Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about "Detergent preparation with liquid ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-phosphate, agglomerated laundry booster

InactiveUS6022843AGood lookingImprove performanceInorganic/elemental detergent compounding agentsSurface-active non-soap compounds and soap mixture detergentsPhosphateBleach

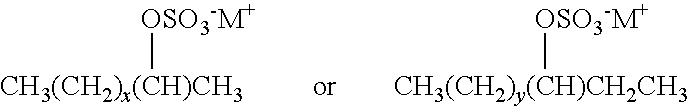

The invention is an improved, non-phosphate, non-bleach, agglomerated laundry booster which has a) a solids portion with i) at least 5% by weight of a first builder selected from the group consisting of alkali metal carbonate, alkali metal bicarbonate, alkali metal sesquicarbonate, and mixtures thereof; and ii) a second builder of at least 25% by weight alkali metal tetraborate pentahydrate; and b) i) a first liquid which comprises an anionic, acidic surfactant, in an amount no greater than about 10% by weight; and ii) a second liquid which comprises an agglomerating agent. The first liquid is neutralized by the first builder of a)i) to form a first set of particles, the second builder forms a second set of particles, and the second liquid co-agglomerates both the first and second sets of particles. The invention also provides a method for preparing this laundry booster.

Owner:THE CLOROX CO

Laundry and cleaning and/or fabric care composition

InactiveUS20060014655A1Increase depositionOrganic detergent compounding agentsFatty substance preservation using additivesEngineeringLaundry

There is provided a laundry and / or cleaning and / or fabric care composition comprising a benefit agent whereby said benefit agent is carried with a carrier material, thereby providing an enhanced deposition on the treated fabric of the benefit agent.

