Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Testing ultrasound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sonography Test. Test Significance: Sonography is an ultrasound based diagnostic imaging technique used to visualize subcutaneous body structures including tendons, muscles, joints, vessels and internal organs.Ultrasounds are commonly used to detect or aid in the detection of abnormalities and conditions related to pregnancy.

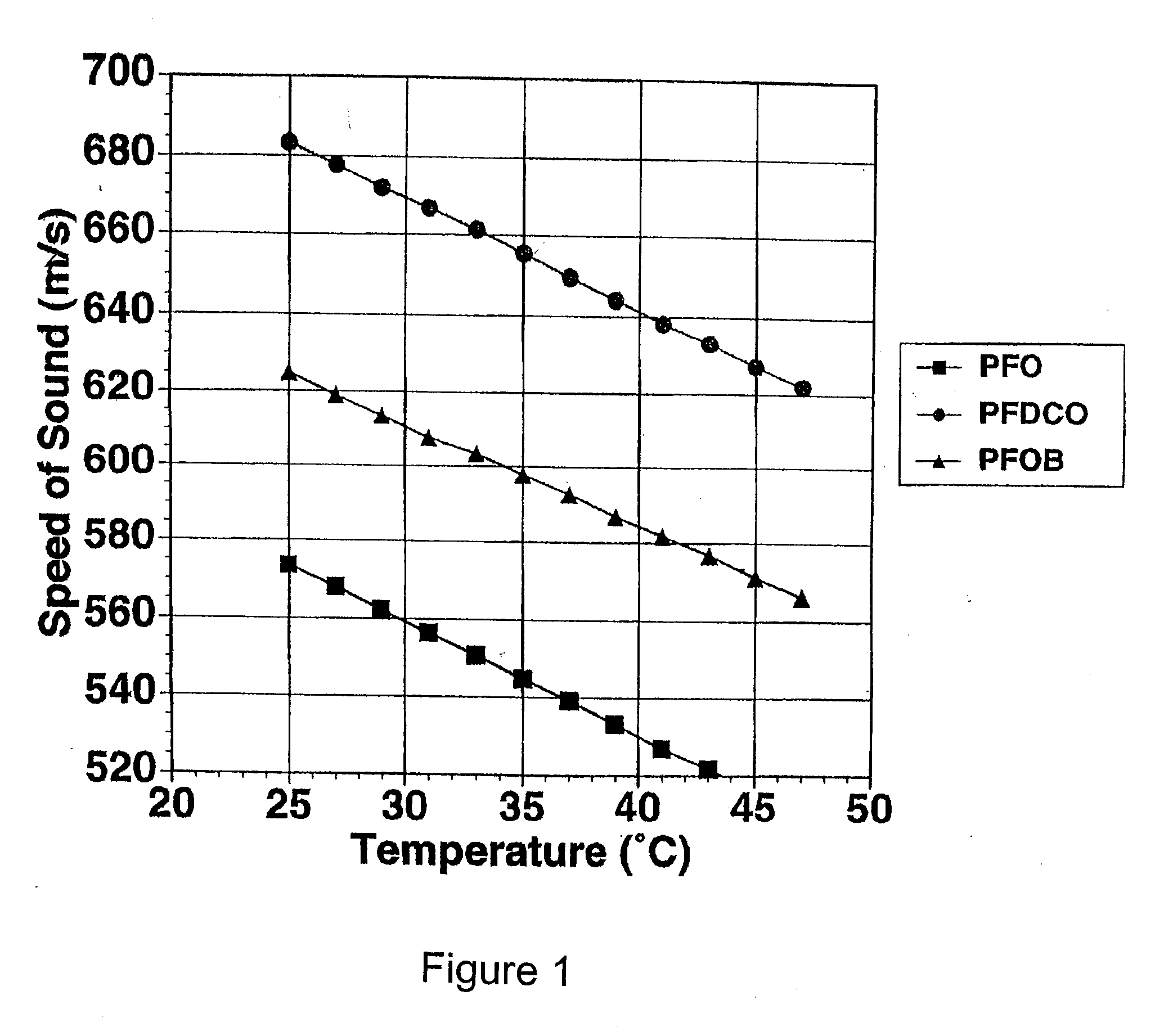

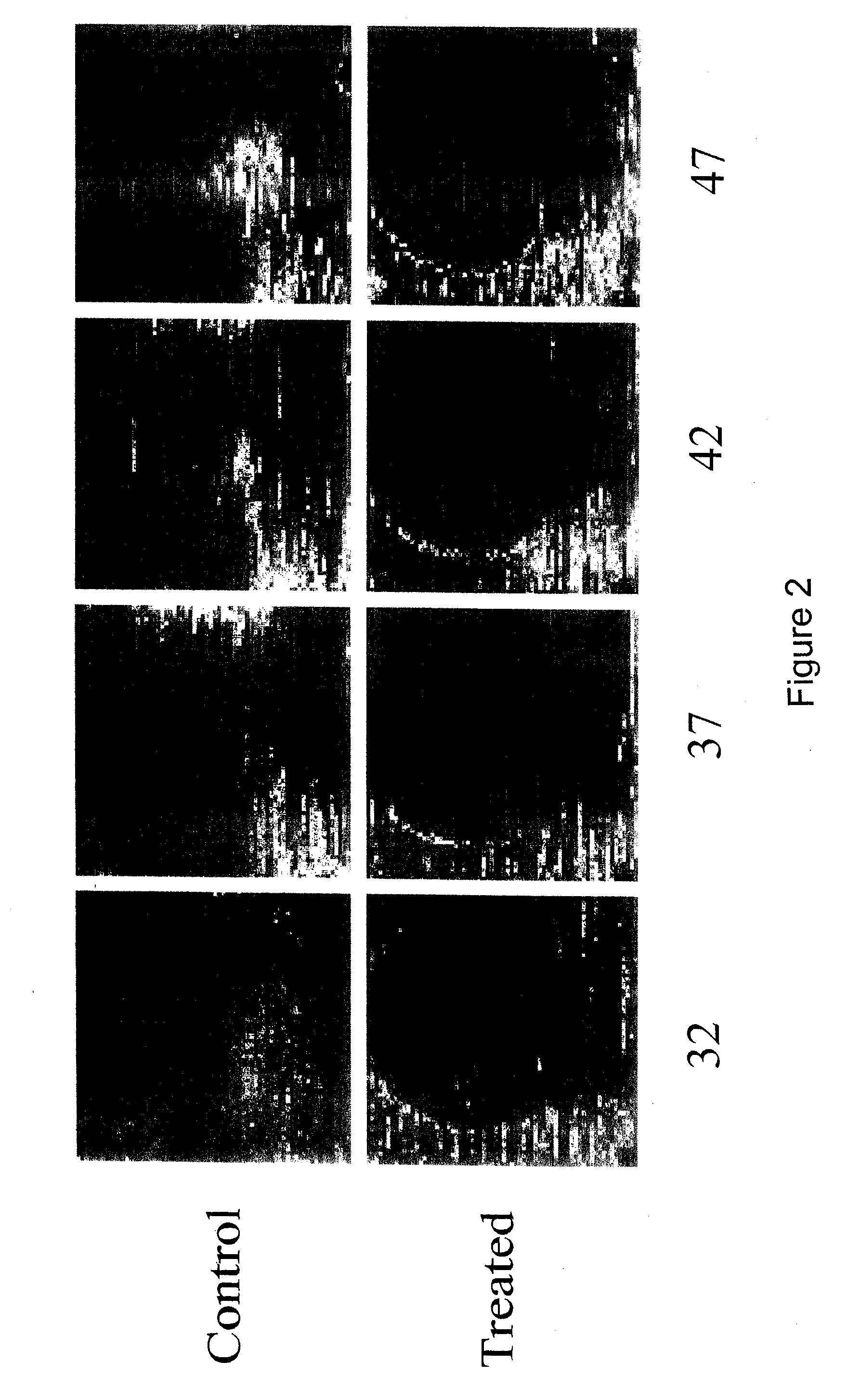

Enhanced ultrasound detection with temperature-dependent contrast agents

InactiveUS7179449B2Enhancing acoustic reflectivityLittle and no detectable change in acoustic reflectivityUltrasonic/sonic/infrasonic diagnosticsBiocideDiagnostic Radiology ModalityImaging modalities

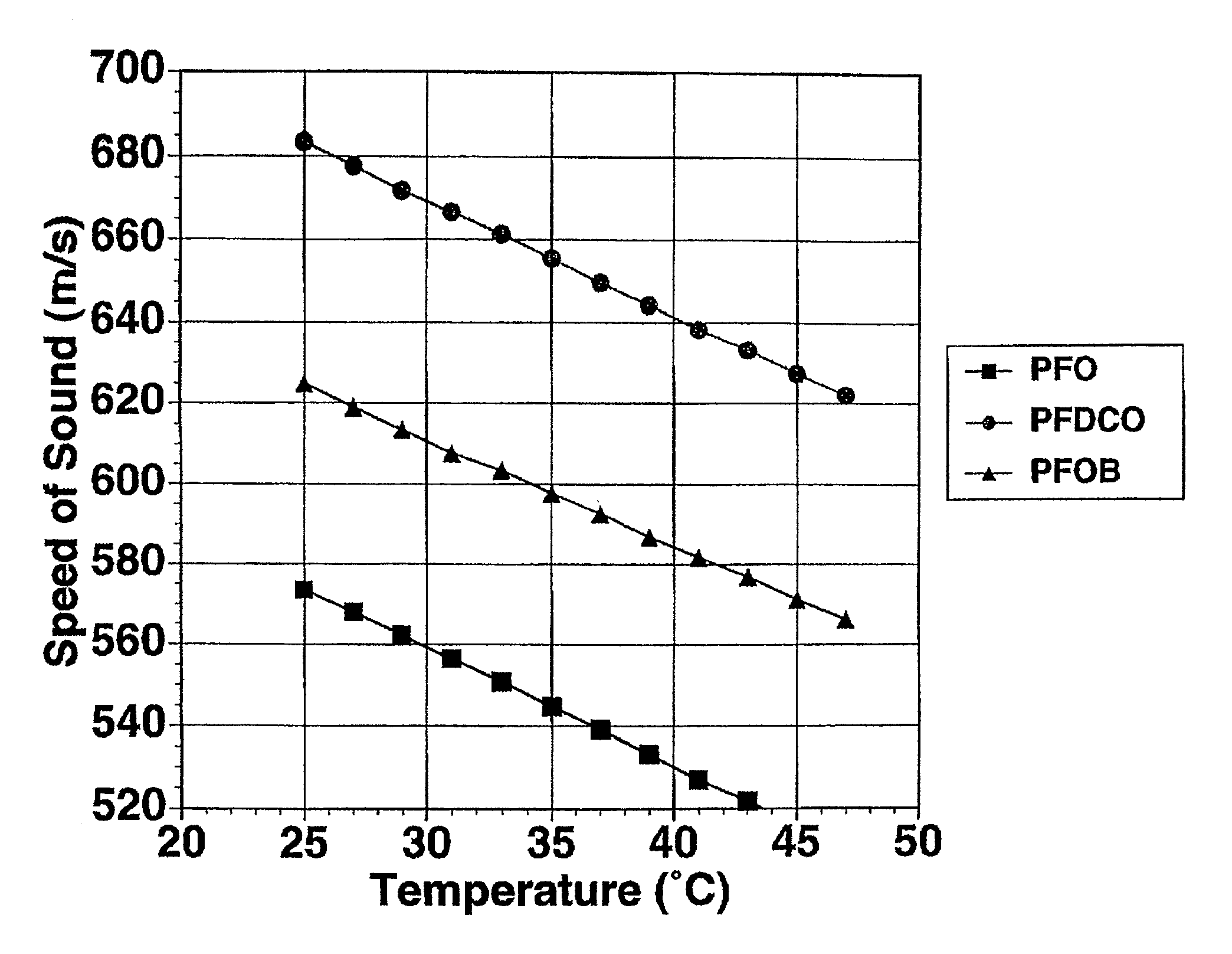

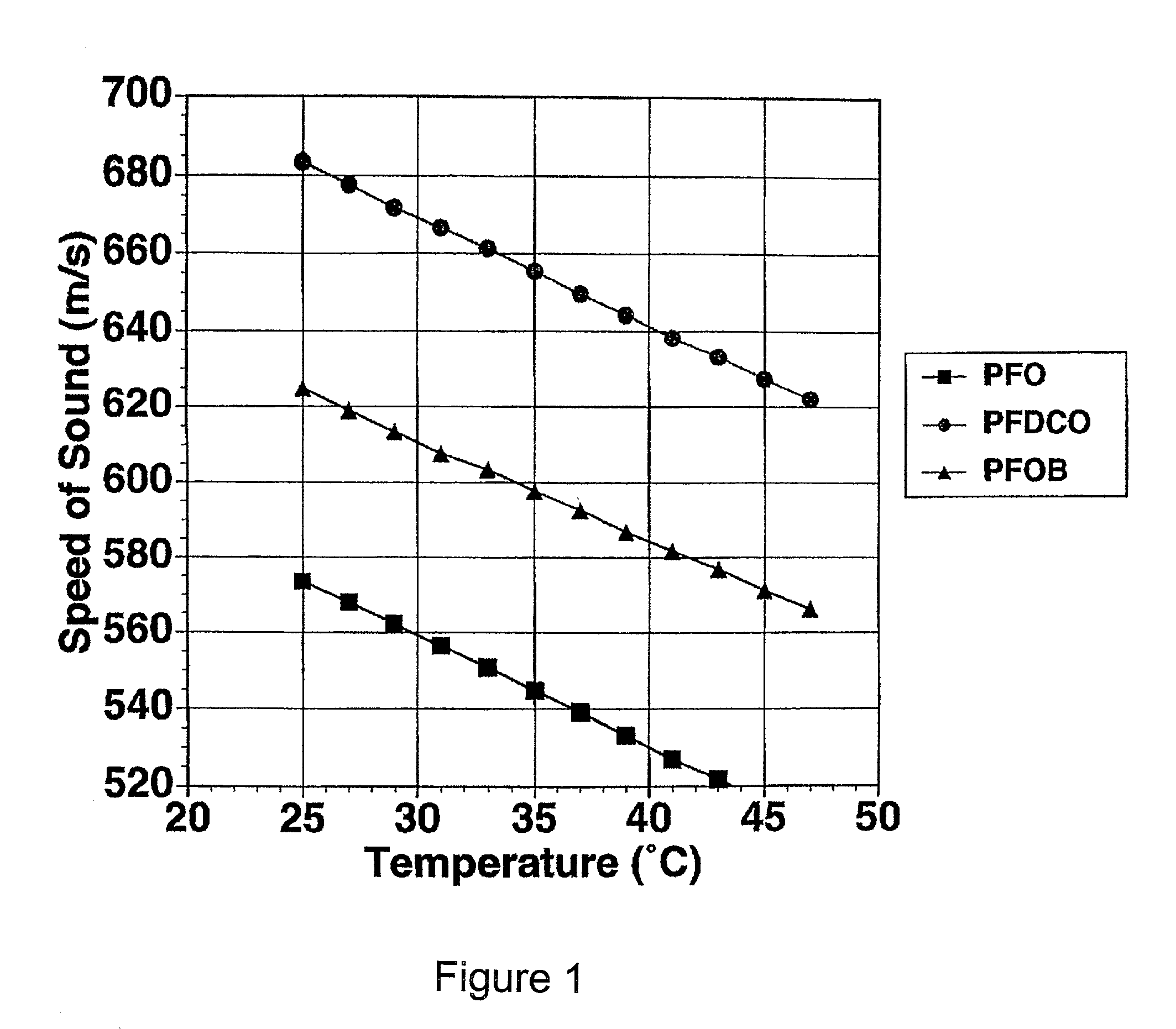

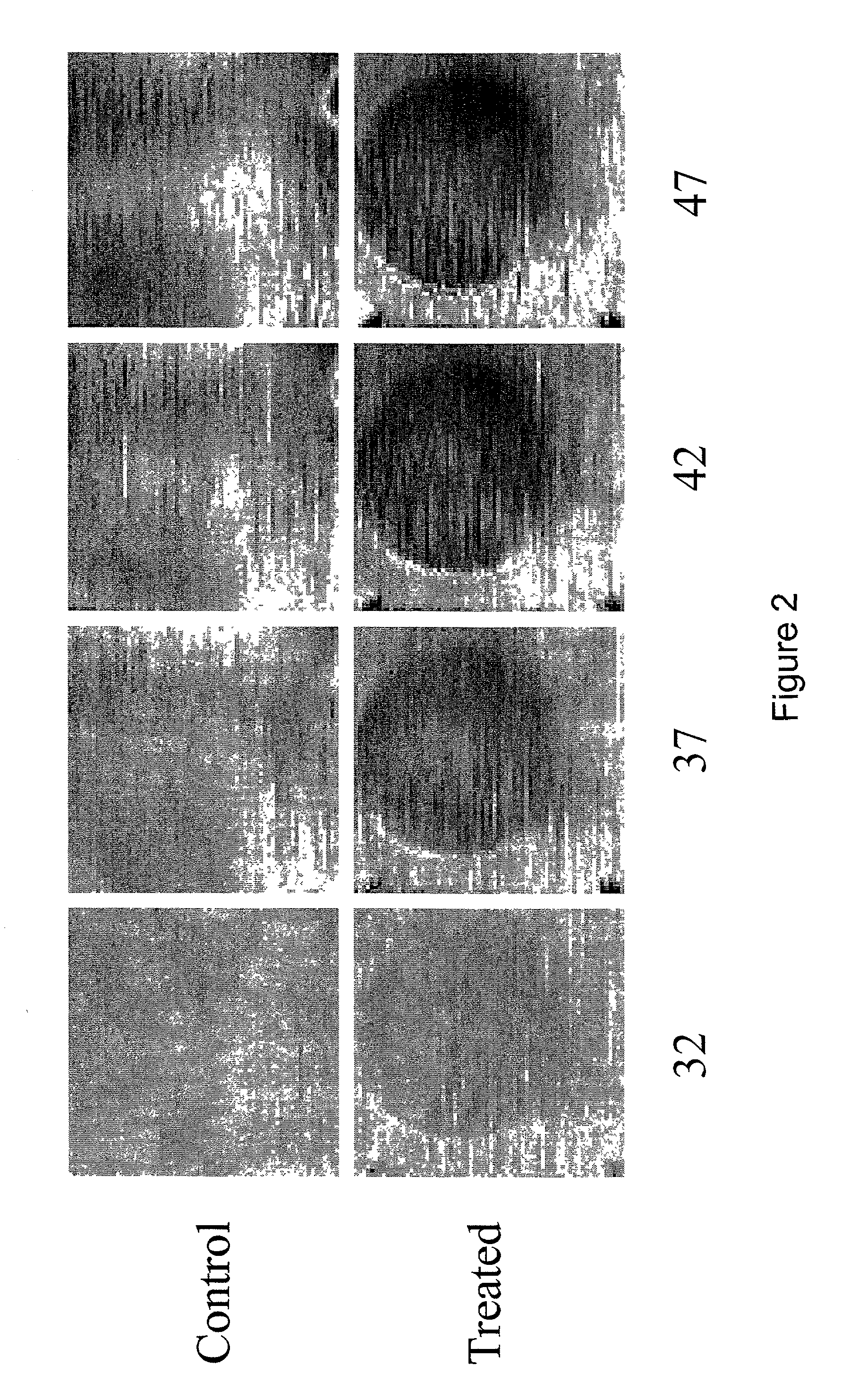

Methods and devices for enhanced ultrasound detection based upon changing temperature and ultrasound reflectivity of a temperature-dependent contrast agent bound to an ultrasound target are disclosed. The methods and devices can be used for enhanced imaging alone or in conjunction with drug delivery, with therapeutic approaches such as hyperthermia or cryotherapy or with other imaging modalities.

Owner:BARNES JEWISH HOSPITAL

Method of identifying, tracing and measuring external and internal membranes of vessel

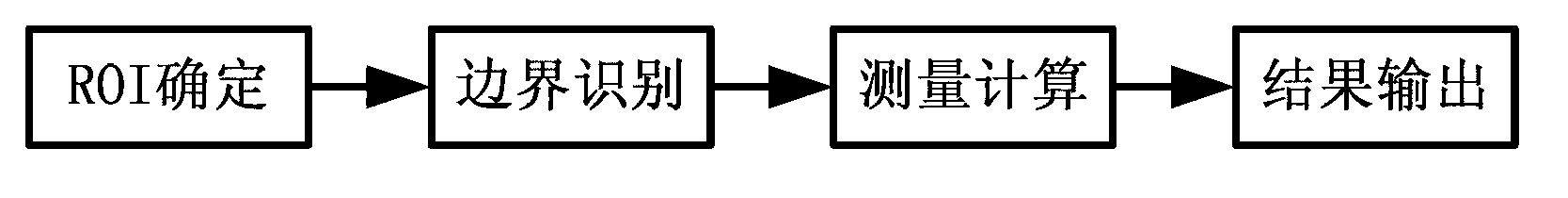

InactiveCN102982314AImprove calibration accuracyIncrease credibilityImage enhancementImage analysisComputer scienceBlood vessel

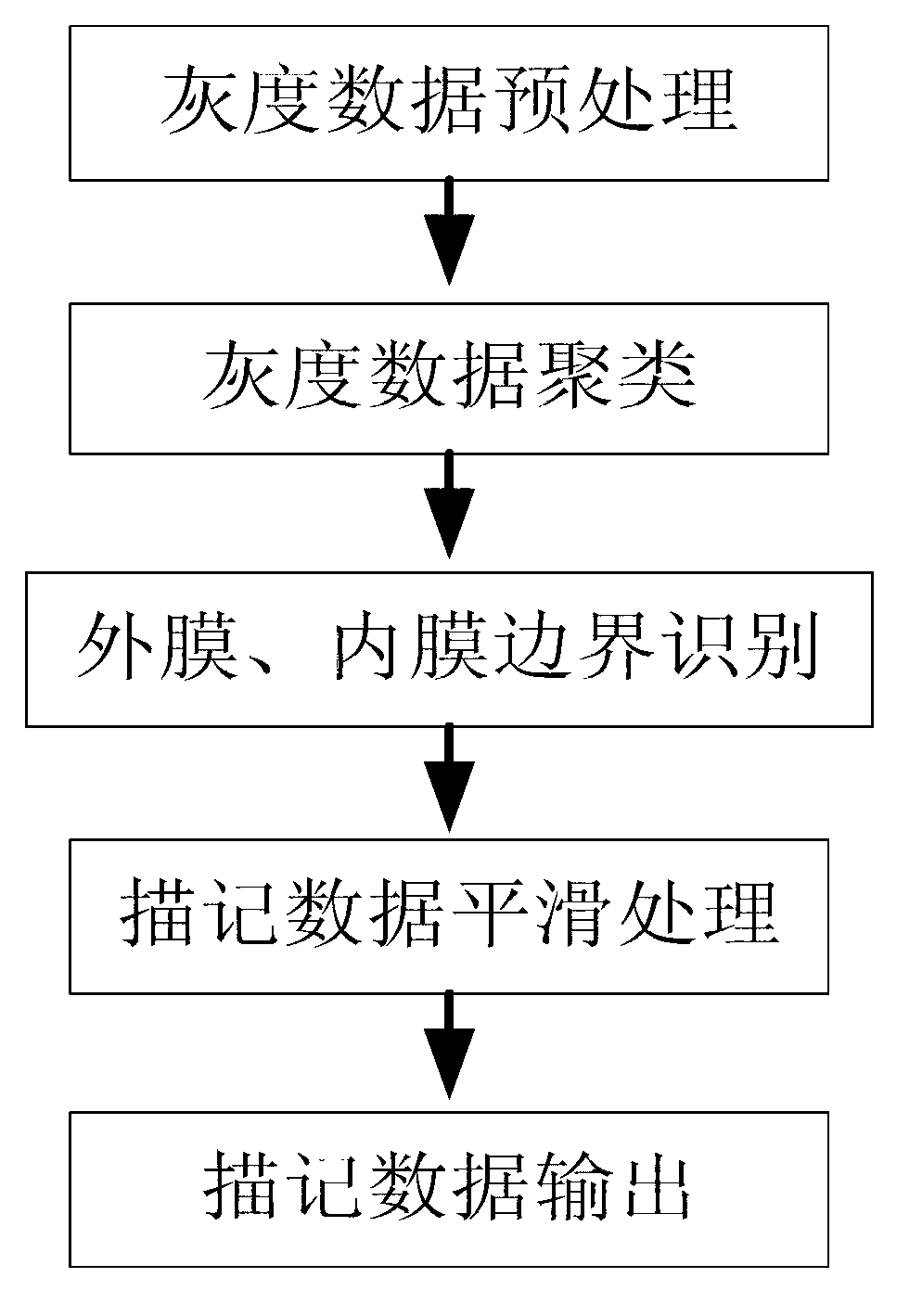

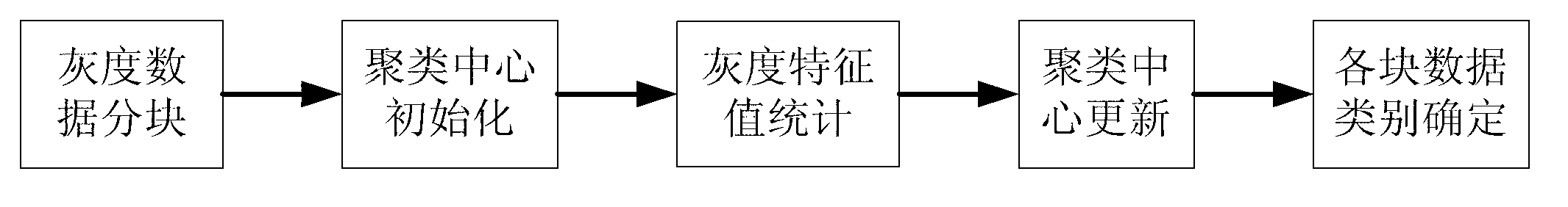

The invention relates to ultrasound detection and discloses a method of identifying, tracing and measuring external and internal membranes of a vessel. The method of identifying, tracing and measuring the external and internal membranes of the vessel includes the following steps. Firstly, data in a zone of interest are obtained. Thirdly, Gray-scale data clustering is carried out on an image of the zone of interest in order to obtain all target zones. Fourthly, boundaries of the external and internal membranes of the vessel are traced. Sixthly, thickness of the vessel is worked out. The method of identifying, tracing and measuring the external and internal membranes of the vessel has the advantages of improving calibration precision of the external and internal membranes of the vessel and media as well as reliability of calculation on irregular vessel function detecting indexes.

