Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about "Evaporating devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

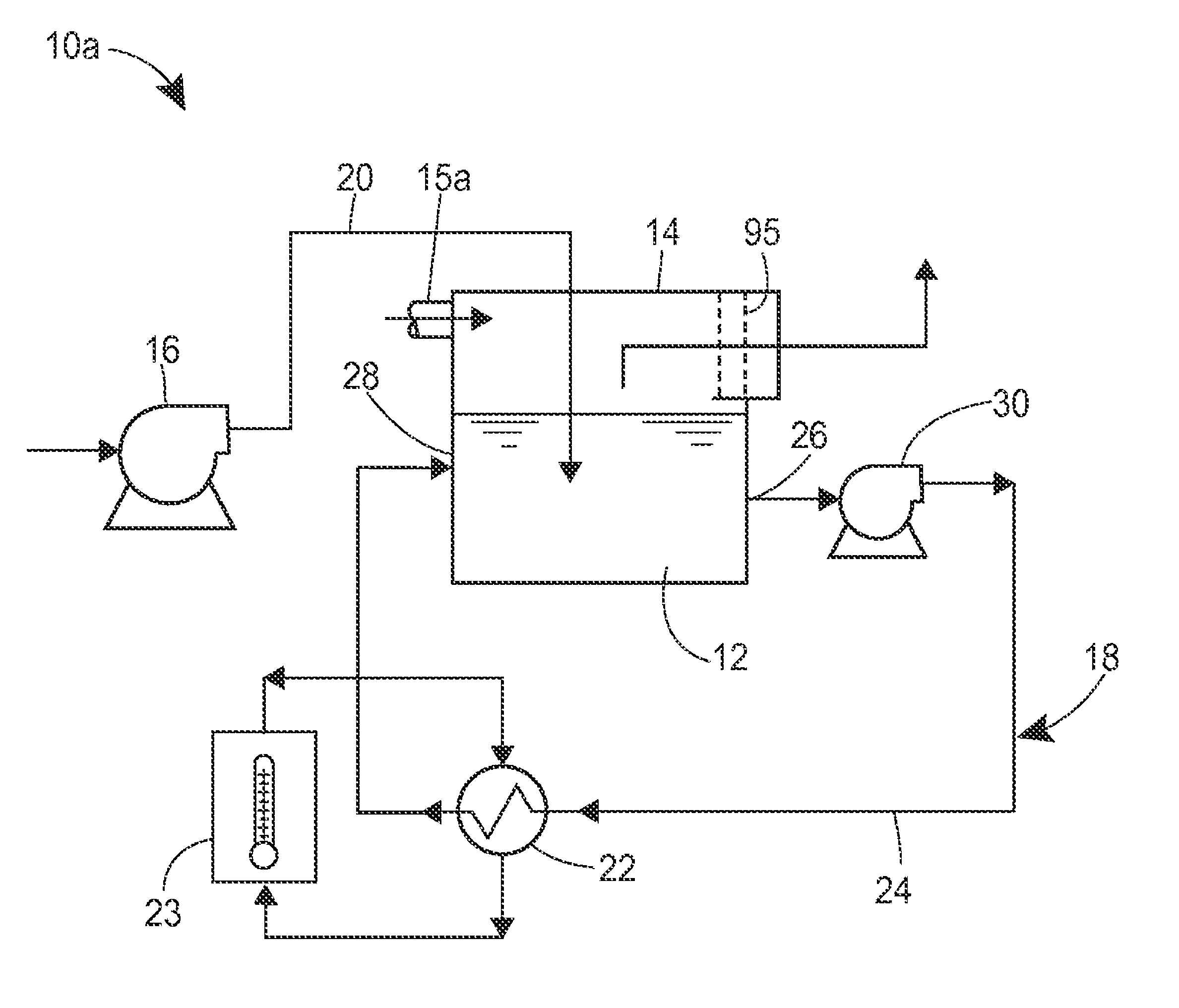

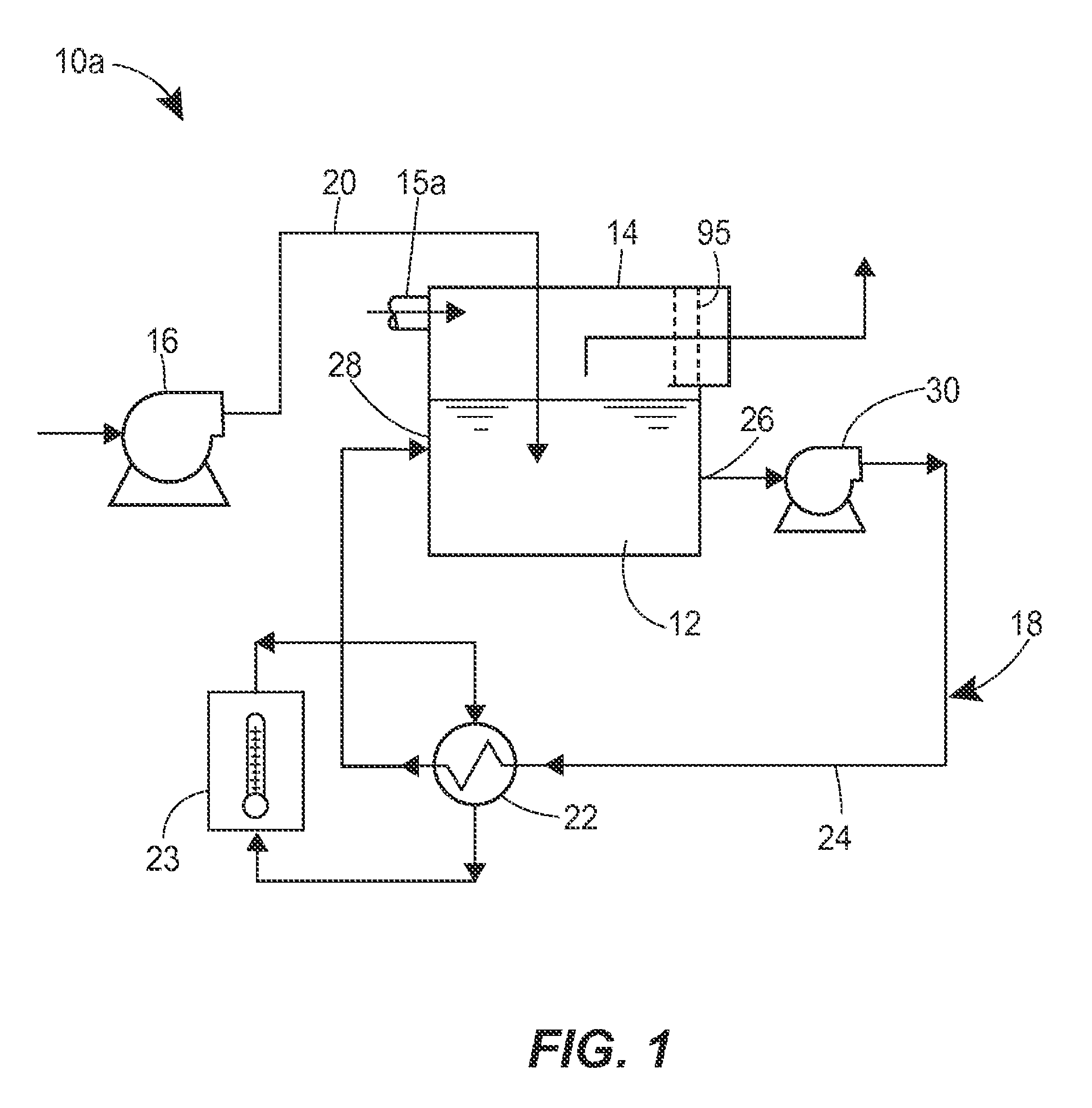

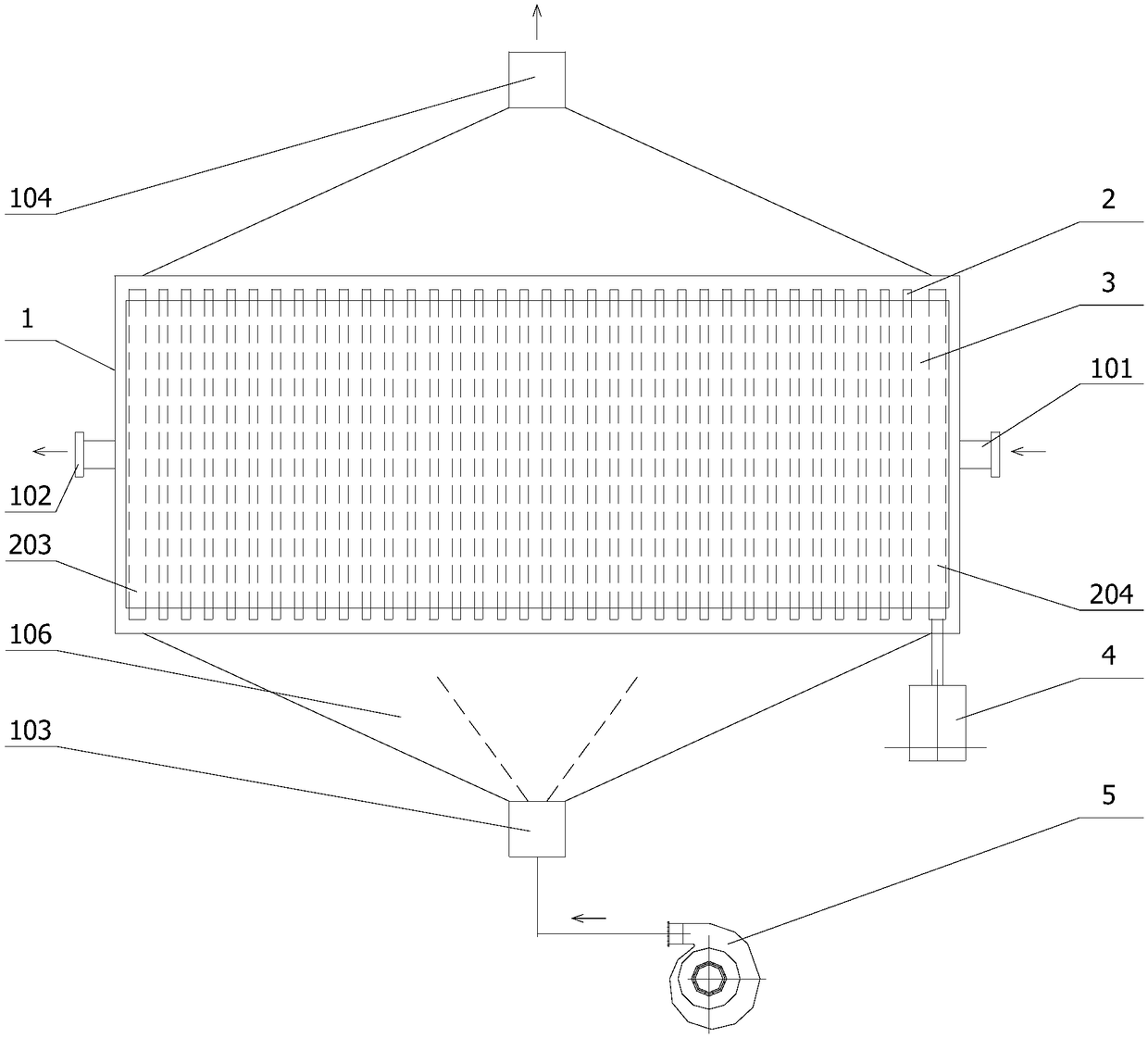

Liquid evaporation system with heated liquid

InactiveUS8623174B1Liquid separation auxillary apparatusDrying using combination processesWater vaporWastewater

A liquid evaporation system for evaporating clean water from a reservoir of wastewater includes a liquid evaporator to evaporate and separate water vapor from the wastewater in a confined space, an air blower to supply air to the liquid evaporator, and a wastewater heating system arranged to collect heat to heat the wastewater in the reservoir.

Owner:HEARTLAND TECH PARTNERS

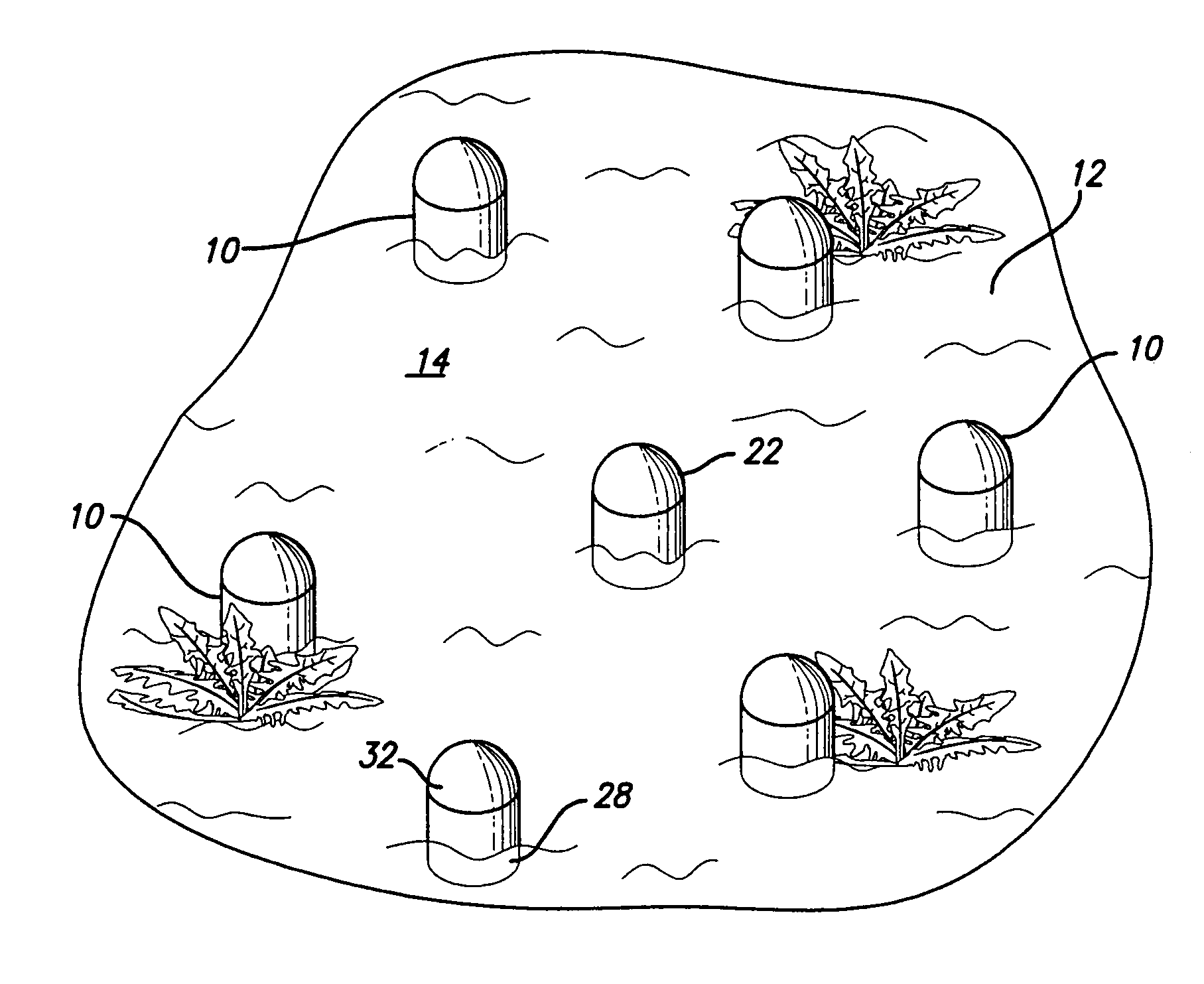

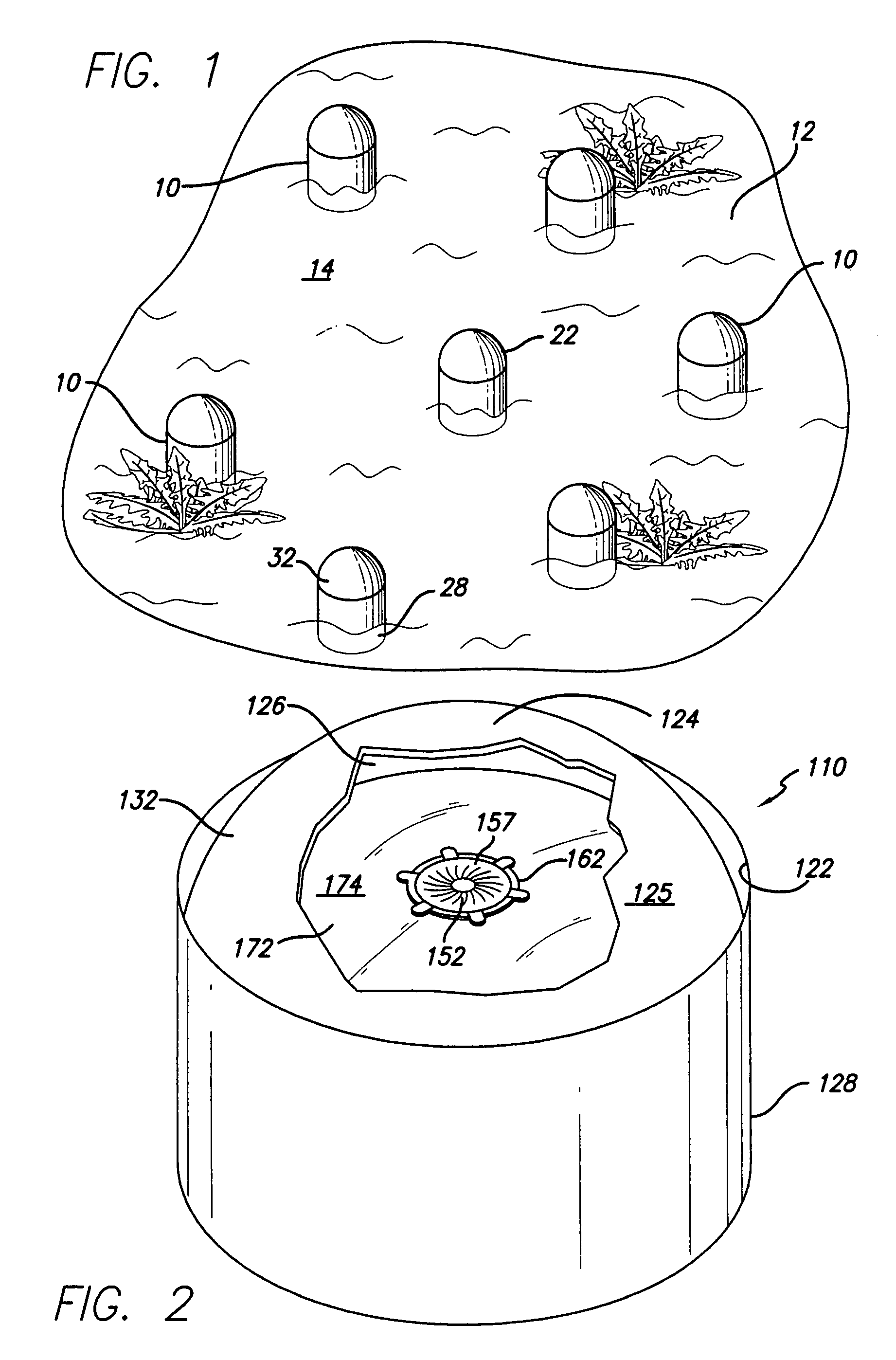

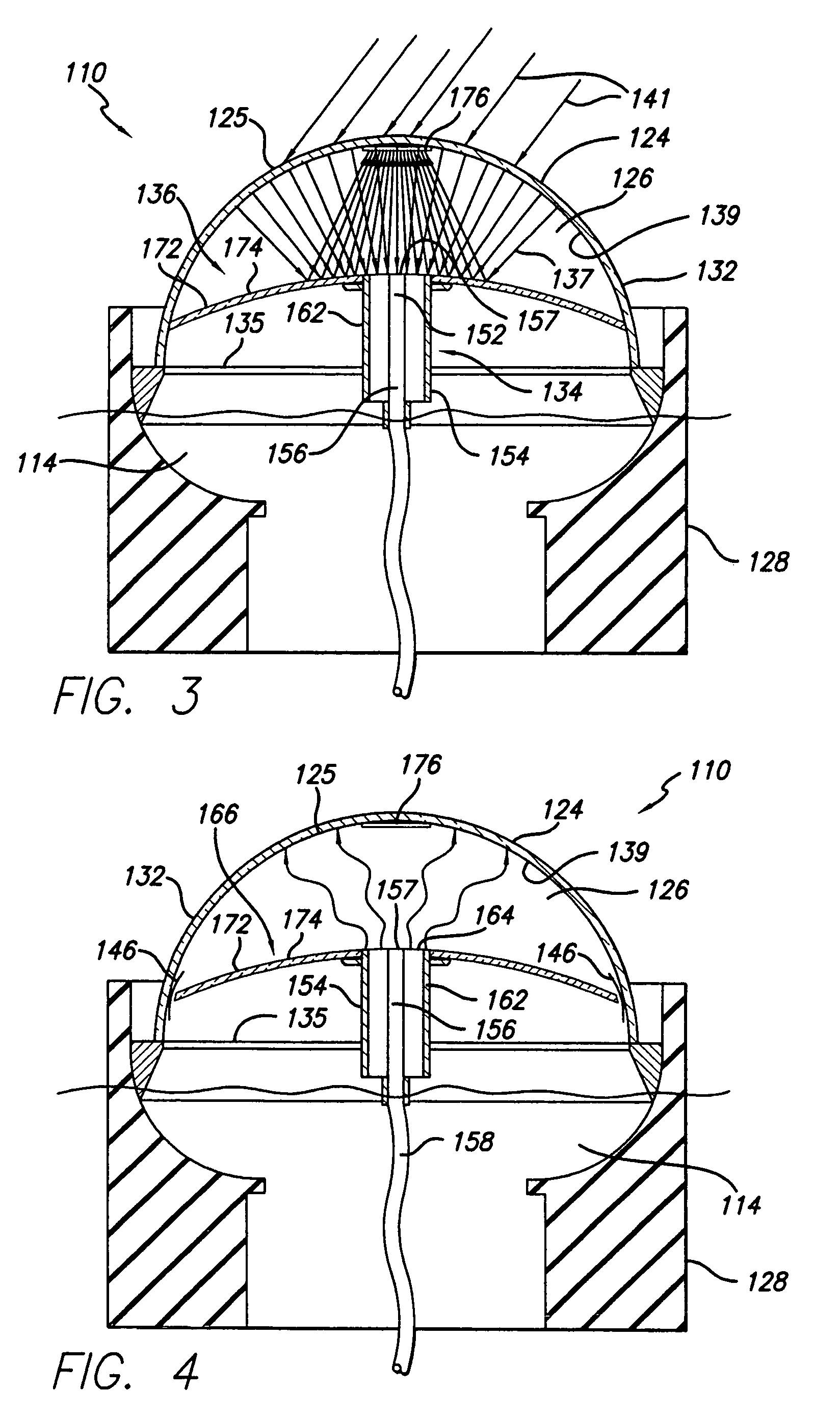

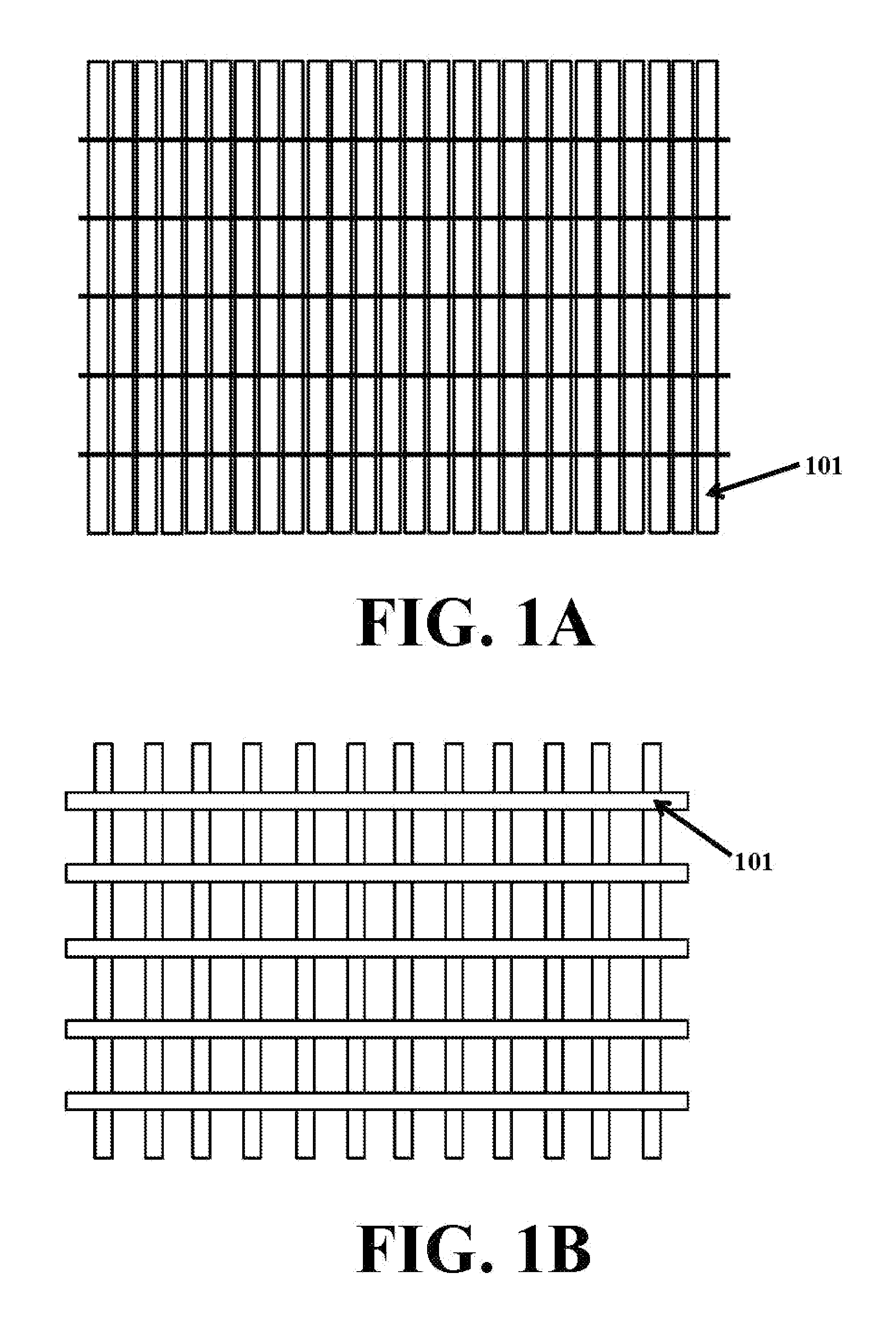

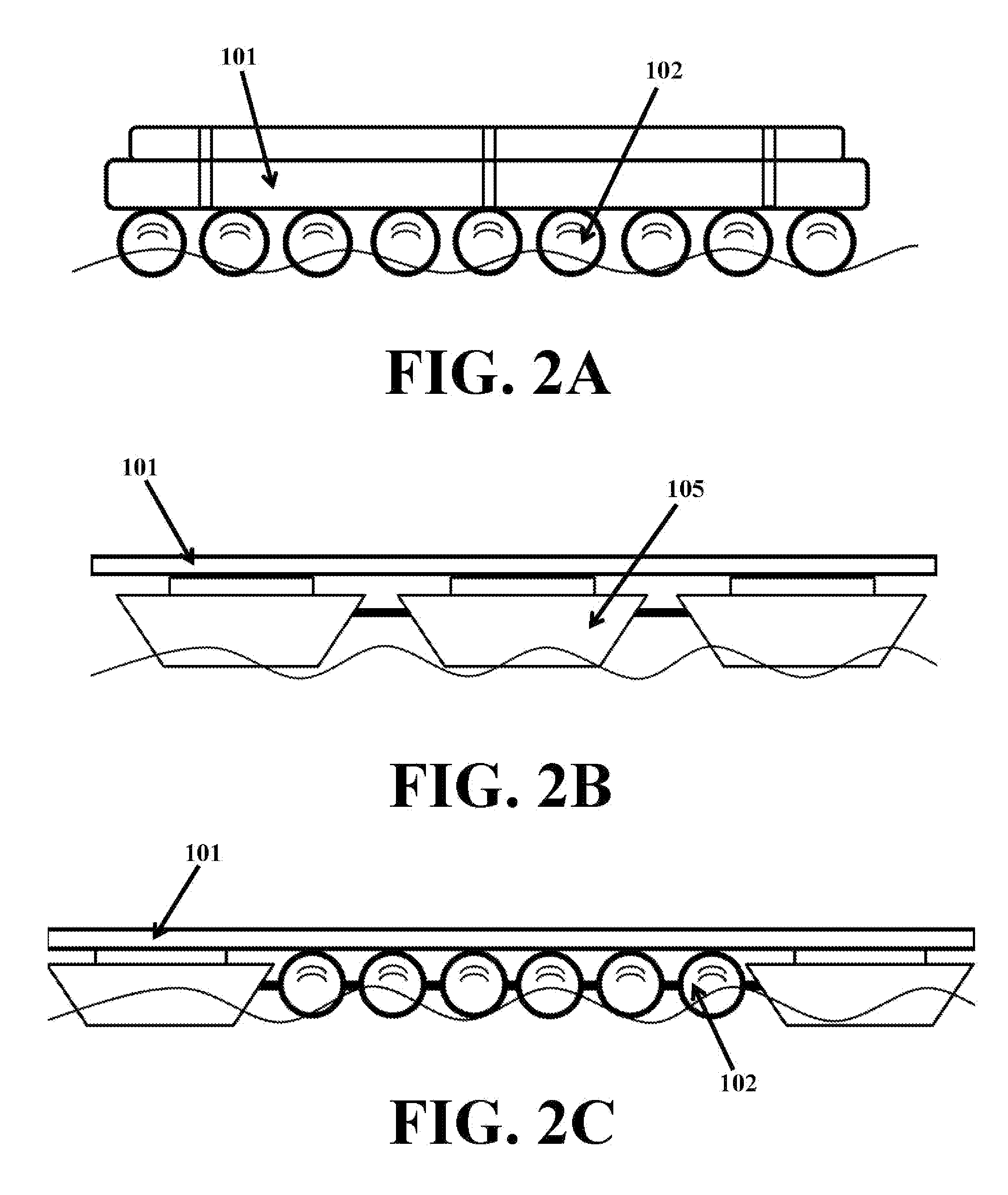

Multi-unit, distributive, regenerable, in situ desalination method

Cultivated field water is desalinated by a series of independent units that float on the water surface, taking up the saline water with a wick, evaporating the water from the wick in desalinating relation by concentrating incident solar radiation with a combination of a lenses and cooperating mirrors onto the upper end portion of the wick while the wick lower end portion is immersed in the field water, capturing the desalinated vapor resulting by condensing within the unit and returning the condensed, desalinated water to the field, and periodically renewing the wick by rinsing the salt from it at a cleaning station beyond the field.

