Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Accumulation will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

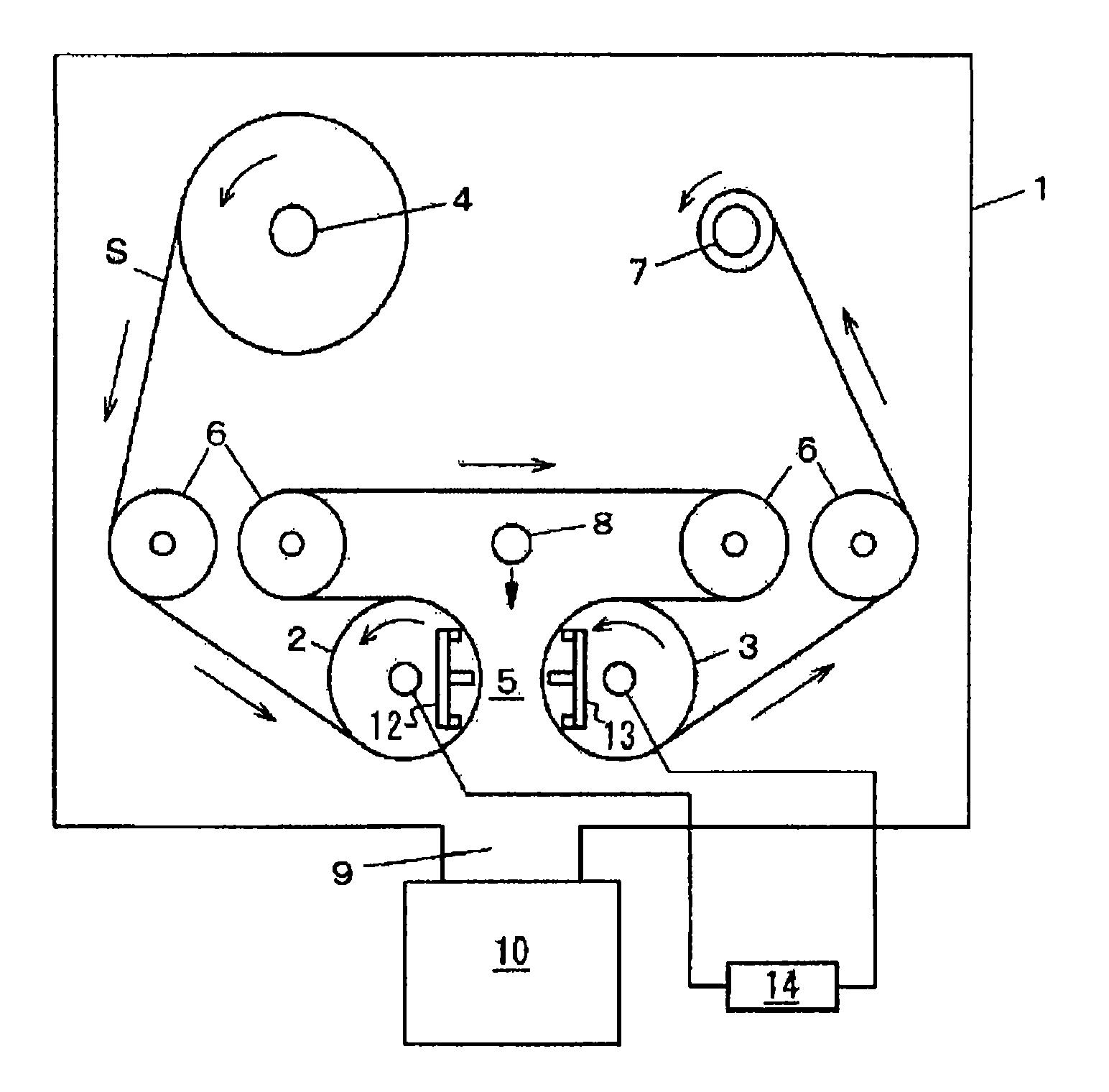

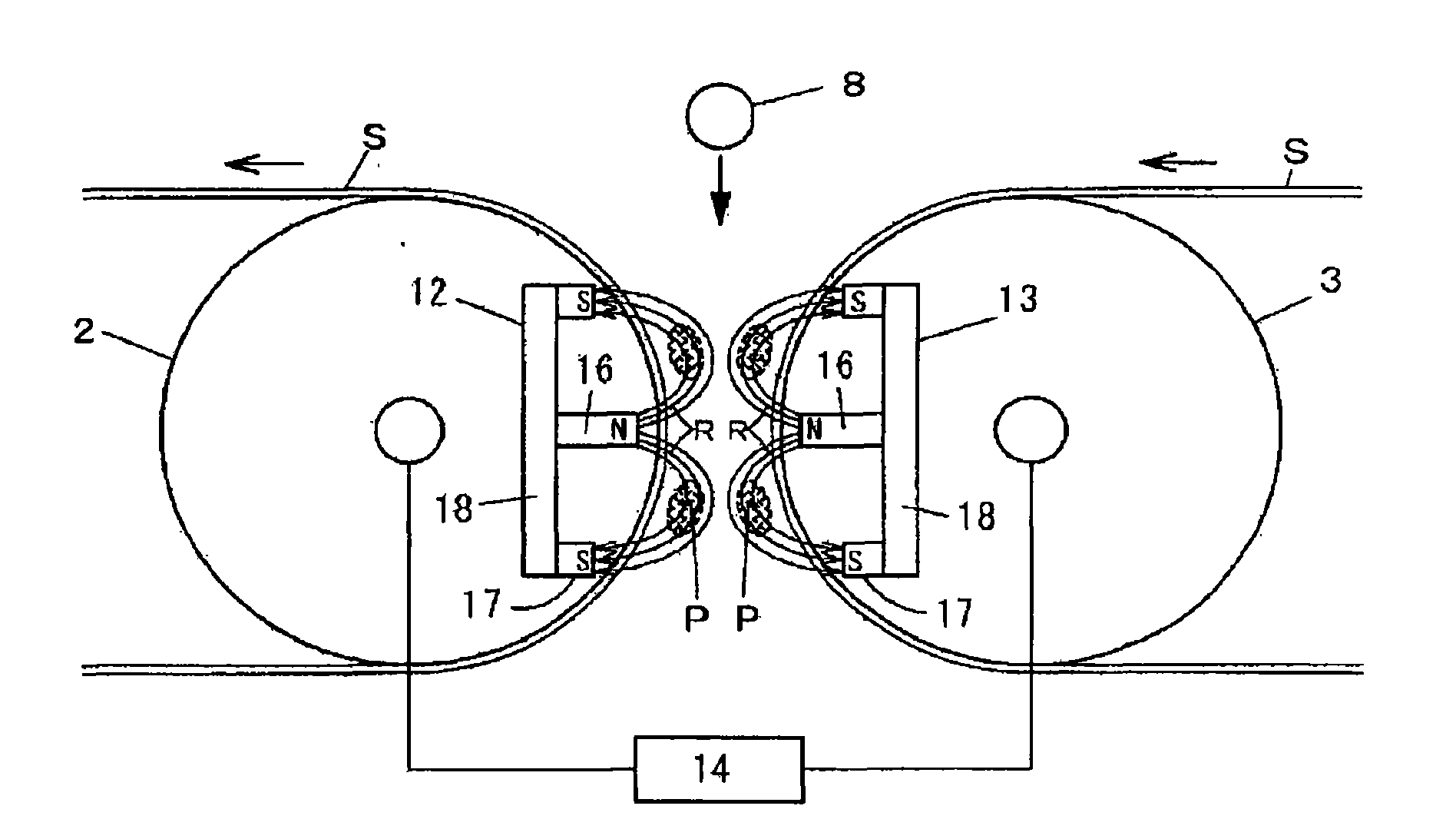

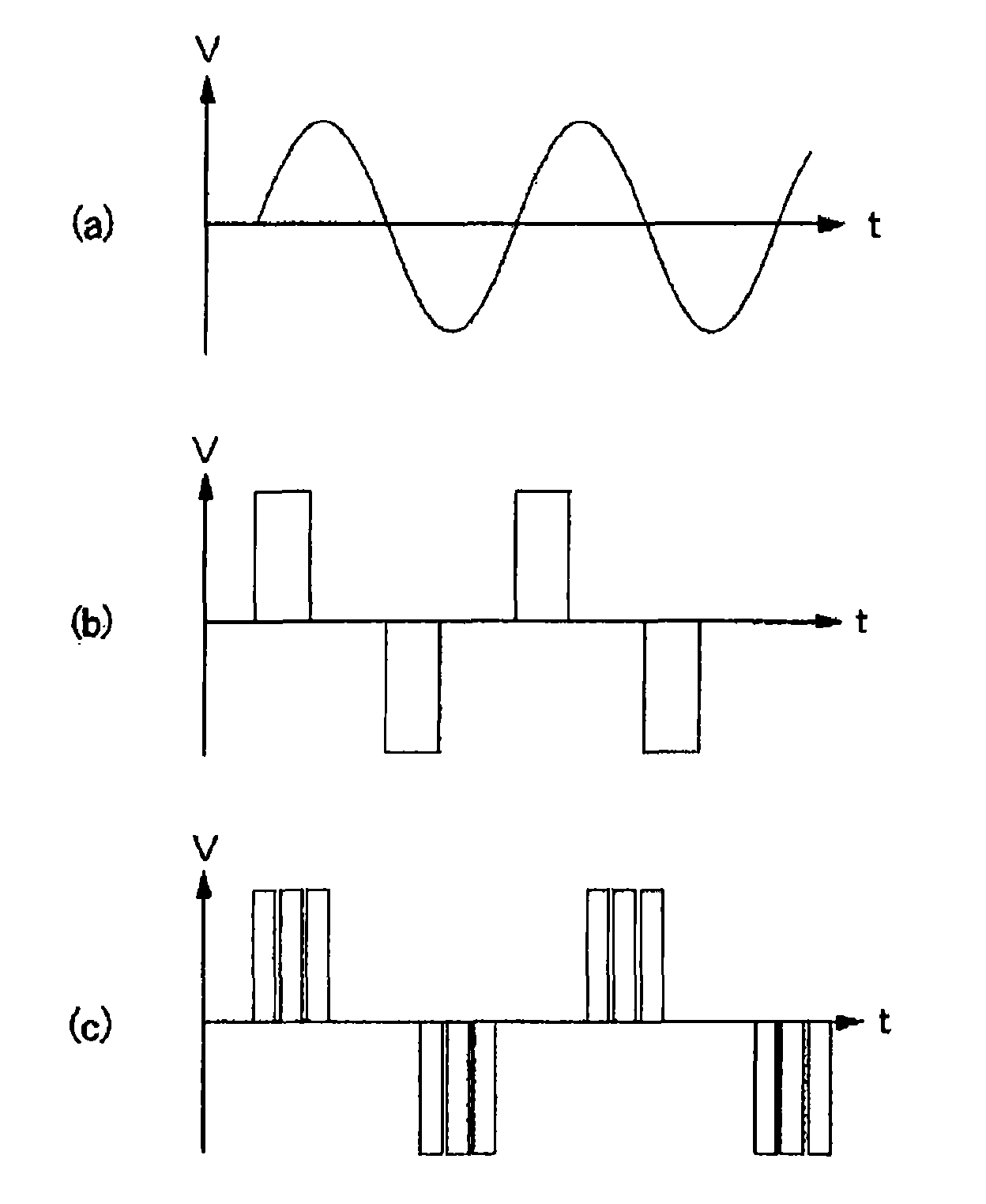

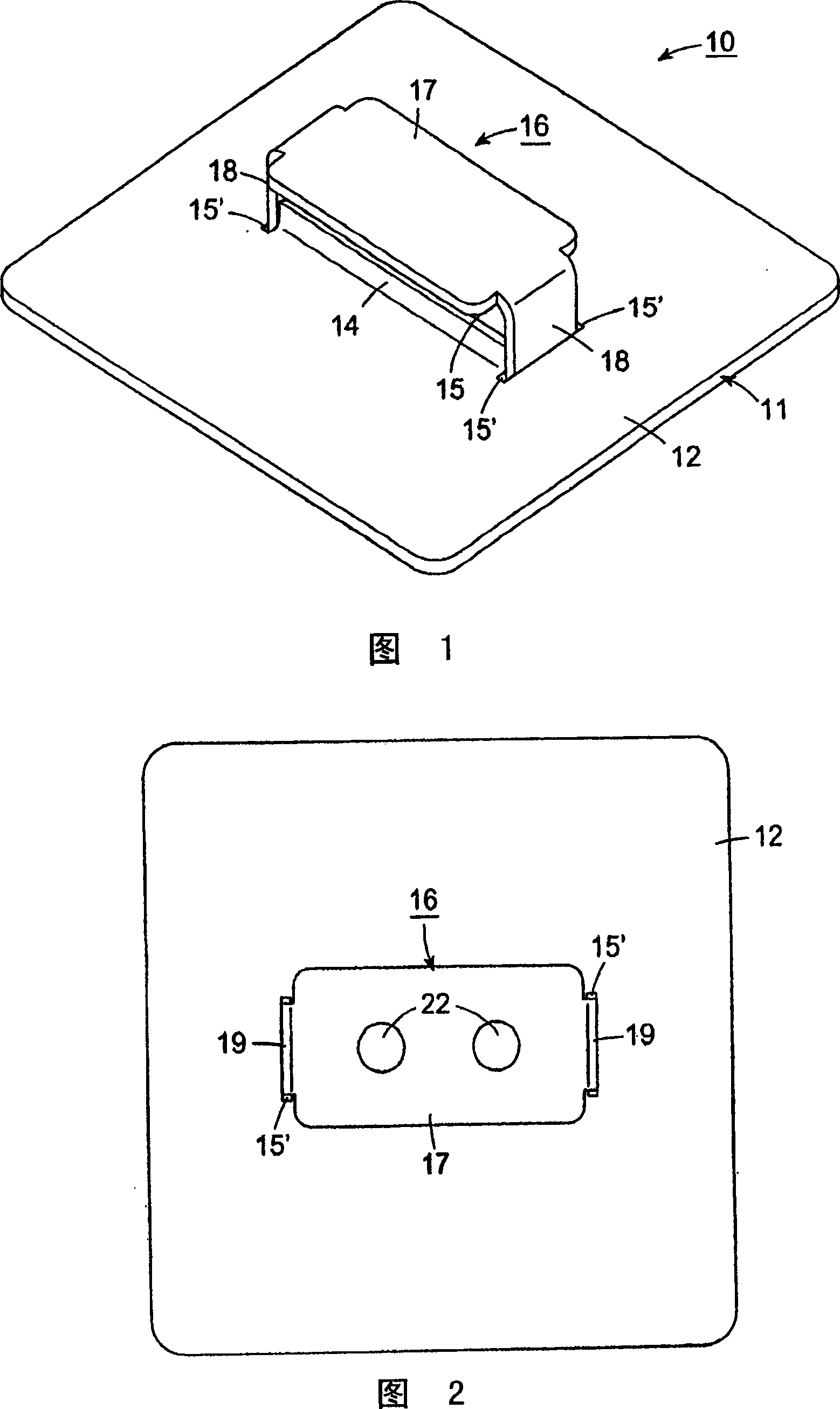

Continuous film forming apparatus

ActiveCN101611168AEfficient formationInhibition defectElectric discharge tubesChemical vapor deposition coatingVacuum pumpingGas supply

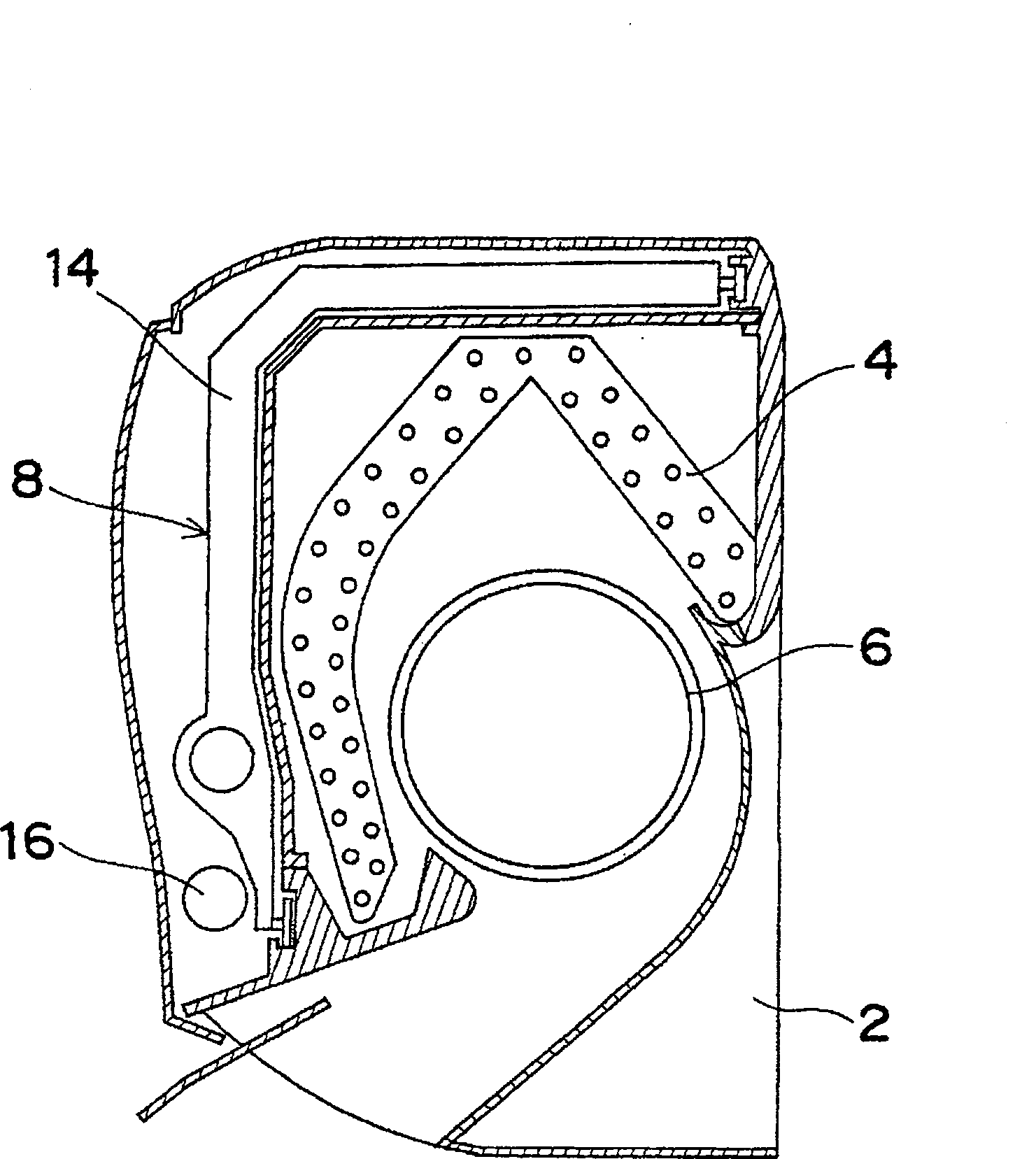

A continuous film forming apparatus comprises a pair of film forming rolls (2, 3) where winding substrates (S) are arranged opposite to each other in parallel, magnetic field generation members (12, 13) provided in respective film forming rolls (2, 3) and generating a magnetic field for converging plasma to the vicinity of the roll surface facing the opposing space (5) between the film forming rolls, a plasma power supply (14) where the polarity of one and the other electrodes is inverted alternately, a gas supply pipe (8) for supplying a film froming gas to the opposing space (5), and a means for vacuum pumping the opposing space (5). The plasma power supply (14) has one electrode connected with one film forming roll (2), and the other electrode connected with the other film forming roll (3).