Owner:SHENZHEN EMPEROR ELECTRONICS TECH

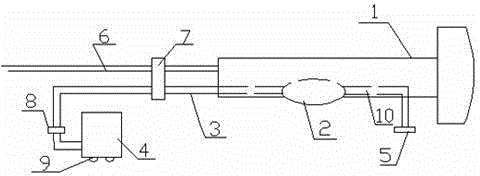

System and method for testing supersonic-wave speed of rock under simulated reservoir conditions

InactiveCN104101647ADisplay the status of the acoustic wave characteristicsAnalysing solids using sonic/ultrasonic/infrasonic wavesTesting ultrasoundDesorption

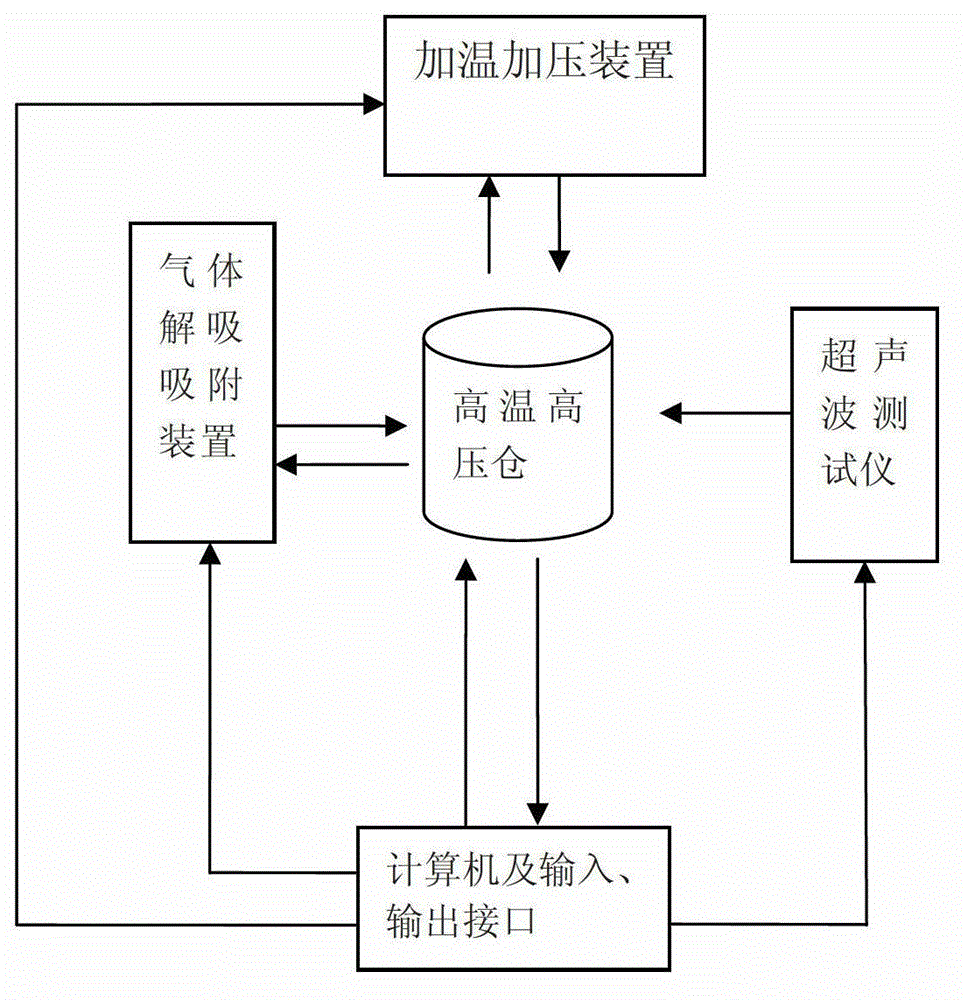

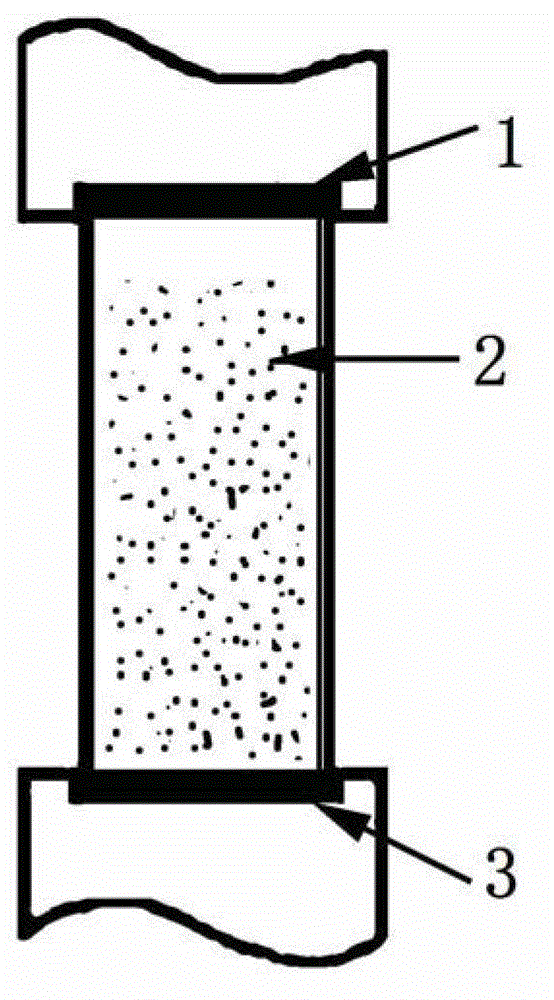

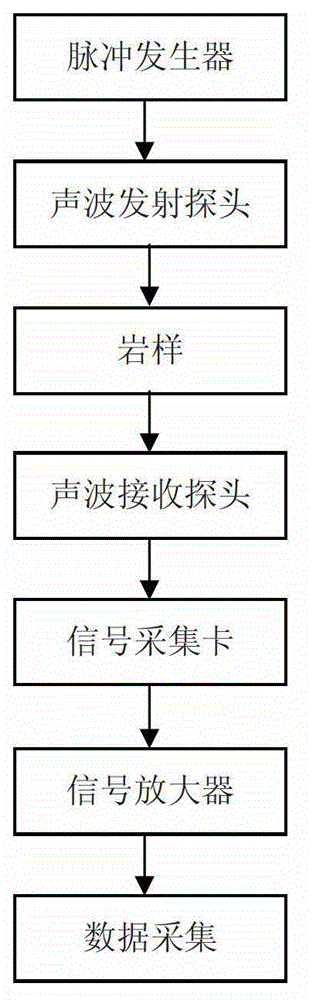

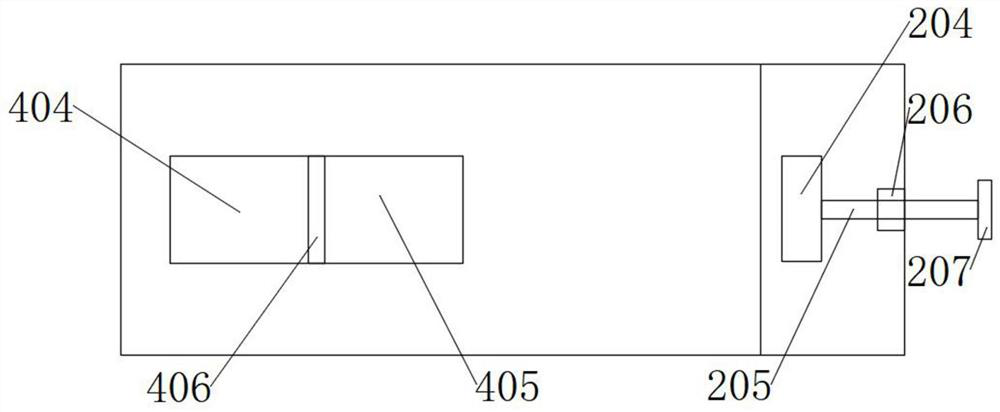

The invention provides a system and a method for testing the supersonic-wave speed of rock under simulated reservoir conditions, and belongs to supersonic-wave detection field. The system for testing the supersonic-wave speed of rock under simulated reservoir conditions comprises a high-temperature high-pressure cabin, a supersonic-wave tester and a gas desorption / adsorption apparatus; a to-be tested sample is disposed in the high-temperature high-pressure cabin; a supersonic-wave probe of the supersonic-wave tester is connected with the to-be tested sample; the gas desorption / adsorption apparatus is connected with the high-temperature high-pressure cabin via a pipe; and the propagation speed of supersonic wave in the to-be tested sample is obtained by using the supersonic-wave tester to test the time of supersonic wave penetrating the to-be tested sample. The system and the method are capable of simulating the pressure high-temperature environment of reservoir rock, supersonic-wave detection is performed on the sample under the conditions of high temperature, high pressure and gas adsorption, and a detection result is finely visually displayed in a data form.

Owner:CHINA PETROLEUM & CHEM CORP +1

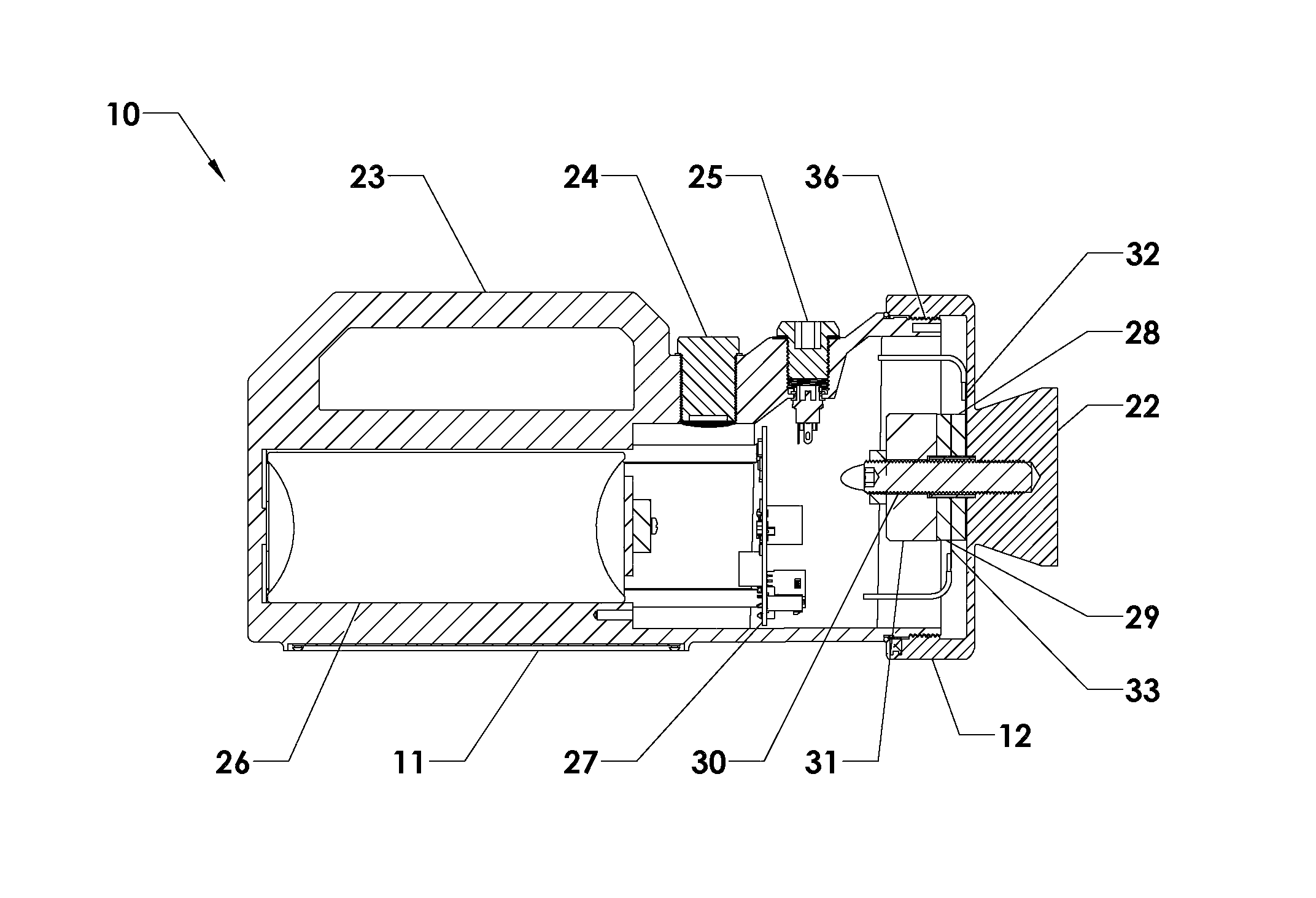

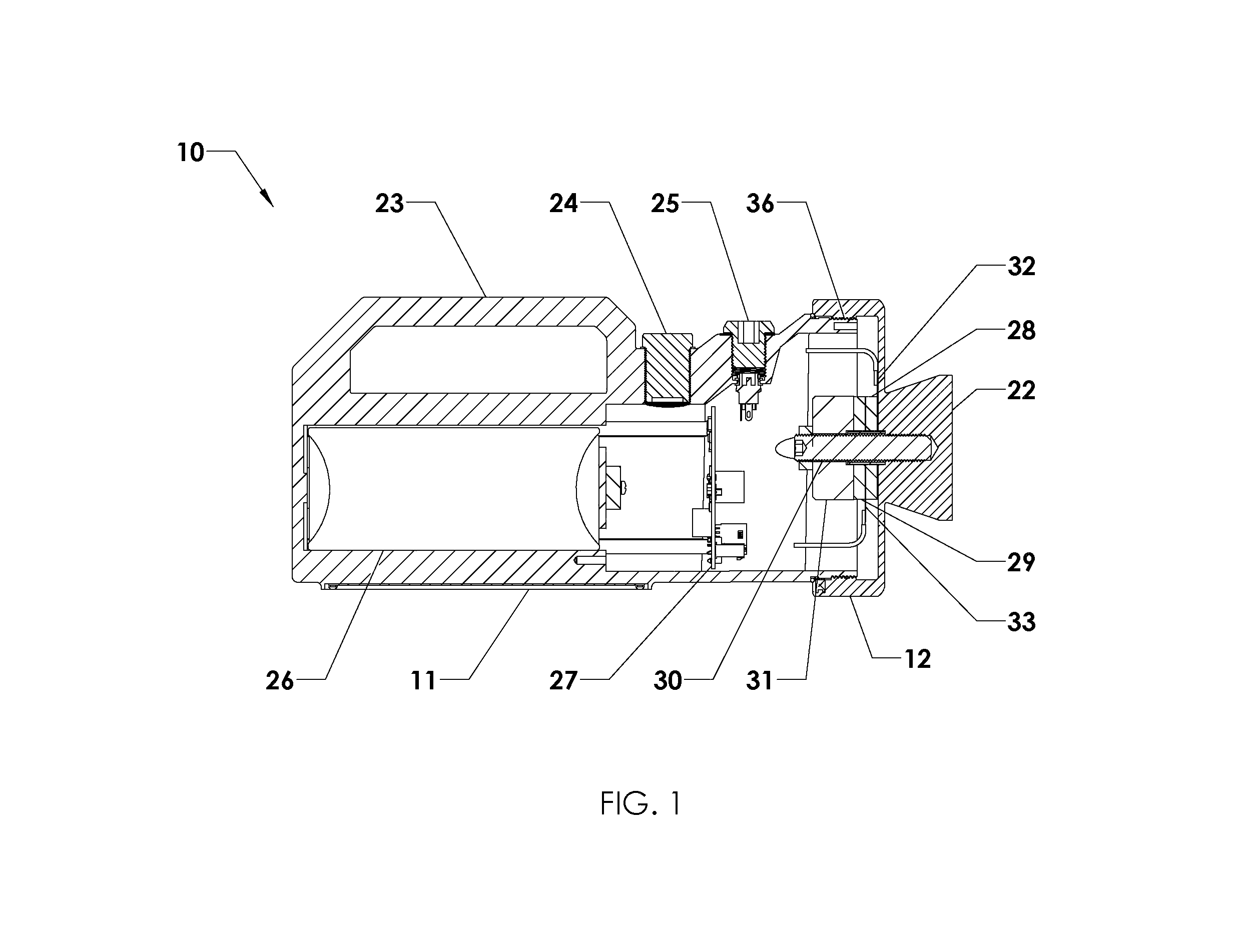

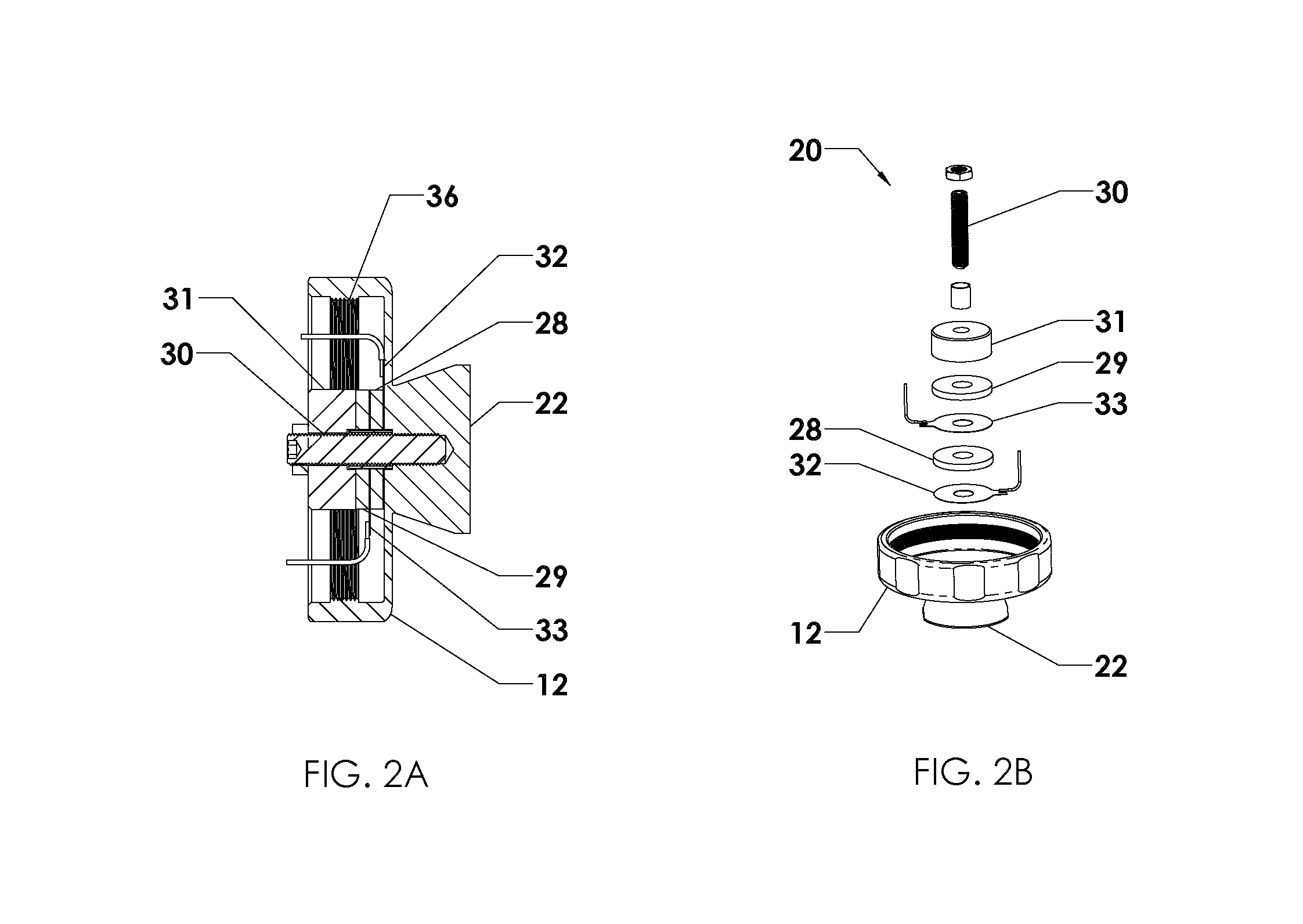

Explosion-proof acoustic source for hazardous locations

ActiveUS20120194973A1Detection of fluid at leakage pointDigital data processing detailsTesting ultrasoundGas detector

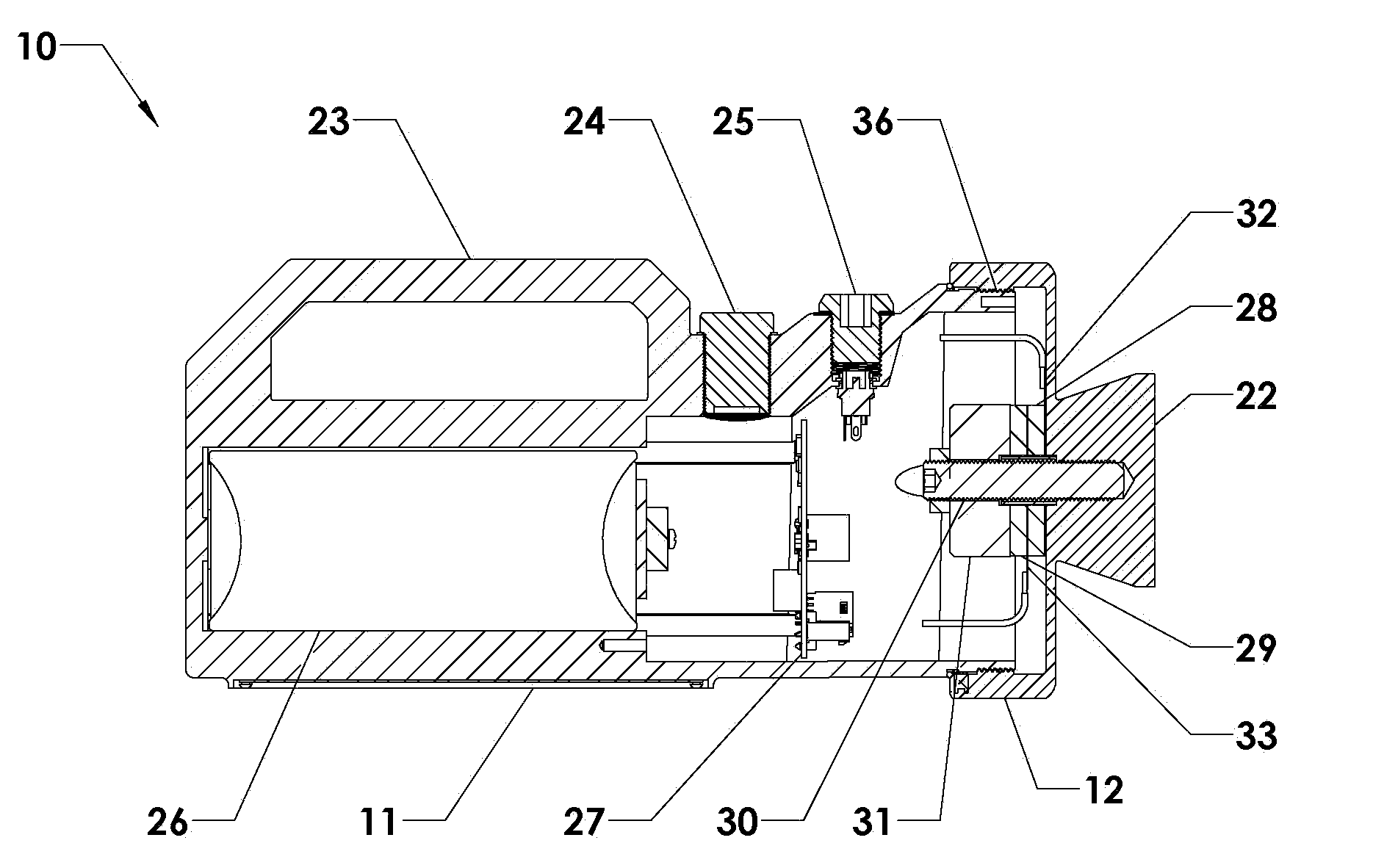

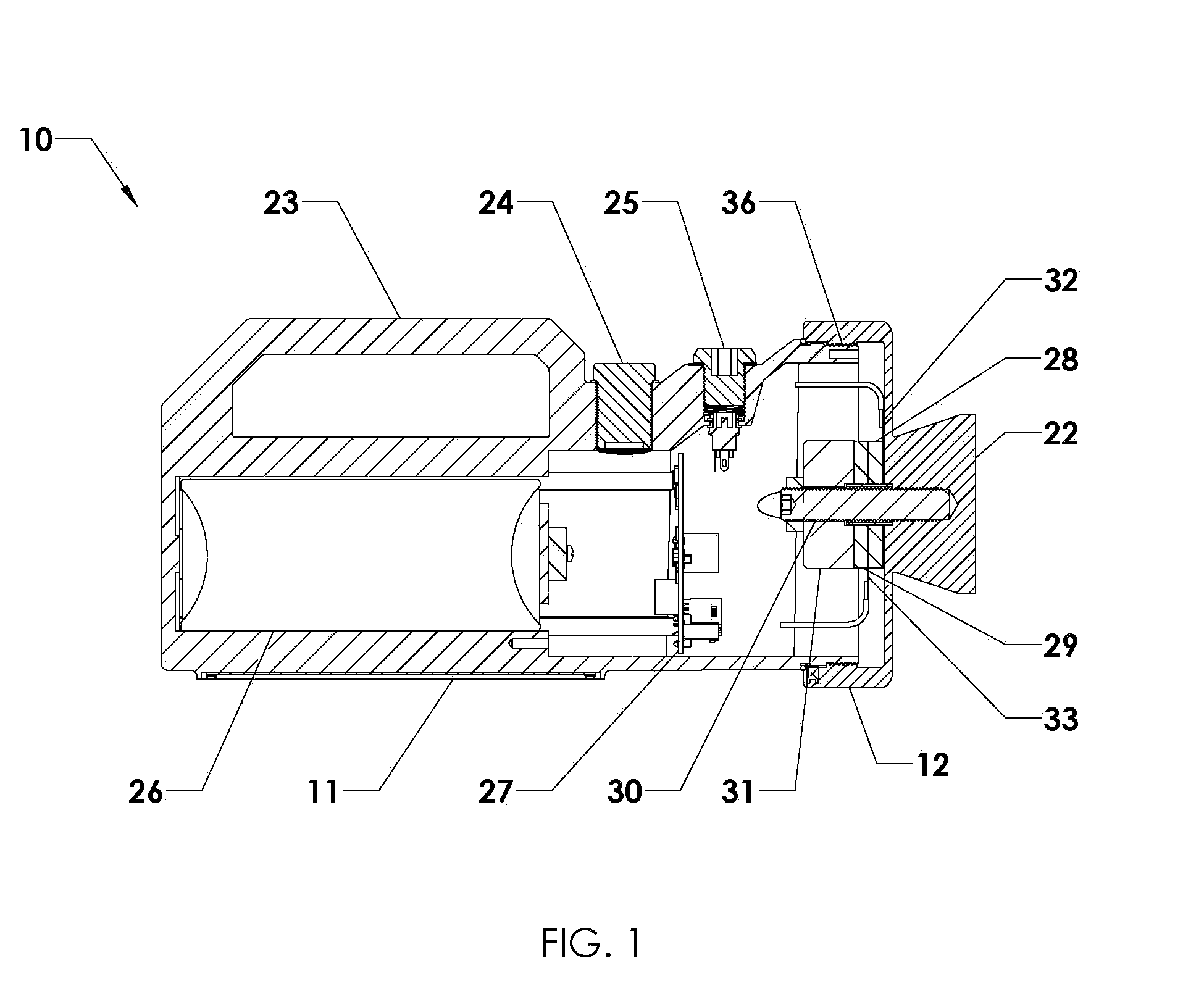

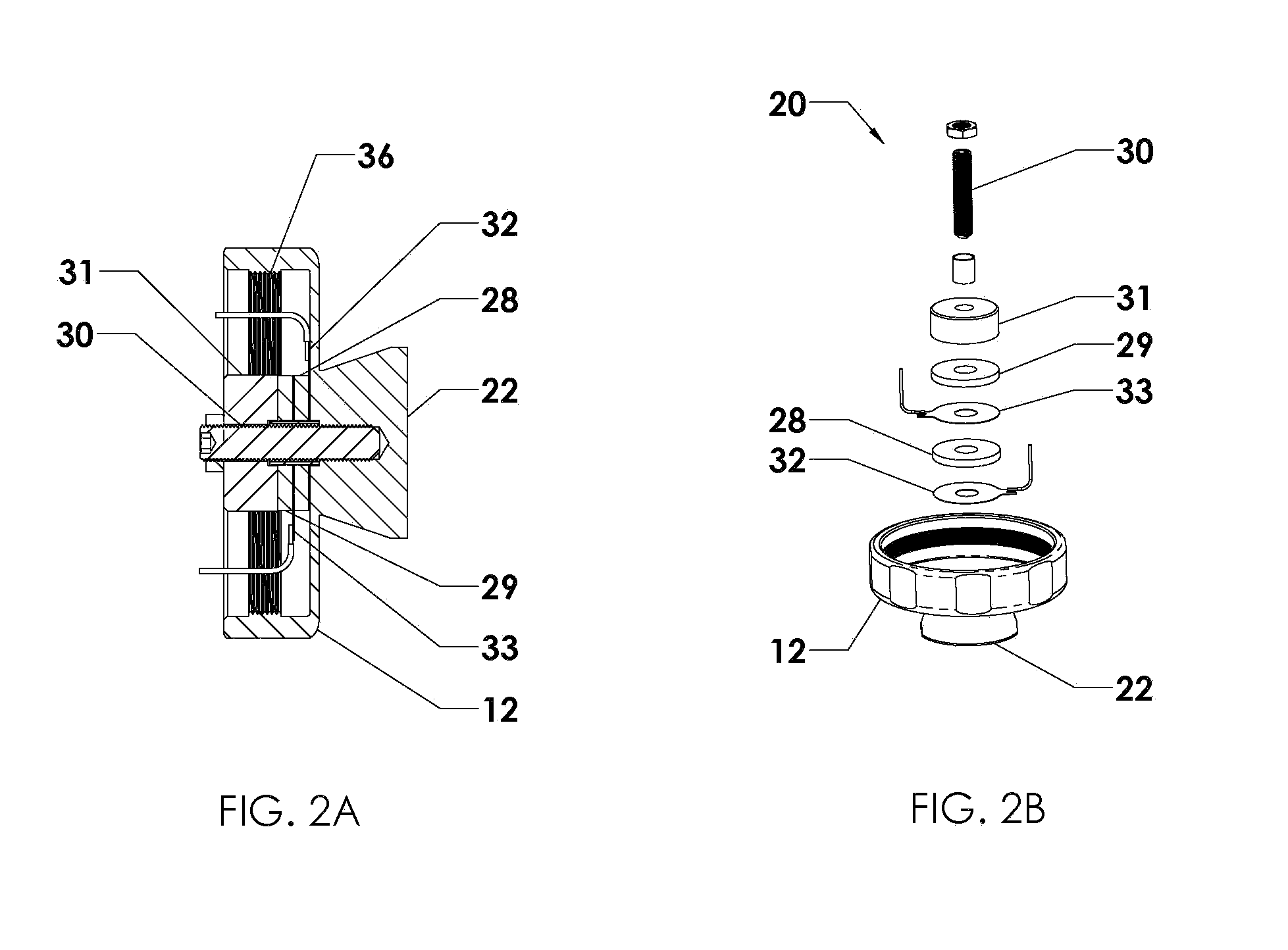

An explosion-proof system for generating acoustic energy. An exemplary embodiment of the system includes a main housing defining an open housing space and an opening. A cover structure is configured for removable attachment to the main housing structure to cover the opening and provide an explosion-proof housing structure. The cover structure includes an integral head mass. An acoustic energy emitting assembly includes the head mass, and an excitation assembly disposed within the explosion-proof housing structure. An electronic circuit is disposed within the explosion-proof housing structure to generate a drive signal for driving the excitation assembly to cause the acoustic energy emitting assembly to resonate and generate acoustic energy. In one embodiment the acoustic energy is a beam of ultrasonic energy useful for testing ultrasonic gas detectors. A method is also described for testing ultrasonic gas leak detectors using an ultrasonic source.

