Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about "Corrosion diminishing boiler components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

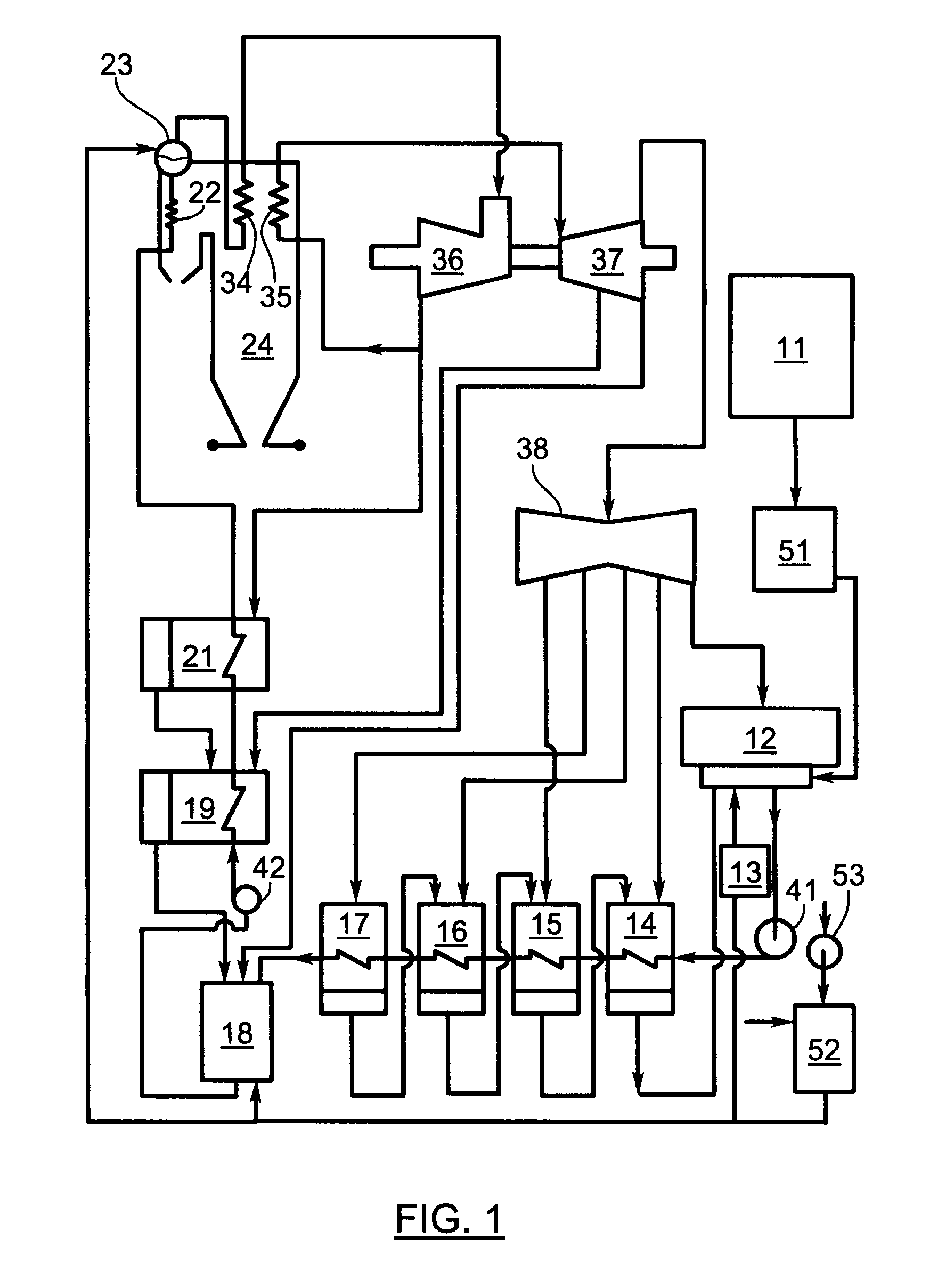

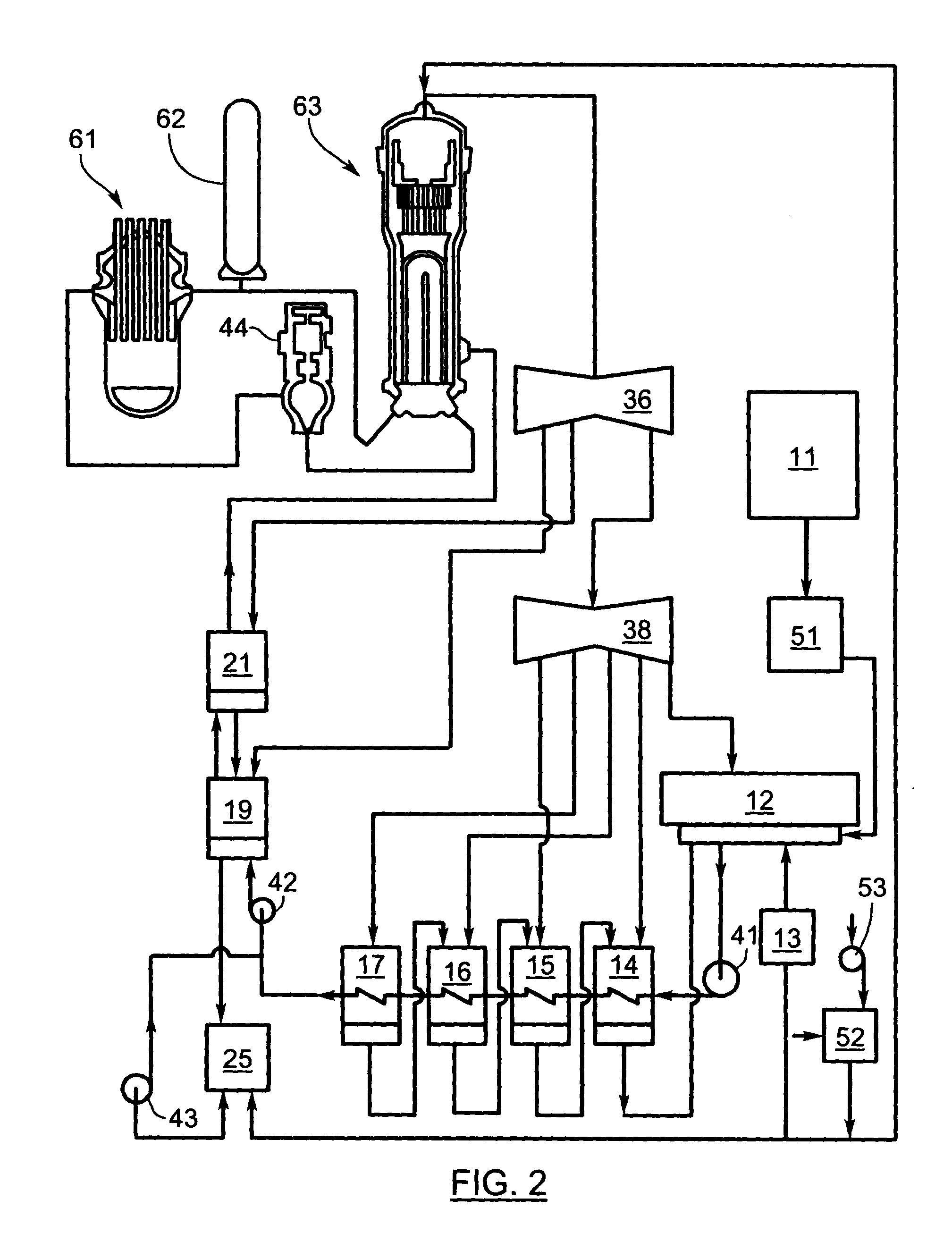

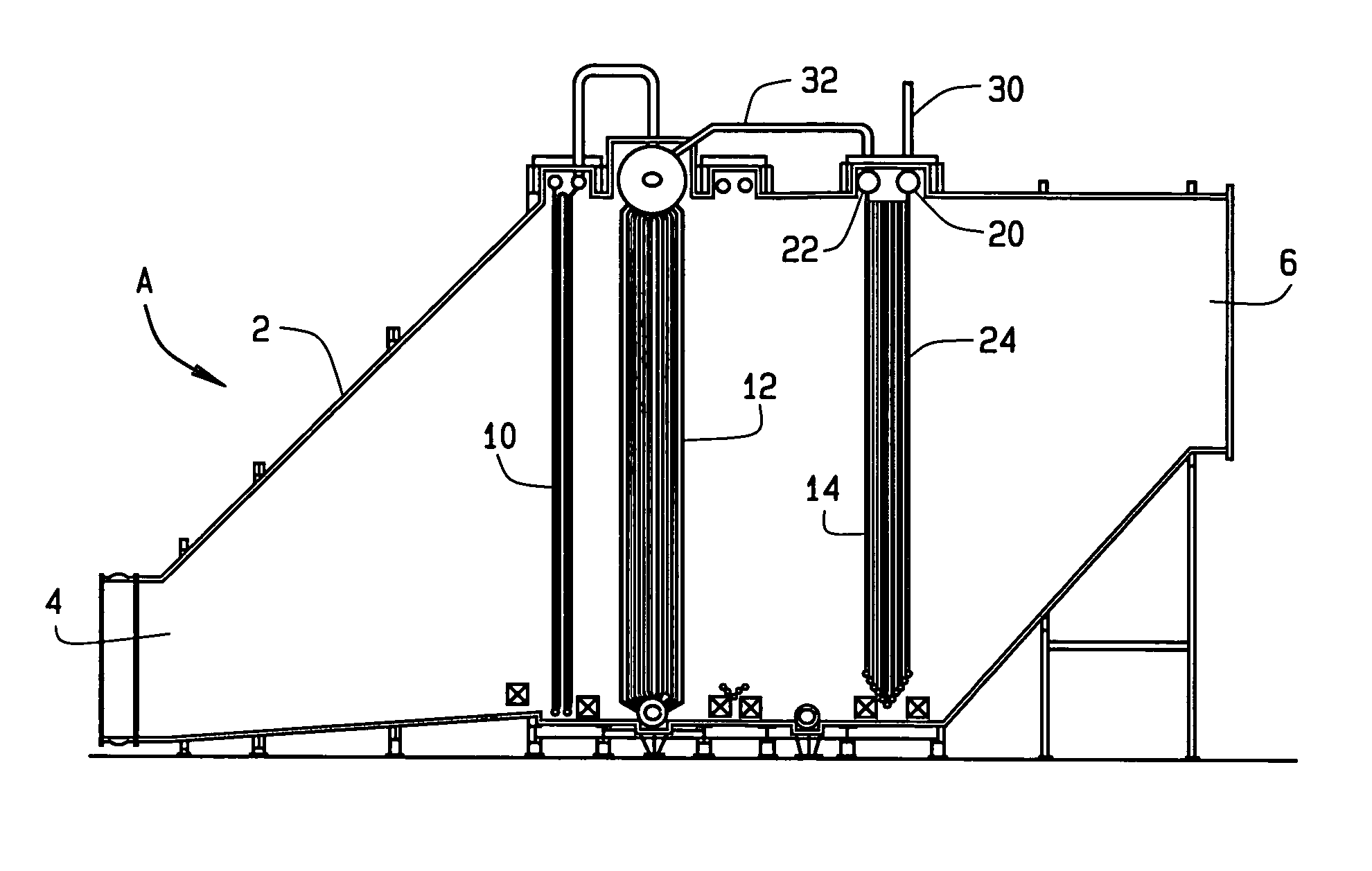

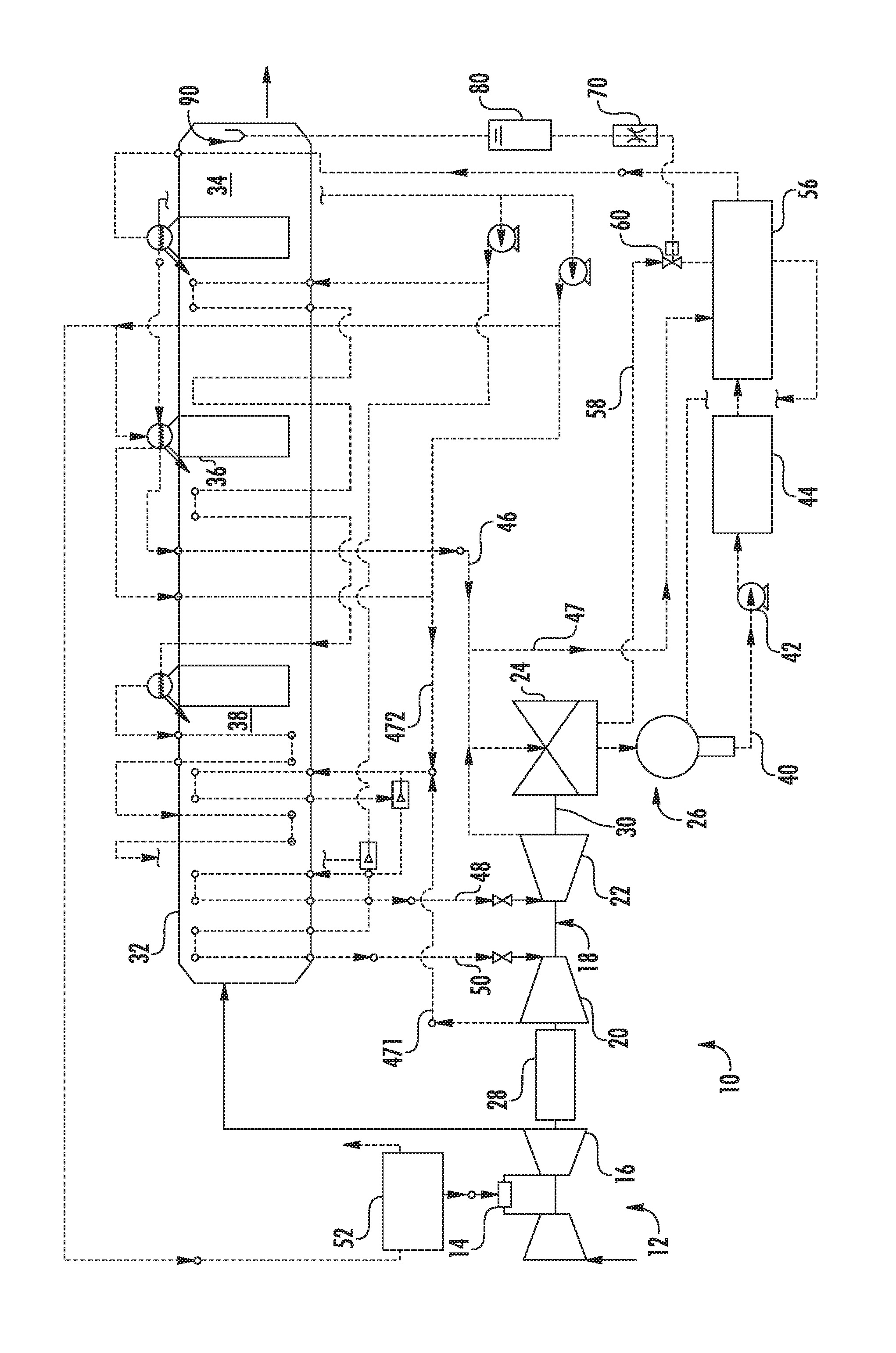

Process and apparatus for heating feedwater in a heat recovery steam generator

InactiveUS20120312019A1Steam generation heating methodsSteam accumulatorsCorrosive acidExhaust fumes