Owner:COON WARREN

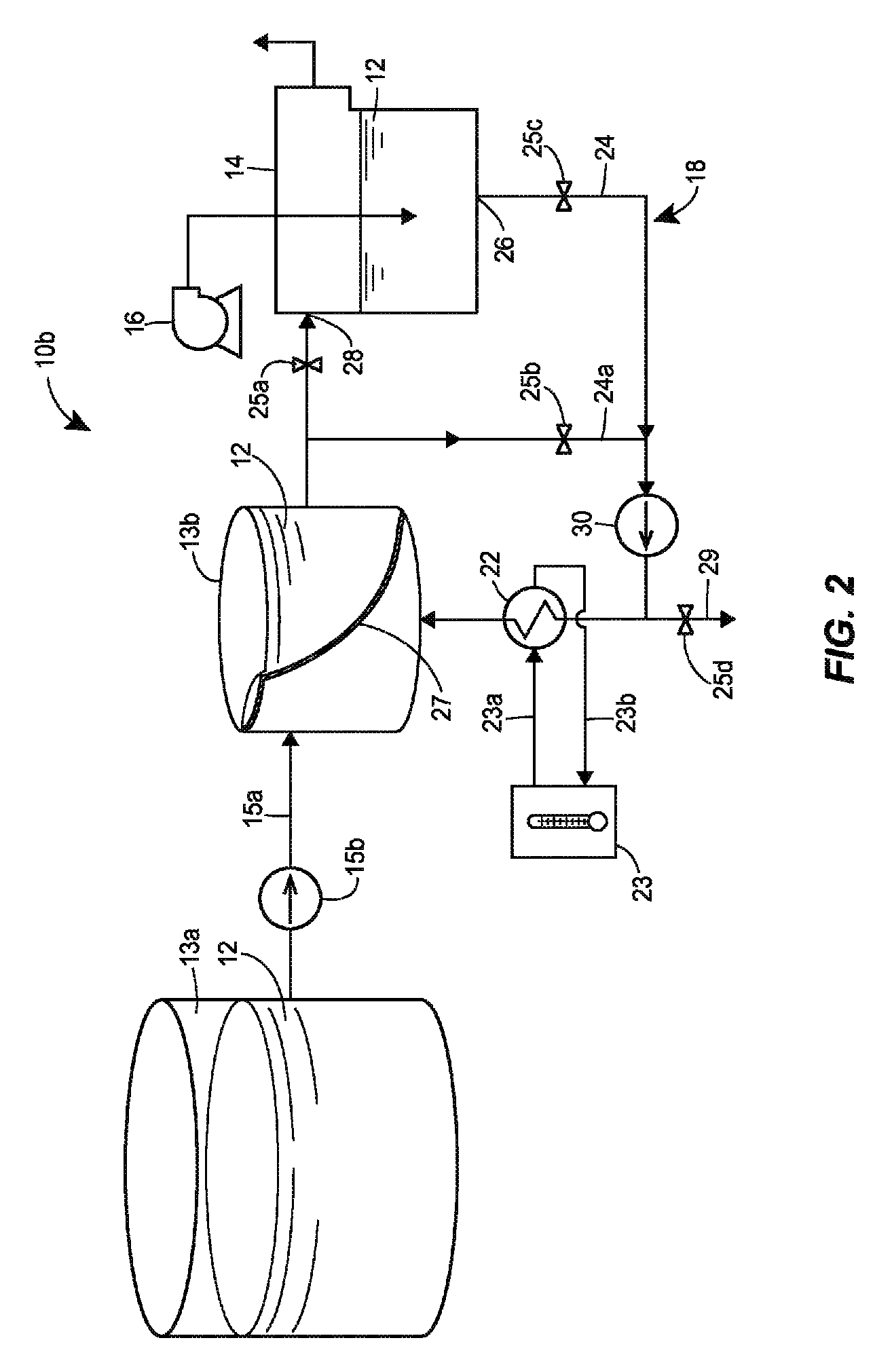

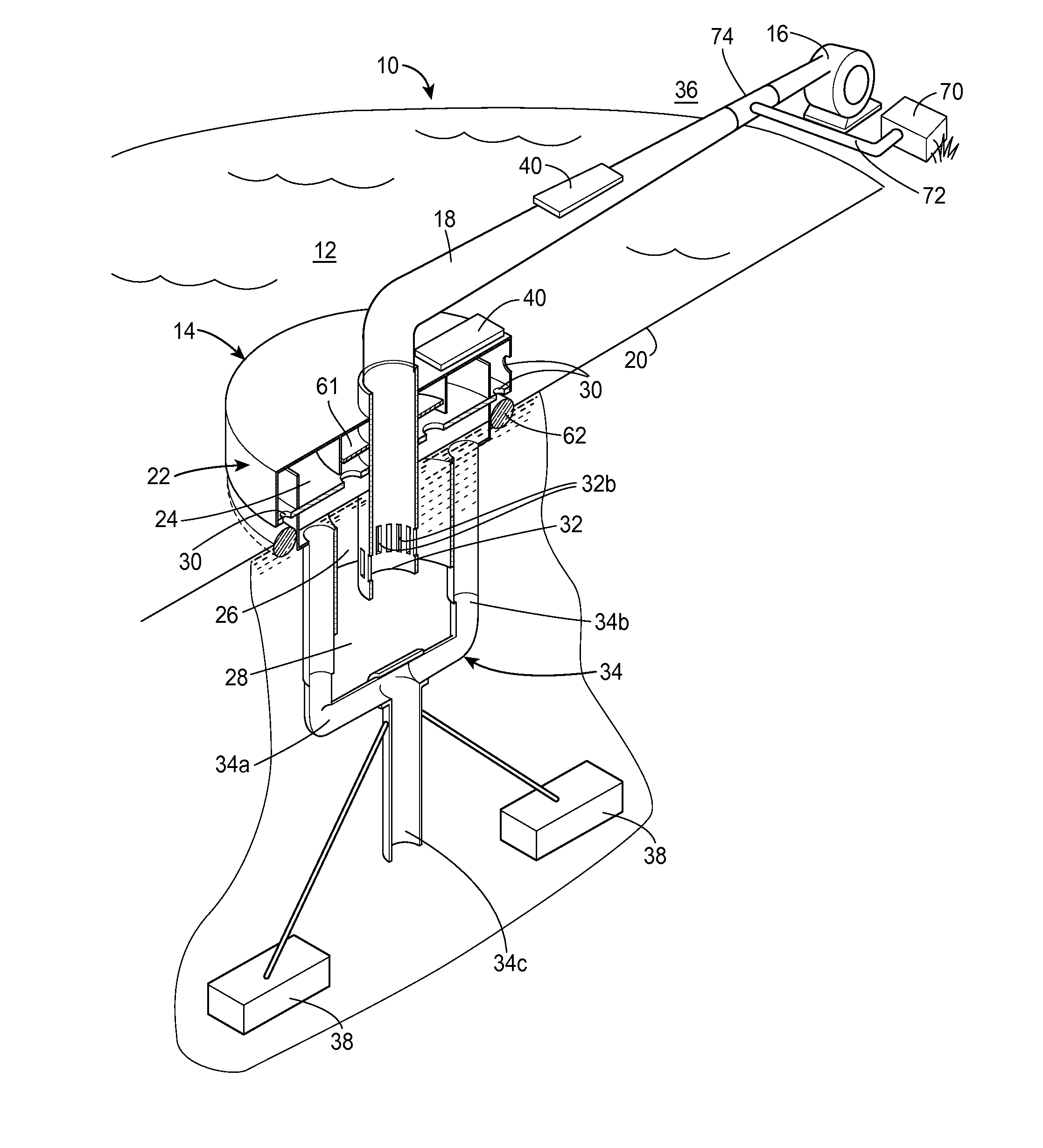

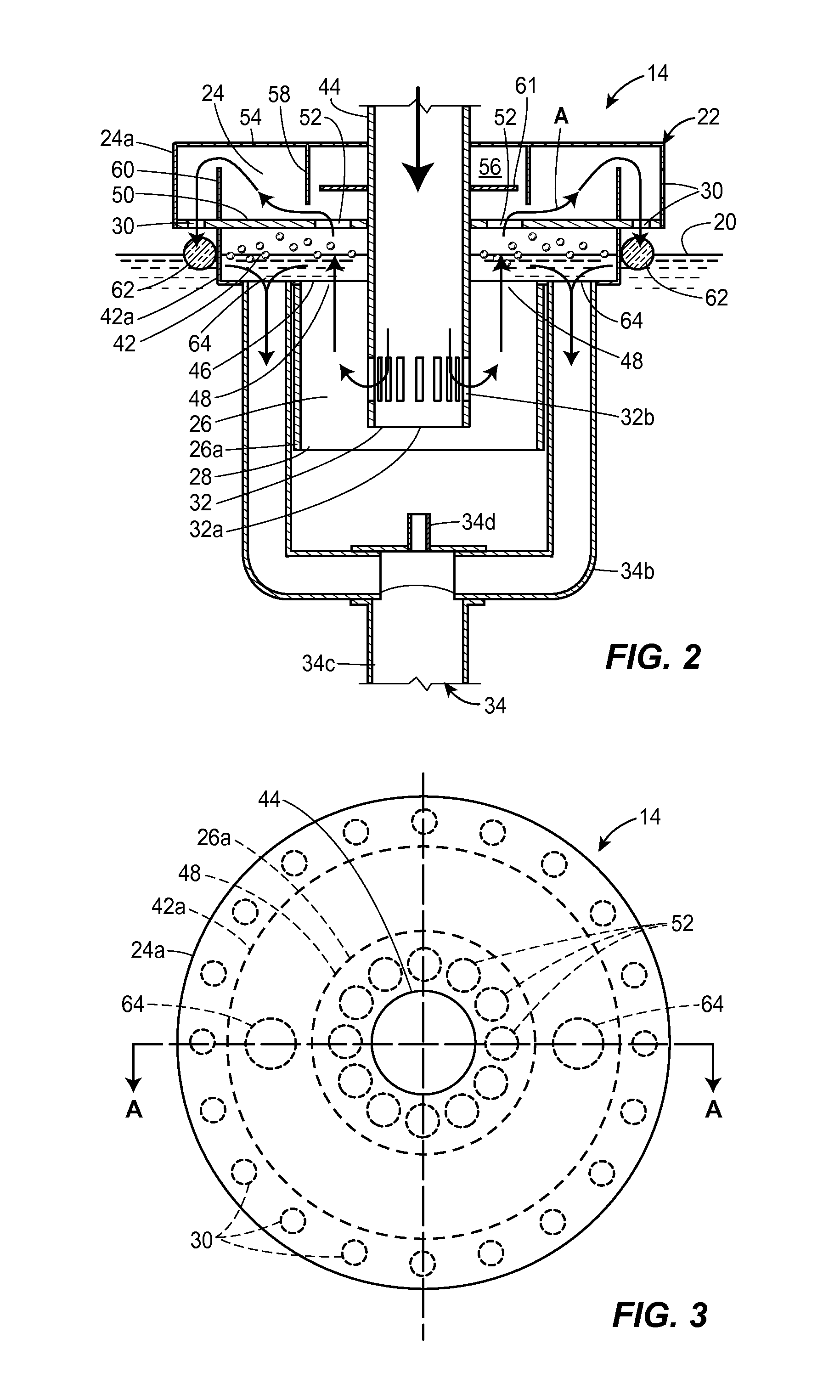

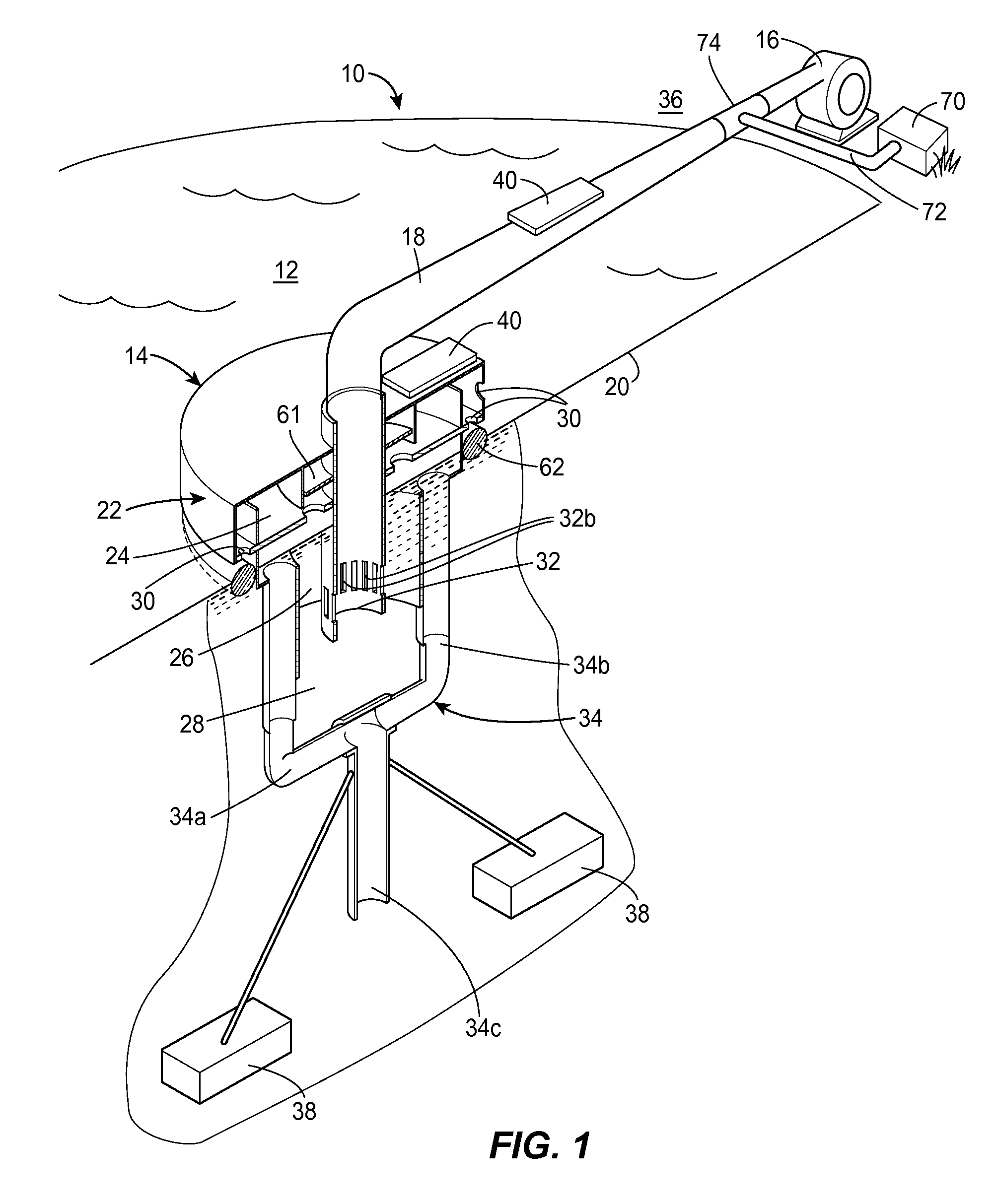

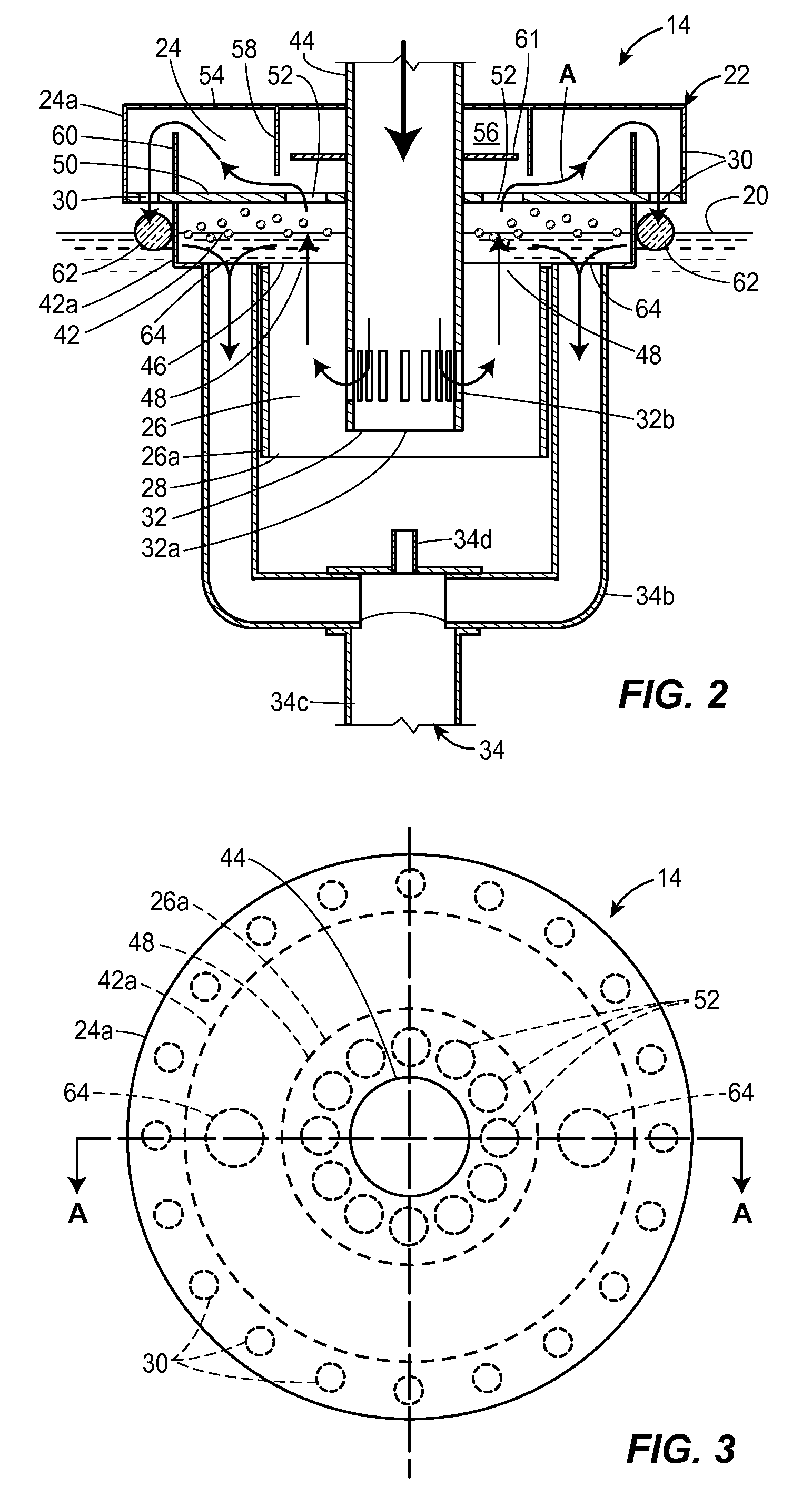

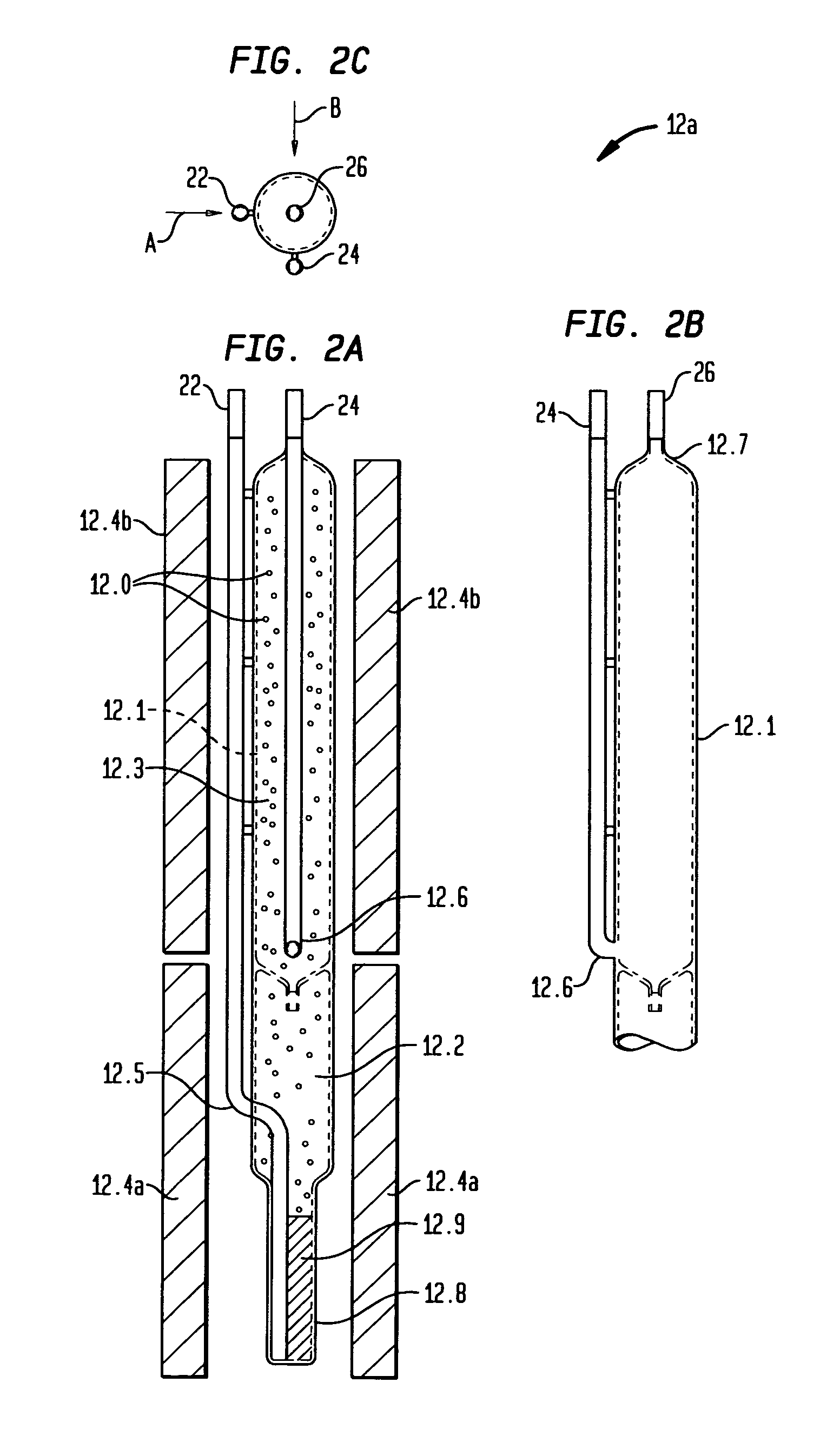

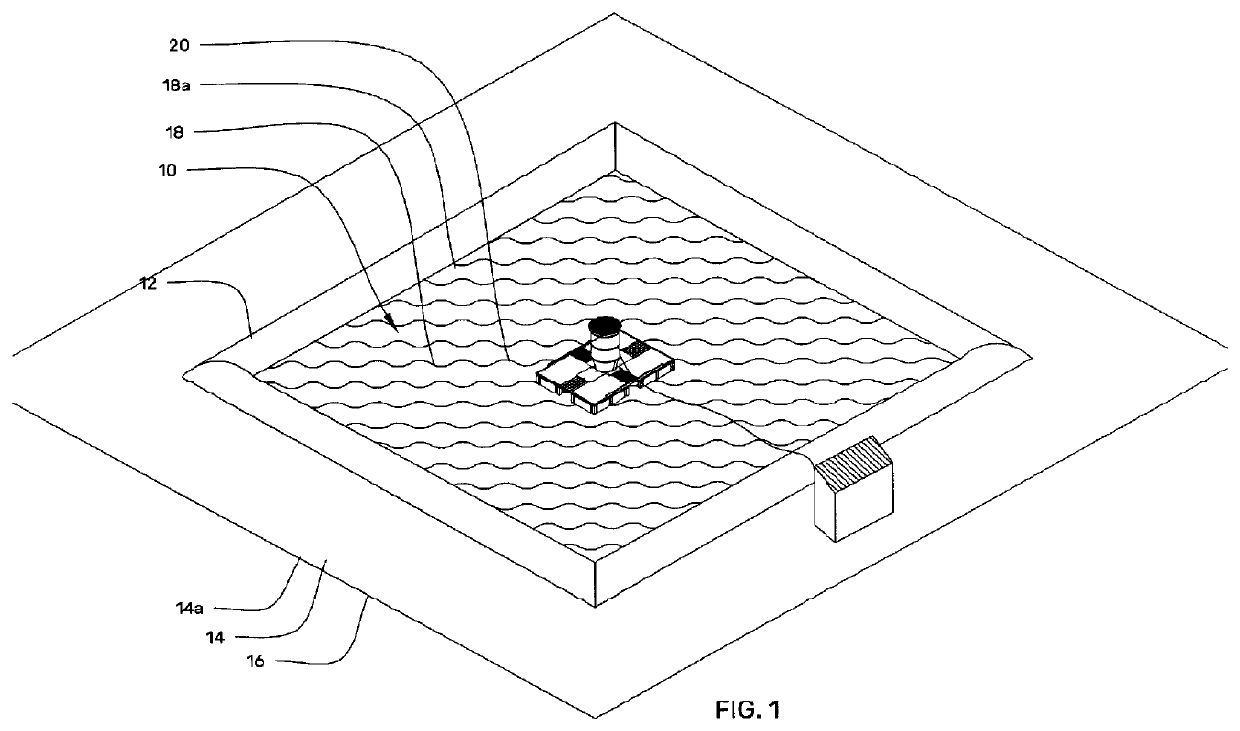

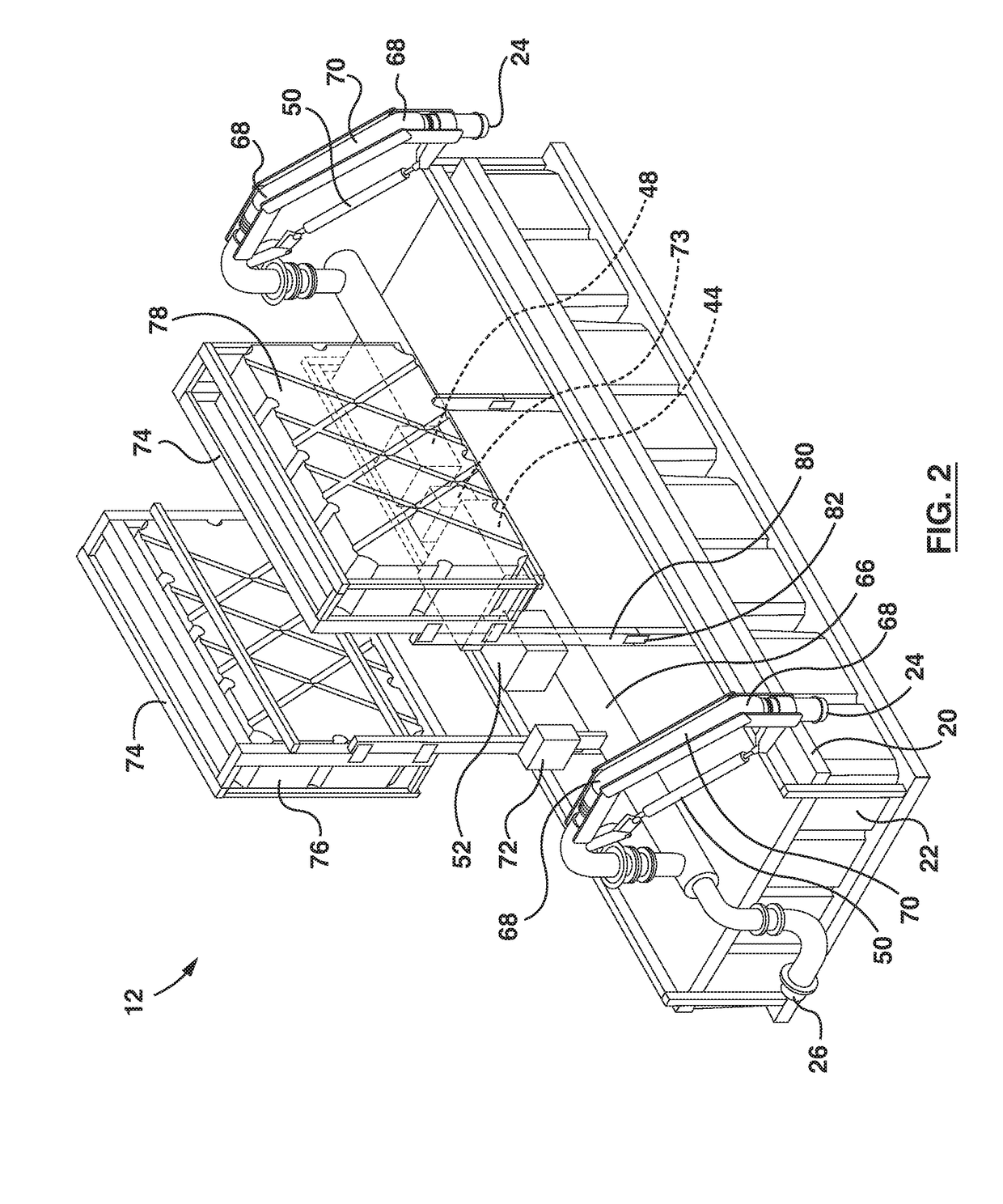

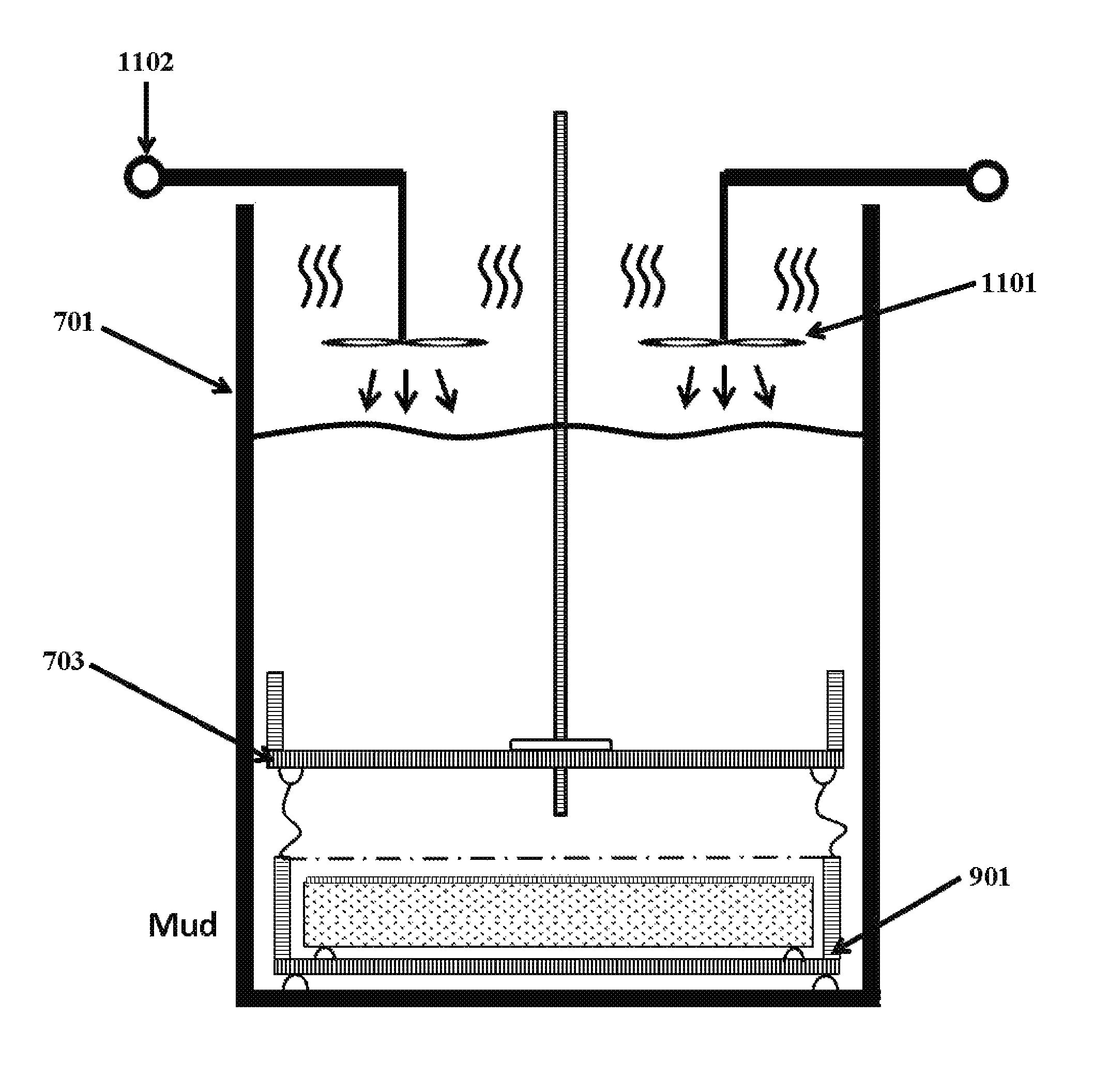

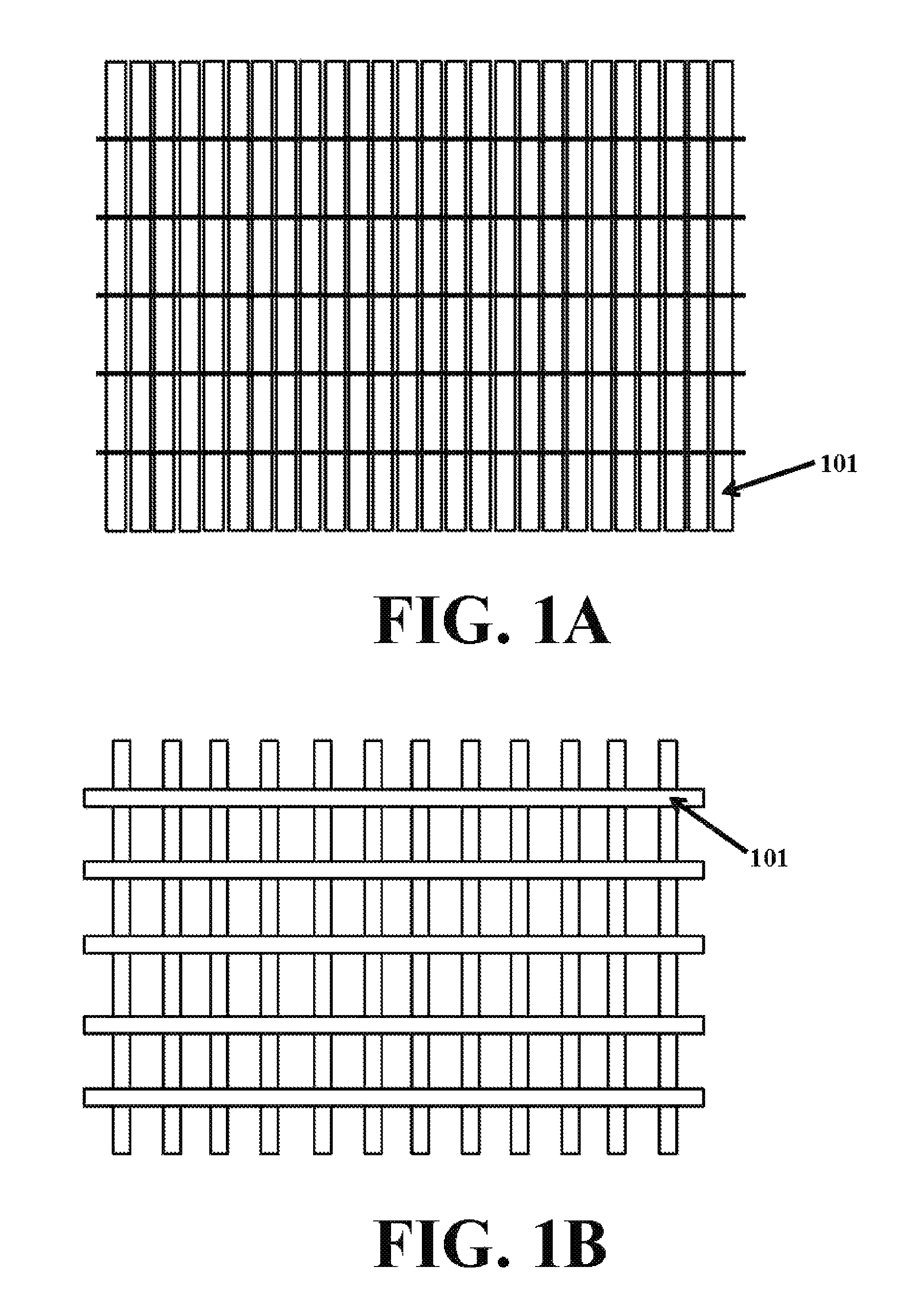

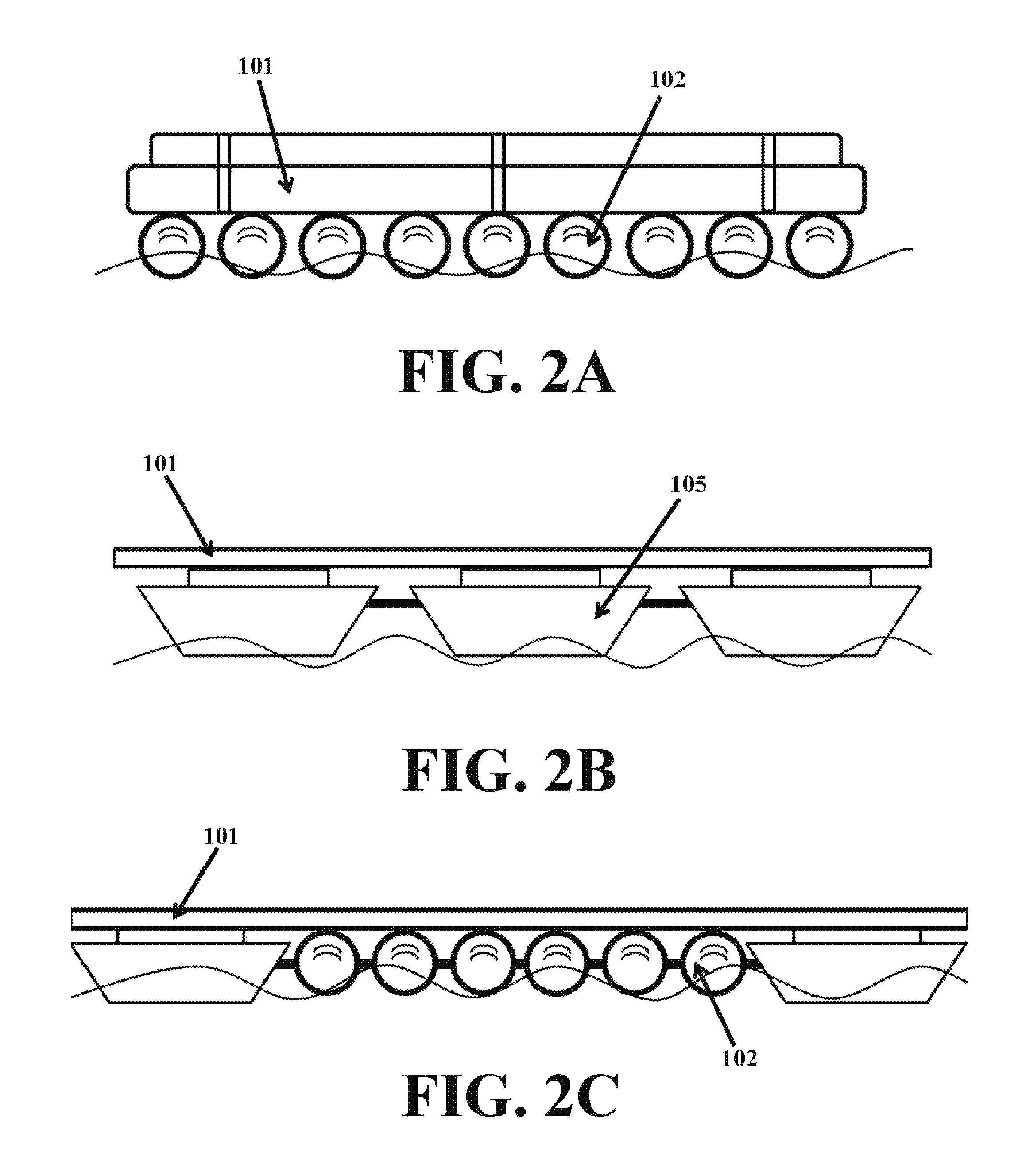

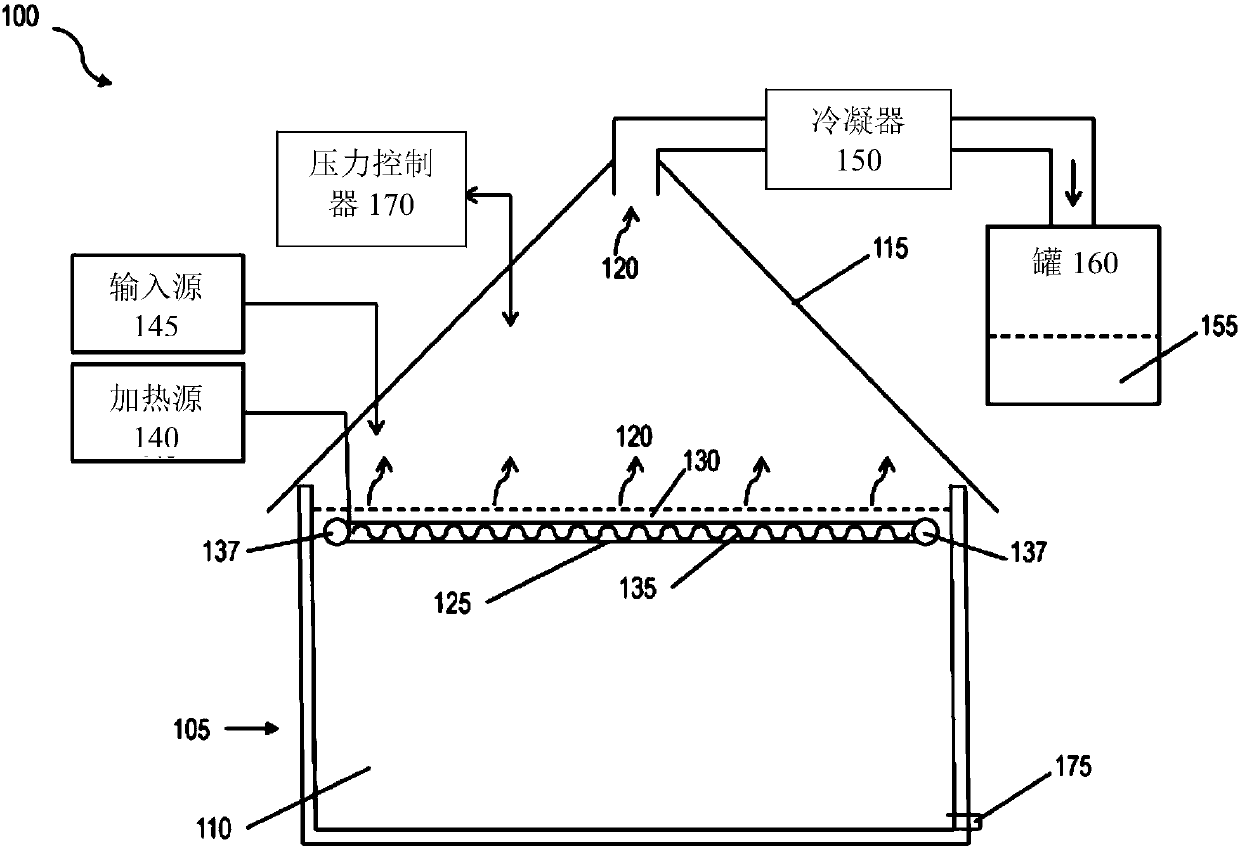

Fluid evaporator for an open fluid reservoir

ActiveUS20130248122A1Drying using combination processesEvaporator accessoriesControl mannerEvaporation

A reservoir evaporation system for evaporating fluid from an open reservoir of effluent containing a contaminant includes a fluid evaporator, an air pump, and an air supply conduit functionally connecting the fluid evaporator with the air pump. The fluid evaporator includes a vessel adapted to be positioned in an operative position partially submerged on the top surface of the effluent in the reservoir with a lower chamber submerged in the effluent and an upper chamber extending above the top surface of the effluent. In operation, air from the air pump mixes with the effluent inside the fluid evaporator and subsequently is discharged through exhaust openings. A fluid discharge pipe can also simultaneously discharge aerated effluent back down into the reservoir. Fluid is thereby separated from the effluent in the lower chamber by evaporation in a controlled manner that minimizes spread of contaminants to surrounding environments by wind.