Owner:MSA TECH

Enhanced ultrasound detection with temperature-dependent contrast agents

InactiveUS20070255117A1Little and no detectable change in acoustic reflectivitySensitive measurementUltrasonic/sonic/infrasonic diagnosticsEchographic/ultrasound-imaging preparationsTesting ultrasoundImaging modalities

Methods and devices for enhanced ultrasound detection based upon changing temperature and ultrasound reflectivity of a temperature-dependent contrast agent bound to an ultrasound target are disclosed. The methods and devices can be used for enhanced imaging alone or in conjunction with drug delivery, with therapeutic approaches such as hyperthermia or cryotherapy or with other imaging modalities.

Owner:BARNES JEWISH HOSPITAL

Cleaning-free medical ultrasonic couplant, and preparation method thereof

InactiveCN102188723ANot contaminatedReduce generationEchographic/ultrasound-imaging preparationsUltrasonographyWater soluble

The invention discloses a cleaning-free medical ultrasonic couplant, and a preparation method thereof. The medical ultrasonic couplant comprises 0.1 to 2% by mass of water-soluble polymer materials, 5 to 30% by mass of volatile components, 0.2 to 2% by mass of skin moisturizing and protecting components, 0.05 to 5% by mass of sterilization components, a pH regulating component and deionized water. The medical ultrasonic couplant can form a thin film on patient skin and requires no cleaning, is safe for patient skin and does not contaminate clothes. Through utilizing the medical ultrasonic couplant, the advantages of simplifying ultrasonic detection processes, saving ultrasonic detection time, saving cleaning paper, reducing dust resulting from cleaning paper, and improving greatly an ultrasonic detection environment and the cleaning and maintenance of ultrasonic instruments. A viscosity of the medical ultrasonic couplant is controlled within a range of 3000 to 12000 centipoises and thus the medical ultrasonic couplant is a couplant with a medium to low viscosity and can be utilized by a spray way. Therefore, compared with the existing high viscosity couplant which is utilized by an extrusion way, the medical ultrasonic couplant provided by the invention is more convenient.

Owner:BEIJING DAOHANG ZHONGFU TECH

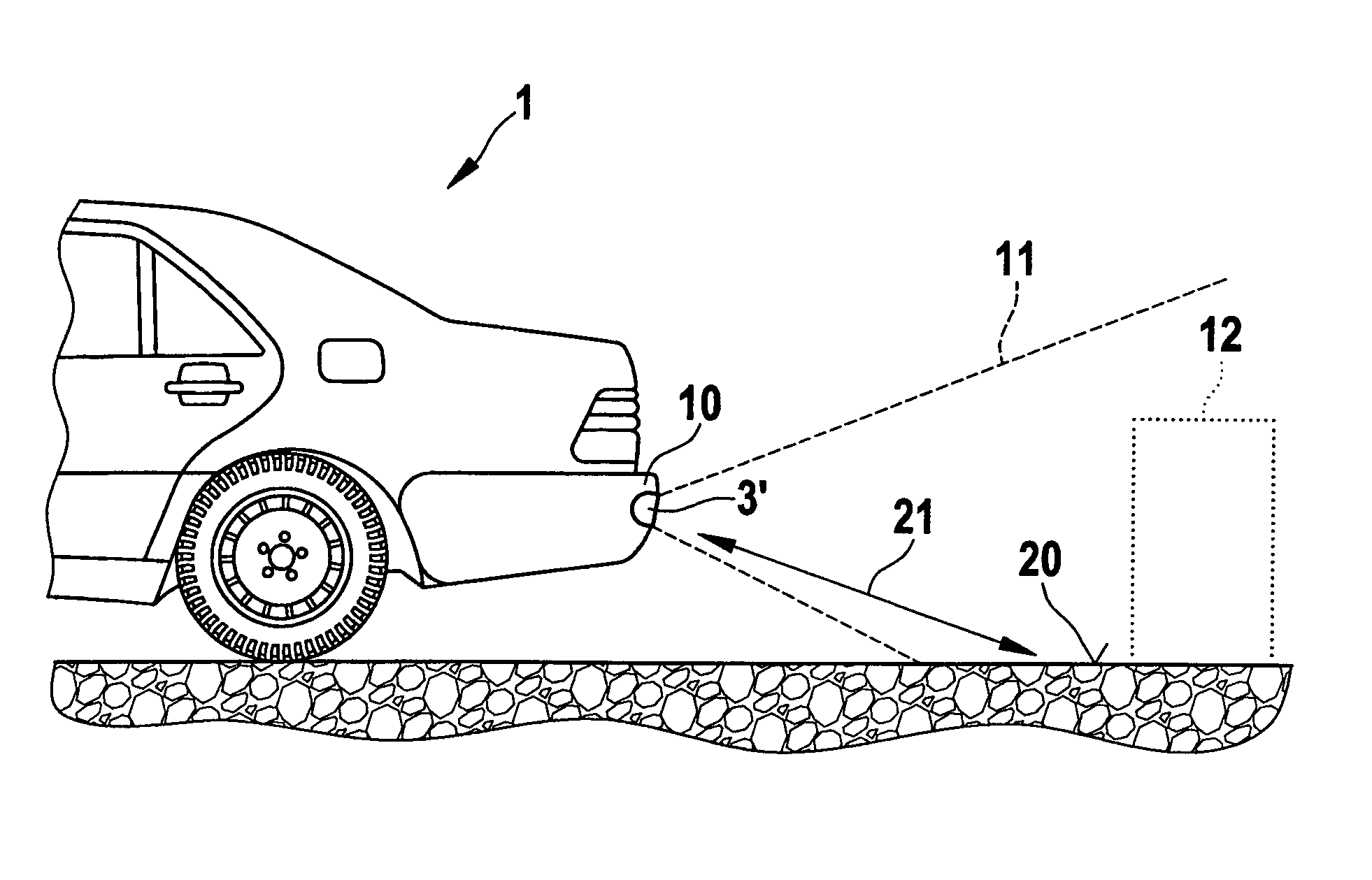

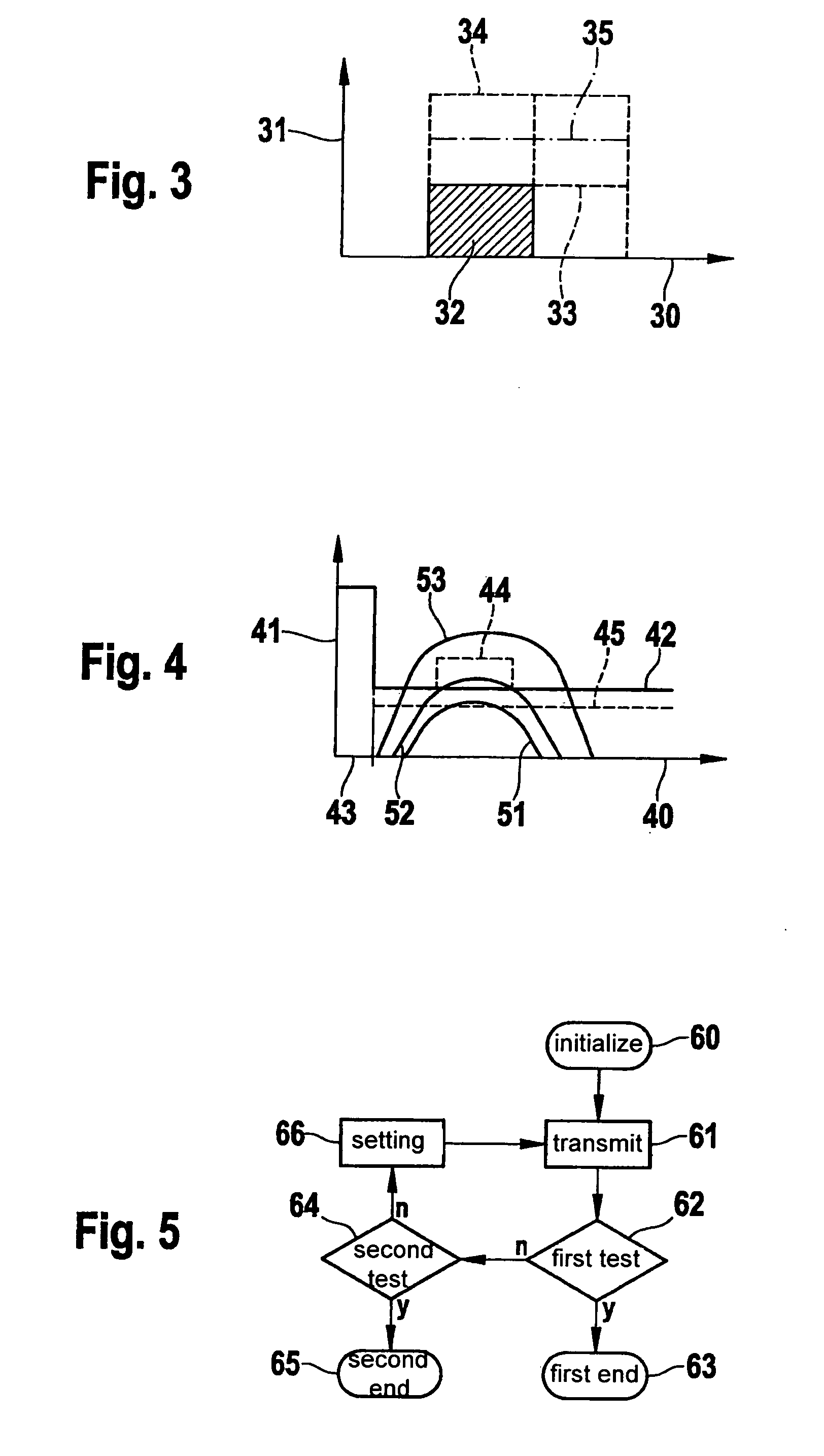

Method for functionally testing an ultrasonic sensor

InactiveUS8064285B2Easy to testIncrease amplitudeDirection finders using ultrasonic/sonic/infrasonic wavesTransmission monitoringTesting ultrasoundFunctional testing

A method for functionally testing an ultrasonic sensor on a motor vehicle in which, in a test operating mode, an ultrasonic signal is emitted whose magnitude is large enough that under conventional conditions this ultrasonic signal is reflected by a ground surface in front of the vehicle and is received again. In this way, it can easily be determined that the ultrasonic sensor is functioning properly.

Owner:ROBERT BOSCH GMBH

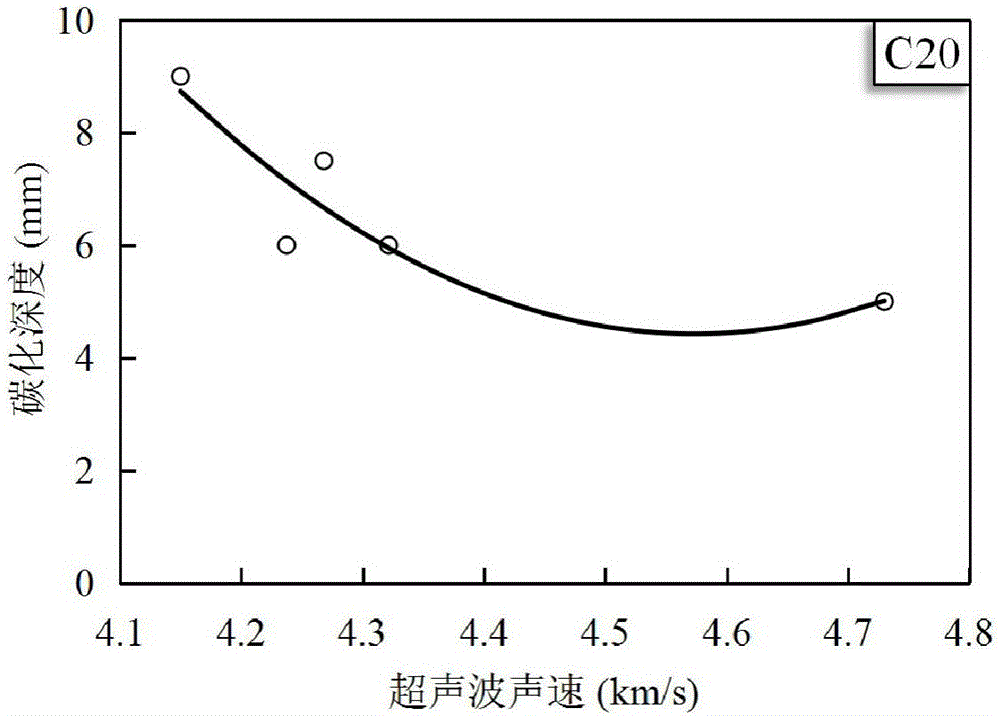

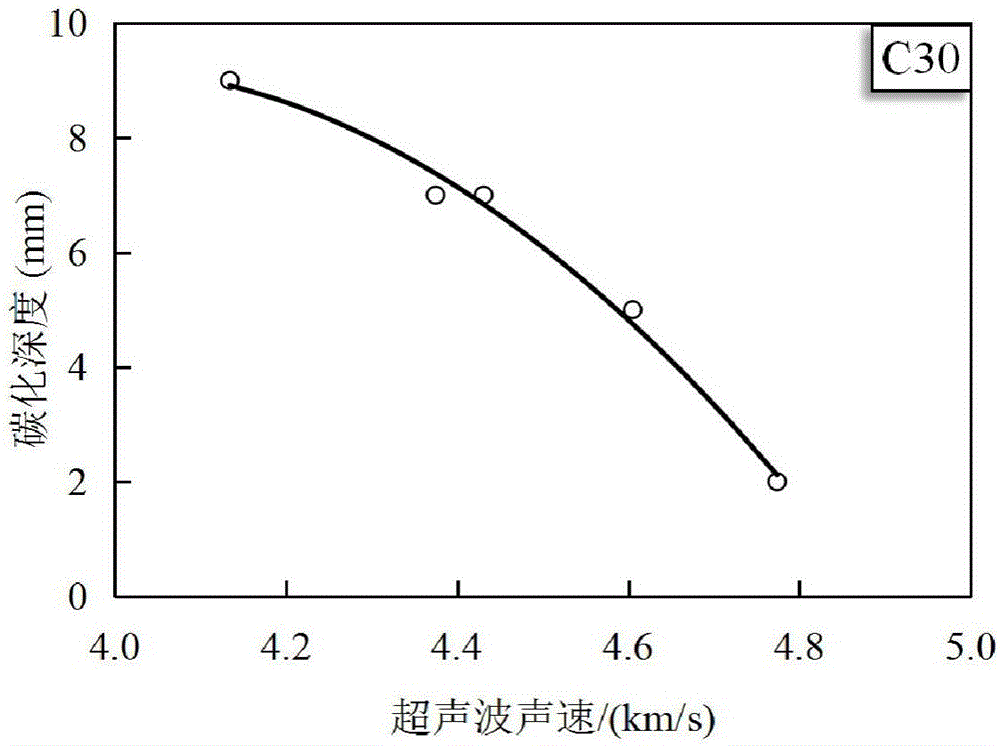

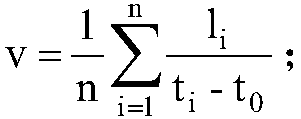

Ultrasonic method based concrete carbonation depth test method

InactiveCN107525852AReduce mistakesIntegrity guaranteedAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by observing effect on chemical indicatorTesting ultrasoundTest sample

The invention discloses an ultrasonic method based concrete carbonation depth test method. The ultrasonic method based concrete carbonation depth test method comprises the following steps: firstly, forming a concrete test piece, and carbonating after a mould is detached and the concrete test piece is cured; secondly, performing an ultrasonic test on the test piece to acquire a sound velocity value of the test piece; thirdly, testing the carbonation depth of the test piece by adopting an indicator method; fourthly, performing fitting analysis on the acquired sound velocity value and a carbonation depth value to obtain the relationship between the sound velocity value and the carbonation depth value, and then acquiring the carbonation depth of corresponding concrete by testing the sound velocity value of the test piece. According to the concrete carbonation depth test method, a concrete carbonation depth test curve is established based on an ultrasonic method, and the carbonation depth of the concrete can be detected by only testing the sound velocity of ultrasonic waves without damaging the test piece; the integrity of a test sample is ensured during a testing process; the damage introduced by splitting the test piece is avoided; meanwhile, the accuracy of a test result is ensured; the test method is simpler.

Owner:SOUTHEAST UNIV

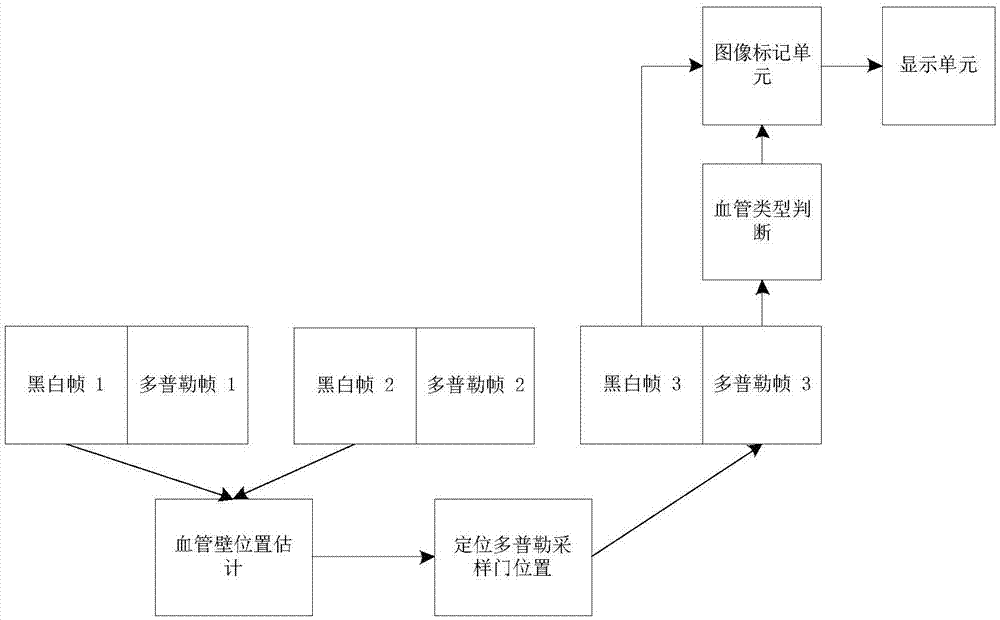

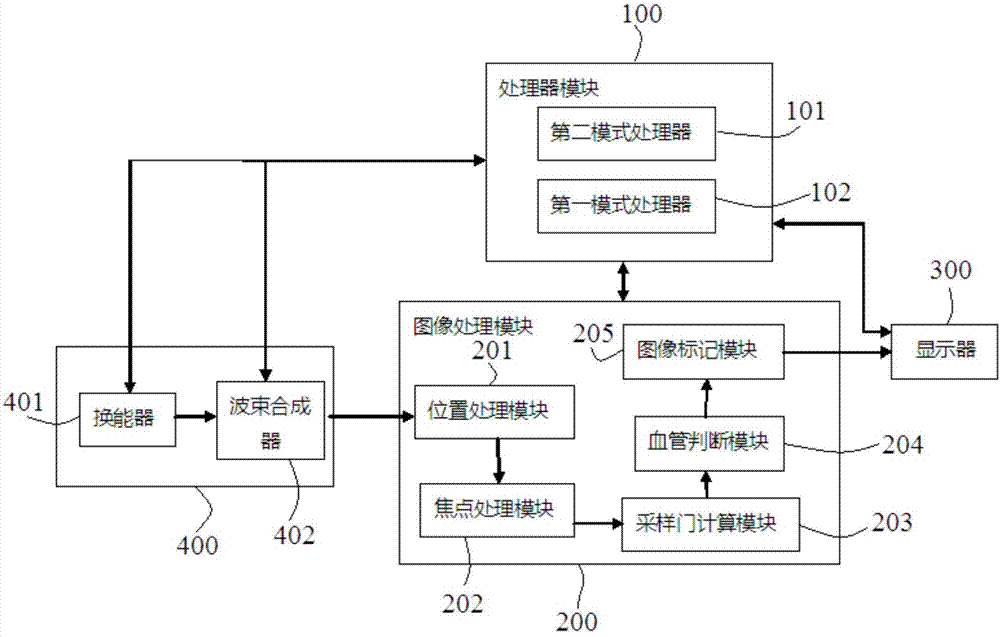

An ultrasonic blood vessel detection system and method

ActiveCN107157515AEasy to operateImprove work efficiencyOrgan movement/changes detectionInfrasonic diagnosticsSonificationDoppler imaging

The invention relates to an ultrasonic blood vessel detection system and method. The method comprises the following steps: (1) performing bi-mode imaging canning and obtaining black-and-white image frames of a black-and-white mode and Doppler image frames of a pulse Doppler mode; (2) acquiring position information of blood vessel walls; (3) acquiring transmitting focus positions under pulse Doppler imaging of the Doppler image frames corresponding to the black-and-white image frames in real time, wherein a processor module performs next-frame pulse Doppler imaging according to the position information of the blood vessel walls and the transmitting focus positions; (4) setting the positions of blood vessels with position information determined as sampling gates and calculating the position information of the sampling gates under pulse Doppler image by a sampling gate calculating module; (5) judging the types of blood vessels at the positions of the sampling gates; (6) labeling the current black-and-white image frames according to the positions of the blood vessels and the information of the types of the blood vessels. The system and the method solve the problem of complicated operation of manual setting of sampling gates, simplify operation of doctors and increase working efficiency.

Owner:CHISON MEDICAL TECH CO LTD

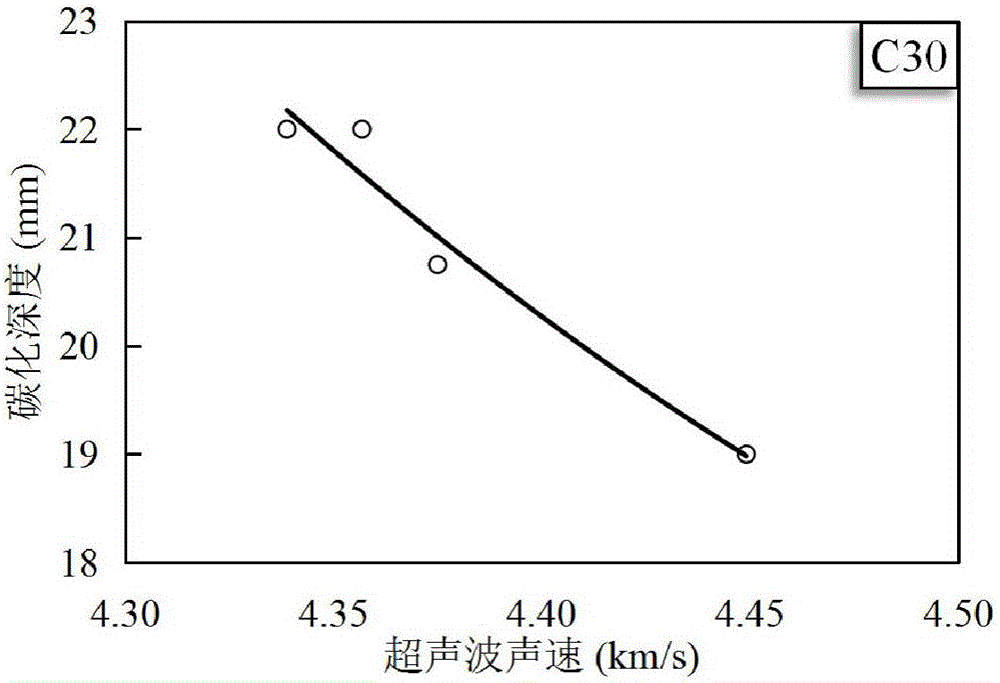

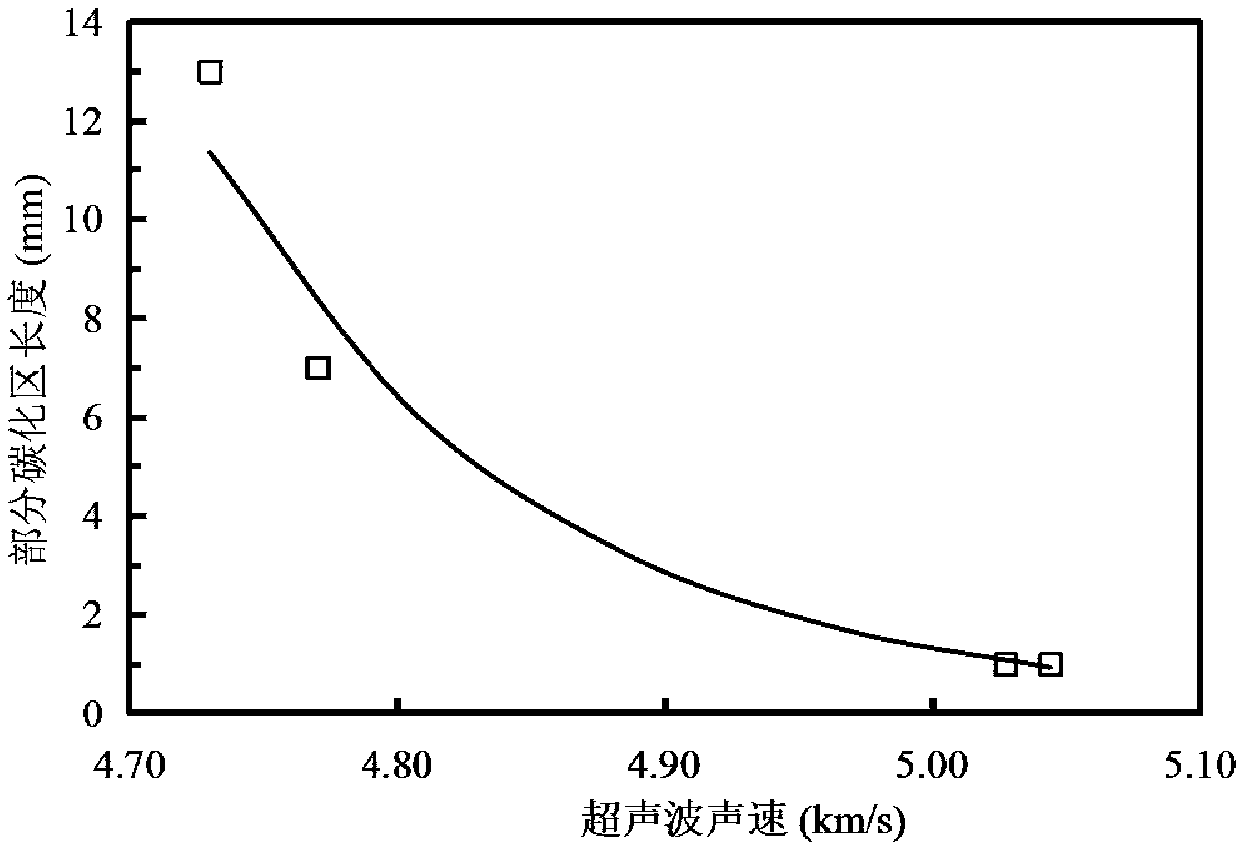

Testing method of concrete partial carbonization area depth

InactiveCN107894462AIntegrity guaranteedAvoid damageAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial weighingTesting ultrasoundCarbonization

The invention discloses a testing method of the concrete partial carbonization area depth. The testing method comprises the following steps of 1, forming a concrete specimen and conducting carbonization processing after form stripping maintenance; 2, obtaining a sound speed value of the specimen through an ultraviolet test; 3, adopting a thermogravimetric analysis method to measure partial carbonization area depth of the specimen; 4, fitting the obtained sound speed value and a partial carbonization area depth value to obtain the relation between the sound speed value and the partial carbonization area depth and obtaining the partial carbonization area depth of corresponding concrete by testing the sound speed value of the specimen. According to the method, by building a fitting relation between the concrete partial carbonization area depth and the ultrasonic wave sound speed of the concrete, on the condition that the specimen is not damaged, the partial carbonization area depth of thecorresponding concrete can be obtained simply by testing the ultrasonic wave sound speed, in the testing process, the integrity of the specimen is guaranteed, and damage caused by cleaving the specimen is also avoided; moreover, the testing method is accurate in testing result and is more concise and more economical.