Owner:KOBE STEEL LTD

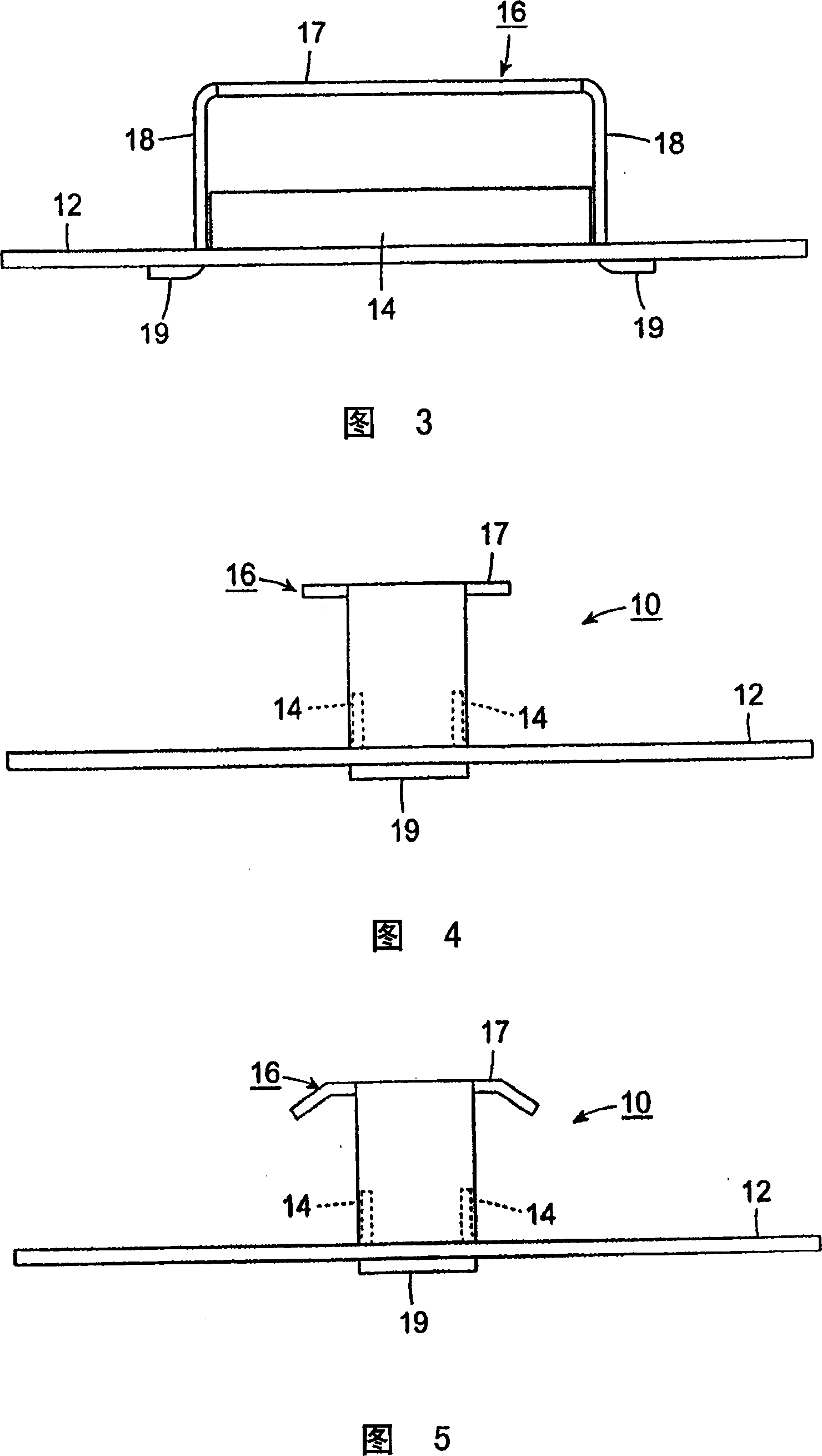

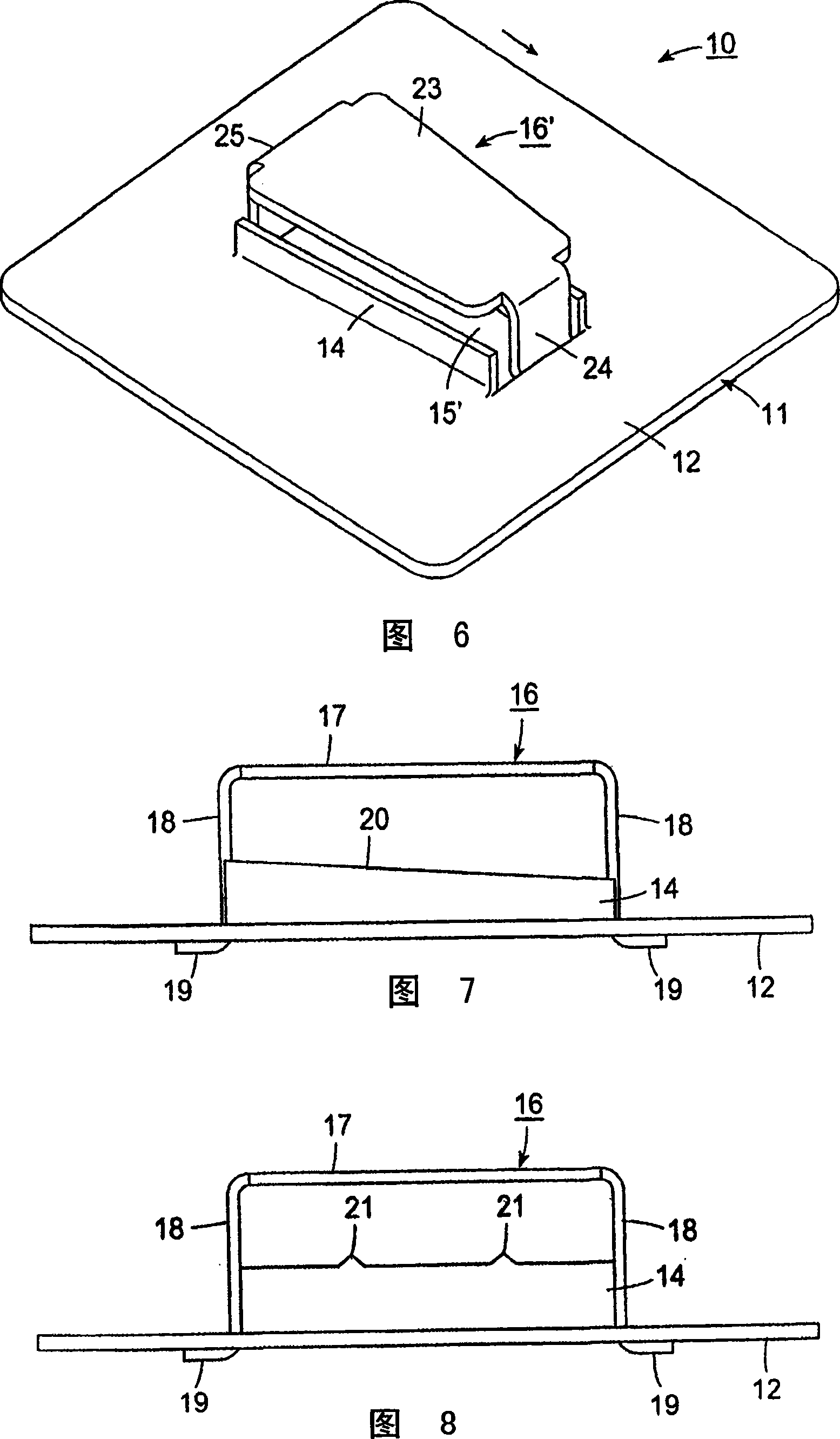

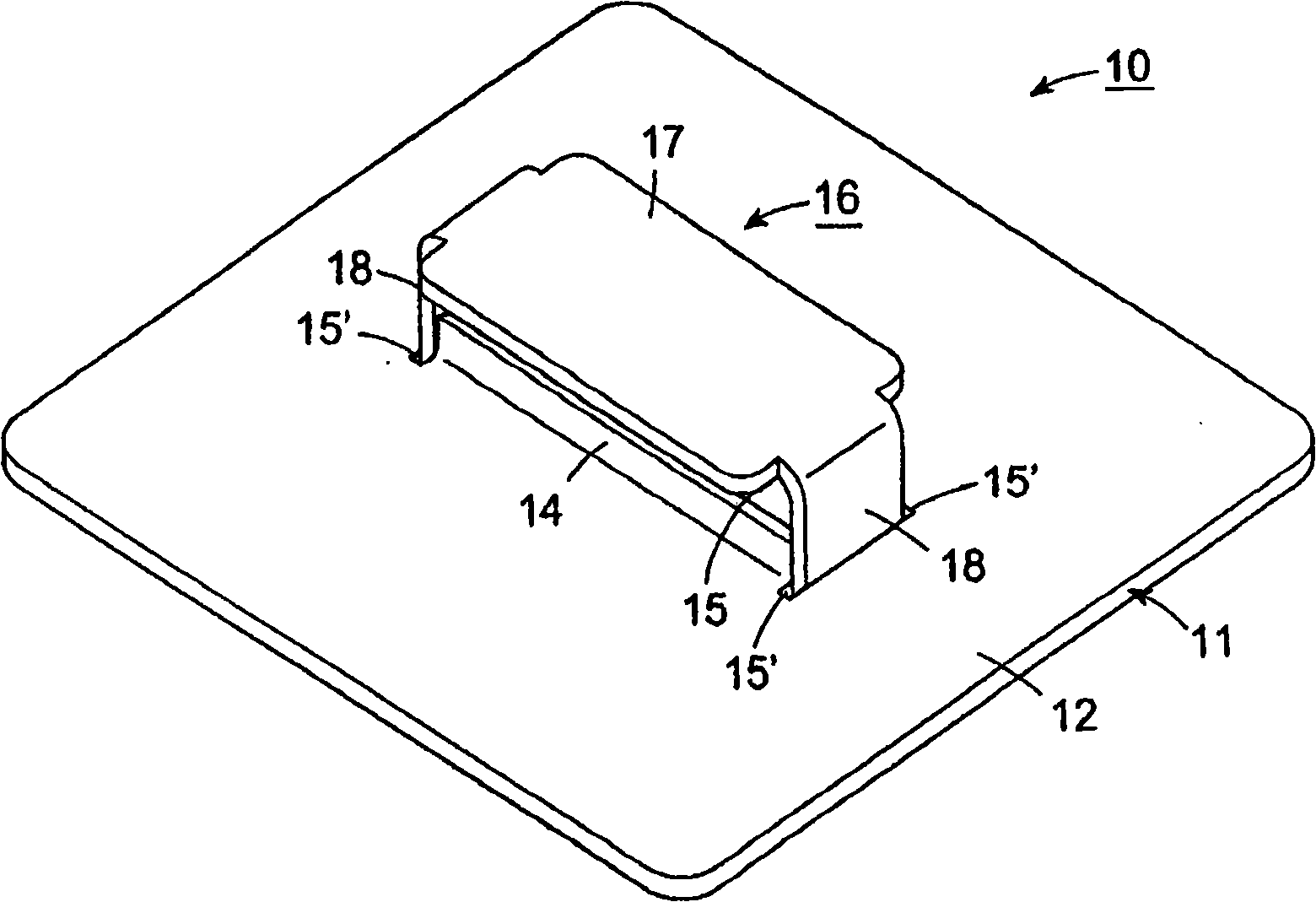

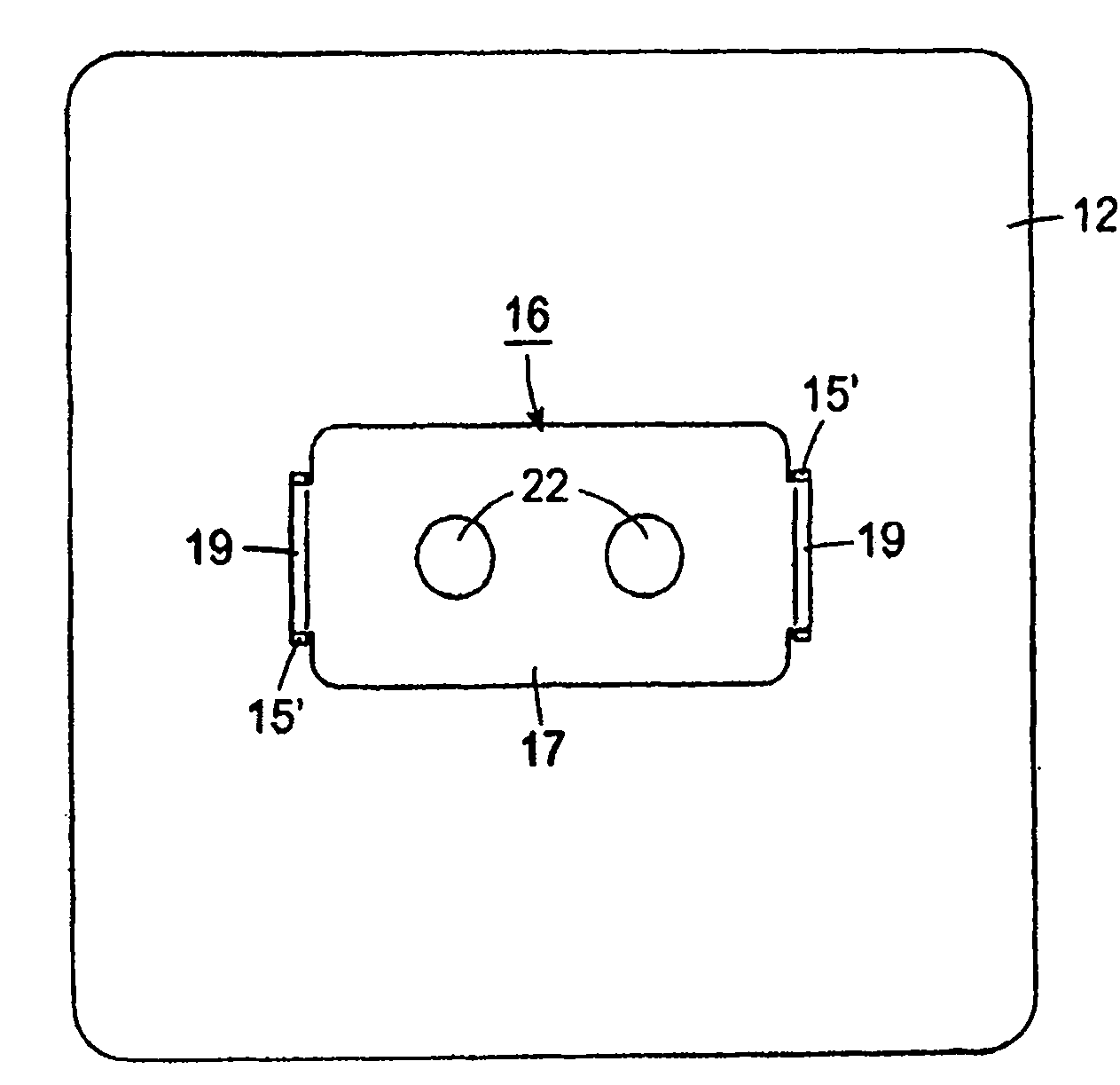

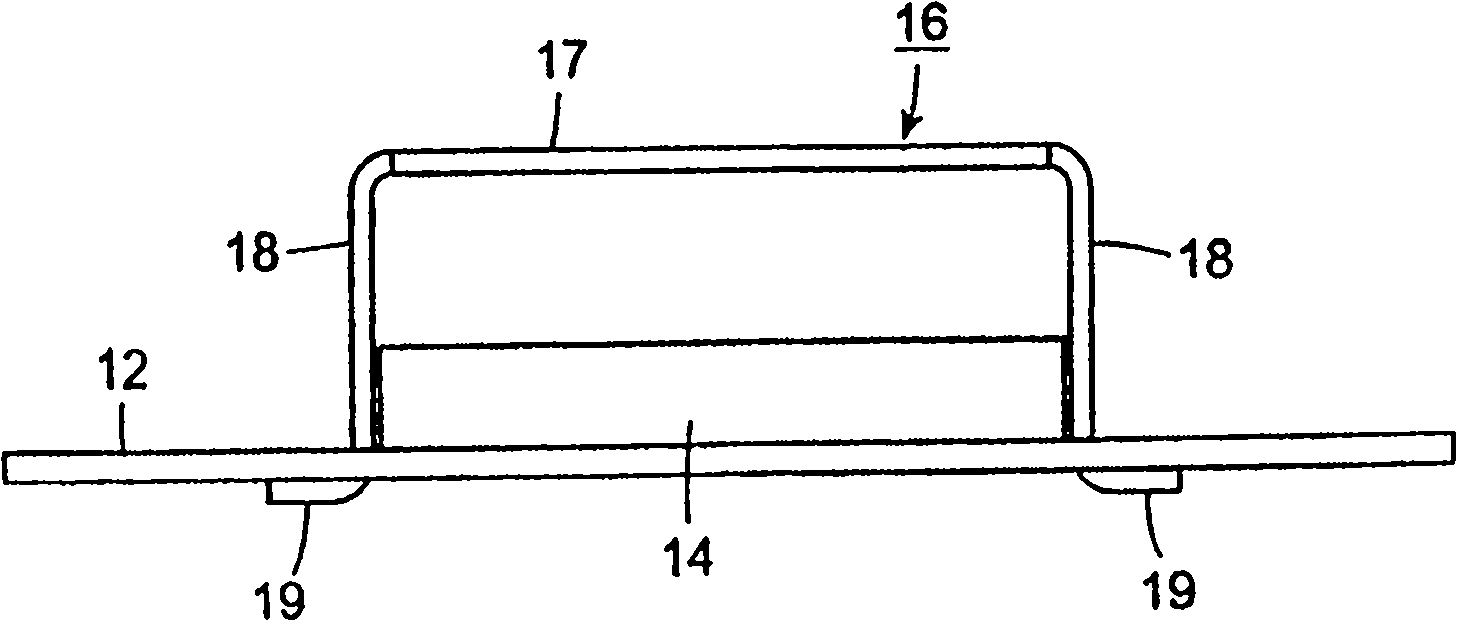

Valve for a contact tray

InactiveCN101138685AReduce loadIncrease capacityDistillation separationEngineeringMechanical engineering

The valve for a contract tray employs an aperture in a deck that is of rectangular or trapezoidal shape with upstanding walls at the sides of the aperture. The valve body is disposed in the aperture with a cover above the aperture and legs that extend downwardly to interfit with at least the upstream end of the walls to block the liquid flow. The valve body may be fixed or movable. In the movableembodiment, the valve body is seated on the walls about the aperture to close the aperture. The ascending vapor lifts the valve to allow bubbling of the vapor in the liquid on the deck.