Owner:HEARTLAND WATER TECH INC

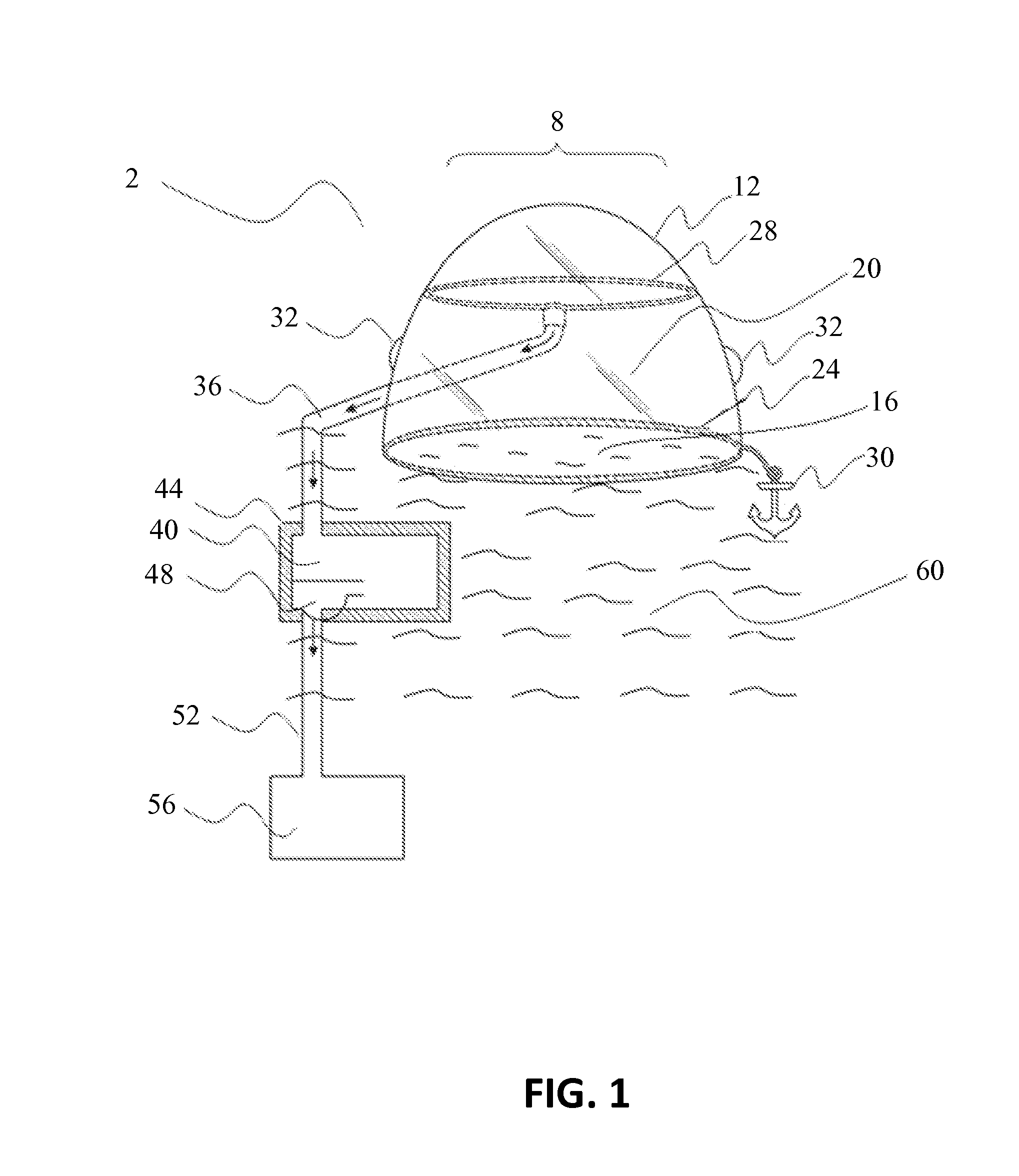

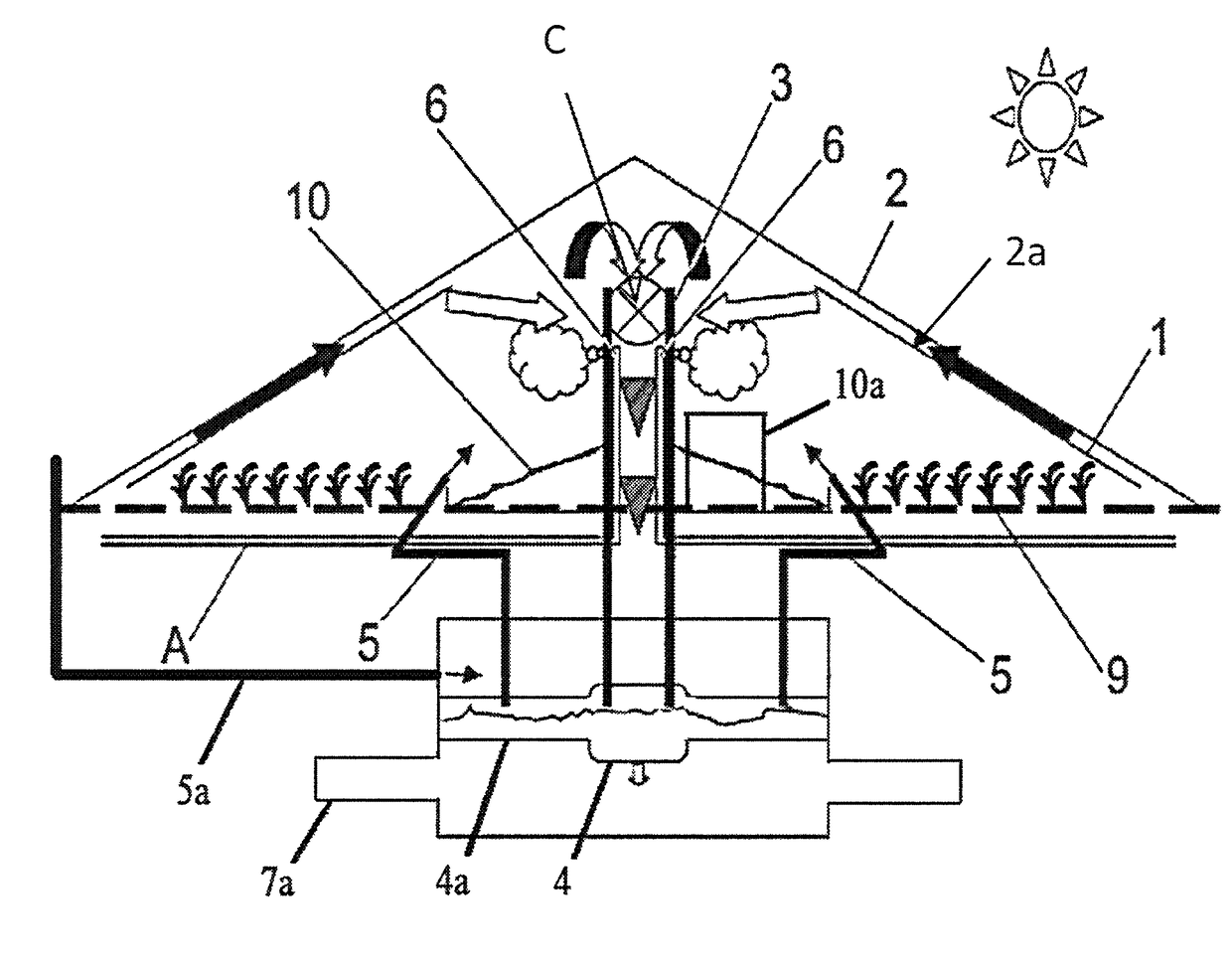

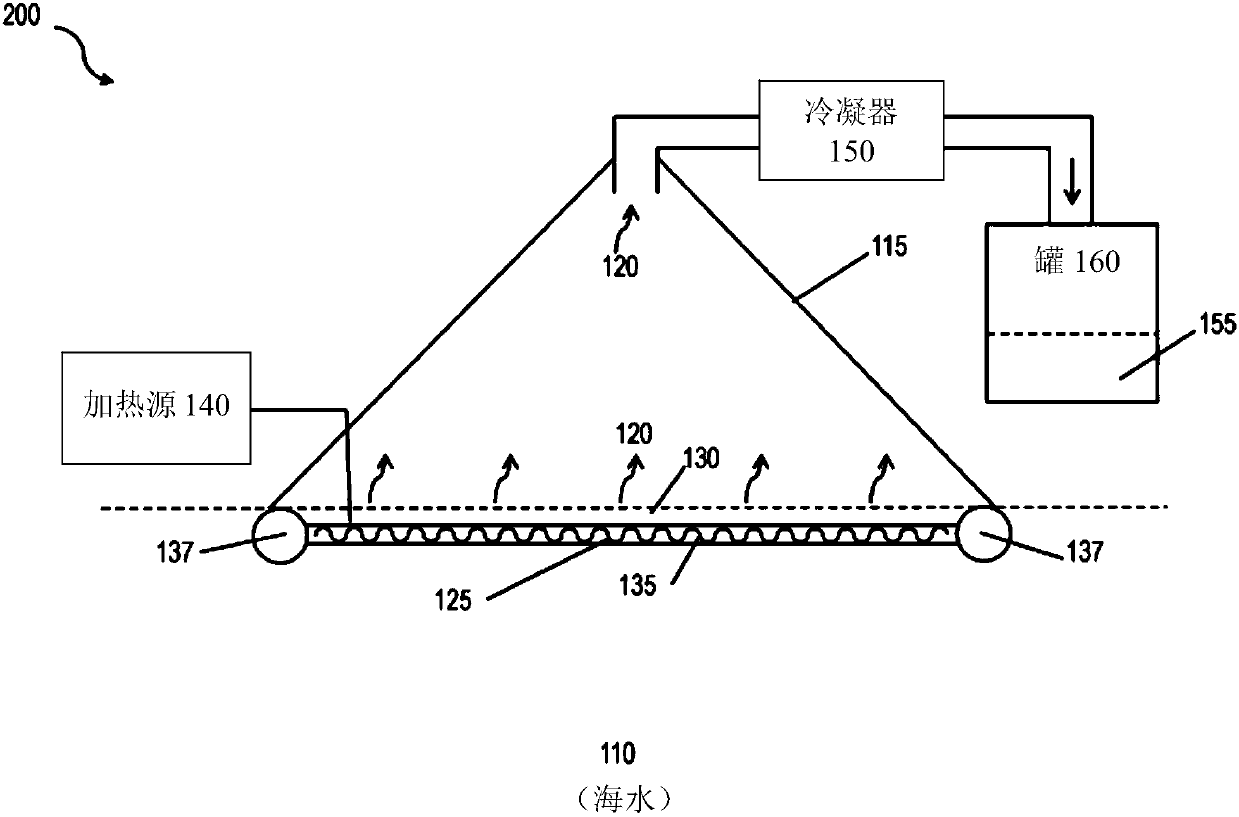

Seawater, brine or sewage solar desalination plant, and desalination method

InactiveUS20140054159A1Comfortable environmentReduce energy consumptionAuxillariesGeneral water supply conservationSaline waterDistillation

A tent or covering with a pyramid-shaped structure, with an inner dark-coloured sheet and an outer transparent sheet, installed on a supporting base anchored to the ground or on floats on the surface of the sea, wherein in the apex of the pyramid there are included vaporizers with micronebulisers for nebulising the water to be treated, a device for capturing humid air through a continuous or sectioned condensation column and for subsoil distillation and heat dissipation in the smaller, water-collecting tank and recirculation of the air devoid of humidity into the enclosure. In addition, it includes a computerised control system of the processes includes controls of the air and nebulised water flow rates and of the working regime of the facility.

Owner:UNIV POLITECNICA DE CATALUNYA

Fluid evaporator for an open fluid reservoir

Owner:HEARTLAND WATER TECH INC

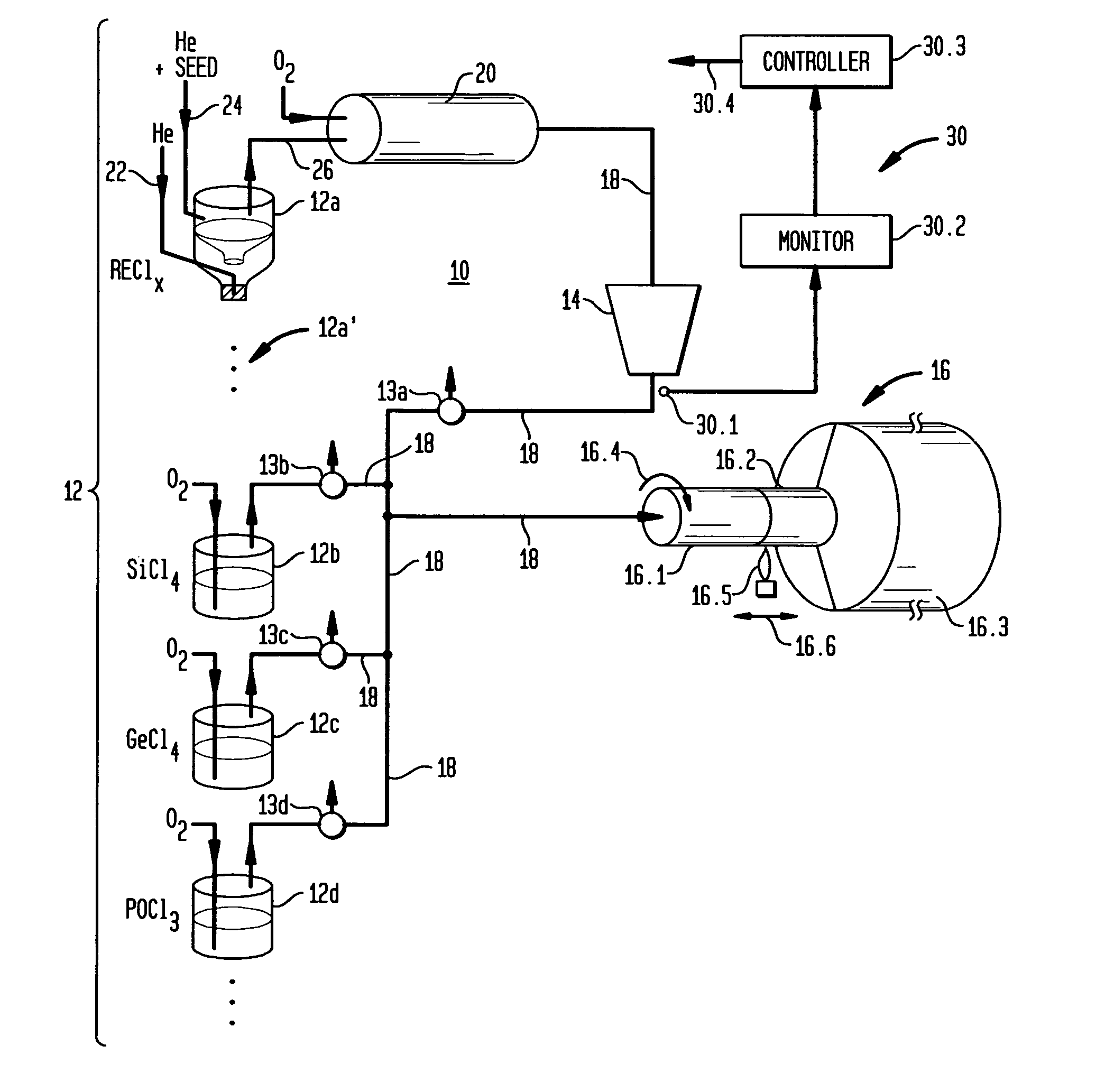

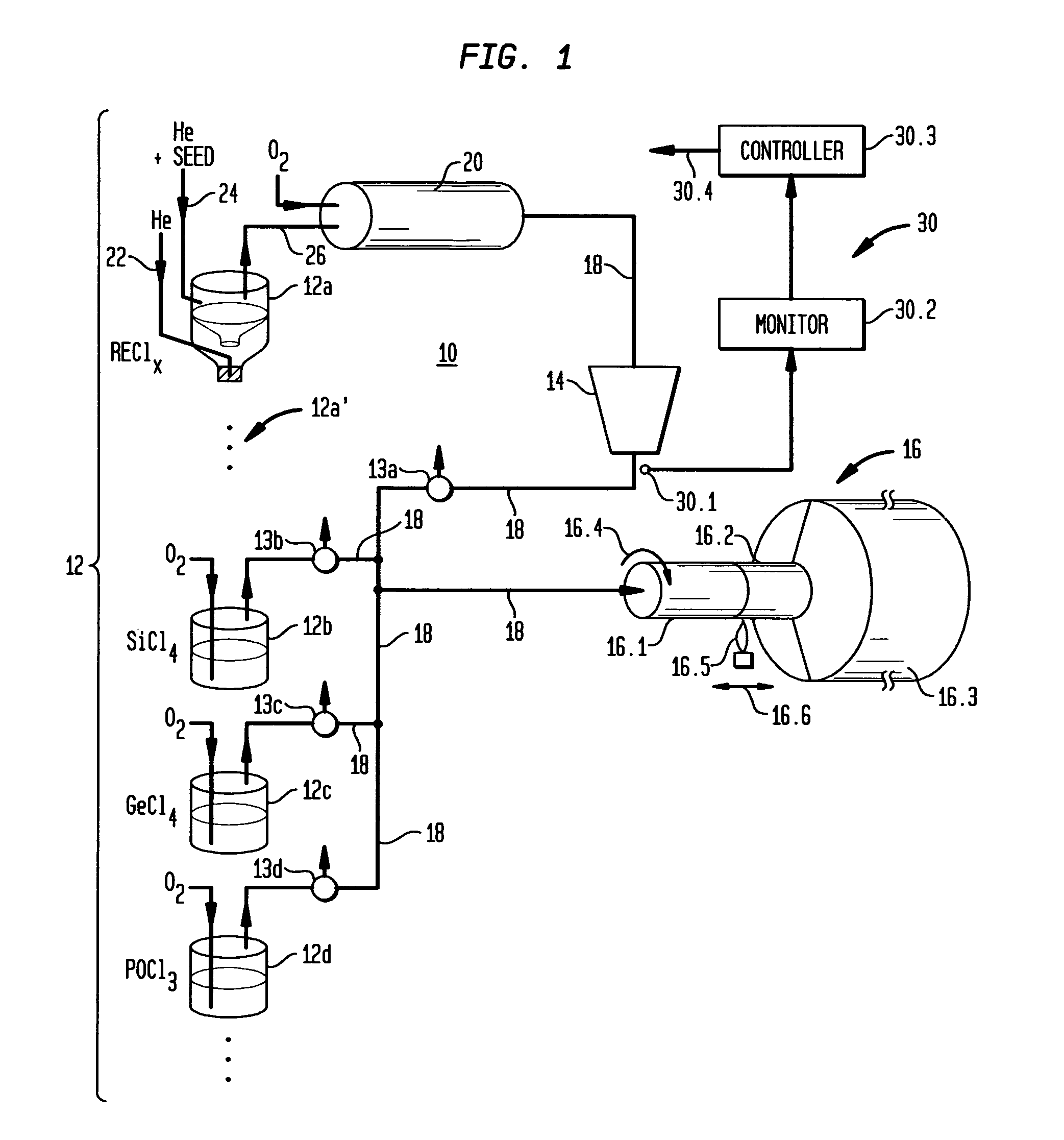

Apparatus and method for fabricating glass bodies using an aerosol delivery system

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

Solar Still Apparatus

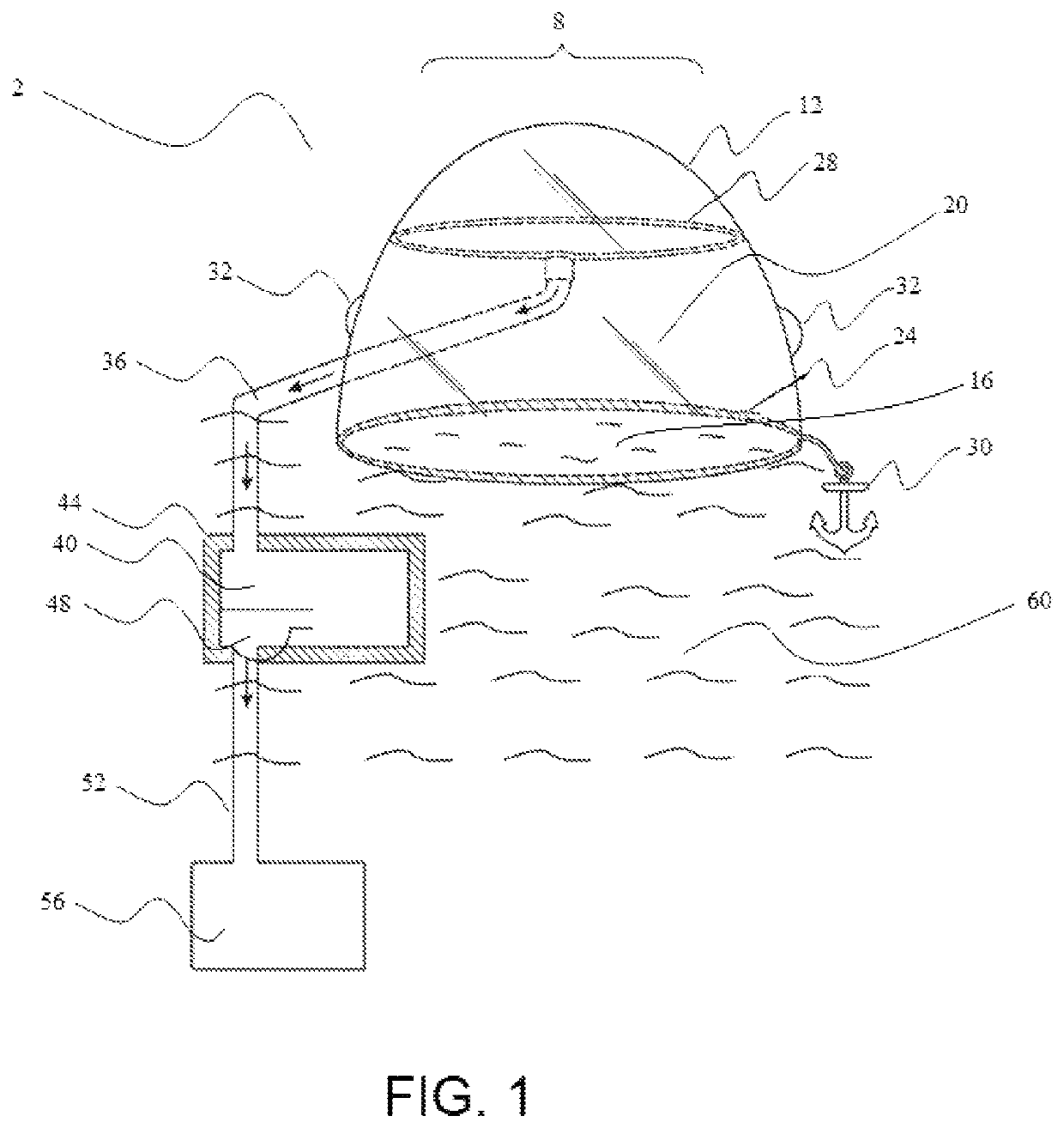

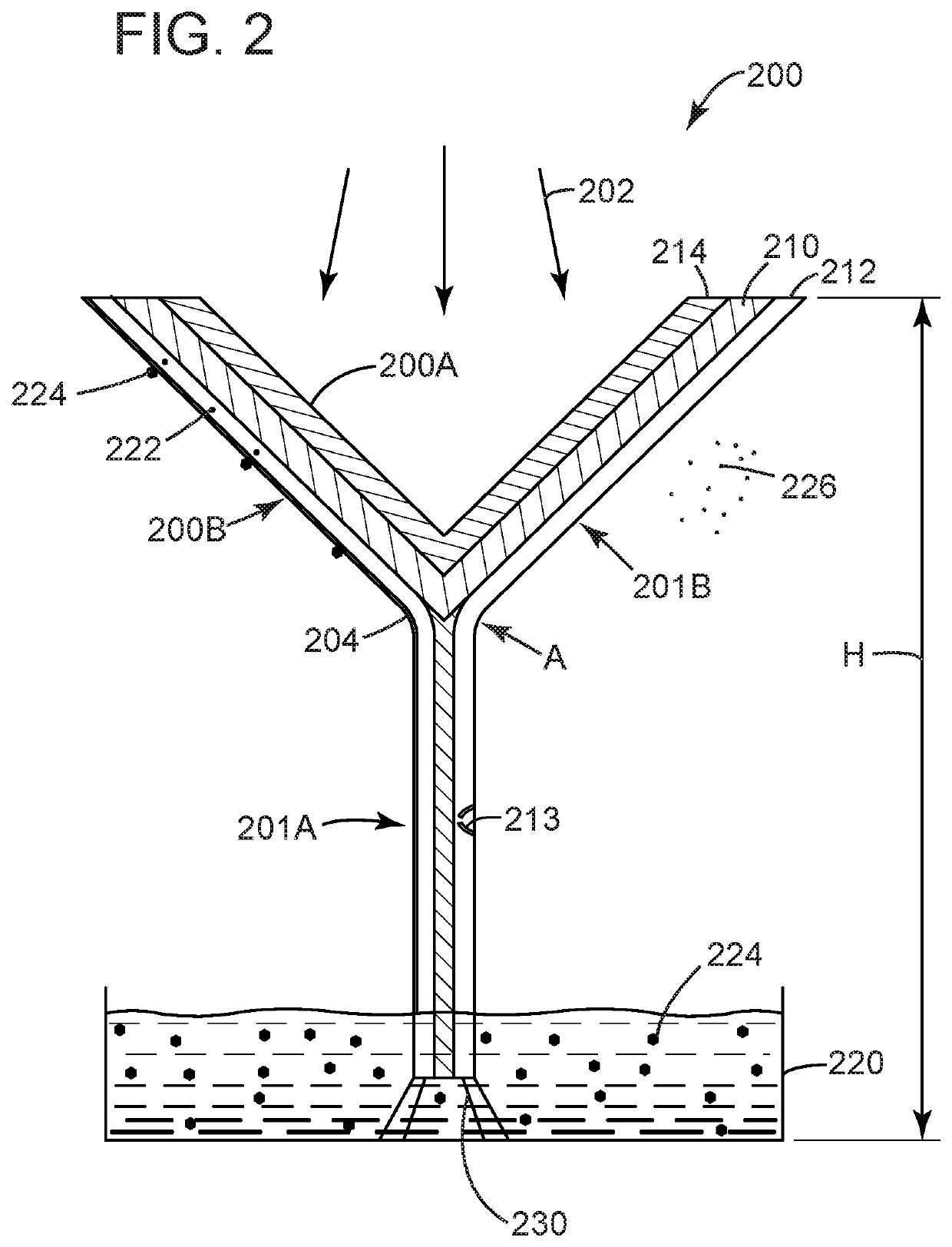

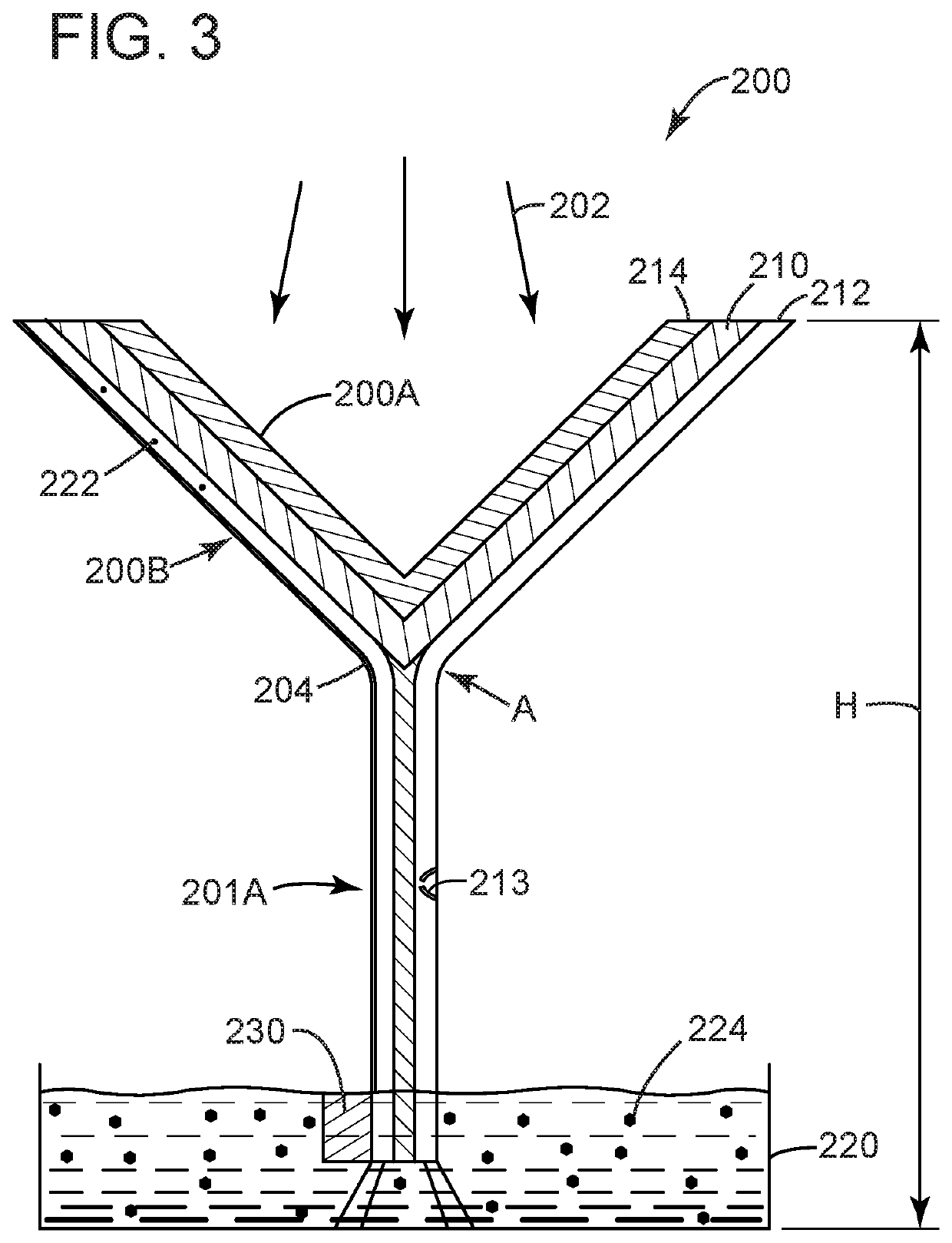

There is provided a solar still apparatus for converting contaminated water contained in a contaminated water body into distillate water, the contaminated water body having a water surface, the solar still apparatus comprising a cover in the form of a geometrical projection comprising a wall, an opening and a chamber, wherein the wall is adapted to be in thermal communication with the external environment for capturing solar heat and in optical communication with the opening for allowing passage of solar rays from the external environment to the opening; the opening is adapted to be in optical communication with the wall and the surface of the contaminated water body for allowing passage of the solar rays from the wall to the surface of the contaminated water body for heating the contaminated water to form a vapor, and adapted to be in fluid communication with the surface of the contaminated water body and the chamber for allowing passage of the vapor from the surface of the contaminated water body inside the chamber; and the chamber is defined by the wall, the chamber being adapted to be in fluid communication with the opening for receiving the vapor formed and condensing the vapor for forming condensed distillate water therefrom.

