Electric door distribution box dust removal mechanism

A technology of distribution box and electric door, applied in substation/distribution device shell, removal of smoke and dust, electrical components, etc., can solve problems such as no major safety problems, device damage, and huge economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

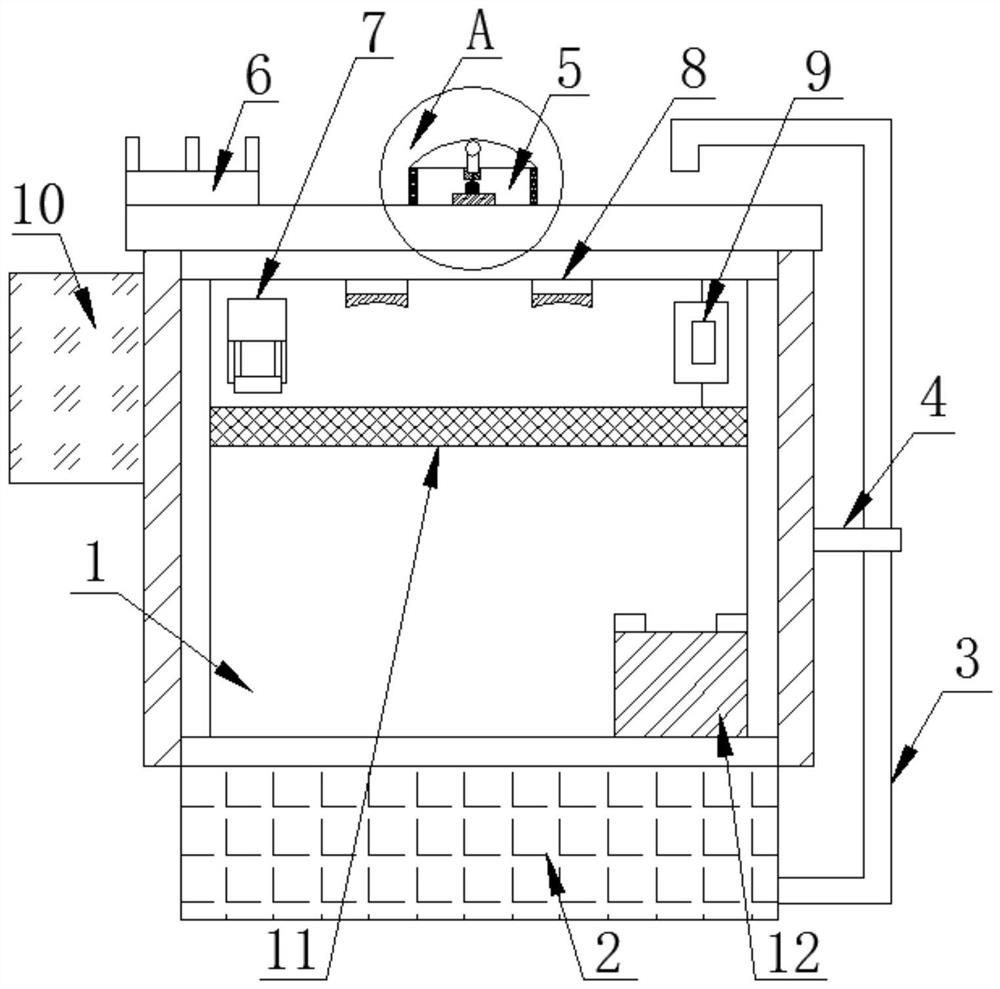

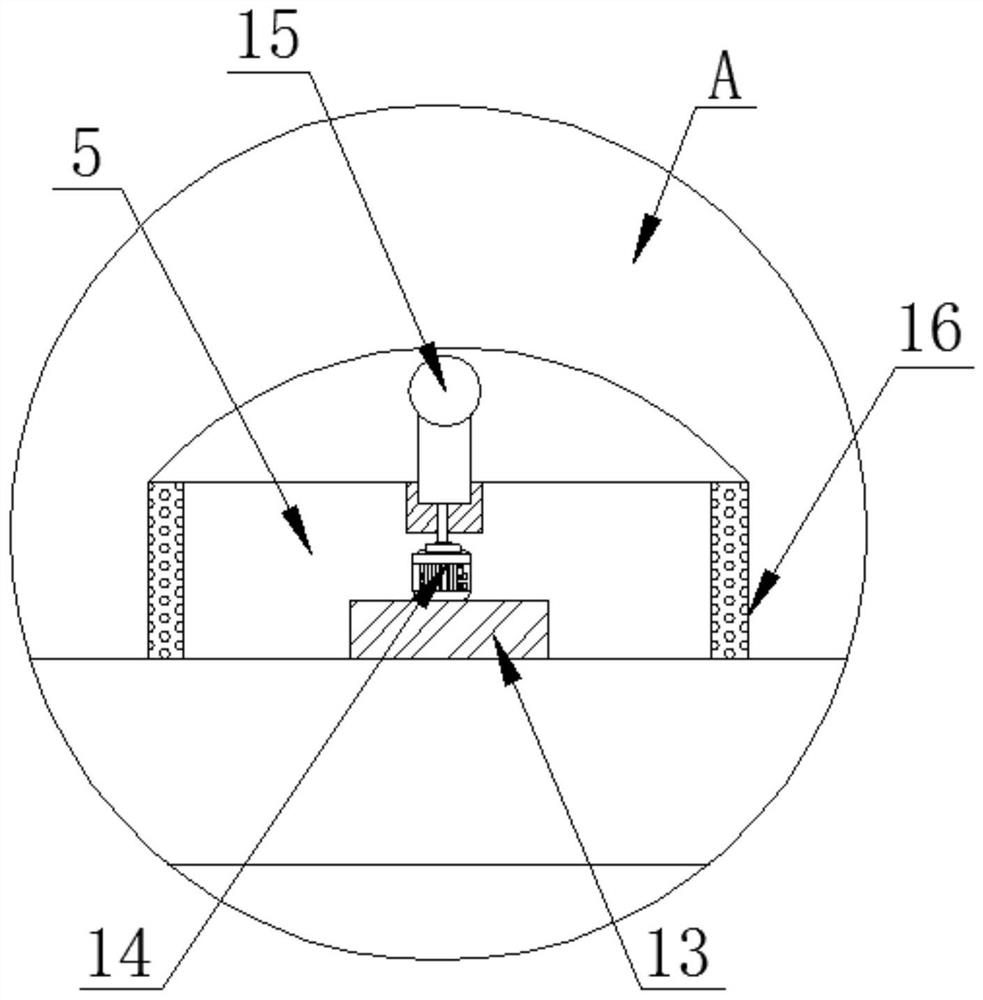

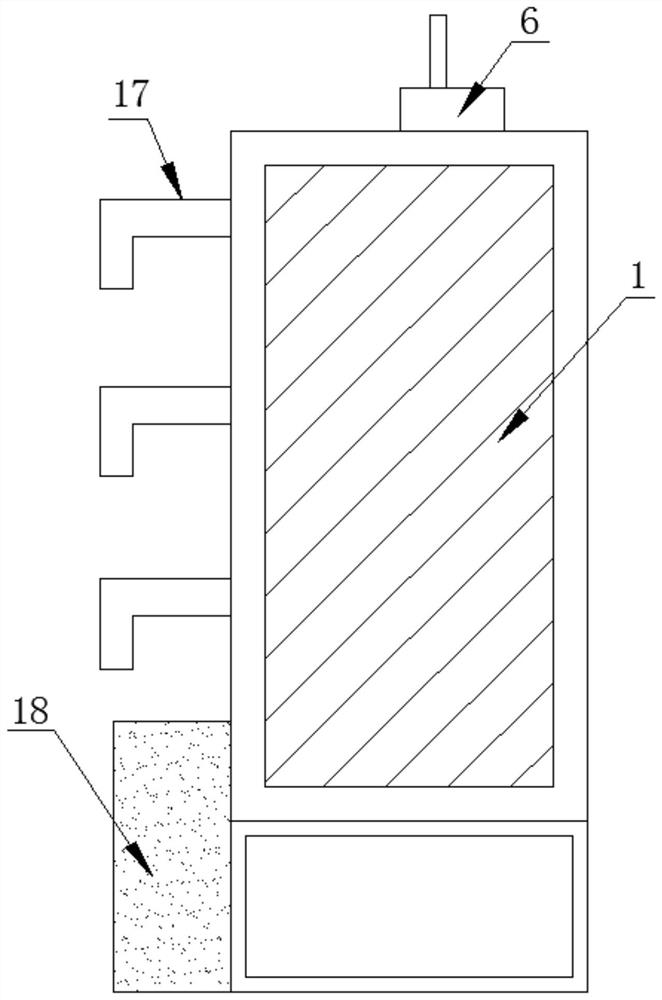

[0026] as attached figure 1 to attach Figure 5 An embodiment of the present invention provides a dust removal mechanism for an electric door power distribution box, including a power distribution box 1 and a tool box 10, a dust removal device 2 is fixedly installed on the bottom of the power distribution box 1, and one part of the dust removal device 2 The side of the return pipe 3 is fixedly sleeved with a return pipe 3, and one side of the return pipe 3 is fixedly sleeved with a fixing frame 4. The top of the distribution box 1 is fixedly equipped with a warning device 5, and the top of the distribution box 1 A wireless receiver 6 is placed on one side, an electric door switch 7 is fixedly installed on one side of the inner cavity top of the distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com