Owner:THE PROCTER & GAMBLE COMPANY

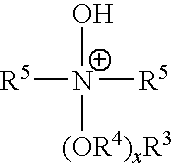

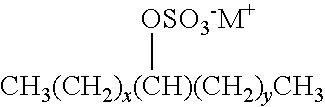

Liquid cleansing composition

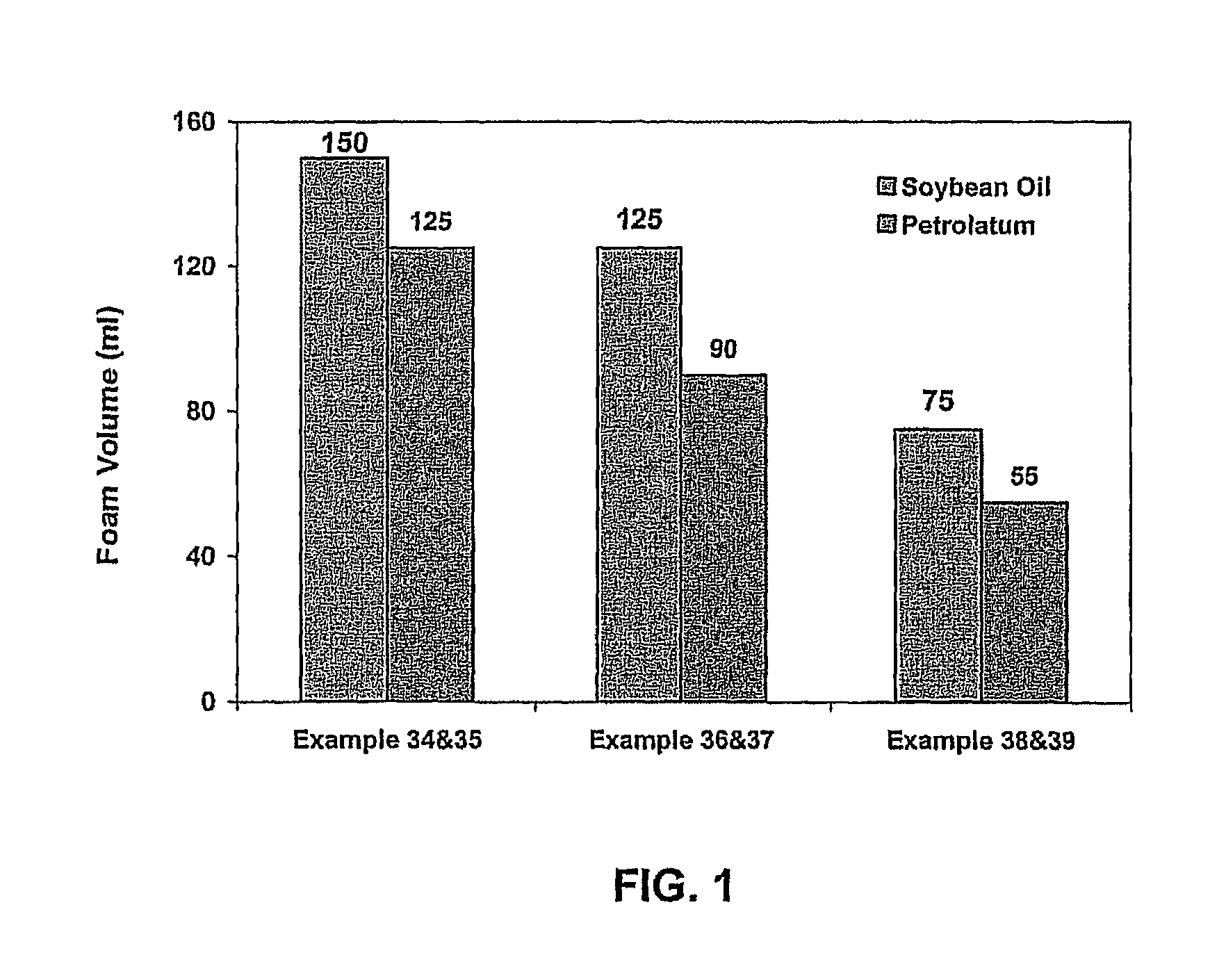

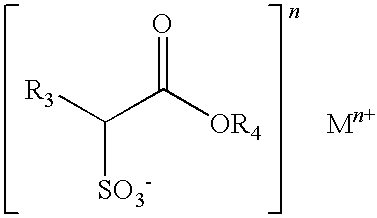

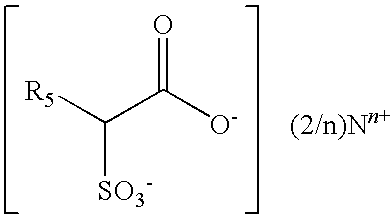

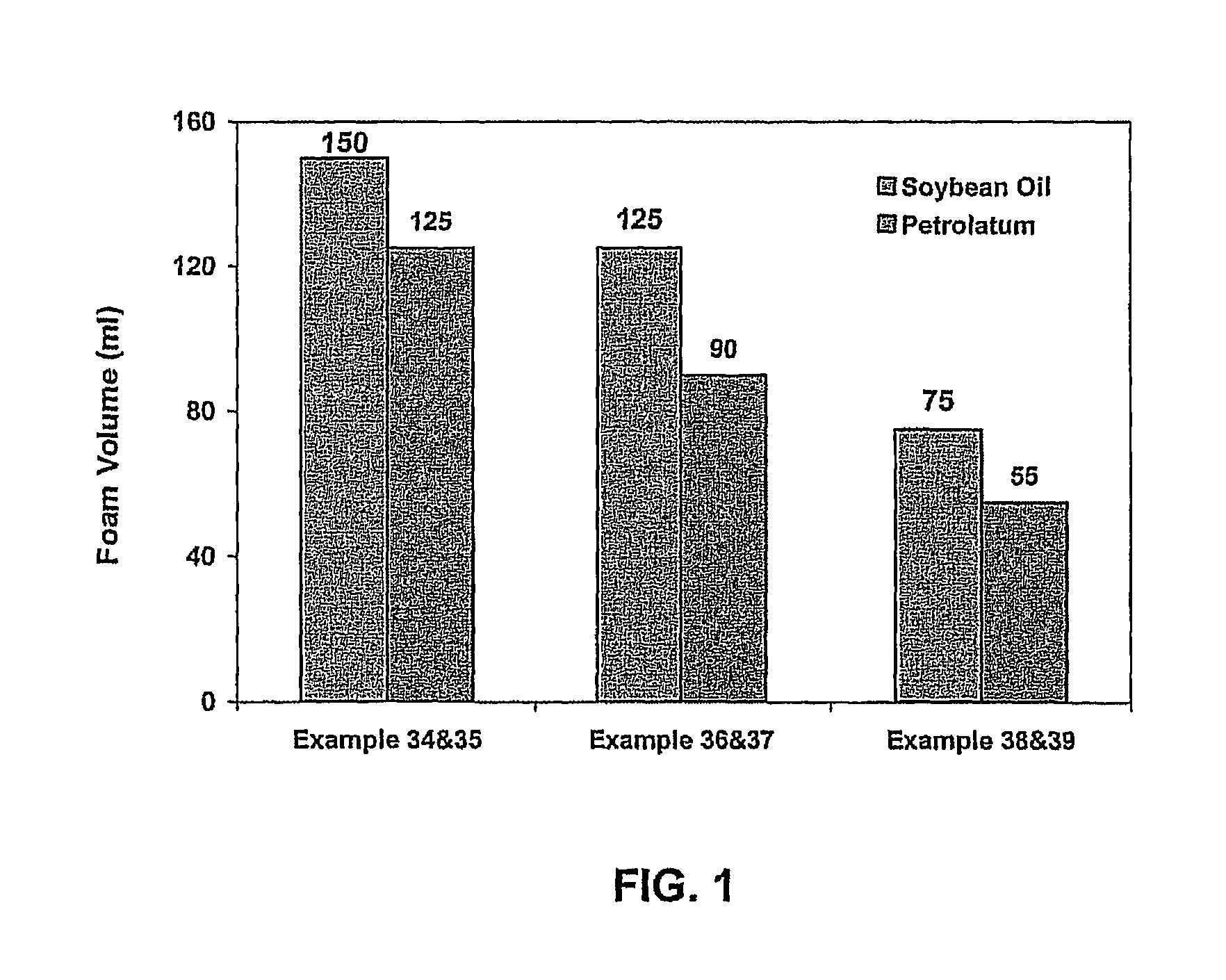

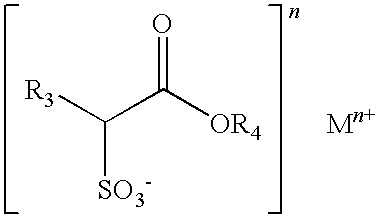

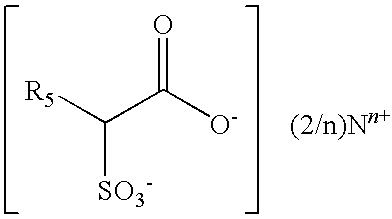

A personal cleansing composition exhibiting enhanced skin feel (i.e., enhanced skin softness, reduced skin irritation, reduced residue, and reduced greasy, tacky, or tight skin feel), enhanced foaming and lather, and good cleansing, more specifically, a personal cleansing composition comprising a mixture of alpha sulfonated alkyl esters or sulfonated fatty acids, or salts thereof, with an alkyl sulfoacetate or ethoxylated alkyl sulfoacetate, or salts thereof, secondary surfactants, and optional additives.

Owner:STEPAN COMPANY

Process for the production of detergent granules

InactiveUS7053038B2Fine granularityPreventing aggregation and cakingInorganic/elemental detergent compounding agentsPigmenting treatmentCarbonationSURFACTANT BLEND

A low shear mechanical granulation process for the production of detergent granules, the process comprising contacting an acid precursor of an anionic surfactant, a non-surfactant acid and a solid carbonated neutralising agent wherein the solid carbonated neutralizing agent has a d3,2 average particle size no more than 90 μm, preferably no more than 80 μm, more preferably no more than 70 μm, still more preferably no more than 60 μm, yet more preferably no more than 50 μm and especially no more than 40 μm.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Laundry and cleaning and/or fabric care composition

InactiveUS20080032910A1Increase depositionOrganic detergent compounding agentsFatty substance preservation using additivesEngineeringLaundry

There is provided a laundry and / or cleaning and / or fabric care composition comprising a benefit agent whereby said benefit agent is carried with a carrier material, thereby providing an enhanced deposition on the treated fabric of the benefit agent.

Owner:THE PROCTER & GAMBLE COMPANY

Method for the production of surfactant granulates containing builders

InactiveUS20050020469A1Favorable solubility profileReadily solubleInorganic/elemental detergent compounding agentsPigmenting treatmentSolubilitySodium bicarbonate

The present invention describes easily soluble surfactant granulates containing builders, having a variable bulk weight and an excellent solubility profile, containing the neutralized from of an anionic surfactant acid and sodium carbonate and sodium hydrogencarbonate, produced by neutralization of mixtures of anionic surfactant acids and builder acids with solid neutralizing agents. The present invention provides a method for producing surfactant granulates, comprising providing a mixture of anionic surfactant acids and builder acids having a weight ratio of 1:500 to 50:1 of builder acid to surfactant acid and contacting the mixture with solid neutralizing agents.

Owner:HENKEL KGAA

Preparation method of oxygen-containing washing agent and oxygen-containing washing agent prepared by same

ActiveCN102634422AImprove performanceImprove washabilityOrganic/inorganic per-compounds compounding agentsDetergent bleaching agentsSodium bicarbonateSilicic acid

The invention provides a preparation method of an oxygen-containing washing agent. The preparation method comprises the following steps of: A, adding 1-10 parts by weight of surfactant, 10-70 parts by weight of sodium carbonate, 1-40 parts by weight of sodium sulfate and a raw material combination containing or not containing additional assistant into a reactor, wherein the additional assistant contains 0-20 parts by weight of sodium bicarbonate, 0-30 parts by weight of silicious sodium salt and 0-10 parts by weight of an anti-dirt redeposition agent; and B, adding an aqueous hydrogen peroxide solution in the reactor, controlling the reaction temperature of the reactor to be 0-60 DEG C, shaping and drying after reaction to obtain 100 parts by weight of the oxygen-containing washing agent the active oxygen content of which is 1-12.33%. The invention also provides the oxygen-containing washing agent prepared by using the preparation method. The preparation method provided by the invention is safe and environment-friendly, and can prepare the oxygen-containing washing agent which has the advantages of uniform component distribution, variable active oxygen content, stable performance,and excellent washing effect.

Owner:HUNAN JIEYU DAILY CHEM NEW TECH

Anionic surfactant powder

InactiveUS20050106118A1Improve stabilityImprove powder propertiesCosmetic preparationsOrganic chemistryInorganic saltsSolubility

To provide an anionic surfactant powder comprising a polyoxyalkylene ether sulfate which powder has high stability in hard water, high low-temperature solubility and is improved in powder characteristics such as caking characteristics, and a method of producing the anionic surfactant powder. An anionic surfactant powder comprising polyoxyalkylene alkyl ether sulfates in which the average addition mol number of alkylene oxides is 0.05 to 2, wherein the content of the polyoxyalkylene alkyl ether sulfates provided with alkylene oxides added thereto in an amount of 4 mol or more is 30 % by weight or less based on the total anionic surfactant, an anionic surfactant powder further comprising a water-soluble inorganic salt, a method of producing each of these anionic surfactant powders, and a detergent composition and a cement additive comprising these anionic surfactant powders.

Owner:KAO CORP

Process for making a detergent product

The present invention provides a process for making a viscous reaction product and making this into a solid or suspendable component, so that it can be incorporated in solid and liquid compositions such as cleaning compositions or for example fabric care compositions. The process comprises the steps of: a) reacting at least two compounds with one another to form a first active material to form a viscous mixed product which has a viscosity of at least 500 cps or even at least 1000 cps at 20.degree. C., thereby preferably mixing this with a second active material; b) mixing the product of step a) with a liquid carrier material, (which can then be suspended in a liquid composition); or if slid components are required, step b) being followed by: c) mixing the mixture of step b) with a solid granulation agent to form a solid component; d) optionally forming the solid component of step c) into granules. In particular, the process is for the production of fabric care components such as perfume components, or antimicrobial components.

Owner:THE PROCTER & GAMBLE COMPANY

Detergent particles

InactiveUS20050256023A1Organic detergent compounding agentsDetergent preparation by chemical meansActive agentPhysical chemistry

Detergent particles obtained by a process comprising the step of dryneutralizing base particles comprising a water-soluble solid alkali inorganic substance (A) with a liquid acid precursor (B) of a non-soap anionic surfactant, wherein the base particles are obtained by a spray-drying method, and wherein the base particles contain the component (A) in an amount of equal to or greater than 4 times the amount equivalent for neutralizing the component (B) and have an average particle size of from 150 to 400 μm; base particles having an average particle size of from 150 to 400 μm, comprising 20 to 80% by weight of a water-soluble solid alkali inorganic substance; a process for preparing detergent particles comprising the steps of (a) preparing a slurry comprising a water-soluble solid alkali inorganic substance (A) in an amount equal to or greater than 4 times the amount equivalent for neutralizing a liquid acid precursor (B) of a non-soap anionic surfactant to be added in step (c); (b) spray-drying the slurry obtained in step (a) to give base particles; and (c) mixing the liquid acid precursor (B) with the base particles obtained in step (b) and dry-neutralizing the resulting mixture; and a detergent composition comprising the detergent particles as defined above. The detergent particles can be used for laundry detergents, dishwashing detergents and the like.