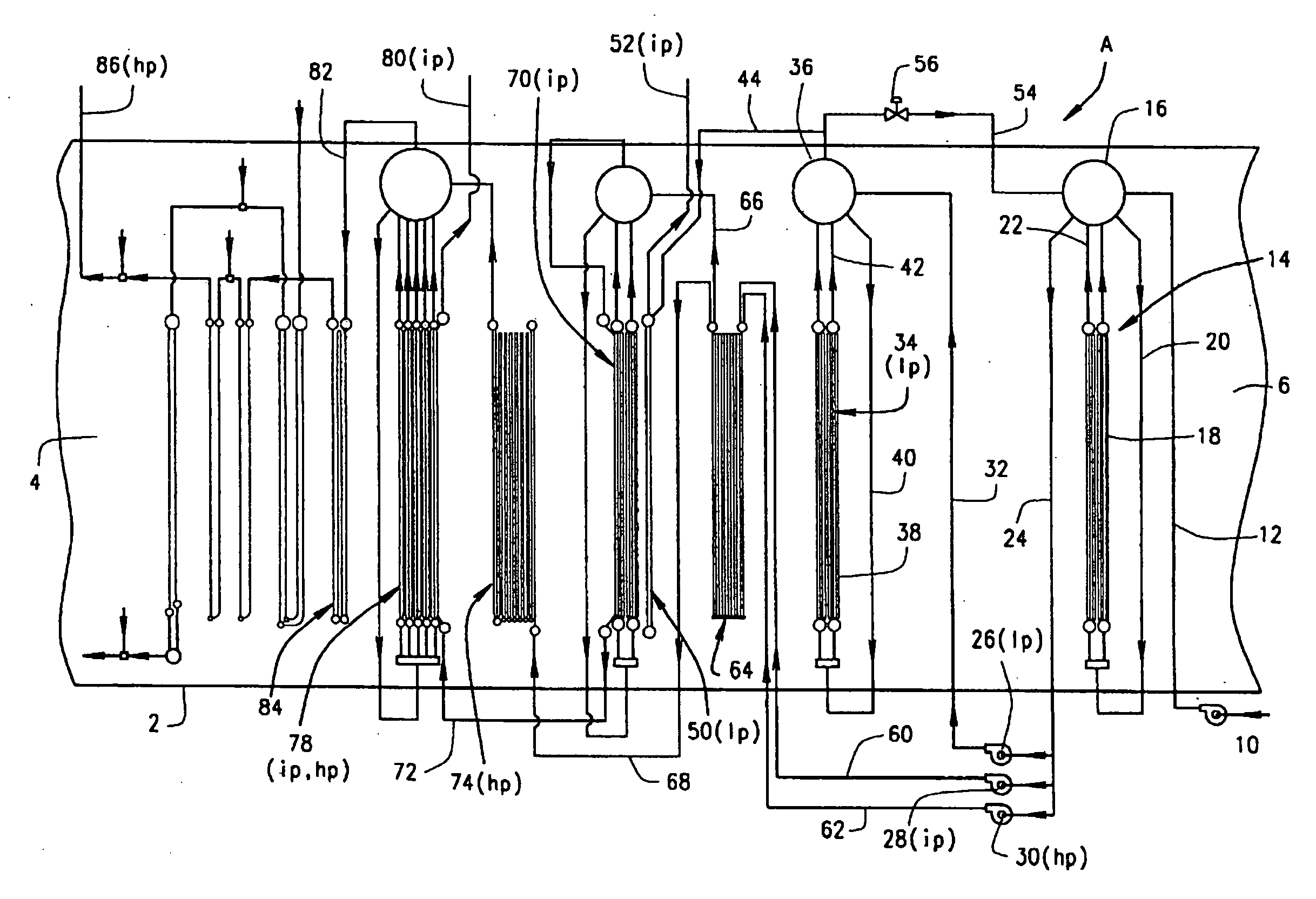

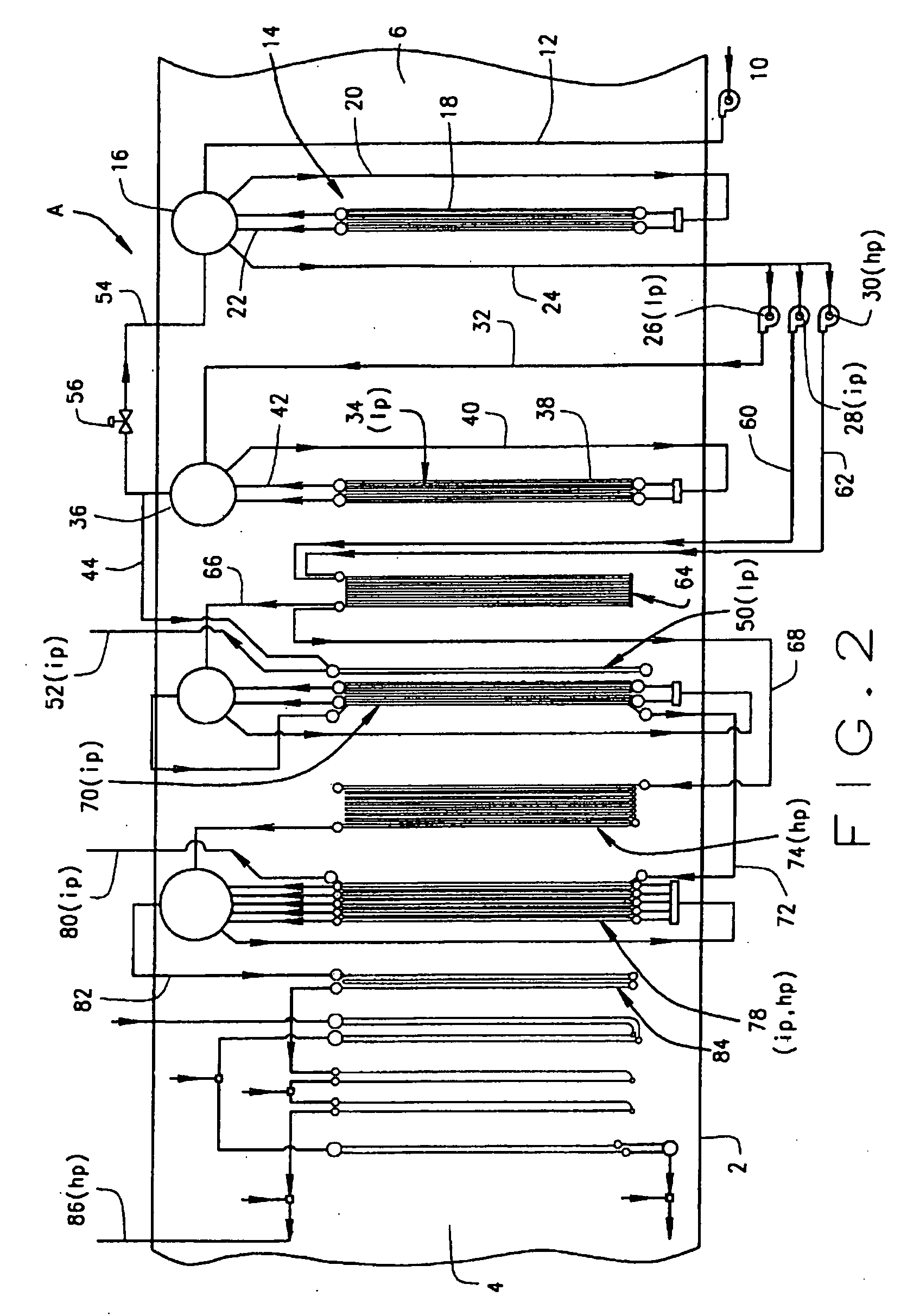

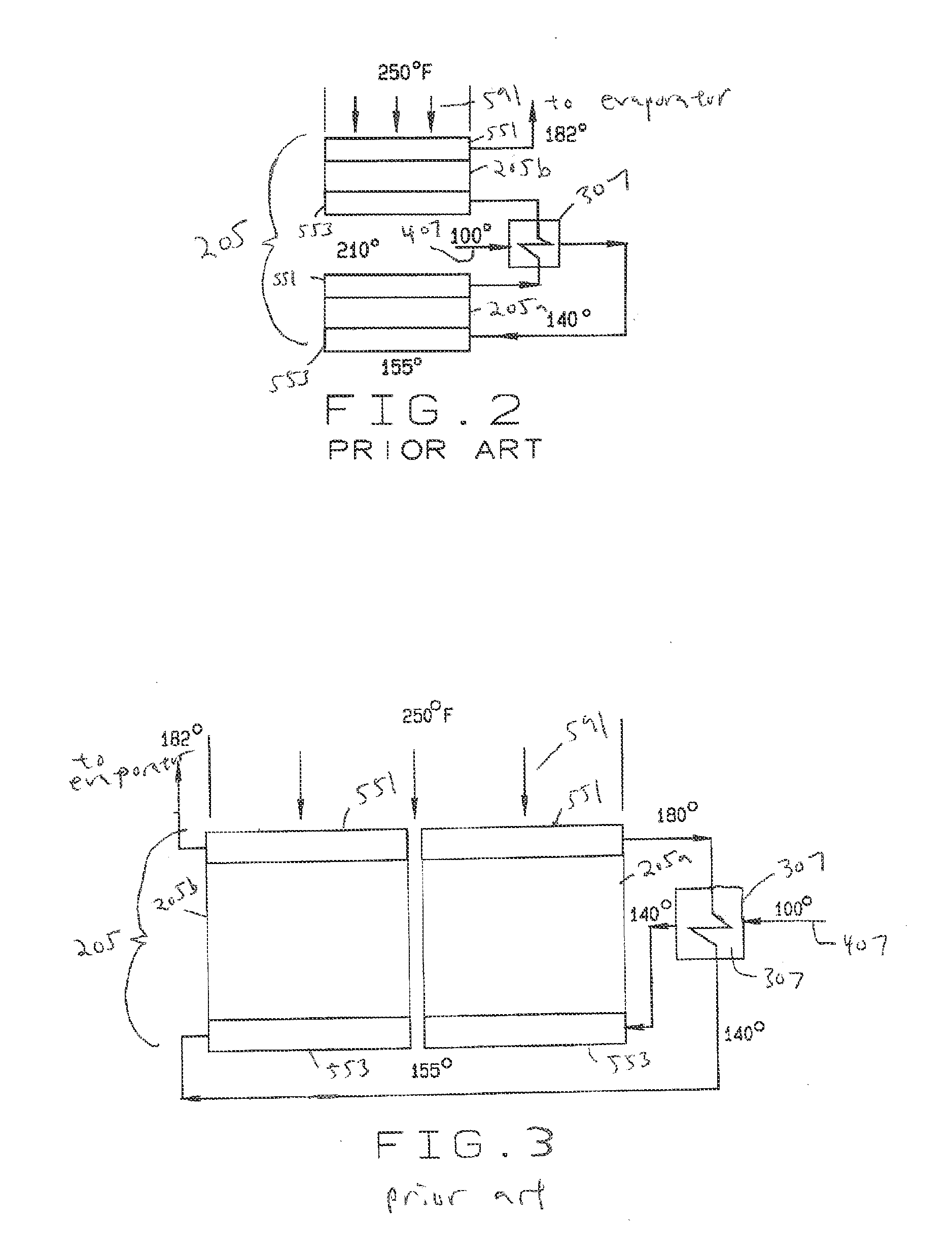

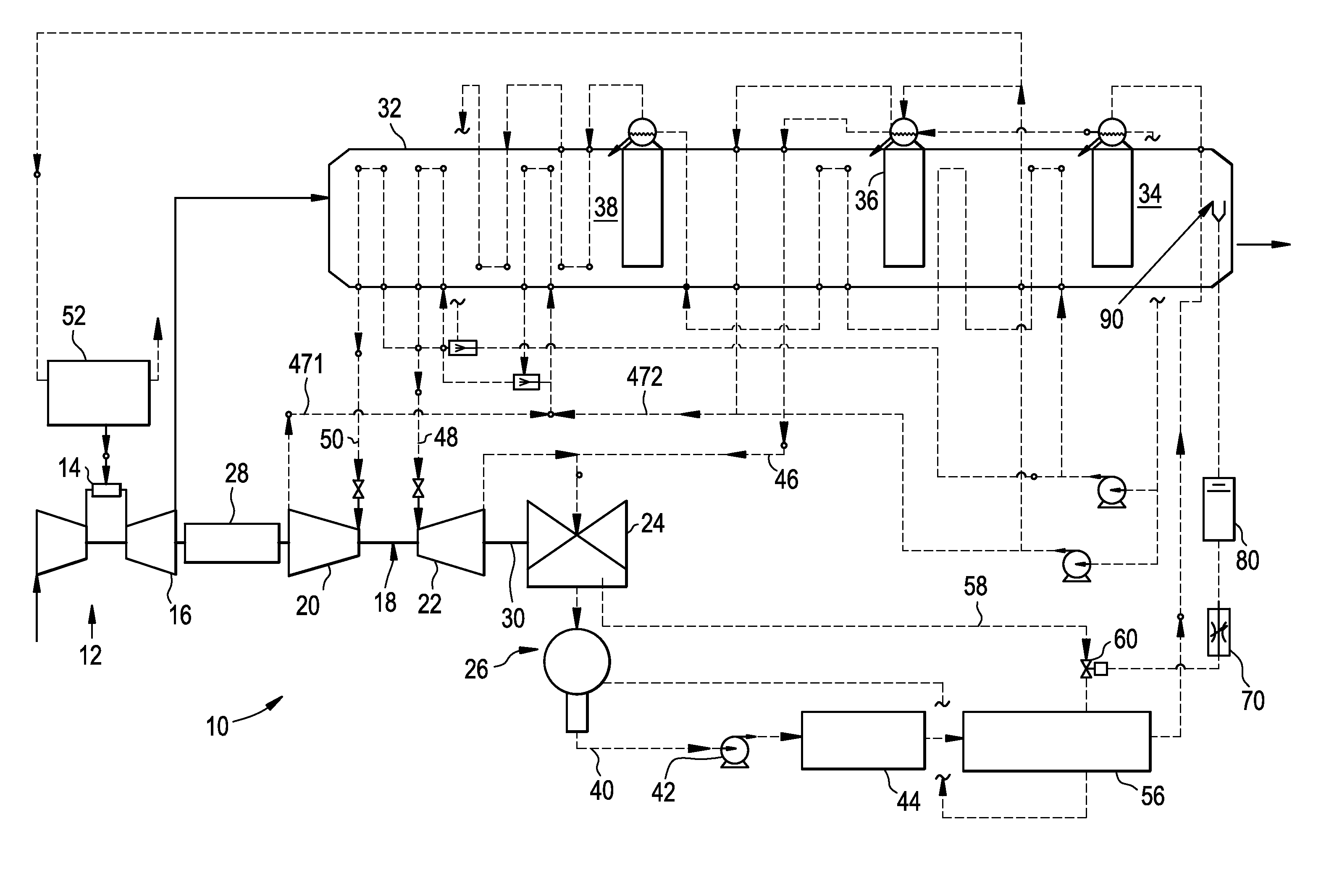

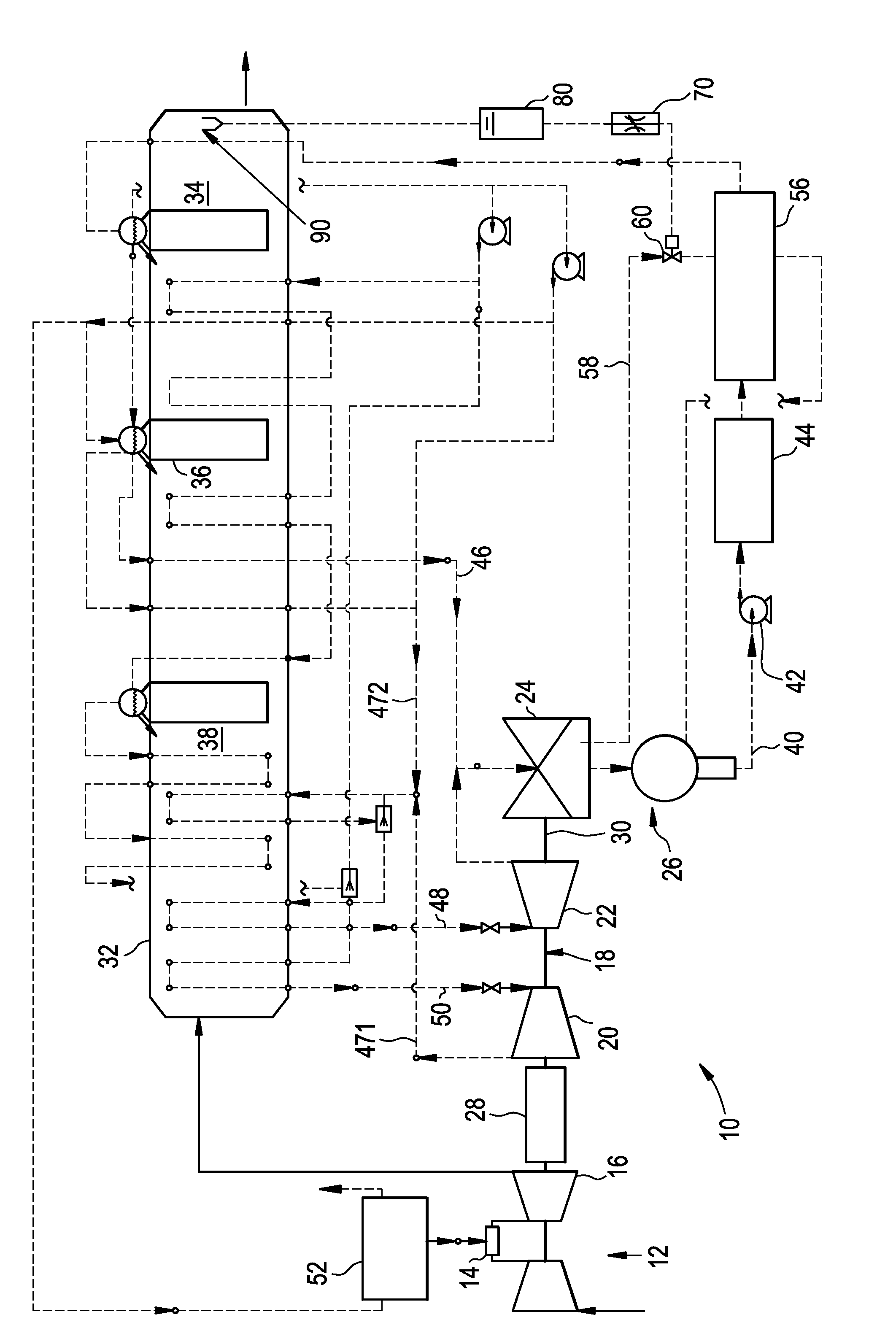

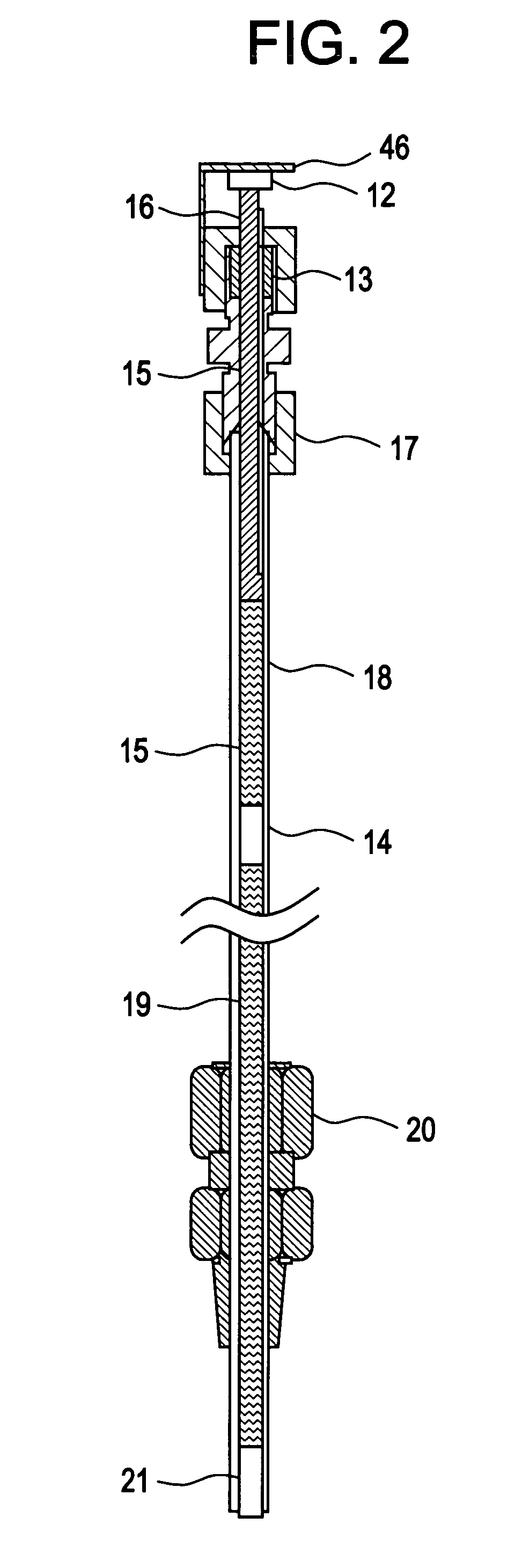

A feedwater heater (14) in a heat recovery steam generator (A,B) lies within a flow of hot exhaust gas. The feedwater heater (14) converts subcooled feedwater into saturated feedwater water, the temperature of which is only lightly above the acid dew point temperature of the exhaust gas so that corrosive acids do not condense on coils (18) of the feedwater heater (14). Yet the temperature of the saturated feedwater lies significantly below the temperature of the exhaust gas at the coils (18), so that the coils (18) operate efficiently and require minimal surface area. Pumps (26, 28, 30) elevate the pressure of the saturated feedwater and direct it into an economizer (64, 90) where, owing to the increase in pressure, the water is again subcooled. The economizer (64, 90) elevates the temperature still further and delivers the higher pressure feedwater to evaporators (34, 70, 78) that convert it into saturated steam that flows on to the superheaters (50, 78, 84). Higher pressure pegging stem admitted to the feedwater heater (14) controls the pressure—and temperature—of saturated steam and water in the feedwater heater (14).

Owner:NOOTER ERIKSEN INC

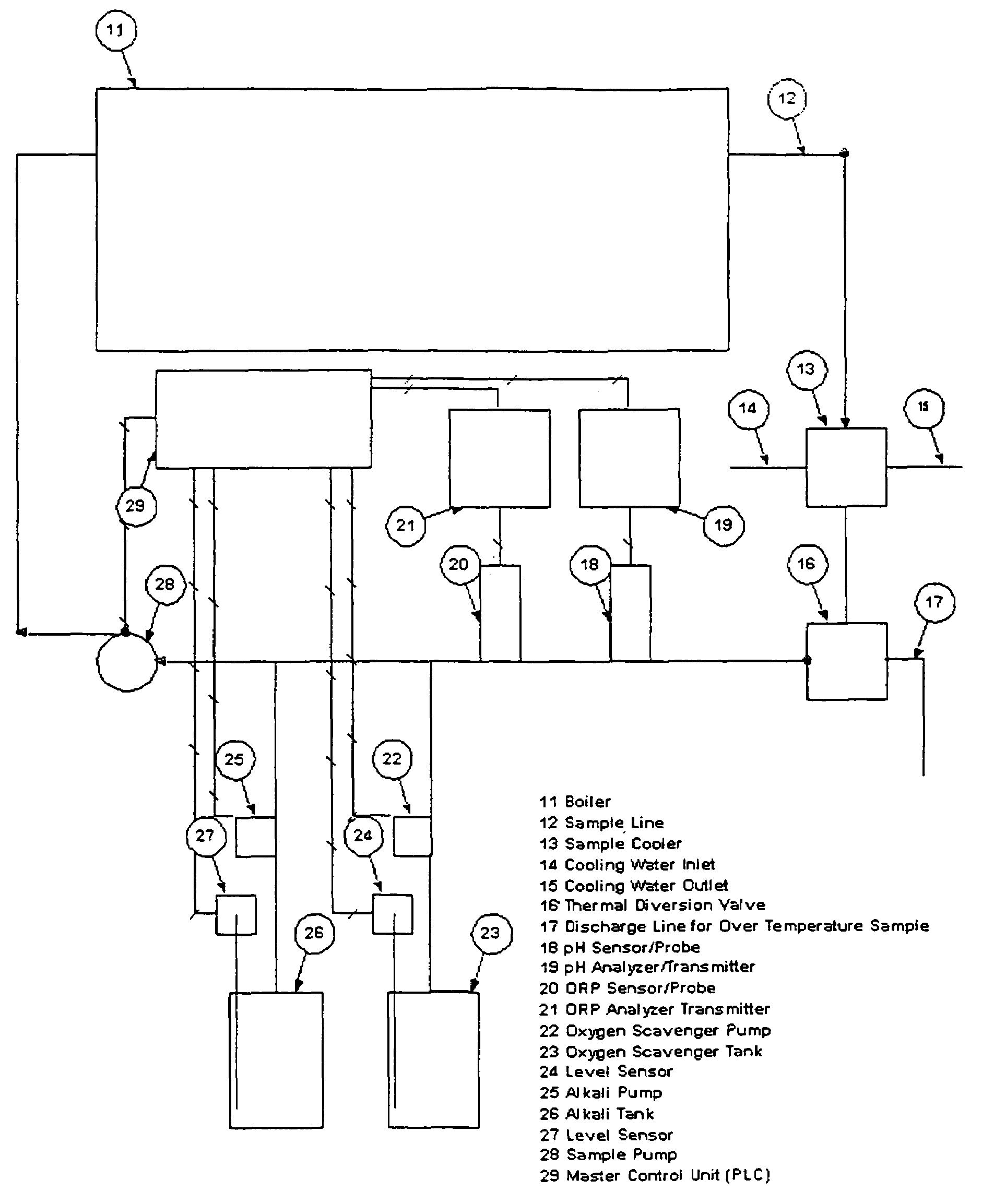

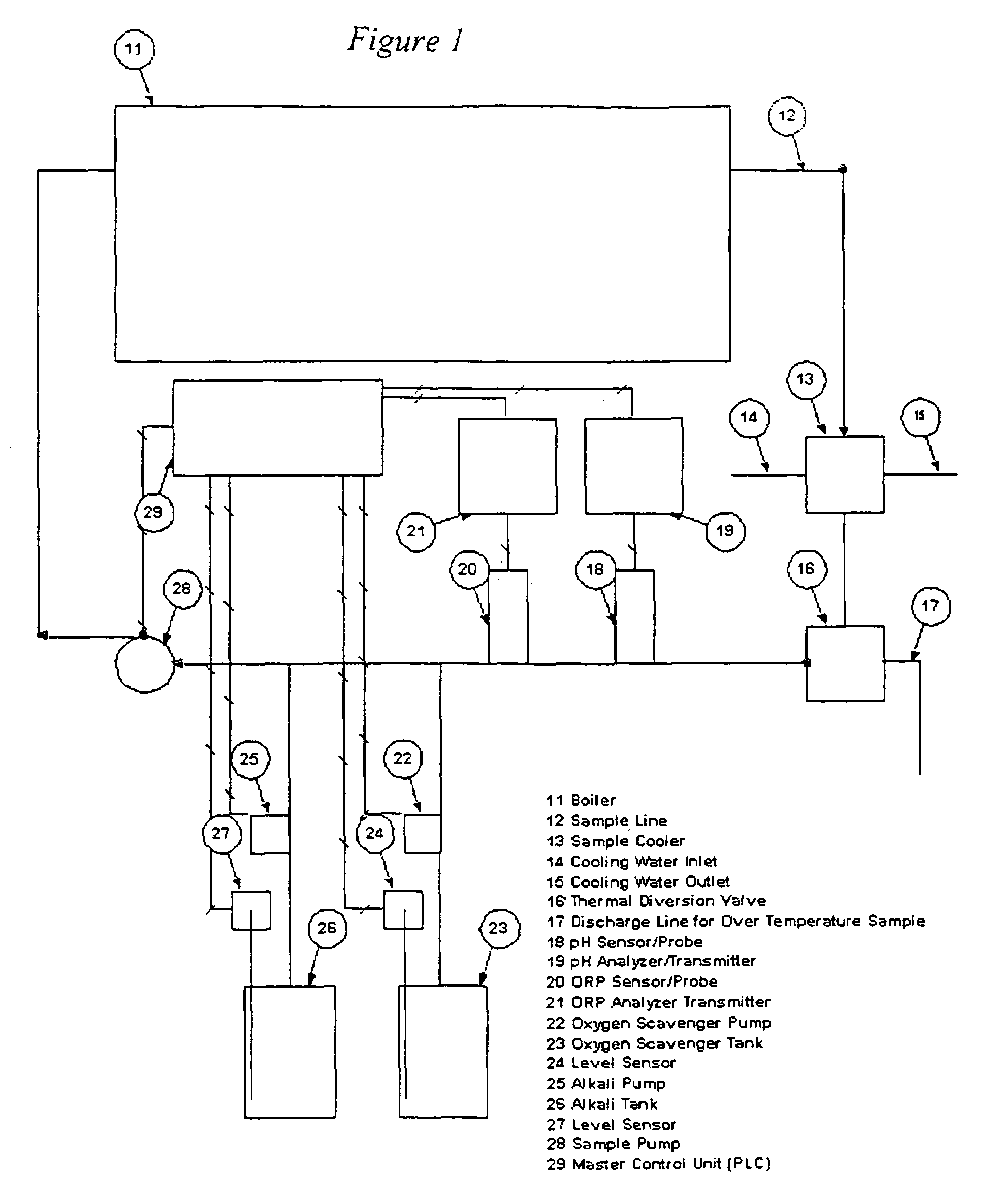

Method of inhibiting corrosion in hot water systems

ActiveUS20060182651A1Reduce in quantityReduce the temperatureWater treatment parameter controlSpecific water treatment objectivesPhysical chemistryThermal water

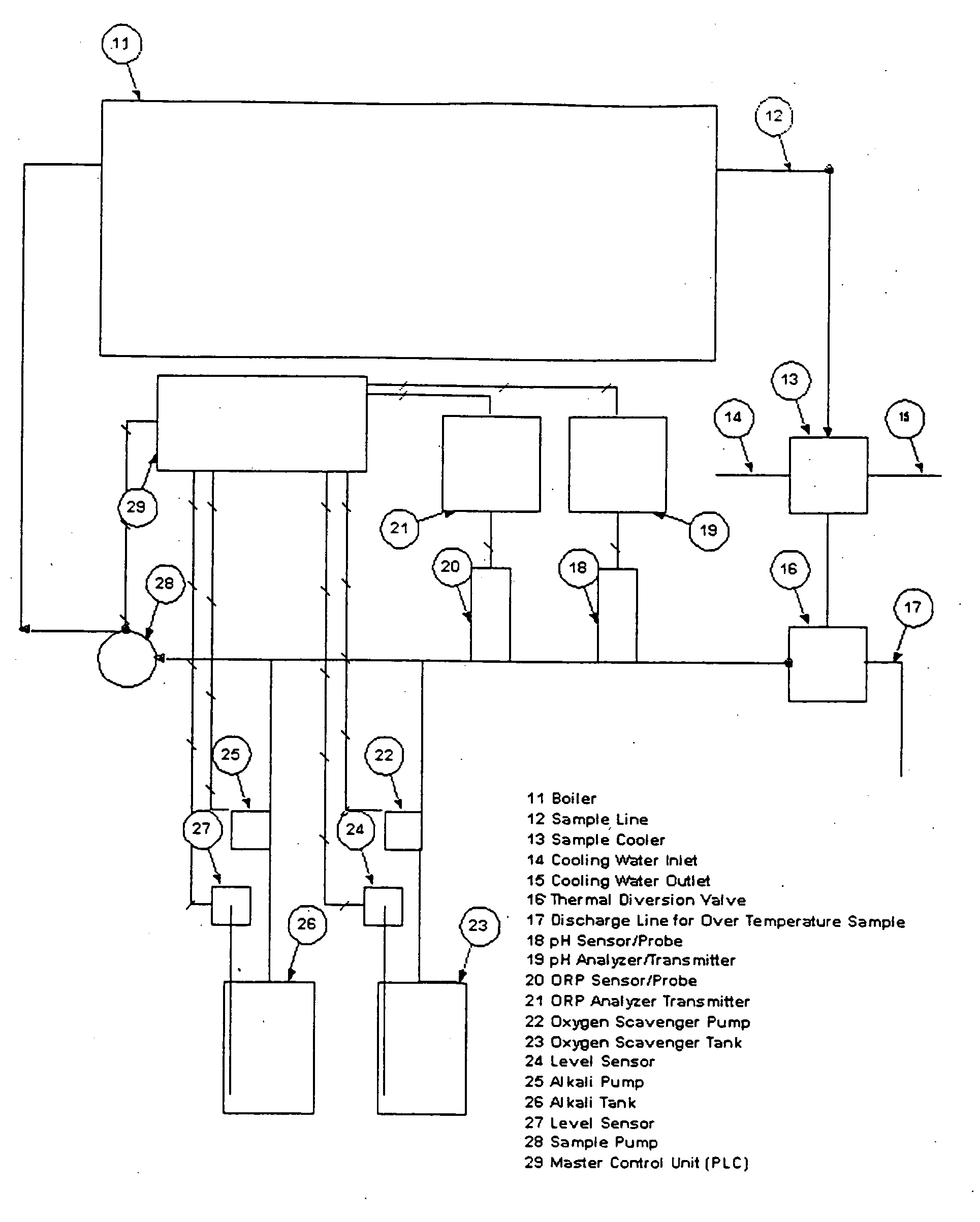

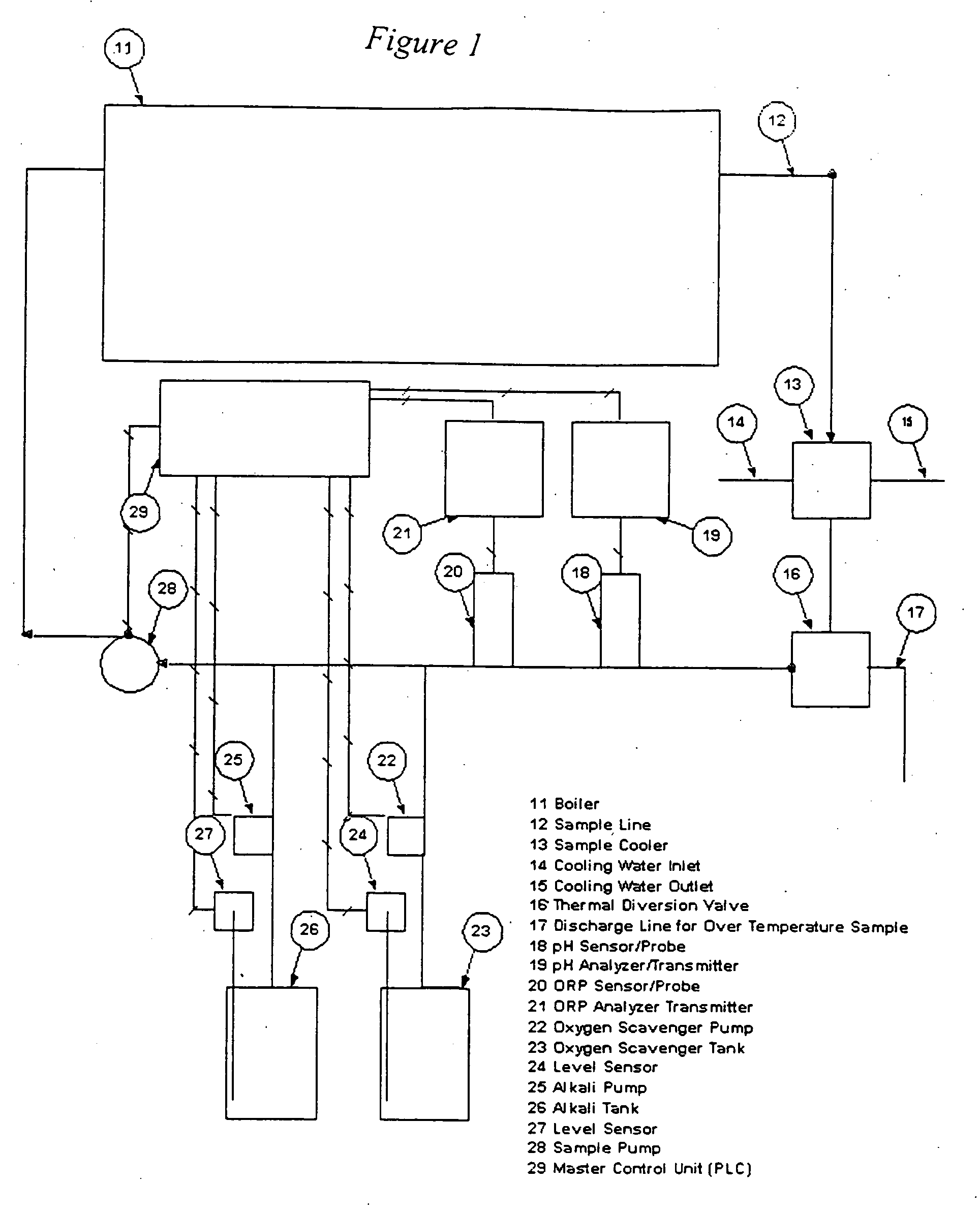

This invention concerns methods and apparatus for measuring oxidation reduction potentials of water in a hot water system at system temperature and pressure and methods of using the measured oxidation-reduction potential to monitor and control the addition of oxygen scavengers or oxygen to the system in order to maintain effective corrosion inhibiting concentrations of the oxygen scavengers or dissolved oxygen in the system.

Owner:ECOLAB USA INC

Automated process for inhibiting corrosion in an inactive boiler containing an aqueous system

ActiveUS20060157420A1Water treatment parameter controlSpecific water treatment objectivesPolymer chemistryMetal

Owner:SOLENIS TECH CAYMAN

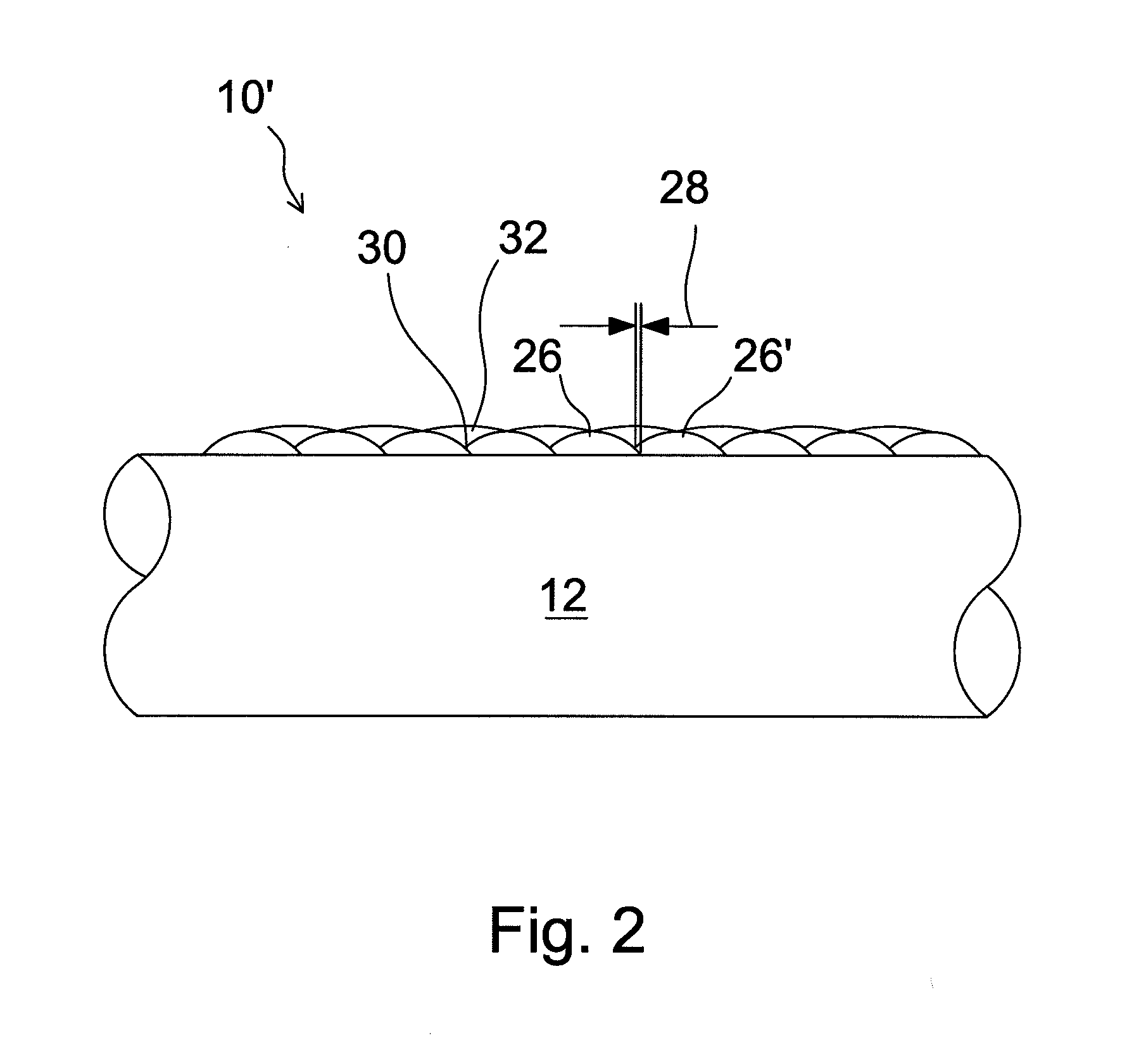

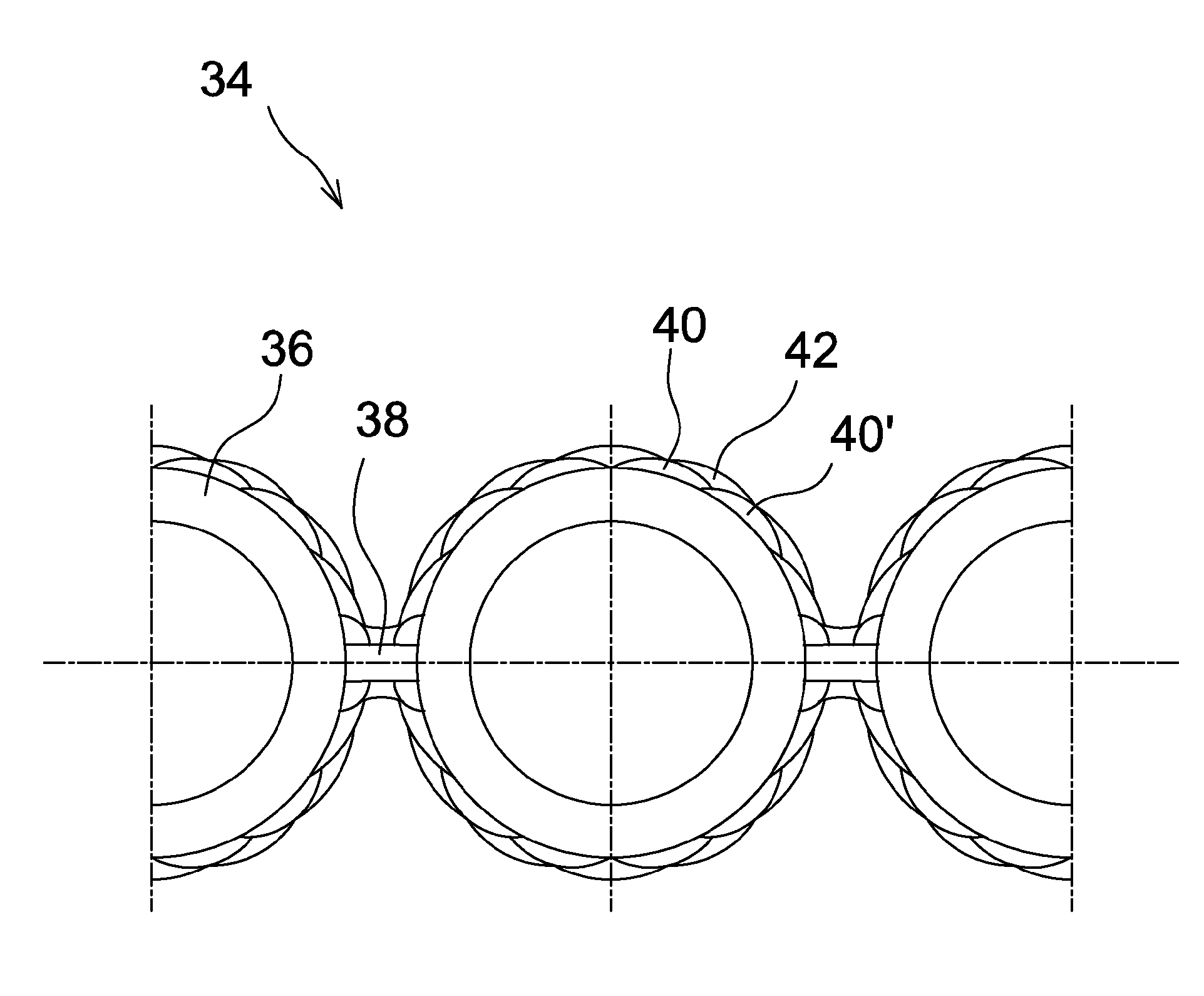

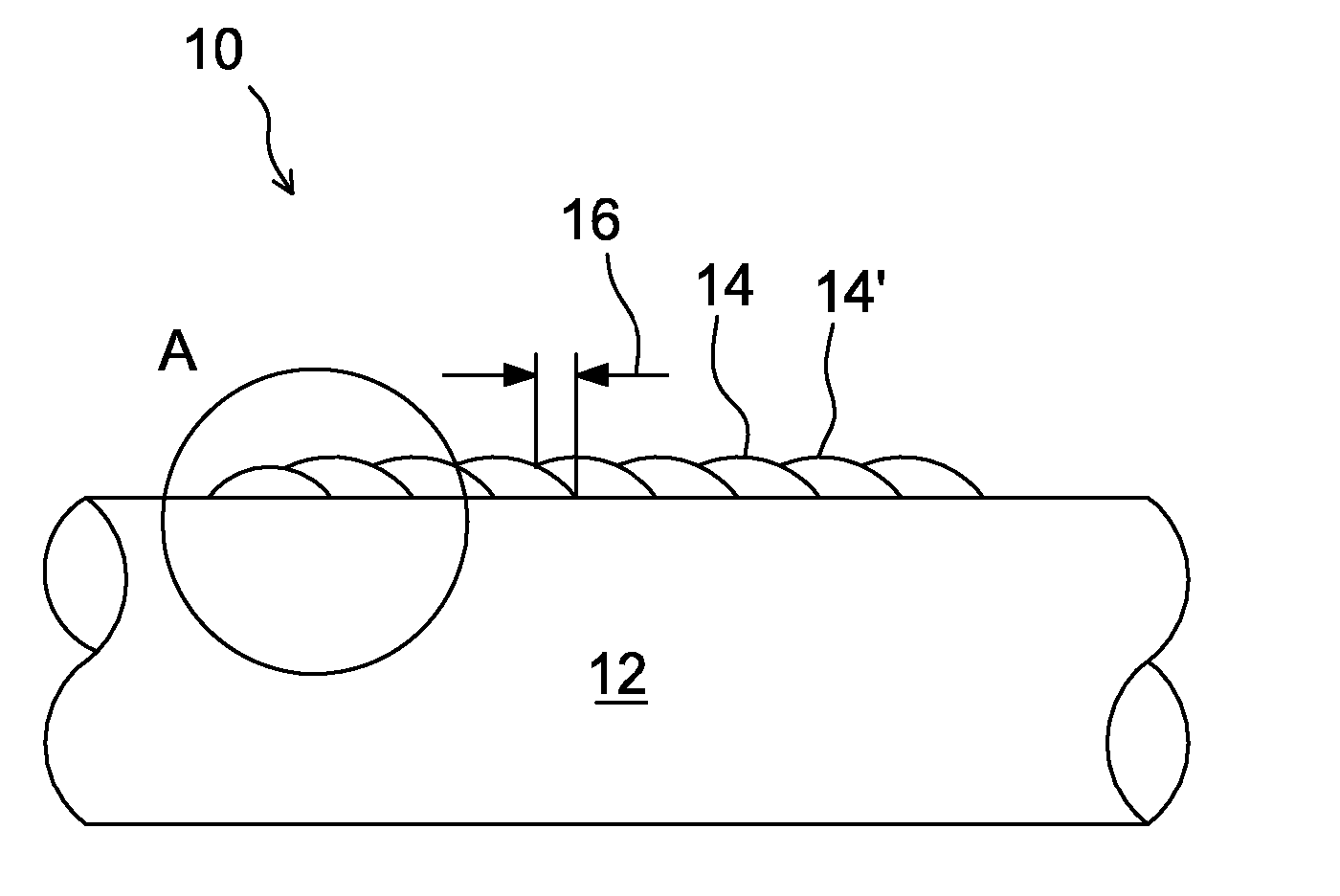

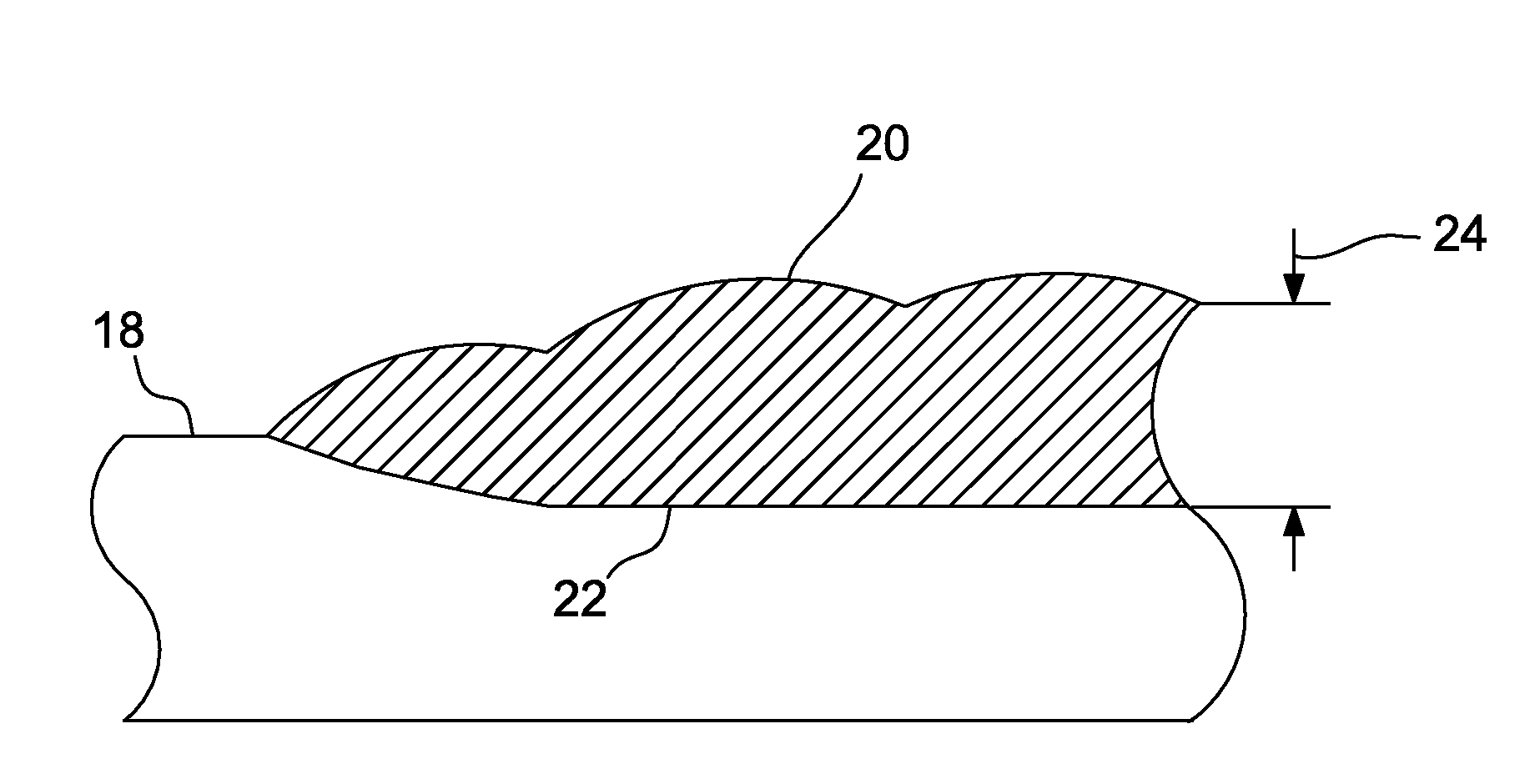

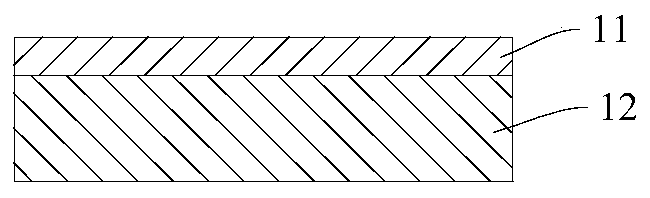

Weld Overlay Structure and a Method of Providing a Weld Overlay Structure

InactiveUS20120214017A1Minimizes problemMinimize dilutionAdditive manufacturing apparatusArc welding apparatusMembrane surfaceHeat transfer tube

