Finless Microchannel Heat Exchanger

A micro-channel heat exchanger and fin technology, which is applied in heat exchange equipment, lighting and heating equipment, evaporator/condenser, etc., can solve the problem of reducing the side area of heat exchange air and failing to ensure heat exchange area and heat exchange capacity and other problems, to achieve the effect of reducing the distance between flat tubes, shortening the defrosting time, and avoiding the reduction of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

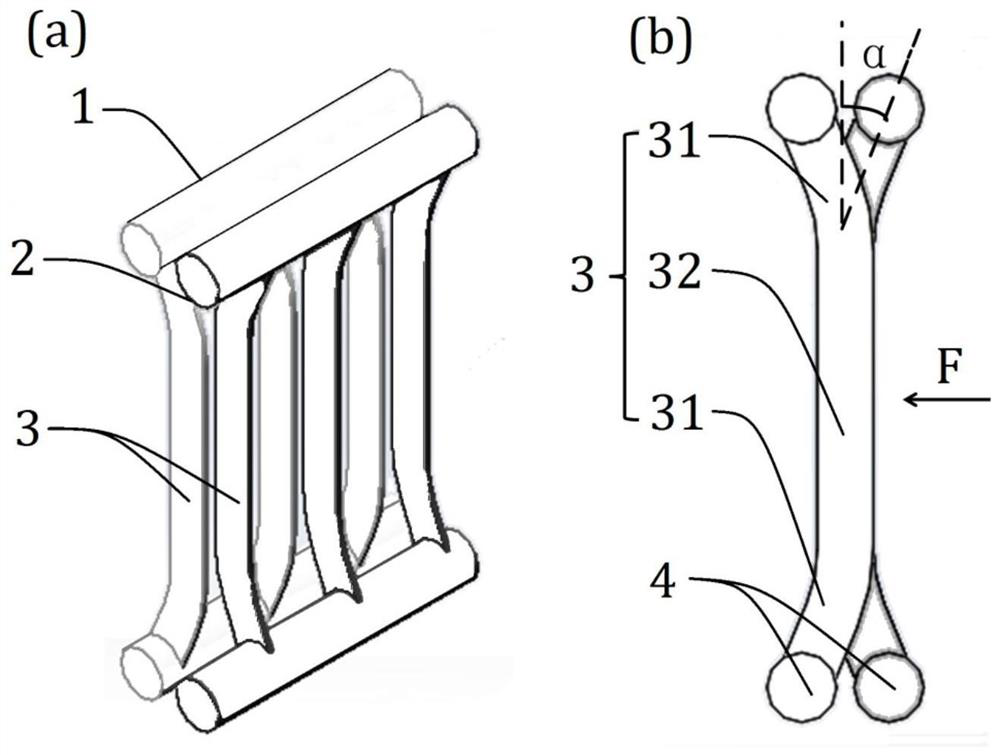

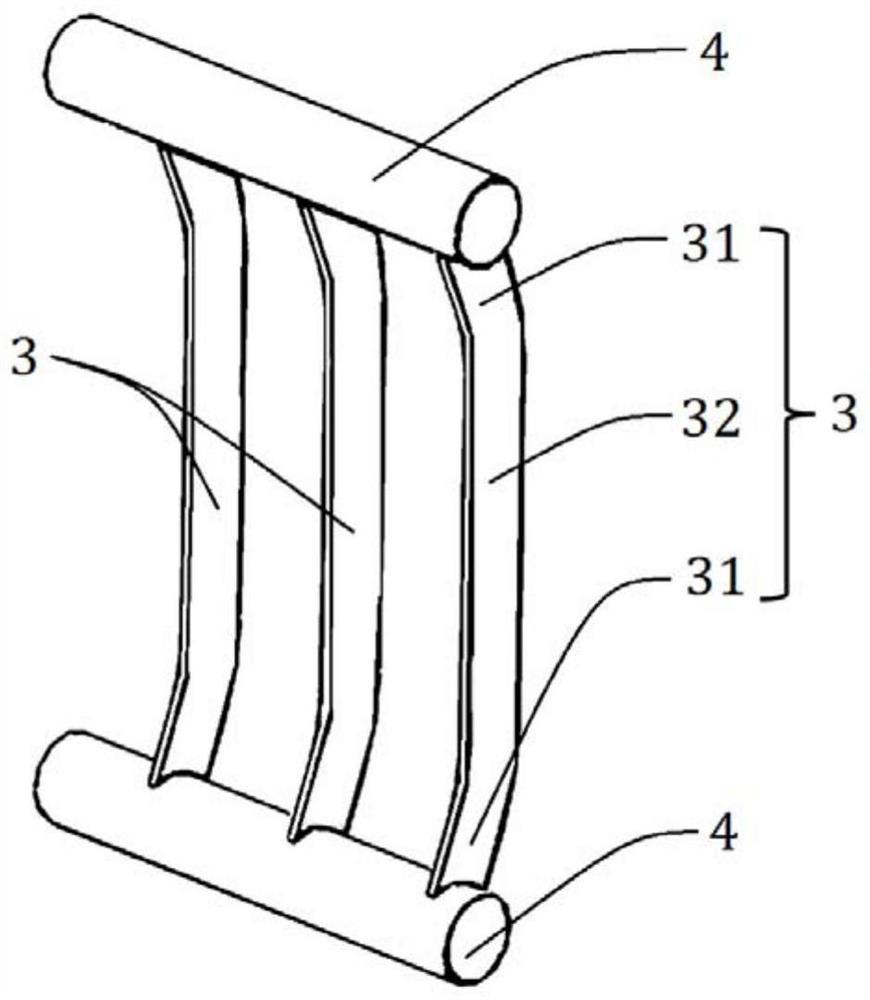

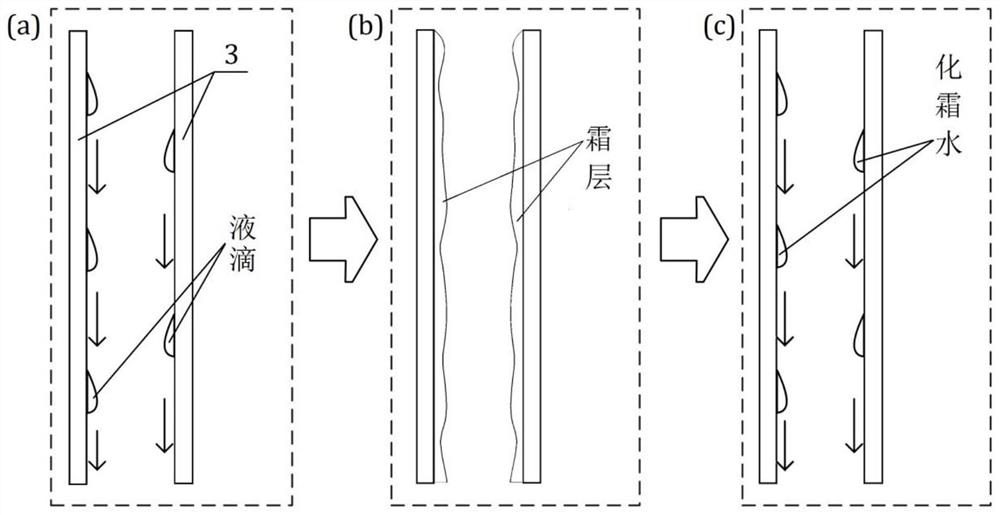

[0023] Such as figure 1 with figure 2 As shown, this embodiment includes a first heat exchange unit 1 and a second heat exchange unit 2 installed in combination, the first heat exchange unit 1 and the second heat exchange unit 2 are each provided with a number of C-shaped flat tubes 3, The C-shaped flat tube 3 includes a straight tube section 32 in the middle and bent sections 31 at both ends;

[0024] The C-shaped flat tubes 3 of the first heat exchange unit 1 and the C-shaped flat tubes 3 of the second heat exchange unit 2 are stacked alternately, and the middle straight tube sections 32 of the C-shaped flat tubes 3 are aligned in the width direction of the flat tubes, Form the effective heat transfer area of the air side flow channel;

[0025] For the convenience of processing, the heat exchange units are processed separately first, and then assembled and installed. After the heat exchanger is assembled, the height and length of the headers 4 of the first heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com