Owner:SOUTHEAST UNIV

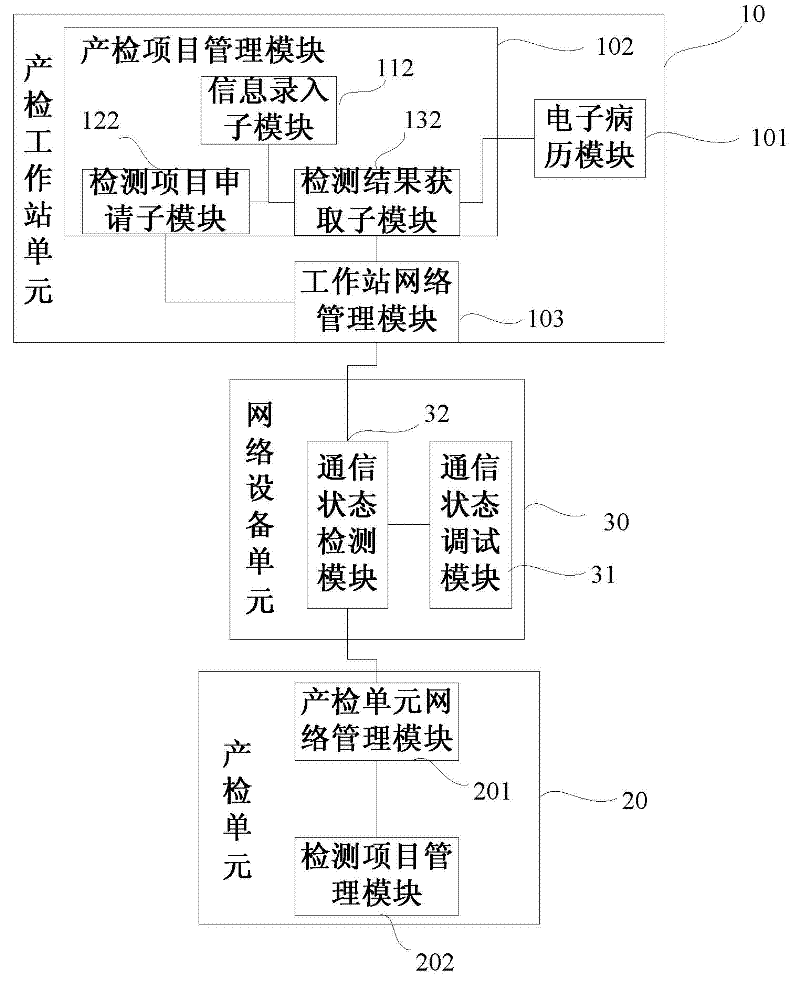

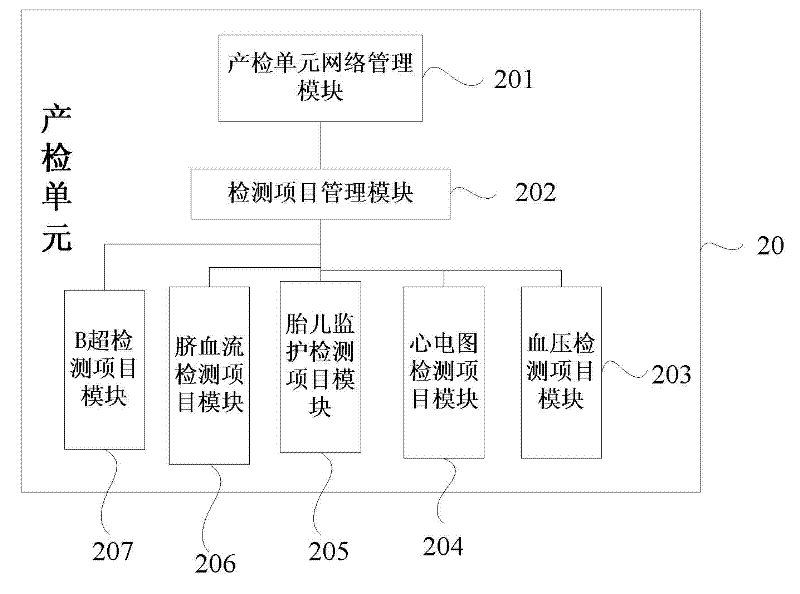

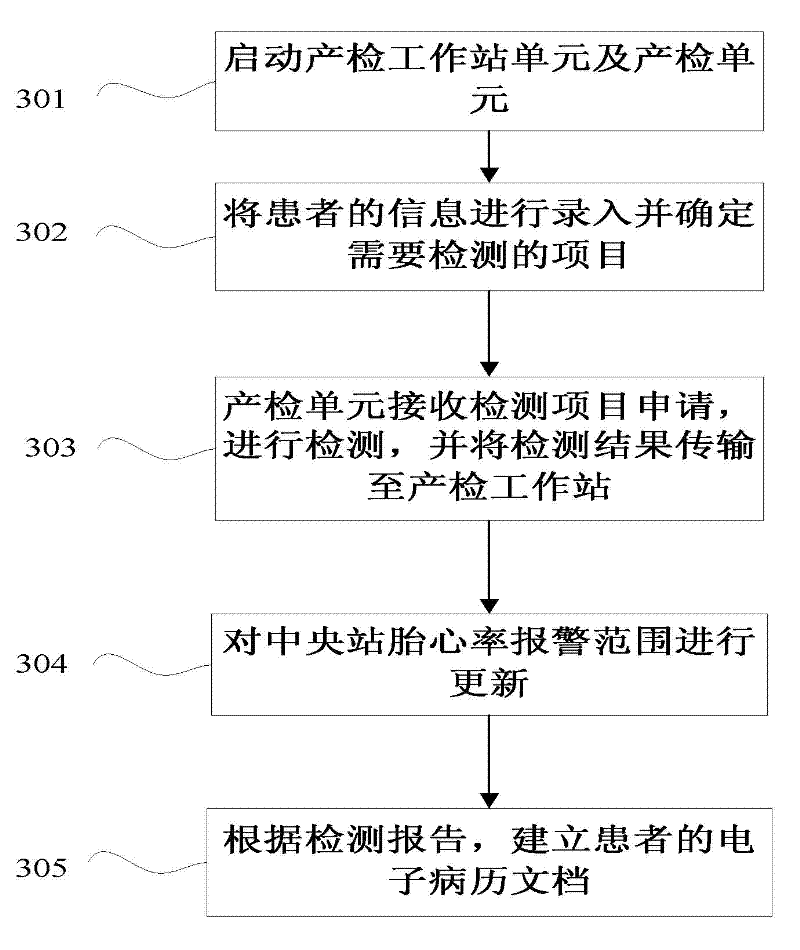

Obstetrical ultrasonic detection method and system

InactiveCN102488530ASolve the comfortSolve the convenienceBlood flow measurement devicesDiagnostic recording/measuringTesting ultrasoundEmergency medicine

The invention relates to an obstetrical ultrasonic detection method and a system. The system comprises an obstetrical examination work station unit, a network equipment unit and an obstetrical examination unit. The obstetrical examination work station unit is used for recording basic information of a patient, and detecting items are applied for according to the basic information of the patient; the obstetrical examination unit is connected with the obstetrical examination work station unit, and is used for receiving application of the detecting items of an obstetrical examination work station, responding to the application of the detecting items and transmitting detected results to the obstetrical examination work station unit; and the network equipment unit is respectively connected with the obstetrical examination work station unit and the obstetrical examination unit, and is used for realizing data exchange between the obstetrical examination work station unit and the obstetrical examination unit. The obstetrical ultrasonic detection method and the system can effectively realize comfort and convenience of obstetrical examination of pregnant women, and simultaneously bring convenience for unified management of examination reports and relevant information of patients for hospitals.

Owner:EDAN INSTR

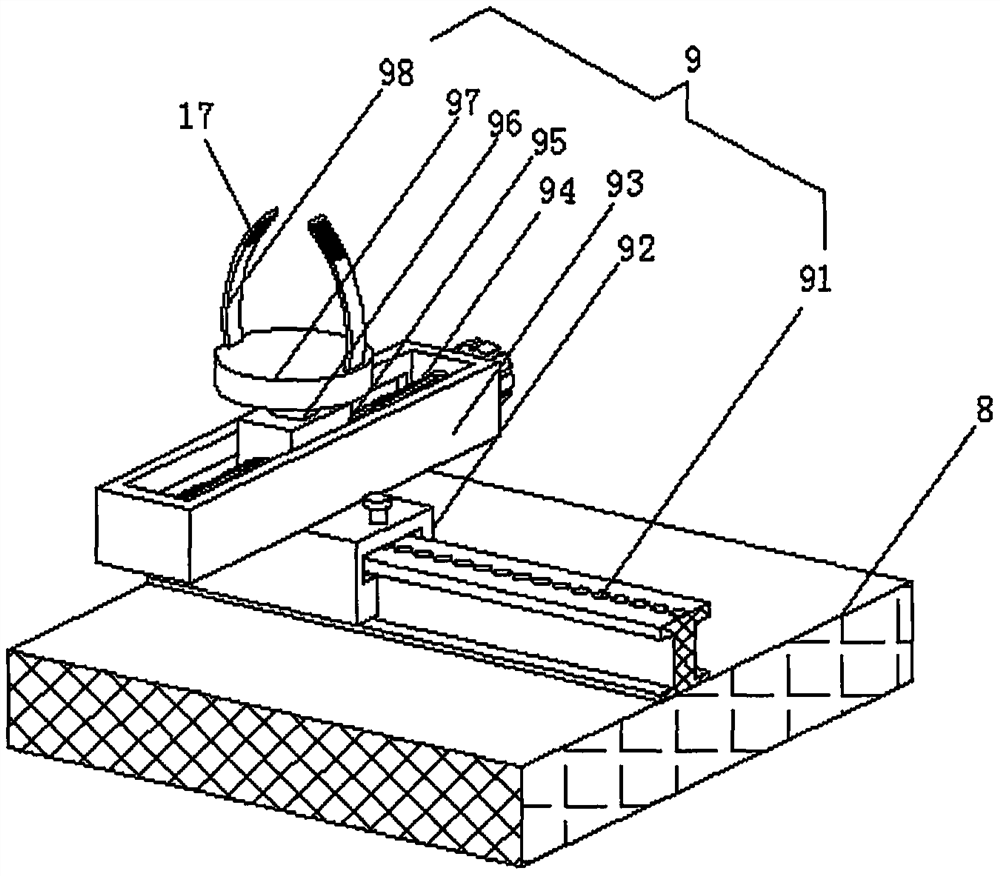

Method for capturing diaphragm movement to assist in judging offline of breathing machine by utilizing ultrasonic AI technology

PendingCN110974298AHigh precisionImprove efficiencyRespiratorsOrgan movement/changes detectionTesting ultrasoundUltrasound probe

The invention discloses a method for capturing diaphragm movement to assist in judging offline of a breathing machine by utilizing an ultrasonic AI technology. The method comprises the following steps: step S1, a doctor detects the diaphragm muscle position of a patient through an ultrasonic probe to capture the diaphragm muscle motion states of expiration and inspiration of the patient, and diaphragm muscle thickness images during expiration and inspiration are generated on a display interface of an ultrasonic detection device; step S2, the doctor detects the diaphragm position of the patientby using the ultrasonic probe to capture diaphragm motion states of expiration and inspiration of the patient, and a diaphragm mobility change image from expiration to inspiration is generated on a display interface of the ultrasonic detection device; step S3, an AI diagnosis device respectively scans the images generated in the step S1 and the step S2, after scanning is completed, the content ofthe images is analyzed and processed, and the specific numerical values of the diaphragm thickness change rate and the diaphragm mobility of the user are measured and calculated; and step S4, the doctor compares the calculated specific numerical values of the diaphragm thickness change rate and diaphragm mobility of the user with the diaphragm thickness change rate cutoff value and the diaphragmmobility cutoff value respectively.

Owner:SUZHOU SCI&TECH TOWN HOSPITAL

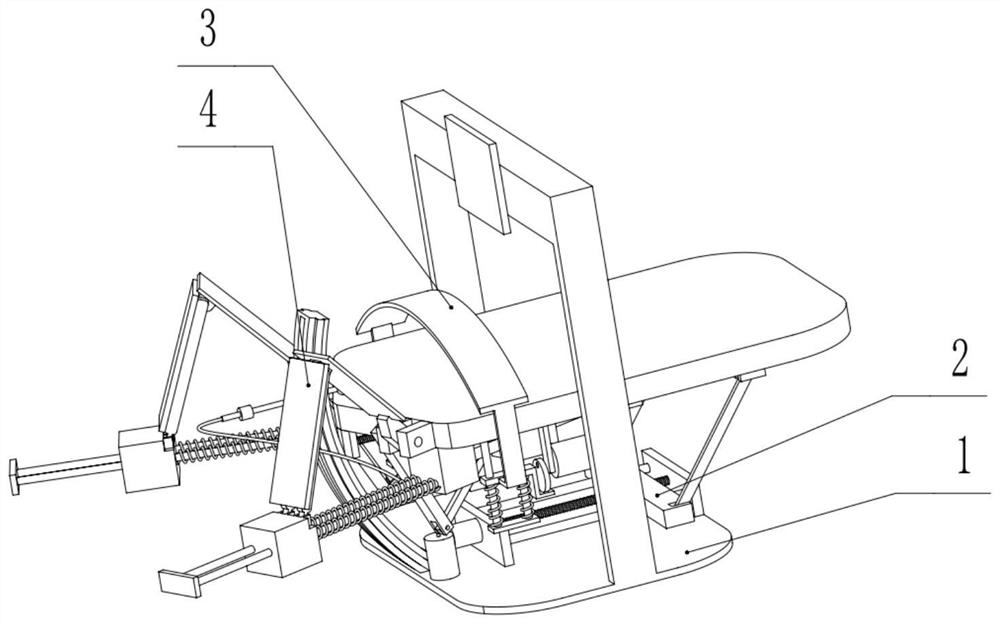

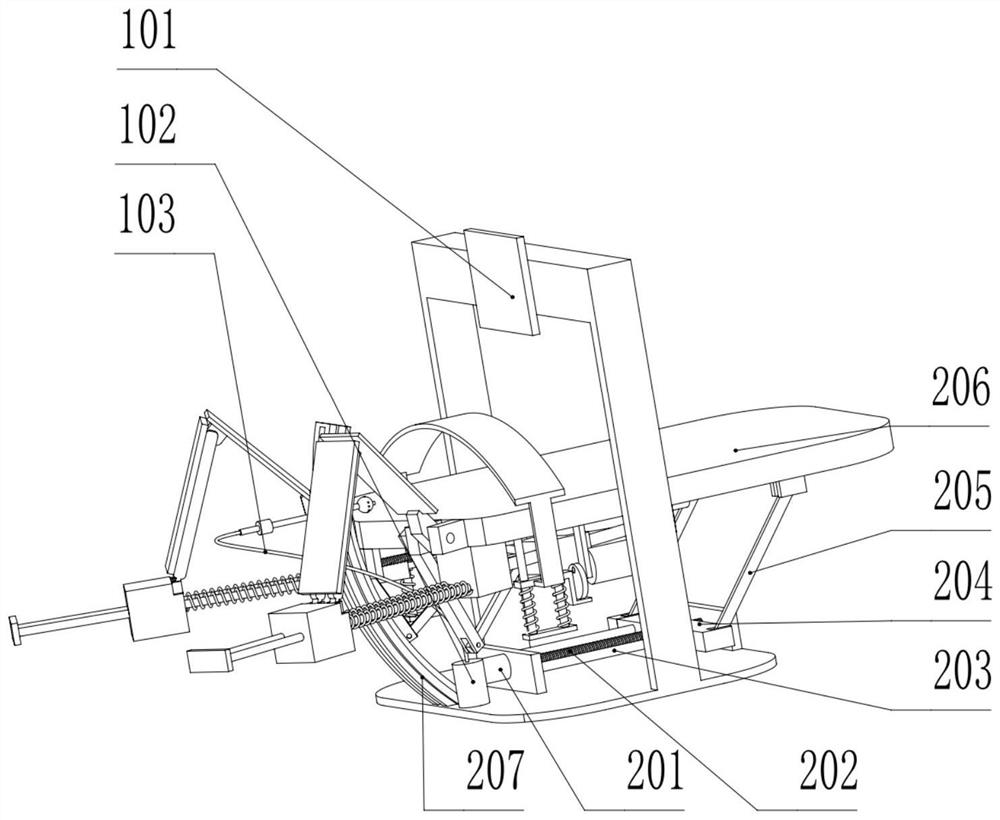

Ovarian cyst detection device

InactiveCN111820951AAdjustable leg positionEasy to operatePatient positioningOrgan movement/changes detectionTesting ultrasoundAnatomy

The invention discloses an ovarian cyst detection device. The ovarian cyst detection device comprises a rack, an inclination adjusting part, an ultrasonic detection part and a leg adjusting part, wherein the rack is a mounting platform of the inclination adjusting part, the ultrasonic detection part and the leg adjusting part; an image screen is arranged on the rack; and a contrast agent is arranged in a contrast agent tube. A detected person lies on an adjustable bed, and a leg posture is adjusted through the leg adjusting part, so that the reproductive organ is exposed in front of an operator; the operator controls an operating handle to inject the contrast agent into the uterus, and the contrast agent is dispersed to the ovary part; and an ultrasonic releaser is used for releasing ultrasonic waves to carry out ultrasound contrast on the ovary, so that the pathology condition of the ovary can be detected. The ovarian cyst is detected by utilizing an ultrasound contrast technology, sothat the pain of the detected person is reduced.

Owner:滨州医学院附属医院

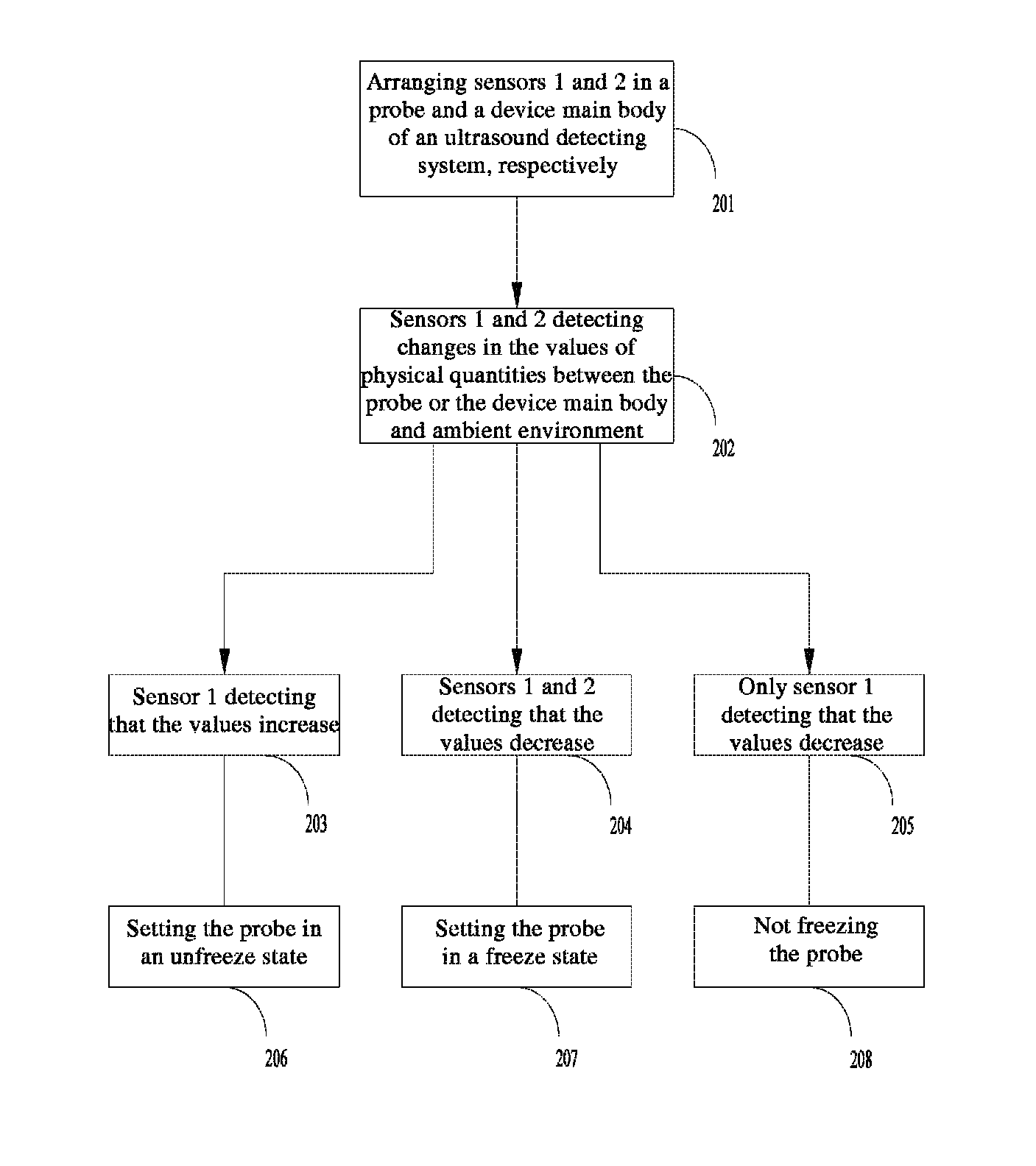

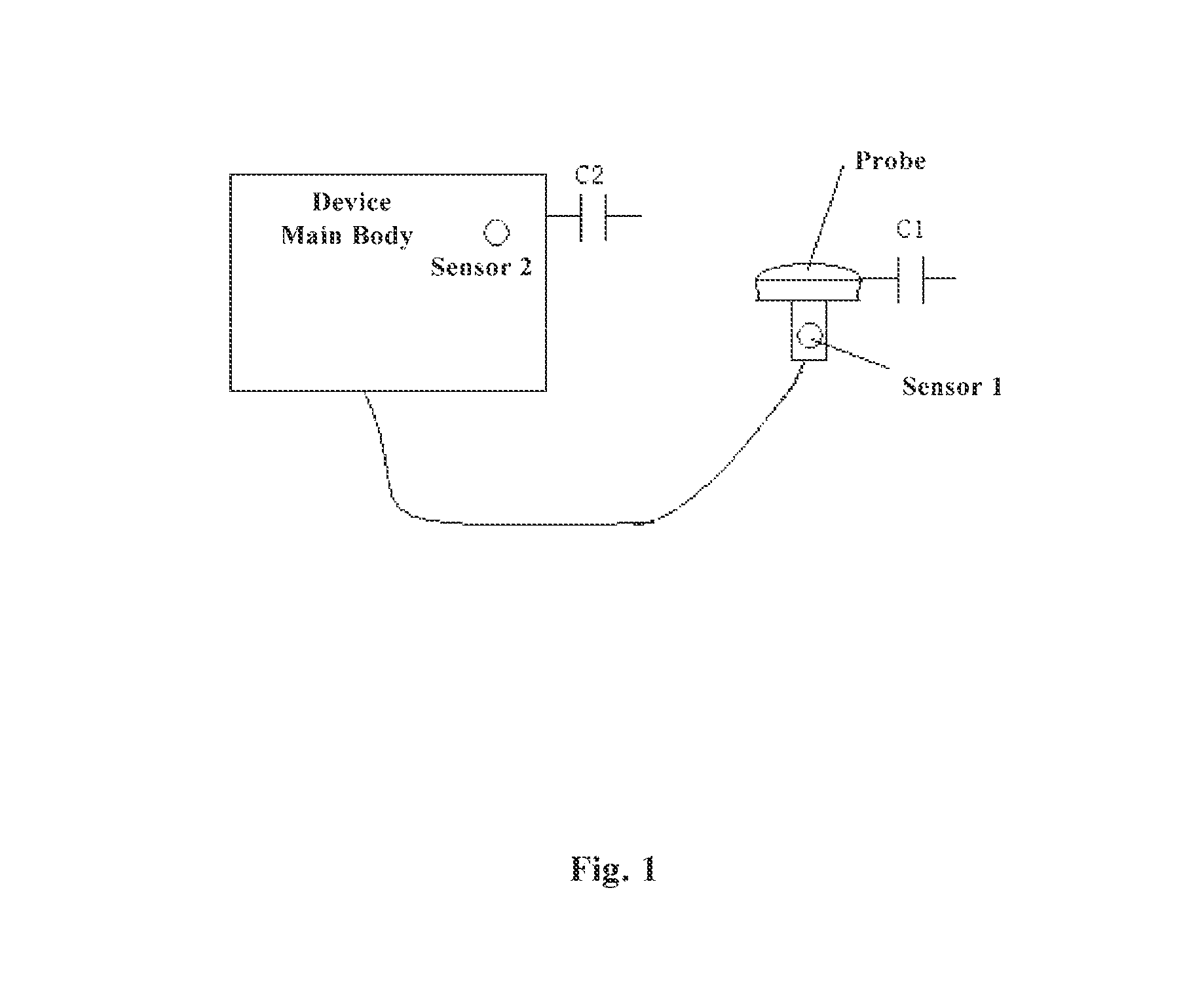

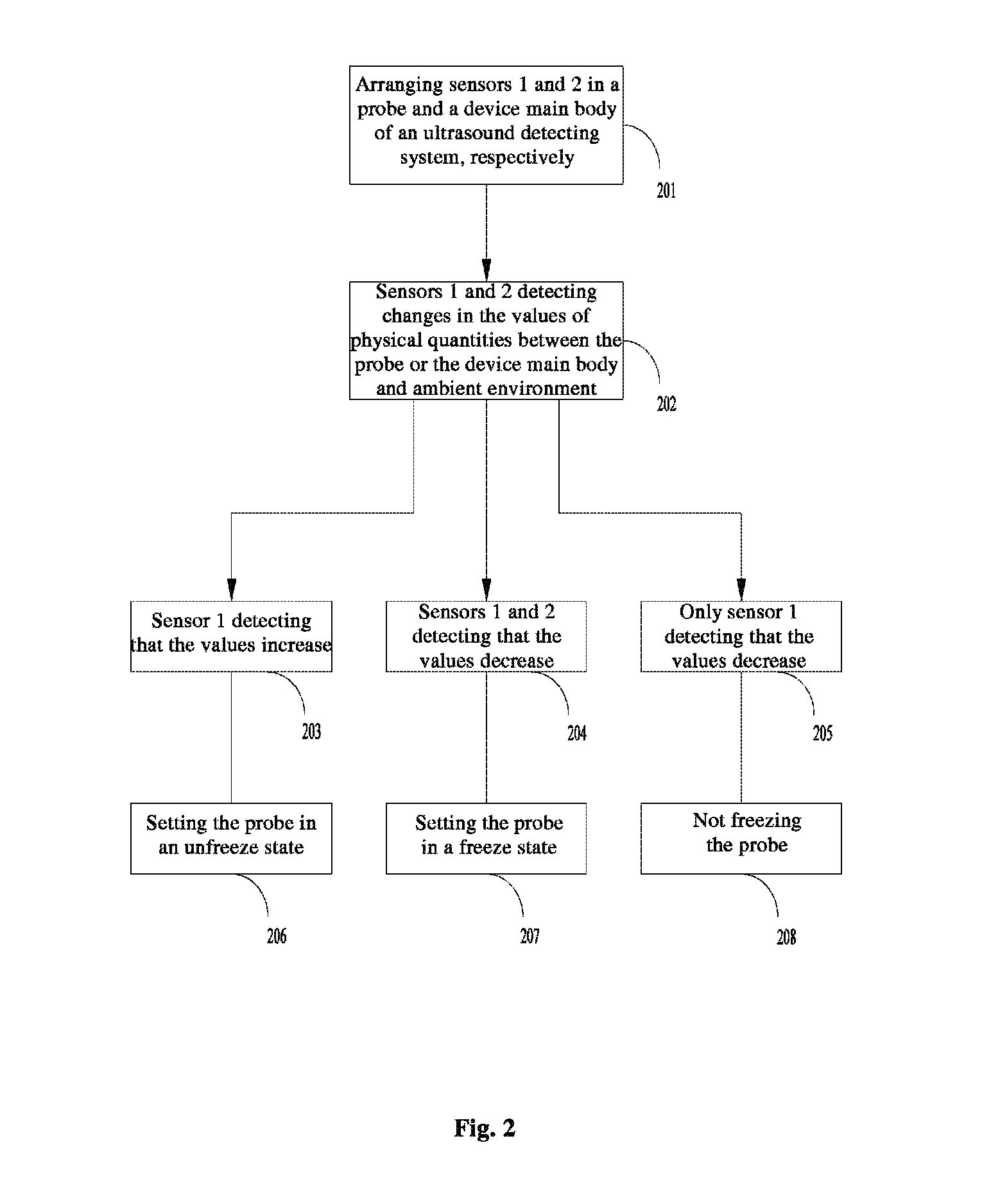

Ultrasound detecting system and method and apparatus for automatically controlling freeze thereof

ActiveUS9204860B2Reduce energy consumptionOrgan movement/changes detectionInfrasonic diagnosticsTesting ultrasoundAutomatic control

An apparatus for automatically controlling a state of operation of an ultrasound detecting system is provided. The apparatus comprises a first sensor disposed in a probe of the ultrasound detecting system and connected to a device main body, wherein the first sensor is configured to detect if the probe is being operated, and a control unit configured to control the state of operation of the ultrasound detecting system based on the detecting results of the first sensor.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Explosion-proof acoustic source for hazardous locations

ActiveUS8797830B2Material analysis using sonic/ultrasonic/infrasonic wavesTesting/calibration apparatusTesting ultrasoundSound sources

An explosion-proof system for generating acoustic energy. An exemplary embodiment of the system includes a main housing defining an open housing space and an opening. A cover structure is configured for removable attachment to the main housing structure to cover the opening and provide an explosion-proof housing structure. The cover structure includes an integral head mass. An acoustic energy emitting assembly includes the head mass, and an excitation assembly disposed within the explosion-proof housing structure. An electronic circuit is disposed within the explosion-proof housing structure to generate a drive signal for driving the excitation assembly to cause the acoustic energy emitting assembly to resonate and generate acoustic energy. In one embodiment the acoustic energy is a beam of ultrasonic energy useful for testing ultrasonic gas detectors. A method is also described for testing ultrasonic gas leak detectors using an ultrasonic source.