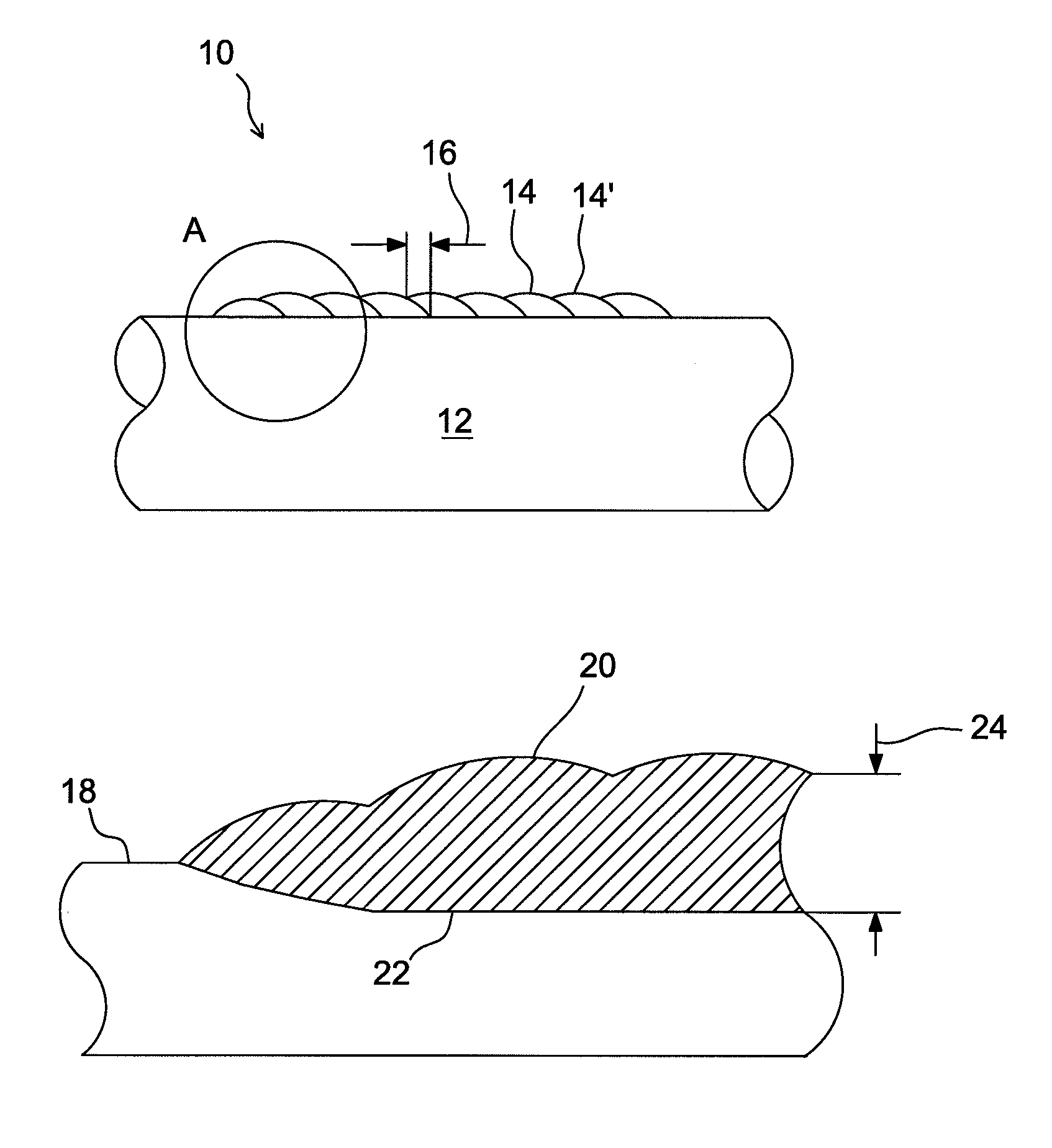

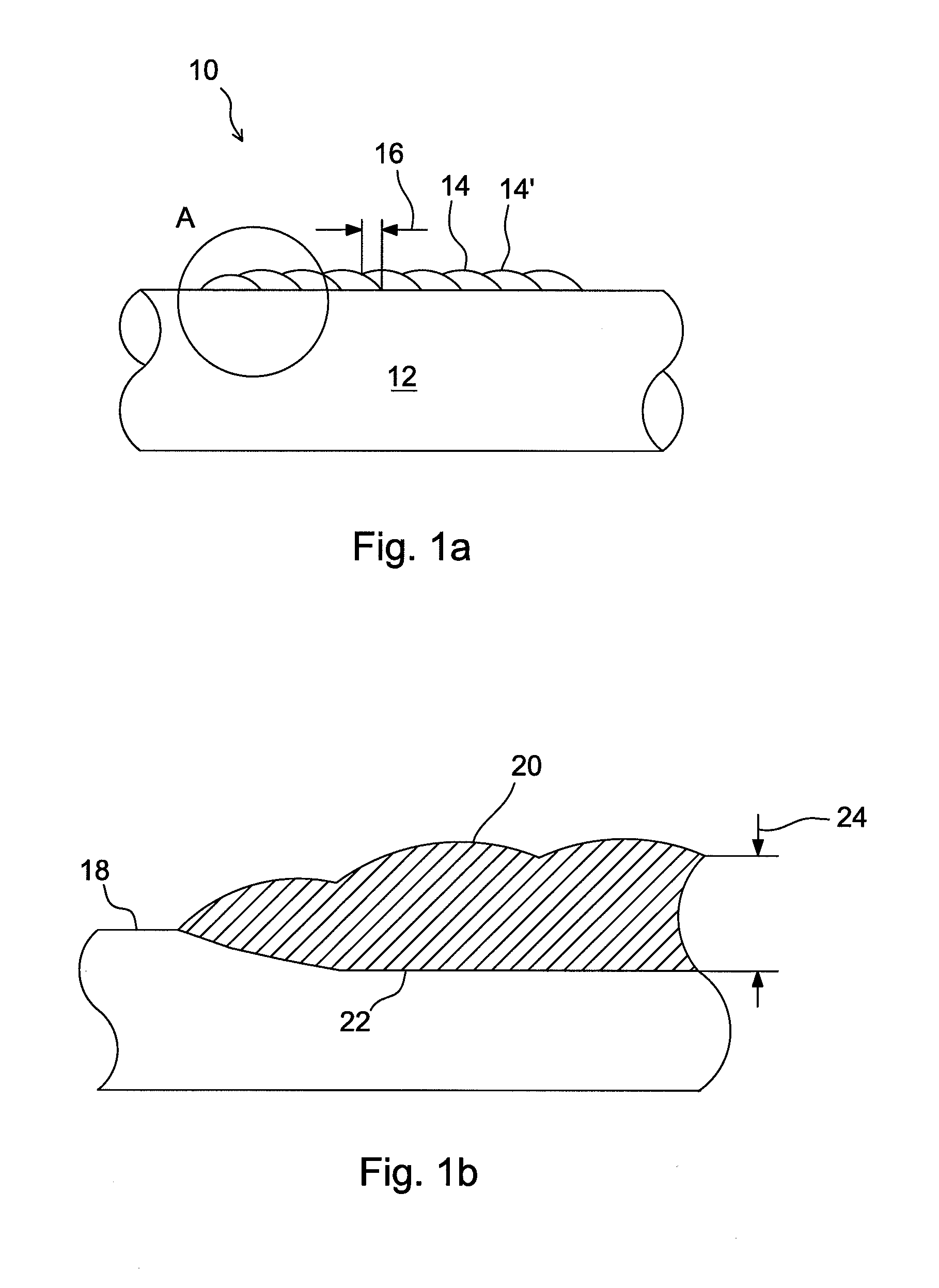

A method of providing a weld overlay structure on a heat transfer tube or a membrane surface. A first continuous bead portion of an overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material. A second continuous bead portion of the overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material, in which the second bead portion partially overlaps with the first bead portion, forming a groove between the first bead portion and the second bead portion. A third continuous bead portion of an overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material into the groove between the first bead portion and the second bead portion, so as to form a relatively smooth surface.

Owner:POURIN WELDING ENG +1

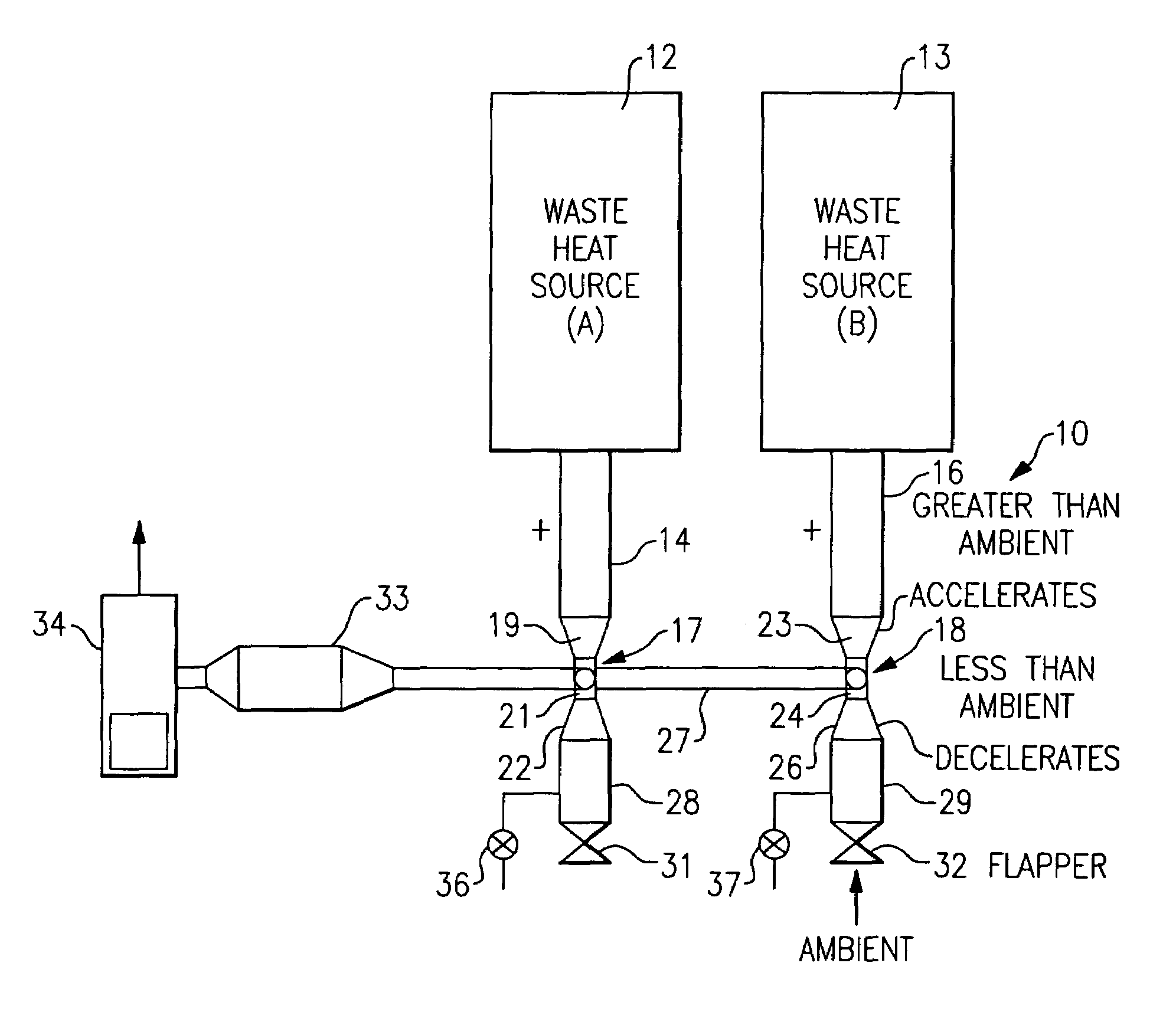

Apparatus for extracting exhaust heat from waste heat sources while preventing backflow and corrosion

InactiveUS7043912B1Reducing temperature and concentration and dewpointLiquid degasificationInternal combustion piston enginesLow speedExhaust fumes

In a waste heat recovery system wherein a heat exchanger derives heat from an engine exhaust, a venturi is fluidly connected to an engine exhaust port so as to thereby increase the flow rate and reduce the pressure in a manifold which is fluidly connected between the venturis and the heat exchanger. A fan is provided downstream of the heat exchanger to draw hot gases from the manifold, through the heat exchanger and discharge it to ambient. But when the fan is not operating during periods in which the engine is operating, the lower pressure manifold will draw ambient air in through the fan and through the heat exchanger, with the ambient air then being entrained in the exhaust gases being discharged from an exhaust channel downstream of the venturi. In one embodiment, a plurality of heat sources are provided with each having its own venturi connected to the common low pressure manifold. One or more of the plurality of waste heat source may be nonoperative or operating at a lower speed, but because of the low pressure manifold, the hot gases from the operative / higher speed waste heat source will not flow to the nonoperative or slower running waste heat source. Check valves are provided to allow the discharge of hot gases to ambient from the exhaust channels but not allow the flow of ambient air into the exhaust channels. A bypass valve is provided to selectively allow for the flow of ambient air into the exhaust channel and into the manifold for purposes of dilution during periods in which the fan is in operation.

Owner:UNITED TECH CORP

Method of preventing corrosion degradation using ni or ni-alloy plating

ActiveUS20090252883A1Prevent degradationPretreated surfacesLiquid/solution decomposition chemical coatingMachine partsPetrochemical

Disclosed herein is a method of preventing corrosion degradation in a defective region including an expansion transition region and / or an expansion region of a heat transfer tube of a steam generator in a nuclear power plant by using nickel (Ni) plating or nickel (Ni) alloy plating. The method can prevent various types of corrosion damage, such as pitting corrosion, abrasion, stress corrosion cracking, lead-induced stress corrosion cracking and the like, occurring during the operation of the steam generator, and particularly, pitting corrosion or primary and secondary stress corrosion cracking, so that the life span of the steam generator is increased, maintenance costs are reduced, and the operation rate of a nuclear power plant is increased, with the result that the unit cost of the production of electric power can be decreased, thereby improving economic efficiency. Further, the method can be usefully used to prevent the corrosion damage of parts and equipment of nuclear, hydroelectric or thermoelectric power plants or of petrochemical plants, and that of industrial and machine parts and equipment, and parts and equipment in a defense industry.

Owner:KOREA ATOMIC ENERGY RES INST +1

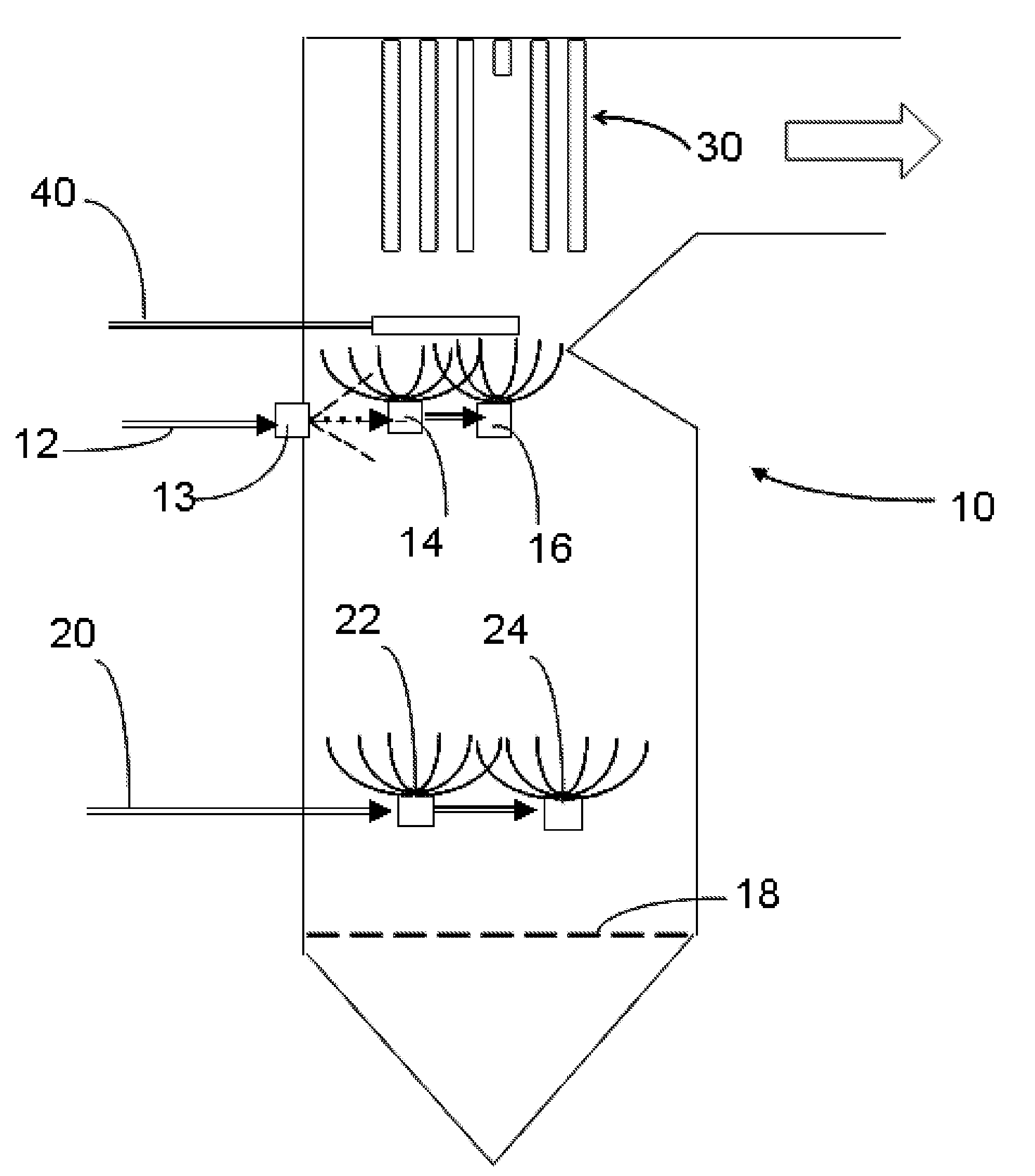

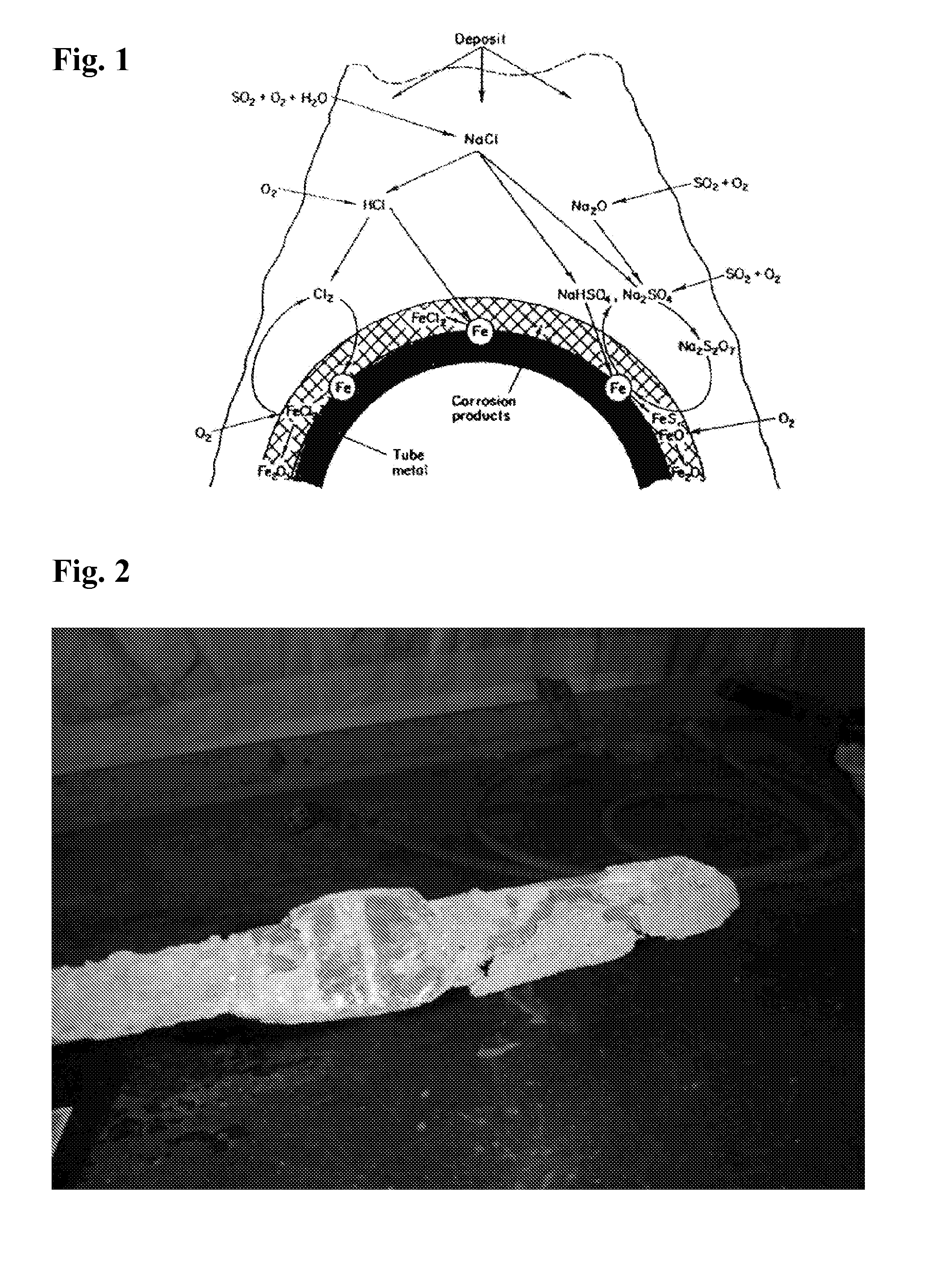

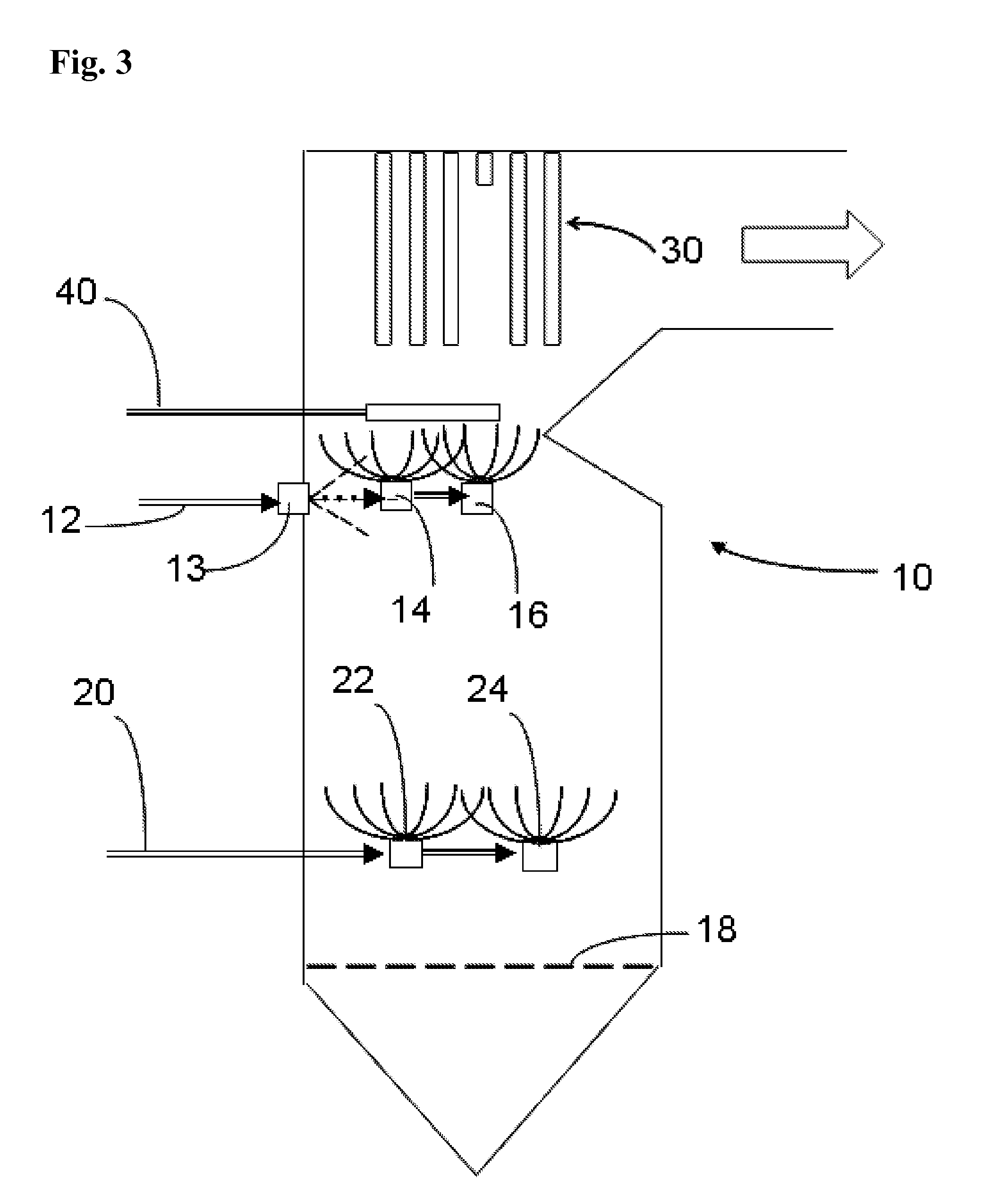

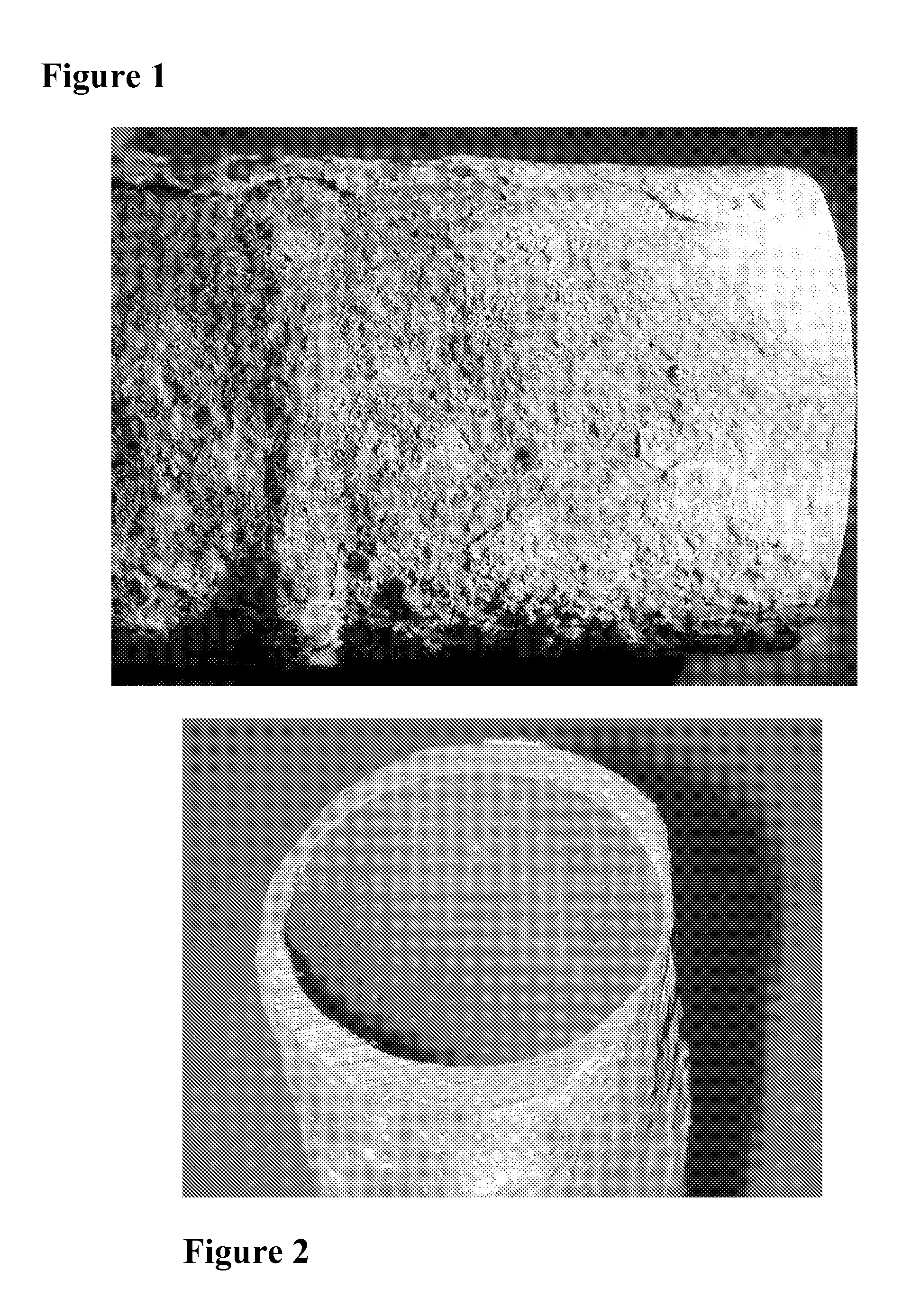

Process for slag and corrosion control in boilers

InactiveUS20070119352A1Reduce corrosionReduce harmWeather/light/corrosion resistanceRotary drum furnacesCombustionSulfur

A slag and corrosion control process is described. The process entails: identifying the location of at least one slagging problem area in a boiler; introducing a slag control chemical comprising magnesium oxide or hydroxide into combustion gases in a location identified as having a slagging problem; identifying the location of at least one corrosion problem area in a boiler; and introducing a corrosion control chemical comprising a sulfate salt, bisulfite salt, sulfuric acid, or sulfur into combustion gases in a location identified as having a corrosion problem. In operation, these slag deposits will be sufficiently friable to be removed by relatively moderate application of physical energy, thus saving time and reducing any damage to the tubes by the cleaning process. The slag deposits are less voluminous and less in weight and are removed quickly. It is an advantage of the invention that slag can be removed with little or no shut down of a boiler.