Owner:KAO CORP

Surfactant Concentrate

ActiveUS20090298739A1Organic detergent compounding agentsSurface-active detergent compositionsSulfateCarboxylic acid

The present relates to a surfactant concentrate comprising at least 75% of an essentially completely neutralized anionic sulphated surfactant and 5% to 25% carboxylic acid, of which 4% to 96% of the carboxylic acid is in its free acid form, the process for making it and a detergent composition containing it.

Owner:THE PROCTER & GAMBLE COMPANY

Liquid cleansing composition comprising a ternary mixture of anionic surfactants

ActiveUS8053400B2Improve skinReduce skin problemsCosmetic preparationsMake-upPolymer scienceSKIN SOFTNESS

A personal cleansing composition exhibiting enhanced skin feel (i.e., enhanced skin softness, reduced skin irritation, reduced residue, and reduced greasy, tacky, or tight skin feel), enhanced foaming and lather, and good cleansing, more specifically, a personal cleansing composition comprising a mixture of alpha sulfonated alkyl esters or sulfonated fatty acids, or salts thereof, with an alkyl sulfoacetate or ethoxylated alkyl sulfoacetate, or salts thereof, secondary surfactants, and optional additives.

Owner:STEPAN COMPANY

Process for preparing detergent particles

InactiveUS7446085B2Organic detergent compounding agentsDetergent preparation by chemical meansActive agentEngineering

Detergent particles obtained by a process comprising the step of dryneutralizing base particles comprising a water-soluble solid alkali inorganic substance (A) with a liquid acid precursor (B) of a non-soap anionic surfactant, wherein the base particles are obtained by a spray-drying method, and wherein the base particles contain the component (A) in an amount of equal to or greater than 4 times the amount equivalent for neutralizing the component (B) and have an average particle size of from 150 to 400 μm; base particles having an average particle size of from 150 to 400 μm, comprising 20 to 80% by weight of a water-soluble solid alkali inorganic substance; a process for preparing detergent particles comprising the steps of (a) preparing a slurry comprising a water-soluble solid alkali inorganic substance (A) in an amount equal to or greater than 4 times the amount equivalent for neutralizing a liquid acid precursor (B) of a non-soap anionic surfactant to be added in step (c); (b) spray-drying the slurry obtained in step (a) to give base particles; and (c) mixing the liquid acid precursor (B) with the base particles obtained in step (b) and dry-neutralizing the resulting mixture; and a detergent composition comprising the detergent particles as defined above. The detergent particles can be used for laundry detergents, dishwashing detergents and the like.

Owner:KAO CORP

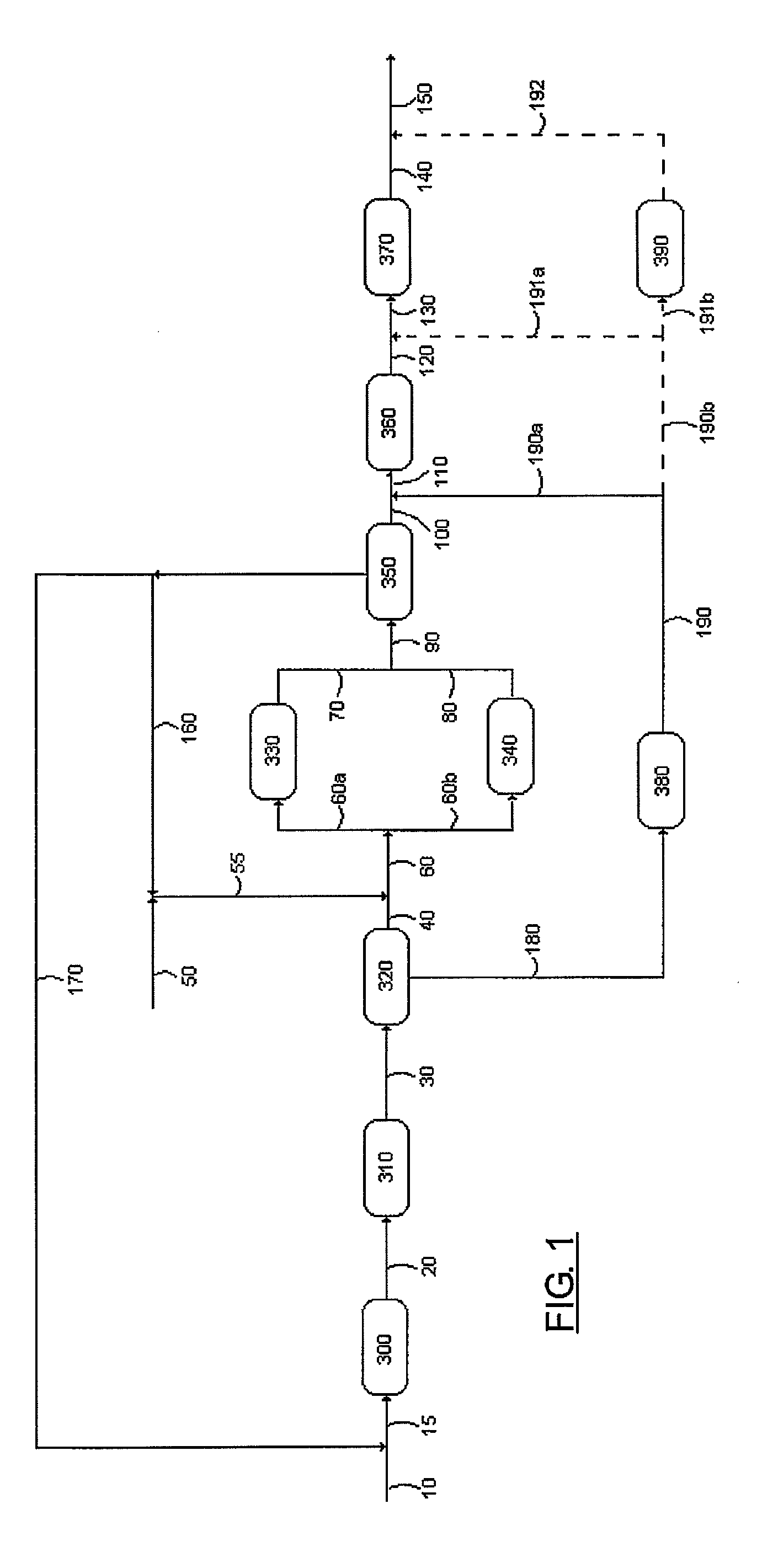

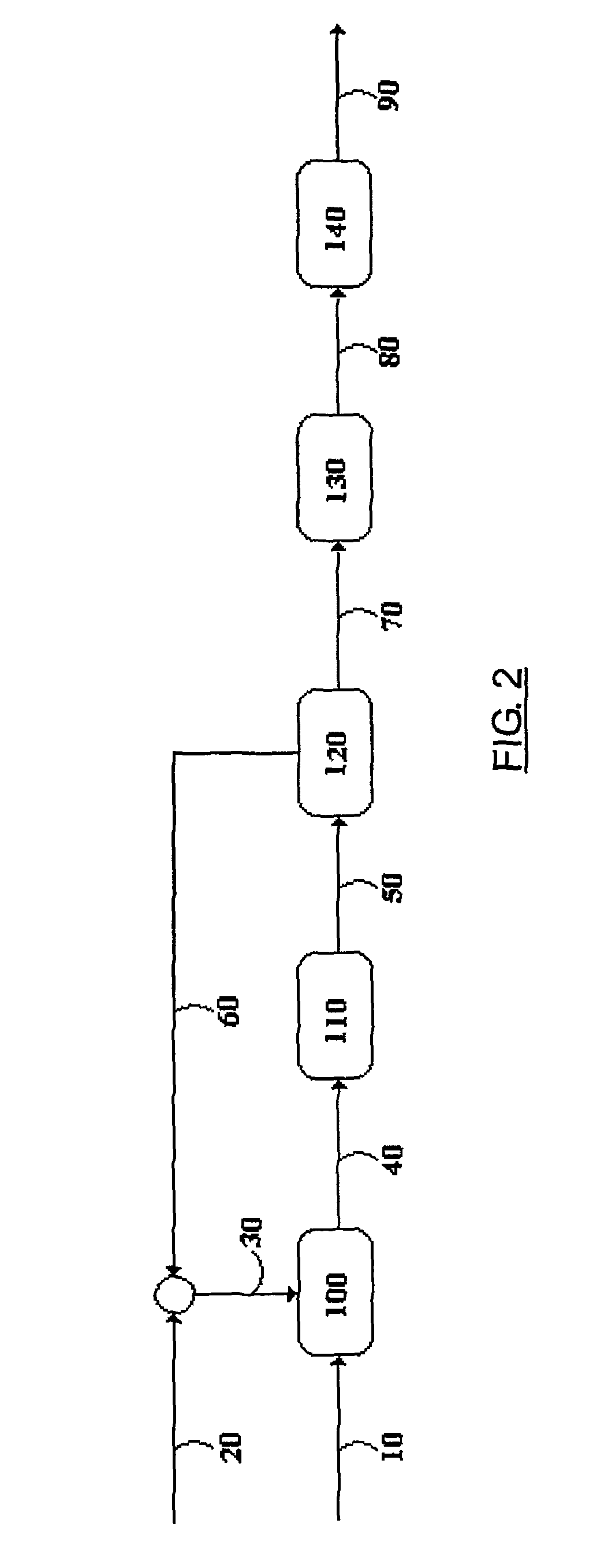

Conversion of Alkylhalides Into Alcohol Alkoxylates

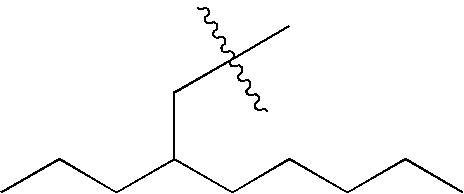

InactiveUS20090270655A1Enhanced overall recoveryCosmetic preparationsOrganic compound preparationAlkaneAlcohol