Owner:MSA TECH

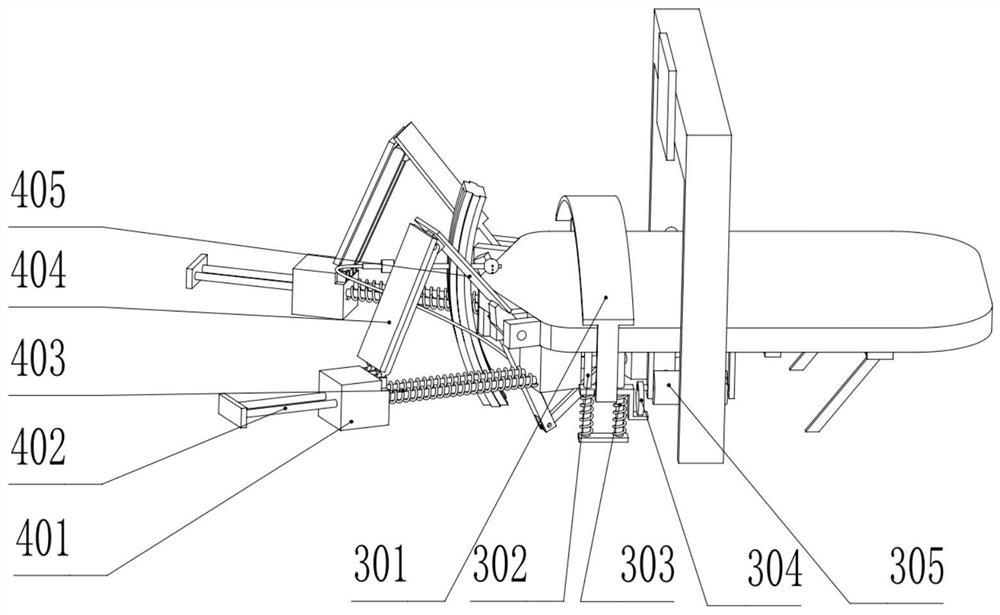

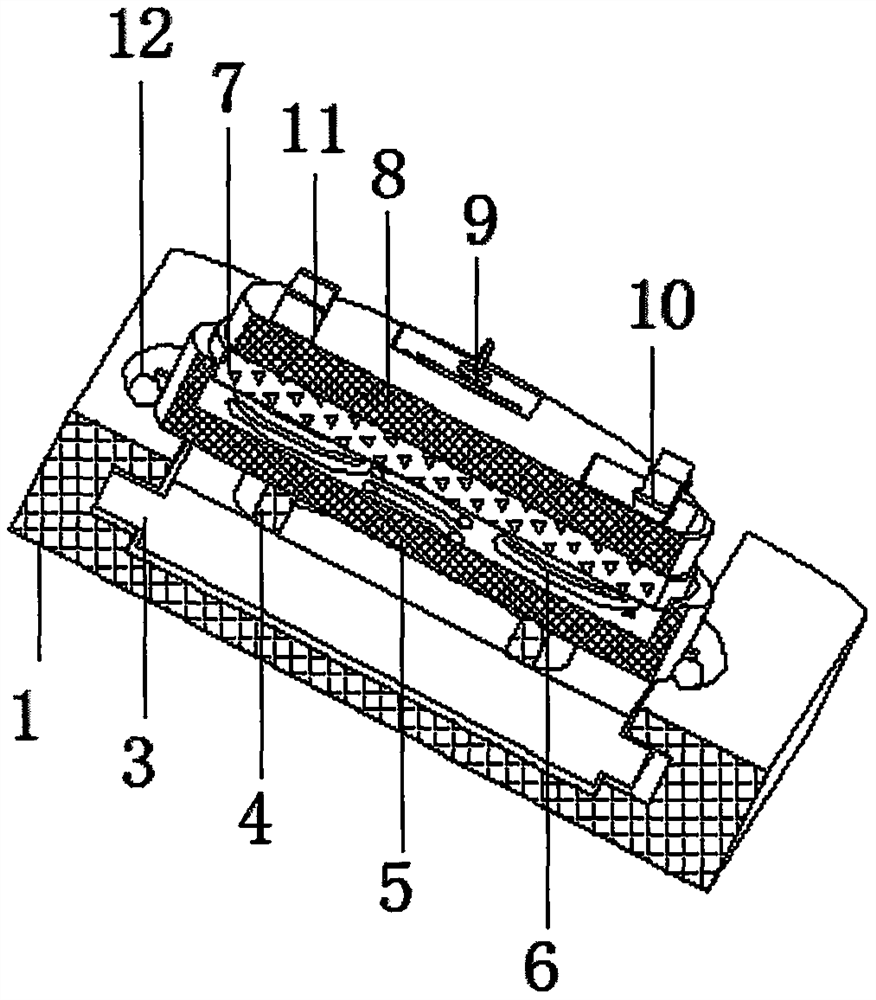

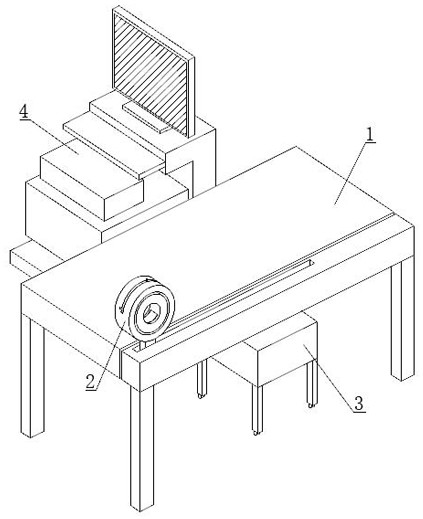

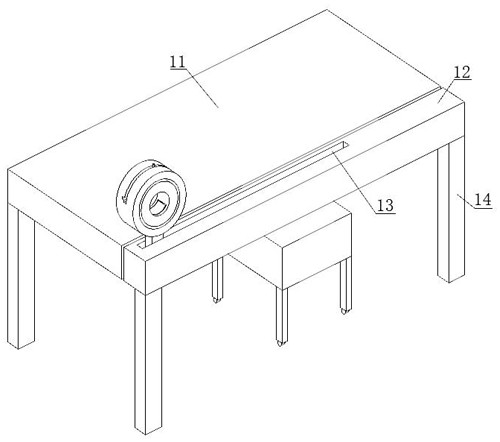

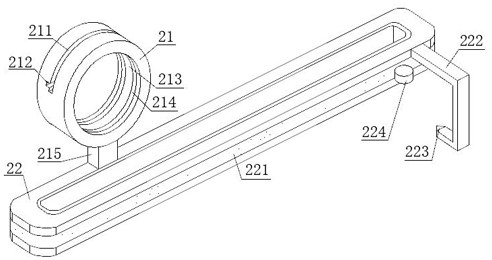

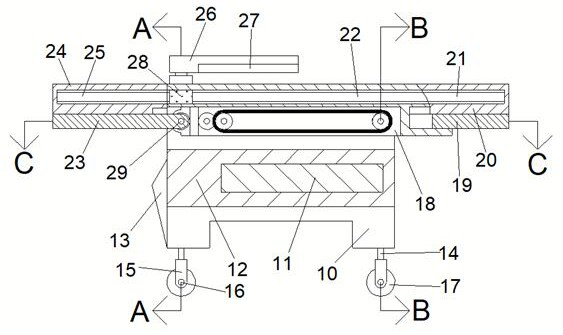

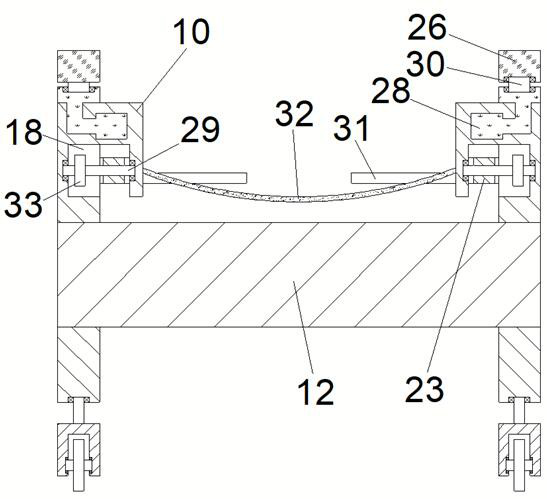

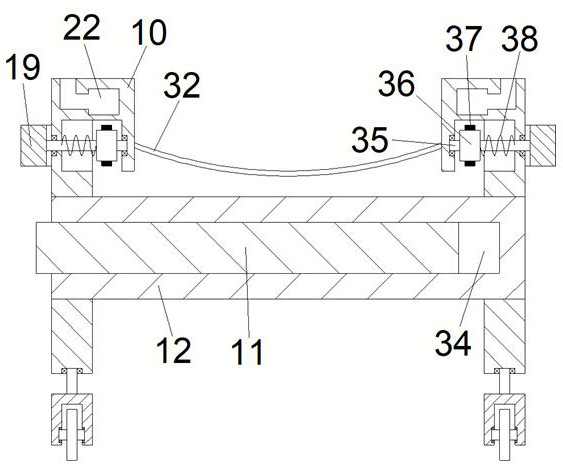

Rock damage test experiment table under ultrasonic vibration

PendingCN109100423AJudging the attenuation statusObtain physical and mechanical changesVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound attenuationTesting ultrasound

The invention discloses a rock damage test experiment table under ultrasonic vibration. The experiment table comprises a guide fixing mechanism, a rock clamping mechanism, a hydraulic pressurization mechanism, an ultrasonic vibration mechanism, a rock amplitude measurement system, a sound emission measurement system and an infrared feature measurement system. According to the rock damage test experiment table under the ultrasonic vibration built by utilizing an amplitude detection technology, a sound emission technology and an infrared detection technology, dynamic testing of rock internal crack development, rock internal stress change, an attenuation condition of a stress wave in a rock and effective rock crushing depth can be realized; and the damage process of the rock under the ultrasonic vibration can be comprehensively tested in multiple aspects, and optimal rock crushing parameters under the ultrasonic action, including a frequency, a static pressure, an amplitude and the like are determined, so that the defects and the errors of a single detection method are reduced, the experiment efficiency is improved, favorable support is provided for the research of an ultrasonic rockcrushing mechanism, and the experiment table has the advantages of being accurate, convenient and economical.

Owner:JILIN UNIV

Novel medical ultrasonic diagnosis probe

InactiveCN104161544ALess discomfortReduce work stressUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsTesting ultrasoundSpray nozzle

The invention belongs to the technical field of medical apparatuses and instruments, and particularly relates to a novel medical ultrasonic diagnosis probe which comprises a probe body and a cable of the probe body. The probe body is provided with a bag. One side of the bag is located inside the probe body. One end of the bag is connected with a coupling agent storage tank through a first pipeline penetrating through the probe body. The other end of the bag is connected with a spray nozzle through a second pipeline penetrating through the probe body. The novel medical ultrasonic diagnosis probe is simple in structure and reasonable in design, ultrasonic detection time is saved, the uncomfortable feeling of a patient is reduced, and work stress of medical staff is relieved.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

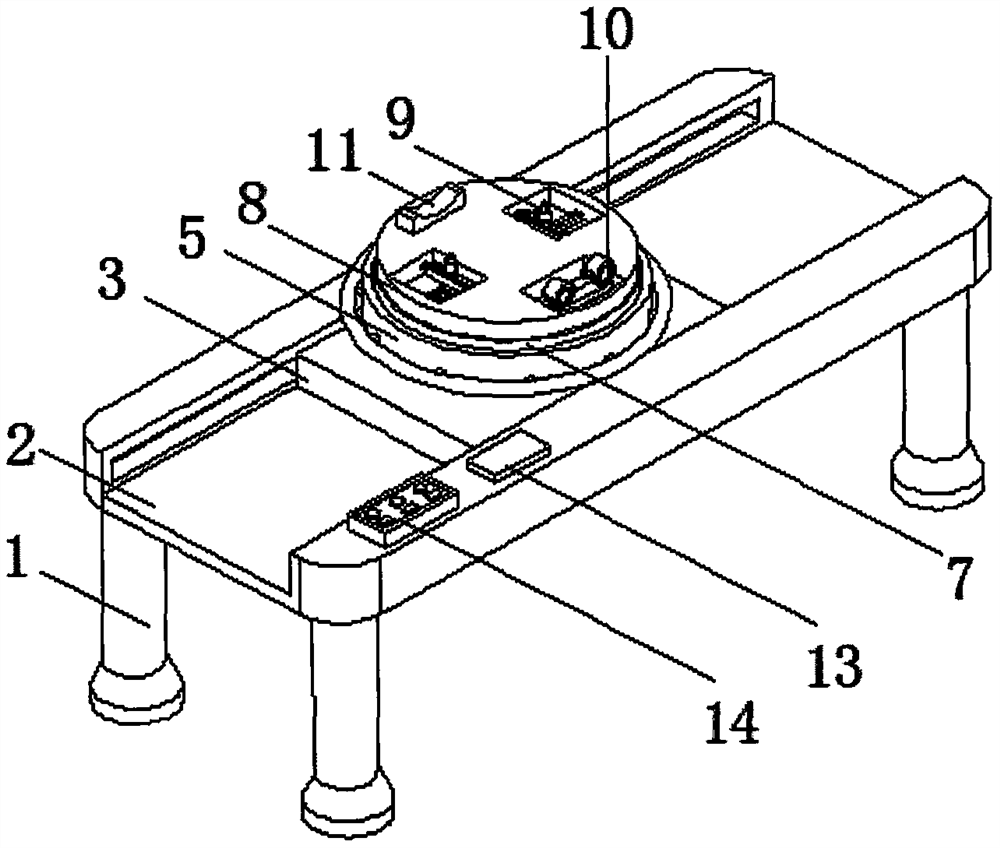

Infant safety diagnosis assistance equipment for ultrasonic department

InactiveCN111772670ASimple structureReduce workloadUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsTesting ultrasoundHand parts

The invention discloses infant safety diagnosis assistance equipment for an ultrasonic department. The equipment comprises a frame body; and a groove is formed in the middle of the upper end of the frame body. The infant safety diagnosis assistance equipment for the ultrasonic department is simple in structure; sliding blocks on two sides of a sliding plate are in sliding connection in side wall sliding grooves of the groove; a rotating ring is rotated, and under the action of a plane bearing, a placement groove plate and an upper device rotate, so that a medical staff can conveniently adjustthe position of an infant in an ultrasonic detection process, and great use convenience is brought to the staff; the hands and legs of the infant are reasonably fixed through a hand fixing device anda leg fixing device, so that the situation that the detection quality is affected due to the fact that the infant moves randomly and laterally in the detection process is avoided; and through regulation and control of a control switch, a music player plays liked comfortable songs to relieve the emotion of the infant, so that the quality of detection and diagnosis is guaranteed, the workload of thestaff is relieved, and the use efficiency of the infant safety diagnosis assistance equipment for the ultrasonic department is improved.

Owner:张伟清

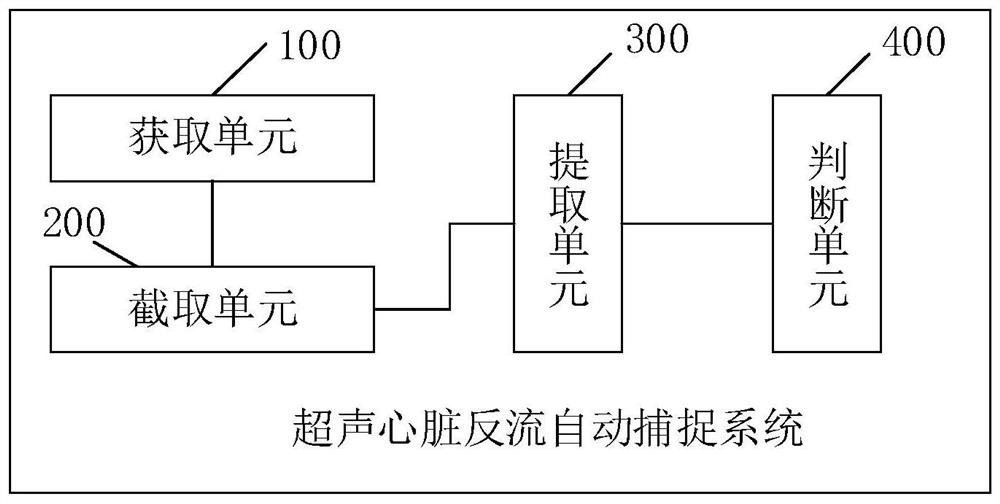

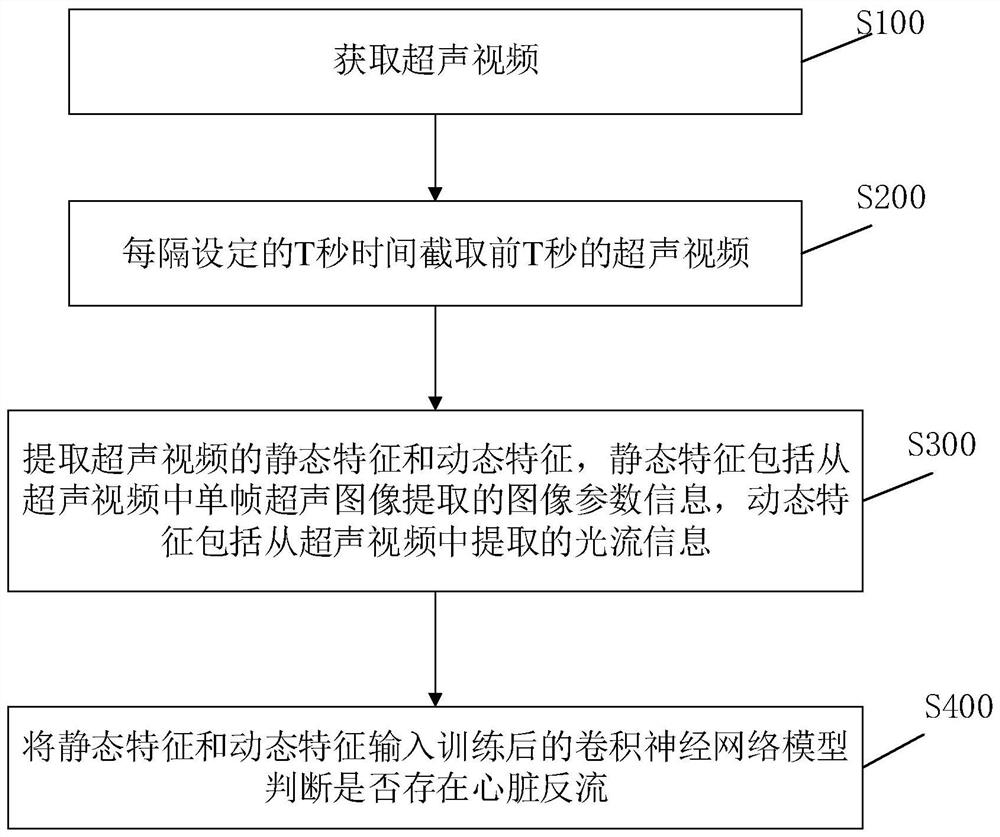

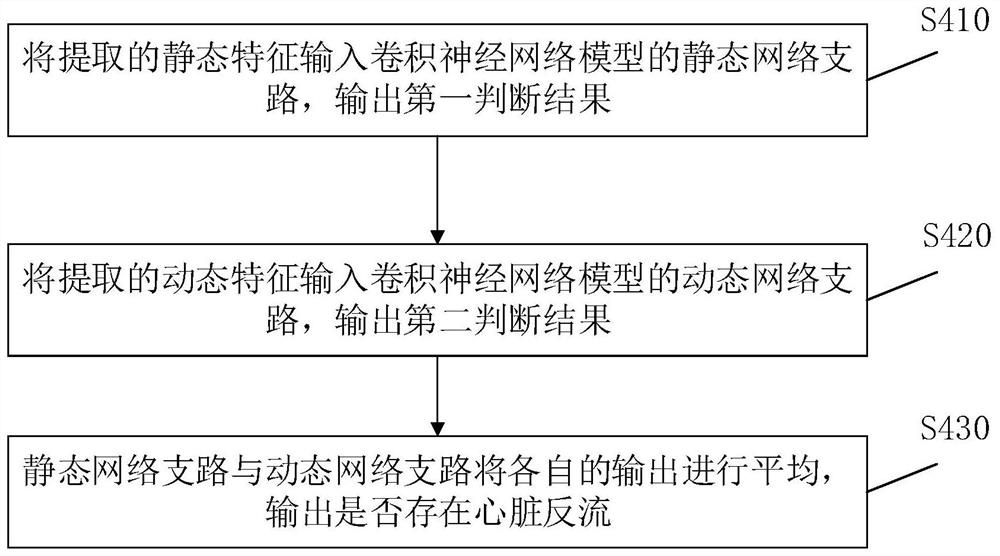

Ultrasonic heart regurgitation automatic capture method and system, and ultrasonic imaging equipment

ActiveCN111820947AImprove work efficiencyImprove detection accuracyImage enhancementImage analysisTesting ultrasoundNerve network

The invention relates to an ultrasonic heart regurgitation automatic capture method and system, and ultrasonic imaging equipment. When ultrasonic inspection is carried out on a heart, detection data are subjected to heart regurgitation automatic capturing. The ultrasonic heart regurgitation automatic capture method includes the steps that an ultrasonic video is acquired; every set T-second time, first T seconds of ultrasound video stream is intercepted, and static features and dynamic features are extracted respectively; and a trained convolutional neural network model judges whether the hearthas regurgitation or not based on the static features and dynamic features. When heart is scanned in the continuous Doppler or pulsed Doppler mode, the ultrasonic imaging equipment to which the ultrasonic heart regurgitation automatic capture method is applied can automatically detect a heart regurgitation phenomenon, and the characteristics of high accuracy and high sensitivity are achieved.