Owner:ALKHAZRAJI SAEED ALHASSAN

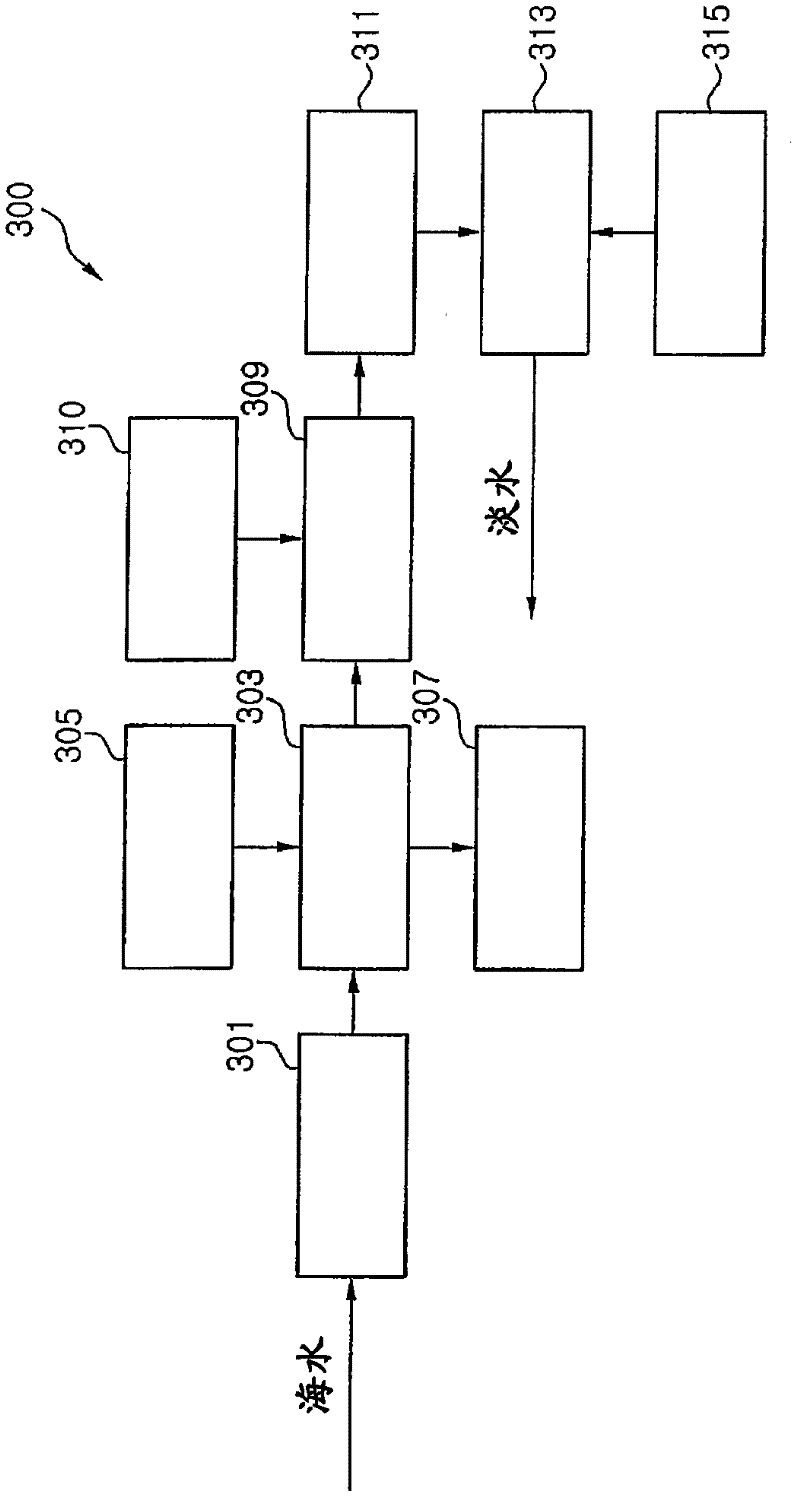

Solar Still System And Related Water Transportation Apparatus

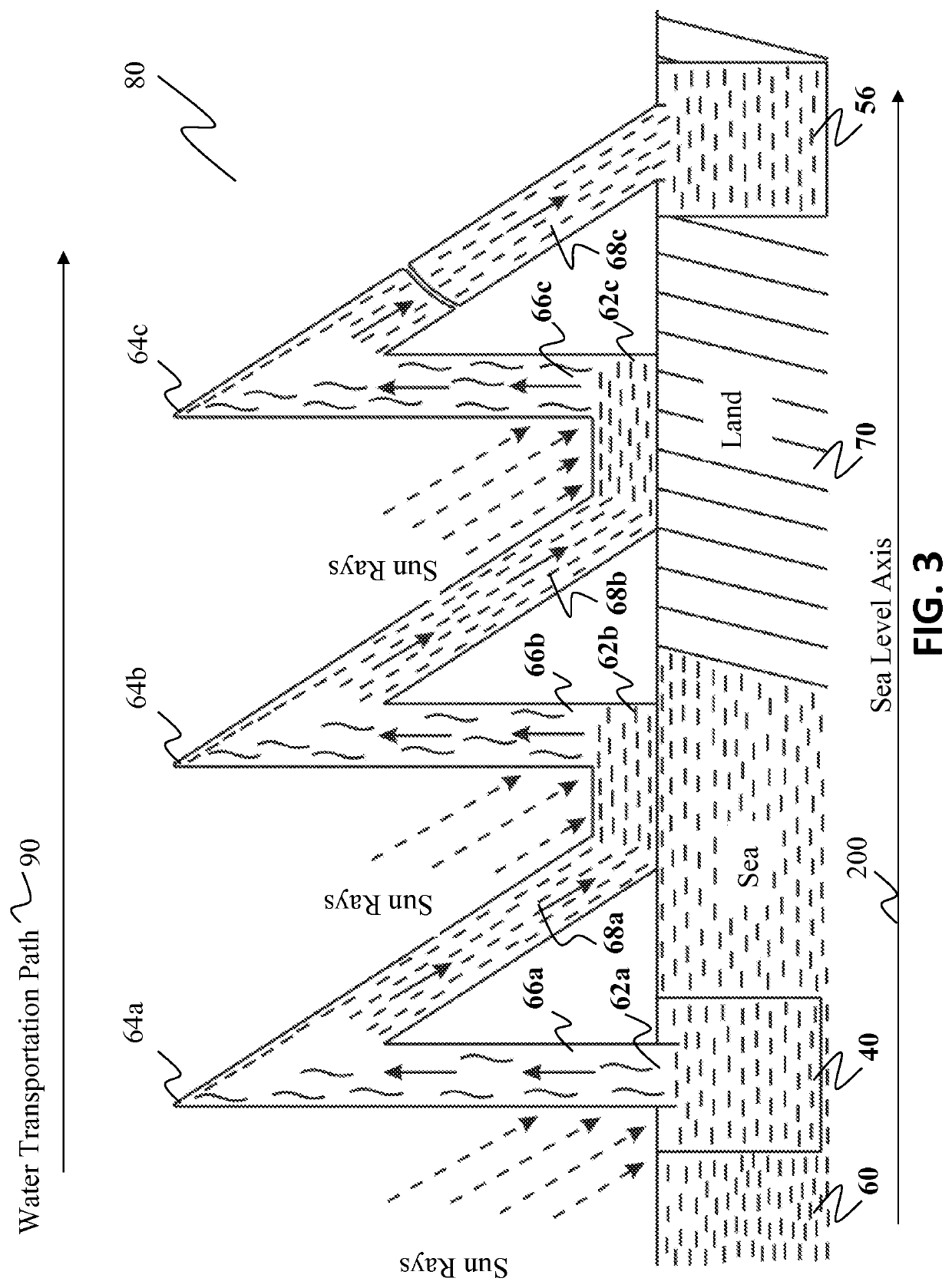

There is provided a water transportation system comprising evaporation zones for converting water into water vapour; condensation zones for condensing the water vapour into condensed water, the condensation zones being in fluid communication with the evaporation zones; water vapour conduits adapted to enable the fluid communication of the water vapour between the evaporation zones and the condensation zones; condensed water conduits adapted to enable the fluid communication of condensed water between the condensation zones and the evaporation zones; wherein the evaporation zones and the condensation zones alternate in position along a water transportation path between a water source site and a water destination site for enabling the transport of water from the water source site to the water destination site through alternating processes of evaporation-condensation and condensation-evaporation of the water.

Owner:ALKHAZRAJI SAEED ALHASSAN

Seawater, brine or sewage solar desalination plant, and desalination method

InactiveUS9623344B2Reduce energy consumptionEasy to handleGeneral water supply conservationSeawater treatmentDistillationEngineering

A tent or covering with a pyramid-shaped structure, with an inner dark-colored sheet and an outer transparent sheet, installed on a supporting base anchored to the ground or on floats on the surface of the sea, wherein in the apex of the pyramid there are included vaporizers with micronebulizers for nebulizing the water to be treated, a device for capturing humid air through a continuous or sectioned condensation column and for subsoil distillation and heat dissipation in the smaller, water-collecting tank and recirculation of the air devoid of humidity into the enclosure. In addition, it includes a computerized control system of the processes includes controls of the air and nebulized water flow rates and of the working regime of the facility.

Owner:UNIV POLITECNICA DE CATALUNYA

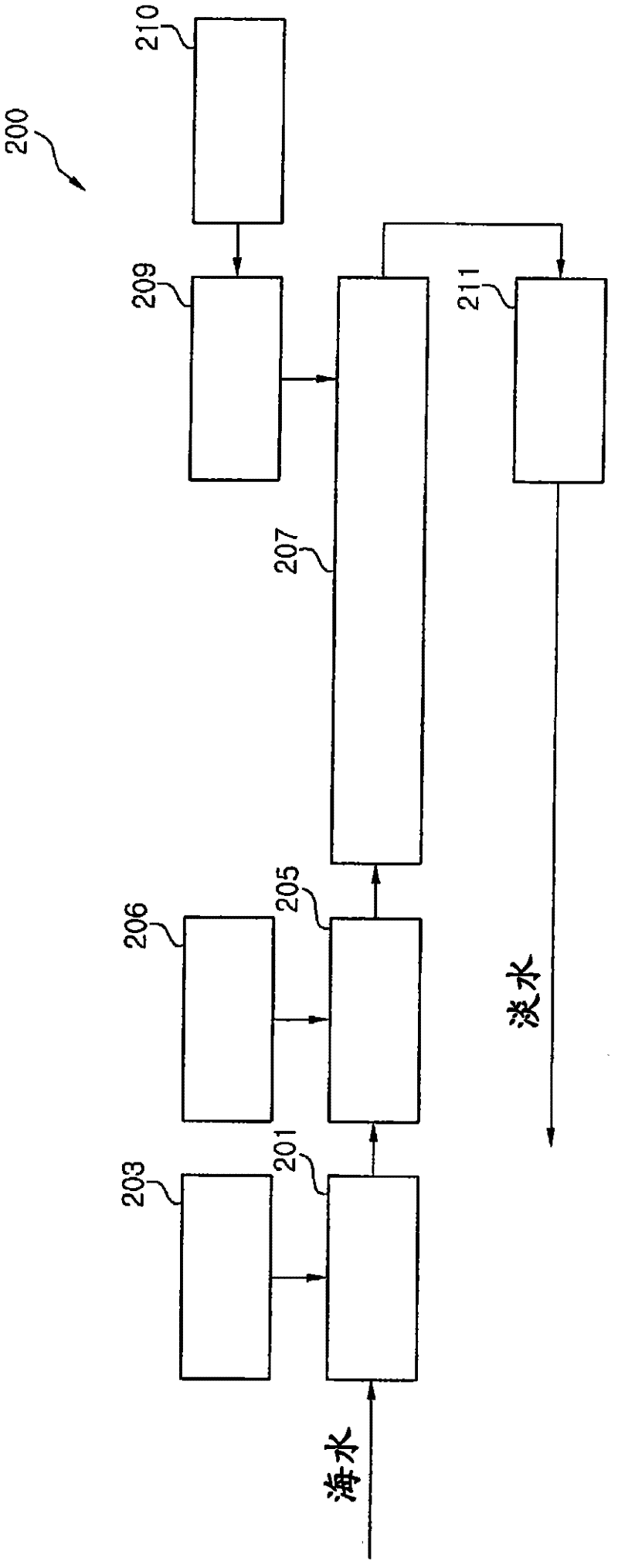

Seawater desalination plant to be installed on a barge, and method for installing same

InactiveCN102448890AEliminate Contamination ConcernsReduce the burden onGeneral water supply conservationAuxillariesElectricityLightering

The invention relates to a seawater desalination plant to be installed atop a barge and designed to float on the sea surface in order to draw seawater from the sea and to perform desalination, as well as to a method for installing a seawater desalination plant to be installed on a barge, involving loading the seawater desalination plant to be installed on a barge onto a heavy cargo transport vessel, or loading the desalination plant together with a power generation plant onto a heavy cargo transport vessel to be towed by a tugboat for installation at the seaside of a region with a water shortage or a shortage of electricity, or of an island.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

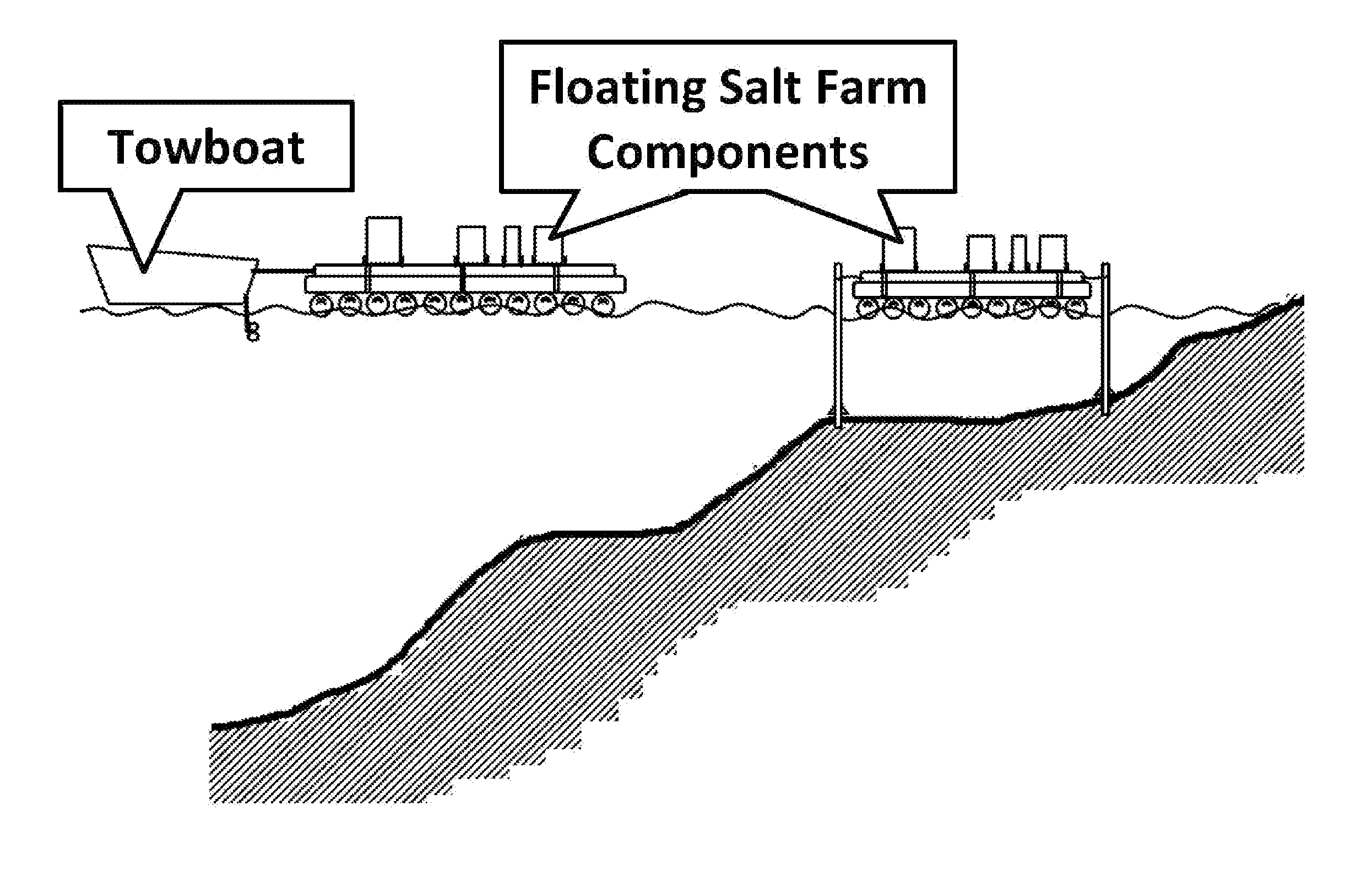

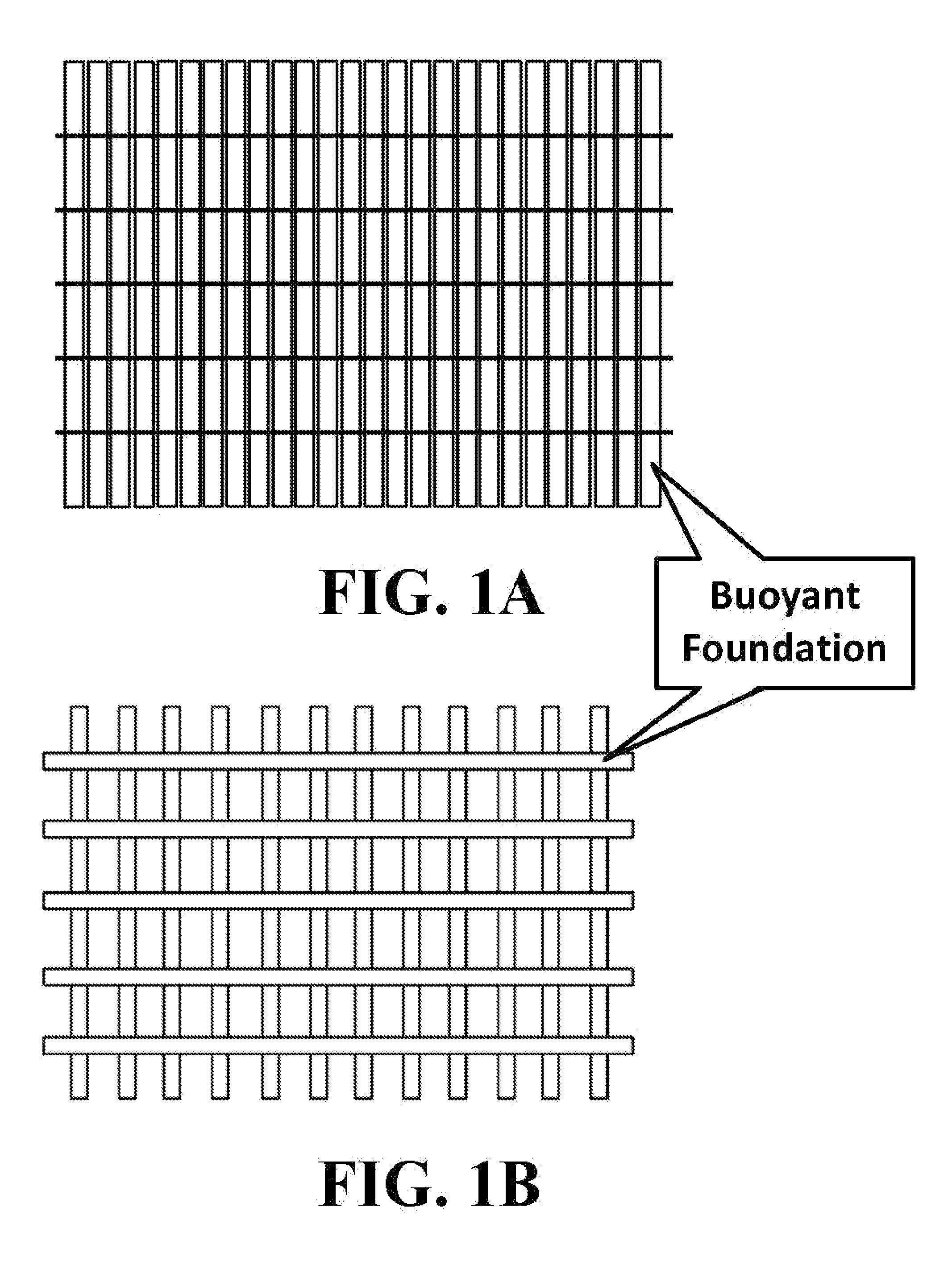

Floating salt farm

ActiveUS20130048226A1Keep dryDrying solid materials with heatEvaporators/condensersEngineeringMechanical engineering