Owner:SULZER CHEMTECH AG

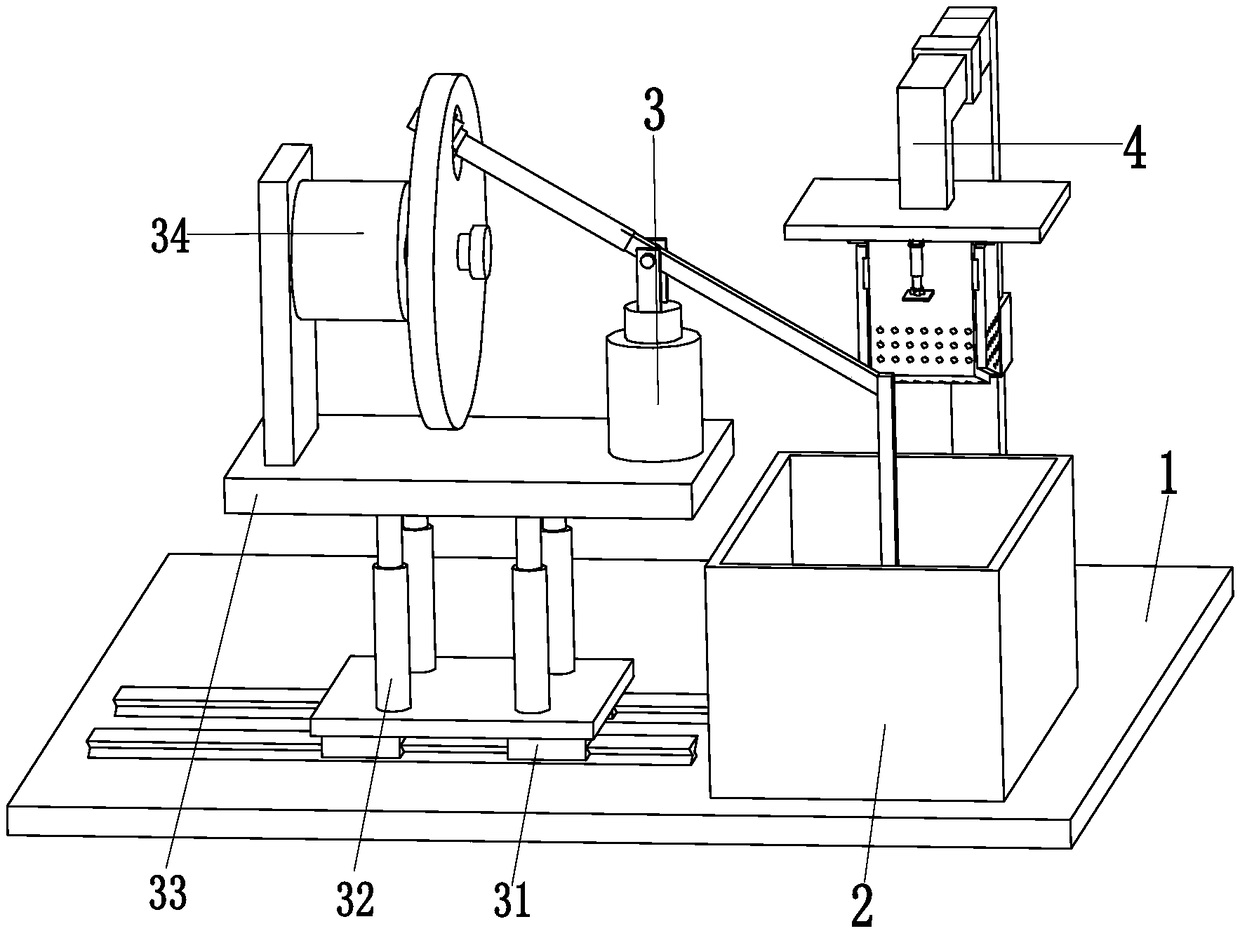

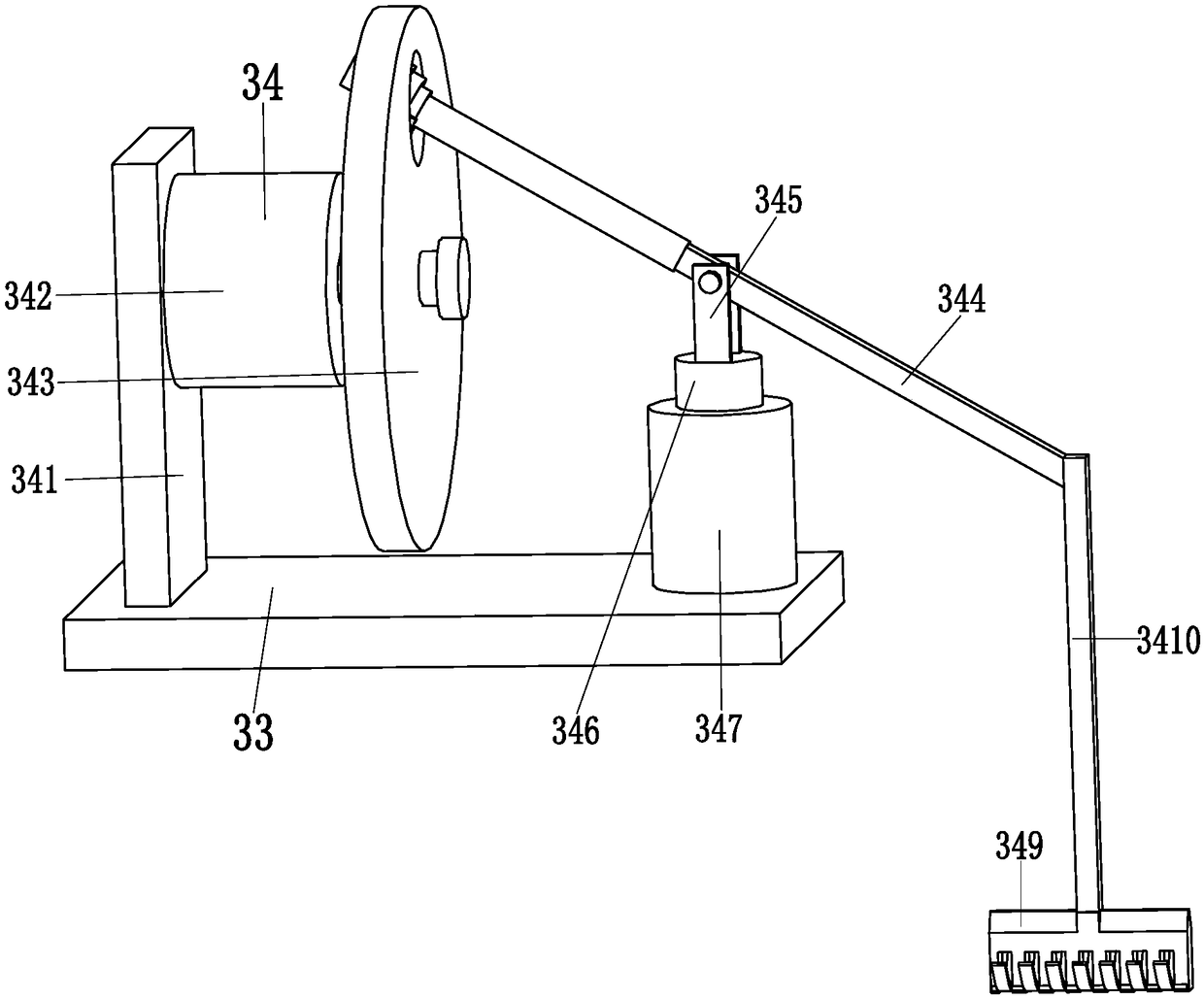

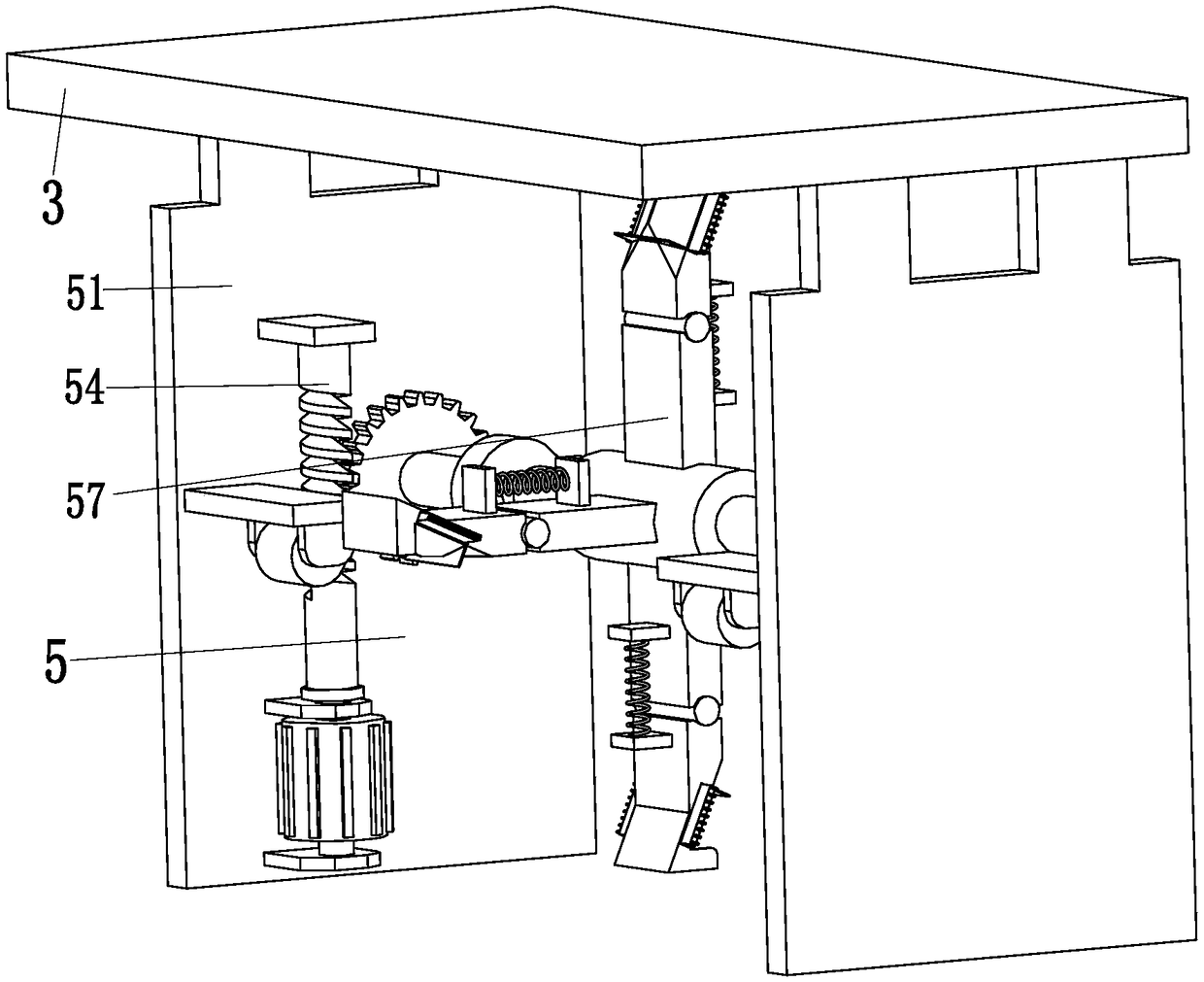

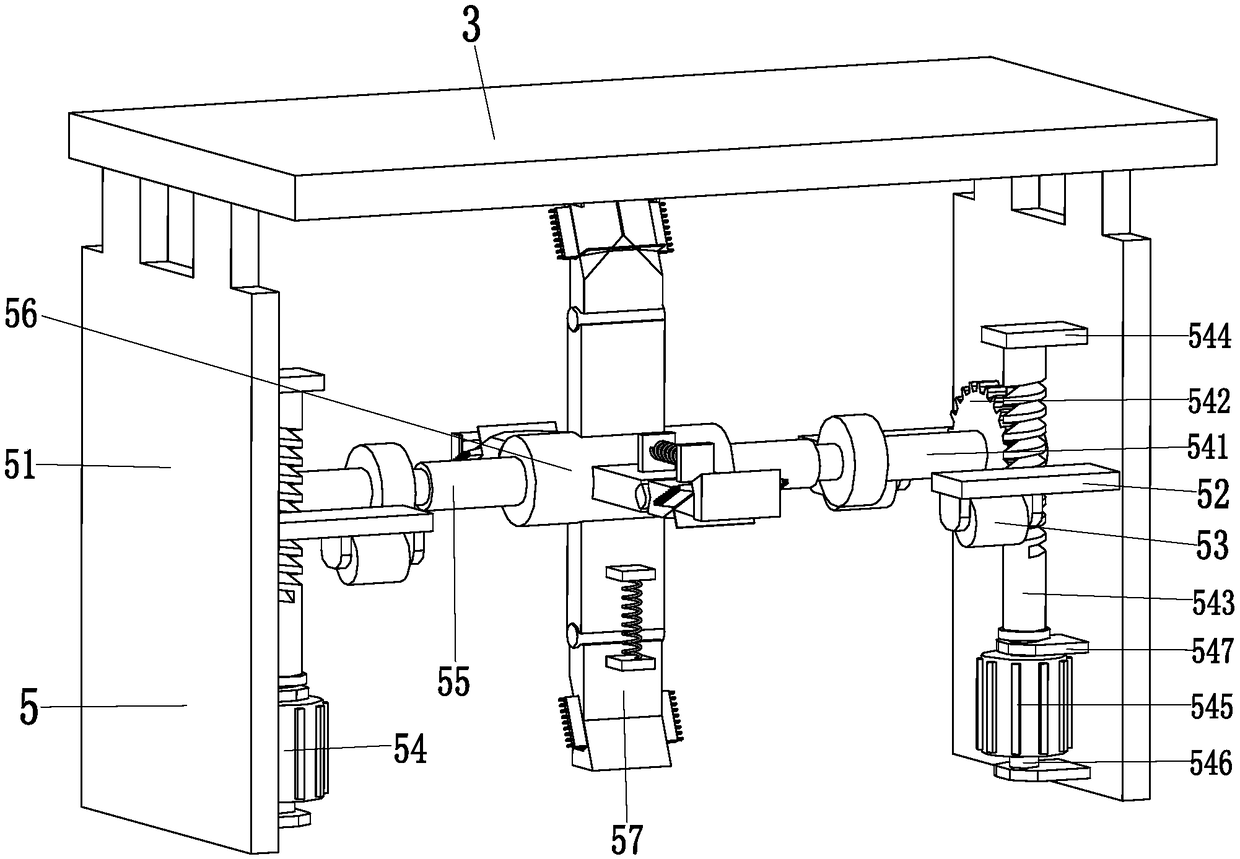

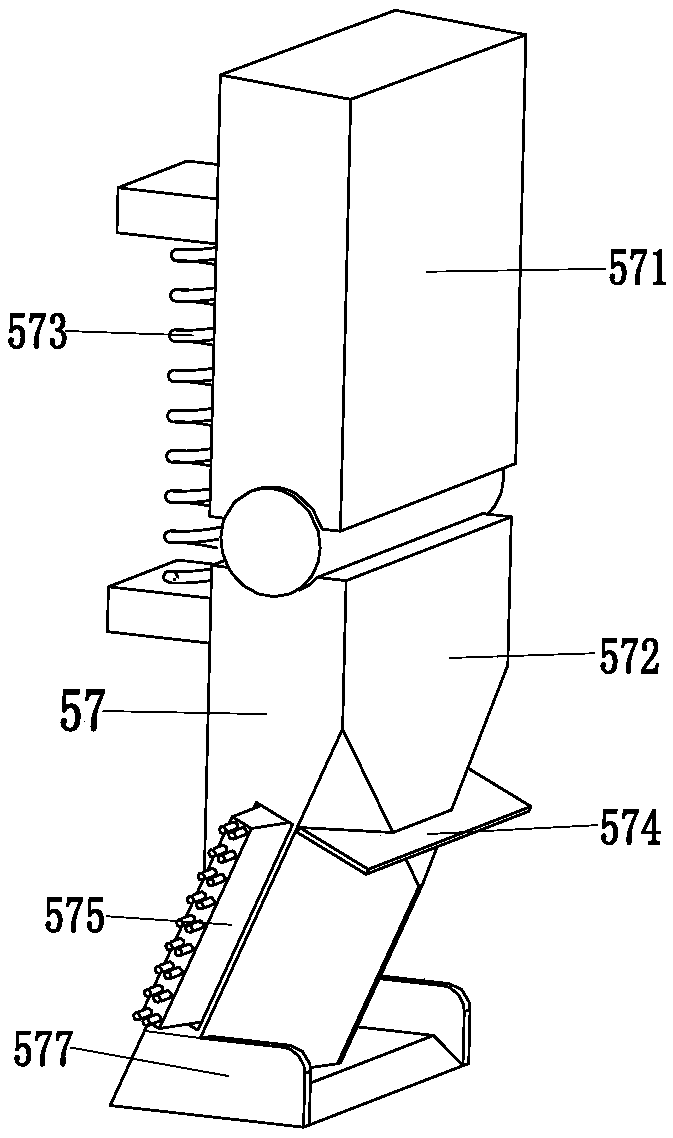

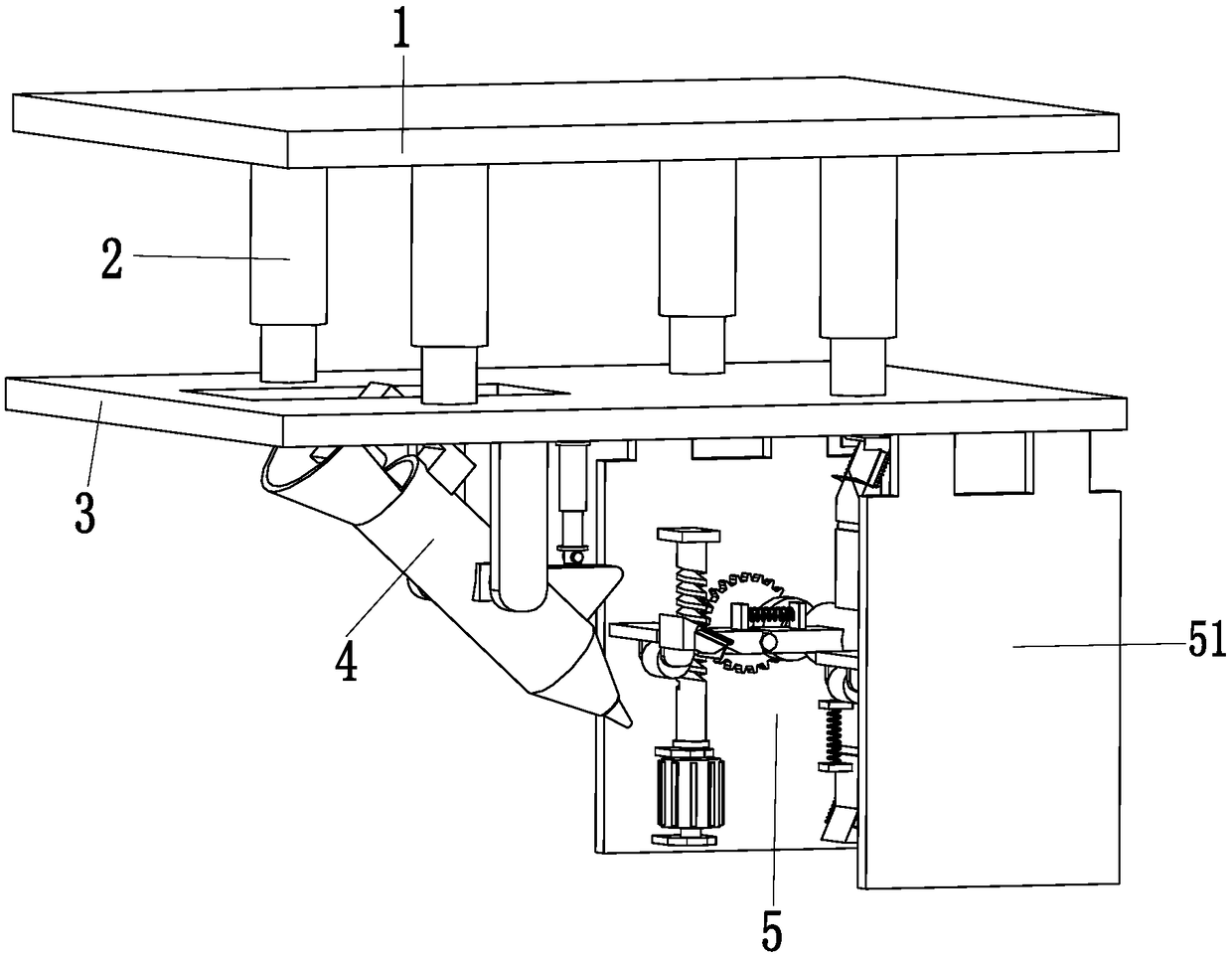

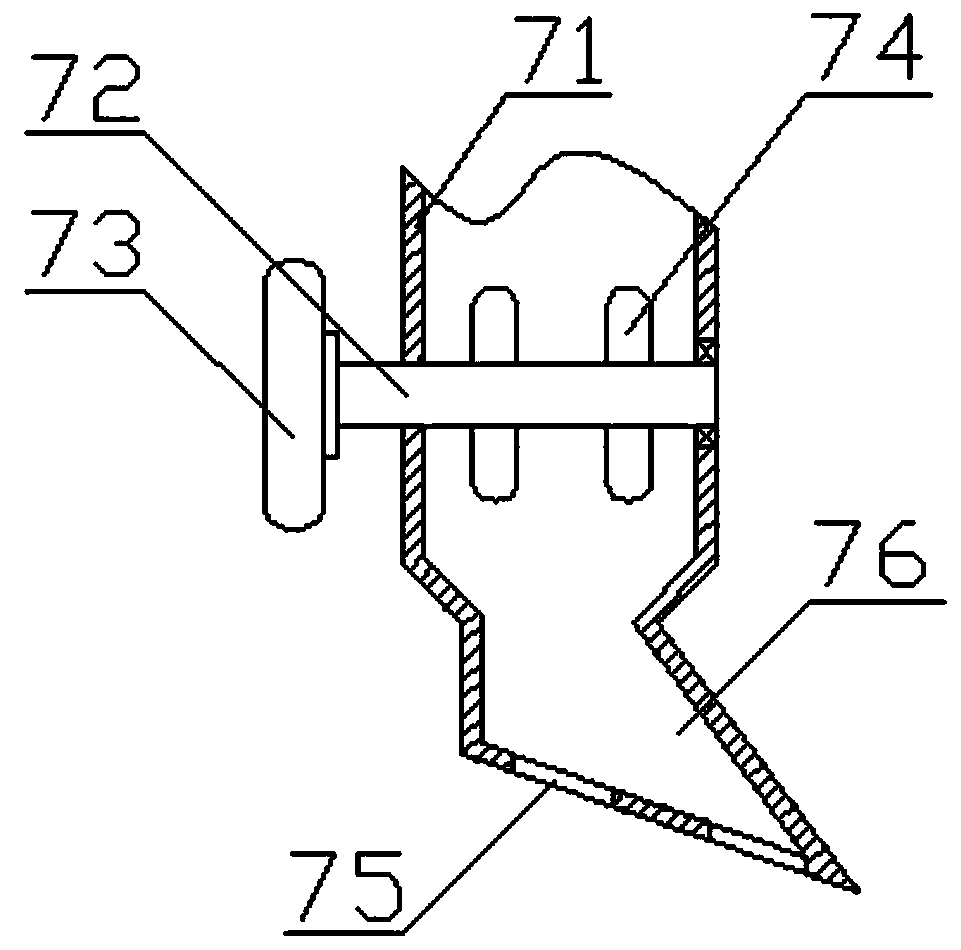

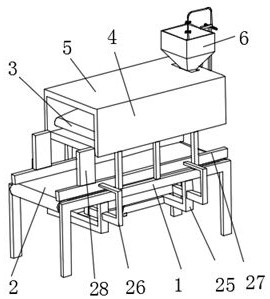

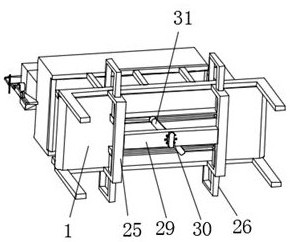

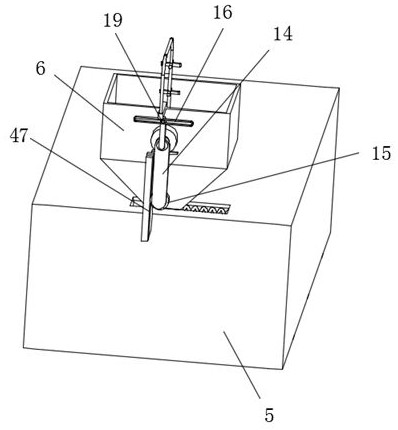

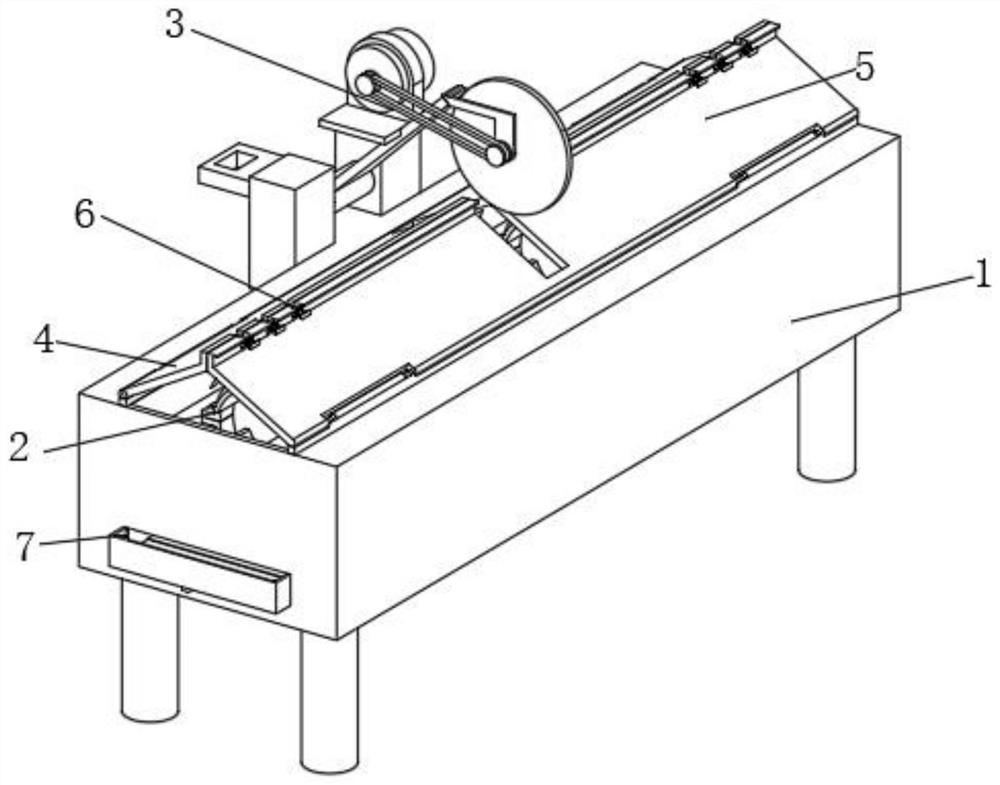

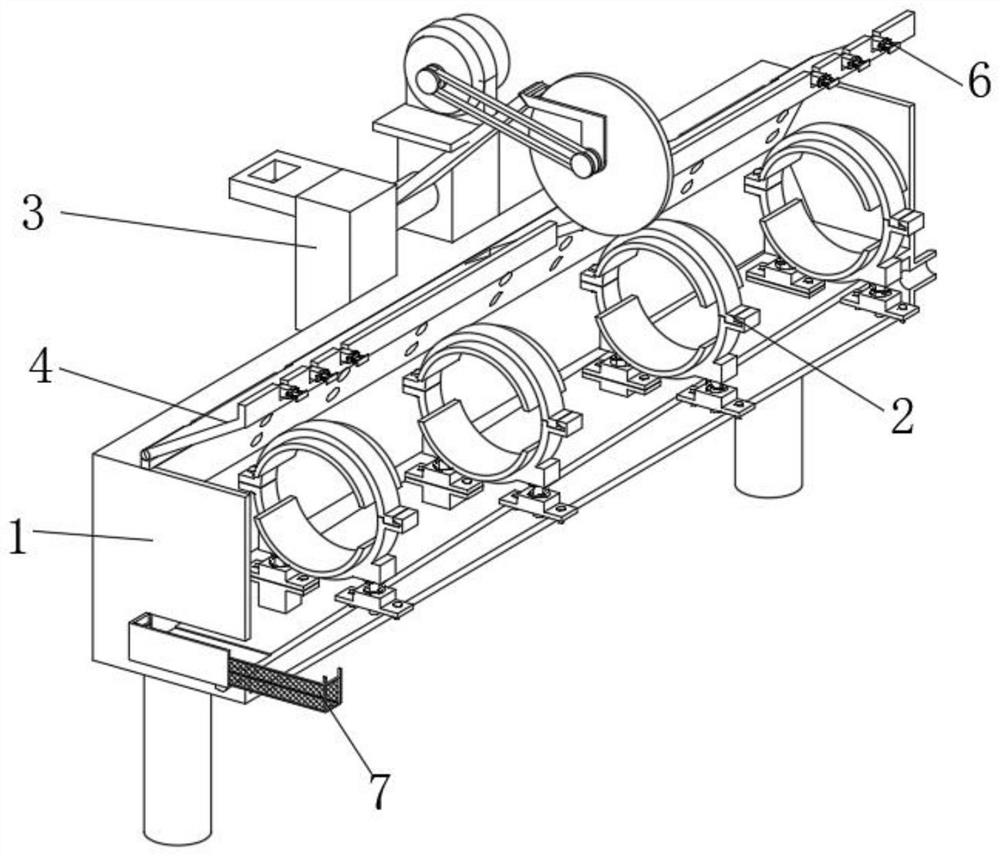

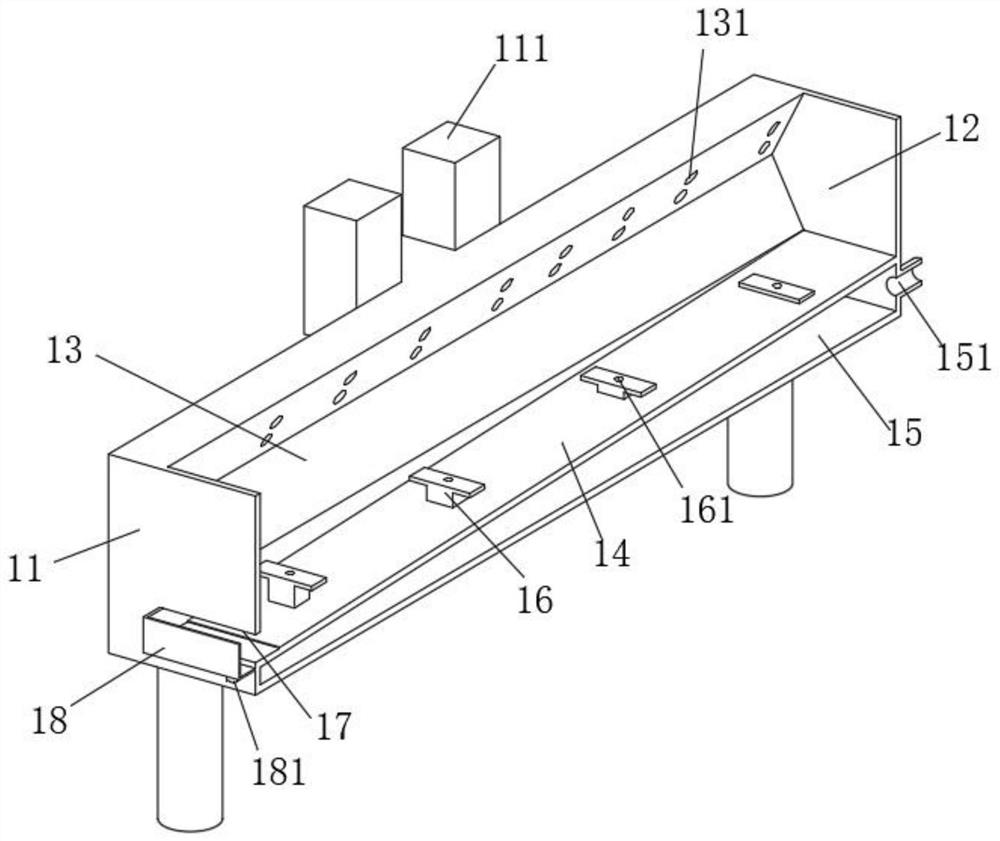

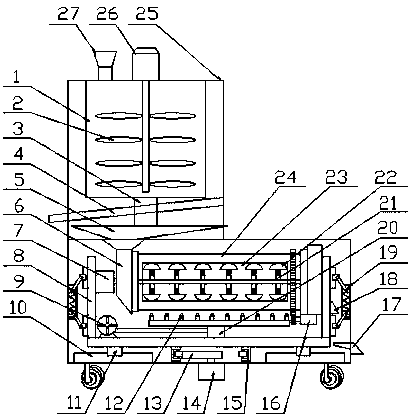

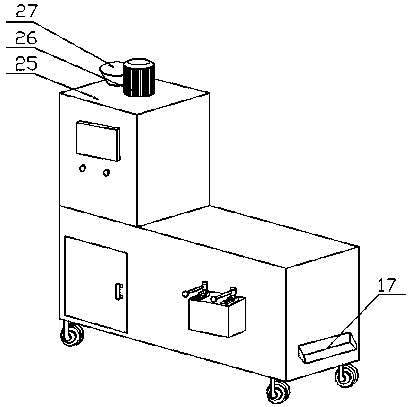

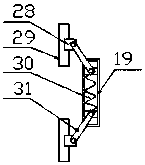