Owner:CHISON MEDICAL TECH CO LTD

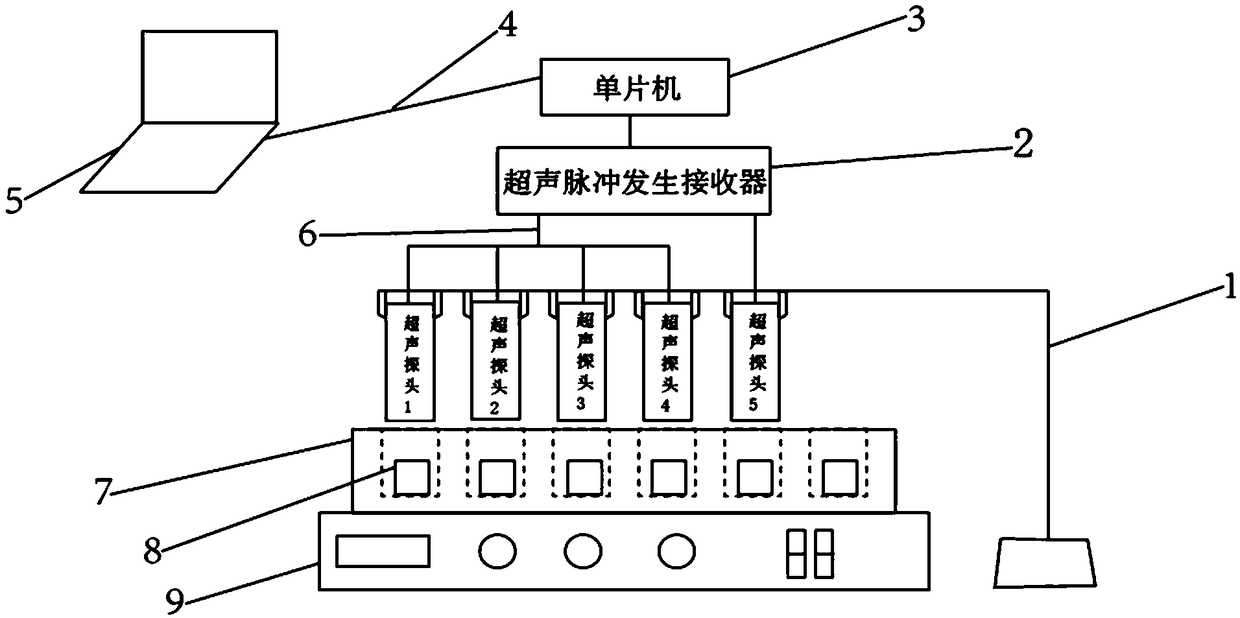

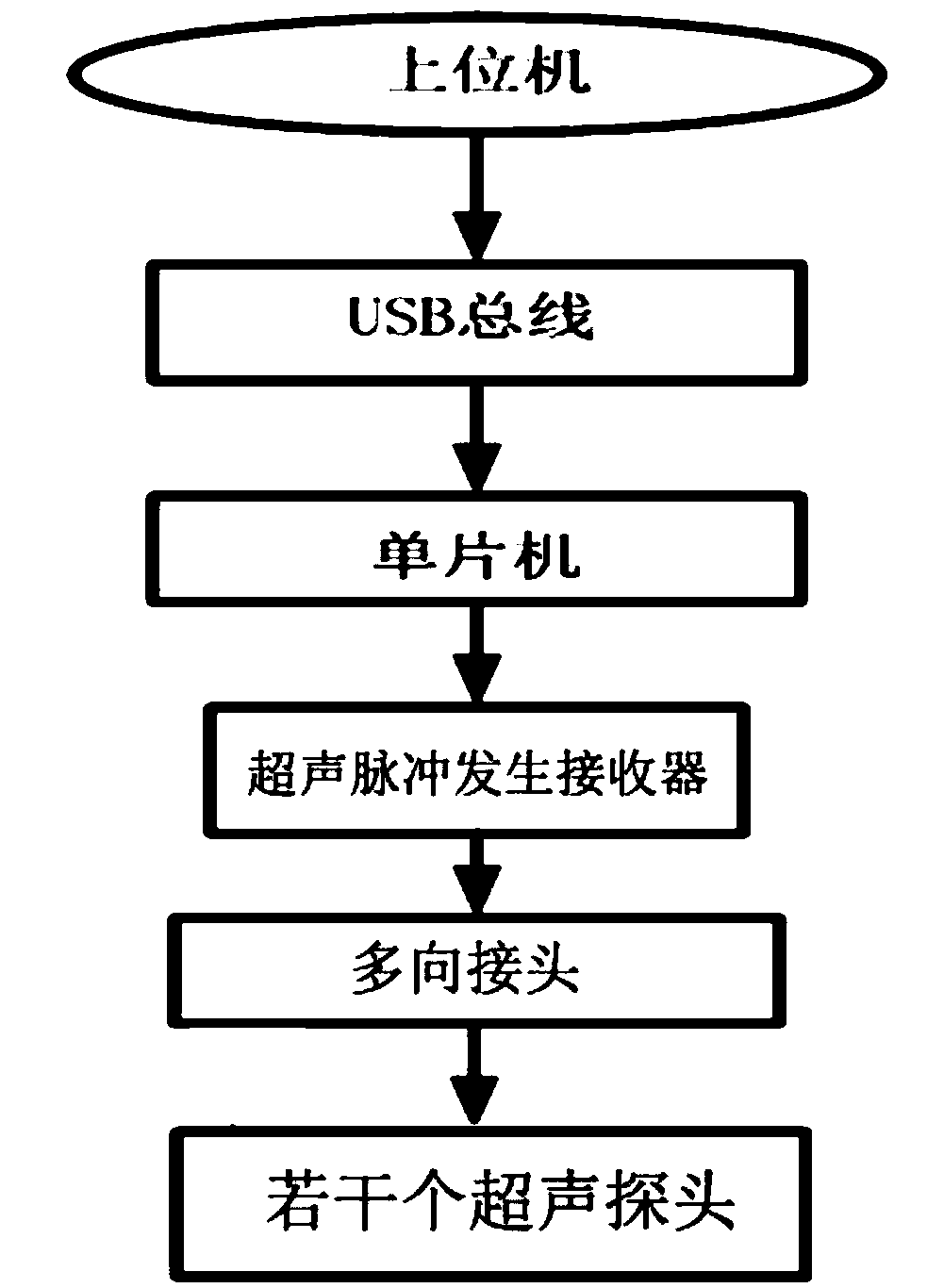

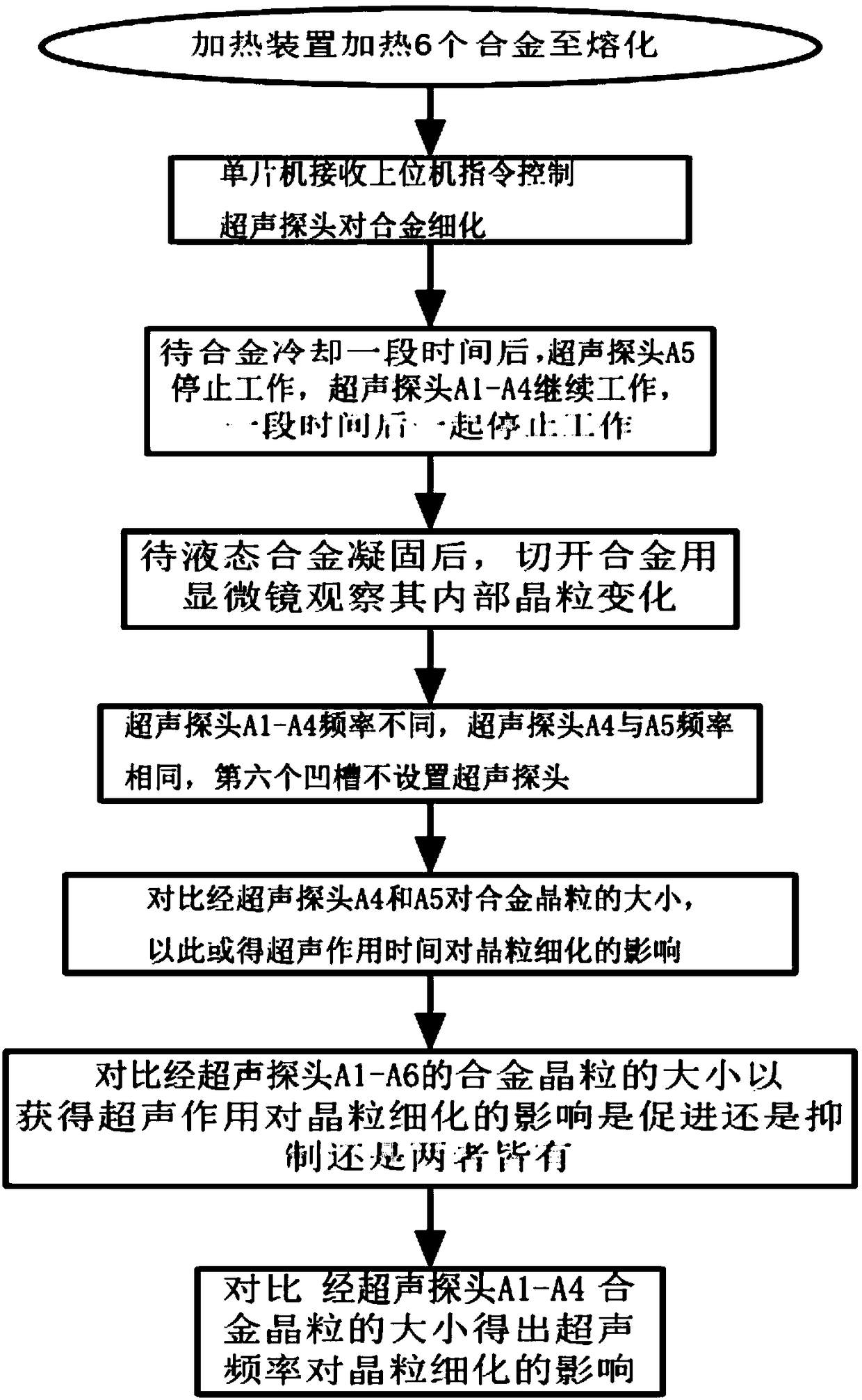

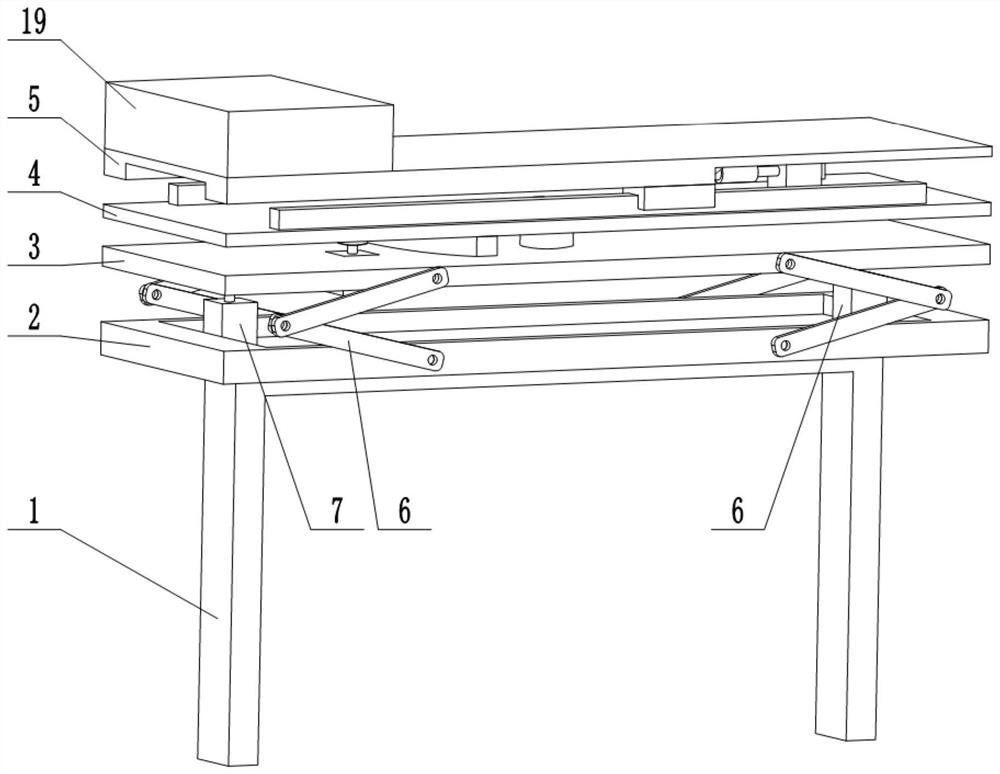

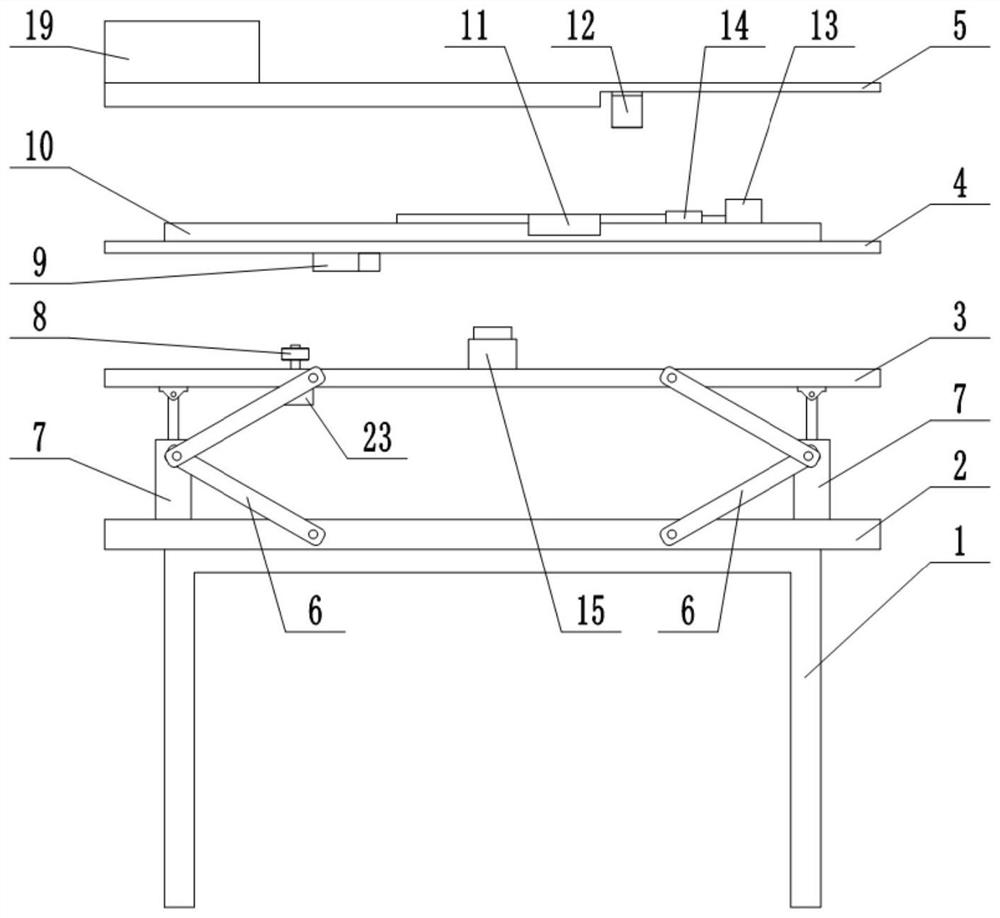

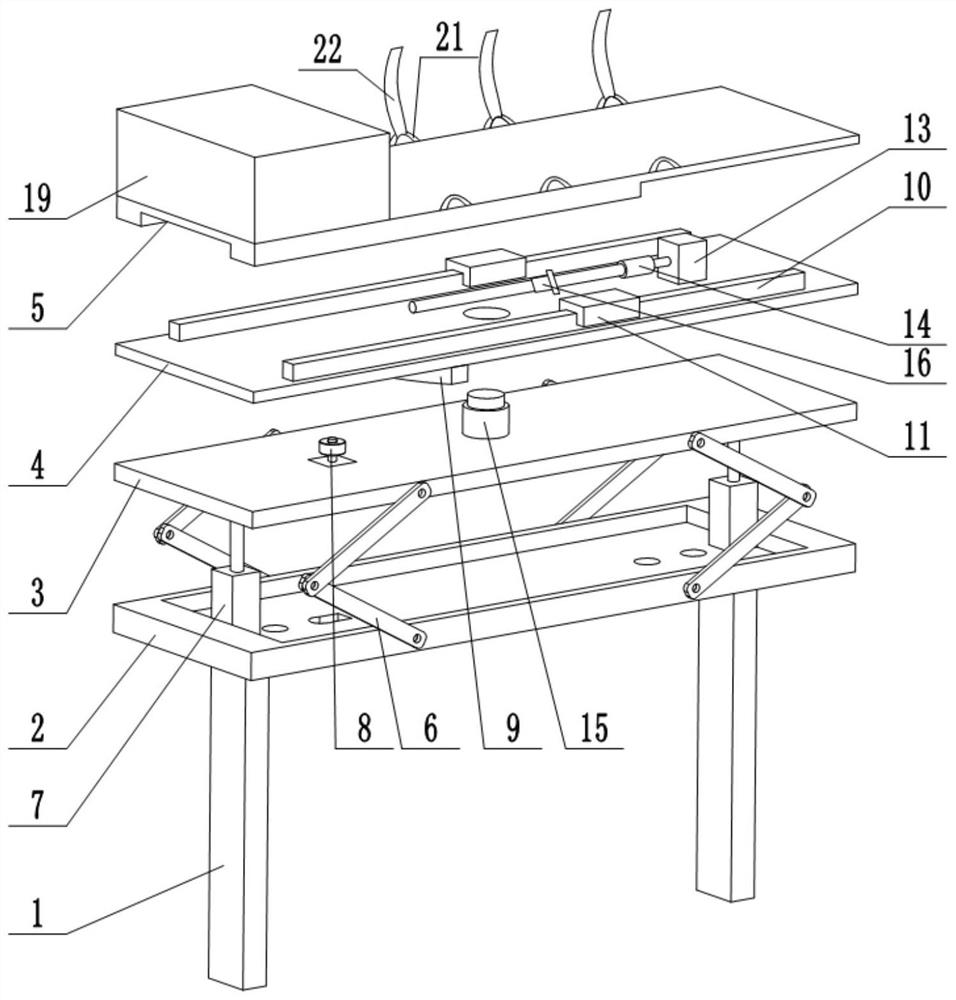

Method and device for testing function of refining of fusion metal grains through ultrasonic waves

InactiveCN109351952ANeglect of external conditionsReduce experimental workloadMicrocontrollerTesting ultrasound

The invention mainly discloses a method and device for testing the function of refining of fusion metal grains through ultrasonic waves. A single-chip microcomputer, an ultrasonic pulse generation receiver, ultrasonic probes and a heating device are included. The single-chip microcomputer and the ultrasonic pulse generation receiver are connected through a wire. The ultrasonic pulse generation receiver is connected with the ultrasonic probes through a multi-direction connector. An alloy is placed on the heating device, the single-chip microcomputer receives upper computer instructions, and signals are transmitted to the ultrasonic pulse generation receiver through the single-chip microcomputer. The ultrasonic pulse generation receiver generates negative-high-voltage pulse signals to drivethe multiple ultrasonic probes to send ultrasonic waves, and the ultrasonic waves refine the alloy liquefied after heating. After the ultrasonic probes stop working and the alloy is cooled and solidified, and the alloy refined through the ultrasonic waves is cut to be observed. The single-chip microcomputer is utilized for control, the multiple ultrasonic probes are controlled, and under the sameoutside conditions, the fusion metal grain refining functions are compared under different ultrasonic frequencies and ultrasonic action time periods.

Owner:HANGZHOU DIANZI UNIV

Wheelchair external fixing device suitable for muscle-bone ultrasonic examination of stroke patient

PendingCN114403927AReduce labor intensityEasy diagnosisPatient positioningOrgan movement/changes detectionTesting ultrasoundGear wheel

The wheelchair external fixing device comprises a connecting frame, a fixing plate, a lifting plate, a rotating plate, a sliding plate and a hand rest, the fixing plate is connected with the connecting frame, the fixing plate is connected with the lifting plate, a lifter is arranged between the fixing plate and the lifting plate, the lifting plate is connected with the rotating plate, and the rotating plate is connected with the sliding plate. A rotating motor, a gear and a gear ring are arranged between the lifting plate and the rotating plate, a guide rail is arranged on the rotating plate, the sliding plate is connected with a sliding block on the guide rail, and a stepping motor and a ball screw nut pair are arranged between the rotating plate and the sliding plate. The rotating motor, the stepping motor and the electric inflator pump are controlled through the controller, automatic movement of the wheelchair external fixing device in multiple directions is achieved, the wheelchair external fixing device is particularly suitable for body position control during muscle-bone ultrasonic detection on a stroke patient, the labor intensity of a doctor for searching for an articular cavity is reduced, the medical efficiency of the doctor is improved, and the medical effect of the doctor is improved. The recovery of the affected limb of the stroke patient is also facilitated.