Owner:FUEL TECH INC

Automated process for inhibiting corrosion in an inactive boiler containing an aqueous system

ActiveUS7208117B2Water treatment parameter controlSpecific water treatment objectivesPolymer chemistryMetal

Owner:SOLENIS TECH CAYMAN

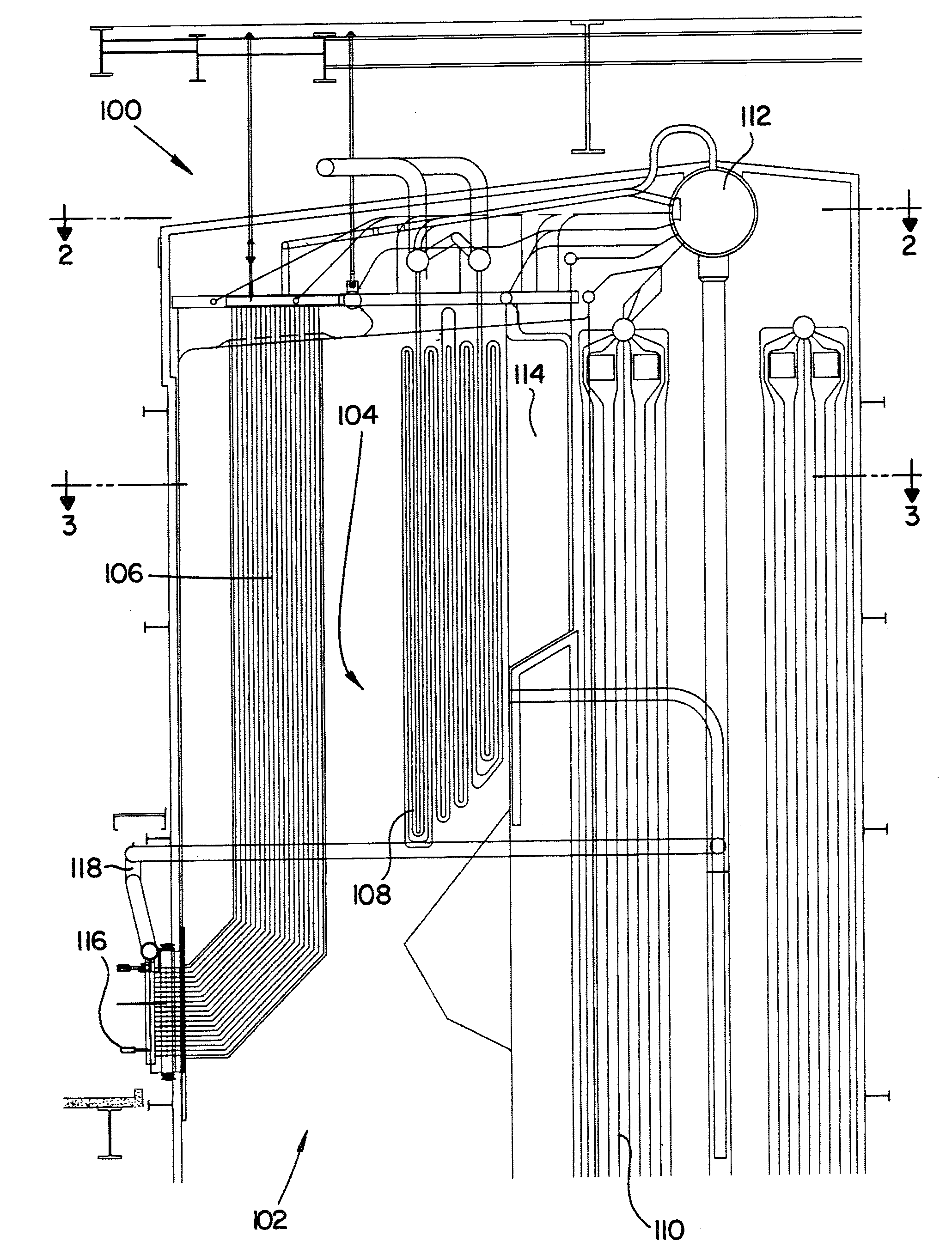

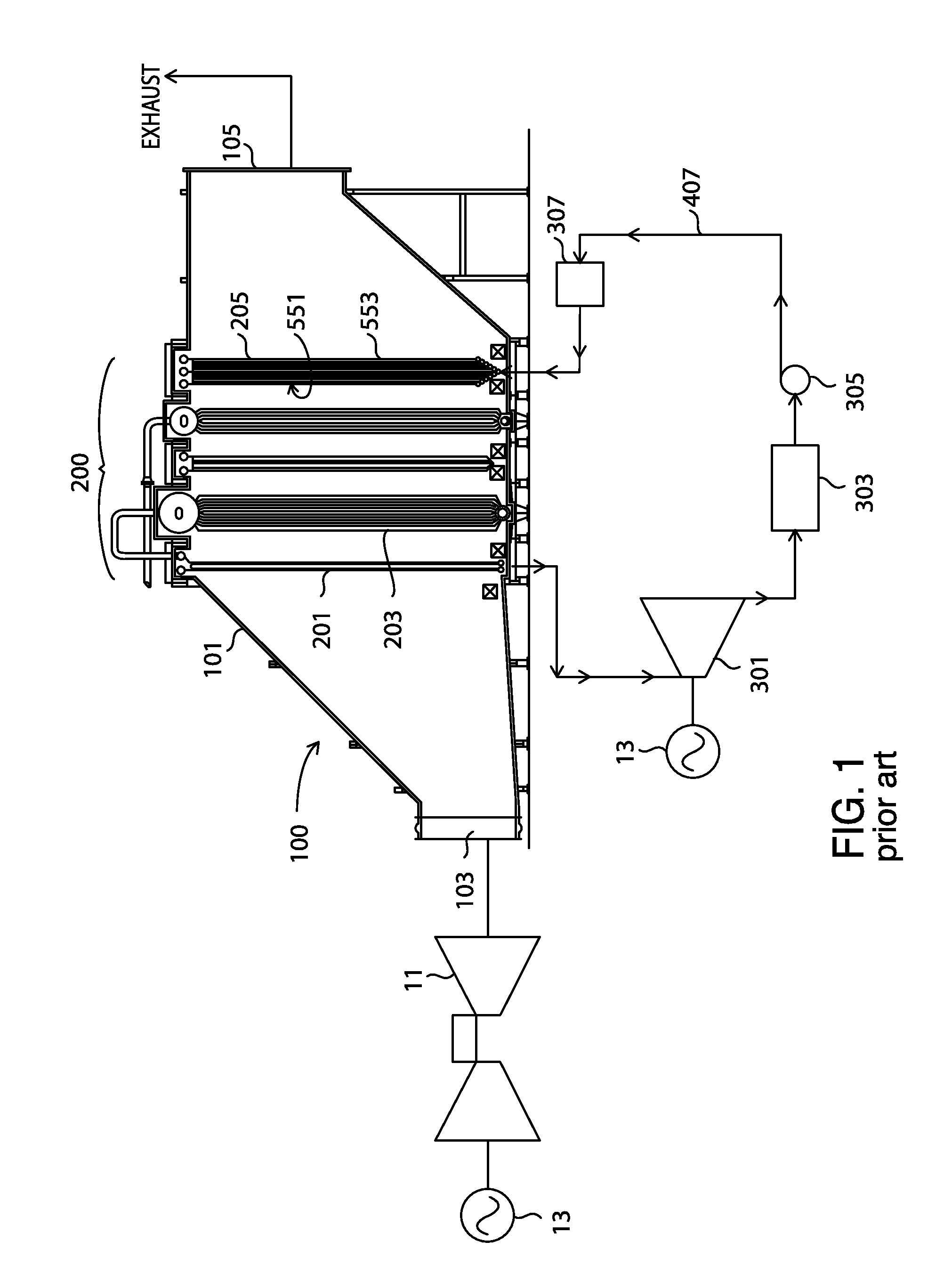

Municipal solid waste fuel steam generator with waterwall furnace platens

ActiveUS20090084327A1Improve heat transfer performanceFurnace exit gas temperatureSolid waste disposalBoiler cleaning apparatusCombustionProcess engineering

A steam generator includes a furnace configured and adapted to generate a stream of furnace exit gases from the combustion of municipal solid waste fuel. At least one superheater is disposed within an upper portion of the furnace or backpass. The superheater is configured and adapted to superheat fluids within the superheater by facilitating heat transfer between fluids within the superheater and furnace exit gases outside the superheater. At least one waterwall furnace platen is disposed within the furnace upstream from the superheater, the waterwall furnace platen is configured and adapted to lower furnace exit gas temperature at the superheater by facilitating heat transfer between fluids within the waterwall furnace platen and furnace exit gases outside the waterwall furnace platen.

Owner:RILEY STOKER +1

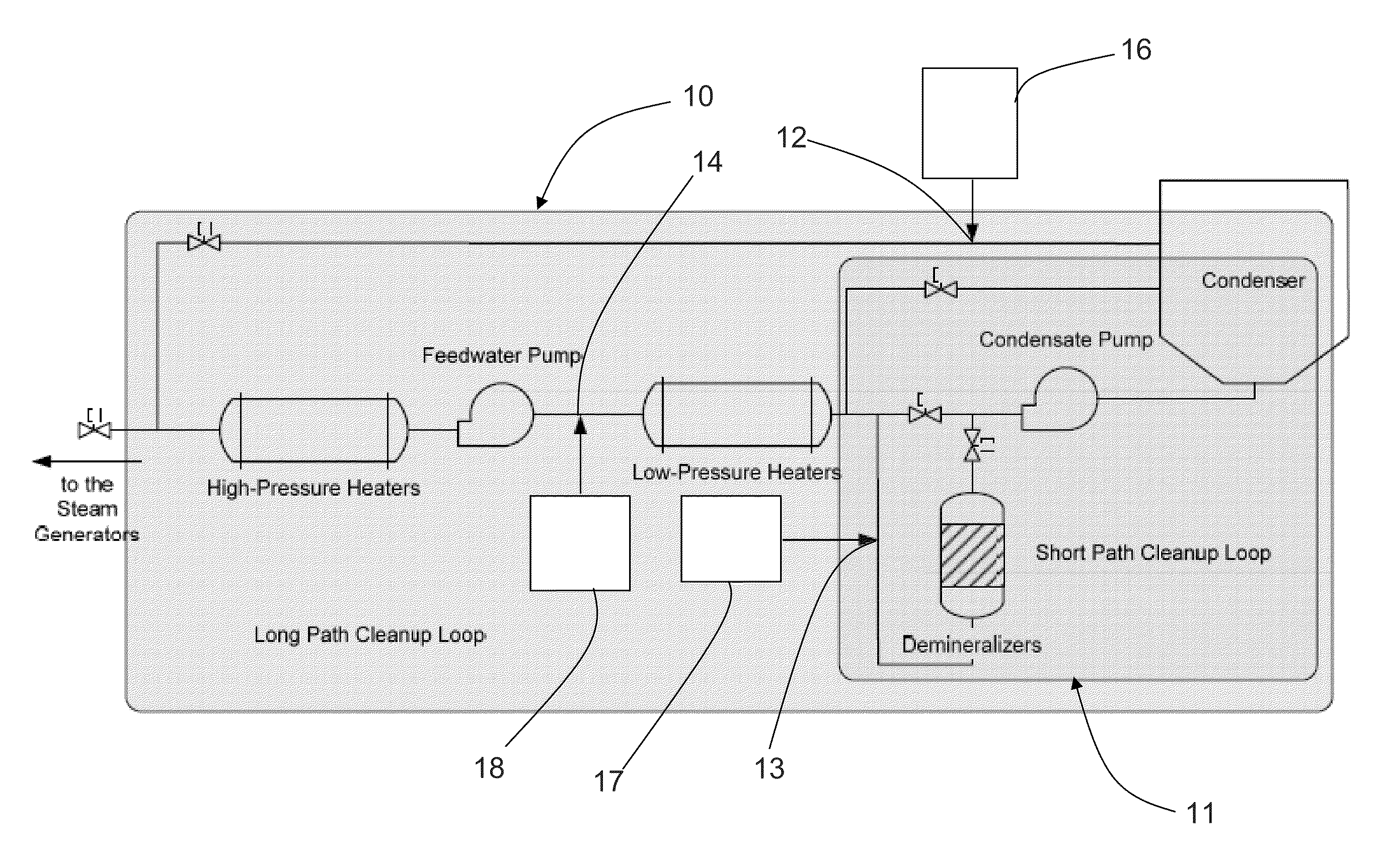

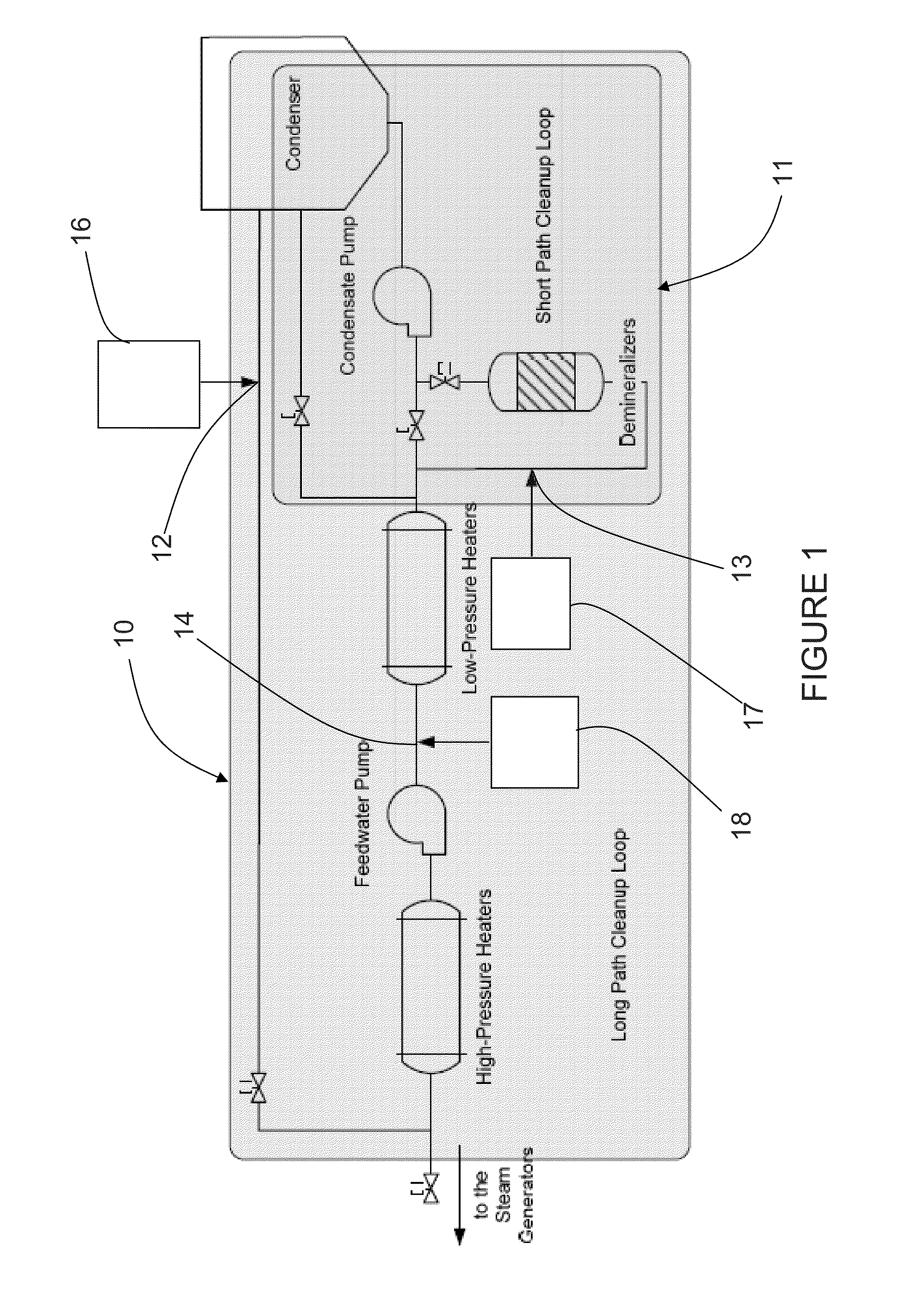

Dispersant application for clean-up of recirculation paths of a power producing facility during start-up

InactiveUS20100300218A1Decrease stockEasy to keepBoiler cleaning apparatusWater softeningChemical separationStart up

A method for reducing corrosion product transport in a power producing facility. The method includes the steps of selecting a chemical dispersant adapted to reduce the deposition of corrosion products in the recirculation path, and using at least one chemical injector to inject the chemical dispersant into a fluid contained in the recirculation path during recirculation path cleanup to increase corrosion product removal.

Owner:ELECTRIC POWER RES INST INC

System and Method for Zero Emissions, Hydrogen Fueled Steam Generator

InactiveUS20080223315A1Easy to completeEfficient heatingBoiler flue tubes/fire tubesSteam superheatersOxygenCarbon-based fuel

As we move towards a hydrogen economy or use hydrogen as an energy carrier, the need to get heat energy and steam out of the hydrogen is arising more frequently. This invention addresses that need without the atmospheric pollutants which would result from burning carbon based fuels or hydrogen freely in the air. Presented is an invention which has very high overall efficiency and generates no oxides of carbon and nearly zero nitrogen oxide compounds. The generated steam can be used for comfort heating, process heating, electric generation and other common applications requiring steam. The invention can also be used for generation of hot water. The process of steam generation is accomplished by precisely metering the mixing and oxidation of hydrogen and oxygen under controlled conditions. The result of this oxidation reaction is simply only water and heat, which are used to generate steam.

Owner:DOLAND GEORGE

High-chromium heat-resistant steel

ActiveUS20160102856A1Improve propertiesEconomic efficiency is excellentBoiler water tubesWater-tube boilersChromiumMartensitic microstructure

The present invention provides a high-chromium heat-resistant steel. The steel contains in mass %, C: 0.08% to 0.13%; Si: 0.15% to 0.45%; Mn: 0.1% to 1.0%; Ni: 0.01% to 0.5%; Cr: 10.0% to 11.5%; Mo: 0.3% to 0.6%; V: 0.10% to 0.25%; Nb: 0.01% to 0.06%; N: 0.015% to 0.07%; B: ≦0.005%, and Al: ≦0.04%. The balance consists of Fe and inevitable impurity elements. The steel shows a martensitic microstructure.

Owner:TENARIS CONNECTIONS

Anticorrosive for boiler

InactiveUS20130140493A1Effectively maintain pHAvoid corrosionOrganic compound preparationOther chemical processesPhosphateSuperheater

The boiler anti-corrosive of the present invention contains an amine compound represented by formula (1):NH2—(CH2)m—O—(CH2)n—OH (1)(wherein each of m and n is an integer of 1 to 3), or contains an oxygen scavenger and the amine compound represented by formula (1).The anti-corrosive is generally used in a boiler operated with a superheater or a steam turbine, or in such a boiler to which treated water is fed, and can more effectively maintain the pH of boiler water and can prevent corrosion not only of the boiler tank but also in the entire boiler system including a feed-condensate system, without adding a large amount of phosphate salt or elevating the Na / PO4 mole ratio to 3 or higher.