A process for converting alkyl halides to alkyl alcohol alkoxylates is described. This is a direct alkoxylation because the alkyl alcohol alkoxylates are made without going through an alkyl alcohol intermediate. The process comprises direct alkoxylation coupling of alkyl halides with a nucleophilic material in the presence of a homogeneous catalyst system to produce alkyl alcohol alkoxylates, wherein the homogeneous catalyst system comprises at least one metal or metal compound which has the ability to form metal-halogen bonds. A process for converting alkanes (paraffins) to alkyl alcohol alkoxylates is also described. This method comprises a) halogenation of at least one alkane to produce at least one alkyl halide; and b) direct alkoxylation coupling of at least a portion of the alkyl halide with a nucleophilic material in the presence of a homogeneous catalyst system to produce alkyl alcohol alkoxylates, wherein the homogeneous catalyst system comprises at least one metal or metal compound which has the ability to form metal-halogen bonds.

Owner:SHELL OIL CO

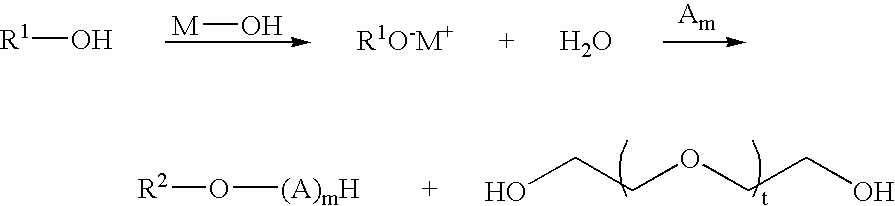

Surfactant composition and method of forming

InactiveUS7504373B2Reduce surface tensionImprove performanceBiocideOrganic detergent compounding agentsActive agentPhysical chemistry

A surfactant composition includes a first surfactant, a second surfactant, and a polyalkylene glycol. The first surfactant is of the general formula R1—O—(A)mH, wherein R1 is an aliphatic hydrocarbon having 10 carbon atoms, A is an alkyleneoxy group having from 2 to 5 carbon atoms, and m is a positive number. The second surfactant is of the general formula R2—O—(B)nH, wherein R2 is an aliphatic hydrocarbon having from 12 to 14 carbon atoms, B is an alkyleneoxy group having from 2 to 5 carbon atoms, and n is a positive number. The polyalkylene glycol is present in the surfactant composition in an amount of from 3 to 20 parts by weight per 100 parts by weight of the surfactant composition.

Owner:BASF CORP

Production process for comprehensive cyclic utilization of sulfonation by-product nigrotic acid

ActiveCN102311893ALow costReduce dosageInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSodium hypochlorite solutionSURFACTANT BLEND

The invention discloses a production process for comprehensive cyclic utilization of the sulfonation by-product nigrotic acid. The process comprises the following steps: 1) adding caustic soda into nigrotic acid for a neutralization reaction so as to allow a surfactant in nigrotic acid to turn to a sodium salt of the surfactant and waste sulfuric acid in nigrotic acid to turn to a raw material for a washing agent, i.e., mirabilite; 2) bleaching the resultant of neutralization of nigrotic acid with a sodium hypochlorite solution; 3) adding clear water into the bleached solution and carrying out spray drying; 4) adding soda ash or 4A zeolite into a product obtained after spray drying for granulation. Nigrotic acid treated with the process provided in the invention turns into particles, main components of which are a surfactant, mirabilite and soda ash, and the particles are extensively applied in washing agents, thereby utmostly realizing utilization of the waste, conservation of cost and a good environmental protection effect.

Owner:上海奥威日化有限公司

Spray-Drying Process

ActiveUS20090325850A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphateSlurry

The present invention relates to a process for preparing a spray-dried powder comprising(i) anionic detersive surfactant;(ii) from 0 wt % to 10 wt % zeolite builder;(iii) from 0 wt % to 10 wt % phosphate builder; and(iv) optionally from 0 wt % to 15 wt % silicate salt;wherein the process comprises the steps of:(a) forming an alkaline slurry in a mixer, the slurry having a viscosity of from X to Y s−1 at a temperature of 70° C. and at a shear rate of 50 s−1, wherein the alkaline slurry is shear thinning; and(b) transferring the alkaline slurry from the mixer through at least one pump to a spray pressure nozzle;(c) contacting a viscosity increasing agent to the alkaline slurry after the mixer and before the spray pressure nozzle so as to increase the viscosity of the alkaline slurry to form a viscous alkaline slurry, step (c) being carried out at an average shear rate of from 10 s−1 to 150 s−1;(d) spraying the viscous alkaline slurry through the spray pressure nozzle into a spray-drying tower;(e) spray-drying the viscous alkaline slurry to form a spray-dried powder; and(f) optionally, contacting an alkalinity source with the alkaline slurry and / or the viscosity increasing agent, and / or the viscous alkaline slurry.

Owner:THE PROCTER & GAMBLE COMPANY

Composition of laundry detergent improving touch feel of clothes and manufacturing method thereof

InactiveCN101068912AImprove stabilityImprove washabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEngineeringCatastrophic failure

A lateral force resisting system according to the present disclosure includes a metal lateral force resisting panel and holdowns. A foundation bolt placement template may be used to locate and support the foundation bolts during fabrication of the foundation and to further secure the frame foundation interface. The metal lateral force resisting panel may be formed from a single piece of material and may include a plurality of ductility apertures forming lateral force resisting elements to enable the panel to flex without catastrophic failure. In a hybrid configuration, a wooden structural frame may be combined with the metal structural panel. The structural panel may be subdivided into multiple panes using ductility apertures to tailor the response of the panel to the lateral force load. The holdowns secure the rigid structural panel to the foundation bolts and may be either a folded strap and pin configuration or self-tightening.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

Process to obtain a highly soluble linear alkylbenzene sulfonate

ActiveUS20090221464A1Organic detergent compounding agentsSurface-active detergent compositionsSulfonateLinear alkylbenzene sulfonate

The present invention refers to a process to obtain a highly soluble linear alkylbenzene sulfonate (LAS). Specifically it comprises the addition, prior or after sulfonation of linear alkylbenzene and / or neutralization of linear alkylbenzene sulfonic acid of an hydrotropic composition. It also refers to a hydrotropic composition, to a highly soluble linear alkylbenzene sulfonate, to the use of the hydrotropic composition for making said linear alkylbenzene sulfonate highly soluble and to a cleaning composition comprising said linear alkylbenzene sulfonate

Owner:CEPSA QUIMICA SA

Process for preparing detergent compositions having high bulk density

InactiveUS6992055B1Surface-active detergent compositionsDetergent compounding agentsWater solubleSURFACTANT BLEND

