Spiral extrusion separator

A technology of screw extrusion and separator, applied in the direction of presses, manufacturing tools, etc., can solve the problems of complex opening of the cover plate, easy accumulation of slag near the cover plate, etc., and achieve simple structure, simple and fast improved structure The effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

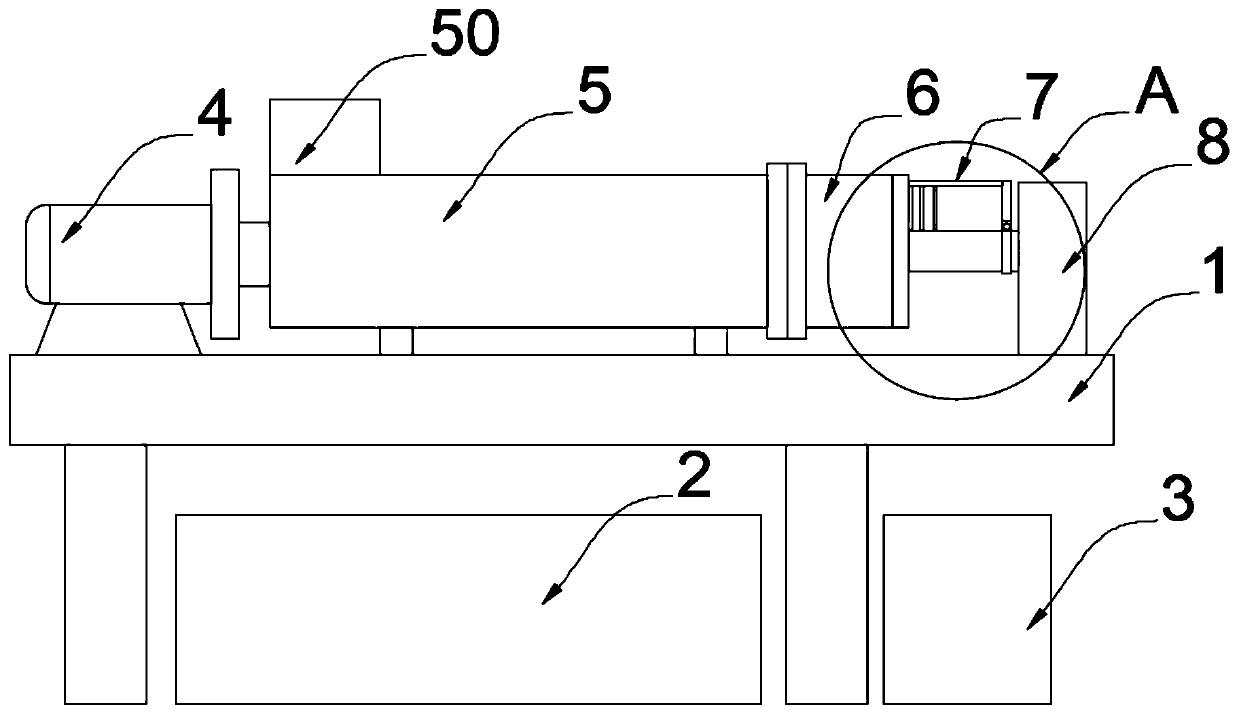

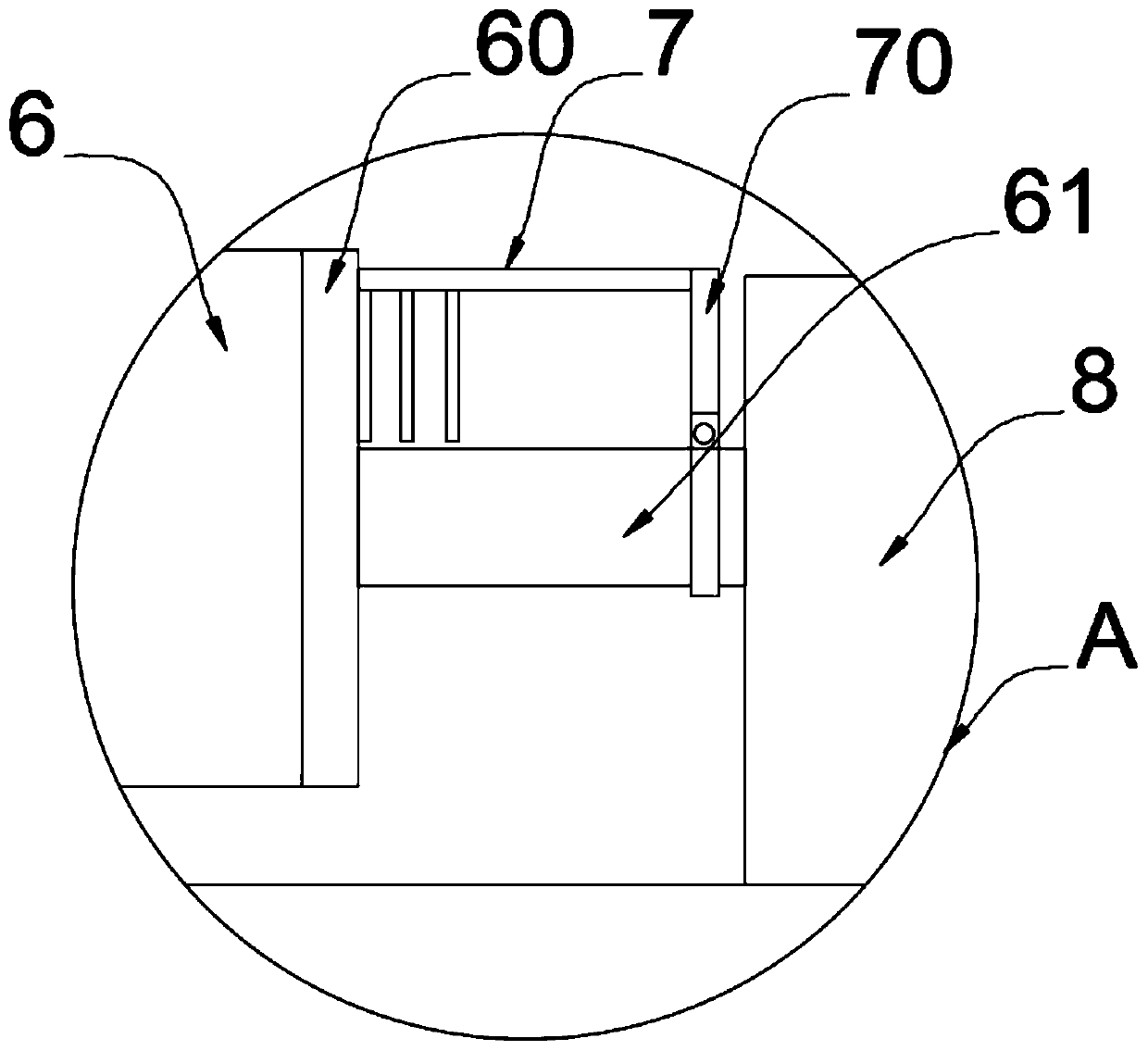

[0023] A screw extrusion separator, such as figure 1 with figure 2 As shown, including the support 1, the bottom of the support 1 is provided with a material receiving trough 2, one side of the material receiving trough 2 is provided with a discharge frame 3, the upper end of the support 1 is equipped with a motor 4, and one side of the motor 4 is equipped with a screw The casing 5, one side of the spiral casing 5 is fixed with a discharge area 6 by bolts, one side of the discharge area 6 is provided with a lever 7, and one side of the lever 7 is welded with a fixed block on the bracket 1 8.