Owner:KURITA WATER INDUSTRIES LTD

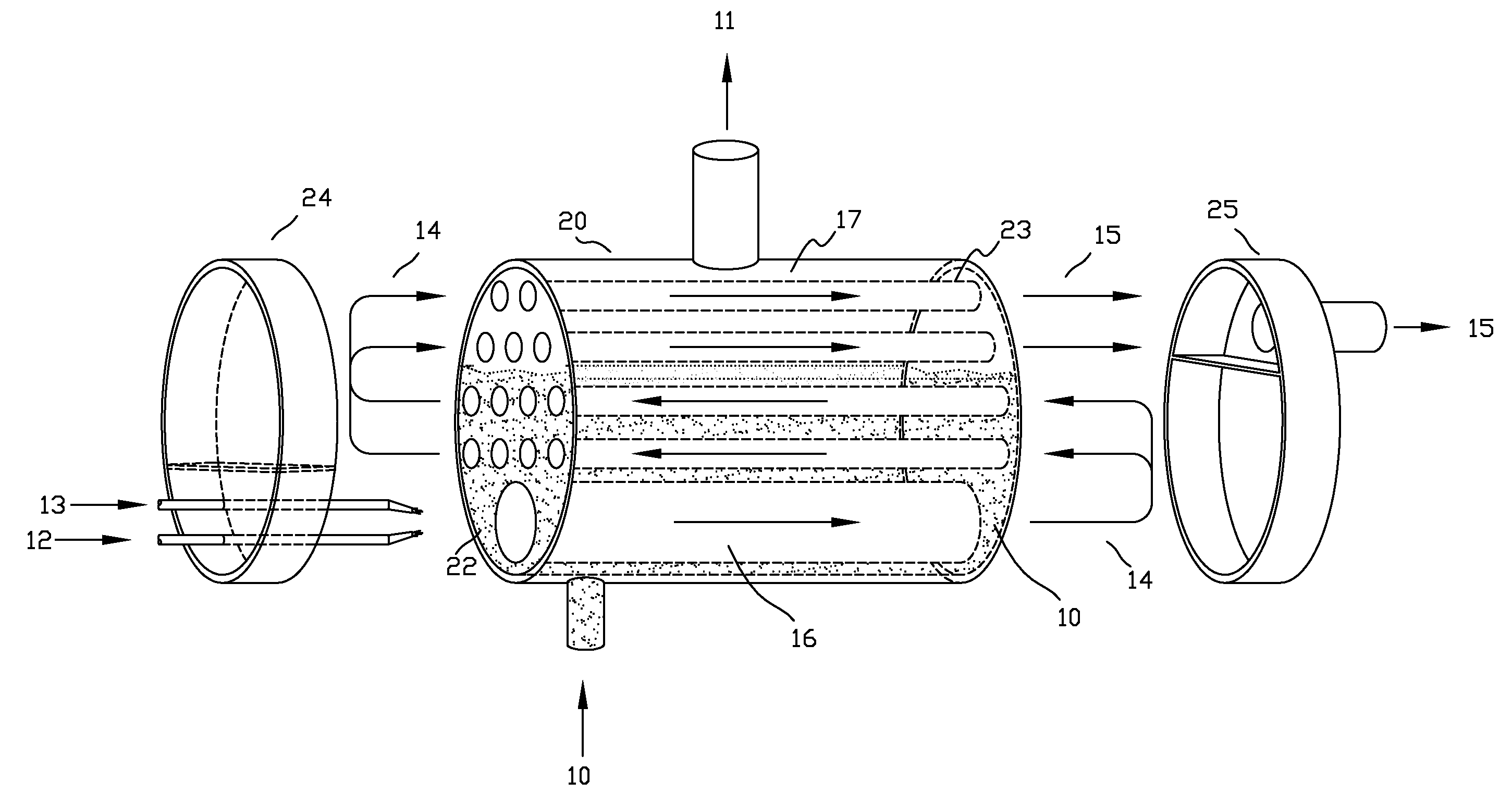

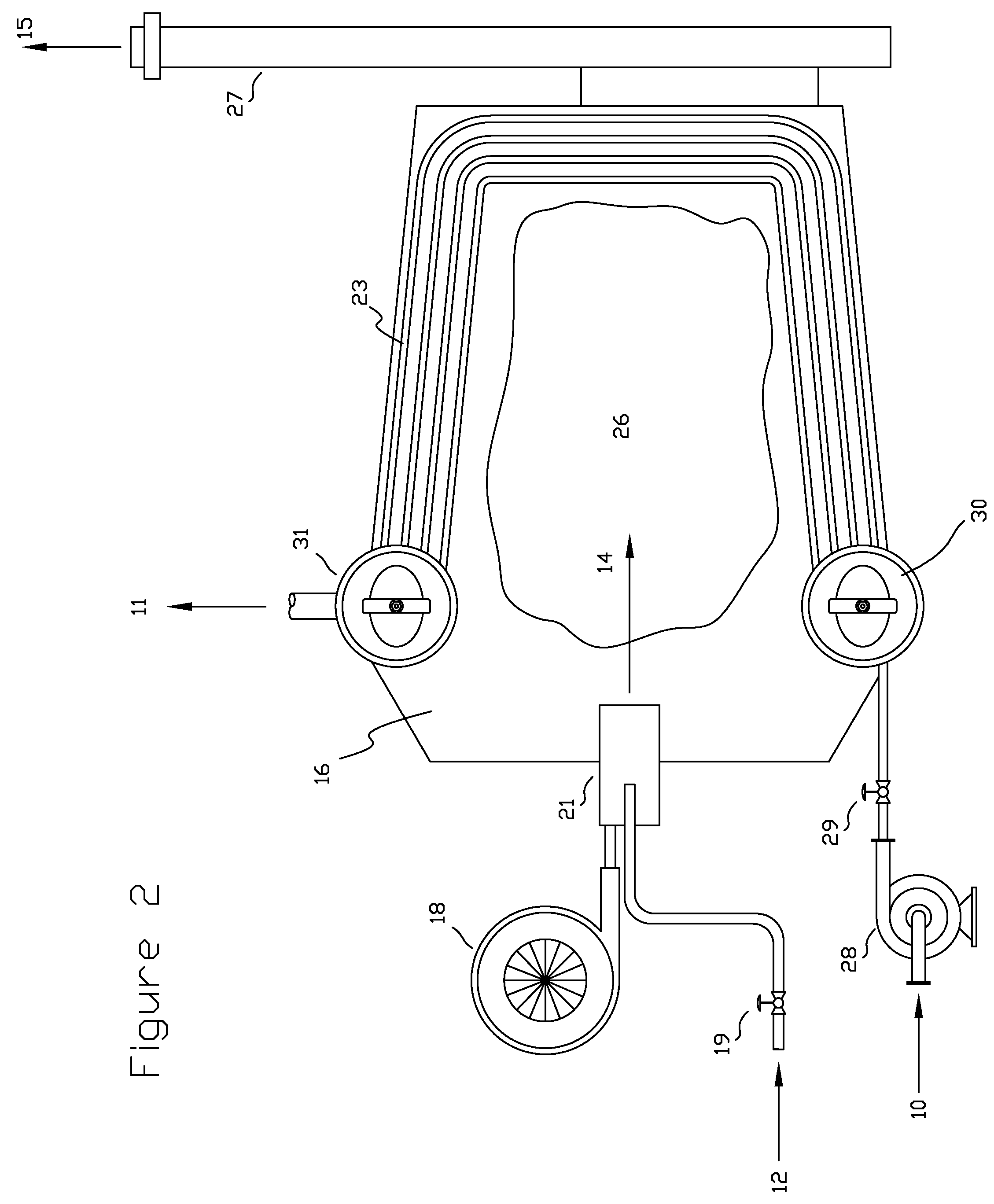

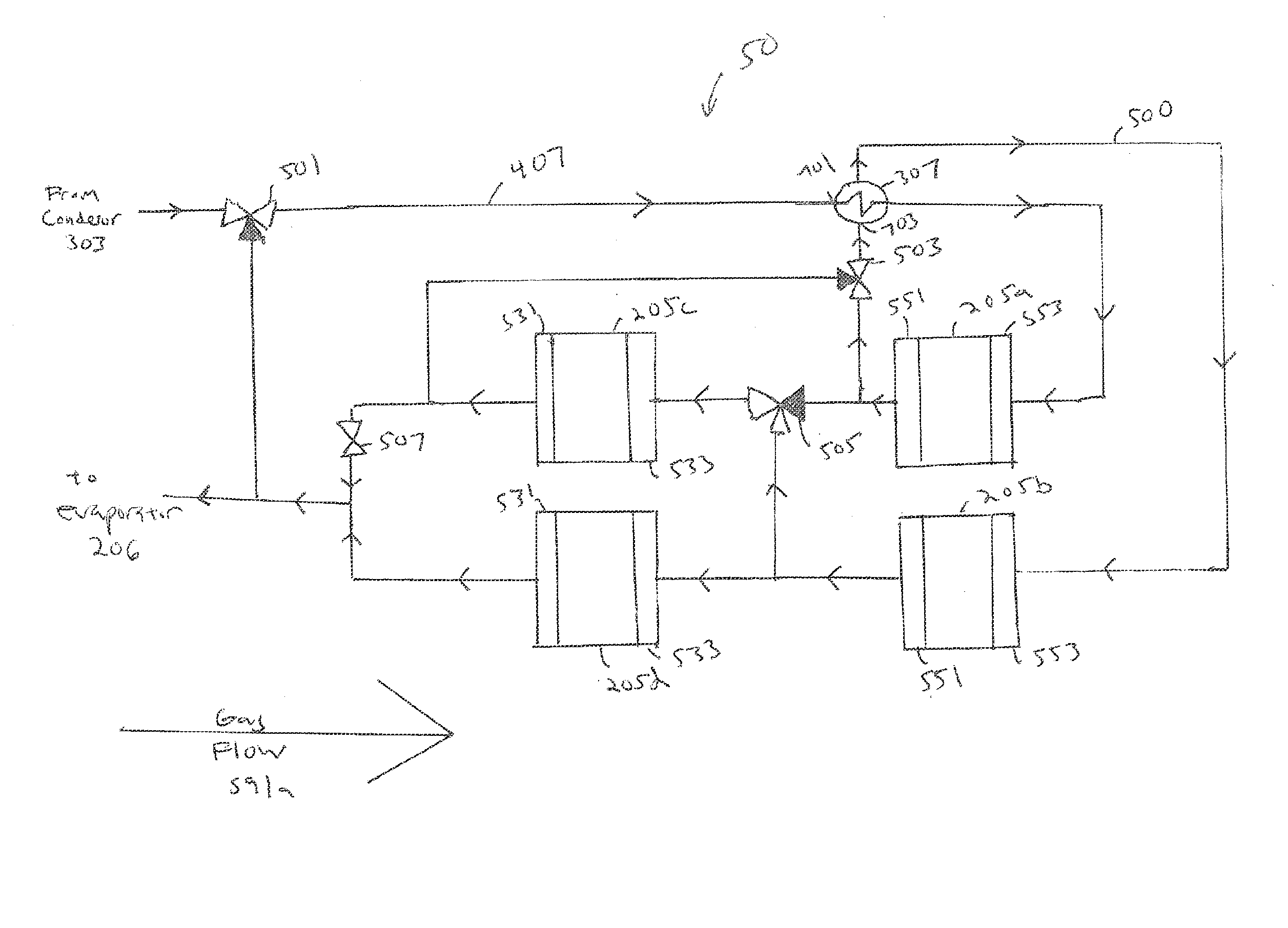

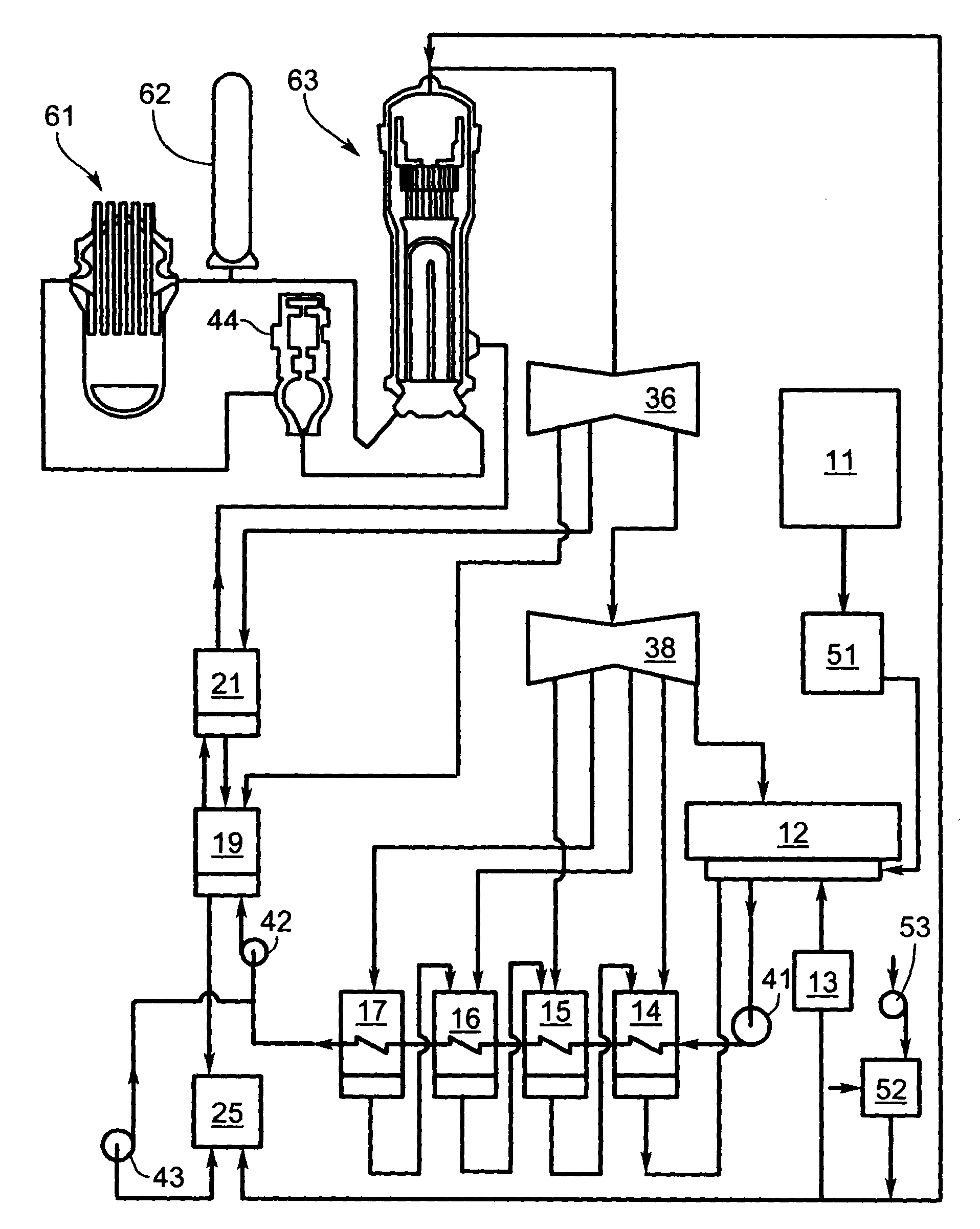

Gas-to-Liquid Heat Exchange System with Multiple Liquid Flow Patterns

Systems and methods for the design of a heat recovery steam generator (HRSG) or similar system that is designed to extract heat from hot gases flowing through a duct which utilizes an external liquid-to-liquid heat exchanger for preheating feedwater. The systems and methods allow for multiple water flow patterns to adjust the temperature of the feedwater into the gas duct.

Owner:NOOTER ERIKSEN INC

Combined Cycle Power Plant

A combined cycle power plant in which a gas turbine engine generates power, a heat recovery steam generator (HRSG) produces steam from high energy fluids produced from the generation of power in the gas turbine engine and a steam turbine engine generates additional power from the steam produced in the HRSG. The combined cycle power plant includes a heating element fluidly interposed between the steam turbine engine and the HRSG to heat fluid output from the steam turbine engine, which is to be fed to the HRSG and a control system to control an amount the fluid output from the steam turbine engine is heated by the heating element based on differences between HRSG and ambient temperatures.

Owner:GENERAL ELECTRIC CO

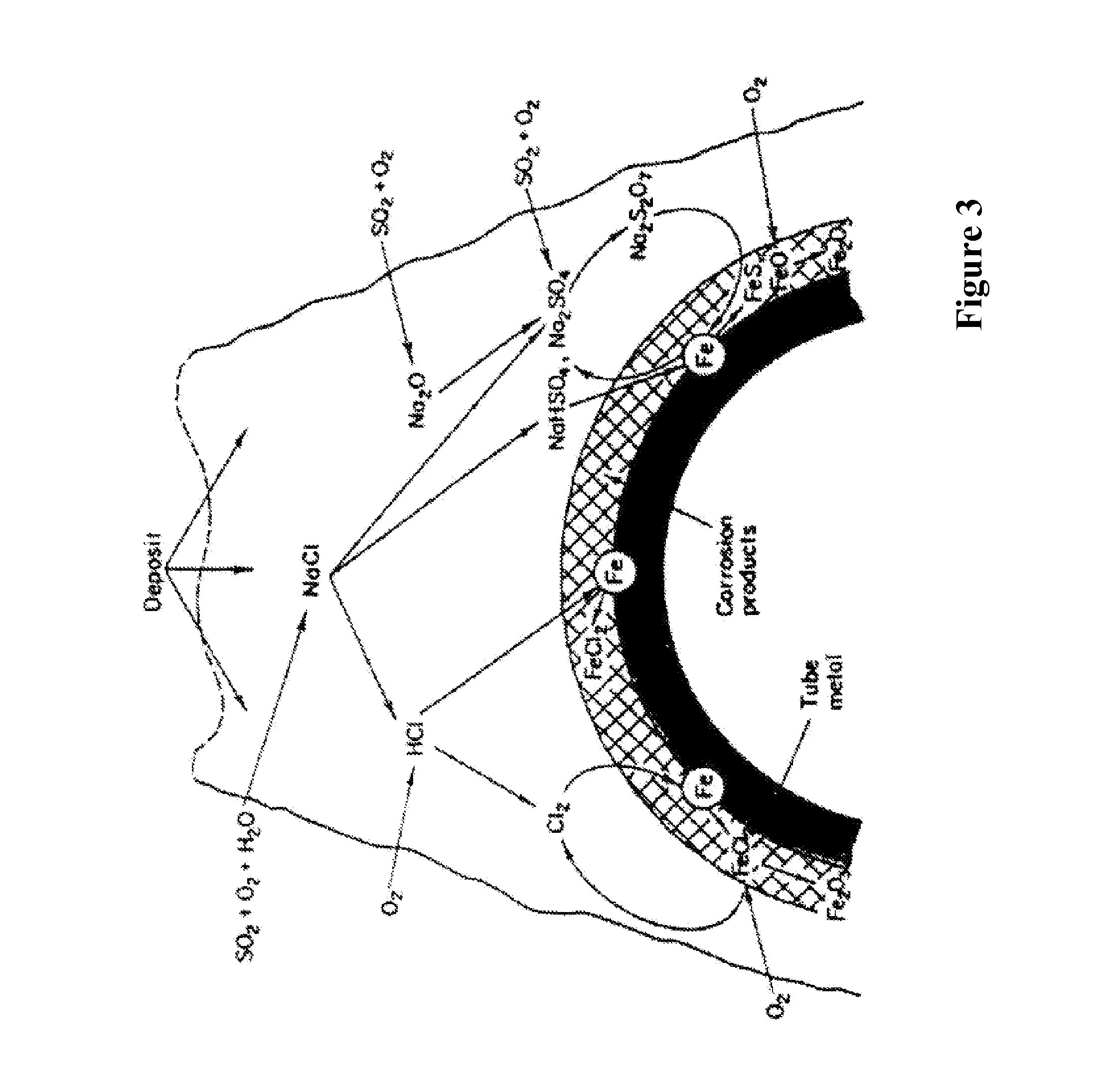

Process for corrosion control in boilers

InactiveUS20060290935A1Reduce corrosionWaste of energyWeather/light/corrosion resistanceSpecific water treatment objectivesRegimenCombustion

A corrosion control process is described. The process is especially useful in the control of chloride corrosion in waste to energy boilers. Corrosion of high temperature surfaces can be assessed by the monitor and controlled introduction of treatment chemicals by targeted in furnace injection reduces corrosion while maximizing combustion efficiency. A corrosion monitor is also described. Before and following selection of corrosion control chemicals and the locations for targeted in furnace injection, injection regimen and chemical selection and introduction parameters are monitored with the aid of the method and apparatus of the invention to adjust one or more control parameters to reduce corrosion. A preferred method will employ a treatment chemical that comprises an SO2 or SO3 reagent, e.g., sulfuric acid, sulfur, a sulfate salt or a bisulfite salt.

Owner:FUEL TECH

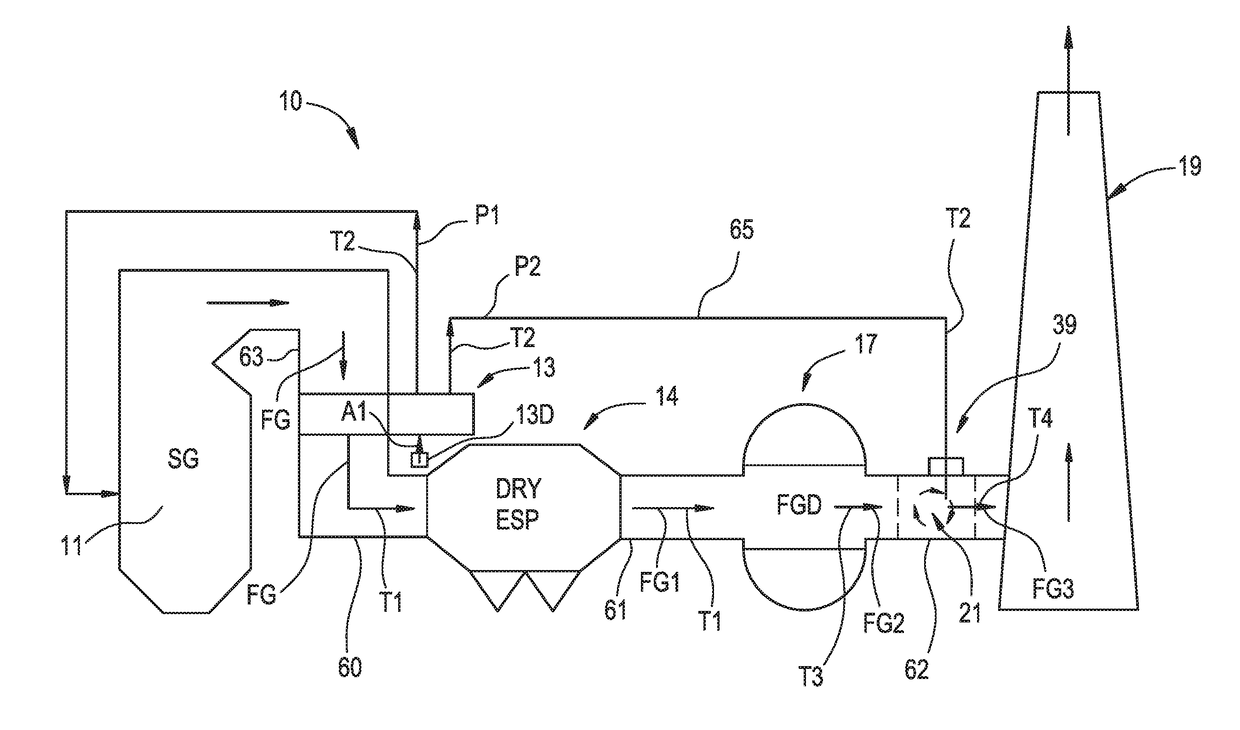

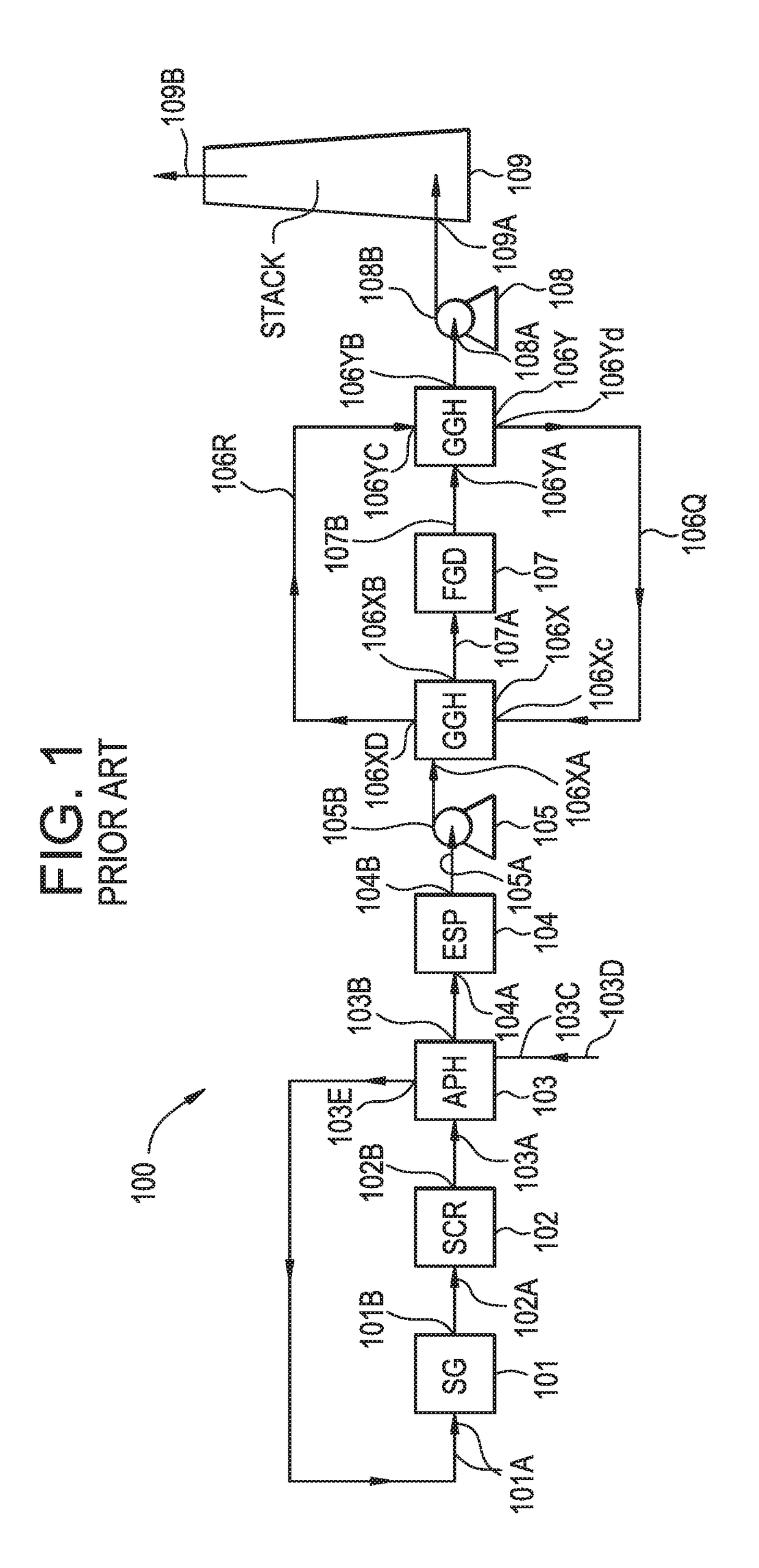

Method and system for improving boiler effectiveness

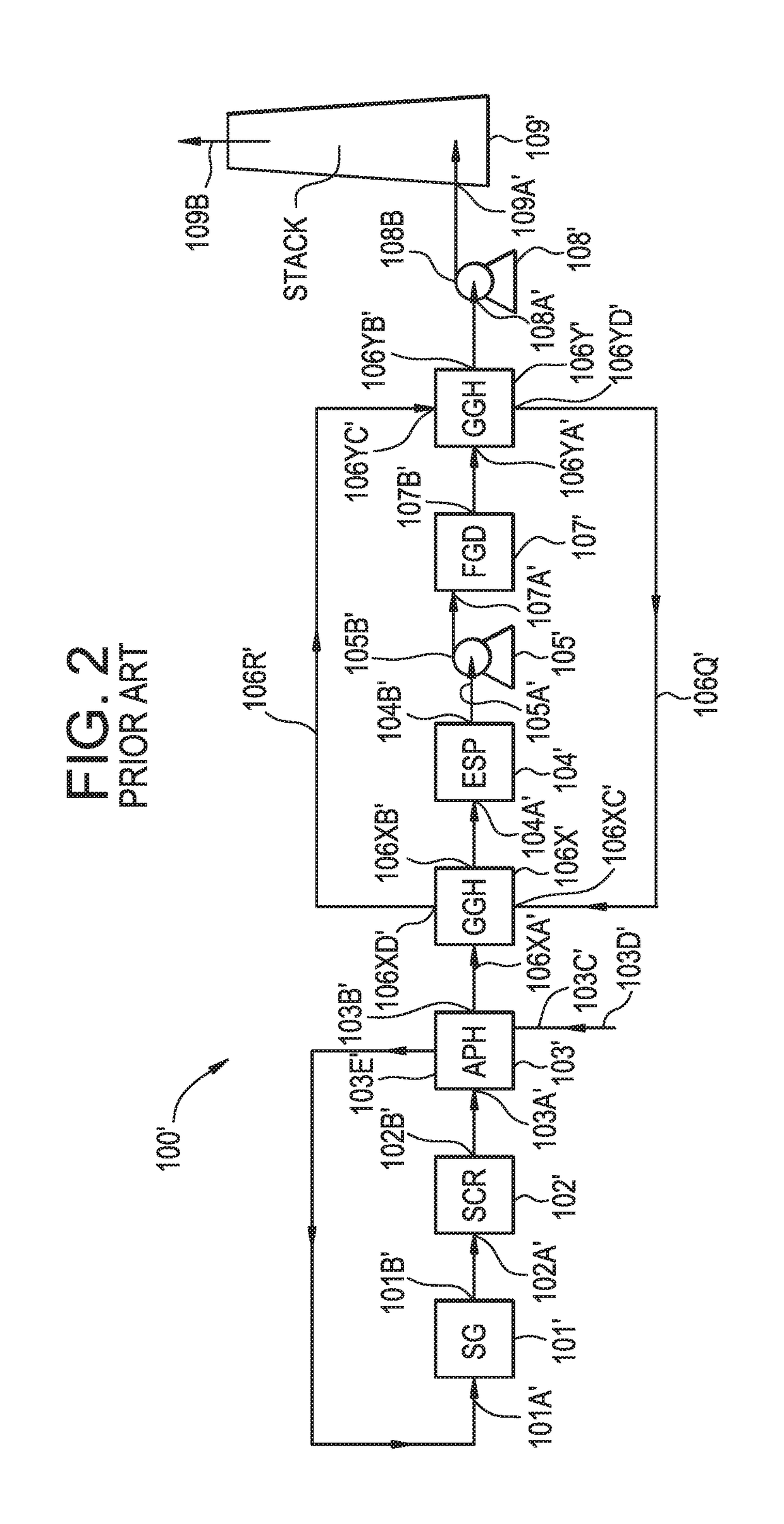

ActiveUS20180010792A1Mitigate visible plume exitingImprove efficiencyEmission preventionDispersed particle separationAir preheaterParticulates

A method for improving effectiveness of a steam generator system includes providing air to an air preheater in excess of that required for combustion of fuel and providing the air at a mass flow such that the air preheater has a cold end metal temperature that is no less than a water dew point temperature in the air preheater and such that the cold end metal temperature is less than a sulfuric acid dew point temperature. The method includes mitigating SO3 in the flue gas which is discharged directly from the air preheater to a particulate removal system and then directly into a flue gas desulfurization system. Flue gas reheat air is fed from the air preheater to heat the flue gas prior to entering a discharge stack to raise the temperature of the flue gas to mitigate visible plume exiting and to mitigate corrosion in the discharge stack.

Owner:ARVOS LJUNGSTROM LLC

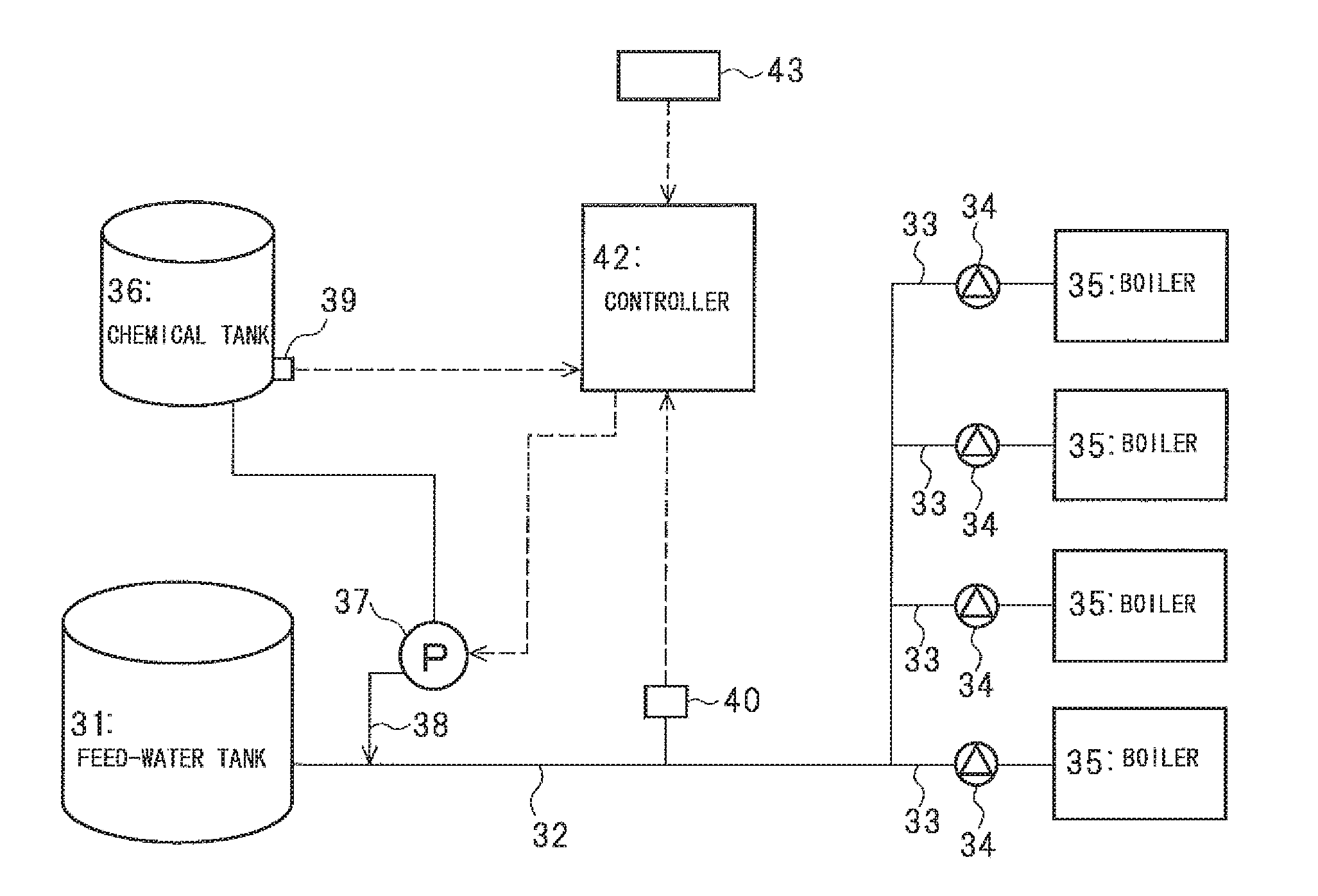

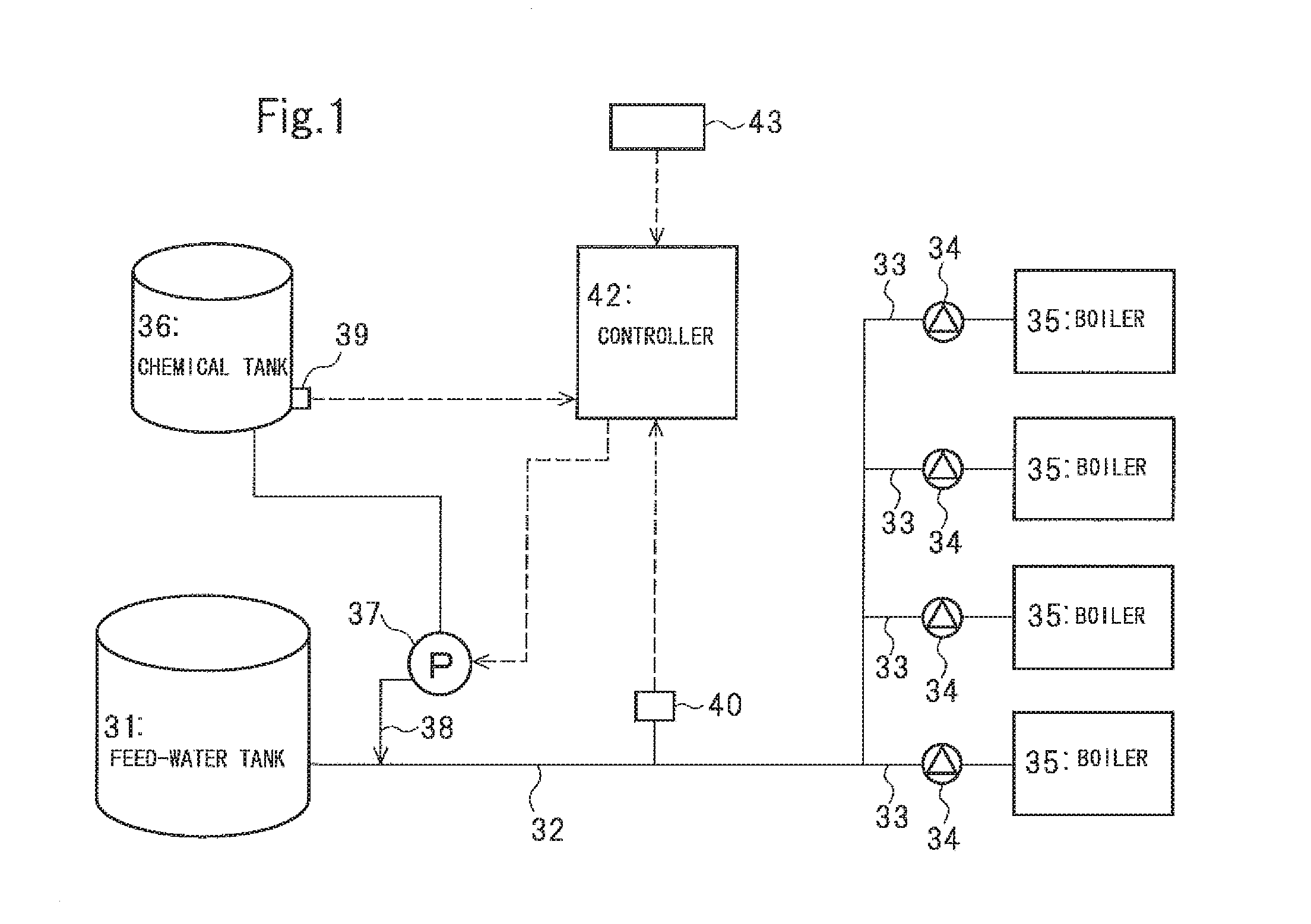

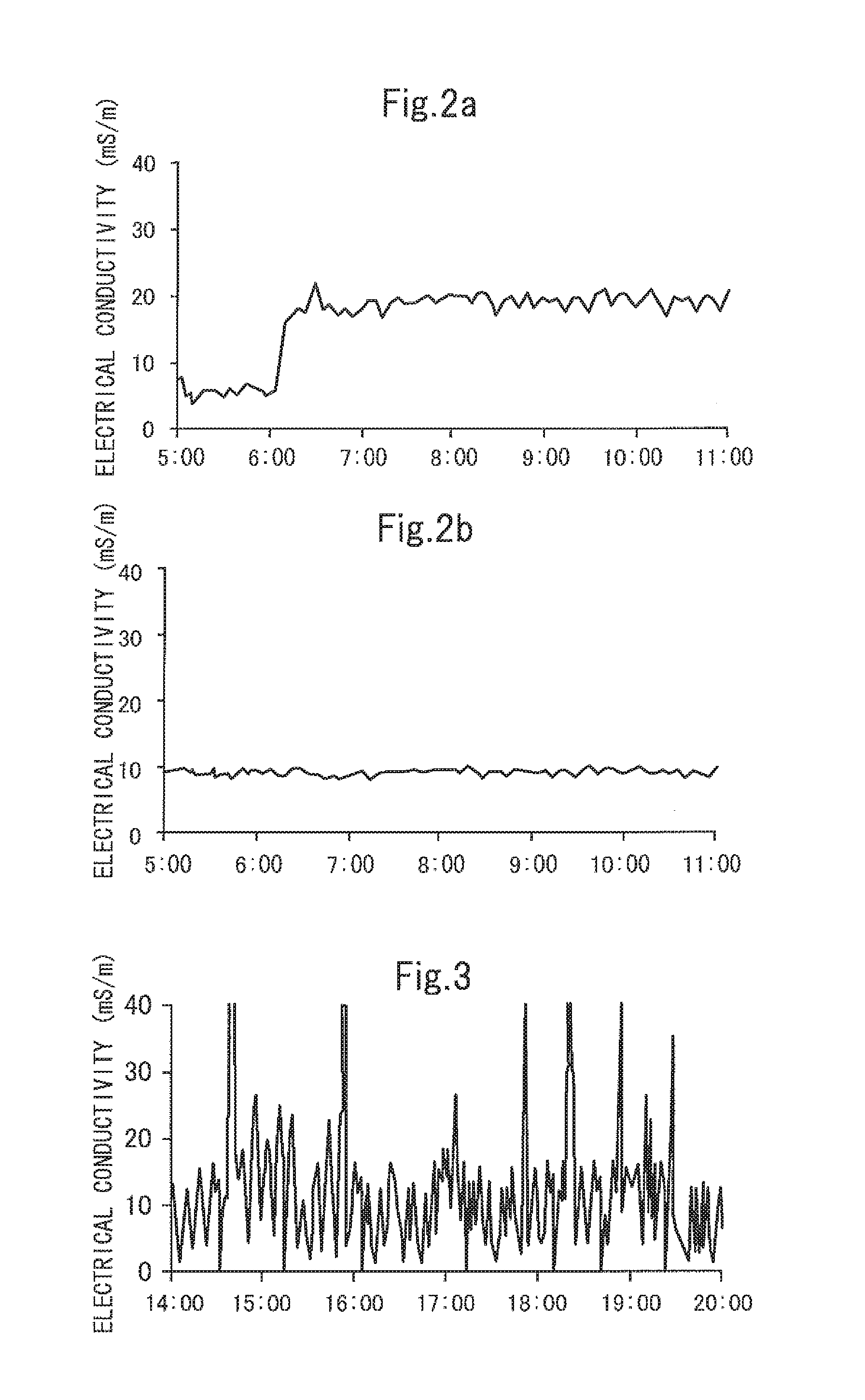

Device and method for controlling chemical injection into boiler

InactiveUS20170008784A1Precise maintenanceAvoid it happening againWater treatment parameter controlWater/sewage treatment by substance additionEngineeringBoiler feedwater

A device for controlling injection of chemical into a boiler and a chemical injection method can control an injection amount such that a chemical concentration is obtained as per a target even in a boiler feed-water facility where a flow rate of feed-water varies to a large extent in a short period. The device controls an amount discharged by a chemical injection pump in proportion to a flow rate measured by a flowmeter. An average chemical concentration in a feed-water is calculated from an amount of feed-water per predetermined period obtained by the flowmeter and a reduction in the amount of chemical in a tank per predetermined period obtained by a sensor. The chemical injection pump is controlled on the basis of the calculated average chemical concentration and a preset target chemical concentration of the feed-water so that the average chemical concentration is within the target chemical concentration range.