Owner:SHANDONG UNIV QILU HOSPITAL

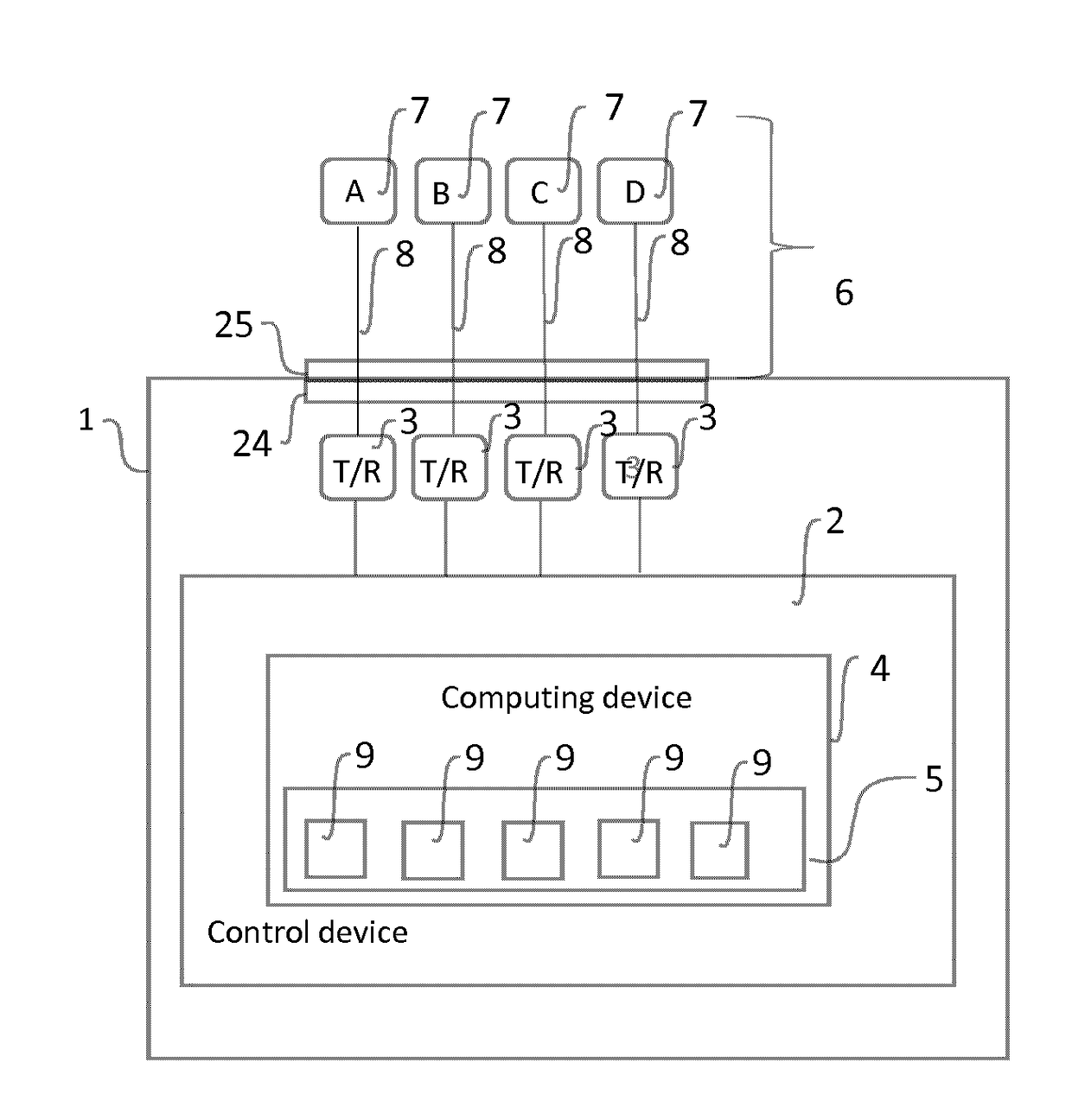

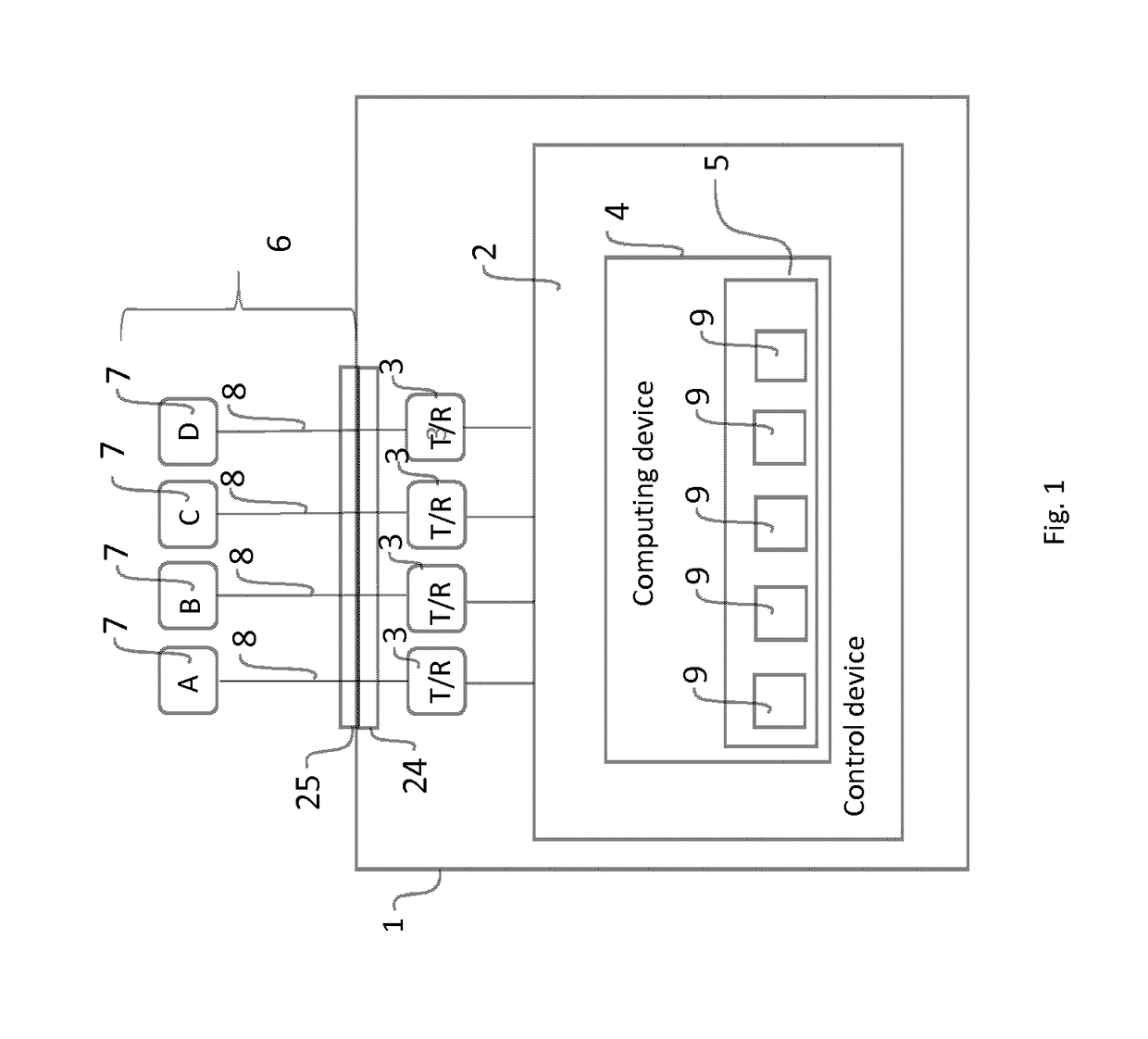

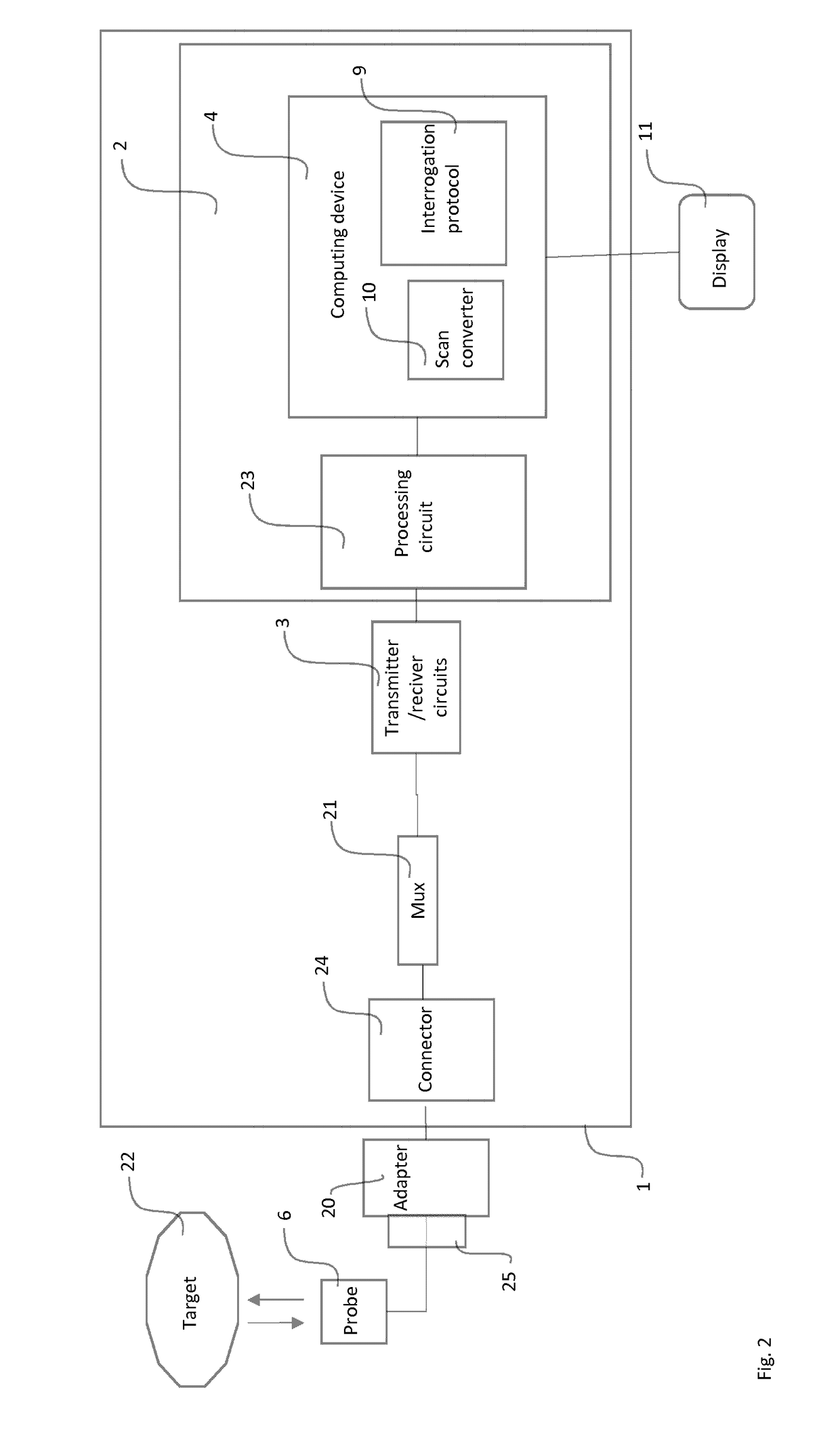

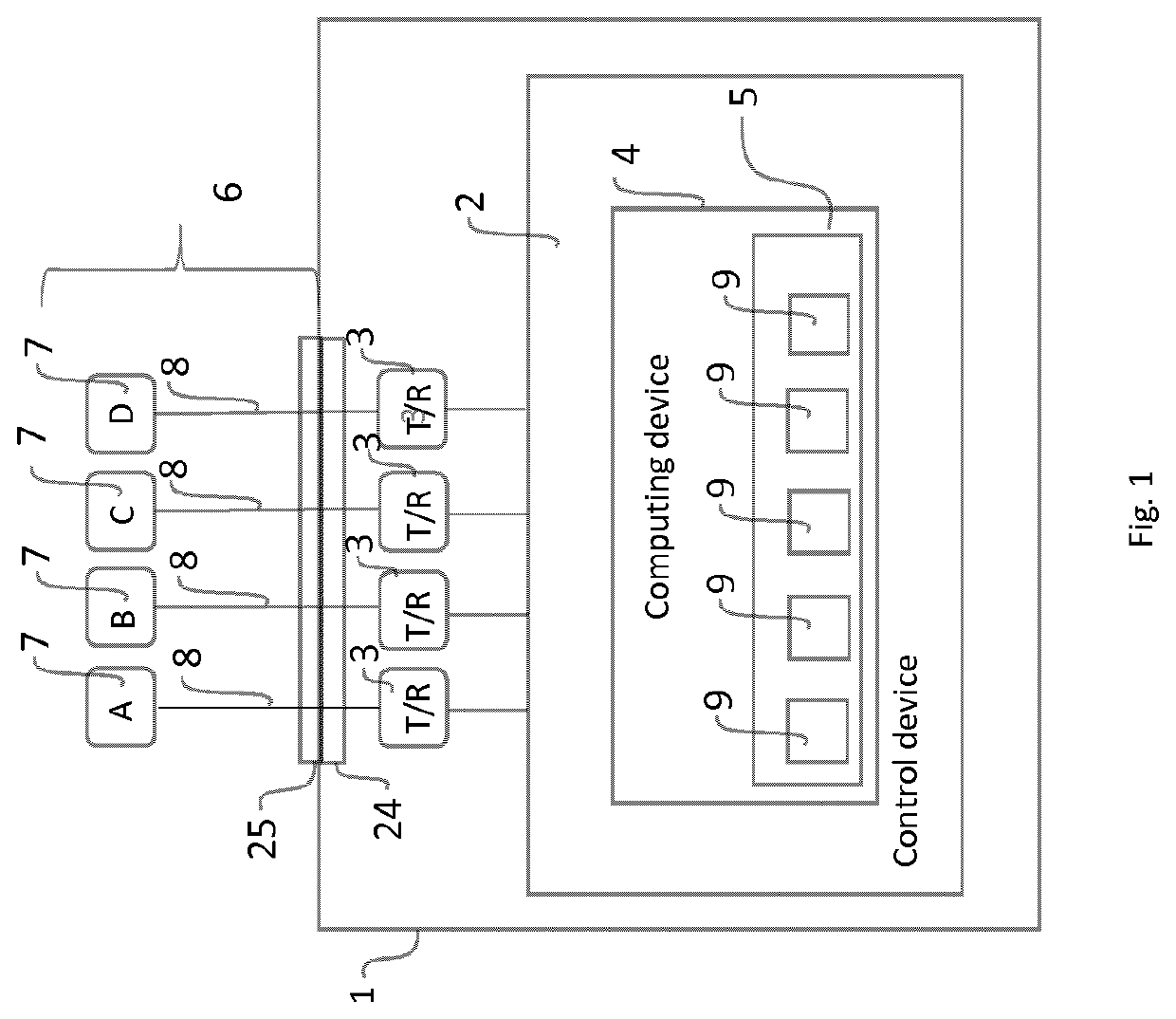

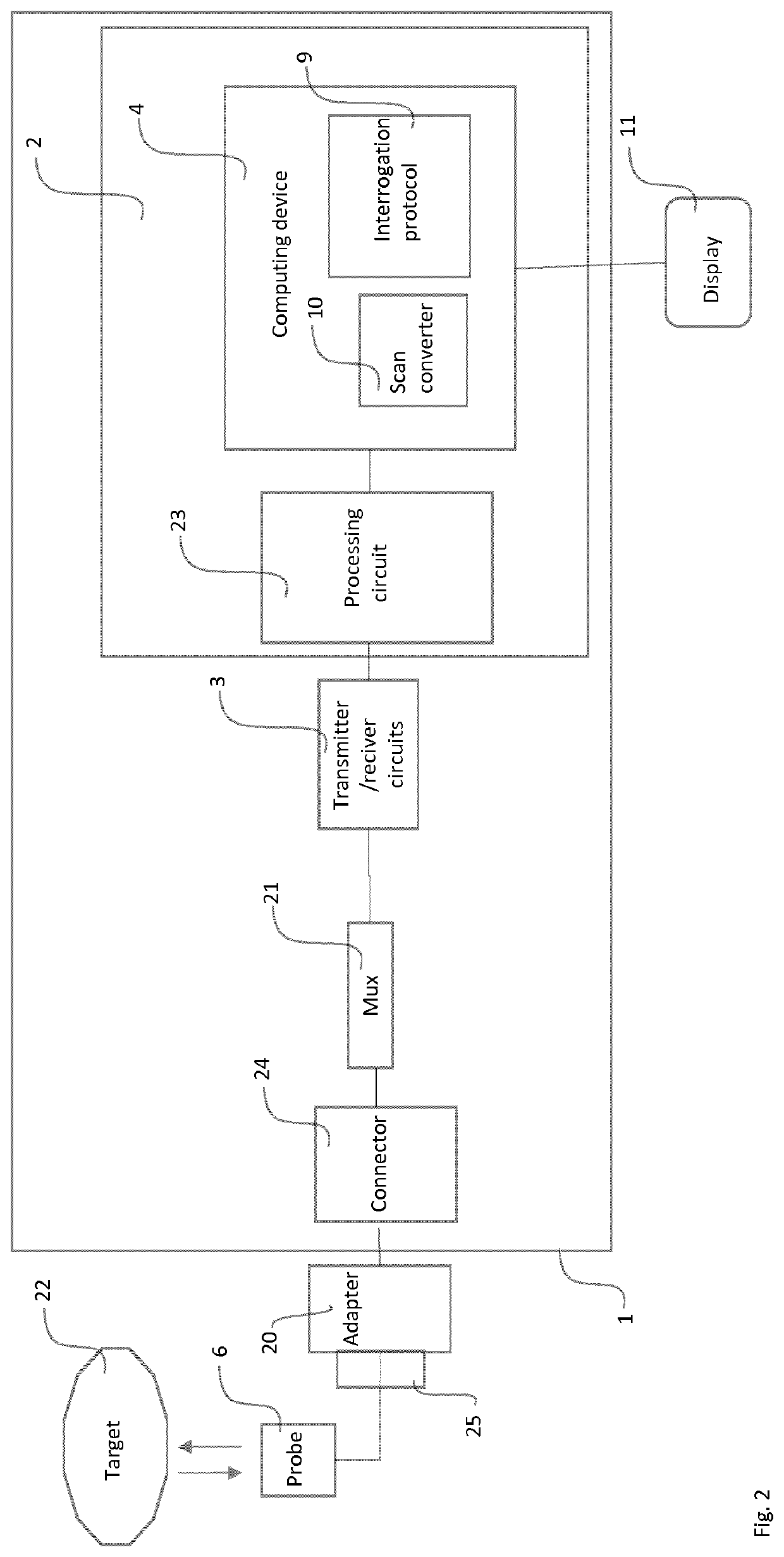

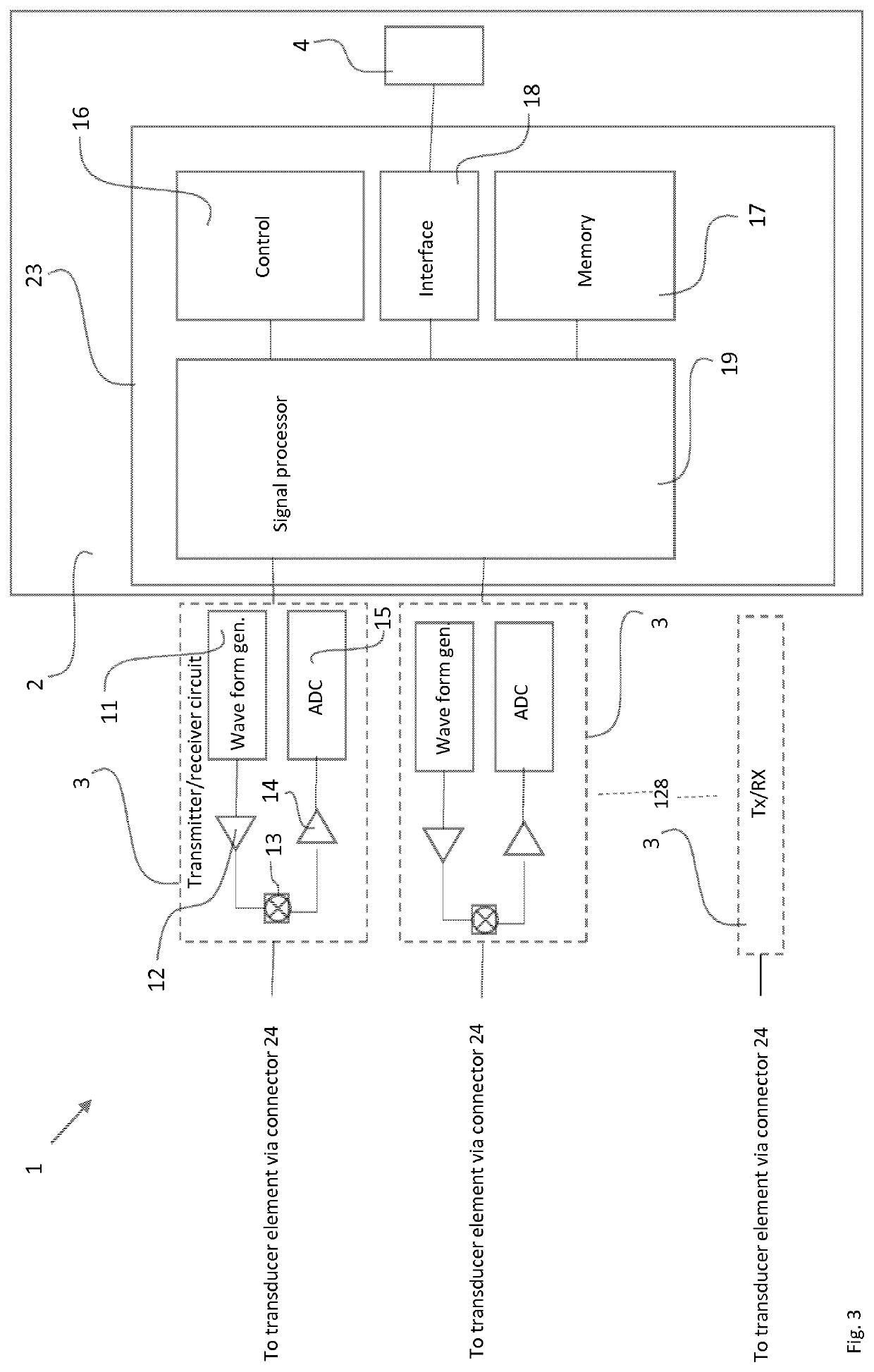

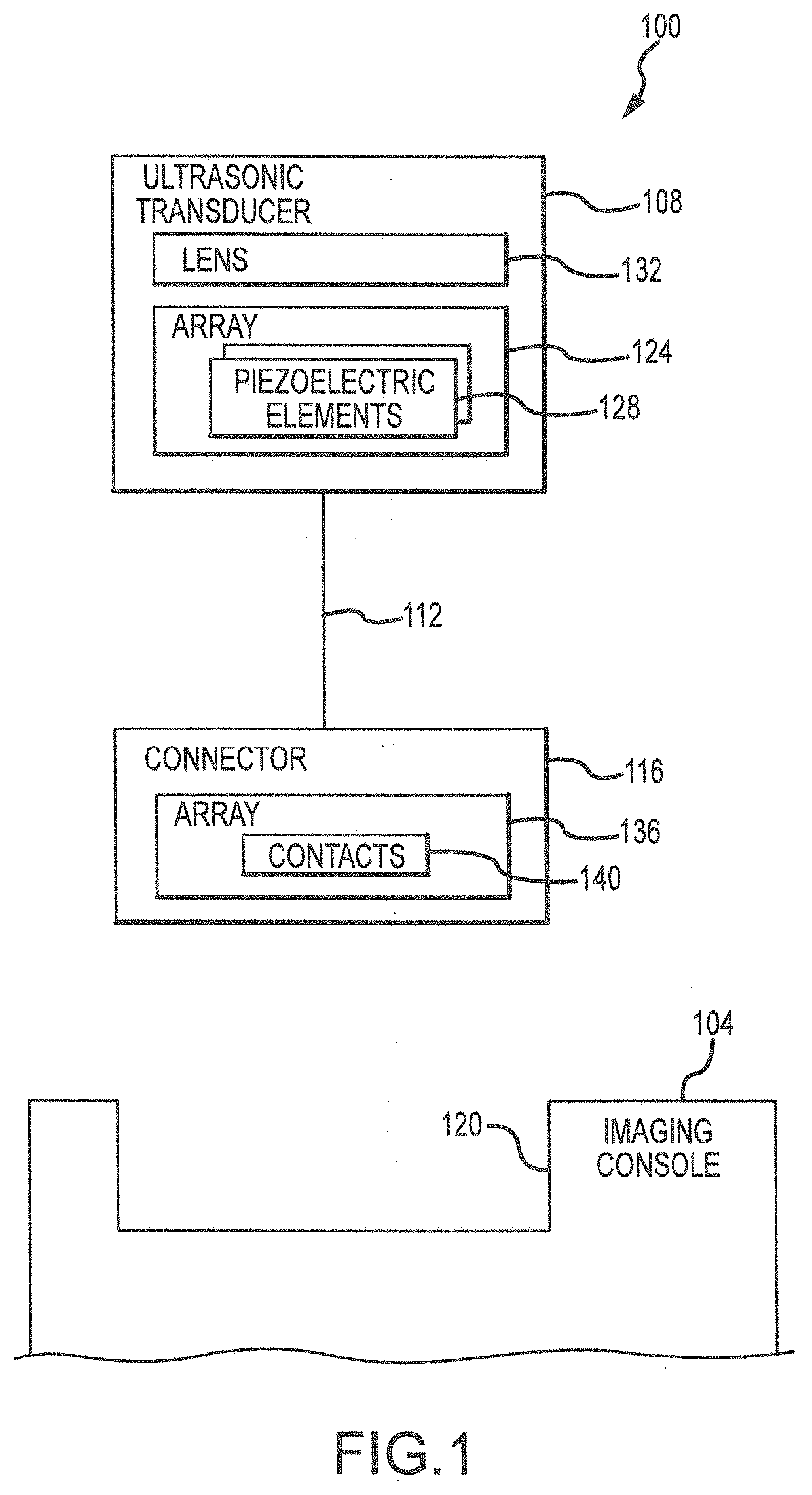

Method and device for the testing of ultrasound probes

ActiveUS20170067858A1Fast switching capabilityEasy diagnosisMaterial analysis using sonic/ultrasonic/infrasonic wavesWave based measurement systemsTesting ultrasoundSonification

There is provided a device for testing ultrasound probes comprising a plurality of transducing elements, said device comprising a plurality of ultrasound transmitter / receiver circuits, a computing device and a control device arranged to control the transmitter / receiver circuits and the computing device arranged to select an interrogation protocol from a plurality of different interrogation protocols, where each interrogation protocol comprises instructions for the order in which the plurality of transmitter / receiver circuits shall send voltage pulses to the transducers of the ultrasound probe.

Owner:BBS FORSALJNINGS

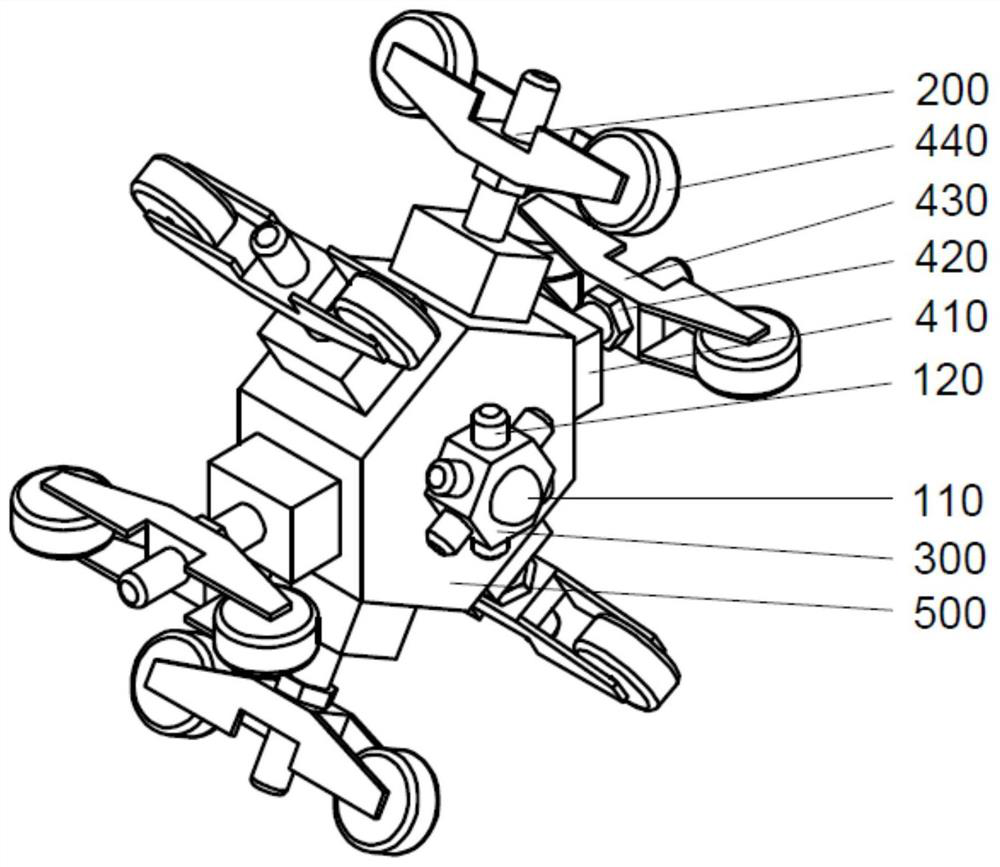

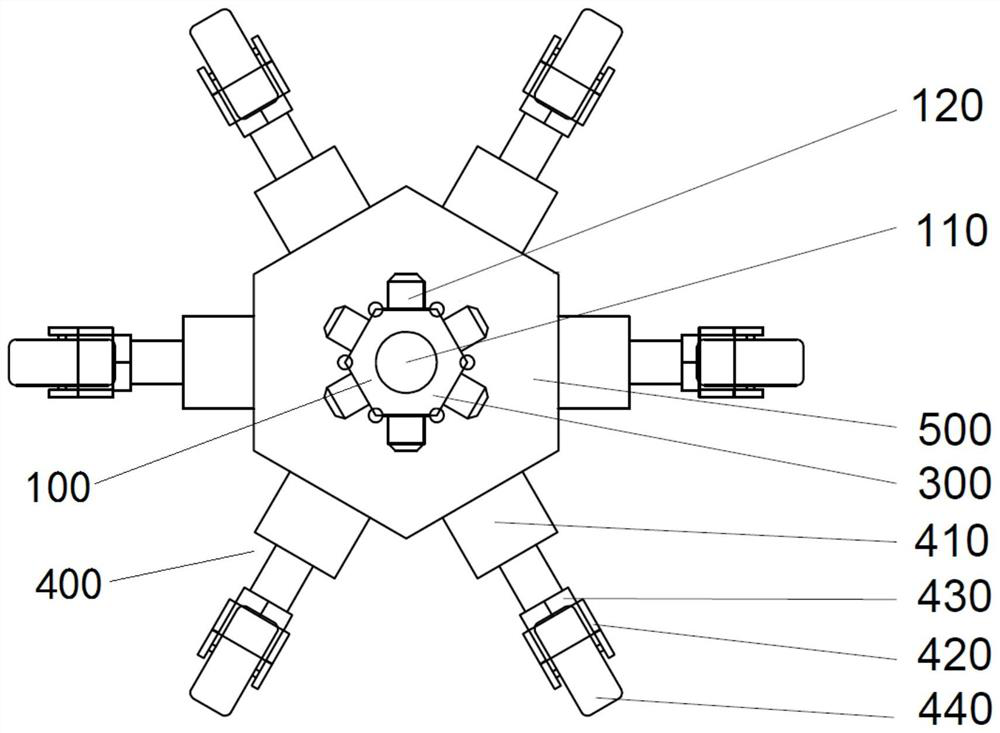

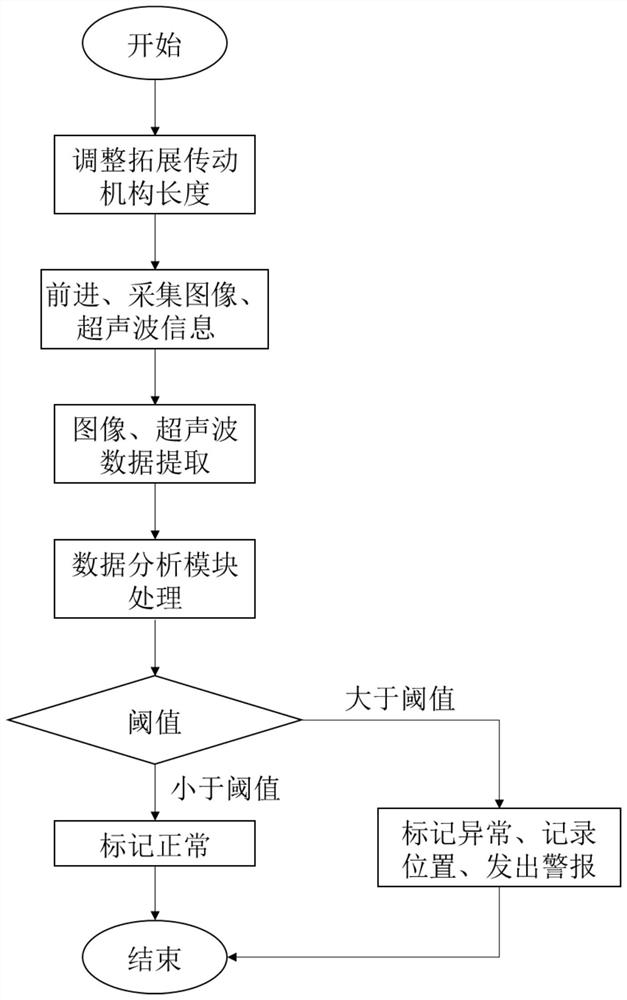

Flexible defect detection device for inner wall of pipeline and working method thereof

PendingCN113484334AImprove detection efficiencyReduce mistakesAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansTesting ultrasoundIdentification device

The invention discloses a flexible defect detection device for a pipeline inner wall and a working method thereof, and belongs to the technical field of pipeline inner wall defect detection. The device comprises a body, an image recognition device, an electromagnetic ultrasonic detection device, a control and processing module, a flexible power mechanism and a power supply device, the image recognition device, the electromagnetic ultrasonic detection device, the flexible power mechanism and the power supply device are respectively connected with the control and processing module; the plurality of flexible power mechanisms are annularly arranged on the side part of the body; and during use, the ends of all the rollers make contact with the inner wall of the pipeline. According to the invention, human eyes are replaced, the detection efficiency is improved, and errors are reduced; the device can obtain enough support in a pipeline and stably advance; and according to the method, defects in the pipeline can be efficiently identified, efficient continuous operation can be carried out in the variable-diameter pipeline, the method does not depend on the skill level and experience of an operator, and the method has a good application prospect.

Owner:XI AN JIAOTONG UNIV

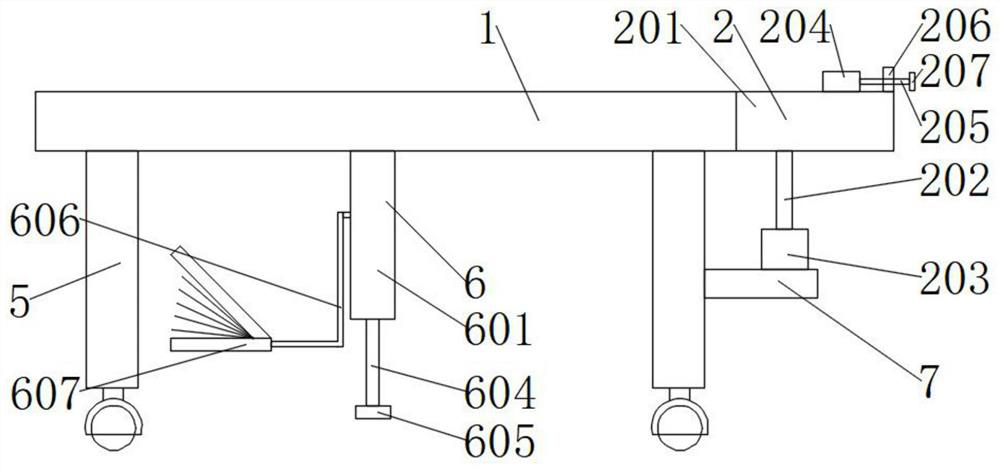

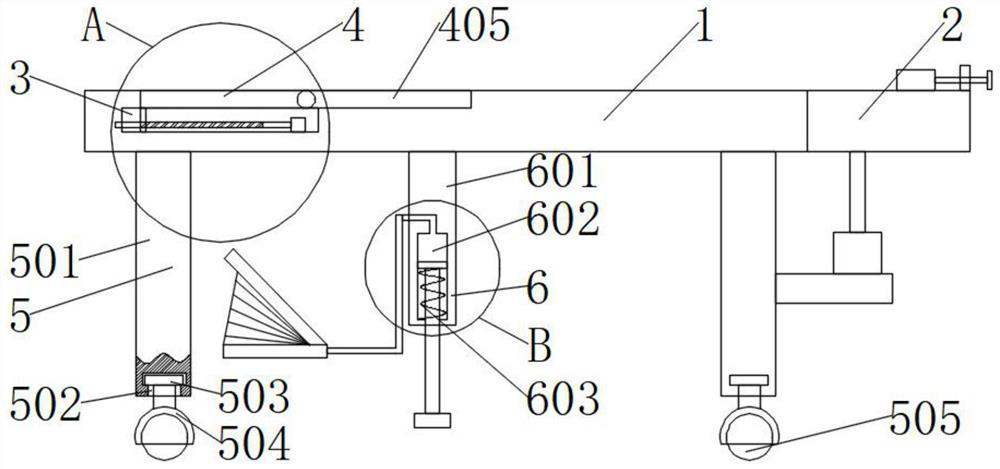

Examination table for ultrasonic department

InactiveCN111657994AConvenient Ultrasonic TestingRelieve pressurePatient positioningOperating tablesTesting ultrasoundEngineering

The present invention provides an examination table for ultrasonic department and relates to the field of medical devices. The examination table for ultrasonic department comprises a bed body, a rightside surface of the bed body is provided with a head adjusting part, a mounting groove is arranged inside the bed body, a leg adjusting part is arranged inside the mounting groove, a moving device isarranged on a lower surface of the bed body, a support plate is arranged at a right side surface of the moving device, a moving stop device is arranged on the lower surface of the bead body and alsolocated at a rear side of the moving device, and a handle is arranged on a front surface of the bed body. By using the moving device and the movement stop device, medical personnel more conveniently moves detection parts to facilitate better observation to examination images, accuracy and convenience of ultrasonic examination are increased, and accommodation is more extensive, by using the head adjusting part and leg adjusting part, some special crowds can be better carry out ultrasonic testing, and the examination table can adapt to examination of more different patients, and the ultrasonic examination is more convenient.

