Boiler Apparatus

a technology of boilers and heat exchange tubes, which is applied in the direction of lighting and heating apparatus, steam boiler components, steam boilers, etc., can solve the problems of affecting the service life of economizers, and affecting the service life of steam boilers. , to achieve the effect of preventing damage to the boiler and the economizer, reducing the corrosion of heat exchange tubes, and reducing the risk of failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

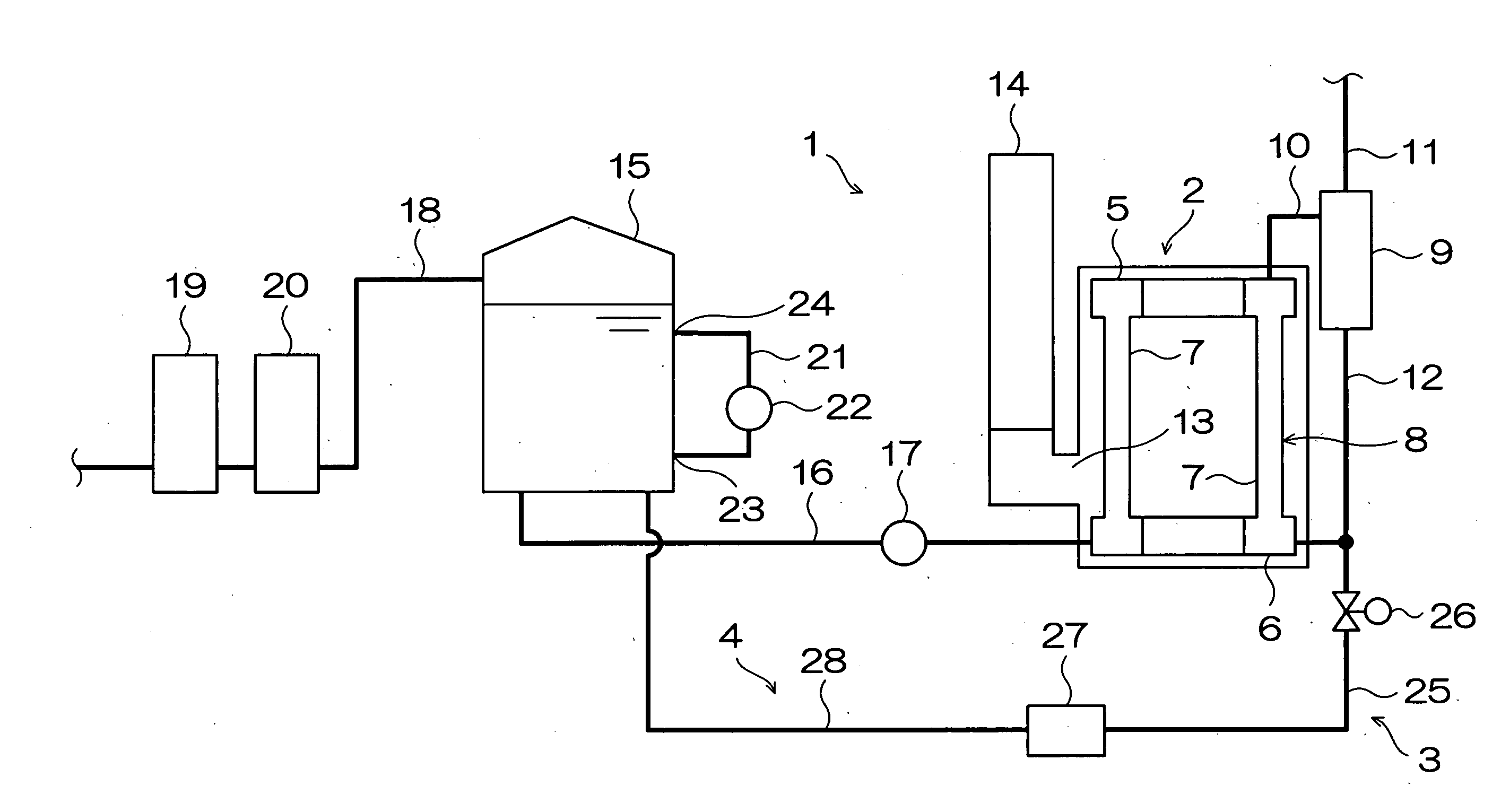

[0045]In the following, a first embodiment of the present invention will be described in detail with reference to the corresponding figure. FIG. 1 is a schematic diagram showing a construction of a boiler apparatus according to the first embodiment of the present invention. The boiler apparatus 1 is mainly equipped with a boiler 2, boiler water gathering means 3, and boiler water adding means 4.