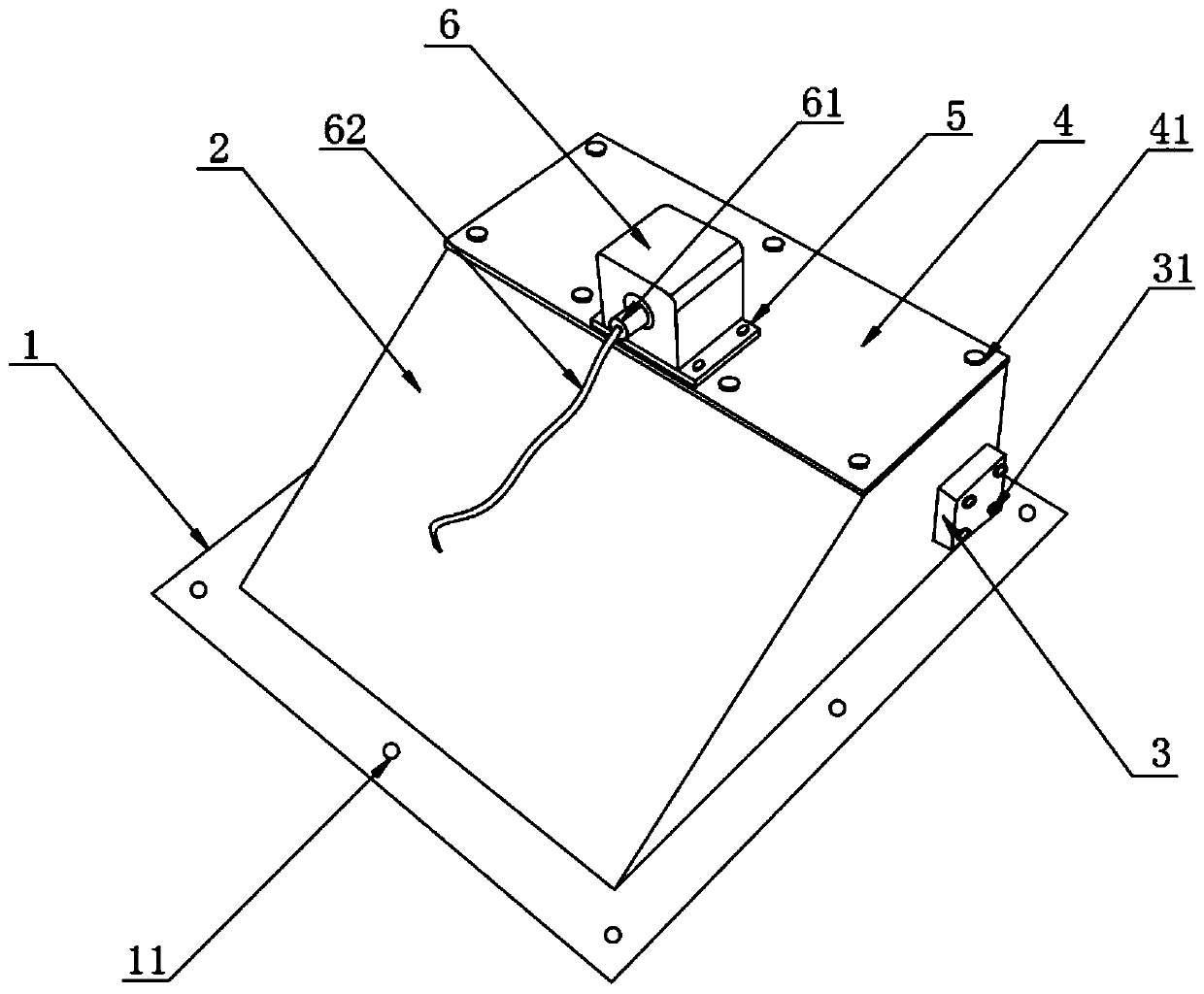

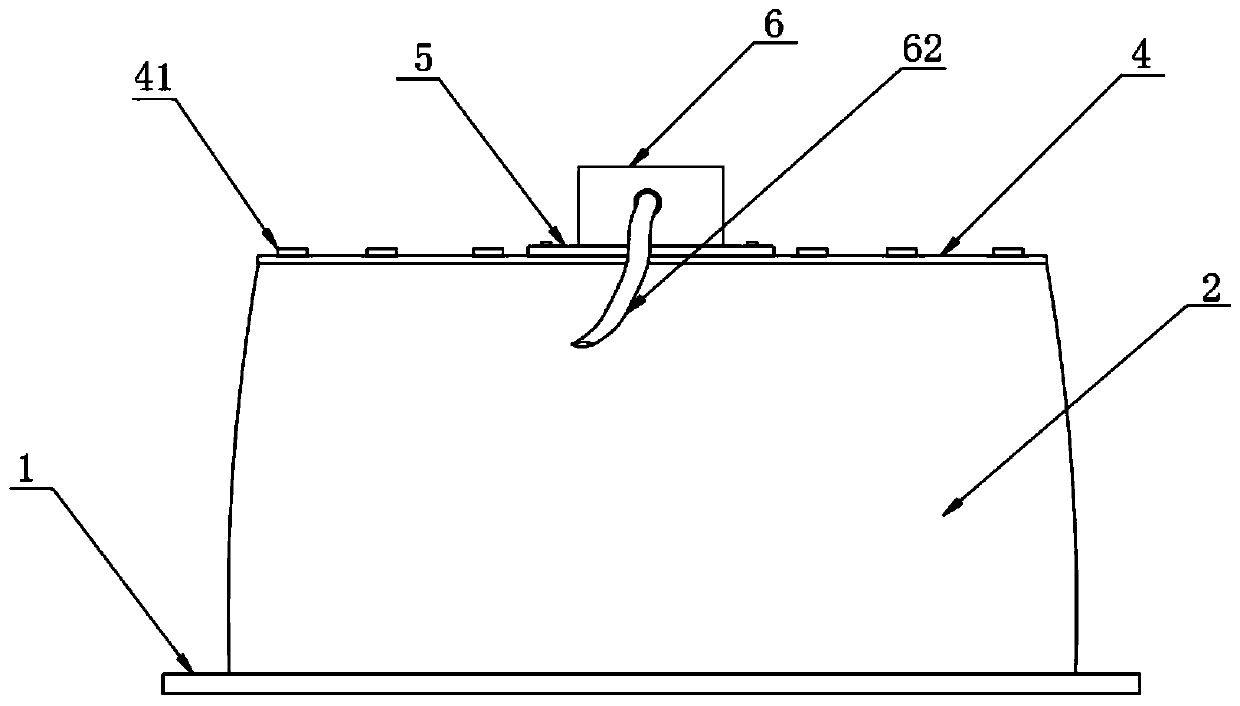

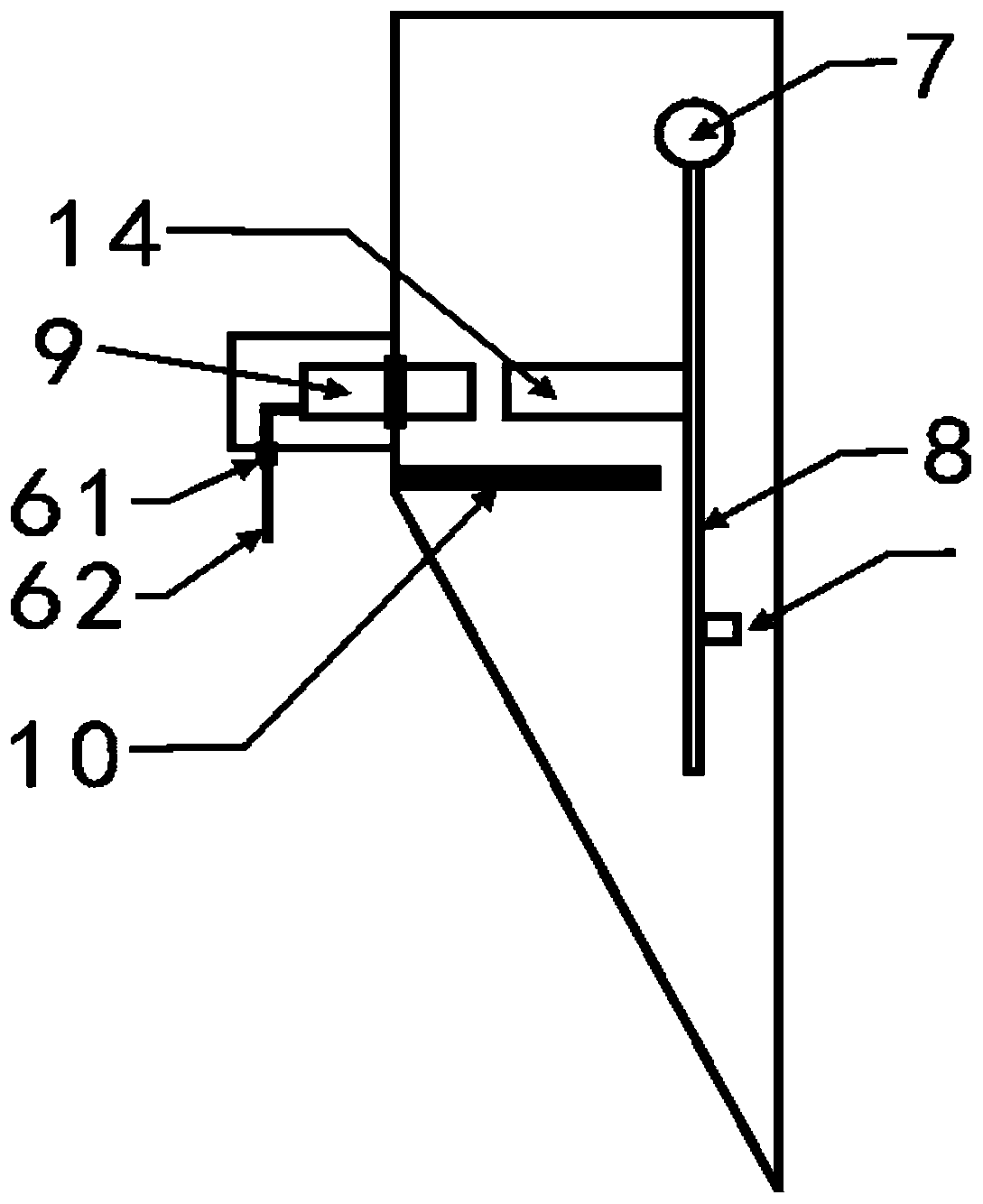

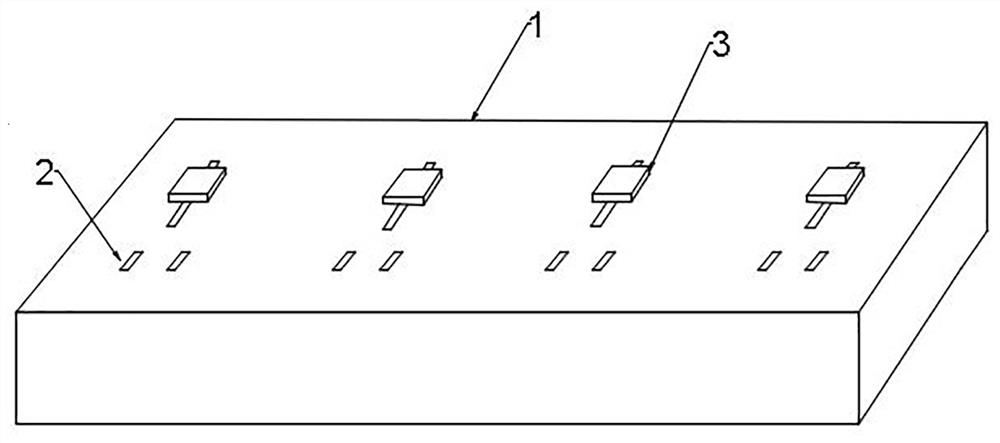

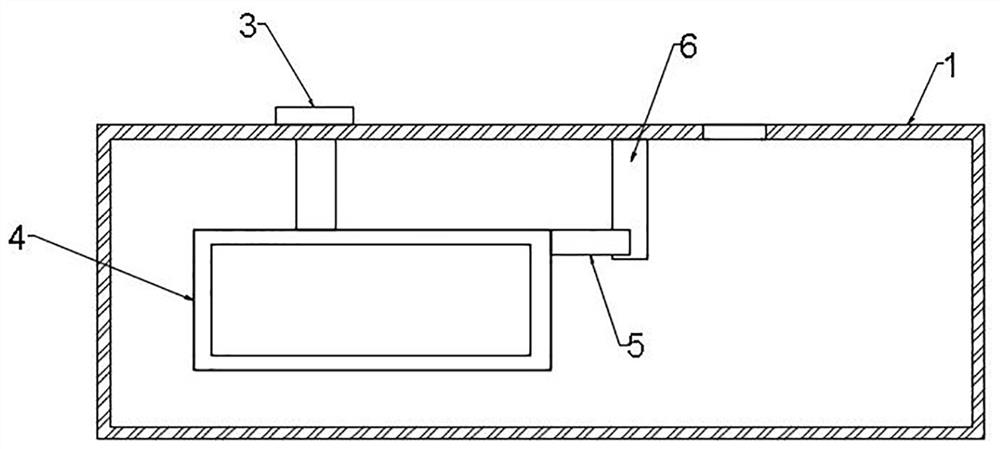

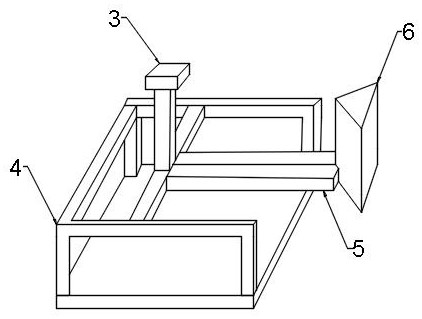

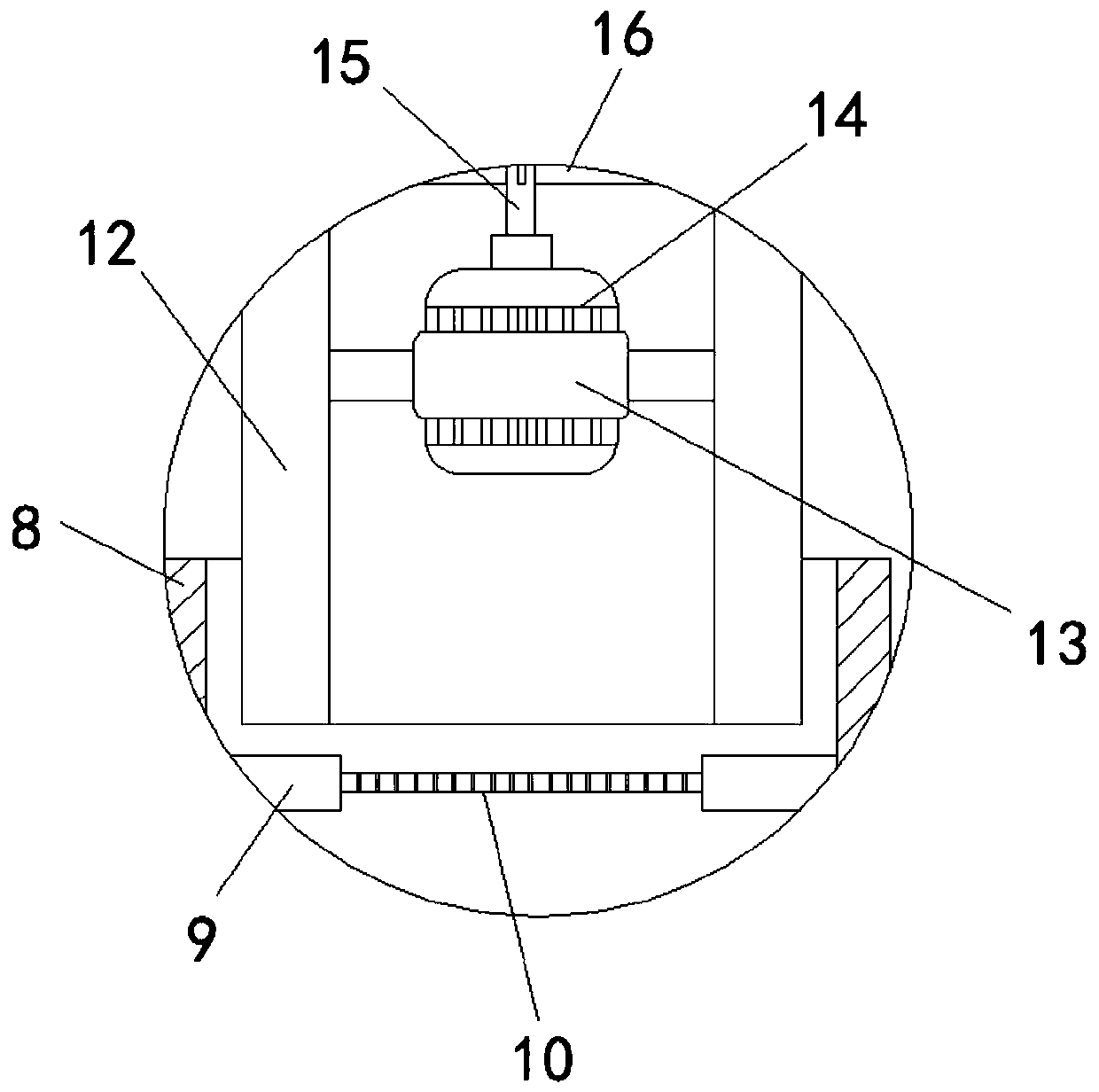

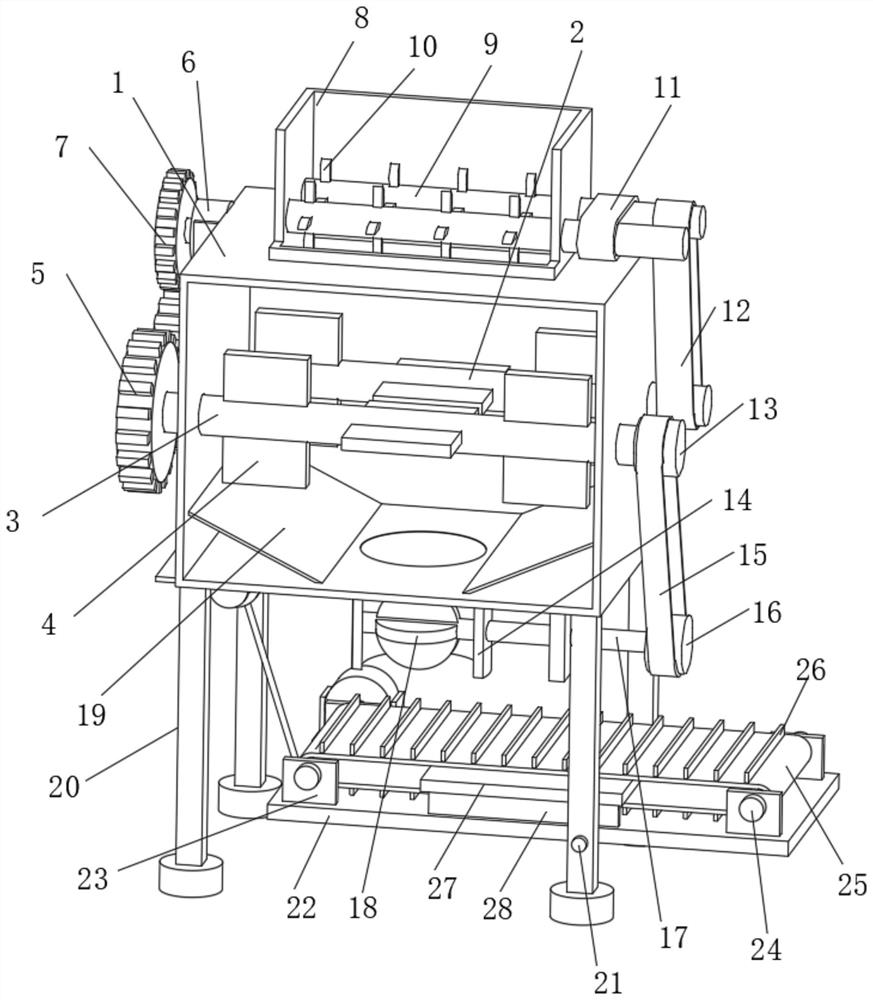

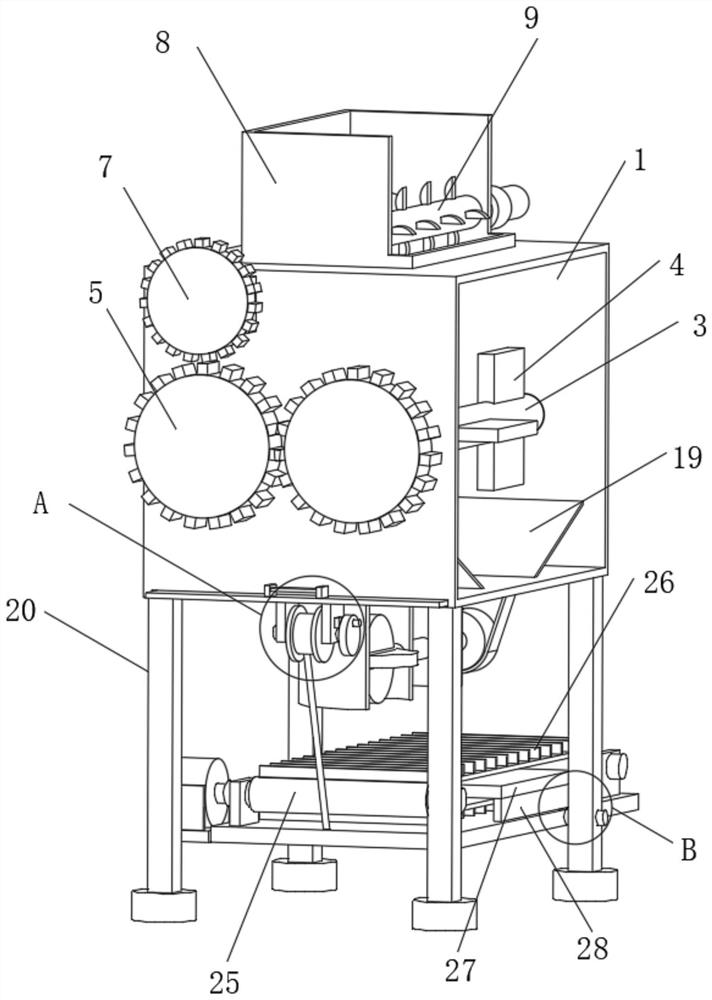

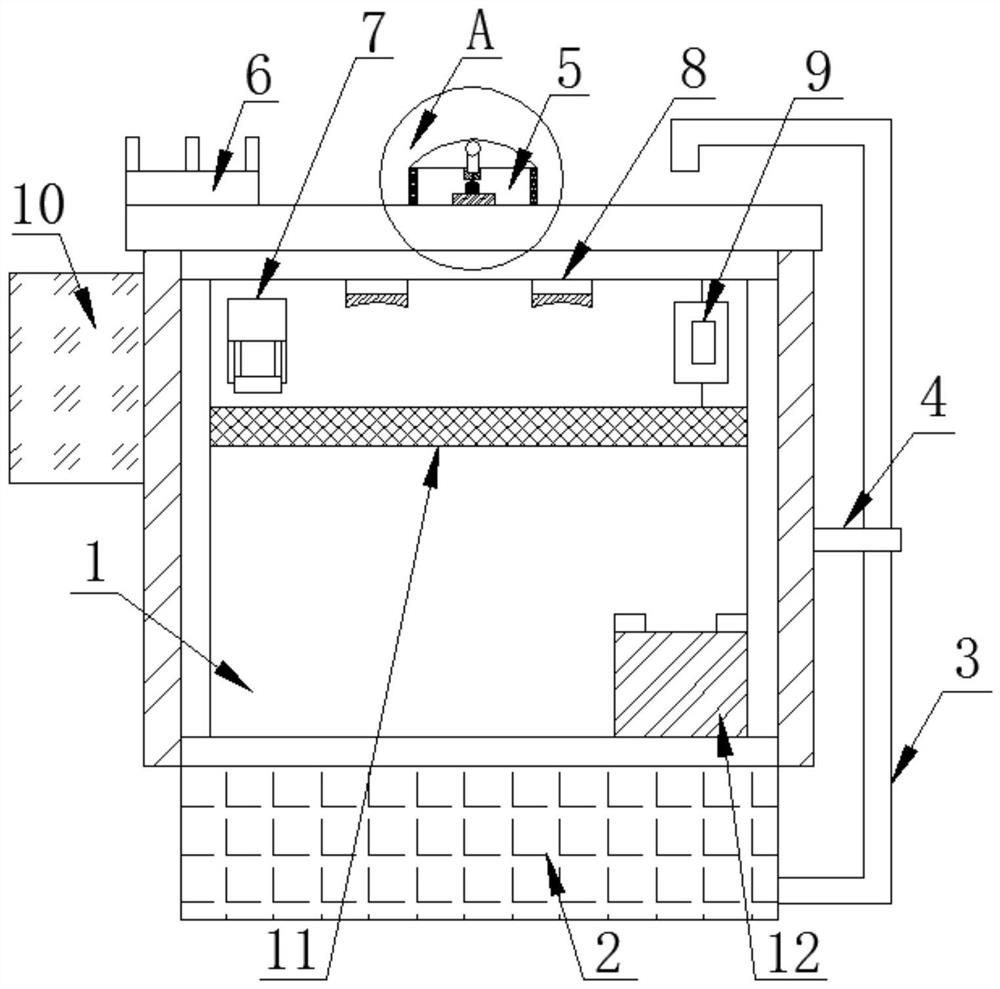

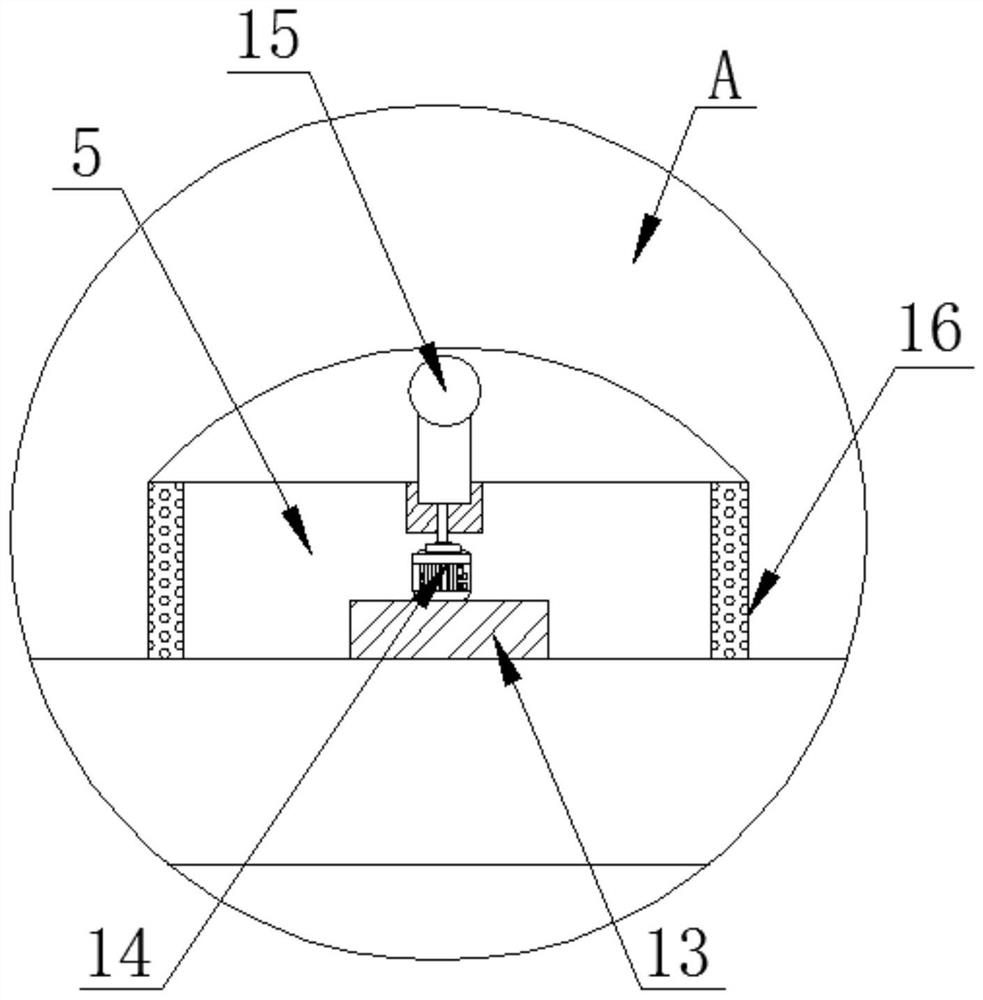

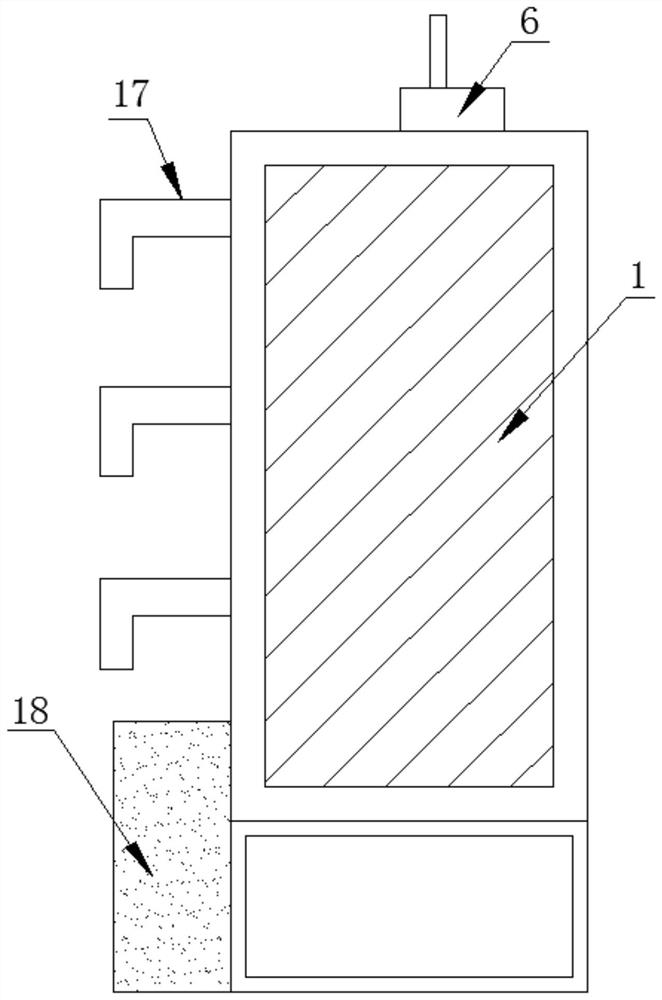

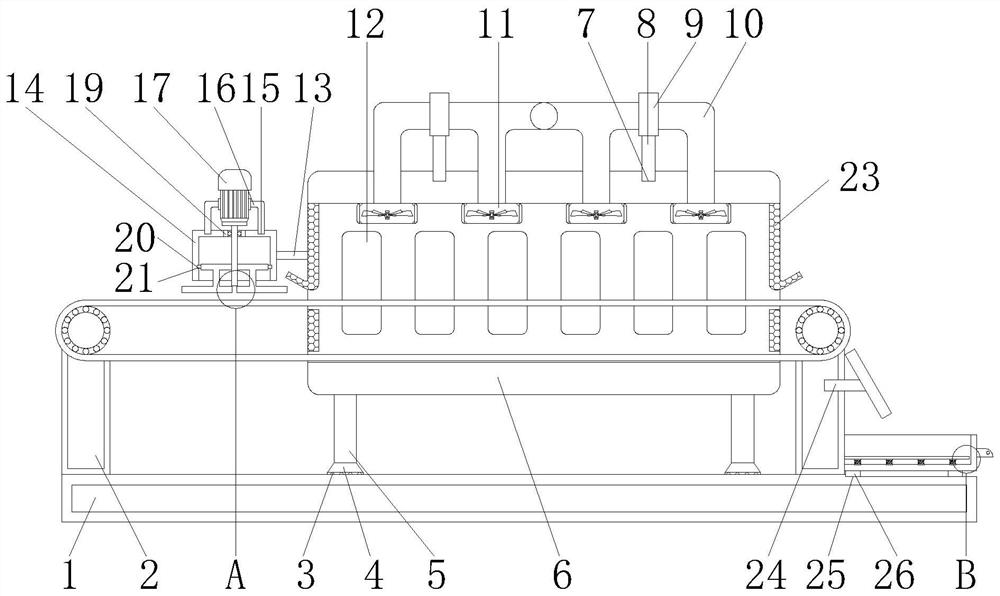

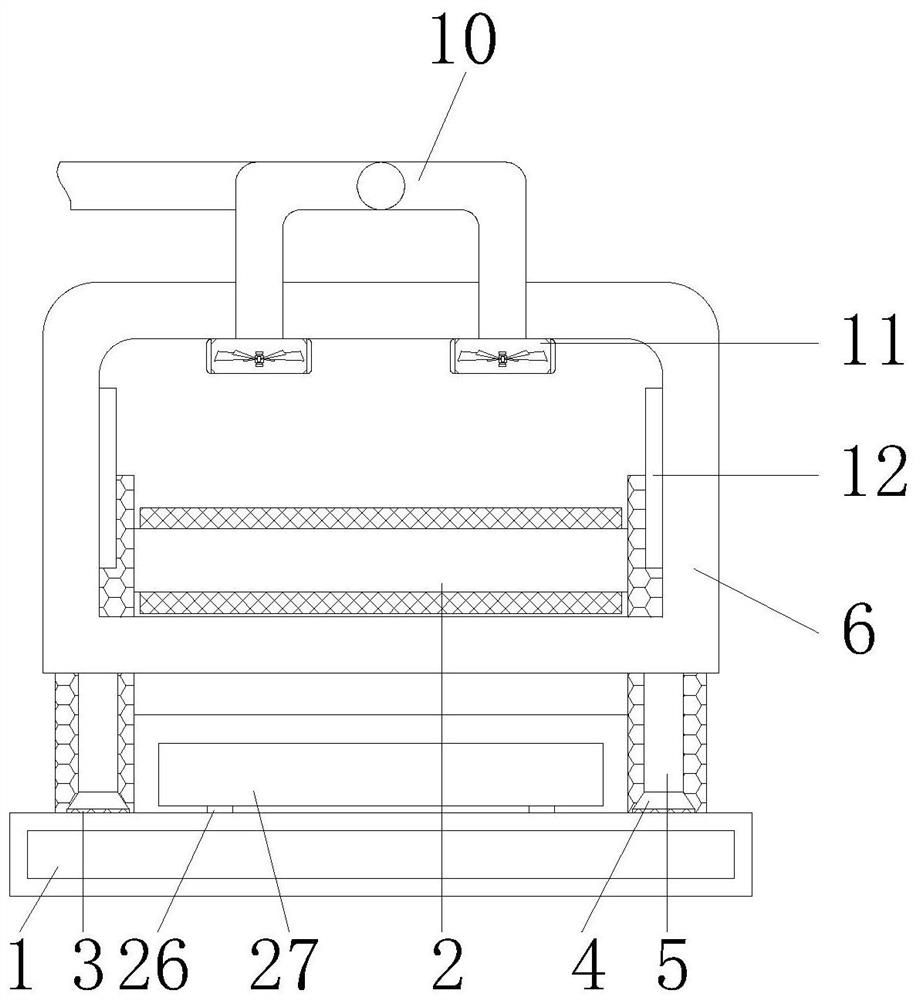

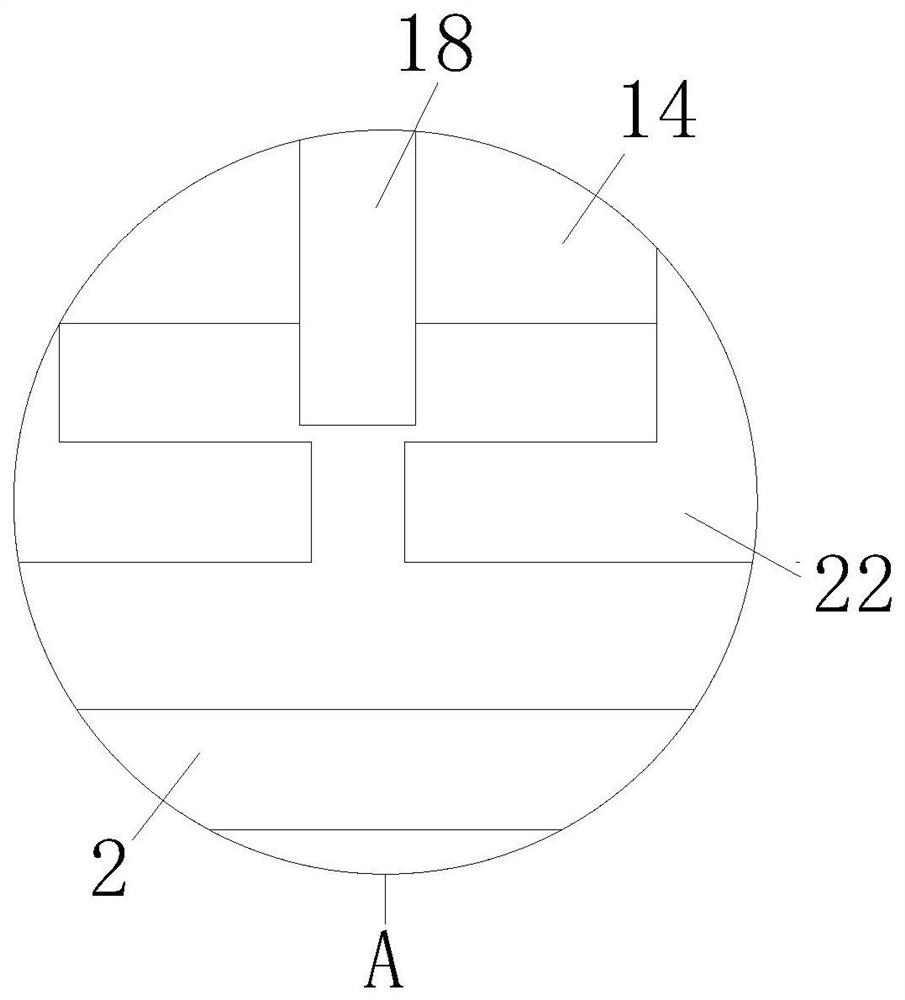

Aluminum processing melting slag cleaning production line and production processing method thereof