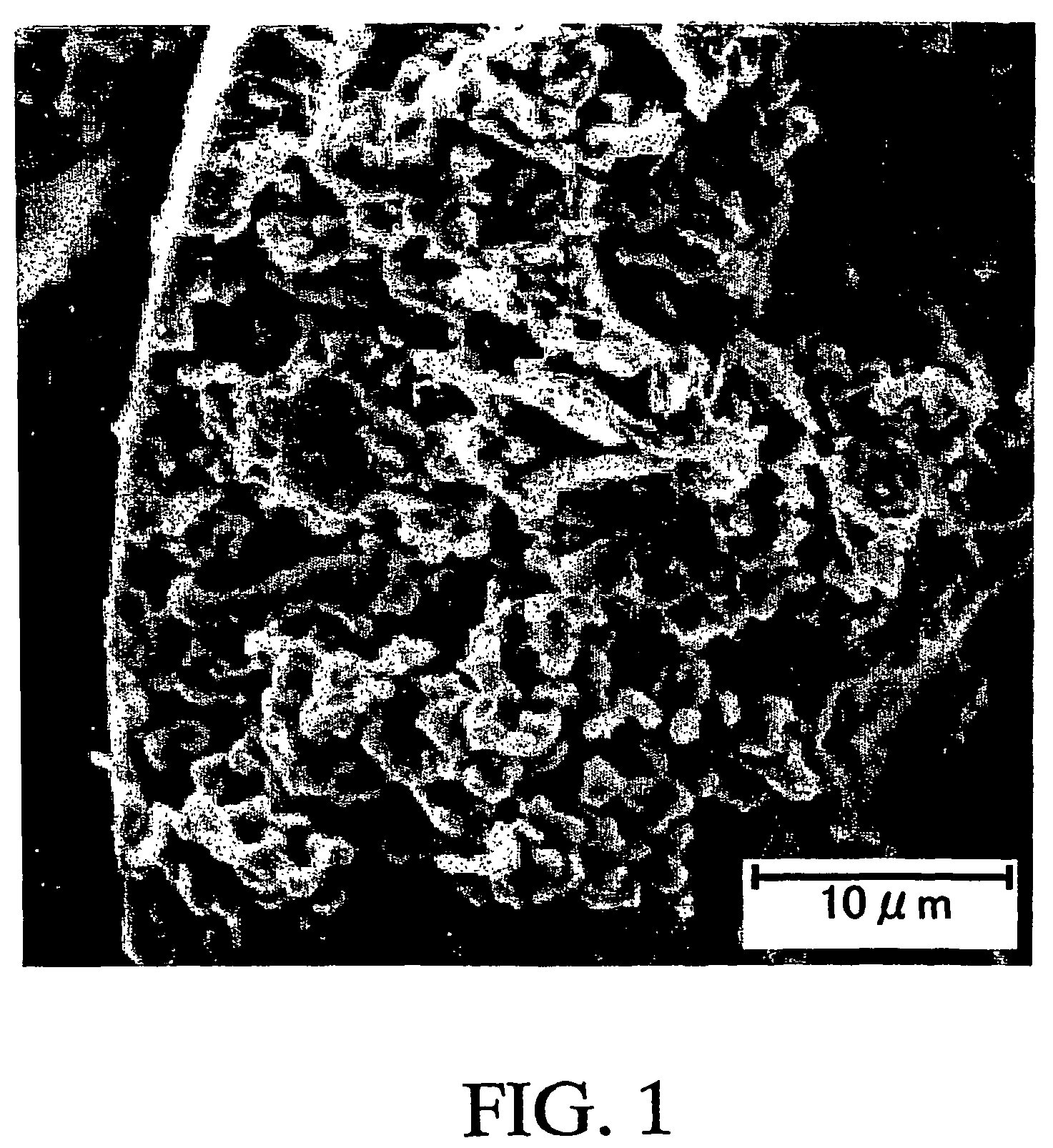

A method for producing detergent granules, includes the step of dry-neutralizing a liquid acid precursor of a non-soap, anionic surfactant with a water-soluble, solid, alkali inorganic substance. In this method, a dry-neutralizing step is carried out in the presence of 0.1 to 1.0 mol of an inorganic acid per mol of the liquid acid precursor of a non-soap, anionic surfactant. The above detergent granules have the features of extremely low tackiness of the granules and containing larger number of micropores. By using the detergent granules, a high-bulk density detergent composition having a small particle size can be obtained at high yields.

Owner:KAO CORP

Method of fomulating a cleaning composition in a concentrated form

InactiveUS20050274399A1Easy to prepareLow toxicitySurface-active detergent compositionsChemical/physical/physico-chemical stationary reactorsOrganic solventDistilled water

A method for formulating a cleaning composition, wherein the cleaning composition comprises a water-soluble organic solvent, an ionic surfactant, a nonionic surfactant, a chelating agent, and distilled water.

Owner:KNOCKOUT GRP

Spray-drying process

Owner:PROCTER & GAMBLE CO

Surfactant concentrate

ActiveUS8026203B2Surface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsCarboxylic acidSURFACTANT BLEND

The present relates to a surfactant concentrate comprising at least 75% of an essentially completely neutralized anionic sulphated surfactant and 5% to 25% carboxylic acid, of which 4% to 96% of the carboxylic acid is in its free acid form, the process for making it and a detergent composition containing it.

Owner:THE PROCTER & GAMBLE COMPANY

Production of anionic surfactant granules by in situ neutralisation

InactiveUS6514930B2Reduce the possibilityReduce riskInorganic/elemental detergent compounding agentsDrying soapPolymer scienceLotion

A process for the production of detergent particles comprises feeding an acid precursor of an anionic surfactant, a neutralizing agent and aluminosilicate detergency builder into a horizontal thin-film evaporator / drier. The evaporator / drier comprises a mixing region, a drying region and a cooling region. Neutralization of the acid precursor is effected, together with granulation, drying and cooling, to form the detergent particles. At least some of the aluminosilicate builder is fed into the thin-film evaporator / drier between the drying region and the cooling region and / or into the cooling region. When all of he aluminosilicate builder is fed into the cooling region, the aluminosilicate is in an amount of more than 20% by weight of the particles exiting the cooling region.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

