Testing method of concrete partial carbonization area depth

A test method and technology for concrete specimens, which are used in measuring devices, analyzing materials, analyzing solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of complex testing methods and high cost, and achieve simple and economical testing methods and ensure integrity. , the test results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

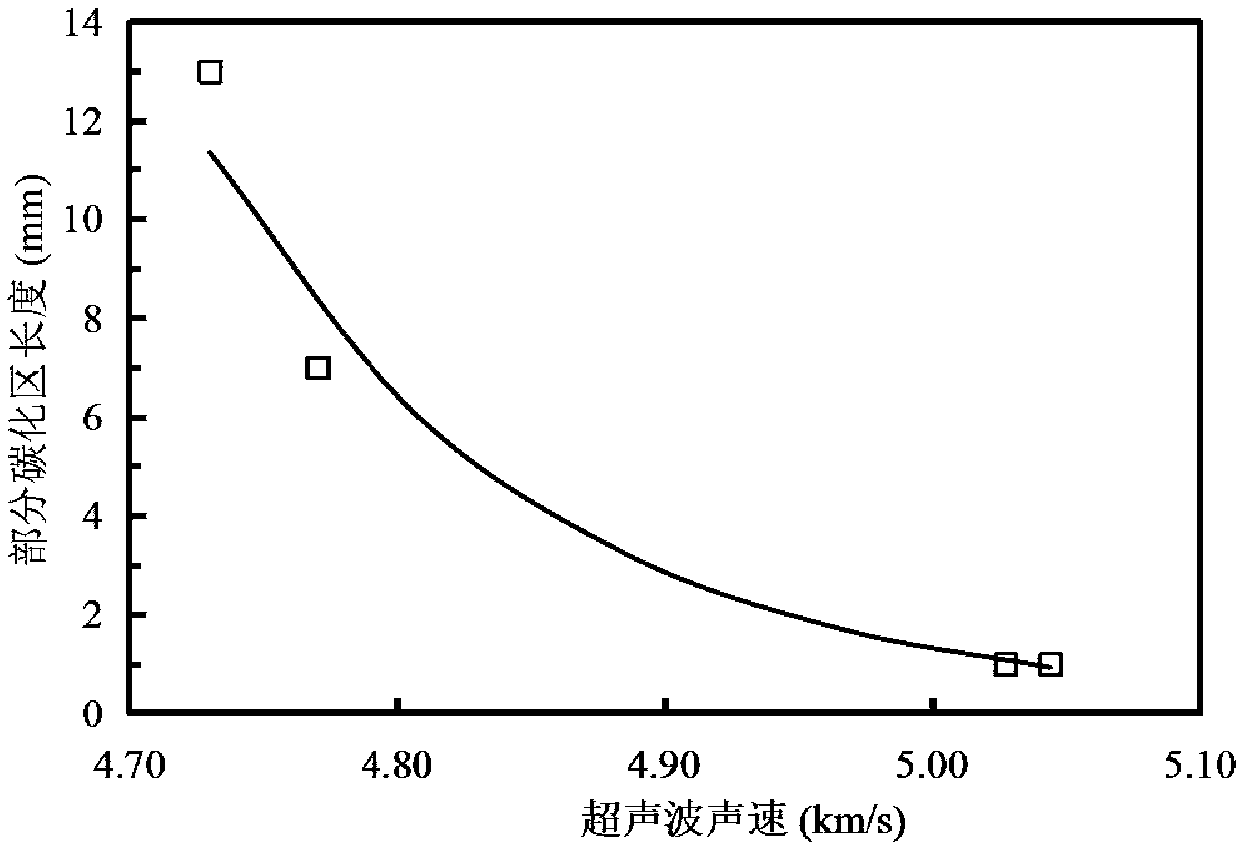

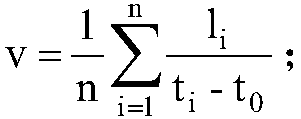

[0033]A method for testing the depth of a concrete partial carbonation zone, comprising the following steps:

[0034] Step 1, specimen molding and carbonization: according to the established mix ratio, the concrete specimens of C20, C30, C40 and C50 were molded, and after demoulding and curing for 28 days, they were placed in a carbonization box for carbonization. The temperature of the carbonization box was 20±2°C, and the relative humidity was 70%, CO 2 The concentration is 20±2%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com