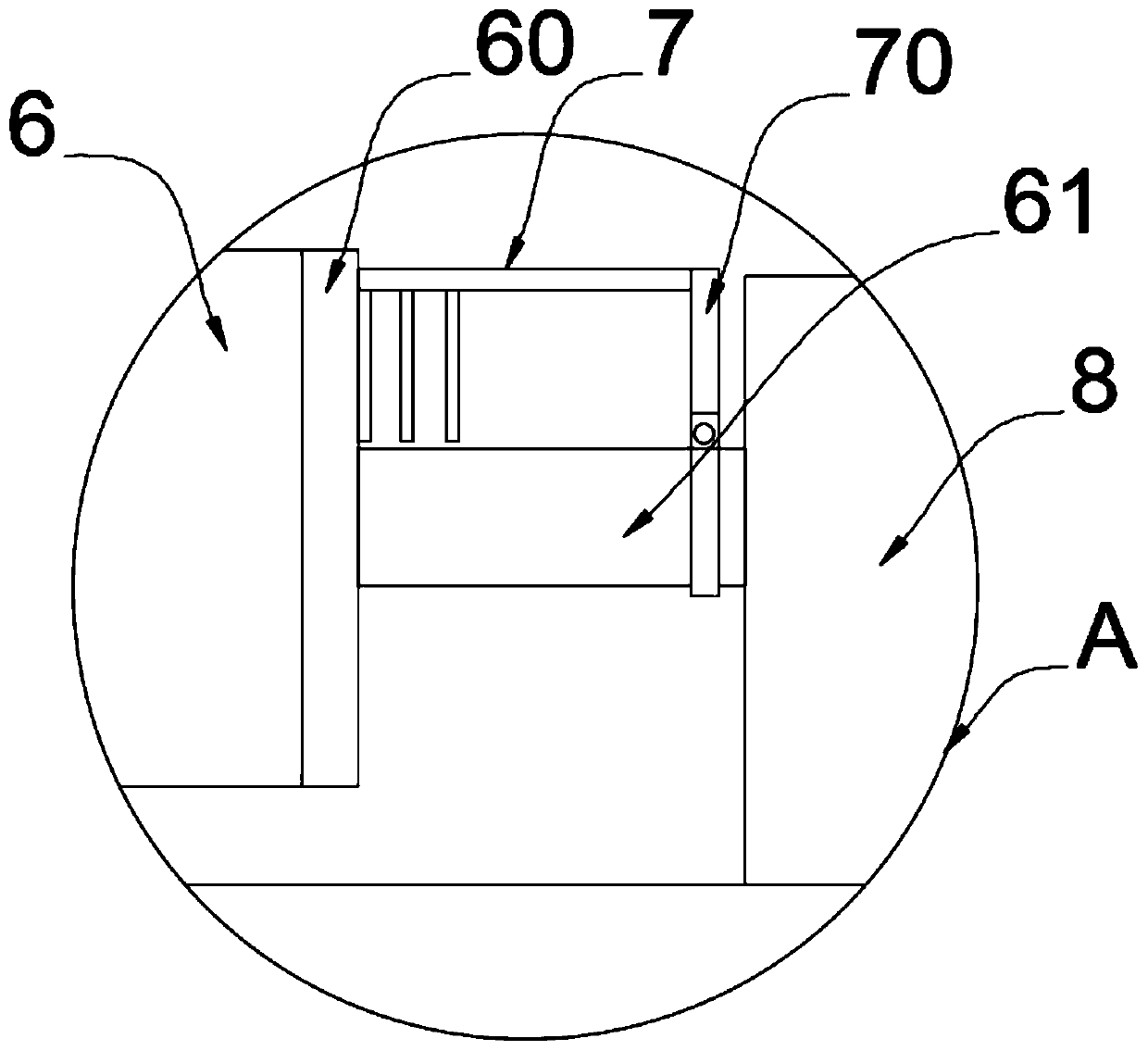

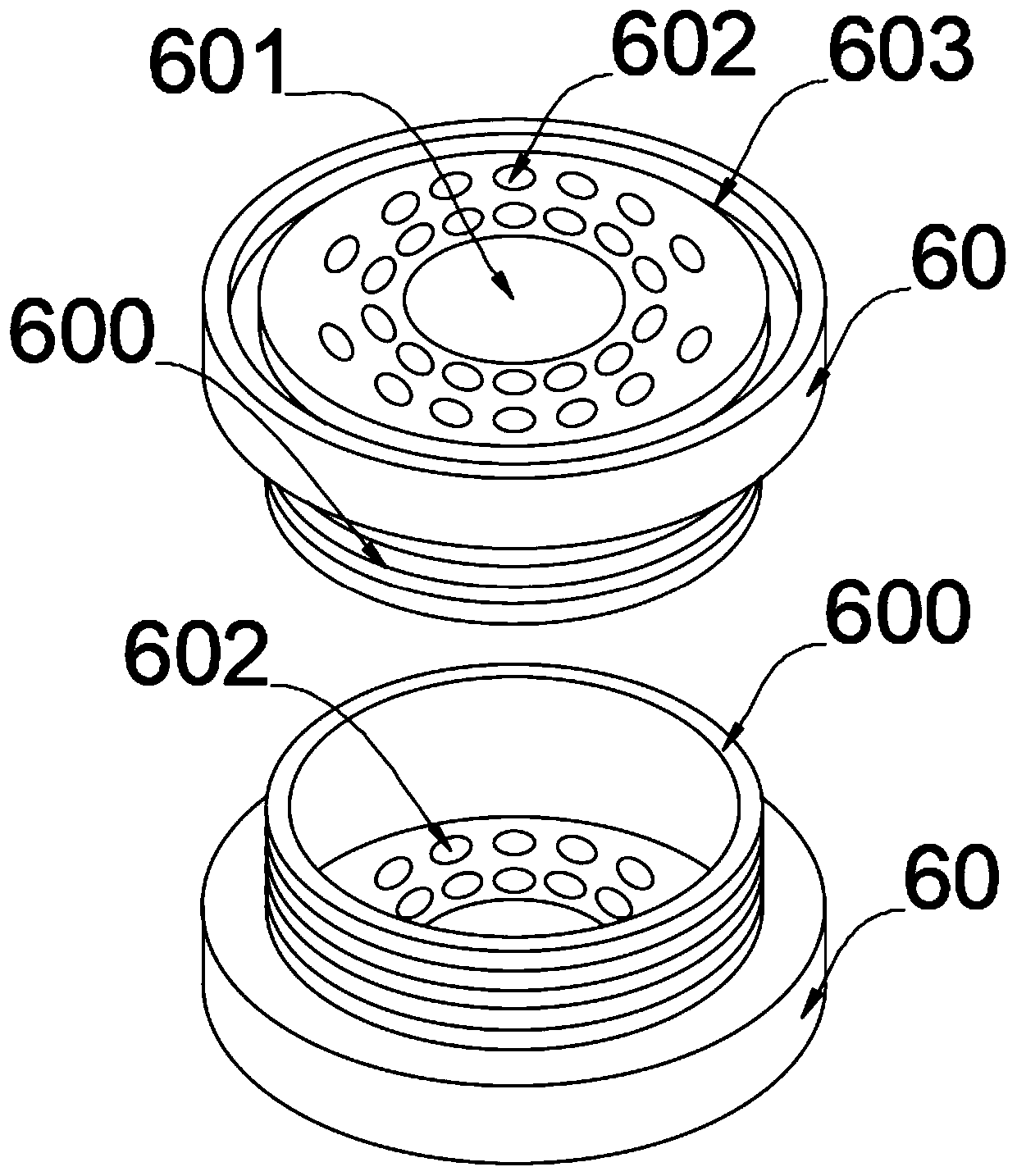

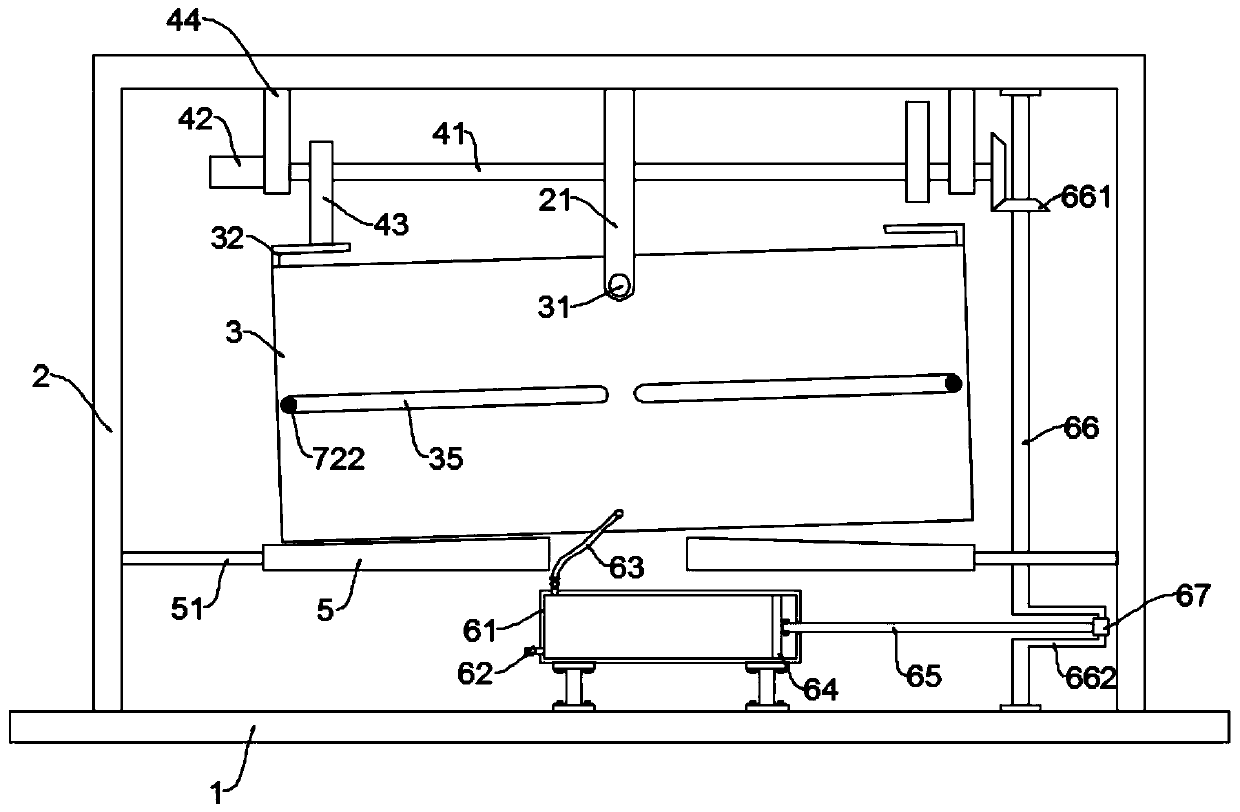

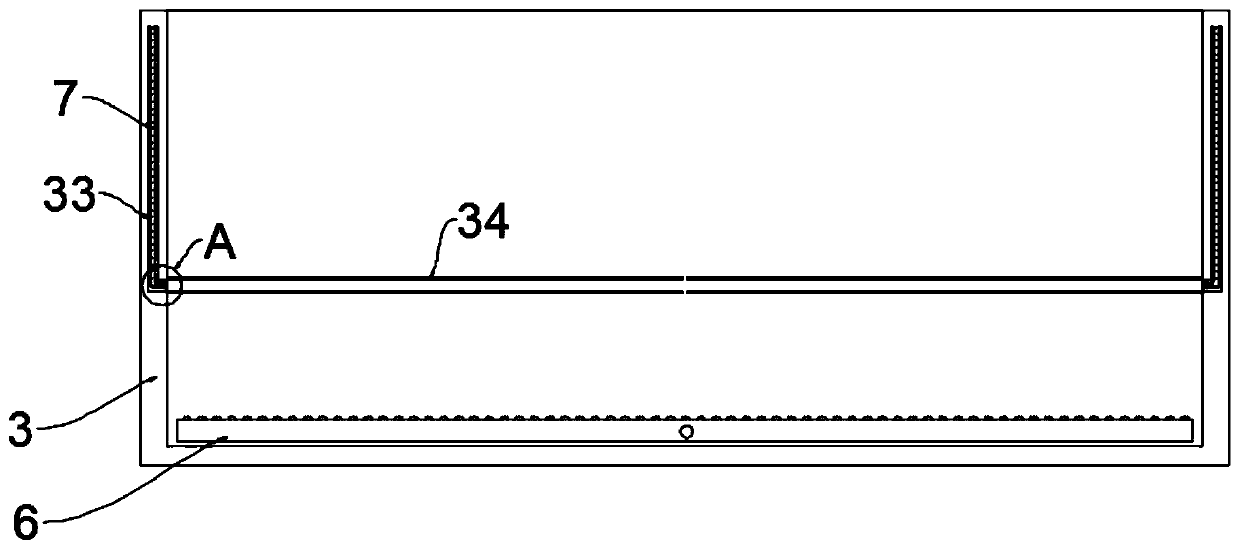

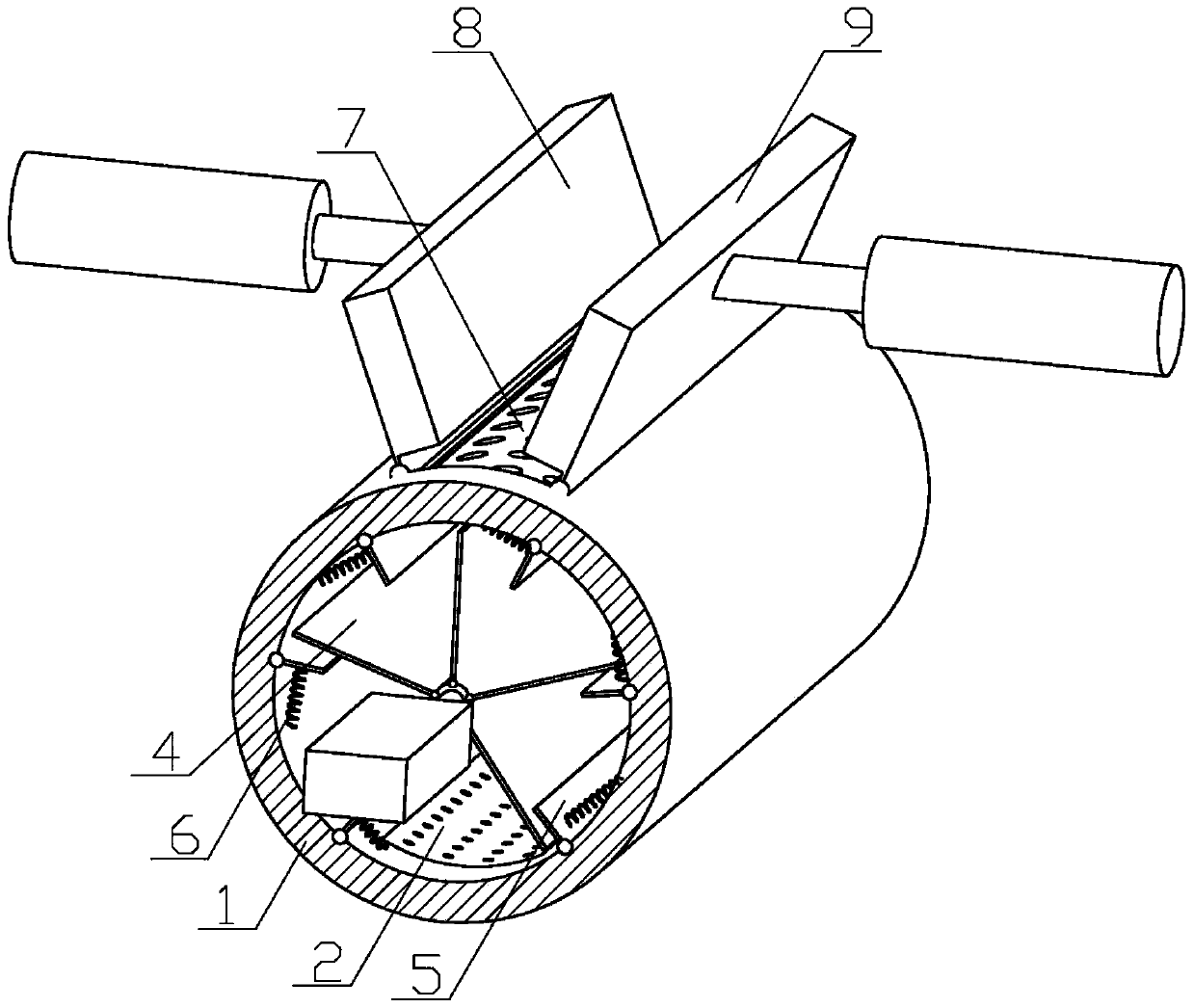

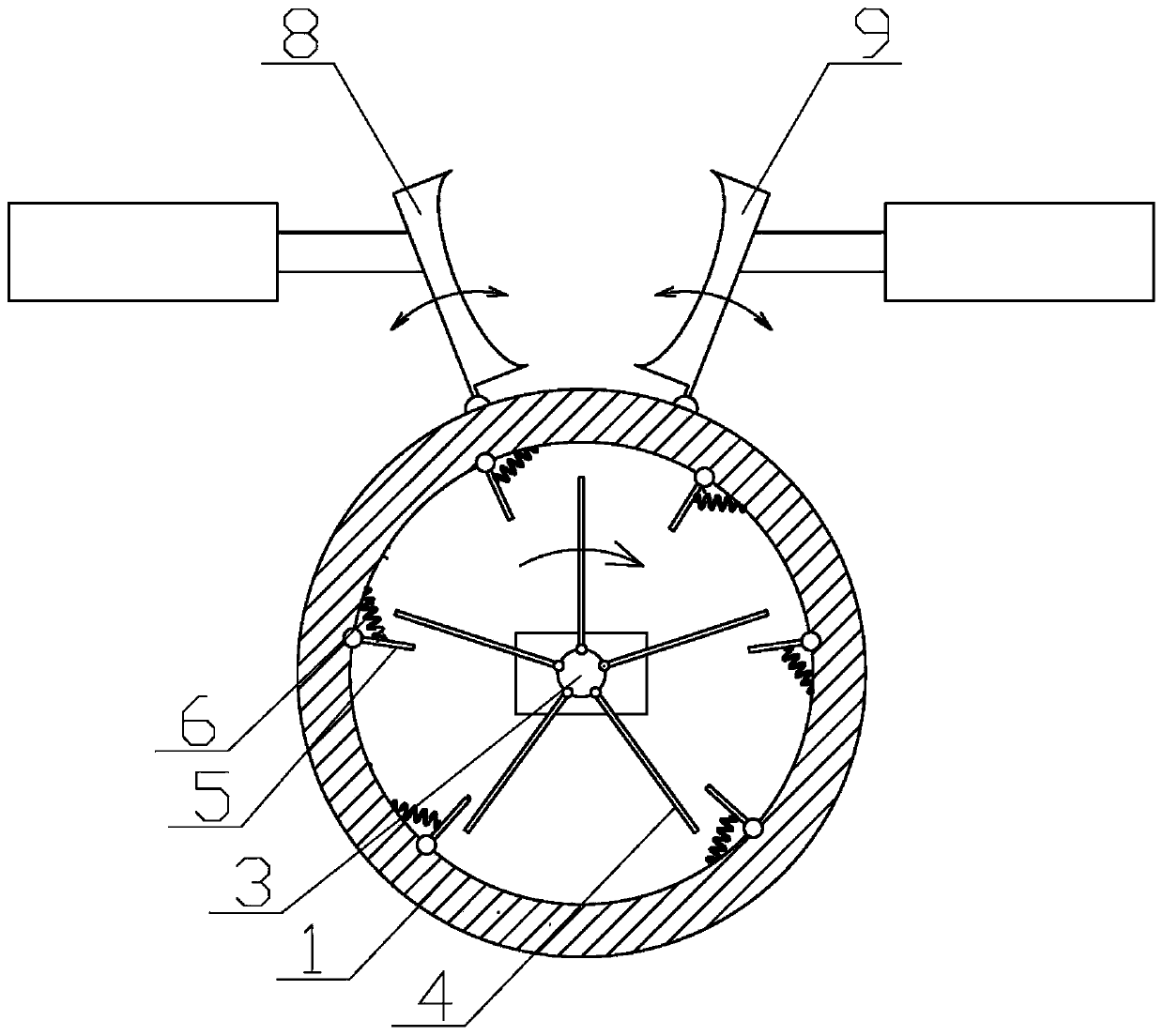

ActiveCN108856696AImprove the mixing effectAccumulation will notStirring devicesCasting cleaning apparatusProduction lineSlag

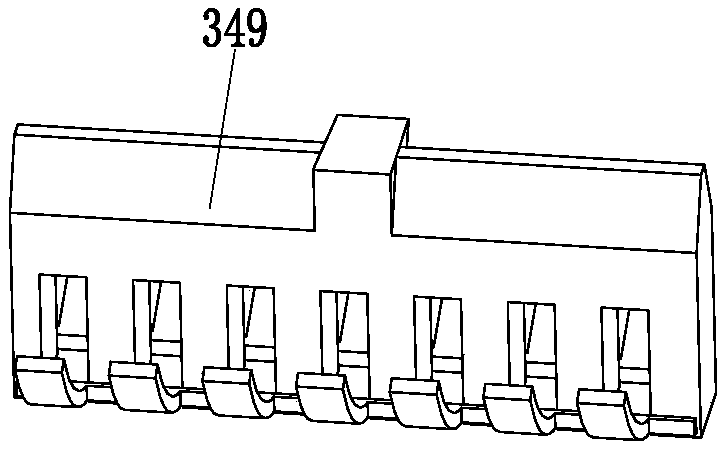

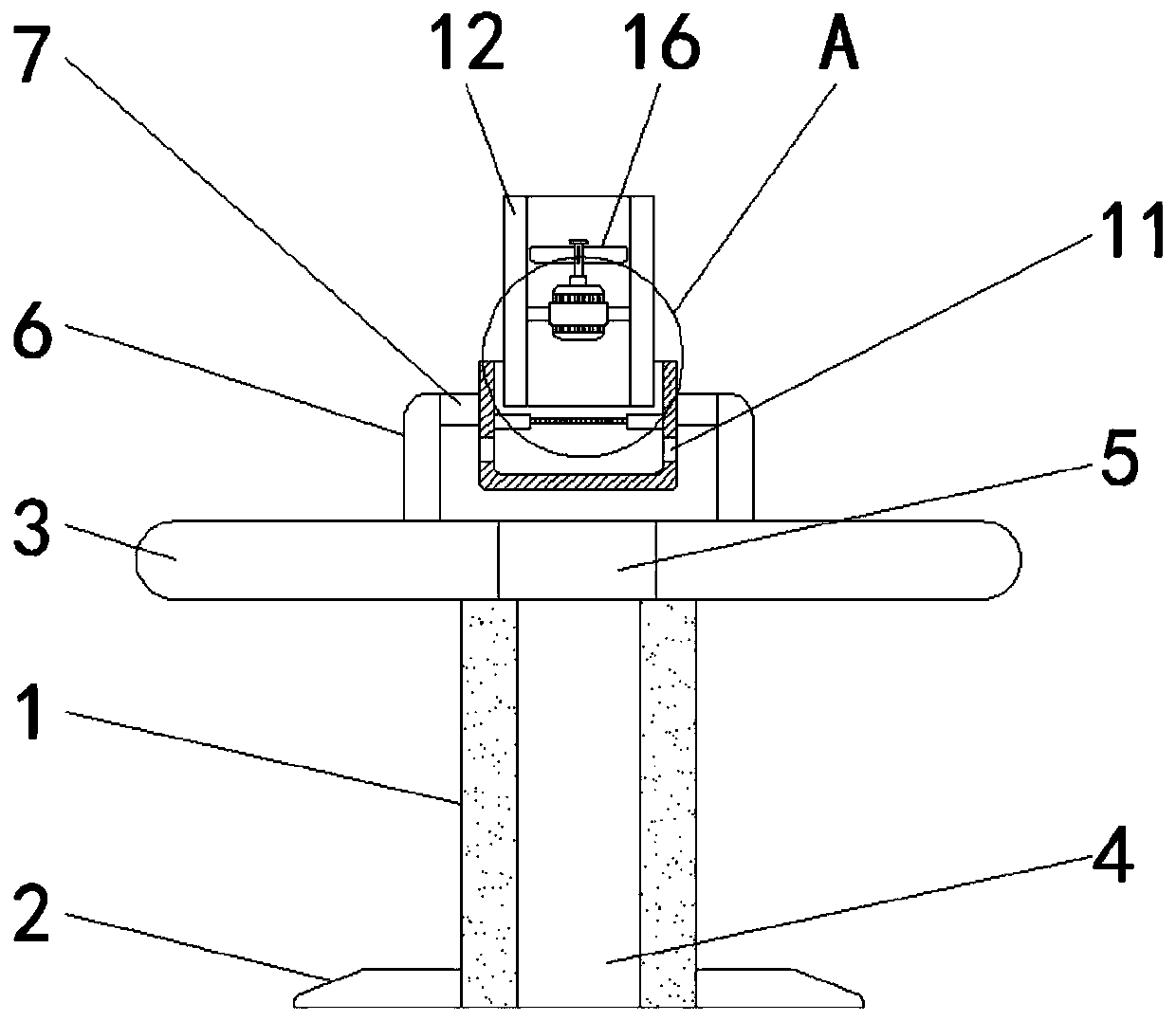

The invention relates to an aluminum processing melting slag cleaning production line and a production processing method thereof. The production line comprises a supporting bottom plate, a melting furnace, a stirring feeding device and a slag cleaning device, the melting furnace is arranged in the middle of the front end of the supporting bottom plate, the stirring feeding device is installed on the top of the supporting bottom plate, the slag cleaning device is located on the rear side of the melting furnace, and the slag cleaning device is connected with the top of the rear end of the supporting bottom plate; the stirring feeding device comprises an electric sliding block group, a stirring push rod, a stirring supporting plate and a stirring mechanism; the stirring mechanism comprises astirring upright plate, a stirring motor, a stirring rotary disc, a stirring connecting rod, a stirring lug seat, a stirring connecting seat, a stirring supporting platform, a clamping supporting chain, a stirring claw and a stirring upright rod. By means of the production line and the production processing method thereof, the existing difficult problems of the failure of performing all-directionstirring on aluminum liquid, poor aluminum liquid stirring effect, the accumulation of a large amount of aluminum on an aluminum liquid stirring rod, the failure of performing all-direction cleaning on impurities on the aluminum liquid, and low efficiency of impurity cleaning on the aluminum liquid in existing aluminum melting process are solved.

Owner:清苑县中久有色金属合金制造有限公司

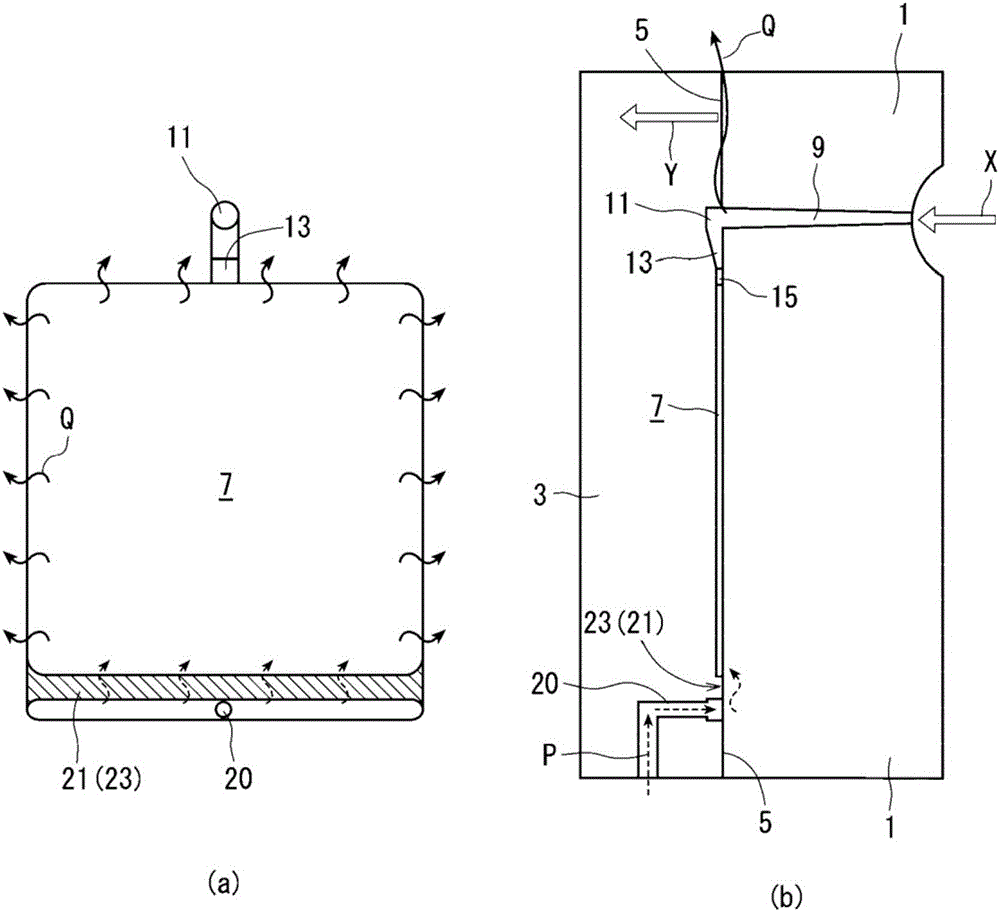

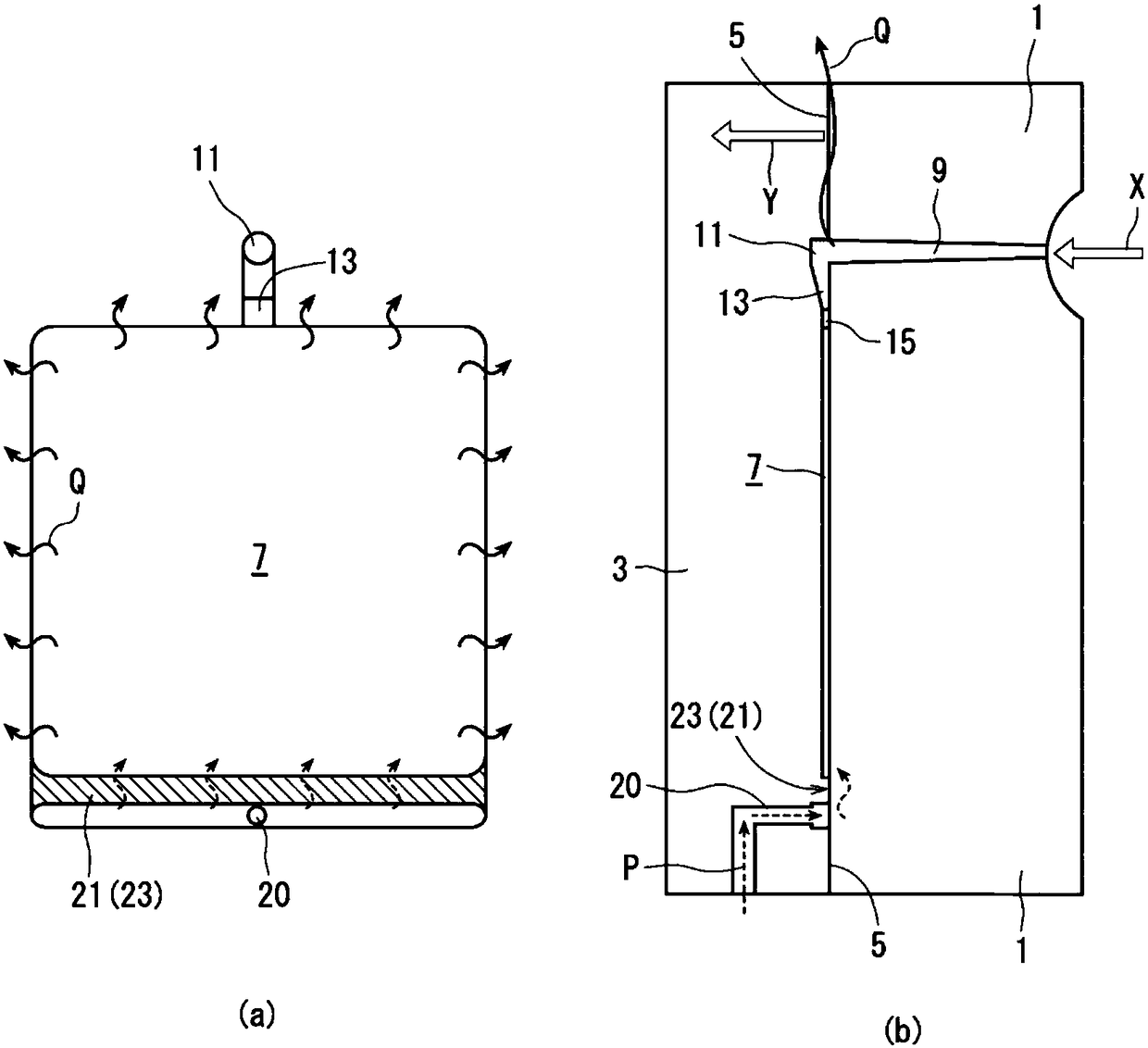

Air conditioner

InactiveCN101040152AReduce the amount of adhesionShorten the timeSpace heating and ventilation safety systemsLighting and heating apparatusPlate heat exchangerBlow out

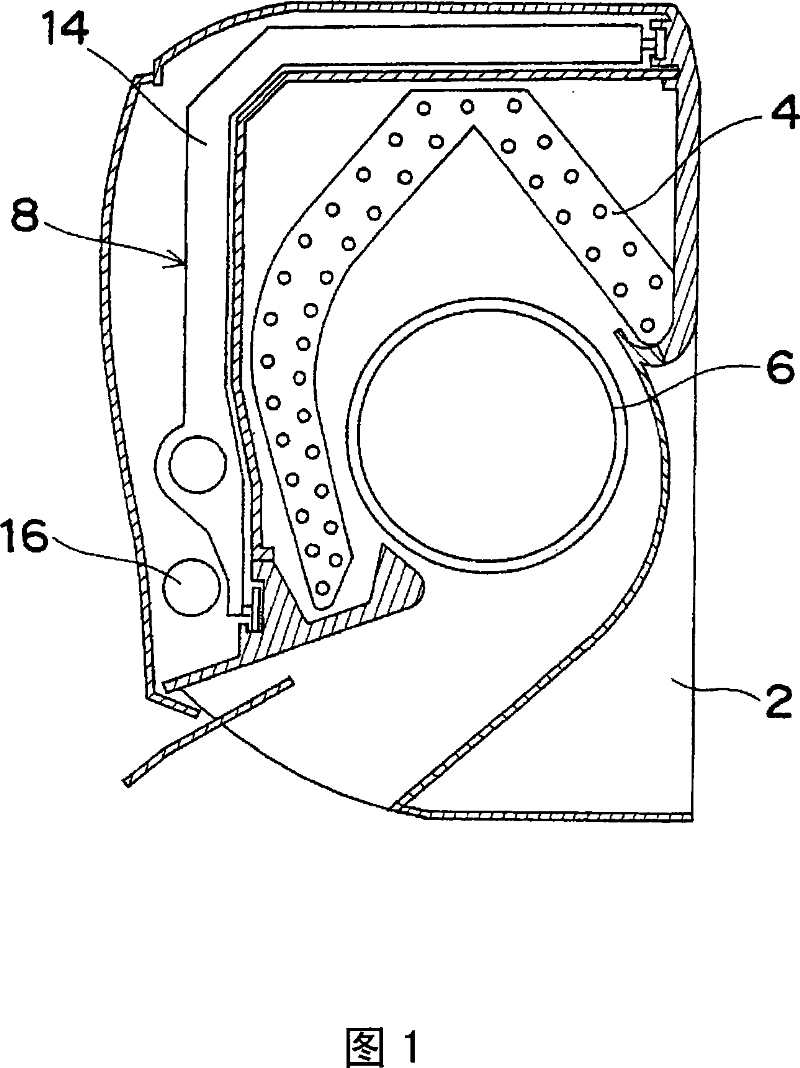

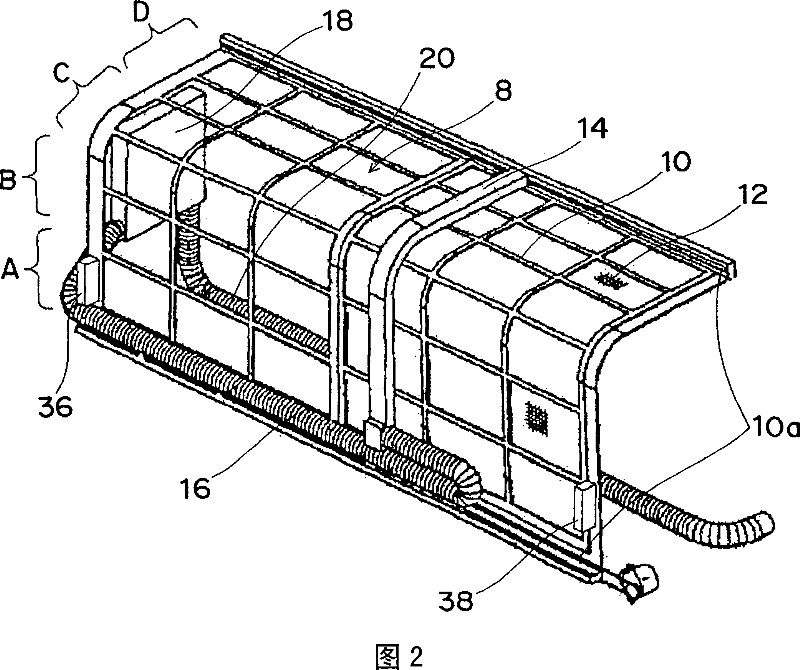

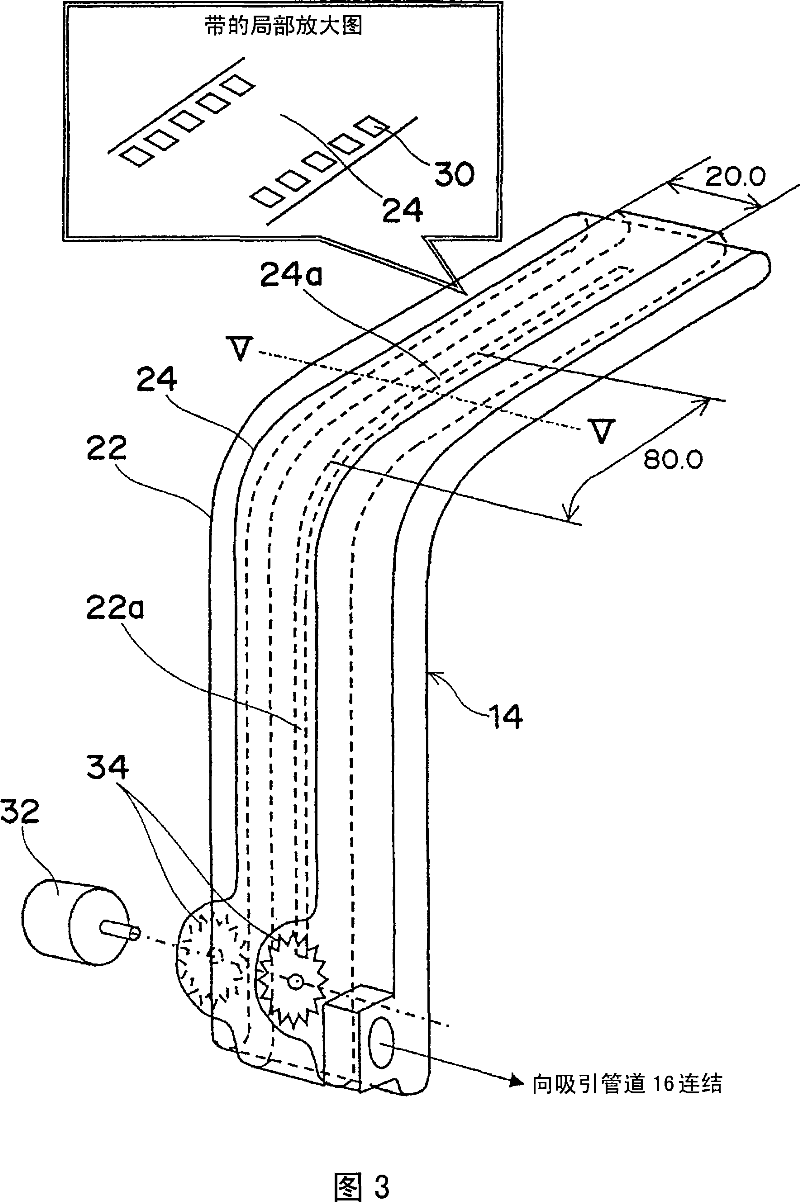

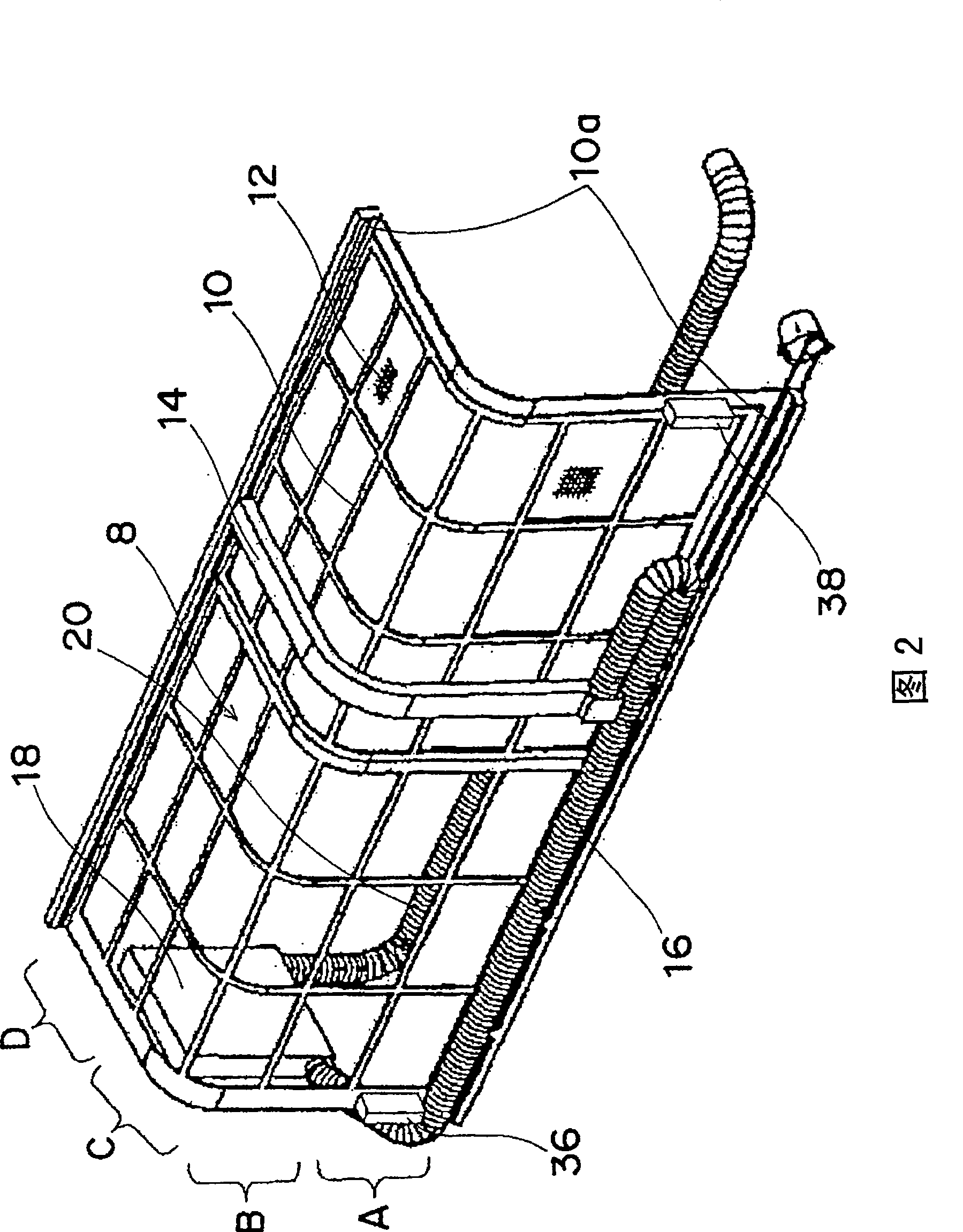

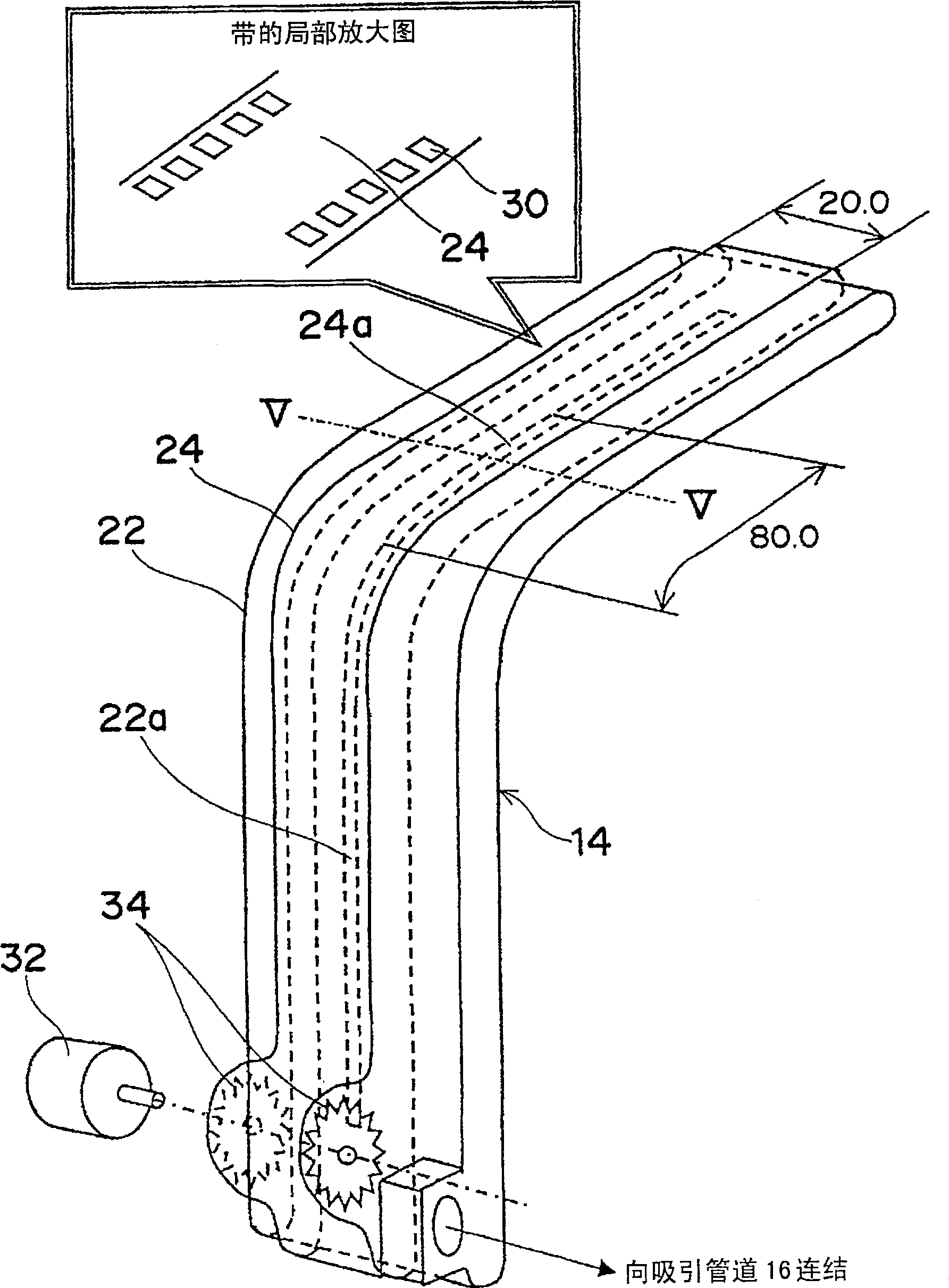

An air conditioner having an indoor unit in which a heat exchanger and a fan for blowing out air that is subjected to heat exchange by the heat exchanger are received. In the air conditioner, there is provided a filter device that is constructed from a filter net for removing dust in the air passing the heat exchanger, a suction nozzle drivable in a first direction, along the filter net, and a suction device connected to the suction nozzle. The suction nozzle has a nozzle body having an opening and a belt having suction holes, the belt being driven in a second direction orthogonal to the first direction, along the opening while covering it. Further, a position detection means for detecting the position in the second direction of the suction holes is installed to enable cleaning performance of the suction nozzle to be changed depending on the position of the suction hole detected by the position detection means.