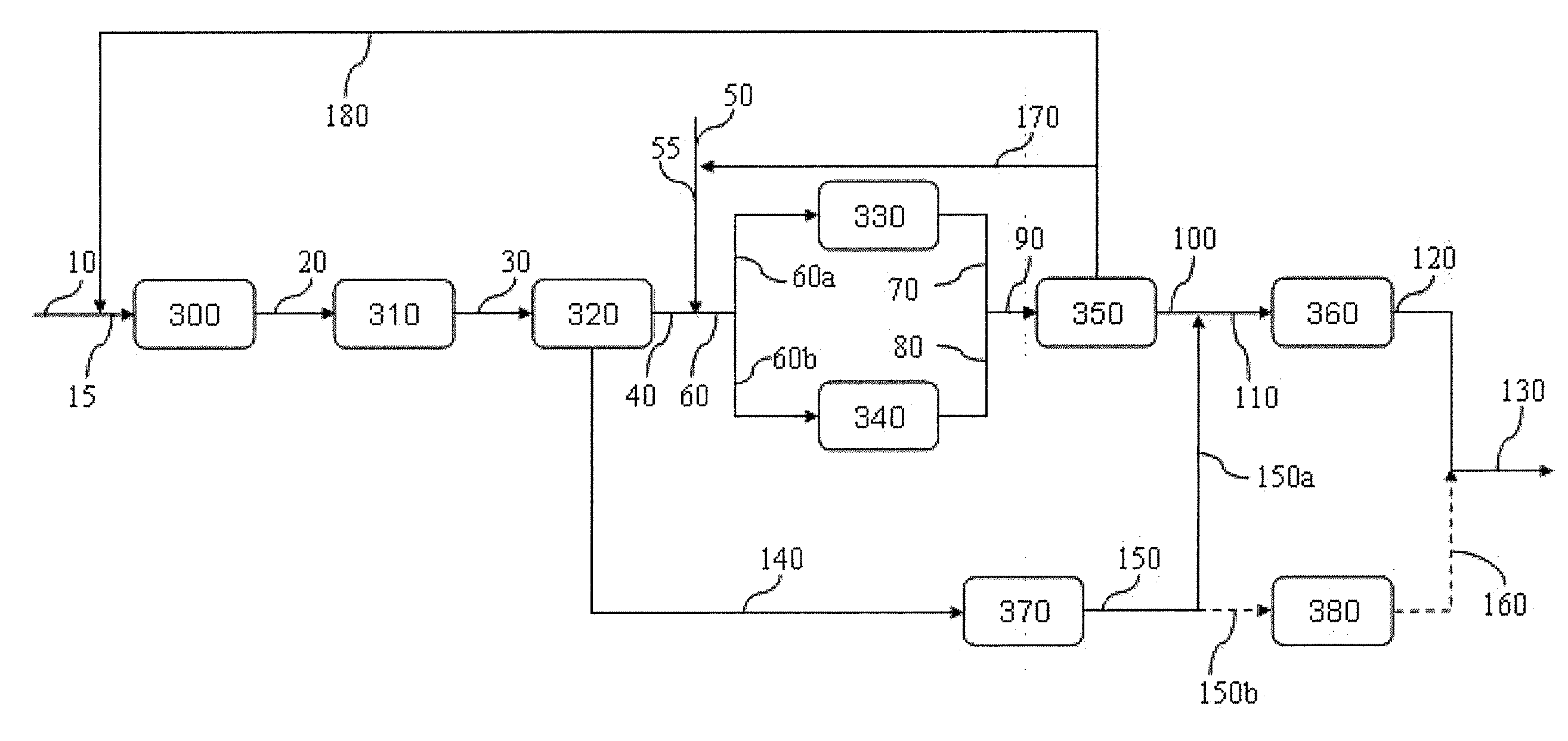

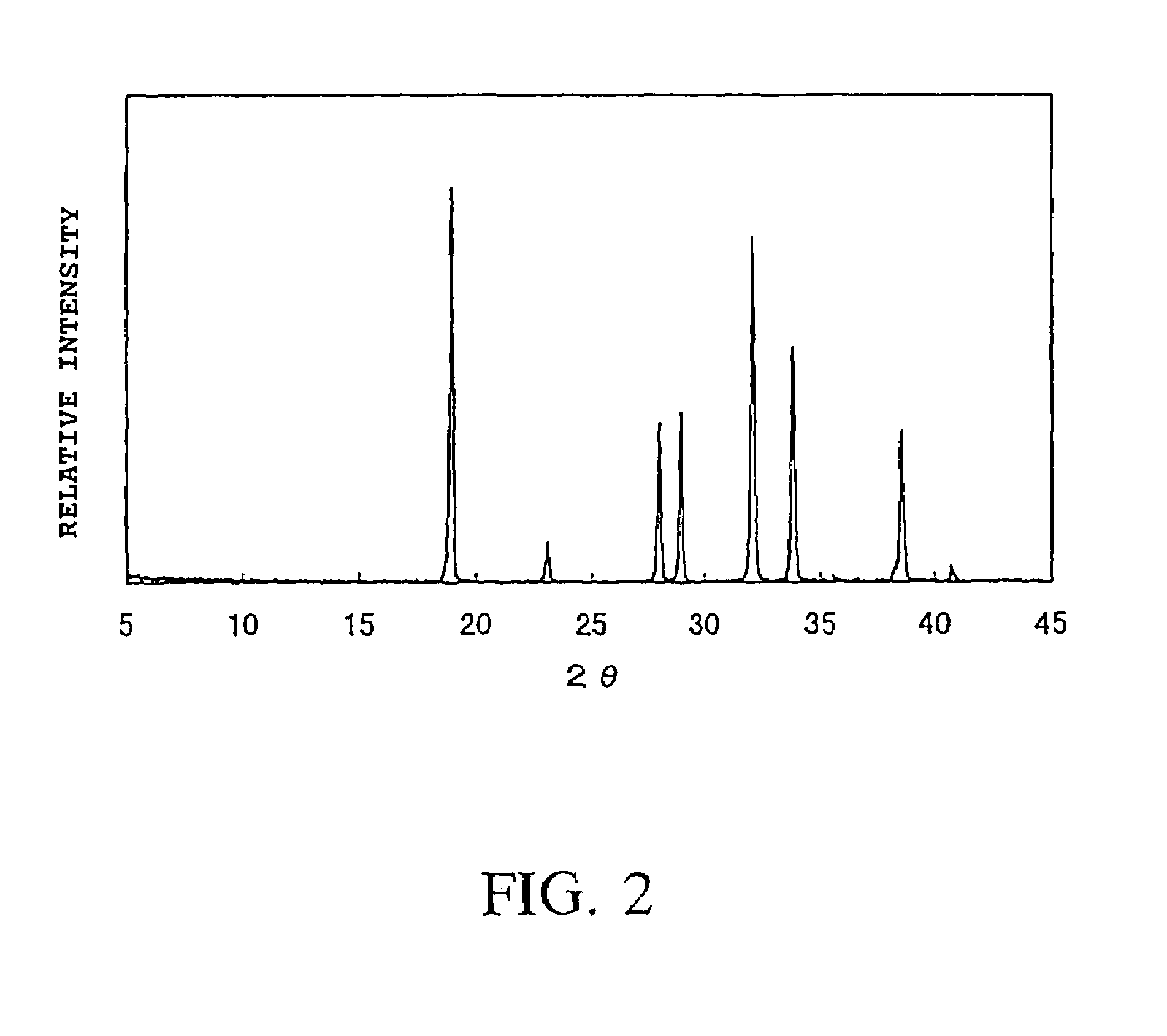

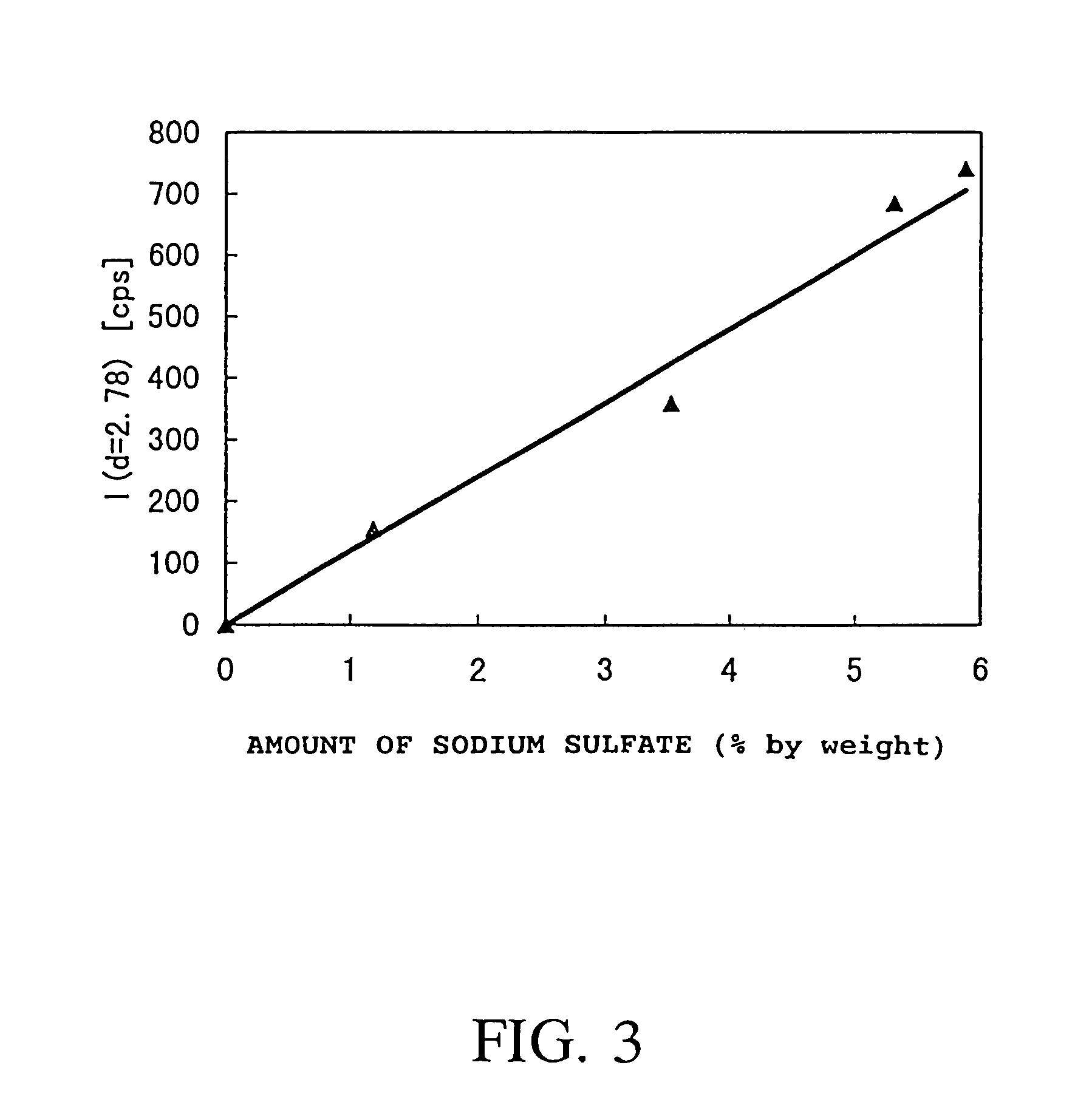

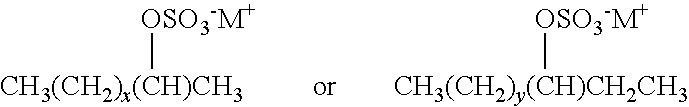

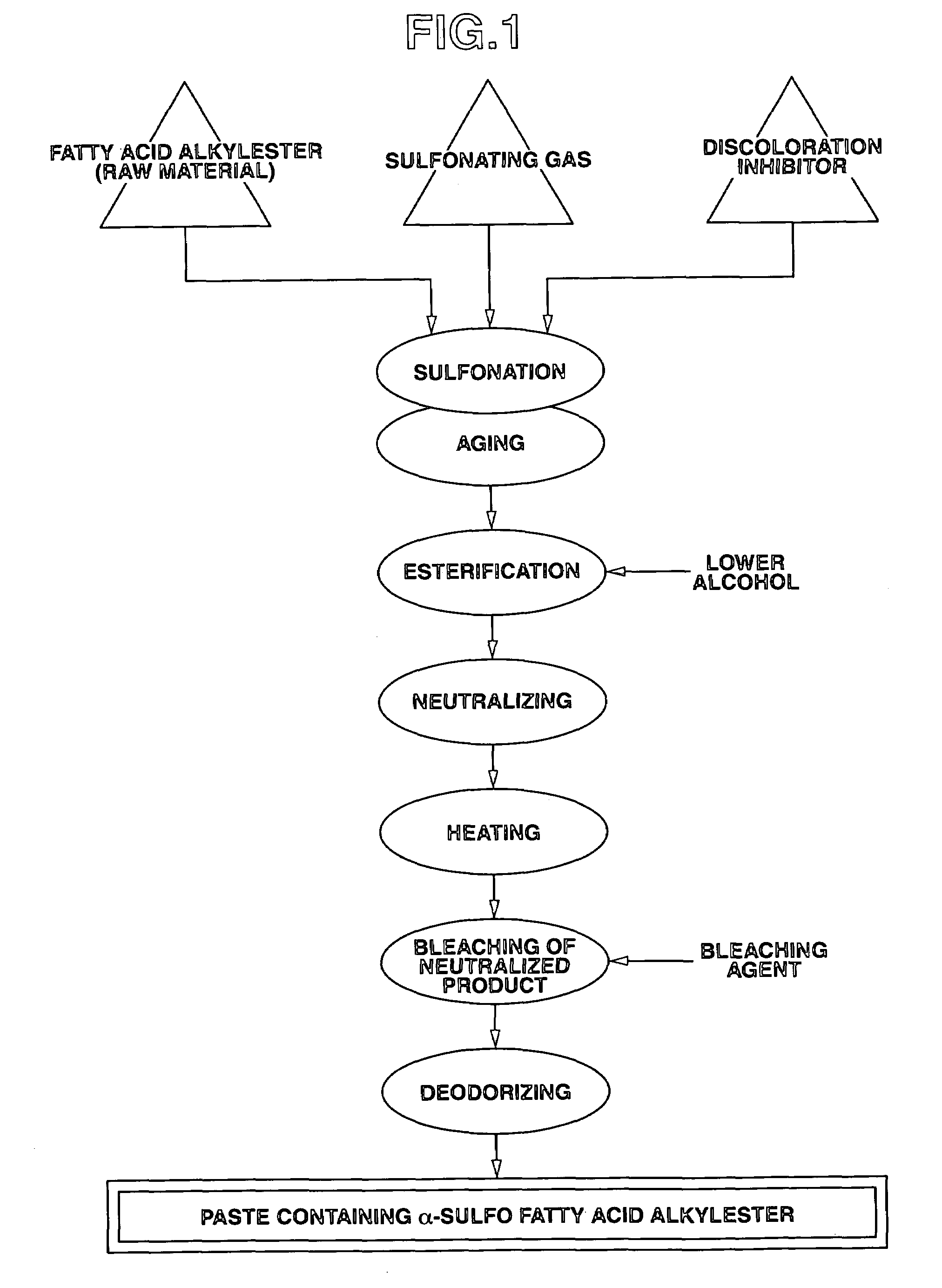

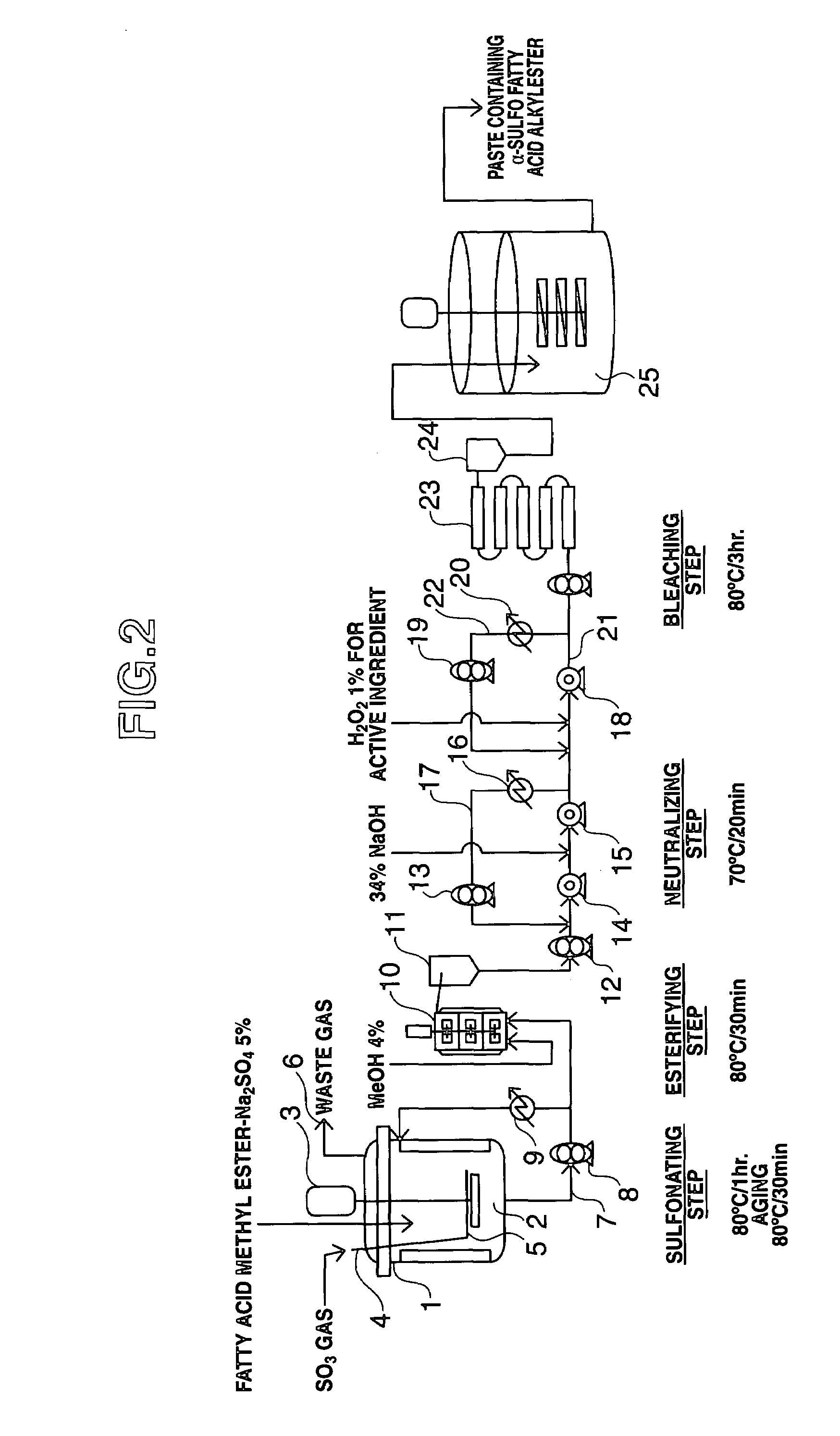

Powders, flakes, or pellets containing salts of a sulfo fatty acid alkyl esters in high concentrations, process for production thereof, granulated detergents, and process for production thereof

ActiveUS7592302B2Maintain good propertiesGood colorNon-ionic surface-active compoundsDrying soapHigh concentrationFatty acid

A process for producing powder, flakes, or pellets containing α-sulfo fatty acid alkylester salt in high concentrations, the process including: (1) a step of preparing a paste containing α-sulfo fatty acid alkylester salt; (2) a step of aging the thus obtained paste; (3) a step of making the aged paste into flakes or pellets containing equal to or less than 10 wt % of water and then optionally crushing the resulting flakes or pellets into a powder having an average particle diameter of 100-1500 μm; and (4) a step of aging The powder, flakes, or pellets.

Owner:LION CORP

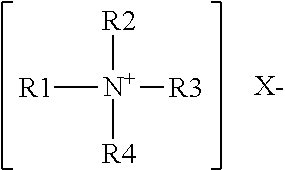

Process for making an ionic liquid comprising ion actives

InactiveUS7737106B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCounterionPhysical chemistry

A process for making ionic liquids containing ion actives, which provide fabric treating benefits, surface treating benefits and / or air treating benefits. The ionic liquid is made from an ion active feedstock and an ionic liquid forming counterion feedstock, which preferably comprises another ion active.