Owner:KURITA WATER INDUSTRIES LTD

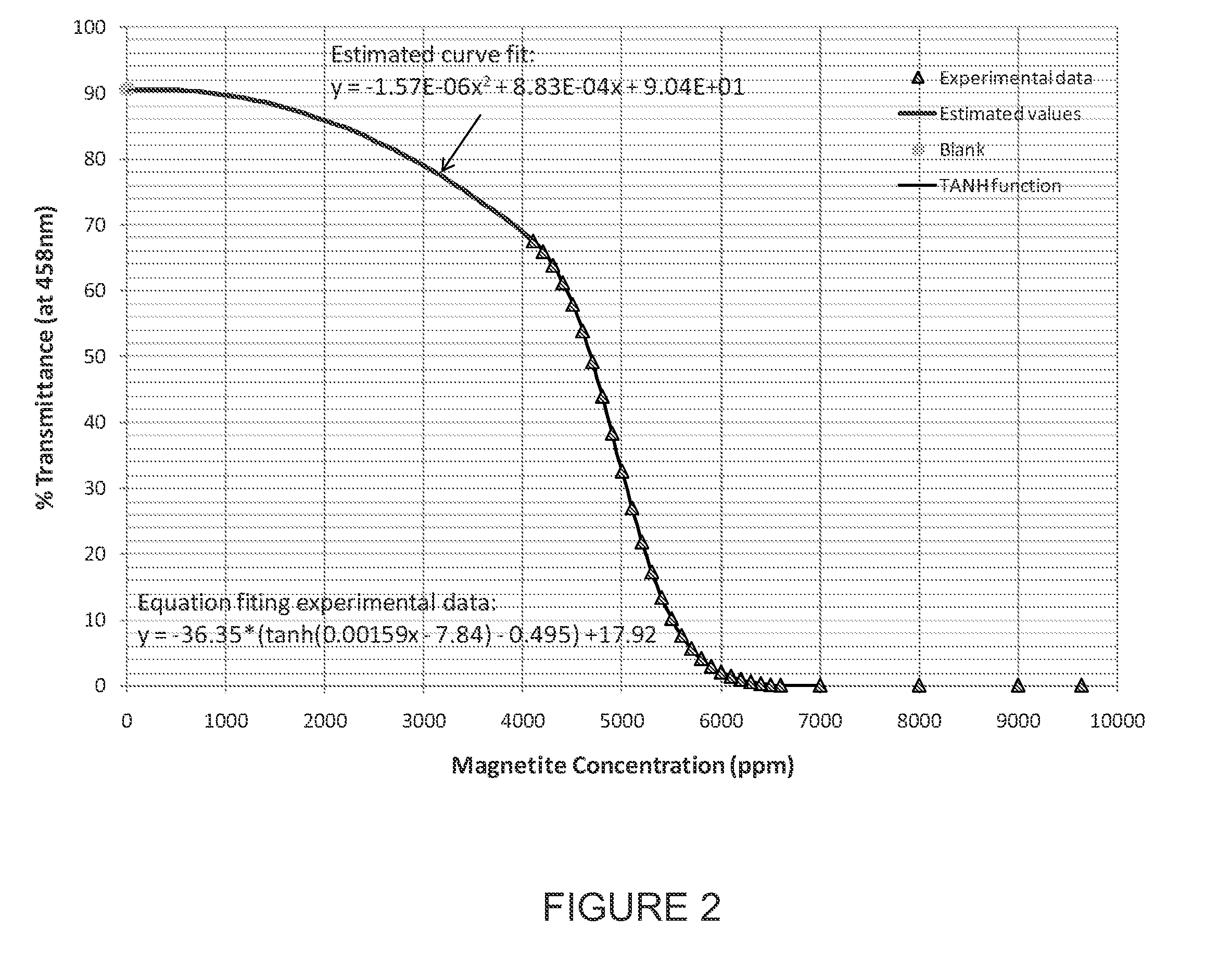

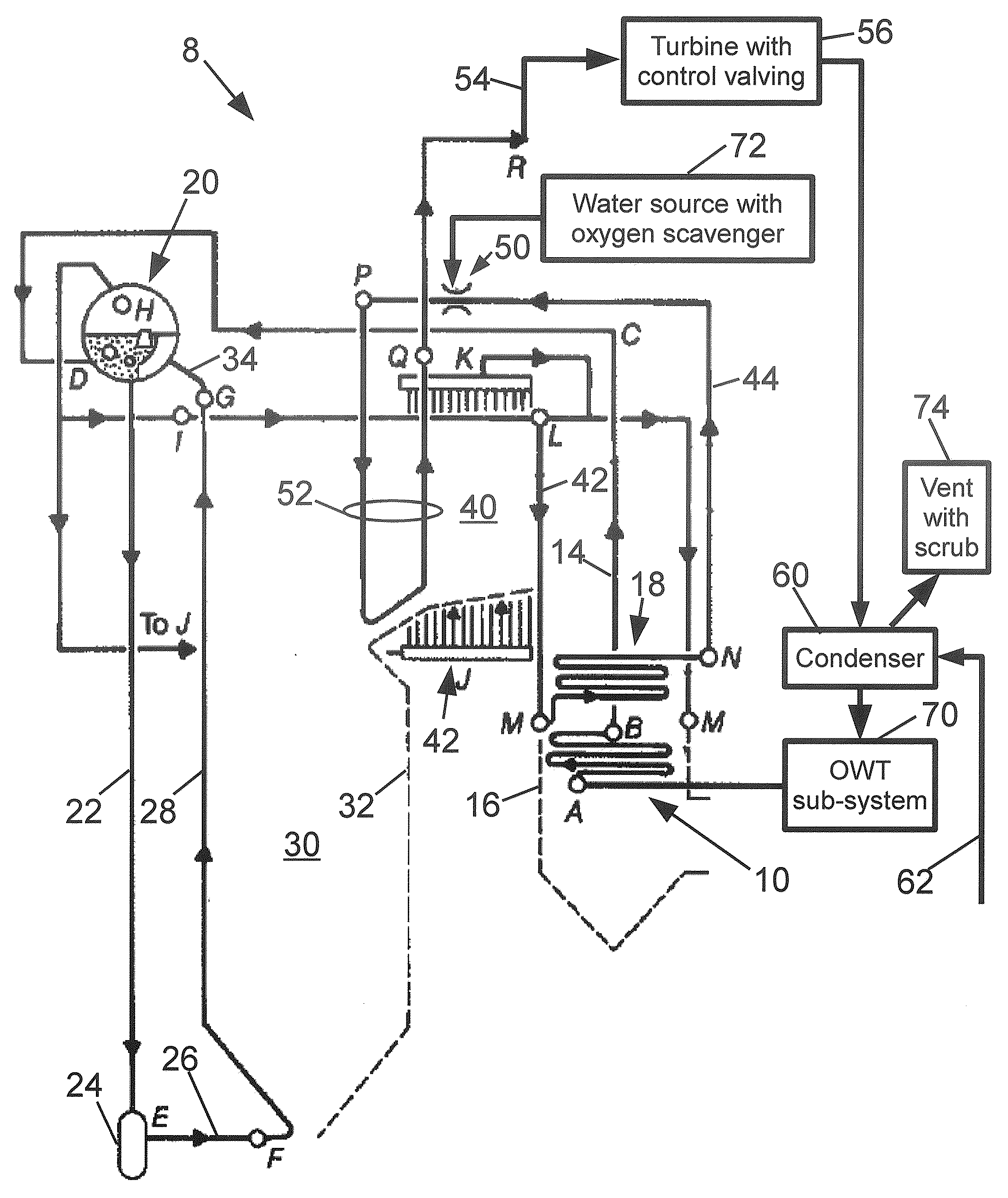

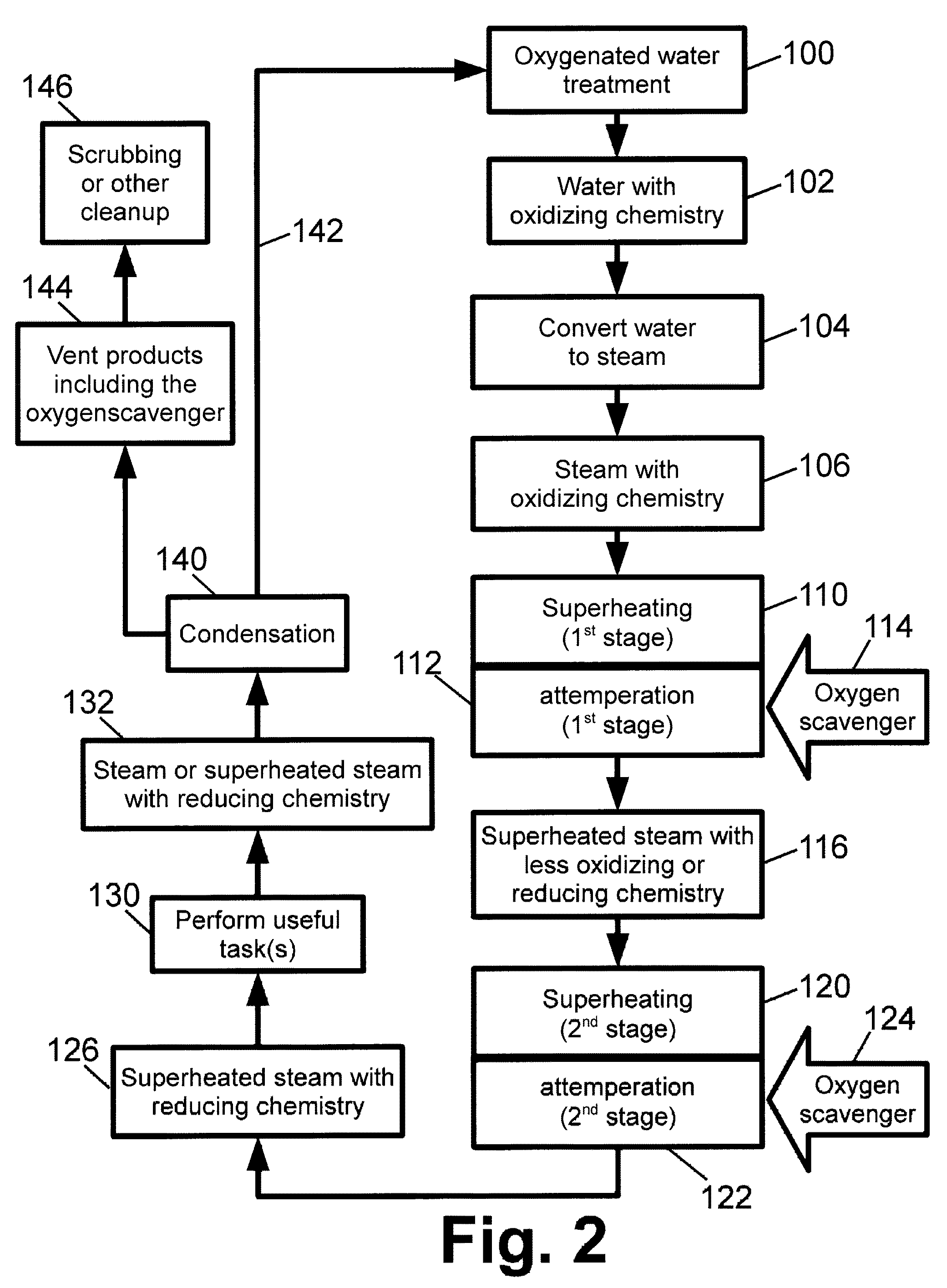

Hybrid water treatment for high temperature steam generators

ActiveUS20110229371A1Less oxidizingLess reducing chemistrySteam/vapor condensersSteam separation arrangementsEngineeringEnvironmental engineering

A steam generation system comprises: an oxygenated water treatment (OWT) sub-system configured to generate water having oxidizing chemistry; a steam generation sub-system configured to convert the water having oxidizing chemistry into steam having oxidizing chemistry; an attemperator or other injection device or devices configured to add an oxygen scavenger to the steam having oxidizing chemistry to generate steam having less oxidizing or reducing chemistry; and a condenser configured to condense the steam having less oxidizing or reducing chemistry into condensed water.

Owner:THE BABCOCK & WILCOX CO

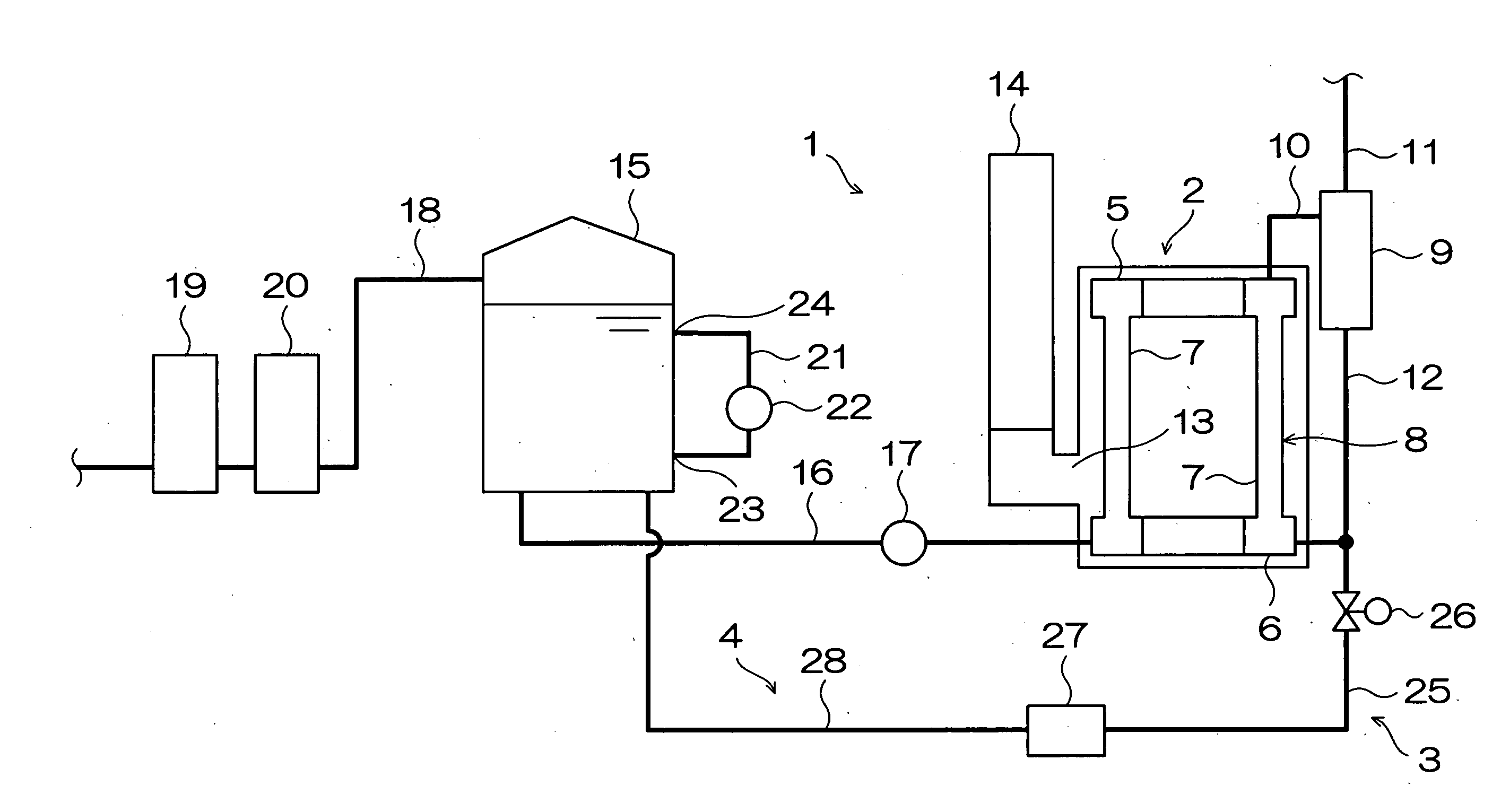

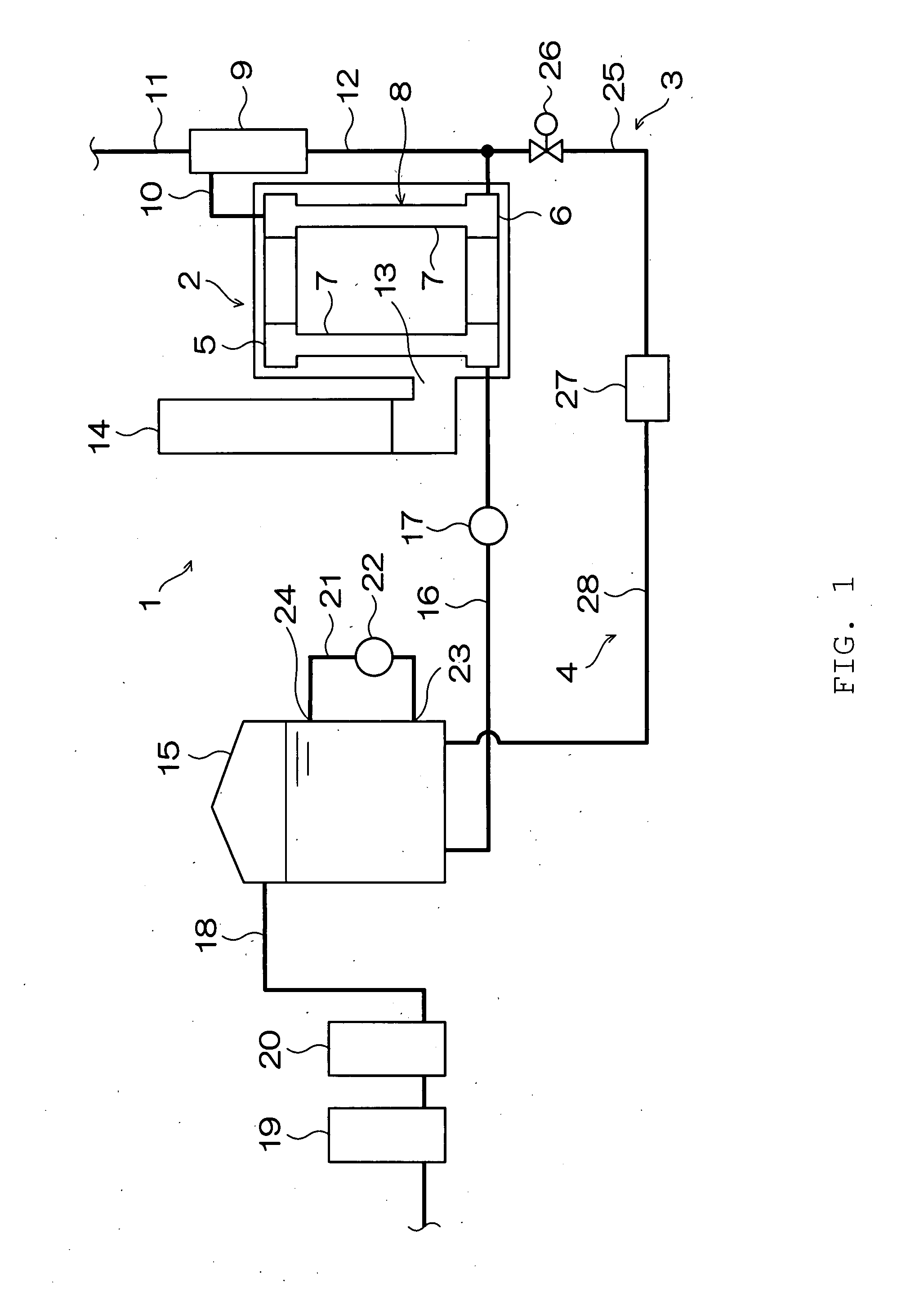

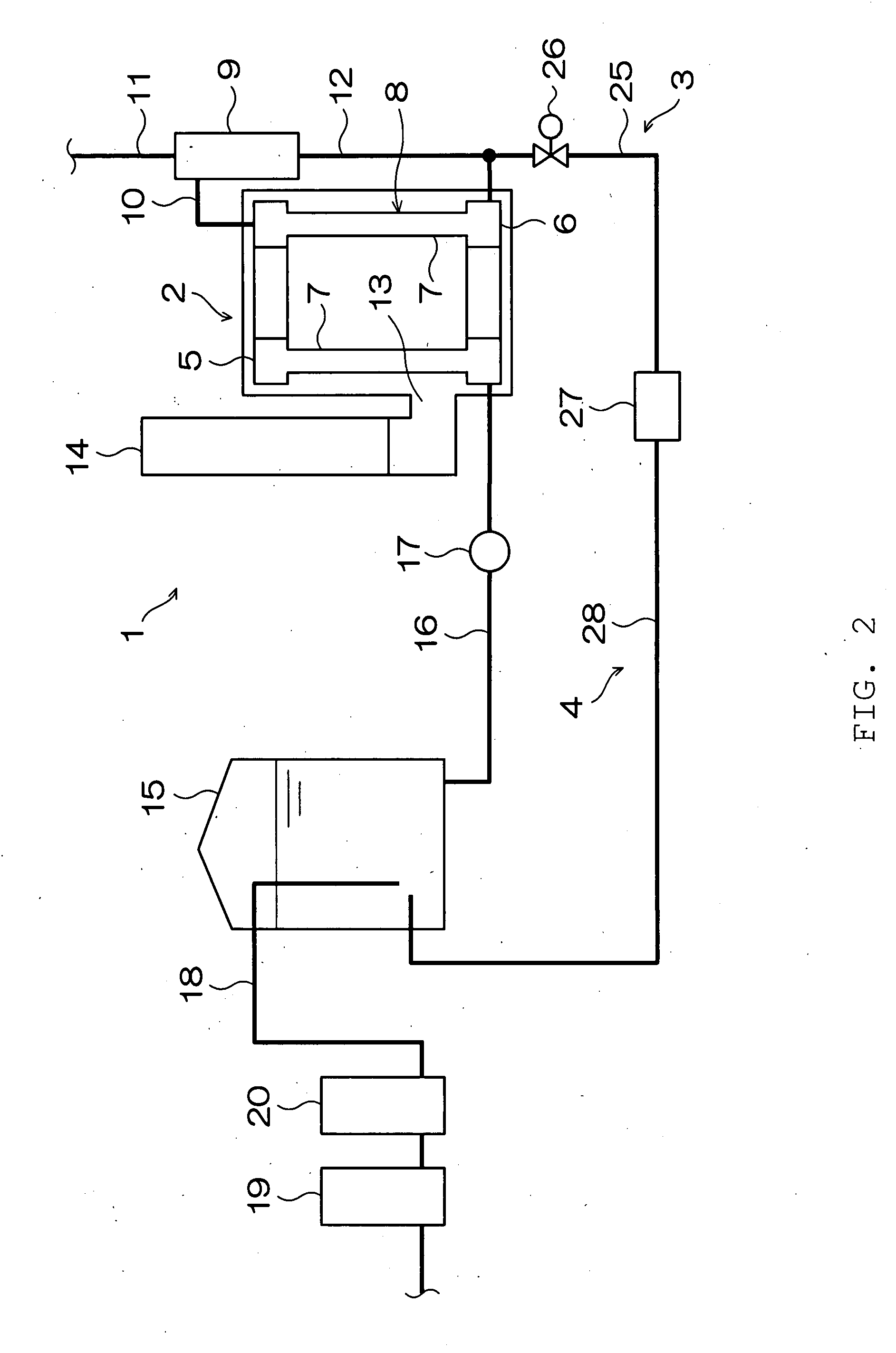

Boiler Apparatus

InactiveUS20080163832A1Suppress generationBoiler water tubesWater-tube boilersCombustionWater quality

To suppress corrosion of heat transfer tubes of a boiler under an influence of water, there is provided a boiler apparatus equipped with a unit for gathering boiler water (3) in a boiler 2 and a unit for adding the gathered boiler water (4) to supply water that has not been supplied to the boiler (2) yet. With this construction, boiler water with concentrated silica, which is an alkaline and corrosion preventive ingredient, is gathered from the boiler (2) in combustion by the boiler water gathering unit (3). The gathered boiler water is added to supply water stored in a supply water tank (15) by the boiler water adding unit (4), and this supply water is adjusted to have a water quality allowing suppression of corrosion of a connecting portion between a lower header (6) and water tubes (7) of the boiler (2).

Owner:MIURA COMPANY LIMITED

Weld overlay structure and a method of providing a weld overlay structure

ActiveCN103459076AControl dilutionFinal texture optimizationAdditive manufacturing apparatusBoiler water tubesMembrane surfaceBiomedical engineering

A method of providing a weld overlay structure (10) on a heat transfer tube (12) or a membrane surface. A first continuous bead portion (26, 40) of an overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material. A second continuous bead portion (26', 40') of the overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material, in which the second bead portion partially overlaps with the first bead portion, forming a groove (30) between the first bead portion and the second bead portion. A third continuous bead portion (32, 42) of an overlay material is applied onto the heat transfer tube or membrane surface by using a weld head to melt the overlay material into the groove (30) between the first bead portion and the second bead portion, so as to form a relatively smooth surface.

Owner:FOSTER WHEELER NORTH AMERICA CORP +1

Corrosion reduction system for power generation plants during shutdown

InactiveUS20110070123A1Reduce corrosionReducing and totally eliminating internal contaminationSpecific water treatment objectivesWater/sewage treatment by ion-exchangePower stationSulfur

The invention involves a method of reducing corrosion inside power generation cycle equipment during plant shutdown and start-up periods by substantially reducing or totally eliminating internal contamination with corrosion causing acidic gases such as carbon dioxide and oxides of sulfur and nitrogen. Acidic gases are removed at their potential points of entry into the cycle either from ingressing ambient air or dissolved in make-up water in different kinds of filters.