Owner:PIOLI SYST

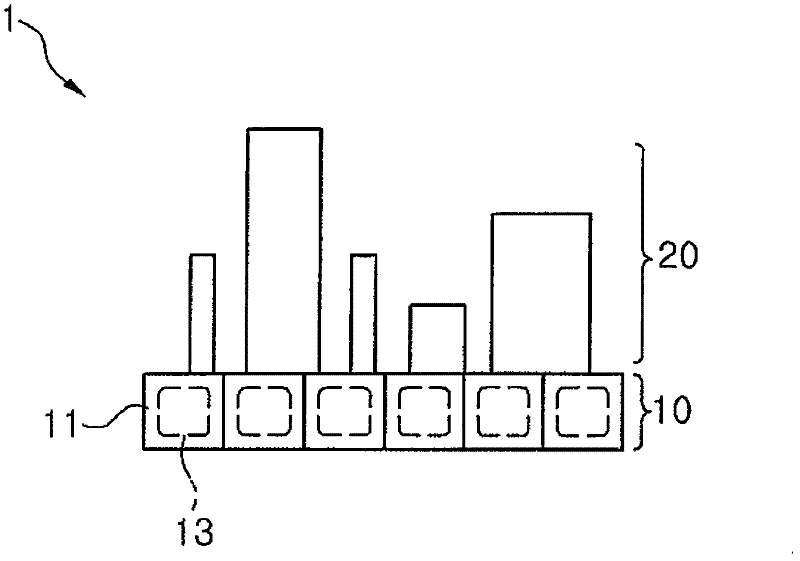

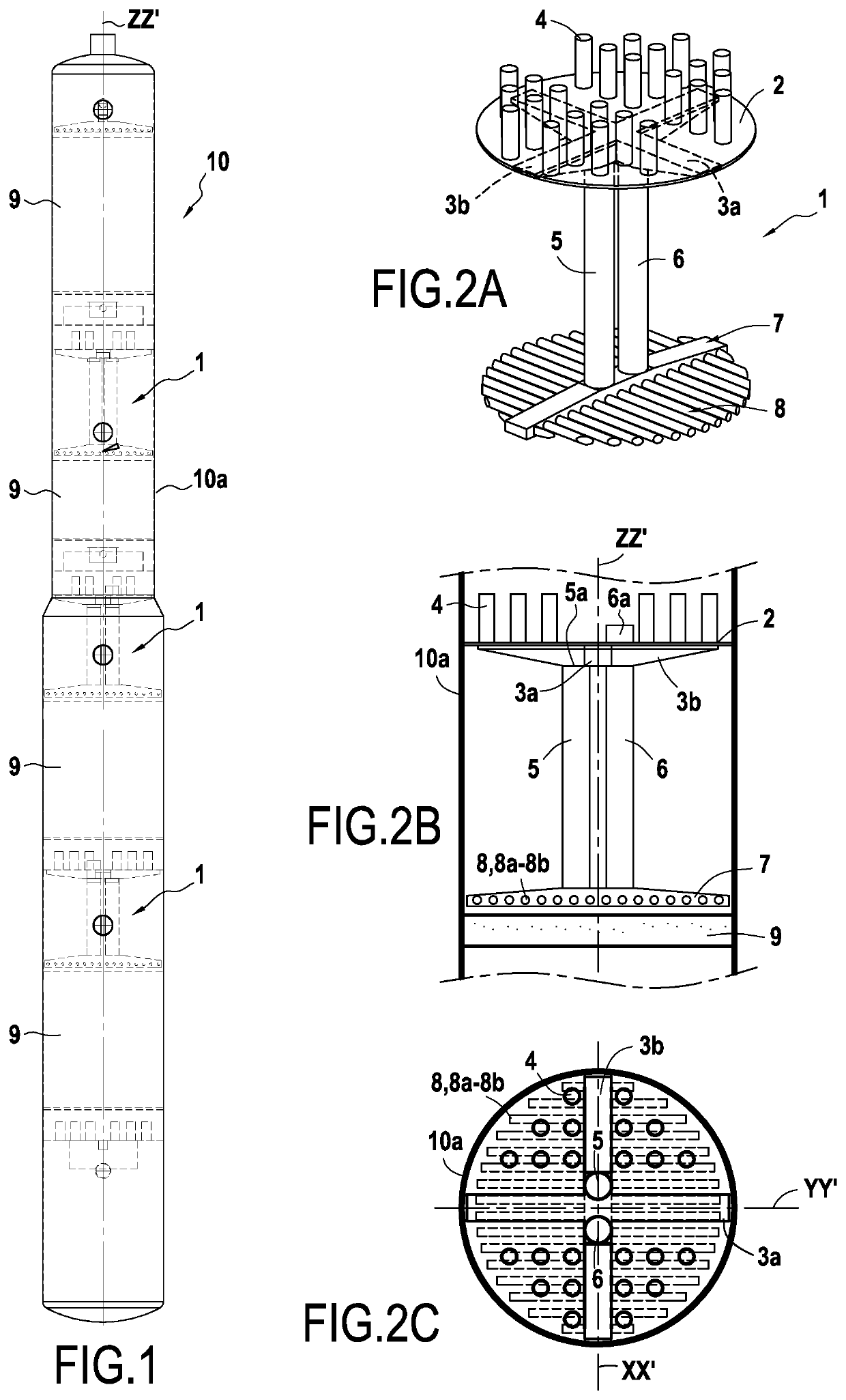

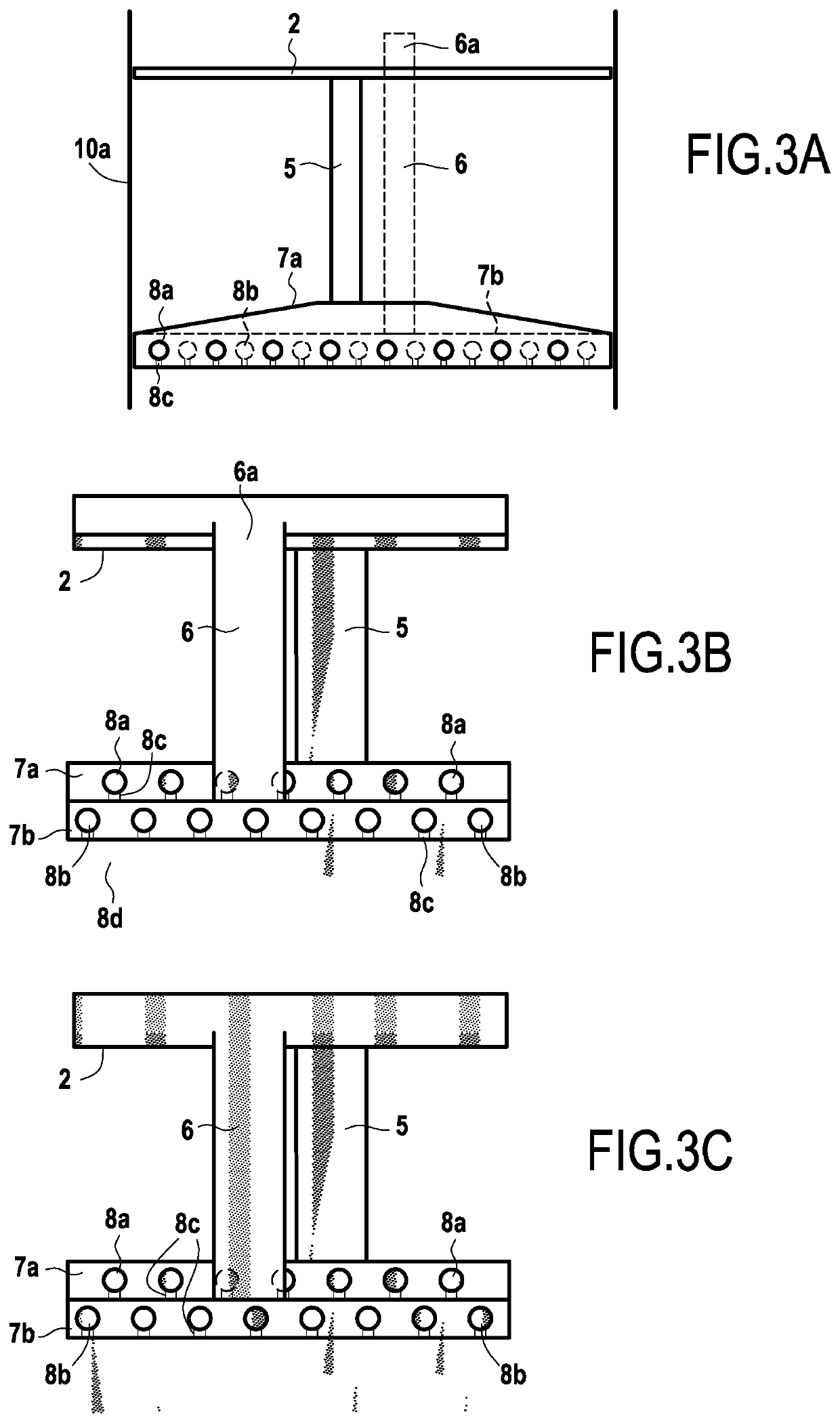

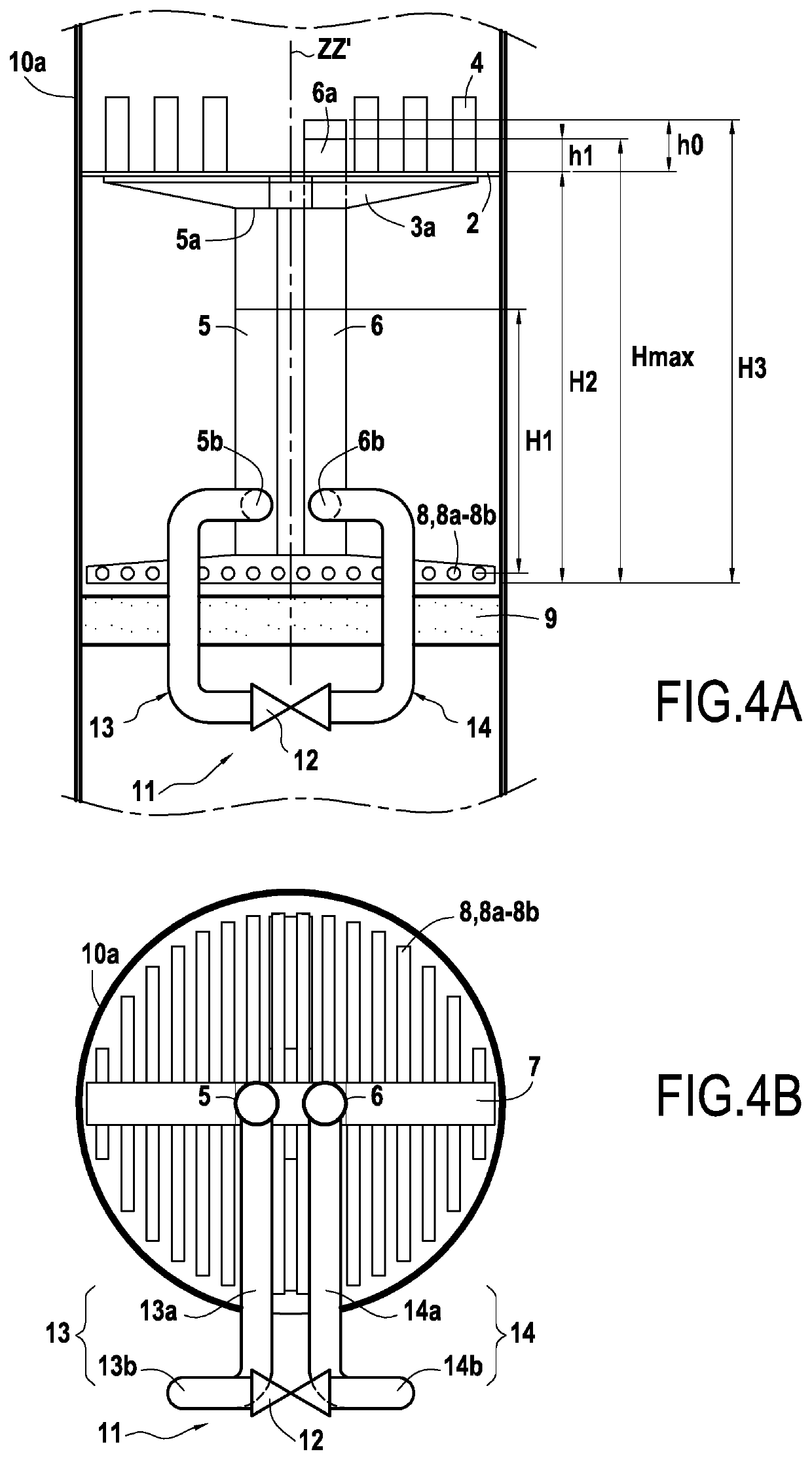

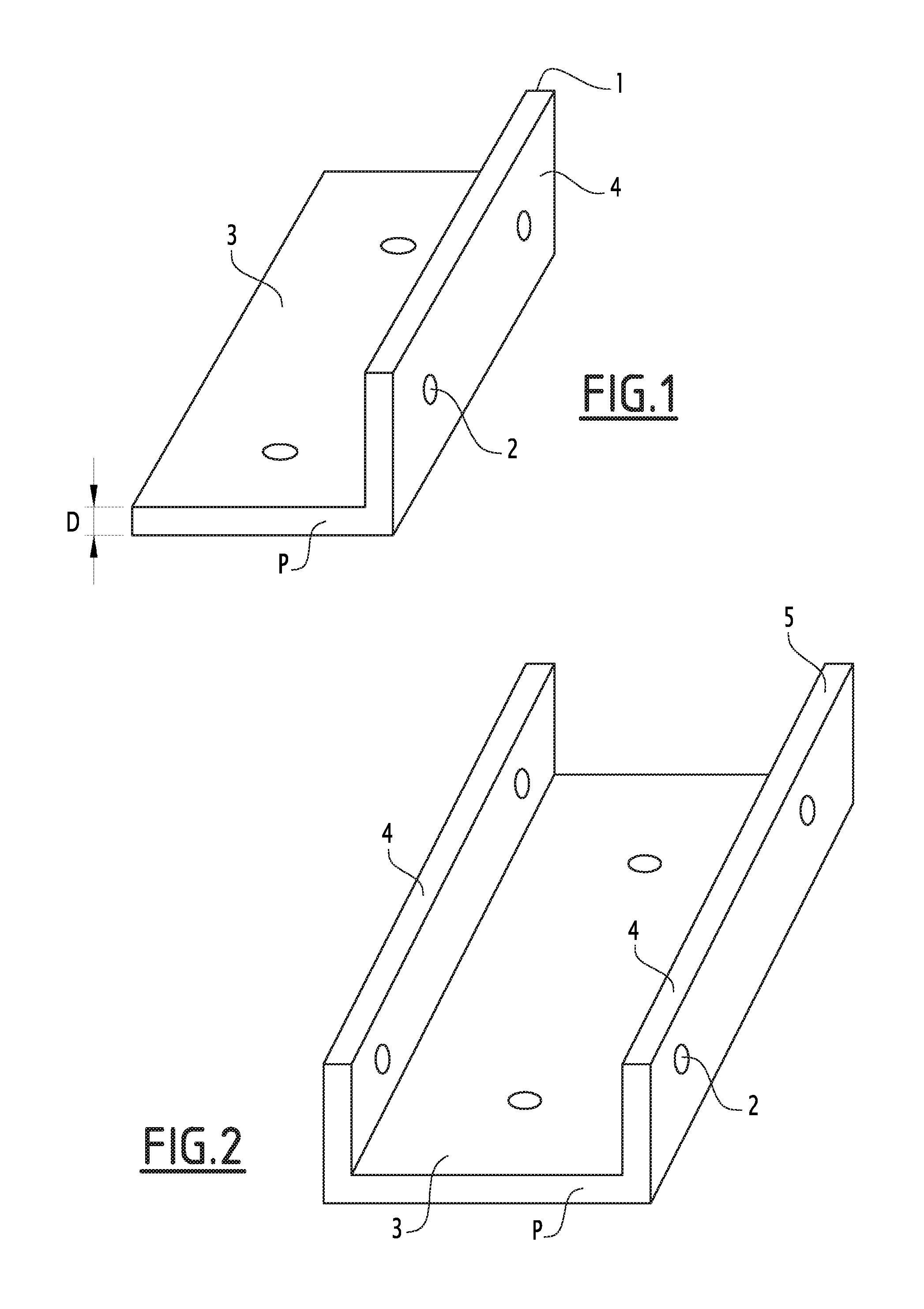

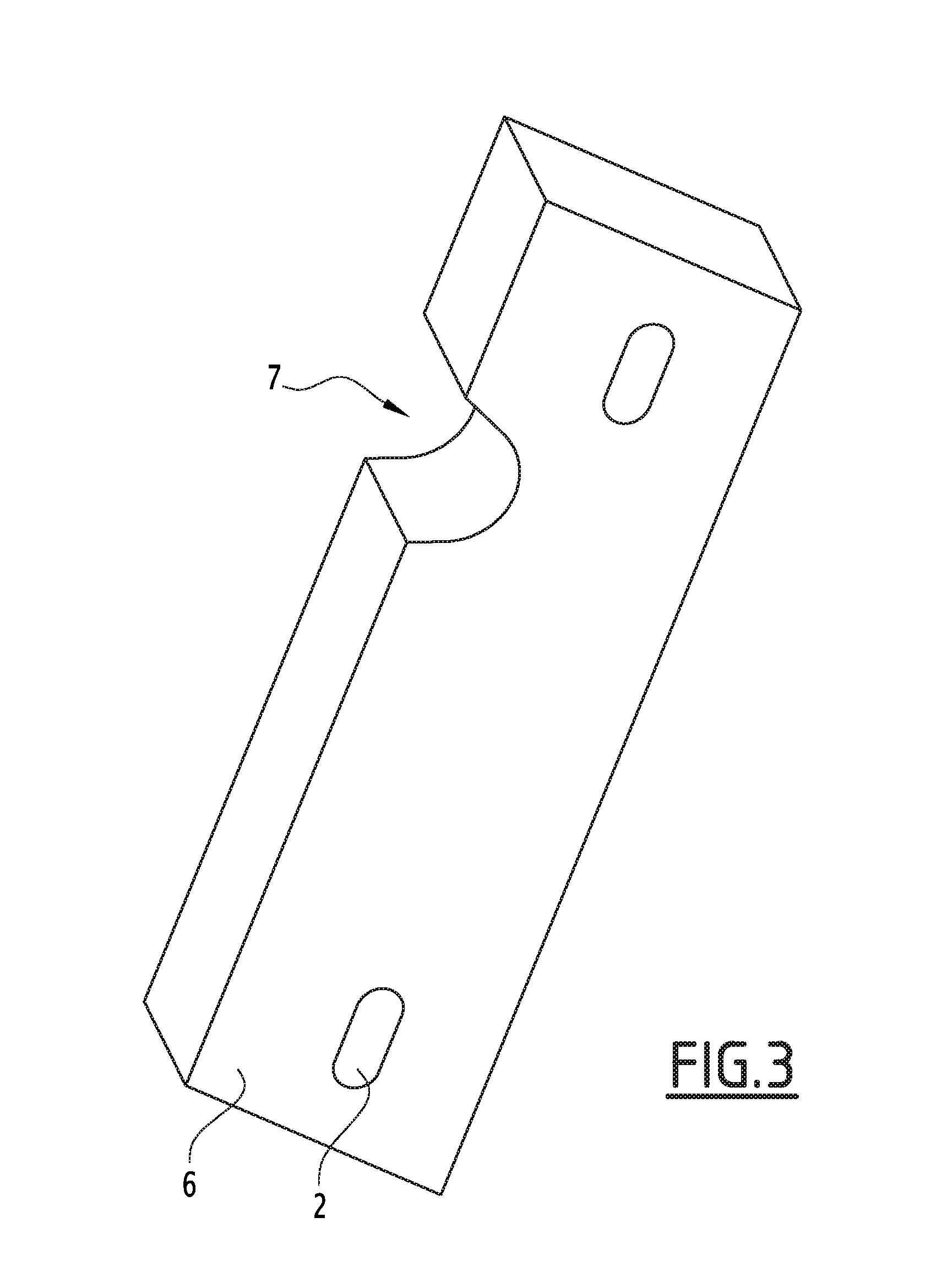

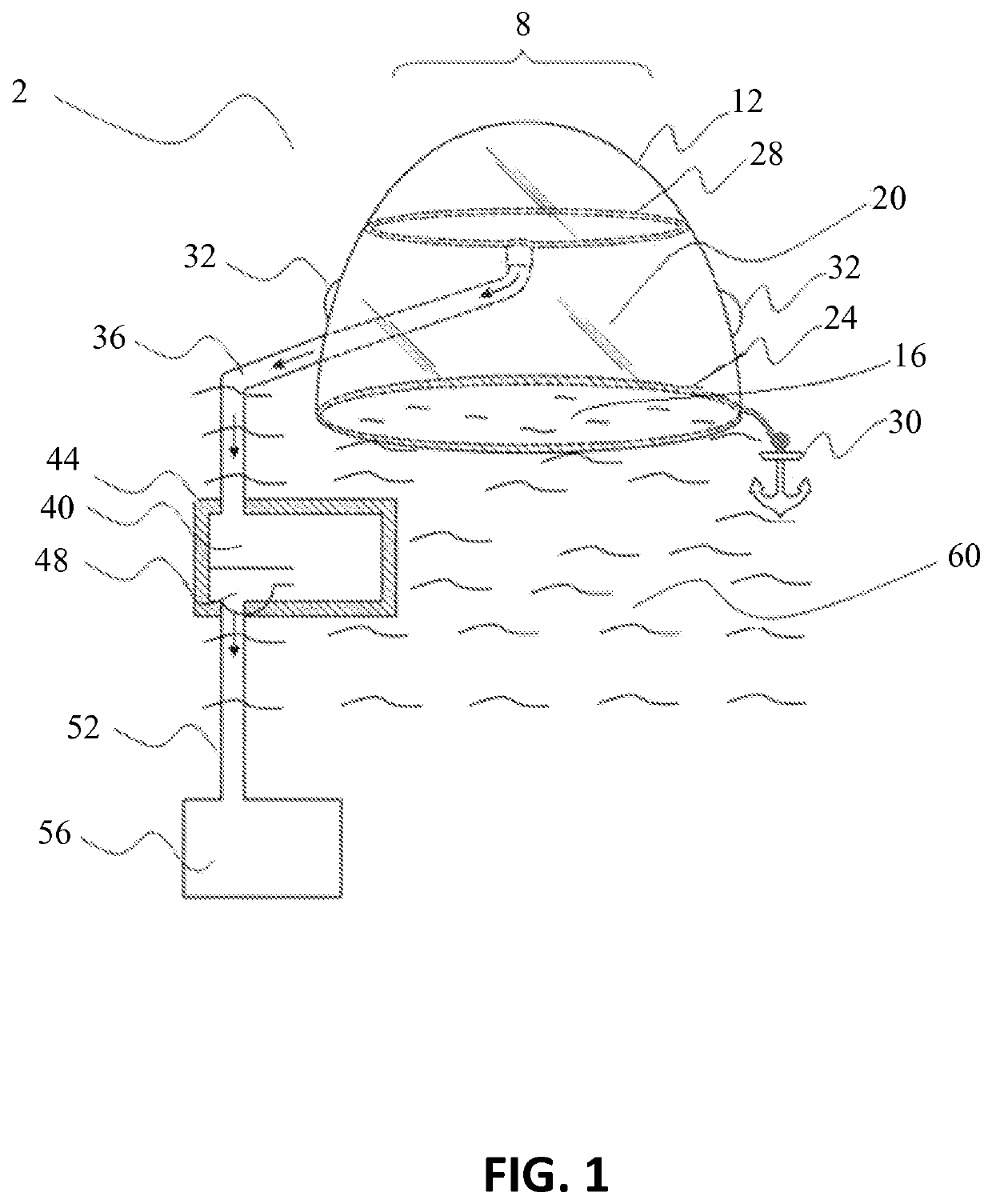

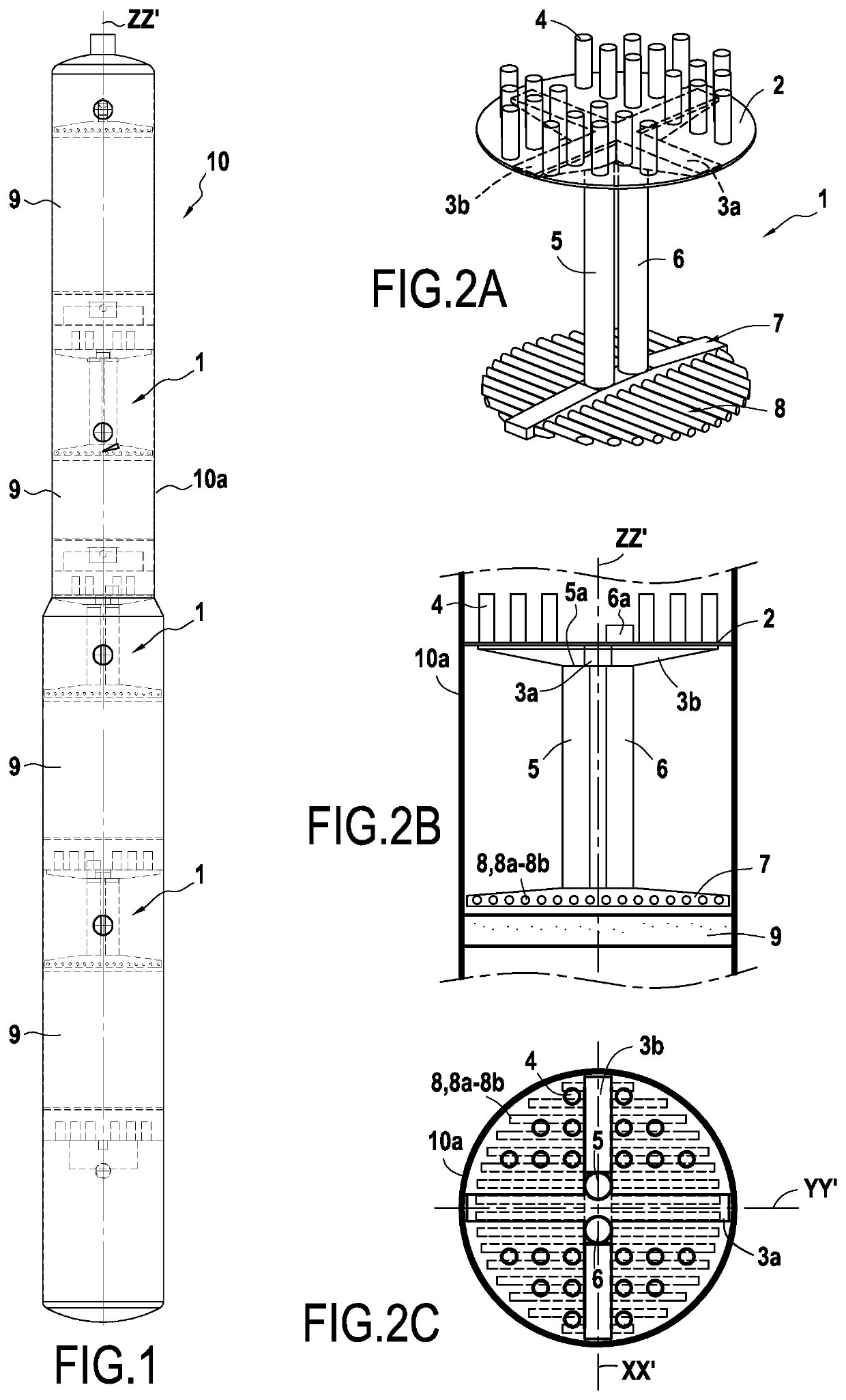

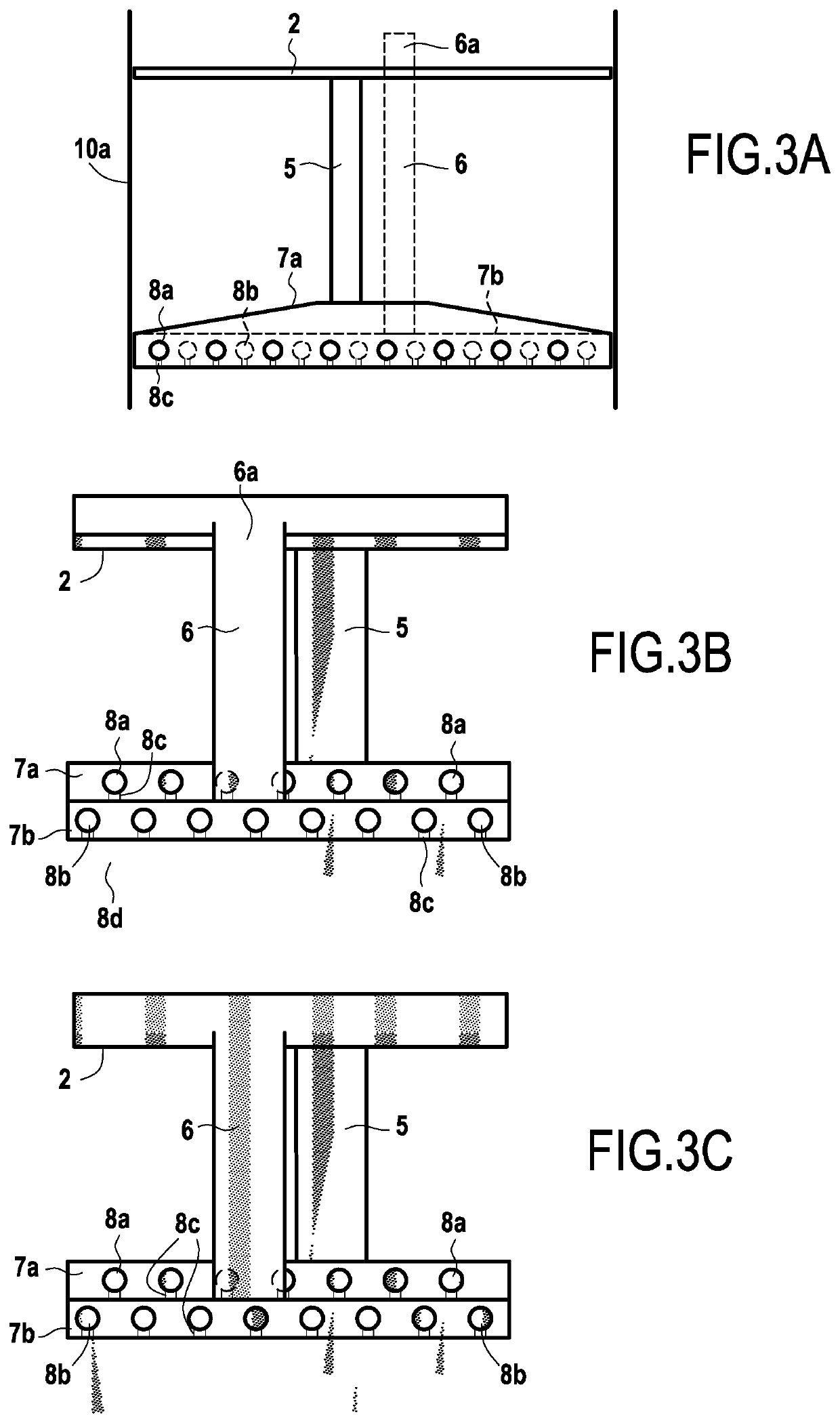

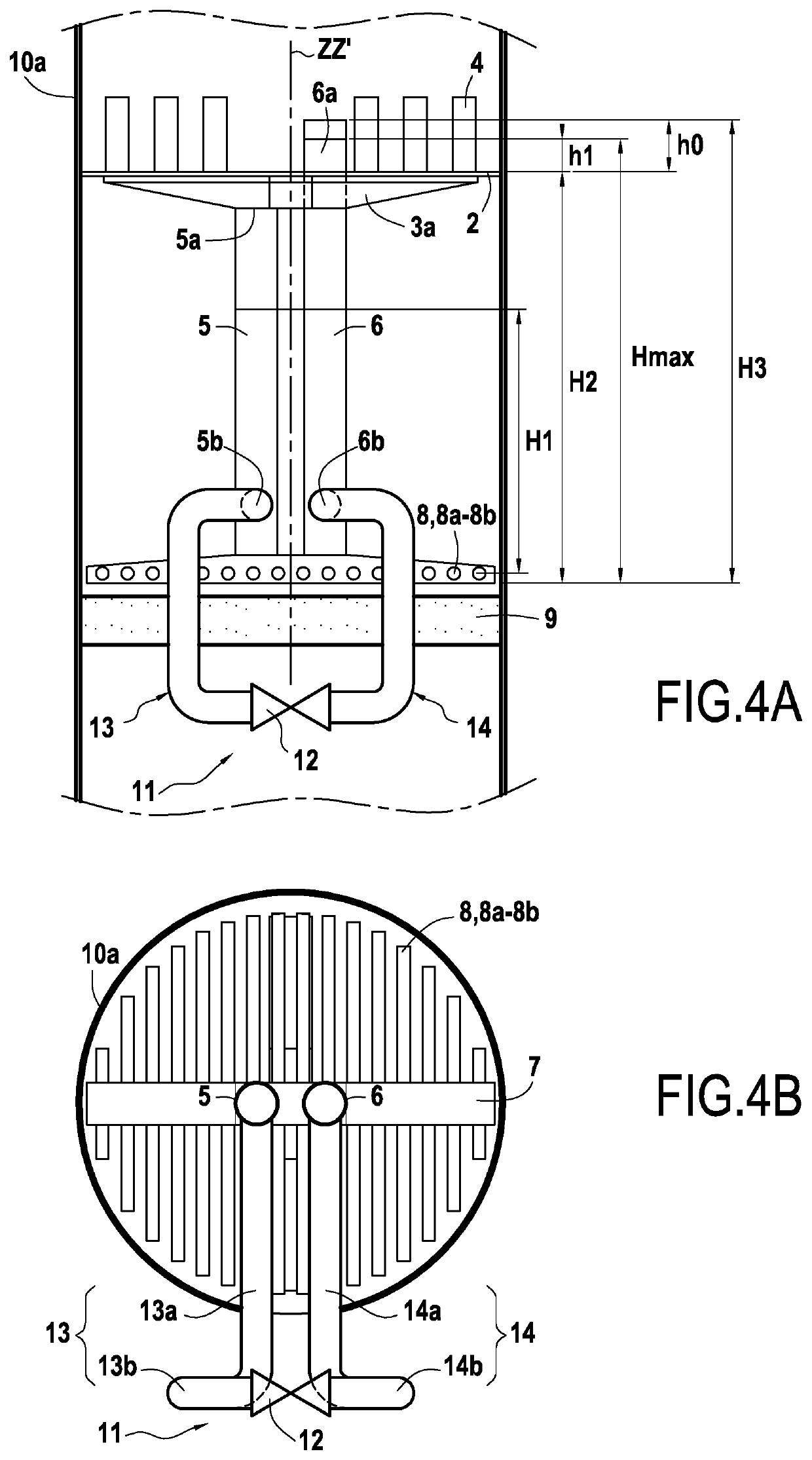

Liquid double distribution device of use in particular in an apparatus in which a liquid phase flows under gravity

ActiveUS20200155960A1Evenly distributedAvoid differencesSolidificationLiquefactionFluid phaseFractionating column

A double liquid distribution device is suitable for a fractionating or wash column comprising a high collector tray connected to a manifold support via at least two longitudinal liquid downflow ducts. The manifold support supports at least two series of transverse tubular manifolds and feeds liquid respectively to the first series of manifolds via a first longitudinal duct and to the second series of manifolds via a second longitudinal duct. Each manifold includes distribution orifices in its under face suitable for distributing the liquid onto the top face of the packing bed. The two longitudinal liquid downflow ducts are connected together in a low portion by a communication device fitted with a valve having controlled opening suitable for allowing the liquid to be transferred between the two longitudinal ducts in controlled manner.