[0046]The boiler 2 is a so-called multi-tubular water tube boiler, and is equipped with a boiler body 8 in which a large number of water tubes (heat transfer tubes) 7 are arranged upright between an upper header 5 and a lower header 6. The upper header 5 is connected to a water separator 9 through a steam supply channel 10, and the upper portion of the water separator 9 is connected to a load apparatus (not shown) through steam piping 11. To recover separated water, the lower portion of the water separator 9 is connected to the lower header 6 through a down corner 12. Further, connected to th...

second embodiment

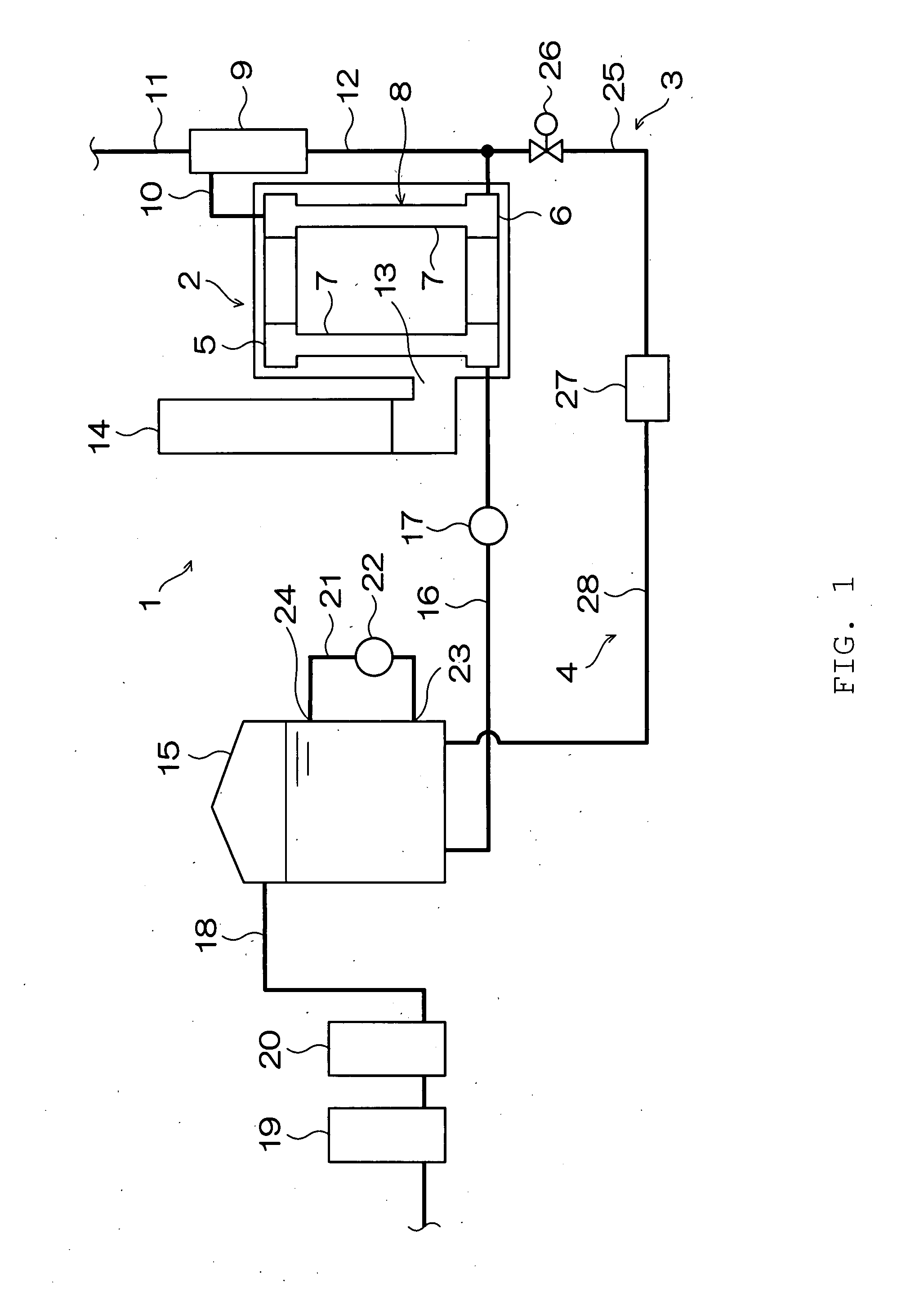

[0056]Next, the second embodiment of the present invention will be described in detail with reference to the corresponding figure. The second embodiment is a modification of the first embodiment of the present invention. FIG. 2 is a schematic diagram showing a construction of a boiler apparatus according to the second embodiment of the present invention. In FIG. 2, components that are the same as those of the first embodiment of the present invention are indicated by the same reference numerals, and a detailed description of such components will be omitted.