Owner:PANASONIC CORP

Construction wall decoration dry hanging stone painting construction equipment and decoration construction method

ActiveCN109025202AAccumulation will notImprove brushing effectBuilding constructionsArchitectural engineeringBuilding construction

Owner:龙元明筑科技有限责任公司

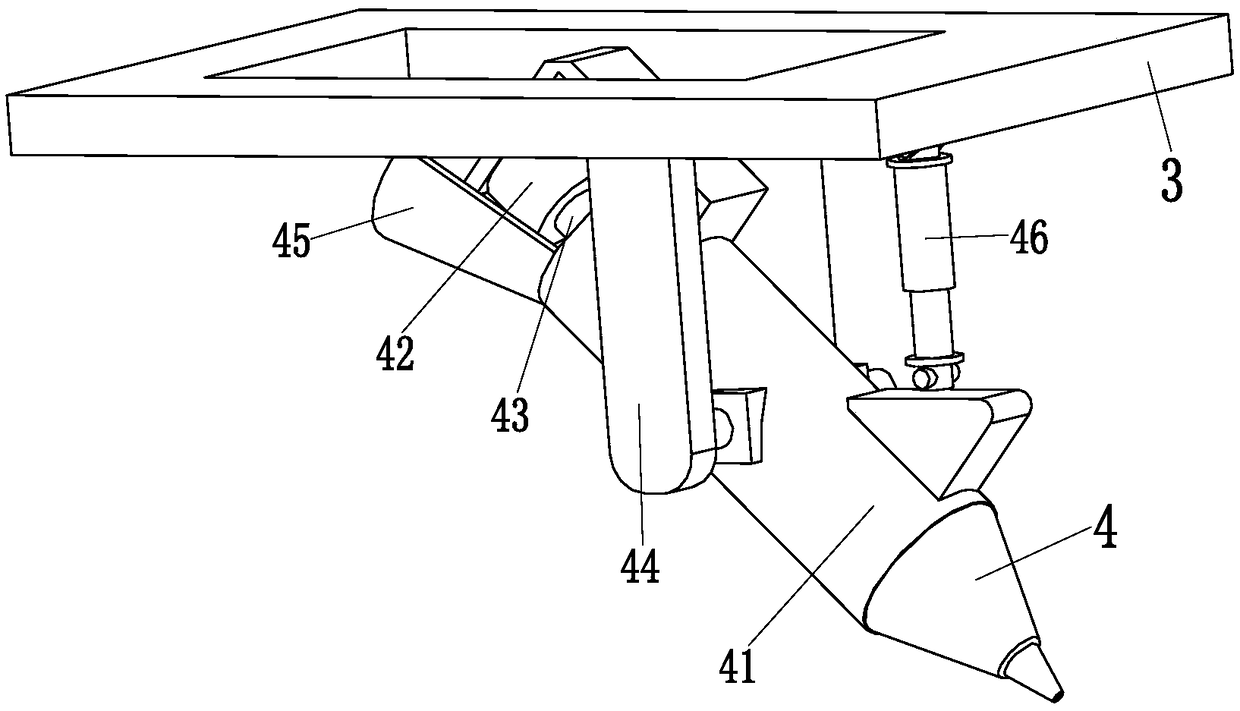

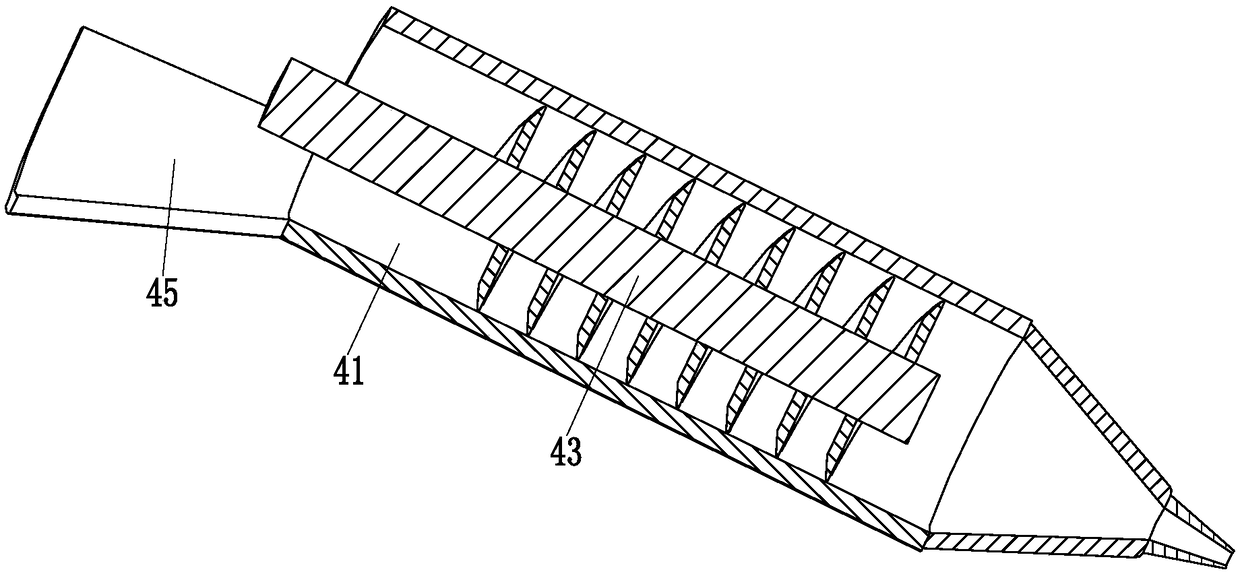

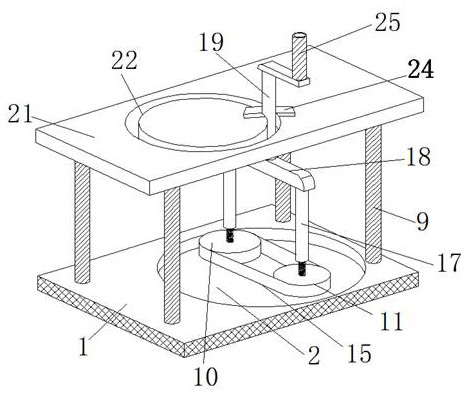

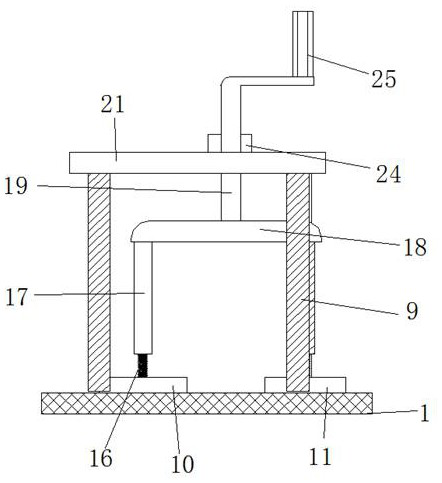

Automatic processing robot for dry hanging stone for building wall decoration material

ActiveCN109025206AAccumulation will notSmooth transmissionBuilding constructionsArchitectural engineeringAutomatic processing

The invention relates to an automatic processing robot for a dry hanging stone for a building wall decoration material. The automatic processing robot comprises a mounting top plate, telescopic push rods, a connecting top plate, a discharging device and a cementing device, wherein the bottom of the mounting top plate is connected with the bottoms of the telescopic push rods, the tops of the telescopic push rods are provided with the connecting top plate, the left end of the connecting top plate is provided with a square groove, the bottom of the left end of the connecting top plate is providedwith the discharging device, and the cementing device is arranged on the bottom of the right end of the connecting top plate; the cementing device comprises a cementing connecting plate, a cementingsupporting plate, a supporting roller, a transmission mechanism, a cementing push rod, a cementing supporting column and a cementing mechanism. The automatic processing robot for the dry hanging stonefor the building wall decoration material can solve the problems that a caulking compound needs to be squeezed and transferred manually when caulking is carried out on an existing dry hanging stone,the caulking compound is manually transferred unevenly, the caulking compound in a stone groove cannot be automatically spread evenly and manually spread evenly in all directions, and the caulking compound can accumulate on the bottom of the stone groove.

Owner:始博实业集团有限公司

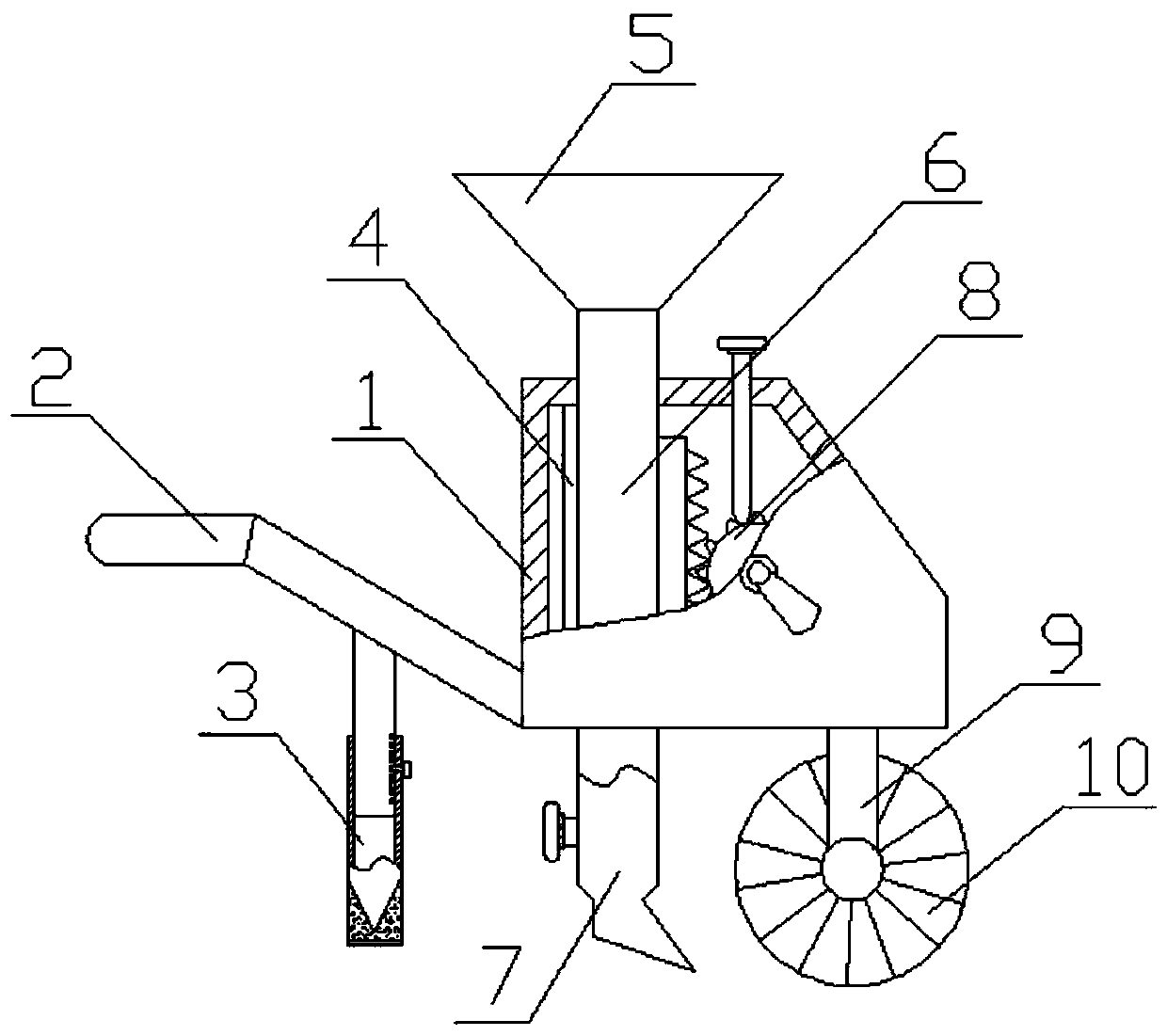

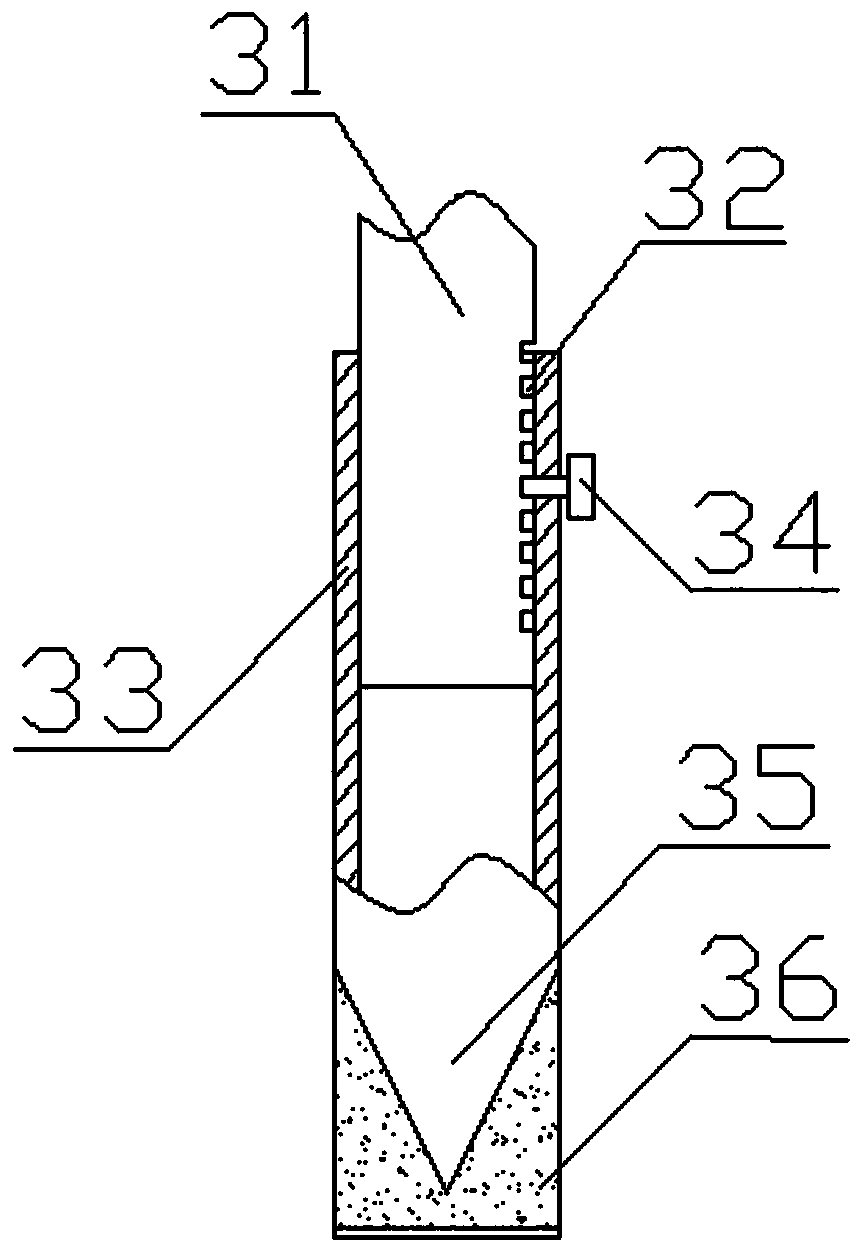

Agricultural seedling fertilizing device

InactiveCN110235578ASo as not to damagePlace stableFertiliser distributersAgricultural engineeringRhizome

The invention provides an agricultural seedling fertilizing device which comprises a device shell, a hand push rod, an adjusting frame, a guiding sliding way, a hopper, a guiding pipe, a fertilizing mechanism, an adjusting mechanism, a supporting column and a movable wheel. The lower middle part of the hand push rod is provided with an adjusting frame through a screw, and the adjusting frame is located at one side of the fertilizing mechanism; the lower end of the guiding pipe penetrates through the interior of the device shell and is communicated with the fertilizing mechanism, and the fertilizing mechanism is located below the exterior of the device shell; the adjusting mechanism is located inside the device shell, and the adjusting mechanism is installed at the other side wall of the guiding pipe. By arranging the adjusting frame, the fertilizing mechanism and the adjusting mechanism, the height of the adjusting frame can be adjusted, the fertilizing process is not disturbed, the material adding process is stable, the problem that fertilizer is stacked into the pipe is effectively solved, the height of the fertilizing part can be adjusted according to the need of people, and therefore the phenomenon that agricultural seedling rhizomes are damaged due to excessively-deep insertion into the land is avoided; people can perform self-operated control, and the device is simple and practical.

Owner:陈晓骏

Automatic mulberry leaf adding machine for young silkworms

The invention discloses an automatic mulberry leaf adding machine for young silkworms, and relates to the technical field of mulberry leaf adding machines. The automatic mulberry leaf adding machine for the young silkworms comprises a mulberry leaf adding machine body, a first conveyor belt and a second conveyor belt are arranged on the mulberry leaf adding machine body, a shield and a top cover are arranged on the second conveyor belt, a sliding groove is formed in the top cover, and a discharging pipe is movably installed in the sliding groove. According to the automatic mulberry leaf adding machine for the young silkworms, through the arrangement of clamping plates and baffles, the clamping plates can fix silkworm trays at the same positions where mulberry leaves fall when the conveying belts convey products, the silkworm trays are prevented from moving due to vibration when the silkworm trays move on the conveying belts, it is guaranteed that the silkworm trays are matched with the falling positions of the mulberry leaves, and meanwhile the baffles can limit the falling positions of the mulberry leaves, so that light mulberry leaves are prevented from falling from two sides of the conveying belts in the falling process, the mulberry leaves are not wasted and can fully fall into the silkworm trays, the situation that part of the young silkworms die due to the fact that the young silkworms do not have enough feed is avoided, and economic loss is avoided.

Owner:重庆祥飞智能科技有限公司

PE pipe cutting device convenient for waste collection

ActiveCN113524289AEasy to fixPrecise positioningPlastic recyclingMetal working apparatusWaste collectionBilateral symmetry

The invention relates to the technical field of pipe cutting, in particular to a PE pipe cutting device convenient for waste collection. The device comprises a mounting base, a plurality of fixing devices are arranged in the mounting base in the length direction of the mounting base in a bilateral symmetry mode, a cutting device is arranged on one side of the upper surface of the mounting base, a left baffle and a right baffle are symmetrically arranged at the positions, close to the middle, of the upper surface of the mounting base, a plurality of connecting devices are arranged on the left baffle, and a filtering device is arranged on one side, close to the bottom, of the mounting seat; the mounting base comprises a mounting shell, and cutting grooves are formed in the mounting shell in a bilateral symmetry mode; each fixing device comprises a fixing bottom frame and a fixing upper cover arranged on the upper side of the fixing bottom frame; and the left baffle and the right baffle each comprise a square baffle, one end of each baffle is fixedly connected with a square pasting strip, and one side, provided with the pasting strip, of the right baffle is fixedly connected with a blocking strip. The PE pipe cutting device mainly solves the problem that waste residues generated by the cutting of a cut PE pipe can be accumulated on the cutting device.

Owner:陕西澄合经纬新材料有限公司

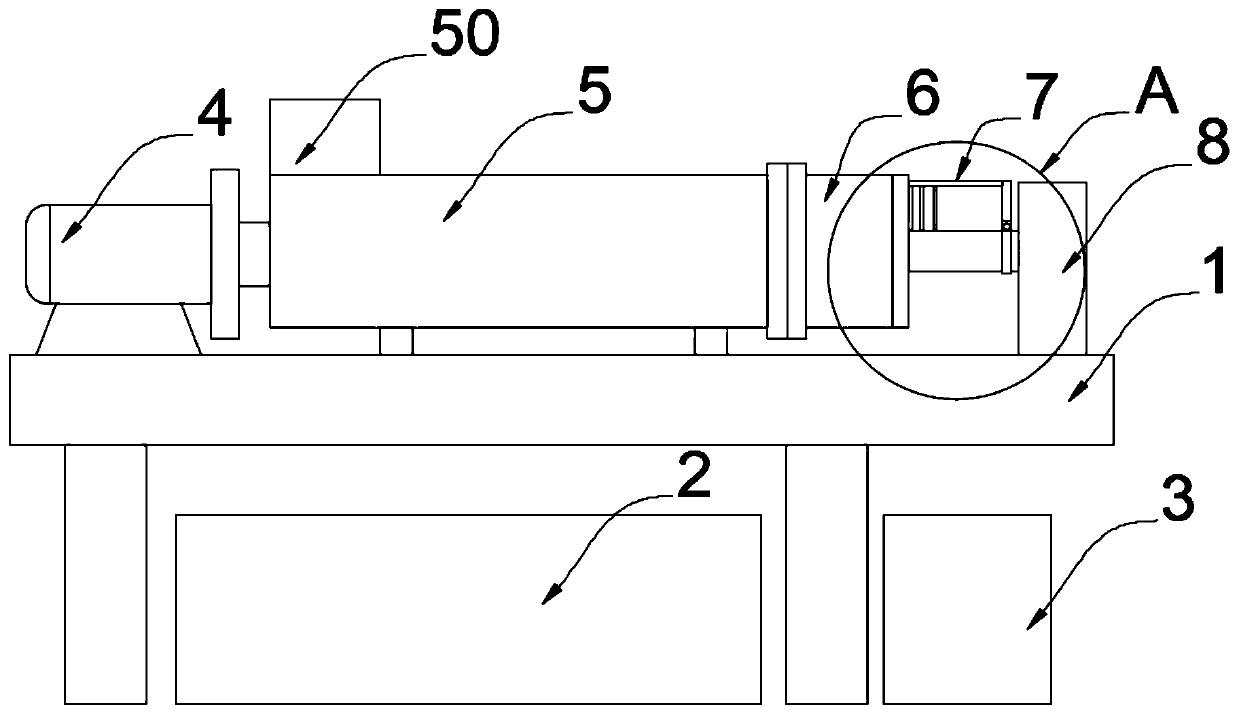

Spiral extrusion separator

The invention relates to the technical field of spiral separators, in particular to a spiral extrusion separator. The separator comprises a support, wherein a material receiving groove is formed belowthe support, a material discharging frame is arranged on one side of the material receiving groove, a motor is installed at one end above the support, one side of the motor is provided with a spiralcasing, one side of the spiral casing is fixedly provided with a discharging area through bolts, one side of the discharging area is provided with a material stirring rod, a fixing block is welded onone side of the material stirring rod and located on the support, a fixing rod is fixed at one end of the material stirring rod through bolts, and a plurality of thin rods are arranged at equal intervals on one side of the material shifting rod. According to the separator, an extruded material slag is discharged through a discharging hole in a discharging plate, the structure is simple, the spaceis saved, installation is convenient, and discharging of the material slag is facilitated; and when the fixing rod rotates with a rotating shaft, so that the thin rods can be driven to shift down accumulated materials on the discharging plate, so that the materials fall into the discharging frame, the structure is simple, the material slag cannot be accumulated, rapid discharging is achieved, andthe phenomenon that pressure in the separator is too large is avoided.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

Mechanical water concentration device for agriculture seeds

InactiveCN111437985AAvoid accumulationAccumulation will notWet separationWater storageAgricultural engineering

The invention discloses a mechanical water concentration device for agriculture seeds. A base, a supporting frame and a water storage frame are included. The water storage frame is provided with a water discharging pipe. A connecting frame is fixed to the inner top face of the supporting frame. The tail end of the connecting frame is rotationally connected and fixed to a pin shaft on the outer wall of the water storage frame, and the supporting frame is further provided with a drive mechanism for driving the water storage frame to swing. The drive mechanism comprises a rotation shaft and a motor, wherein the rotation shaft is rotationally connected and fixed to two vertical plates of the supporting frame, the motor is arranged on one vertical plate, the periphery of the rotation shaft is in cup joint with two cams in a fixed manner, contact plates which are in one-to-one correspondence with the two cams are fixed to the top of the water storage frame, and the two cams are opposite in direction at the same time. The water storage frame is movably connected to the supporting frame through the connecting frame, in cooperation with the arrangement of the drive mechanism, the water storage frame can swing, accordingly, the seeds in the water storage frame can be scattered, seed stacking is avoided, and seed damage is avoided.