Owner:STODOLA JAN

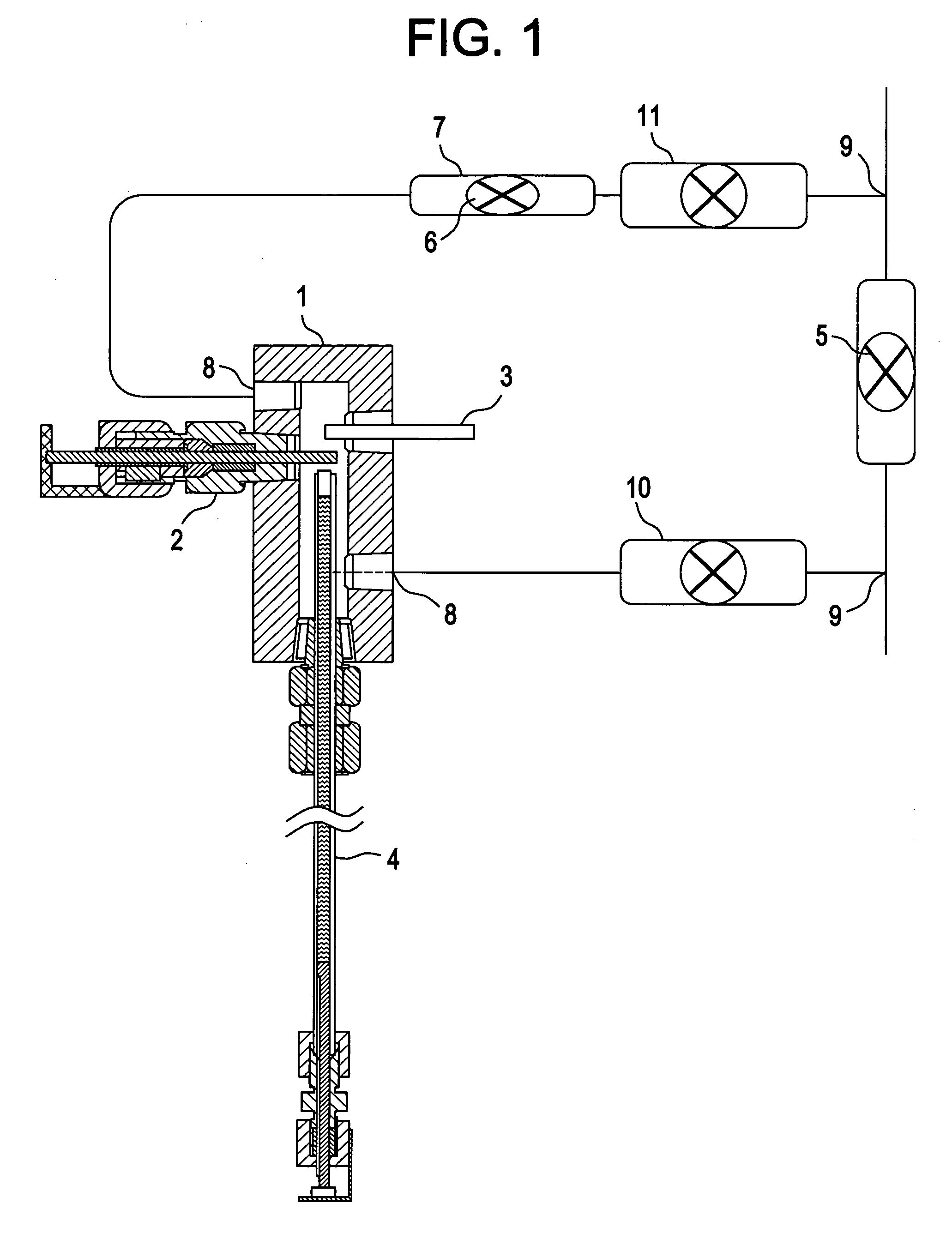

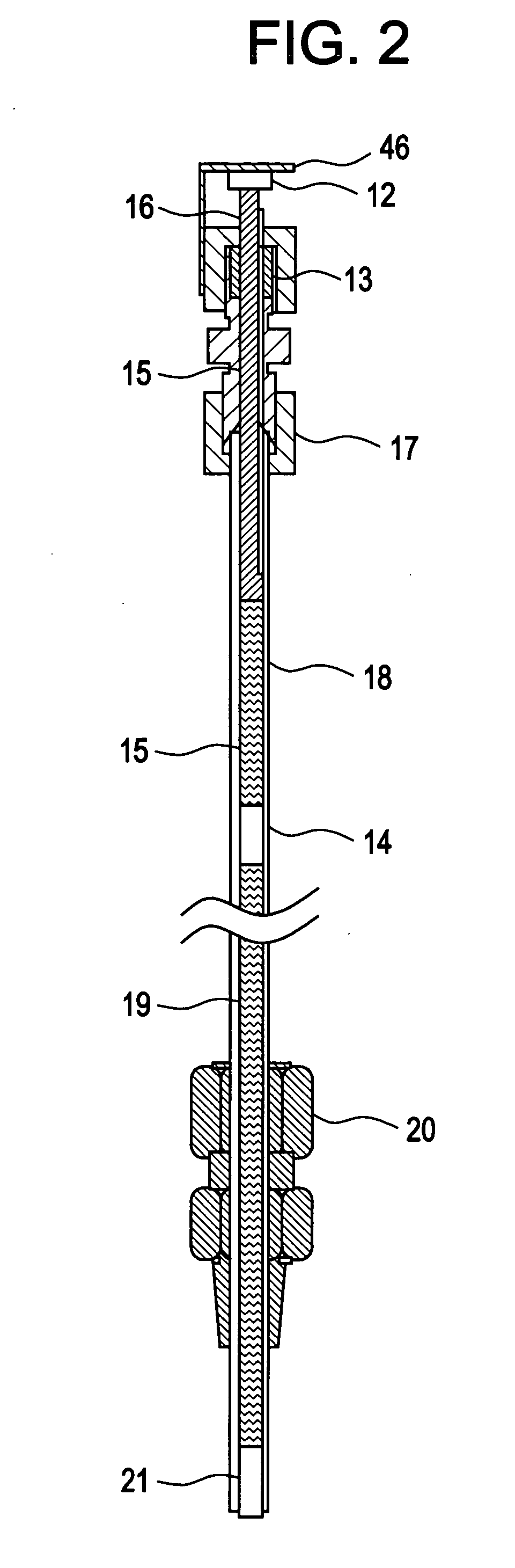

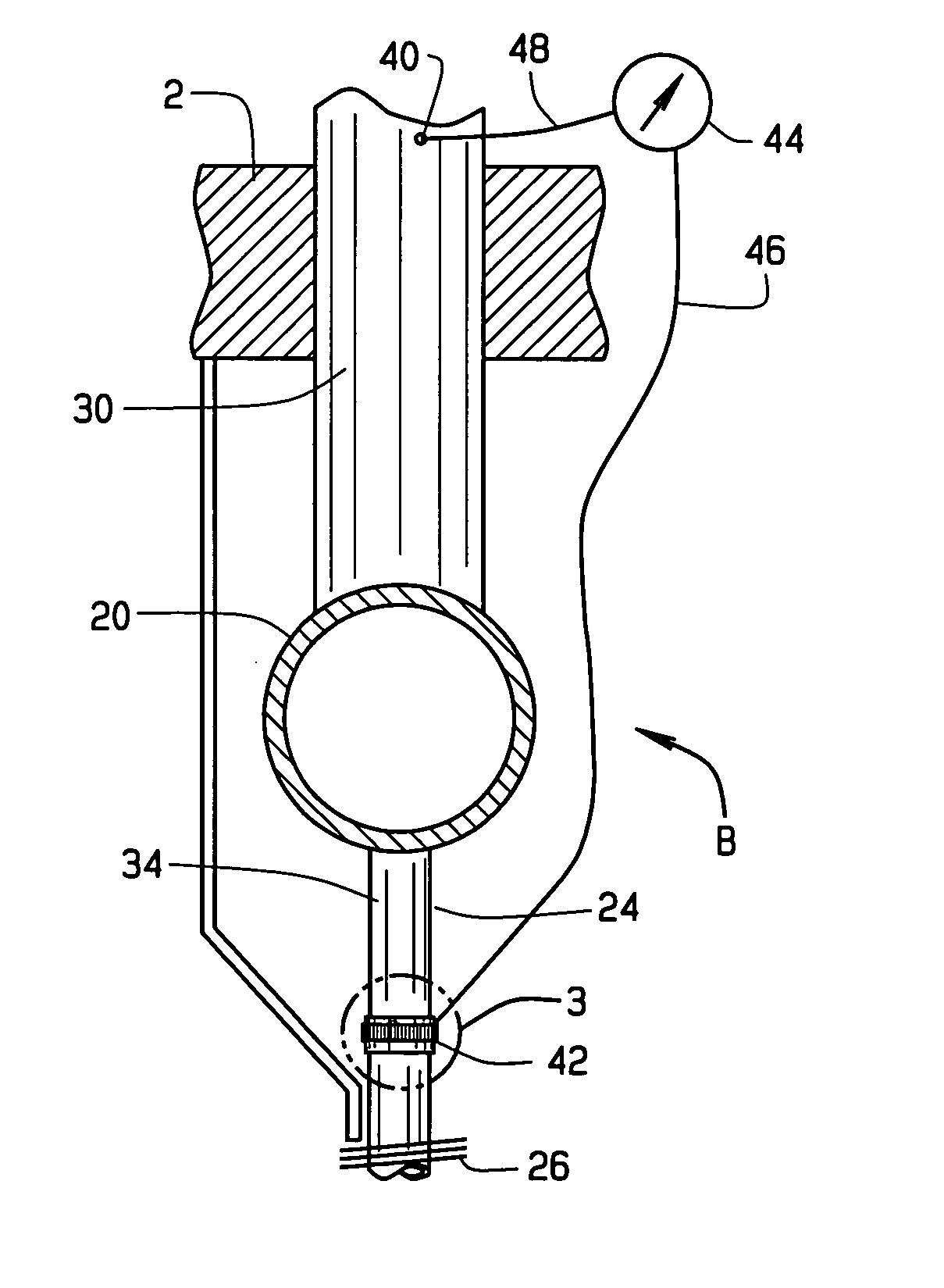

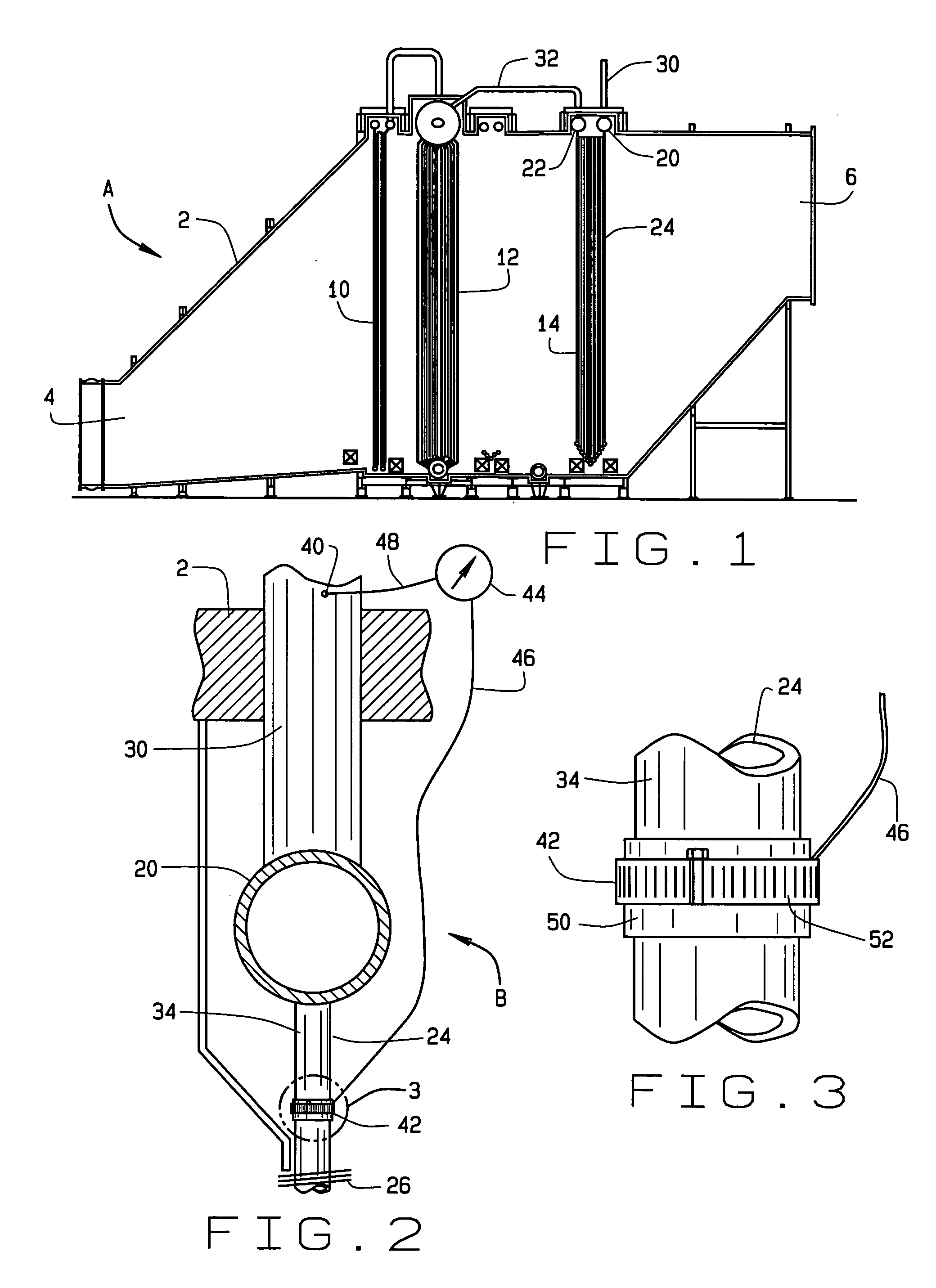

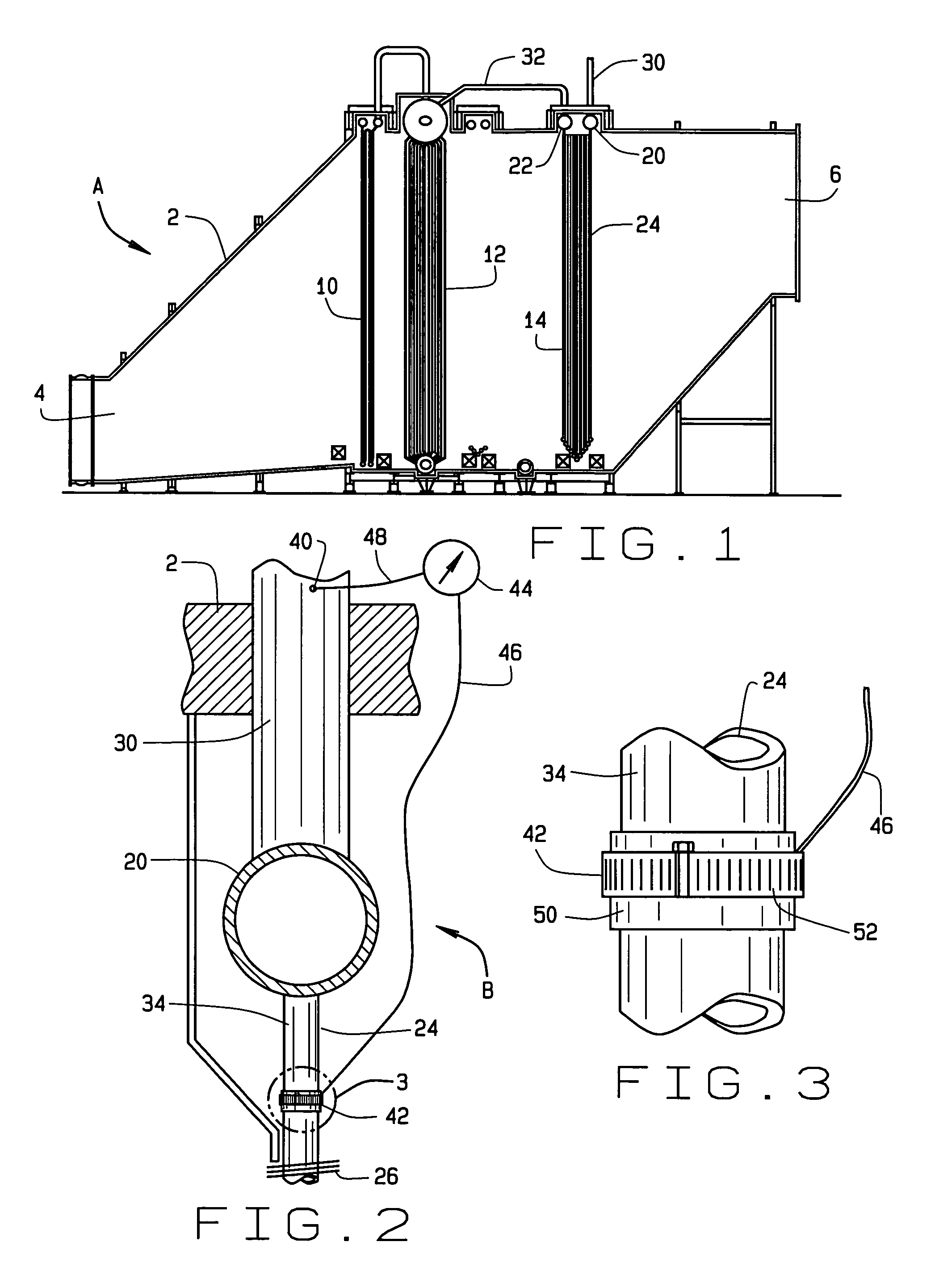

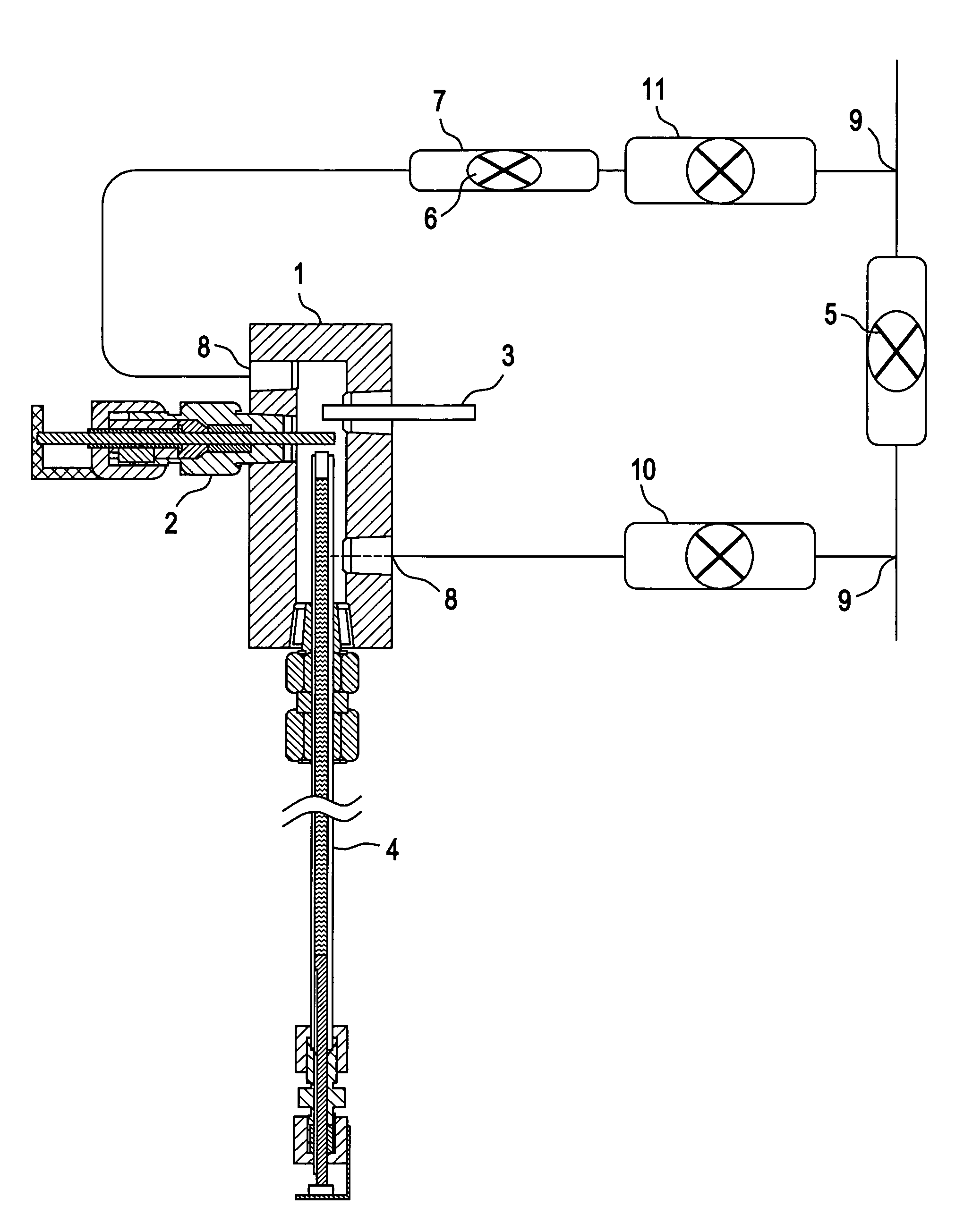

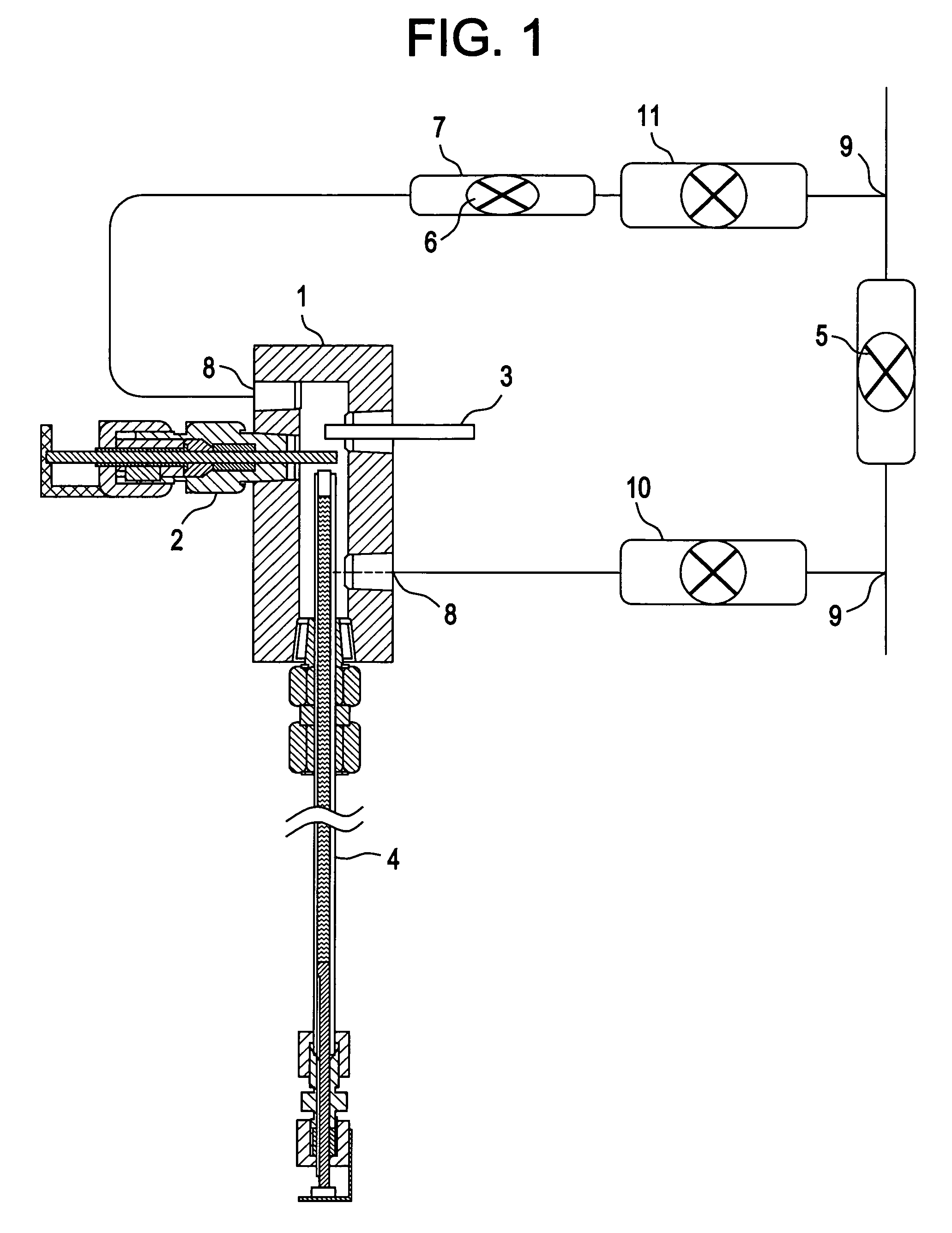

Apparatus and process for detecting condensation in a heat exchanger

A feedwater heater for an HRSG is provided with a monitoring unit for detecting the presence of condensation in the feedwater heater. The monitoring unit includes a dielectric band around one of the tubes of the feedwater heater near the location where the feedwater is directed into the heater and a conductive band located around the dielectric band. The unit also includes a conductivity sensor installed between a ground on the feedwater heater and the conductive element. Hot gases containing moisture pass through the feedwater heater, and if the temperature of surfaces in the region of the tube around which the dielectric and conductive bands extend drops below the dew point of the gas, an electrically conductive condensate will appear those surfaces and on the tube and will flow over the dielectric band, completing an electric circuit between the tube and the conductive band. The conductivity sensor detects this and hence detects the presence of the condensation.

Owner:NOOTER ERIKSEN INC

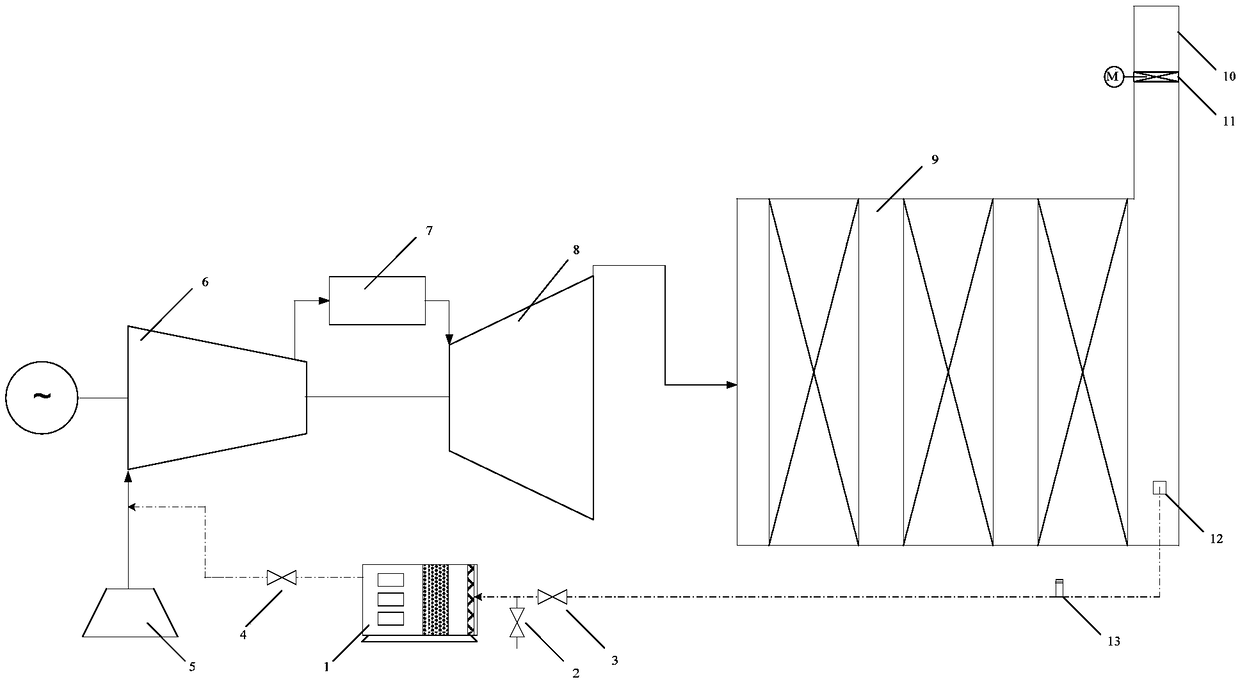

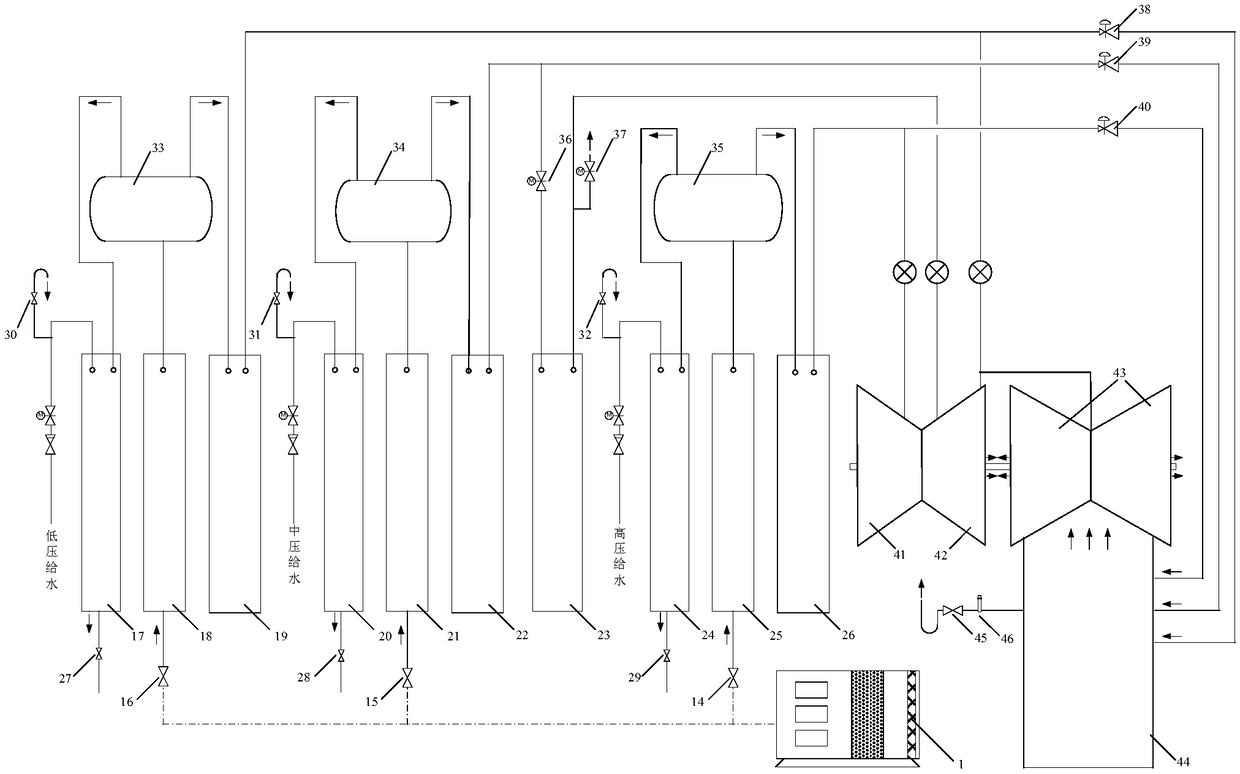

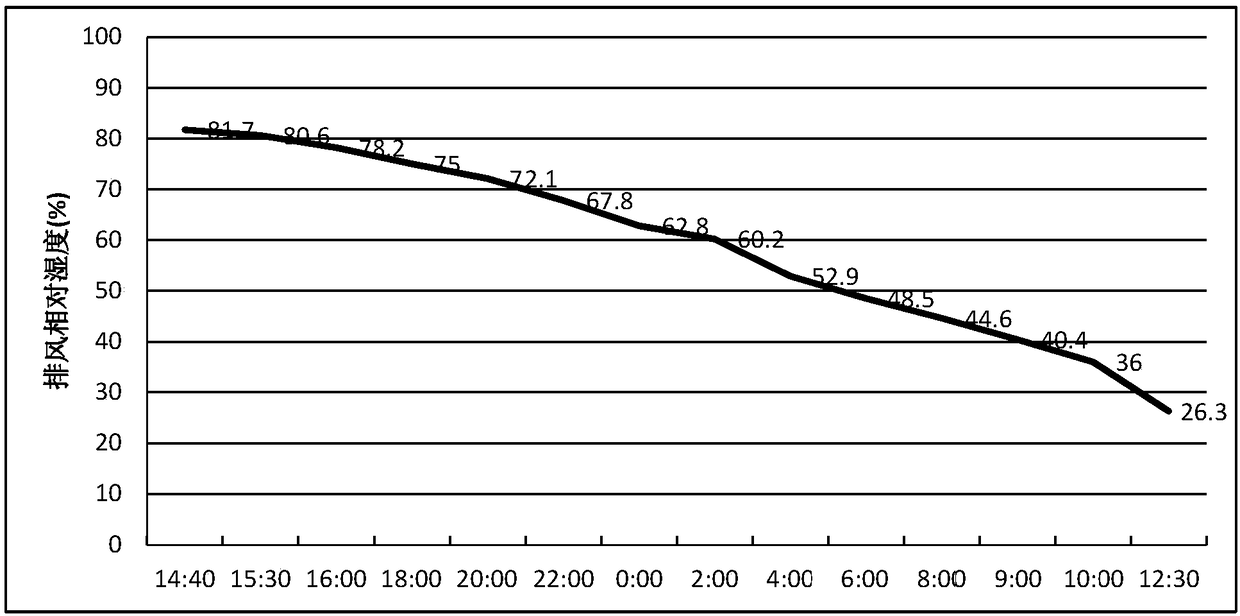

Corrosion prevention technology of combustion gas-steam combined cycle unit thermal system standby

ActiveCN108644016AMeeting stand-by corrosion protection needsComprehensive coverageDrying solid materials with heatGas turbine plantsOperation modeEngineering

The invention discloses a corrosion prevention technology of combustion gas-steam combined cycle unit thermal system standby. The corrosion prevention technology comprises a combustion gas-smoke system dry-air protection technology and an afterheat unit moisture system dry-air combined protection technology; the combustion gas-smoke system dry-air protection technology adopts a low-humidity dry-air aeration-drying scheme; the afterheat unit moisture system dry-air combined protection technology adopts a protection scheme combining chemical corrosion inhibition with dry-air drying; and the afterheat unit moisture system dry-air combined protection technology comprises the following four steps of afterheat drying, corrosion inhibitor protection, aeration drying and humidity maintenance. Thecorrosion prevention technology completely adapts to the characteristics of the structure, the operation mode, frequent standby and uncertain outage time of a combustion gas-steam combined cycle unitthermal system, total-system and total-period corrosion prevention of the thermal system in the outage state can be achieved, equipment corrosion during outage is controlled to the greatest extent, and the corrosion prevention technology has the remarkable advantages such as wide application scope, flexible operation, economy, environmental protection and the like.