Owner:狄显强

Method and device for the testing of ultrasound probes

ActiveUS10509014B2Easy diagnosisImprove rendering capabilitiesMaterial analysis using sonic/ultrasonic/infrasonic wavesWave based measurement systemsTesting ultrasoundVoltage pulse

Owner:BBS FORSALJNINGS

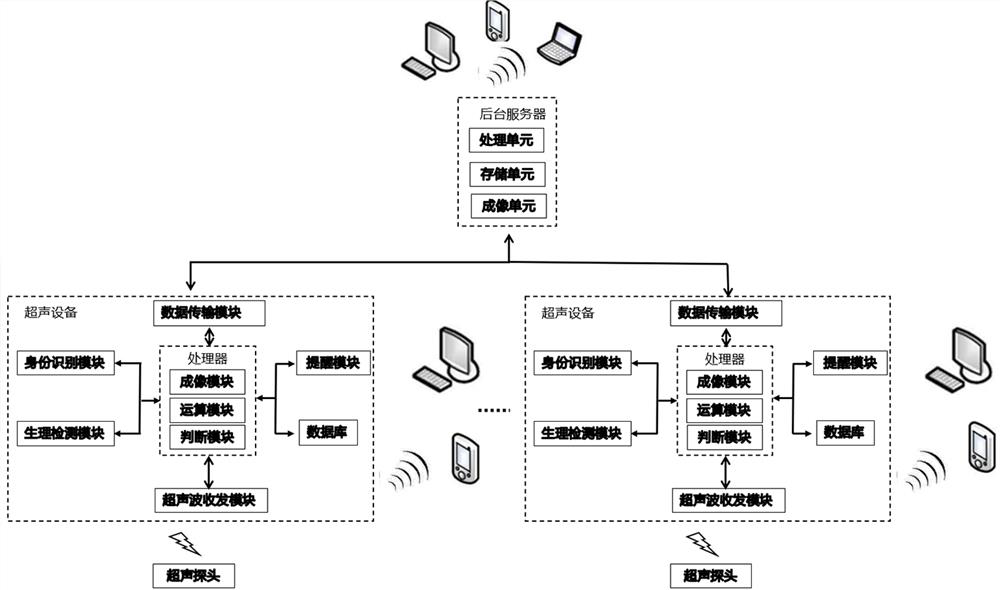

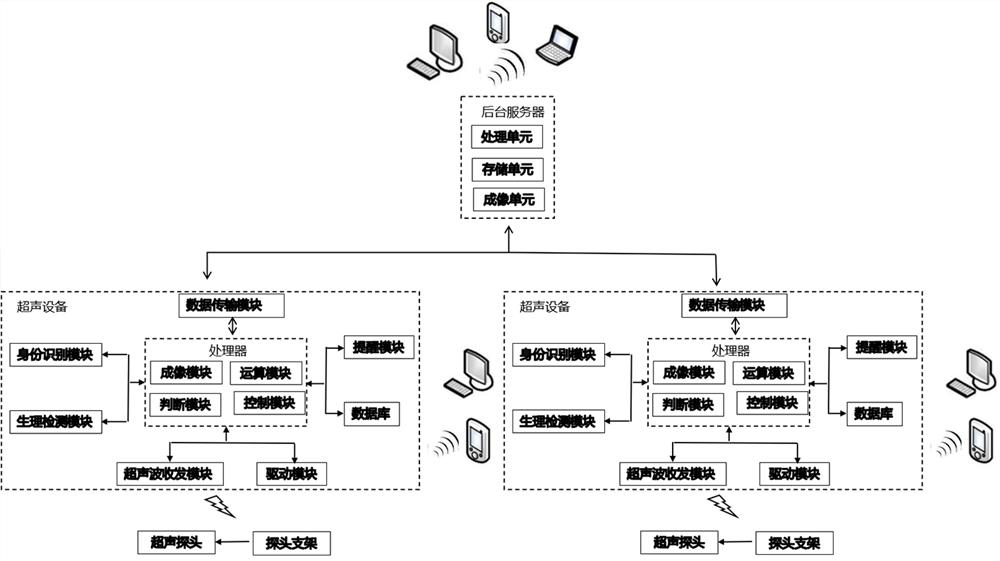

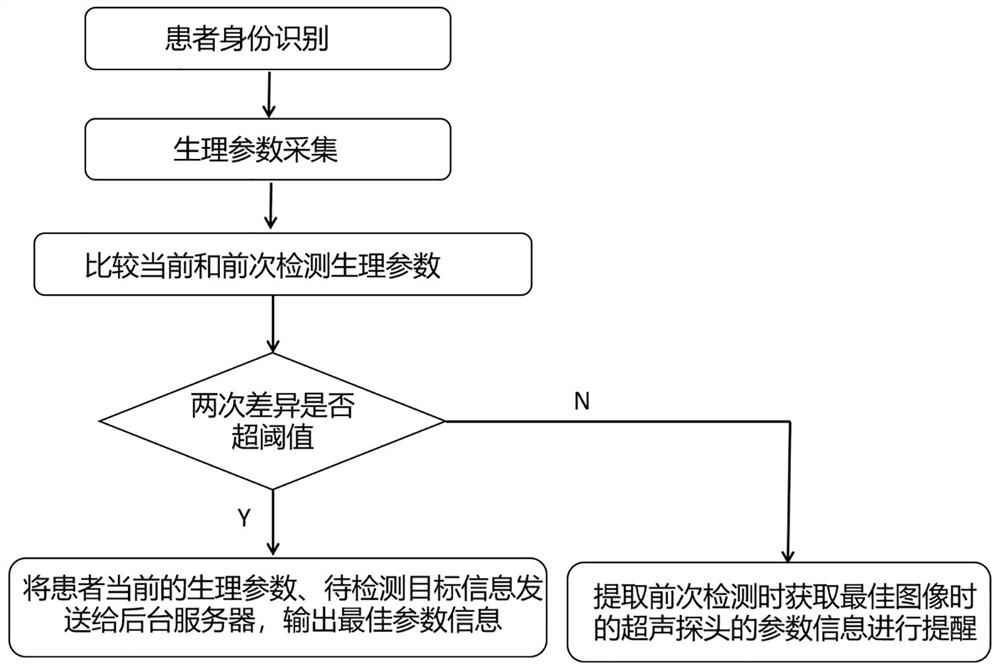

Imaging control system and method of medical ultrasonic detection equipment

InactiveCN114557722AStart fastWith identification functionInfrasonic diagnosticsSonic diagnosticsTesting ultrasoundIdentity recognition

The invention relates to an imaging control system and method for medical ultrasonic detection equipment, and the system comprises a plurality of ultrasonic equipment, a background server and a remote control terminal, can store the diagnosis historical information of a patient, has an identity recognition function, and can extract the parameter information of a probe when the patient captures an optimal image in the previous detection after obtaining the identity of the patient. Medical staff can directly refer to the kit, so that the detection time is shortened, and inexperienced staff can quickly master the kit conveniently. Handheld terminal equipment is further arranged, so that medical staff can check the imaging result in real time in the detection process, and the probe is adjusted in time. And the system has an automatic detection function, can generate a probe control instruction according to the physiological parameters of the patient and the historical doctor-seeing information, controls the probe to automatically carry out ultrasonic detection, realizes remote control, and saves professional ultrasonic detection personnel.

Owner:HENAN MEDICAL COLLEGE

Pre-positioning device for ultrasonic detection and implementation method thereof

InactiveCN114271859AEasy to detectIncrease health protection effectOperating chairsOperating tablesTesting ultrasoundPhysical medicine and rehabilitation

The invention discloses a pre-positioning device for ultrasonic detection and an implementation method thereof, belongs to the technical field of muscle-bone ultrasonic detection, and aims to solve the problems that when an existing device is used for muscle-bone detection, limb parts of a patient are inconvenient to position and control, the detection effect can be influenced by unconscious actions or twisting of the patient, the detection difficulty degree is increased, and the detection time is shortened. The problem that non-woven fabrics are inconvenient to arrange one by one when a traditional device is used for carrying out muscle-bone ultrasonic detection is solved. According to the device, the component circular block is moved to a designated position, a detected part is clamped in the clamping groove, a doctor can conveniently detect the detected part by utilizing the rotatability of the rotary circular block in the component circular block, and when the component circular block moves, the seat covered with disposable non-woven fabric is pushed out through the linkage structure, so that a patient sits, and the detection efficiency is improved. The limb part of a patient is positioned and controlled, the detection effect is prevented from being affected by unconscious action or twisting of the patient, and health protection is achieved through disposable non-woven fabric.

Owner:PINGMEI SHENMA MEDICAL GRP GENERAL HOSPITAL

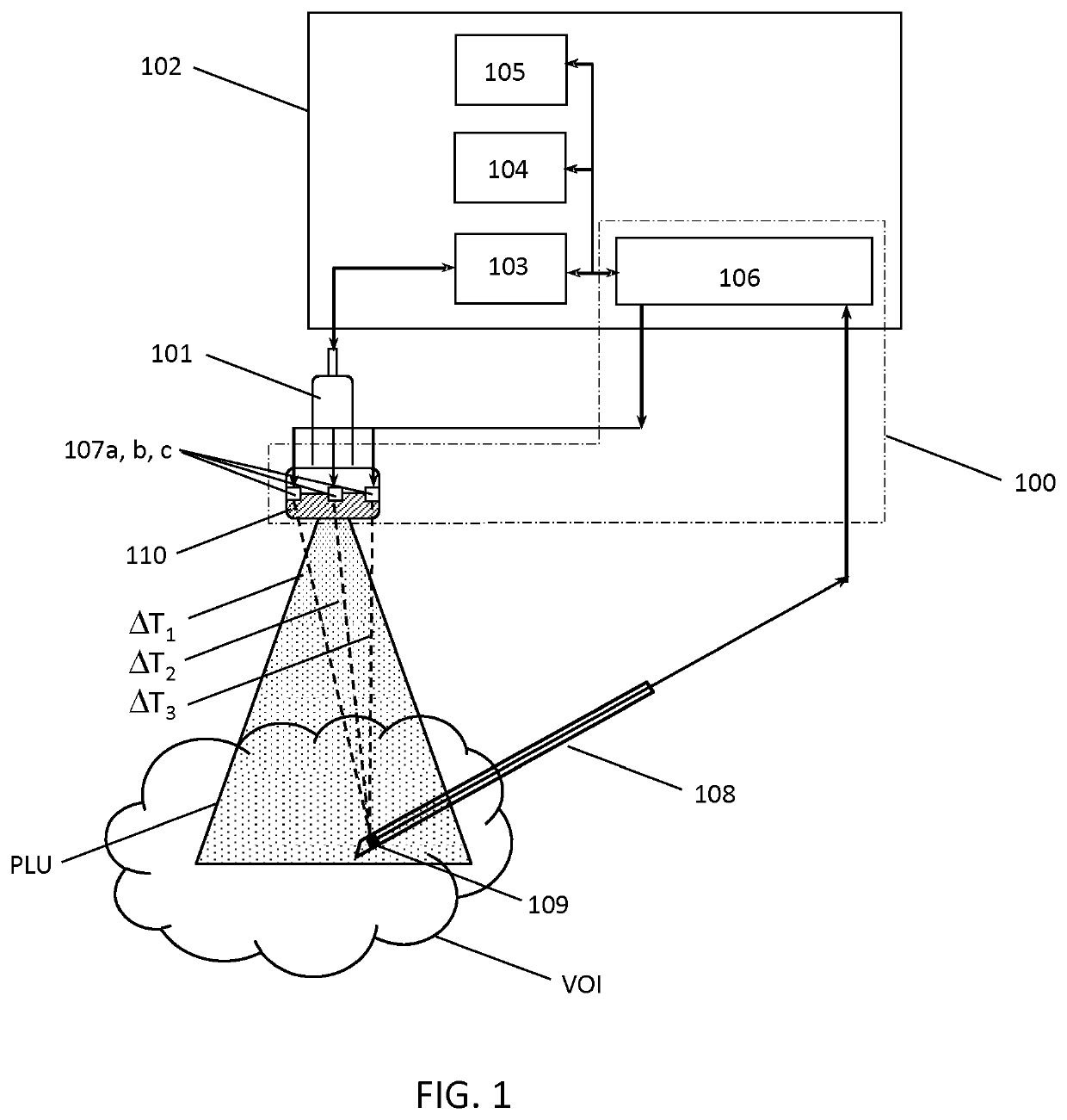

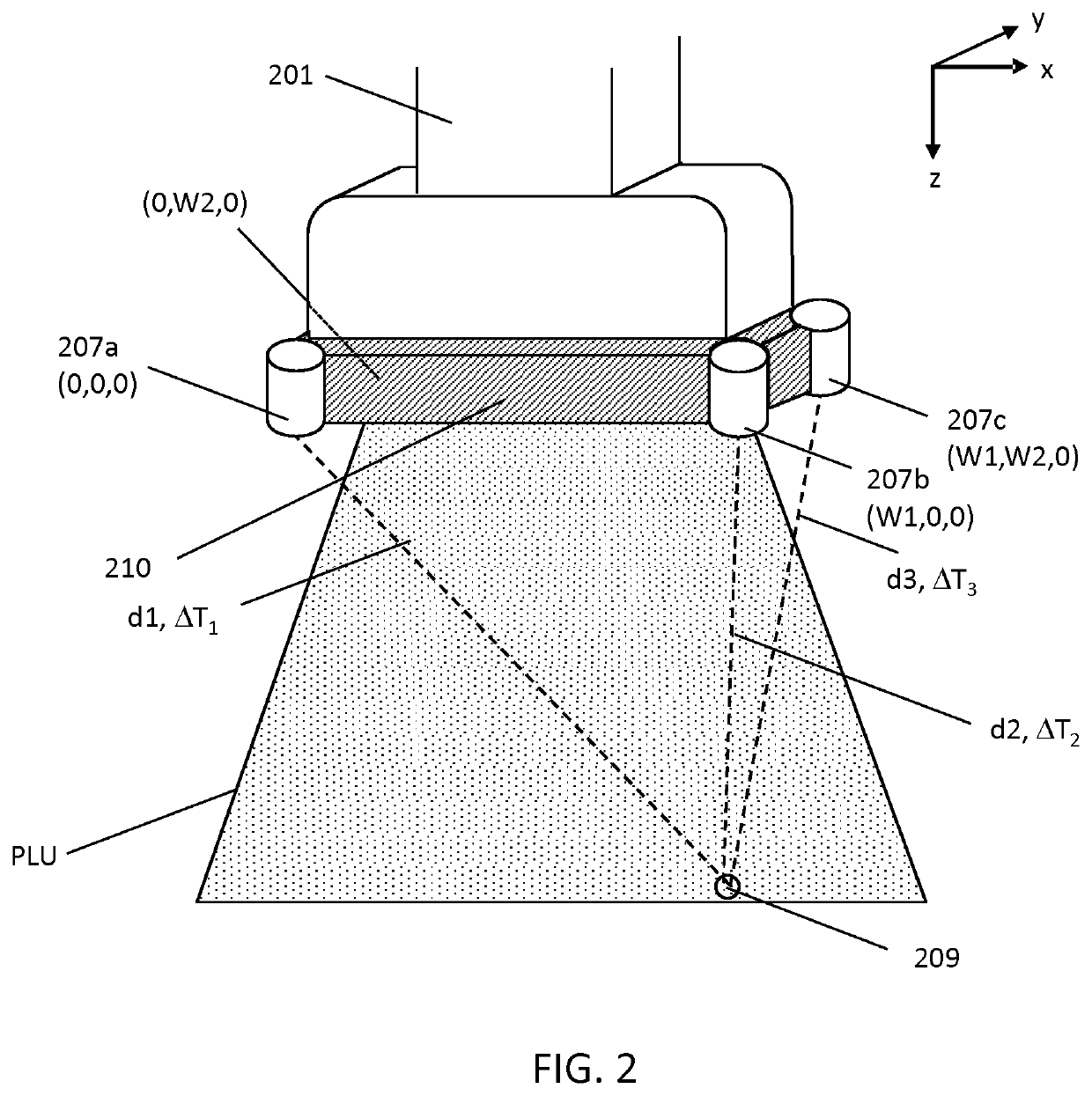

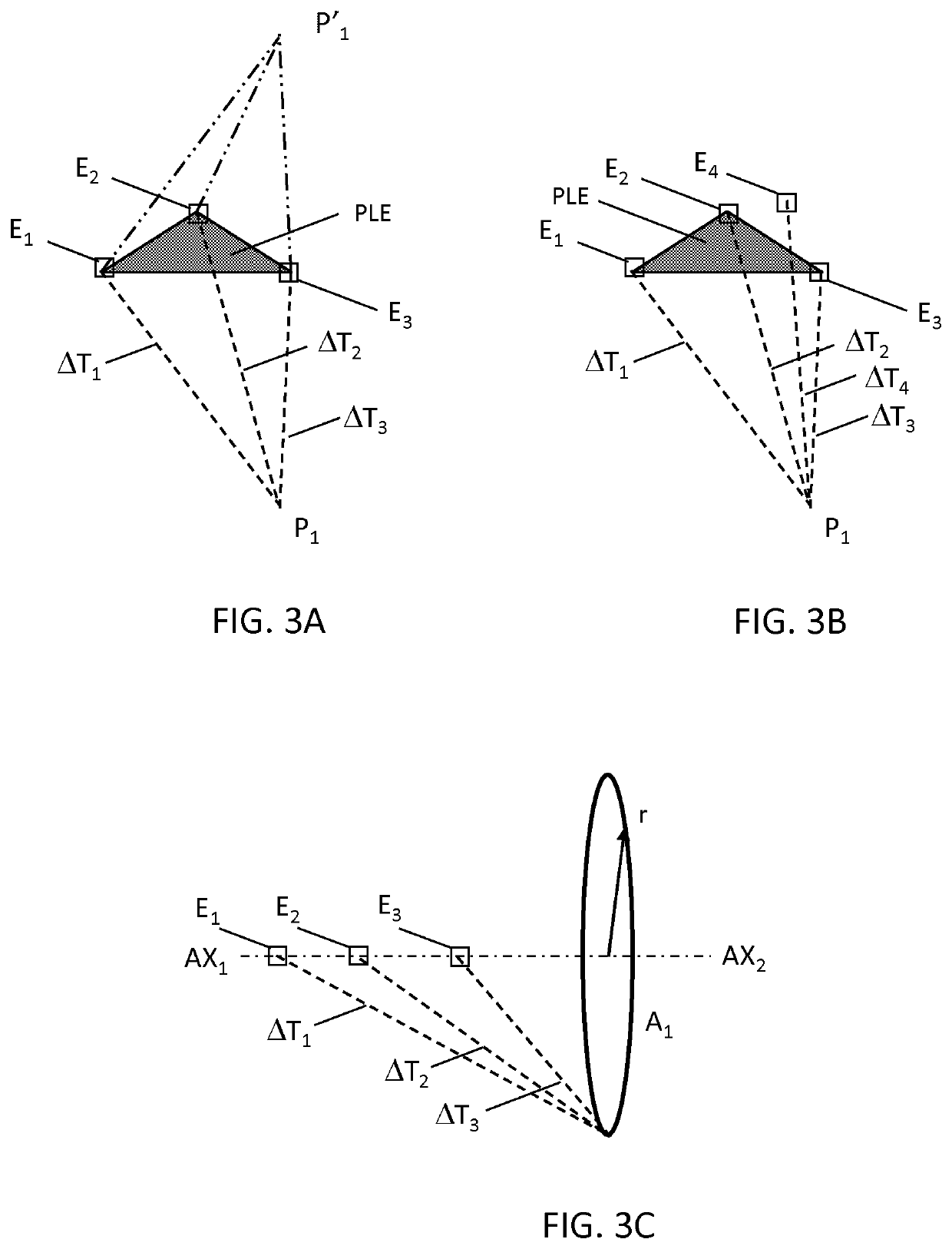

Ultrasound based tracking

ActiveUS11413011B2Improve visibilityOptical rangefindersOrgan movement/changes detectionUltrasound imagingTesting ultrasound

The present invention relates to an ultrasound-based system for localizing a medical device within the field of view of an ultrasound imaging probe. A localization system is provided that includes at least three ultrasound emitters that are arranged on a frame; and a position triangulation unit. The frame is adapted for attachment to an ultrasound imaging probe. The position triangulation unit determines a spatial position of the ultrasound detector relative to the at least three ultrasound emitters based on signals received from an ultrasound detector that is attached to the medical device. The frame includes a detachable reference volume comprising a background volume and an inclusion or void. When the detachable reference volume is attached to the frame and the frame is attached to the ultrasound imaging probe the inclusion or void provides a corresponding image feature within the field of view of the ultrasound imaging probe for use in calibrating the field of view of the ultrasound imaging probe with the coordinate system of the localization system.

Owner:KONINKLJIJKE PHILIPS NV

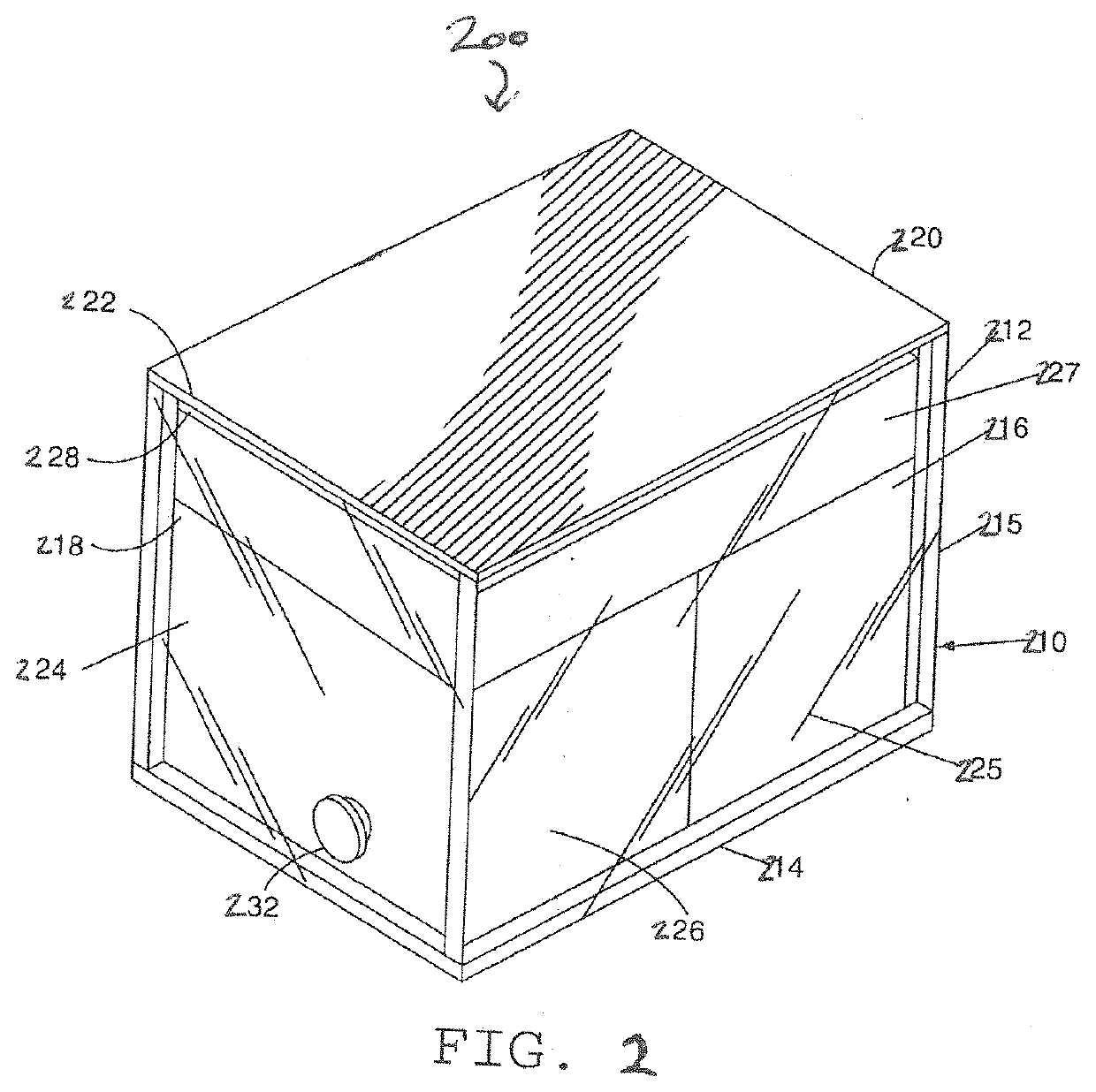

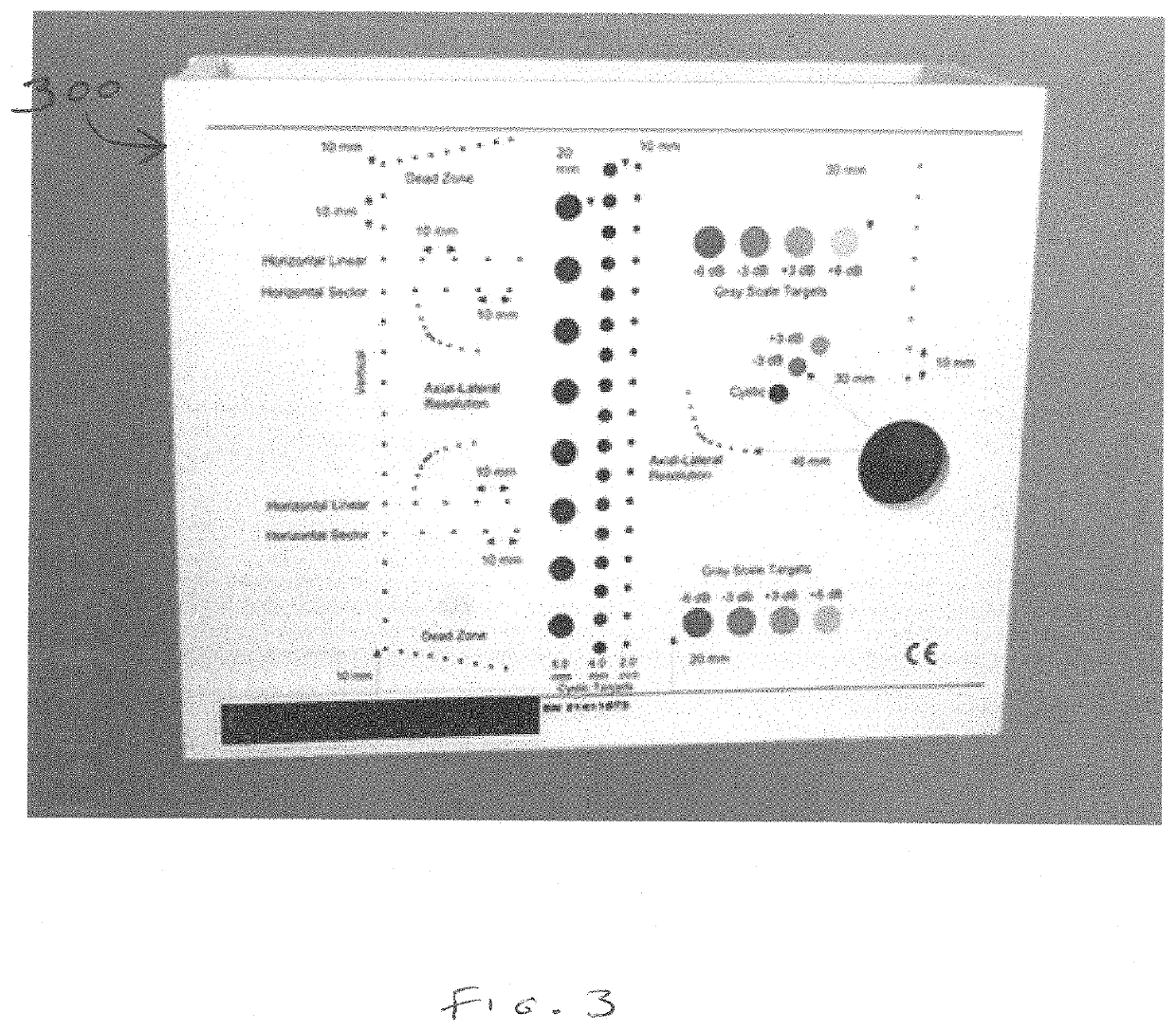

Testing system for ultrasonic imaging system

InactiveUS20200297326A1Reduce alignment requirementsRapid and precise alignmentUltrasonic/sonic/infrasonic diagnosticsProcessing detected response signalTesting ultrasoundUltrasonic imaging

A system for use in testing ultrasound systems that includes a tissue mimicking phantom and computer-readable instructions that are configured to automatically compare images of the phantom obtained by the ultrasound system to one or more reference images (e.g., indicating how the obtained images should appear) and provide output that assists personnel in assessing the operationality of the ultrasound system. Any appropriate digital recording device may be used to digitally store signals received from outputs of the ultrasound system for use by the image comparison module on a real-time basis or after full acquisition of the phantom images.

Owner:ACERTARA ACOUSTIC LAB

Medical ultrasonic detection auxiliary equipment

ActiveCN112353417AAvoid running back and forthEasy to movePatient positioningWalking aidsPatient roomTesting ultrasound

The invention discloses medical ultrasonic detection auxiliary equipment. The equipment comprises two sets of two side plates which are symmetrical front and back, a connecting beam is fixedly installed between the two side plates, and a storage device storage cavity is formed in the connecting beam; an ultrasonic signal storage device is arranged in the storage device storage cavity in a slidingmode and extends backwards out of the storage device storage cavity, a storage device pull ring is fixedly installed on the rear end wall of the ultrasonic signal storage device, and moving devices used for rapid movement of equipment are fixedly installed on the lower end faces of the side plates on the two sides. According to the medical ultrasonic detection auxiliary equipment, on one hand, theequipment is convenient to move, when a patient needs to be examined, the equipment can be directly carried for examination in a ward, and the patient is prevented from running back and forth betweenthe ward and an examination room; and on the other hand, the equipment can also be used as a daily activity tool for patients with physical disabilities, and the conditions can be checked and recorded anytime and anywhere according to the actual requirements of the patients, so that the patients can better know the conditions of themselves.

Owner:QINGDAO CENT HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com