Owner:李涛涛

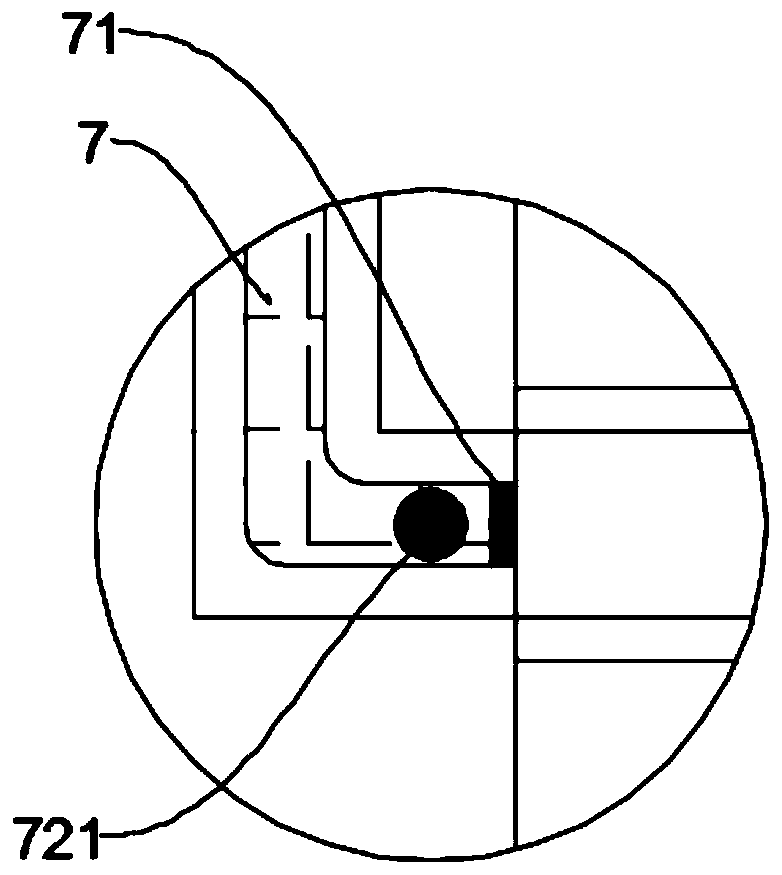

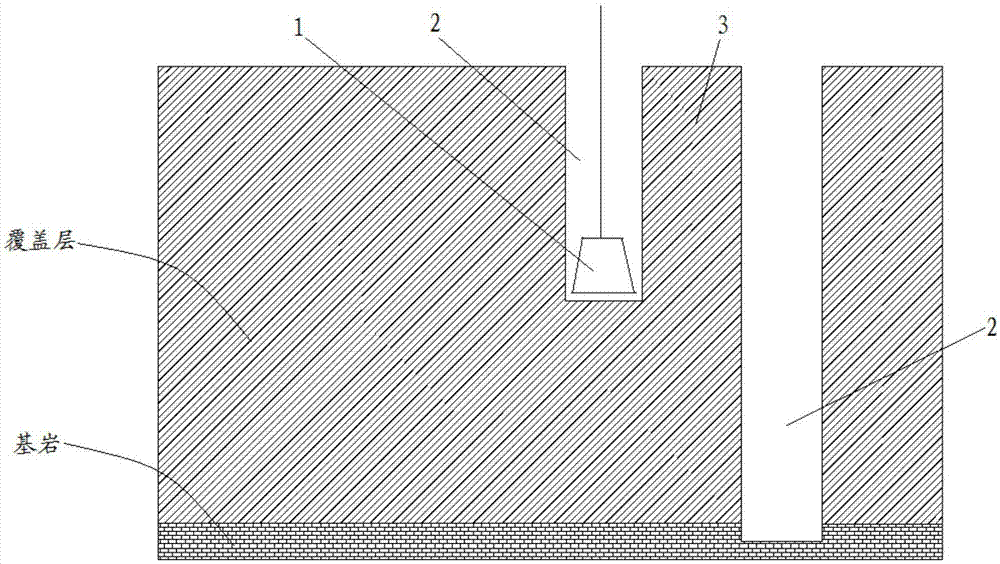

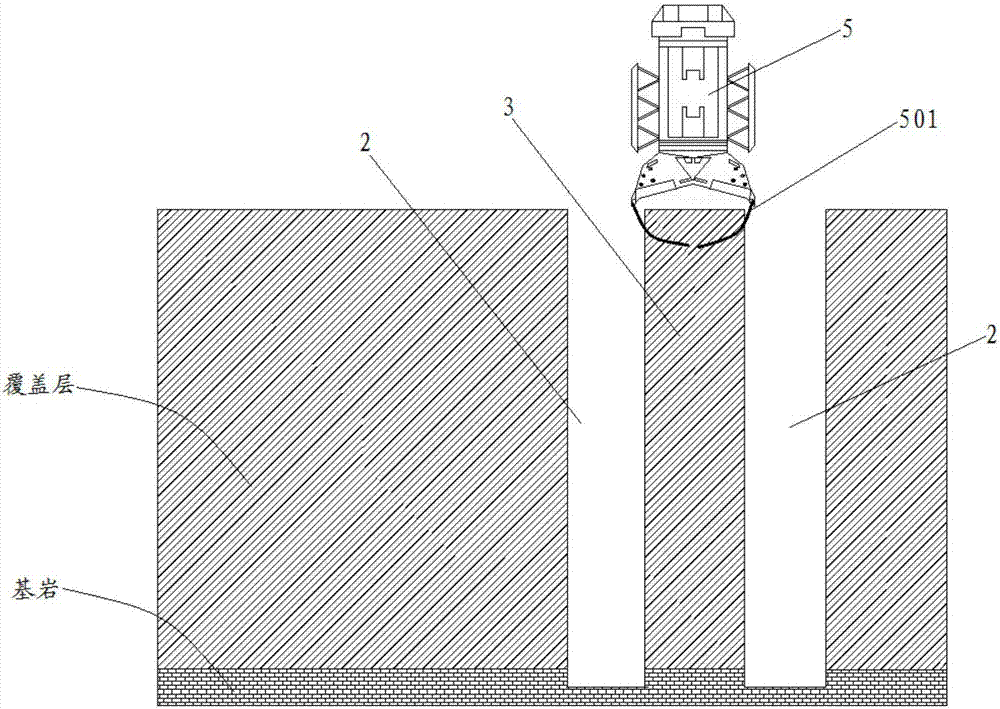

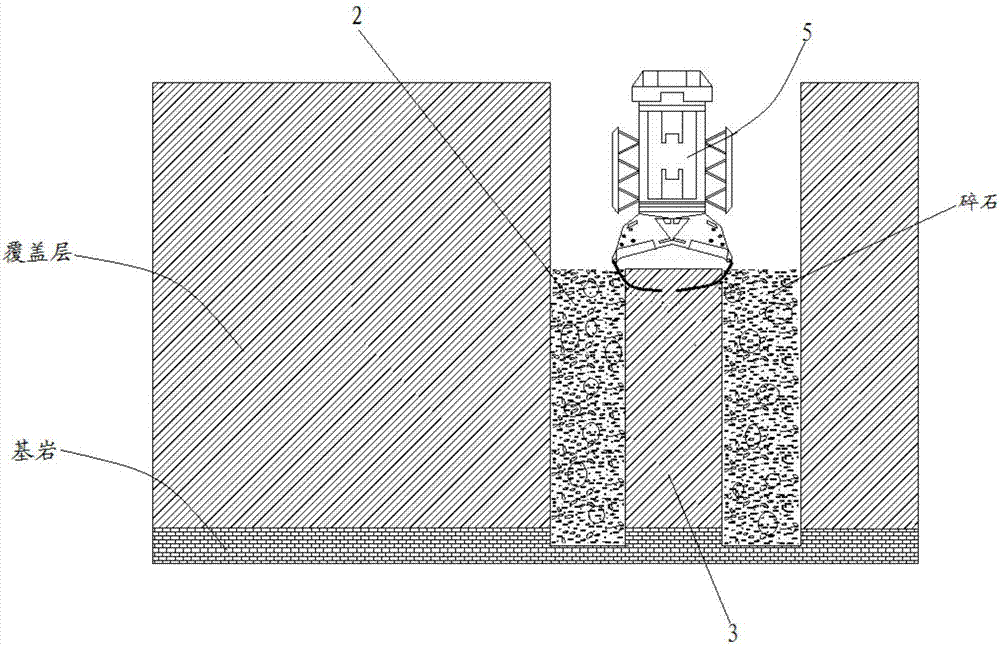

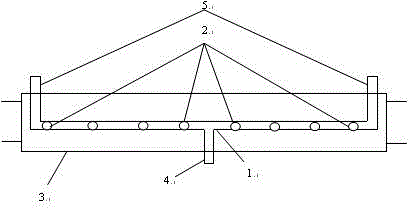

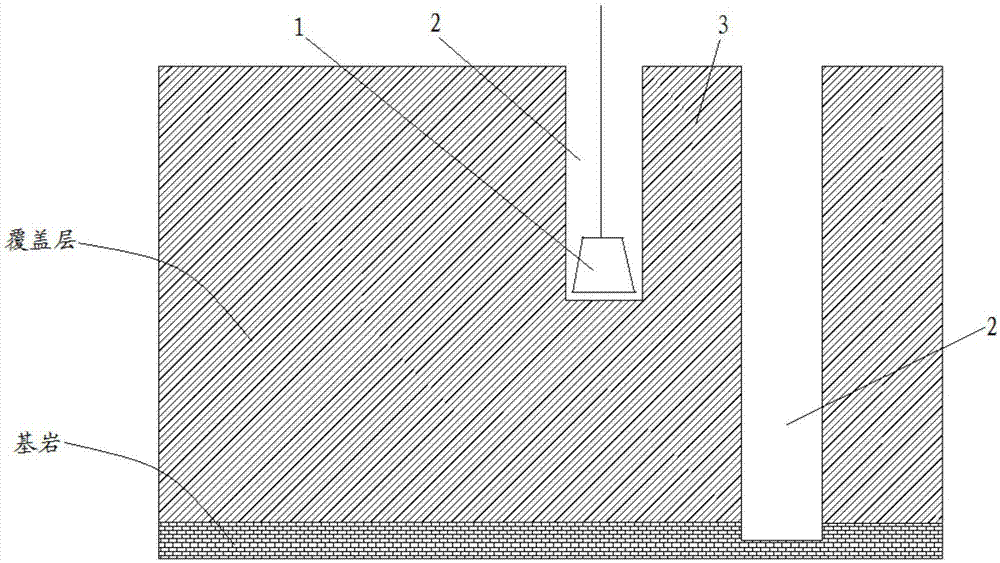

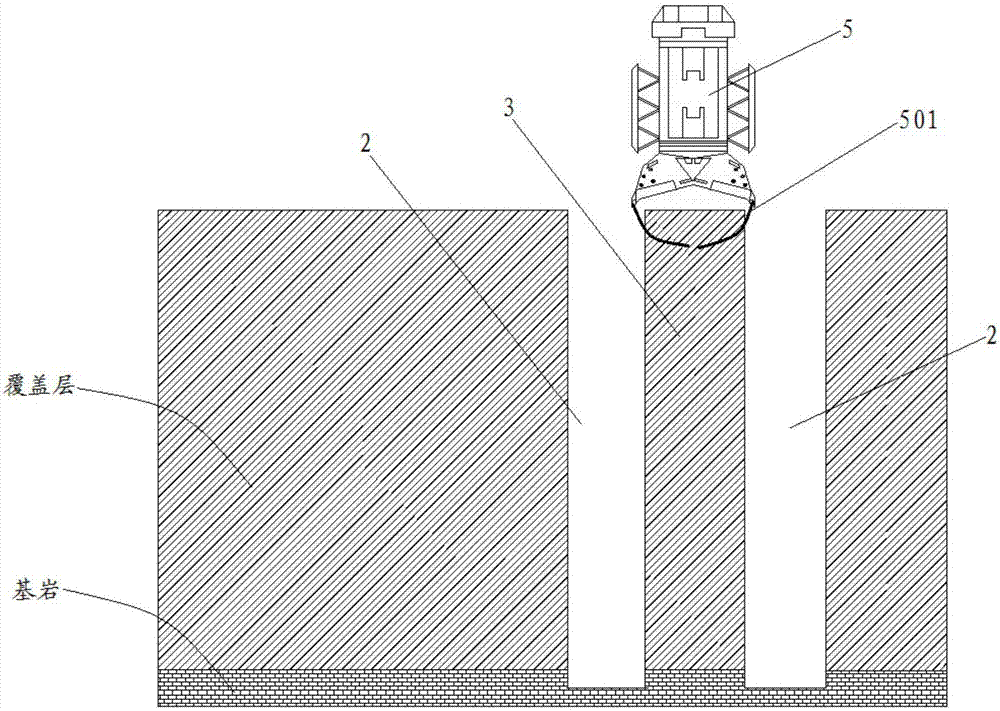

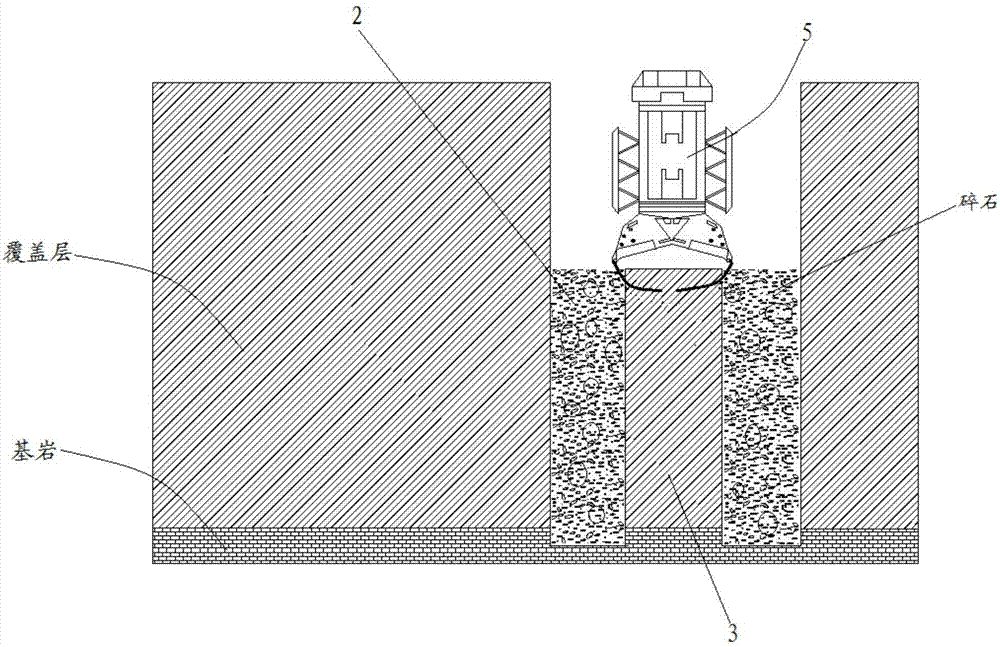

Slotted hole backfill grabbing method

ActiveCN107059976AImprove crawling efficiencyAvoid accumulationReciprocating drilling machinesSoil-shifting machines/dredgersChipsealStructural engineering

The invention discloses a slotted hole backfill grabbing method, and belongs to the field of concrete diaphragm wall slotted holes. The method includes the steps that firstly, a percussion drill is used for drilling two main holes (2) in a manner of spacing by a preset distance, and a column body (3) is formed between the two adjacent main holes; secondly, the two adjacent main holes (2) are filled with assisting objects (4); and thirdly, a grab bucket (5) with two symmetrical calipers (501) is used for grabbing, damaging and moving out the column body (3) between the two main holes (2). According to the method, the constructed main holes are filled with the assisting objects, and therefore macadam which cannot be grabbed by the grab bucket cannot be accumulated in the main holes, and the grabbing efficiency of the grab bucket is greatly improved.

Owner:SINOHYDRO FOUND ENG

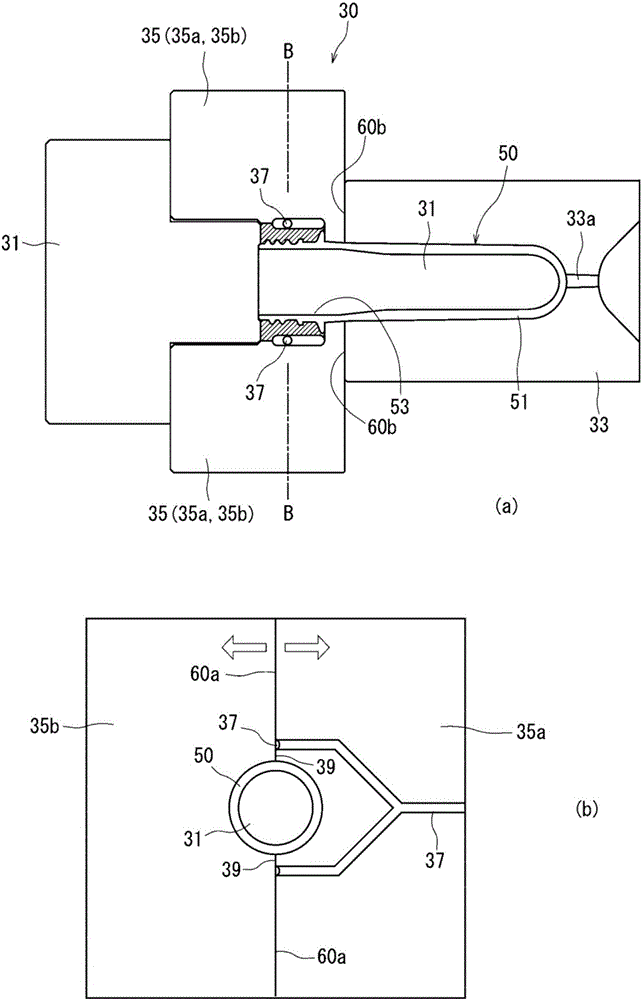

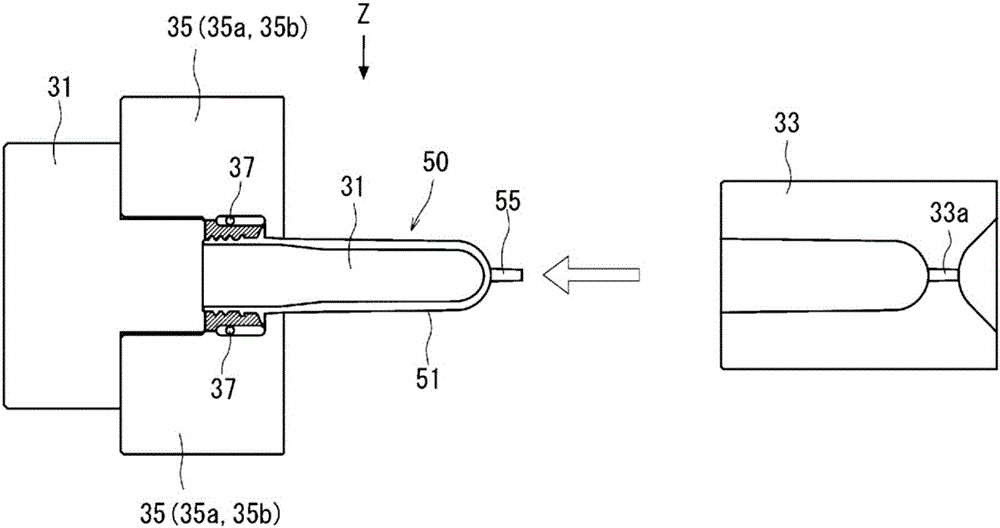

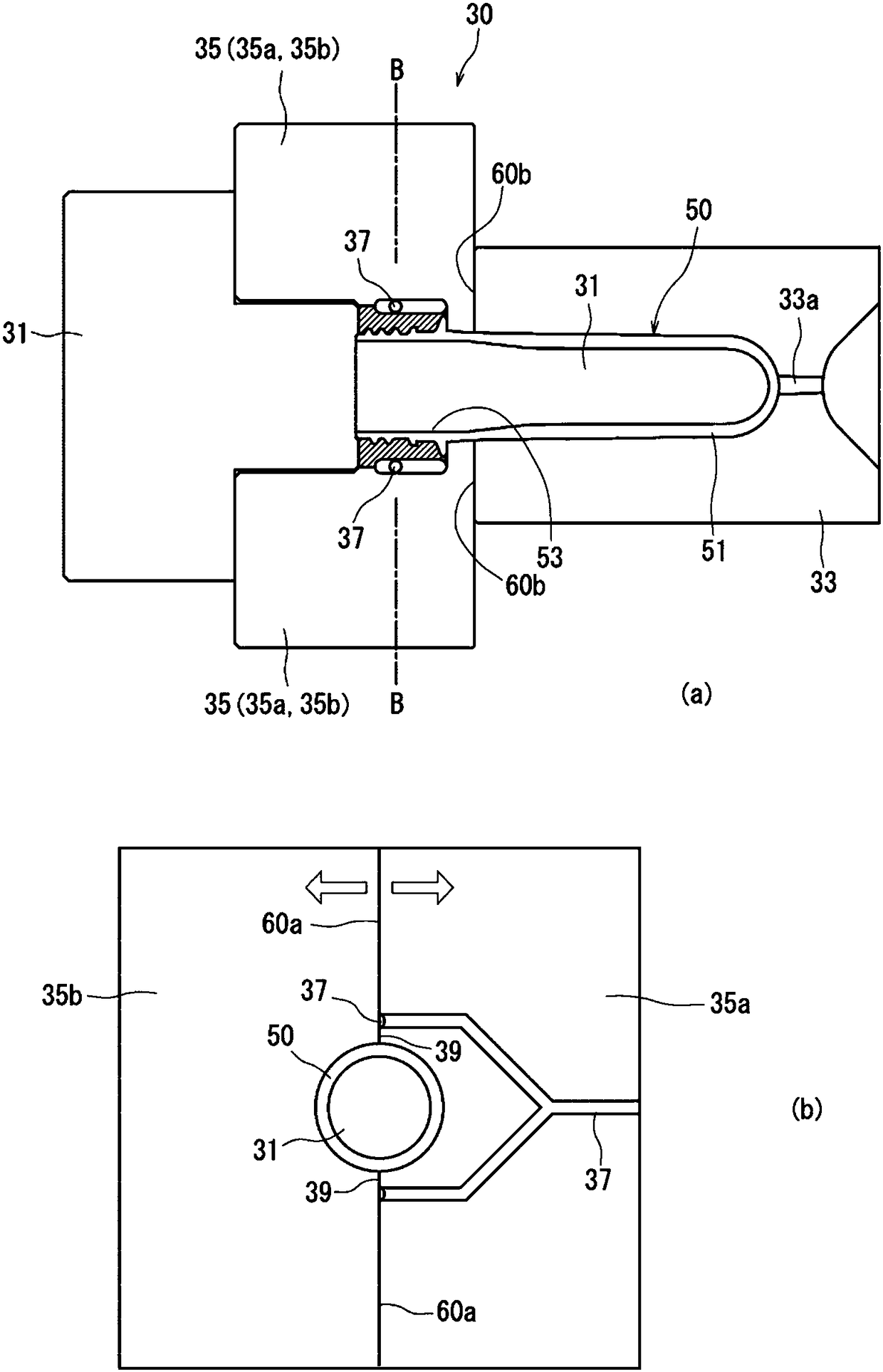

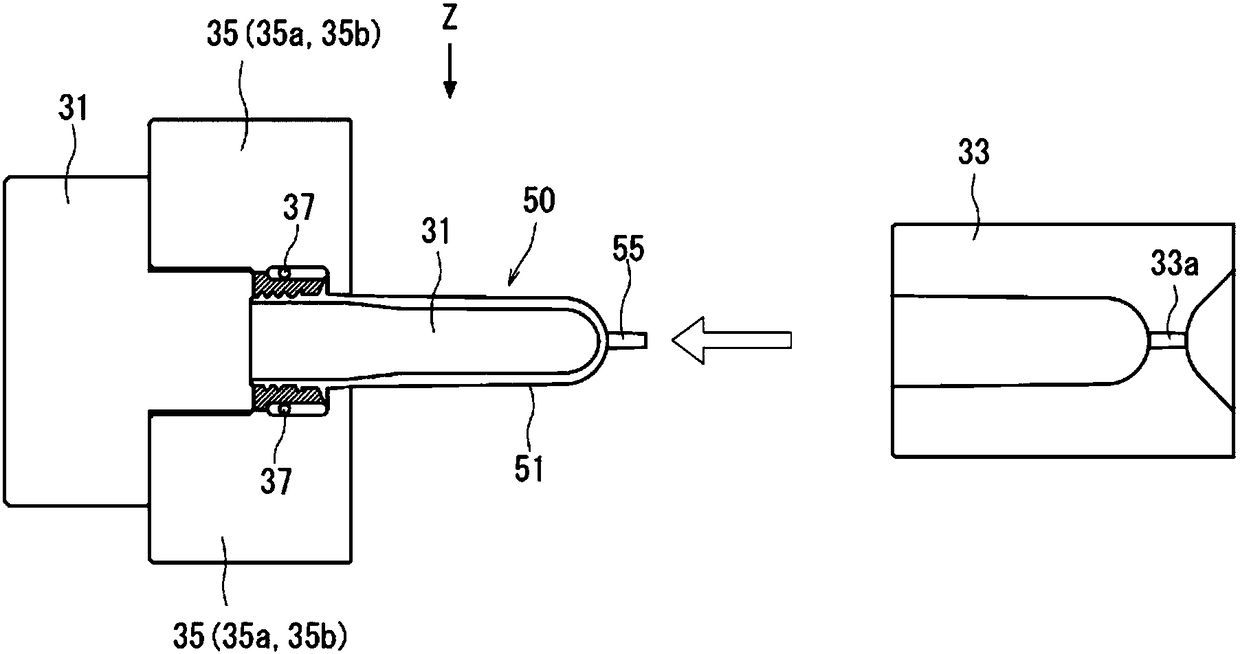

Plastic molding method

This plastic molding method that uses a molding die (30), which has a split mold structure and in which air vent holes (39) that communicate with a gas flow channel (37) are formed on the splitting surfaces of the split mold that face each other, and molds resin using the molding die (30), is characterized in that: resin is supplied to the molding die (30) and molded; after removing the obtained molding from the molding die and prior to supplying resin to the molding die (30) in the next molding cycle, cleaning gas (G) is supplied from the gas flow channel (37) to the air vent holes (39) when at least a portion of the molding die (30) containing air vent holes (39) is formed; and the cleaning gas (G) is discharged from a flow channel separate from the gas flow channel (37). With said method, it is possible to effectively prevent accumulation of oligomers in the vent grooves and perform automatic cleaning without stopping the molding cycle.

Owner:TOYO SEIKAN GRP HLDG LTD +1

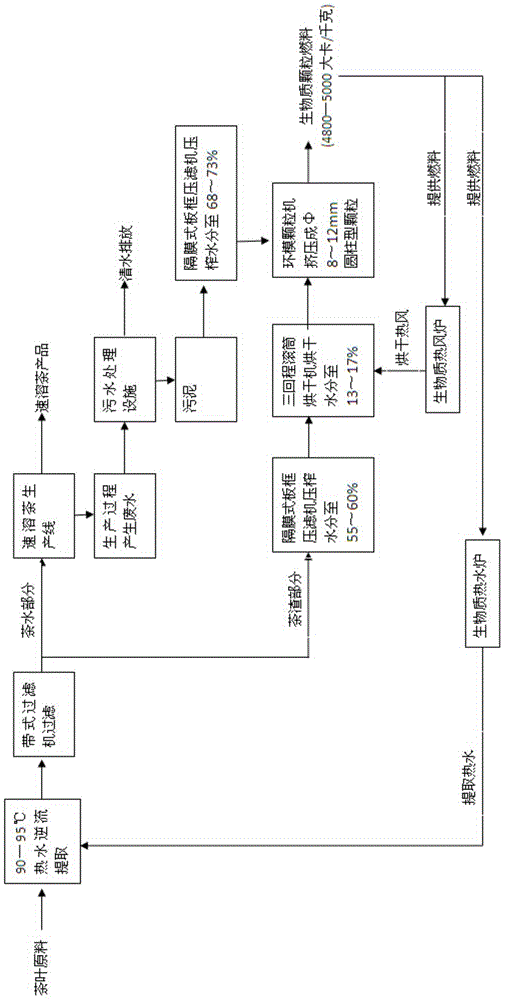

Energy-saving and environment-friendly comprehensive utilization method of tea resources

The invention discloses an energy-saving and environment-friendly comprehensive utilization method for tea resources. The energy-saving and environment-friendly comprehensive utilization method comprises the following steps: (1), taking tea raw materials, and extracting by hot water to obtain a tea water part and a tea residue part after solid-liquid separation; (2), preparing the tea water part into an instant tea product through an instant tea production line, wherein wastewater is generated in a production process; (3), carrying out sewage treatment onto the wastewater, separating clear water which reaches emission standards and sludge after the treatment, and discharging clear water; (4), drying the sludge through pressing by a diaphragm type plate-and-frame filter press; (5), drying the tea residue part obtained in the step (1) through pressing by the diaphragm type plate-and-frame filter press; (6), placing the dried tea residue into a three-pass stoke roller dryer for drying; (7), carrying out extrusion forming on the dried sludge obtained in the step (4) and the dried tea residue obtained in the step (6) by a ring-mould granulator after mixing to obtain a tea residue biomass particle fuel; and (8), using the tea residue biomass particle fuel as a fuel for a biomass water heater and a biomass hot air furnace.

Owner:南京融点食品科技有限公司

Dedusting kneading device for tea leaf processing

InactiveCN110214825AImprove cleanlinessImprove tea qualitySievingPre-extraction tea treatmentTea leafElectromagnetic valve

The invention discloses a dedusting kneading device for tea leaf processing. The dedusting kneading device comprises a mounting frame, a drying drum and a main kneading device body; a feed inlet is formed in the upper end of the main kneading device body, a fourth rotary motor is arranged at one side of the feed inlet, a sifting rotating shaft is arranged at the lower end of the fourth rotary motor, and a sifting net is arranged at one side of the sifting rotating shaft; a first electromagnetic valve outlet is formed in the lower end of the sifting net, a waste discharging slant plate is arranged at one side of the first electromagnetic valve outlet, and a funnel is arranged at the lower end of the waste discharging slant plate; the mounting frame is arranged at the lower end of the funnel, several first slide blocks are arranged at the lower end of the mounting frame, first slide rails are arranged at the lower ends of the first slide blocks, and several idler wheels are arranged at one sides of the first slide rails. Through the fourth rotary motor, the sifting rotating shaft is driven to stir tea leaves, so that through through holes in the surface of the sifting net, impuritiessuch as dust are sifted out, the cleanliness of the tea leaves is improved, and the quality of the tea leaves is improved.

Owner:温其锋

Chute blockage detector

InactiveCN110282338AAccumulation will notThe shortcoming that the change is not effective and easy to get stuckChutesAgricultural engineeringElectric power

The invention discloses a chute blockage detector and particularly relates to the field of detection equipment. The chute blockage detector comprises a main plate; a main base is arranged at the top of the main plate; the main base and the main plate are integrated; a back cover plate is arranged at the back of the main base; a sensor protective cover is arranged at the top of the back cover plate; a sensor is arranged in the sensor protective cover; a rotating main shaft is arranged in the main base; main shaft bearing pedestals are arranged on the two sides of the main base; the rotating main shaft is connected with the main shaft bearing pedestals; an action position positioning rod is arranged in the main base; reset springs are arranged at the two ends of the rotating main shaft; a limiting reset baffle is arranged on one side of the internal part of the main base; the rotating main shaft is welded with a movable push plate; and the back side of the movable push plate is welded with an induction block. Through the rotating main shaft, the reset springs, the positioning rod, the reset baffle, the push plate and a proximity switch, when a blanking cylinder chute is blocked, the stacked materials extrude the movable push plate in the blockage detector, the movable push plate is offset by a certain angle by a thrust, the induction block at the back triggers the proximity switch, the proximity switch sends out a warning or stopping signal to a work pre-warning end to remind staff and the next detection work can be conducted continuously, so that the chute blockage detector guarantees that the materials are not stacked in the detector and can be widely applied to industries such as grains, electric power, coal, cement and petrochemistry.