Owner:PROCTER & GAMBLE CO

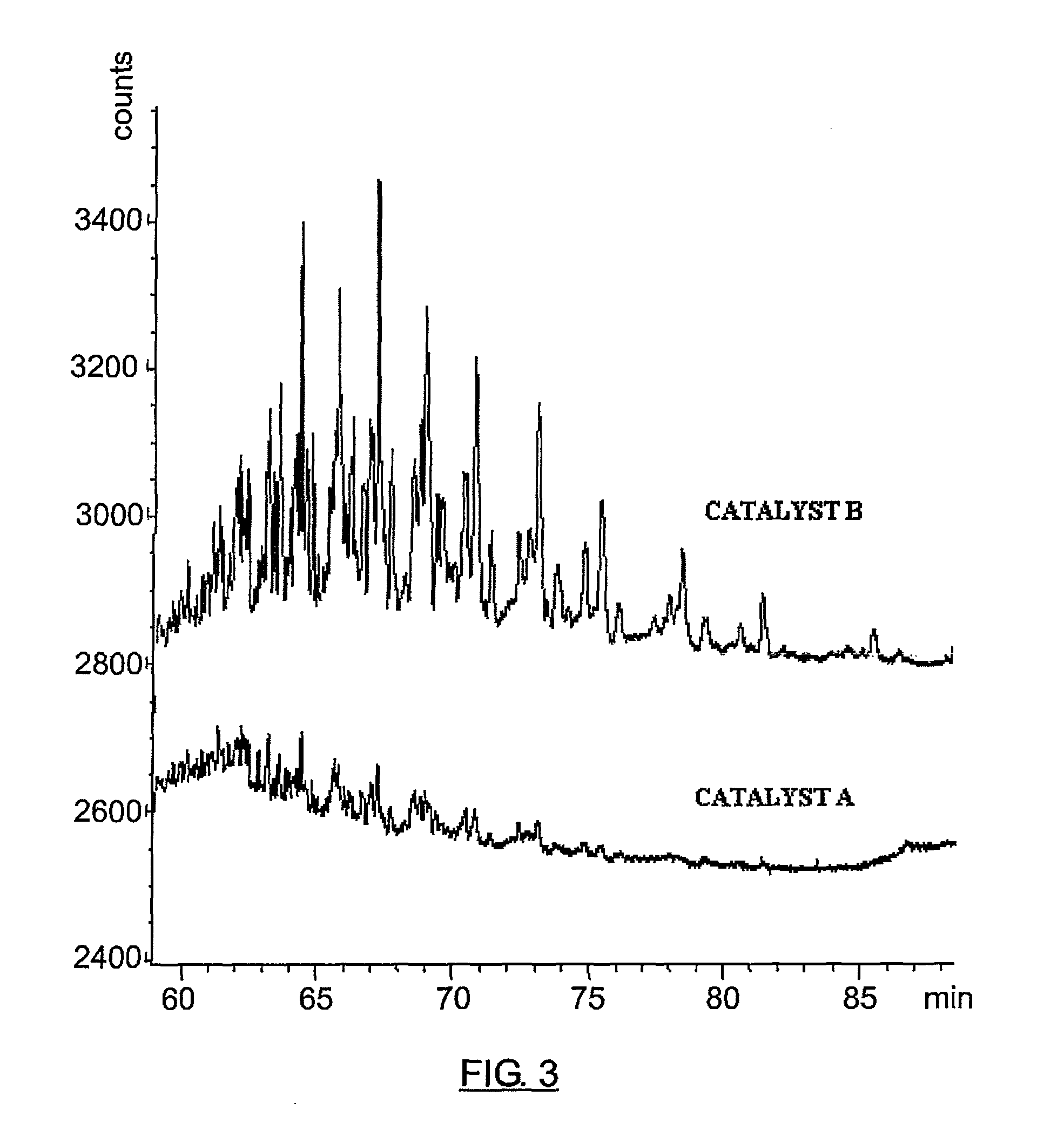

Process for obtaining highly soluble linear alkylbenzene sulfonates

ActiveUS8034973B2Molecular sieve catalystsMolecular sieve catalystLinear alkylbenzene sulfonateLinear alkylbenzene

The present invention relates to a process for obtaining a highly soluble linear alkylbenzene sulfonate with an adjustable 2-phenyl isomer content and an extremely low sulfonation color, in which a catalytic system based on highly stable solid catalysts and with a high selectivity for linear monoalkylated compounds is used.

Owner:CEPSA QUIMICA SA

Production of anionic surfactant granules by in situ neutralisation

InactiveUS6518234B2Reduce the possibilityReduce riskDrying soapCooling soapSURFACTANT BLENDChemistry

A process for the production of detergent particles, comprises feeding an acid precursor of an anionic surfactant and a neutralising agent into a horizontal thin-film evaporator / drier comprising a mixing region, a drying region and a cooling region. The resultant detergent particles are graded to separate an oversize granule fraction in which at least 70 wt % of the particles have a minimum diameter of 1000 mum. This fraction is fed back into the process.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

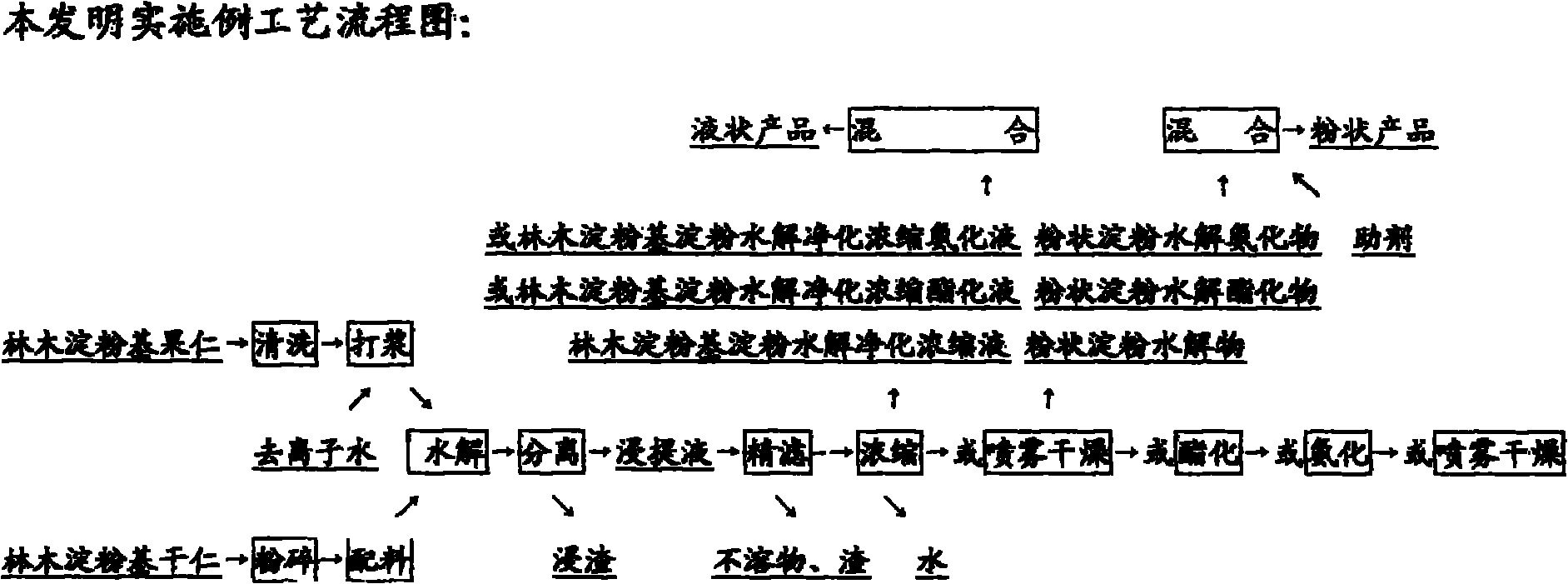

Method for preparing tree-starch based natural biomass detergent

InactiveCN102041204ANon-ionic surface-active compoundsNon-surface-active detergent compositionsLiquid productStain

The invention relates to a method for preparing tree-starch based natural biomass detergent from raw materials of starch based plant, comprising the processing steps of grinding, steaming, hydrolyzing, pulping, pulp refining, fine separating, or esterifying or aminating, refining and compounding. The tree-starch based natural biomass detergent can be liquid product and powdery product. The tree-starch based natural biomass detergent is mainly used for the environmentally-friendly washing and cleaning of the utensils, fruits, vegetables and body, has good oil stain removing effect and is all natural, non-toxic, safe and environmentally friendly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Mechanism of urea/solid acid interaction under storage conditions and storage stable solid compositions comprising urea and acid

ActiveUS20180249706A1Stable solidification matrixStable solidificationBiocideOrganic detergent compounding agentsSolid acidNuclear chemistry

Solid rinsing, cleaning and / or sanitizing compositions for various applications are provided. In particular, solid compositions include a complex of urea and an acid having desireable storage stability previously unavailable in solid urea / acid compositions. Stable solid compositions are disclosed and methods of making the same to overcome conventional limitations associated with with forming kinetically and thermodynamically stable solids that utilize urea / acid compositions.

Owner:ECOLAB USA INC

Popular searches

Inorganic non-surface-active detergent compositions Resin soap manufacturing Detergent powders/flakes/sheets Detergent preparation with liquid ingredients Aqueous liquid non-soap compositions Essential-oils/perfumes Dry-cleaning apparatus for textiles Soap detergent compositions Biochemical fibre treatment Softening compositions

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com