Owner:SAIPEM SPA

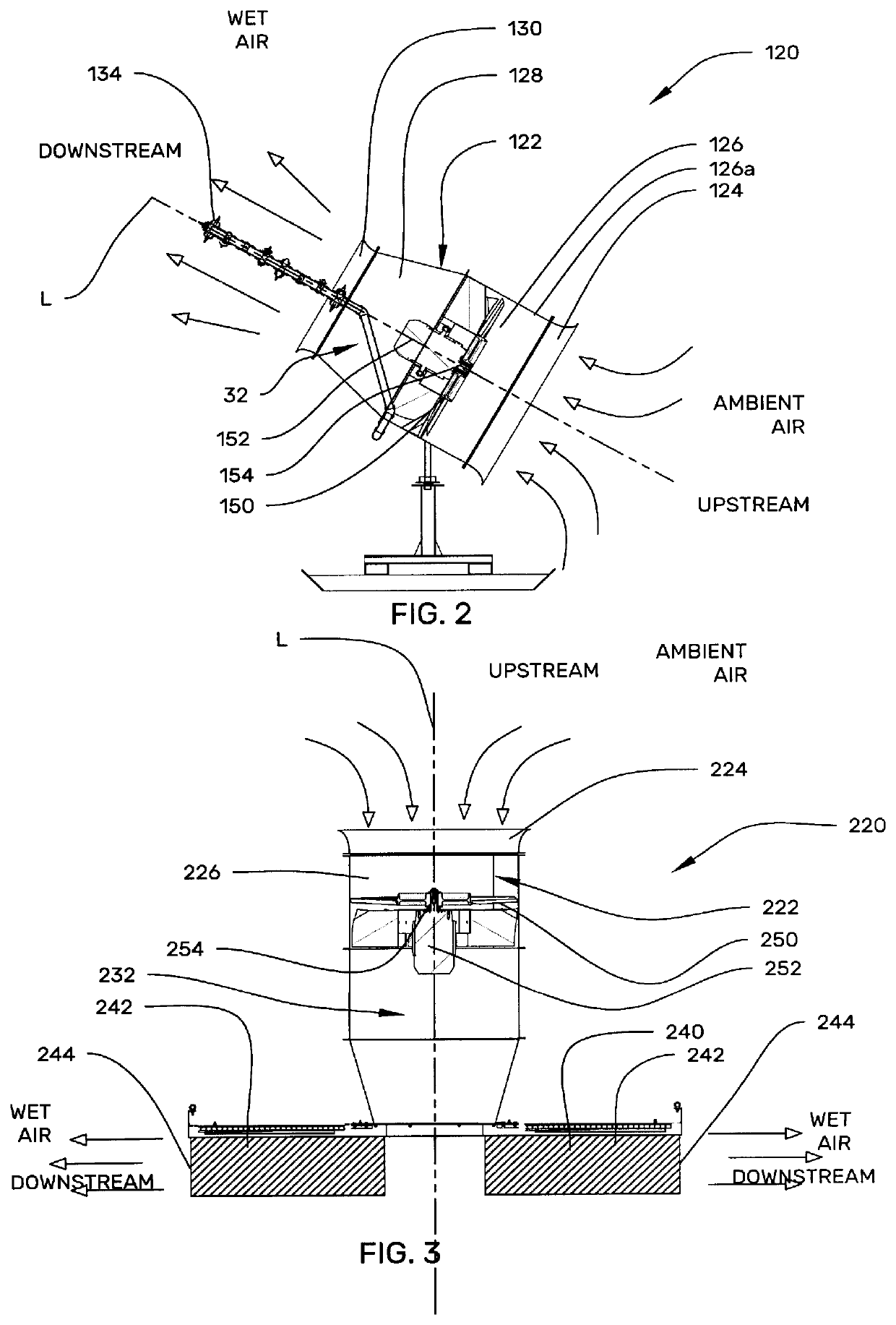

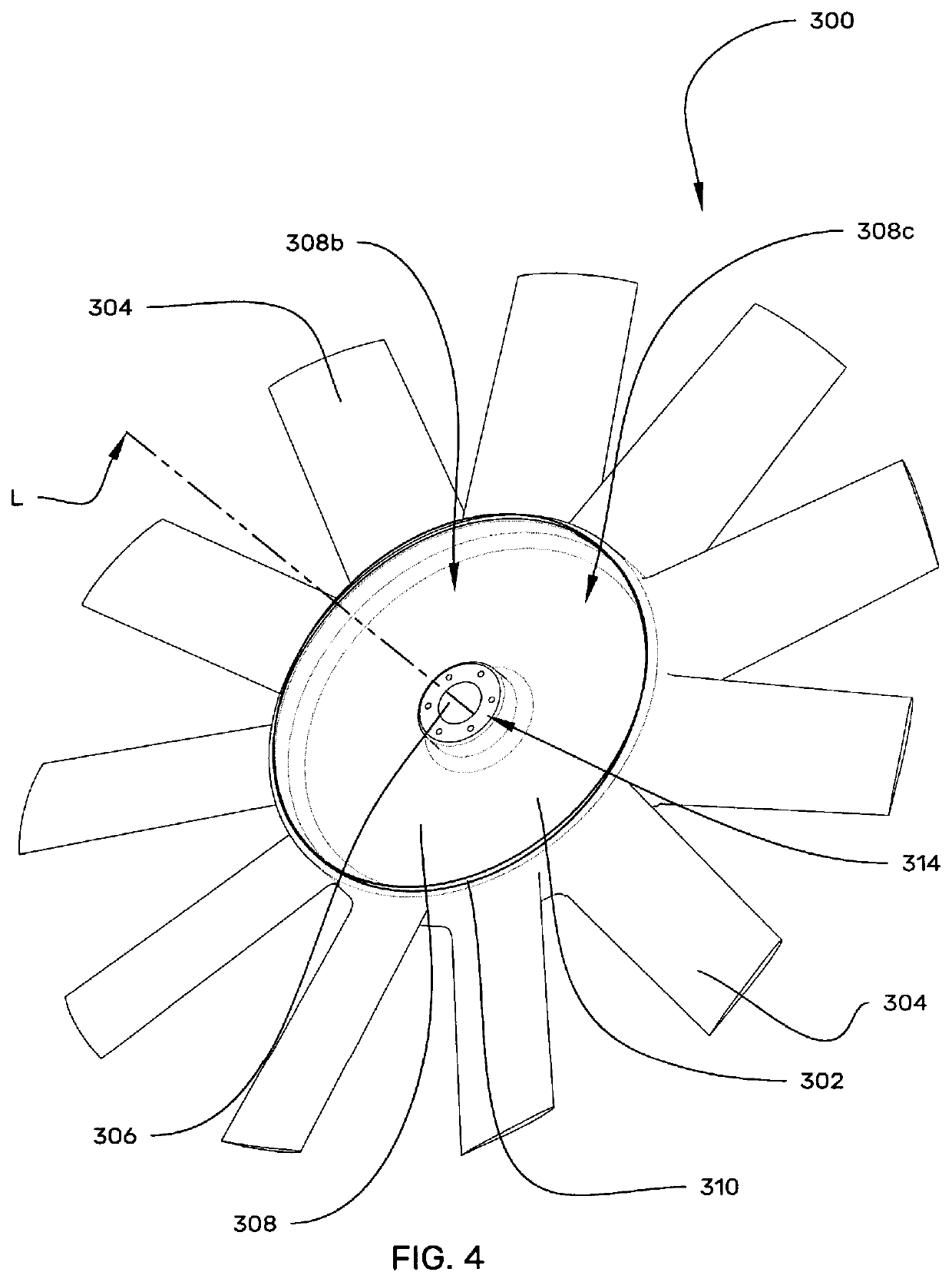

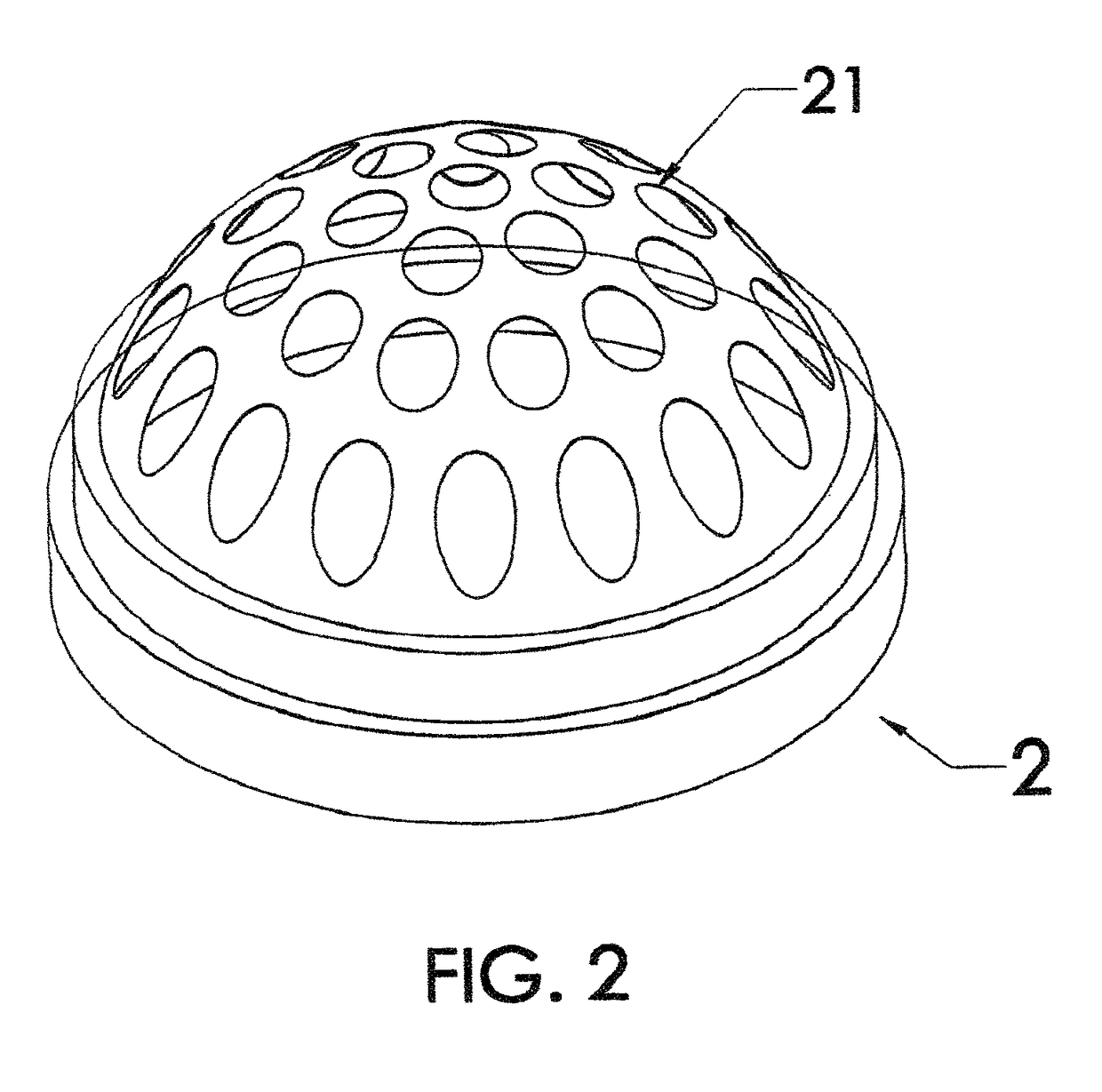

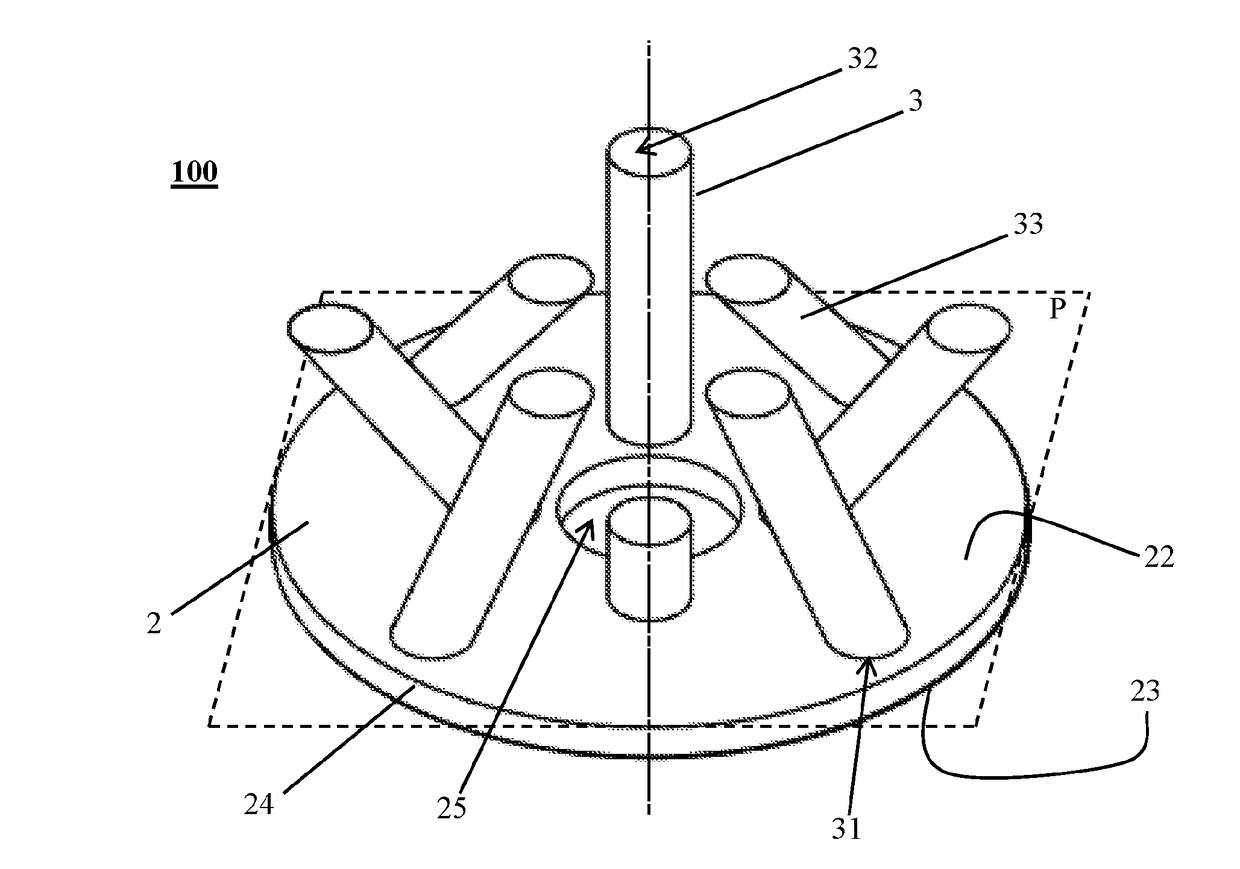

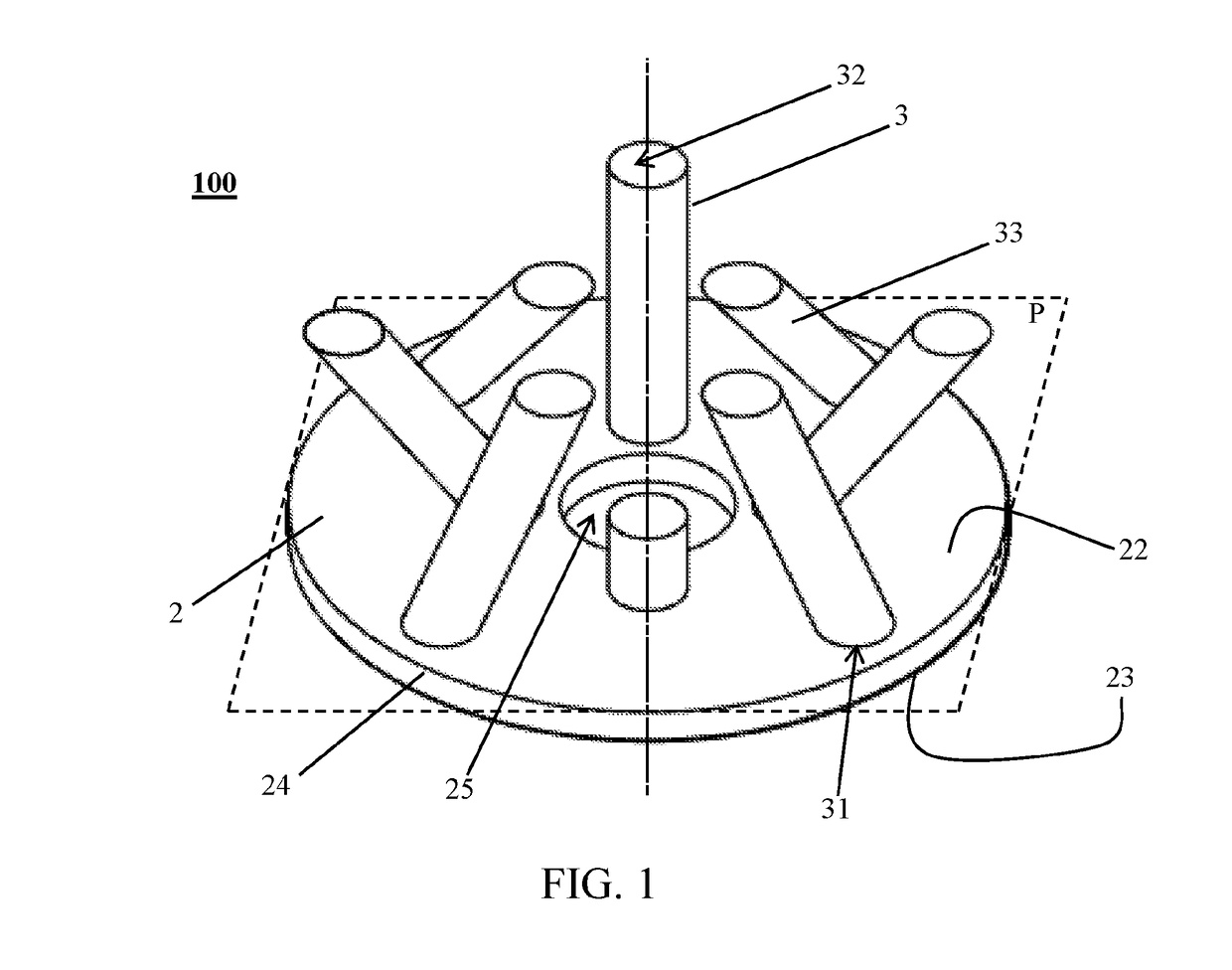

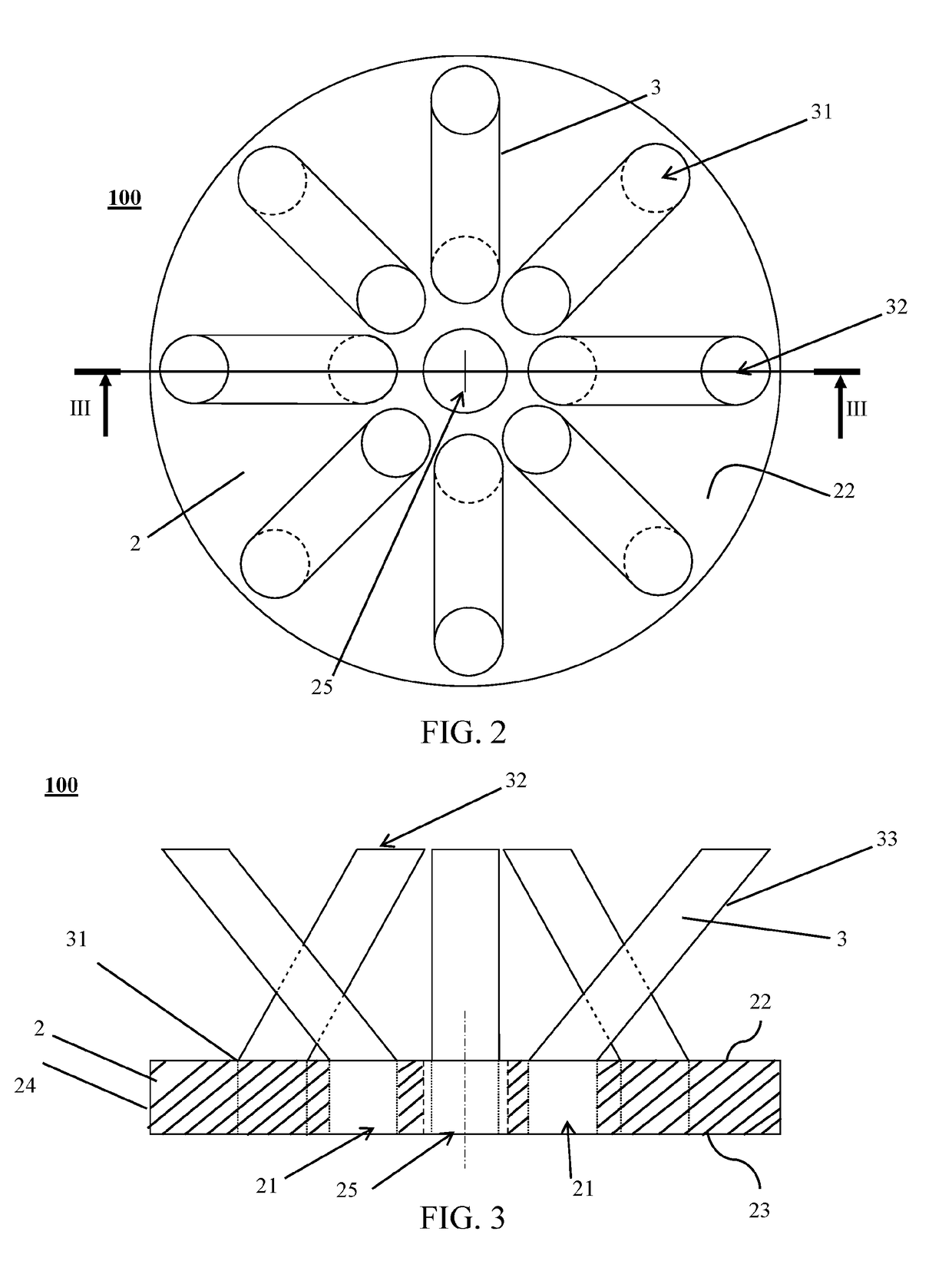

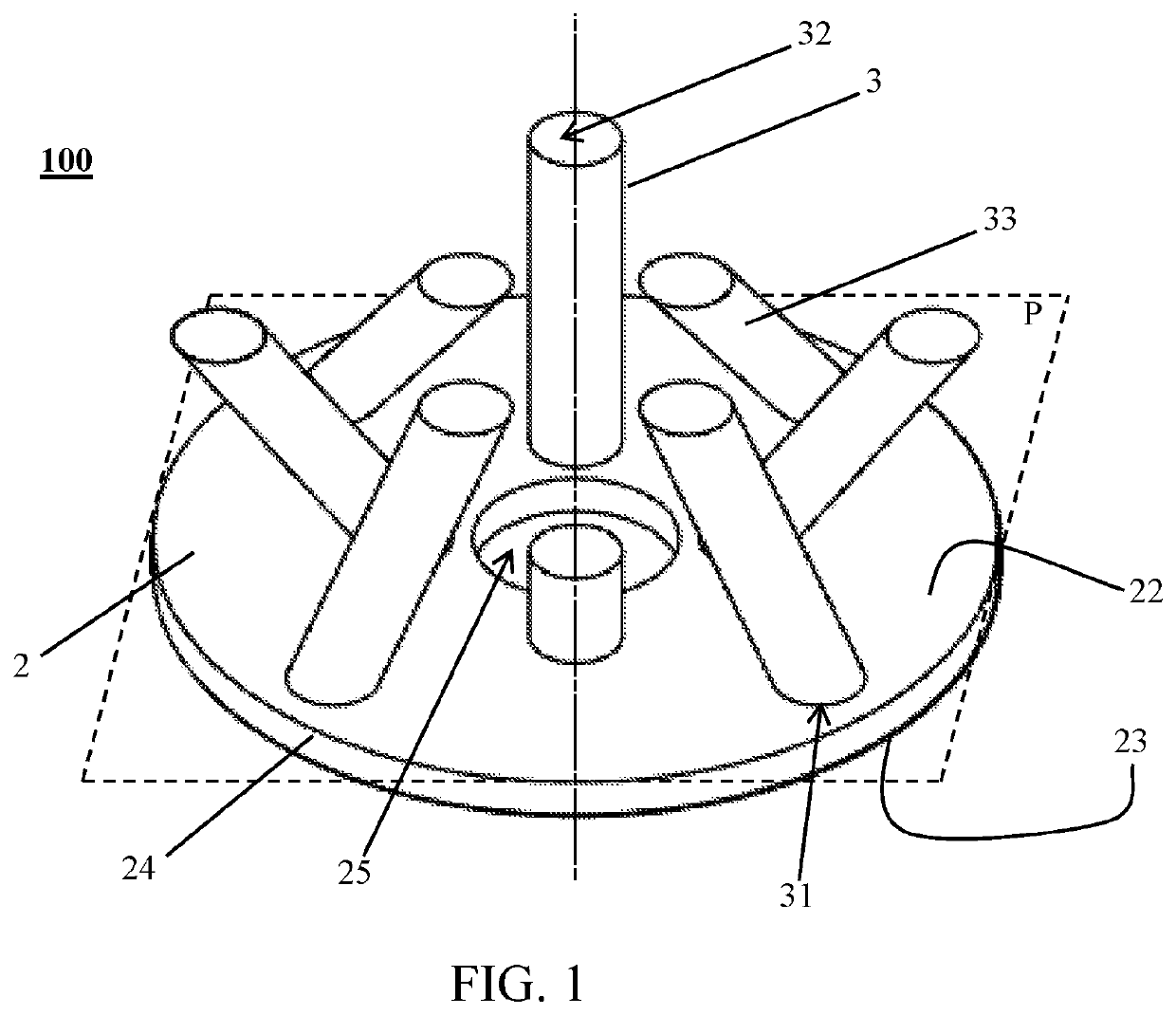

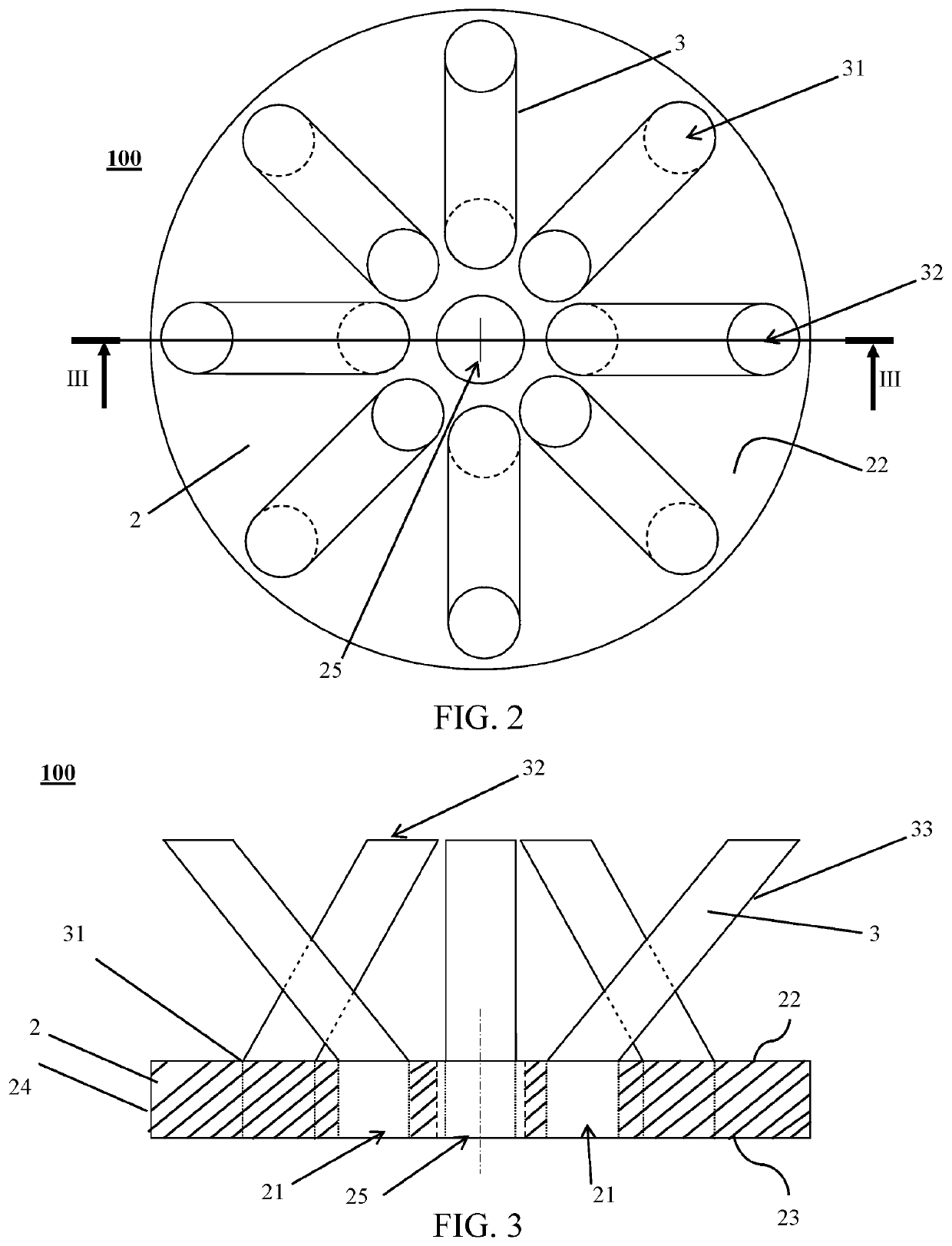

Impeller for ambient water evaporators, and related system and method

An impeller design is provided for use in evaporating water from an ambient water body. The impeller includes a hub and a plurality of impeller blades. The blades have one or more profiles that correspond to certain profiles characterized by the National Advisory Committed for Aeronautics parameters known as NACA 4 parameters. One or more blade angles also may more specifically identify the blade profiles. The impeller blades also may be identified by a plurality of profiles on a given blade, preferably including a base profile and a tip profile. The impeller optionally but preferably is made of a fiberglass material. In preferred embodiments it constitutes an integrated unit, such as a unitary molded or cast unit. It may be coated by a suitable corrosion-resistant coating, for example, such as a clear coat or gel coat. Various features of the impeller hub also are disclosed. An impeller system also is disclosed. The system includes an impeller as described above and means for mitigating non-longitudinal flow in the air flow channel in which the impeller caused air movement. The means for mitigating non-longitudinal flow preferably includes a plurality of guide vanes disposed downstream of the impeller.

Owner:RESOURCE WEST

Method and device for water evaporation

A solar-powered system includes a support portion; and an evaporation portion having a pumping layer and a photothermal layer. The support portion pumps a fluid to the evaporation portion, the pumping layer evaporates the fluid based on solar power; and the photothermal layer is insulated from the pumping layer.

Owner:KING ABDULLAH UNIV OF SCI & TECH

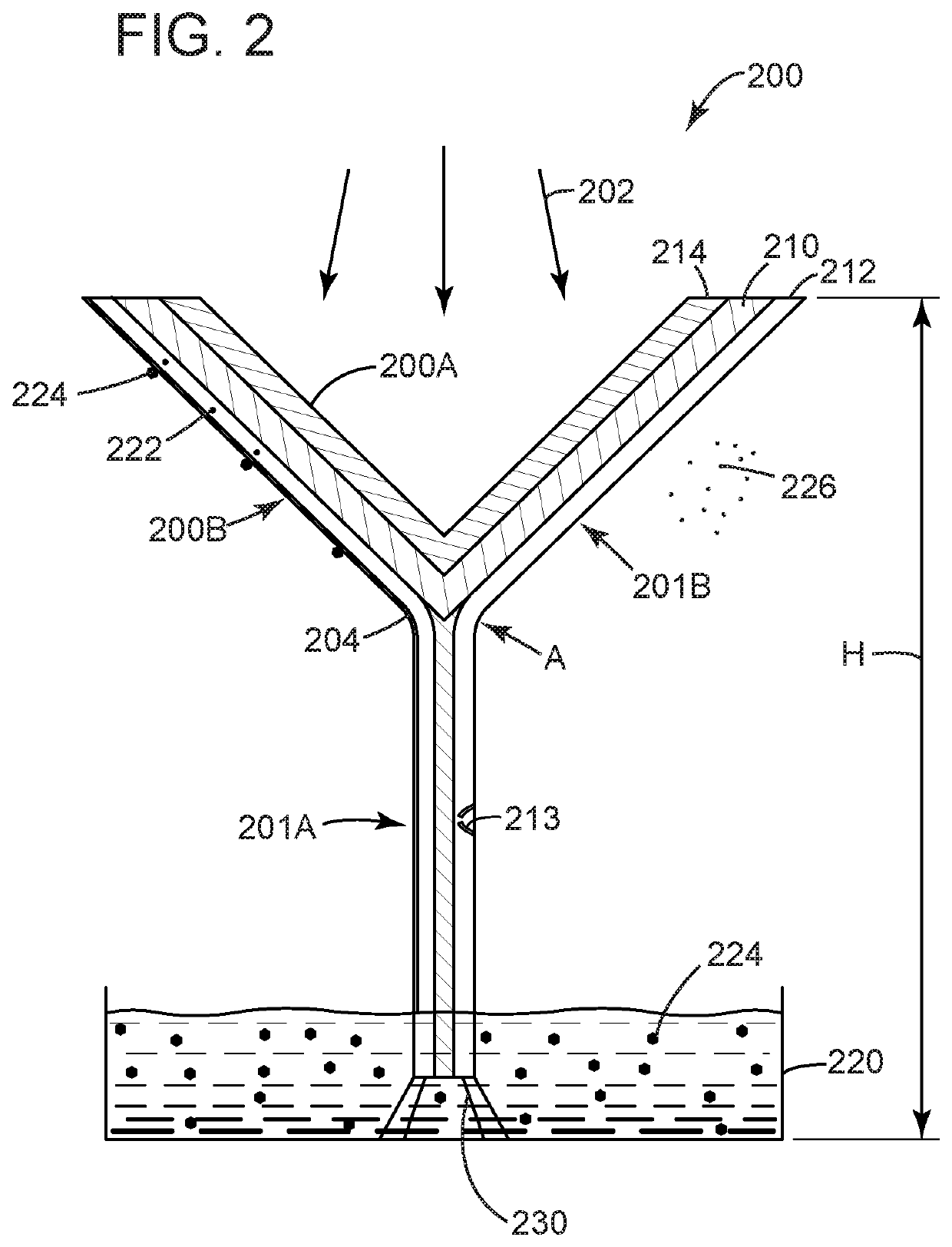

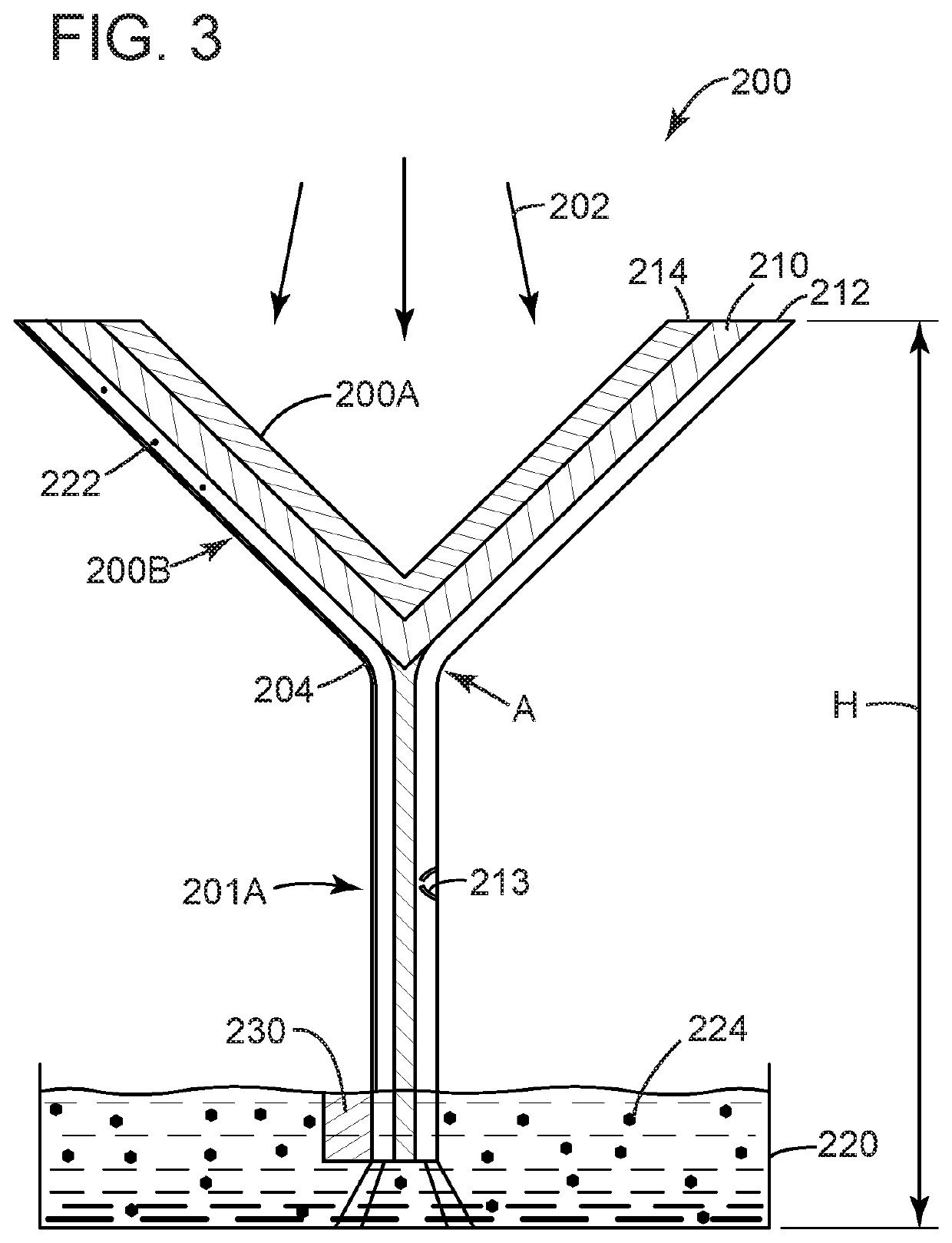

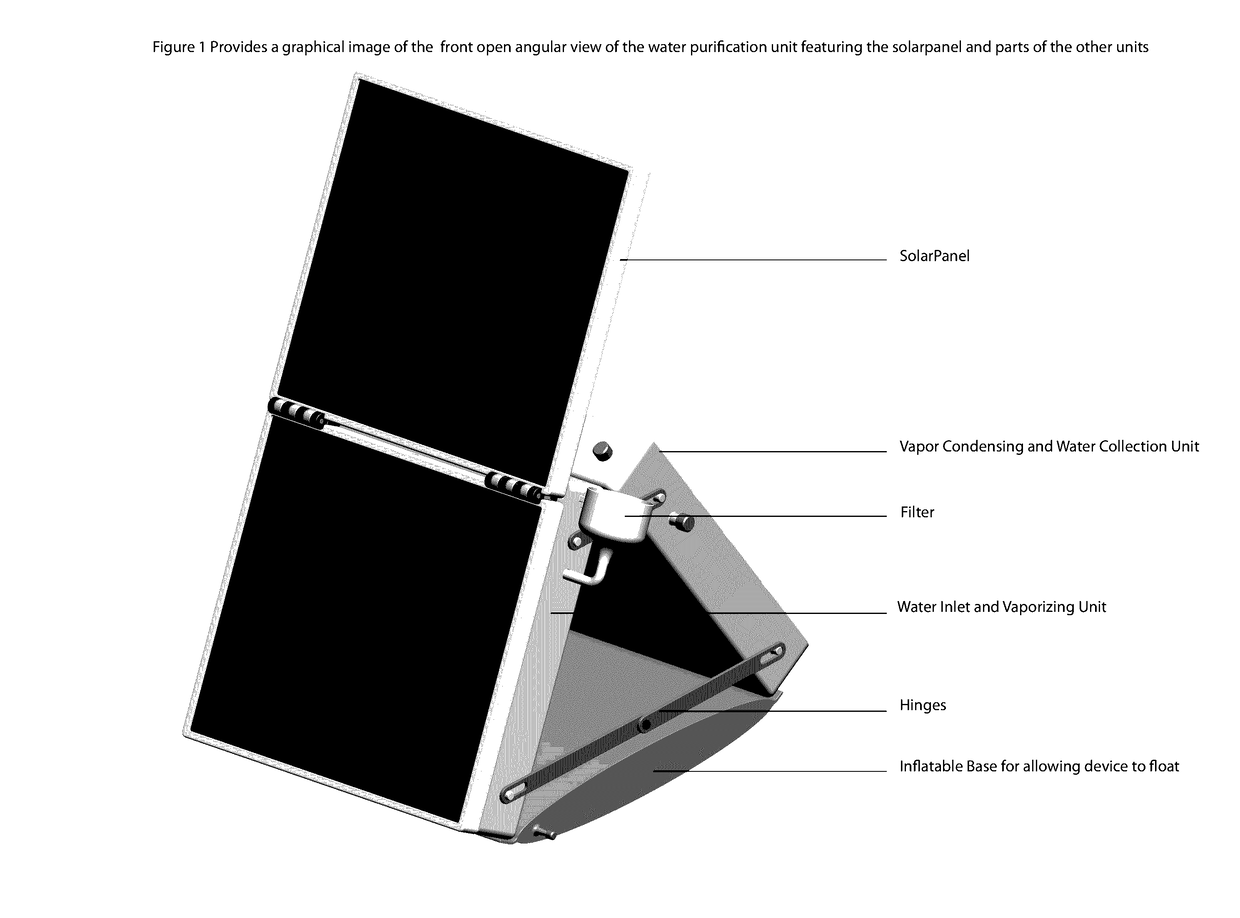

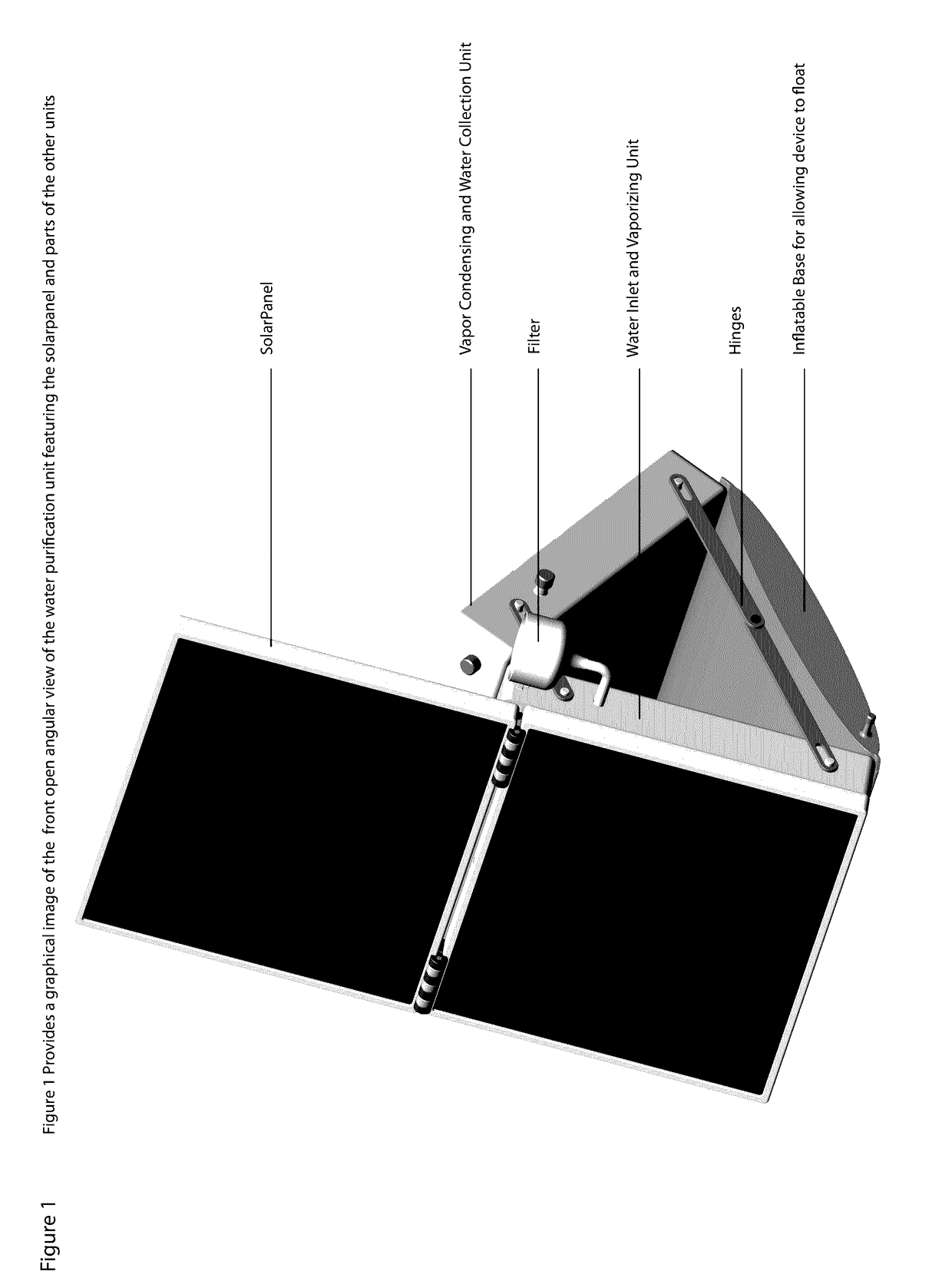

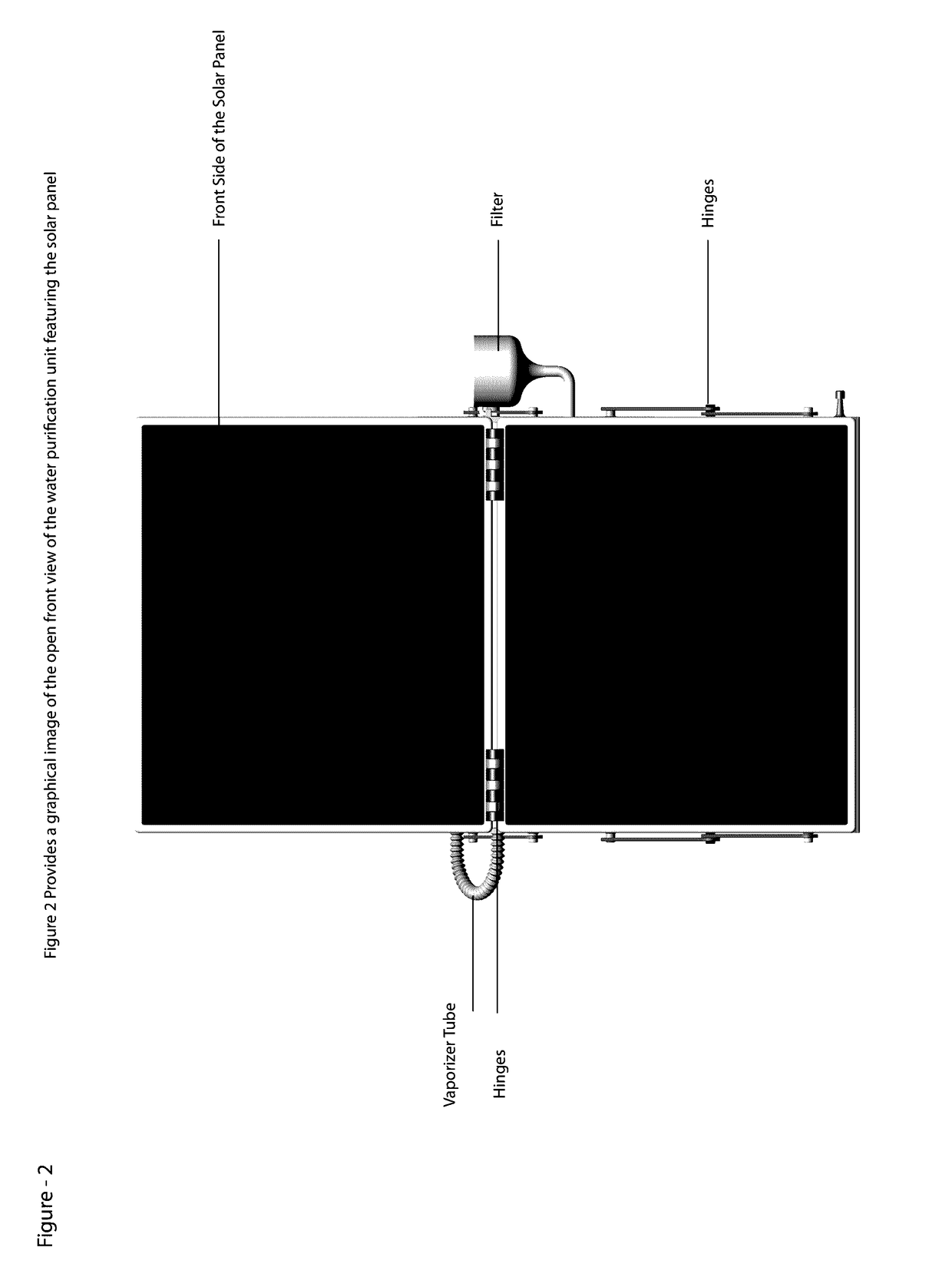

Methods and devices comprising solar power for water purification

InactiveUS20170113948A1Easy to transportQuality improvementGeneral water supply conservationSeawater treatmentSolar waterEnvironmental engineering

The invention disclosed herein comprises novel methods and devices for water purification. The invention comprises the use of solar powered water purification units comprising, wherein said units may be portable, and comprise a vapor condensing unit, a water collection unit, a filter, a water inlet, and a vaporization unit. The water purification units comprise components for collecting solar energy, including but not limited to solar panels. The devices may optionally include an inflatable component enabling the device to be used on water as well as on solid surfaces.