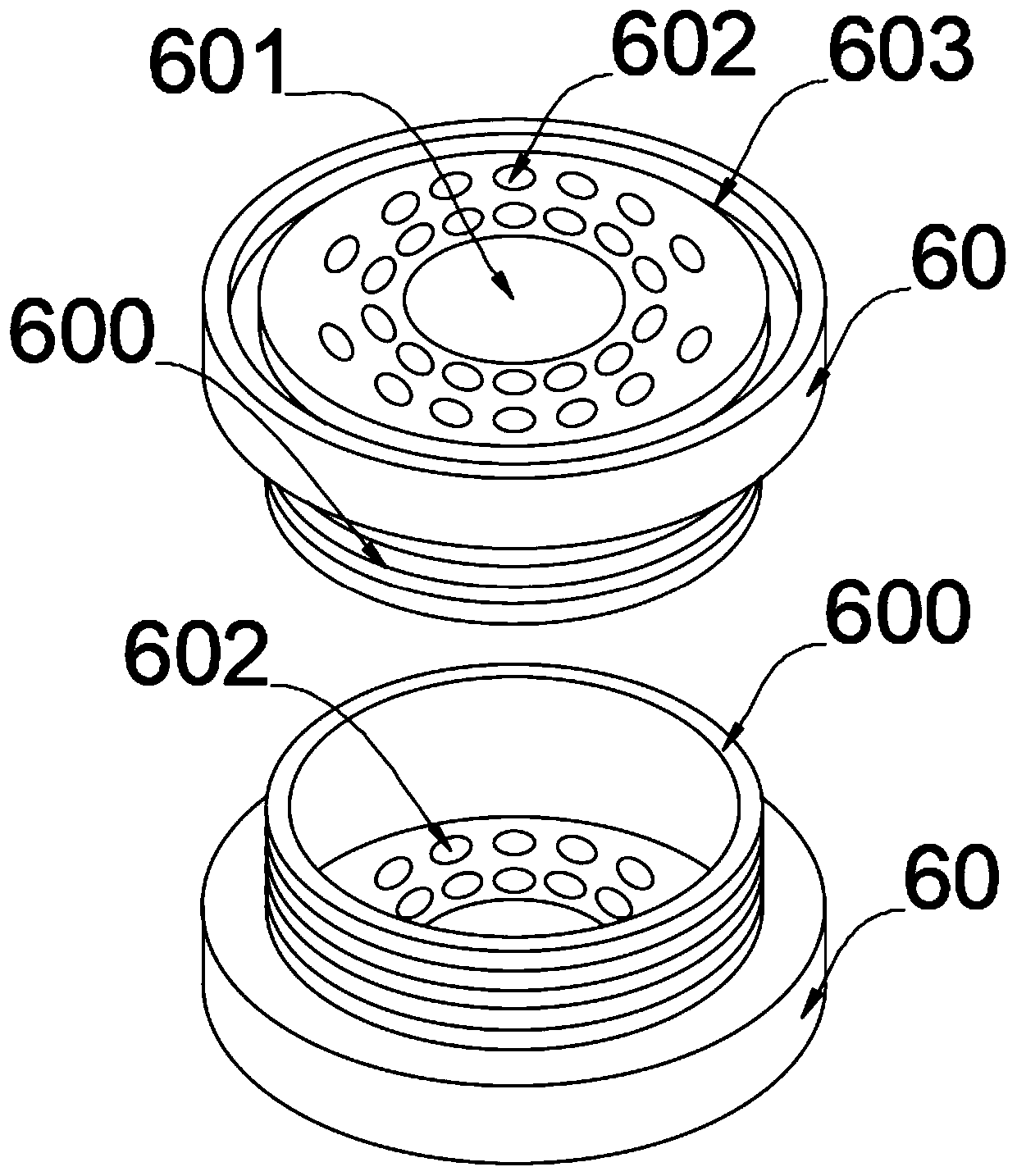

[0024] Specifically, the discharge tray 60, the material shifting rod 7 and the thin rod 72, the fixing rod 70 and the fixing ring 701 of this embodiment are all made of plastic molds, and all use PA plastic raw materials, that is, nylon, which has a high Mechanical strength, heat resistance, and wear resistance make their structures stable, durable, rust-free, and easy to replace.

...

Embodiment 2

[0027] In the specific implementation, because the opening method of the original structure cover plate on the side of the discharge area is too cumbersome and takes up space, and the extruded slag has a high adhesiveness, in order to simplify the original structure at the end of the discharge area, the material The slag is not easy to accumulate, and the inventor improves the material shifting rod 7, as a preferred embodiment, as image 3 , Figure 4 with Figure 5 As shown, one end of the driving rod 7 is fixed with a fixed rod 70 by a bolt, the other end of the driving rod 7 is connected with a roller 71, and one side of the driving rod 7 is equidistantly provided with some thin rods 72, and one part of the fixed rod 70 The side is provided with a fixing hole 700, the bottom end of the fixing rod 70 is provided with a fixing ring 701, the bottom end of the fixing ring 701 is provided with a notch 702, one side of the fixing ring 701 is connected with a snap ring 703, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com