Corrosion reduction system for power generation plants during shutdown

a power generation plant and shutdown technology, applied in the direction of corrosion diminishing boiler components, specific water treatment objectives, water/sludge/sewage treatment, etc., can solve the problems of overheating tube failure, hydrogen damage, and under deposit corrosion attack, so as to reduce or eliminate internal contamination. , the effect of reducing the corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

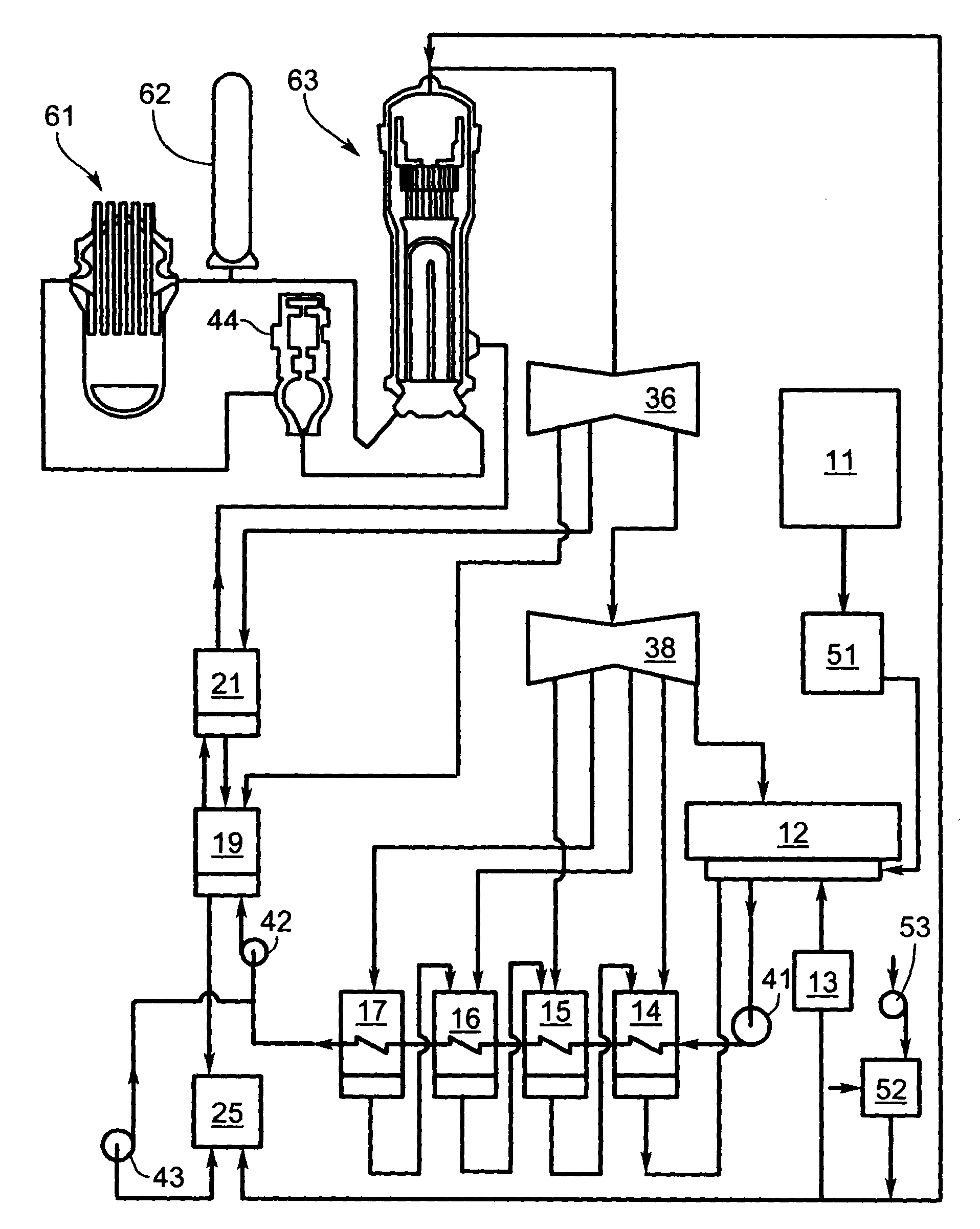

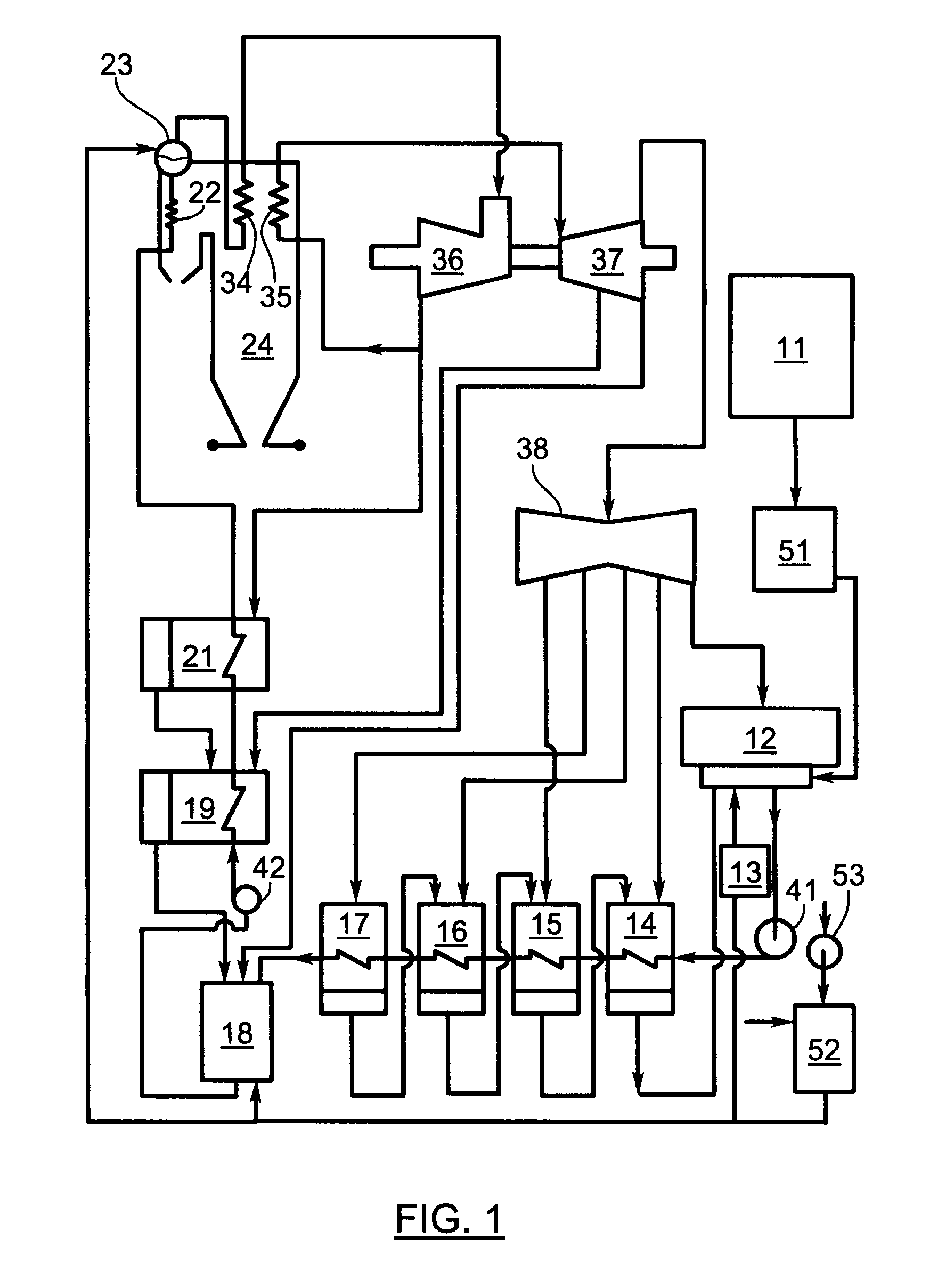

