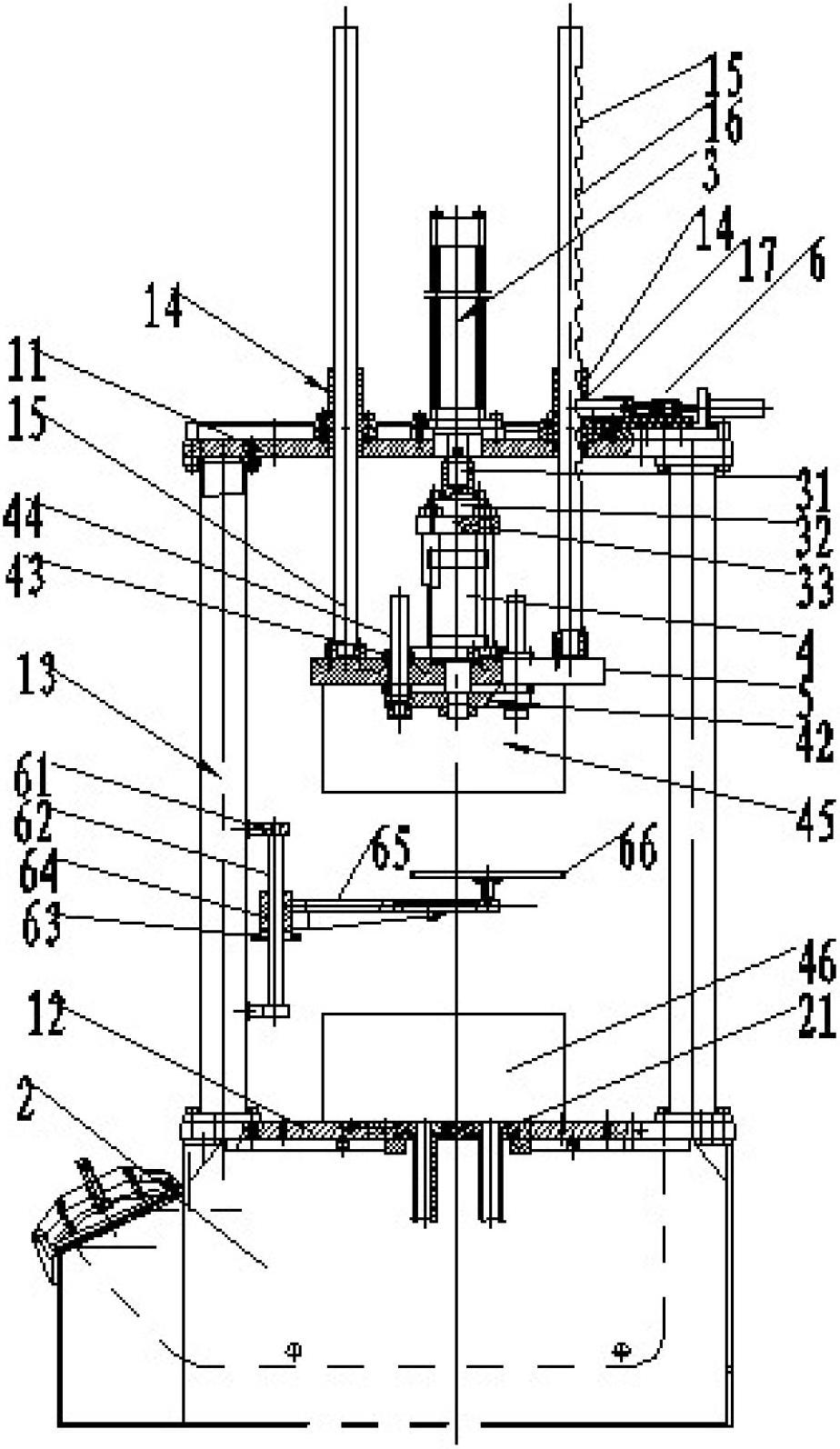

Method for low-pressure casting thin-wall long-sized castings and equipment used by same

A low-pressure casting, long-size technology, applied in the field of low-pressure casting methods and the equipment used, can solve the problems of complex design of the mold gating system, poor exhaust, cold insulation joints, etc., so as to reduce labor intensity of workers and reduce pouring risers. , Good product forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The low-pressure casting method of thin-walled and long-sized castings of the present invention, the low-pressure casting method of thin-walled, long-sized castings, first melts the metal material, closes the furnace body, prepares the mold,

[0035] (1) Inspection equipment;

[0036] (2) Mold preheating: the upper mold is opened about 100mm, the heater is put into the mold cavity, and the ignition is preheated. The preheating temperature is 280-300 degrees, and the heating time is 1-1.5 hours;

[0037] (3) Adding aluminum to the holding furnace: add the dissolved metal liquid to the holding furnace;

[0038] (4) Sand core preparation: The sand core is installed on the core making machine, and the coated sand is used to fill the model with compressed air, and then heated and sintered.

[0039] (5) Set the process parameters, clean the mold cavity, put in the sand core, and close the mold;

[0040] (6) Injection: Low-pressure pouring is used to fill the mold, the pouri...

Embodiment 2

[0045] The low-pressure casting method of thin-walled and long-sized castings of the present invention, the low-pressure casting method of thin-walled, long-sized castings, first melts the metal material, closes the furnace body, prepares the mold,

[0046] (1) Inspection equipment;

[0047] (2) Mold preheating: the upper mold is opened about 100mm, the heater is put into the mold cavity, and the ignition is preheated. The preheating temperature is 280-300 degrees, and the heating time is 1-1.5 hours;

[0048] (3) Adding aluminum to the holding furnace: add the dissolved metal liquid to the holding furnace;

[0049] (4) Sand core preparation: The sand core is installed on the core making machine, and the coated sand is used to fill the model with compressed air, and then heated and sintered.

[0050] (5) Set the process parameters, clean the mold cavity, put in the sand core, and close the mold;

[0051] (6) Injection: Low-pressure pouring is used to fill the mold, the pouring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com