Owner:上海晶感智能技术有限公司

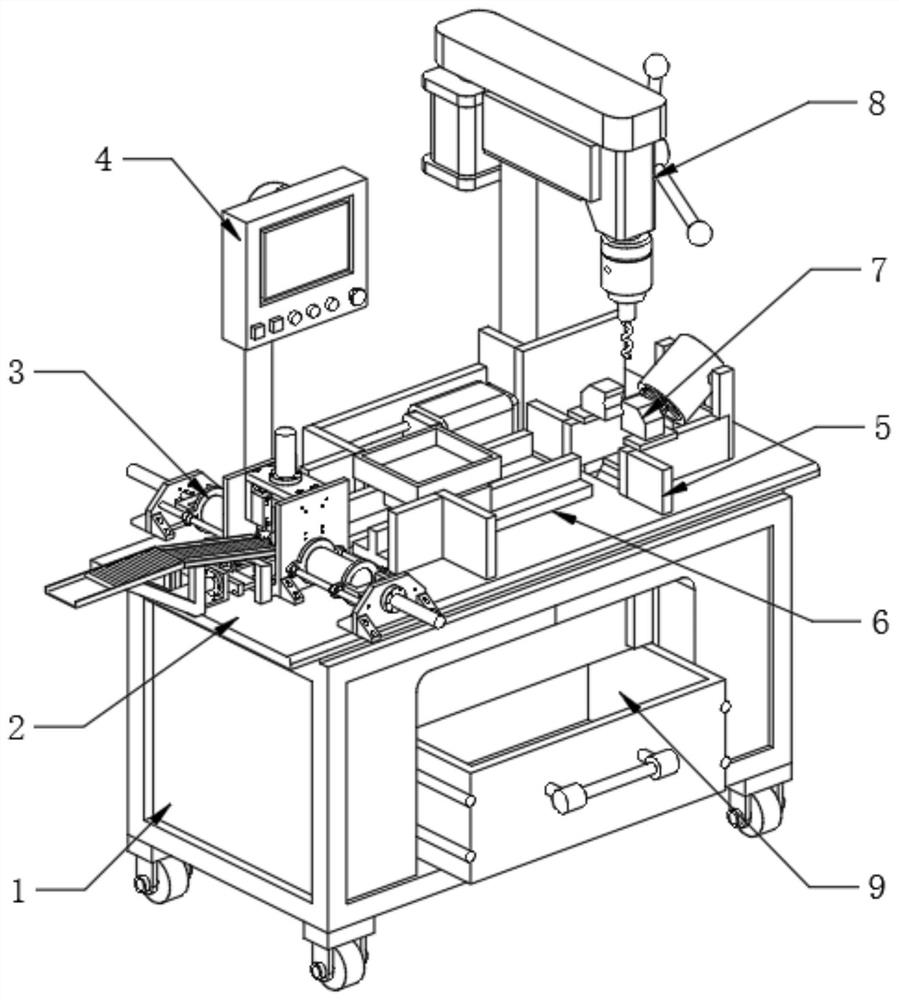

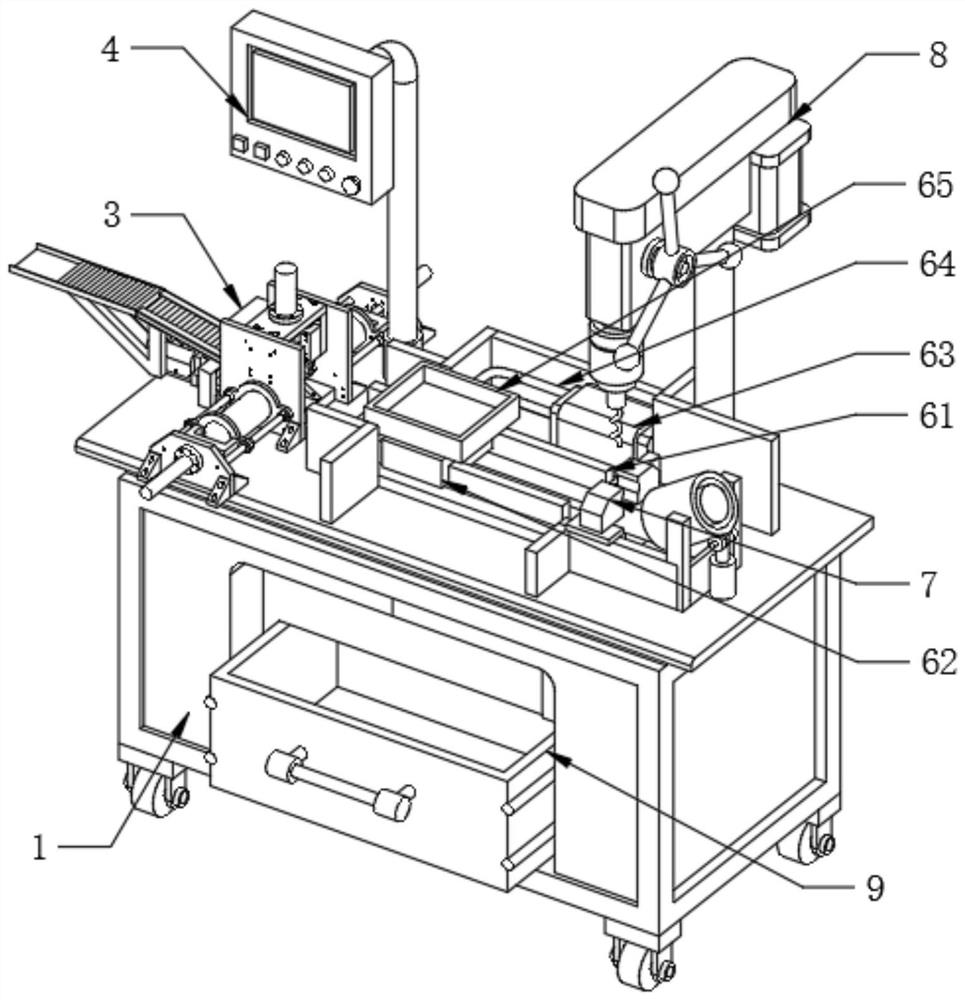

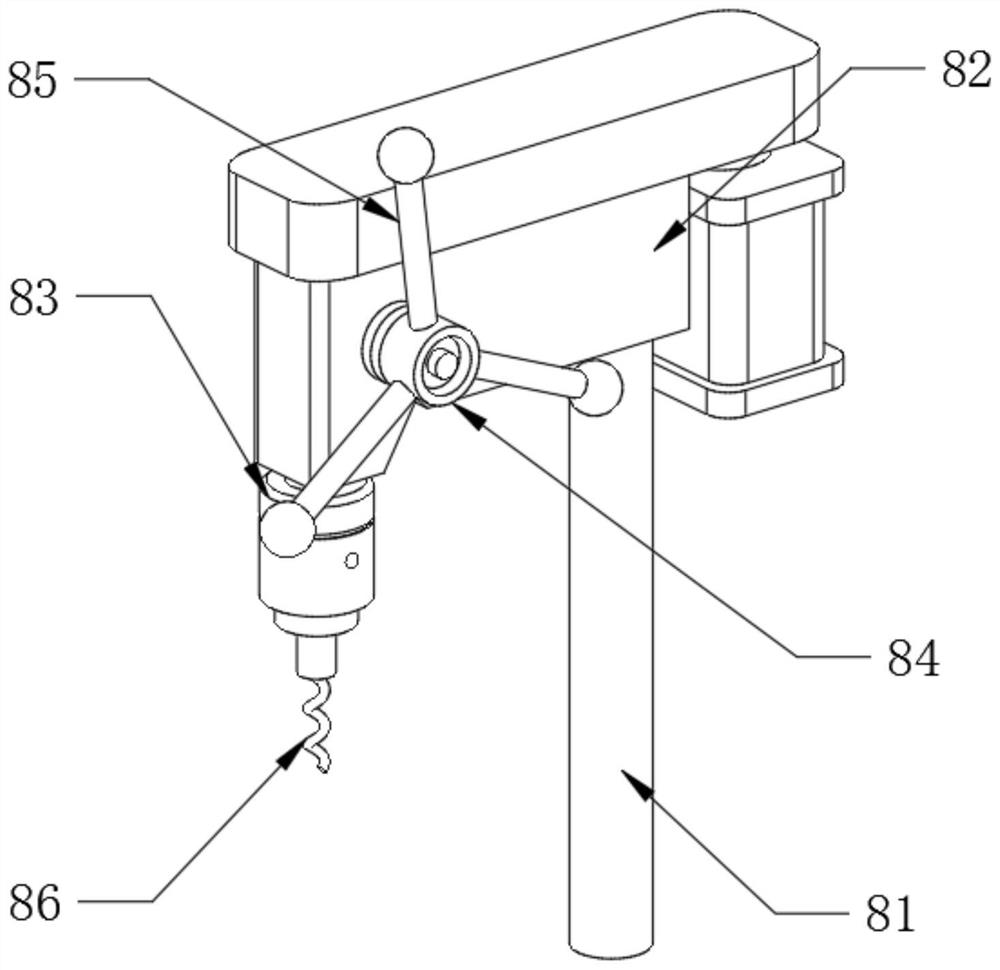

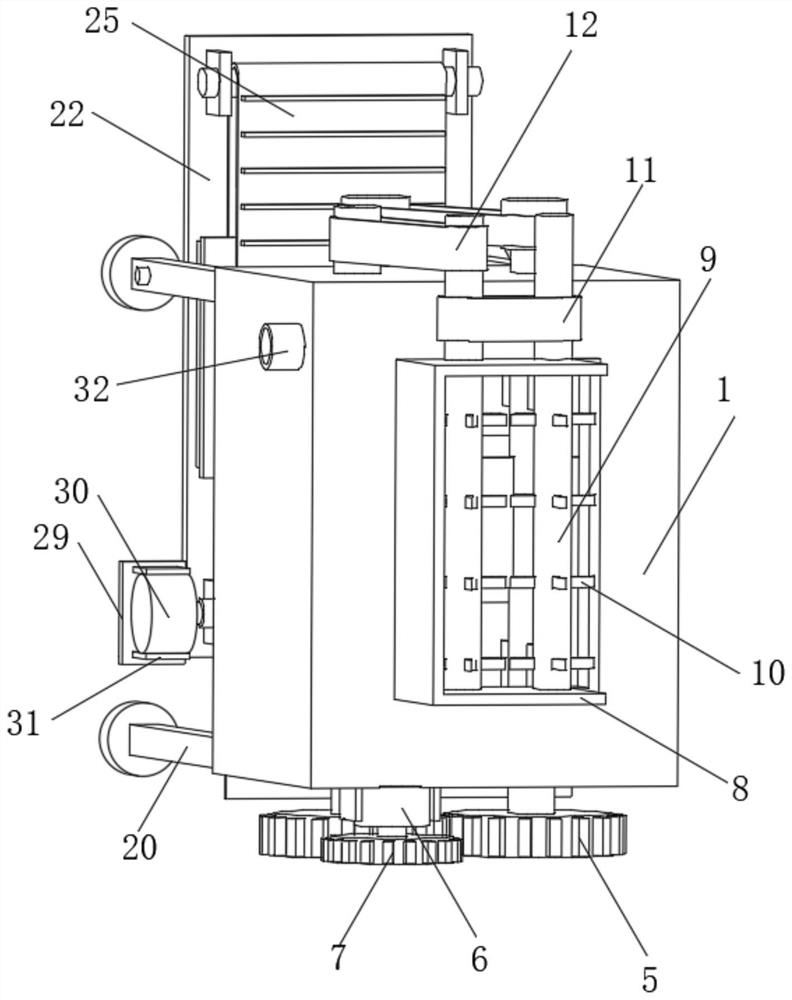

Multi-station building deformed steel bar sleeve drilling, chamfering and tapping integrated equipment

PendingCN113352103AAccumulation will notAvoid the inconvenience of long-distance transferOther manufacturing equipments/toolsMaintainance and safety accessoriesConstruction engineeringSteel bar

The invention discloses multi-station building deformed steel bar sleeve drilling, chamfering and tapping integrated equipment. The equipment comprises a bearing box, a bottom plate, a chamfering mechanism, a control box, a baffle, a conveying mechanism, a clamping head and a tapping and drilling integrated mechanism. The equipment starts from the problems arising from the practical application, the equipment integrates drilling, chamfering and tapping on one device, the inconvenience of long distance transfer between multiple processing flows is avoided, in addition, in a scrap cleaning mechanism, an installation cylinder is made to rotate through the pushing action of an electric push rod, so that the air outlet direction of a fan is adjusted to be consistent with the stacking position of scraps, the scraps roll into a scrap guide groove under the action of wind power and fall into a scrap collecting box through the scrap guide groove to be collected, when the scraps are collected to a certain amount, a handle pulls the scrap collecting box to slide to be separated from the bearing box, the scraps are guided out, the scraps cannot be accumulated at the corresponding cutting positions due to the real-time cleaning effect, and it is guaranteed that follow-up machining operation is conducted smoothly.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Electric power safety power supply device

ActiveCN113078497AThere will be no situation where the plug cannot be pulled out by handSolve the problem of easy to pull the plugCouplings bases/casesElectrical connectionControl theory

The invention discloses an electric power safety power supply device which comprises a socket shell, a bearing frame and an insertion piece clamping mechanism. The socket shell is provided with a through groove allowing the bearing frame to move, the bearing frame comprises a push piece and a bearing seat, the bearing seat is fixedly connected with an insertion piece clamping mechanism, the insertion piece clamping mechanism comprises split pieces and a separation column arranged between the split pieces, the split pieces are split columns which are attached to each other, and the separation column is fixedly connected to the inner wall of the socket shell. One end of each split piece is fixedly connected with the bearing seat, the other end faces the jacks, and the width of each split piece is smaller than the distance between the jacks. According to the invention, the bearing seat drives the conductive sheet and the split sheet to move towards the lower part of the jack, the width of the split sheet is continuously increased in the moving process of the split sheet, the split sheet gradually abuts against the insertion sheet so that the insertion sheet cannot be pulled out, the split sheet can only loosen abutting against the insertion sheet by moving the bearing seat, and the separation of the bearing seat enables the insertion sheet to lose electric connection. The problem that when the plug is not easy to pull out, children are easy to pick the plug is solved.

Owner:STATE GRID CORP OF CHINA +2

Air conditioner

InactiveCN100480594CAvoid residueIncrease the number of attractionSpace heating and ventilation safety systemsLighting and heating apparatusPlate heat exchangerBlow out

Owner:PANASONIC CORP

Information technology teaching equipment with good heat dissipating effect

InactiveCN110720747AImprove cooling effectReduced service lifeOffice tablesDispersed particle filtrationElectric machineryEngineering

The invention relates to the technical field of teaching equipment, and discloses information technology teaching equipment with a good heat dissipating effect. The information technology teaching equipment includes a supporting rod, the left side and the right side of the supporting rod are fixedly provided with grounding plates, the top of the supporting rod is fixedly provided with a placing plate, and the bottom of the supporting rod is provided with a winding displacement hole with one end penetrating through and extending to the above of the supporting rod. Through arrangement of an installing tube, a locating ring, a drive motor, an extension shaft and fan blades, when users use the equipment, six computers are distributed at the six edges of the placing plate, heat generated in working process of the computers is accumulated at the center of the top of the placing plate, the drive motor is started to drive the fan blades to rotate and blow to the above of the installing tube, and hot air near the placing plate is pumped through an air inlet hole by the rotation of the fan blades. Therefore, air near a hexagon table and air in a computer room interact mutually, the heat nearthe computers cannot be accumulated, and service life of the computers cannot be shortened.

Owner:徐州维泰淮海技术创新服务有限公司

Forming method of plastic material

The forming method of the present invention is to use a forming die (30) having a split die structure and having a vent hole (39) communicating with a gas flow path (37) formed on a split surface serving as a butting face of the split die, using the A molding method of a plastic material in which a molding die (30) is resin-molded, the molding method of the plastic material is characterized in that a resin is supplied into the molding die (30) for molding; After the internal removal but before the resin is supplied to the molding die (30) in the next molding cycle, the cleaning gas (G) is injected in a state where at least the part of the molding die (30) including the vent hole (39) is formed. The gas flow path (37) is supplied to the exhaust hole (39); the cleaning gas (G) is discharged from a flow path independent of the gas flow path (37). Using the method described above, it is possible to effectively prevent oligomers from accumulating in the discharge tank, which can be cleaned automatically without stopping the molding cycle.

Owner:TOYO SEIKAN GRP HLDG LTD +1

Tubular metal hot airflow radiator for LED fluorescent lamp tube

InactiveCN106195723AEasy to useAffect lighting effectsPoint-like light sourceLighting heating/cooling arrangementsDaylightEngineering

The invention provides a tubular metal hot airflow radiator for an LED fluorescent lamp tube. A plurality of LED filaments are mounted on the tubular metal hot airflow radiator so as to enable the LED filaments to run through the fluorescent lamp tube internally. During use, hot airflow is formed in the tubular metal hot airflow radiator, so that heat generated by the LED filaments is pumped out from the tubular metal hot airflow radiator and then is discharged. Since the hot airflow only passes the tubular metal hot airflow radiator internally and does not enter the fluorescent lamp tube, dust does not gather in the fluorescent lamp tube and the situation that an illumination effect is affected due to dust gathering of the LED filaments is avoided. The problems that the LED fluorescent lamp tube is poor in heat dissipation effect and the illumination effect of an LED fluorescent lamp capable of heat dissipation is affected due to dust gathering of the LED filaments caused by the fact the hot airflow passes the lamp tube internally are solved. The tubular metal hot airflow radiator has the advantages that the size is small, the weight is light, the cost is low, the heat dissipation effect is good, dust does not gather in the lamp tube, and an excellent market development prospect is realized.

Owner:HUBEI UNIV OF ARTS & SCI

Concrete production-oriented production device with good mixing effect

ActiveCN114043627AStir to mix fully and evenlyImprove the coagulation effectSolid waste managementDischarging apparatusGear wheelElectric machinery

The invention discloses a concrete production-oriented production device with a good mixing effect. The device comprises a stirring box, a first stirring rod and a second stirring rod are rotatably connected in the stirring box, six correspondingly distributed stirring blades are fixedly mounted outside the first stirring rod and the second stirring rod, a first motor is fixedly mounted outside the stirring box, first transmission gears and a second transmission gear are fixedly mounted at the output end of the first motor, the second transmission gear is in meshed connection with teeth of one of the first transmission gears, and a feeding opening is formed in the top of the stirring box. Through cooperation of the first stirring rod, the second stirring rod, the stirring blades, two crushing shafts and crushing blades, cement and stone can be fully and uniformly mixed, so that concrete quality is better; and through cooperation of a rotating shaft rod and blockage cleaning blades, it can be guaranteed that a discharging opening is not blocked; and through cooperation of a conveying belt, a limiting plate and a supporting plate, it can be guaranteed that the discharged concrete can be directly conveyed to a loading object.

Owner:佛山市顺德区和乐商品混凝土有限公司

Woven bag raw material crushing device

The invention discloses a woven bag raw material crushing device. A barrel is fixed on a support, a feeding hole and a discharging hole are formed in the side wall of the barrel, the connecting line of the feeding hole and the discharging hole is vertically arranged, a first filter screen is installed in the discharging hole, a rotating shaft is coaxially and rotationally installed in the barrel,a plurality of blades are hinged to the rotating shaft, the plane where the blades are located is parallel to the axis direction of the rotating shaft, the blades are uniformly arranged in the circumferential direction of the rotating shaft, a plurality of crushing plates are arranged on the inner wall of the barrel, and the multiple crushing plates are located on the rotating path of one end, faraway from the rotating shaft, of the blades; and plastic particles to be crushed enter the cylinder from the feeding hole, the rotating shaft drives the multiple blades to rotate so as to stir the plastic particles in the barrel; and the plastic particles move along the inner wall of the barrel under the action of centrifugal force and are accumulated between the included angles between the multiple crushing plates and the inner wall of the barrel, and the multiple blades are used for beating the stacked plastic particles, so that the plastic particles are crushed and broken more thoroughly,and the crushed plastic particles are discharged through the first filter screen.

Owner:ANHUI YINGSHANG COUNTY TIANCHENG PRINTING PACKAGING CO LTD

Household anti-accumulation rose petal grinding device

InactiveCN112823895AAvoid accumulationAccumulation will notCocoaGrain treatmentsGrinding wheelRose flower

The invention relates to the technical field of rose grinding, and discloses a household anti-accumulation rose petal grinding device. The device comprises a base, wherein a grinding groove is formed in the base, a first grinding disc and a second grinding disc are in lap joint with the upper portion of the grinding groove, a first grinding wheel and a second grinding wheel are movably installed in the first grinding disc and the second grinding disc, sweeping pieces are movably installed above the first grinding wheel and the second grinding wheel, grinding bars are movably installed at the upper portions of buffer springs, and a cross beam is fixedly installed at the upper portions of the grinding bars. According to the household anti-accumulation rose petal grinding device, the first grinding wheel and the second grinding wheel are movably mounted in the first grinding disc and the second grinding disc, and the sweeping pieces are movably mounted above the first grinding wheel and the second grinding wheel, rose petals accumulated at the edge of the grinding groove can be swept to positions below the first grinding disc and the second grinding disc to be ground again, and the situation that the rose petals are accumulated at the edge and need to be manually treated is avoided.

Owner:HUNAN UNIV OF TECH

Valve for a contact tray

InactiveCN101138685BReduce loadIncrease capacityDistillation separationMechanical engineeringEngineering

Owner:SULZER CHEMTECH AG

Electric door distribution box dust removal mechanism

PendingCN114256750AProtection securityAccumulation will notSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDust controlEngineering

The invention discloses an electric door distribution box dust removal mechanism, and particularly relates to the field of distribution boxes, the electric door distribution box dust removal mechanism comprises a distribution box body and a tool box, the bottom of the distribution box body is fixedly provided with a dust removal device, one side of the dust removal device is fixedly sleeved with a return pipe, one side of the return pipe is fixedly sleeved with a fixing frame, and the top of the distribution box body is fixedly provided with a warning device. According to the scheme, the top of the distribution box is provided with the rotary warning device, after the electrically operated gate is damaged, the interior of the distribution box is in contact with a power supply, so that the electrically operated gate cannot move continuously, and if pedestrians are not reminded to move the electrically operated gate by external force in time, the electrically operated gate is damaged, and the economic loss is huge; according to the utility model, the rotary warning device is adopted, so that when the electrically operated gate breaks down, the warning device at the top of the distribution box can immediately operate, emit light with bright eyes and carry out rotary prompt, and passers-by and workers are prompted in time along with the sound of the loudspeaker.

Owner:苏州中控自动化仪表系统成套有限公司

Wormwood drying device for wormwood bath bag production and processing method of wormwood drying device

PendingCN112964049AAccumulation will notSpeed up dryingDrying solid materialsHeating arrangementEngineeringMechanical engineering

The invention discloses a wormwood drying device for wormwood bath bag production and a processing method of the wormwood drying device. The wormwood drying device comprises a bottom plate and rubber non-slip mats, wherein a conveying device is fixedly connected to the top of the bottom plate, an arc-shaped limiting plate is fixedly installed at the side of the conveying device, and a non-slip base is fixedly connected to the top of each rubber non-slip mat; and a supporting column is fixedly mounted at the top of each non-slip base. According to the wormwood drying device for wormwood bath bag production and the processing method of the wormwood drying device, through the arrangement of a motor, a connecting rod and a special-shaped scraping plate, after a worker places washed folium artemisiae argyi on the conveying device, the motor rotates, the folium artemisiae argyi stacked on the top of the conveying device can be smoothed through the special-shaped scraping plate through the connecting rod, and then the folium artemisiae argyi which is not smoothed is smoothed for the second time through protection plates at the side of an outer shell, so that the folium artemisiae argyi cannot be stacked together during drying, the drying speed of the folium artemisiae argyi is improved to a certain degree, and the situation that the folium artemisiae argyi stacked together is inconvenient to dry is avoided.

Owner:SHANGHAI KEDUN MEDICAL INSTR SCI & TECH

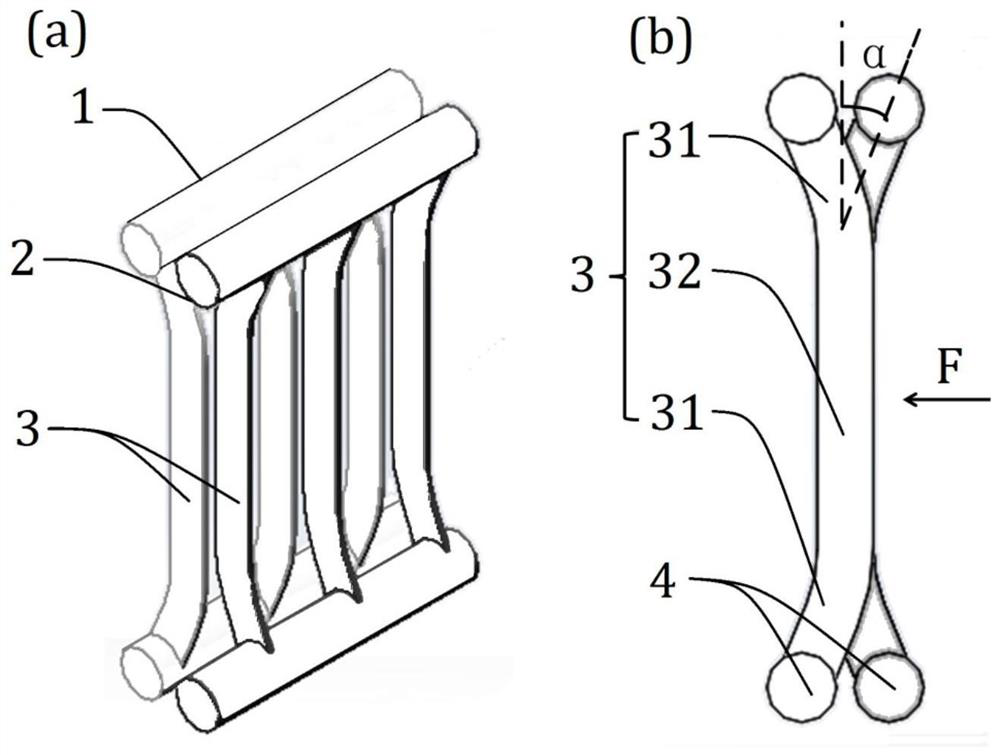

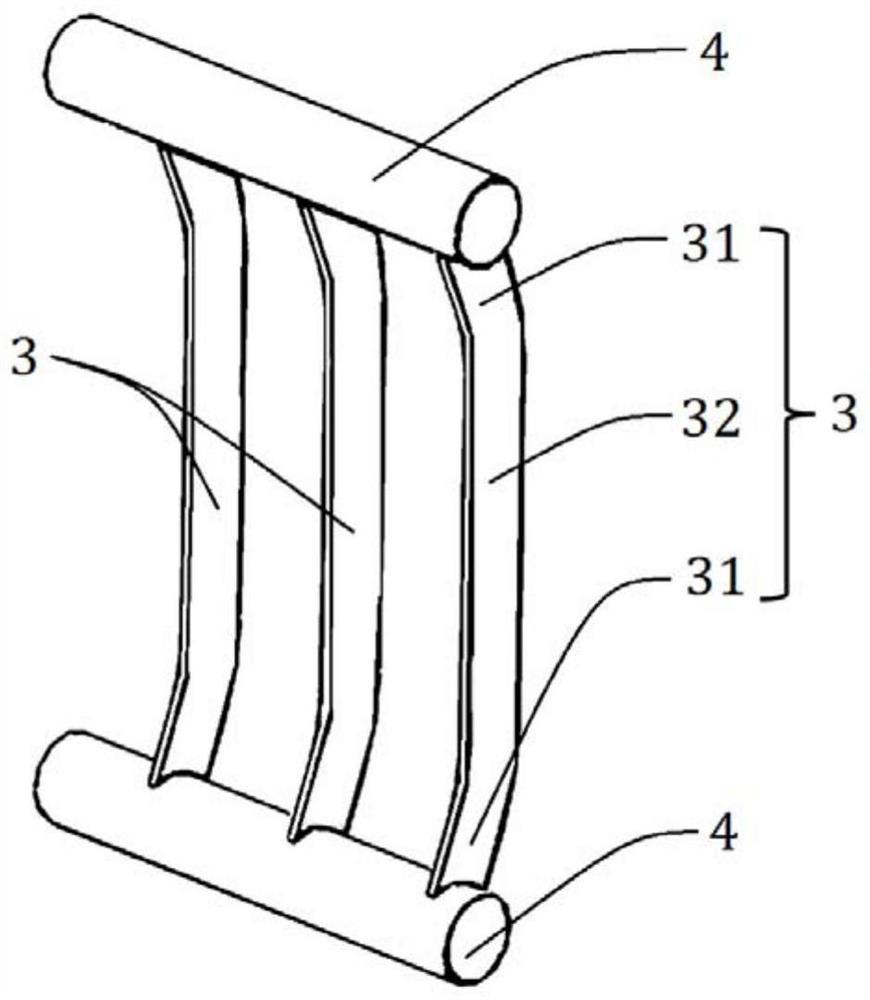

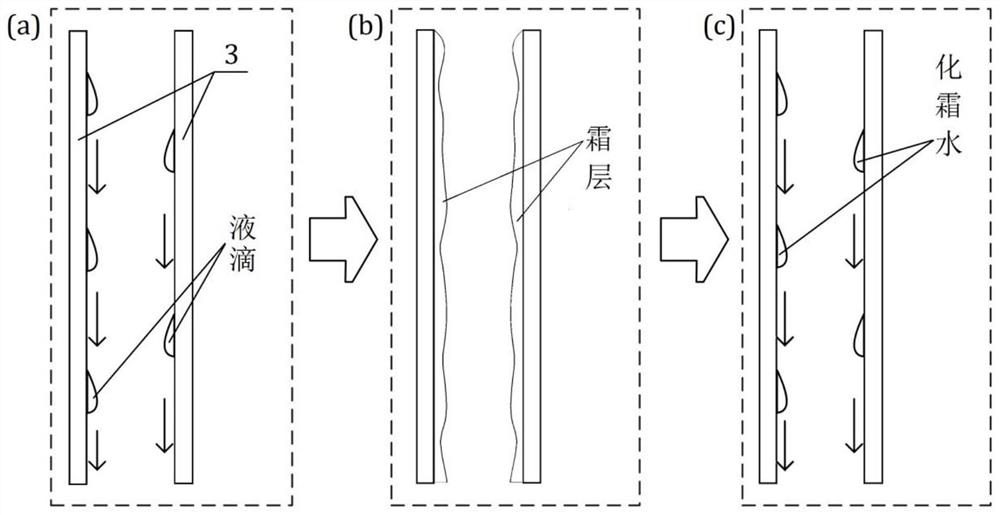

Finless Microchannel Heat Exchanger

ActiveCN106440527BIncrease the number ofReduce spacingEvaporators/condensersCorrosion preventionStraight tubeEngineering

A finless microchannel heat exchanger in the field of heat exchanger technology, comprising a combined first heat exchange unit and a second heat exchange unit, the first heat exchange unit and the second heat exchange unit are both set There are several C-shaped flat tubes, and the C-shaped flat tubes include a straight tube section in the middle and bent sections at both ends; the C-shaped flat tubes of the first heat exchange unit and the C-shaped flat tubes of the second heat exchange unit are stacked alternately Set, and the middle straight pipe section of the C-shaped flat pipe is aligned in the width direction of the flat pipe. The invention can avoid accumulation of dust layer and accumulation of water droplets on the basis of ensuring heat exchange performance, and shorten defrosting time.

Owner:SHANGHAI KELING ENERGY TECH

A method for backfilling and grabbing a slotted hole

ActiveCN107059976BImprove crawling efficiencyAvoid accumulationReciprocating drilling machinesSoil-shifting machines/dredgersCrushed stoneEngineering

The invention discloses a slotted hole backfill grabbing method, and belongs to the field of concrete diaphragm wall slotted holes. The method includes the steps that firstly, a percussion drill is used for drilling two main holes (2) in a manner of spacing by a preset distance, and a column body (3) is formed between the two adjacent main holes; secondly, the two adjacent main holes (2) are filled with assisting objects (4); and thirdly, a grab bucket (5) with two symmetrical calipers (501) is used for grabbing, damaging and moving out the column body (3) between the two main holes (2). According to the method, the constructed main holes are filled with the assisting objects, and therefore macadam which cannot be grabbed by the grab bucket cannot be accumulated in the main holes, and the grabbing efficiency of the grab bucket is greatly improved.

Owner:SINOHYDRO FOUND ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com