Owner:VEERAPPAN KRITHIKA RAMU

Manure agitation vessel with remote power source

A system for agitating manure includes a vessel shaped to be placed in a manure storage installation. The vessel includes a vessel frame having floatation for providing floatation to the vessel, at least one outlet nozzle attached to the vessel frame for agitating the manure, and a control system attached to the vessel frame for controlling the direction of the at least one outlet nozzle. The system includes a land based power source separated from the vessel having a fluid pump for pumping fluid from a land based input nozzle to supply fluid to the at least one outlet nozzle on the vessel. The system includes a fluid conduit connecting the land based power source to the at least one outlet nozzle and a remote control for user control of the control system of the vessel.

Owner:1863385 ONTARIO INC

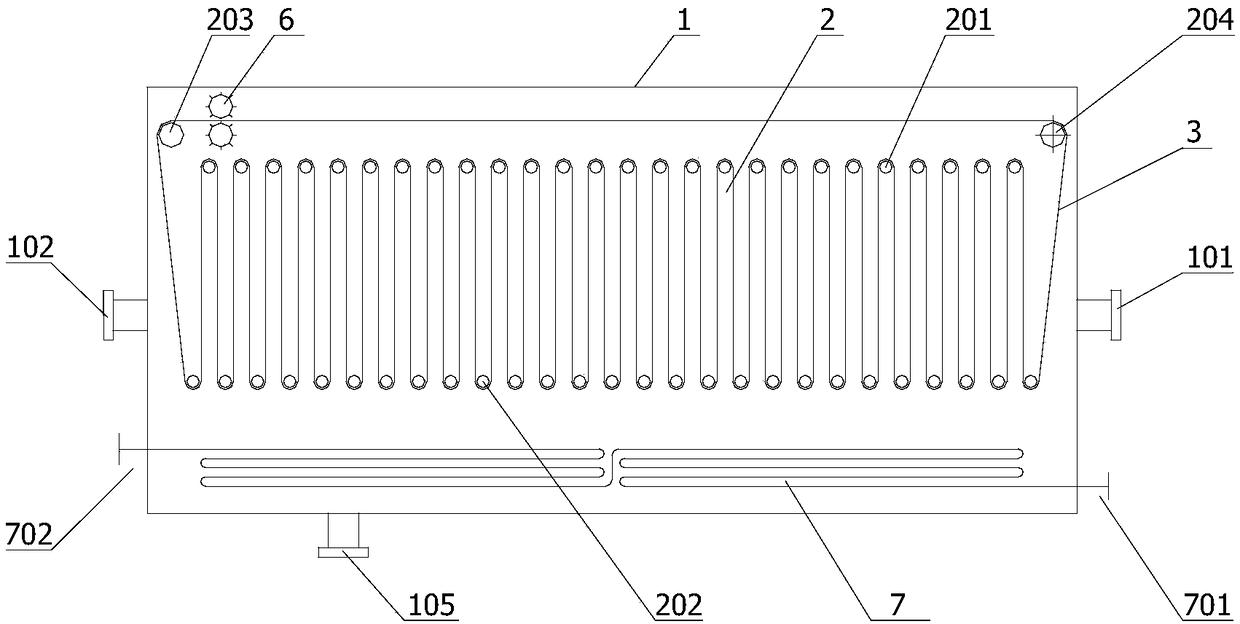

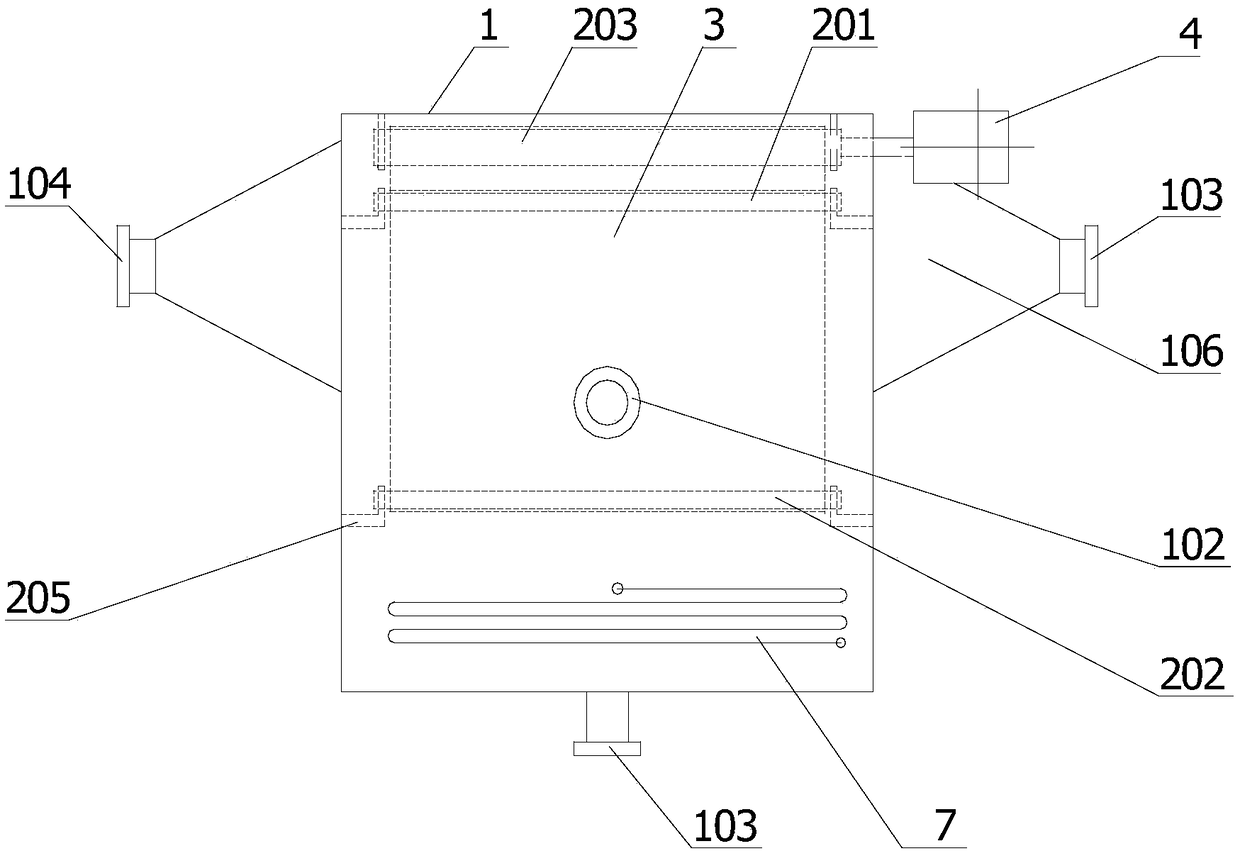

Liquid evaporation device and process

PendingCN108452542AImprove evaporation efficiencySimple structureSeawater treatmentEvaporator accessoriesClosed loopEvaporation

Owner:MEIQING TECH BEIJING CO LTD

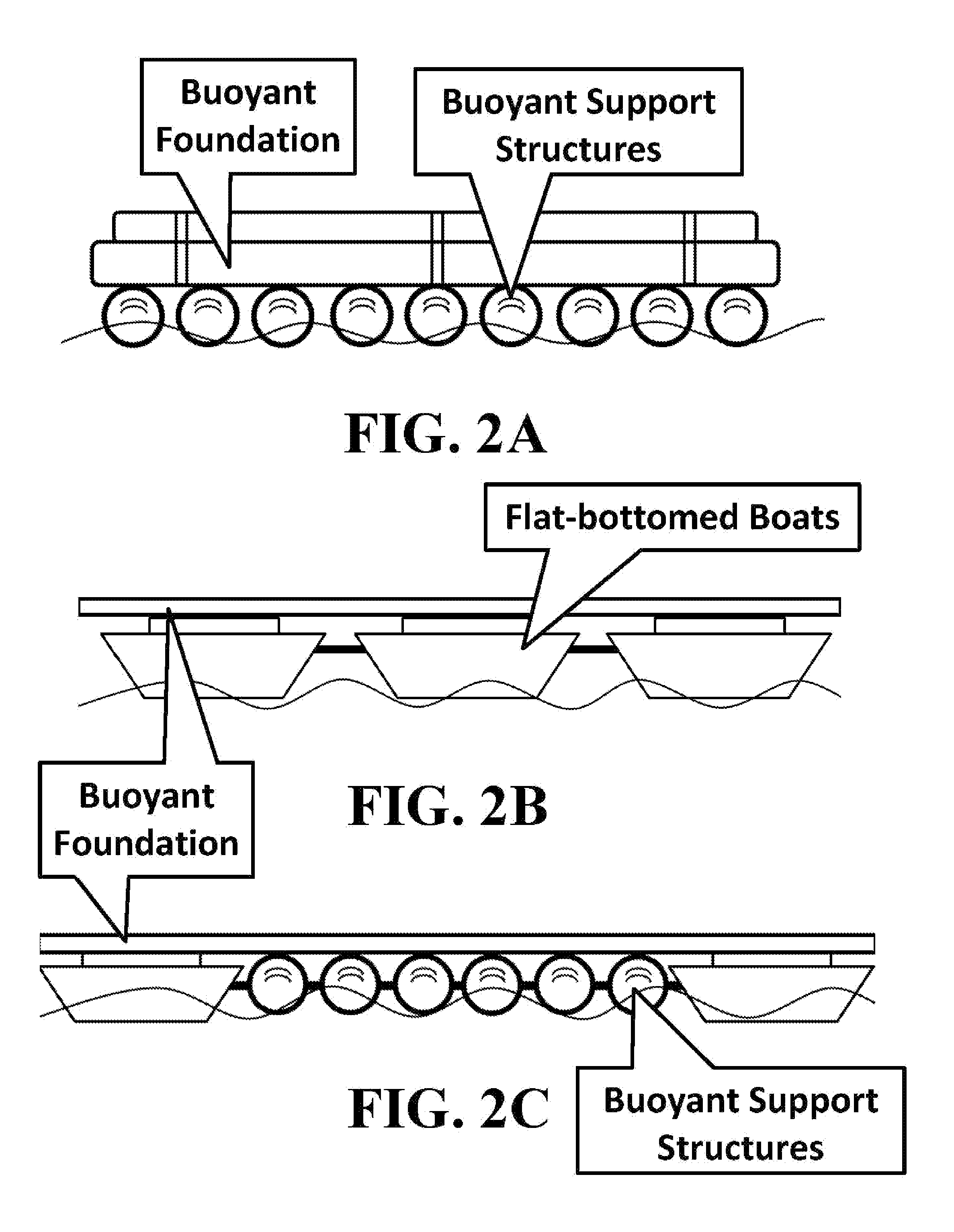

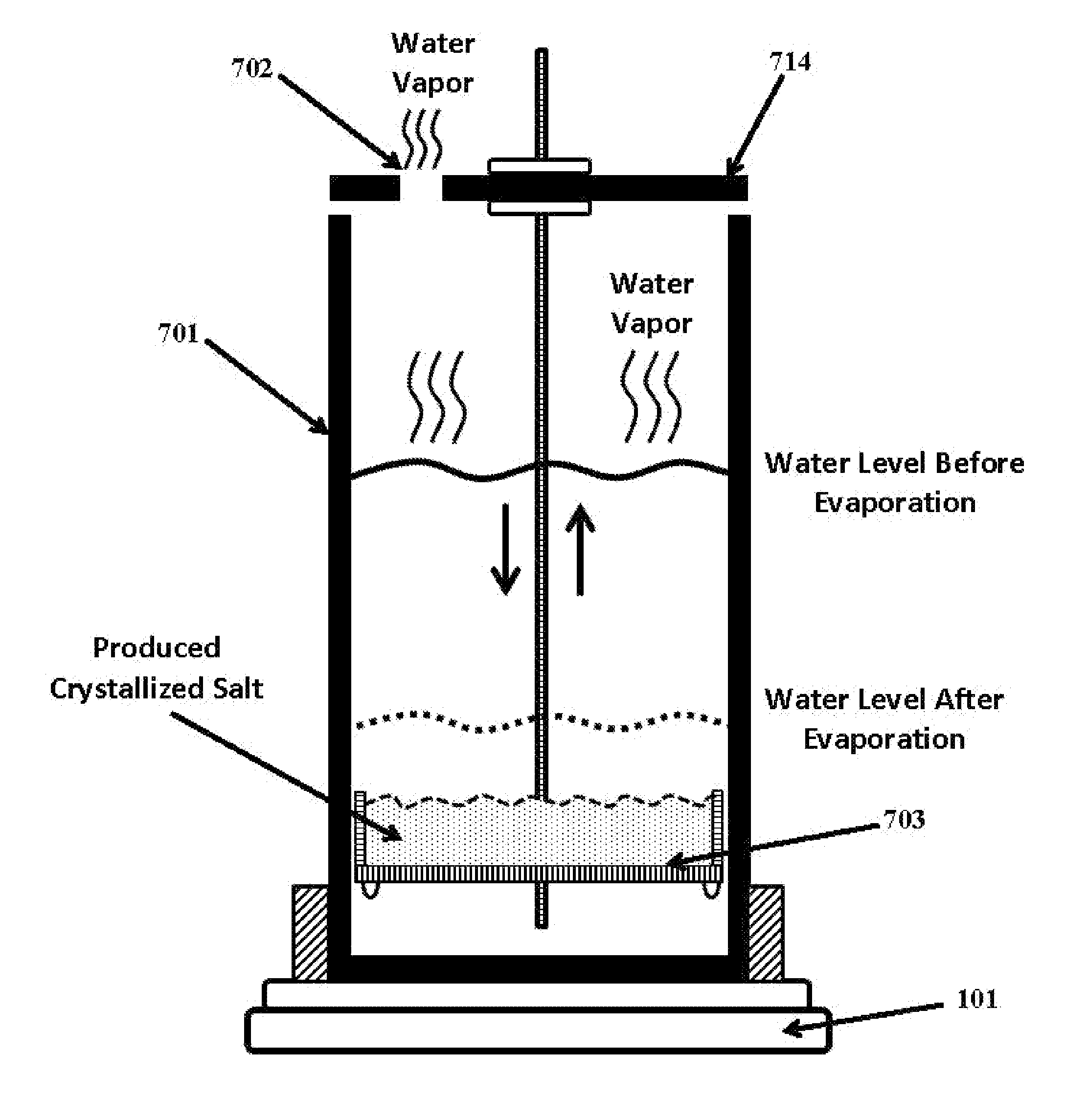

Floating salt farm

A floating salt farm in which its purpose is to produce crystallized salt and bittern at offshore locations through the evaporation process using extracted seawater. The floating salt farm components can be consisted of a seawater tank, an evaporator tank, a heating tank, a deposit tank, a storage tank, and photovoltaic panels, which these components are installed onto the buoyant foundation. The evaporator tank component can consist of an evaporator plate and an evaporator bin. The evaporator plate, which captures the produced crystallized salt during the evaporation process, has a sieve surface. The contents inside the evaporator bin can affect the properties of the produced crystallized salt and bittern, such as their mineral compositions, during the evaporation process. The seawater can be extracted from desired water depths and / or in the proximity of volcanic sites, in which the seawater can have affected mineral compositions due to volcanic activity.

Owner:PIOLI SYST

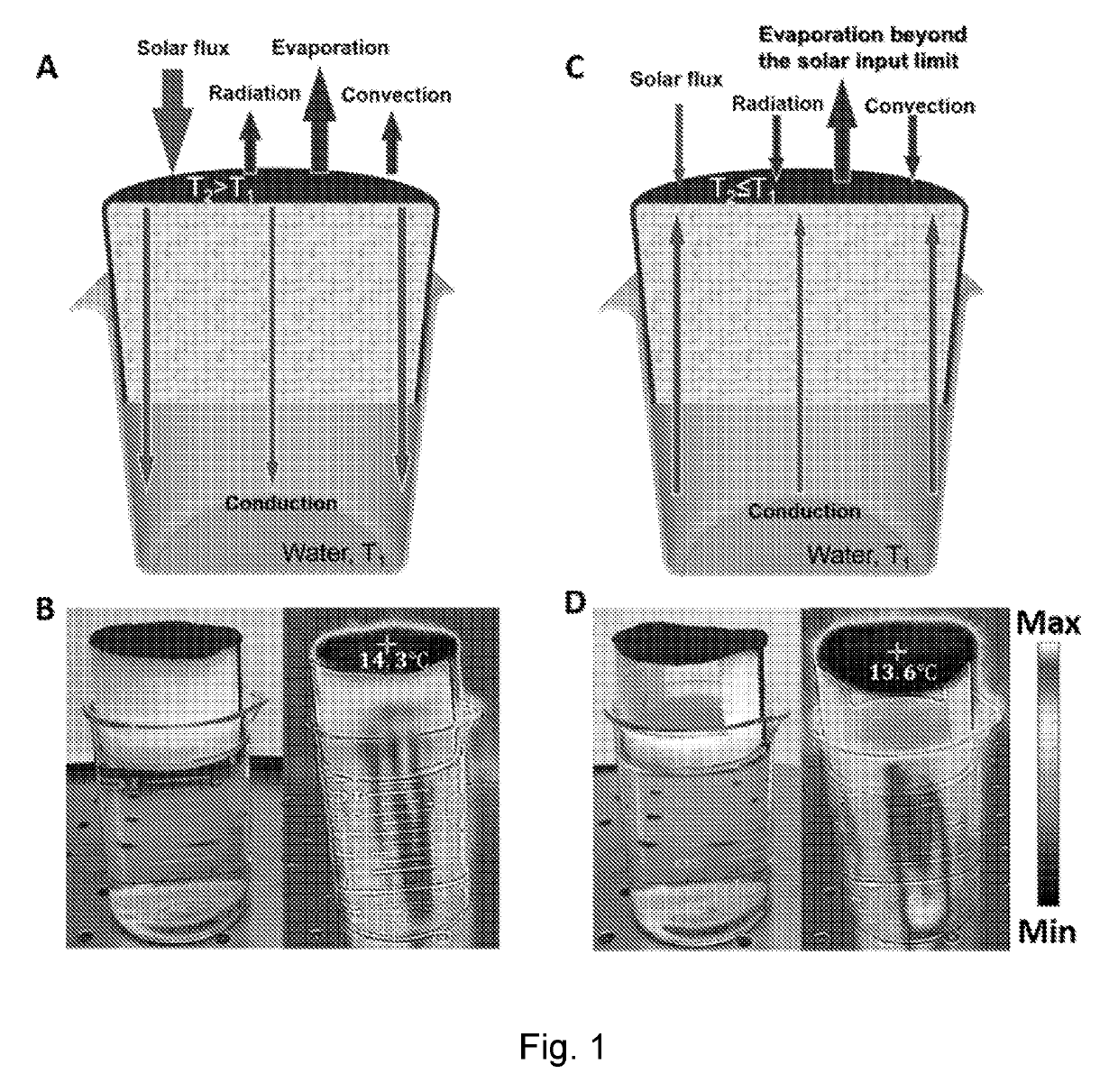

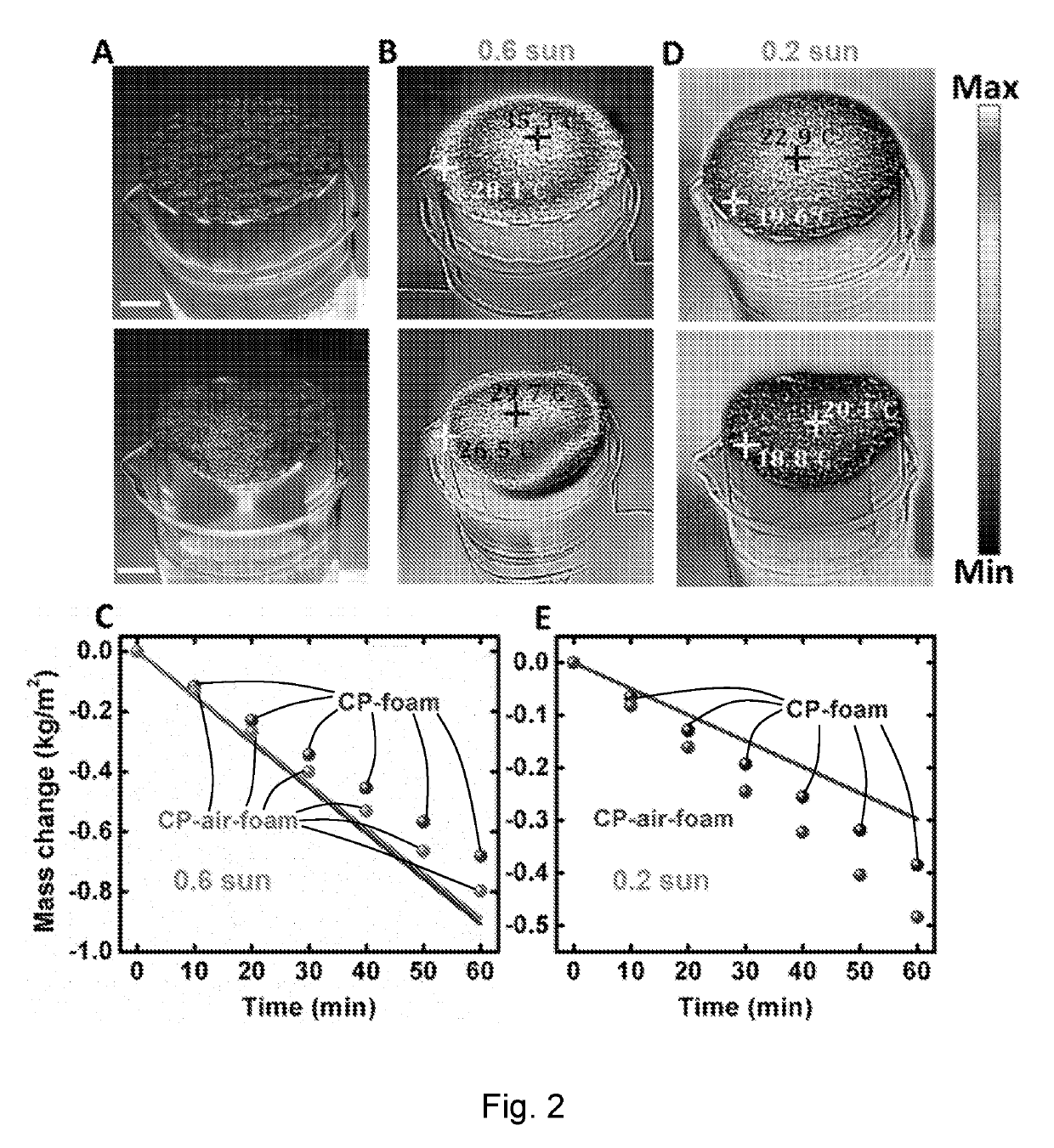

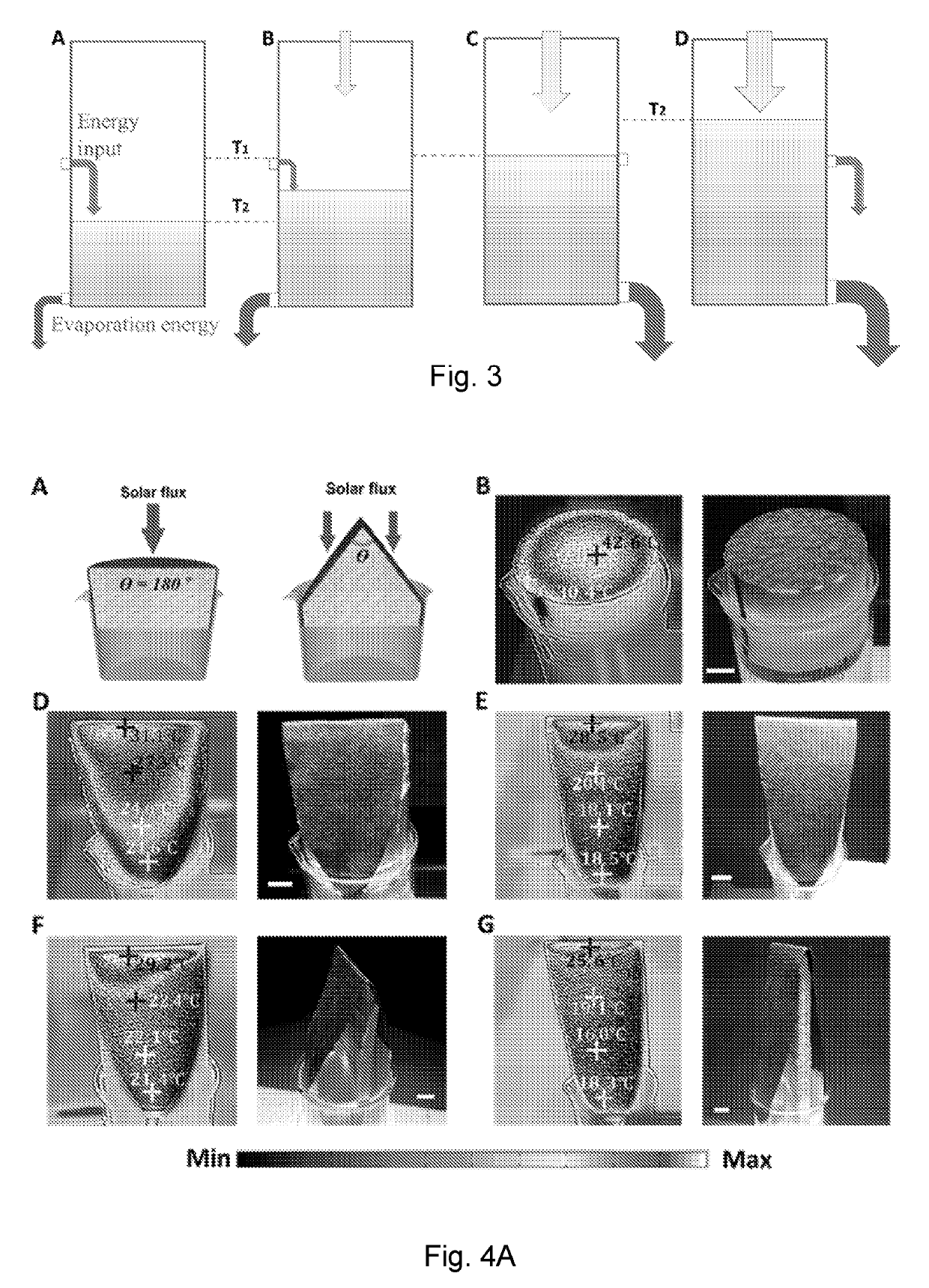

System and method for solar vapor evaporation and condensation

ActiveUS20190322543A1Low costSafe handlingSeawater treatmentVapor condensationRoom temperatureEvaporation

A solar vapor generator system and method are provided. In some embodiments, the system has near perfect energy conversion efficiency in the process of solar vapor generation below room temperature. Remarkably, when the operation temperature of the system is below that of the surroundings, the total vapor generation will be higher than the upper limit that can be produced by the input solar energy.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

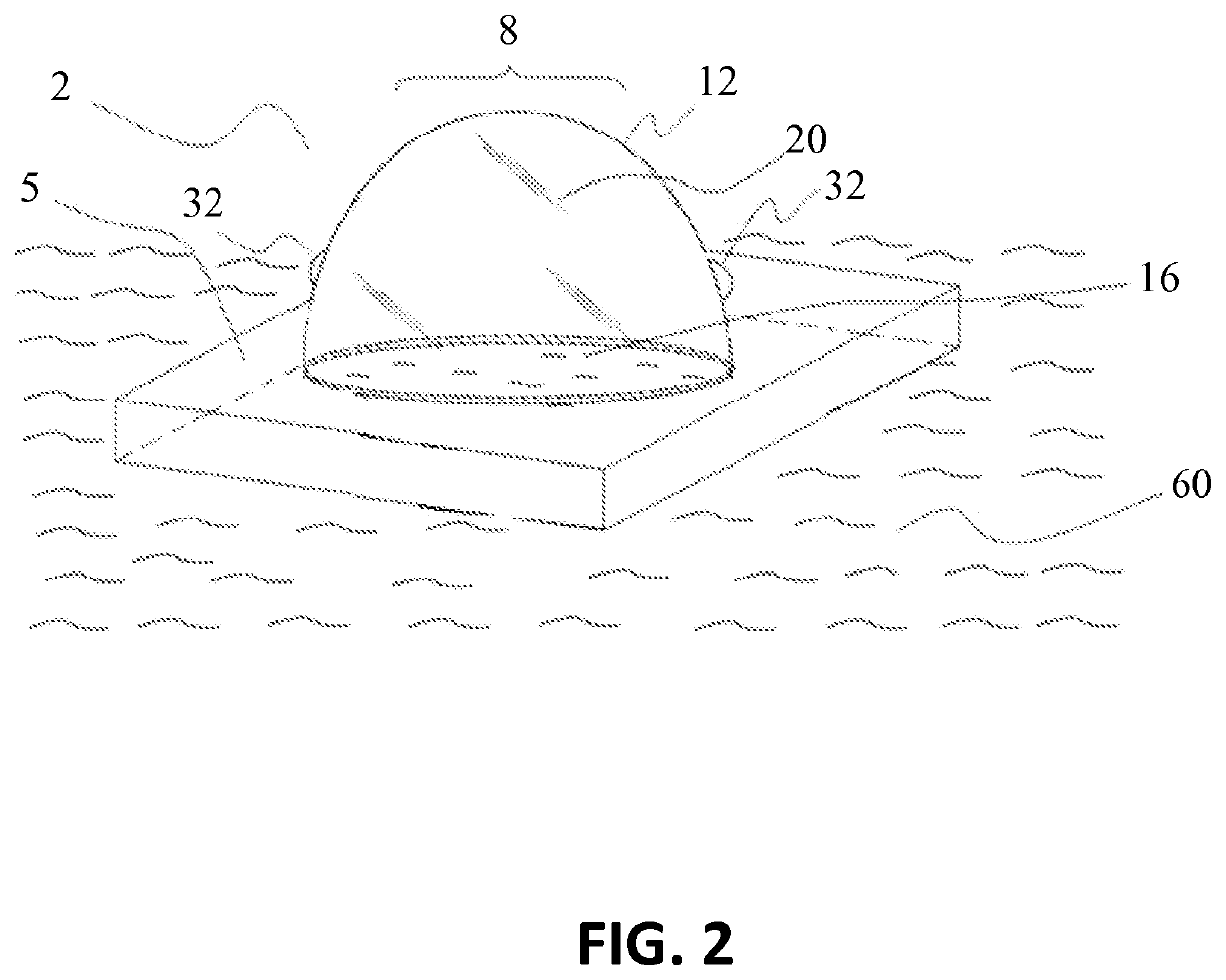

Means and devices to collect water vapors

A water vapor collector assembly, which consists of an optional capillary net, a dome, a water conveying channel, an optional capillary mat, a floatation base, and a water tube anchor, which many of it can be looped together by ropes and tubes and can float on sea surface to take sun rays to generate freshwater.

Owner:HSIA CHIH YU +2

Gas redirecting device for liquid-gas contacting column

ActiveUS20180318752A1Avoid introducingGas treatmentDispersed particle separationProduct gasEngineering

The present invention relates to a gas-redirecting device presenting an upper plane and a plurality of gas-redirecting tubes comprising an inlet end and an outlet end. For each gas-redirecting tube, the orthogonal projections of the inlet end and the outlet end onto the upper plane have an over-lapping area of at most 50% of the total area of the upper plane covered by the orthogonal projections. Also provided is a liquid-gas contacting column comprising a gas-redirecting device, a floating support comprising a liquid-gas contacting column, at least two packed beds and a method for improving the efficiency of a liquid-gas contacting column which is based on redirecting the gas from a wetted zone of a lower packed bed to a wetted zone of the higher packed bed.

Owner:TOTAL PUTEAUX FR +2

Floating salt farm

InactiveUS20150053356A1General water supply conservationDistillation in boilers/stillsElectricityMarine engineering

The present invention, the floating salt farm, is a system situated at offshore locations for producing crystallized salt and bittern through the evaporation of seawater. The energy storage tank, which is a floating salt farm component, is a storing component for accumulating electricity generated from various energy sources. A plurality of photovoltaic panels is fixed on the buoyant foundation situated at offshore locations or a barge, which is a movable structure.