[0057]In the second embodiment of the present invention, the water supply channel 18 extends toward the bottom of the supply water tank 15. That is, the supply water that has undergone treatment at the water softener 19 and the deoxidizer 20 flows to the bottom of the supply water tank 15. Further, the other end of the boiler water supply channel 28 is connected to the lower portion of the supply water tank 15 at a position in clo...

third embodiment

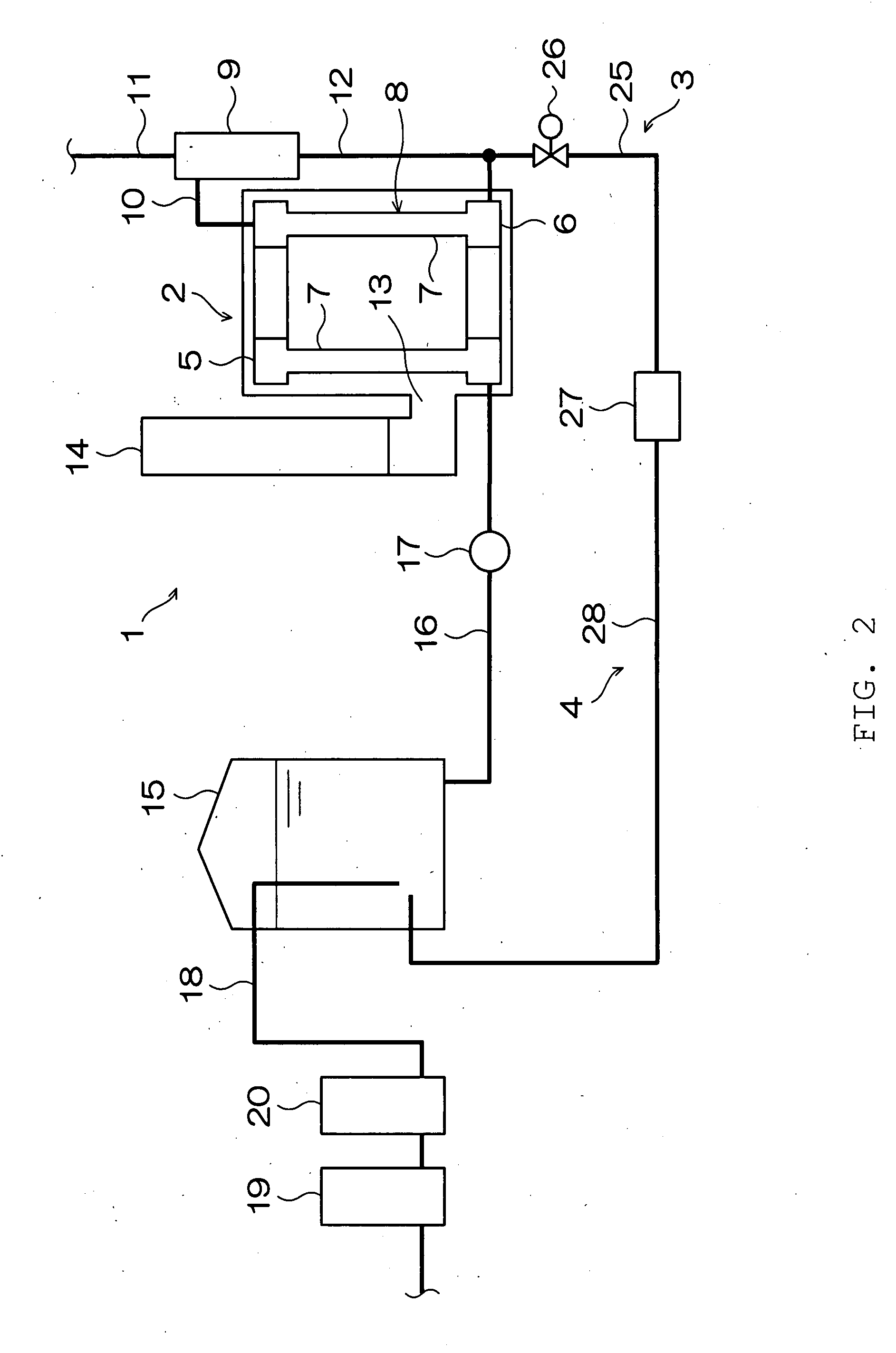

[0062]Next, a third embodiment of the present invention will be described in detail with reference to the corresponding figure.

[0063]FIG. 3 is a schematic diagram showing a construction of a boiler apparatus according to the third embodiment of the present invention. In FIG. 3, the components that are the same as those of the first embodiment and the second embodiment are indicated by the same reference numerals, and a detailed description of such components will be omitted. A boiler apparatus 29 according to the third embodiment is mainly equipped with an economizer 30 in addition to the boiler 2, the boiler water gathering means 3, and the boiler water adding means 4.

[0064]In the boiler 2, the gas duct 13 is connected to an exhaust gas inlet 31 of the economizer 30. Further, the exhaust pipe 14 is connected to an exhaust gas outlet 32 of the economizer 30. In an exhaust gas circulation space 33 of the economizer 30, there is provided a heat transfer tube 34 causing supply water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com