Owner:HANGZHOU E ENERGY ELECTRIC POWER TECH +1

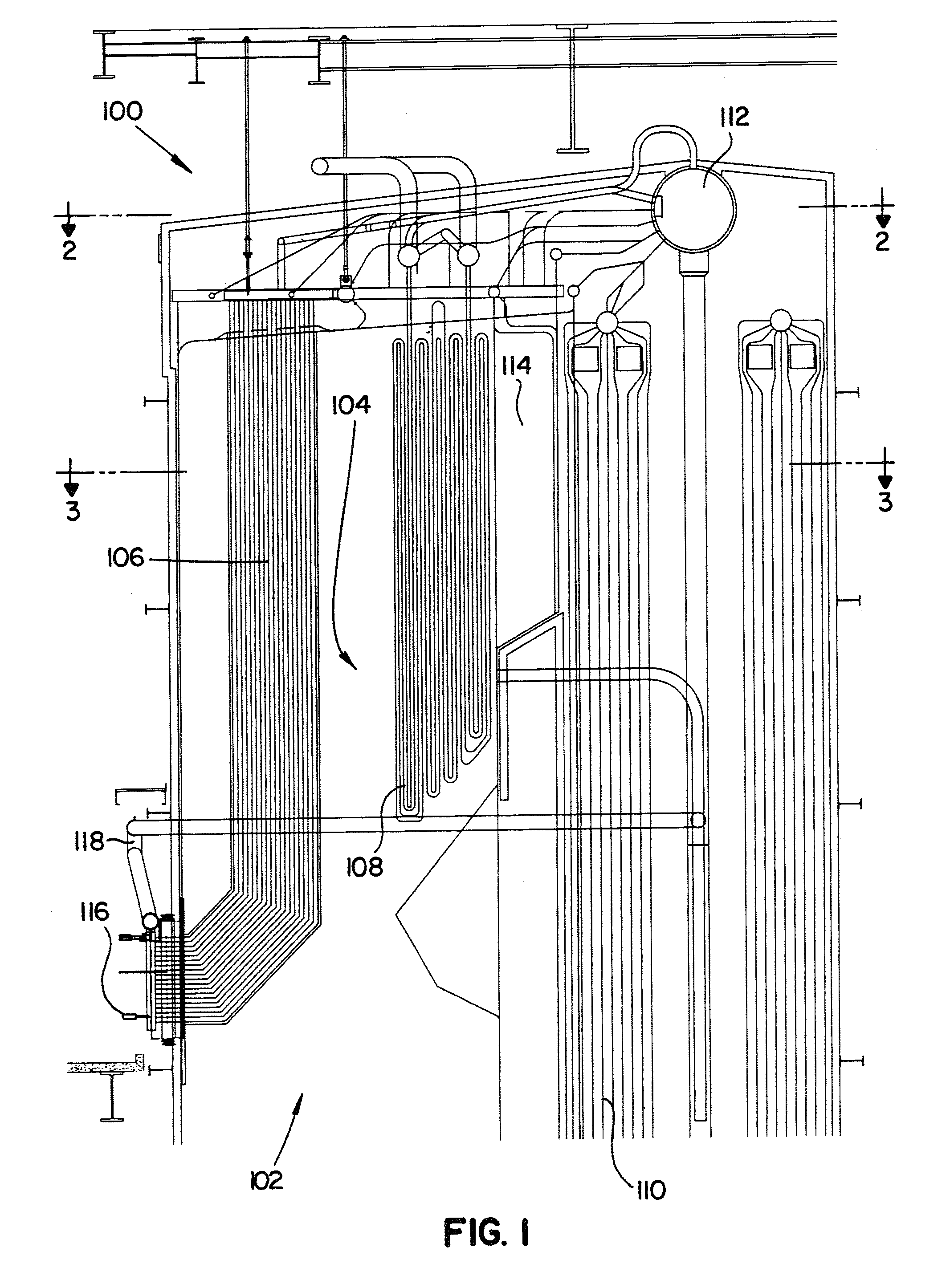

Apparatus and process for detecting condensation in a heat exchanger

A feedwater heater for an HRSG is provided with a monitoring unit for detecting the presence of condensation in the feedwater heater. The monitoring unit includes a dielectric band around one of the tubes of the feedwater heater near the location where the feedwater is directed into the heater and a conductive band located around the dielectric band. The unit also includes a conductivity sensor installed between a ground on the feedwater heater and the conductive element. Hot gases containing moisture pass through the feedwater heater, and if the temperature of surfaces in the region of the tube around which the dielectric and conductive bands extend drops below the dew point of the gas, an electrically conductive condensate will appear those surfaces and on the tube and will flow over the dielectric band, completing an electric circuit between the tube and the conductive band. The conductivity sensor detects this and hence detects the presence of the condensation.

Owner:NOOTER ERIKSEN INC

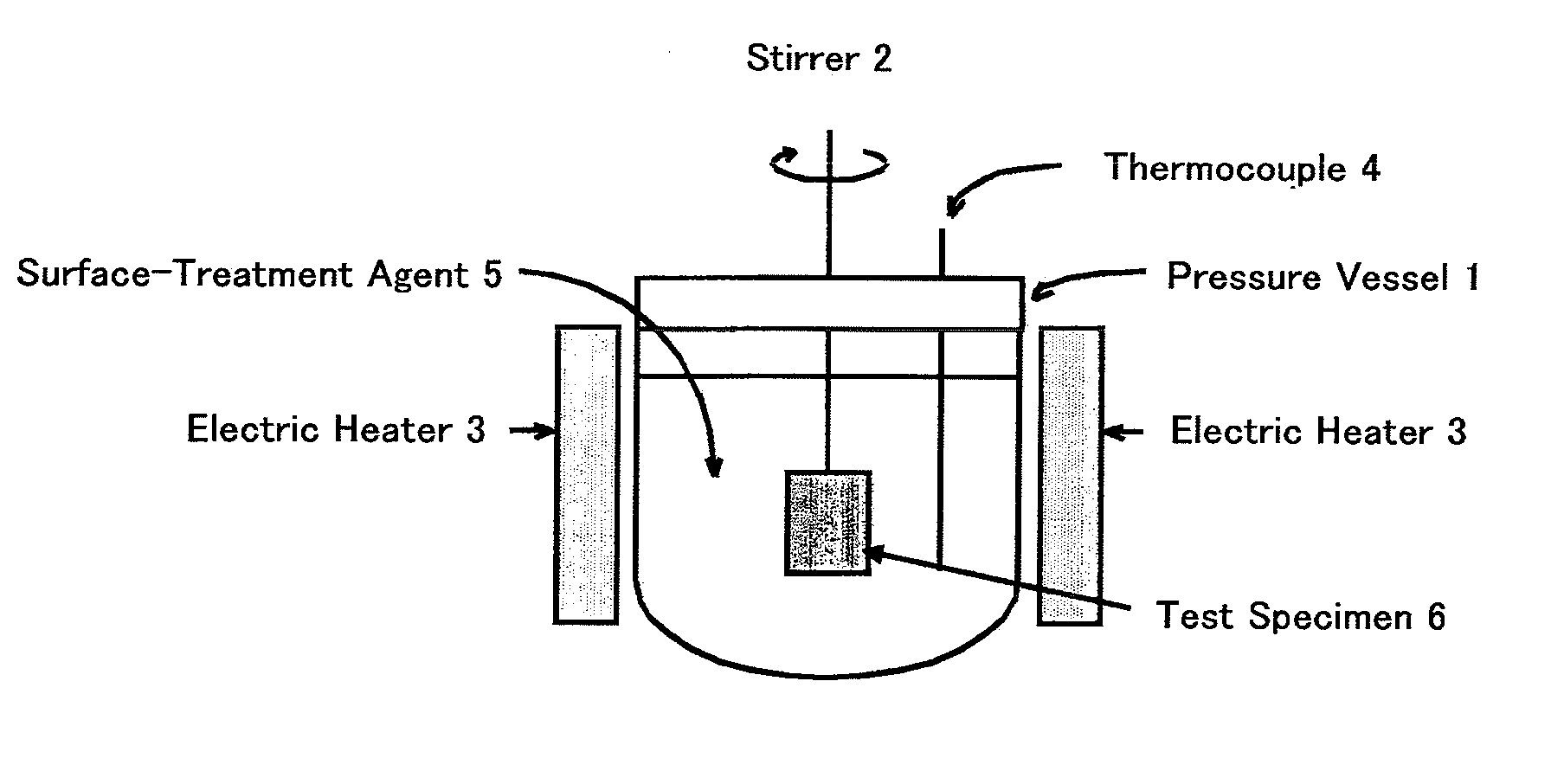

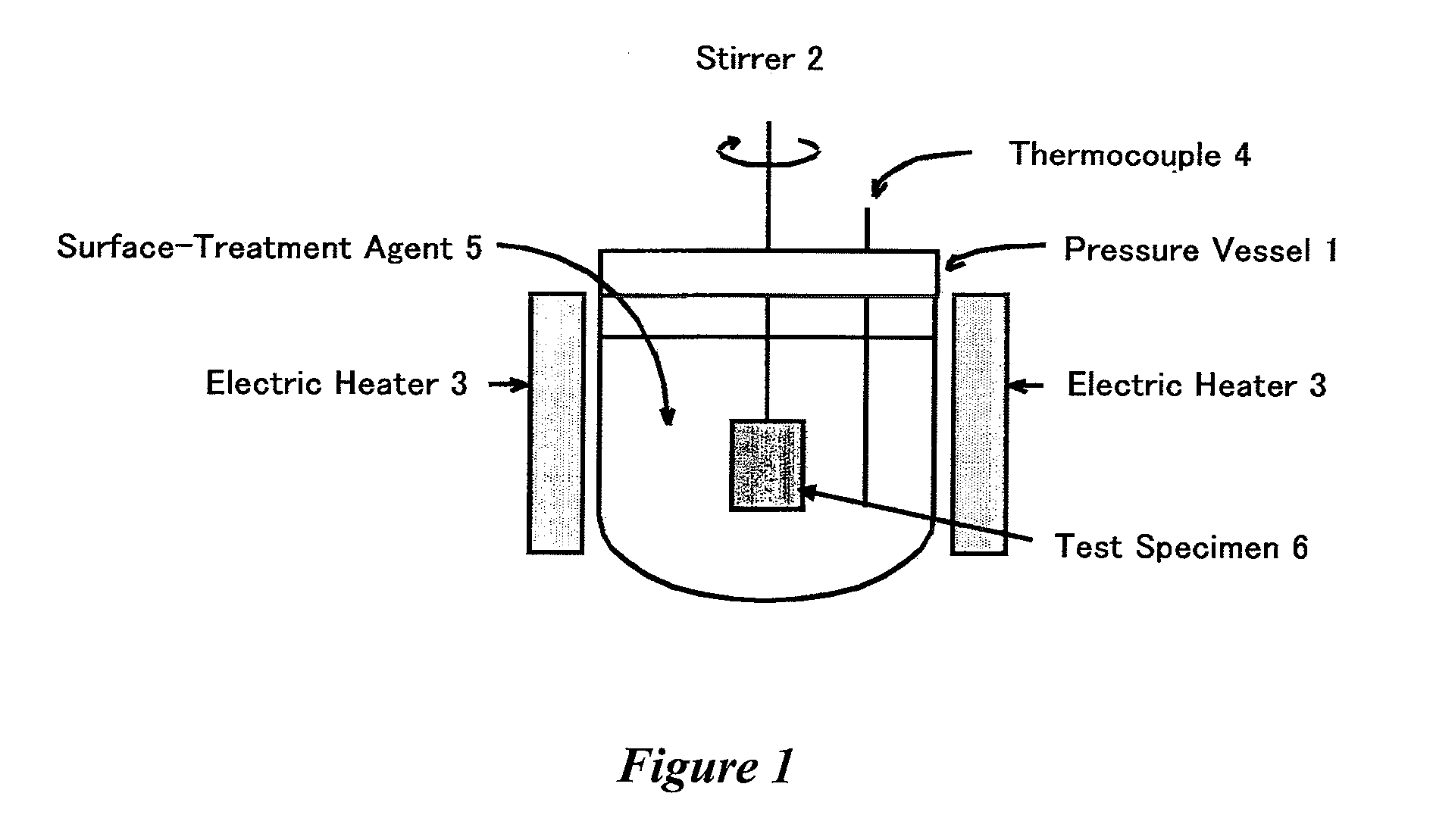

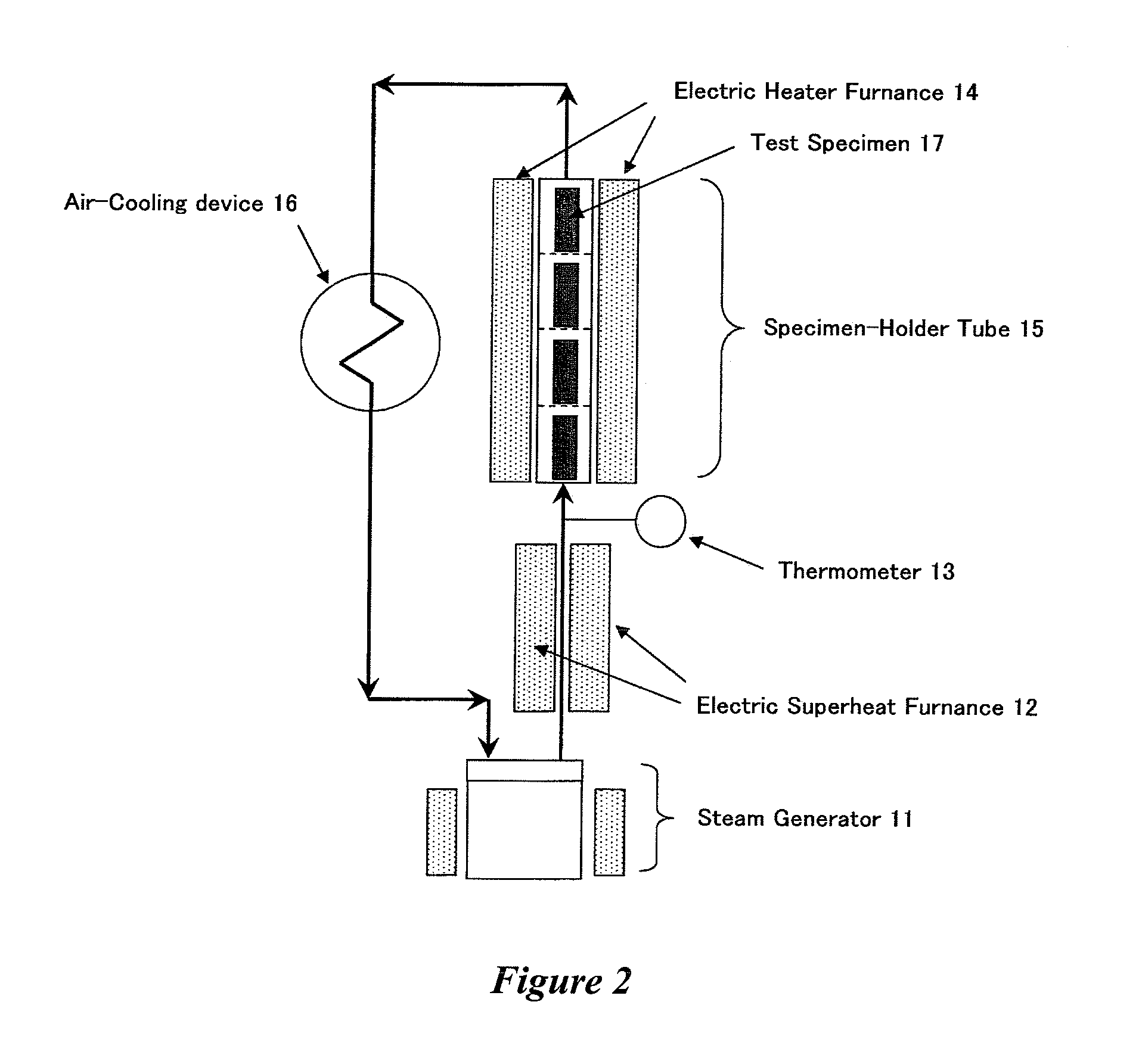

Method for treatment of iron-based metal surface exposed to superheated steam

InactiveUS20120145187A1Reduce frequencyImprove reliabilityCorrosion diminishing boiler componentsCarboxylic acidSuperheated steam

The present invention provides a surface treatment method for suppressing the formation and growth of superheated steam oxide scale on an iron-based metal surface exposed to superheated steam, comprising treating said iron-based metal surface with a surface-treatment agent which comprises a polyoxy saturated aliphatic mono- or di-carboxylic acid or a salt thereof and an amine compound represented by the following formula (I):Z(CH2CH2NH)nCH2CH2NH2 (I)wherein Z represents H or OH or NH2 group, and n is an integer of 0-5.

Owner:CHUBU ELECTRIC POWER CO INC +1

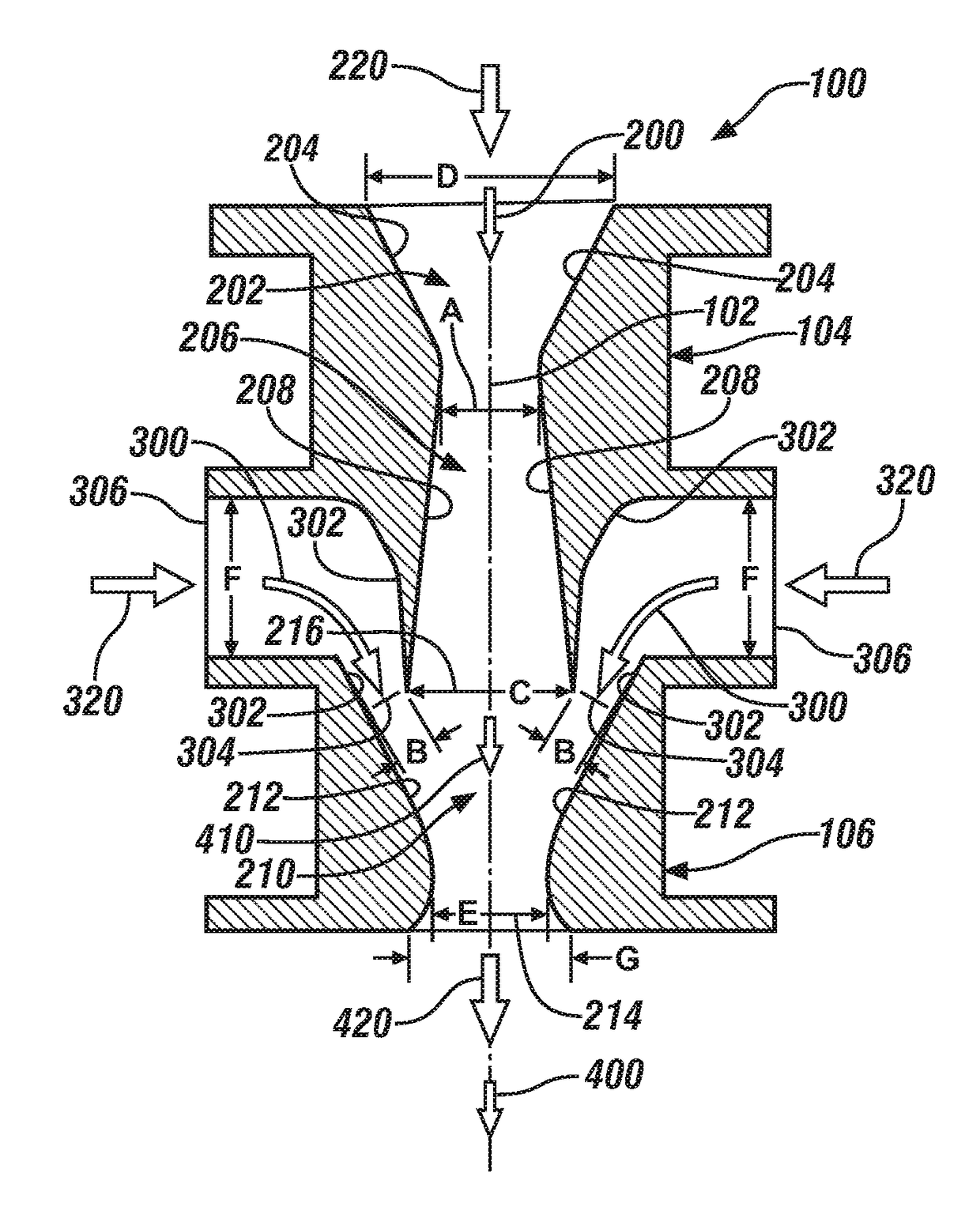

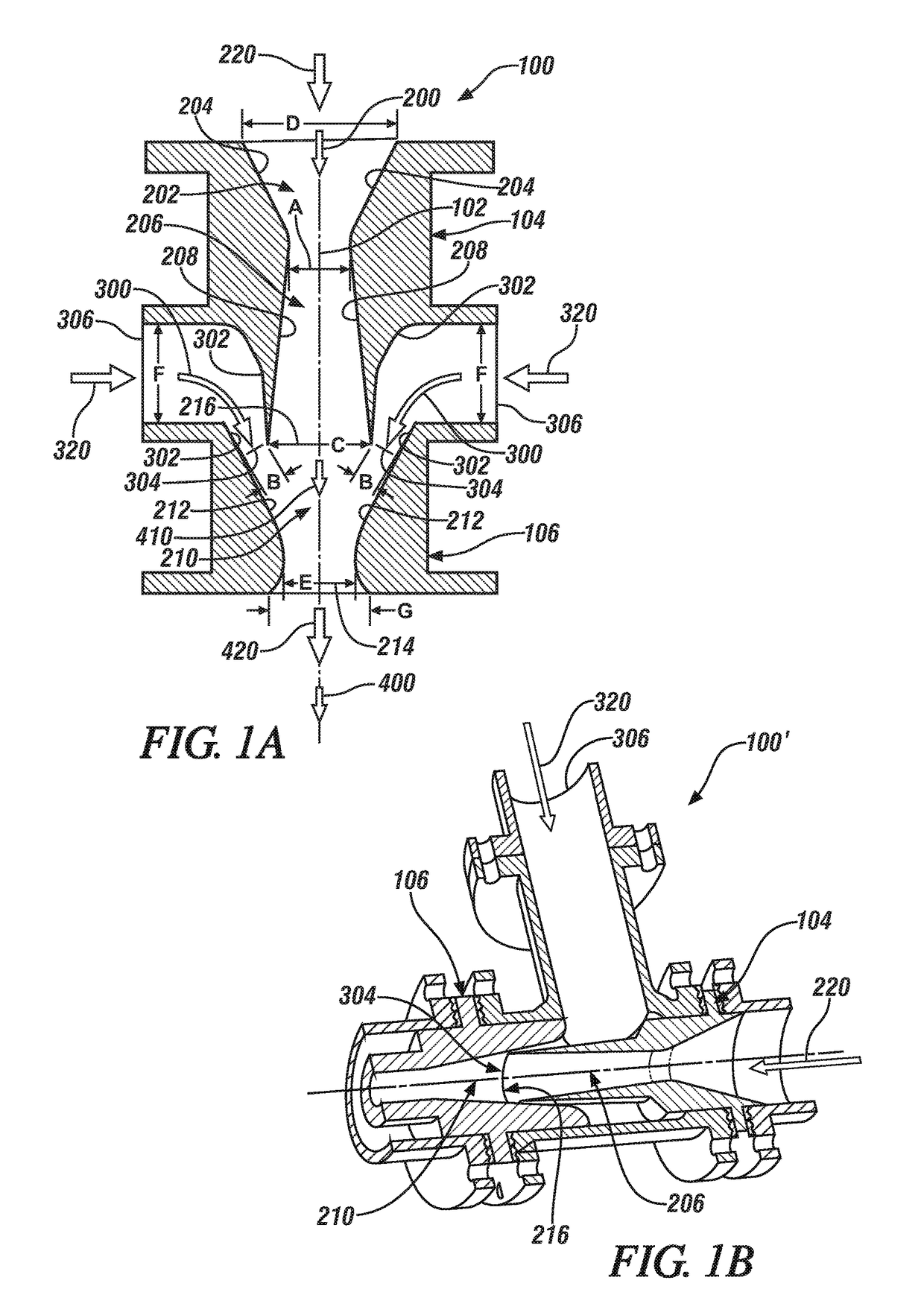

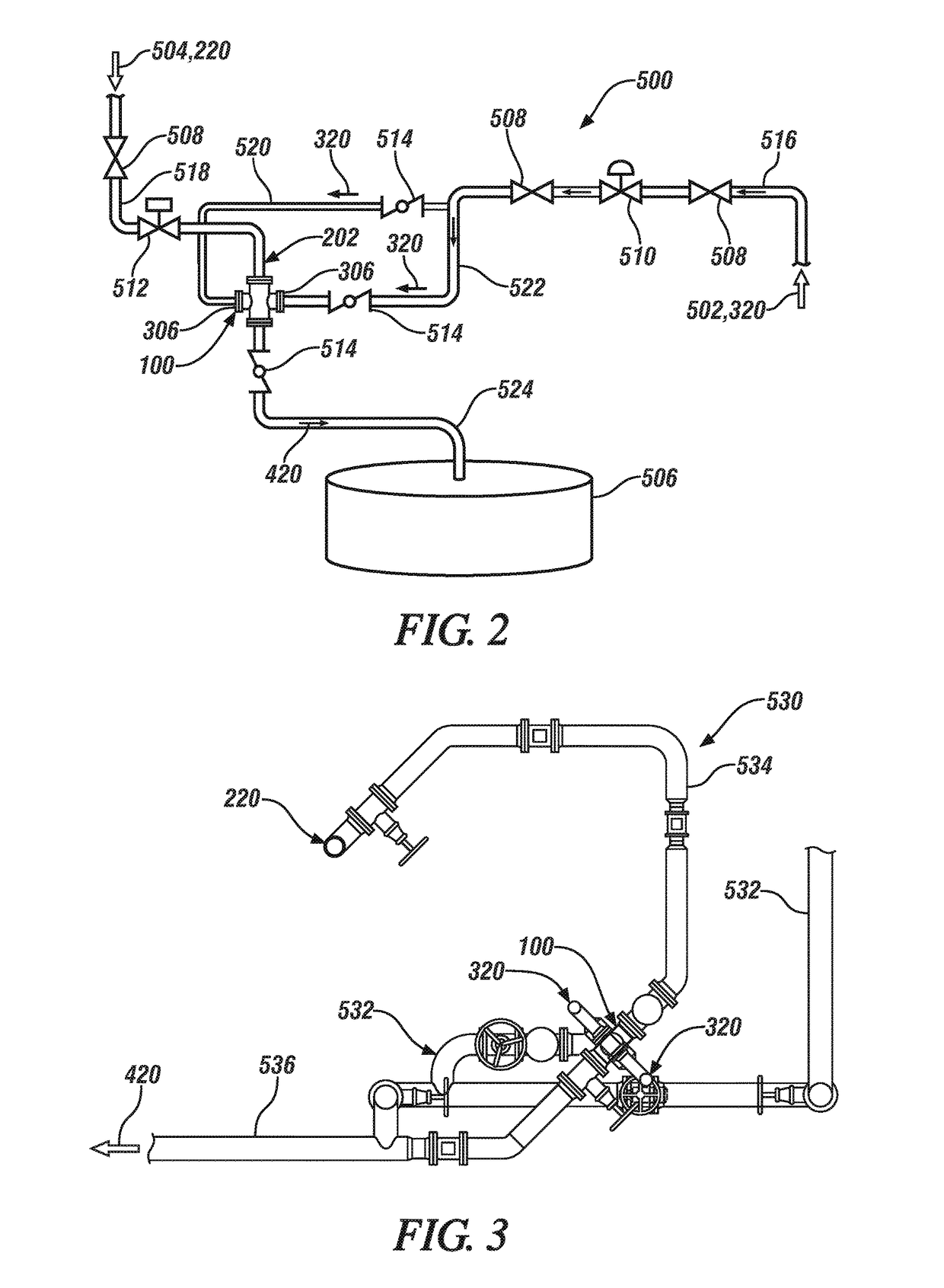

Multiphase device and system for heating, condensing, mixing, deaerating and pumping

An energy saving deaerator device includes: a first incoming flow path that generally follows a central axis of the device from a conically shaped inlet having converging sidewalls, to an expansion chamber having diverging sidewalls, to a compression chamber having converging sidewalls, to an outlet, a first entry port of the compression chamber being defined by an outlet of the expansion chamber; a second incoming flow path having sidewalls that converge to form a ring shaped second entry port of the compression chamber, the ring shaped second entry port being disposed around and concentric with the first entry port; and, wherein the first and second incoming flow paths converge at the compression chamber, with both flow paths being directed toward the outlet, to form an outgoing flow path.

Owner:KREMER ROBERT

Method of inhibiting corrosion in hot water systems

ActiveUS7635449B2Avoid corrosionEliminate needWater treatment parameter controlSpecific water treatment objectivesPhysical chemistryThermal water

This invention concerns methods and apparatus for measuring oxidation reduction potentials of water in a hot water system at system temperature and pressure and methods of using the measured oxidation-reduction potential to monitor and control the addition of oxygen scavengers or oxygen to the system in order to maintain effective corrosion inhibiting concentrations of the oxygen scavengers or dissolved oxygen in the system.

Owner:ECOLAB USA INC

Combined cycle power plant

A combined cycle power plant in which a gas turbine engine generates power, a heat recovery steam generator (HRSG) produces steam from high energy fluids produced from the generation of power in the gas turbine engine and a steam turbine engine generates additional power from the steam produced in the HRSG. The combined cycle power plant includes a heating element fluidly interposed between the steam turbine engine and the HRSG to heat fluid output from the steam turbine engine, which is to be fed to the HRSG and a control system to control an amount the fluid output from the steam turbine engine is heated by the heating element based on differences between HRSG and ambient temperatures.

Owner:GE INFRASTRUCTURE TECH INT LLC

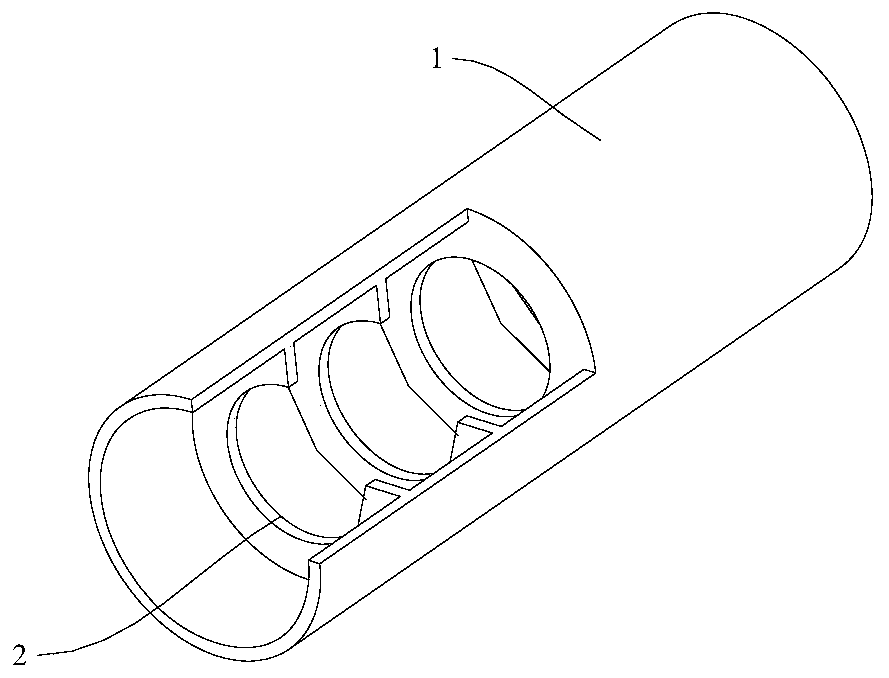

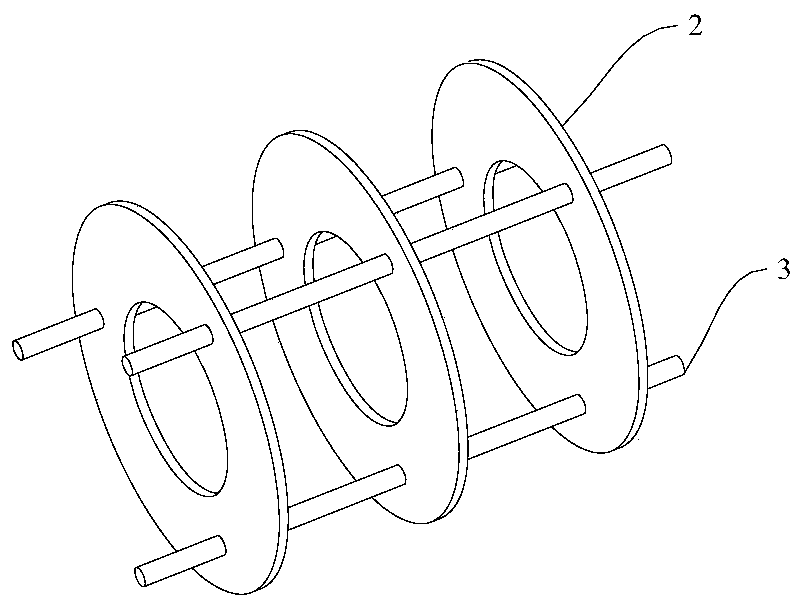

Heat exchange tube of waste heat boiler

ActiveCN110763066AAvoid corrosionEnhanced disturbance heat transferBoiler flue tubes/fire tubesBoiler water tubesCoated surfaceMaterials science

The invention discloses a heat exchange tube of a waste heat boiler. The heat exchange tube comprises a tube body. An anti-corrosion coating is sprayed to the outer surface of the tube body. Components of the anti-corrosion coating comprise Al2O3, CaAl2O4 and Ca3(PO4)2. On the surface of the nanometer anti-corrosion coating, HF reacts with Al2O3, CaAl2O4 and Ca3(PO4)2 to generate AlF3 and Ca5(PO4)3F to closely wrap the surface of the coating, and therefore corrosion of HF to the interior of the coating and the heat exchange tube is effectively stopped. Meanwhile, due to the adoption of the anti-corrosion coating with the specific components, the heat exchange tube can resist fluorine corrosion under the high temperature being 600 DEG C or above, and the heat exchange tube can be used underthe largest high temperature being 1000 DEG C or above.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com