Owner:PIOLI SYST

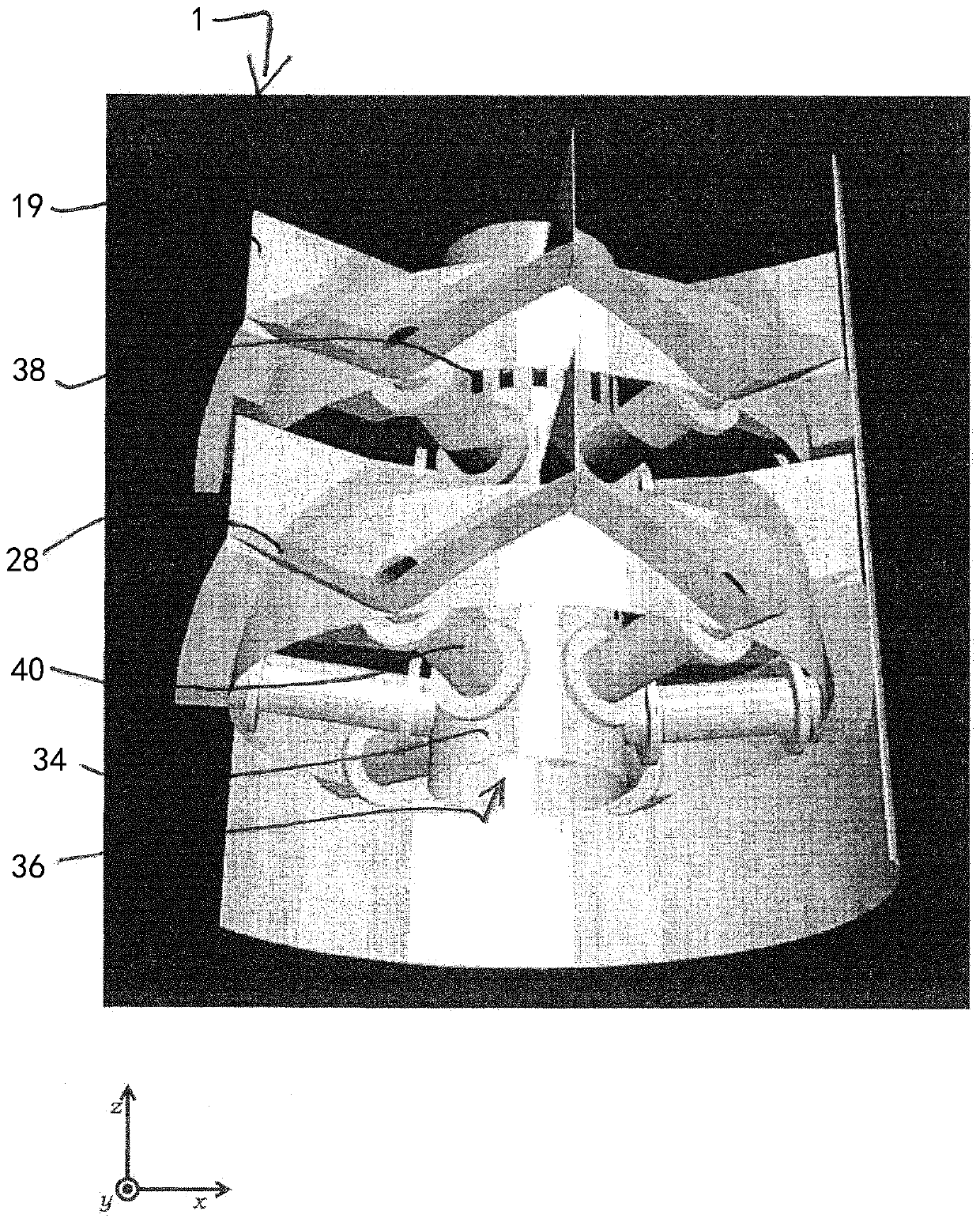

Fluid contact tray particularly for the use in an offshore fractionation column

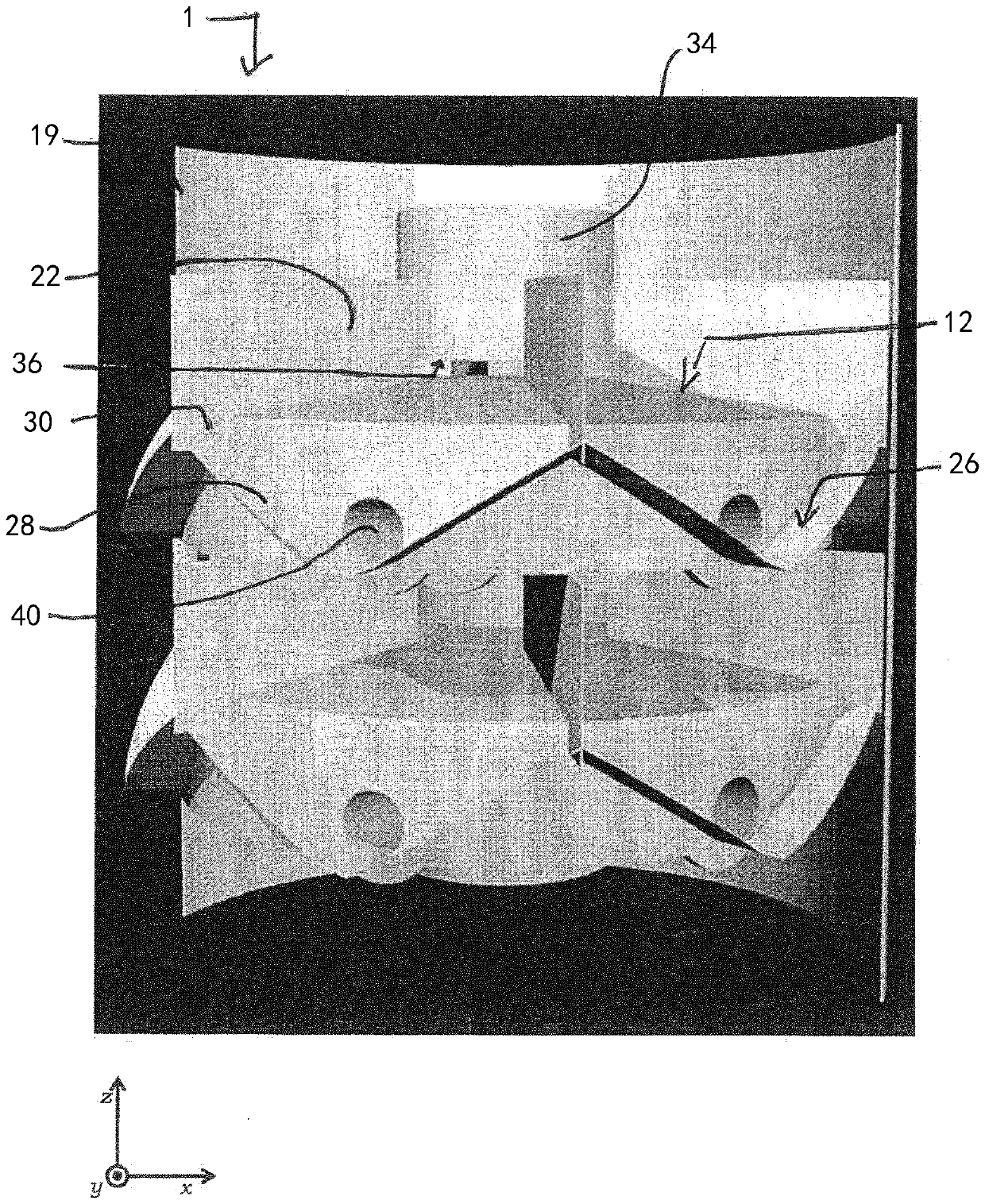

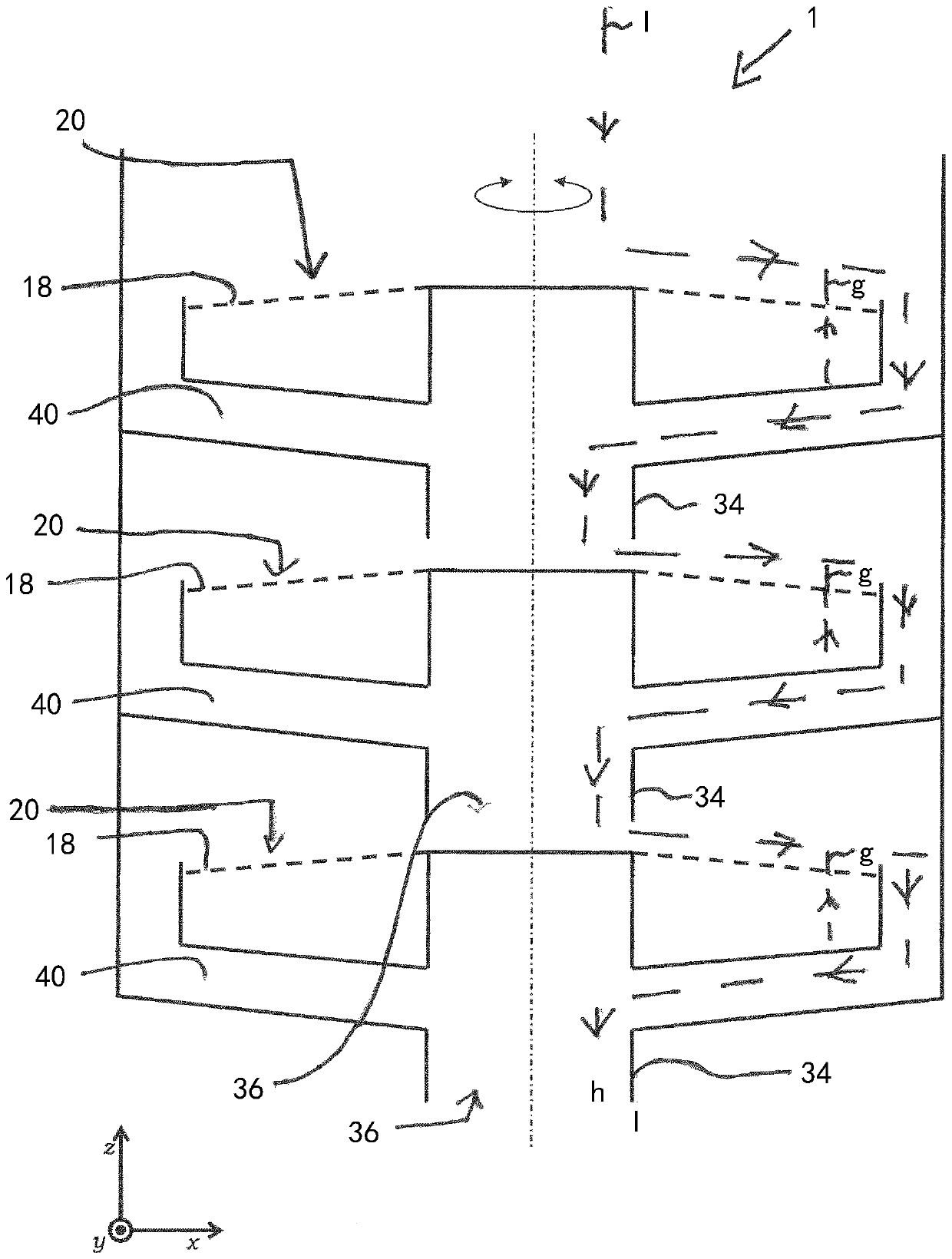

A fluid contact tray (10) for a fractionation column (1), in particular a vapor-liquid contact tray suitable for the use in an offshore fractionation column, comprises: a tray deck (12) comprising an active mass transfer surface (20) suitable for contacting two fluids (l, g) of different densities, wherein the active mass transfer surface (20) comprises one or more orifices (18) for the passage of a fluid / gas (g), and wherein at least two at least partially radially extending separation walls (22-1, 22-2, 22-3, 22-4) and / or at least one separation weir (42) are arranged on the active mass transfer surface (20), which divides the active mass transfer surface (20) into at least two sections (24-1, 24-2, 24-3, 24-4), an annular channel (26) suitable for collecting fluids / liquids (l), which is arranged at the peripheral area of the active mass transfer surface (20) and at least partially embraces the mass transfer surface (20), a central downcomer (34) for collecting and discharging a fluid / liquid (l) from the annular channel (26), wherein the central downcomer (34) has the form of a hollow body with an opening (36) in the bottom section thereof being suitable for the distribution of liquid vertically downwardly, and wherein the central downcomer (34) is non-rotatably fixed at the fluid contact tray (10), and at least one conducting means (40) for transferring fluid collected in the annular channel (26) from the annular channel (26) to the central downcomer (34). This fluid contact tray (10) is in particular useable for offshore applications, such as for a fractionation column located on a FLNG or FPSO vessel.

Owner:SULZER MANAGEMENT AG

Solar still apparatus

There is provided a solar still apparatus for converting contaminated water contained in a contaminated water body into distillate water, the contaminated water body having a water surface, the solar still apparatus comprising a cover in the form of a geometrical projection comprising a wall, an opening and a chamber, wherein the wall is adapted to be in thermal communication with the external environment for capturing solar heat and in optical communication with the opening for allowing passage of solar rays from the external environment to the opening; the opening is adapted to be in optical communication with the wall and the surface of the contaminated water body for allowing passage of the solar rays from the wall to the surface of the contaminated water body for heating the contaminated water to form a vapor, and adapted to be in fluid communication with the surface of the contaminated water body and the chamber for allowing passage of the vapor from the surface of the contaminated water body inside the chamber; and the chamber is defined by the wall, the chamber being adapted to be in fluid communication with the opening for receiving the vapor formed and condensing the vapor for forming condensed distillate water therefrom.

Owner:ALKHAZRAJI SAEED ALHASSAN

Railway bogie with a winterproof piping and writing ptoecting impact guard

ActiveUS20160375914A1Improve impactLow thermal conductivitySeawater treatmentRailway wheel guards/bumpersBogieFlying debris

A railway bogie includes one or more operative components for the operation of the railway bogie and an impact guard protecting the one or more operative components from flying debris. The impact guard is made of a high density polyethylene (HDPE). The railway bogie can be used in Jacobs bogies of multiple units operating under wintery conditions.

Owner:ALSTOM TRANSPORT TECH SAS

Solar still system and related water transportation apparatus

There is provided a water transportation system comprising evaporation zones for converting water into water vapour; condensation zones for condensing the water vapour into condensed water, the condensation zones being in fluid communication with the evaporation zones; water vapour conduits adapted to enable the fluid communication of the water vapour between the evaporation zones and the condensation zones; condensed water conduits adapted to enable the fluid communication of condensed water between the condensation zones and the evaporation zones; wherein the evaporation zones and the condensation zones alternate in position along a water transportation path between a water source site and a water destination site for enabling the transport of water from the water source site to the water destination site through alternating processes of evaporation-condensation and condensation-evaporation of the water.

Owner:ALKHAZRAJI SAEED ALHASSAN

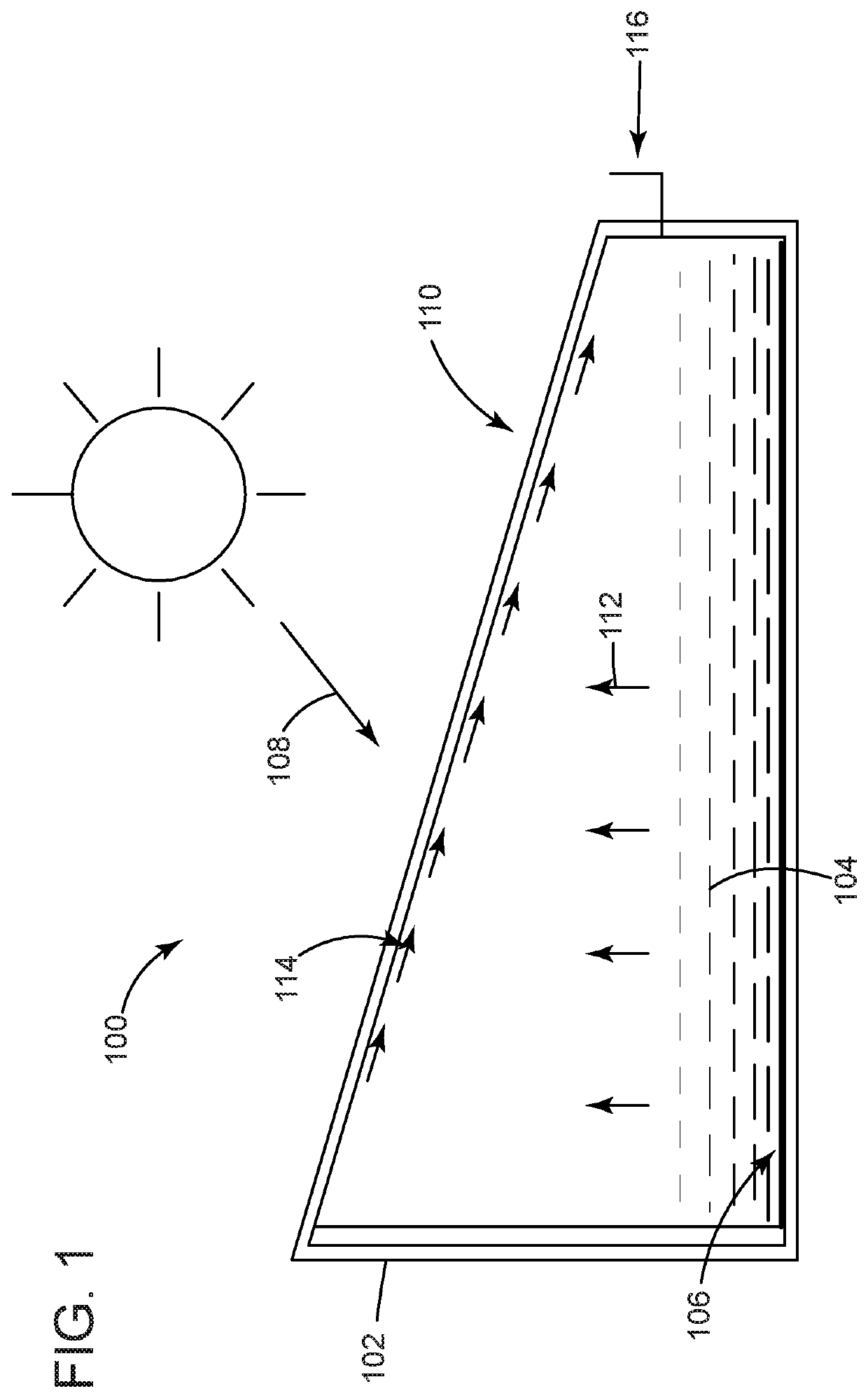

Method and device for water evaporation

A solar-powered system includes a support portion; and an evaporation portion having a pumping layer and a photothermal layer. The support portion pumps a fluid to the evaporation portion, the pumping layer evaporates the fluid based on solar power; and the photothermal layer is insulated from the pumping layer.

Owner:KING ABDULLAH UNIV OF SCI & TECH

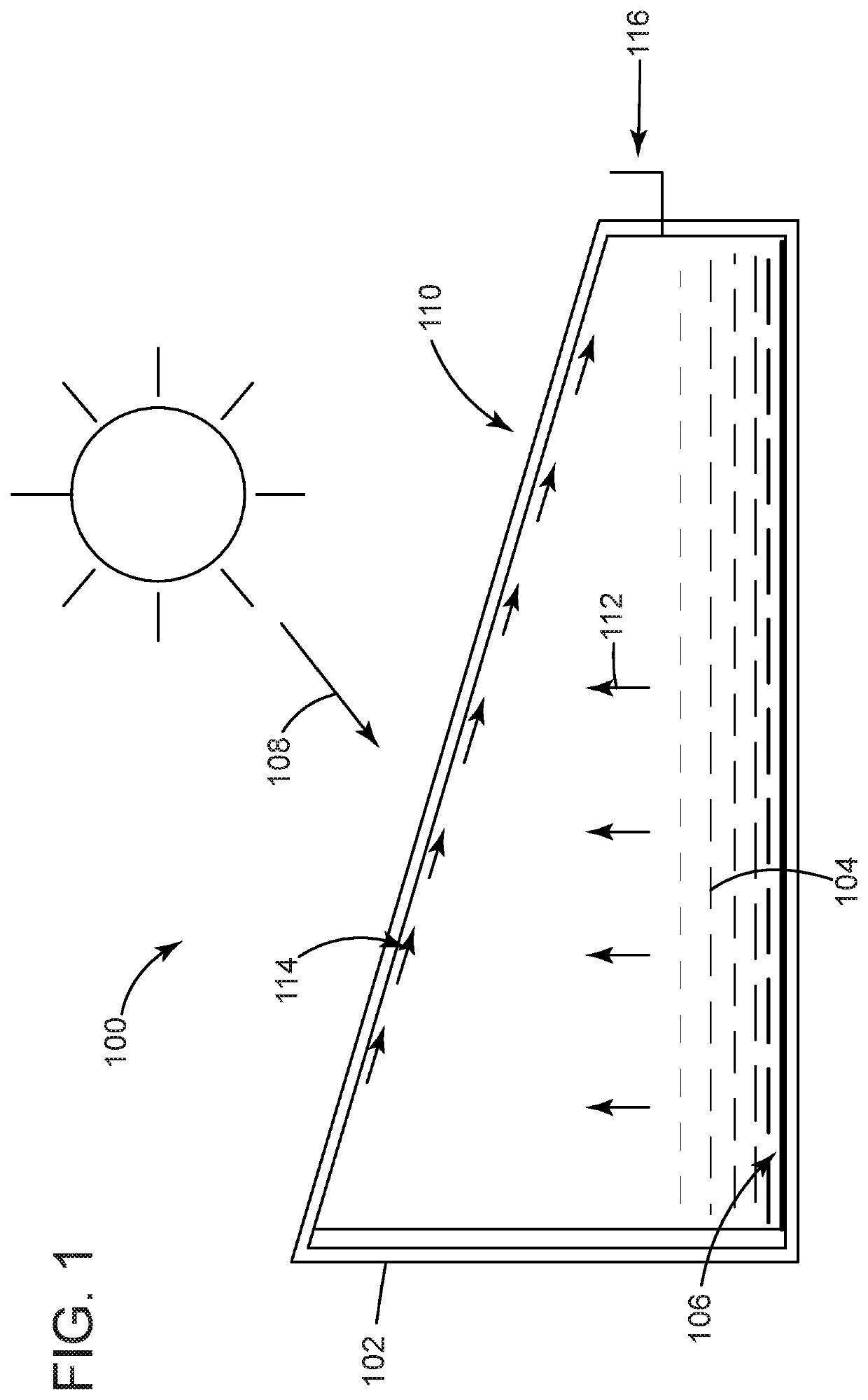

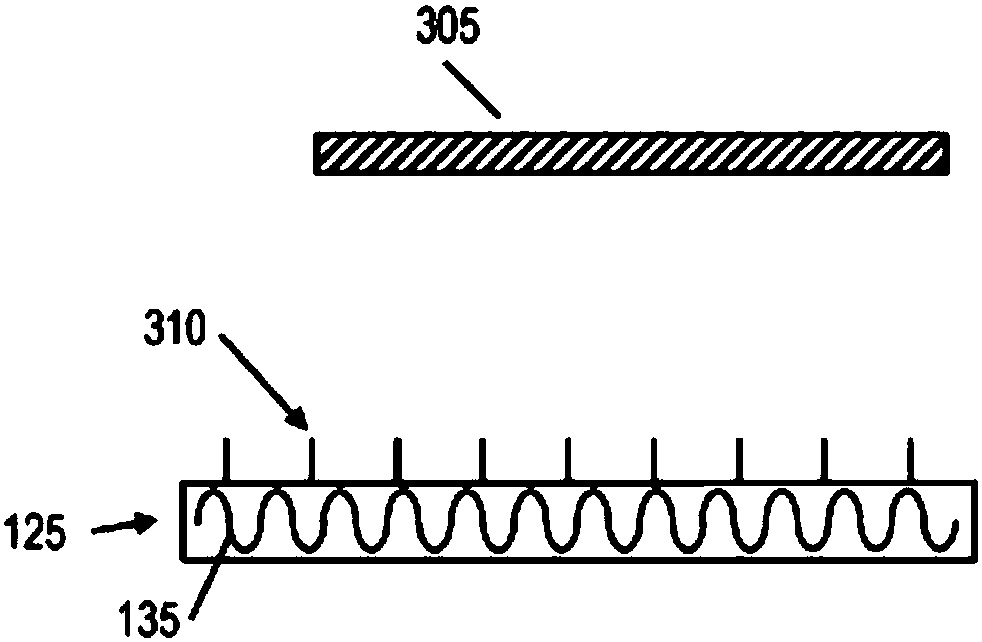

Liquid purification with film heating

ActiveCN107848839ALow costReduce pollutionGeneral water supply conservationSeawater treatmentHigh energyPotable water

A purification system can provide for efficient heating of liquid via film heating, which, rather than heating a large volume of liquid, can heat a thin layer of liquid thus reducing the amount of energy required to evaporate the liquid. Film heating can enable evaporation of liquids using less energy than other methods. In addition, when liquids (e.g., seawater) having dissolved solids (e.g., salts) are heated, both the liquid and the solids must be heated. As evaporation occurs, the concentration of solids increases and more energy must be supplied to the liquid in order to cause evaporation. Because purification system can heat only a layer of liquid, less energy is required to heat the solids, which can allow for higher energy efficiencies in purifying liquids. These efficiencies can lead to decreased cost of potable water. Related apparatus, systems, techniques, and articles are also described.

Owner:BREAKTHROUGH TECH LLC

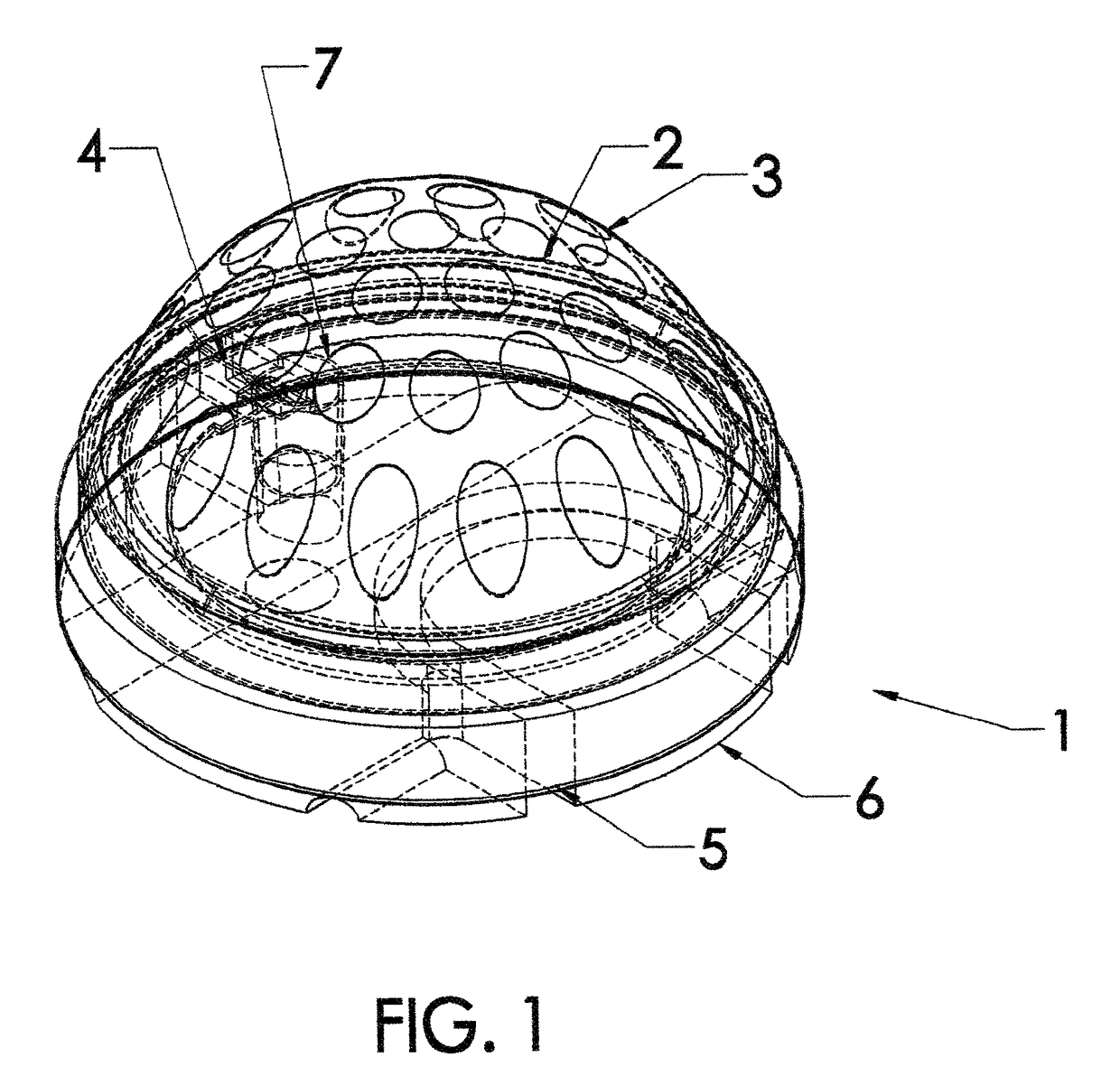

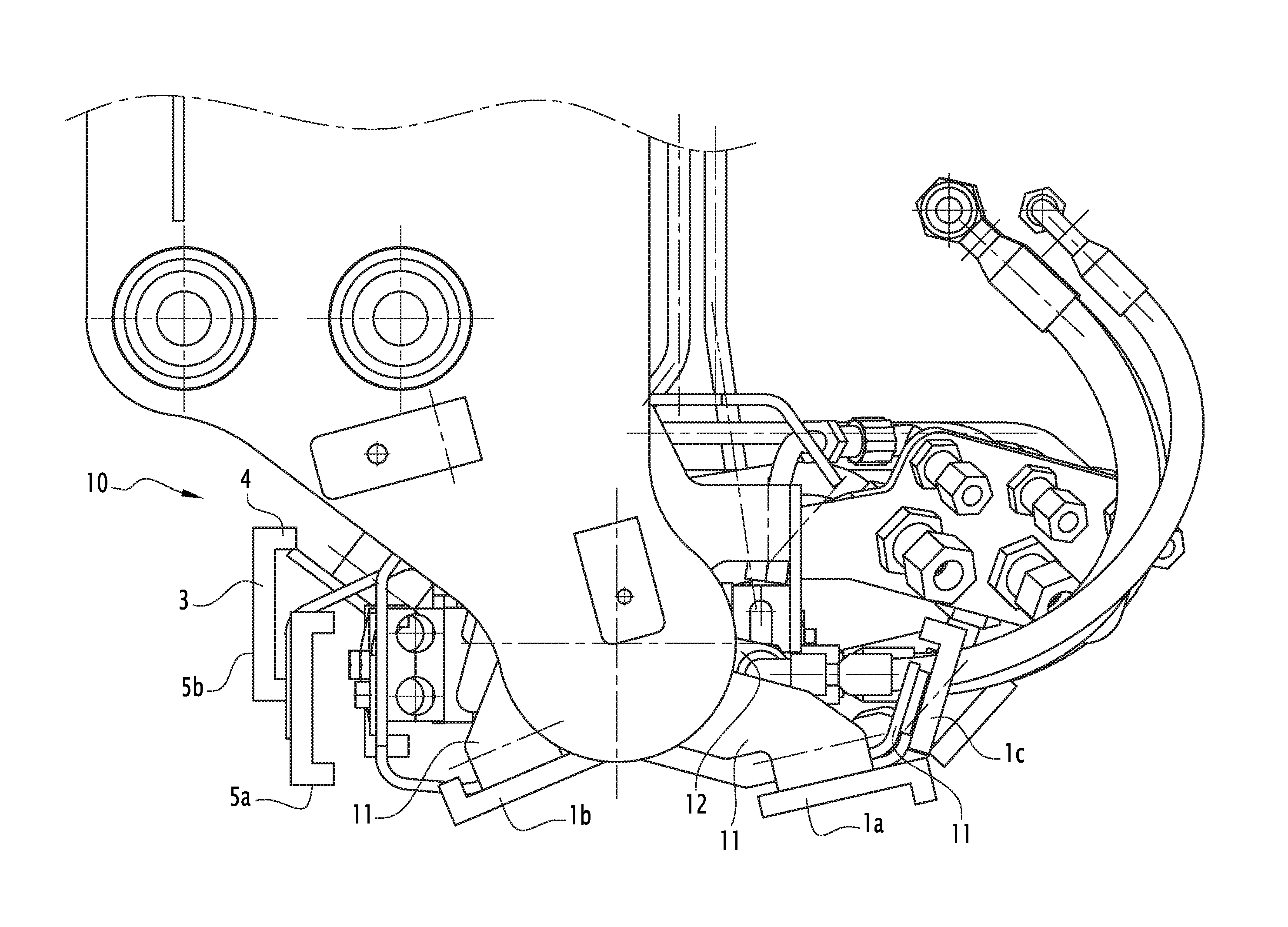

Liquid double distribution device of use in particular in an apparatus in which a liquid phase flows under gravity

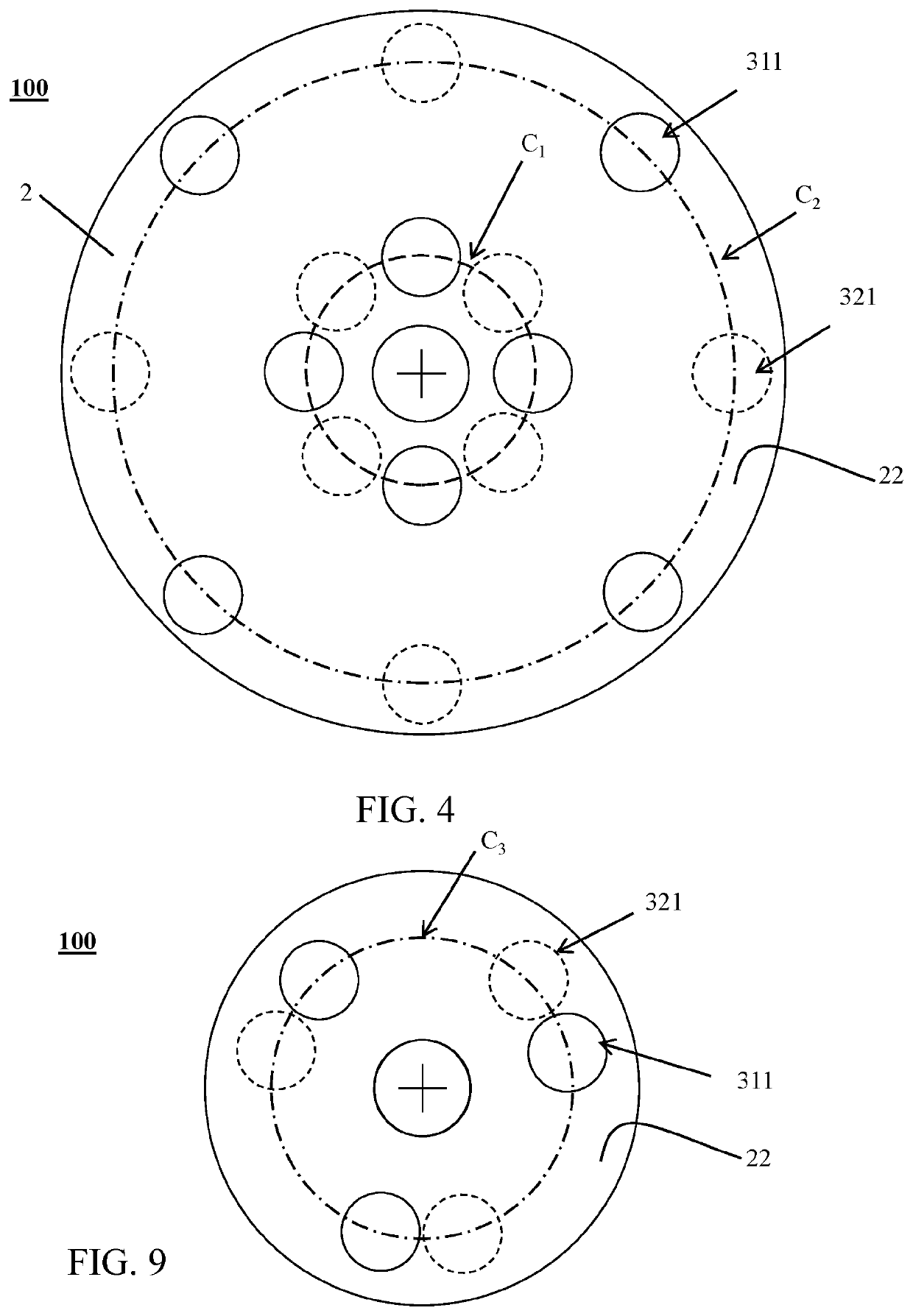

ActiveUS11167221B2Evenly distributedAvoid differencesSolidificationLiquefactionFluid phaseEngineering

A double liquid distribution device (1) suitable for use in in a fractionating or wash column (10) including a high collector tray (2) connected to a manifold support (7) via at least two longitudinal liquid downflow ducts (5, 6), the manifold support (7) supporting at least two series of transverse tubular manifolds (8, 8a 8b) and serving to feed liquid respectively to the first series of manifolds (8a) via a first longitudinal duct (5) and to the second series of manifolds (8b) via a second longitudinal duct (6), each manifold (8, 8a 8b) including distribution orifices (8c) in its under face that are suitable for distributing the liquid onto the top face of the packing bed (9). The two longitudinal liquid downflow ducts (5, 6) are connected together in a low portion (5b, 6b) by a communication device (11) fitted with a valve (12) having controlled opening that is suitable for allowing the liquid to be transferred between the two longitudinal ducts in a controlled manner.

Owner:SAIPEM SPA

Gas redirecting device for liquid-gas contacting column

ActiveUS10821396B2Avoid introducingGas treatmentDispersed particle separationEngineeringMechanical engineering

The present invention relates to a gas-redirecting device presenting an upper plane and a plurality of gas-redirecting tubes comprising an inlet end and an outlet end. For each gas-redirecting tube, the orthogonal projections of the inlet end and the outlet end onto the upper plane have an over-lapping area of at most 50% of the total area of the upper plane covered by the orthogonal projections. Also provided is a liquid-gas contacting column comprising a gas-redirecting device, a floating support comprising a liquid-gas contacting column, at least two packed beds and a method for improving the efficiency of a liquid-gas contacting column which is based on redirecting the gas from a wetted zone of a lower packed bed to a wetted zone of the higher packed bed.

Owner:TOTAL PUTEAUX FR +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com