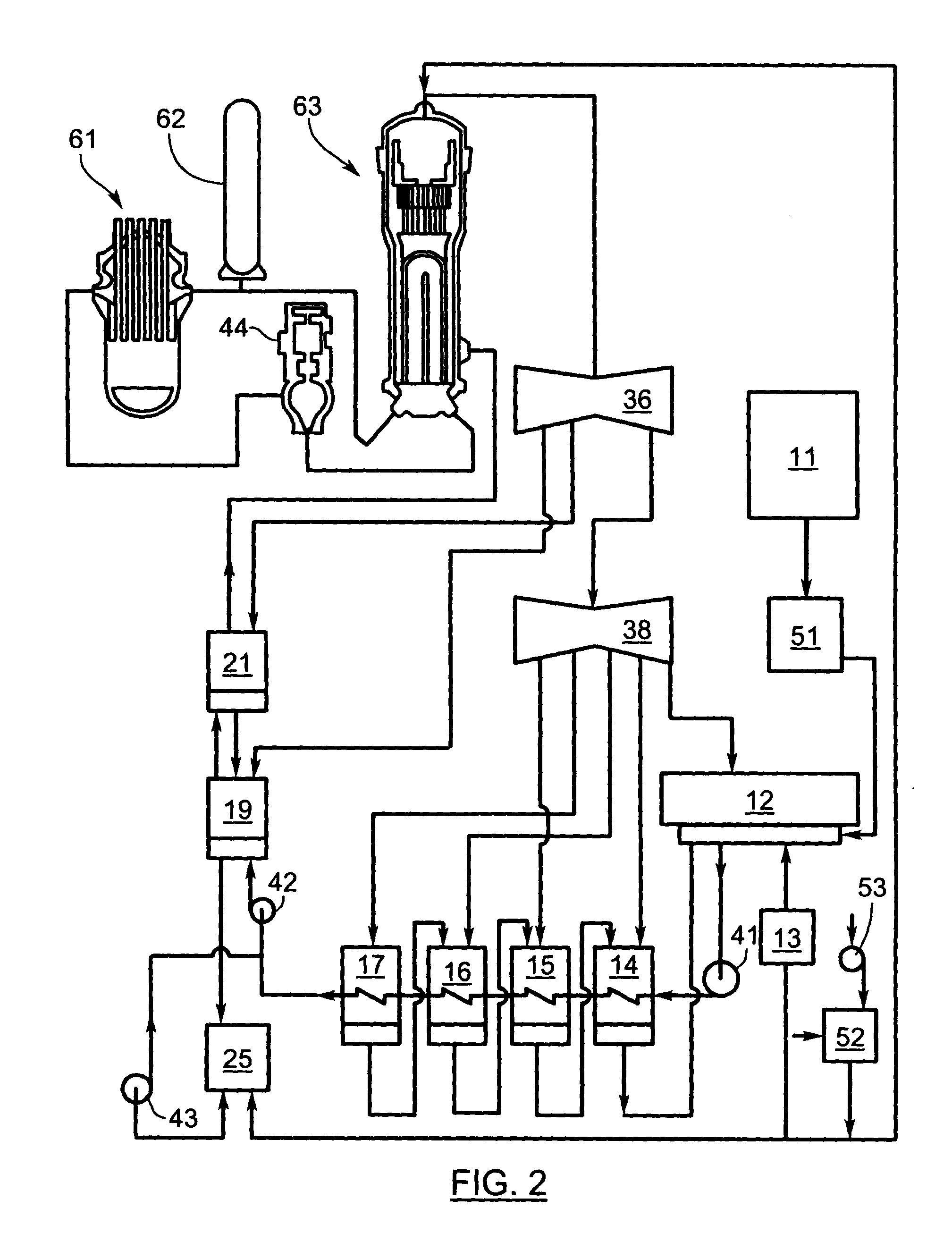

[0024]In order to more clearly understand the present invention part numbers as assigned in the following parts list will be used:

Part NumberDescription11make-up water (condensate) storage12main steam condenser13vacuum breaker14low pressure heater15low pressure heater16low pressure heater17low pressure heater18de-aerating heater19high pressure heater21high pressure heater22economizer23steam drum24boiler25drain tank34superheater35reheater36high pressure turbine37intermediate pressure turbine38low pressure turbine41condensate extraction pump42boiler feed pump43drains pump44pump51water anion polisher52acidic gases filter53air blower61nuclear reactor62pressurizer63steam generator

[0025]The first device (51) is the water anion polisher (WAP), which consists of a tank with anion exchanger designed to remove acidic contaminants from any water flowing into the cycle from a storage tank. It is preferred that the device 51 is installed on the effluent from each water storage tank. As an altern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion properties | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com